Page 1

Page 1 of 47Watson-Marlow Bredel E-Manuals

Search manual for ...

Go

WATSON-MARLOW BREDEL E-MANUALS

PB0339gb-03

Watson-Marlow 521CC pumps

Contents

1. Declaration of conformity

2. Declaration of incorporation

3. Warranty

3.1 One year warranty - 521P/RC

and 521P/R2C models with air

motors

3.2 Two year warranty - 521CC

models with electric motors

4. Information for returning pumps

5. Peristaltic pumps - an overview

6. Safety notes

7. Dimensions

8. Unit installation

9. AC three-phase motors

9.1 AC three-phase motor wiring

9.2 AC three-phase troubleshooting

9.3 AC three-phase motors:

maintenance

9.4 Gearbox maintenance - simplex

(single pumphead) units

9.5 Gearbox maintenance - duplex

(twin pumphead) units

9.6 AC three-phase motors: pump

specifications

10. Varmeca drives

10.1 Installation

10.2 Connections

10.3 Cables and protection devices

10.4 Commissioning / start-up

10.5 Single phase connection

diagram

10.6 Keypad indicator light display

10.7 Specifications

10.8 Inverter factory settings

10.9 Care and maintenance

11. Air motors

11.1 Installation

11.2 Lubrication

11.3 Operation

11.4 Starting

11.5 Shutdown procedure

11.6 Specifications

11.7 Troubleshooting

12. 520RC, 520R2C and 520REC pumpheads

12.1 520RC, 520R2C and 520REC key

safety information

12.2 520RC, 520R2C and 520REC:

good pump installation practice

12.3 520RC, 520R2C and 520REC:

pumphead position, removal and

replacement

13. 520RC, 520R2C and 520REC installation

13.1 Opening the pumphead guard

13.2 520RC and 520R2C tube loading

13.3 520REC: fitting the drain port

13.4 520REC element loading

13.5 520REC element connection

14. 520RC, 520R2C and 520REC

maintenance

15. 520RC, 520R2C and 520REC rotor

settings

16. Pumphead spares

17. Flow rates

18. Tubing and element part numbers

19. 520 series pumping accessories

20. Trademarks

21. Patient-connected use: warning

22. Publication history

23. Decontamination certificate

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 2

Page 2 of 47Watson-Marlow Bredel E-Manuals

1 Declaration of conformity

When this pump unit is used as a stand alone pump it complies with: Machinery

Directive 2006/42/EC, EMC Directive 2004/108/EC.

2 Declaration of incorporation

When this pump unit is to be installed into a machine or is to be assembled with other

machines for installations, it must not be put into service until the relevant machinery has

been declared in conformity with the Machinery Directive 2006/42/EC.

Responsible person: Christopher Gadsden, Managing Director, Watson-Marlow Limited,

Falmouth, Cornwall TR11 4RU, England. Telephone +44 (0) 1326 370370 Fax +44 (0) 1326

376009.

The information in this user guide is believed to be correct at the time of publication.

However, Watson-Marlow Limited accepts no liability for errors or omissions. WatsonMarlow Bredel has a policy of continuous product improvement, and reserves the right to

alter specifications without notice. This manual is intended for use only with the pump it

was issued with. Earlier or later models may differ. The most up-to-date manuals appear on

the Watson-Marlow website: http://www.watson-marlow.com

Product codes used in this manual

CC Close-coupled

F Fixed speed

DF, FD Hazardous atmosphere fixed speed

P Pneumatic variable speed

PD Pneumatic variable speed with duplex gearbox

I, V Stand-alone inverter driven

VI Varmeca IP55 integrated inverter driven

DFX, DFD Hazardous atmosphere fixed speed with duplex gearbox

FX, FD Fixed speed with duplex gearbox

RC 520RC 1.6mm wall tubing two-roller pumphead for close-coupled drives

R2C 520R2C 2.4mm wall tubing two-roller pumphead for close-coupled drives

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 3

Page 3 of 47Watson-Marlow Bredel E-Manuals

3 Warranty

3.1 One year warranty - 521P/RC and 521P/R2C models

with air motors

Watson-Marlow Limited warrants, subject to the conditions below, through either WatsonMarlow Limited, its subsidiaries, or its authorised distributors, to repair or replace free of

charge, any part of this product which fails within one year of delivery of the product to the

end user. Such failure must have occurred because of defect in material or workmanship

and not as a result of operation of the product other than in accordance with the

instructions given in this manual.

3.2 Two year warranty - 521CC models with electric

motors

Watson-Marlow Limited warrants, subject to the conditions below, through either WatsonMarlow Limited, its subsidiaries, or its authorised distributors, to repair or replace free of

charge, any part of this product which fails within two years of delivery of the product to the

end user. Such failure must have occurred because of defect in material or workmanship

and not as a result of operation of the product other than in accordance with the

instructions given in this manual.

Conditions of and specific exceptions to the above warranties are:

Tubing as a consumable item is excluded.

Products must be returned by pre-arrangement carriage paid to Watson-Marlow Limited,

its subsidiaries, or its authorised distributor.

All repairs or modifications must have been made by Watson-Marlow Limited, its

subsidiaries or its authorised distributors or with the express permission of WatsonMarlow Limited, its subsidiaries, or its authorised distributors.

Products which have been abused, misused, or subjected to malicious or accidental

damage or electrical surge are excluded.

Warranties purporting to be on behalf of Watson-Marlow Limited made by any person,

including representatives of Watson-Marlow Limited, its subsidiaries, or its distributors,

which do not accord with the terms of this warranty shall not be binding upon WatsonMarlow Limited unless expressly approved in writing by a Director or Manager of WatsonMarlow Limited.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 4

Page 4 of 47Watson-Marlow Bredel E-Manuals

4 Information for returning pumps

Equipment which has been contaminated with, or exposed to, body fluids, toxic chemicals

or any other substance hazardous to health must be decontaminated before it is returned to

Watson-Marlow or its distributor. A certificate included at the rear of these operating

instructions, or signed statement, must be attached to the outside of the shipping carton.

This certificate is required even if the pump is unused. If the pump has been used, the

fluids that have been in contact with the pump and the cleaning procedure must be

specified along with a statement that the equipment has been decontaminated.

5 Peristaltic pumps - an overview

Peristaltic pumps are the simplest possible pump, with no valves, seals or glands to clog or

corrode. The fluid contacts only the bore of a tube, eliminating the risk of the pump

contaminating the fluid, or the fluid contaminating the pump. Peristaltic pumps can operate

dry without risk.

How they work

A compressible tube is squeezed between a roller and a track on an arc of a circle, creating

a seal at the point of contact. As the roller advances along the tube, the sea l al so advances.

After the roller has passed, the tube returns to its original shape, creating a partial vacuum

which is filled by fluid drawn from the inlet port.

Before the roller reaches the end of the track, a second roller compresses the tube at the

start of the track, isolating a packet of fluid between the compression points. As the first

roller leaves the track, the second continues to advance, expelling the packet of fluid

through the pump's discharge port. At the same time, a new partial vacuum is created

behind the second roller into which more fluid is drawn from the inlet port.

Backflow and siphoning do not occur, and the pump effectively seals the tube when it is

inactive. No valves are needed.

The principle may be demonstrated by squeezing a soft tube between thumb and finger and

sliding it along: fluid is expelled from one end of the tube while more is drawn in at the

other.

Animal digestive tracts function in a similar way.

Suitable applications

Peristaltic pumping is ideal for most fluids, including viscous, shear-sensitive, corrosive and

abrasive fluids, and those containing suspended solids. They are especially useful for

pumping operations where hygiene is important.

Peristaltic pumps operate on the positive displacement principle. They are particularly

suitable for metering, dosing and dispensing applications. Pumps are easy to install, simple

to operate and inexpensive to maintain.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 5

Page 5 of 47Watson-Marlow Bredel E-Manuals

6 Safety notes

In the interests of safety, this pump and the tubing selected should only be used by

competent, suitably trained personnel after they have read and understood this manual,

and considered any hazard involved. Any person who is involved in the installation or

maintenance of this equipment should be fully competent to carry out the work. In the UK

this person should also be familiar with the Health and Safety at Work Act 1974.

This symbol, used on the pump and in this manual, means: Caution, risk

of electric shock.

This symbol, used on the pump and in this manual, means: Caution, refer

to accompanying documents.

This symbol, used on the pump and in this manual, means: Do not allow

fingers to contact moving parts.

This symbol, used on the pump and in this manual, means: Recycle this

product under the terms of the EU Waste Electrical and Electronic

Equipment (WEEE) Directive.

Fundamental work with regard to lifting, transportation,

installation, starting-up, maintenan ce an d re pair should be

performed by qualified personnel only. No voltage must be

applied while work is being carried out on the geared motor.

The motor must be secured against accidental start-up.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 6

