Telcoma STONE 300 GR, STONE 400 GR, STONE 600 GR Installation Manual

IO 18/E Rev. 00

OPERATORS FOR SWING GATES

STONE 300-400-600 GR / 220V

INSTALLATION MANUAL

Our compliments for your excellent choice. The STONE 300-400-600

GR electro-mechanical gear motor has been produced for reliability

and high quality.

This Manual will offer information you may need to install your gear

motor assuring long-lasting performance and to safeguard your safety.

HOWEVER CAUTION IS UNQUESTIONABLY INDISPENSABLE

AND NOTHING IS BETTER THAN PREVENTING ACCIDENTS.

GR products have been made to conform with rules and laws in force

at time of manufacture.

This manual is designed exclusively for the specialized

installation expert in the criteria of construction and equipment to

assist in the protection against accidents in the installation and use of

the gate; door and automation of such gates (adhere to the rules and

laws in force).

On completion the installer should issue to the end consumer an

instruction manual according to EN 12635.

Before proceeding with the installation the installer must provide

an analysis of the identification and management of risks as per the

standards EN 12453 and EN 12445.

All wiring of the various external electrical components

connected to the automation (e.g. Photocells, flashing lights, keypads

etc) must be carried out according to EN 60204-1 and the

amendments made of the point 5.2.2 of EN 12453.

It is prohibited to do any repair or adjustment of the equipment if

you have not taken all necessary precautions to avoid possible

accidents (example: power supply disconnected, engine block). All

mechanisms in motion must be equipped with appropriate protections.

The mains power line must be protected for maximum current in

locked rotor condition as per government electrical laws.

Install the gear motor on gates that conform to EN 12604.

Perform the measure of strength developed by the gear motor

and adopt the measures as per EN 12445.

Positioning photocells: These safety devices must be installed at

a height not exceeding 70cm from the ground and at a distance from

the floor movement of the door of no more than 20cm. Their proper

functioning of the photocells must be verified at the end of installation

according to Section 7.2.1 of EN12445.

Keep the activation controls of automation out of reach of

children. The controls should be installed at a minimum 1.5m height

above the ground and outside the range of actions of moving parts

such as the gate.

All activation actions must be executed only at points from

where the automation is fully visible.

Operate the remote only in view of automation.

Store carefully this manual in a suitable place known to all

interested people.

Any unauthorized and arbitrary modification made to this

product, releases the company CARDIN ELETTRONICA Spa and

from any liability resulting from damage or injury to things, people or

animals.

The non-observance of regulations and of safety standards here

listed releases the company CARDIN ELETTRONICA Spa from any

liability resulting from damage or injury to things, people or animals.

The automation must be coupled to a control board equipped

with torque regulation that provides an anti crushing safety as

described in EN 12453 - EN 12445

SAFETY RULES

During the installation and the use of the automation, pay attention to

the following safety rules:

Distance security!

Mechanisms moving!

Do not install automation in an environment saturated with

explosive mixtures!

Electric Shock!

Use gloves!

Use welding glasses!

Maintain ear protection!

MAINTENANCE

All repairs must be carried out by qualified people.

Before each intervention remove power through the switch and

lock in that position

The equipment must be maintained so as to preserve the

conditions that ensure safe and efficient operation

Always use original spare parts

Do not make interventions that modify the machine.

The modified equipment requires new CE mark

The settings of the operator must be performed by qualified

personnel, in accordance with the rules of reference. During these

operations provide the presence of two operators for safety.

IO 18/E Rev. 00

DEMOLITION

You have to operate the elimination of the materials in conformity with

the regulations in force. All materials must be divided by type (copper,

aluminium, plastic, electrical parts, etc)

DISMANTLING

In order to move away the automation, follow these instructions:

1 - cut off the power supply and disconnect the electrical installation;

2 - dismantle the control console and all the other components of the

installation.

If you have noticed that some components have been damaged, you

have to replace them.

CONFORMITY DECLARATION:

It’s in accordance with Machine Directive 39/89/CE and following

modify.

It’s in accordance with the following directive CE:

Electromagnetic compatibility Directive 89/336/CEE and following

modify.

Low tension Directive 73/23/CEE and following modify.

Have been applied the following harmonized norms:

EN292/1/2, EN 294, EN60335-1, UNI EN 12453, and what applicable

of the EN12445-2000.

USE OF THE AUTOMATION

The gearmotor STONE 300-400-600 GR was designed and built for

the opening of gates with max of 5 m leaf or weight max. 200kg. The

CARDIN ELETTRONICA Spa assumes no responsibility for a purpose

other than that provided by gearmotor STONE 300-400-600 GR. Since

automation can be put into motion in view by button or remotely by

remote control, it is essential to check frequently the perfect efficiency

of all safety devices. It is advisable to check periodically (every six

months) the regulation of electronic friction of which must be equipped

the electronic control board.

PRELIMINARY CHECKS

1 - Read carefully the instructions enclosed in this manual.

