Page 1

APRIL 2000

P/N: 432-10020

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

®

MB-1 THRU MB-3-2

MOUNTING BRACKET KITS

FOR F200 SERIES FILTER HOUSINGS

PRODUCT PURPOSE & FUNCTION:

Van Air's Mounting Bracket Kits are designed for wall mounting F200 series filter housings. Brackets and mounting compo-

nents are made of zinc plated steel or stainless steel for superior corrosion resistance.

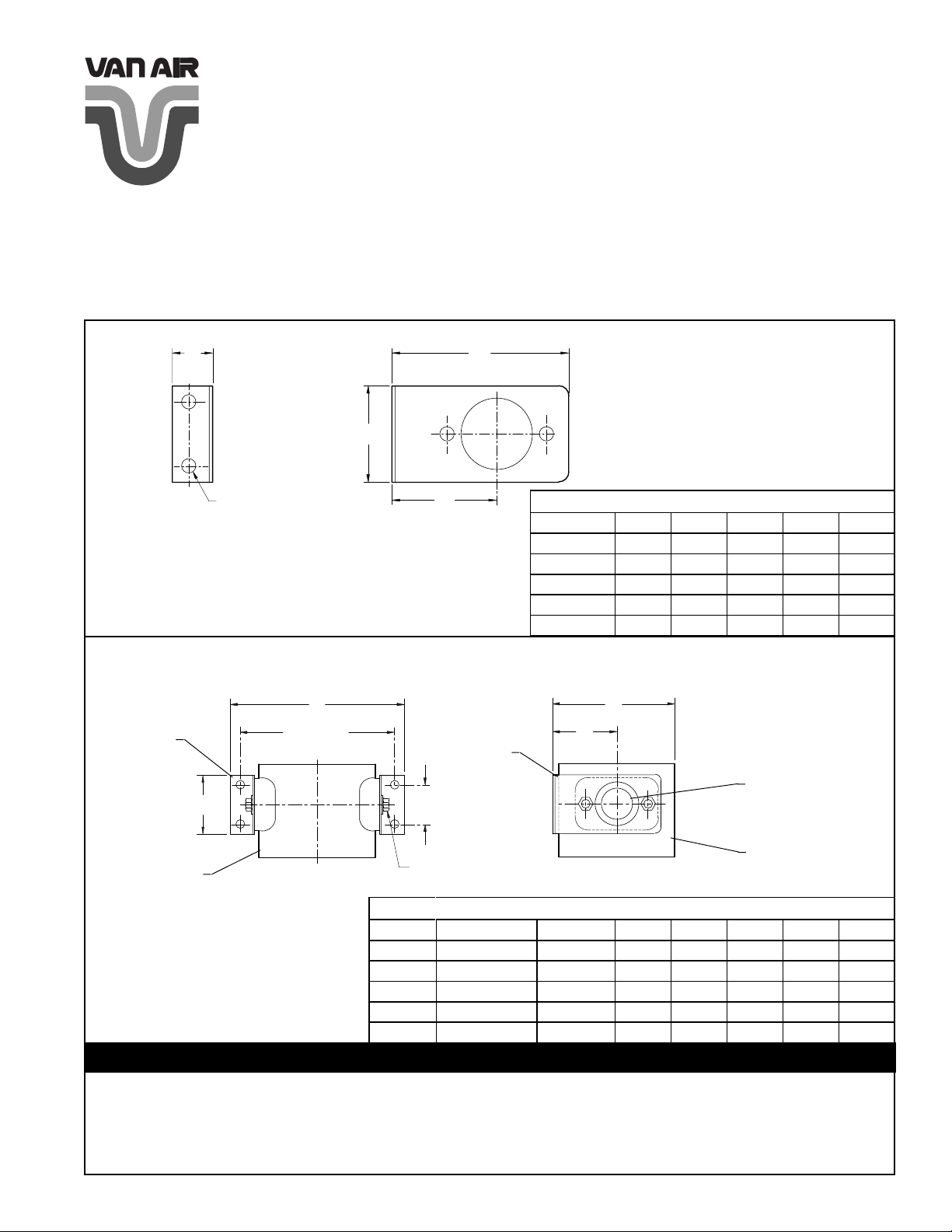

FIGURE 1 MOUNTING BRACKET DIMENSIONS

C

B

E

FIGURE 2 INSTALLED DIMENSIONS

VIEW FROM FRONT OF FILTER

A

D

TYPE A B C D E

MB-1 2-15/16 1-9/16 13/16 1-3/4 1/4

MB-1-2 2-15/16 1-9/16 13/16 1-3/4 1/4

MB-2 4-5/16 2-3/8 1 2-9/16 5/16

MB-2-2 4-3/4 2-3/4 1 2-3/4 5/16

MB-3-2 7-1/8 4-15/16 1-3/16 3-15/16 3/8

VIEW FROM SIDE OF FILTER

MOUNTING BRACKET DIMENSIONS

D

C

