Page 1

- Data Brochure

Snow Detector & Melting Control 662

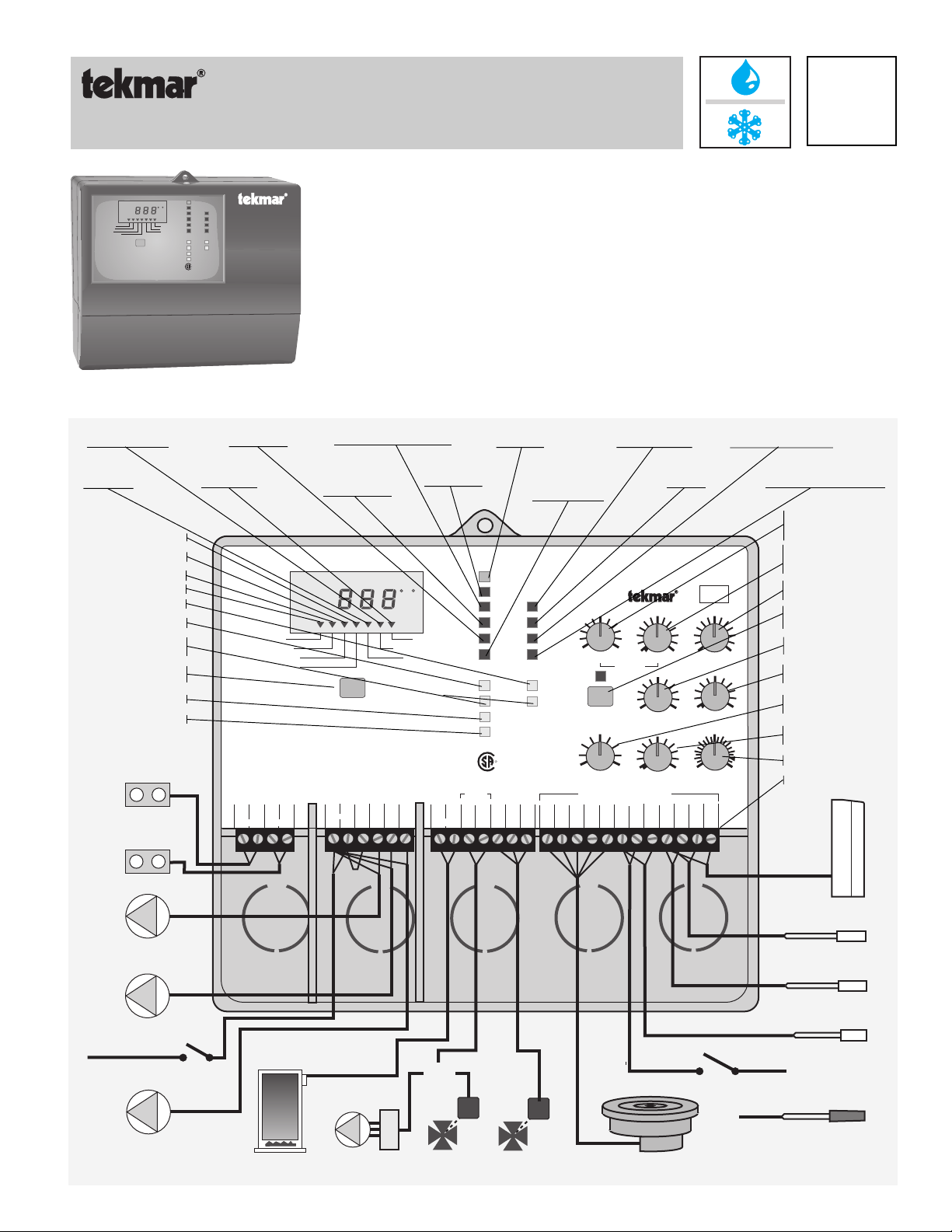

The tekmar Snow Detector & Melting Control 662 is a microprocessor-based control which,

OUTSIDE

FC

Supply

Return

Slab

Boiler Return

To change between

°F and °C, press and

hold for 1 sec.

Item

Snow Detector & Melting Control 662

Mixing Operation

Power

Remote

CWCO

WWCO

Idling

Melting

Maximum

Water

Target ∆T

Actual ∆T

% Output

∆T

Maximum

Minimum

Supply

Return

Pump 1

Pump 2

Closing

Opening

Boiler

Warning

R

LR 58223

NRLT/C

together with the Snow/Ice Sensor 090, activates and controls the rate of heat delivery to a snow

melt system. This versatile control has three modulating outputs to control the heat delivery for

most pump and/or valve arrangements. Protection of both the snow melt slab and the boiler is

achieved through several safety features. Faster pick up times are also ensured through a

viscosity compensation function which optimizes the rate of heat delivery to the slab during start

up. The 662 combines all the necessary features to make snow melting safe and trouble free.

Sequence of Operation pg. 2

Installation . . . . . . . . . . pg. 3

Settings . . . . . . . . . . . . pg. 7

Display Operation . . . . pg. 8

D 662

07/99

Testing . . . . . . . . . . . . . pg. 9

Error Messages . . . . . . pg. 10

Technical Data . . . . . . . pg. 12

Limited Warranty. . . . . pg. 12

Relative Energy

usage in ∆T x Hours

Boiler return

temperature

Target slab ∆T

Actual slab ∆T

Supply temperature to slab

Slab surface temperature

Boiler pump is on

System pump is on

Valve is

opening/closing

LCD display

item select

Boiler operating

Fault warning

Output:

Melt relay is closed

when control is

in melting mode.

Output:

Warning relay is

activated if sensor

fault is detected

Water is detected

by the sensor

Current % Heat

Output to slab

Slab

Supply

Actual ∆T

Target ∆T

The Snow/Ice Sensor is installed in a hostile environment.

It should be cleaned and checked on a regular basis.

Snow Detector & Melting Control 662

Floating / Variable Speed / 4-20 mA

Use Nº 20 AWG or larger copper conductors rated for at least 75°C / 300V

1

3

2

4

Warning

Melt

Slab is warm enough,

no snow melting is required

Snow detected:

control is in

Melting mode

To change between

°F and °C, press and

hold for 1 sec.

Item

5

78

6

Com

Power

P1

Pmp

Pmp

N

Pmp

L

OUTSIDE

FC

% Output

Usage (∆T x hrs)

Boiler Return

9

10

P2

Var

Pmp

Remote Enable

Signal present

1000Ω

1112131415

4-20

Boiler

+–

120 Vac power

supply is on

Power

Remote

WWCO

Melting

Water

Maximum

Supply

Pump 1

Opening

Boiler

Warning

R

LR 58223

NRTL/C

16

Com

4-20

Opn

Mix

Mix

Control is limiting supply

temperature to Max.

Supply setting

Power

System Pumps

Variable Pump

Mix Relays

Other Relays

Enclosed Energy Management Equipment

Manufactured

in Canada by

CWCO

Idling

Maximum

∆T

Minimum

Return

Pump 2

Closing

17

18 19 202122 23

Cls

Red

Mix

Sen

39°F

34 44

Melting

Test

30°F

10

∆T Max.

