Van Air Systems PLD 8-2.8 User Manual

INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

PIPE LINE DEHYDRATOR FOR NATURAL GAS

PLD 8-2.8 thru PLD 36-2.8

PN 32-0280

REV A

FEBRUARY 2011

WARNING

DO NOT REMOVE, REPAIR OR REPLACE ANY ITEM ON THIS VESSEL WHILE IT IS UNDER

PRESSURE.

DO NOT OPERATE IF THERE IS A LEAK IN VESSEL. IMMEDIATELY TAKE VESSEL OUT OF

SERVICE AND CALL YOUR CERTIFYING AUTHORITY. IF THERE IS A LEAK, DEPRESSURIZE

VESSEL, INSPECT, REPAIR AND OR REPLACE AS NECESSARY.

DO NOT OPERATE ABOVE MAXIMUM WORKING PRESSURE (MWP) AND OR ABOVE MAXIMUM

OPERATING TEMPERATURE (DEGREES OF).

DO NOT WELD OR GRIND VESSEL. IT WILL NOT BE SAFE TO OPERATE.

DO NOT OPERATE IF THE VESSEL HAS BEEN DAMAGED BY FIRE. TAKE OUT OF SERVICE

IMMEDIATELY AND NOTIFY YOUR CERTIFYING AUTHORITY.

ANY DAMAGE TO VESSEL CAN MAKE IT UNSAFE. INSPECT OUTSIDE AND INSIDE OF

VESSEL REGULARLY FOR CORROSION OR ANY DAMAGE (I.E., DENTS, GOUGES OR BULGES).

IF DAMAGED, TAKE OUT OF SERVICE IMMEDIATELY. CALL YOUR CERTIFYING AUTHORITY.

1.0 OPERATION

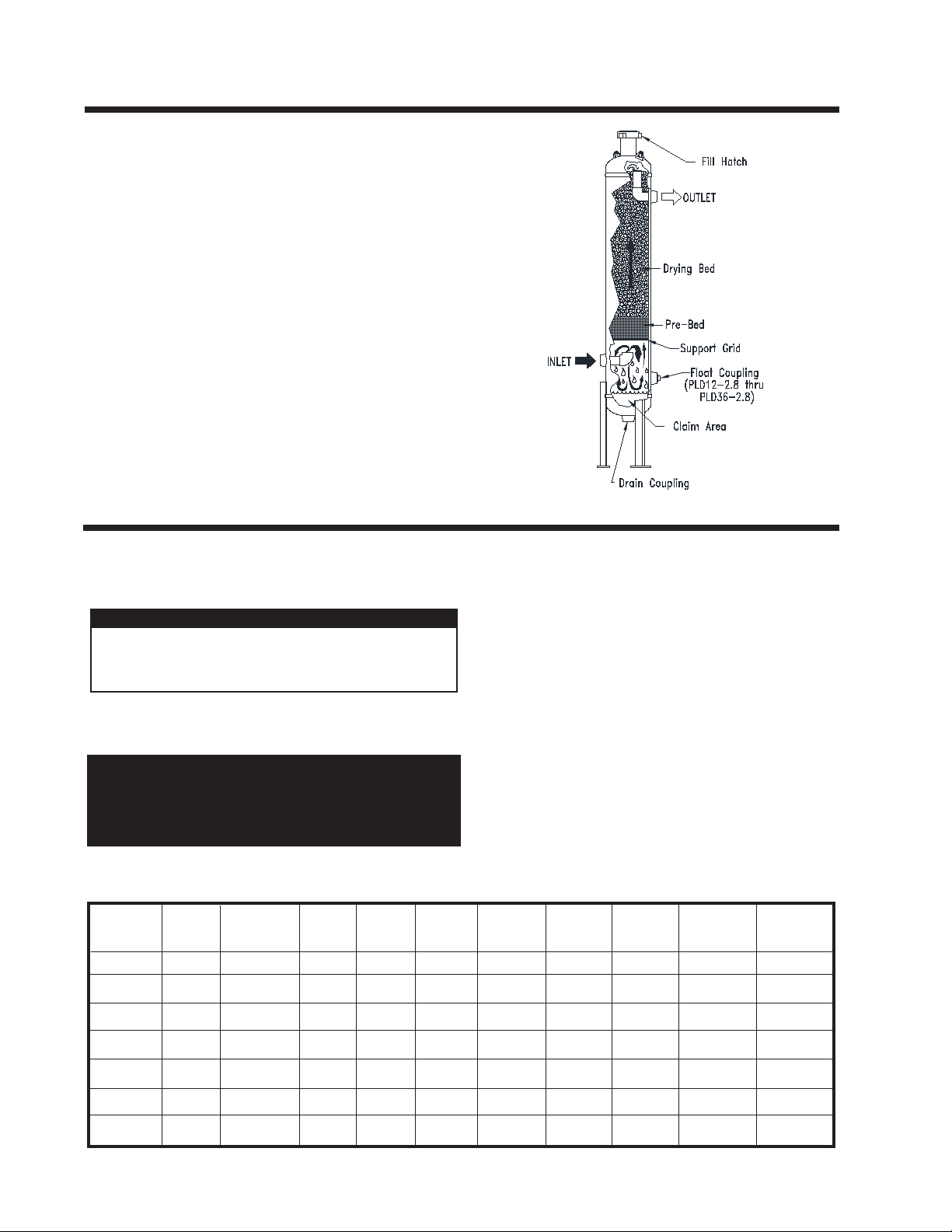

A Pipeline Dehydrator removes the water vapor (humidity) present in the gas stream. The process cleans and dries the gas as it

