INSTALLATION INSTRUCTIONS

DISPOSABLE CARTRIDGE MS-16

FOR IN-LINE DESICCANT DRYER ID15/IND

AND MINI DRYER MODEL MD4/IND

VAN AIR PART NUMBER: 26-0889

August 2008

P/N: 432-00161-B

WHEN TO REPLACE CARTRIDGE:

Crystals in moisture indicator will change from blue to

pink when molecular sieve in cartridge is saturated with moisture. Install a fresh cartridge when crystals in moisture indicator

turn pink. When air supply is reconnected, crystals in moisture

indicator will turn blue again and remain blue until another

cartridge change is required.

WARNING

BEFORE INSTALLING NEW CARTRIDGE, READ THE

FOLLOWING INSTRUCTIONS CAREFULLY.

REPLACING OLD CARTRIDGE:

Close inlet and outlet shut-off valves (and open bypass if

1.

provided); or lock out all compressed air supply to dryer.

Slowly open ball valve on bottom of housing and allow unit

2.

to depressurize completely.

WARNING

DO NOT PRESSURIZE MINI DRYER UNTIL MS-16 CARTRIDGE IS INSTALLED.

Grasp bottom portion of housing (bowl) with one hand and

3.

turn clamp knob with the other to loosen. Slide clamp down

and off vessel.

Remove used cartridge from head and discard the cartridge.

4.

Remove new cartridge from packaging.

5.

Push new cartridge onto boss of dryer head.

6.

Reinstall bowl and clamp. Make sure that the bowl is tight

7.

against the head and the o-ring is correctly seated in the

groove.

Close the ball valve and slowly pressurize the vessel. If any

8.

leaks occur, depressurize vessel completely and correct the

problem before repressurizing.