2 - Make sure that the gate has a rather solid structure and that there

is no friction points in its movement.

3 - Make sure that the leaf is suitably balanced, even after the

installation of the gear motor.

4 - Check that the electrical installation is in accordance with the

characteristic required by the gear motor.

TECHINICAL DATA

SCHEDULED MAINTENANCE

DESCRIPTION

FREQUENCY

ENTRUSTED

OPERATION

Photocells cleaning

Monthly

Operator

Clean with damp cloth

Control of gate hinges and supports, balancing of the

gate

Annual

Operator

Check the status of welds and corrosion.

Unhook the engine and check the

balancing and the eventual points of

friction.

Controlling the sensitivity of electronic friction (torque

adjustment) of the control board.

Semiannual

Technician

Check the adjustment of the couple as

described in EN 12453 - EN 12445

Monitoring current dispersion

Annual

Technician

Verify that the dispersion of current is

less than 7.5 A

Control of signals

Semiannual

Operator

Verify that the safety warning signage is

complete and intact

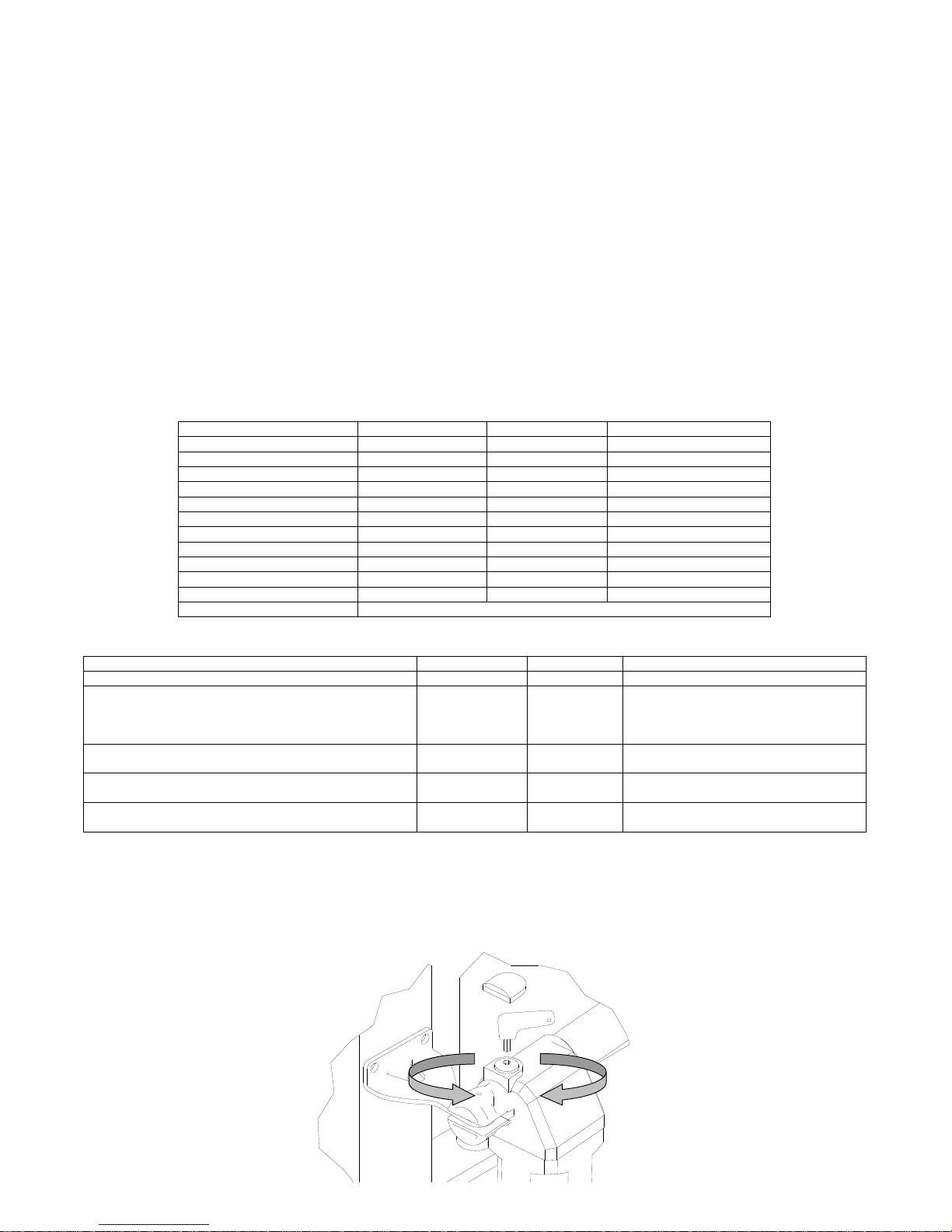

EMERGENCY MANOEUVRE

For the manual door locking and unlocking act with the supplied key on the screw C (See FIG 1-2).

1 - Remove the protection cap

2 - insert the key into the seat allocation as in Figure 1

3 - Turn the key in the sense of the arrow to the top of the gearmotor to unlock and in the opposite block.

