Van Air Systems Connector Kits User Manual

APRIL 2000

P/N 432-10021

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

®

FOR F200 SERIES FILTER HOUSINGS

PRODUCT PURPOSE & FUNCTION:

Van Air's Connector Kits are designed to connect (2) F200 series filter housings together for dual filtration applications.

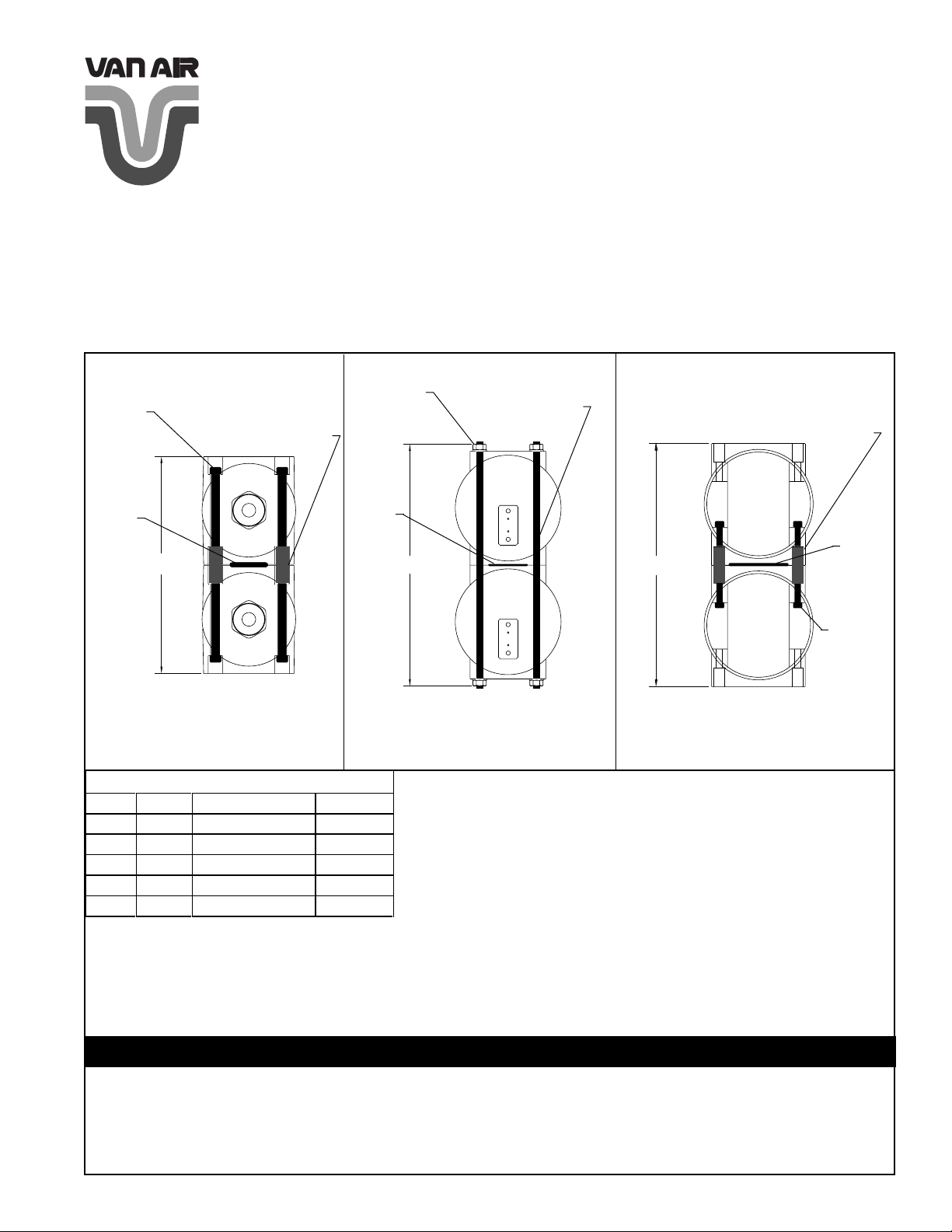

CK-1 & CK-1-2

SCREW

4 PLACES

O-RING

STANDOFF

2 PLACES

A

WASHER

4 PLACES

O-RING

CK-1 THRU CK-3-2

CONNECTOR KITS

CK-2 & CK-2-2

NUT &

A

TIE ROD

2 PLACES

A

CK-3-2

STANDOFF

2 PLACES

O-RING

KIT INCLUDES (4) SCREWS, (2) STANDOFFS & (1)