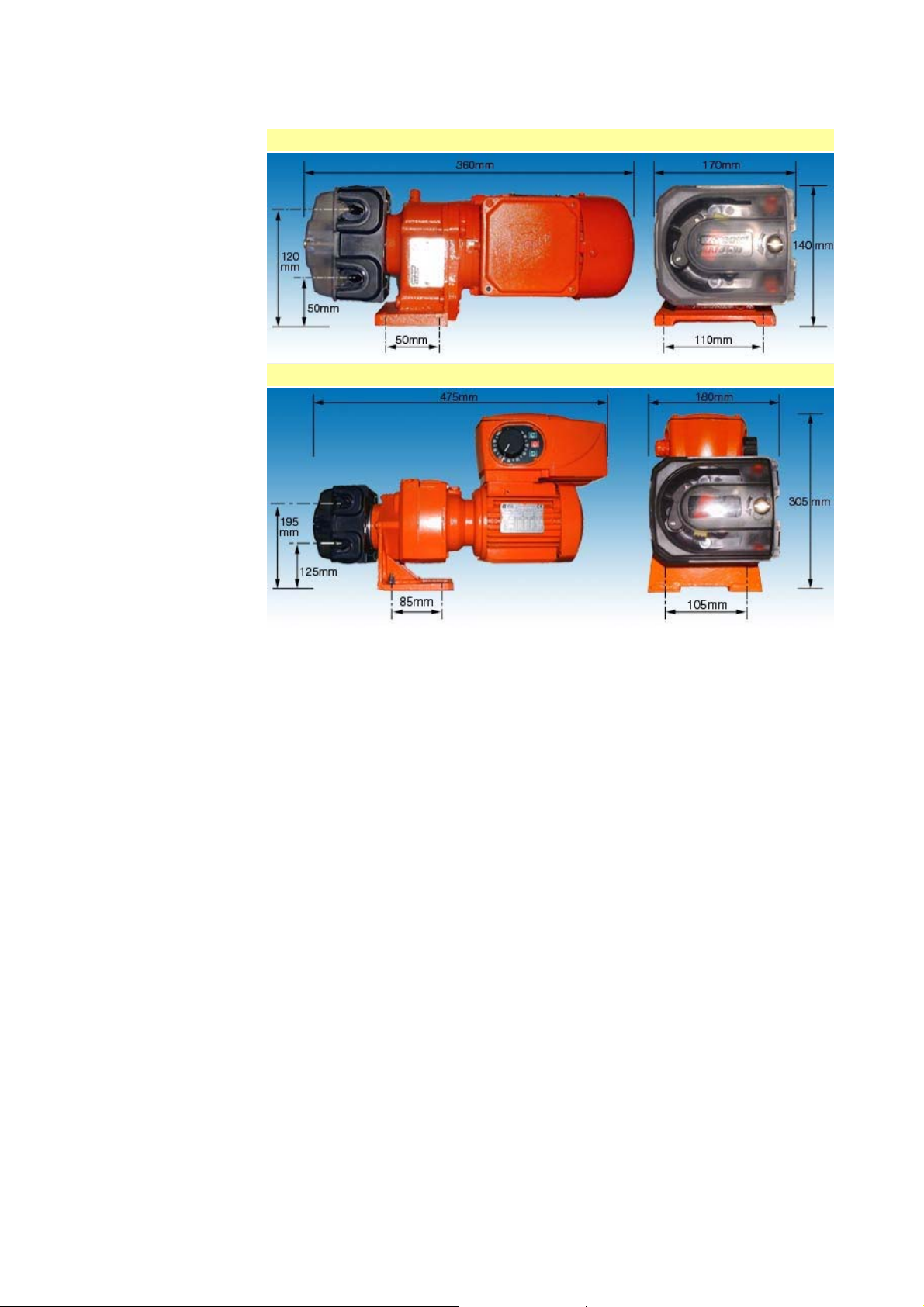

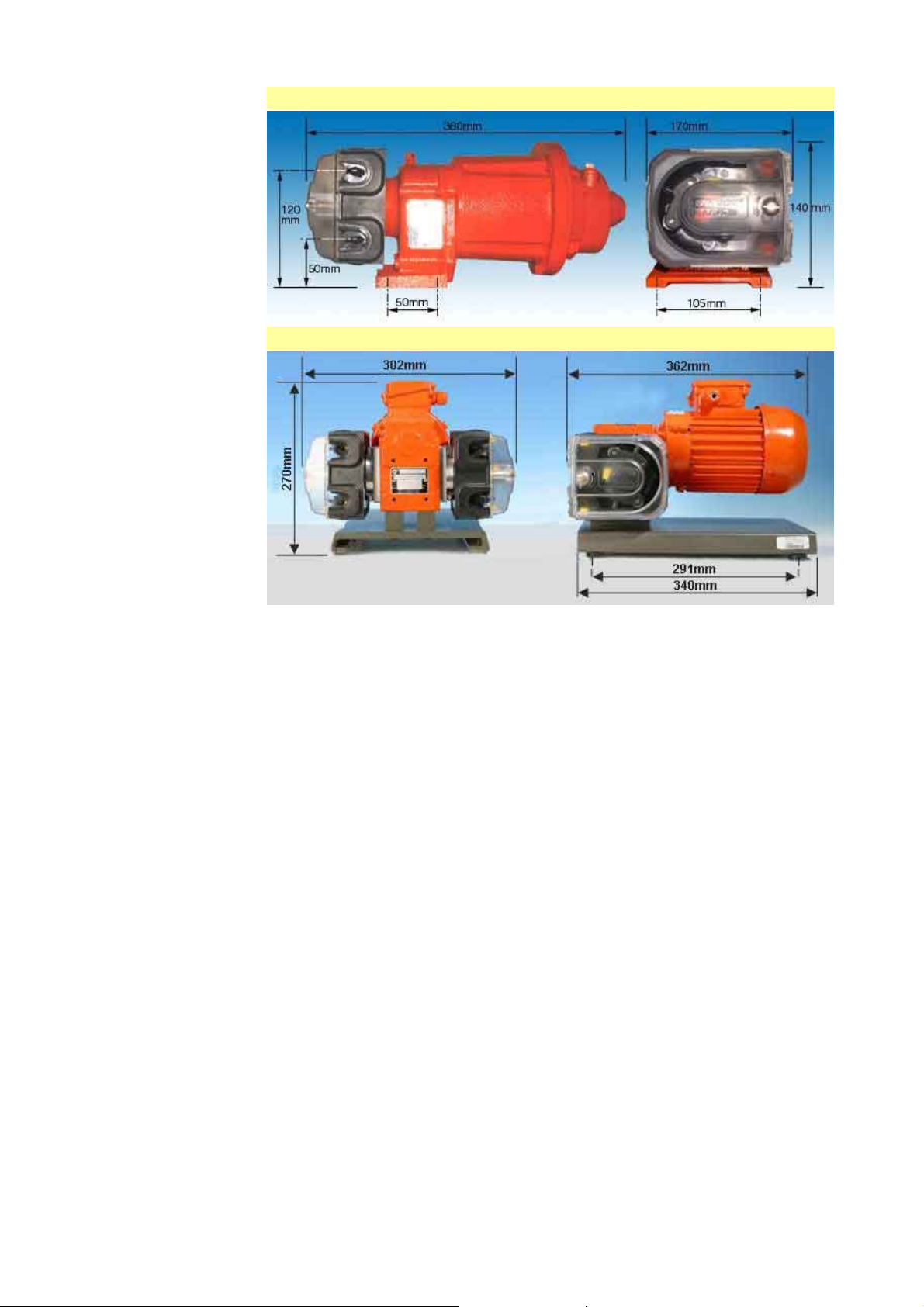

7 Dimensions

521F/RC, 521F/R2C, 521DF/RLA, 521DF/RL2A

521VI/RC, 521VI/R2C

Page 6 of 47Watson-Marlow Bredel E-Manuals

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 7

521P/RC, 521P/R2C

521DFX/RLA, 521DFX/RL2A

Page 7 of 47Watson-Marlow Bredel E-Manuals

Note: The pumphead fitted to the 521DFX is the 501RLA, not he 520RC as shown here.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 8

Page 8 of 47Watson-Marlow Bredel E-Manuals

8 Unit installation

Site the pump on a flat, horizontal, vibration-proof surface. allowing a free flow of air

around it. Ensure that there is 1m of straight, flexible tubing before the pumphead inlet and

after the pumphead outlet. Close-coupled simplex pumps must be bolted down with four M8

bolts through the gearbox foot mounting holes. The pumphead will need to be removed

before locating the bolts. See section 17: 520RC and 520R2C maintenance.

Duplex pumps are baseplate-mounted as standard.

The pump may be set up so that the direction of rotor rotation is clockwise or ant iclockwise, whichever is convenient. Please note, however, that tube life will be greater if

the rotor rotates clockwise; and that performance against pressure will be maximised if the

rotor rotates anti-clockwise.

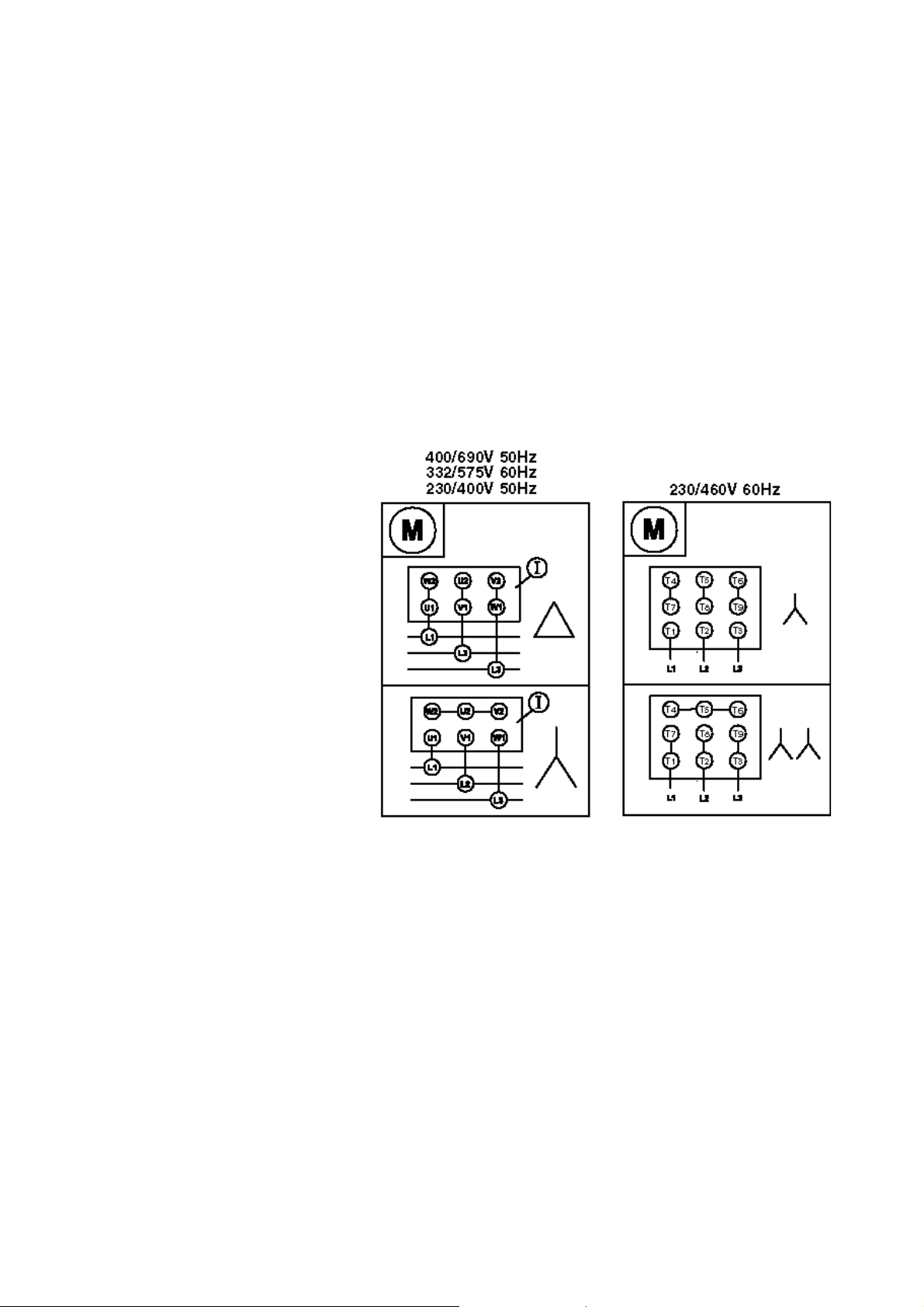

9 Standard AC three-phase motors (integrated)

9.1 AC (IEC) three-phase motors: motor wiring

For Nema C face motors or other options follow manufacturers' guidelines.

Ensure that

the mains

voltage and

frequency

are in

accordance

with the

motor

nameplate

information.

Secure

protective

conductor

connections.

If the motor

runs in the

wrong

direction for

your needs,

interchange

any two

phases.

Close the terminal box and unused cable entrance holes in a dust-tight and watertight

manner, ensuring that the IP55 protection is maintained.

A current overload relay should be fitted to a contact-breaker appropri ate to the current

rating of the motor. Connect the motor in a ccordance with the wiring diagram in the

motor terminal box.