STONE 300 GR

STONE 400 GR

STONE 600 GR

Maximum length of the gate

3,0m

4,0 m

5,0 m

Maximum weight of the gate

200Kg

200Kg

200Kg

Stroche

30cm

40cm

60cm

Power

180 W

180 W

180 W

Power supply

220 V

220 V

220V

Absorption

0,9 A

0,9 A

0,9 A

Max. Thrust

1600 N

1600 N

1600 N

Operating temperature

-25°C +60°C

-25°C +60°C

-25°C +60°C

Opening time

17sec.

22sec.

33sec.

Thermal protection

150°C

150°C

150°C

Use frequency

35%

35%

35%

Lubrication

GREASE

ANTICLOCKWISE:

RELEASED

CLOCKWISE:

BLOCKED

FIG 1

IO 18/E Rev. 00

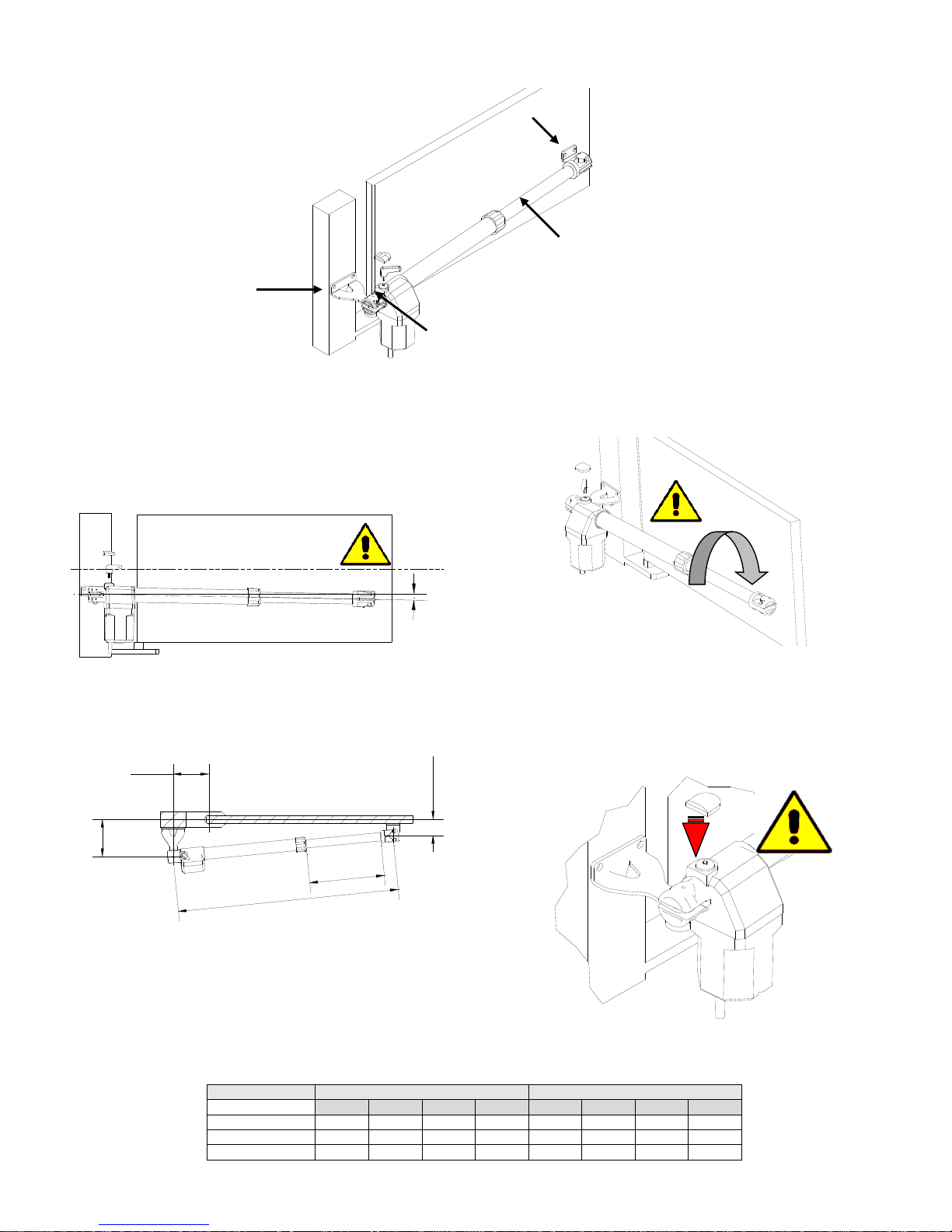

INSTALLATION

INSTALLATION

To operate a good installation of the gear motors STONE 300-400-600

GR, follow these instructions:

1 - Open the box and take out gear motor. Make sure that it has not

been damaged during the transport.

2 - Make sure that the leaf of the gate is perfectly horizontal.