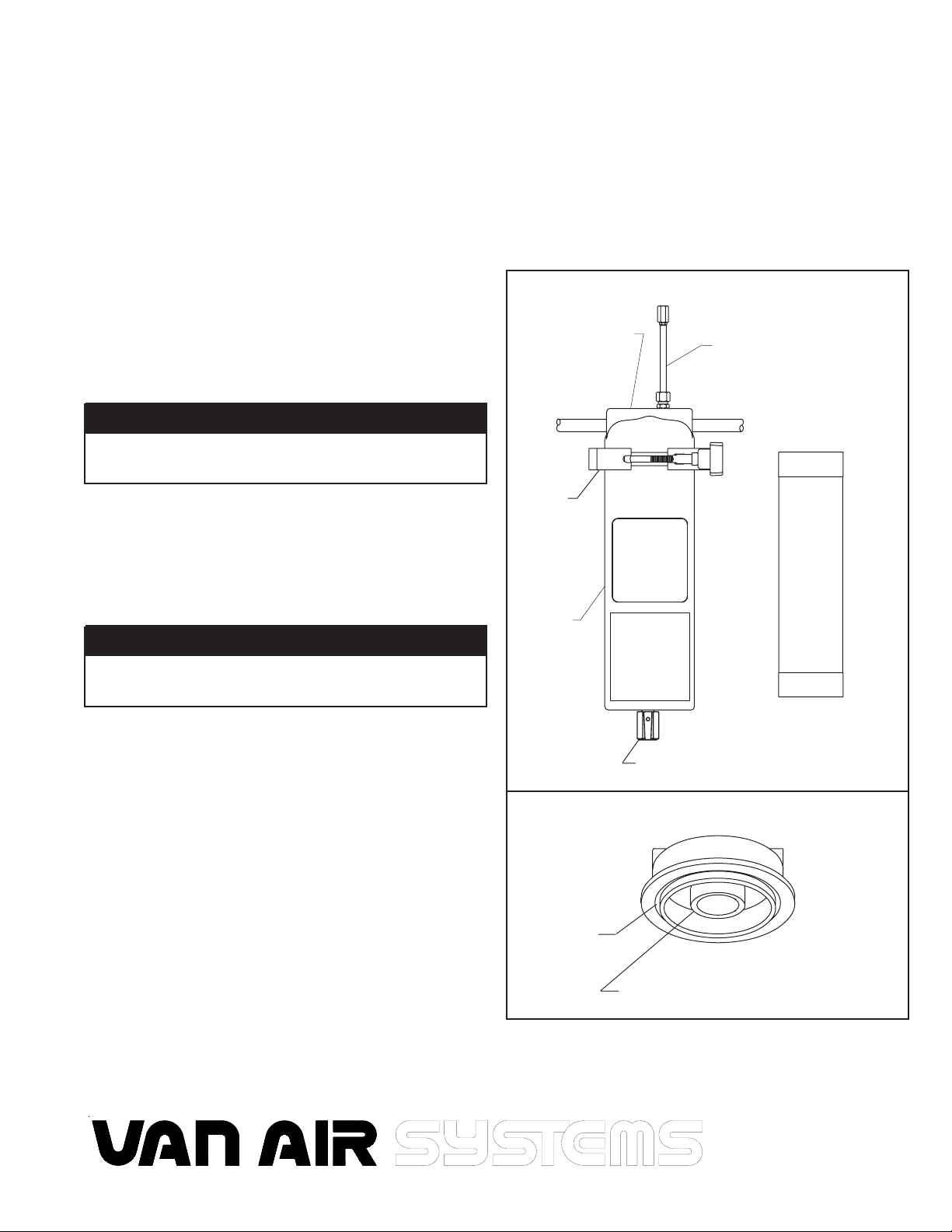

DRYER WITH CARTRIDGE

HEAD

INLET

1/2" NPT

CLAMP

BOWL

VIEW FROM BOTTOM OF DRYER HEAD

O-RING

GROOVE

A

1/4" BALL VALVE

(NOTE: CARTRIDGE SHIPPED

IN BOX WITH DRYER.)

MOISTURE

INDICATOR

OUTLET

1/2" NPT

B

MS-16 MOLECULAR

SIEVE CARTRIDGE

BOSS (INSTALL CARTRIDGE

HERE)

2950 Mechanic Street

Lake City, PA 16423-2095

Phone: 814-774-2631

www.vanairsystems.com

Fax: 814-774-3482

2950 Mechanic Street, Lake City, PA

consulted for specific requirements.

16423-2095

Phone: 814/774-2631

Or 800/840-9906

Order Fax: 814/774-3482

Corporate Fax: 814/774-0778

E-mail: vanair@vanairsystems.com

www.vanairsystems.com

U.S. Department of Labor Occupational

Safety and Health Administration (nonmandatory form)

May be used to comply with OSHA’s

Hazard Communication Standard, 29

CFR 1910.1200. Standard must be

Material Safety Data Sheet

Section 1 – Chemical Product Information Date Prepared: May 1, 2000

Product: Molecular Sieve 1/8” & 1/16”

Part No.: 33-0317, 33-0249 & 33-0265

O

1 1

E

Section 2 – Hazardous Ingredients/Identity Information

Hazardous Components

(Specific Chemical Identity/Common Name(s)) CAS Registry Number OSHA Typical Wt. % CERCLA RQ

Zeolites 1318-02-1 Y >90% Not Established

Quartz 14808-60-7 Y <1.0% Not Established

Kaolin 1332-58-7 Y 0-10% Not Established

Bentonite clay 1302-78-9 Y 0-10% Not Established

Clay, attapulgite 12174-11-7 Y 0-10% Not Established

Sepiolite 15501-74-3 Y 0-10% Not Established

The substances marked with a “Y” in the OSHA column are identified as hazardous chemicals according to the criteria of

the OSHA Communication Standard (29 CFR 1910.1200)

This material is classified as hazardous under Federal OSHA regulation.

This product complies with TSCA inventory requirements. For chemical identity purposes, TSCA considers Zeolites as

crystalline aluminosilicates consisting of a mixture of silicon oxide (CAS# 7631-86-9) & aluminum oxide (CAS# 1344-28-1)

in various proportions with metallic oxides.

Hazard Categories Under Criteria of SARA Title IIII Rules (40 CFR Part 370) WHMIS

Immediate (Acute) Health Y Fire N D2A Carcinogen

Delayed (Chronic) Health Y Reactive N D2B Eye Irritant

Sudden Release of Pressure N

Section 3 – Physical Chemical Characteristics

Boiling Point: Not applicable Vapor Density (Air=1): Not applicable

Specific Gravity (Water=1): .64 - .72 Solubility in Water: Insoluble.

