Troy-Bilt TB146 EC Owner's Manual

TB146 EC

4-Cycle

Electric Start Capable

Cultivator

Operator’s Manual

Unpacking the Unit |

Assembling the Unit |

|

|

|

|

Wheel Bracket |

|

Clevis Pin |

|

|

Wheel |

|

|

|

|

Assembly |

|

|

|

1 |

2 |

3 |

Cotter Pin |

4 |

|

Remove all contents from the carton.

Assembling the Unit

Handlebar Knobs

5

Tighten the two handlebar knobs to secure the handlebars. Readjust the throttle cable and switch wires. NOTE: Do not over tighten the handlebar knobs.

Starting the Unit

Primer Bulb

Insert the wheel assembly into |

Align the hole in the wheel |

Loosen the two handlebar |

the wheel bracket. The "J" |

bracket with the desired hole |

knobs. Swing the handlebars |

shape of the wheel assembly |

in the wheel assembly. Insert |

up into the operating position. |

should point away from the |

the clevis pin through the |

NOTE: Do not pinch the |

unit. |

aligned holes. Insert the cotter |

throttle cable or switch wires. |

|

pin into the clevis pin. |

|

Starting the Unit

6 |

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

7 |

|

|

|

||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|||

Set the unit on a flat, level |

Place the unit on a level surface. |

DO NOT Squeeze the throttle |

|

||||||||

surface. Unscrew the oil fill |

Remove the fuel cap. Fill the fuel |

control. |

|

||||||||

plug. Pour the entire bottle of |

tank. Replace the fuel cap. Move |

|

|

|

|||||||

oil into the oil fill hole. Reinstall |

the unit at least 30 ft. (9.1 m) |

|

|

|

|||||||

the oil fill plug. |

from the fuel container and the |

|

|

|

|||||||

NOTE: DO NOT overfill. Never |

fueling site before starting the |

|

|

|

|||||||

add oil directly into the fuel |

engine. |

|

|

|

|||||||

tank. DO NOT mix oil with |

NOTE: Use fresh unleaded |

|

|

|

|||||||

gasoline. |

gasoline (less than 30 days old). |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 X