3 - Place the gear motor inclined approximately 1º below the

horizontal line(picture 3 )

1°

4- Fix the support plate A on the pillar beside the leaf, taking in account

the measures shown in Table 1. Do not forget inclination.

1°

Z

W

6.0

Y

X

5 - Install the gear motor on to the support plate A and fix it with the bolt.

6 - With gate’s leaf closed, turn and slide the screw of gear motor’s D

shaft, until the end of the stroke-

7 - Screw D shaft back on 1 complete turn of 360º. (picture5)

8 - Place B support plate in the hole of D shaft and position it against

the gate leaf. Fix it to the gate leaf taking in account the inclination

(point nr.3).

9 - Proceed in the same way with the other gate leaf.

10 - Connect the electrical wires and safety devices: Place the

mechanical limit stops

11 – Place the cover on the unblocking screw (C) (picture 6)

TAB 1

MOTOR

ROTATION 95 °

ROTATION 120 °

W X Y Z W X Y Z

STONE300

922

140

140

378

922

160

120

378

STONE400

1122

145

145

478

1122

170

110

478

STONE600

1532

280

280

678

1532

310

120

678

A

A – Pillar bracket

B – Gate bracket

D – Piston rod

C – Release

FIG 2

360°

FIG 3

FIG 4

FIG 5

FIG 6

IO 18/E Rev. 00

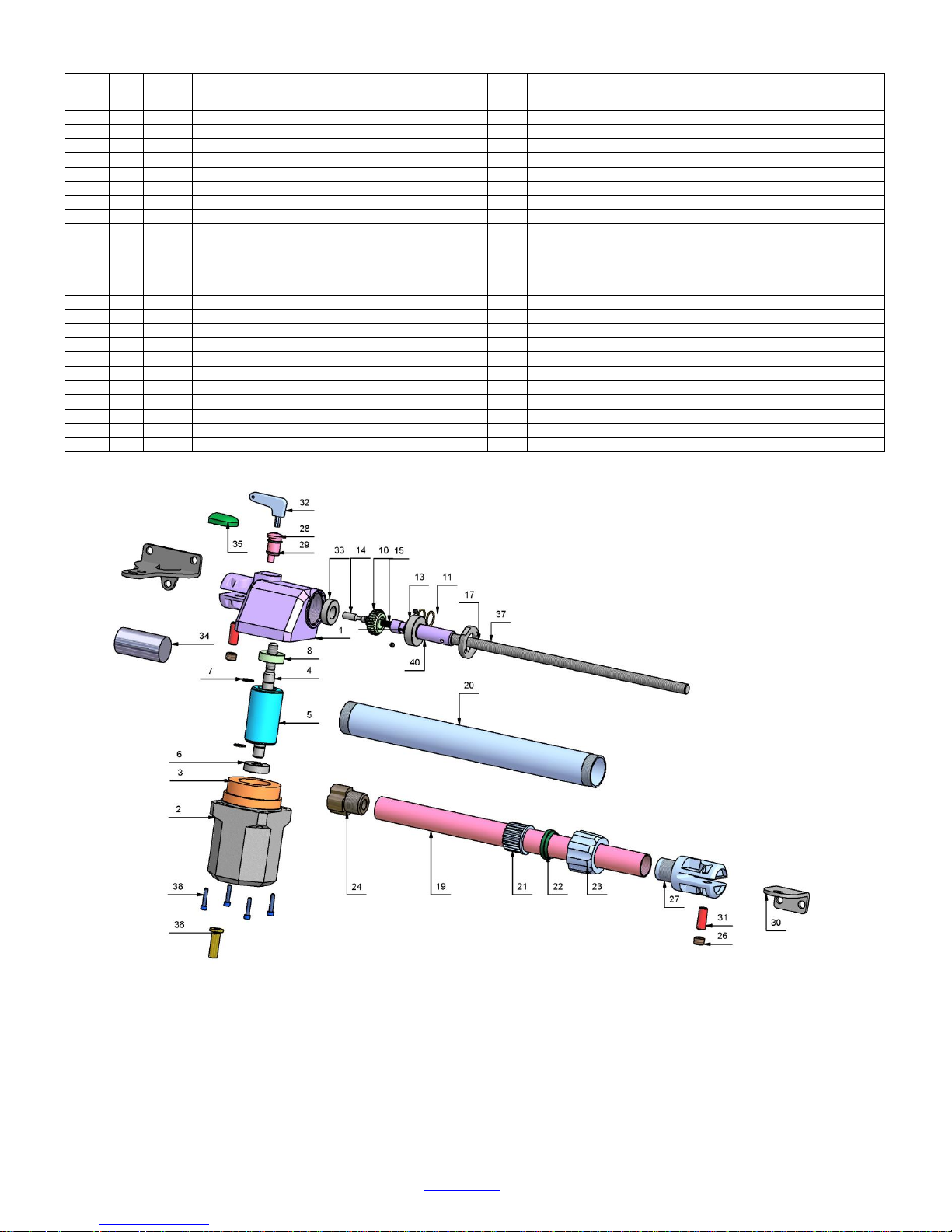

SPARE PARTS

PART

QTy

CODE

DESCRIPTION

PART

Q.TY

CODE

DESCRIPTION

1 1 100645

REDUCTION GEAR COVER LF. BLACK

20 1 100715

BLACK ALUMINIUM TUBE 400mm STROKE

1 1 100644

REDUCTION GEAR COVER RG. BLACK

20 1 100763

GREY ALUMINIUM TUBE 400mm STROKE

1 1 100759

REDUCTION GEAR COVER LF. GREY

20 1 100739

BLACK ALUMINIUM TUBE 600mm STROKE

1 1 100758

REDUCTION GEAR COVER RG. GREY

20 1 100764

GREY ALUMINIUM TUBE 600mm STROKE

2 1 100647

MOTOR CASING RG. BLACK

21 1 100829

PISTON ROD GUIDE

2 1 100761

MOTOR CASING RG. GREY

22 1 100625

SCRAPER RING

3 1 100840

STATOR 220V 4 POLES 45mm 1400rpm

23 1 100827

PISTON ROD LOCK NUT

4 1 100651

IRREVERSIBLE MOTOR SHAFT

24 1 100828

FEMALE SCREW

5 1 100841

ROTOR 45mm

25 1 100823

WALL BRACKET

6 1 100278

BEARING 6202 ZZ

26 2 100705

GRUB SCREW M14X10

7 2 100706

HELASTIC RING E15

27 1 100646

ALUMINIUM PISTON ROD TERMINAL BLACK

8 1 100291

BEARING 6202 2RS

27 1 100906

ALUMINIUM PISTON ROD TERMINAL GREY

10 1 100650

IRREVERSIBLE TOOTH WHEEL

28 1 100624

ALUMINIUM UNCLAMPING

11 2 100789

HELASTIC RING E20

29 2 100657

O-RING

12 1 100709

BEARING 6004 ZZ

30 1 100825

GATE BRACKET

13 2 100658

