UC2906

UC3906

Sealed Lead-Acid Battery Charger

FEATURES

• Optimum Control for Maximum

Battery Capacity and Life

• Internal State Logic Provides

Three Charge States

• Precision Reference T racks

Battery Requirements Over

Temperature

• Controls Both Voltage and

Current at Charger Output

• System Interface Funct ions

• Typical Standby Supply

Current of only 1.6mA

DESCRIPTION

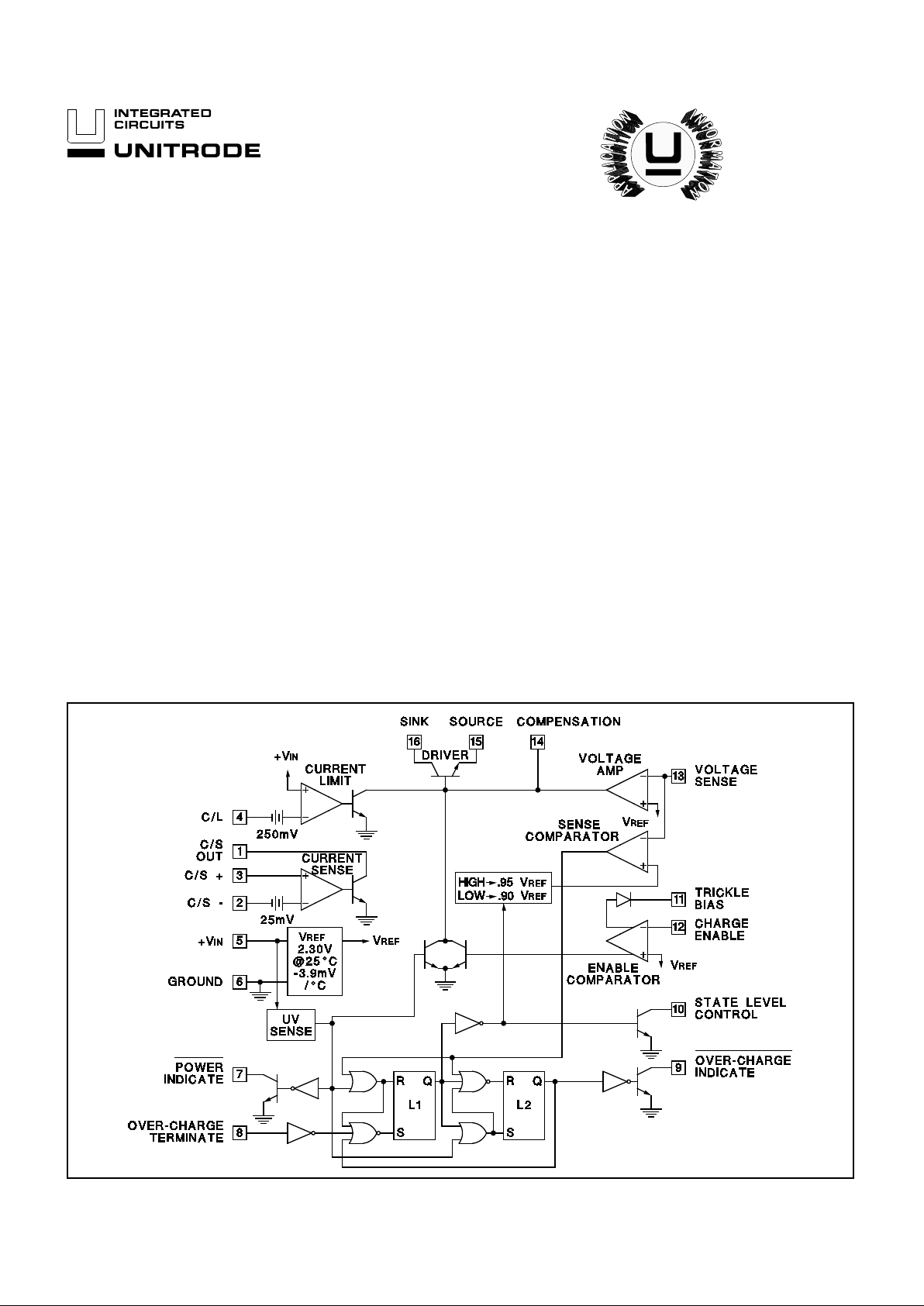

The UC2906 series of batter y charger controllers contains all of the necessary

circuitry to optimally control the charge and hold cycle for s ealed lead-acid batteries. These integrated circuits monitor and control both the output voltage and current of the charger through three separate charge states; a high current