When a thermal protection switch is fitted in the motor, the le ads will be found in the

motor terminal box. They should be connected to open the circuit and stop the pump if

an over-temperature condition occurs.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

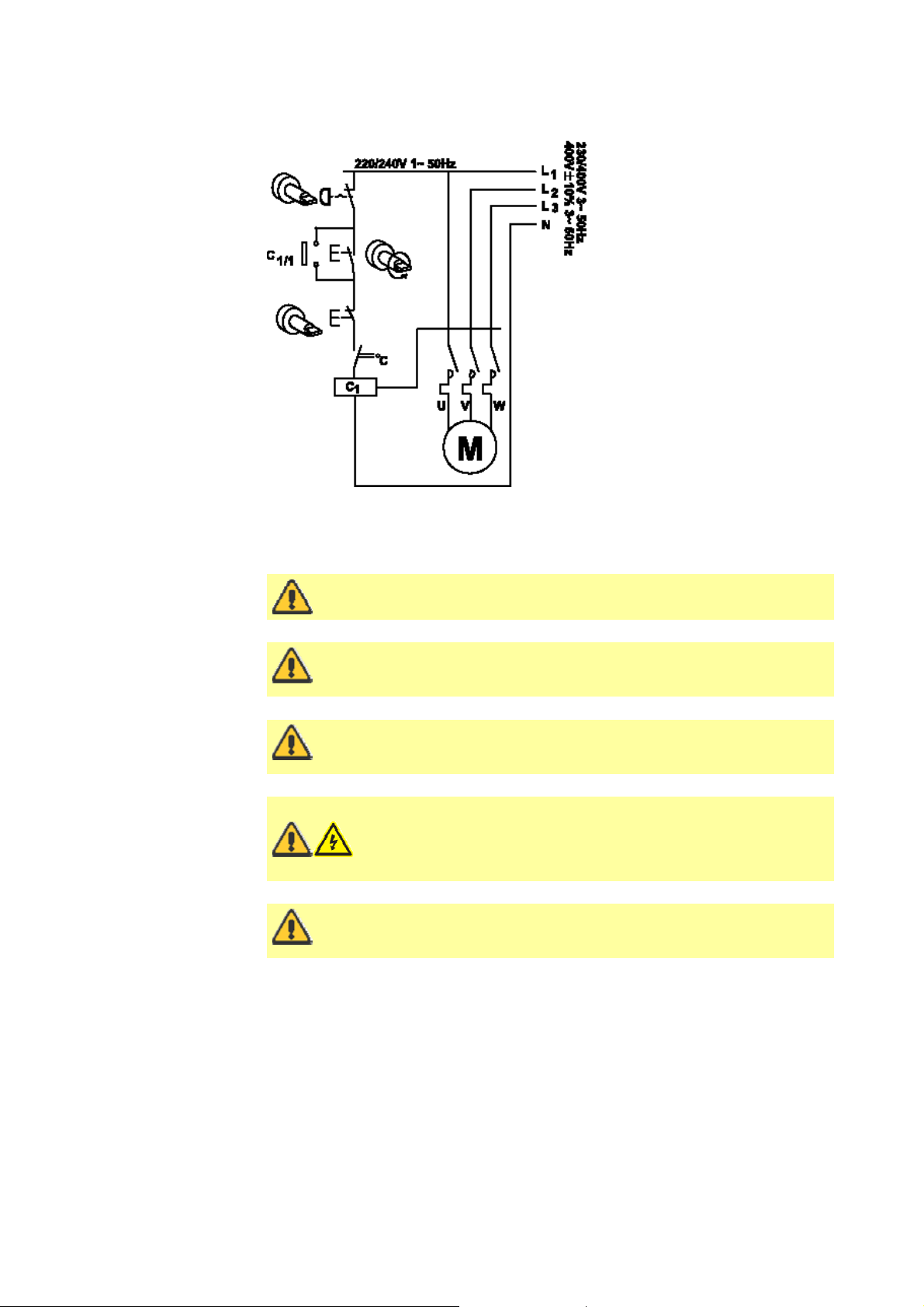

Page 9

Page 9 of 47Watson-Marlow Bredel E-Manuals

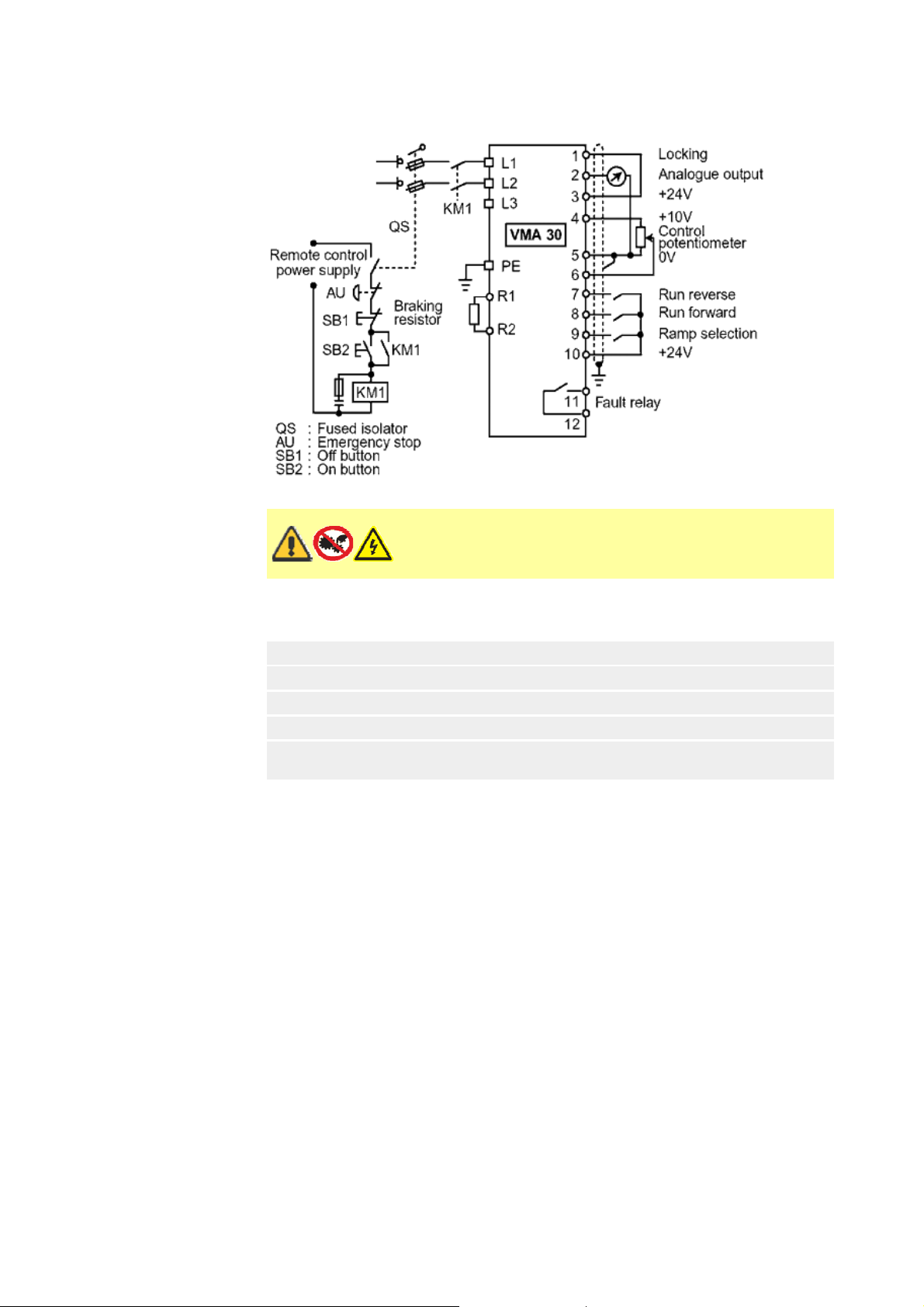

See the drawing below for drive motor connections, showing possible ancillary switches

and connections.

The ancillary switches should be rated to 220/240V 1ph 50Hz/60Hz. The Start contact

should have a sprung return which will disengage following energisation of coils C1 and

C1/1.

Ensure that an emergency stop switch is fitted within reach of the pump.

Do not under any circumstances wire switches directly across any of the

phases of a three-phase supply. If in doubt disconnect the pump

immediately.

Do not connect ancillary switches to the terminal box of a flame-proof

motor unless the switch has a suitable hazardous-atmosphere rating for

the area in which it is to be mounted.

AC three-phase motors must be connected to a suitable earth

terminal. It is imperative that the equipment is powered via an

isolating device and a circuit-breaking device (power contactor)

which can be controlled by an external safety system (emergency

stop, fault detector).

Correct installation and use of an AC three-phase motor with a suitably

rated frequency inverter is the responsibility of the user and should be

carried out by qualified personne l o n ly .

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 10

Page 10 of 47Watson-Marlow Bredel E-Manuals

9.2 AC three-phase motors: troubleshooting

If the pump will not start make the following checks to determine whether servicing is

required:

Check that mains power is available to the pump.

Check that the motor is connected in the correct Star/Delta configuration.

Check that the pump is not stalled by incorrect fitting of tubing.

Always check to ensure that a hazardous atmosphere motor gearbox is

suitably rated for the hazardous zone area in which it is to be mounted.

Hazardous atmosphere moto r s sh ould be installed only by qualifie d

personnel.

Any deviation from normal operating conditions (increased power

consumption, temperature, vibrations, noise) or warning signals by

monitoring equipment suggest malfunction. Inform the responsible

maintenance personnel at once. If in doubt disconnect the pump

immediately.

9.3 AC three-phase motors: maintenance

Thoroughly clean and regrease the motor assembly every 10,000 working hours or after

two years at the latest.

Remove any dust deposits from the fan cover to avoid overheating.

Dismount anti-friction bearings for cleaning and refill with a grease such as BP

Energrease LS 2 or Mobil Mobilux 2.

Ensure that the bearing cage is packed about 1/3 full with an evenly distributed

lubricating grease such as BP Energrease LS 2 or Mobil Mobilux 2.

9.4 AC three-phase motors: gearbox maintenance simplex (single pumphead) units

Combine a lubricant change with a thorough cleaning of the gear unit every 10,000

working hours or after two years at the latest.

Extreme working conditions (high air humidity, aggressive media and large temperature

variations) will reduce the interval between lubricant changes.

The first oil change should be carried out after approximately 1,000 working hours to

compensate for run-in abrasion. Examples of suitable lubricating oils are BP Energol GRXP 220 and Mobil Mobilgear 630.

