Van Air Systems PD-7 User Manual

INSTALLATION, OPERATION, AND MAINTENANCE INSTRUCTIONS

PRESSURE DIFFERENTIAL GAUGE KIT

RECOMMENDED FOR INSTALLATION ON VME SERIES MIST ELIMINATORS

SPECIFICATIONS

PD-7 KIT p/n 84-0841

MAX. OPERATING PRESSURE ..................... 3000 PSIG

MAX. OPERATING TEMPERATURE .............. 175

OPERATING RANGE ...................................... 0-5 PSID

DIMENSIONS ................... 4"L, 1-1/2"W, 2-1/16"H

PRESSURE PORT CONNECTIONS .............. 1/8" NPT

INSTALLATION

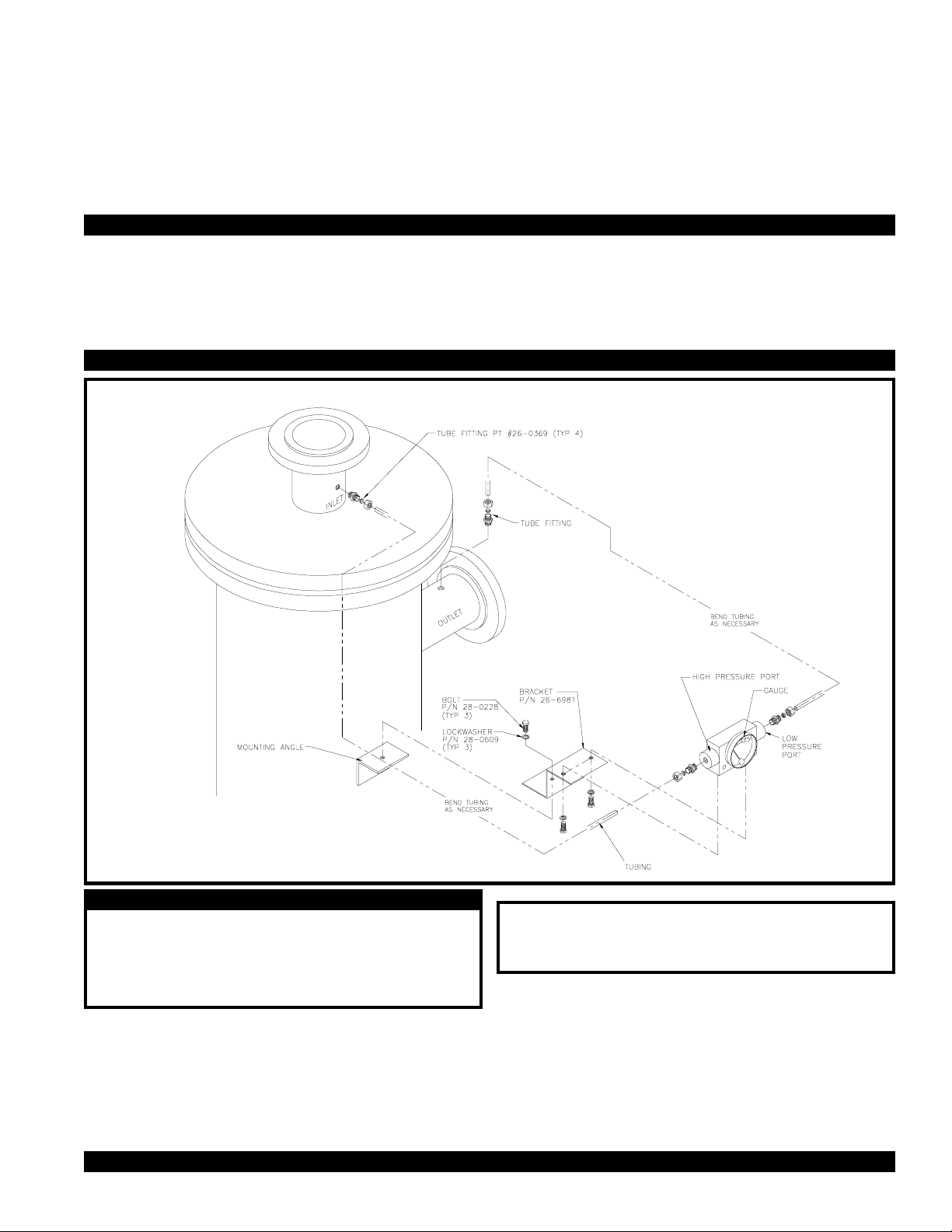

FIGURE 1 INSTALLATION

DECEMBER 2004

P/N 32-0247-A

FOR

PD-7

O

F

WARNING

CAREFULLY READ THESE INSTRUCTIONS BEFORE

INSTALLING THE PRESSURE DIFFERENTIAL KIT.

MAKE SURE THAT THE COMPONENT OR PIPING IS

DEPRESSURIZED BEFORE INSTALLING THE PRESSURE

DIFFERENTIAL KIT.

Completely depressurize the piping and component that the kit is to be

installed on.