bulk-charge state, a controlled over-charge, and a precision float-charge, or

standby, state.

Optimum charging conditions are maintained over an extended temperature

range with an internal reference that tracks the nominal temperature characteristics of the lead-acid cell. A typical standby supply current requirement of only

1.6mA allows these ICs to predictably monitor ambient temperatures.

Separate voltage loop and current limit amplifiers regulate the output voltage and

current levels in the charger by controlling the onboard driver. The driver will supply up to 25mA of base drive to an external pass device. Voltage and current

sense comparators are used to sense the battery condition and respond with

logic inputs to the charge state logic. A charge enable comparator with a trickle

bias output can be used to implement a low current turn-on mode of the charger,

preventing high curren t charging during abnormal conditions such as a shorted

battery cell.

Other features inclu de a su ppl y unde r-voltage sense circuit with a logic output to

indicate when input power is present. In addition the over-charge state of the

charger can be externa lly monitored and termin ated using the over-charge indicate output and over-charge terminate input.

BLOCK DIAGRA M

SLUS186 - SEPTEMBER 1996

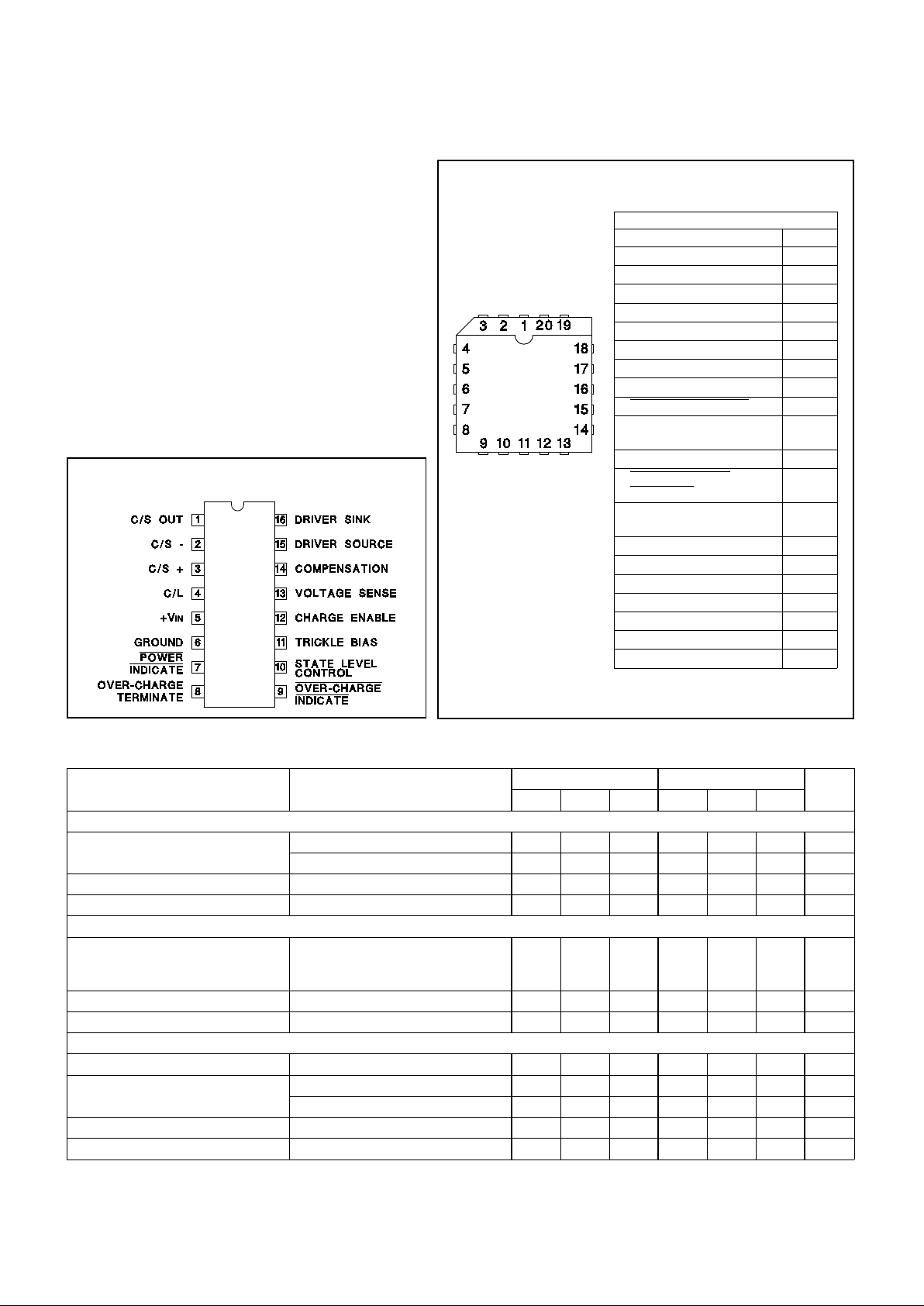

CONNECTION DIAG RAMS

UC2906

UC3906

Supply Voltage (+ VIN). . . . . . . . . . . . . . . . . . . . . . . . . . . 40V

Open Collector Output Voltages. . . . . . . . . . . . . . . . . . . 40V