9.5 AC three-phase motors: gearbox maintenance duplex (twin pumphead) units

The gearbox is filled for life with synthetic lubricant so no maintenance is required.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 11

Page 11 of 47Watson-Marlow Bredel E-Manuals

9.6 AC three-phase motors: gearbox maintenance pump specifications

Control range See motor nameplate

Voltage/frequency See motor nameplate

Power consumption See motor nameplate

Full load current See motor nameplate

Operating temperature range 5C to 40C, 41F to 104F

Storage temperature range -40C to 70C, -40F to 158F

Noise <70dB(A) at 1m

Standards BS EN60529 (IP55)

Machinery directive 2006/42/EC

EMC directive 2004/108/EC

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 12

Page 12 of 47Watson-Marlow Bredel E-Manuals

10 Varmeca drives

The Varmeca drive is an IP65 integrated electronically-variable speed drive fitted to a

standard enclosure IP55 motor gearbox. Standard Varmeca drives are single-phase but

three-phase Varmecas are available.

Standard Varmeca drives are set up for manual control with the run command enabled.

Current will be applied directly to the motor as soon as mains power is switched on.

Subsequently, speed, direction of rotation and stop control can be achieved from the control

knob and keypad.

For information on how to set up the Varmeca for remote control, please refer to

the Leroy Somer Varmeca-30 manual.

This Varmeca-30 must be connected to an approved earth terminal.

It is imperative that the equipment is powered via an isolating

device and a circuit-breaking device (power contactor) which can

be controlled by an external safety system (emergency stop, fault

detector).

The Varmeca-30 is fitted with safety devices which stop the motor in the event of a fault.

The motor can become jammed for mechanical reasons. Voltage fluctuations and power

cuts may also stop the motor.

Removing the cause of a shutdown can lead to restarting, which may be dangerous for

certain installations. It is essential that the user guards against the motor restarting after

shutdown, if this is undesirable.

10.1 Varmeca drives: installation

The standard Varmeca integrated drive requires no connection other than to the mains

power supply.

The Varmeca motor fan cools the whole unit. Make sure that the ventilation air inlet is

free of obstruction.

It is the responsibility of the owner or user to ensure that the installation, operation and

maintenance of the inverter complies with he alth and safety regulations of the relevant

country of use.

Before carrying out any work, disconnect and lock the drive power

supply. For single phase units, wait two minutes to make sure that

the capacitors have fully discharged. After connection work, make

sure that the seals are firmly in place, and the screws and cable

glands are watertight to ensure IP65 protection. Clear any

condensation from the drain holes at the bottom of the motor.

10.2 Varmeca drives: connections

The voltages on the power terminal blocks and the cables connected to them may cause

fatal electric shocks. The drive stop function does not protect against these high

voltages.

The drive power supply must be protected against overloads and short circuits.

It is vital to respect the rating of protection devices.

Connections should be made with copper conductors only.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 13

Page 13 of 47Watson-Marlow Bredel E-Manuals

10.3 Varmeca drives: cables and protection devices

Circuit breakers must be of the D-curve type suitable for a motor with an inverter.

Comply with the size of protection (gl) fuses given in the table below.

The cable size may vary according to legislation applicable in the country of use, which

will take precedence over the values given in the table below without exception.

Power VMA

230V/1/50/60Hz

110V/1/50/60Hz

0.25kW

1/3HP

0.25kW

1/3HP

rating

A or B

21M-025

A or B

21M-025

Current

(A)

gl fuses or circuit

breaker (A)

3.5 8 1.5

6.8 16 2.5

Cable

(sq mm)

NB: The mains current value is a typical value which depends upon the source impedance.

The higher the impedance, the lower the current. The fuses (UL approved) are intended for

installations capable of delivering 5,000A maximum at 480V.

10.4 Varmeca drives: commissioning / start-up

Remove the cover and connect a suitably rated mains cable via the cable gland to

connection points L1, L2 and PE (earth) of the Varmec a terminal block.

Secure the connection cover and cable gland into position, ensuring that the IP65 sealing

is not compromised.

The Varmeca must not be switched on with the connection cover

removed.

The motor Run command has been enabled: the motor will start as

soon as it is switched on.

Power-up at the mains: the green indicator lamp lights and remains on continuously.

Start rotation by pressing a direction button for one second.

Set the speed reference using the side control knob, adjusting speed between 10Hz and

80Hz. The speed control knob is calibrated in percentages of maximum speed.

Press the Stop button to stop the unit.

Varmeca drives fitted with electrical interlock pumpheads

Commissioning / start-up: as standard Varmeca units.

If the guard switch is activated:

Press the Stop button twice to reset the unit after the pumphead guard has been closed

Re-start rotation by pressing a direction button for one second

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 14

Page 14 of 47Watson-Marlow Bredel E-Manuals

10.5 Varmeca drives: single phase connection diagram

Before switching on the Varmeca-30 motor, check that

electrical connections are correct and that any moving parts

are mechanically protected. The Varmeca-30 must not be

switched on with the protective cover removed.

10.6 Varmeca drives: keypad indicator light display

Steady green light

Flashing green light

Flashing green and red lights

Flashing red light

Steady red light

Fault: under/over voltage

Fault: short circuit; locked motor rotor; faulty winding

insulation; I²t overheating; or internal fault

Mains connected

Motor current overload

Motor current limit

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 15

Page 15 of 47Watson-Marlow Bredel E-Manuals

10.7 Varmeca drives: Varmeca-30 specifications

Power supply Single phase, 208V -10% to 240V +10%, 50/60Hz

110V -10% to 120V +10%, 50/60Hz ±2%

Power range 0.25kW, 1/3HP

Maximum hourly mains

stop/starts

Overload 150% of nominal current for 60 seconds, 10 times

Efficiency 97.5% motor efficiency

Filter type Class B EMC filter (domestic and light industrial level)

Motor frequency variation range 10Hz-80Hz at constant torque

Enclosure IP65: Varmeca drive; IP55: motor

Storage temperature -40C to +70C (IEC 68.2.1), -40F to 158F

Operating temperature -20C to 50C, -4F to 122F; power derated by 1% per

degree C above 40C, 1% per 1.8 degrees F above

Altitude Up to 1000m without derating

UL standard Conforming to UL508c (E211799)

Weight 21kg, 46lb

±2%

10

per hour

104F

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 16

T

Page 16 of 47Watson-Marlow Bredel E-Manuals

10.8 Varmeca inverter factory settings

The Watson-Marlow 521VI/RC and 521VI/R2C inverter default settings are listed in the

table below. For more information on each parameter and its options, consult the LeroySomer Varmeca-30 operating instructions.

Parameter Set

P01 F MIN 8 8Hz

P02 REF 0V -

4mA

P03 F MAX 80 80Hz

P04 REF 10V -

20mA

P05 ACCEL 3 3s

P06 DECEL 3 3s

P07 STOP

MODE

P08 Un MOT 400V 400V

P09 FN MOT 50Hz 50Hz

P10 U / F C C: 0.25-1.1kW;

P11 BOOST 8% Adapted to

P12

OVERBOOST

P13 F PWM 11 11: 0.25-2.2kW;

P14 CONFIG Standard

value

8 8Hz

80 80Hz

RAMP RAMP

20% Adapted to

Possible

settings

D: 1.5-7.5kW

motor according

to power

motor according

to power

8: 3-4kW

Standard

Parameter Set

P15 VP1-1 50Hz

P16 VP2-1

VP1-2

P17 VP2 40Hz

P18 VP3-2 70Hz

P19

ROTATION

P20 SELECT

3

P21 PI K PRO 10

P22 PI K INT 10

P23 F MOT P24 I MOT P25 FAULT 0

P26 STOP F

min

P27 LOG

CDC-VMA

P28 CAL MOT 21M

value

60Hz

FORWARD FORWARD

OUTPUT N

0

-

025:520

Possible

settings

Adapted

according to

motor power

10.9 Varmeca care and maintenance

emperature variations and excessive humidity encourage the formation of condensation.

If this occurs, the condensation drain plugs at the bottom of the motor should be

removed, even in a very humid atmosphere.

No specific servicing is required for Varmeca-30 motors, apart from regularly removing

dust from the fan grille and the cooling fins at the bottom of the unit.

Dismantling the Varmeca-30 while it is under warranty will invalidate the warranty.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 17

Page 17 of 47Watson-Marlow Bredel E-Manuals

11 Air motors

The air motor is designed for air only. Do not allow corrosive,

flammable or explosive gases or particulate material to enter the

motor. Water vapour, oil-based contaminants or other liquids must

be filtered out. The recommended air pressure should not exceed

7bar (100 psig) maximum.

Always disconnect the air supply before servicing.

11.1 Air motors: installation

The air motor is supplied with a silencer installed. The silencer incorporates a speed limiter.

Install a moisture trap and filter in the air line ahead of the motor. If condensates need to

be flushed out of the motor, use clean, dry air at low pressure. For efficiency of output and

speed control, use air lines of the same size or next pipe size larger than the intake port of

the motor.

A four-way valve which can be connected by piping to both air ports of the motor will make

reversing possible. Use a pressure regulator or a simple shut-off valve to obtain the desired

power and conserve air to regulate speed and torque. The motor should be regulated to

run at no more than 3000rpm.

The air motor should be mounted on a solid baseplate, preferably of metal, which in turn

should be anchored to a shelf, floor or other machinery.

11.2 Air motors: lubrication

Use a detergent SAE#10 automotive engine oil. Lubrication is necessary for all moving

parts and rust prevention. We recommend that an automatic air lubricator be installed in

the air line just ahead of the motor.

Automatic lubrication: An in-line oiler should be adjusted to feed one drop per minute for

high speed or continuous duty use. Do not overfeed oil. Contamination of the exhaust air

may occur.

Manual lubrication: Shut the pump down after every eight hours of operation, and add

10-20 drops of oil through the inlet port.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 18

Page 18 of 47Watson-Marlow Bredel E-Manuals

11.3 Air motors: operation

Do not drive an air motor with flammable or explosive gases nor operate

the unit in an atmosphere containing them. Solid or liquid material

leaving the motor can cause eye or ski n da ma ge . Ke ep away from the air

stream. Do not drive an air motor in excess of the recommended speed,

which is governed by a limiter on the outlet port. Do not allow an air

motor to run at high speed with no load: excessive internal heat build-up,

loss of internal clearances and rapid motor damage will result.

11.4 Air motors: starting

Starting torque is less than running torque. It could vary depending on where the vanes

stop in relation to the air intake port. To regulate speed and torque, use a pressure

regulator or simple shut-off valve to obtain desired power and conserve air.

11.5 Air motors: shutdown procedure

Turn off the air supply and remove the air lines from the motor.

Use clean, dry air at low pressure to flush out condensates such as water.

Re-lubricate the air motor with a squirt of oil in the chamber. Rotate the shaft by hand

several times.

Plug or cap each port.

