Van Air Systems D12, D36 User Manual

P/N 32-0272 rev B

INSTALLATION, OPERATION, & MAINTENANCE INSTRUCTIONS

FOR

SINGLE TOWER

COMPRESSED AIR DRYER

MODELS

D-12 through D-36

JUNE 2002

WARNING

DO NOT REMOVE, REPAIR, OR REPLACE ANY ITEM ON THE

DRYER WHILE IT IS UNDER PRESSURE. DEPRESSURIZE THE

DRYER COMPLETELY BEFORE STARTING INSTALLATION AND/

OR MAINTENANCE PROCEDURES. SERIOUS PERSONAL

INJURY MAY RESULT IF THESE SAFETY RULES ARE NOT

FOLLOWED.

DO NOT OPERATE THIS PRESSURE VESSEL ABOVE MAXIMUM

WORKING PRESSURE (MWP) AT MAXIMUM OPERATING

TEMPERATURE (OF) AS SHOWN ON THE ASME DATA PLATE.

THIS ASME CODE VESSEL MUST BE PROTECTED BY A

PRESSURE RELIEF VALVE. Refer to OSHA 1910.169 Par. b,

Sub. Par (3) and ASME Boiler and Pressure Vessel Code,

Section VIII, Division 1, UG-125 through UG-136. Also check

government regulations, i.e., state and local codes.

DO NOT WELD, GRIND, OR SAND VESSEL, OR IT WILL NOT

BE SAFE TO OPERATE. (Note: Any alteration to the vessel

will void the ASME Code Certification and the warranty.)

ANY DAMAGE TO THE VESSEL CAN MAKE IT UNSAFE.

INSPECT OUTSIDE AND INSIDE OF VESSELS REGULARLY

FOR BULGES, CORROSION, DENTS, GOUGES, LEAKS OR

SIGNS OF FIRE. IF DAMAGED, TAKE OUT OF SERVICE

IMMEDIATELY AND NOTIFY YOUR CERTIFYING AUTHORITY.

USE THE PROPER SAFETY RULES FOR THE GAS BEING

PROCESSED.

DO NOT REMOVE THE HATCH COVER UNTIL ALL AIR

PRESSURE IS OUT OF THE VESSEL. PUSH ON THE HATCH

COVER BY HAND TO FIND OUT IF THE VESSEL PRESSURE IS

REDUCED TO ZERO.

DO NOT TRY TO TIGHTEN THE HATCH COVER IF YOU HEAR

OR FEEL A LEAK. IMMEDIATELY SHUT OFF THE AIR OR GAS

SUPPLY TO THE VESSEL AND REDUCE THE DRYER

PRESSURE TO ZERO.

ALWAYS INSTALL A NEW GASKET EVERY TIME THE HATCH

COVER IS REMOVED, OR AT LEAST ONCE PER YEAR.

REPLACE THE HATCH COVER EVERY FIVE YEARS

REGARDLESS OF CONDITION. USE VAN AIR AUTHORIZED

PARTS ONLY.

DO NOT USE POWER TOOLS OR CHEATER BARS TO

TIGHTEN THE NUT ON THE COVER. TOO MUCH FORCE CAN

DISTORT THE COVER AND/OR THE GASKET. IF DAMAGED

BY OVERTIGHTENING, THE COVER CAN BLOW OUT AND

CAUSE SERIOUS INJURY. (Note: Tighten the nut until it is

snug only. When pressure is in the vessel, the seal will be

complete.)

INSPECT THE COVER AND SEALING SURFACE EVERY TIME

THE COVER IS REMOVED, OR AT LEAST ONCE PER YEAR,

FOR DAMAGE SUCH AS CORROSION, CRACKS, OR

DISTORTION. IF THERE IS ANY DAMAGE, INSTALL A NEW

COVER AND GASKET. USE VAN AIR AUTHORIZED PARTS

ONLY.

