Page 1

®

ME•Pro

Mechanical Engineeri ng

User’s Manual

A software Application

for the TI-89 and TI-92 Plus

Version 1.0 by

da V

inci Technologies Group Inc

Page 2

ME••••Pro®

A software Application

For TI-89 and TI-92 Plus

User’s Guide

August 2000

© da Vinci Technologies Group, Inc.

Rev. 1.0

da Vinci Technologies Group, Inc.

1600 S.W. Western Blvd

Suite 250

Corvallis, OR 97333

www.dvtg.com

2

Page 3

Notice

This manual and the examples contained herein are provided “as is” as a supplement to ME•

Pro

application software available from Texas Instruments for TI-89, and TI-92 Plus platforms. da Vinci

Te chnologies Gro up, Inc. (“da V inci”) makes no warranty of any kind with r egard t o this manual

or the accompanying software, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. da Vinci shall not be lia ble for any errors or f or

incidenta l or consequ ent ial dama ges in connec tion with the furnishing, per f ormance, or use of this

manual , or the examp l es her ei n .

Copyr ight da Vinci Technologies Gr oup, Inc. 2000. All rights reserved.

PocketProfessional and ME•Pro are registered trademarks of da Vinci Technologies Group, Inc.

TI-GRAPH LINK is a trademark of Texas Instruments Incorporated, and Acrobat is a registered

trademark of Adobe Systems Incorporated.

We welcome your comments on the software and the manual. Forward your comments, preferably by

e-mail, to da Vinci at support@dvtg.com.

Acknowledgements

The ME•Pro software was developed by Chris Bunsen, Dave Conklin, Michael Conway, Curtis Gammel, and

Megh a Shyam with the gene r ou s support of TI’ s developmen t te a m . The user ’ s gu ide wa s developed by Mi cha e l

Conway, Curtis Gammel, Melinda Shaffer, and Megha Shyam. Many helpful comments from the testers at

Texas Instrume nts and other locations during β testing phase is gratefully acknowledged.

3

Page 4

Table of Contents

TABLE OF CONTENTS4

HAPTER

C

NTRODUCTION TO

1: I

1.1 Key Featur es of ME•Pro....................................................................................................12

1.2 Purchasing, Downloading and Installing ME•Pro...............................................................13

1.3 Ordering a Manual.............................................................................................................13

1.4 Memory Requirements......................................................................................................13

1.5 Differences between TI-89 and TI-92 plus.......................................................................... 13

1.6 Starting ME•Pro................................................................................................................13

1.7 How to use this Manual......................................................................................................14

1.8 Manual Disclaimer............................................................................................................. 14

1.9 Summary.................................................................................................................... ....... 15

PART I: ANALYSIS……………………………………………………………………………………...16

HAPTER

C

NTRODUCTION TO ANALYSIS

2: I

2.1 Introduction.......................................................................................................................17

2.2 Features of Analysis...........................................................................................................18

2.3 Finding Analysis................................................................................................................18

2.4 Solving a Problem in Analysis ...........................................................................................18

2.5 Tips for Analysis ...............................................................................................................20

2.6 Function keys ....................................................................................................................20

2.7 Session Folders, Variable Names.......................................................................................22

2.8 Overwriting of variable values in graphing......................................................................... 22

2.9 Reserved Variables............................................................................................................22

HAPTER

C

TEAM TABLES

3: S

3.1 Saturated Steam Properties................................................................................................. 23

3.2 Superheated Steam Properties............................................................................................23

3.3 Air Properties ....................................................................................................................23

3.4 Using Steam Tables ...........................................................................................................24

3.5 Validity Range for Temperature and Pressure..................................................................... 25

HAPTER

C

HERMOCOUPLES

4: T

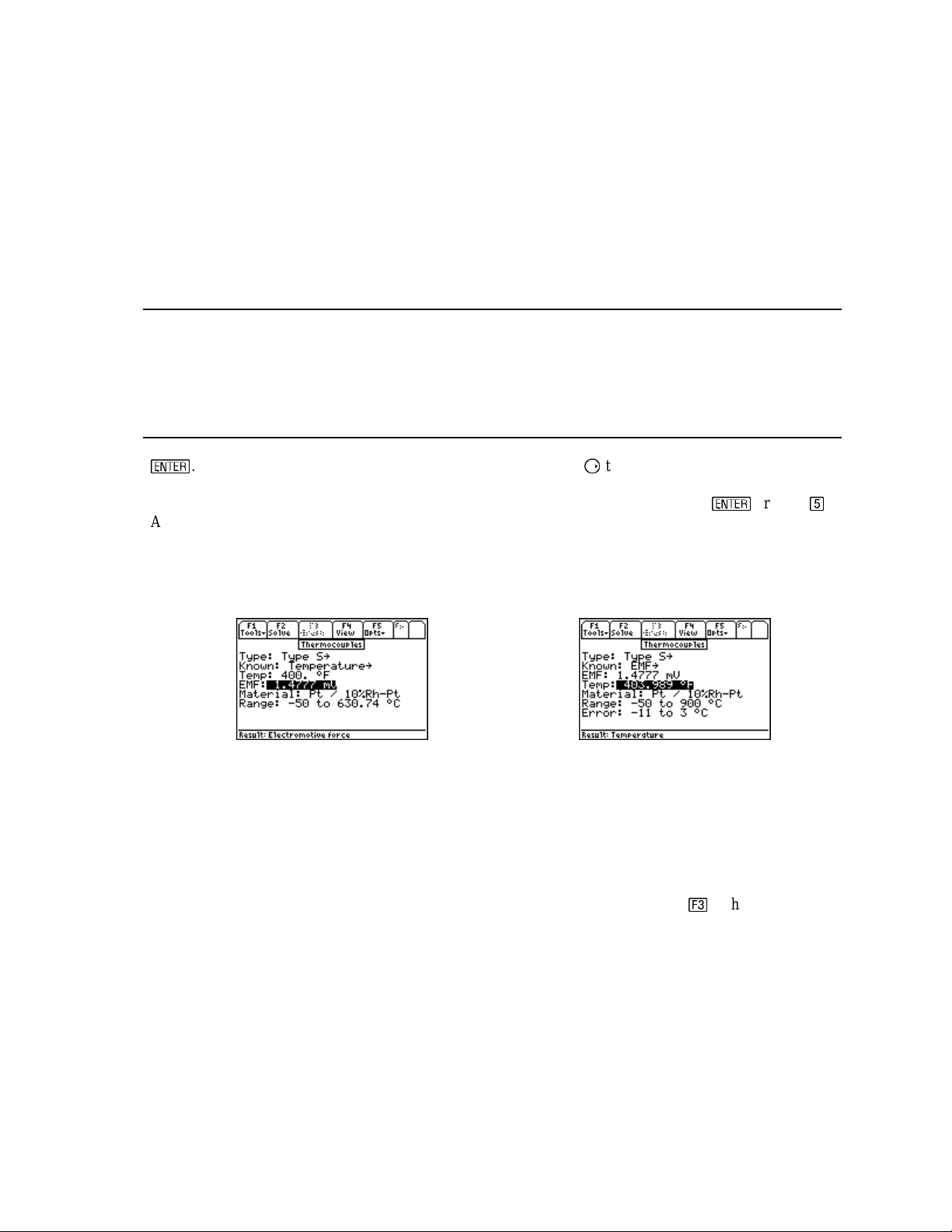

4.1 Introduction.......................................................................................................................26

4.2 Using the Thermocouples Function ....................................................................................26

4.3 Basis for Temperature/Voltage Conversions.......................................................................27

HAPTER

C

APITAL BUDGETING

5: C

5.1 Using Capital Budgeting.................................................................................................... 28

HAPTER

C

FOR MECHANICAL ENGINEERS

6: EE

6.1 Impedance Calculations..................................................................................................... 32

6.2 Circuit Performance...........................................................................................................33

6.3 Wye ↔ ∆ Conversion........................................................................................................ 34

HAPTER

C

7: E

FFLUX

..........................................................................................................................36

7.1 Constant Liquid Level........................................................................................................36

7.2 Varying Liquid Level......................................................................................................... 36

7.3 Conical Vessel................................................................................................................... 37

7.4 Horizontal Cylinder ........................................................................................................... 38

7.5 Large Rectangular Orifice.................................................................................................. 38

7.6 ASME Weirs......................................................................................................................... 39

7.6.1 Rectangular Notch .......................................................................................................... 39

7.6.2 Triangular Weir ..............................................................................................................39

7.6.3 Suppressed Weir .............................................................................................................40

7.6.4 Cipolletti Weir................................................................................................................40

HAPTER

C

ECTION PROPERTIES

8: S

8.1 Rectangle........................................................................................................................... 42

••••

RO

P

ME

............................................................................................12

..........................................................................................17

................................................................................................................23

............................................................................................................26

.......................................................................................................28

...................................................................................32

.....................................................................................................42

ME⋅Pro for TI-89, TI-92 Plus

Table of Contents

4

Page 5

8.2 Hollow Rectangle.............................................................................................................. 43

8.3 Circle.................................................................................................................................43

8.4 Circular Ring.....................................................................................................................44

8.5 Hollow Circle....................................................................................................................45

8.6 1 Section - Uneven.............................................................................................................45

8.7 I Section - Even ................................................................................................................. 46

8.8 C Section........................................................................................................................... 47

8.9 T Section ...........................................................................................................................48

8.10 Trapezoid.........................................................................................................................48

8.11 Polygon ........................................................................................................................... 49

8.12 Hollow Polygon............................................................................................................... 50

HAPTER

C

ARDNESS NUMBER

9: H

.......................................................................................................52

9.1 Compute Hardness Number ...............................................................................................52

PART II: EQUATIONS………………………………………………………………………………… ...54

HAPTER

C

NTRODUCTION TO EQUATIONS

10: I

.....................................................................................55

10.1 Solving a Set of Equations ...............................................................................................55