19 |

10 |

11 |

12 |

Press primer bulb 10 times, |

Stand in starting position. |

DO NOT squeeze the throttle |

Then squeeze the throttle |

or until fuel is visible |

WARNING: Tines WILL |

control. |

control for an additional 30 to |

|

Pull starter rope in controlled |

60 seconds to let the engine |

|

|

ROTATE on START. Always stand |

||

|

motion until unit starts. Wait |

warm up further. The unit may |

|

|

in starting position with foot on |

||

|

60 seconds. |

be used during this period. |

|

|

wheel when starting the unit. |

||

|

|

|

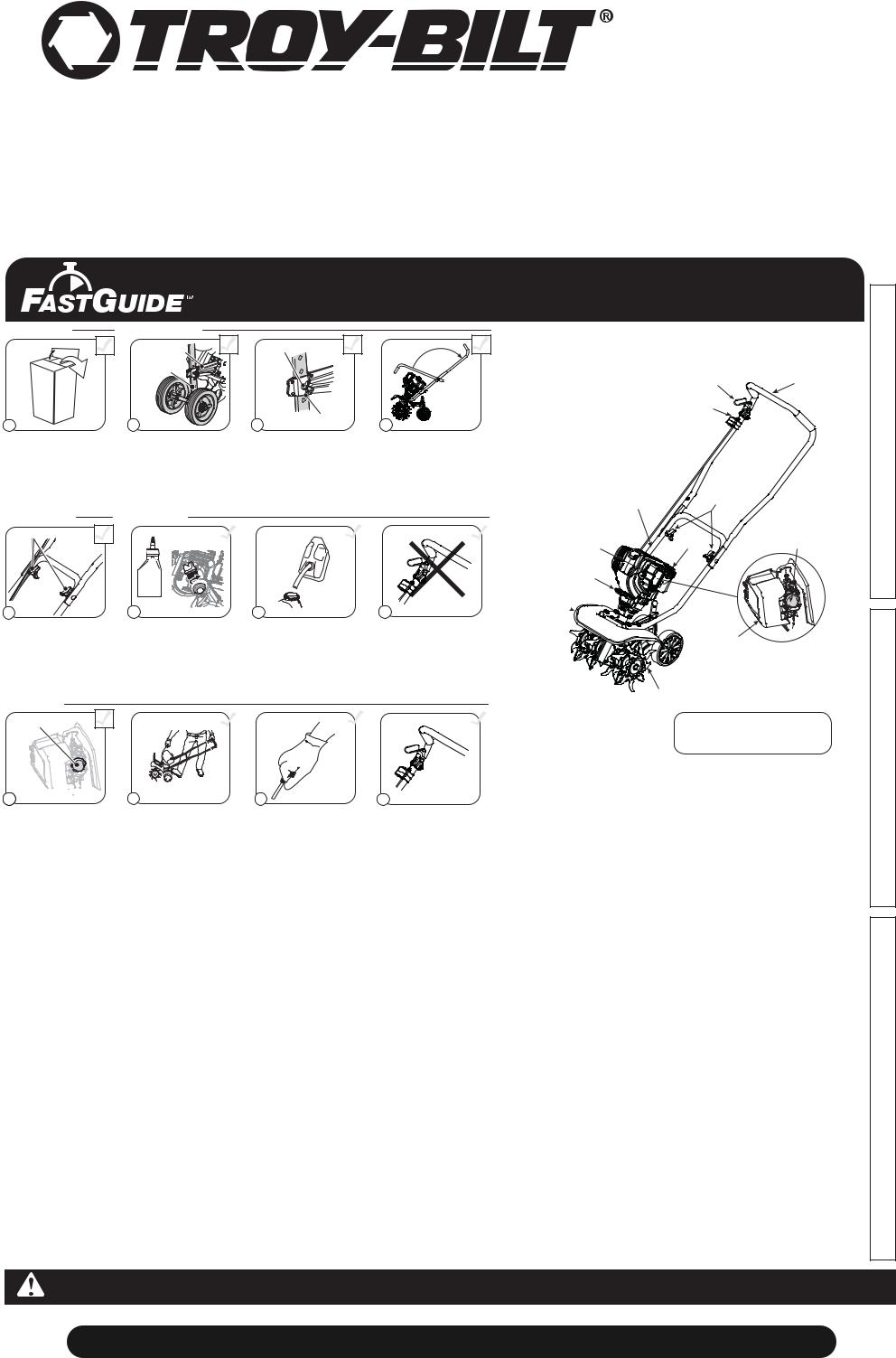

NO ASSEMBLY TOOLS REQUIRED

Electric Starter or |

Throttle Control |

Upper Handle |

|

Power Start Bit Optional! |

|||

|

|

||

THESE OPTIONAL ACCESSORIES |

On/ Off Switch |

|

|

ARE SOLD SEPARATELY! |

|

This unit has an alternate starting method that many find easier to use than pulling a rope. Please contact a local retailer or call 1-800-828-5500 for more information. Information may also be found at www.troybilt.com

|

Handle Knobs |

|

|

Lower Handle |

|

Choke Lever |

Fuel Cap |

Primer Bulb |

|

|

Starter Rope

Tine Shield

|

Air Filter |

|

Cover |

|

Tines |

DIDN’T START? |

IF THE ENGINE IS HOT |

Repeat the starting instructions. |

|

If the unit still fails to start, |

Go back to Step 9 |

|

|

refer to the operator’s manual |

|

for additional starting and |

|

troubleshooting information. |

|

Need Help?

In cold weather (below 40°F),

refer to the operator's manual for Call 1-800-828-5500 additional starting instructions.

English — Page 1

Español — Page 7

IMPORTANT: READ THE OPERATOR’S MANUAL THOROUGHLY AND FOLLOW THE SAFE OPERATION PRACTICES WHILE OPERATING THE UNIT.

NEED HELP? CALL 1-800-828-5500 IN U.S. OR 1-800–668–1238 IN CANADA

769-07453A P00 |

02/12 |

TABLE OF CONTENTS

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Oil and Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Starting and Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Cleaning and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Optional Accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

All information, illustrations, and specifications in this manual are based on the latest product information available at the time of printing. We reserve the right to make changes at any time without notice.

Copyright© 2012 MTD SOUTHWEST INC, All Rights Reserved.

SERVICE

DO NOT RETURN THIS UNIT TO THE RETAILER. PROOF OF PURCHASE WILL BE REQUIRED FOR WARRANTY SERVICE.

For assistance regarding the assembly, controls, operation or maintenance of the unit, please call the Customer Support Department at 1-800-828-5500 in the United States or 1-800-668-1238 in Canada. Additional information about the unit can be found on our website at www.troybilt.com or www.troybilt.ca.

For service, please call the Customer Support Department to obtain a list of authorized service dealers near you. Service on this unit, both within and after the warranty period, should only be performed by an authorized and approved service dealer. When servicing, use only identical replacement parts.

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the states of California, Maine, Oregon and Washington.

All U.S. Forest Land and the state of California (Public Resources Codes 4442 and 4443), Oregon and Washington require, by law that certain internal combustion engines operated on forest brush and/or grasscovered areas be equipped with a spark arrestor, maintained in effective working order, or the engine be constructed, equipped and maintained for the prevention of fire. Check with your state or local authorities for regulations pertaining to these requirements. Failure to follow these requirements could subject you to liability or a fine. This unit is factory equipped with a spark arrestor. If it requires replacement, ask your LOCAL SERVICE DEALER to install the Accessory Part #753-06238 Muffler Assembly.

