Troy-bilt TB500ML User Manual

Ver. 090816

Model 45700

Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty

READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE THIS MACHINE. FAILURE TO COMPLY WITH THESE

INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

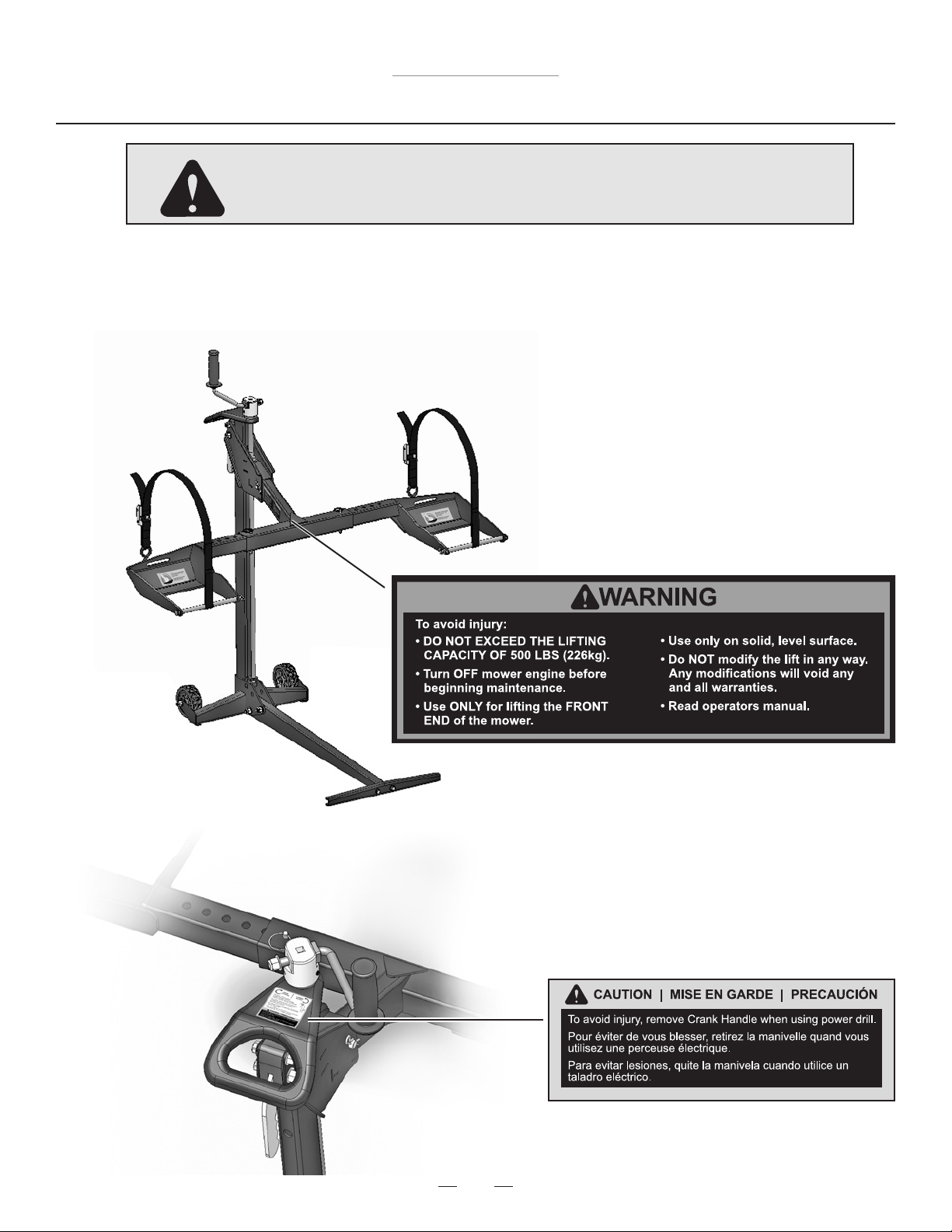

WARNING

BY MOJACK DISTRIBUTORS, LLC

2

Troy-Bilt TB500ML

Introduction

Patent #: U.S., 8,448,920

Patent #: U.S., 8,387,953

© 2013 (MoJack Distributors, LLC)

MoJack and the MoJack logo are registered trademarks of MoJack Distributors, LLC.

This manual contains assembly, parts, operating,

maintenance, adjustment and safety instructions

for your lift.

BEFORE USING YOUR LIFT, CAREFULLY READ

THIS MANUAL IN ITS ENTIRETY.

By following these operating, maintenance and

safety instructions, you will prolong the life of your

lift and promote safe operation.

If additional information is needed, or should you

require a trained service mechanic, contact your

authorized MoJack equipment dealer or distributor

or call MoJack at 1-877-575-3173.

All MoJack parts are thoroughly tested and inspected

before leaving the factory to ensure that they comply

with all relevant safety standards.

NOTE: Please save this manual for future reference.

NOTE: Location of unit Serial Number.

Submit your questions online at:

www.theMoJack.com

Need Assistance?

Please DO NOT return this product to the store.

Our Customer Service Department is ready to help!

1-877-575-3173

3

Troy-Bilt TB500ML

Warnings and Safety Instructions

IMPORTANT: The mower lift is intended for use with mowers only. Do not exceed 500 lbs. (226 kg) front end weight.

It should never be used to service other types of machinery unless there is an approved accessory tted for the type of machinery.

Please contact MoJack for approved accessories.

Read and understand all safety and operating instructions before using the mower lift.

Never allow anyone unfamiliar with the safety or operating instructions to use the lift.

Follow all safety and servicing instructions provided by the lawn mower’s manufacturer before using the lift.

Do not modify the lift in any way. Any modications will void any and all warranties and could compromise your personal

safety.

When using the lift, keep ALL bystanders at a safe distance away from the mower lift.

The lift must be used on a solid level surface.

Only lift the FRONT end on the mower.

Do not lift the front end and back end of the mower at the same time.

Only use the lift for mowers that are less than 500lbs (226 kg) front end weight and properly ts in the provided wheel pads

(ie. 10” to 17” diameter and within outside wheel measurements of 31.5” to 62.5”).

Always stop engine and remove key before beginning any work on the mower.

Always place mower in neutral or disengage the hydraulic drive by following the mower owner’s manual.

Never operate the engine while using the mower lift.

Do not exceed the lifting capacity of 500 lbs. (226 kg) front end weight. If you have a question regarding weight of your

machine, please contact the manufacturer at 1-877-575-3173 or a local MoJack Dealer.

If the lift Tower is leaning while lifting or lowering the mower, this indicates an overload condition.

REMOVE THE MOWER IMMEDIATELY.

Towe r must be secured in place with the Tower Clevis Pin before using the lift.

Carrier Locking Handle must be locked into Tower before starting any service on mower.

Do not remove safety warnings or decals from lift.

Before each use, always check for any worn, loose or damaged parts on the lift. If any damaged parts are present, do not

use the lift and contact MoJack.

Do not climb on mower while it is lifted, being lifted or being lowered.

No one should be on the mower while it is lifted, being lifted or being lowered.

After the mower is raised to a working height, always place wheel chocks (not included) behind the back tires of the mower.

Wheel Pads must be equal distance from the Lift Arm to maintain proper balance.

Always secure front mower tires with enclosed safety straps.

Remove all mower attachments before using the lift. Remove all front mower attachments (ballast, bumper or brush guard)

that interferes with handle before using the lift.

Some mowers which are equipped with a fuel tank vent may spill fuel when lifted. If this happens, run fuel level down in

the tank to prevent spilling.

Always use proper personal protection equipment.

Failure to follow these warnings may result in property damage and serious bodily injury or death.

4

Troy-Bilt TB500ML

NOTE: There can be additional safety information contained on parts

and components sourced from suppliers that is not reproduced in this

instruction manual.

CAUTION: Avoid injury!

This symbol and text highlight potential hazards or death to the operator or bystanders

that may occur if the hazards or procedures are ignored.

Warnings and Safety Decals

5

Troy-Bilt TB500ML

LIMITED WARRANTY

For two years for residential use and one year for commercial use MoJack warrants the product against failure due to defect

in material or workmanship when product is used properly. MoJack will replace any defective part at no cost. This warranty

does not cover any product that has been altered or adjusted, or any product that has been misused or abused. THIS IS

THE CUSTOMER’S SOLE AND EXCLUSIVE REMEDY. MOJACK DISCLAIMS ALL IMPLIED WARRANTIES, INCLUDING

THE WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. MOJACK SHALL NOT BE

LIABLE FOR ANY INCIDENTIAL OR CONSEQUENTIAL DAMAGES. SOME STATES OR PROVINCES DO NOT ALLOW

THE EXCLUSION OR LIMITATION OF THE IMPLIED WARRANTIES OR THE REMEDIES FOR BREACH OF THE

IMPLIED WARRANTIES, SO THESE EXCLUSIONS MAY NOT APPLY TO YOU. THIS LIMITED WARRANTY GIVES YOU

SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE OR

PROVINCE TO PROVINCE.

What does this warranty cover?

This warranty covers against a failure due to a defect in material or workmanship within two years of purchase for

residential use and within one year of purchase for commercial use.

What does this warranty NOT cover?

This warranty does not cover any jack which has been altered or adjusted in any way from its original model. It will not

cover any jack which has been damaged due to misuse, abuse, accident or negligence. This warranty does not cover

incidental or consequential damages.

What is the period of coverage?

Two-year warranty for residential use, one-year for commercial use from date of purchase for the original owner.

What will MoJack do to correct problems?

We will replace any defective part (within the coverage period) at no charge.

How can I get service?

In order to be eligible for service under this warranty you MUST register your jack within thirty (30) days of purchasing.

You must keep your receipt as proof of date of sale. You can register your new jack on our website at www.themojack.com

or by calling our toll-free number 1-877-575-3173.

How do I contact MoJack about a warranty issue?

You can contact us from our website at www.themojack.com or by calling our toll-free number 1-877-575-3173.

Do I have other rights under State Law?

This warranty gives you specic legal rights, and you may also have other rights which vary from state to state.

What is the return policy?

Please refer to the Return Policy and Procedures of your place of purchase for returns and refunds.