10.2 Viewing an Equation or Result in Pretty Print ..................................................................56

10.3 Viewing a Result in different units ...................................................................................56

10.4 Viewing Multiple Solutions..............................................................................................57

10.5 when (…) - conditional constraints when solving equations .............................................. 58

10.5 Arbitrary Integers for periodic solutions to trigonometric functions................................... 58

10.7 Partial Solutions...............................................................................................................59

10.8 Copy/Paste.......................................................................................................................59

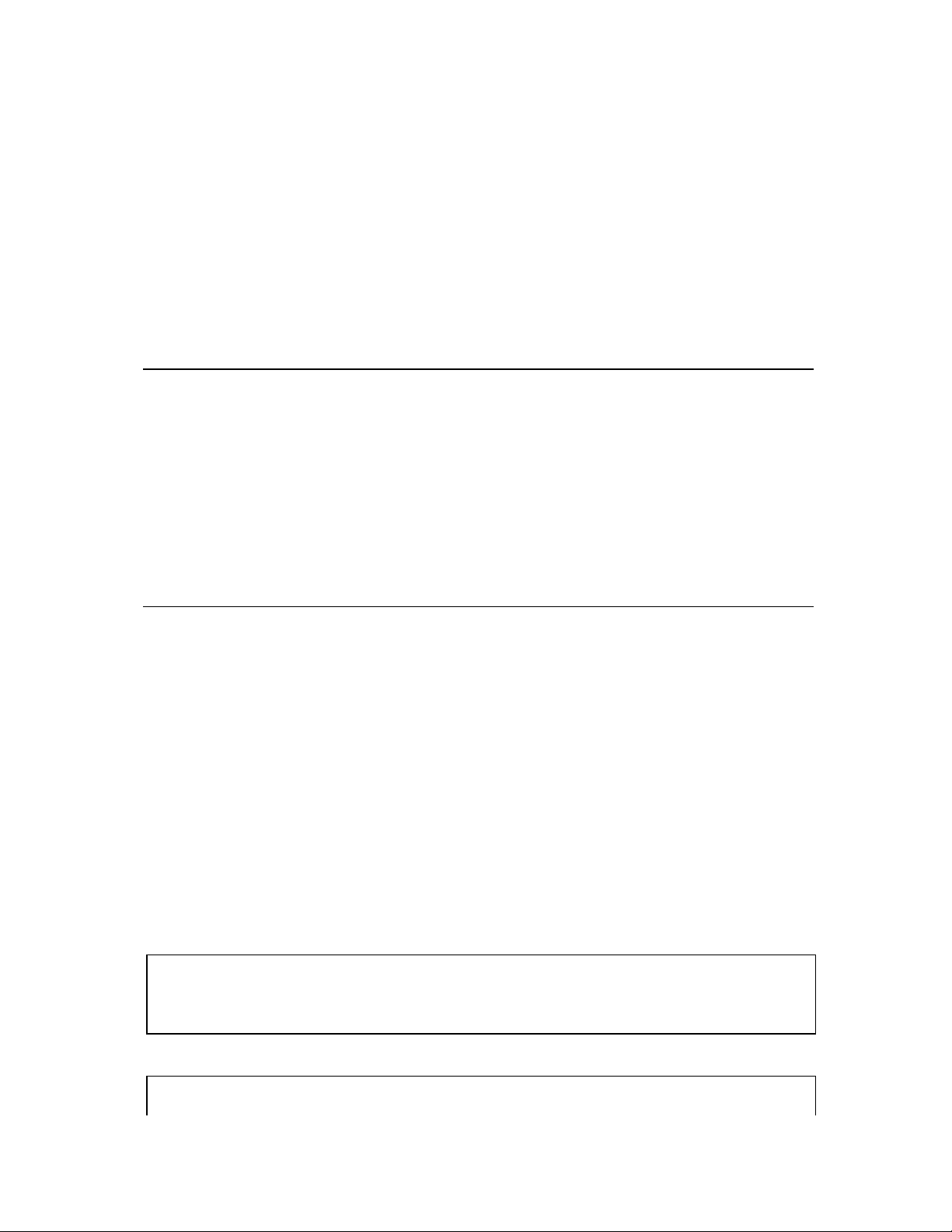

10.9 Graphing a Function.........................................................................................................59

10.10 St oring a nd re c alling variabl e value s in M E•Pro-creation of session folders.................... 61

10.11 solve, nsolve, and csolve and user-defined functions (UDF)........................................ 61

10.12 Entering a guessed value for the unknown using nsolve ..................................................61

10.13 Why can't I compute a solution?.....................................................................................62

10.14 Care in choosing a consistent set of equations.................................................................62

10.15 Not e s for the adva nced user in troubleshooting calculations ............................................ 62

HAPTER

C

EAMS AND COLUMNS

11: B

..................................................................................................64

11.1 Simple Beams......................................................................................................................64

11.1.1 Uniform Load...............................................................................................................64

11.1.2 Point Load ....................................................................................................................66

11.1.3 Moment Load ............................................................................................................... 68

11.2 Cantilever Beams.................................................................................................................70

11.2.1 Uniform Load...............................................................................................................70

11.2.2 Point Load ....................................................................................................................71

11.2.3 Moment Load ............................................................................................................... 73

11.3. Columns............................................................................................................................. 75

11.3.1 Buckling.......................................................................................................................75

11.3.2 Eccentricity, Axial Load................................................................................................ 76

11.3.3 Secant Formula ............................................................................................................. 77

11.3.4 Imperfections in Columns .............................................................................................79

11.3.5 Inelastic Buckling .........................................................................................................81

HAPTER

C

12: EE

FOR MES

................................................................................................................83

12.1 Basic Electricity...................................................................................................................83

12.1.1 Resistance Formulas......................................................................................................83

12.1.2 Ohm’s Law and Power..................................................................................................84

12.1.3 Temperature Effect ....................................................................................................... 85

12.2 DC Motors...........................................................................................................................86

12.2.1 DC Series Motor ...........................................................................................................86

12.2.2 DC Shunt Motor............................................................................................................88

12.3 DC Generators..................................................................................................................... 90

12.3.1 DC Series Generator ..................................................................................................... 90

12.3.2 DC Shunt Generator......................................................................................................91

ME⋅Pro for TI-89, TI-92 Plus

Table of Contents

5

Page 6

12.4 AC Motors...........................................................................................................................92

12.4.1 Three φ Induction Motor I............................................................................................. 92

12.4.2 Three φ Induction Motor II............................................................................................ 94

12.4.3 1 Induction Motor......................................................................................................... 96

HAPTER

C

13: G

AS LAWS

.....................................................................................................................98

13.1 Ideal Gas Laws....................................................................................................................98

13.1.1 Ideal Gas Law...............................................................................................................98

13.1.2 Constant Pressure.......................................................................................................... 99

13.1.3 Constant Volume........................................................................................................ 101

13.1.4 Constant Temperature.................................................................................................103

13.1.5 Internal Energy/Enthalpy............................................................................................. 104

13.2 Kinetic Gas Theory........................................................................................................ 106

13.3 Real Gas Laws................................................................................................................... 108

13.3.1 van der Waals: Specific Volume..................................................................................108

13.3.2 van der Waals: Molar form.......................................................................................... 109

13.3.3 Redlich-Kwong: Sp.Vol.............................................................................................. 110

13.3.4 Redlich-Kwong: Molar................................................................................................112

13.4 Reverse Adiabatic.......................................................................................................... 113

13.5 Polytropic Process.......................................................................................................... 115

HAPTER

C

14: H

EAT TRANSFER

.........................................................................................................118

14.1 Basic Transfer Mechanisms ............................................................................................... 118

14.1.1 Conduction ................................................................................................................. 118

14.1.2 Convection..................................................................................................................120

14.1.3 Radiation .................................................................................................................... 121

14.2 1 1D Heat Transfer ................................................................................................................ 122

14.2.1 Conduction..................................................................................................................... 122

14.2.1.1 Plane Wall ............................................................................................................... 122

14.2.1.2 Convective Source ................................................................................................... 123

14.2.1.3 Radiative Source......................................................................................................125

14.2.1.4 Plate and Two Fluids................................................................................................127

14.2.2 Electrical Analogy .......................................................................................................... 128

14.2.2.1 Two Conductors in Series......................................................................................... 129

14.2.2.2 Two Conductors in Parallel ...................................................................................... 131

14.2.2.3 Parallel-Series.......................................................................................................... 132

14.2.3 Radial Systems ...............................................................................................................135

14.2.3.1 Hollow Cylinder....................................................................................................... 135

14.2.3.2 Hollow Sphere ......................................................................................................... 136

14.2.3.3 Cylinder with Insulation Wrap.................................................................................. 137

14.2.3.4 Cylinder - Critical radius..........................................................................................139

14.2.3.5 Sphere - Critical radius.............................................................................................141

14.3 Semi-Infinite Solid.............................................................................................................142

14.3.1 Step Change Surface Temperature............................................................................... 142

14.3.2 Constant Surface Heat Flux......................................................................................... 143

14.3.3 Surface Convection..................................................................................................... 145

14.4 Radiation........................................................................................................................... 146

14.4.1 Blackbody Radiation................................................................................................... 146

14.4.2 Non-Blackbody radiation ............................................................................................148

14.4.3 Thermal Radiation Shield............................................................................................ 149

HAPTER

C

HERMODYNAMICS

15: T

.....................................................................................................152

15.1 Fundamentals................................................................................................................. 152

15.2 System Properties .............................................................................................................. 153

15.2.1 Energy Equations........................................................................................................ 153

15.2.2 Maxwell Relations ...................................................................................................... 155

15.3 Vapor and Gas Mixture...................................................................................................... 157

15.3.1 Saturated Liquid/Vapor ............................................................................................... 157

15.3.2 Compressed Liquid-Sub cooled ...................................................................................159

ME⋅Pro for TI-89, TI-92 Plus

Table of Contents

6

Page 7

15.4 Ideal Gas Properties........................................................................................................... 160