Amplifier and Comp arato r Input Voltages . . . -0.3V to +40V

Over-Charge Te rm inate I nput Volt age. . . . . . -0.3V to +40V

Current Sense Amplifier Output Cur ren t . . . . . . . . . . 80mA

Other Open Collector Output Currents. . . . . . . . . . . . 20mA

Trickle Bias Voltage Differe nt ial with res pect to V

IN. . . -32V

Trickle Bias Outpu t Current . . . . . . . . . . . . . . . . . . . . -40mA

Driver Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80mA

Power Dissipation at T

A = 25°C(Note 2) . . . . . . . . 1000mW

Power Dissipation at T

C = 25°C (Note 2). . . . . . . . 2000mW

Operating Junct ion Te mp era ture . . . . . . . . -55°C to +150°C

Storage Temperature . . . . . . . . . . . . . . . . . -65°C to +150°C

Lead Tempera ture (Solderin g, 10 Seconds) . . . . . . . 300°C

Note 1: Voltage s are reference d to ground (Pin 6) . Current s

are positive into, negat ive out of, the specif ied te rminals.

Note 2: Consult Packag in g sect ion of Dat abo ok f or ther ma l

limitations and considerat ions of packages .

DIL-16, SOIC- 16 (T O P VIEW)

J or N Package, DW Package

PACKAGE PIN FUNCTION

FUNCTION PIN

N/C 1

C/S OUT 2

C/S- 3

C/S+ 4

C/L 5

N/C 6

+VIN 7

GROUND 8

POWER INDICATE 9

OVER CHARGE

TERMINATE

10

N/C 11

OVER CHARGE

INDICATE

12

STATE LEVEL

CONTROL

13

TRICKLE BIAS 14

CHARGE ENABLE 15

N/C 16

VOLTAGE SENSE 17

COMPENSATION 18

DRIVER SOURCE 19

DRIVER SINK 20

PLCC-20, LCC-20

(TOP VIEW)

Q, L Packages

ABSOLUTE MAXI MUM RATING S (Note 1)