11.6 Air motors: Air motor specifications

Maximum

speed

3,000rpm 7.0bar,

Maximum

pressure

100psig

Maximum

torque

26Nm,

19.2 lb-ft

Maximum air

consumption

14.15 l/s, 30cfm 0.0635mm,

Total internal

end clearance

0.0025in

Total top

clearance

0.0381mm,

0.0015in

11.7 Air motors: troubleshooting

Reason Low

Dirt, foreign material

Internal rust

Misalignment

Insufficient air

pressure

Air line too small

Restricted exhaust

Poor lubrication

Jammed machine

Compressor too small

Compressor too far

from unit

torque

Low

speed

Won't

run

Runs

hot

Runs well then

slows down

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 19

Page 19 of 47Watson-Marlow Bredel E-Manuals

12 520RC, 520R2C and 520REC pumpheads

Identification of parts

1 Guard latch 5 Rotor cap 9 Pumping roller

2 Guard (520RC, 520R2C) 6 Tube guide roller 10 Tube clamp slider (520RC, 520R2C)

3 Track 7 Rotor 11 Tube clamp (520RC, 520R2C)

4 Clutch button cover 8 Follower roller 12 Guard with seal (520REC)

13

Drain port (520REC)

12.1 520RC, 520R2C and 520REC key safety information

Before opening the pumphead guard, ensure that the following

safety directions are followed.

For close-coupled drives, ensure that the pump is isolated fr om the mains voltage.

Ensure that there is no pressure in the pipeline.

Primary operator protection from rotating parts of the pump is provided by the tool-

unlockable safeguard.

Secondary (backup) protection is available in the form of an electrical interlock which

stops the pump if the pumphead guard is opened (and only for so long as the guard is

opened). The electrical interlock on close-coupled pumps should never be used as

primary protection. Always disconnect the mains power supply to the pump before

opening the pumphead guard.

If a tube failure has occurred, ensure that any fluid in the pumphead has been allowed to

drain to a suitable vessel, container or drain.

Ensure that protective clothing and eye protection are worn if hazardous fluids are being

pumped.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 20

Page 20 of 47Watson-Marlow Bredel E-Manuals

12.2 520RC, 520R2C and 520REC: good pump installation

practice

General recommendations

The pump may be set up so that the direction of rotor rotation is clockwise or counterclockwise, whichever is convenient. Please note, however, that for the 520R and 501RL

pumpheads tube life will be greater if the rotor rotates clockwise; and that performance

against pressure will be maximised if the rotor rotates counter-clockwise. To achieve 4 bar

and 7 bar pressures using a 520RE pump and the appropriate rotor and element, the pump

must rotate counter-clockwise.

Peristaltic pumps are self-priming and self-sealing against backflow. No valves are required

in inlet or discharge lines, except as described below. Valves in the process flow must be

opened before the pump operates. Users are advised to fit a pressure relief device between

the pump and any valve on the discharge side of the pump to protect against damage

caused by accidental operation with the discharge valve closed. Users of 520RE pumps at

pressures up to 4 bar and 7 bar are advised to fit a non-return valve between the pump and

the discharge pipework to avoid the sudden release of pressurised fluid in the unlikely event

of element failure.

Do keep delivery and suction tubes as short and direct as possible - though ideally not

shorter than 1m - and follow the straightest route. Use bends of large radius: at least four

times the tubing diameter. Any valves in the pipeline (not usually needed with a selfpriming peristaltic pump) must not restrict the flow.

Do use suction and delivery pipes equal to or larger than the bore of the tube in the

pumphead. When pumping viscous fluids use pipe runs with a bore several times larger

than the pump tube.

Do site the pump at or just below the level of the fluid to be pumped if possible. This will

ensure flooded suction and maximum pumping efficiency.

Do keep the pumphead track and all moving rollers clean and free from debris.

When using Marprene or Bioprene tubing, re-tension the tube after the first 30 minutes

of running.

Tube selection: The chemical compatibility list published in the Watson-Marlow catalogue

is only a guide. If in doubt about the compatibility of a tube material and the duty fluid,

request a Watson-Marlow tube sample card for immersion trials.

A correctly engineered installation will promote long tube life. Please ensure that these

guidelines are followed:

Avoid tight pipeline bends, pipe reducers and lengths of smaller bore tubing than the

pumphead section, particularly in pipelines on the suction side.

Ensure that at least 1m of smooth bore flexible tubing is connected to the discharge port

of the pumphead to help to minimise impulse losses and pulsation in the pipeline. This is

specially important with viscous fluids and when connecting to rigid pipework.

Ensure that connecting pipework and fittings are suitably rated to handle the predicted

pipeline pressure. If rigid pipework must be used close to the pumphead, a drop-out

section of pipe will simplify tube replacement.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 21

Page 21 of 47Watson-Marlow Bredel E-Manuals

12.3 520RC, 520R2C and 520REC: pumphead position,

removal and replacement

The pumphead track can be fitted in one of two orientations to provide left or right

input/output port positions, and clockwise or anti-clockwise rotor rotation, whichever is

convenient. Please note, however, that tube life will be greater if the rotor rotates

clockwise; and that performance against pressure will be maximised if the rotor rotates

anti-clockwise.

To reposition the track

Isolate the pump from the mains power supply.

Open the pumphead guard as described under Opening the pumphead guard, below.

Remove the rotor as described under Rotor removal.

Undo and withdraw the four track-retaining screws using a slotted screwdriver.

Remove the track.

Relocate the track in the desired position. Replace and tighten the track-retaining screws.

Replace the rotor as described under Rotor replacement below.

Close the guard, pushing it fully home until the latch engages.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 22

Rotor removal

Remove any tubing from the pumphead.

Open the flexible rotor cap in the centre of the rotor.

Undo and withdraw the central locating screw using a slotted screwdriver.

Pull the rotor hub off its dogged shaft.

Between the hub and the shaft is a split collet. If the collet

is retained by the shaft, pull it off, loosening it if necessary

by tapping it lightly. Avoid levering it off using a

screwdriver or other tool. If the collet is retained within

the hub, remove it, loosening it if necessary by reinserting

the central locating screw a turn or two and tapping the

screw head lightly.

Page 22 of 47Watson-Marlow Bredel E-Manuals

Rotor replacement

Re-locate the split collet onto the drive shaft, rotating it until it fully engages the dog. Fit

the rotor body over the drive shaft as one unit.

Open the flexible rotor cap in the centre of the rotor. Use a slotted screwdriver to tighten

the central locating screw to a torque of 3Nm (2.2 lb-ft) to prevent collet slip during

operation. When fitted correctly, the tube guid e rollers should align with the outer face of

the track. Close the flexible rotor cap.

Close the guard and ensure that the rotor is clear of t he guard by observing the first few

rotor rotations.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 23

Page 23 of 47Watson-Marlow Bredel E-Manuals

13 520RC, 520R2C and 520REC installation

13.1 Opening the pumphead guard

Isolate the pump from the mains power supply.

Unlock the pumphead guard by turning the guard fastener ¼ turn anticlockwise with a

flat-head screwdriver.

Open the guard to its full extent to create maximum clearance for the tube ports.

Ensure that the rollers rotate freely and that the tube clamps are clean.

13.2 520RC and 520R2C tube loading

520RC continuous tubing pumpheads are factory-set to accept Watson-Marlow 1.6mm-wall

tubing. 520R2C continuous tubing pumpheads for close-coupled drives are factory set to

accept Watson-Marlow 2.4mm-wall tubing. Pumping performance may be adversely

affected if Watson-Marlow tubing is not used.

Mark a 225mm length onto the section of the tubing which is to be located into the

pumphead.

Open the lower spring-loaded tube clamp and locate tubing, with the first 225mm length

mark aligned to the inside face of the spring-loaded part of the tube clamp. Release the

clamp.

Disengage the rotor clutch by fully depressing the yellow clutch button on the side of the

rotor hub and turning the hub a few degrees while the clutch button is still depressed.

The rotor can now rotate independently of the gearbox and motor for one full revolution.

If the clutch re-engages before tube fitting is complete, depress the clutch button again

and turn the rotor a few degrees.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 24

Page 24 of 47Watson-Marlow Bredel E-Manuals

Feed the tubing around the pumphead track, turning the rotor as necessary. Make sure

the tubing is not twisted. Ensure that the second 225mm mark is adjacent to the inner

edge of the upper tube clamp.

Open the upper spring-loaded tube clamp and locate the tubing into it, making sure ther e

is no residual twist in the tubing, and that the tube sits centrally between the tube guide

rollers. Release the clamp.

The spring-loaded tube clamps must grip the tubing tightly enough to stop it moving in

and out of the pumphead but must not over-squeeze the tube and throttle fluid flow. The

tubing clamps are fitted with yellow sliders which can be clicked into two positions while

the clamps are held open: the outer position will allow the clamps to grip the tube

tightly; the inner will grip the tube loosely. Adjust the sliders to prevent tube movement

during a few trial rotations of the rotor.

Close the guard, pushing it fully home until the latch engages.

Connect suitable pipework to the pumphead tubing using appropriate connectors.

Remember, when using Marprene or Bioprene tubing, re-tension the tubing after 30

minutes of running, as it may grow in length as it beds in. Re-tension so that 225mm of

tubing sits between the inside faces of the spring-loaded parts of the tube clamps.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 25

Page 25 of 47Watson-Marlow Bredel E-Manuals

13.3 520REC: fitting the drain port

The drain port is an optional extra, supplied with the pumphead. It is strongly

recommended that users fit it before the pump is operated. This may be done with the rotor

in position or removed.

Remove the drain plug from the bottom of the pumphead. The drain plug is flexible. It

may be removed using finger pressure from within the pumphead, or by accessing its

flange from outside with a fingernail.

Drop the port into position from inside the pumphead.

Fit the supplied port retaining nut (3/8in BSP) and finger-tighten.

Fit drainage pipework as required (not supplied).

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 26

Page 26 of 47Watson-Marlow Bredel E-Manuals

13.4 520REC element loading

520RE tubing element pumpheads are factory-set to accept Watson-Marlow 2.4mm-wall

tubing elements. Elements fitted with either quick-release industrial connectors or Tri-clamp

sanitary connectors may be used; however, it is vital to match the pressure rating of

the element with the pressure rating of the pumphead so that the correct rollerspringing and occlusion settings are used. The pressure rating of the pumphead appears on

the flexible rotor cap in the centre of the rotor. The pressure rating of the element appears

on the connector sleeve.

Note that the rotor cap and the element connector sleeve are colour-coded.

Note: To achieve 4 bar and 7 bar pressures using a 520RE pump and th e appropriate rotor

and element, the pump must rotate counter-clockwise.

Element and rotor pressure ratings

Colour of flexible rotor cap and element connector sleeve

Grey Beige Blue

520REL

Pressures

up to 2 bar (30 psi)

3.2mm, 6.4mm and 9.6mm

Industrial

Marprene TL

Bore sizes

Sanitary

Bioprene TL

Pumpsil

Neoprene

ChemSure

Element connectors for industrial and sanitary use

Industrial Sanitary

Check that the conical connector sleeve of the element to be fitted is the

same colour as the pumphead rotor cap

Pumpsil

Sta-Pure

ChemSure

Industrial

Marprene TM

ChemSure

520REM

Pressures

up to 4 bar (60 psi)

Bore sizes

3.2mm and 6.4mm

Sanitary

Bioprene TM

Sta-Pure

520REH

Pressures

up to 7 bar (100 psi)

Bore size

3.2mm

Industrial

Marprene TH

Sta-Pure

Sanitary

Bioprene TH

Sta-Pure

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 27

Page 27 of 47Watson-Marlow Bredel E-Manuals

520REC element loading procedure

Note: The element loading procedure is the same for industrial (pictured) and sanitary

elements.