15.4.1 Specific Heat...............................................................................................................160

15.4.2 Quasi-Equilibrium Compression..................................................................................162

15.5 First Law...............................................................................................................................163

15.5.1 Total System Energy...................................................................................................163

15.5.2 Closed System: Ideal Gas...............................................................................................167

15.5.2.1 Constant Pressure.....................................................................................................167

15.5.2.2 Binary Mixture......................................................................................................... 169

15.6 Second Law........................................................................................................................... 171

15.6.1 Heat Engine Cycle .......................................................................................................... 171

15.6.1.1 Carnot Engine..........................................................................................................171

15.6.1.2 Diesel Cycle............................................................................................................. 173

15.6.1.3 Dual Cycle............................................................................................................... 177

15.6.1.4 Otto Cycle................................................................................................................180

15.6.1.5 Brayton Cycle .......................................................................................................... 184

15.6.2 Clapeyron Equation.....................................................................................................186

HAPTER

C

ACHINE DESIGN

16: M

.......................................................................................................188

16.1 Stress: Machine Elements .................................................................................................. 188

16.1.1 Cylinders .................................................................................................................... 188

16.1.2 Rotating Rings............................................................................................................ 189

16.1.3 Pressure and Shrink Fits.............................................................................................. 190

16.1.4 Crane Hook................................................................................................................. 192

16.2 Hertzian Stresses................................................................................................................193

16.2.1 Two Spheres...............................................................................................................193

16.2.2 Two Cylinders............................................................................................................ 195

16.3.1 Bearing Life................................................................................................................ 197

16.3.2 Petroff's law................................................................................................................ 198

16.3.3 Pressure Fed Bearings................................................................................................. 199

16.3.4 Lewis Formula............................................................................................................200

16.3.5 AGMA Stresses.......................................................................................................... 201

16.3.6 Shafts..........................................................................................................................203

16.3.7 Clutches and Brakes ........................................................................................................... 204

16.3.7.1 Clutches....................................................................................................................... 204

16.3.7.1.1 Clutches ................................................................................................................ 204

16.3.7.2 Uniform Wear - Cone Brake.....................................................................................206

16.3.7.3 Uniform Pressure - Cone Brake................................................................................ 207

16.4 Spring Design........................................................................................................................208

16.4.1 Bending.......................................................................................................................... 208

16.4.1.1 Rectangular Plate.....................................................................................................208

16.4.1.2 Triangular Plate........................................................................................................ 209

16.4.1.3 Semi-Elliptical......................................................................................................... 210

16.4.2 Coiled Springs................................................................................................................ 212

16.4.2.1 Cylindrical Helical - Circular wire............................................................................ 212

16.4.2.2 Rectangular Spiral.................................................................................................... 213

16.4.3 Torsional Spring............................................................................................................. 215

16.4.3.1 Circular Straight Bar ................................................................................................215

16.4.3.2 Rectangular Straight Bar...........................................................................................216

16.4.4 Axial Loaded.................................................................................................................. 217

16.4.4.1 Conical Circular Section........................................................................................... 217

16.4.4.2 Cylindrical - Helical..................................................................................................... 219

16.4.4.2.1 Rectangular Cross Section .....................................................................................219

16.4.4.2.2 Circular Cross Section ........................................................................................... 220

HAPTER

C

UMPS AND HYDRAULICS

17: P

............................................................................................222

17.1 Basic Definitions ...........................................................................................................222

17.2 Pump Power .................................................................................................................. 223

17.3 Centrifugal Pumps.............................................................................................................225

ME⋅Pro for TI-89, TI-92 Plus

Table of Contents

7

Page 8

17.3.1 Affinity Law-Variable Speed.......................................................................................225

17.3.2 Affinity Law-Constant Speed......................................................................................226

17.3.3 Pump Similarity.......................................................................................................... 227

17.3.4 Centrifugal Compressor............................................................................................... 228

17.3.5 Specific Speed ............................................................................................................229

HAPTER

C

AVES AND OSCILLATION

18: W

...........................................................................................231

18.1 Simple Harmonic Motion...................................................................................................231

18.1.1 Linear Harmonic Oscillation........................................................................................231

18.1.2 Angular Harmonic Oscillation..................................................................................... 232

18.2 Pendulums.........................................................................................................................233

18.2.1 Simple Pendulum........................................................................................................233

18.2.2 Physical Pendulum...................................................................................................... 235

18.2.3 Torsional Pendulum....................................................................................................236

18.3 Natural and Forced Vibrations.............................................................................................. 236

18.3.1 Natural Vibrations...........................................................................................................236

18.3.1.1 Free Vibration..........................................................................................................236

18.3.1.2 Overdamped Case (ξ>1)........................................................................................... 238

18.3.1.3 Critical Damping (ξ=1) ............................................................................................ 239

18.3.1.4 Underdamped Case (ξ<1)......................................................................................... 241

18.3.2 Forced Vibrations ........................................................................................................... 244

18.3.2.1 Undamped Forced Vibration.....................................................................................244

18.3.2.2 Damped Forced Vibration ........................................................................................ 245

18.3.3 Natural Frequencies...........................................................................................................247

18.3.3.1 Stretched String........................................................................................................ 247

18.3.3.2 Vibration Isolation ................................................................................................... 248

18.3.3.3 Uniform Beams............................................................................................................249

18.3.3.3.1 Simply Supported..................................................................................................250

18.3.3.3.2 Both Ends Fixed.................................................................................................... 251

18.3.3.3.3 1 Fixed End / 1 Free End....................................................................................... 252

18.3.3.3.4 Both Ends Free...................................................................................................... 254

18.3.3.4 Flat Plates.................................................................................................................... 255

18.3.3.4.1 Circular Flat Plate.................................................................................................. 255

18.3.3.4.2 Rectangular Flat Plate............................................................................................257

HAPTER

C

EFRIGERATION AND AIR CONDITIONING

19: R

...................................................................259

19.1 Heating Load.................................................................................................................259

19.2 Refrigeration......................................................................................................................261

19.2.1 General Cycle .............................................................................................................261

19.2.2 Reverse Carnot............................................................................................................ 262

19.2.3 Reverse Brayton.......................................................................................................... 263

19.2.4 Compression Cycle.....................................................................................................264

HAPTER

C

TRENGTH MATERIALS

20: S

...............................................................................................267

20.1 Stress and Strain Basics ..................................................................................................... 267

20.1.1 Normal Stress and Strain.............................................................................................267

20.1.2 Volume Dilation.........................................................................................................268

20.1.3 Shear Stress and Modulus............................................................................................ 269

20.2 Load Problems...................................................................................................................270

20.2.1 Axial Load.................................................................................................................. 270

20.2.2 Temperature Effects....................................................................................................271

20.2.3 Dynamic Load ............................................................................................................272

20.3 Stress Analysis ..................................................................................................................274

20.3.1 Stress on an Inclined Section ....................................................................................... 274

20.3.2 Pure Shear...................................................................................................................275

20.3.3 Principal Stresses........................................................................................................276

20.3.4 Maximum Shear Stress................................................................................................277

20.3.5 Plane Stress - Hooke's Law..........................................................................................278

20.4 Mohr’s Circle Stress..........................................................................................................280

ME⋅Pro for TI-89, TI-92 Plus

Table of Contents

8

Page 9

20.4 Mohr’s Circle Stress.......................................................................................................280

20.5 Torsion.............................................................................................................................. 281

20.5.1 Pure Torsion............................................................................................................... 281

20.5.2 Pure Shear...................................................................................................................283

20.5.3 Circular Shafts............................................................................................................ 284

20.5.4 Torsional Member.......................................................................................................285

HAPTER

C

LUID MECHANICS

21: F

.....................................................................................................288

21.1 Fluid Properties .......................................................................................................... ....... 288

21.1.1 Elasticity..................................................................................................................... 288

21.1.2 Capillary Rise............................................................................................................. 289

21.2 Fluid Statics............................................................................................................. ............. 291

21.2 1 Pressure Variation........................................................................................................... 291

21.2.1.1 Uniform Fluid.......................................................................................................... 291

21.2.1.2 Compressible Fluid..................................................................................................292

21.2.1 Pressure Variation........................................................................................................... 292

21.2.1.3 Troposphere.............................................................................................................292

21.2.1.4 Stratosphere............................................................................................................. 293

21.2.2.1 Floating Bodies........................................................................................................294

21.2.2.2 Inclined Plane/Surface.............................................................................................. 296

21.3 Fluid Dynamics.................................................................................................................297

21.3.1 Bernoulli Equation...................................................................................................... 297

21.3.2 Reynolds Number ....................................................................................................... 299

21.3.3 Equivalent Diameter....................................................................................................300

21.3.4 Fluid Mass Acceleration.................................................................................................. 302

21.3.4.1 Linear Acceleration .................................................................................................. 302

21.3.4.2 Rotational Acceleration ............................................................................................303

21.4 Surface Resistance............................................................................................................. 304

21.4.1 Laminar Flow – Flat Plate ........................................................................................... 304

21.4.2 Turbulent Flow – Flat Plate.........................................................................................306

21.4.3 Laminar Flow on an Inclined Plane..............................................................................309

21.5 Flow in Conduits ................................................................................................................... 311

21.5.1 Lamina r F l ow: Smooth Pipe....................................................................................... 311

21.5.2 Turbulent Flow: Smooth Pi pe..................................................................................... 313

21.5.3 Turbulent Flow: Rough Pipe....................................................................................... 316

21.5.4 Flow pipe Inlet............................................................................................................ 319

21.5.5 Series Pipe System...................................................................................................... 321

21.5.6 Parallel Pipe System .................................................................................................... 322

21.5.7 Venturi Meter.................................................................................................................324

21.5.7.1 Incompressible Flow ................................................................................................ 324

21.5.7.2 Compressible Flow...................................................................................................327

