Van Air Systems MHL-Series Desiccant Air Dryer Operations and Maintenance Manual

MHL-SERIES

HEATLESS DRYER

INSTALLATION, OPERATION &

MAINTENANCE MANUAL

®

October 2008

32-0296 Rev A

TABLE OF CONTENTS

SECTION 1 General Information: Pg 2

Model Numbers

Serial Numbers

Description of Operation

SECTION 2 Safety Instructions: Pg 3

Installation/Maintenance Safety

Operation Safety

SECTION 3 Specifications: Pg 3

Dimensions & Weights

Air Flow Capacities

SECTION 4 Installing the Dryer: Pg 4-6

Location

Electrical Connections

Piping and Connections

Recommended Filters

Recommended Dryer Installation

SECTION 5 Start-Up Procedure Pg 7

SECTION 6 Maintenance and Repair Pg 7

SECTION 7 Troubleshooting Guide Pg 8

SECTION 8 Replacement Parts Pg 9-10

SECTION 9 Wiring Diagram Pg 11

SECTION 10 Warranty Pg 11

Page 1

Van Air Systems MHL-Series Desiccant Air Dryer Operations and Maintenance Manual

SECTION 1 GENERAL INFORMATION

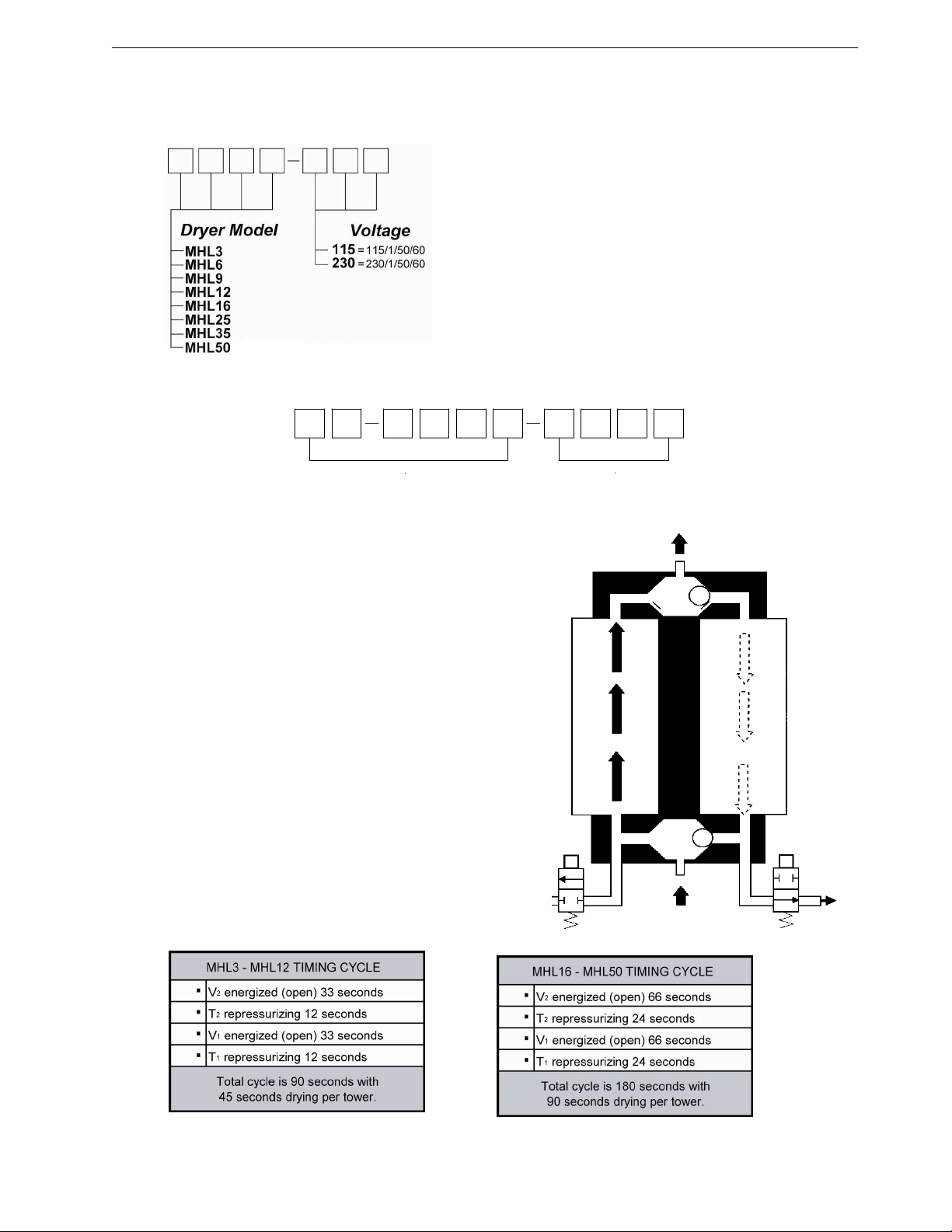

1.1 MODEL NUMBER CODING

Indicator are standard equipment.