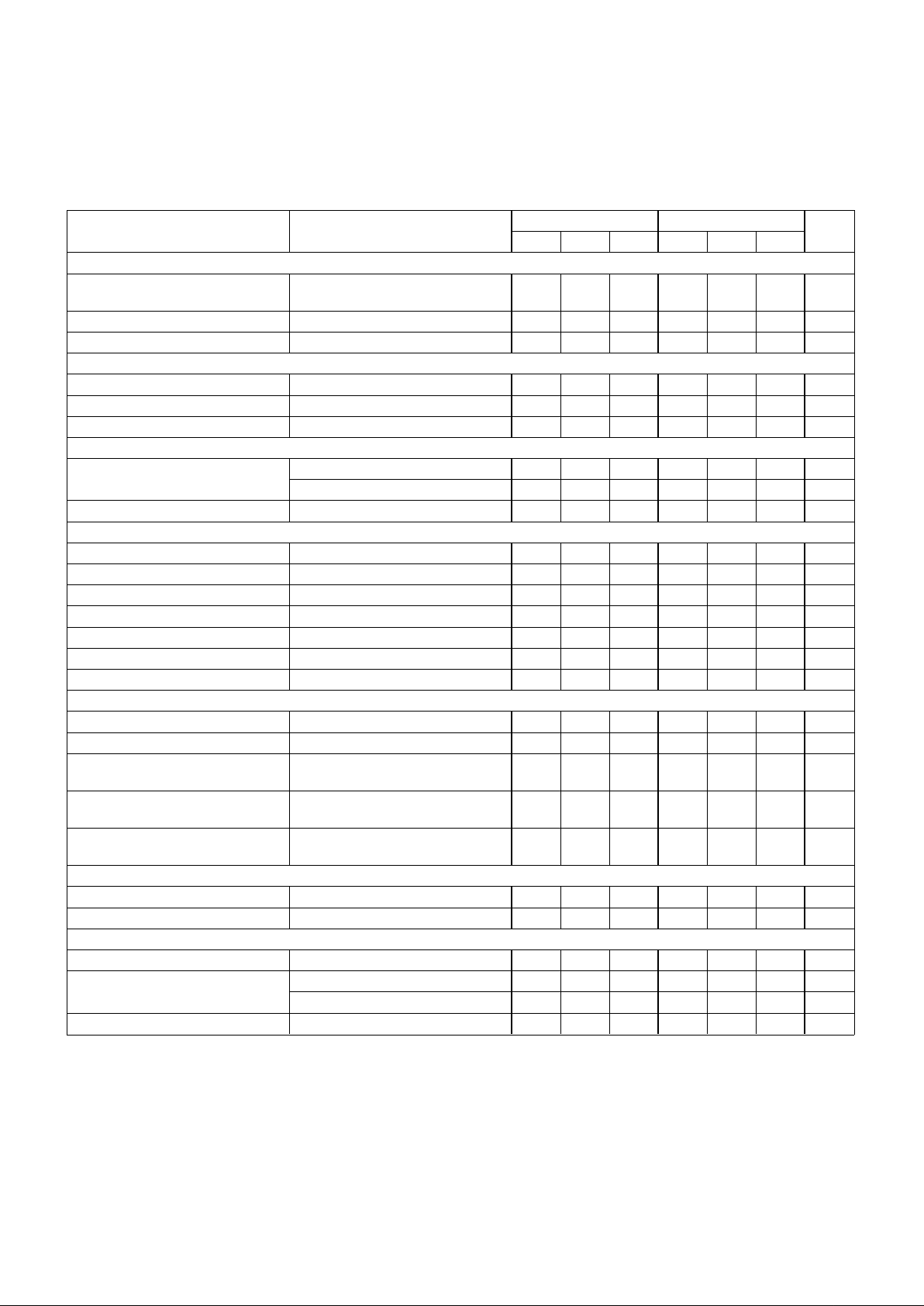

PARAMETER TEST CONDITIONS UC2906 UC3906 UNITS

MIN TYP MAX MIN TYP MAX

Input Supply

Supply Current +V

IN = 10V 1.6 2.5 1.6 2.5 mA

+V

IN = 40V 1.8 2.7 1.8 2.7 mA

Supply Under-Voltage Threshold +V

IN = Low to High 4.2 4.5 4.8 4.2 4.5 4.8 V

Supply Under-Voltage Hysteresis 0.20 0.30 0.20 0.30 V

Internal Reference (V

REF)