21.6 Impulse/Momentum............................................................................................................... 330

21.6.1 Jet Propulsion ............................................................................................................. 330

21.6.2 Open Jet..........................................................................................................................331

21.6.2.1 Vertical Plate ........................................................................................................... 331

21.6.2.2 Horizontal Plate ....................................................................................................... 332

21.6.2.3 Stationary Blade.......................................................................................................333

21.6.2.4 Moving Blade..........................................................................................................335

HAPTER

C

YNAMICS AND STATICS

22: D

.............................................................................................338

22.1 Laws of Motion ............................................................................................................. 338

22.2 Constant A ccelerat ion........................................................................................................ 340

22.2.1 Linear Motion............................................................................................................. 340

22.2.2 Free Fall .....................................................................................................................341

22.2.3 Circular Motion........................................................................................................... 342

22.3 Angular Motion................................................................................................................. 343

22.3.1 Rolling/Rotation.......................................................................................................... 343

22.3.2 Forces in Angular Motion............................................................................................ 345

ME⋅Pro for TI-89, TI-92 Plus

Table of Contents

9

Page 10

22.3.3 Gyroscope Motion.......................................................................................................346

22.4 Projectile Motion ........................................................................................................... 347

22.5 Collisions..............................................................................................................................349

22.5.1 Elastic Collisions ............................................................................................................ 349

22.5.1.1 1D Collision............................................................................................................. 349

22.5.1.2 2D Collisions........................................................................................................... 350

22.5.2 Inelastic Collisions.......................................................................................................... 351

22.5.2.1 1D Collisions........................................................................................................... 351

22.5.2.2 Oblique Collisions.................................................................................................... 352

22.6 Gravitational Effects.......................................................................................................... 354

22.6.1 Law of Gravitation...................................................................................................... 354

22.6.2 Kepler's Laws ............................................................................................................. 356

22.6.3 Satellite Orbit..............................................................................................................358

22.7 Friction..............................................................................................................................360

22.7.1 Frictional Force........................................................................................................... 360

22.7.2 Wedge........................................................................................................................ 362

22.7.3 Rotating Cylinder........................................................................................................363

22.8 Statics................................................................................................................................364

22.8.1 Parabolic cable............................................................................................................ 364

22.8.2 Catenary cable............................................................................................................365

PART III: REFERENCE ……………………………………………………………………….368

HAPTER

C

NTRODUCTION TO REFERENCE

23: I

...................................................................................369

23.1 Introduction................................................................................................................... 369

23.2 Finding Reference.......................................................................................................... 369

23.3 Reference Screens.......................................................................................................... 370

23.4 Using Reference Tables .................................................................................................370

HAPTER

C

NGINEERING CONSTANTS

24: E

..........................................................................................372

24.1 Using Constants............................................................................................................. 372

HAPTER

C

25: T

RANSFORMS

..............................................................................................................374

25.1 Using Transforms ..........................................................................................................374

HAPTER

C

ALVES AND FITTING LOSS

26: V

.........................................................................................376

26.1 Valves and Fitting Loss Screens.....................................................................................376

HAPTER

C

RICTION COEFFICIENTS

27: F

............................................................................................377

27.1 Friction Coefficients Screens..........................................................................................377

HAPTER

C

ELATIVE ROUGHNESS OF PIPES

28: R

................................................................................378

28.1 Relative Roughness Screens ........................................................................................... 378

HAPTER

C

ATER-PHYSICAL PROPERTIES

29: W

...................................................................................379

29.1 Water-Physical Properties Screens..................................................................................379

HAPTER

C

ASES AND VAPORS

30: G

.....................................................................................................380

30.1 Gases and Vapors S creens.............................................................................................. 381

HAPTER

C

HERMAL PROPERTIES

31: T

................................................................................................382

31.1 Thermal Properties Screens............................................................................................ 382

HAPTER

C

UELS AND COMBUSTION

32: F

............................................................................................383

32.1 Fuels and Combustion Screens.......................................................................................383

HAPTER

C

33: R

EFRIGERANTS

...........................................................................................................385

33.1 Refrigerants Screens ...................................................................................................... 386

HAPTER

C

34: SI P

REFIXES

...............................................................................................................387

34.1 Using SI Prefixes........................................................................................................... 387

HAPTER

C

REEK ALPHABET

35: G

......................................................................................................388

PART IV: APPENDIX AND INDEX…………………………………………………………….…….389

PPENDIX

A

REQUENTLY ASKED QUESTIONS

A F

.................................................................................390

A.1 Questions and Answers...................................................................................................390

A.2 General Questions........................................................................................................... 390

A.3 Analysis Questions.......................................................................................................... 392

A.4 Equations Questions........................................................................................................ 392

A.5 Graphing.........................................................................................................................395

ME⋅Pro for TI-89, TI-92 Plus

Table of Contents

10

Page 11

A.6 Reference........................................................................................................................ 396

PPENDIX

A

B W

ARRANTY

ECHNICAL SUPPORT

, T

................................................................................397

B.1 da Vinci License Agreement............................................................................................397

B.2 How to Contact Customer Support................................................................................... 398

PPENDIX

A

C: TI-89 & TI-92 P

LUS

EYSTROKE AND DISPLAY DIFFERENCES

- K

...................................399

C.1 Display Property Differences between the TI-89 and TI-92 Plus......................................399

C.2 Keyboard Differences Between TI-89 and TI-92 Plus ..................................................... 400

PPENDIX

A

RROR MESSAGES

D E

.......................................................................................................404

D.1 General Error Messages..................................................................................................404

D.2 Analysis Error Messages................................................................................................. 405

D.3 Equation Messages.......................................................................................................... 405

D.4 Reference Error Messages...............................................................................................406

PPENDIX E: SYSTEM VARIABLES AND RESERVED NAMES

A

.............................................................407

INDEX ……………………………………………………………………………………………………408

ME⋅Pro for TI-89, TI-92 Plus

Table of Contents

11

Page 12

Chapter 1: Introduction to ME••••Pro

Thank you for purchasing the ME•Pro, a m ember of the PocketProfessiona l® Pro software series designed

by da Vin ci Technologies Group, Inc., t o meet the porta ble computing needs of student s an d p rofessionals

in mechanical engineering. The software is organized in a hierarchical manner so t hat the topics easy to

find. We hope that you will find the ME•Pro to be a valuable companion in your career as a student and a

professional of m echanical engi neering.

Topics in this chapter include:

Key Features of ME•Pro

Purchasing, Download and Installing ME•Pro

Ordering a Manual

Memory Requirements

Differences between the TI-89 and TI-92 Plus

Starting the ME•Pro

How to use this Manual

Manual Disclaimer

Summary

1.1 Key Features of ME••••Pro

The manual is organized into t hree sections representing the main menu headings of ME•Pro.

Analysis Equations Reference

Steam Tables Beams and Columns Engineering Constants

Thermocouples EE For MEs Transforms

Capital Budgeting Gas Laws Valves/Fitting Loss

EE For MEs Heat Transfer Friction Coefficients

Efflux Thermodynamics Roughness of Pipes

Section Properties Machine Design Water Physical Properties

Hardness Number Pumps and Hydraulic Machines Gases and Vapors

Waves and Oscillation Thermal Properties

Refrigeration and Air Conditioning Fuels and Combustion

Strength Materials Refrigerants

Fluid Mechanics SI Prefixes

Dynamics and Statics Greek Alphabet

Thes e main topi c headings a re further divi d ed int o sub- topics. A brief descri ption of the main sections of

the software is listed below:

Analysis: Chapt er s 2-9

Analysis is organized into 7 topics and 25 sub-topics. The software tools available in this section

incorporate a va riety of an alysis methods used by mech anical en g ineers. Examples include Steam

Tables, Thermocouple Calculations, EE for MEs; Efflux, Section Properties, Hardness Number

Computations and Capital Budgeting. Wh er e appropriate, dat a en t er ed supports commonly used units.

Equations: Chapters 10-22

This section contains over 1000 equations organized under 12 major subjects in over 150 sub -topics. The

equations in each sub-topic have been selected to provide maximum coverage of the subject material. In

ME⋅Pro for TI-89, TI-92 Plus

Chapter 1 - Introduction to ME-Pro

12

Page 13

addition, the math engine is able to compute multiple or partial solutions to the equation sets. The

computed values are filtered to identify results that h ave engineering merit. A powerful built-in unit

management feature permits inputs in SI or other customary measurement systems. Over 80 diagrams

help clar ify the essentia l na ture of th e problems covered by the equations. Topics covered include, Beams

and Columns; EE for MEs; Gas Laws; Heat Transfer; Thermodynamics; Machine Design; Pumps

and Hydraulic Machines; Waves and Oscillation; Strength of Materials; Fluid Mechanics; and,

Dynamics and Statics.

Reference: Chapters 23-25

The Reference section contains tables of information commonly needed by mechanical engineers. Topics

include, values for Constants used by mechanical engineers; Laplace and Fourier Transform tables;

Valves and Fitting Loss; Friction Coefficient; Roughness of Pipes; Water Physical Properties;

Gases and Vapors; Thermal Properties; Fuels and Combustion; Refrigerants; SI prefixes; and the

Greek Alphabet.

1.2 Purchasing, Downloading and Installing ME••••Pro

The ME•Pro software can on ly be purch ased on- lin e from the Tex a s Instruments I nc. Online Stor e at

http://www.ti.com/calc/docs/store.htm. Th e software can be installed directly from your computer to your

calculator using TI-GRAPH LINK

downloading and installing ME•Pro software are available from TI’s website.

TM

hardware and software (sold separ at ely). Directions for purchasing,

1.3 Ordering a Manual

Chapters and Appe ndices of the Manual for ME•Pro can be downloa ded through TI’ s Web Store an d

viewed using the free Adobe Acrobat Reader

Printed manuals can be purchased separately from da Vinci Technologies Group, Inc. by visiting the

website http://www.dvtg.com/ticalcs/docs

TM

that can be downloaded from http://www.adobe.com.

or calling (541) 754-2860, Extension 100.