Vapor Pressure (mm Hg): Not applicable Evaporation Rate (Butyl Acetate=1): Not applicable

Melting Point: Not applicable Appearance & Odor: Off-White beads with no odor

Section 4 – Fire and Explosion Hazard Information

Flash Point: Not applicable Flash Point Method: Not applicable

Upper Flammable Limit: Not applicable Lower Flammable Limit: Not applicable

Fire Fighting Instructions: Non-flammable

Extinguishing Media: Use extinguishing agent applicable to surrounding fire conditions.

Fire and Explosion Hazards: None known.

Section 5 – Reactivity Information

Stability: This material is chemically stable under normal and anticipated storage and

Incompatibility (Materials to avoid): Reacts with HF and strong acids and alkalis.

Hazardous decomposition/byproducts: None.

Hazardous Polymerization: Will not occur.

handling conditions.

Van Air Systems, Inc. Molecular Sieve Material Safety Data Sheet Page 2 of 4

Date Prepared: May 1, 2000

Section 6 – Health Hazard Information

Emergency Overview

Off-white beads with no odor.

CAUTION!

MAY CAUSE EYE IRRITATION.

CANCER HAZARD. CONTAINS CRYSTALLINE SILICA WHICH CAN CAUSE CANCER.

Repeated and prolonged inhalation of respirable particles can cause lung cancer and delayed lung damaged (silicosis).

Carcinogenicity: No.

NTP: No.

IARC Monographs: Quartz Class 2A carcinogen.

OSHA Regulated: No.

Emergency and First Aid Procedures

Eyes: Flush with water for at least 15 minutes, lifting upper & lower eyelids.

Skin: Flush with plenty of water. Remove contaminated clothing and shoes. Wash clothing

before reuse.

Inhalation: Remove to fresh air.

Ingestion: Do NOT induce vomiting. Give water to drink. Get medical attention immediately.

NEVER GIVE ANYTHING BY MOUTH TO AN UNCONSIOUS PERSON.

IF IRRITATION DEVELOPS AND PERSISTS SEEK MEDICAL ATTENTION

Potential Health Effects:

Inhalation and skin contact are expected to be the primary routes of occupational exposure to this material.

Zeolites will become hot as they absorb water. Prolonged contact can cause burns to moist body tissues.

Repeated and prolonged inhalation of this material may cause a form of disabling lung disease (commonly known

as silicosis). Clinical signs and symptoms of silicosis include cough, shortness of breath, wheezing and

impairment of lung function. Impairment of lung function may be progressive. In the usual case of silicosis, there

is a slow deterioration of capacity for physical effort, decreased chest expansion, and an increased susceptibility

to tuberculosis and other respiratory infections.

Short term, extremely heavy exposures to dust of this material (particularly small-sized particles) can result in

acute silicosis. This disease is rapidly progressive with diffuse pulmonary involvement, which may develop within

months of initial exposure. Individuals with acute silicosis may suffer an abrupt onset of violent coughing, labored

breathing and weight loss; death has been known to occur within one to two years.

Please see Section 10 – Toxicological Information for more information.

Section 7 – Precautions for Safe Handling and Use

Small/Large Spills:

Stop the leak, if possible. Ventilate the space involved. Absorb, sweep up, and place in container for disposal.

Reduce dust spreading with a water spray. Shut off or remove all ignition sources. Prevent waterway

contamination. Construct a dike to prevent spreading. Protect workers with water spray. Collect run-off water

and transfer to drums or tanks for later disposal. Avoid creating a dusty atmosphere. Consult a regulatory

specialist to determine appropriate state or local reporting requirements, for assistance in waste characterization

and/or hazardous waste disposal and other requirements listed in pertinent environmental permits.

Clean up procedures: Transfer to containers, preparatory for later disposal. Avoid generation of dusts. Place in

non-sparking containers for recovery or disposal. Remove from spill location. Flush area with water spray, collect

rinsate.

Waste Disposal Method:

Recover, reclaim or recycle when practical. Dispose of in accordance with federal, state and local regulations.

Handling:

Avoid breathing dust. Avoid contact with eyes, skin and clothing. Wash thoroughly after handling. Use only with

adequate ventilation. Keep dr y. Contact with water rele as es heat.

Van Air Systems, Inc. Molecular Sieve Material Safety Data Sheet Page 3 of 4

Date Prepared: May 1, 2000

Storage:

Keep material dry; moisture may affect product quality. Moist air or chemical vapors will reduce the operating life

of this material. This material will release heat when absorbing water vapors. If a large quantity of this material

quickly absorbs an equal amount of water, the material can become hot enough to cause thermal burns of the

skin. Material recommended for re-packaging: high density polyethylene (HDPE), polypropylene (PP),

polytetrafluoroethylene (PTFE), fiberboard with moisture barrier.