Warranty and Returns

6

Troy-Bilt TB500ML

5

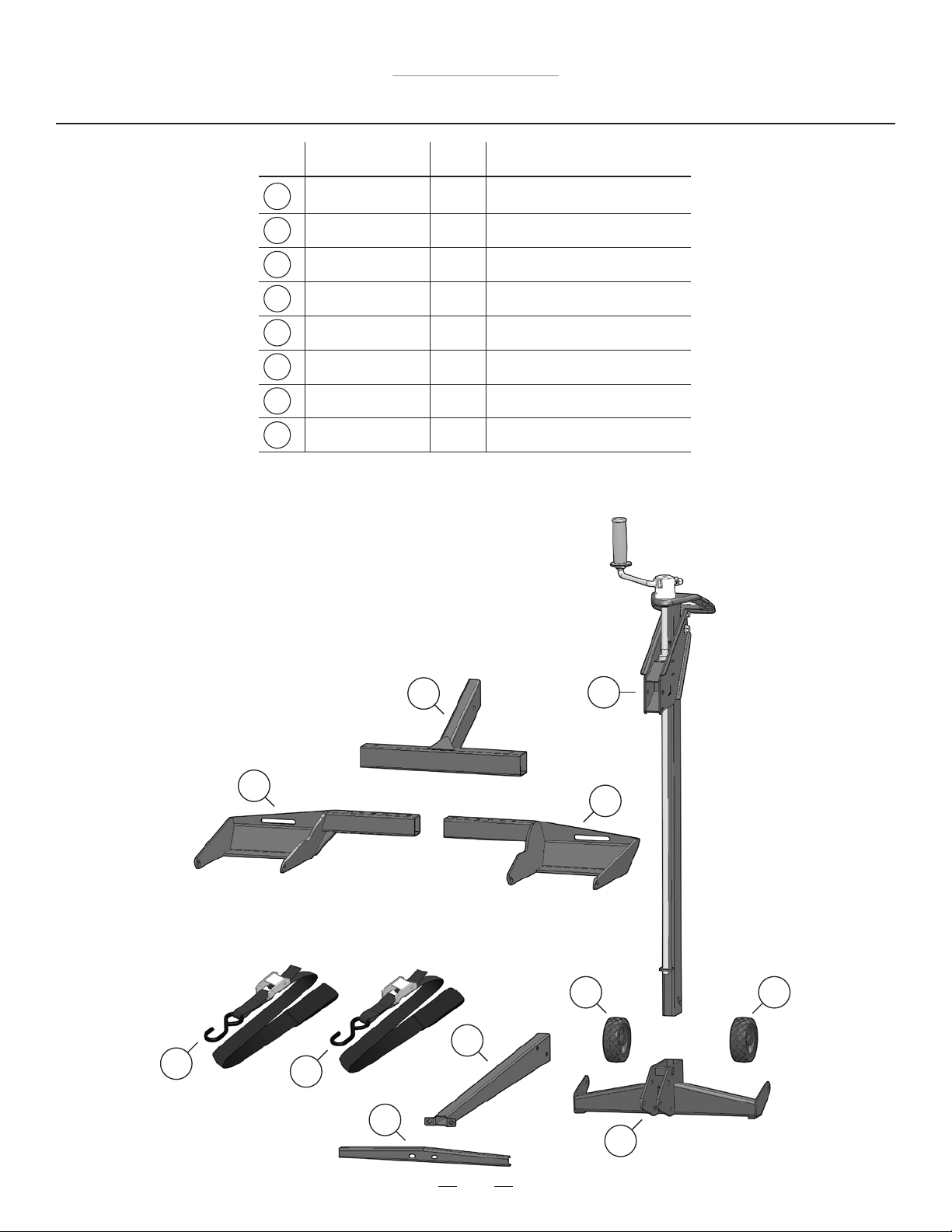

Parts List

5

Par t

No.

Qty.

Description

Tower Assembly

Lift Arm

Base Floor Tube

Base

Base Support Channel

Wheel Pad

Safety Strap

Wheels

509-0014

509-0026

509-0033

509-0048

509-0036

509-0039

009-0007

010-0013

6

7

1

1

1

1

1

2

2

2

Item

No.

1

2

3

4

6

3

8

2

1

6

7

7

4

8

8

7

Troy-Bilt TB500ML

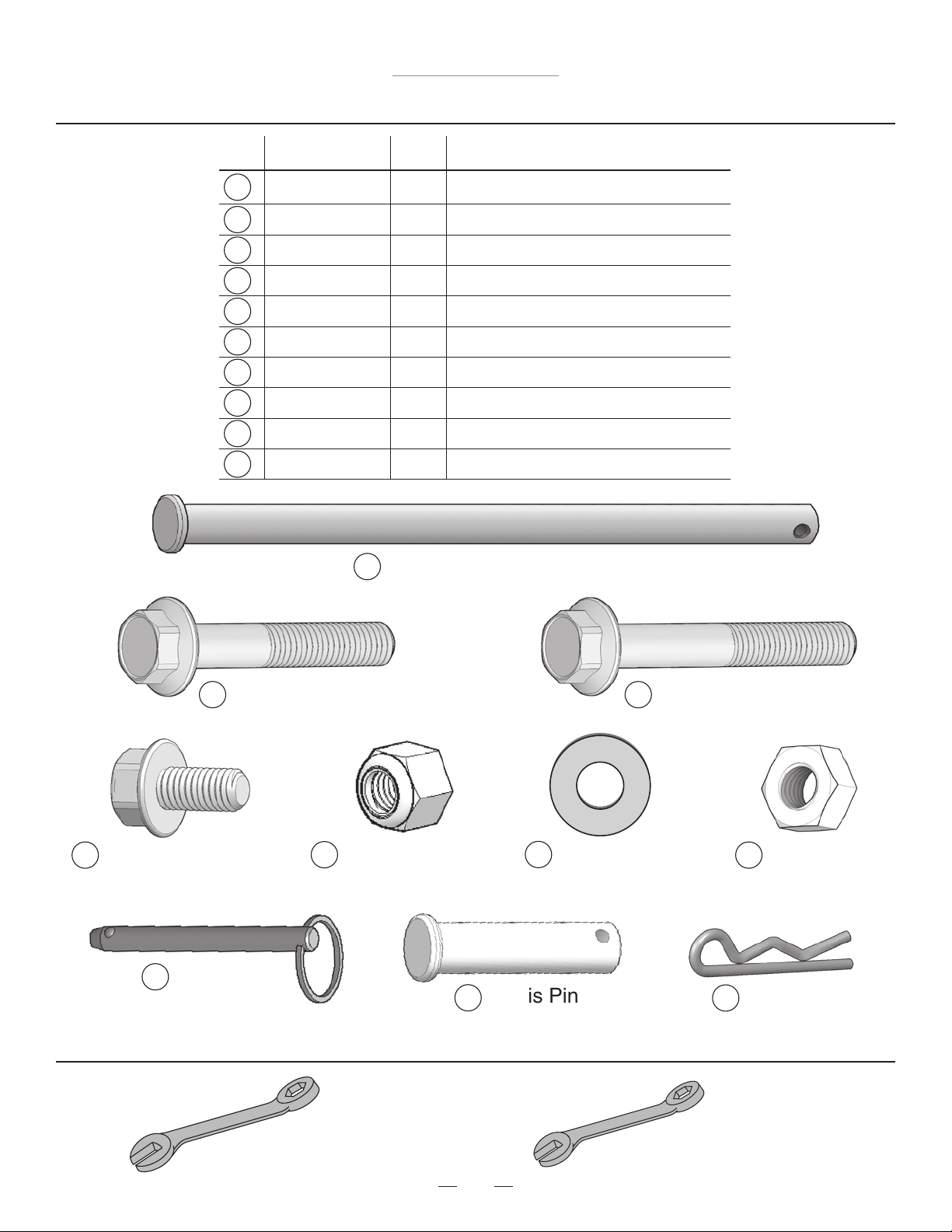

9

Wheel Pad Support Rod

Hardware List

Tools Needed for Assembly (not included)

17mm Wrench (2 each)

13

Par t

No.

Qty.

Description

16

2

2

2

2

4

4

2

2

2

4

Item

No.

9

10

11

12

17

Clevis Pin

16

Push Pin

12

Flange Head Bolt

M8-1.25 X 16

13

Nylon Lock Nut

M10-1.5

10

Flange Head Bolt

M10-1.5 X 60

18

Hair Pin

14

Washer M10

14

15

Nut M10

11

Flange Head Bolt

M10-1.5 X 65

18

15

Wheel Pad Support Rod

Flange Head Bolt M10-1.5 X 60

Flange Head Bolt M10-1.5 X 65

Flange Head Bolt M8-1.25 X 16

Nylon Lock Nut – M10-1.5

Washer – M10

Nut – M10

Push Pin

Clevis Pin

Hair Pin

509-0040

003-0005

003-0016

003-0007

002-0001

001-0014

002-0008

001-0013

001-0012

001-0010

17

12mm Wrench (1 each)