TOWING BALL

31 2 100654

PIN

14 1 100655

UNCLAMPING PIN

32 1 100218

UNCLAMPING KEY

15 1 100641

UNCLAMPING SPRING

33 1 100707

BEARING 6003 ZZ

17 1 100661

ALUMINIUM LOCK NUT

34 1 100184

CAPACITOR 8µF

17 100909

FIBRE LOCK NUT

35 1 100755

UNCLAMPING CAP

19 1 100712

STAINLESS STEEL TUBE 300mm STROKE

36 1 100748

CABLE PRESS

19 1 100713

STAINLESS STEEL TUBE 400mm STROKE

37 + 40

1

100716 + 100998

ENDLESS SCREW 40 + release shaft

19 1 100738

STAINLESS STEEL TUBE 600mm STROKE

37 + 40

1

100717 + 100998

ENDLESS SCREW 50 + release shaft

20 1 100714

BLACK ALUMINIUM TUBE 300mm STROKE

37 + 40

1

100740 + 100998

ENDLESS SCREW 70 + release shaft

20 1 100762

GREY ALUMINIUM TUBE 300mm STROKE

38 4 100313

CAP SCREW M5X16

CARDIN ELETTRONICA Spa

Via Del Lavoro, 73

31013 Codognè, Fraz. Cimavilla TV

Tel. +39 0438 404011 Fax. +39 0438 401831

www.cardin.it

1

ZVL933.00 Mod: 12-05-2016

ITALIANO

ENGLISH

FRANÇAIS

DEUTSCH

ESPAÑOL

ATTENTION! Before installing this device read the

following instructions carefully!

Conformity declaration Page 2

Important remarks Page 8

Electrical connection Pages 8-9

Programming procedure Pages 10-11

Remote control Page 12

Function modes Page 12

Indications on the display Page 12

Technical specications Page 28

ATTENTION! Avant de commencer la pose, lire attentivement les instructions!

Déclaration de conformité Page 2

Consignes importantes Page 13

Branchement électrique Pages 13-14

Procédé de programmation Pages 15-16

Commande via radio Page 17

Modes de fonctionnement Page 17

Indications de l’afcheur Page 17

Caractéristiques techniques Page 28

ACHTUNG! Bevor mit der Installation begonnen wird,

sollte die Anleitung aufmerksam gelesen werden.

Konformitätserklarung Seite 2

Wichtige Hinweise Seite 18

Elektrischer Anschluss Seiten 18-19

Programmierverfahren Seiten 20-21

Funkbefehl Seite 22

Betriebsmodus Seite 22

Displayanzeigen Seite 22

Technische Eigenschaften Seite 28

¡ATENCIÓN! Antes de iniciar la instalación del sistema,

leer atentamente las instrucciones.

Declaración de conformidad Página 2

Advertencias importantes Página 23

Conexionado eléctrico Páginas 23-24

Procedimiento de programación Página 25-26

Mando vía radio Página 27

Modalidad de funcionamiento Página 27

Indicaciones en el display Página 27

Datos técnicas Página 28

ATTENZIONE! Prima di iniziare l'installazione leggere

le istruzioni attentamente!