1.4 Memory Requirements

The ME•Pro program is installed in the system memory portion of the Flash ROM that is separate from the

RAM available to the user. ME•Pro uses RAM to store some of its session information, including values

entered and computed by the user. The exact amount of mem ory requi red depe n d s on the number of userstored variables and the number of session folders designated by the user. To view the available memory in

your TI calculator, use the function

. It is recommended that at least 10K of free RAM be

available for installation and use of ME•Pro.

1.5 Differences between TI-89 and TI-92 plus

ME•Pro is designed for two models of graphing calculators from Texas Instruments, the TI-92 Plus and the

TI-89. For consistency, keystrokes and symbols used in the manual are consistent with th e TI-89.

Equivalent key strokes for the TI-92 Plus are listed in Appendix D.

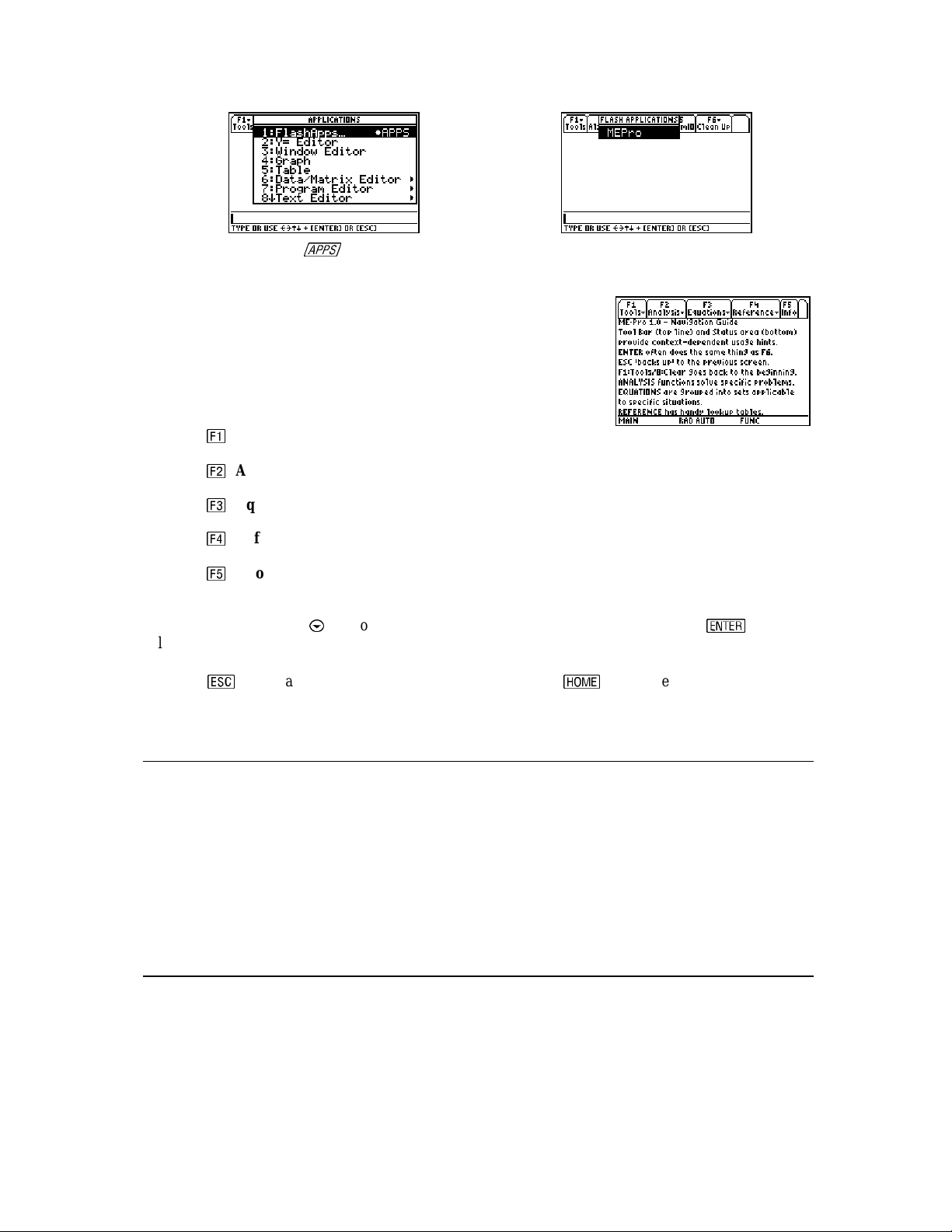

1.6 Starting ME••••Pro

To begin ME•Pro, start by pressing t he

move t he cu rsor bar to

press the

key to get to the home screen of ME•Pro. Alternatively, press

ME•Pro and press the

FlashApps...

key to get to the home screen of ME•Pro.

/

key. This accesses a pull down menu. Use the $ key to

. an d press

. Then move the highlight bar to ME•Pro and

/

; then, scroll to

ME⋅Pro for TI-89, TI-92 Plus

Chapter 1 - Introduction to ME-Pro

13

Page 14

Pull down Menu for

/

(FlashApps...option is at the top of the list)

Pull down Menu on for FlashApps...

(ME•Pro will be in the list)

The ME•Pro home screen is displayed to the right. The tool bar at the

top of the screen lists the titles of the main sections of ME•Pro which

can be activated by pressing the function keys.

b

: Tools: Editing features, information about ME•Pro in A: About.

c

: Analysis: Accesses the Analysis section of the software.

d

: Equations: Accesses the Equations section of the software.

e

: Reference: Accesses the Reference section of the software.

f

: Info: Helpful hints on ME•Pro.

To select a topic, use the $ ke y to mov e the highl i ght bar to the d e s ired top ic and pr e s s

, or

alternatively type the number next to the item. The Analysis, Equation and Reference menus are

organized in a menu tree of topics and sub-topics. The user can r eturn to a previous level of ME•Pro by

pressing . You can exi t ME•Pro at any time by pressing the

key. When ME•Pro is restarted ,

the software returns to its previous location in th e program.

1.7 How to use this Manual

The manual section, chapter heading and page number appear at the bottom of each page. The first chapter

in ea ch of the Analysis, Equations and Reference sections gives an overview of succeeding chapters and

introduces the navigation and computation features common to each of the main sections. For example,

Chapter 2 explains the basic layout of the Analysis section menu and the navigation principles, giving

examples of fe atu re s common to all topi cs in Analysis. Each topic in Analysis has a chapter dedicated to

describing its functionality in detail. The titles of these chapters correspond to the topic headings in the

software menus . They contain example problems and scr een di s p lays of the compu ted solut ions. Troubl eshooting information, commonly as ked questions , and a bibliograp hy use d to develop the sof tware a re

provided in appendixes.

1.8 Manual Disclaimer

The calculator screen displays in the manual were obtained during the testing stages of the software. Some

screen displays may appear slightly different due to final chan ges made in the software while the Manual

was being comple ted.

ME⋅Pro for TI-89, TI-92 Plus

Chapter 1 - Introduction to ME-Pro

14

Page 15

1.9 Summary

The designers of ME•Pro invite your comments by logging on to our website at http://www.dvtg.com or

by e-mail to improvements@dvtg.com

easy with the software by providing the following features:

• Easy-to-use, menu-based interface .

• Computational efficiency for speed and performance.

• Helpful-hints and context-sensitive information provided in the status line.

• Advanced ME analysis routines, equations, and reference tables.

• Comprehensive manual documentation for examples and quick reference.

. We hope that you agree we have made complex computations

ME⋅Pro for TI-89, TI-92 Plus

Chapter 1 - Introduction to ME-Pro

15

Page 16

Part I: Analysis

ME⋅Pro for TI-89, TI-92 Plus

Analysis -

16

Page 17

Chapter 2: Introduction to Analysis

2.1 Introduction

The analysis section contains subroutines and tools designed to perform specific calculations. Computations

include estimating thermodynamic properties of water at different temperature and pressure, in Steam

∆

Tables, computing fluid flow rates through different shaped orifices in Efflux, performing Wye to

conversions of AC circuits in EE for MEs, and evalueating cash flow for different projects in Capital

Budgeting. The computations are strictly top-down (i.e. the inputs and outputs are generally the same) and

the interface for each section guides the user through the solving process. A brief description of some of the

diff erent sections in Analys is appear below:

Steam Tables (3 sections): Saturated Steam, Superheated Steam, Air Properties computes the

thermodynamic parameters of steam including saturated pressure, enthalpy, entropy, internal energy, and

specific volume of the liquid and vapor forms of water given entri es of temperature and/or pressure. This

final topic covered computes the thermodynamic properties of dry air at different temperature s.