8

Troy-Bilt TB500ML

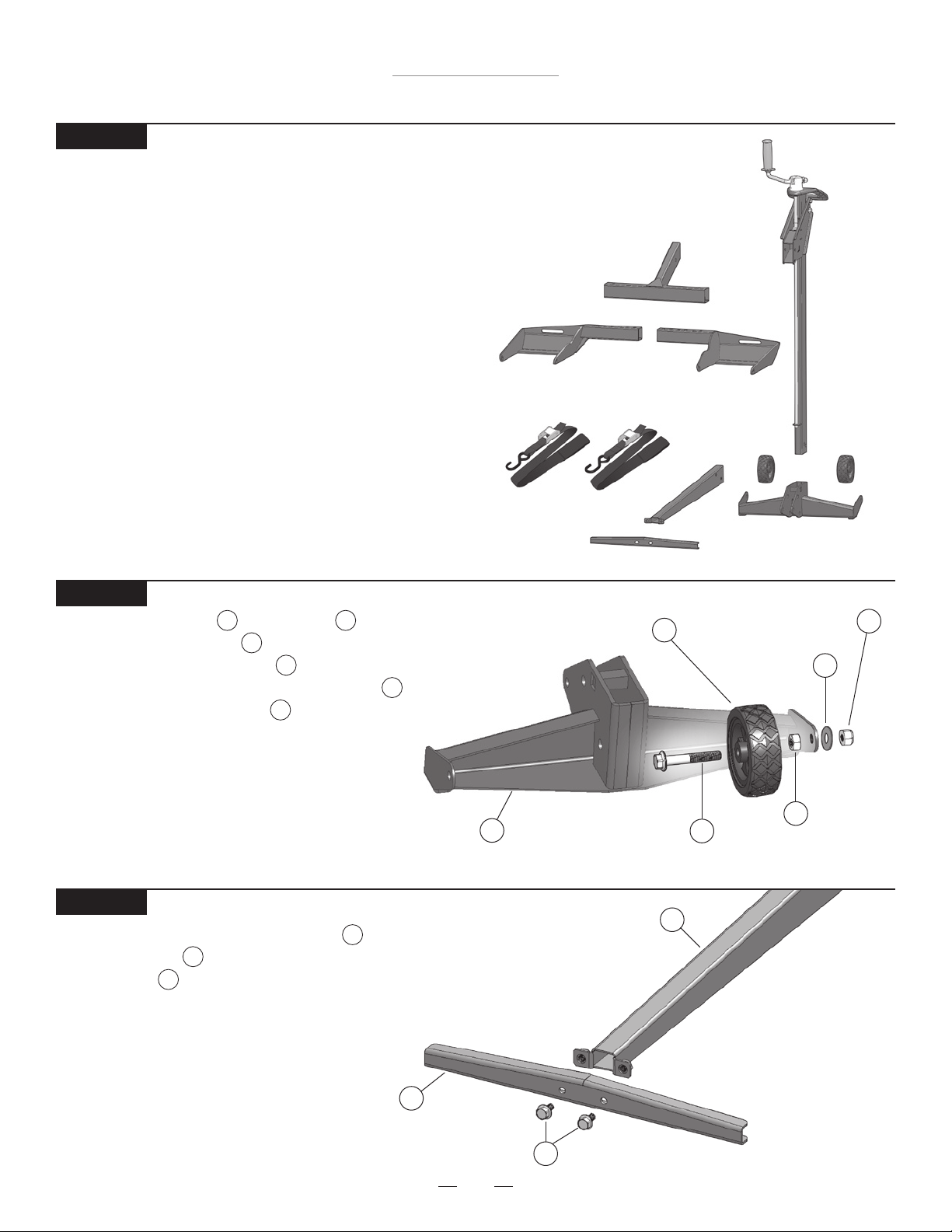

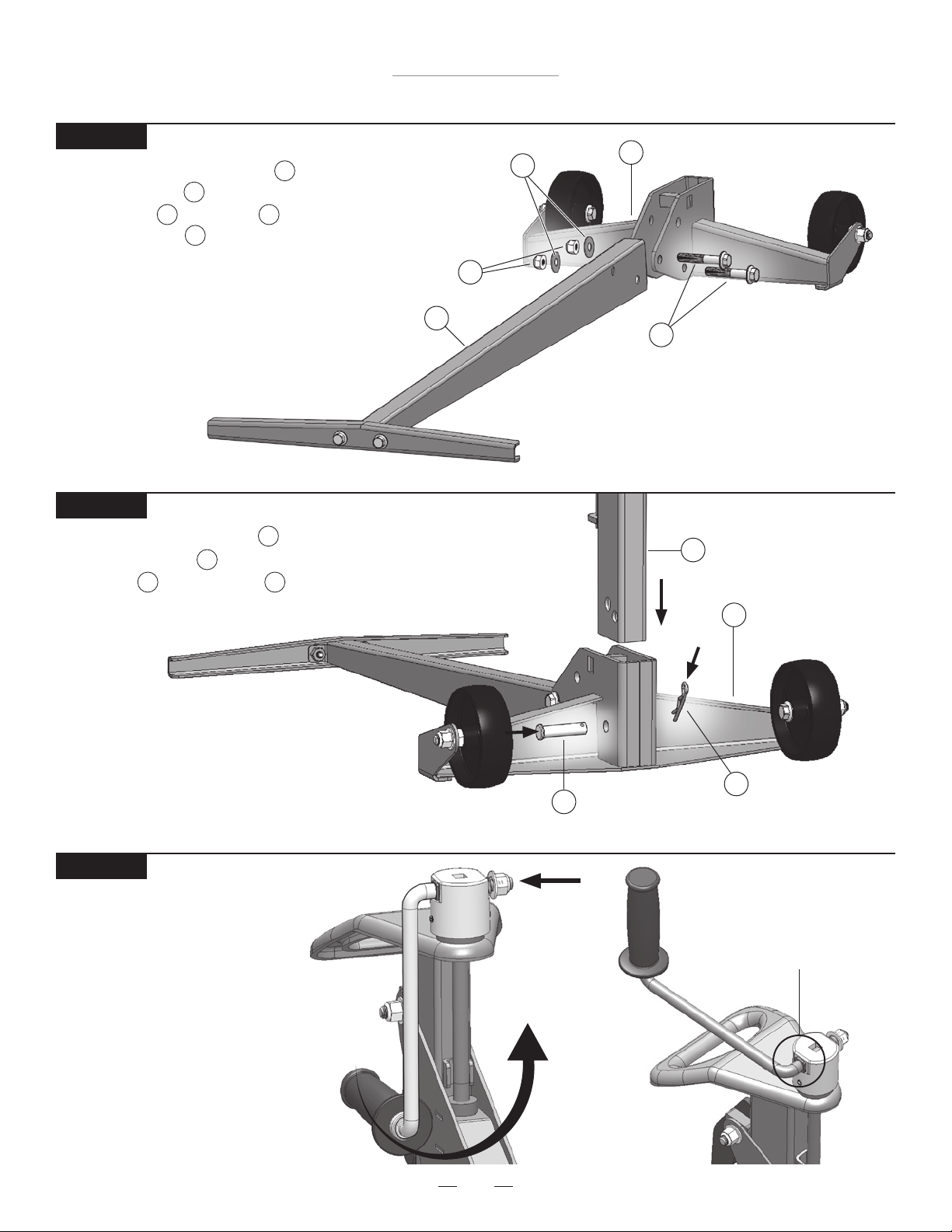

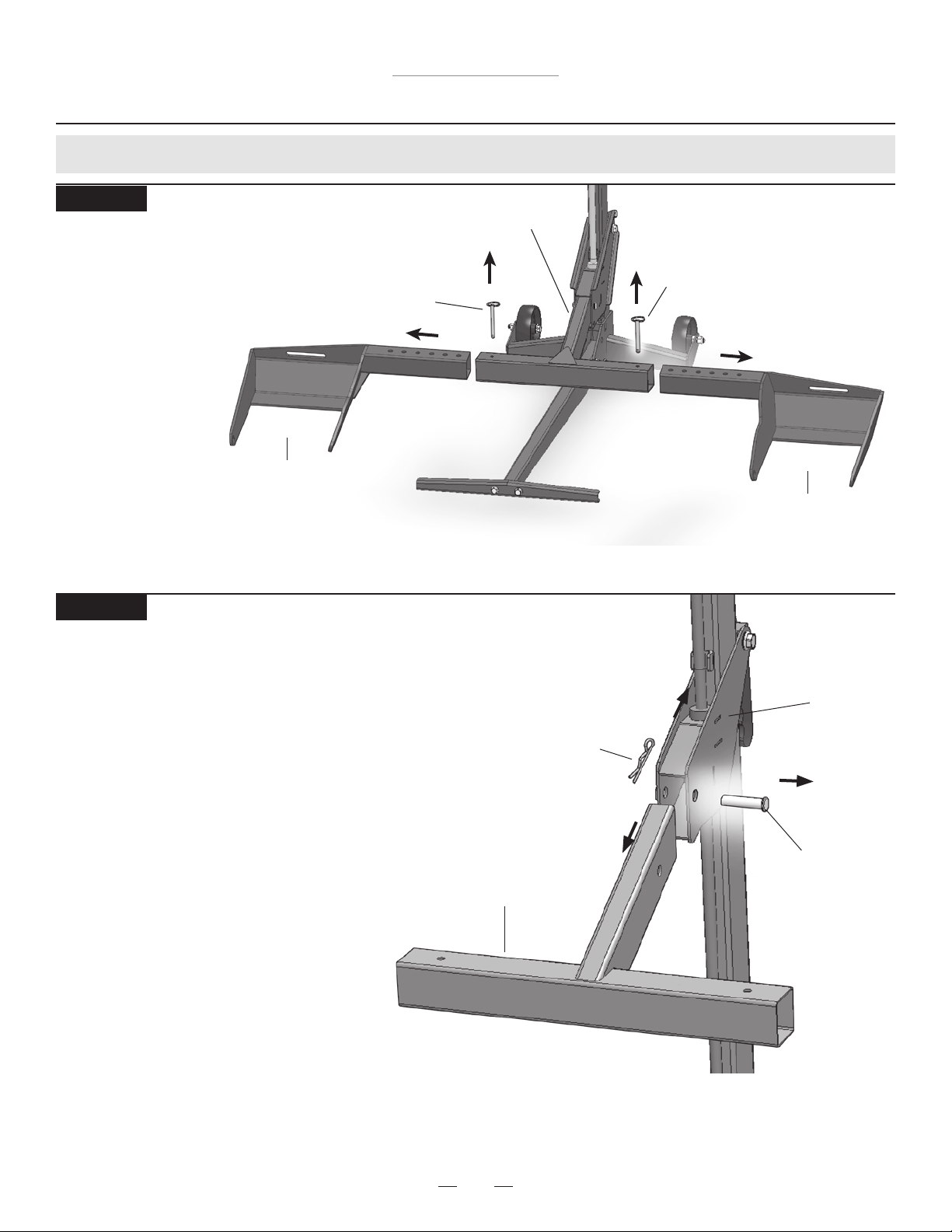

Assemble the Base Support Channel to the

Base Floor Tube by inserting the two

Flange Bolts and tighten with 12mm wrench.

Assembly Instructions

STEP 1

Remove lift from package.

Inventory items to be certain all parts and hardware

are present. If any parts or hardware are missing,

please contact MoJack at 1-877-575-3173 or

email us at parts@themojack.com.