Do not apply power here

Brn

Blu

Yel

Blk

Sen

Sen

Sen

Sen

Weather is too cold,

snow melting is off

Control is in

Idling mode

120 V ac 50/60 Hz 300 VA

120 V ac 6 A 1/3 hp, pilot duty 240 VA 2 A

120 V ac 50/60 Hz 2.2 A 1/6 hp, internally fused

24 V ac 10 A, pilot duty 48 VA 2 A

120 V ac 10 A 1/3 hp, pilot duty 240 VA 2 A

29°F

24

Off 35

Idling

Surface

150°F

100 200

Max. Supply

0°F

-20

50

Off

CWCO

24 25

Com

Bret

Rem

Sen

Sen

En

26

Com

Sen

25

27 28

Ret

Sen

2094

1234567

50 %

20 80

Sensitivity

100°F

60

Off 150

Min. Boil Return

130 sec

30

Motor Speed /

Pump Response

29

Sup

Out

Sen

Sen

Control is limiting heat

output to Max ∆T setting

Control is maintaining

Min. boiler return temperature

Desired slab surface

temperature during

melting mode

Desired slab surface

temperature during

idling mode

H11002

Input: Outdoor

Sensor Sensitivity to

water

Test button to initiate

test sequence

Maximum Supply

temperature

Min. Boiler Return

temperature

Max. Temperature

drop across slab

Cold Weather Cut-off

temperature

Motor Speed setting

Terminal Plugs

Sensor 070

(Included)

Date

S/N

230

tekmar

motor

Output: Turn on

system pump P1

Output: Turn on

boiler pump P2

120 Vac

Power Supply

Output:

operate pump at

varying speeds

Output:

Turn on boiler

OR

Output: control

4-20 mA device

M

M

Output: control

Floating Action

Input: System Supply

Sensor 071

Input: System Return

Sensor 071

Input: Boiler Return

Sensor 071

Input: Remote Enable

Signal.

OR

Input: Slab Sensor 072

Detects slab temperature

Input: Snow/Ice Sensor 090 installed with Sensor Socket 091.

Both of these components must be ordered separately.

only. Does not detect Snow/Ice.

(Included)

(Included)

(Included)

(Optional)

(Included)

(Optional)

Page 2

In order for this control to operate effectively, it must be installed in a well designed melting system. The Application Brochures A 662

provide a series of schematics which can be used with this control. Any deviations from these drawings must be discussed with a tekmar

factory representative to ensure that system performance is not compromised. The application drawings are not final designs - each

component within the system must be correctly sized for the control to operate effectively. It is important that the sequence of operation

and the application drawings for this control are fully understood to ensure that the control selected is compatible with its intended use.

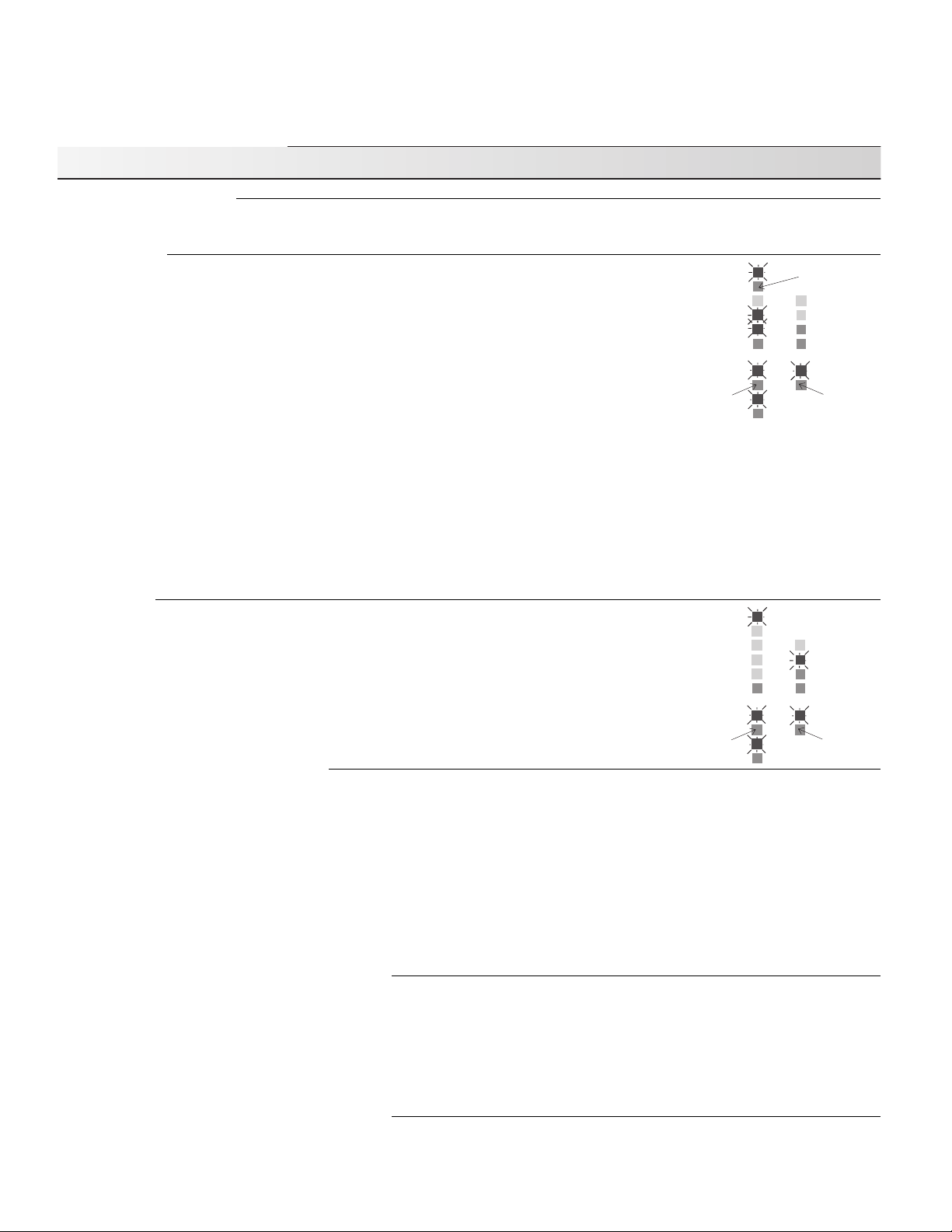

Sequence of Operation

Powering up the control

After the Snow Detector & Melting Control 662 is powered up, the red status lights and the LCD segments are turned on for 7 seconds.

The control then displays the “Outdoor” temperature.

Melting Mode

Operation using a Snow/ Ice Sensor 090 - The control continually monitors the Snow/Ice Sensor

090. When water is detected, the “Water” light turns on and if the control is not in WWCO or

CWCO (see page 3 for an explanation of these terms), melting mode begins.

Operation using a Remote Enable - Melting mode can also be initiated if a remote enable signal

is present (terminals Com Sen and Rem Sen shorted together) and the control is not in WWCO

or CWCO. The remote enable is typically used with multiple Snow Melting Controls and Snow/

Ice Sensors. It can be also be used to manually turn the melting system on by wiring a switch

between the remote terminals. A remote enable switch must be installed when a Slab

Opening light is

on if the melting

system requires

more heat

Sensor 072 is used as this sensor cannot detect water.

Once the control is in melting mode, the Melting relay and boiler pump (relay P2 Pmp) are turned

on. After a 4 second delay, the system pump (relay P1 Pmp) is turned on and after 8 seconds, heat is applied to the snow melt system

through either a variable speed pump, a floating action mixing valve or a 4-20 mA device. The opening and closing lights indicate

whether the control is increasing or decreasing the heat applied to the snow melt system. Essay E 021 compares the use of these

devices for controlling the system temperature and also discusses the sizing and operation of the variable speed pump. Information

on floating action can be found in Essay E 000. The 4-20 mA, variable speed pump and mixing valve outputs operate simultaneously.

The 4-20 mA output can therefore be used to provide a remote readout of the pump or valve operation. The control remains in melting

mode until no water is detected for at least 30 seconds and the slab is up to temperature for at least 30 minutes. Cold Weather or

Warm Weather Cut Off can also terminate melting mode. When the control exits melting mode the boiler and system pumps are

operated for an additional 90 seconds to purge the boiler. If the control switches from melting to idling mode, the boiler is not purged.