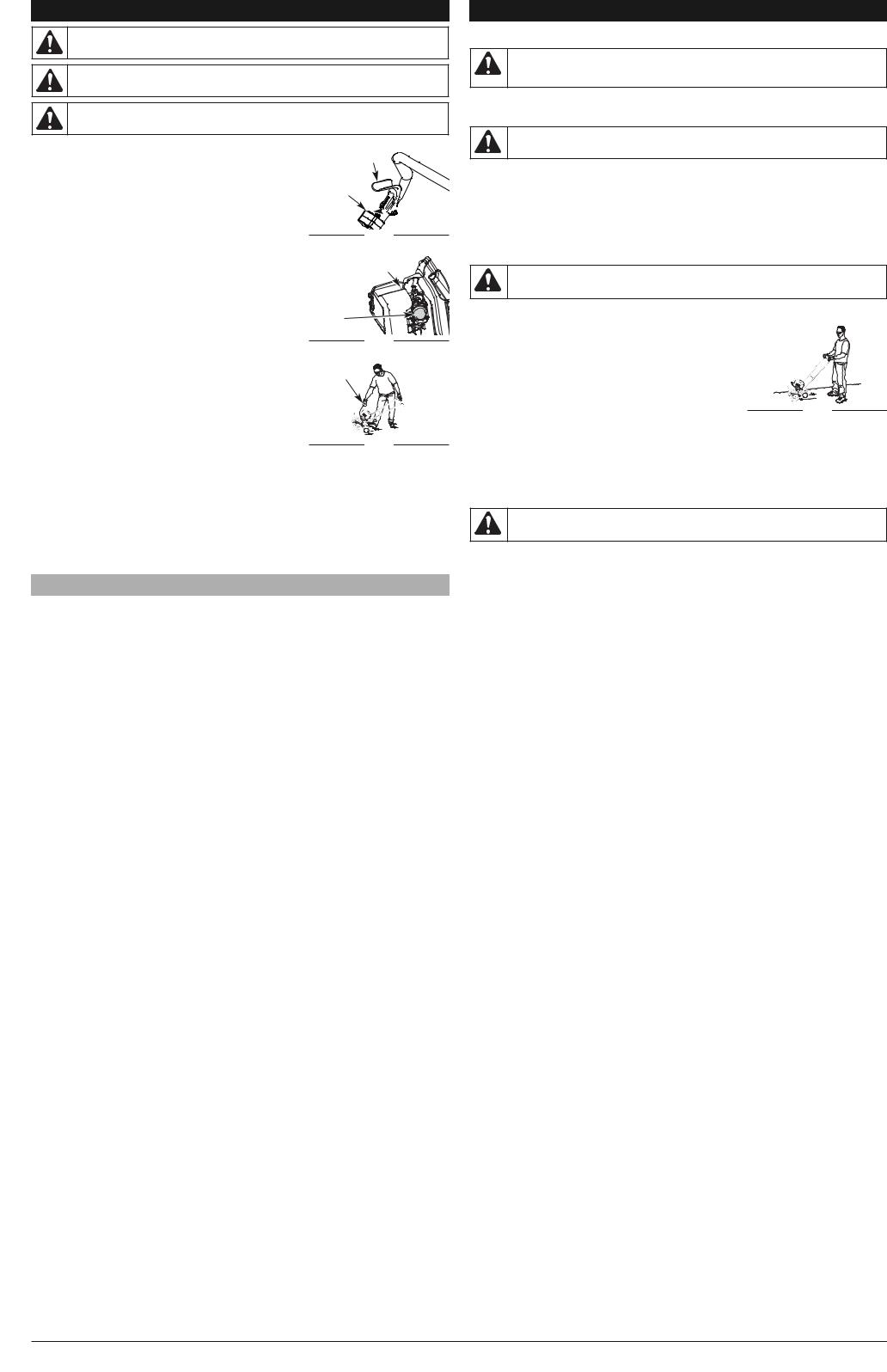

SAFETY

The purpose of safety symbols is to attract attention to possible dangers. The safety symbols, and their explanations, deserve careful attention and understanding. The safety warnings do not by themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper accident prevention measures.

SYMBOL MEANING

DANGER: Signals an EXTREME hazard.

Failure to obey a safety DANGER signal WILL result in serious injury or death to yourself or to others.

WARNING: Signals a SERIOUS hazard.

Failure to obey a safety WARNING signal CAN result in serious injury to yourself or to others.

CAUTION: Signals a MODERATE hazard.

Failure to obey a safety CAUTION signal MAY result in property damage or injury to yourself or to others.

NOTE: Advises you of information or instructions vital to the operation or maintenance of the equipment.

READ THE OPERATOR’S MANUAL AND FOLLOW ALL WARNINGS AND SAFETY INSTRUCTIONS. FAILURE TO DO SO CAN RESULT IN SERIOUS INJURY TO THE OPERATOR AND/OR BYSTANDERS.

FOR QUESTIONS, CALL 1-800–828-5500 IN U.S. OR 1-800-668-1238 IN CANADA

• IMPORTANT SAFETY INSTRUCTIONS •

CALIFORNIA PROPOSITION 65

WARNING: Engine exhaust, some of its constituents and certain finished components contain or emit chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. Wash hands after handling.

READ ALL INSTRUCTIONS BEFORE OPERATING

WARNING: When using the unit, all safety rules must be followed. Please read these instructions before operating the unit in order to ensure the safety of the operator and any bystanders. Please keep these instructions for later use.

•Read the instructions carefully. Be familiar with the controls and proper use of the unit.

•Do not operate this unit when tired, ill or under the influence of alcohol, drugs or medication.

•Children and teens under the age of 15 must not use the unit, except for teens guided by an adult.

•All guards and safety attachments must be installed properly before operating the unit.

•Inspect the unit before use. Replace damaged parts. Check for fuel leaks. Make sure all fasteners are in place and secure. Replace parts that are cracked, chipped, or damaged in any way. Do not operate the unit with loose or damaged parts.

•Carefully inspect the area before starting the unit. Remove all debris and hard or sharp objects such as glass, wire, etc.

•Be aware of the risk of injury to the head, hands and feet.

•Clear the area of children, bystanders and pets; keep them outside a 50-foot (15 m) radius, at a minimum. Even then, they are still at risk from thrown objects. Encourage bystanders to wear eye protection. If you are approached, stop the unit immediately.

•Squeeze the throttle control and check that it returns automatically to the idle position. Make all adjustments or repairs before using the unit.

SAFETY WARNINGS FOR GAS UNITS

WARNING: Gasoline is highly flammable, and its vapors can explode if ignited. Take the following precautions:

•Store fuel only in containers specifically designed and approved for the storage of such materials.

•Always stop the engine and allow it to cool before filling the tank. Never remove the fuel tank cap or add fuel when the engine is hot. Always loosen the fuel tank cap slowly to relieve any pressure in the tank before fueling.

•Always add fuel in a clean, well-ventilated outdoor area where there are no sparks or flames. DO NOT smoke.

•Never operate the unit without the fuel cap securely in place.

•Avoid creating a source of ignition for spilled fuel. Wipe up any spilled fuel from the unit immediately, before starting the unit. Move the unit at least 30 ft. (9.1 m) from the fueling source and site before starting the engine. DO NOT smoke.

SAFETY

•Never start or run the unit inside a closed room or building. Breathing exhaust fumes can kill. Operate this unit only in a well ventilated outdoor area.

WHILE OPERATING

•Wear safety glasses or goggles that meet current ANSI Z87.1 standards and are marked as such. Wear ear/hearing protection when operating this unit. Wear a face or dust mask if the operation is dusty.

•Wear heavy long pants, boots, gloves and a long sleeve shirt. Do not wear loose clothing, jewelry, short pants, sandals or go barefoot. Secure hair above shoulder level.