ows through a vessel which is lled with a special drying agent

(desiccant). The dehydrator operates automatically. There are no

moving parts and no external source of power is required.

"Wet" natural gas enters the lower portion of the dryer where liquid

water and solid particles are separated by gravity and fall to the

bottom of the vessel. The gas moves upward through the prebed

and drying bed of Van Gas desiccant tablets. The tablets attract

and absorb moisture from the gas as it ows through the desiccant

bed. The tablets dissolve gradually as they absorb the moisture

and the liquid falls to the bottom of the vessel. The liquid run off in

the prebed creates an extended surface area capable of removing

additional moisture from the gas. This conserves the absorbent

desiccant tablets. The "dry" natural gas ows through the dryer

outlet.

The solution of dissolved desiccant and water that falls into the

claim area at the bottom of the vessel must be drained regularly to

prevent the vessel from ooding. An automatic drain valve can be

installed to prevent the vessel from ooding.

2.0 INSTALLATION

2.1 LOCATION

The ability of a dehydrator to dry natural gas is dependent on

the correct location of the unit. Temperature and pressure are

the keys to selecting the proper location.

IMPORTANT

ALWAYS PROCESS THE GAS THROUGH THE

DEHYDRATOR AT THE LOWEST TEMPERATURE

AND THE HIGHEST PRESSURE.

INLET GAS TEMPERATURE: Lower inlet gas temperatures will

result in a lower moisture content at the outlet of the dehydrator.

Locate the dehydrator at the point where temperature is the lowest.

CAUTION

The gas temperature should not exceed:

100°F for GASDRY PRIME

80°F for GASDRY PEAK

100°F for GASDRY MAX

MAXIMUM CAPACITIES - MSCFD

1,000 STANDARD CUBIC FEET PER DAY

AFTERCOOLING: If the gas being processed has been compressed

mechanically, an aftercooler, nned tubing or extended run of piping

will usually be necessary to reduce the inlet gas temperature to the

dehydrator.

OPERATING PRESSURE: More gas can be processed through the

dehydrator at higher pressures. Locate the dehydrator at the highest

practical pressure, but do not exceed the maximum rated working

pressure of the dehydrator. Refer to the capacity chart located below.

CAPACITY: The chart below indicates the maximum ow rate

through the dehydrator for a 24 HOUR period. To calculate the

capacity for a rate per minute just multiply the MSCFD RATE (from

chart ) by 0.6944 example:

A PLD 12-2.8 operating at 50 PSIG has a maximum MSCFD rate of

79. To gure the SCFM multiply 79 MSCFD x 0.6944 which equals

54.86SCFM

NOTE: This is the MAX instantanious ow that can be processed

through the dehydrator without deterioration of the drying

performance.

MODEL

NO.

PLD 8-2.8

PLD 12-2.8

PLD 16-2.8

PLD 20-2.8

PLD 24-2.8

PLD 30-2.8

PLD 36-2.8

PAGE 2

PART

NO.