Idling Mode

When the melting system starts off from a cold temperature, the time required for the slab to reach

“Melting” temperature can be excessive. To decrease this start up time, the slab can be maintained

at an “Idling” temperature until melting is required. The idling feature is also useful for preventing

frost and light ice formation. When the control is in idling mode, control operation is similar to melting

mode except the “Melting” and “Water” lights are off and the “Idling” light is on.

Opening light is

on if the melting

system requires

more heat

Snow melt system protection features

The 662 control has several features for protection of the snow melt system:

- to protect the slab from cracking due to thermal stresses, the control limits the rate of heat applied to the slab through a “∆T Max”

setting. The ∆T represents the difference between the slab supply and return fluid temperatures which are measured by the control.

If this temperature difference approaches the “∆T Max” setting, the “Maximum ∆T” light turns on and the control operates the valve

or pump to maintain the ∆T at the “∆T Max” setting.

- to protect the piping and other components in the system, the control limits the supply temperature to a “Max. Supply” setting. When

the melt system supply temperature approaches the maximum supply setting, the “Maximum Supply” light turns on and the control

operates the valve or pump to reduce the supply temperature.

- to prevent the flue gases in the boiler from condensing, the control limits the boiler return temperature to a “Min. Boil. Return” setting.

When the boiler return temperature approaches this setting, the “Minimum Return” light turns on and the control operates the valve

or pump to increase the boiler return temperature.

∆T compensation for changes in fluid viscosity

Glycol solutions used in snow melt systems have widely varying viscosities between high and low temperatures. As the glycol solution

temperature drops, viscosity increases causing a reduction in flow rate. This reduction in flow rate reduces the rate of heat output

if the fluid temperature drop across the slab (∆T) remains constant. To compensate for this, the control increases the Maximum ∆T.

This compensation is only applied when the fluid temperature is below 30°F, which is the temperature at which the viscosity of a typical

40% ethylene glycol / 60% water solution starts to increase significantly. The compensation feature is designed for fluids containing

40% ethylene glycol or 30 % propylene glycol; however, if the glycol percentage in the solution is lower than these values, the quality

of heat regulation is not significantly affected. When the control is compensating for viscosity changes, the “Maximum ∆T” light flashes.

Ramping the ∆T during melting system start up

When the control turns on the melting system, the “Target ∆T” is slowly ramped up to the maximum ∆T to prevent thermal shock of

the slab. If the temperature of the fluid returning to the boiler (source) is sufficient, the ramping time is less than 17 minutes. If the

heat source is not dedicated to snow melting and there are other heat demands on the source, the ramping time may be longer.

2

Power

Remote

WWCO

Melting

Water

Maximum

Supply

Pump 1

Opening

Boiler

Warning

Power

Remote

WWCO

Melting

Water

Maximum

Supply

Pump 1

Opening

Boiler

Warning

If a remote signal is

present, the Remote

light turns on

CWCO

Idling

Maximum

∆T

Minimum

Return

Pump 2

Closing

Closing light is on

if the melting

system requires

less heat

CWCO

Idling

Maximum

∆T

Minimum

Return

Pump 2

Closing

Closing light is on

if the melting

system requires

less heat

Page 3

Warm Weather Cut Off (WWCO)

n

If the “Slab” and “Outdoor” temperatures rise above the “Melting” temperature, heating the slab is

no longer required. The control therefore shuts down the melting system and enters WWCO.

During WWCO the “Closing” light remains on continuously and the heat supplied through the valve

or variable speed pump is reduced to zero. When the “Outdoor” or “Slab” temperature drops below

the “Melting” temperature, the control exits WWCO and continues with normal operation.

Cold Weather Cut Off (CWCO)

Maintaining the slab at a “Melting” or “Idling” temperature in extremely cold weather can be

expensive and may even be impossible. When it does snow at these colder temperatures, the snow

is usually dry, light and less slippery. The control therefore turns the melting system off when the

“Outdoor” temperature drops below the “CWCO” setting. During CWCO the “Closing” light remains

on continuously and the heat supplied through the valve or pump is reduced to zero. The heater

If a remote

signal is

present, the

Remote light

turns on

If water is

detected the

Water light

turns on

Power

Remote

WWCO

Melting

Water

Maximum

Supply

Pump 1

Opening

Boiler

Warning

Note:

In Cold Weather Cut

Off, the CWCO light is

on and the WWCO

light is off

CWCO

Idling

Maximum

∆T

Minimum

Return

Pump 2

Closing

Closing light is o

to turn off the

melting system

in the Snow/ Ice Sensor 090 is kept on during CWCO until the control detects snow. If snow is detected, the heater is turned off but

the control retains the snow detected information. When the outdoor temperature rises above the “CWCO” temperature, the control

exits CWCO and if the Snow/Ice Sensor 090 detected snow during CWCO, the control initiates melting mode.

Warning Light and Relay

Pump 2

If a sensor fault occurs, the Warning relay and light are turned on and an error message is given. The look-up

table provided on pages 10 and 11 can be used to determine which sensor has the fault.

Pump 1

Opening

Boiler

Warning

Closing

Exercising of the Pumps and Valves

To prevent the pumps or valves from seizing after long inactive periods, the pumps

and valves are operated after every 3 days of no operation. The Pump P1 and Pump

P2 relays are turned on for 20 seconds and the mixing valve or variable speed pump

output is run fully open and/or fully closed. During exercising, the LCD screen

alternates between two special characters as illustrated in the diagram.

Slab

Supply

Actual ∆T

Target ∆T

% Output

Usage (∆T x hrs)

Boiler Return

Slab

Supply

Actual ∆T

Target ∆T

% Output

Usage (∆T x hrs)

Boiler Return

Installation

Caution

Improper installation and operation of this control could result in damage to equipment and possibly even personal

injury. It is your responsibility to ensure that this control is safely installed according to all applicable codes and

standards. This electronic control is not intended for use as a primary limit control. Other controls that are intended

and certified as safety limits must be placed into the control circuit.

Step One Getting ready

Check the contents of this package. If any of the contents listed are missing or damaged, please refer to the Limited Warranty

and Product Return Procedure on the back of this brochure and contact your wholesaler or tekmar sales agent for assistance.

Type 662 includes:

• One Snow Detector & Melting control 662 • One Outdoor Sensor 070

• Three Universal Sensors 071 • One Slab Sensor 072

• One Data Brochure D 662 • Application Brochures A 662 • One Data Brochure D 001

Other information available:

• Essay E 021 • Essay E 000 • Essay E 600

Read Brochures A 662 and select the correct Application for your job.

Note: This control can be installed with EITHER a Snow/Ice Sensor 090 and Sensor Socket 091 OR a Slab Sensor 072. The

Snow/Ice Sensor 090 and Sensor Socket 091 are not included with the type 662 and must be ordered separately.

Carefully read the details of the Sequence of Operation sections in all applicable brochures to ensure that you have chosen the

proper control and understand its functions within the operational requirements of your system.

Step Two Mounting of the base

The control should be removed from its base by pressing down on the release clip in the wiring chamber and sliding upwards

on the control. The base is then mounted in accordance with the instructions in the Data Brochure D 001.

Step Three Rough-in Wiring

All electrical wiring terminates in the control base wiring chamber. It has standard 7/8" (22mm) knock-outs that accept all common

wiring hardware and conduit fittings. Before breaking out the knock-outs, check the wiring diagram and select those sections of

the chamber with common voltages. Do not allow the wiring to cross over sections as safety dividers, installed later, prevent this.