•This unit has a clutch. The tines remain stationary when the engine is idling. If they do not, take the unit to a Troy-Bilt or other qualified service dealer for an adjustment.

•Be sure the tines are not in contact with anything before starting the unit.

•Use the unit only in daylight or good artificial light.

•Avoid accidental starting. Be in the starting position whenever pulling the starter rope. The operator and unit must be in a stable position while starting. Refer to Starting and Stopping.

•Use the right tool. Only use this tool for its intended purpose.

•Use extreme caution when reversing or pulling the unit towards you.

•Do not overreach. Always keep proper footing and balance. Take extra care when working on steep slopes or inclines.

•Always hold the unit with both hands when operating. Keep a firm grip on both handles or grips.

•Keep hands, face, and feet away from all moving parts. Do not touch or try to stop the tines when they are rotating.

•Do not touch the engine or muffler. These parts get extremely hot from operation, even after the unit is turned off.

•Do not operate the engine faster than the speed needed to cultivate. Do not run the engine at high speed when you are not cultivating.

•Always stop the engine when cultivating is delayed or when walking from one cultivating location to another.

•If you strike or become entangled with a foreign object, stop the engine immediately and check for damage. Do not operate before repairing damage. Do not operate the unit with loose or damaged parts.

•Turn the engine to off and disconnect the spark plug for maintenance or repair.

•Use only original equipment manufacturer (OEM) replacement parts and accessories for this unit, as listed in the Parts List section of this manual. Use of any other parts or accessories could lead to serious injury to the user, or damage to the unit, and void the warranty.

•Keep the unit clean of vegetation and other materials that may become lodged between the tines and guard.

•To reduce fire hazard, replace a faulty muffler and spark arrestor. Keep the engine and muffler free from grass, leaves, excessive grease or carbon build up.

OTHER SAFETY WARNINGS

•Never store the unit with fuel in the tank, inside a building where fumes may reach an open flame (pilot lights, etc.) or sparks (switches, electrical motors, etc.).

•Allow the engine to cool before storing or transporting. Be sure to secure the unit while transporting.

•Store the unit in a dry place, secured or at a height to prevent unauthorized use or damage. Keep out of the reach of children.

•Never douse or squirt the unit with water or any other liquid. Keep handles dry, clean and free from debris. Clean after each use, see Cleaning and Storage instructions.

•Clean tines with a household cleaner to remove any gum buildup. Oil the tines with machine oil to prevent rust.

•Keep these instructions. Refer to them often and use them to instruct other users. If you loan this unit to others, also loan them these instructions.

SAVE THESE INSTRUCTIONS

• SAFETY AND INTERNATIONAL SYMBOLS •

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read the operator's manual for complete safety, assembly, operating, maintenance, and repair information.

SYMBOL MEANING

•SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in conjunction with other symbols or pictographs.

•READ OPERATOR'S MANUAL

WARNING: Read the operator’s manual(s) and follow all warnings and safety instructions. Failure to do so can result in serious injury to the operator and/or bystanders.

•WEAR EYE AND HEARING PROTECTION

WARNING: Thrown objects and loud noise can cause severe eye injury and hearing loss. Wear eye protection meeting current ANSI Z87.1 standards and ear protection when operating this unit. Use a full face shield when needed.

•UNLEADED FUEL

Always use clean, fresh unleaded fuel

•OIL

Refer to operator’s manual for the proper type of oil.

•DO NOT USE E85 FUEL IN THIS UNIT

WARNING: It has been proven that fuel containing greater than 10% ethanol will likely damage this engine and void the warranty.

•ON/OFF STOP CONTROL

ON / START / RUN

•ON/OFF STOP CONTROL

OFF or STOP

•KEEP BYSTANDERS AWAY

WARNING: Keep all bystanders, especially children and pets, at least 50 feet (15 m) from the operating area.

• THROWN OBJECTS AND ROTATING CUTTER CAN CAUSE SEVERE INJURY

WARNING: Small objects can be propelled at high speed, causing injury. Keep away from the rotating rotor.

• HOT SURFACE

WARNING: Do not touch a hot engine. These parts get extremely hot from operation and may cause severe burns. When the unit is turned off the engine will remain hot for a short time.

• GARDEN CULTIVATORS – ROTATING TINES CAN CAUSE SEVERE INJURY

WARNING: Stop the engine/motor and allow the tines to stop before installing or removing tines, or before cleaning or performing any maintenance. Keep hands and feet away from rotating tines.

•NO STEP

Always keep proper footing and balance. Do not overreach, take extra care when working on steep slopes or inclines.

•PLACE RIGHT FOOT HERE

Avoid accidental starting. Stand in the starting position whenever pulling the starter rope. The operator and unit must be in a stable position while starting.

2

KNOW YOUR UNIT

APPLICATIONS

•Cultivating sod and light to medium soil

•Cultivating in garden areas, around trees, etc.

•Edging

Throttle Control

On/Off Control

NO ASSEMBLY TOOLS REQUIRED

Handlebar Knobs

Spark Plug

Muffler

Fuel Cap

Starter Rope

Grip

Tine Guard

Wheel Support

Wheel Support

Bracket

Air Filter Cover

Cultivator Tines

Handlebar

Oil Fill Plug

Primer Bulb

ASSEMBLY

INSTALLING AND ADJUSTING THE WHEEL ASSEMBLY

WARNING: To prevent serious personal injury, the wheel assembly must be installed when operating the unit.

WARNING: To avoid injury from the tines, wear heavy gloves and a long sleeve shirt when installing the wheel assembly.

Installing the Wheel Assembly |

Wheel Bracket |

||

1. |

Insert the wheel assembly into the wheel bracket. The "J" |

||

Clevis Pin |

|||

|

shape of the wheel assembly should point away from the unit |

||

|

(Fig. 1). |

|

|

2. |

Align the hole in the wheel bracket with the desired hole in the |

Cotter Pin |

|

|

wheel assembly (Fig. 1). |

Wheel |

|

3. |

Insert the clevis pin through the aligned holes (Fig. 1). |

||

Assembly |

|||

4. |

Insert the cotter pin into the clevis pin (Fig. 1). |

||

Fig. 1 |

|||

|

|

||

NOTE: It may be necessary to adjust the position of the wheel assembly before using the unit.

