Troy-Bilt TB25BP Operator's Manual

STOP ALTO

For problems or questions, DO NOT return this product to the store.

Contact your Customer Service Agent .

Para problemas o preguntas, NO devolver este

producto a la tienda Contacte a su Agente de Servicio al Cliente.

U.S.A. Imported by: |

For Consumer Assistance Please Call |

MTD LLC |

|

P.O. Box 361131 |

Para La Ayuda Del Consumidor Llame Por Favor |

Cleveland, OH 44136-0019 |

U.S.A. 1-800-520-5520

Made in Taiwan / Hecho en Taiwan

Operator’s Manual

2-Cycle

GAS BACKPACK BLOWER Model TB25BP

CAUTION: Before using this product, read this manual and follow all safety rules and operating instructions.

•SAFETY

•ASSEMBLY

•OPERATION

•MAINTENANCE

•PARTS LIST

P/N 9096-MD1802 PRINTED IN TAIWAN

TABLE OF CONTENTS

Warranty |

Page |

2 |

Operation |

Page |

12 |

Safety Rules |

Pages |

3 - 7 |

Maintenance |

Pages |

13 - 15 |

Oil and Fuel information |

Page |

8 |

Troubleshooting |

Page |

16 |

Assembly |

Page |

9 |

Specifications |

Page |

17 |

Starting / Stopping instrustion |

Pages |

10 - 11 |

Parts List |

Page |

18 |

WARRANTY STATEMENT

TWO YEAR LIMITED WARRANTY ON TROY BILT GAS BACKPACK BLOWER

For two years from the date of purchase, when this Blower is used and maintained according to the operator’s manual, Troy Bilt will repair any defect in material or workmanship free of charge.

This warranty excludes the spark plug and air filter, which are expendable parts that can wear out from normal use in less than two years.

If this Blower is used for commercial or rental purposes, this warranty applies for only 30 days from the date of purchase.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THIS BLOWER TO THE NEAREST TROY BILT REPAIR CENTER IN THE UNITED STATES CALL 1-800-520-5520 FOR LOCATIONS.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

CALIFORNIA PROPOSITION 65 WARNING

WARNING

THE ENGINE EXHAUST FROM THIS PRODUCT CONTAINS CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the states of California, Maine, Oregon and Washington.

All U.S. Forest Land and the state of California (Public Resources Codes 4442 and 4443), Oregon and Washington require, by law that certain internal combustion engines operated on forest brush and/or grass-cov- ered areas be equipped with a spark arrestor, maintained in effective working order, or the engine be constructed, equipped and maintained for the prevention of fire. Check with your state or local authorities for regulations pertaining to these requirements. Failure to follow these

requirements could subject you to liability or a fine. This unit is factory equipped with a spark arrestor. If it

requires replacement, ask a Troy Bilt or other qualified service dealer to install the Spark Arrestor Kit.

2

RULES FOR SAFE OPERATION

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and their explanations, deserve your careful attention and understanding. The safety warnings do not by themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper accident prevention measures.

SYMBOL MEANING

SAFETY ALERT: Indicatesdanger, warning or caution. Attention is required in order to avoid serious personal injury. May be used in conjunction with other symbols or pictographs.

NOTE: Advises you of information or instructions vital to the operation or maintenance of the equipment.

Read the Operator’s Manual(s) and follow all warnings and safety instructions.

Failure to do so can result in serious injury to the operator and/or bystanders.

SYMBOL MEANING

DANGER: Failure to obey a safety warning will result in

serious injury to yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

WARNING: Failure to obey a safety warning can

result in injury to yourself and others. Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

CAUTION: Failure to obey a safety warning may

result in property damage or personal injury to yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

• IMPORTANT SAFETY INSTRUCTIONS •

READ ALL INSTRUCTIONS

BEFORE OPERATING

•Read the instructions carefully. Be familiar with the controls and proper use of the unit.

WARNING: When using the unit, you must follow the

safety rules. Please read these instructions before operating the unit in order to ensure the safety of the operator and any bystanders. Please keep these instructions for later use.