Power should not be applied to any of the wires during the rough-in wiring stage.

•

EITHER:

base.

•

OR:

See page 5 for very important details on sensor location and installation.

• Run the wiring from the other system components to the base.

• Run 120 V ac to the power terminals on the control.

• Multi-strand 16 AWG wire is recommended for the 120 V ac wiring due to its superior flexibility and ease of installation into the

terminal.

Install the Snow/Ice Sensor 090 according to the instructions in Data Brochure D 090 and run the wiring back to the

See Data Brochure 090 for very important details on sensor location and installation.

Install the Slab Sensor 072 according to the instructions in the Data Brochure D 001 and run the wiring back to the base.

Use a clean 120 V ac power source to ensure proper operation.

3

Page 4

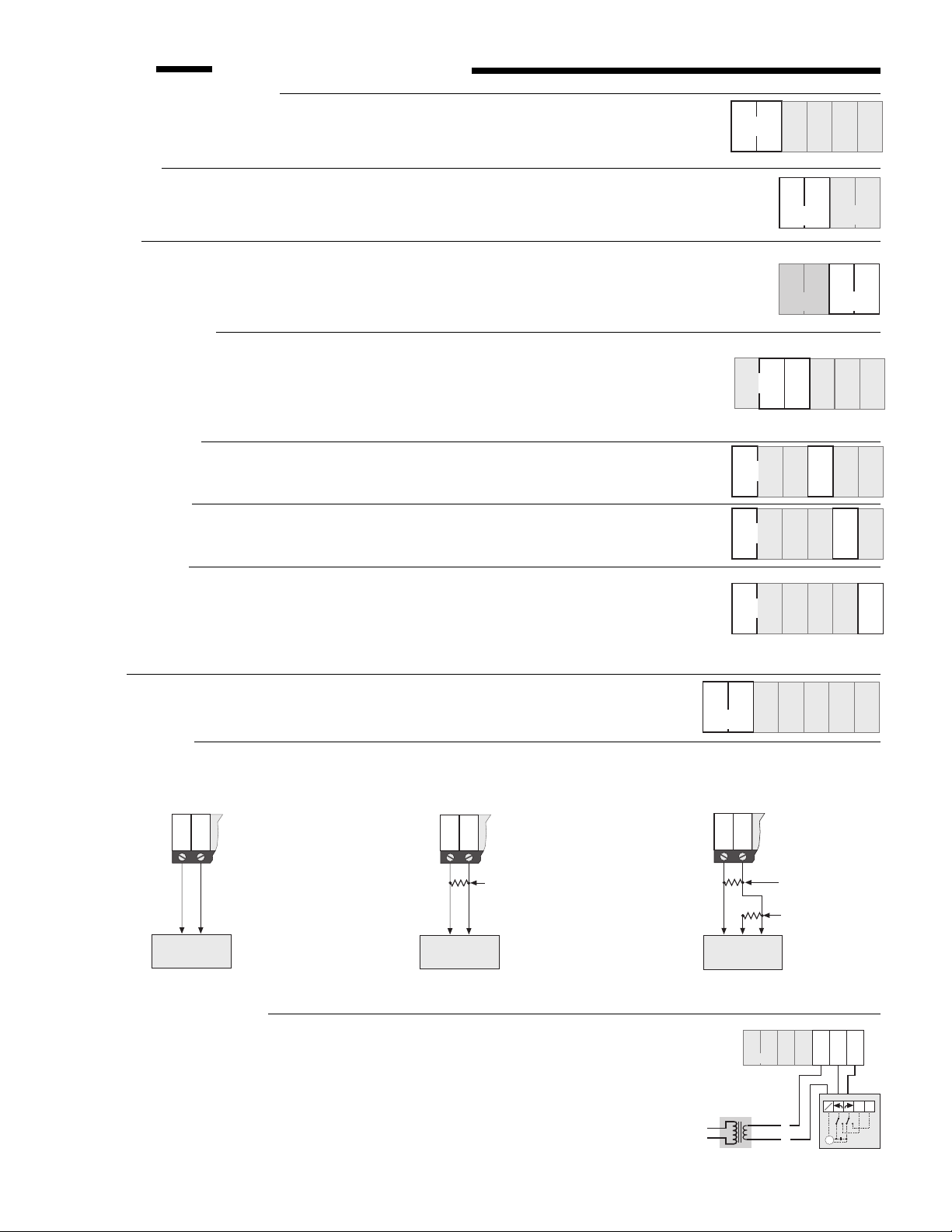

Step Four Electrical connections to the control

Power and output connections

• The installer should test to confirm no voltage is present at any of the wires.

• Install the control back into the base by sliding it down until it snaps in firmly.

• Connect the 120 V ac power supply to terminals

Melt Output

• Connect the melting device to terminals

Melt

(dry) relay contact inside the control which closes when the control enters melting mode. The

most common devices to be enabled by the 662 are pumps, heating devices or other controls.

Warning

• If desired, connect a warning device to terminals

a dry relay contact inside the control which closes when there is a sensor or wiring fault.

Caution

: The 662 is an operating control and is not certified as a safety device. If safety

considerations are critical, a separate alarm system must be installed.

Pump Power Supply

• Terminal

and

Com Pmp

P2 Pmp

(7) is the common power supply terminal for both terminals

(9).

• If the pumps P1 and P2 are operated from the same 120 V ac power supply as the control,

connect the terminal

Power L (6)

to the terminal

• If a separate power supply is required for P1 and/or P2, contact tekmar for details.

System Pump P1

• Connect the System Pump to terminals

Power N — P1 Pmp

to a dry relay contact which closes when the control requires System Pump operation.

Boiler Pump P2

• Connect the Boiler Pump to terminals

Power N — P2 Pmp

to a dry relay contact which closes when the control requires Boiler Pump operation.

Variable Speed

• Connect the variable speed pump to terminals

operated by this circuit must be permanent capacitor, impedance protected with a locked rotor

current less than 2.2 amps. The Snow Detector & Melting Control 662 has an internal 2.5 amp

fuse for overload protection.

This fuse is not field replaceable.

return and repair procedures if this fuse is blown.

Boiler

• Connect the boiler or the boiler control to the terminals

lead to a dry relay contact which closes when the control requires boiler operation.

4-20 mA Device

• Connect the positive 4 - 20 mA lead to terminal

resistance allowed in the 4 - 20 mA circuit is 1000 Ω. The 4 - 20 mA output can be converted to a voltage output by connecting

a resistor between terminals 13 and 14.

Power N — L

(5 and 6).

(1 and 2). These terminals lead to an unpowered

Warning

Com Pmp (7)

(3 and 4). These terminals lead to

.

(5 and 8). These terminals lead

(5 and 9). These terminals lead

Power N —Var Pmp

(5 and 10).