Section 8 – Control Measures

Engineering Controls:

Investigate engineering techniques to reduce exposures below airborne exposure limits. Provide ventilation if

necessary to control exposure levels below airborne exposure limits (see below). If practical, use local

mechanical exhaust ventilation at sources of air contamination such as open process equipment.

Eye/Face Protection:

Where there is potential for eye contact, wear chemical goggles and have eye flushing equipment available.

Skin Protection:

Wear appropriate chemical resistant protective clothing and chemical resistant gloves to prevent skin contact.

Consult glove manufacturer to determine appropriate type glove material for given application. Rinse

contaminated skin promptly. Wash contaminated clothing and clean protective equipment before reuse. Wash

skin thoroughly after handling.

Respiratory Protection:

Avoid breathing dust. When airborne exposure limits are exceeded (see below), use NIOSH approved respiratory

protection equipment appropriate to the material and/or its components. Consult respirator manufacturer to

determine appropriate type equipment for given application. Observe respirator use limitations specified by

NIOSH or the manufacturer. For emergency and other conditions where exposure limit may be significantly

exceeded, use an approve full face positive-pressure, self-contained breathing apparatus or positive-pressure

airline with auxiliary self-contained air supply. Respiratory protection programs must comply with 29 CFR

1910.134.

Airborne Exposure Guidelines for Ingredients

Exposure Limits Value

Kaolin

ACGIH TWA 2 mg/m3

Quartz

ACGIH TWA 0.1 mg/m3

-Only those components with exposure limits are printed in this section.

-Skin contact limits designated with a “Y” above have skin contact effect. Air sampling alone is insufficient to accurately

quantitate exposure. Measures to prevent significant cutaneous absorption may be required.

Section 9 – Toxicological Information

Data on this material and/or its components are summarized below.

Sodium Aluminosilicate

Kidney effects were observed in rats and dogs administered high dose levels in their feed for one month, while

blood effects were also observed in dogs. Long-term inhalation by rats and dogs produced inflammation in the

lungs associated with accumulation of particulate. Chronic pneumonitis and acute bronchopneumonia were also

seen in rats. No adverse effects were noted in rats and rabbits or their offspring following administration in the

drinking water during pregnancy.

Quartz

Chronic inhalation of crystalline silica may cause a progressive pneumoconiosis (silicosis), a form of disabling

lung disease (pulmonary fibrosis). Data from animals studies on crystalline forms of silica confirm the capacity of

free crystalline silica to induce a fibrinogenic response in lungs. Studies on a variety of laboratory animals (rats,

guinea pigs, rabbits, and monkeys) using inhalation as well as intratracheal routes of exposure indicate the ability

of crystalline silica to produce silicosis similar to that seen in man. In addition, experiments in animals have

confirmed human experience that the presence of crystalline silica in the lung increased susceptibility to

tuberculosis and other lung infections. Crystalline silica inhaled in the form of quartz is classified as “carcinogenic

Van Air Systems, Inc. Molecular Sieve Material Safety Data Sheet Page 4 of 4

Date Prepared: May 1, 2000

to humans” by the IARC, and respirable forms of crystalline silica are listed as substances that “may reasonably

be anticipated to be carcinogens” by the National Toxicology Program. The IARC listing is based on the

determination that there is sufficient evidence in humans for the carcinogenicity of inhaled crystalline silica in the

form of quartz from occupational exposures.

Epidemiology studies cited by IARC give indications of increased risk for lung cancer from inhaled crystalline

silica (quartz) resulting from occupational exposure. Studies involving heavy industrial exposure to silica in

granite and foundry workers, brick factories and sandblasting produced increased levels of protein and enzymes

in urine, which is indicative of kidney damage.

Section 10 – Regulatory Information

Right to Know Lists Products Listed

California Prop 65 – Carcinogen

California list of Known Carcinog ens Quartz

Massachusetts Right to Know

Massachusetts Right to Know Substance List Quartz

New Jersey Right to Know

New Jersey Right to Know Substance List Quartz & Zeolites

Pennsylvania Right to Know

Pennsylvania Hazardous Substance List Kaolin & Quartz

Loading...

Loading...