PAGE 1

SECTION 1 INTRODUCTION

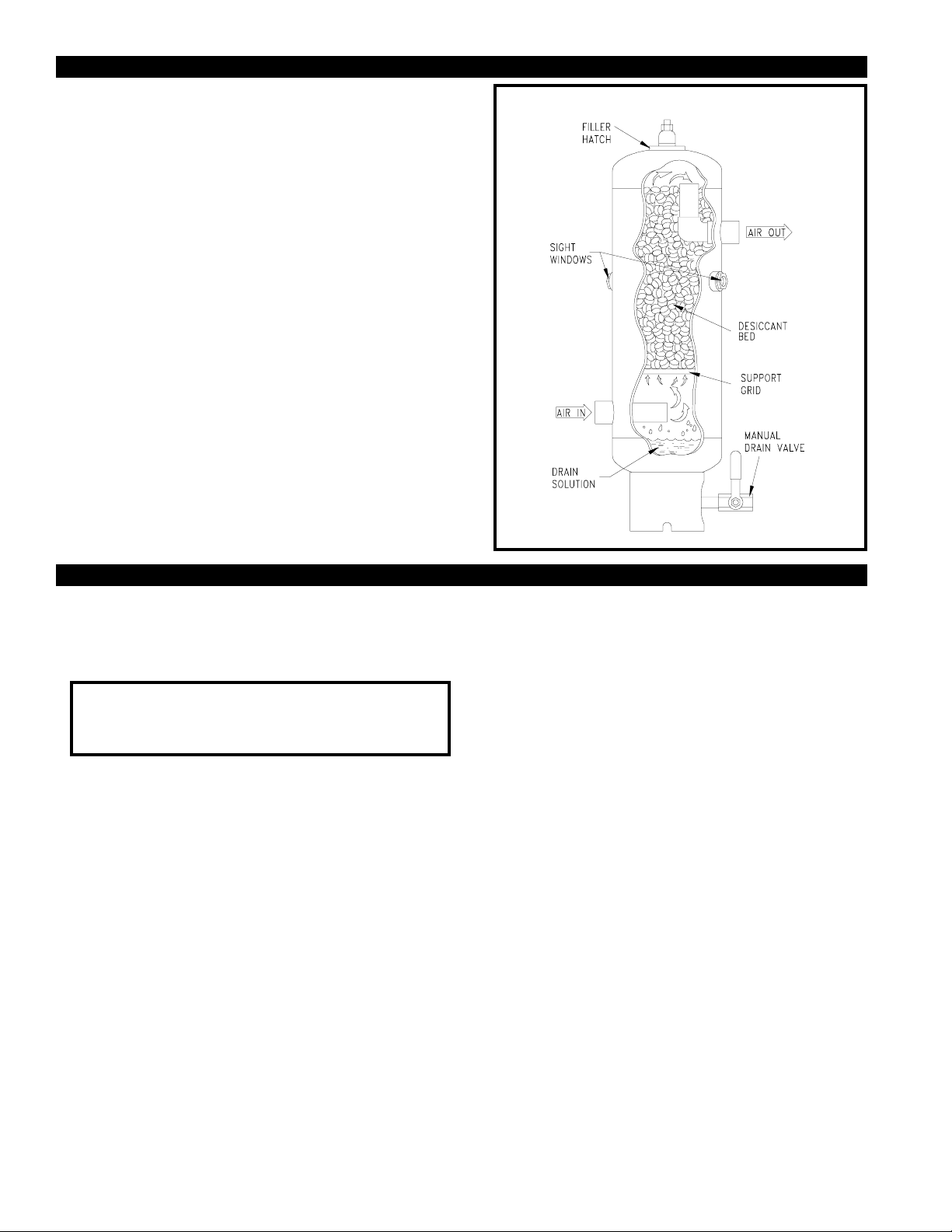

1.0 PURPOSE OF OPERATION

The purpose of installing a Van Air single tower dryer in a

compressed air system is to remove the water vapor (humidity)

which has been drawn into the system at the compressor intake.