Dichiarazione di conformità Pagina 2

Avvertenze importanti Pagina 3

Collegamento elettrico Pagine 3-4

Procedura di programmazione Pagine 5-6

Comando via radio Pagina 7

Modalità di funzionamento Pagina 7

Indicazioni del display Pagina 7

Caratteristiche tecniche Pagina 28

230 Vac Motors

PROGRAMMATORE ELETTRONICO PER IL COMANDO DI PORTE E PORTONI MOTORIZZATI

ELECTRONIC PROGRAMMER CONTROLLING MOTORISED GATES AND DOORS

PROGRAMMATEUR ÉLECTRONIQUE POUR LA COMMANDE DE PORTES ET PORTAILS MOTORISÉS

ELEKTRONISCHER STEUERUNGSEINHEIT FÜR DIE AUTOMATISIERUNG VON TÜREN UND TOREN

PROGRAMADOR ELECTRONICO PARA EL CONTROL DE LAS PUERTAS MOTORIZADAS

Questo prodotto è stato testato e collaudato nei laboratori della casa costruttrice, la quale ne ha verificato la

perfetta corrispondenza delle caratteristiche con quelle richieste dalla normativa vigente. This product has been

tried and tested in the manufacturer's laboratory who have verified that the product conforms in every aspect to

the safety standards in force. Ce produit a été testé et essayé dans les laboratoires du fabriquant. Pour l'installer

suivre attentivement les instructions fournies. Dieses Produkt wurde in den Werkstätten der Herstellerfirma

auf die perfekte Übereinstimmung ihrer Eigenschaften mit den von den geltenden Normen vorgeschriebenen

getestet und geprüft. Este producto ha sido probado y ensayado en los laboratorios del fabricante, que ha

comprobado la perfecta correspondencia de sus características con las contempladas

por la normativa vigente.