Note: Tower Pressure Gauges & outlet Moisture

1.2 SERIAL NUMBER CODING

MONTH/YEAR OF MANUFACTURE

1.3 DESCRIPTION OF OPERATION

The MHL-SERIES Air Dryers use the pressure swing adsorption

method of drying compressed air. This requires two identical

towers containing beds of hygroscopic desiccant.

Incoming wet air enters the dryer through a shuttle valve where it

is directed to the bottom of the tower containing dry desiccant.

The desiccant in this tower removes 99.7+% of the water vapor

from the air when operated at catalog conditions. The dried air

leaving the top of the tower is directed to the outlet through a

second shuttle valve. In this outlet shuttle valve a built-in orifice

allows a portion of the dried air to flow into the other tower being

regenerated. The orifice reduces the high pressure air down close

to atmospheric pressure which lowers the dew point of the dried

air even further.

The tower being regenerated/purged of moisture is connected to

an energized solenoid valve for a controlled period of time. The

electrical signal to the solenoid is monitored by an LED light on the

solid state timer. After the desiccant is regenerated, the timer deenergizes the solenoid valve. Air continues to flow through the

orifice to repressurize the regenerated tower to line pressure. The

middle light on the timer indicates the repressurization function.

Next, the timer opens the valve on the tower containing the wet

desiccant. This shifts the shuttle valves, and the tower with the

wet desiccant is regenerated while the other tower continues to dry

the air. Examining the flow schematic to the right demonstrates

the dryer process operation.

TOWER T

DRYING

INLET AIR

VALVE V

CLOSED

1

SERIAL #

DRY OUTLET AIR

1

WET INLET AIR

SHUTTLE VALVE

WITH

FIXED ORIFICE

TOWER T

REGENERATING

(PURGING)

VALVE V

OPEN

2

2

Page 2

Van Air Systems MHL-Series Desiccant Air Dryer Operations and Maintenance Manual

MTG

8

9

10

11

29

34

59

65

SECTION 2 SAFETY INSTRUCTIONS

2.1 INSTALLATION/MAINTENANCE SAFETY

Before starting or installing the dryer, be sure that all power to

the unit is off, valves are shut, and the air circuit is at

atmospheric pressure. DO NOT remove, repair, or replace any

component, control filter, or part, while the air circuit is

energized or under pressure. Turn off the main to the dryer

and de-pressurize the unit before starting installation or

maintenance procedures.

MANUFACTURER WILL NOT BE RESPONSIBLE FOR

DAMAGE TO EQUIPMENT AS A RESULT OF IMPROPER

WIRING OR ELECTRICAL INSTALLATION. IT IS THE

CUSTOMERS RESPONSIBILITY TO ENSURE THAT THE

ELECTRICAL INSTALLATION IS CORRECT AND UP TO

APPLICABLE CODES.

When installing the dryer, ensure that the NEMA rating of the

control box is applicable to the installation.

Dryer is rated NEMA 4.

2.2 OPERATION SAFETY

DO NOT OPERATE THE DRYER ABOVE THE STATED

WORKING PRESSURE (SEE SPECIFICATION TABLE).

FAILURE, INJURY AND EQUIPMENT DAMAGE COULD

RESULT.

EXCEPT as otherwise specified by the manufacturer, this

product is specifically designed for compressed air service

and use with any other gas or liquid is a misapplication. Use

with or injection of certain hazardous liquids or gases in the

system (i.e., alcohol or liquid petroleum gas) could be

harmful to the unit and result in a combustible condition or

cause hazardous external leakage. Manufacturer’s

warranties are void in the event of a misapplication and

manufacturer assumes NO RESPONSIBILITY for any

resulting loss. Before using equipment with fluids or gases

other than air, or for non-industrial applications, consult Van

Air Systems for written approval.