•Do not operate this unit when tired, ill, or under the influence of alcohol, drugs, or medication.

•Children must not operate the unit. Teens must be accompanied and guided by an adult.

•All guards and safety attachments must be installed properly before operating the unit.

•Inspect the unit before use. Replace damaged parts. Check for fuel leaks. Make sure all fasteners are in place and secure. Replace parts that are cracked, chipped, or damaged in any way. Do not operate the unit with loose or damaged parts.

•Carefully inspect the area before starting the unit. Remove all debris and hard or sharp objects such as glass, wire, etc.

•Clear the area of children, bystanders, and pets. At a minimum, keep all children, bystanders, and pets out-

side a 50 feet (15 m.) radius; there still may be a risk to |

|

bystanders from thrown objects. Bystanders should be |

|

encouraged to wear eye protection. If you are |

|

approached, stop the unit immediately. |

3 |

|

FUEL SAFETY WARNINGS

WARNING: Gasoline is highly flammable, and its

vapors can explode if ignited. Take the following precautions:

•Store fuel only in containers specifically designed and approved for the storage of such material.

•Avoid creating a source of ignition for spilled fuel. Do not start the engine until fuel vapors dissipate.

•Always stop the engine and allow it to cool before filling the fuel tank. Never remove the cap of the fuel tank, or add fuel, when the engine is hot. Never operate the unit without the fuel cap securely in place. Loosen the fuel tank cap slowly to relieve any pressure in the tank.

•Add fuel in a clean, well-ventilated outdoor area where there are no sparks or flames. Slowly remove the fuel cap only after stopping engine. Do not smoke while fueling or mixing fuel. Wipe up any spilled fuel from the unit immediately. Always wipe unit dry before using.

•Move the unit at least 30 feet (9.1 m) from the fueling source and site before starting the engine. Do not smoke. Keep sparks and open flames away from the area while adding fuel or operating the unit.

RULES FOR SAFE OPERATION

WHILE OPERATING

•Never start or run the unit inside a closed room or building. Breathing exhaust fumes can kill. Operate this unit only in a well-ventilated outdoor area.

•Wear safety glasses or goggles that are marked as meeting ANSI Z87.1 standards and are marked as such. Wear ear/hearing protection when operating this unit.

•Never run the unit without the the proper equipment attached. When using this unit, always install the blower tubes depending on blower application.

•To reduce the risk of hearing loss associated with sound level(s), always wear ear/hearing protection when operating this unit.

•Wear heavy long pants, boots, gloves, and a long sleeve shirt. Do not wear loose clothing, jewelry, short pants, sandals, or go barefoot. Secure hair above shoulder level.

•To avoid static electricity shock, do not wear rubber gloves or any other insulated gloves while operating this unit.

•Use the unit only in daylight or good artificial light.

•Keep outside surfaces free from oil and fuel.

•Avoid accidental starting. Be in the starting position whenever pulling the starter rope. The operator and unit must be in a stable position while starting. Refer to

Starting/Stopping Instructions.

•Do not set unit on any surface except a clean, hard area while engine is running. Debris such as gravel, sand, dust, grass, etc. could be picked up by the air intake and thrown out by the discharge opening, damaging unit, property, or causing serious injury to bystanders or operator.

•Use the right tool. Only use this tool for its intended purpose.

•Do not force unit. It will do the job better and with less likelihood of injury at a rate for which it was designed.

•Do not overreach or use from unstable surfaces such as ladders, trees, steep slopes, rooftops, etc. Always keep proper footing and balance.

•Always hold the unit with a firm grip when operating.

•Keep hands, face, and feet away from all moving parts. Do not touch or try to stop the impeller when it is rotating. Do not operate without guards in place.

•Do not put any object into openings. Do not use with any opening blocked; keep free of dirt, debris, and anything that may reduce the air flow.

•Do not touch the engine or muffler. These parts get extremely hot from operation, even after the unit is turned off.

•Do not operate the engine faster than the speed needed to do the job. Do not run the engine at high speed when not in use.