Base Support Channel

5

Base Floor Tube

3

Flange Bolts

12

STEP 3

5

3

12

STEP 2

Assemble the Wheel to the Base

by inserting Flange Bolt through the

wheel and threading the Nut . Insert

Flange Bolt through the Base, add Washer

and secure with Nylock Nut .

Repeat with second Wheel.

Note: Do not over tighten Nylon Lock Nut.

Base

4

Wheel

8

Flange Bolt

11

Washer

14

Nut

15

Nylock Nut

13

8 4

11

15

14

13

9

Troy-Bilt TB500ML

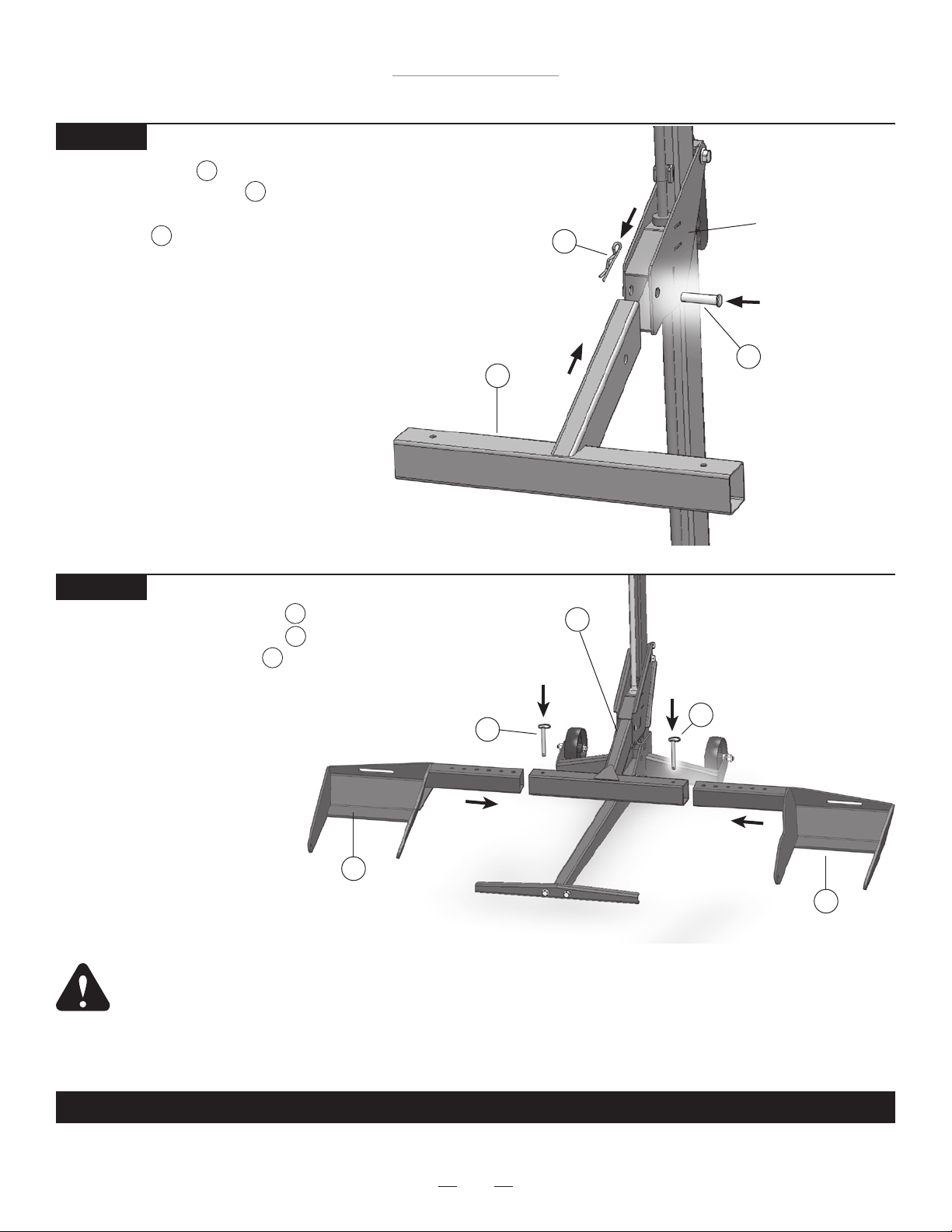

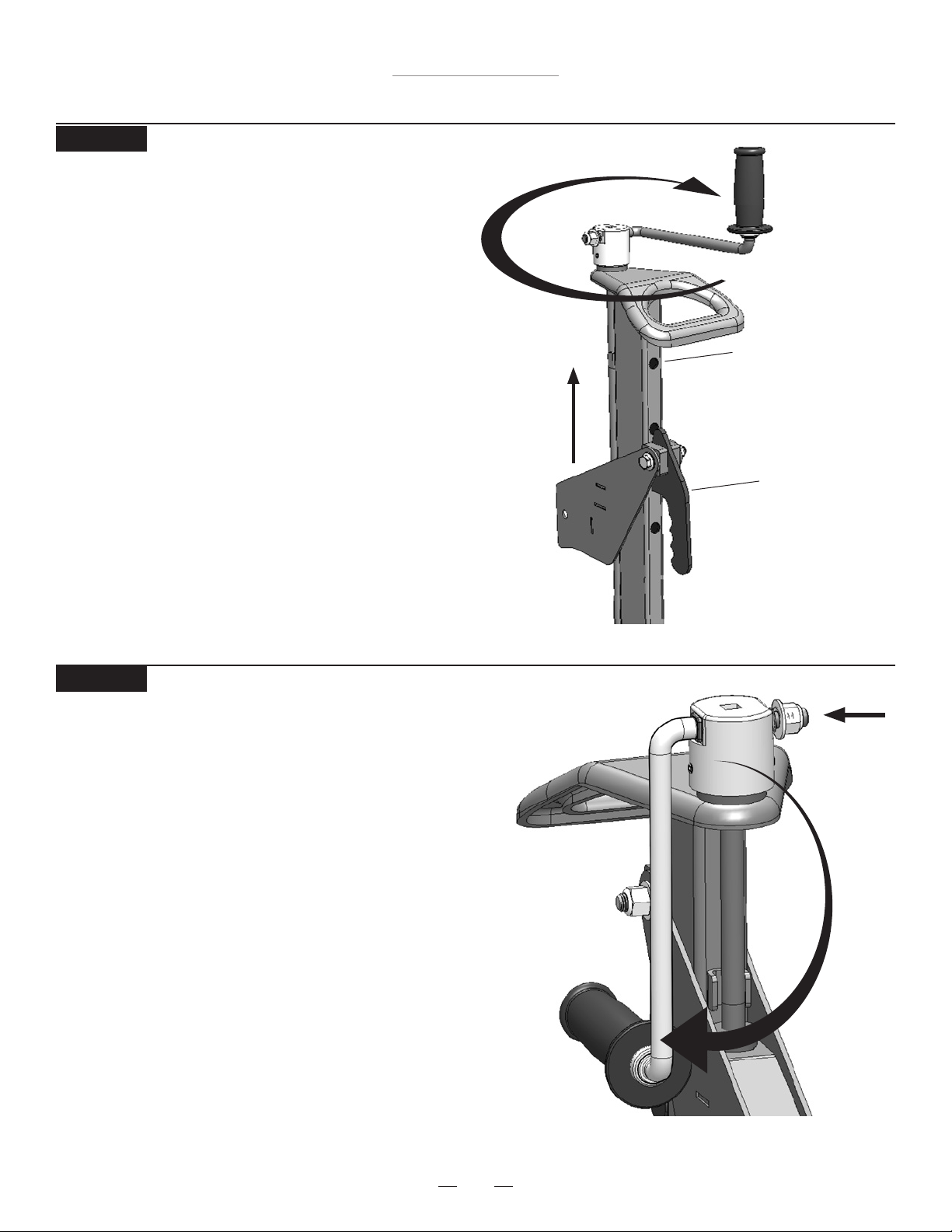

Assemble Base with Wheels to the

Base Floor Tube by inserting the two

Flange Bolts , Washers and

Nylon Lock Nuts and tighten with

15mm wrenches.

Assembly Instructions

STEP 5

Insert the Tower Assembly to the

Base with Wheels and affix with

Clevis Pin and Hair Pin as shown.

1

4

17 18

Towe r

1

Clevis Pin

17

Hair Pin

18

Base with Wheels

4

Locked Position

STEP 6

Push in side of handle and

rotate from storage position

to the operating position.

Allow to seat into the locked

position.