Voltage Level (Note 3) Measured as Regulating Level at

Pin 13 w/ Driver Current = 1mA,

T

J = 25°C

2.275 2.3 2.325 2.270 2.3 2.330 V

Line Regulation +V

IN = 5 to 40V 38 38mV

Temperature Coeff icient -3.9 -3.9 mV/°C

Voltage A m pl if ier

Input Bias Current Total Input Bias at Regulating Level -0.5 -0.2 -0.5 -0.2 µA

Maximum Output Current Source -45 -30 -15 -45 -30 -15 µA

Sink 30 60 90 30 60 90 µA

Open Loop Gain Driver current = 1mA 50 65 50 65 dB

Output Voltage Swing Volts above GND or below +V

IN 0.2 0.2 V

Unless otherwise st ated, these specif icat ions apply fo r T

A = -40°C to +70°C for the

UC2906 and 0°C to +70°C for the UC3906, +V

IN = 10V, TA = TJ.

ELECTRICAL CHARACTERISTICS:

Note 3. The referenc e volt age will change as a function of power dissipat ion on the die according t o the tem per ature coef ficie nt of

the reference and the t her mal resist anc e, junct ion-t o-am bient .

2

PARAMETER TEST CONDITIONS UC2906 UC3906 UNITS

MIN TYP MAX MIN TYP MAX

Driver

Minimum Supply to Source

Different ial

Pin 16 = +V

IN, IO = 10mA 2.0 2.2 2.0 2.2 V

Maximum Output Current Pin 16 to Pin 15 = 2V 25 40 25 40 mA

Saturation Voltage 0.2 0.45 0.2 0.45 V

Current Limit Amplifier

Input Bias Current 0.2 1.0 0.2 1.0 µA

Threshold Voltage Of f set below + V

IN 225 250 275 225 250 275 mV

Threshold Supply Sen sitivit y +V

IN = 5 to 40V 0.03 0.25 0.03 0.25 %/V

Voltage Sense Compar ator

Threshold Voltage As a func tion of V

REF, L1 = RESET 0.945 0.95 0.955 0.945 0.95 0.955 V/V

As a function of V

REF, L1 = SET 0.895 0.90 0.905 0.895 0.90 0.905 V/V

Input Bias Current Total Input Bias at Thresholds -0.5 -0.2 -0.5 -0.2 µA

Current Sense Comparato r

Input Bias Current 0.1 0.5 0.1 0.5 µA

Input Offs et Cu rr ent 0.01 0.2 0.01 0.2 µA

Input Offset Voltag e Referenced t o Pin 2, I

OUT = 1mA 202530202530mV

Offset Supply Sensitivity +V

IN = 5 to 40V 0.05 0.35 0.05 0.35 %/V

Offset Common Mode Sensitivity CM V = 2V to +V

IN 0.05 0.35 0.05 0.35 %/V

Maximum Output Current V

OUT = 2V 25 40 25 40 mA

Output Saturat io n Volta ge I

OUT = 10mA 0.2 0.45 0.2 0.45 V

Enable Comparator

Threshold Voltage As a func tion of V

REF 0.99 1.0 1.01 0.9 9 1.0 1.01 V/V

Input Bias Current -0.5 -0.2 -0.5 -0.2 µA

Trickle Bias Maximu m Outpu t

Current

V

OUT = +VIN − 3V 25 40 25 40 mA

Trickle Bias Maximu m Outpu t

Voltage

Volts below +V

IN, IOUT = 10mA 2.0 2.6 2.0 2.6 V

Trickle Bias Reverse Hold-Of f

Voltage

+V

IN = 0V, IOUT = -10µA 6.3 7.0 6.3 7.0 V

Over-Charg e Termi na te Inpu t

Threshold Voltage 0.7 1.0 1.3 0.7 1.0 1.3 V

Internal Pull-Up Current At Threshold 10 10 µA

Open Collector Outputs (Pins 7, 9, and 10)