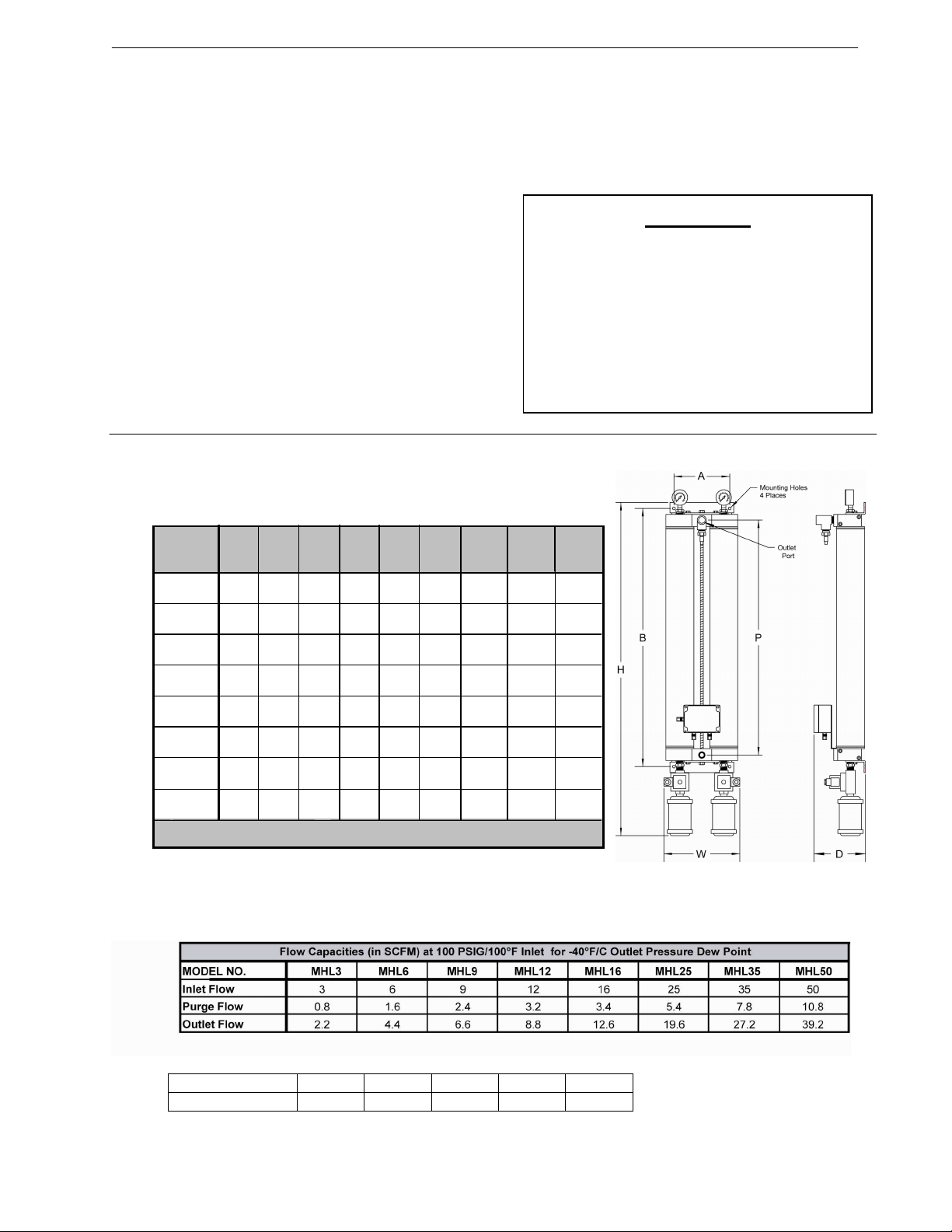

SECTION 3 SPECIFICATIONS

3.1 DIMENSIONS & WEIGHTS

MODEL

H W D P A B

PORTS

(npt)

MHL3

MHL6

13.6 7.4 5.2 9.3 5.8 2.8 3/8

18.2 7.4 5.2 13.0 5.8 2.8 3/8

HOLE

DIA.

0.3

0.3

WEIGHT

(lbs)

MHL9

MHL12

MHL16

MHL25

MHL35

17.3 7.4 5.2 12.1 5.8 2.8 3/8

20.1 7.4 5.2 14.9 5.8 2.8 3/8

33.0 9.5 6.5 20.7 7.0 23.6 1/2

41.9 9.5 6.5 29.5 7.0 32.5 1/2

39.3 10.0 7.0 26.5 9.0 30.1 1/2

0.3

0.3

0.4

0.4

0.4

MHL50

NOTE: MHL16-MHL35 dryer shown with bracket top and bottom. MHL3-MHL12 has single 4-hole bracket.