80-1397

80-1399

80-1401

80-1403

80-1405

80-1468

80-1407

MAXIMUM

WORKING

PRESSURE

280 PSIG

280 PSIG

280 PSIG

280 PSIG

280 PSIG

280 PSIG

280 PSIG

50 PSIG

42

79

125

192

280

447

672

100 PSIG

75

141

221

341

497

793

1191

150 PSIG

108

202

317

489

714

1139

1711

175 PSIG

124

233

365

563

822

1312

1970

200 PSIG

141

263

413

638

930

1485

2230

225 PSIG

157

294

462

712

1038

1658

2490

250 PSIG

173

325

510

786

1147

1831

2749

280 PSIG

193

362

567

875

1277

2038

3061

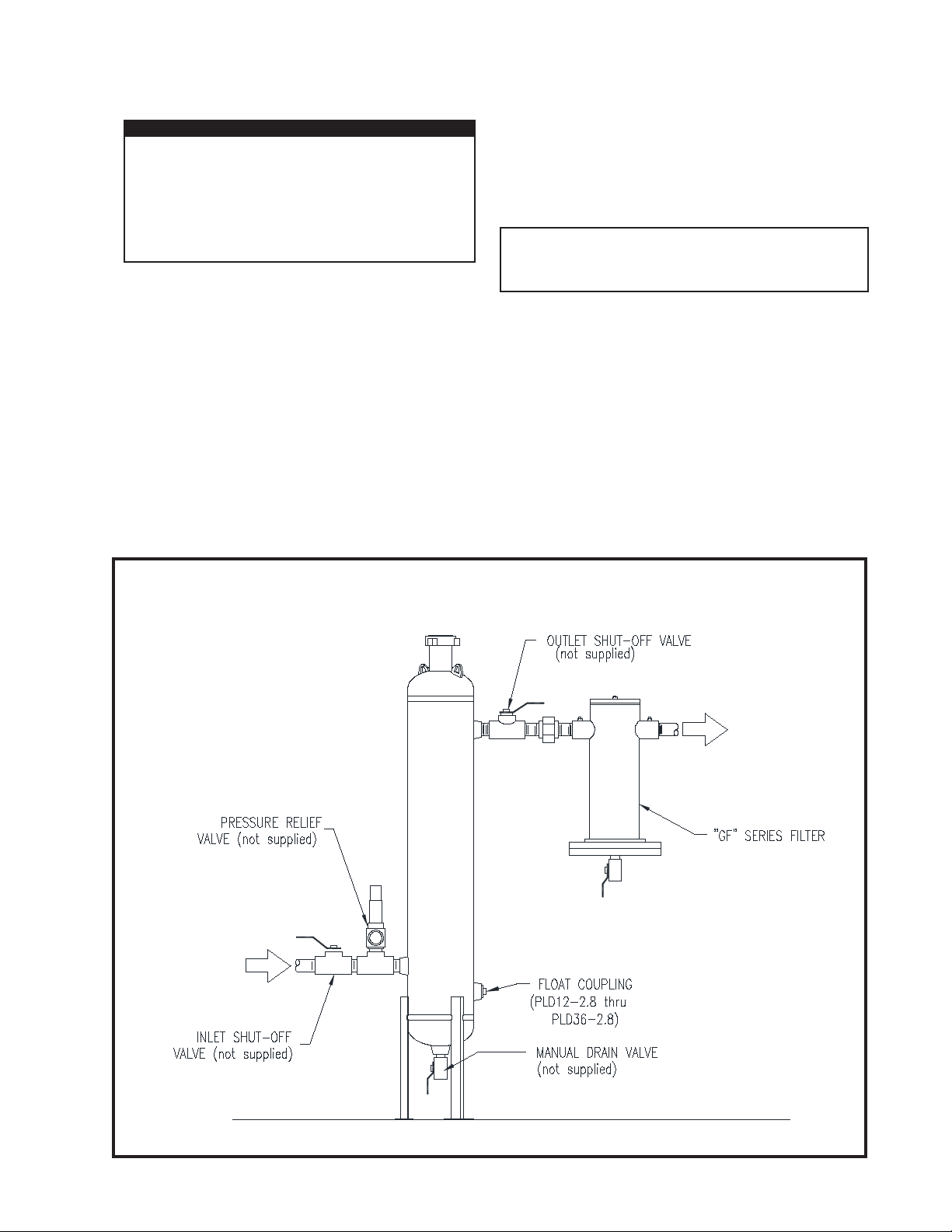

2.2 PIPING AND ANCILLARY EQUIPMENT

2.3 INLET AND OUTLET PIPING

IMPORTANT

COMPLY WITH ALL FEDERAL, STATE, AND

LOCAL REGULATIONS CONCERNING

INSTALLATION OF NATURAL GAS SYSTEMS.

COMPLIANCE TO AND KNOWLEDGE OF ALL

REGULATIONS IS THE RESPONSIBILITY OF

THE INSTALLER.

Make sure that the temperature of gas is not over the maximum

for the desiccant being used. If gas temperature is too high, cool it

prior to the dehydrator.

Mount the dehydrator on a level surface capable of supporting the

weight of the vessel, such as a cement pad or a skid.

Install a pressure relief valve in the up-stream piping (relief

valve not furnished). A relief valve must be installed to

conform with the ASME Boiler and Presssure Vessel Codes,

Section VIII, Division 1 UG-125, Paragraph (1) and OSHA

standards. Also comply with all applicable Federal, State,

and Local codes.

FIGURE 2-A RECOMMENDED INSTALLATION

Two shut-off valves should be installed (not furnished with

dehydrator)-one at dryer inlet and another at dryer outlet. See

Figure 2-A Recommended Installation.

Connect the inlet and outlet piping as shown in Figure 2-A.

NOTE

Inlet and outlet shut-off valves will make start-up

and addition of desiccant easier.

2.4 AFTERFILTER

Van Gas "GF" Series Filters can be installed downstream of the

dehydrator to remove particulate contamination from the natural

gas. Contact Van Gas for details.

2.5 DRAIN VALVE

Install a drain valve (not furnished with dehydrator) in the drain

coupling at the bottom of the tower (except on PLD8-2.8). A oat/

auto drain valve system is available. Contact Van Gas for details.

PAGE 3

Loading...

Loading...