•Always stop the engine when operation is delayed or when walking from one location to another.

•Stop the engine for maintenance, repair, to install or remove the blower tubes attachments. The unit must be stopped and the impeller no longer turning to avoid contact with the rotating blades.

•If you strike or come into contact with a foreign object, stop the engine immediately and check for damage. Do not operate before repairing damage. Do not operate the unit with loose or damaged parts.

•Use only original equipment manufacturer replacement parts when servicing this unit. These parts are available from your authorized service dealer. Do not use unauthorized parts, accessories, or attachments for this unit. Doing so could lead to serious injury to the user, or damage to the unit, and void your warranty.

•Never use this unit for spreading chemicals, fertilizers or other substances which may contain toxic materials.

•To reduce fire hazard, replace faulty muffler and spark arrestor. Keep the engine and muffler free from grass, leaves, excessive grease or carbon build up.

•Turn the engine off and disconnect the spark plug for maintenance of repair.

•Never point the blower or blowing debris in the direction of people, animals or in the direction of windows. Always direct the blowing debris away from people, animals, and windows. Use extra caution when blowing debris near solid objects such as trees, automobiles, walls, etc.

4

RULES FOR SAFE OPERATION

OTHER SAFETY WARNINGS

•Always disconnect the spark plug before performing maintenance or accessing movable parts.

•Never store the unit, with fuel in the tank, inside a building where fumes may reach an open flame (pilot lights, etc.) or sparks (switches, electrical motors, etc.).

•Allow the engine to cool before storing or transporting. Be sure to secure the unit while transporting.

•Store the unit in a dry place, secured, or at a height to prevent unauthorized use or damage. Keep out of the reach of children.

•Never douse or squirt the unit with water or any other liquid. Keep handles dry, clean, and free from debris. Clean after each use, see Cleaning and Storage instructions.

•Keep these instructions. Refer to them often and use them to instruct other users. If you loan this unit to others, also loan these instructions to them.

SPECIAL NOTE: Exposure to vibrations through prolonged use of gasoline powered hand tools could cause blood vessel or nerve damage in the fingers, hands, and joints of people prone to circulation disorders or abnormal swelling. Prolonged use in cold weather has been linked to blood vessel damage in otherwise healthy people. If symptoms occur such as numbness, pain, loss of strength, change in skin color or texture, or loss of feeling in the fingers, hands or joints, discontinue use of this tool and seek medical attention. An anti-vibration system does not guarantee avoidance of these problems. Users who operate power tools on a regular basis must closely monitor their physical condition and the condition of this tool.

SAVE THESE INSTRUCTIONS

5

RULES FOR SAFE OPERATION

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read the operator's manual for complete safety, assembly, operating and maintenance and repair information.

SYMBOL |

MEANING |

SYMBOL |

MEANING |

• SAFETY ALERT SYMBOL

Indicates danger, warning, or caution. May be used in conjunction with other symbols or pictographs.

• READ OPERATOR'S MANUAL

WARNING: Read the

Operator’s Manual(s) and follow all warnings and safety instructions. Failure to do so can result in serious injury to the operator and/or bystanders.

•WEAR EYE, HEARING AND HARDHAT PROTECTION

WARNING: Thrown

objects and loud noise can cause severe eye injury and hearing loss. Wear eye protection meeting ANSI Z87.1-1989 standards and ear protection when operating this unit. Wear a hard hat. Use a full face shield when needed.

• MINIMUM OPERATING DISTANCE

WARNING: Keep

children, bystanders, and animals 50 feet (15 meters) away. If approached stop unit immediately.

•UNLEADED FUEL

Always use clean, fresh unleaded fuel.

•OIL

Refer to operator's manual for the proper type of oil.