Maximum Working Pressure: 150 PSIG

Maximum Ambient Temperature: 120° F

47.4 10.0 7.0 33.5 9.0 37.1 1/2

Dimensions shown in inches.

3.2 AIR FLOW CAPACITIES

0.4

CAUTION:

FLOW MULTIPLIERS FOR VARIOUS PRESSURES

PRESSURE 80 90 100 110 120

MULTIPLIER 0.683 0.833 1.000 1.087 1.174

Page 3

Van Air Systems MHL-Series Desiccant Air Dryer Operations and Maintenance Manual

SECTION 4 INSTALLING THE DRYER

4.1 LOCATION

DO NOT INSTALL DRYER IN AN ENVIRONMENT OF

CORROSIVE CHEMICALS, EXPLOSIVE GASES, OR AREAS

OF HIGH AMBIENT TEMPERATURE CONDITIONS.

Install the dryer indoors. Dryers are not meant to be installed

outdoors exposed to the weather. If the dryer must be installed

outdoors, it must be in a weatherproof enclosure that provides

for proper temperature control.

When mounting, allow 2.5 inches above unit for tower removal

and replacement.

The dryer may be installed in a vertical or horizontal (laying

flat) orientation. Installation on its side may contribute to

possible shuttle valve shifting problems.

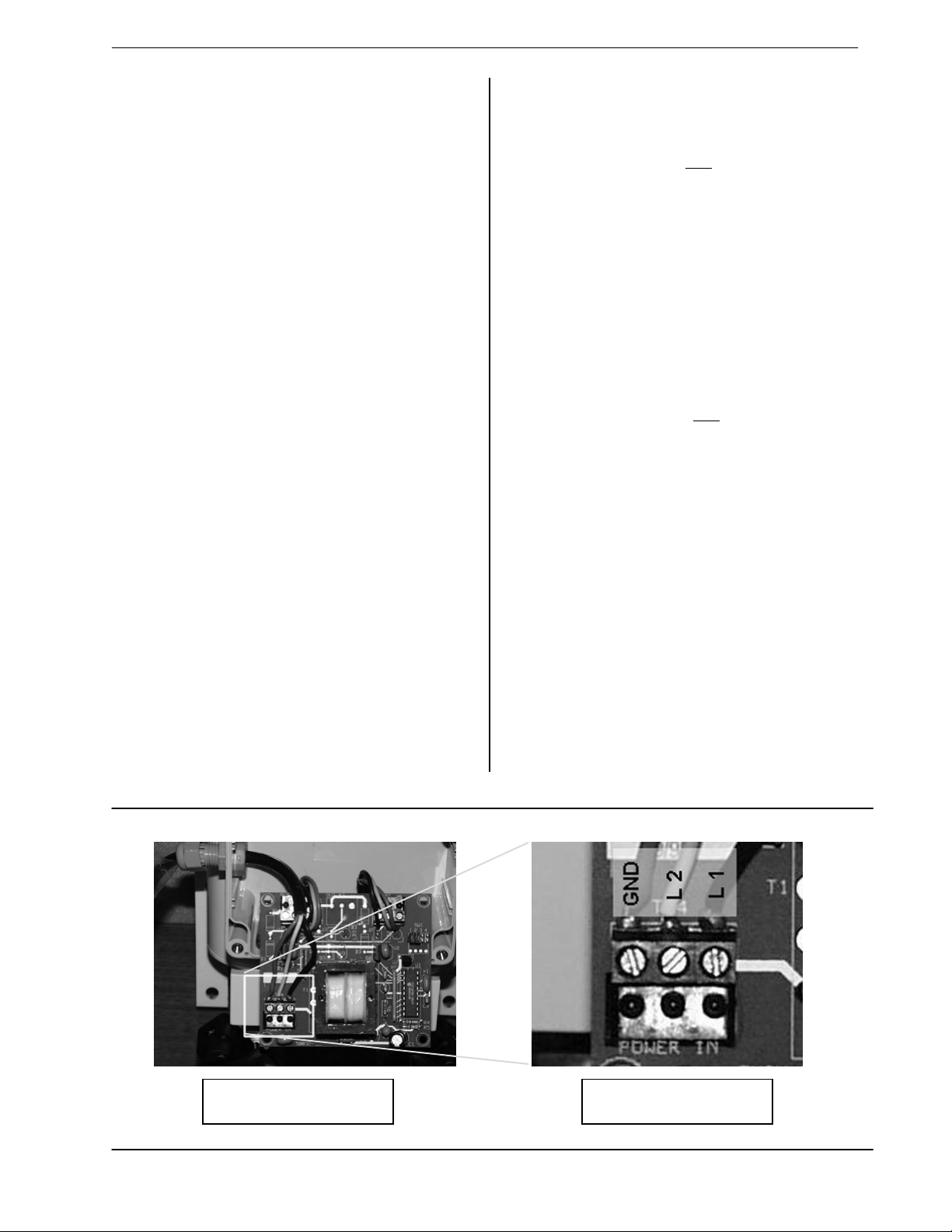

4.2 ELECTRICAL CONNECTIONS

Before wiring, check the dryer nameplate for electrical

characteristics. Standard electrical characteristics are 115

volt, 1 phase, 50/60 Hz. Models operating on 230 volts are

available.

IMPORTANT! No overload protection is provided in the dryer

and unit should be wired into a protected circuit.

IMPORTANT! When installing electrical service to this

machine, comply with the National Electrical Code as well as

state and local building codes.

NOTE: Dryer cycle timer has infinite memory capacity. Dryer

may be wired to compressor pressure switch or auxiliary

contacts to allow dryer to start and stop with compressor or

machine tool. Contacts must supply same voltage and phase

as dryer requires.

A six foot power cord is installed as standard on the dryer. The

cord on the115V dryers has a plug. The cord on the 230V

dryers does not have a plug. The control box and bulkhead

fittings are NEMA 4 rated.

• If a NEMA 1 installation is desired:

A. You may simply plug the power cord into a standard

outlet.

- or -

B. Use standard flexible conduit, and follow the

instructions for installing liquid-tight conduit below.

Use only flexible conduit as installing rigid conduit

may damage polycarbonate control box. Connect to

inlet power terminal strip with 18 gauge stranded

wire only.

• If maintaining the NEMA 4 installation is

desired:

A. Cut off the plug and use a NEMA 4 gasketed

bulkhead fitting suitable for .180” diameter power