Maximum Output Current V

OUT = 2V 2.5 5 2.5 5 mA

Saturation Voltage I

OUT = 1.6mA 0.25 0.45 0.25 0.45 V

I

OUT = 50µ A 0 .0 3 0.05 0.03 0.05 V

Leakage Curr ent V

OUT = 40V 13 13µA

ELECTRICAL CHARACTERISTICS:

Unless otherwise st ated, these specif icat ions apply fo r TA = -40°C to +70°C for the

UC2906 and 0°C to +70°C for the UC3906, +V

IN = 10V, TA = TJ.

UC2906

UC3906

3

Dual Level Float Charg er Ope ration s

The UC2906 is shown configured as a dual level float

charger in Fig ure 1. All high currents are handled by the

external PNP pass transistor with the driver supplying

base drive to this device. This scheme uses the TRICKLE

BIAS output and the charge enable comparator to give

the charger a low current turn on mode. The ou tput current of the charger is limited to a low-level until the battery

reaches a specified voltage, preventing a high current

charging if a battery cell is shorted. Figure 2 shows the

state diagram o f the charger. Upon turn on the UV sense

circuitry puts the charger in state 1, the high rate bulkcharge state. In this state, once the enable threshold has

been exceeded, the charger will supply a peak current

that is determined by the 250mV offset in the C/L amplifier and the sensing resistor R

S.

To guarantee full re-charge of the battery, the charger’s

voltage loop has an elevated regulating level, V

OC, during

state 1 and state 2. When the battery voltage reaches

95% of VOC, the charger enters the over-charge state,

state 2. The charge r stays in this state until the OVERCHARGE TERMINATE pin goes high. In Figure 1, the

charger use s the curren t sense amplifier to generate this

signal by sensing when the charge current has tapered to

a specified level, I

OCT. Alternatively the over-charge could

have been controlled by an external source, such as a

timer, by using the

OVER-CHARGE INDICATE signal at

Pin 9. If a load is applied to the battery and begins to discharge it, the charger will contribute its full output to the

load. If the battery drops 10% below the float level, the

charger will reset itself to state 1. When the load is removed a full charge cycle will follow. A graphical representation of a charge, and discharge, cycle of the dual

lever float charger is shown in Figure 3.

UC2906

UC3906

Figure 1. T he UC2906 in a Dual Level Float Charger

OPERATION AND APPLICATI ON INFO RMATI ON

Internal Reference Temperature Characteristic and

T o leran ce

4

Design procedure

1.) Pick divider current, ID. Recommended value is

50µA to 1 0 0µ A.

2.)

R

C

= 2.3

V

⁄

I

D

3.)

R

A

+

R

B

=

R

SUM

= (

V

F

− 2.3V )⁄

I

D

4.)

R

D

= 2.3

VR

SUM

⁄ (

V

OC

−

V

F

)

5.)

R

A

= (

R

SUM

+

R

X

) (1 −2.3

V

⁄

V

T

)

where:

R

X

=

RCR

D

⁄

(

R

C

+

R

D

)

6.)

R

B

=

R

SUM

−

R

A

7.)

R

S

= 0.25

V

⁄

I

MAX

8.)

R

T

= (

V

IN

−

V

T

− 2.5V )

⁄

I

T

Note:V

12 = 0.95

V

OC

V

31 = 0.90

V

F

I

OCT

=

I

MAX

10

For further design and applicat ion inf ormation se e

UICC Appl ication Not e U-10 4

Explanati on: Dual Level Float Charger

A. Input power turns on, batter y charge s at trickle cur ren t rat e.

B. Battery volt age reaches V T enab ling the driver and turning

off the trickle bias output , battery cha rges at l

MAX rate.

C. Transition voltage V

12 is reached and the charger indicates

that it is now in the over-charge state, state 2.

D. Ba tter y voltage appr oach es the ove r-char ge leve l V

OC and

the charge cur re nt begins t o taper.