Model

Date

Instruction manual

Series

PRG230M2

V0.2

01-04-2016

ZVL593.00

CARDIN ELETTRONICA spa

Via del lavoro, 73 – Z.I. Cimavilla

31013 Codognè (TV) Italy

Tel: +39/0438.404011

Fax: +39/0438.401831

email (Italian): Sales.office.it@cardin.it

email (Europe): Sales.office@cardin.it

Http: www.cardin.it

V. 02.2017

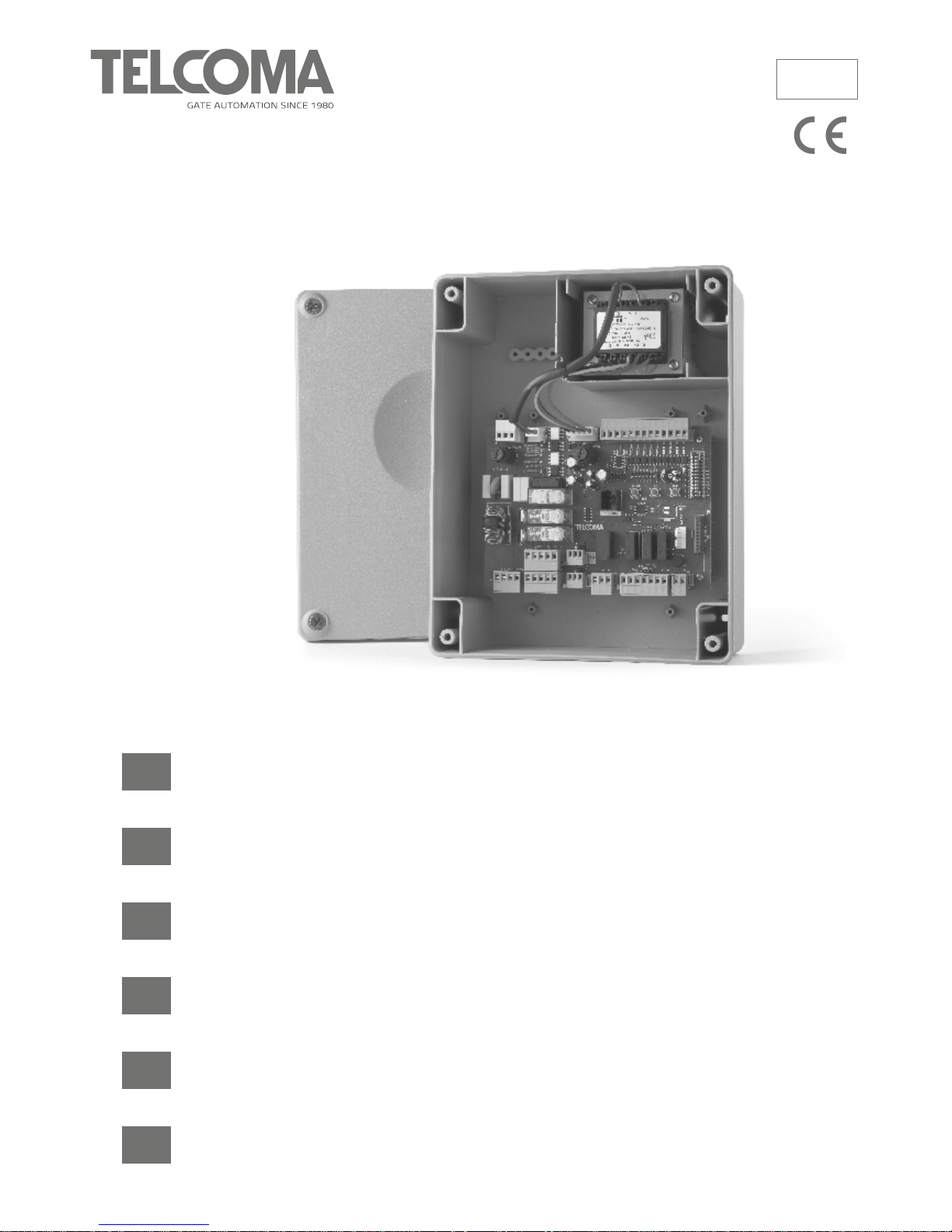

ZVL601

CENTRALE COMANDO PER 1-2 MOTORI 230V

Istruzioni d’uso e di programmazione

CENTRALE DE COMMANDE POUR 1-2 MOTEURS 230V

Notice d'emploi et de programmation

CENTRAL DE MANDO PARA 1 O 2 MOTORES DE 230 V

Instrucciones de uso y programación