cord to enter a NEMA 4 rated junction box.

- or -

A. To use flexible liquid-tight conduit and stranded 18

gauge wire:

1. Remove clear cover from control box.

2. Loosen nuts on (3) bulkhead connectors and

push an inch or two of each of the electrical

cords back into the control box to allow slack to

pull out solid state timer board. Remove four

screws holding solid state timer board and pull

back gently to expose the “power in” terminal

block. With small screwdriver, loosen wire

clamps on terminal block and disconnect power

cord wires.

3. Remove (1) backing nut from inlet power cord

bulkhead fitting and remove power cord and

bulkhead fitting.

4. Enlarge existing hole to proper size to install

your own liquid-tight conduit fitting. Use only

flexible liquid-tight conduit as installing rigid

conduit may damage polycarbonate control box.

5. Connect to “power in” terminal block with 18

gauge stranded wire only.

BACK SIDE OF

TIMER BOARD

POWER IN

TERMINAL BLOCK

Page 4

Van Air Systems MHL-Series Desiccant Air Dryer Operations and Maintenance Manual

Filter

Replacement Element

Filter

Replacement Element

Filter

Replacement Element

For

Filter

Replacement Element

4.3 PIPING AND CONNECTIONS

Inlet and outlet piping should be schedule 40 pipe or equivalent

I.D. tubing. See specification chart for inlet/outlet NPT thread

size. All piping should be deburred and threaded to a proper

depth and length before installation. Threads should be

inspected for cleanliness and depth of cut. Good quality pipe

compound or Teflon tape should be used in the makeup of

joints to ensure a good, airtight fit of piping components.

Install a pipe union at the inlet and outlet ports for easy

disconnection prior to tower replacement.

NOTE ON INLET PIPING AND

PIPE JOINTS: Make sure piping is

clean inside. Apply pipe thread

sealant sparingly to the male

threads of fittings, keeping the

sealant back from the first two

threads. Contamination getting

into inlet shuttle valve could cause

dryer to malfunction.

Recommended Filters

Model

MHL3

MHL6

MHL9

MHL12

MHL16

MHL25

MHL35

MHL50

Filter

Replacement Element

Filter

Replacement Element.

Filter

Replacement Element

Filter

Replacement Element.

0.01 Micron Coalescing

F200-25-3/8-C-AD-PD6

F200-25-3/8-C-AD-PD6

F200-25-3/8-C-AD-PD6

F200-25-3/8-C-AD-PD6

F200-25-1/2-C-AD-PD6

F200-25-1/2-C-AD-PD6

F200-55-1/2-C-AD-PD6

F200-55-1/2-C-AD-PD6

It is recommended that a bypass line with shut-off valves be

installed to provide constant air flow to the system should the

dryer require servicing.