The Van Air process dries the air as it flows through the vessel,

which is filled with a special drying agent. The dryer operates

automatically. There are no moving parts and no external source of

power is required. If an automatic drain is installed, a power source

is required only to operate the valve.

The wet air enters the centrally located inlet which channels the flow

into the lower portion of the dryer. Liquid water and solid particles

are separated by gravity and fall to the bottom of the vessel.

The process air moves upward through the bed of desiccant tablets

which attract and absorb the moisture from the air before it flows

through the dryer outlet. The tablets dissolve gradually as they

absorb the moisture.

The tablets create a structured bed that does not crush under its

own weight. In the bed of an operating dryer, the lower tablets are

consumed first.

The tablets above the sight windows are virtually unused and serve

as a reserve supply. When the reserve supply is depleted, the dryer

must be refilled to maintain performance.

The solution, which consists of dissolved desiccant and water, falls

into the claim area at the bottom of the vessel. The dryer must be

drained at least once a shift to remove the accumulated solution.

The drain solution may contain libricatants and must be disposed of

properly.

FIGURE 1 DRYER DETAILS

SECTION 2 INSTALLATION

2.1 LOCATION

The ability of a dryer to provide dry compressed air depends on the

correct location of the unit. Inlet air temperature and pressure are

the keys to selecting the proper location.

temperatures remain within a fixed range, locate the dryer in the

coolest indoor area. When air equipment or piping is located in an

air conditioned area, install the dryer in the coolest area--usually the

air conditioned area.

2.1-E AIR RECEIVER

ALWAYS PROCESS AIR THROUGH THE DRYER AT THE

IMPORTANT

LOWEST POSSIBLE TEMPERATURE AND THE HIGHEST PRACTICAL PRESSURE.

2.1-A INLET AIR TEMPERATURE

The dew point of the outlet air is directly related to the inlet air

temperature and the type of desiccant being used. The lower the

inlet temperature, the lower the dew point of the outlet air.

Determine the lowest ambient temperature where the compressed

air is used or where the lines are located. If you are using DRYO-LITE or 10BF desiccants, do not exceed 100oF inlet air temperature. If you are using SP desiccant, do not exceed 80oF inlet air

temperature.

2.1-B AFTERCOOLING

Air discharged by the compressor is extremely hot (from 150oF to

350oF). An aftercooler, finned tubing or extended run of piping will

usually be necessary to reduce the inlet air temperature to the

dryer.

2.1-C OUTDOOR AIR USAGE

If some or all of the air supplied by the Van Air single tower dryer

will be used outdoors, install the dryer outdoors in the coolest

possible area. M ake sure that the dryer is not exposed to ambient

temperatures below the minimum design temperature stamped

on the vessel data tag. When the dryer will be exposed to the

direct rays of the sun, install a sun shield to protect it (i.e. a roof).

2.1-D INDOOR AIR USAGE

If all of the air from the dryer will be used indoors where

PAGE 2

In relation to the air receiver, the Van Air single tower dryer should

be located where it will be provided with the coolest inlet temperature.

If the receiver is located in an area where the ambient temperature

is lower than the outlet air from the aftercooler, locate the dryer

downstream of the receiver to allow additional cooling of the air

before it enters the dryer. (Exception: In systems where usage

creates sudden demands on the air supply, locate dryer before the

receiver to minimize air surges through the dryer.) If the ambient

temperature around the receiver is higher than the outlet air

temperature from the aftercooler, locate the dryer between the

aftercooler and the receiver.

2.1-F SPECIAL EQUIPMENT INSTALLATION

If the Van Air dryer is being installed on a branch line to protect a

specific piece of air-operated equipment, locate the dryer on the high

pressure side of any pressure regulators.

2.1-G OPERATING PRESSURE

More air can be processed through the dryer at higher pressures.