O-RING

KIT INCLUDES (2) TIE RODS, (4) NUTS, (4) WASHER & (1)

O-RING

CONNECTING KIT DETAILS

TYPE A USED ON (F200-) PART NO

CK-1 7 55 84-0723

CK-1-2 5-3/4 15 THRU 25 84-10133

CK-2 10-3/4 85 THRU 265 84-0724

CK-2-2 11-1/4 350 THRU 500 84-10134

CK-3-2 15-3/4 600 THRU 1000 84-10135

SCREW

4 PLACES

KIT INCLUDES (4) SCREWS, (2) STANDOFFS & (1) O-RING

WARNINGS

READ INSTRUCTIONS CAREFULLY BEFORE CONNECTOR FILTERS.

•

DO NOT INSTALL CONNECTING KIT TO EQUIPMENT THAT IS UNDER PRESSURE.

•

DO NOT CONNECT DIFFERENT FILTER MODELS.

•

DO NOT OPERATE IF THERE IS A LEAK. TAKE FILTERS OUT OF SERVICE IMMEDIATELY.

•

PRINTED IN THE USA ©2000 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423

INSTALLING CK-1 & CK-1-2

INSTALLING CK-2 & CK-2-2

INSTALLING CK-3-2

1.

Remove filter heads from filter bowls.

2.

Apply grease to o-ring and place it on the

recess around the inlet/outlet area of one

filter head.

3.

Place (1) standoff in each thru-hole.

4.

Place (1) screw through each thru-hole on

the other side of the filter head and thread

into each standoff until snug.

5.

Join the other head by holding each head

together with the standoffs in each thruhole between the heads as shown in Fig-

ure 1.(NOTE: Be sure that the heads are

connected in the correct flow direction.)

6.

Place (1) screw through each thru-hole on

the other side of the second filter head and

thread into each standoff until snug.

7.

Gradually tighten each screw down in a

alternating crisscross pattern to ensure an

even seal between the filter heads.

8.

Follow Installation instructions on page 3

of the F200 Series Filter Housing instruction manual that is provided with each filter.

(NOTE: Read all instructions carefully before installing filters.)

Remove filter heads from filter bowls.

1.

Place each tie rod through the thru-holes of

2.

one of the filter heads.

Place (1) washer on ends of the tie rods on

3.

far side of the filter head.

Thread (1) nut onto each tie rod over each

4.

washer.

Apply grease to o-ring and place it in the

5.

recess around the inlet/outlet area of one

filter head.

Join the other head (with o-ring between

6.

them) by feeding the tie rods through each

thru-hole until each filter head is together

as shown in Figure 1. (NOTE: Be sure that

the heads are connected in the correct

flow direction.)

Place (1) washer on other end of the tie

7.

rods on outer side of the filter head.

Thread (1) nut onto each tie rod over each

8.

washer.

Gradually tighten each screw down in a

9.

alternating crisscross pattern to ensure an

even seal between the filter heads.

Follow Installation instructions on page 3

10.

of the F200 Series Filter Housing instruction manual that is provided with each filter

(NOTE: Read all instructions carefully before installing filters.)

Remove filter heads from filter bowls.

1.

Remove each blanking plates from the

2.

filter heads.

Apply grease to o-ring and place it in the

3.

recess around the inlet/outlet area of one

filter head.

Place (1) standoff in each thru-hole.

4.

Place (1) screw through each thru-hole

5.

inside the filter head and thread into each

standoff until snug.

Join the other head by holding each head

6.

together with the standoffs in each thruhole between the filter heads as shown in

Figure 1. (NOTE: Be sure that the heads

are connected in the correct flow direction.)

Place (1) screw through each thru-hole

7.

inside the second filter head and thread

into each standoff until snug.

Gradually tighten each screw down in a

8.

alternating crisscross pattern to ensure an

even seal between the filter heads.

Follow Installation instructions on page 3

9.

of the F200 Series Filter Housing instruction manual that is provided with each filter

(NOTE: Read all instructions carefully before installing filters.)