Thermocouples: This tool converts a specified tempe rature to an emf output in millivolts (mV) or from emf

output millivolts (mV) to a specified temperature. The software supports T, E, J, K, S, R and B type

thermocouples. These computation algor i t hms result from the IPTS -68 sta ndards adopted in 1968 and

modified in 1985.

circuit

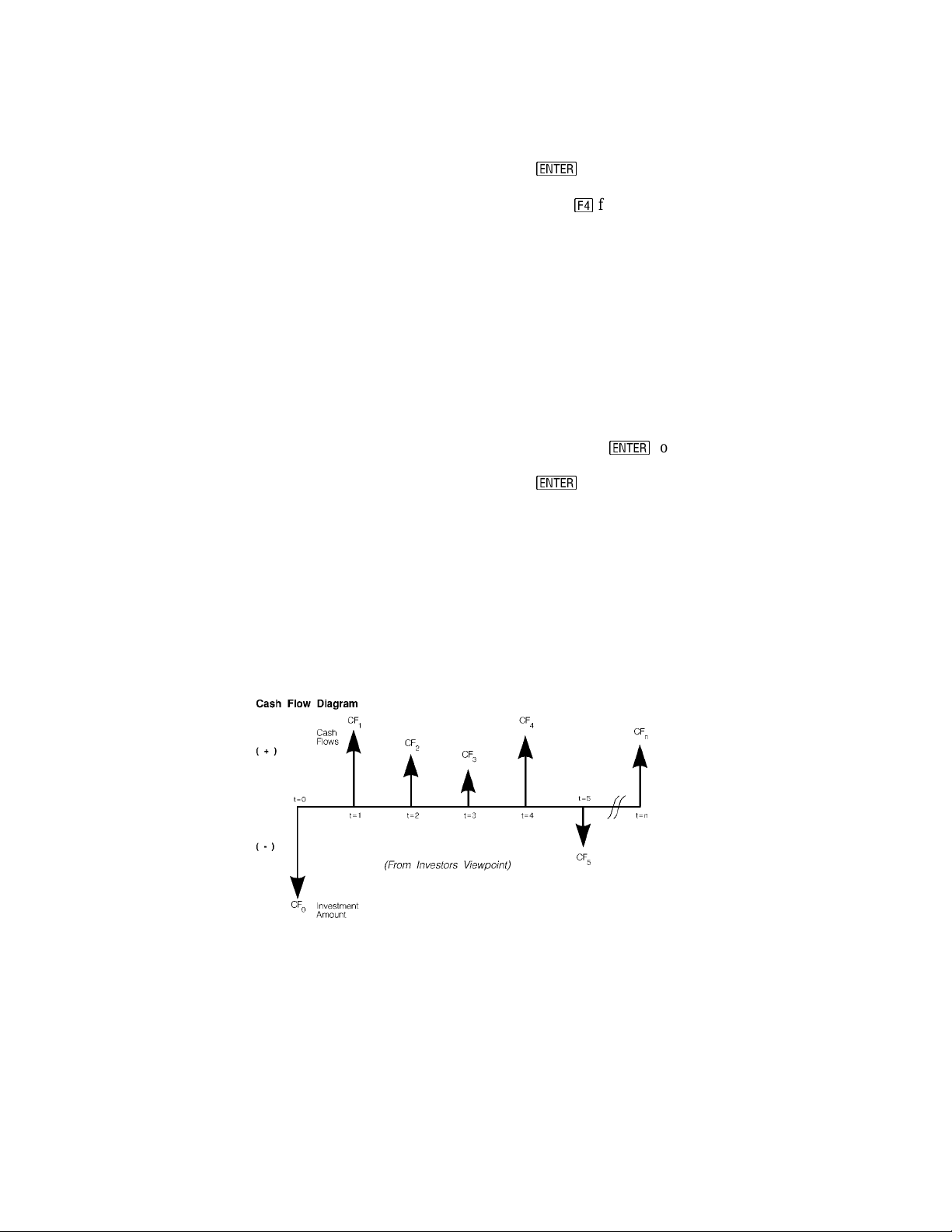

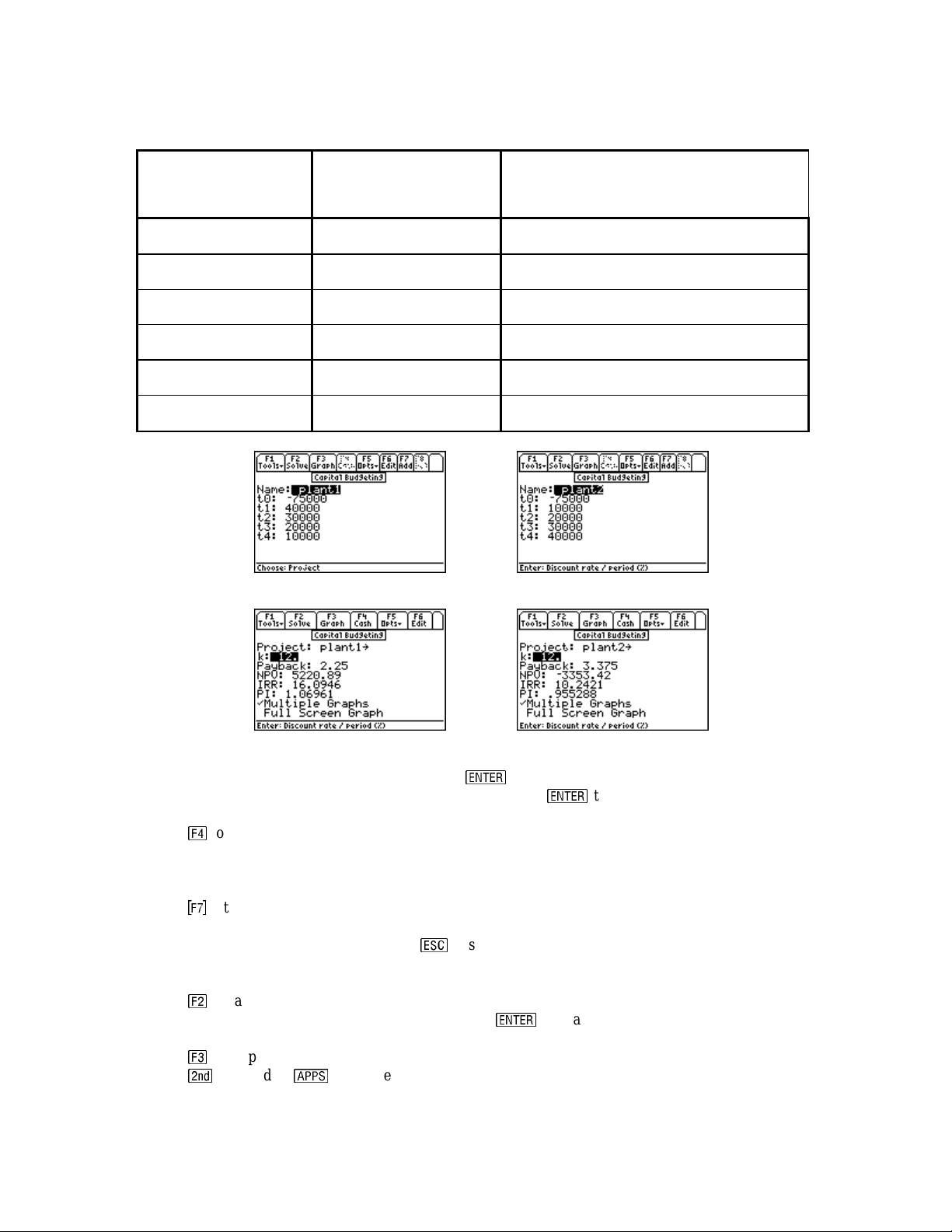

Capital Budgeting: This section performs analysis of capital expenditure for a project and compares

projects against one another. Four measures of capital budgeting are included in thi s section: Payback

period (Payback); Net Present Value (NPV); Internal Rate of Return (IRR); and Profitability Index (PI).

This module provides the capability of entering, storing and editing capital expenditures for nine different

project s. Project s can be graph ed on NPV vs. k scale.

EE for Mechanical Engineers (3 sections): Performs e valuations on three types of circ u its: Impedance

↔∆

calculations; Circuit Performance; Wye

impedance admittance of a circuit consisting of a resistor, capacitor and inductor connected in Series or

Parallel. Performance parameters section computes load voltage and current, complex power delivered,

power factor, m axim u m power a va ilabl e to the l oad, a nd the load i mpedance req u ired t o receive the

maximum power from a single power source. The final segment of the software converts configurations

expressed as a Wye to its ∆∆∆∆ equivalent. It also performs the reverse computation.

Efflux (6 sections): Constant Liquid level; Varying liquid level; Conical Vessel; Horizontal Cylinder;

Large Rectangular Orifice; ASME Weirs (Rectangular notch; Triangular Weir; Suppres s ed Weir; Cipolletti

Weir) This section contai ns methods to compute fluid flow via cross sections of different shapes.

Section Properties (1 2 s ect ions): Rectangle; Hollow Rectangle; Circle; Circular Ring (Annulus); Uneven

I-section; Even I-section; C section; T section; Trapezoid; Polygon (n-s ided); Hollow P olygon (n-sided, side

thickness) Computes are a moment and location of center of mass for diff erent shaped cross sections.

Computed parameters inc lude the cross section area, the pol ar moment o f inertia, the area moment of inertia

and radius of gyration on x and y axes.

Hardness Number: A dimensionless number is a measure of the yield of a material from impact. Brinell

and Vicker developed two popular methods of measuring the Hardness number. These tests consist of

dropping a 10 mm ball of steel with a specified load such as 500 lbf and 3000 lbf. This steel ball results in

an indentation in the material. The diameter of indentation indicate s o f the hardness numbe r using e ither the

Brinell's or Vicker's formulation.

Circuit conversion

Impedance Calcula tions,

computes the

ME⋅Pro for TI -89, TI-92 Plus

Chapter 2- Introduction to Analysis

17

Page 18

2.2 Features of Analysis

Unit Management: Appropriate unit menus for appending units to variable entries or converting computed

results are accessible in most sections.

Numeric Computation – Variable entries must consist of real numbers (unless specified). Algebraic

expressions must consis t of defined variables so a numeri c val u e can be condensed upon entry.