STEP 4

4

10

3

14

Nylon Lock Nuts

13

Base Floor Tube

3

Flange Bolts

10

Base with Wheels

4

Washer

14

13

10

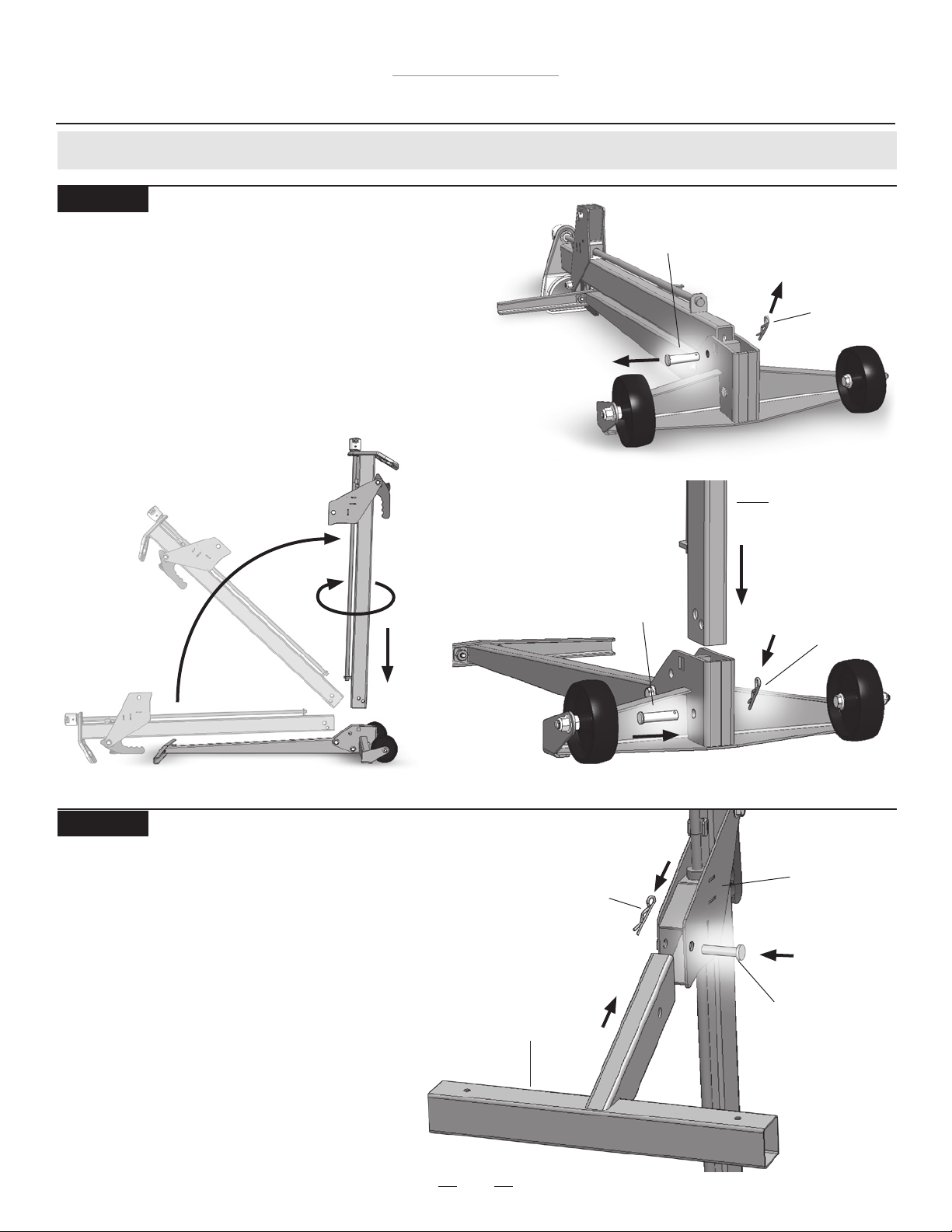

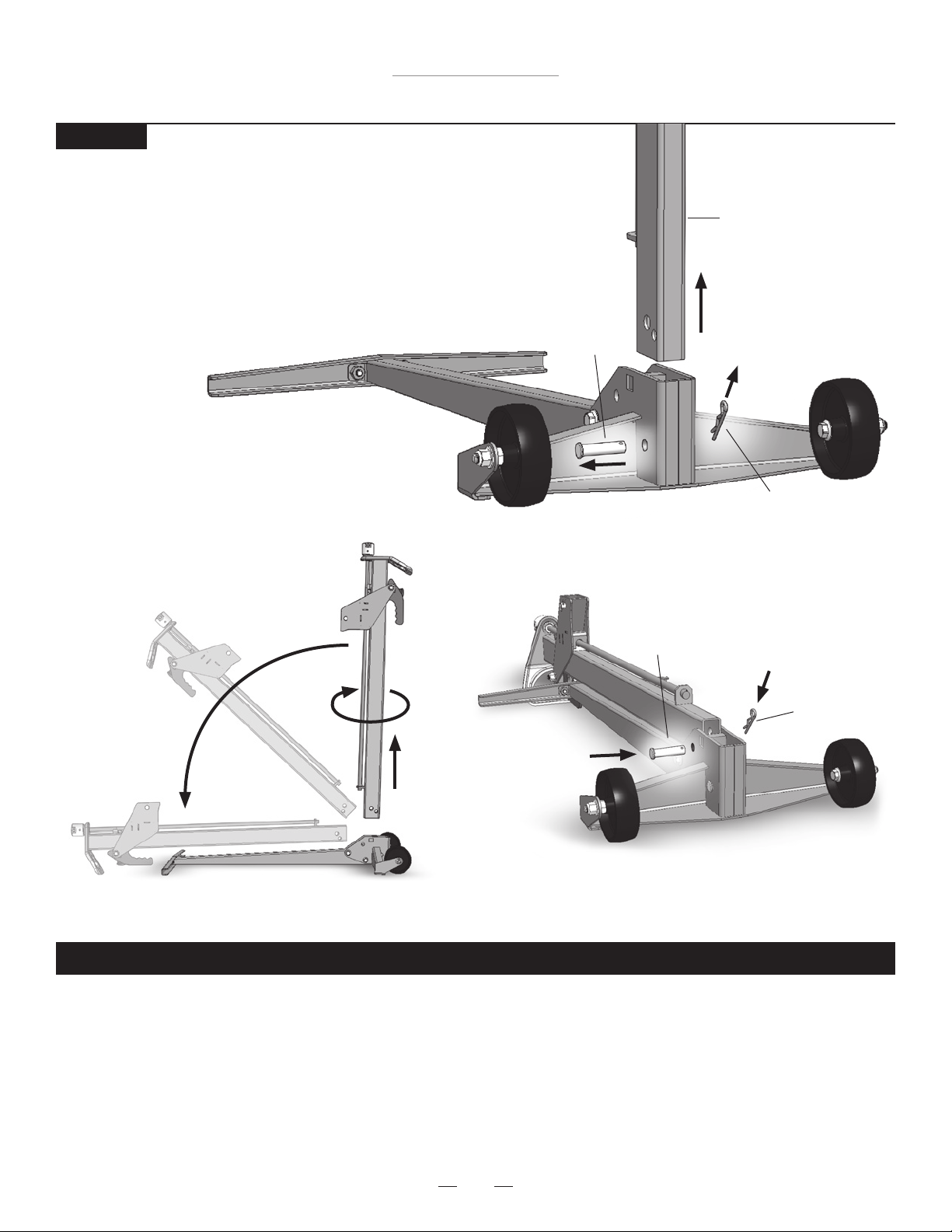

Troy-Bilt TB500ML

THIS COMPLETES ASSEMBLY.

STEP 7

Insert the Lift Arm into the Carrier

and insert the Clevis Pin through

the hole in Carrier and lock by fastening

the Hair Pin to the Clevis Pin.

2

17

18

Hair Pin

18

Lift Arm

2

Carrier

Clevis Pin

17

Assembly Instructions

Push Pin

16

Lift Arm

2

Wheel Pad Lift Arm

6

STEP 8

Slide the Wheel Pad Lift Arms

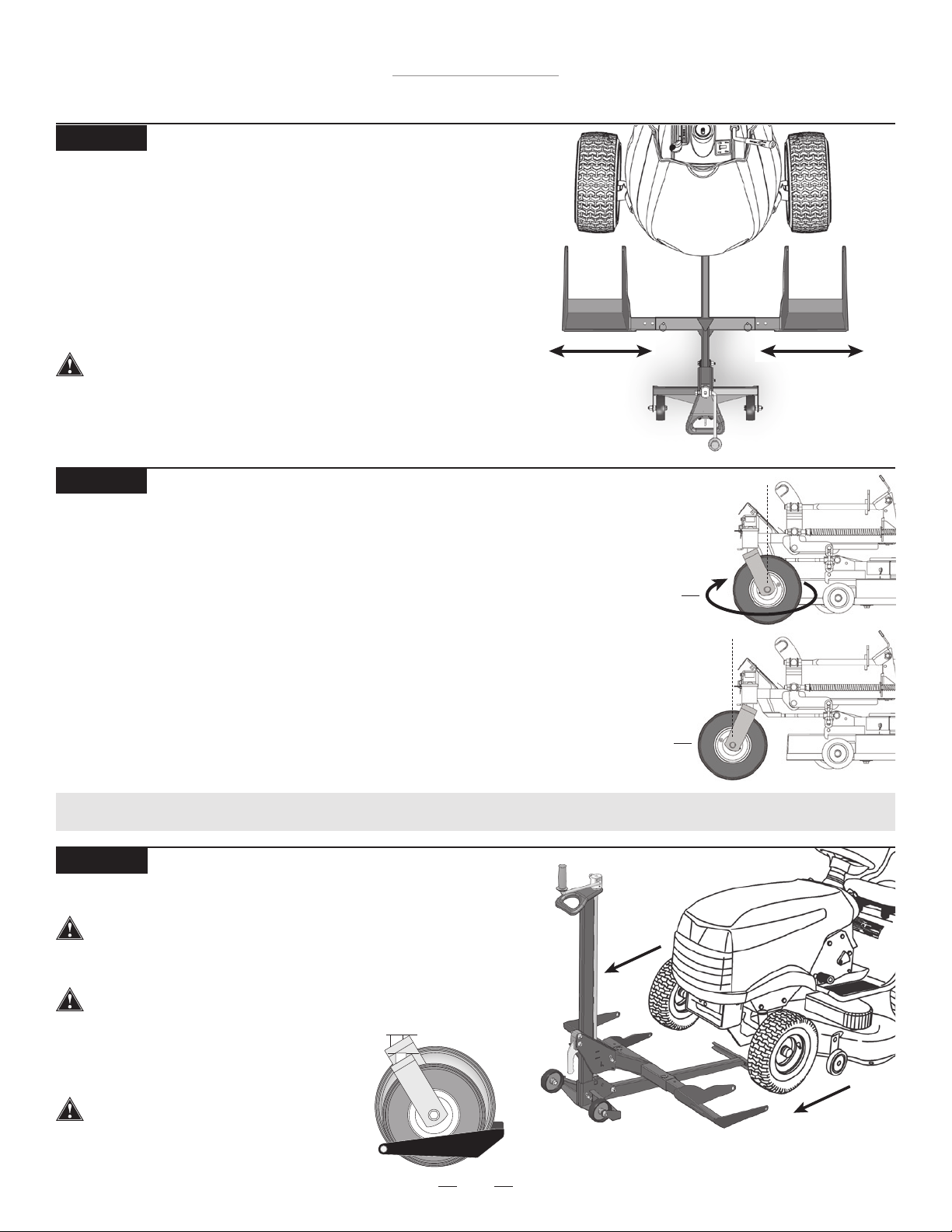

onto both sides of the Lift Arm

and secure with Push Pins .