Locate the dryer at the highest practical pressure, but do not exceed

the maximum rated working pressure of the dryer. Refer to the

Maximum Capacities chart on Page 3 for the maximum working

pressure for your dryer.

2.2 PIPING AND ANCILLARY EQUIPMENT

Locate the dryer in the proper location as explained in the previous

section.

If the dryer is being installed in an existing piping system, make sure that

the pipe is free of scale and rust.

SECTION 2 INSTALLATION

FIGURE 2 MAXIMUM CAPACITIES -SCFM (Nm3/hr)

MODEL

NO.

D-12

D-16

D-20

D-24

D-30

D-36

MAXIMUM

WORKING

PRESSURE

250 PSIG

250 PSIG

200 PSIG

200 PSIG

200 PSIG

175 PSIG

5 PSIG

0.3 Bar

17

29

27

45

43

73

64

109

107

182

146

248

10 PSIG

0.7 Bar

22

37

33

57

54

91

81

137

135

229

183

311

20 PSIG

1.4 Bar

30

51

47

80

76

128

113

193

189

321

257

437

40 PSIG

2.8 Bar

48

81

74

126

119

203

179

304

298

506

405

689

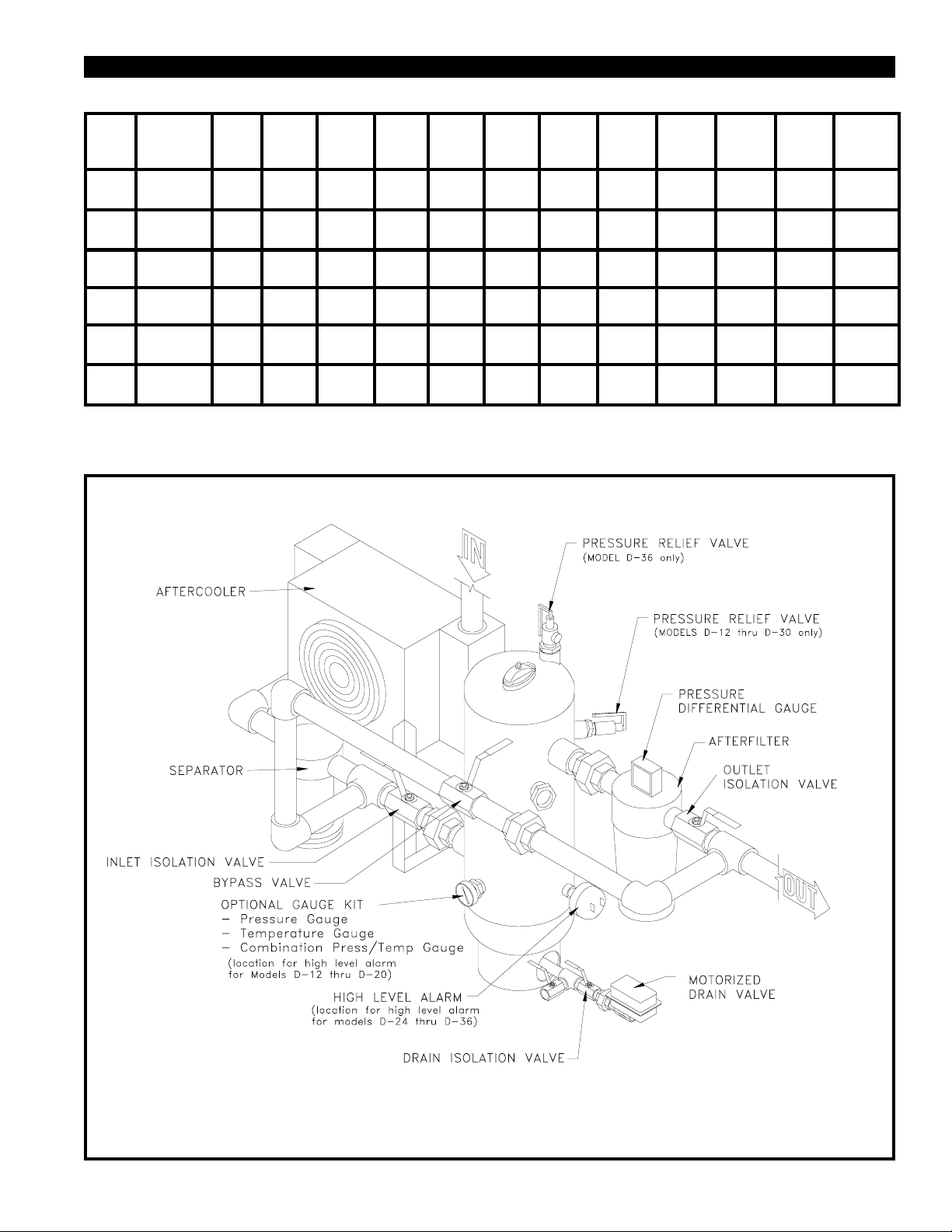

FIGURE 3 RECOMMENDED INSTALLATION DRAWING

60 PSIG

4.1 Bar

65

111

101

172

163

277

244

415

407

692

554

941

80 PSIG

5.5 Bar

83

140

128

217

206

351

310

526

516

877

702

1192

100 PSIG

6.9 Bar

100

170

155

263

250

425

375

637

625

1062

850

1444

125 PSIG

8.6 Bar

122

207

189

321

304

517

457

776

761

1293

1035

1759

150 PSIG

10.3 Bar

144

244

223

378

359

610

538

915

897

1525

1221

2074

175 PSIG

12.1 Bar

165

281

256

436

414

703

620

1054

1034

1757

1406

2390

200 PSIG

13.8 Bar

187

318

290

493

468

795

702

1193

1170

1988

--

--

250 PSIG

17.2 Bar

231

392

358

608

--

--

--

--

--

--

--

--

NOTE:

ITEMS CALLED OUT IN THIS DRAWING

ARE NOT SUPPLIED WITH THE DRYER.

REFERENCE FIGURES 1 & 4 FOR ITEMS

INCLUDED WITH DRYER.