Select an appropriate Watson-Marlow 520RE tubing element, paying attention to

pressure capability, bore size, tubing material and type of connector. See the table above

for pressure ratings. Check that the connector sleeve of the element to be fitted is

the same colour as the pumphead rotor cap.

Slide the connector D-flange at one end of the element into the lower connector D-slot.

Disengage the rotor clutch by fully depressing the yellow clutch button on the side of the

rotor hub and turning the hub a few degrees while the clutch button is still depressed.

The rotor can now rotate independently of the gearbox and motor for one full revolution.

If the clutch re-engages before tube fitting is complete, depress the clutch button again

and turn the rotor a few degrees.

Feed the tubing element around the pumphead track, turning the rotor as necessary.

Make sure the tubing is not twisted or pinched between the guide rollers and the track.

Slide the second connector D-flange into the upper connector D-slot.

Check that the element lies snugly in the middle of the track and that the connectior

flanges are pushed fully home.

Close the guard, pushing it fully home until the latch engages.

Connect suitable pipework to the pumphead tubing using appropriate connectors. See

below.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 28

Page 28 of 47Watson-Marlow Bredel E-Manuals

13.5 520REC element connection

Select suitable tubing to connect to the tubing element supply and discharge connectors.

Check that its pressure rating is appropriate to the application.

Sanitary ¾in Tri-clamp connectors

Sanitary connectors are connected to a tubing system using Tri-clamps and EPDM gaskets.

Hold the connector end of the supply or discharge tube against the element connector,

with a gasket between them.

Use a Tri-clamp to engage both flanges squarely, close it and tighten.

Industrial quick-release connectors

Industrial connectors are connected to a tubing system using quick-release fittings.

Hold the pump securely and push the female fitting (available from Watson-Marlow

Bredel) over the element until it clicks into place.

To disconnect, hold the pump securely and pull the connector outer sleeve and twist

counter-clockwise while pulling the female connector away.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 29

Page 29 of 47Watson-Marlow Bredel E-Manuals

14 520RC, 520R2C and 520REC maintenance

Always isolate the pump from the mains power supply before opening the

guard or performing any positioning, removal or maintenance activity.

As part of regular cleaning and maintenance (and at least every three months), lubricate

the pivot points, the follower rollers and the tube guide rollers with Ultra Lube (PA 1240),

which is a non-toxic perfluoroether-based grease.

The stainless steel pumping rollers run on externally-sealed bearings and are lubricated

for life.

Check that the pumphead track, rotor, rollers and spring-loaded tube clamps are clean

and operating properly.

If fluid is spilled inside the pumphead it should be cleaned as soon as possible, as

reducing pumphead exposure time to contamination will prolong service life.

To clean the pumphead, remove the rotor as described under Rotor removal, below.

Flush the pumphead out with water and mild detergent, or suitable cleaning agent. Clean

the rotor and rollers in the same way. If specific cleaning agents are required to clean the

spillage, consult the general guide to cleaning with solvents below or Watson-Marlow

technical support office before proceeding, in order to confirm chemical compatibility.

Note: the pumphead guard, rotor cap and clutch boot should be removed in advance of

some cleaning regimes. See the table below. These components are available as spares if

damaged.

Replace the rotor as described above.

General guide to cleaning with solvents

Chemical Cleaning precautions

Aliphatic hydrocarbons Remove guard. Minimise rotor cap and clutch boot exposure

Aromatic hydrocarbons Remove guard. Minimise rotor cap and clutch boot exposure

Ketone solvents Remove guard. Minimise rotor cap and clutch boot exposure

Halogenated/chlorinated

solvents

Alcohols, general No precaution necessary.

Glycols Minimise rotor cap and clutch boot exposure to less than one

Ester solvents Remove guard. Minimise rotor cap and tube clamp location

Ether solvents Not recommended: possible risk to polycarbonate tube

to less than one minute (risk of attack).

Re-lubricate follower and tube guide rollers.

to less than one minute (risk of attack).

Re-lubricate follower and tube guide rollers.

to less than one minute (risk of attack).

Re-lubricate follower and tube guide rollers.

Not recommended: possible risk to polycarbonate tube

clamp adjusters and polypropylene tube clamp locators.

Re-lubricate follower and tube guide rollers.

minute (risk of attack).

Re-lubricate follower and tube guide rollers.

cap exposure to less than one minute (risk of attack).

Re-lubricate follower and tube guide rollers.

clamp adjusters and polypropylene tube clamp locators.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 30

Page 30 of 47Watson-Marlow Bredel E-Manuals

15 520RC, 520R2C and 520REC rotor settings

520RC, 520R2C and 520REC pumpheads are factory-set to give optimum tube life with

Watson-Marlow tubing. Radial roller positions should not be adjusted in any circumstances

as this will adversely affect pumphead performance and invalidate warranty. Tamper-proof

rotor arm occlusion setting screws are fitted to warn operators from occlusion adjustment.

Tubing with a wall thickness other than 1.6mm or 2.4mm can be used only with a

pumphead set up for that purpose during manufacture. Contact Watson-Marlow technical

support.

Note: 520RC, 520R2C, and 520REC pumpheads can not be adapted to use tube with walls

thicker than 2.4mm.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 31

16 Pumphead spares

520RC/520R2C 520RELC/520REMC/520REHC

Page 31 of 47Watson-Marlow Bredel E-Manuals

1 MNA2050A (520RC, 520R2C)

2 MNA2044A (520RC, 520R2C) Track assembly for close-coupled pumps

3 MNA2076A

(520RC - 1.6mm wall tube)

MNA2077A

(520R2C - 2.4mm wall tube)

MNA2148A (grey) (520RELC)

MNA2149A (beige) (520REMC)

MNA2150A (blue) (520REHC)

4 MN2011M

S60022

5 MNA2043A

(520RC - 1.6mm wall tube)

MNA2001A

(520R2C - 2.4mm wall tube)

MNA2138A

(520RELC - 0-2 bar, 0-30 psi)

MNA2139A

(520REMC - 2-4 bar, 30-60 psi)

MNA2140A

(520REHC - 4-7 bar, 60-100 psi)

6 MNA2006A (520RC, 520R2C)

MN2002M (520RC, 520R2C)

MN2131M (520REC)

7 MNA2005A (520RC, 520R2C)

MN2002M (520RC, 520R2C)

8 MN2034B

MN2005M

9 MNA2147A (520REC) Pumphead guard complete with

10 MNA2145A (520REC) Track assembly for close-coupled pumps

11 MN2023T and MN2003T (520REC) Drain port and nut

Rotor assembly complete with pumping rollers,

complete with tool-unlockable latch

complete with spring-loaded tube clamps

Rotor cover, rotor cap and clutch button

follower rollers and tube guide rollers

Tube clamp location plug

Tube clamp location plug

Guard latch spring cartridge

seal and tool-unlockable latch

Pumphead guard

Clutch

Clutch spring

Bottom (LH) tube clamp

Drain plug

Top (RH) tube clamp

Guard latch spring

Parts may be ordered individually.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 32

Page 32 of 47Watson-Marlow Bredel E-Manuals

17 Flow rates

Pumping conditions

For precise and repeatable performance it is important to determine flow rates

under operating conditions for each new piece of tubing.

When rotating counter-clockwise, 520R, 520R2 and 520RE pumpheads' flow rates

are directly proportional to rotor speed. When rotating clockwise, 520R, 520R2

and 520RE pumpheads' flow rates are directly proportional to rotor speed up to

1.5 bar; their performance above 1.5 bar should be determined empirically.

Note: 520RE pumpheads should be used rotating counter-clockwise if pressures

above 1.5 bar are required.

If you wish to run the pump at a speed not shown in the tables below, flow figures

can be reached by dividing the maximum flow shown in the tables below by the

maximum rpm figure, and multiplying the result by your required speed in rpm.

Actual flow rates achieved may vary because of changes in temperature, viscosity, inlet and

discharge pressures, system configuration and tubing performance against time. Flow rates

may also vary due to normal manufacturing tolerances of the tubing. These tolerances will

make flow rate variance more pronounced at smaller bore sizes.

520R and 520R2

All performance figures for the 520R and 520R2 pumpheads have been recorded against

peak pipeline pressures.

Although rated to 2bar (30psi) peak pressure, this pump will generate in excess of 2bar

(30psi) peak pressure if the pipeline is restricted. Where it is important that 2bar (30psi) is

not exceeded, pressure relief valves should be installed in the pipeline.

Viscosity handling is maximised by using 2.4mm wall tubing with the 520R2 pumphead.

Flow rates are normalised test values obtained using 225mm (8 7/8) of new tubing

(measured from the inside faces of the tube clamps), and the pumphead rotating clockwise

pumping water at 20C with negligible inlet and discharge pressures.

Note: Flow rates quoted are for 1.6mm and 2.4mm wall tubes of nominal bore. Tubes of

0.5mm and 0.8mm bore are only available in 1.6mm wall thickness except for platinumcured silicone. Tubes of 9.6mm bore are only available in 2.4mm wall thickness.

520RE

Performance figures for the 520REL and 520REM have been recorded against 2bar peak

pressure and 4bar peak pressure respectively.

Performance figures for the 520REH have been recorded against 7bar constant pressure.

Although the 520REL is rated to 2bar (30psi) peak pressure, the 520REM is rated to 4bar

(60psi) peak pressure and the 520REH is rated to 7bar (100psi) constant pressure the

pumps will generate in excess of these pressures if the system pressures exceed this.

Where it is important that these rated pressures are not exceeded, pressure relief valves

should be installed in the pipeline.