NOTE: The Wheel Pads can be

moved in or out to t different mower

widths. Use the conguration that

works best with your model of

lawn mower.

NOTE: The Safety Straps must

be used during operation

(see Step 9 of the Operating

Instructions).

6

2

16

Push Pin

16

WARNING: Wheel pads must be equal distance from the Lift Arm to maintain proper balance.

For additional information, see see Step 6 of the Operating Instructions.

Wheel Pad Lift Arm

6

11

Troy-Bilt TB500ML

Operating Instructions

Before using the mower lift, carefully read this manual in its entirety.

Some steps of the Operating Instructions are repeated from the

Assembly Instructions. The Operating Instructions will show a full

working cycle of the mower lift.

12

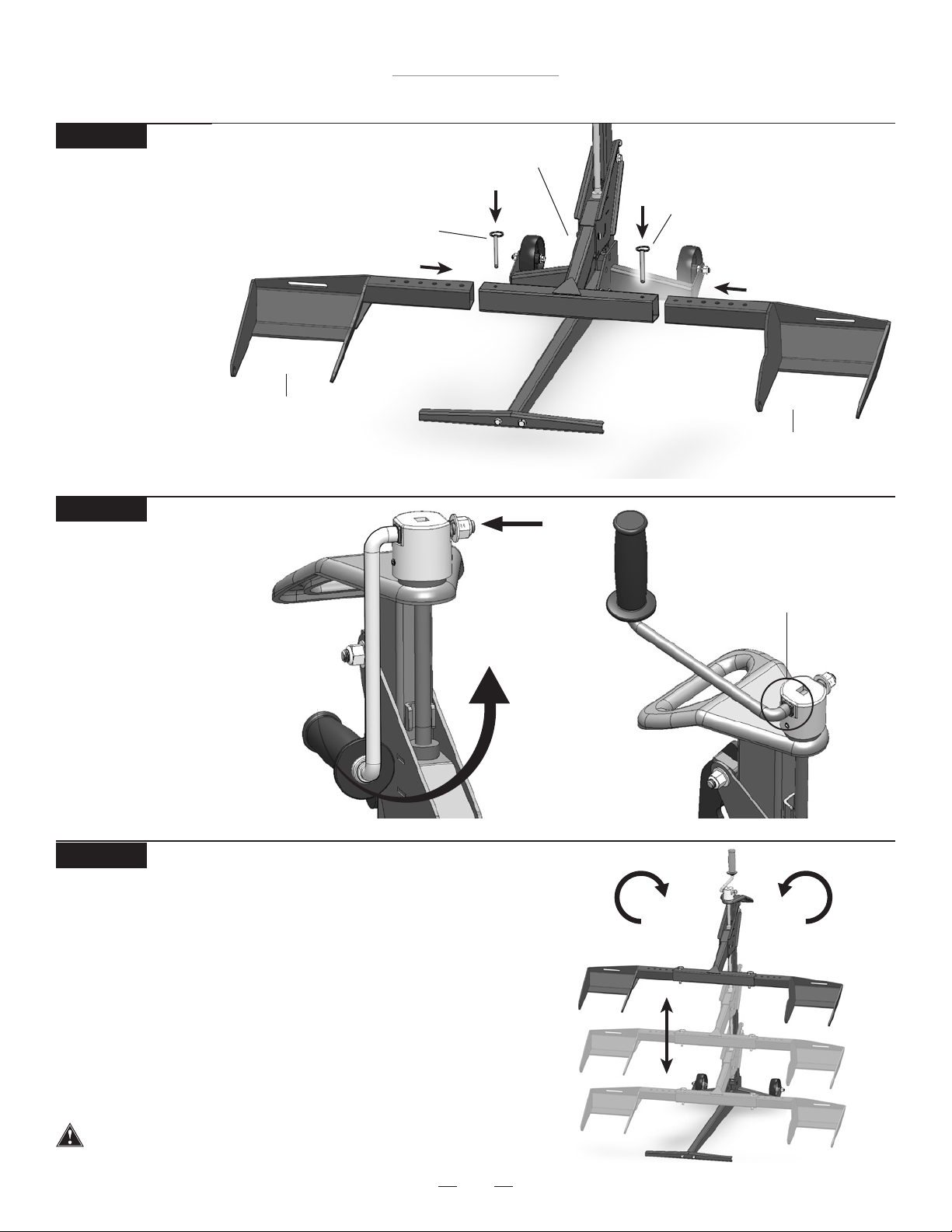

Troy-Bilt TB500ML

Clevis Pin

Hair Pin

Operating Instructions

Preparing for use (Steps 1 - 7)

STEP 1

STEP 2

Hair Pin

Lift Arm

Carrier

Clevis Pin

Installing Lift Arm

• Insert the Lift Arm into the Carrier and insert

the Clevis Pin through the hole in Carrier and

lock by fastening the Hair Pin to the Clevis Pin.

Clevis Pin

Hair Pin

Towe r

Unfolding the Mower Lift (if not applicable, skip to Step 2)

• Remove Hair Pin and Clevis Pin from the Wheel Frame.

• Remove the Tower out of the Wheel Frame.

• Rotate Tower 180 degrees and insert into Wheel Frame.

• Secure the Tower to the Wheel Frame by inserting

Clevis Pin and Hair Pin.

13

Troy-Bilt TB500ML

Push Pin

Push Pin

Lift Arm

Wheel Pad Lift Arm

Operating Instructions

STEP 3

Installing Wheel Pad Lift Arms

• Slide Wheel Pad Lift Arms

into both sides of the

Lift Arm and secure

with Push Pins.

STEP 4

Preparing the handle

• Push in side of handle

and rotate from storage

position to the operating

position. Allow to seat

into the locked position.

Wheel Pad Lift Arm

Locked Position

STEP 5

Familiarize yourself with the jack

• Practice raising and lowering the Lift Arm before attempting to

lift the mower (see Steps 10 – 13 on how to raise and lower

the Lift Arm).

• Practice Step 15 if you intend to raise or lower the

mower with a drill attachment.

NOTE: Remove all front mower attachments that interfere with

handle before using the lift.

When using the lift, keep ALL bystanders at a safe

distance away from the mower lift.

RAISE LOWER

14

Troy-Bilt TB500ML

Operating Instructions

STEP 6

Aligning Wheel Pads to Fit Mower

• Position the jack in front of the mower.

• Remove Push Pins and adjust the wheel pad to align with

the mower’s front tires.

• Replace the Push Pins to lock the Wheel Pad Lift Arms to

the Lift Arm.

Wheel Pad Lift Arms must be equal distance from the

Lift Arm to maintain proper balance.

Using the Lift (Steps 8 - 15)

STEP 8

Move mower onto jack

The jack must be used on a solid level surface.

• Drive or roll the mower onto the Wheel Pads.

Stop engine and remove the key.

NOTE: Wheel Pads accommodate wheel

sizes from 10” – 17” (25cm – 43cm).

Not for use with tires

over 17” (43cm) in size.

STEP 7

(optional – if not applicable, skip to Step 8)

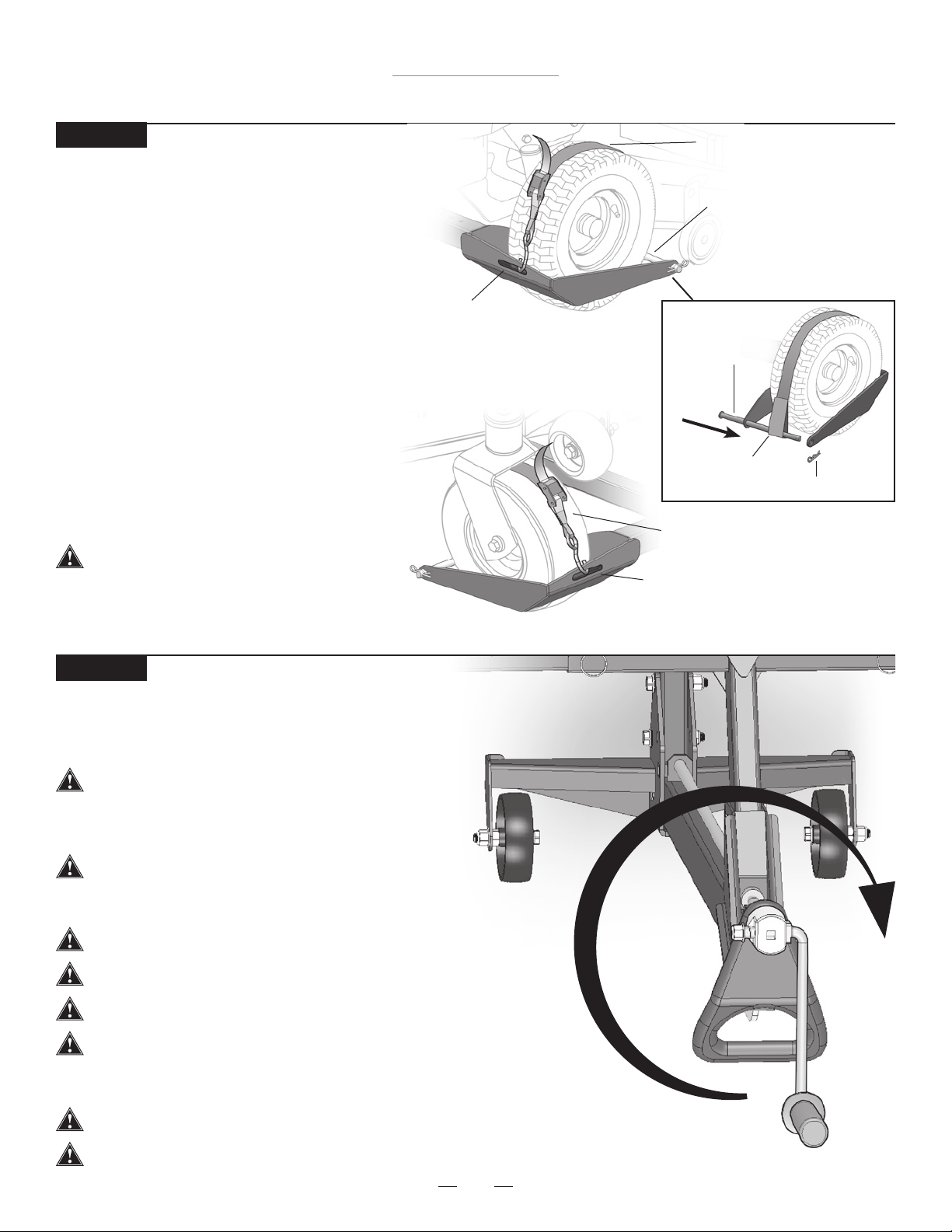

In some cases, the mower deck or anti-scalping wheels will hit the

Lift Arm while the mower is being raised. This is often the case if

part of the deck (including the anti-scalping wheels) protrudes past

the center line of the front wheels of the mower. If this happens:

• Rotate the front tires 180° so that they are in the reverse position.