Contact tekmar for details on

Boiler

(11 and 12). These terminals

4-20 +

(13) and the negative 4 - 20 mA lead to terminal

P1 Pmp

Pumps

(8)

11

Boiler

56

Power

N L

5

Power

N L

Power

N L

Power

N L

Power

N L

13

12

4-20

+

4 - 20 –

89

7

Com

P1

Pmp

Pmp

2

1

Melt

2

1

Melt

89

7

6

Com

P1

Pmp

Pmp

7

Com

Pmp

7

Com

Pmp

7

Com

Pmp

8

P1

Pmp

8

P1

Pmp

8

P1

Pmp

65

65

65

14

Com

4-20

Mix

–

(14). Maximum

10

Var

P2

Pmp

Pmp

34

Warning

34

Warning

10

Var

P2

Pmp

Pmp

9

10

Var

P2

Pmp

Pmp

10

9

Var

P2

Pmp

Pmp

9

10

Var

P2

Pmp

Pmp

1615

17

Opn

Cls

Mix

Mix

1413

1

4-20

C

4-20

–

+

M

+

–

4 - 20 mA

Actuating Motor

Connection to Operate

a 4 - 20 mA Device

Operate a 1 - 5 Vdc or 2 - 10 Vdc Device

1413

1

4-20

4-20 C

–

+

M

500 Ω resistor

4-20 mA converted

to 2-10 Vdc output

OR

250 Ω resistor

4-20 mA converted

to 1-5 Vdc output

+

–

1-5 or 2-10 Vdc

Actuating Motor

Converting the 4 - 20 mA Output to

Floating Action Mixing Valve

• Connect one side (R) of a 24 V ac transformer to terminal

• Connect the (C) side of the transformer to terminal

N/C

Com Mix

(15).

on the tekmar 010 Actuating Motor.

For other makes of actuating motors, refer to the manufacturers' installation instructions.

• Connect the OPEN terminal of the Actuating Motor (CCW) to the terminal

Opn Mix

the control. This terminal leads to a relay contact which closes to provide 24 V ac to open

the valve.

• Connect the CLOSE terminal of the Actuating Motor (CW) to the terminal

Cls Mix

the control. This terminal leads to a relay contact which closes to provide 24 V ac to close

the valve.

4

(16) on

(17) on

14

13

1

4-20

C

4-20

–

+

M

66.5 Ω resistor

237 Ω resistor

B

R

W

0 - 135Ω "Slidewire"

Actuating Motor

Converting the 4 - 20 mA Output to

Operate a 0 - 135Ω Actuating Motor

13

12

24Vac

4-20

R

C

14

4-20

+

–

11

Boiler

Separate Class II

Transformer

L

N

15

Com

Mix

16

17

Opn

Cls

Mix

Mix

N

12

C

M

type 010

Page 5

Sensor and unpowered input connections

2

R

E

2

e

E

Power should never be applied to these terminals. Damage to the control will result.

Snow/Ice Sensor 090 (Must be ordered separately)

For automatic detection of snow or ice, the tekmar Snow/Ice Sensor 090 is required. This sensor must be installed flush with

the slab surface and 1/2 way between the heating pipes.

See Data Brochure D 090 for installation instructions regarding the

Snow/Ice Sensor 090 and Sensor Socket 091.

• Connect the red wire from the sensor cable to terminal

• Connect the black wire from the sensor cable to terminal

• Connect the blue wire from the sensor cable to terminal

• Connect the yellow wire from the sensor cable to terminal

• Connect the brown wire from the sensor cable to terminal

Red Sen

Blk Sen

Blu Sen

Yel Sen

Brn Sen

(18).

(19).

(20).

(21).

(22).

18 19 21

20

Blk BrnRed Blu Yel

Sen

Sen Sen Sen Sen

22

Slab Sensor 072

If a Snow/Ice Sensor 090 is not ordered, the Slab Sensor 072 must be installed.

072 sensor, a remote enable switch turns the melting system on.

wires to terminals

Blk Sen — Brn Sen

(19 and 22). The 072 sensor cable is 20 feet (6m) long

Connect the two sensor

but it can be extended to a maximum overall length of 1000 feet (300 m). If extension becomes

necessary, splices should be properly soldered and waterproofed and be protected in an

accessible, waterproof junction box. Use at least 18 AWG wire for extensions.

Important Note:

control. The Slab Sensor 072 must be installed

1" (25 mm) below the surface of the slab.

Proper sensor placement is critical for correct operation of the 662

1/2 way between the heating pipes and

Although the 072 sensor can be placed directly

With the

19

Blk

Sen

20

Sen Sen

1/ 2 X

18 21

Red Blu Yel

Sen

22

Brn

Sen

X

into the slab, we recommend that the sensor be installed in tubing or conduit in such a

manner that the sensor can be removed and replaced in case of failure.

Outdoor Sensor

• Connect the two wires from the Outdoor Sensor 070 to the

terminals

Com Sen — Out Sen

(26 and 29).

System Supply Sensor

• Connect the two wires from the Universal Sensor 071 – which should

be mounted on the system supply pipe to the slab – to terminals

Sen — Sup Sen

(26 and 28).

Com

18 19 21

20

Blk BrnRed Blu Yel

Sen

Sen Sen Sen Sen

18 19 21

20

Blk BrnRed Blu Yel

Sen

Sen Sen Sen Sen

22

22

23

Com

Sen

23

Com

Sen

24 25 26

RemEnBret

Sen

24 25 26

RemEnBret

Sen

Com

Sen

Com

Sen

Ret

Sen

Ret

Sen

System Return Sensor

• Connect the two wires from the Universal Sensor 071 – which should

be mounted on the system return pipe from the slab – to terminals

Com Sen — Ret Sen

(26 and 27).

18 19 21

20

Blk BrnRed Blu Yel

Sen

Sen Sen Sen Sen

22

23

Com

Sen

24 25

RemEnBret

Sen

26

Com

Sen

27

Ret

Sen

Boiler Return Sensor

• Connect the two wires from the Universal Sensor 071 – which should

be mounted on the return pipe to the boiler– to terminals

— Bret Sen

(23 and 25).

Remote Enable Signal (Optional)

• If a remote device is used to enable the control, connect the two

wires from the device to terminals

Com Sen — Rem Sen

(23 and 24).

Com Sen

18 19 21

20

Blk BrnRed Blu Yel

Sen

Sen Sen Sen Sen

18 19 21

20

Blk BrnRed Blu Yel

Sen

Sen Sen Sen Sen

22

22

23

Com

Sen

23

Com

Sen

RemEnBret

RemEnBret

24 25 26

Sen

24 25 26

Sen

Com

Sen

Com

Sen

27 28

Ret

Sen

27 28

Ret

Sen

23

Com

Sen

23

Com

Sen

27 28

Sup

Sen

27 28

Sup

Sen

28

Sup

Sen

Sup

Sen

Sup

Sen

R

1"

(25 mm)

29

Out

Sen

29

Out

Sen

29

Out

Sen

29

Out

Sen

29

Out

Sen

10A

1234

12 4

Melt

relay closes

when in

melting mode

10A

Warning

Melt

Warning

relay closes when a

sensor fault occurs

56789

Power

LN

System Pump

relay closes to turn

on System Pump

Power

Requirements

120 V ac ± 10%,

50/60Hz.

6A

6A

2.2A

10A

1000

10A 10A

Ω

10

Com

Com

PmpP1PmpP2Pmp

Boiler Pump

relay closes to

turn on Boiler

Pump

Var

Pmp

Variable Speed

Pump

output varies from

0% to 100%

Boiler

Boiler

relay closes

to turn on

boiler

Note: This is not a wiring diagram. For

detailed wiring schematics refer to the

Application Brochures A 662.

4-20

4-20

+

4 to 20 mA

modulating

output

Mix

-

Actuating Motor

5

Do not apply power here

17 18 19 20 21 22 23 24 25 26 27

Red

Blk

Blu

Yel

Brn

Com

Sen

Brown

Sen

Rem

En

Opn

Mix

relays close to

operate Mixing

Valve motor

Cls

Mix

Sen

Red

Sen

Black

Snow/Ice

Sen

Blue

Sensor

090

Sen

Yellow

OR

Slab

Sensor 072

or 073

Bret

Com

Sen

Sen

Boiler

Return

Sensor

071

System

Return

Sensor

071

Remote Enable

signal

(Optional)

Ret

Sen

662

2811 12 13 14 15 16

Sup

Sen

29

Out

Sen

Outdoor

Sensor

070

Supply

Sensor

071

Page 6

Step Five Testing the wiring

Slab

Supply

Actual ∆T

Target ∆T

% Output

Usage (∆T x hrs)

Boiler Return

• Before applying power to the control for testing, each terminal plug must be unplugged from its

6

header on the control. Pull straight down to unplug.