Adjusting the Wheel Assembly

1.Remove the cotter pin from the clevis pin (Fig. 1).

2.Remove the clevis pin from the wheel bracket and wheel assembly (Fig. 1).

3.Align the hole in the wheel bracket with the desired hole in the wheel assembly (Fig. 1).

NOTE: Moving the wheel assembly down will raise the wheel height. Moving the wheel assembly up will lower the wheel height.

4.Insert the clevis pin through the aligned holes (Fig. 1).

5.Insert the cotter pin into the clevis pin (Fig. 1).

OIL AND FUEL

USING THE RIGHT OIL

Use a high-quality SAE 30 weight oil of API (American Petroleum Institute) service class SJ. DO NOT use dirty oil. Failure to use clean oil of the correct type can cause premature engine wear and failure.

ADDING OIL: INITIAL USE

WARNING: OVERFILLING THE CRANKCASE MAY CAUSE SERIOUS PERSONAL INJURY. Check the oil level before each use. The importance of maintaining the proper oil level cannot be overemphasized. Change the oil according to the Maintenance Schedule.

NOTE: This unit was shipped without oil in the crankcase. Oil must be added before starting the unit.

NOTE: This unit comes with a 3.04 fluid oz. (90 ml) bottle of oil.

1.Unscrew the top of the oil bottle. Remove the paper seal. Reinstall the top of the oil bottle.

2.Remove the cap from the oil bottle. Cut the tip off the funnel spout (Fig. 4).

3.Set the unit on a flat, level surface.

4.Unscrew the oil fill plug (Fig. 5).

5.Pour the entire bottle into the oil fill hole (Fig. 5). DO NOT overfill. Refer to Checking the Oil Level.

NOTE: Never add oil directly to the fuel tank. This unit has a fourcycle engine. DO NOT mix oil with gasoline.

6.Wipe up any oil that may have spilled.

7.Reinstall the oil fill plug.

NOTE: Make sure the O-ring is in place on the oil fill plug (Fig. 5).

NOTE: Save the empty oil bottle. Use the bottle to measure the correct amount of oil during future oil changes.

USING THE RIGHT FUEL

Funnel

Spout

Fig. 4

Oil Fill Plug

O-Ring

Oil Fill

Hole

Fig. 5

The use of old fuel is the most common cause of performance problems. Use only fresh, clean unleaded gasoline.

Definition of Blended Fuels

Today's fuels are often a blend of gasoline and oxygenates such as ethanol, methanol or MTBE (ether). Alcohol-blended fuel absorbs water. As little as 1% water in the fuel can make fuel and oil separate, forming acids when stored. ALWAYS use fresh fuel (less than 30 days old).

NOTE: Dispose of old fuel according to federal, state and local regulations.

Using Blended Fuels

If using a blended fuel:

•Always use fresh unleaded gasoline

•Use the fuel additive STA-BIL® or an equivalent

•Drain the tank and run the engine dry before storing the unit

WARNING: DO NOT USE E85 FUEL IN THIS UNIT. It has been proven that fuel containing greater than 10% ethanol will likely damage this engine and void the warranty.

Using Fuel Additives

Use a fuel additive, such as STA-BIL Fuel Stabilizer or an equivalent, to inhibit corrosion and minimize gum deposits. Add 0.8 oz. (23 ml) of fuel additive per gallon of fuel, according to the instructions on the container. NEVER add fuel additives directly to the unit's fuel tank.

FUELING THE UNIT

WARNING: Gasoline is extremely flammable. Ignited vapors may explode. Always stop the engine and allow it to cool before filling the fuel tank. Do not smoke while filling the tank. Keep sparks and open flames at a distance from the area.

WARNING: Remove the fuel cap slowly to avoid injury from fuel spray. Never operate the unit without the fuel cap securely in place.

WARNING: Add fuel in a clean, well ventilated outdoor area. Wipe up any spilled fuel immediately. Avoid creating a source of ignition for spilled fuel. Do not start the engine until fuel vapors dissipate.

1.Position the unit with the fuel cap facing up.

2.Remove the fuel cap.

3.Place the fuel container spout into the fill hole on the fuel tank and fill the tank. NOTE: Do not overfill the tank.

4.Wipe up any fuel that may have spilled.

5.Reinstall the fuel cap.

6.Move the unit at least 30 ft. (9.1 m) from the fuel container and the fueling site before starting the engine.

POSITIONING THE HANDLEBARS

1.Loosen the two knobs on the inside of the handlebars (Fig. 2).

2.With the unit upright, swing the handlebars up into the operating position (Fig. 3).

NOTE: Take care not to pinch the throttle cable or switch wires when positioning the handlebar.

3. Tighten the knobs to secure the handlebars in place. NOTE: Do not over-tighten the knobs.

Handlebar Knobs

Fig. 2

Fig. 3

3

STARTING AND STOPPING

WARNING: Tines WILL ROTATE when STARTING. Always stand in starting position with foot on wheel when starting the unit.

WARNING: Operate this unit only in a well-ventilated outdoor area. Carbon monoxide exhaust fumes can be lethal in a confined area.

WARNING: Avoid accidentally starting the unit. To avoid serious injury, the operator and the unit must be in a stable position when pulling the starter rope (Fig. 8).

STARTING INSTRUCTIONS

1.Check the oil level. Refer to Checking the Oil Level.

2.Fill the fuel tank. Refer to Fueling the Unit.

NOTE: There is no need to turn the unit on. The On/Off switch is in the ON ( I ) position at all times (Fig. 6).