• Slide the lift as close to the wheels as possible.

NOTE: Reference Step 6 for Aligning Wheel Pads to t

ZTR mower.

Reverse

Wheel

Position

Forward

Wheel

Position

15

Troy-Bilt TB500ML

Wheel Pad

Slot

Safety Strap

Wheel

Support

Rod

Safety

Strap

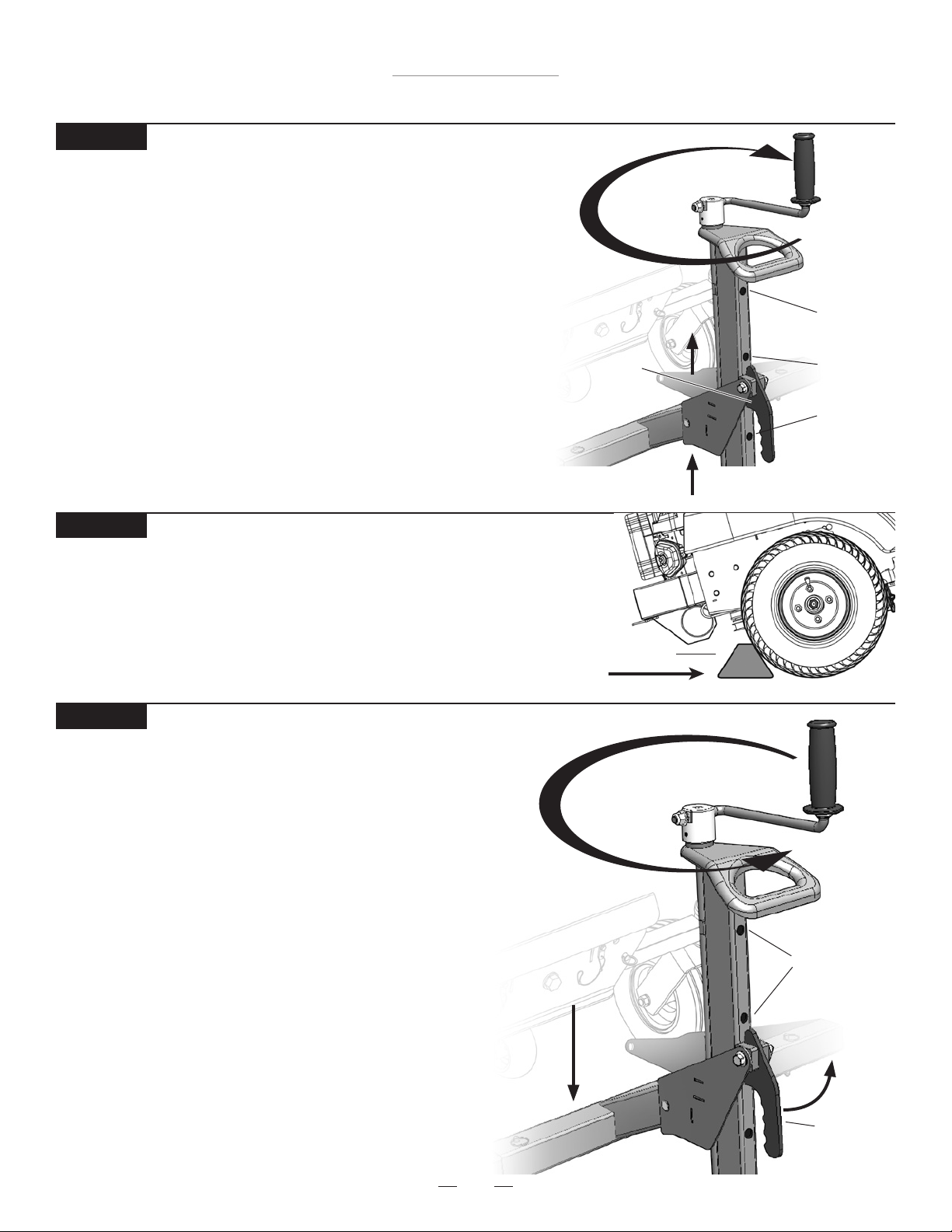

STEP 9

Operating Instructions

STEP 10

Raising the Mower

• Raise the mower by rotating the Crank Handle clockwise.

• See Step 15 for raising the mower with drill attachment.

If the lift Tower is leaning while lifting or lowering

the mower, this indicates an overload condition.

REMOVE THE MOWER IMMEDIATELY.

The jack must be used on a solid level surface.

The engine must be turned off and key removed.

The mower must be in neutral when raising or

lowering to allow the wheels roll as the mower is

raised or lowered.

The parking brake must be off during this step.

Always use attached safety straps. The Safety Straps must be rmly tightened.

Do not exceed the lifting capacity of 500 lbs.

(226 kg) front end weight. If you have a question

regarding weight of your machine, please contact

MoJack at 1-877-575-3173.

Mower deck must be raised to highest setting.

Strapping Front Mower Tires to Wheel Pads

• Secure the front mower tires to the Wheel

Pads using the Safety Straps. Secure the

hook on the Safety Strap to the Wheel Pad

Slot. The Safety Strap hook should always be

facing upward.

• Extend the Safety Strap over the top of tire.

• Insert the Wheel Support Rod through one

hole on the Wheel Pad, through the loop on

the Safety Strap and through the other side of

the Wheel Pad. Secure with Large Hair Pin.

• Squeeze the metal buckle and pull end of

strap to tighten the Safety Straps over the top

of the tires to secure mower to Wheel Pads.

NOTE: Inspect Safety Strap for wear before

each use.

Always secure front mower tires with

enclosed safety straps.

Wheel Pad

Slot

Wheel

Support Rod

Safety Strap

Loop

Hair Pin

16

Troy-Bilt TB500ML

STEP 13

Operating Instructions

Lowering the Mower

• Remove wheel chocks.

• Release the parking brake.

• Mower must be in neutral or hydraulic drive disengaged.

• Pull and hold the Carrier Locking Handle out and turn

the Crank Handle counter clockwise until Wheel Pads

are rmly on the ground. The Carrier Locking Handle

must be pulled out until it clears the bottom Tower

Hole. It may be necessary to raise the Carrier

slightly to allow the Carrier Locking Handle to be

pulled out.

NOTE: The lift is equipped with a clutch to protect itself

from accidental damage. If the Carrier Locking Handle is

not disengaged when lowering, the clutch will release the

Crank Handle from the screw and rotate freely.

To re-engage the Crank Handle, turn clockwise for

a few turns.

STEP 12

Preparing the Mower for Service

• Place wheel chocks (not included) behind the back tires of the

mower.

• Apply the parking brake on the mower.

• The Carrier Locking Handle must be locked into one of the

two Tower Holes.

Wheel Chock

Tower Holes

Carrier

Locking

Handle

STEP 11

Raising Lift Arm to Locking Position

• Raise the Lift Arm until the Carrier Locking Handle drops into one

of the three Tower Holes. The Tower Locking Holes are the

automaticsafety engagement system.

• The Carrier Locking Handle automatically drops into the Tower

Holes as the Carrier passes the Tower Holes when raising.

Locking engagement occurs at 14”, 19” and 24”.

NOTE: When lowering the Lift Arm, the Carrier Locking Handle must

be held out by the operator until it clears the bottom Tower Hole.

NOTE: The lift is equipped with a clutch to protect itself from

accidental damage. If the Carrier Locking Handle is not disengaged

when lowering, the clutch will release the Crank Handle from the

screw and rotate freely. To re-engage the Crank Handle,

turn clockwise for a few turns.