•ON/OFF CONTROL

ON / START / RUN

•ON/OFF CONTROL

OFF OR STOP

•BLUE CHOKE LEVER POSITIONS 1 • FULL Choke Position

2 • PARTIAL Choke Position

3 • RUN Position

6

RULES FOR SAFE OPERATION

KNOW YOUR BLOWER

22

23

21

20

19

18

15

BLOWER COMPONENTS

1.THROTTLE TRIGGER

2.THROTTLE LOCK

3.ON/OFF IGNITION SWITCH

4.TOP ASSIST HANDLE

5.SPARK PLUG WIRE / SPARK PLUG

6.CHOKE LEVER

7.STARTER HANDLE

8.AIR CLEANER COVER

9.FUEL CAP

10.FUEL TANK

11.PRIMER BULB

12.HARNESS

13.CONTROL HANDLE

14.OPERATING TUBE

|

|

4 |

|

3 |

5 |

|

|

|

2 |

|

7 |

1

11

11

8

8

9

9

|

10 |

12 |

6 |

|

17

24  13

13

24

14

15

16

15.HOSE CLAMP

16.FLEX TUBE

17.THROTTLE LINKAGE

18.MUFFLER COVER

19.SPARK ARRESTER SCREEN

20.VENTED BACK PAD

21.INTERMEDIATE TUBE

22.56mm NOZZLE

23.40mm CONCENTRATOR NOZZLE

24.THROTTLE LINKAGE CLIPS

7

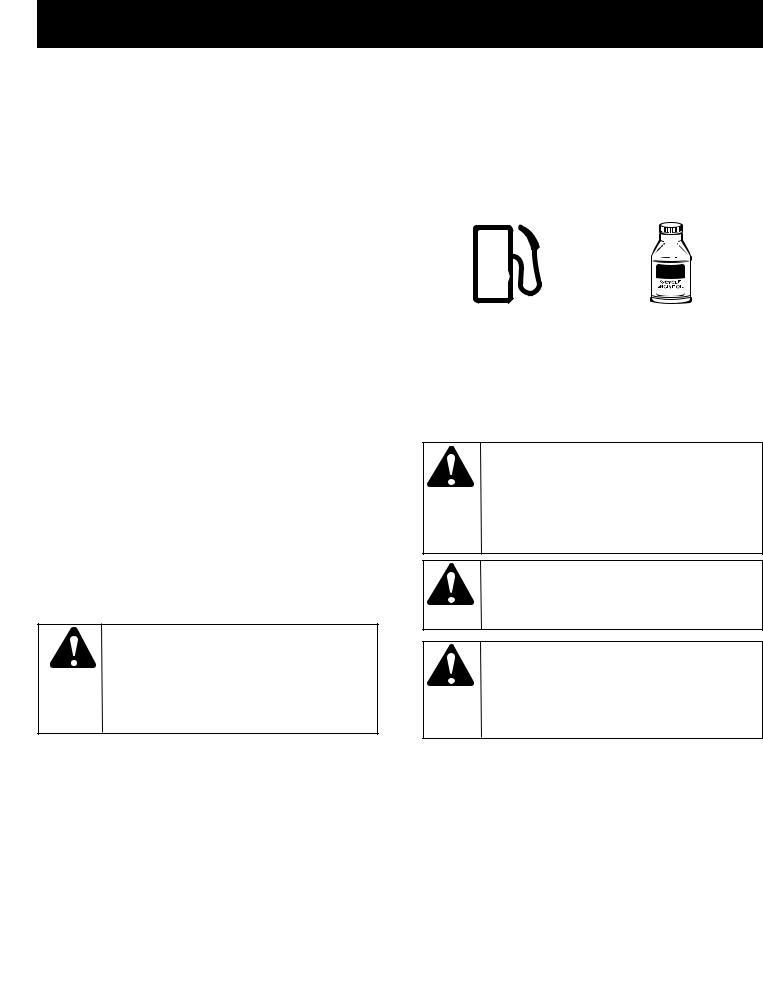

OIL AND FUEL INFORMATION

OIL AND FUEL MIXING INSTRUCTIONS

Old and/or improperly mixed fuel are the main reasons for the unit not running properly. Be sure to use fresh, (less than 60 days old) clean unleaded fuel. Follow the instructions carefully for the proper fuel/oil mixture.