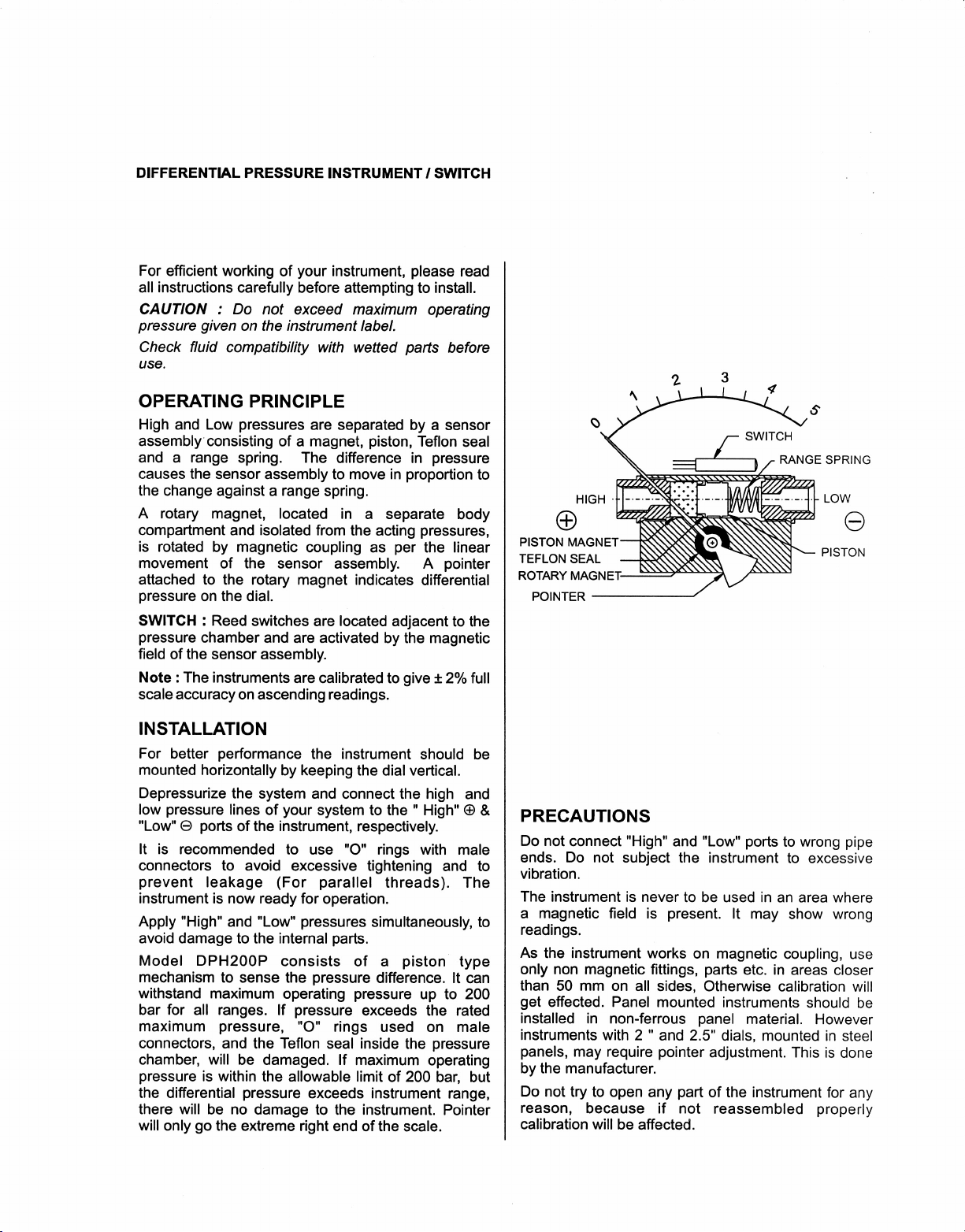

Figure 1 shows a typical assembly/installation of the PD-7 series pressure

differential gauge on a VAN AIR VME series Mist Eleminator.

Mount the PD-7 on the mounting bracket. Use the fasteners provided with

the kit. Mount the kit to the desired surface. The VME vessel has a angle

bracket on the front for the installation of the PD-7 and bracket.

MAINTENANCE

MAINTENANCE IS PER THE GAUGE INSTRUCTION SHEET.

To ensure an accurate reading, make sure that both tubing lines

IMPORTANT

to the PD-7 are equal in length. Use as few as possible bends in

the tubing lines.

Install the necessary tubing from the inlet side of the vessel or piping to be

measured to the HIGH PRESSURE port of the PD-7. Use the tubing and

fittings as shown in FIGURE 1. Use pipe sealant on all threaded pipe

connections.

Complete the tubing connection from the outlet side of the vessel or piping

to be measured to the LOW PRESSURE port of the PD-7. Use the tubing

and fittings as shown in FIGURE 1. Use pipe sealant on all threaded pipe

connections.

Loading...

Loading...