4.4 REQUIRED FILTERS

Always install a 0.01 micron coalescing prefilter with automatic

drain before dryer to remove entrained particulates, liquid

moisture and oil which can cause damage to the desiccant

beds. A 1.0 micron particulate afterfilter should be installed

after the dryer to remove any desiccant dust that may migrate

from the desiccant beds.

Pre-Filter

E200-15/25-C

E200-15/25-C

E200-15/25-C

E200-15/25-C

E200-15/25-C

E200-15/25-C

E200-55-C

E200-55-C

NOTE: If purge air is required to

be piped to a remote location, it is

necessary to use oversized tubing

or piping to prevent back-pressure.

Restricting the purge flow can

cause the dryer to malfunction.

After-Filter

1.0 Micron Particulate

F200-25-3/8-RB-MD-PD6

E200-15/25-RB

F200-25-3/8-RB-MD-PD6

E200-15/25-RB

F200-25-3/8-RB-MD-PD6

E200-15/25-RB

F200-25-3/8-RB-MD-PD6

E200-15/25-RB

F200-25-1/2-RB-MD-PD6

E200-15/25-RB

F200-25-1/2-RB-MD-PD6

E200-15/25-RB

F200-55-1/2-RB-MD-PD6

E200-55-RB

F200-55-1/2-RB-MD-PD6

E200-55-RB

Page 5

Van Air Systems MHL-Series Desiccant Air Dryer Operations and Maintenance Manual

TYPICAL POINT

-OF-

USE INSTALLATION

TYPICAL SYSTEM DRYER INSTALLATION

20 0 80 60

40 20 0

20 0 80 60

40 20 0 80 60

7

8

9

After

Aftercooler

10

11

4.5 RECOMMENDED DRYER

INSTALLATION

1

3

2

4

11

5

6

9

7

6

6

2

2

80

100

60 100

40

120

120

140

140

160

160

10

1

3

2

4

2

100

100

40

120

120

140

140

160

160

10

2

8

6

5 7

6

6

11

2

2

8

6

9

6

Ref.# Description

1 Compressor

2 Shut-off Valve

3 Flex Connector

4

5 Liquid Separator

6 Drain Valve

Ref.# Description

Pre-Filter, 0.01 Micron Coalescing, With Automatic Drain

-Filter, 1.0 Micron Particulate, With Manual Drain

Storage Tank

MHL-Series Desiccant Dryer

Check Valve

Page 6

Van Air Systems MHL-Series Desiccant Air Dryer Operations and Maintenance Manual

SECTION 5 START UP PROCEDURE

BEFORE STARTING THIS DRYER, FOLLOW THE

INSTALLATION INSTRUCTIONS AND PROCEDURES

COMPLETELY.

DO NOT REMOVE, REPAIR OR REPLACE ANY ITEM ON

THE DRYER WHILE THE DRYER IS UNDER PRESSURE.

INITIAL START UPS

1. Confirm that all piping and electrical connections are

proper.

2. Shut off electrical power.

3. If a bypass is installed around the dryer, open the inlet

and outlet isolation valves. Close the bypass valve.

WARNING - When operating this dryer without the

mufflers, use hearing protection.

4. Wait approx. 20 seconds to equalize pressure in the

desiccant chambers.

5. Turn on the electrical power. Dryer should start cycling.

6. Verify purge cycle timing as described in Dryer Operation

section.

7. Verify that a small amount of air is purging from the

moisture indicator. When sample air is dry, the silica gel

remains dark blue. If the sample air is moist, indicating a

problem, the color changes to light pink. At start-up the

moisture indicator may show pink, but it should return to

blue after 30 to 40 minutes of dryer operation.

SECTION 6 MAINTENANCE AND

REPAIR

WARNING - DO NOT REMOVE, REPAIR, OR REPLACE ANY

ITEM ON THE DRYER WHILE THE DRYER IS UNDER

PRESSURE.

BEFORE BEGINNING ANY REPAIRS, MAINTENANCE, OR

INSTALLATION WORK, VERIFY THAT THE POWER IS OFF

AND THE DRYER IS DEPRESSURIZED.

BEFORE WORKING ON THE DRYER OR RELATED

EQUIPMENT, ENSURE THAT ALL PERSONNEL HAVE

READ AND UNDERSTAND THE SAFETY AND OPERATION

INSTRUCTIONS IN THIS MANUAL.