PAGE 3

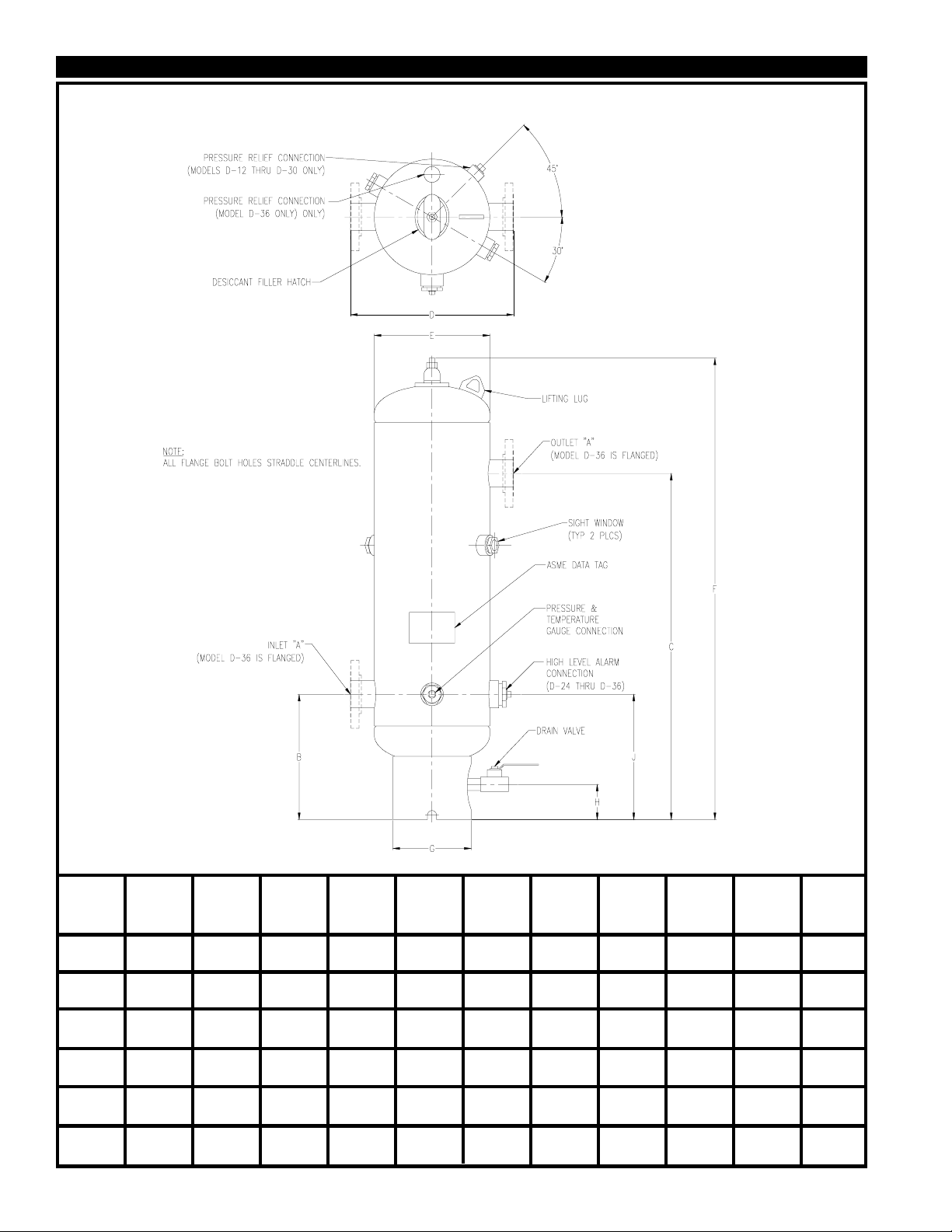

SECTION 2 INSTALLATION

FIGURE 4 DRYER DIMENSIONAL DETAILS

MODEL

NO.

D-12

D-16

D-20

D-24

D-30

D-36

PAGE 4

APPROX

WEIGHT

w/o Desiccant

130 LBS

145 LBS

210 LBS

285 LBS

640 LBS

780 LBS

A

2" NPT

2" NPT

2" NPT

2" NPT

3" NPT

3" 150#

FLANGE

B

13-7/8"

352.4mm

15-1/2"

393.7mm

15-3/4"

400.1mm

17"

431.8mm

21-7/8"

555.6mm

24-5/8"

65.5mm

C

38-1/4"

971.6mm

41-3/4"

1060.5mm

42-5/8"

1082.7mm

44"

1117.6mm

44-7/8"

1139.8mm

48-5/8"

1235.1mm

D

18"

457.2mm

19-1/2"

495.3mm

23-1/2"

596.9mm

26"

660.4mm

32"

812.8mm

44-5/8"

1133.5mm

E

12-3/4"

323.9mm

16"

406.4mm

20"

508mm

24"

609.6mm

30"

762mm

36-5/8"

930.3mm

F

51"

1295mm

54-5/8"

1387.5mm

55-7/8"

1419.2mm

58-3/4"

1492.3mm

63-1/2"

1612.9mm

69-3/8"

1762.1mm

G

8-5/8"

219.1mm

12-3/4"

323.9mm

16"

406.4mm

16"

406.4mm

24"

609.6mm

24"

609.6mm

H

3-7/8"

98.4mm

3-1/2"

88.9mm

3-3/8"

85.7mm

3-3/4"

95.3mm

4-3/8"

111.1mm

5"

127mm

J

NA

NA

NA

NA

NA

NA

17"

431.8mm

19-5/8"

498.5mm

21-5/8"

549.3mm

Loading...

Loading...