ELECTRONIC CONTROL UNIT FOR 1 or 2 230V-MOTORS

Programming and user instructions

STEUERZENTRALE FÜR 1-2 MOTOREN MIT 230V

Gebrauchs- und Programmierungsanweisungen

BESTURINGSKAST VOOR 1-2 230V MOTOREN

Gebruiksaanwijzing en programmeerinstructies

I

F

E

GB

D

NL

mod. T600

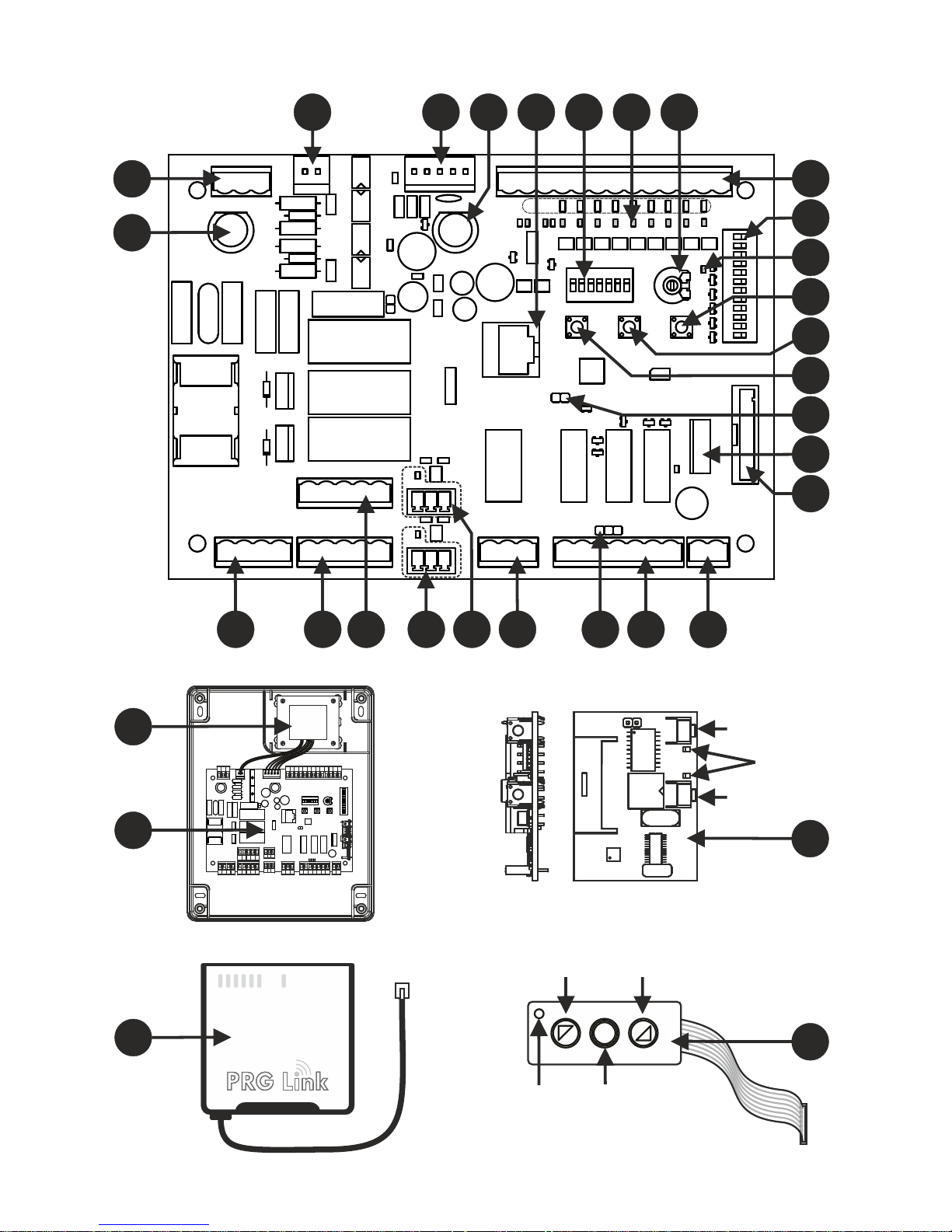

1

2

28

29

P1 (P/P)

STOP*

PA

Spia

PC

P2 (PED)

Led

3 4 5 86 9 10

12

14

15

16

18

19

20

13

17

11

22 21232627 2425

7

Art. XXXOC2

Art. TAST 3F

30

32

31

MEMORIA

Fig. A Fig. B

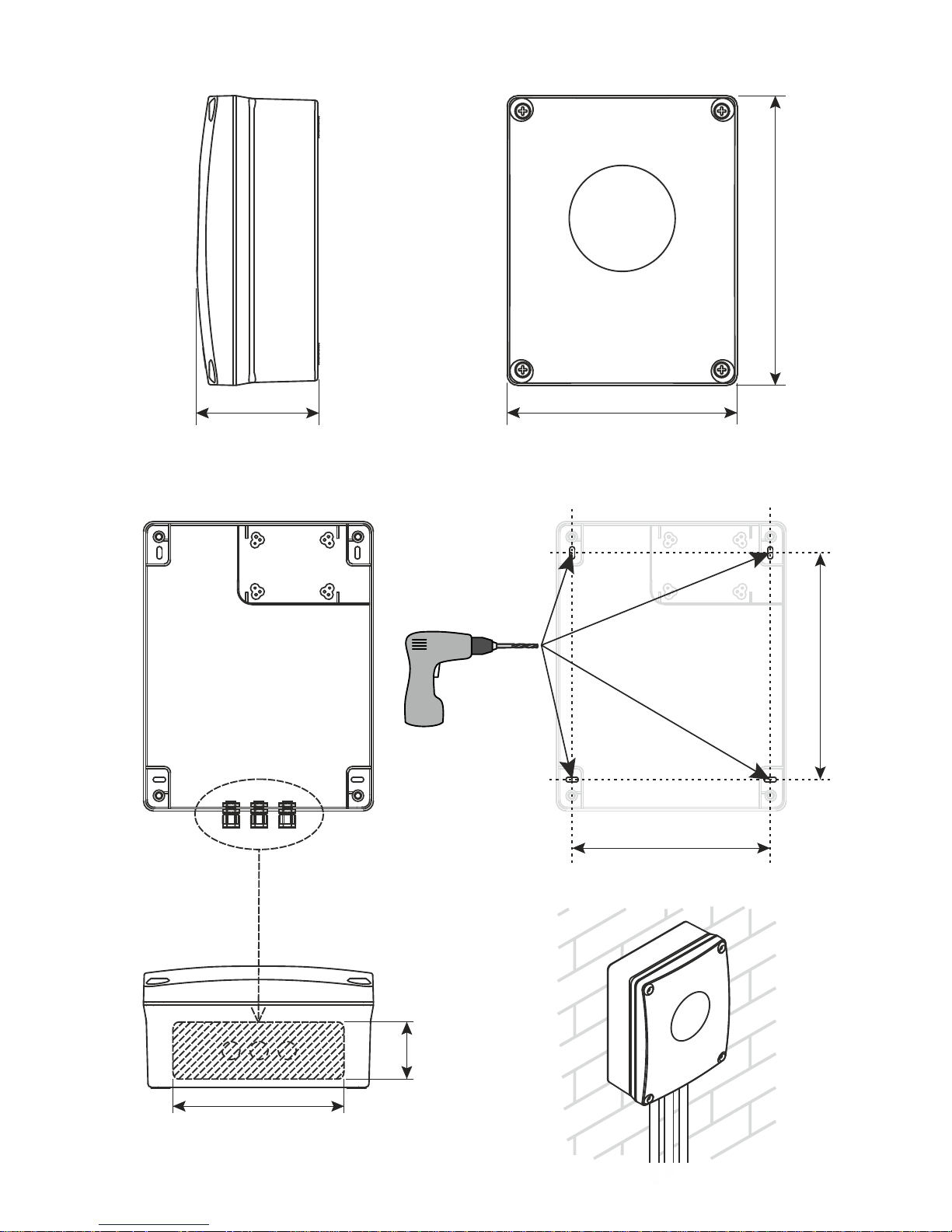

1

7

222

190

150

50

118

280

220

(mm)

8

Loading...

Loading...