Definition of Blended Fuels

Today's fuels are often a blend of gasoline and oxygenates such as ethanol, methanol, or MTBE (ether). Alcohol-blended fuel absorbs water. As little as 1% water in the fuel can make fuel and oil separate and leads to formation of acids during storage. When using alcoholblended fuel, use fresh fuel.

Using Blended Fuels

If you choose to use a blended fuel, or its use is unavoidable, follow recommended precautions:

•Always use the fresh fuel mix explained in your operator's manual

•Always agitate the fuel mix before fueling the unit

•Drain the tank and run the engine dry before storing the unit

Using Fuel Additives

The bottle of 2-cycle oil that came with your unit contains a fuel additive which will help inhibit corrosion and minimize the formation of gum deposits. It is recommended that you use our 2-cycle oil with this unit.

If unavailable, use a good 2-cycle oil designed for air-cooled engines along with a fuel additive, such as STA-BIL® Gas Stabilizer or an equivalent. Add 0.8 oz. (23 ml.) of fuel additive per gallon of fuel according to the instructions on the container. NEVER add fuel additives directly to the unit's fuel tank.

CAUTION: For proper engine operation and maxi-

mum reliability, pay strict attention to the oil and fuel mixing instructions on the 2-cycle oil container. Using improperly mixed fuel can severely damage the engine.

To Obtain Correct Fuel Mix:

Thoroughly mix the proper ratio of 2-cycle engine oil with unleaded gasoline in a separate fuel can. Use a 40:1 fuel/oil ratio. Do not mix them directly in the engine fuel tank. See the table below for specific gas and oil mixing ratios.

NOTE: One gallon (3.8 liters) of unleaded gasoline mixed with one 3.2 oz. (95 ml.) bottle of

|

|

|

|

|

|

|

|

|

|

|

|

|

+ |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

UNLEADED GAS |

|

|

2 CYCLE OIL |

||||

|

|

|

|

||||

1 GALLON US |

|

|

3.2 FL. OZ. |

||||

(3.8 LITERS) |

|

|

(95 ml) |

||||

|

|

|

|

|

|

||

|

|

1 LITER |

|

|

25 ml |

||

|

|

|

|

|

|

|

|

MIXING RATIO - 40:1

WARNING: Gasoline is extremely flamma-

ble. Ignited Vapors may explode. Always stop the engine and allow it to cool before filling the fuel tank. Do not smoke while filling the tank. Keep sparks and open flames at a distance from the area.

WARNING: Remove fuel cap slowly to avoid injury

from fuel spray. Never operate the unit without the fuel cap securely in place.

WARNING: Add fuel in a clean, well ventilated out-

door area. Wipe up any spilled fuel immediately. Avoid creating a source of ignition for spilled fuel. Do not start the engine until fuel vapors dissipate.

2-cycle oil makes a 40:1 fuel/oil ratio.

NOTE: Dispose of the old fuel/oil mix in accordance to Federal, State and Local regulations.