IF COLD... For cold weather conditions (below 40°F), flip the Red Cold Weather Start Lever (Fig. 7) back to the closed position and continue to step 3. DO NOT flip this lever back if the temperature is above 40°F.

NOTE: DO NOT squeeze the throttle control until step 6.

3.Slowly press and release the primer bulb 10 times (Fig. 7). If fuel cannot be seen in the primer bulb, press and release the primer bulb until fuel is visible.

NOTE: Make sure to always have the unit tilted back slightly to bring the tines off the ground when starting.

4.Hold the handlebar with one hand and grab the starter rope with the other hand, do not squeeze the throttle control (Fig. 8). Using one foot to hold down the cultivator. Pull the starter rope in a controlled motion until the unit starts.

Throttle Control

On ( I )

/ Start

Off (O)

/ Stop

/ Stop

Fig. 6

Fig. 6

Red Cold Weather

Start Lever

Primer

Bulb

Fig. 7

IF COLD... For cold weather conditions (below 40°F), flip the Cold Weather Start Lever forward to the open position after the unit has started and before squeezing the throttle control.

5.Once the unit starts, wait 60 seconds.

6.Squeezing the throttle control for an additional 30 to 60 seconds to let the engine warm up. The unit may be used during this time.

IF... The engine does not start, go back to step 3.

IF... The engine stops while squeezing the throttle, go back to step 4. IF... The engine is hot, go back to step 3.

STOPPING INSTRUCTIONS

1. Release the throttle control and allow the engine to idle.

Starter Rope |

Starting |

Grip |

Position |

Fig. 8

2.Press and hold the On/Off switch in the OFF (O) position until the engine comes to a complete stop (Fig. 6).

IF USING THE OPTIONAL PLUG-IN POWER START OR POWER BIT START ACCESSORY

NOTE - This Unit Can Use a Plug-In Power Start or Power Bit Start Optional Accessory!

Please refer to the Plug-In Power Start or Power Bit Start operator’s manual for proper use of these features. (Items may be Sold Separately! Please refer to page 6 of this manual for more information about purchasing these accessories.)

STARTING INSTRUCTIONS

1.Check the oil level. Refer to Checking the Oil Level.

2.Fill the fuel tank. Refer to Fueling the Unit.

NOTE: There is no need to turn the unit on. The On/Off switch is in the ON ( I ) position at all times (Fig. 6).

IF COLD... For cold weather conditions (below 40°F), flip the Red Cold Weather Start Lever (Fig. 7) down to the start/closed position and continue to step 3. DO NOT flip this lever down if the temperature is above 40°F.

3.Slowly press and release the primer bulb 10 times (Fig. 7). If fuel cannot be seen in the primer bulb, press and release the primer bulb until fuel is visible.

NOTE: Make sure to always have the unit tilted back slightly to bring the tines off the ground when starting.

4.Hold the handlebar with one hand. Place the Plug-In Power Start or Power Bit Start into the back of the unit. Refer to the Operation section of the Plug-In Power Start or Power Bit Start operator’s manual.

5.Do Not squeeze the throttle control, press and hold the Plug-In Plug-In Power Start or drill’s ON

(I) button for 2 second intervals until unit starts.

6.Once the unit starts, remove the Plug-In Power Start or drill from the rear of the unit and wait 60 seconds.

IF COLD... For cold weather conditions (below 40°F), flip the Red Cold Weather Start Lever forward to the open position after the unit has started and before squeezing the throttle control.

7.Squeezing the throttle control for an additional 30 to 60 seconds to let the engine warm up. The unit may be used during this time.

IF... The engine does not start, go back to step 3.

IF... The engine stops while squeezing the throttle, go back to step 4.

IF... The engine is hot, go back to step 3.

STOPPING INSTRUCTIONS

1.Release the throttle control and allow the engine to idle.

2.Press and hold the On/Off switch in the OFF (O) position until the engine comes to a complete stop (Fig. 6).

OPERATION

OPERATING TIPS

WARNING: Dress properly to reduce the risk of injury when operating this unit. Do not wear loose clothing or jewelry. Wear eye and ear/hearing protection. Wear heavy long pants, boots and gloves. Do not wear short pants, sandals or operate barefoot.

1.Move the cultivator to the work area prior to starting the engine. Transport the cultivator by pushing or pulling it along on its wheels.

WARNING: To prevent serious personal injury, never pick-up or carry the unit while the engine is running.

2.Start the unit by following the Starting Instructions.

3.With the engine running and the tines off the ground, depress the throttle control to increase the engine speed.

4.While holding the upper handle with both hands, slowly lower the cultivator until the tines make contact with the ground (Fig. 9).

5.As cultivating action begins, tilt the cultivator up slightly using the handle so that the tines can penetrate the ground.

6.Once the ground has been broken, continue at a moderate pace.

WARNING: To prevent serious personal injury, use extreme caution when reversing or pulling the unit backwards.

7.If the tines are digging too deep or not deep enough, adjust the wheel bracket as described in

Adjusting Tine Depth.

ADJUSTING THE TINE DEPTH

The tines should penetrate most garden soils approximately 5 to 6 inches. If necessary, adjust the tines as follows:

1. Stop the engine and allow it to cool. Grasp the spark plug wire |

|

firmly and pull the cap from the spark plug. |

Fig. 9 |

2.Raise the wheel height for shallower tine penetration or lower

the wheel height for deeper tine penetration. Refer to Adjusting the Wheel Assembly in the

Assembly Instructions section.

3.Reconnect the spark plug wire and continue use.

TRANSPORTING THE UNIT

WARNING: To prevent serious personal injury, always stop the engine when operation is delayed or when transporting the unit from one location to another.

1.Stop the engine.

2.Tilt the unit back until the tines clear the ground.

3.Push or pull the unit to the next location to be cultivated.