PREVENTIVE MAINTENANCE SCHEDULE

This is a suggested schedule based on average dryer

conditions. As conditions such as dirty environment, humidity

conditions, ambient temperature, etc. change, the frequency of

the inspections may change.

Daily

1. Inspect the dryer for proper operation.

2. Inspect inlet filters and drains for proper operation.

3. Verify proper inlet and ambient air conditions.

Weekly

1. Check pop-up indicators on prefilter and afterfilter. If

indicator shows red, change filter element.

Semi-Annually

1. Inspect entire assembly for loose connections, screws,

etc.

2. Perform audible inspection of purge cycling and purge

flow.

3. Visual inspection of exhaust area for signs of oil or

desiccant attrition.

Page 7

Van Air Systems MHL-Series Desiccant Air Dryer Operations and Maintenance Manual

A1

A2

ature should not exceed 100°F.

Reduce inlet air temperature to proper level.

An aftercooler may need to be installed after

A3 Air flow through dryer in

sor output, or if installed at

use, total of air usage downstream of dryer plus purge flow)

A4

The inlet air pressure should be 100 psig.

Increase inlet pressure or call factory to

A5 Dirty or obstructed inlet

A6

ce hole of debris. Use air gun to

A7

Check magnetic field from coil operation. Place iron or steel

ote: see Section 1, for

A8 Oil contamination of

Verify coalescing inlet filtration is adequate and functioning

Towers must be replaced if contamination is

A9

t operating

Verify correct timing cycle by observing tower indicator lights on

A10

If purge air is piped away from unit,

oversized piping should be used and length

Improper operating

Dirty or obstructed inlet

Inlet or outlet shuttle not

Inlet or outlet shuttle not

Timer not operating

Timer not operating

Incoming power may not be "clean". Fluctuations in voltage can

rs

Dirty or obstructed inlet

With dryer pressurized, remove power from dryer. Check purge

SECTION 7 TROUBLESHOOTING GUIDE

A

PROBLEM: AIR DRYER DELIVERS WET AIR

POSSIBLE CAUSE

No power to unit.

High inlet air temperature. The inlet air temper

excess of rated capacity.

Low inlet pressure.

CHECK

Power supply.

Make sure inlet flow to dryer (compres

point-ofdoes not exceed inlet flow rating of dryer.

CORRECTIVE ACTION

Correct power problem.

compressor.

Reduce air usage downstream.

resize dryer for actual inlet conditions.

Check inlet airline filter elements.

air filter.

Purge orifice plugged. Remove and inspect purge orifice.

Solenoid coil burned out.

material (a screwdriver works well) at top of coil to feel the

effect when coil should be energized. (N

timing cycle for your unit.)

desiccant beds.

Timer no

properly.

Purge flow restricted. Check mufflers (or purge piping if installed) for excessive back-

B

PROBLEM: RESTRICTED FLOW THROUGH UNIT

POSSIBLE CAUSE

B1

conditions.

B2

air filter.

B3 Plugged air passages. Check inlet and outlet air passages and piping for blockages.

C

PROBLEM: EXCESSIVE PURGE / BLOWDOWN

POSSIBLE CAUSE

C1

shifting.

C2

shifting.

C3 Purge orifice plugged. See A6 above.

C4

properly.

C5

properly.

C6

air filter.

C7 Leakage.

properly.

front panel. (Note: see Section 1, for timing cycle for your unit.)

pressure. Note: unit is originally supplied with "no-clog" mufflers.

CHECK

See A2, A3, A4 above.

See A5 above.

CHECK

See A3, A4, A5, A6 above.

Check for damage or contamination of inlet and outlet shuttles.

See A9 above.

occur in power circuits shared by devices such as electric moto

and welding equipment.

See A5 above.

ports on dryer and air system connections for large leaks.

Replace.

Clean orifi

clean.

Replace.

suspected.

Replace timer if defective.

of run should be as short as possible.

CORRECTIVE ACTION

Clear restrictions.

CORRECTIVE ACTION

Clean or replace as necessary.

Supply line voltage from another source.

Repair as necessary.

Page 8

Van Air Systems MHL-Series Desiccant Air Dryer Operations and Maintenance Manual

80

80

11

1

11

SECTION 8 REPLACEMENT PARTS

1

6

60

10

40

12

20

14

0

16

5

TYP 8 PLCS

2

7

14

8

9

See chart on next page for part information.

MHL Dryer Exploded View

11

13

60

10

40

12

20

14

0

16

4

12

16

17

15

3

13

MHL3 - 12

11

BUSHING (AS REQ’D.)