2.3 Finding Analysis

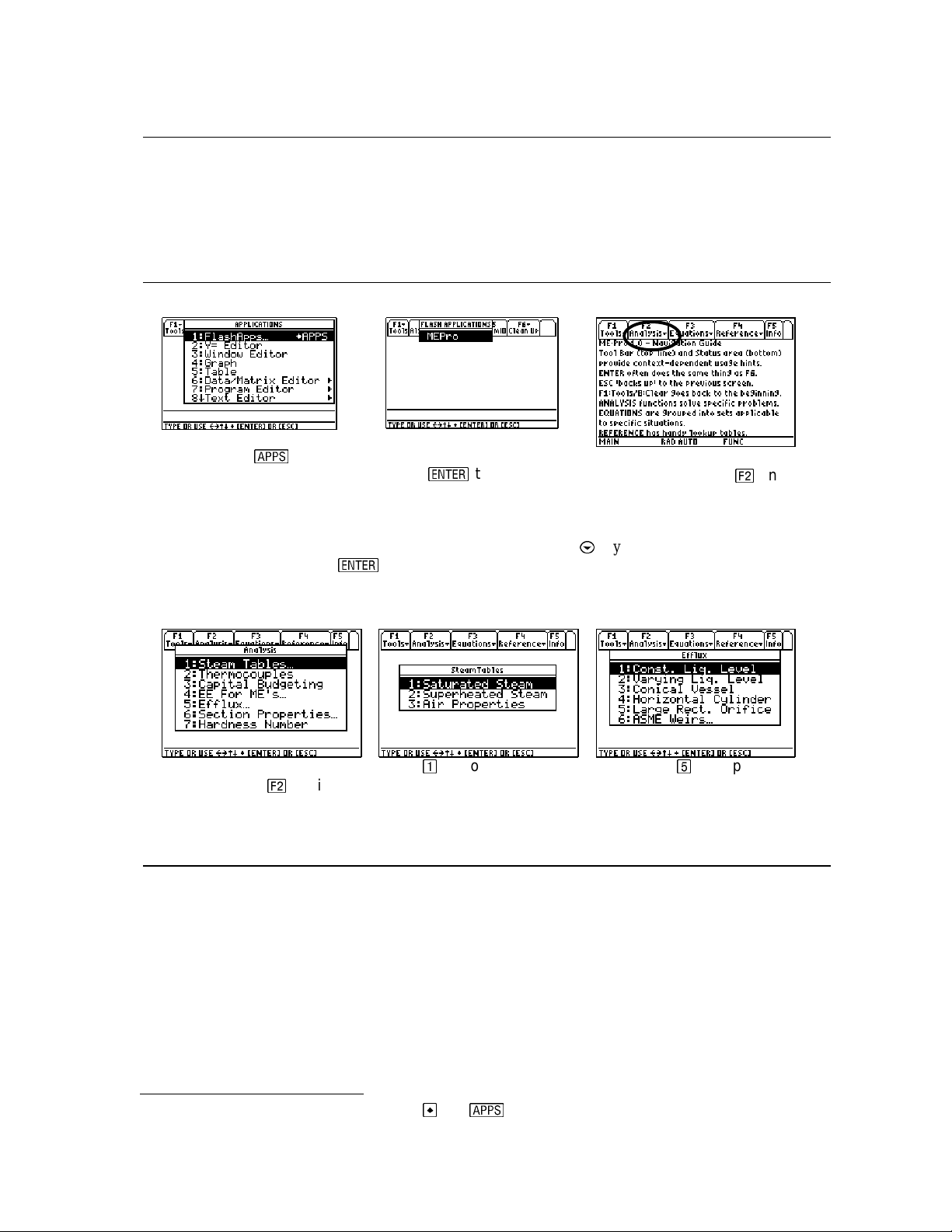

The following panels illustrate how to start ME•Pro and locate the

Analysis

section.

1. Press the

HOME screen to list the

applications stored in your

calculator.

There are seven sections under

desired heading and pressing

/

key in the

Analysis

2. Press 1:FlashApps and

press

to display the

applications stored in the

Flash section of memory.

1

3. HOME screen of ME

Analysis is listed as c on the

top function key row.

Pro.

•

. To sel ect a topic, use t he $ ke y to mov e the highl i ght bar to the

, or alternatively type the number next to the item to select. If a topic

contains several sections (Steam Tables, EE for MEs, Efflux, Section properties, an ellipsis (…) will appear

next to the title (see below).

From t he home screen of

ME•Pro

Press c

to display

Press for topics in

Tables

…

Steam

…or, press Z for topics in

Efflux.

the Analysis menu…

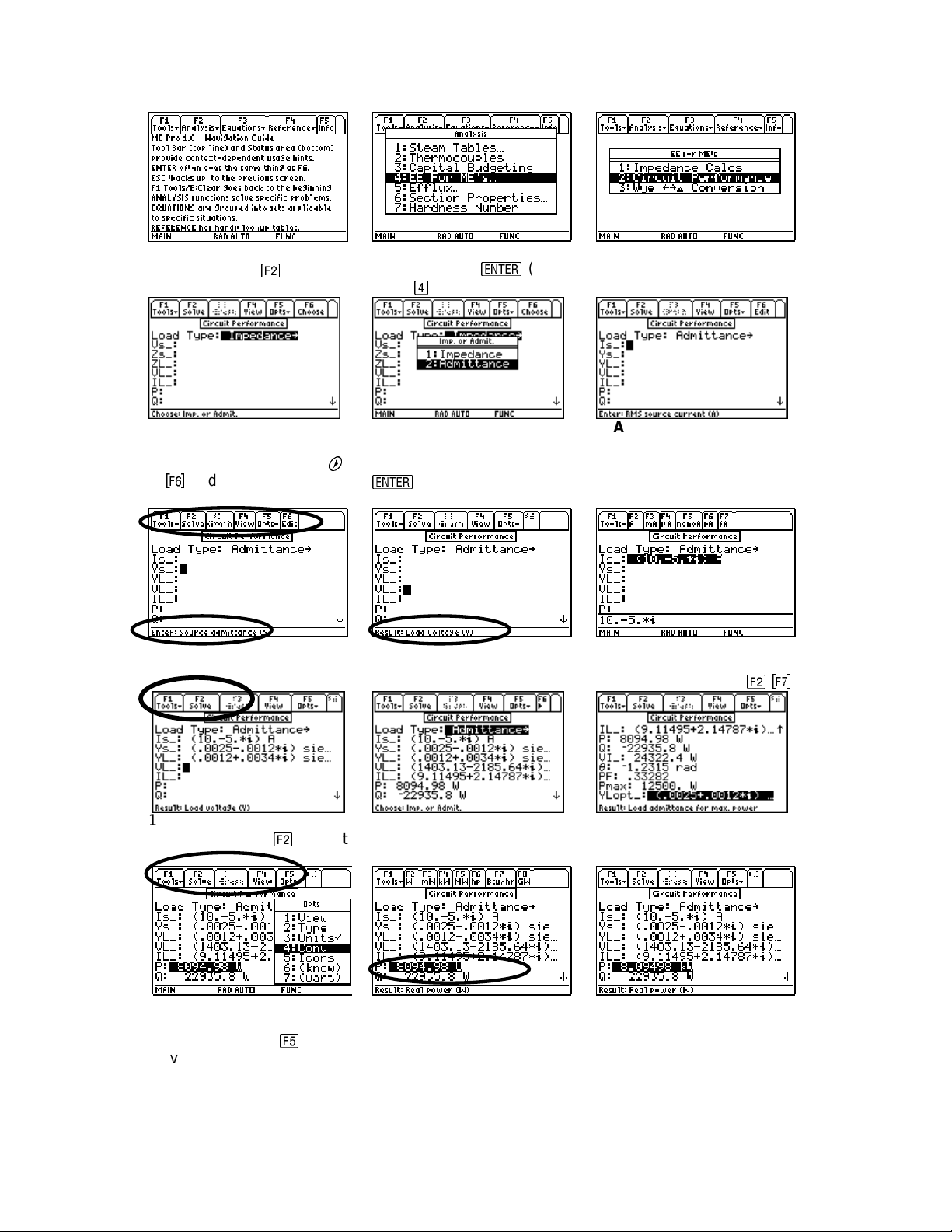

2.4 Solving a Problem in Analysis

The following example presents some of the navigational features in Analysis. This example is drawn from

Chapter 6: EE for MEs.

Problem - Calculate the performance parameters of a circuit consisting of a current source (10 - 5*i) with a

source admittance of .0025 - .0012*I, a load of .0012 + .0034*i. Display the real result of power in

kilowatts.

1

Steps 1 and 2 can be combined by pressing and

ME⋅Pro for TI -89, TI-92 Plus

Chapter 2- Introduction to Analysis

/

.

18

Page 19

1. From the home screen of

Pro, Press c to display

ME

•

the menu of Analysis.

4. While the cursor is

highlighting Load Type,

press the right arrow key,

or g to display the menu for

Load Type.

7. Variable descriptions

beginning with ‘Enter’ require

numeric entries.

2. Move the cursor to EE for

MEs and press

press Y).

5. In the menu for Load

Type move the cursor to

Admittance and press

.

(or

3. Select Circuit

Performance from the

submenu in EE for Mes.

6. Admittance is now

selected for Load Type and

the appropriate variables are

displayed.

8. Variable descriptions

beginning with the word

‘Resu lt’ are computed fields.

9. When entering a value,

press a function key to add

the appropriate units (c-h).

10. Following entry of all

input fields, pres s c: Solve to

compute the results.

13. To display a result in

different unit s , highlight the

variable and press f:Opts

move the cursor to 4

:Conv.

ME⋅Pro for TI -89, TI-92 Plus

Chapter 2- Introduction to Analysis

11. Results: Upper Half 12. Results: Lower Half

14. The unit menu for the

variable appears in the top

bar. Press t he func tion key

,

15. The computed value for

Real Power, P, is now displaye d

in kilowatts (kW).

corresponding to the desired

units.

19

Page 20

There are two types of interfaces in

Type 1: Input/Output/Choose Fields (Steam Tables, Thermocouples, EE for MEs, Efflux, Section

Properties, and Hardness Number). This input form lists the variables for which a numeric entry is required

and prompts the user to choose a calculation setting if applicable before computing the results. The entries

and results are always displayed in the same screen.