Flow rates are normalised test values obtained using 520 elements and the pumphead

rotating anticlockwise pumping water at 20C with negligible inlet and discharge pressures.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 33

Continuous tubing

520RC Neoprene, Sta-Pure, Chem-Sure, PVC, Pumpsil (ml/min)

Speed

range

521F/RC, 521F/R2C

521I/RC, 521I/R2C

6-60rpm

21213rpm

29291rpm

521P/RC, 521P/R2C

26-

257rpm

521VI/RC, 521VI/R2C

6-63rpm

22220rpm

27275rpm

521FX/RC, 521FX/R2C

521DFX/RC, 521DFX/R2C

521IX/RC, 521IX/R2C

6-54rpm

21206rpm

0.5mm 0.8mm 1.6mm 3.2mm 4.8mm 6.4mm 8.0mm 9.6mm

0.26-

2.6

0.9-9.2 2.3-23 9.2-94 37-370 83-840

1.2-132 3.2-32 13-130 51-510

1.1-11 2.9-28 11-110

0.26-

2.7

0.95-

9.5

1.2-12 3.0-30 12-120 48-480

0.26-

2.3

0.9-8.9 2.3-23 9.2-91 37-360 83-820

0.66-

6.6

0.66-

6.9

2.4-24 9.7-97 39-390 87-870

0.66-

5.9

2.6-26 11-110 24-240 42-420 66-660 95-950

1101200

464500

2.6-28 11-110 24-250 42-440 66-690 95-1000

2.6-24 11-95 24-210 42-380 66-590 95-860

1001000

1101100

1501500

2002000

1801800

1501500

1901900

1501500

2302300

3203200

2902800

2402400

3003000

2302300

Page 33 of 47Watson-Marlow Bredel E-Manuals

3303400

4604600

4104100

3503500

4304400

3303300

520RC Marprene / Bioprene 64 shore tubing (ml/min)

Speed

range

521F/RC, 521F/R2C

521I/RC, 521I/R2C

6-60rpm

21213rpm

29291rpm

521P/RC, 521P/R2C

26-

257rpm

521VI/RC, 521VI/R2C

6-63rpm

22220rpm

27275rpm

521FX/RC, 521FX/R2C

521DFX/RC, 521DFX/R2C

521IX/RC, 521IX/R2C

0.5mm 0.8mm 1.6mm 3.2mm 4.8mm 6.4mm 8.0mm 9.6mm

0.25-

2.5

0.86-

8.7

1.2-12 3.0-31 12-120 49-490

1.1-11 2.7-27 11-110 44-430 98-970

0.25-

2.6

0.90-

9.0

1.1-11 2.8-29 11-120 45-460

0.25- 0.63-

0.63-

6.3

2.2-22 8.8-89 35-360 79-810

0.63-

6.6

2.3-23 9.2-92 37-370 83-830

2.5-25 10-100 23-230 40-400 63-630 91-910

1101100

2.5-26 10-110 23-240 40-420 63-660 91-950

1001000

1401400

1902000

1701700

1501500

1801800

2202200

3003100

2702700

2302300

2802900

3203200

4404400

3903900

3303300

4104200

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 34

Page 34 of 47Watson-Marlow Bredel E-Manuals

6-54rpm

21-

206rpm

2.2 5.7 2.5-23 10-91 23-200 40-360 63-570 91-820

0.86-

8.4

2.2-22 8.8-87 35-350 79-780

1401400

2202200

3203100

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 35

Page 35 of 47Watson-Marlow Bredel E-Manuals

520RC Fluorel (ml/min)

Speed range 1.6mm 3.2mm 4.8mm 6.4mm 8.0mm

521F/RC, 521F/R2C

521I/RC, 521I/R2C

6-60rpm

21-213rpm

29-291rpm

521P/RC, 521P/R2C

26-257rpm

521VI/RC, 521VI/R2C

6-63rpm 1.9-20 7.7-81 17-180 31-320 48-500

22-220rpm 7.0-70 28-280 63-630 110-1100 180-1800

27-275rpm

521FX/RC, 521FX/R2C

521DFX/RC, 521DFX/R2C

521IX/RC, 521IX/R2C

6-54rpm

21-206rpm

1.9-19 7.7-77 17-170 31-310 48-480

6.7-68 27-270 60-610 110-1100 170-1700

9.3-93 37-370 84-840 150-1500 230-2300

8.3-82 33-330 75-740 130-1300 210-2100

8.6-88 35-350 78-790 140-1400 220-2200

1.9-17 7.7-69 17-160 31-280 48-430

6.7-66 27-260 60-590 110-1100 170-1600

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 36

520RC Neoprene, Sta-Pure, Chem-Sure, PVC, Pumpsil (USGPH)

Speed

range

521F/RC, 521F/R2C

521DF/RLA, 521DF/RL2A

521P/RC, 521P/R2C

521V/RC, 521V/R2C

5.7-57rpm

22.7227rpm

521VI/RC, 521VI/R2C

6.3-63rpm

22-220rpm

27.5275rpm

521FD/RC, 521FD/R2C

521DFD/RC, 521DFD/R2C

6.5-65rpm

24.7247rpm

0.5mm 0.8mm 1.6mm 3.2mm 4.8mm 6.4mm 8.0mm 9.6mm

0.004-

0.04

0.015-

0.15

0.004-

0.04

0.015-

0.15

0.019-

0.19

0.004-

0.04

0.017-

0.17

0.01-

0.1

0.04-

0.4

0.01-

0.1

0.04-

0.4

0.05-

0.5

0.01-

0.1

0.04-

0.4

0.04-

0.4

0.16-

1.6

0.04-

0.4

0.15-

1.5

0.19-

1.9

0.05-

0.5

0.17-

1.7

0.16-

1.6

0.63-

6.3

0.18-

1.8

0.61-

6.1

0.77-

7.7

0.18-

1.8

0.69-

6.9

0.36-

3.6

1.4-14 2.5-25 4.0-40 5.7-57

0.40-

4.0

1.4-14 2.5-25 3.8-38 5.5-55

1.7-17 3.1-31 4.8-48 6.9-69

0.41-

4.1

1.6-16 2.8-28 4.3-43 6.2-62

0.64-

6.4

0.70-

7.0

0.73-

7.3

Page 36 of 47Watson-Marlow Bredel E-Manuals

0.99-

9.9

1.1-11 1.6-16

1.1-11 1.6-16

1.4-14

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 37

520RC Marprene / Bioprene 64 shore tubing (USGPH)

Speed

range

521F/RC, 521F/R2C

521DF/RLA, 521DF/RL2A

521P/RC, 521P/R2C

521V/RC, 521V/R2C

5.7-57rpm

22.7227rpm

521VI/RC, 521VI/R2C

6.3-63rpm

22-220rpm

27.5275rpm

521FD/RC, 521FD/R2C

521DFD/RC, 521DFD/R2C

6.5-65rpm

24.7247rpm

0.5mm 0.8mm 1.6mm 3.2mm 4.8mm 6.4mm 8.0mm 9.6mm

0.004-

0.04

0.015-

0.15

0.004-

0.04

0.014-

0.14

0.018-

0.18

0.004-

0.04

0.016-

0.16

0.01-

0.1

0.04-

0.4

0.01-

0.1

0.04-

0.4

0.05-

0.5

0.01-

0.1

0.04-

0.4

0.04-

0.4

0.15-

1.5

0.04-

0.4

0.15-

1.5

0.18-

1.8

0.04-

0.4

0.16-

1.6

0.15-

1.5

0.60-

6.0

0.17-

1.7

0.59-

5.9

0.73-

7.3

0.17-

1.7

0.66-

6.6

0.34-

3.4

1.4-14 2.4-24 3.8-38 5.4-54

0.38-

3.8

1.3-13 2.3-23 3.7-37 5.3-53

1.6-16 2.9-29 4.6-46 6.6-66

0.39-

3.9

1.5-15 2.6-26 4.1-41 5.9-59

0.61-

6.1

0.67-

6.7

0.69-

6.9

Page 37 of 47Watson-Marlow Bredel E-Manuals

0.95-

9.5

1.0-10 1.5-15

1.1-11 1.6-16

1.4-14

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 38

Page 38 of 47Watson-Marlow Bredel E-Manuals

520RC Fluorel (USGPH)

Speed range 1.6mm 3.2mm 4.8mm 6.4mm 8.0mm

521F/RC, 521F/R2C

521DF/RLA, 521DF/RL2A

521P/RC, 521P/R2C

521V/RC, 521V/R2C

5.7-57rpm

22.7-227rpm

521VI/RC, 521VI/R2C

6.3-63rpm

22-220rpm

27.5-275rpm 0.14-1.4 0.56-5.6 1.3-13 2.2-22 3.5-35

521FD/RC, 521FD/R2C

521DFD/RC, 521DFD/R2C

6.5-65rpm

24.7-247rpm

0.03-0.3 0.12-1.2 0.26-2.6 0.46-4.6 0.72-7.2

0.12-1.2 0.46-4.6 1.0-10 1.8-18 2.9-29

0.03-0.3 0.13-1.3 0.29-2.9 0.51-5.1 0.80-8.0

0.11-1.1 0.45-4.5 1.0-10 1.8-18 2.8-28

0.03-0.3 0.13-1.3 0.30-3.0 0.53-5.3 0.82-8.2

0.13-1.3 0.50-5.0 1.1-11 2.0-20 3.1-31

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 39

Elements

Page 39 of 47Watson-Marlow Bredel E-Manuals

520RELC Neoprene,

Sta-Pure, Chem-Sure,

Pumpsil (ml/min)

Speed range 3.2mm 6.4mm 9.6mm 3.2mm 6.4mm 9.6mm

521F/RELC, 521I/RELC

6-60rpm

21-213rpm

29-291rpm

521P/RELC

26-257rpm 46-450 180-1800 410-4100 44-430 170-1700 390-3900

521VI/RELC

6-63rpm 11-110 42-440 95-1000 10-110 40-420 91-950

22-220rpm

27-275rpm

521FX/RELC, 521IX/RELC

5-54rpm

21-206rpm

Speed range 3.2mm 6.4mm 9.6mm 3.2mm 6.4mm 9.6mm

521F/RELC, 521I/RELC

6-60rpm 0.167-1.7 0.67-6.7 1.5-15 0.160-1.6 0.64-6.4 1.4-14

21-213rpm 0.586-5.9 2.3-24 5.3-53 0.559-5.7 2.2-23 5.0-51

29-291rpm 0.809-8.1 3.2-32 7.3-73 0.772-7.7 3.1-31 7.0-70

521P/RELC

26-257rpm

521VI/RELC

6-63rpm 0.167-1.8 0.67-7.0 1.5-16 0.160-1.7 0.64-6.7 1.4-15

22-220rpm 0.614-6.1 2.5-25 5.5-55 0.586-5.9 2.3-23 5.3-53

27-275rpm 0.753-7.7 3.0-31 6.8-69 0.719-7.3 2.9-29 6.5-66

521FX/RELC, 521IX/RELC

5-54rpm 0.167-1.5 0.67-6.0 1.5-14 0.160-1.4 0.64-5.8 1.4-13

21-206rpm 0.586-5.7 2.3-23 5.3-52 0.559-5.5 2.2-22 5.0-49

11-110 42-420 95-950 10-100 40-400 91-910

37-370 150-1500 330-3400 35-360 140-1400 320-3200

51-510 200-2000 460-4600 49-490 190-2000 440-4400

39-390 150-1500 350-3500 37-370 150-1500 330-3300

48-480 190-1900 430-4400 45-460 180-1800 410-4200

8.8-95 35-380 79-860 8.4-91 34-360 76-820

37-360 150-1500 330-3300 35-350 140-1400 320-3100

520RELC Neoprene,

Sta-Pure, Chem-Sure,

Pumpsil (USGPH)

0.725-7.2 2.9-29 6.5-65 0.692-6.8 2.8-27 6.2-62

520RELC Marprene /

Bioprene TL (ml/min)

520RELC Marprene /

Bioprene TL (USGPH)

520REMC Sta-Pure,

Chem-Sure, (ml/min)

Speed range 3.2mm 6.4mm 3.2mm 6.4mm

521F/REMC, 521I/REMC

6-60rpm 11-110 42-420 10-100 40-400

21-213rpm 37-370 150-1500 35-360 140-1400

29-291rpm 51-510 200-2000 49-490 190-2000

521P/REMC

26-257rpm

521VI/REMC

46-450 180-1800 44-430 170-1700

520REMC Marprene /

Bioprene TM (ml/min)