TYP 2 PLCS

7

2

6

14

8

9

10

Page 9

Van Air Systems MHL-Series Desiccant Air Dryer Operations and Maintenance Manual

KIT CONTAINS

2

1

SCREW

1

2

CF CF CF CF CF CF CF

1

1

1

VITON O

CALL FACTORY

See Exploded View on previous page for reference numbers.

REPLACEMENT PARTS

REF# DESCRIPTION

QTY

MHL3

MHL6

MHL9

FOR MODEL

MHL12

MHL16

MHL25

MHL35

MHL50

1

2

3

4

5

6

7

8

8a

9

10

11

12

13

14

15

16

16a

17

not shown

not shown

not shown

not shown

TOWER GAUGE KIT

DESICCANT TOWER

SHUTTLE DISC, INLET

SHUTTLE DISC, OUT W/ORIFICE

END BLOCK, TOP-L OR BOTTOM-RT

END BLOCK, TOP-RT OR BOTTOM-L

SOLENOID VALVE ASSY 115 VOLT

SOLENOID VALVE ASSY 230 VOLT

PURGE MUFFLER KIT

TIE ROD

INLET/OUTLET SHUTTLE VALVE SEAT

SHUTTLE VALVE BODY

DRYER MOUNTING BRACKET

SOLENOID DIN CONNECTOR

CONTROL BOX BRACKET

TIMER, SS, 115 VAC

TIMER, SS, 230 VAC

CONTROL BOX ENCLOSURE

-RING KIT

Street Tee

Bushing

Moisture Indicator

50-0100

1

1

1

1

1

1

1

1

1

1

1

1

*

1

1

1

50-0102

50-0109

50-0111

50-0118

50-0120

50-0122

50-0124

50-0126

50-0128

50-0131

50-0133

50-0135

50-0137

50-0139

50-0141

50-0143

50-0145

50-0146

50-0152

50-0148

50-0154

50-0100

50-0103

50-0109

50-0112

50-0118

50-0120

50-0122

50-0124

50-0126

50-0128

50-0131

50-0133

50-0135

50-0137

50-0139

50-0141

50-0143

50-0145

50-0146

50-0152

50-0148

50-0154

50-0100

50-0104

50-0109

50-0113

50-0118

50-0120

50-0122

50-0124

50-0126

50-0128

50-0131

50-0133

50-0135

50-0137

50-0139

50-0141

50-0143

50-0145

50-0146

50-0152

50-0148

50-0154

50-0100

50-0105

50-0109

50-0114

50-0118

50-0120

50-0122

50-0124

50-0126

50-0128

50-0131

50-0133

50-0135

50-0137

50-0139

50-0141

50-0143

50-0145

50-0146

50-0152

50-0148

50-0154

50-0101

50-0106

50-0110

50-0115

50-0119

50-0121

50-0123

50-0125

50-0127

50-0129

50-0132

50-0134

50-0136

50-0138

50-0140

50-0142

50-0144

50-0145

50-0147

50-0153

50-0149

50-0154

50-0101

50-0107

50-0110

50-0116

50-0119

50-0121

50-0123

50-0125

50-0127

50-0129

50-0132

50-0134

50-0136

50-0138

50-0140

50-0142

50-0144

50-0145

50-0147

50-0153

50-0149

50-0154

50-0101

50-0108

50-0110

50-0117

50-0119

50-0121

50-0123

50-0125

50-0127

50-0129

50-0132

50-0134

50-0136

50-0138

50-0140

50-0142

50-0144

50-0145

50-0147

50-0153

50-0149

50-0154

50-0101

50-0158

50-0110

50-0157

50-0119

50-0121

50-0123

50-0125

50-0127

50-0129

CF

50-0132

50-0134

50-0159

50-0138

50-0140

50-0142

50-0144

50-0145

50-0147

50-0153

50-0149

50-0154

NOTE:

*VITON O-RING KIT INCLUDES ALL O-RING SEALS

NOTE:

CF -

Page 10

Van Air Systems MHL-Series Desiccant Air Dryer Operations and Maintenance Manual

SECTION 9 WIRING DIAGRAM

SOLID STATE TIMER

WIRE CONNECTIONS

Tower #2

Solenoid Valve

BLACK

WHITE

GND GND

SECTION 10 WARRANTY

Per Van Air Terms and Conditions

POWER IN

GROUND

NEUTRAL

HOT

GREEN

Tower #1

WHITE

BLACKGREEN

Solenoid Valve

Page 11

Van Air Systems MHL-Series Desiccant Air Dryer Operations and Maintenance Manual

Page 12

Loading...

Loading...