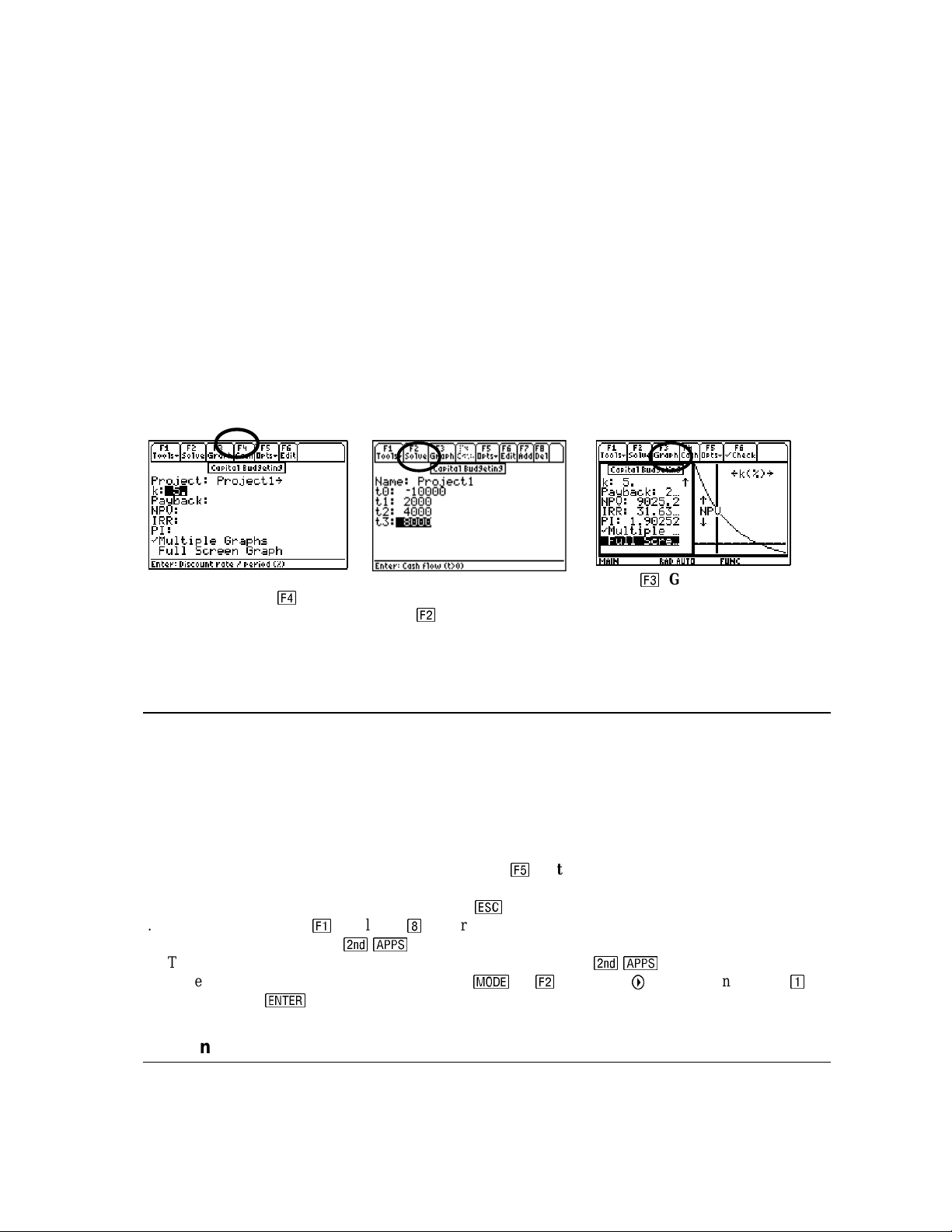

Type 2: Multiple Forms/Graphing (Capital Budgeting) This interface includes most of the features of

Type 1 with the additional screens used for entering cash flow for individual projects. The graphing

feat ures of t he calculator are enabled i n t his section for v i sualizing the rate of return (Net Present Value vs.

discount rate). An example of this interface is described briefly in this chapter, but in mor e detail in Chapter

5: Capital Budgeting.

Capital Budgeting

relevant data such as

displays below illustrate the basic user interface.

Input Screen for Capital

Budgeting

display Cash Flow for Project

1.

. Press e to

allows the user to compare relative financial performance of several projects with

Interest rate or discount rate (k), IRR, NPV, or Payback period. The screen

Analysis

A separate screen displays

the Cash Flow for ‘Project 1’.

Press c: Solve to r evert to

the previous screen.

:

Press d: Graph. Select ing

‘Multiple Graphs’

overlap of plots for different

projects (Projec t 1, Project 2,

etc.)

allows the

2.5 Tips for Analysis

The following instructions are useful in the Analysis section:

1. If an ellipsis (…) appears at the end of a menu title, a menu of subtopics exists i n this se ct i on .

2. An arrow ‘→→→→’ to the right of a heading, as in Load T ype, indicates an additional menu.

3. Variables ending with an underscore ‘_’, such as Vs_, Zs_, and IL_, allow complex values.

4. Descriptions for variables generally appear in the status line when the variable is highlighted.

5. Variables for which an entr y is required will have a description prefaced by the word ‘Enter’.

Computed variables begin with the word, ‘Result’.

To convert values from one unit to another, press

6.

th e variable at t h e top of the screen. Press the functio n key co rresponding to the appropriate units.

7. To return to the previous level of ME•Pro, press ..

8. To exit ME•Pro, press b: Tools and N: Clear.

9. To return to ME•Pro, p ress

10. To toggle between a graph and ME•Pro in split-screen mode, press

11. To remove the split screen in ME•Pro. 1) Press

Full Screen, 5)

: Save.

/

.

f:Opts, and 4:Conv to dis play the unit menu for

/

.

, 2) c: Page 2, 3) ": Split Screen App., 4) :

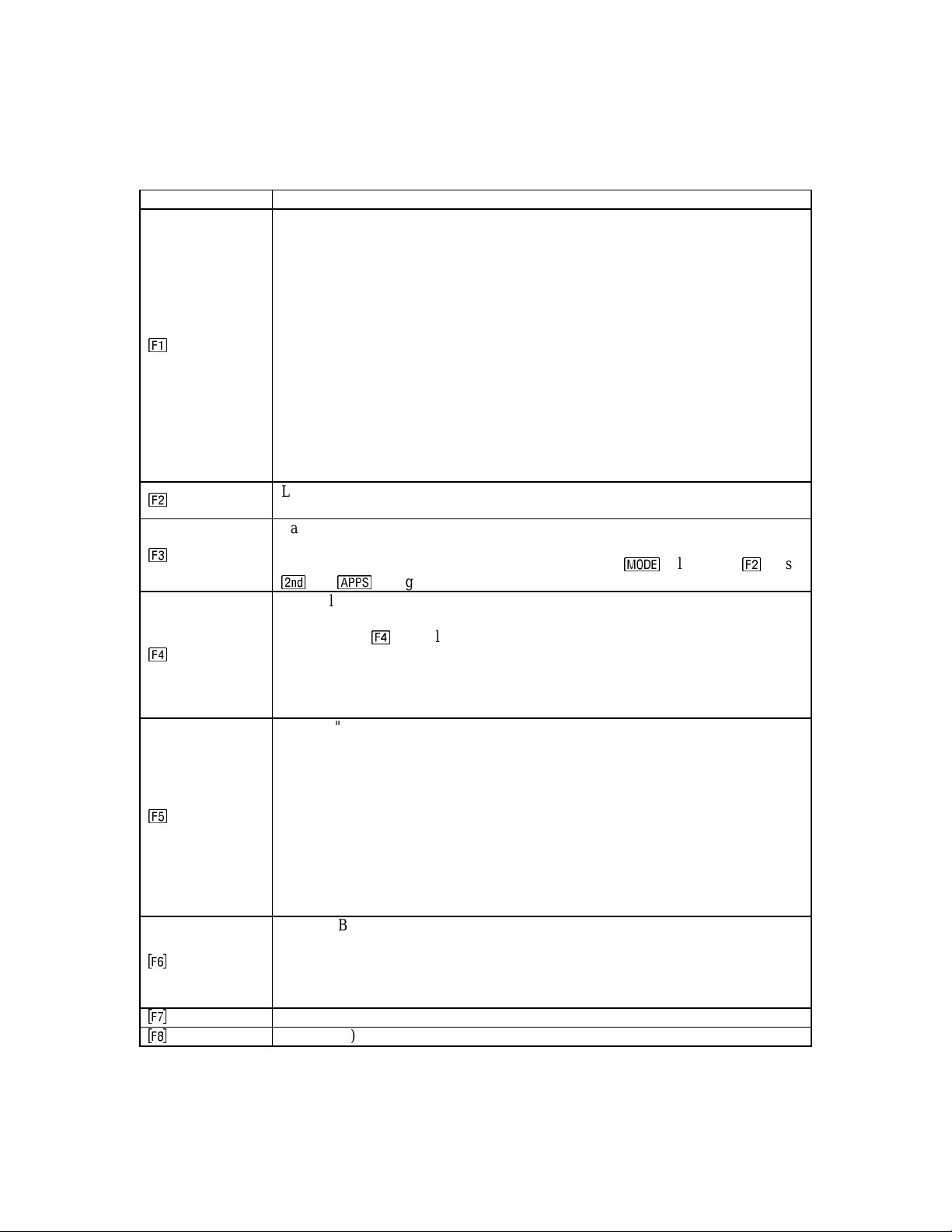

2.6 Function keys

Analysis

When

are s p ecific to the cont ex t of the section. Th ey are listed in Table 2-1:

functions are selected, the function keys in the tool bar access or activate features, which

ME⋅Pro for TI -89, TI-92 Plus

Chapter 2- Introduction to Analysis

20

Page 21

Table 2-1 Description of Analysis Function keys

Function Key Description

and

Tools

Solve

Graph

/

b

c

d

e

Labeled "

screen level. Th ese fu nctions are:

1: Open – This opens an existing folder to store or recall variables used in an

ME•Pro session.

2: (save as) – Not active in Analysis.

3: New – Creates a new folder for storing variable values used in an ME•Pro

session.