4

MAINTENANCE

WARNING: To prevent serious injury, never perform maintenance or repairs while the unit is running. Always allow the unit to cool before servicing or repairing the unit. Disconnect the spark plug wire to prevent the unit from starting accidentally.

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency stated in the table. These procedures should also be a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require special tools or skills. If you are unsure about these procedures, take your unit to any non-road engine repair establishment, individual or authorized service dealer.

NOTE: Maintenance, replacement, or repair of the emission control devices and system may be performed by any non-road engine repair establishment, individual or authorized service dealer.

NOTE: Please read the California/EPA statement that came with the unit for a complete listing of terms and coverage for the emissions control devices, such as the spark arrestor, muffler, carburetor, etc.

FREQUENCY |

MAINTENANCE REQUIRED |

|

|

|

|

Every 10 hours |

• Clean and re-oil the air filter. Refer to Maintaining the Air Filter. |

|

|

|

|

After the first 10 |

• Change the oil. Refer to Changing the Oil. |

|

• Check the rocker arm clearance. Refer to Checking the Rocker Arm |

||

hours and every 40 |

||

hours |

Clearance. |

|

• Check the spark plug condition and gap. Refer to Maintaining the Spark Plug. |

||

|

||

|

|

TINE REMOVAL AND REPLACEMENT

WARNING: To prevent serious personal injury, always wear heavy gloves when handling the tines.

All tines should be replaced at the same time as they will wear evenly through normal use. Work on one side at a time.

1. |

Make sure the unit is off. |

Inner Tine Hubs |

|

Outer Tines |

|||

NOTE: It may be necessary to lay the cultivator back in a horizontal |

|||

|

|||

|

position on a flat level surface with the upper handle touching |

|

|

|

the ground. It may also be necessary to wash any dirt off the |

|

|

|

tines and shaft for ease of removal. |

|

|

2. |

Remove the retainer from the clevis pin that is between the 2 |

Align Holes |

|

|

outer tines (Fig. 11). |

||

|

Tine Shaft |

||

3. |

Remove the clevis pin and slide the tines off of the shaft (Fig. 11). |

Fig. 10 |

|

4. |

Clean and oil the shaft. |

|

|

5. |

Slide on the new tines with the hubs facing each other (Fig. 10). |

Clevis Pin |

|

NOTE: Make sure the single tine goes on the tine shaft first with |

|||

|

|||

|

the double tines on the outside and holes on the outer tines are |

|

|

|

aligned with the outer hole on the shaft (Fig. 10). |

|

|

6. |

Secure the new tines to the shaft by sliding the clevis pin into |

|

|

|

the holes between the 2 outer tines (Fig. 11). |

|

|

7. |

Insert the retainer into the clevis pin to secure the tines. |

Retainer |

|

8. |

Repeat step 2 through 7 for the opposite side. |

Fig. 11 |

|

CHECKING THE OIL LEVEL

WARNING: OVERFILLING THE CRANKCASE MAY CAUSE SERIOUS PERSONAL INJURY. Check the oil level before each use. The importance of maintaining the proper oil level cannot be overemphasized.

1. Stop the engine and allow it to cool.

2. Set the unit on a flat, level surface. Position the unit so that the engine is horizontal (Fig. 12).

NOTE: Failure to keep the engine level may cause the oil to overfill.

3. Clean the area around the oil fill plug (Fig. 5) to prevent debris

from entering the oil fill hole. 4. Unscrew the oil fill plug.

5. Look into the oil fill hole; use a flashlight if necessary. The oil |

|

Fig. 12 |

|

level should just touch the bottom thread of the oil fill hole |

|

||

|

|

||

(Fig. 13). If the oil level is too low, add oil to the oil fill hole until |

Oil Fill |

Maximum |

|

the oil level touches the bottom thread of the oil fill hole. |

|||

Hole |

Oil Level |

||

NOTE: DO NOT overfill the crankcase. |

|||

|

|

6. Wipe up any oil that may have spilled. 7. Reinstall the oil fill plug.

NOTE: Make sure the O-ring is in place on the oil fill plug (Fig. 5).

Bottom

Thread

Fig. 13

CHANGING THE OIL

Change the oil while the engine is still warm. The oil will flow freely and carry away more impurities.

1. Clean the area around the oil fill plug (Fig. 5) to prevent debris from entering the oil fill hole.

2.Unscrew the oil fill plug.

3.Tip the unit vertically to pour the oil out of the oil fill hole and

|

into a container (Fig. 14). Allow ample time for complete |

|

|

|

|

|

|

|

|

|

|

|

Fig. 14 |

|

|

|

|

|

|

|

|

|

drainage. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: Dispose of the old oil according to federal, state and local |

|

|

|

|

|

|

|

|

|

|

|

regulations. |

|

|

|

|

|

|

|

|

|

4. |

Wipe up any oil that may have spilled. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

5. |

Pour 3.04 fl.oz. (90 ml) of SAE 30 SJ oil into the oil fill hole. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

NOTE: DO NOT overfill. Refer to Checking the Oil Level. |

Fill Line |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||||

NOTE: Use the empty oil bottle saved from the initial use to |

|

|

|

|

|

|

|

|

|

|

|

measure the correct amount of oil. Fill the bottle to the top of |

|

|

|

|

|

|

|

|

|

|

the label to approximate 3.04 fl.oz. (90 ml) of oil (Fig. 15). |

|

|

|

|

|

|

|

|

|

|

|

Fig. 15 |

|

|

|

|

|

|

|

|

6. |

Wipe up any oil that may have spilled. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

||

7. |

Reinstall the oil fill plug. |

|

|

|

|

|

|

|

|

|

NOTE: Make sure the O-ring is in place on the oil fill plug (Fig. 5).

MAINTENANCE

MAINTAINING THE AIR FILTER

WARNING: To avoid serious personal injury, always stop the engine and allow it to cool before cleaning or maintaining the unit.