E. Charg e curren t ta pe rs to l

OCT. The current sense amplifier

output, in this case tied to the OC TERMINATE input,

goes high. The charger changes to the float state and

holds the battery voltage at V

F.

F. Here a load (>l

MAX) begins to discharg e the batt ery.

G. The load discharges the ba ttery suc h that the batte ry

voltage falls below V

31. The charger is now in stat e 1,

again.

UC2906

UC3906

OPERATION AND APPLICATI ON INFO RMATI ON (co ntinu ed)

Figure 2. State Diagram and Design Equation s for the Dual Level Flo at Charg er

Figure 3. Typical Charge Cycle: UC2906 Dual Level Flo at Charger

5

Compensa ted Refere nce Match es Battery Req uireme nts

When the charger is in the float state, the battery will be

maintained at a precise float voltage, V

F. The accuracy of

this float state will maximize the standby life of the battery

while the bulk-charge and over-charge states guarantee

rapid and full re-charge. All of the voltage thresholds on

the UC2906 are deri ved from the internal referen ce. This

reference has a temperature coefficient that tracks the

temperature characteristic of the optimum-charge and

hold levels for sealed lead-acid cells. This further guarantees that proper charging occurs, even at temperature extremes.

Dual Step Current Charg er Ope ration

Figures 4, 5 and 6 i ll ustrate the UC2906’s use in a different charging scheme. The dual step current charger is

useful when a large string of series cells must be

charged. The holding-charge state maintains a slightly

elevated voltage across the batteries with the holding current, 1

H. This will tend to guarantee equal charge distribu-

tion between the cell s. The bulk-charge state is similar to

that of the fl oat charger with the exception that when V

12

is reached, no over-charge state occurs since Pin 8 is tied

high at all times. The current sense amplifier is used to

regulate the holding current. In some applications a series

resistor, or external buffering transistor, may be required

at the current sense output to prevent excessive power

dissipation on the UC2906.

A PNP Pass Device Reduces Minimum Input to Output Differenti al

The configuration o f the driver on the UC2906 a llows a

good bit of flexibilit y when interfacing to an external pass

transistor. The two chargers shown in Figures 1 and 4

both use PNP pass devices, although an NPN device

driven from the source output of the UC2906 driver can

also be used. In situati ons where the charger must operate with low input to output differentials the PNP pass device should be configured as shown in Figure 4. The PNP

can be operated in a saturated mode with only the series

diode and sense resistor a ddi ng to the minimum differential. The series diode, D1, in many applications, can be

eliminated. This diode prevents any discharging of the

battery, except through the sensing divider, when the

charger is attached to the battery with no input supply

voltage. If discharging under this condition must be kept

to an absolute minimum, the sense divider can be referenced to the

POWER INDICATE pin, Pin 7, instead of

ground. In thi s manne r the open col lector off state of Pin

7 will prevent the divider resistors from discharging the

battery when the input supply is removed.

UC2906

UC3906

Figure 4. T he UC2906 in a Dual Step Current Char ger

OPERATION AND APPLICATI ON INFO RMATI ON (continued)

6

A. Input power turns on, bat t er y charges at a rate of IH + IMAX.

B. Battery voltage reaches V12 and th e voltage loop switch es

to the lower level V

F. The battery is now fed with the holding

current I

H.

C. An external load starts to discharge the battery.

D. When V

F is reached the charger will supply the full

current I

MAX + IH.

E. The discharge cont in ues an d the bat t ery volta ge reache s

V21 causing the charg er to switch bac k to state 1.

OPERATION AND APPLICATI ON INFO RMATI ON (continued)

UC2906

UC3906

Explanati on: Dual Step Cur re nt Cha rger

Figure 5. State Diagram and Design Equation s for the Dual Step Cur rent Charge r

Figure 6. Typical Charge Cycle: UC2906 D ual Step Current Charger

UNITRODE INTEGRATED CIRCUITS

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. 603-424-2410 • FAX 603-424-3460

7

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...