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 40

Page 40 of 47Watson-Marlow Bredel E-Manuals

6-63rpm

22-220rpm

27-275rpm

521FX/REMC, 521IX/REMC

5-54rpm 8.8-95 35-380 8.4-91 34-360

21-206rpm 37-360 150-1500 35-350 140-1400

Speed range 3.2mm 6.4mm 3.2mm 6.4mm

521F/REMC, 521I/REMC

6-60rpm

21-213rpm 0.586-5.9 2.3-24 0.559-5.7 2.2-23

29-291rpm 0.809-8.1 3.2-32 0.772-7.7 3.1-31

521P/REMC

26-257rpm 0.725-7.2 2.9-29 0.692-6.8 2.8-27

521VI/REMC

6-63rpm

22-220rpm

27-275rpm

521FX/REMC, 521IX/REMC

5-54rpm 0.167-1.5 0.67-6.0 0.160-1.4 0.64-5.8

21-206rpm 0.586-5.7 2.3-23 0.559-5.5 2.2-22

11-110 42-440 10-110 40-420

39-390 150-1500 37-370 150-1500

48-480 190-1900 45-460 180-1800

520REMC Sta-Pure,

Chem-Sure, (USGPH)

0.167-1.7 0.67-6.7 0.160-1.6 0.64-6.4

0.167-1.8 0.67-7.0 0.160-1.7 0.64-6.7

0.614-6.1 2.5-25 0.586-5.9 2.3-23

0.753-7.7 3.0-31 0.719-7.3 2.9-29

520REMC Marprene /

Bioprene TM (USGPH)

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 41

Page 41 of 47Watson-Marlow Bredel E-Manuals

520REHC Marprene,

Bioprene TH,

Sta-Pure (ml/min)

Speed range 3.2mm 3.2mm

521F/REHC, 521I/REHC

6-60rpm 12-120 0.195-1.9

21-213rpm 43-440 0.681-6.9

29-291rpm 59-600 0.940-9.4

521P/REHC

26-257rpm

521VI/REHC

6-63rpm 12-130 0.195-2.0

22-220rpm 45-450 0.713-7.1

27-275rpm 55-560 0.875-8.9

521FX/REHC, 521IX/REHC

5-54rpm 10-110 0.195-1.8

21-206rpm 43-420 0.681-6.7

53-530 0.843-8.3

520REHC Marprene,

Bioprene TH,

Sta-Pure (USGPH)

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 42

Page 42 of 47Watson-Marlow Bredel E-Manuals

18 Tubing and element part numbers

1.6mm wall tubing for 520R pumpheads

mm inch # Marprene Bioprene Chem-Sure

0.5 1/50" 112

0.8 1/32" 13

1.6 1/16" 14

3.2 1/8" 16

4.8 3/16" 25

6.4 1/4" 17

8.0 5/16" 18

mm inch # PVC Fluorel Neoprene

0.8 1/32" 13

1.6 1/16" 14

3.2 1/8" 16

4.8 3/16" 25

6.4 1/4" 17

8.0 5/16" 18

mm inch # Pumpsil Sta-Pure

0.5 1/50" 112

0.8 1/32" 13

1.6 1/16" 14

3.2 1/8" 16

4.8 3/16" 25 913.A048.016 960.0048.016

6.4 1/4" 17

8.0 5/16" 18

Note: 1.6mm wall Chem-Sure and Sta-Pure tubing are supplied in 305mm lengths.

902.0005.016 903.0005.016

902.0008.016 903.0008.016

902.0016.016 903.0016.016 965.0016.016

902.0032.016 903.0032.016 965.0032.016

902.0048.016 903.0048.016 965.0048.016

902.0064.016 903.0064.016 965.0064.016

902.0080.016 903.0080.016 965.0080.016

920.0008.016

950.0016.016 970.0016.016 920.0016.016

950.0032.016 970.0032.016 920.0032.016

950.0048.016 970.0048.016 920.0048.016

950.0064.016 970.0064.016 920.0064.016

950.0080.016 970.0080.016 920.0080.016

913.A005.016

913.A008.016

913.A016.016 960.0016.016

913.A032.016 960.0032.016

913.A064.016 960.0064.016

913.A080.016 960.0080.016

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 43

Page 43 of 47Watson-Marlow Bredel E-Manuals

2.4mm wall tubing for 520R2C pumpheads

mm inch # Marprene Bioprene Pumpsil

0.5 1/50" 913.A005.024

0.8 1/32" 913.A008.024

1.6 1/16" 119

3.2 1/8" 120

4.8 3/16" 15

6.4 1/4" 24

8.0 5/16" 121

9.6 3/8" 122

mm inch # Chem-Sure Sta-Pure

1.6 1/16" 119

3.2 1/8" 120

4.8 3/16" 15

6.4 1/4" 24

8.0 5/16" 121 965.0080.024 960.0080.024

Note: 2.4mm wall Chem-Sure and Sta-Pure tubing are supplied in 355mm lengths.

9.6mm bore tubing is supplied in 610mm lengths.

902.0016.024 903.0016.024 913.A016.024

902.0032.024 903.0032.024 913.A032.024

902.0048.024 903.0048.024 913.A048.024

902.0064.024 903.0064.024 913.A064.024

902.0080.024 903.0080.024 913.A080.024

902.0096.024 903.0096.024 913.A096.024

965.0016.024 960.0016.024

965.0032.024 960.0032.024

965.0048.024 960.0048.024

965.0064.024 960.0064.024

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 44

Page 44 of 47Watson-Marlow Bredel E-Manuals

2.4mm wall elements for 520RE pumpheads

0-2 bar (0-30 psi) pressure rated elements

Industrial

mm inch # Marprene TL Pumpsil Neoprene Chem-Sure

3.2 1/8" 16

6.4 1/4" 17

9.6 3/8" 122

Sanitary

mm inch # Bioprene TL Pumpsil Sta-Pure Chem-Sure

3.2 1/8" 16

6.4 1/4" 17 903.0064.PFT 913.A064.PFT 960.0064.PFT 965.0064.PFT

9.6 3/8" 122 903.0096.PFT 913.A096.PFT 960.0096.PFT 965.0096.PFT

2-4 bar (30-60 psi) pressure rated elements

Industrial

mm inch # Marprene TM Chem-Sure

3.2 1/8" 16

6.4 1/4" 17

Sanitary

mm inch # Bioprene TM Sta-Pure

3.2 1/8" 16 903.P032.PFT 960.M032.PFT

6.4 1/4" 17 903.P064.PFT 960.M064.PFT

902.0032.PFQ 913.A032.PFQ 920.0032.PFQ 965.0032.PFQ

902.0064.PFQ 913.A064.PFQ 920.0064.PFQ 965.0064.PFQ

902.0096.PFQ 913.A096.PFQ 920.0096.PFQ 965.0096.PFQ

903.0032.PFT 913.A032.PFT 960.0032.PFT 965.0032.PFT

902.P032.PFQ 965.M032.PFQ

902.P064.PFQ 965.M064.PFQ

4-7 bar (60-100 psi) pressure rated elements

Industrial

mm inch # Marprene TH Sta-Pure

3.2 1/8" 16

Sanitary

mm inch # Bioprene TH Sta-Pure

3.2 1/8" 16

902.H032.PFQ 960.H032.PFQ

903.H032.PFT 960.H032.PFT

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 45

Page 45 of 47Watson-Marlow Bredel E-Manuals

19 520 series pumping accessories

Accessory Description Part code Pump compatibility

520ANC Network cable, RS232, with 9-pin D-

520ANX Network extension cable with 9-pin D-

520ANA Network adaptor, 25-pin to 9-pin D-

520AB Batch records cable with 9-pin D-

520AF Footswitch with 25-pin D-connector 059.3002.000 520U, 520Du, 520Di

520AH Handswitch with 25-pin D-connector 059.3022.000 520U, 520Du, 520Di

520AV Proximity switch 059.5072.000 520Di

520AVN Proximity switch 059.507N.000 520DiN

505LTC Tube clamp set for 505L pumphead 059.4001.000 520Di

505AS Filling stand 059.5001.000 All models

520AL Dispensing lance for use with 520AFN

505AFN Filling needle set 059.5101.000 All models

620AL Leak detector kit, bare lead 069.7131.000 520UN, 520DuN,

connectors

connectors

connectors

connectors

filling needles

Filling needle 1.6mm bore 059.5100.016 All models

Filling needle 3.2mm bore 059.5100.032 All models

Filling needle 4.8mm bore 059.5100.048 All models

Filling needle 6.4mm bore 059.5100.064 All models

Filling needle 8.0mm bore 059.5100.080 All models

Tube monitor with 25-pin D-connector 059.4501.520 520U, 520Du, 520Di

Tube monitor, bare lead 059.450N.520 520UN, 520DuN,

059.3121.000 520Du, 520Di

059.3122.000 520Du, 520Di

059.3123.000

059.3125.000 520Di

059.5052.000 All models

520DiN

520DiN

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 46

Page 46 of 47Watson-Marlow Bredel E-Manuals

20 Trademarks

Watson-Marlow, Bioprene, LoadSure and Marprene are trademarks of Watson-Marlow

Limited.

Fluorel is a trademark of 3M.

Sta-Pure and Chem-Sure are trademarks of W.L.Gore and Associates.

21 Warning not to use pumps in patientconnected applications

Warning These products are not designed for use in, and should not be used for patient-

connected applications.

22 Publication history

PB0339gb-02; m-521cc-gb-03.htm: Watson-Marlow 521CC

First published 02 03. This edition 02 06.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Page 47

Page 47 of 47Watson-Marlow Bredel E-Manuals

23 Decontamination certificate

In compliance with the UK Health and Safety at Work Act and the Control of Substances

Hazardous to Health Regulations, you are required to declare the substances which have

been in contact with product(s) you return to Watson-Marlow or its subsidiaries or

distributors. Failure to do so will cause delays. Please ensure that you fax us this form and

receive an RGA (Returned Goods Authorisation) before you despatch the product(s). A copy

of this form must be attached to the outside of the packaging containing the product(s).

Please complete a separate decontamination certificate for each product.

You are responsible for cleaning and decontaminating the product(s) before return.

Your name

Address

Postcode/zip

Telephone

Product type

To speed the repair, please

describe all known faults

The product has ...

Names of chemicals handled

with product(s)

Precautions to be taken in

handling these chemicals

Company

Country

Fax

Serial number

Been used Not been used

If the product has been used, please complete all the following sections. If the product has

not been used, please just sign this form.

Action to be taken in the

event of human contact

Signature

I understand that the personal data collected will be kept confidentially in accordance with

the UK Data Protection Act 1998.

RGA number

Your position

Date

Please print out, sign and fax to Watson-Marlow Pumps at +44 1326 376009.

14/12/2009file://M:\staging\pdfs-global\m-521-cc-gb-03.htm

Loading...

Loading...