8

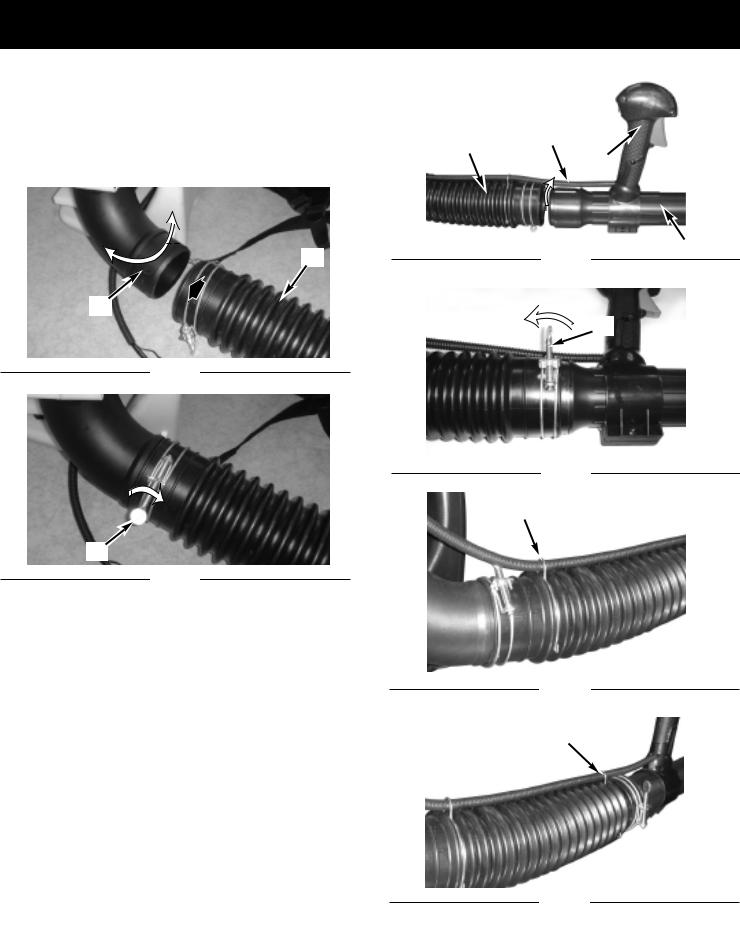

ASSEMBLY INSTRUCTIONS

ATTACH FLEX TUBE

Put the hose clamp(C) on the flex tube before connecting the flex tube and the fan’s outlet tube together.

Connect the flex tube (B) to the fan’s outlet tube (A) (Fig. 1) with a hose clamp (C) (Fig. 2) and tighten securely (Fig. 2).

B

A

Fig. 1

C

Fig. 2

ATTACH OPERATING TUBE

NOTE: keep the throttle cable as straight as possible when connecting the blower tubes.

1.Place the unit on flat surface during assembly. Insure screw mechanism of clamp is positioned away from operator.

2.Put the hose clamp (C) on the flex tube and the operating tube before connecting them together.

3.Turn the throttle linkage mark (D) so it aligns with the throttle handle (F) (Fig.3). Insert the operating tube (E) into the flex tube (B) (Fig. 3) and then tighten securely with a hose clamp (G)(Fig. 4).

4.Attached throttle linkage clips (# 24-know your blower) - to both ends of the flex tube to secure the throttle cable. ( See Fig. 5 and Fig. 6)

9

D

B

F

180˚

180˚

E

Fig. 3

G

Fig. 4

THROTTLE LINKAGE CLIPS

Fig. 5

THROTTLE LINKAGE CLIPS

Fig. 6

ASSEMBLY INSTRUCTIONS

ATTACH INTERMEDIATE TUBE AND CONCENTRATOR NOZZLE

Connect the intermediate tube (H) and concentrator nozzle (I) or 56mm nozzle (J) (you can only use I nozzle at time). Push the tubes together and turn them clockwise so that they lock together (Fig. 7). Use concentrator nozzle when you need more airflow in tight places: flower beds, under decks, etc.