FILTER INLET/

OUTLET

CONNECTION

FILTER HEAD

BRACKET

FILTER

HEAD

E

A

(DRILL HOLES)

BRACKET

F

TYPE USED ON F200- PART NO A B C D E

MB-1 55 84-0720 4-1/2 1-1/4 1-3/4 3-5/16 5-1/4

MB-1-2 15 THRU 25 84-10130 3-3/4 1-1/4 1-3/4 3 4-7/16

MB-2 85 THRU 265 84-0721 5-15/16 1-9/16 2-9/16 4-7/8 6-11/16

MB-2-2 350 THRU 500 84-10131 6-1/2 2 2-3/4 5-1/4 7-5/16

MB-3-2 600 THRU 1000 84-10132 9-5/16 3-3/4 3-15/16 7-7/16 10-1/4

B

(DRILL HOLES)

HEX NUT

(4 EACH)

INSTALLED DIMENSIONS

WARNINGS

READ INSTRUCTIONS CAREFULLY BEFORE MOUNTING FILTER.

•

DO NOT INSTALL MB TO EQUIPMENT THAT IS UNDER PRESSURE.

•

DO NOT DRILL MOUNTING HOLES BEFORE ENSURING THAT NOTHING WILL BE DAMAGED WHILE DRILLING.

•

DO NOT MOUNT FILTER WITH UNDERSIZED SCREWS.

•

PRINTED IN THE USA ©2000 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423