Carrier

Locking

Handle

19” – Second

Locking Hole

height

Tower Locking

Holes are the

automatic

safety

engagement

system

24” – Third

Locking Hole

height

14” – First

Locking Hole

height

17

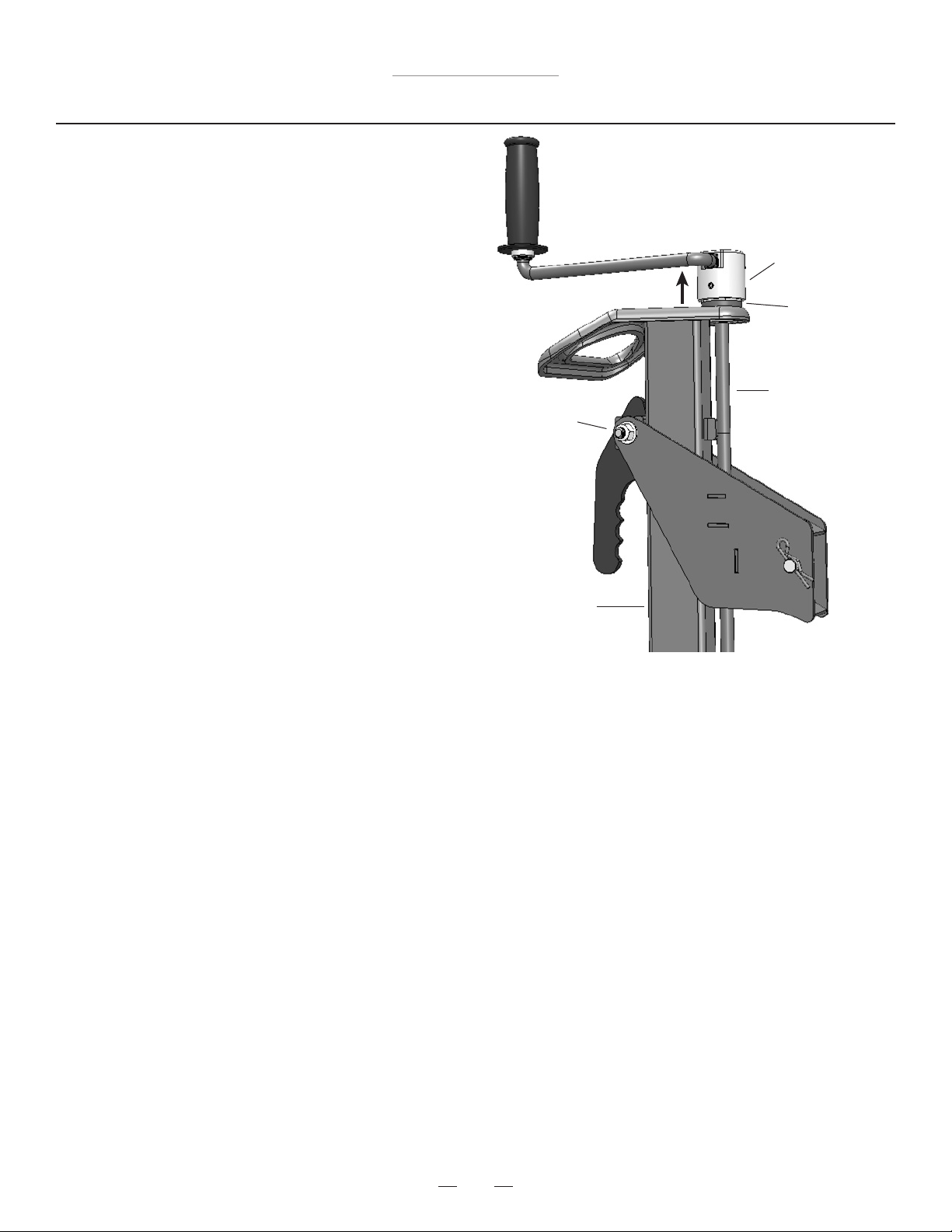

Troy-Bilt TB500ML

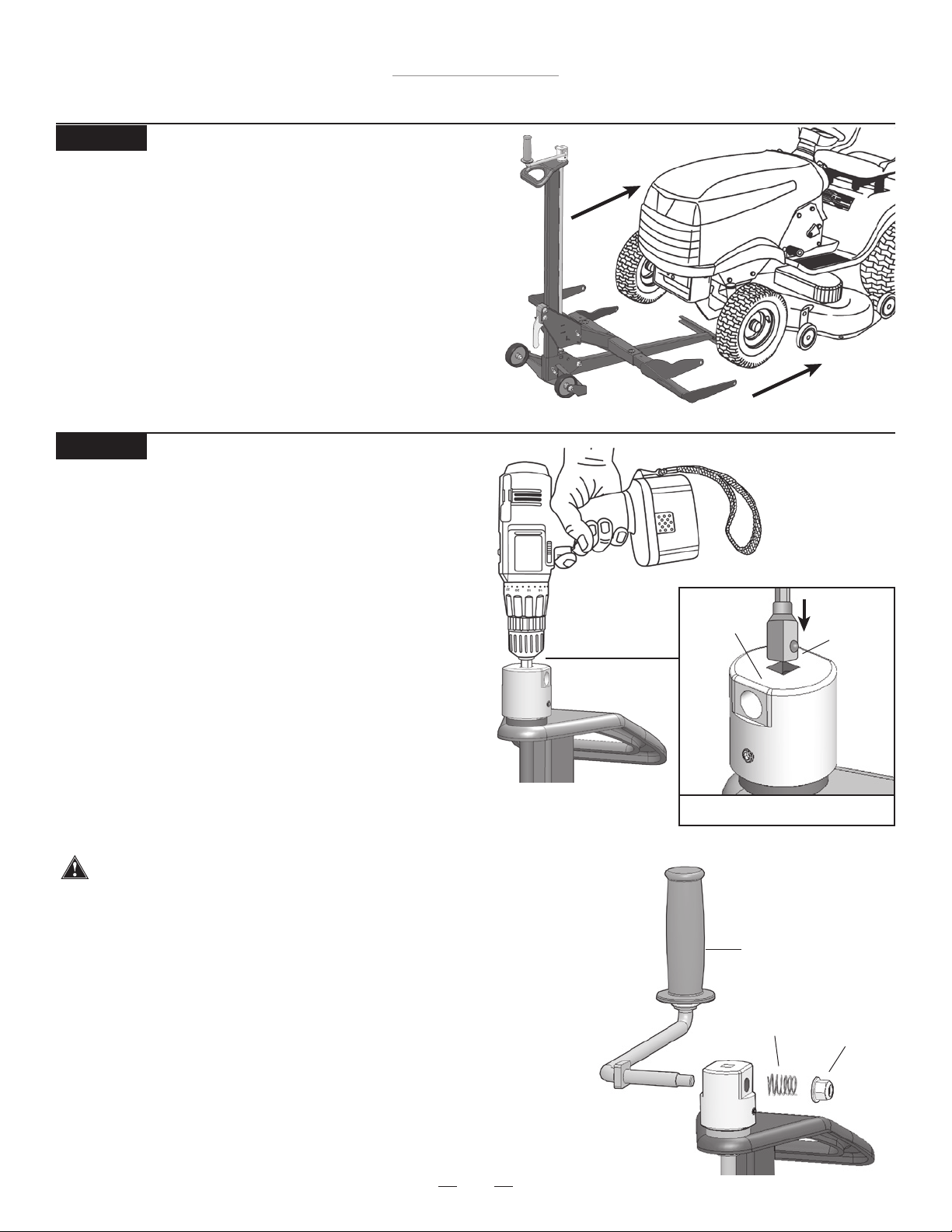

Square Driver not included

Nylock

Locking

Nut

Spring

Crank

Handle

Before using a drill,

remove the Crank

Handle

Raising the lift with a power drill

(optional – power drill not included)

The lift can be raised or lowered by using a variable

speed corded drill (7 amp minimum) or variable speed

cordless drill (18V minimum). The drill will require a

3/8” square driver (not included).

• Remove Crank Handle by taking off the Nylon Lock

Nut and Spring using 15mm wrench.

After Crank Handle removal, re-attach Spring and

Nylon Lock Nut to Crank Handle to prevent loss.

• Firmly insert the 3/8” square driver in the Square

Receiver. Rotate the drill forward (clockwise) to

raise the Lift Arm and rotate the drill in reverse

(counterclockwise) to lower the Lift Arm.

• Carrier Locking Handle must be manually pulled out when lowering

until it clears the bottom Tower Hole.

NOTE: Crank Handle must be removed in order to use the drill attachment.

Follow all other operating instructions while using the drill

attachment. Replace the Crank Handle as necessary for future use.

NOTE: When re-assembling handle, take care not to over-tighten

the Nylon Lock Nut against the spring. There should be enough

free space for the handle to be pushed in to move from storage

position to operating position.

NOTE: When re-assembling the handle, a “popping” sound may

occur due to the re-engagement of the clutch system.

Operating Instructions

STEP 15

Operator must have a rm grip on the drill before raising or

lowering the Lift Arm.

3/8”

Square

Driver

Square

Receiver

STEP 14

Removing the Mower from the lift

• Remove the Safety Straps from front mower tires.

• Drive or roll the mower off of the Wheel Pads.

Make sure drill is

fully charged and

set at highest

torque.

18

Troy-Bilt TB500ML

Hair Pin

Lift Arm

Carrier

Clevis Pin

Operating Instructions

STEP 17

Removing the Lift Arm

• While holding the Lift Arm, remove the

Hair Pin and Clevis Pin from Lift Arm.

• Slide the Lift Arm out of the Carrier.

• Store the Hair Pin and Clevis Pin in the

Lift Arm to prevent loss.

Preparing for Storage (Steps 16 - 20)

Push Pin

Push Pin

Lift Arm

Wheel Pad Lift Arm

Wheel Pad Lift Arm

STEP 16

Removing the Wheel Pads

• Remove Push Pins and

pull the Wheel Pad

Lift Arms out of the

Lift Arm.

• Store the Push Pins

in the Lift Arm to

prevent loss.

19

Troy-Bilt TB500ML

Operating Instructions

STEP 19

Rotate Crank Handle to Storage position

• Push in side of handle and rotate from operating

position to the storage position. Allow to seat into

the locked position.

STEP 18

Raise Carrier

• Raise the Carrier by turning the Crank Handle

clockwise until the Carrier Locking Handle

drops into the top Tower Hole.

Top Tower Hole

Carrier

Locking

Handle

20

Troy-Bilt TB500ML

STEP 20

THE LIFT IS NOW READY FOR STORAGE OR TRANSPORT.

Clevis Pin

Hair Pin

Moving the Tower Assembly to Storage position

• Remove Hair Pin and Clevis Pin from bottom of Tower Assembly.

• Raise the Tower out of the Base by pulling up on the Lift Handle.

• Rotate Tower Assembly 180 degrees and lower into storage position.

• Secure the Tower by inserting Clevis Pin and Hair Pin to lock

Tower Assembly in storage position.

Tower Assembly

Clevis Pin

Hair Pin

Operating Instructions

21

Troy-Bilt TB500ML

Maintenance Schedule

• Before each use, always check for any worn, loose or

damaged parts on the lift. If any damaged parts are

present, do not use the lift and contact MoJack at

1-877-575-3173.

• Clean and oil the entire screw thread after every fty

(50) uses or at least once a year using light machine

oil.

• Place lithium grease between the Crank Handle Base

and the brass bearing after every fty (50) uses or once

a year. Without weight on carrier, lift the Crank Handle

to create a small gap between the brass bearing and

the Crank Handle Base. Use a small brush to apply the

lithium grease between the two surfaces.

• Spray grease or lube in Carrier Locking Handle pivot

after every fty (50) uses or at least once a year.

• Wipe clean and lightly apply grease to front and back

of Tower Assembly after every fty (50) uses or at least

once a year.

Screw Thread

Brass Bearing

Crank Handle

Base

Carrier

Locking

Handle

pivot

Towe r

Assembly

Loading...

Loading...