B D H I

40mm

56mm

J

Fig. 7

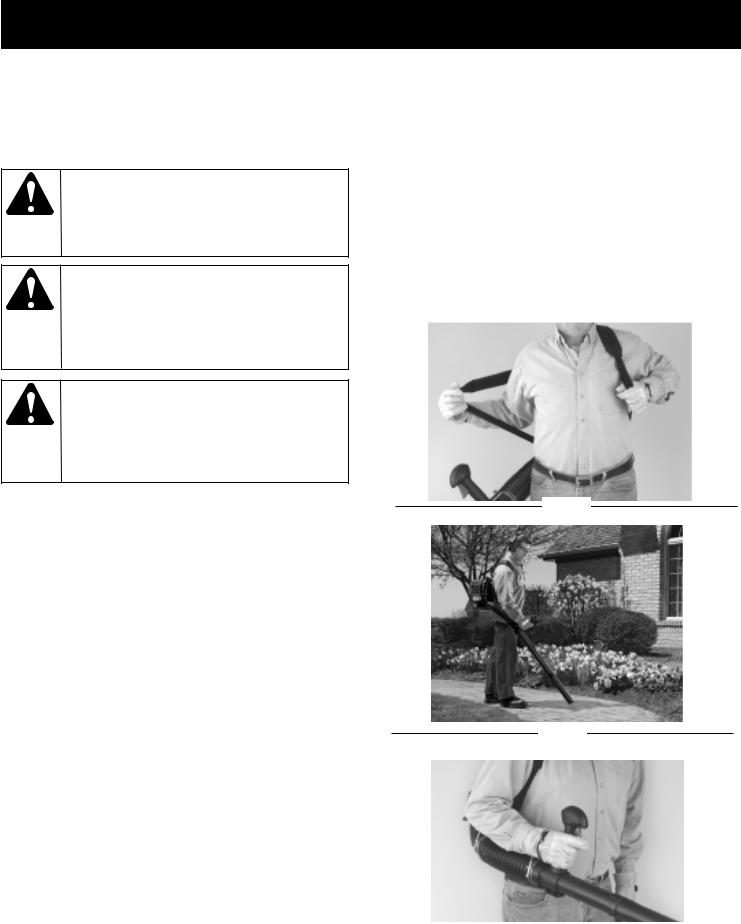

ADJUST BACK PACK HARNESS AND CONTROL HANDLE

1.Place blower on your back by slipping arms through the shoulder straps as if you were putting on a jacket (Figure 8).

2.Adjust backpack harness and control handle.

3.Once adjustments have been made, to the straps for user comfort, remove the blower from your back and place on level ground in an upright position.

Fig. 8

STARTING/STOPPING INSTRUCTIONS

STARTING A COLD ENGINE (Above 55˚F)

Mix the bottle of 2-cycle oil (included) with 1 gallon of unleaded gasoline (less than 30 days old). Combine them in a separate container using a 40:1 ratio. Pour into fuel tank.

1.Squeeze throttle (A) and push throttle lock (B) to advance throttle for starting. (Figure 9)

2.Pump “primer bulb” (C) 10 times. (Figure 10)

3.Move choke lever to Choke “1”.(Figure 11)

4.With the unit on the ground, hold the top assist handle and step on the bottom of the frame with foot. Pull starter rope 3 times. (Figure 12)

C

Fig. 10

B

A

Fig. 9 |

|

|

|

Fig. 11 |

|

||||

|

|

|

||

|

|

|

|

|

10

STARTING/STOPPING INSTRUCTIONS

NOTE: The unit uses the Spring Assist TM starting system, which significantly reduces the effort required to start the engine. You must pull the starter rope out far enough to hear the engine attempt to start. There is no need to pull the rope briskly--there is no harsh resistance when pulling. Be aware that this starting method is vastly different from (and much easier than) what you may be used to.

5.Move choke lever to “2” (Fig.13)

6.Pull starter rope again 1~6 times (Fig.14)

7.The engine should start. After 30 sec. Move choke to “3”.(Fig.15)

8.Squeeze throttle and release to disengage lock ; Unit is now at idle.(Fig.9)

NOTE: If engine fails to start after repeated attempts, refer to Troubleshooting section.

NOTE: Always pull starter rope straight out. Pulling starter at an angle will cause rope to rub against the eyelet. This friction will cause the rope to fray and wear more quickly. Always hold starter handle when rope retracts. Never allow rope to snap back from extended position. This could cause rope to snag or fray and also damage the starter assembly.