Page 2

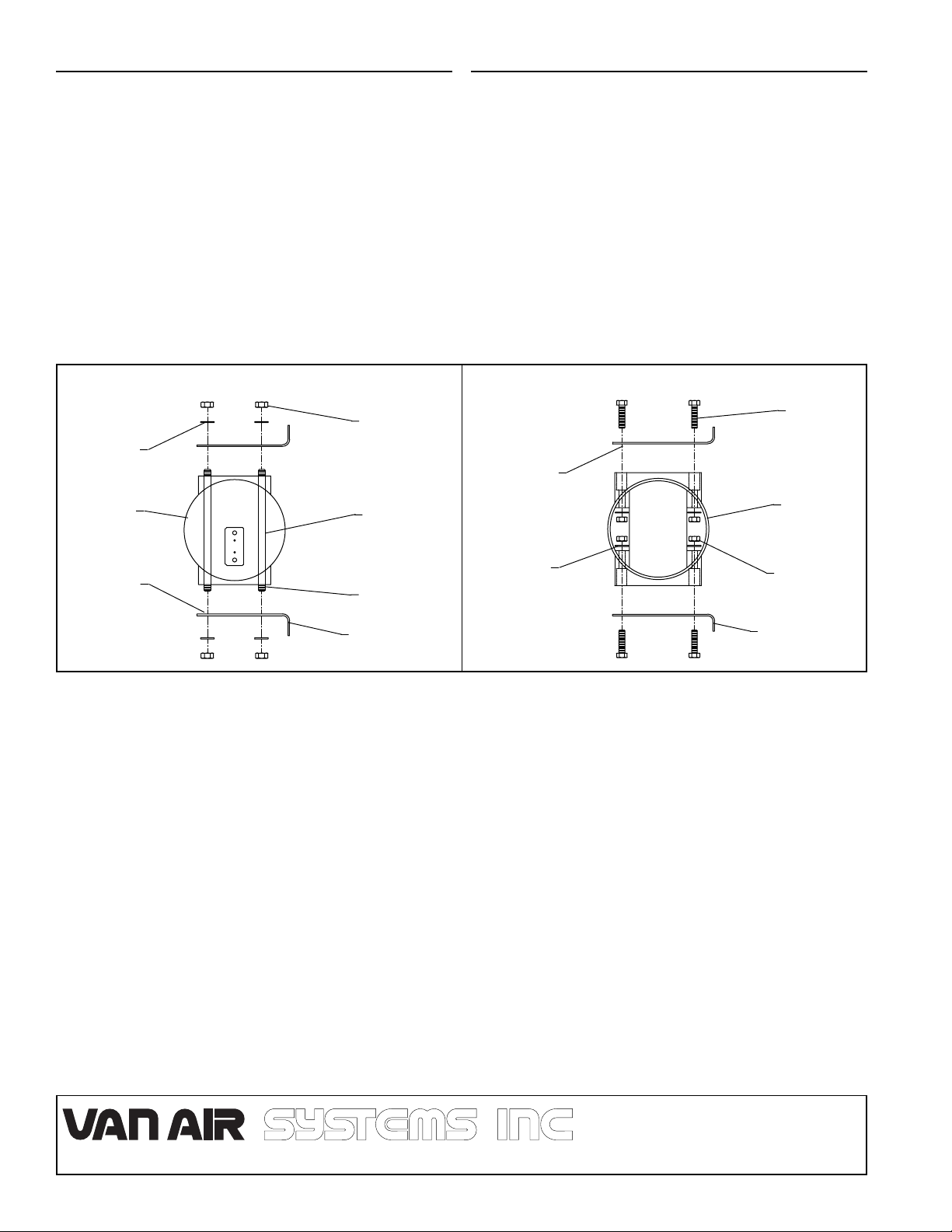

INSTALLING BRACKETS (MB-1 THRU 2-2)

INSTALLING BRACKETS (MB-3-2)

1.

Remove filter head from the filter bowl.

2.

Place (1) tie rod into each thru-hole until the threaded ends can be

seen on either side of the filter head.

3.

Place (1) mounting bracket onto each side of filter head, threading tie

rod ends through bracket holes as shown in Figure 3A. (Be sure that

the filter head will be mounted in the correct flow direction).

4.

Place (1) washer onto end of each tie rod.

5.

Thread (1) nut onto end of each tie rod and tighten down with a 12mm

or 1/2 inch wrench.

FIGURE 3A MB-1 THRU MB-2-2 DETAILS (TOP VIEW)

HEX NUT

4 PLACES

WASHERS

4 PLACES

FILTER

HEAD

TIE ROD

2 PLACES

Remove filter head from the filter bowl.

1.

Remove blanking plate from top of filter head

2.

Place (1) mounting bracket on one side of the filter head as shown in

3.

Figure 3B. (Be sure that the filter head will be mounted in the correct

flow direction).

Place (1) screw into each thru-hole going through the mounting

4.

bracket and into the filter head.

Place (1) washer onto each screw inside the filter head.

5.

Thread (1) nut onto each screw and tighten down with a 12mm or

6.

1/2 inch wrench.

Place (1) mounting bracket on the other side of the filter head as

7.

shown in Figure 3B.

Place (1) screw into each thru-hole going through the mounting

8.

bracket and into the filter head.

Place (1) washer onto each screw inside the filter head.

9.

Thread (1) nut onto each screw and tighten down with a 12mm or

10.

1/2 inch wrench.

FIGURE 3B MB-3-2 DETAILS (TOP VIEW)

HEX SCREW

4 PLACES

MOUNTING

BRACKET

2 PLACES

FILTER

HEAD

MOUNTING

BRACKET

2 PLACES

THREADED

END

THIS SIDE FACES

SUPPORT OR

WALL

WASHERS

4 PLACES

HEX NUT

4 PLACES

THIS SIDE FACES

SUPPORT OR

WALL

2950 Mechanic Street

Lake City, PA 16423-2095

Phone: 814/774-2631

MAKING COMPRESSED AIR AND GAS WORK BETTER SINCE 1944.

Fax: 814/774-3482

©2000 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423 PRINTED IN THE USA

Loading...

Loading...