• These tests are to be performed using standard testing practices and procedures and should only

be carried out by properly trained and experienced persons.

• A good quality electrical test meter capable of reading from at least 0 — 200 Volts ac, and at least

0 — 2,000,000 Ohms, is essential to properly test this control.

Test the sensors

• In order to test the sensors, the actual temperature at each sensor must be known. A good quality

digital thermometer with a surface temperature probe is recommended for ease of use and

accuracy of testing. Where a thermometer is not available, a spare sensor can be strapped

alongside the one to be tested and the readings compared. Test the Snow/Ice Sensor 090

according to the instructions in brochure D 090, and the remaining sensors according to the

brochure D 001.

Test the power supply

• Before applying power, make sure exposed wiring or terminals are not grounded or in contact with other wires. Turn on the

120 V ac power and, using an AC voltmeter, measure the voltage between terminals

Power N – L

(5 and 6). You should measure

between 110 and 130 V ac.

Test the Outputs

• If a device is connected to the

Melt

(1 and 2) terminals, make sure power to the circuit is off and install a jumper in the terminal

plug between terminals 1 and 2. When the device is powered up, it should operate. If it does not turn on, check the wiring

from the terminal plug to the device and refer to any installation or trouble shooting information supplied with the device. If

the device is operating properly, disconnect the power and remove the jumper.

• Repeat this procedure for any devices connected to the

• If a pump is connected to the

between the

Com Pmp — P1 Pmp

P1 Pmp

(8) terminal, make sure power to the circuit is off and install a jumper in the terminal plug

(7 and 8) terminals. When the circuit is powered up, the pump should start. If it does not,

Warning

(3 and 4) terminals and the

Boiler

check the wiring from the terminal plug to the pump and refer to any installation or troubleshooting information supplied with

the pump. If the pump operates properly, disconnect the power and remove the jumper. Repeat this procedure for a pump

connected to the

• If a variable speed pump is connected to the

and install a jumper in the terminal plug between the

P2 Pmp (9)

terminal.

Power N — Var Pmp

Power L — Var Pmp

(5 and 10) terminals, make sure power to the circuit is off

(6 and 10) terminals. When the 120 V ac circuit is

powered up, the variable speed pump should operate at full speed. If it does not, check the wiring from the terminal plug to the

pump and refer to any installation or troubleshooting information supplied with the pump. If the pump operates properly,

disconnect the power and remove the jumper.

• A separate 24 V ac transformer is used to drive the actuating motor for the mixing valve. Make sure power to the transformer

is off and install a jumper in the terminal plug between terminals

Com Mix – Opn Mix

(15 and 16). When the transformer is

powered up, the mixing valve should drive fully open and then stop. Turn off the power to the transformer, remove the jumper

and install it in the terminal plug between terminals

Com Mix – Cls Mix

(15 and 17). When the transformer is powered up,

the mixing valve should drive fully closed and then stop. If it does, disconnect the power and remove the jumper.

• The 4 - 20 mA output terminals (13 and 14) cannot be tested without power applied to the control. Since no power is supplied

to the control at this point, the 4 - 20 mA output cannot be tested. Please refer to the operation test below.

Connect the control

• Turn the power off and make sure all test jumpers have been removed from the plugs.

• Connect the plugs to the control by carefully aligning them with their respective headers and pushing them upwards. The plugs

should snap firmly into the headers.

• Install the supplied safety divider(s) between the low voltage (less than 30 V ac) and the line voltage (120 V ac) wiring chambers.

Apply power to the control.

5

Power

N

L

Disconnect terminal

plug from its header

(11 and 12) terminals.

Com

Pmp

10

9

8

7

Var

P2

P1

Pmp

Pmp

Pmp

Test the 4 - 20 mA output

The 4 - 20 mA device can be tested as follows:

• Connect the positive wire from the 4 - 20 mA device to terminal 13 on the control.

• Connect the negative wire from the 4 - 20 mA device to the red (+) lead on the

milliamp meter.

• Connect the black (-) lead from the milliamp meter to terminal 14 on the control.

• When the Opening light turns on, the initial percentage output is zero and the meter

should read 4 mA.

• As the % Output increases, the meter reading should increase until 100% Output

is reached at which point the meter should read 20mA.

• When the Closing light comes on the meter should start at 20mA and eventually

reach 4mA when the display shows 0% Output.

6

4-20

+

M

Reading should

be 4 mA

4-20

1413

1

C

–

M

Test the 4 - 20 mA

output using a

milliamp meter

1000 mA = 1 amp

6.4 mA

Milliamp

-

+

Slab

Supply

Actual ∆T

Target ∆T

Reading should

be 20 mA

% Output

Usage (∆T x hrs)

Boiler Return

Page 7

Settings

Step Six Essential control settings

Before adjusting the dial settings, read through the sequence of operation to ensure that you understand how the control operates.

The dials are factory set at the midpoint of each setting. This reflects typical settings for many systems and is therefore a good

starting point.

Melting Surface Temperature

The “Melting” dial setting is the desired slab surface temperature when the control is in melting mode and is

also used as the Warm Weather Cut Off temperature. The “Melting” temperature is usually set based on local

weather conditions. In some areas, heavy snowfall can load a slab at temperatures well above freezing; in

these areas, the dial should be set higher. If the melting system response is sluggish, increasing the “Melting”

dial setting can cause the system to melt faster; however, it is important to remember that increasing this

setting generally increases energy consumption.

Idling Surface Temperature

The “Idling” dial setting is based on the requirements of the user. If minimizing the time required for the slab

to reach “Melting” temperature is important then the dial is set slightly below freezing (<32°F). If black ice or

frost formation is a concern, the dial is set slightly above freezing (>32°F). It is important to remember that

“Idling” increases energy consumption. “Idling” can also be turned Off.

Water Detection Sensitivity

The sensitivity of the Snow/Ice Sensor to water can be adjusted using the “Sensitivity” dial. As snow becomes

contaminated with dirt, and as the sensor surface itself becomes dirty, the control may incorrectly indicate

the presence of water. If this condition occurs, clean the surface of the sensor and/or turn down the sensitivity

setting. If the snow and rain in your area is very clean, the sensitivity setting may need to be increased before

snow is detected.

Note:

The Snow/Ice Sensor 090 is installed in a hostile environment and should be cleaned on a regular basis with a wire

brush. After cleaning, check operation by pressing the test button to cycle the control through the test routine.

Maximum Supply Temperature

Some tubing manufacturers recommend that their products not be operated continuously at temperatures

greater than 140°F (60°C). Engineers also recommend that concrete slabs not be subjected to temperatures

in excess of 160°F (70°C). This dial setting permits the installer to limit the maximum temperature of the water

supplied to the snow melting slab. If the system supply water temperature approaches this setting, the

“Maximum Supply” light turns on and the control operates the mixing valve (or variable speed pump) to limit

the output and reduce the “Supply” temperature.

Minimum Boiler Return Temperature

To prevent problems of flue gas condensation in the boiler, this adjustment is set to the minimum boiler return

temperature as specified by the boiler manufacturer. When the boiler return approaches this setting, the

“Minimum Return” light turns on and the control operates the mixing valve (or variable speed pump) to limit

the output until the boiler return can warm up. If a minimum boiler return temperature is not required, as with

condensing or electric boilers, this adjustment can be set to “Off”.