Fig. 12

Fig. 13

IMPORTANT IDLING INFORMATION

In some cases due to operating conditions (altitude, tem- |

D |

|||||

perature etc.) your blower may need a slight adjustment |

|

|

|

|

||

to the idle speed. |

|

|

|

|

||

After warm up, If unit does not Idle after restarting 2 |

|

|

|

|

||

times, follow these steps to adjust idle. |

|

|

|

|

||

1. Locate the idle adjustment screw (E) on the carbure- |

|

|

|

|

||

|

tor (Figure 16). |

|

|

|

|

|

2. Using a Phillips or slotted screwdriver - turn screw |

|

|

|

|

||

|

|

|

|

|||

|

1/4 to 1/2 turn clockwise (to the right). Unit should |

|

|

|

|

|

|

then idle properly. |

|

|

|

|

|

STOPPING THE ENGINE |

|

|

|

|

||

Emergency Stopping Procedure. When it is necessary |

|

|

|

|

||

to stop blower engine immediately, DEPRESS the OFF |

|

|

|

|

||

“STOP ” switch until the engine stops completely |

|

|

|

|

||

(Figure 9). |

|

|

|

|

||

Normal Stopping Method. For normal stopping, release |

|

|

|

|

||

trigger and allow engine to return to idle speed. Then |

|

|

|

|

||

DEPRESS the OFF “STOP ” switch until the engine |

|

|

|

|

|

|

|

|

|

|

|

||

stops completely. (Figure 9) |

|

|

|

|

||

STARTING A WARM ENGINE (Engine has been |

|

|

|

|

||

stopped for no more than 15-20 minutes). |

|

|

E |

|||

1. |

Set throttle (see step 1 for starting a cold engine), |

|

|

|

|

|

|

chuck “3”, pull starter rope. |

|

|

|

|

|

2. |

If engine does not start, or starts and then stops |

|

|

|

|

|

|

after 5 rope pulls, follow procedure “STARTING A |

|

|

|

|

|

|

COLD ENGINE”. |

|

|

|

|

|

Fig. 14

Fig. 15

11 |

|

Fig. 16 |

|

OPERATING INSTRUCTIONS

BLOWER OPERATIONS

1.Use the blower for trees, shrubs, flower beds, and hard-to-clean areas.

2.Use the unit around buildings and for other normal cleaning procedures.

3.Use the blower around walls, overhangs, fences, and screens.

WARNING: Because of flying debris, always wear

American National Standards Institute approved shielded safety glasses or face shield when operating blower.

WARNING: Before using your blower, review Safety

Precautions in your User Manual, and all regulations for operation of the unit. These precautions and regulations are for your protection.

CAUTION: DO NOT operate the blower with other

people or animals in the immediate vicinity. Allow a minimum of 50 feet (15 meters) between operator and other people or animals.

4.We recommend that a face mask be worn when operating blower in dusty areas.

5.Stand away from the debris, at a distance that will easily allow you to control the direction of blown debris. Never blow debris in direction of bystanders.

6.To control velocity of airstream, blower can be operated at any speed between idle and full throttle. Experience with the unit will help you determine the amount of airflow necessary for each application.

7.Operate power equipment only at reasonable hours--not early in the morning or late at night when people might be disturbed. Comply with times listed in local ordinances.

8.To reduce sound levels, limit the number of pieces of equipment used at any one time.

9.Operate power blowers at the lowest possible throttle speed to do the job.

10.Check your equipment before operation, especially the muffler, air intakes and air filters.

11.Use rakes and brooms to loosen debris before blowing.In dusty conditions, slightly dampen surfaces when water is available.

12.Conserve water by using power blowers instead of hoses for many lawn and garden applications, including areas such as gutters, screens, patios, grills, porches and gardens.

13.Watch out for children, pets, open windows or freshly washed cars, and blow debris safely away.

14.Use intermediate tube plus nozzle of your choice so the airstream can work close to the ground.

15.After using blowers and other equipment, CLEAN UP! Dispose of debris in trash receptacles.

OPERATION INSTRUCTIONS

1.Follow the instructions “STARTING A COLD ENGINE”.

2.Once unit is running, place unit on your back by slipping arms through the shoulder straps as if your were putting on a jacket (Figure 17).

3.When preparing to clear an area of debris, always position yourself so that you can control the direction debris will be blown .

4.The control handle and the flexibility of the blower tube assembly will allow you to clear the most hard- to-reach areas. (Fig. 18)

5.The hand grip, throttle trigger, throttle lock and ignition on/off switch are all mounted on a swivel handle that offers a wide range of operating positions and comfort (Figure 19).

Fig. 17

Fig. 18

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

Fig. 19 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Loading...

Loading...