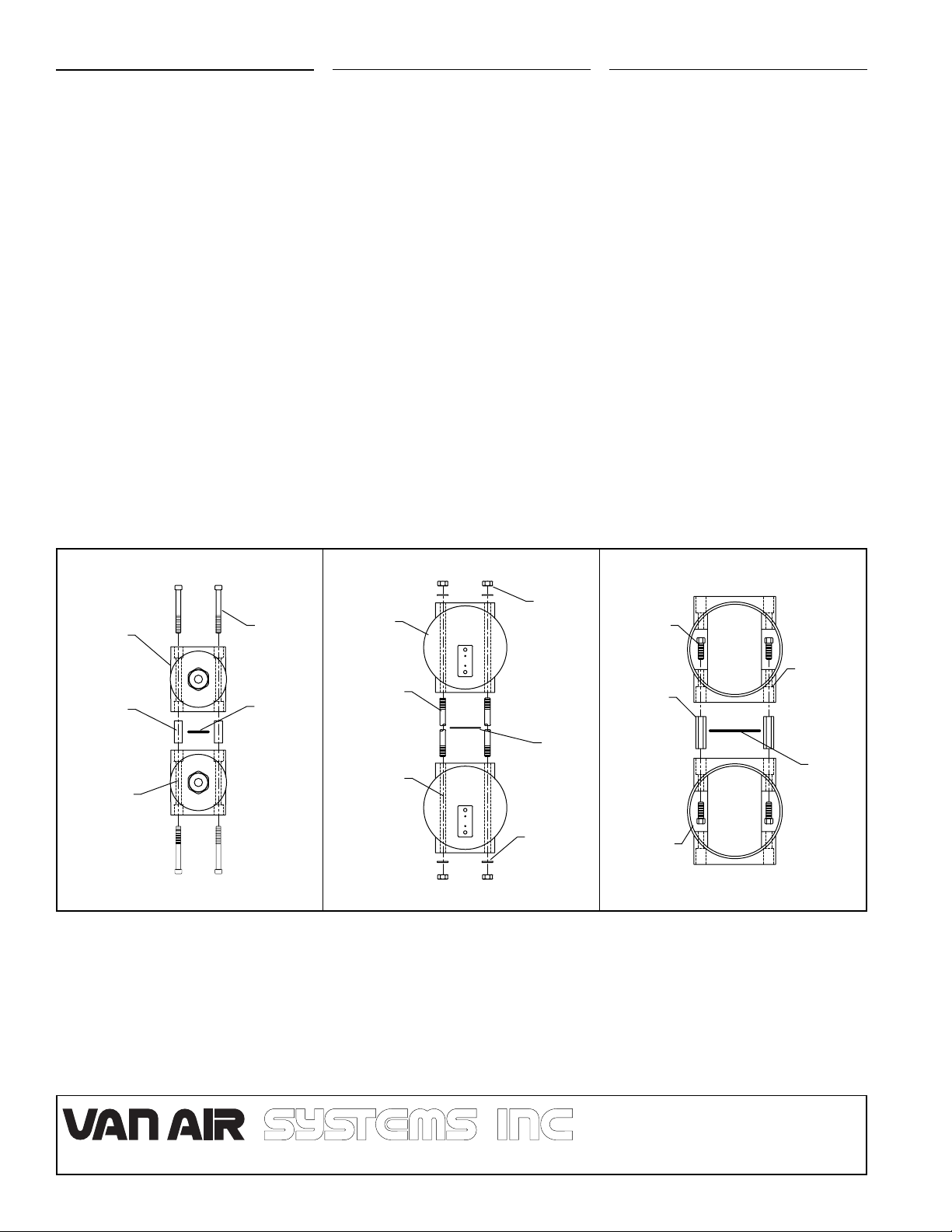

FIGURE 1A CK-1 & CK-1-2 DETAILS

FILTER

HEAD

2 PLACES

STANDOFF

2 PLACES

THRU-HOLES

2 PLACES

SCREWS

4 PLACES

O-RING

FIGURE 1B CK-2 & CK-2-2 DETAILS

NUT

FILTER

HEAD

2 PLACES

TIE ROD

2 PLACES

THRU-HOLES

2 PLACES

4 PLACES

O-RING

WASHER

4 PLACES

FIGURE 1C CK-3-2 DETAILS

SCREWS

4 PLACES

STANDOFF

2 PLACES

FILTER

HEAD

2 PLACES

THRUHOLES

4 PLACES

O-RING

2950 Mechanic Street

Lake City, PA 16423-2095

Phone: 814/774-2631

MAKING COMPRESSED AIR AND GAS WORK BETTER SINCE 1944.

Fax: 814/774-3482

©2000 VAN AIR SYSTEMS INC. 2950 MECHANIC STREET, LAKE CITY, PA 16423 PRINTED IN THE USA

Loading...

Loading...