∆

T Max. (Maximum Rate of Heat Delivery )

The 662 control limits the rate of heat applied to a slab to prevent excessive thermal stress. The rate of heat

delivery to the slab is dependant on the difference between the melting system supply and return

temperatures. The control measures these temperatures and calculates the difference to give the ∆T. If this

calculated ∆T approaches the “∆T Max” setting, the control operates the valve or pump to maintain the ∆T

at the “∆T Max” setting. The “∆T Max” dial is normally set at 5°F to 10°F above the design ∆T or it is specified

directly by the system designer. If this is not the case, set the dial at 30°F.

Note: The control may exceed its “∆T Max” setting if the supply temperature is lower than 30°F (see page 2 —

∆T compensation for changes in fluid viscosity).

CWCO (Cold Weather Cut Off)

The “CWCO” is the lowest temperature at which the melting system continues to operate. This temperature

is set based on the capacity of the snow melt system and the economics of melting in extreme conditions.

Motor Speed /

Pump Response

Pump Response (variable speed pump) - When using a variable speed pump, this dial sets the minimum

time required for the injection pump to go from 0% to 100% speed (ramp up). The primary purpose of limiting

the pump ramp up time is to avoid instability. If the pump ramps up faster than the snow melt system can

respond, the pump may continually ramp up and down trying to satisfy the snow melt system. For example:

A heat exchanger between the boiler loop and the system loop with heavy steel pipe that is slow to transfer

heat, has a delay between the time the control signals the pump to add heat to the system and the time the heat can affect

the system and be sensed by the control. To prevent oscillations of the pump speed, the “Pump Response” is set to a longer

time. In a system with a low mass, dedicated, high input boiler and no heat exchanger, the system responds faster and therefore

a shorter time can be set on the “Pump Response” dial. To avoid pump instability, experimentation is usually required; however,

most standard installations work well with settings in the 30 to 50 second range.

34 44

Melting

29°F

24

Off 35

Idling

Surface

50%

20 80

Sensitivity

150°F

100 200

Max. Supply

100°F

60

Off 150

Min. Boil. Return

10

∆T Max

0°F

-25

Off

CWCO

130 sec

30

Motor Speed /

Pump Response

39°F

Surface

30°F

50

25

230

tekmar

motor

7

Page 8

Motor Speed/

Pump Response (con't)

Motor Speed (mixing valve and 4-20 mA outputs) - When operating a valve, the control uses the information from the “Motor

Speed” dial setting to synchronize various control actions to the valve position and its rate of change. Set this adjustment to match

the time required for the actuating motor to drive from the fully closed to the fully open position.

The 662 Display & Indicator Lights

POWER-UP DISPLAY

Slab

Supply

Actual ∆T

Target ∆T

ACTUAL ∆T

Slab

Supply

Actual ∆T

Target ∆T

After power-up,

OUTSIDE

°F°

C

% Output

Usage (∆T x hrs)

Boiler Return

°

F

% Output

Usage (∆T x hrs)

Boiler Return

the control

shows the

"OUTSIDE"

temperature

Press and

release the

item button

Item

OUTDOOR TEMPERATURE SLAB SURFACE TEMP.

Slab

Supply

Actual ∆T

Target ∆T

TARGET ∆T

Slab

Supply

Actual ∆T

Target ∆T

Usage (∆T x hrs)

Boiler Return

OUTSIDE

°

F

% Output

Usage (∆T x hrs)

Boiler Return

°

F

% Output

Press and

release the

item button

Item

Press and

release the

item button

Item

Slab

Supply

Actual ∆T

Target ∆T

BOILER RETURN TEMP.

Slab

Supply

Actual ∆T

Target ∆T

°

F

% Output

Usage (∆T x hrs)

Boiler Return

Usage (∆T x hrs)

Boiler Return

Press and

release the

item button

Item

% Output

Press and

release the

item button

SYSTEM SUPPLY TEMP.

Slab

Supply

Actual ∆T

Target ∆T

Item

Slab

Supply

Actual ∆T

Target ∆T

°

F

Usage (∆T x hrs)

Boiler Return

ENERGY USAGE

Usage (∆T x hrs)

% Output

Boiler Return

% Output

Press and

release the

item button

Item

Press and

release the

item button

% HEAT OUTPUT

Press and hold the item

button for at least 1

second to switch

Item

between °F and °C

Slab

Supply

Actual ∆T

Target ∆T

% Output

Usage (∆T x hrs)

Boiler Return

Press and

release the item

button to scroll

through the

displays again

• Outdoor temperature is the temperature measured by the Outdoor Sensor 070.

• Slab Surface temperature is the temperature of the slab surface as measured by the Snow/Ice Sensor 090. If a Slab Sensor 072

is used, the control provides a best guess for the slab surface temperature when the sensor is placed 1" below the surface.

• System Supply temperature is the temperature of the water/glycol solution entering the slab. This temperature may be limited by

the control to protect the snow melting system components (see Settings - Max. Supply).

• Actual

∆T is the difference between the system supply and return temperatures which gives an indication of the present heat output

to the melt system. The Actual ∆T may be limited by the control to protect the slab (see Settings - ∆T Max).

• Target

∆T is the ∆T (heat output) that the control is trying to achieve. If the Actual ∆T is below the Target ∆T, the control is trying to

increase the heat to the slab. The Actual ∆T may never reach the Target ∆T because the system supply or boiler return temperatures

may be limited (see Settings -Max. Supply, Min. Boil. Return).

• Boiler Return Temperature is the temperature of the fluid entering the boiler. This sensor reading may cause the control to limit the

heat output to the slab in order to protect the boiler (see Settings - Max Boil. Return).

• Relative Energy Usage ( ∆T x hours). This display allows the user to estimate the amount of energy used by the snow melt system.

The relative energy usage is displayed by alternating between two numbers. When the °C or °F segment is off, the thousands are

display . When the °C or °F segment is on, the units are displayed . The energy consumption can be estimated by multiplying the

∆T x hrs by the system flow rate (in US GPM) and by the constant K given in the adjacent table. The accumulated energy usage

information can be cleared while the control is in the energy usage display. To do this, press and hold the item button for 1 second

and then press the test button.

Example - ∆T x hrs = 005 (thousands) 225 (units) = 5225 °F x hours

System flow = 20 US GPM

Fluid = 40% glycol & 60% water, therefore K = 462

Energy Usage = 5225 x 20 x 462 = 48,279,000 BTU

K values are calculated averages for

most ethylene glycol

solutions at 50°F

(10°C). K increases

with higher temperatures.

% Glycol by

weight

0%

10%

20%

30%

40%

50%

Freezing

point

32°F

25°F

15°F

3°F

-13°F

-35°F

@ 50°F

Item

500

496

487

477

462

439

K

• % Output - If a variable speed pump is used, this display indicates the percentage of maximum flow through the pump. If the pump

flow rate is 50% of maximum flow, the % Output is 50%. If floating valve action is used, this display indicates the percentage the valve

is open. If the valve is half open, the % Output is 50%. If a 4-20 mA device is used, this display indicates the percentage of current

output (between 4 and 20 mA) supplied to the device. If the % Output is 50%, the control is delivering 12 mA to the device.

8

Page 9

Indicator lights

y

m

Power light on • The 120 V ac power supply is connected and the control is energized.

Remote light on • The remote enable input is activated.

WWCO light on • The control is in Warm Weather Cut Off.

CWCO light on •

The control is in Cold Weather Cut Off.

Melting light on • The control is in melting mode.

Idling light on • The control is in idling mode.

Water light on • The snow/ice sensor is detecting the presence of water.

Maximum ∆T light • The control is limiting the temperature drop through the slab to the ∆T Max setting.