Failure to maintain the air filter can result in poor performance or can

cause permanent damage to the engine. Engine failure due to improper

cause permanent damage to the engine. Engine failure due to improper  Cover Screw

Cover Screw

air filter maintenance is not covered by the product warranty.

air filter maintenance is not covered by the product warranty.

Cleaning the Air Filter

1. |

Open the air filter cover by unscrewing the cover screw (Fig. 16). |

|

2. |

Remove the air filter from inside the air filter housing (Fig. 17). |

Air Filter |

3. |

Wash the air filter in detergent and water. Rinse the air filter |

Cover |

|

thoroughly and allow it to dry. |

Fig. 16 |

4. |

Lightly coat the air filter with clean SAE 30 oil. |

|

5.Squeeze the air filter to spread and remove excess oil.

6.Reinstall the air filter inside the air filter housing (Fig. 17).

NOTE: Operating the unit without the air filter and air filter cover will VOID the warranty.

7.Insert the hooks on the air filter housing into the slots on the air filter cover (Fig. 17).

8.Swing the air filter cover to the left and align the cover screw with the cover screw hole (Fig. 17). Tighten the cover screw to secure the air filter cover.

NOTE: Do not over tighten as this may strip the screw.

ADJUSTING THE IDLE SPEED

Cover Screw |

Air Filter Housing |

Hole |

|

Air Filter |

|

Slots |

Hooks |

Fig. 17

WARNING: The tines may spin during idle speed adjustments. Wear protective clothing and observe all safety instructions to prevent serious personal injury.

NOTE: Careless adjustments can seriously damage the unit. A

qualified service dealer should make carburetor adjustments. Idle Speed

Screw

If, after checking the fuel and cleaning the air filter, the engine still will not idle, adjust the idle speed screw as follows:

1. Start the engine. Refer to Starting and Stopping.

2. Release the throttle control and let the engine idle. If the engine |

|

|

stops, use a small Phillips screwdriver to turn the idle speed |

|

|

screw clockwise, 1/8 of a turn at a time (as needed) until the |

Fig. 18 |

|

engine idles smoothly (Fig. 18). |

||

|

3.If the engine is idling too quickly, turn the idle speed screw counterclockwise, 1/8 of a turn at a time (as needed) to reduce the idle speed (Fig. 18).

Checking the fuel, cleaning the air filter, and adjusting the idle speed should solve most engine problems. If not, and any of the following conditions are true, take the unit to a qualified service dealer:

•the engine will not idle

•the engine hesitates or stalls on acceleration

•there is a loss of engine power

CHECKING THE ROCKER ARM CLEARANCE |

Screws |

Screws |

||

This adjustment requires disassembly of the engine. If you feel |

||||

|

|

|||

unsure or unqualified to perform this, take the unit to a qualified |

|

|

||

service dealer. |

|

|

||

The engine must be cold when checking or adjusting the rocker |

|

|

||

arm clearance. This task should be performed inside, in a clean, |

|

|

||

dust-free area. |

|

|

||

1. |

Remove the 6 screws from the engine cover with a flat-head |

|

Fig. 19 |

|

|

screwdriver or T-25 Torx screwdriver (Fig. 19). Remove the |

|

||

|

|

|

||

|

engine cover. |

|

|

|

2. |

Disconnect the spark plug wire. |

Screw |

Rocker Arm |

|

3. |

Clean the area around the spark plug. |

|

Cover |

|

Spark Plug |

|

|||

4. |

Remove the spark plug from the cylinder with a 5/8 in. socket, |

|

||

Hole |

|

|||

|

turning counterclockwise. |

|

|

|

5. |

Clean the rocker arm cover. |

|

|

|

6. |

Remove the screw from the rocker arm cover with a flat-head |

|

|

|

|

screwdriver or T-25 Torx screwdriver (Fig. 20). Remove the |

|

Fig. 20 |

|

|

rocker arm cover and gasket (Fig. 21). |

|

||

7. |

Look into the spark plug hole (Fig. 20) and pull the starter rope |

|

|

|

|

slowly to move the piston. Make sure: |

Gasket |

Adjusting Nuts |

|

|

• The piston is at the top of its travel (top dead center) |

INTAKE |

|

|

|

• Both rocker arms move freely and both valves are closed |

|

||

|

|

|

||

|

If these statements are not true, repeat this step. |

|

|

|

8. |

Use a feeler gauge to measure the clearance between one of |

|

EXHAUST |

|

|

the valve stems and its corresponding rocker arm (Fig. 22). |

Rocker Arms |

|

|

|

Repeat this process for the other valve stem and rocker arm. |

|

||

|

The recommended clearance is 0.003 – 0.006 in. (0.076 – 0.152 |

|

Fig. 21 |

|

|

mm). Use a standard automotive 0.005 in. (0.127 mm) feeler |

|

|

|

|

gauge. The feeler gauge should slide between the rocker arm |

Adjusting |

|

|

|

and valve stem with a slight amount of resistance, without |

Feeler Guage |

||

|

Nut |

|||

|

binding (Fig. 22). |

|

||

|

|

|

||

9. If the clearance is not within specification:

a. |

Turn the adjusting nut with a 5/16 inch (8 mm) wrench or |

0.003 - 0.006 in. |

|

nut driver (Fig. 22). |

(0.076 - 0.152 mm) |

• |

To increase clearance, turn the adjusting nut |

Valve |

|

counterclockwise. |

Stem |

• |

To decrease clearance, turn the adjusting nut clockwise. |

Fig. 22 |

b. Recheck both clearances and adjust as necessary.

10.Install a new gasket and reinstall the rocker arm cover. Torque the screw to: 20–30 in•lb (2.2–3.4 N•m).

11.Inspect and reinstall the spark plug. Refer to Maintaining the Spark Plug.

12.Reconnect the spark plug wire.

13.Reinstall the engine cover. Check the alignment of the engine cover before tightening the screws. Tighten the screws.

5

Loading...

Loading...