Max. Supply light • The control is limiting the supply temperature to the Max. Supply setting.

Min. Return light • The control is operating to keep the boiler return fluid hotter than the Min. Boil. Return setting.

Pump 1 light • The system pump (P1) relay is on.

Pump 2 light • The boiler pump (P2) relay is on.

Test light on • The control is proceeding through the programmed test routine.

Opening light on • The Open relay is on.

Closing light on • The Close relay is on.

Boiler light on • The Boiler relay is on.

Warning light on • The Warning relay is on.

Testing the Control Functions

Step Seven Operational test of control functions

LCD display, indicator lights and Snow/Ice Sensor

When the test button is pressed the red status lights and the LCD segments are turned on

for 7 seconds. The current to the Snow/Ice Sensor's internal heater is then increased and

if the temperature at the centre of the sensor does not rise at least 2°F within 45 seconds

an error message is given. If the centre of the sensor is hotter than 120°F or the outdoor

temperature is below -5°F, the control skips this part of the test. During the 45 seconds,

the control continues with the rest of the test sequence.

Warning on

The Warning relay and light turn on and the LCD shows “W A” to indicate that the external

Warning device is being tested. If the warning device does not activate, the wiring from the

control should be checked and the warning device examined for possible faults. After 10

seconds, the “Warning” light and relay are turned off and the test continues.

Note: The test routine can be halted at this, or any of the following steps, by pushing the Test button once. If this is down, the “Test”

light flashes and the control is held in a pause mode for 5 minutes after which time it automatically exits the test routine. Pushing

the “Test” button during the 5 minute pause allows the control to resume the test routine at the next step.

Melting on

The “Melting” light and relay turn on and the LCD shows “ME” to indicate that the melting

device is being tested. If the device connected to the melt relay does not activate, there

may be a fault with the wiring to the melting device or with the melting device itself - check

both. After 10 seconds, the “Melting” light and relay are turned off and the test continues.

Boiler Pump P2 on

The “Pump P2” light and relay turn on and the LCD shows “P 2” to indicate that Pump P2

is being tested. If the pump does not turn on, the wiring to the pump and the pump itself

should be checked. This pump remains on through the next part of the test sequence.

Boiler Pump P2 on and Boiler on

After Pump P2 has been on for 10 seconds, the “Boiler” light and relay are turned on and

the LCD shows “b” to indicate that the boiler is being tested. If the boiler does not turn on,

check the wiring to the boiler and the boiler itself. After another 10 seconds, both the boiler

and the boiler pump are turned off.

Pump P1 on

The Pump P1 relay and light turn on and the LCD shows “P 1” to indicate that Pump P1

is being tested. If the pump does not turn on, check the wiring to the pump and the pump

itself. After 10 seconds, the “Pump P1” light and relay turn off and the test continues.

Opening on — % Output Increasing

The “Opening” light and relay turn on and the LCD flashes between

“OPn” and the current “% Output”. The time for the device to go from 0%

to 100% is set on the “Motor Speed / Pump Response” dial. During this

time, the 4-20 mA, mixing valve or variable speed pump output should

increase from 0 to 100 %. If the device does not operate or the output

does not increase, check the wiring to the device and the device itself.

9

OUTSIDE

°F°

C

% Output

% Output

Power

Remote

WWCO

Melting

Water

Maximum

Supply

Pump 1

Opening

Boiler

Warning

CWCO

Idling

Maximum

∆T

Minimum

Return

Pump 2

Closing

Pump 1

Opening

Boiler

Warning

Power

Remote

WWCO

Melting

Water

Maximum

Suppl

Pump 1

Opening

Boiler

Warning

Pump 1

Opening

Boiler

Warning

Pump 1

Opening

Boiler

Warning

Pump 1

Opening

Boiler

Warning

Te s t

Pu

Clo

CWCO

Idling

Maximum

∆T

Minimum

Return

Pump 2

Closing

Pump 2

Closing

Pump 2

Closing

Pump 2

Closing

Page 10

Closing on — % Output Decreasing

After the Opening relay has turned off, the “Closing” light and relay turn

on and the LCD flashes between "CLS" and the current “% Output”. The

time for the device to go from 100% to 0% is set on the “Motor Speed /

Pump Response” dial. During this time, the 4-20 mA, mixing valve or

variable speed pump output should decrease from 100 to 0 %.

% Output

Pump 1

Opening

Boiler

Warning

Pump 2

Closing

Step Eight Troubleshooting

% Output

First observe the system operating parameters. The source of the problem can often be found by noting a temperature or time

reading which seems unreasonable. The indicator lights are also useful in assessing the current state of the control system.

Observing what the control is doing, and understanding the sequence of operation greatly aids in isolating the problem. The next

step is to press the test button and observe the system components working in sequential order. If a fault in a sensor or its wiring

is detected during or after the test sequence, an error message is displayed. The error message look up table provided below

can be used to locate the fault. Once the error is identified, refer to Step Five for testing of the wiring and sensors. After any repair

has been completed, press the Test button to confirm that correct operation has been restored.

Step Nine Before you leave

• Make sure wiring dividers are installed in their proper locations between compartments having different voltages.

• Install the wiring cover over the wiring chamber and secure it to the base with the two screws provided. Place the front cover on

the control and snap it into place. Install a lock if security is required.

•

Place this brochure, and all other brochures relating to the installation, in the protective plastic bag supplied with the control. Place

the bag in a conspicuous location near the control for future reference.

• It is important to explain the operation of the control and melting system to all users who may be operating it.

Error Messages

If a fault occurs during normal operation or during the test routine, the LCD flashes back and forth between the word "Err"

and one of the error codes listed.

OUTDOOR SENSOR – OPEN CIRCUIT

Check the Outdoor Sensor and wiring from the terminal plug to the sensor. When

the control has this error, it continues to operate the system assuming an outdoor

temperature of 20°F (-6.6°C)

OUTDOOR SENSOR – SHORT CIRCUIT

Check the Outdoor Sensor and the wiring from the terminal plug to the sensor. When

the control has this error, it continues to operate the system assuming an outdoor

temperature of 20°F (-6.6°C)

SUPPLY SENSOR – OPEN CIRCUIT

Check the System Supply Sensor and the wiring from the terminal plug to the

sensor. When the control has this error, the melting system is shut down.

SUPPLY SENSOR - SHORT CIRCUIT

Check the System Supply Sensor and the wiring from the terminal plug to the sensor.

When the control has this error, the melting system is shut down.

SYSTEM RETURN SENSOR - OPEN CIRCUIT

Check the System Return Sensor and the wiring from the terminal plug to the sensor.

When the control has this error, the melting system is shut down.

SYSTEM RETURN SENSOR – SHORT CIRCUIT

Check the System Return Sensor and the wiring from the terminal plug to the sensor.

When the control has this error, the melting system is shut down.

BOILER RETURN SENSOR – OPEN CIRCUIT

Check the Boiler Return Sensor and the wiring from the terminal plug to the sensor.

When the control has this error, the melting system is shut down unless the "Min. Boil

Return" dial is turned off.

BOILER RETURN SENSOR – SHORT CIRCUIT

Check the Boiler Return Sensor and the wiring from the terminal plug to the sensor.

When the control has this error the melting system is shut down.

090 YELLOW SENSOR – OPEN CIRCUIT

Check the 090 yellow temperature sensor (black and yellow wires, terminals 19 &

21), and the wiring from the terminal plug to the sensor. When the control has this

error, the melting system is shut down.

10

Page 11

090 YELLOW SENSOR – SHORT CIRCUIT

Check the 090 yellow temperature sensor (black and yellow wires, terminals 19 &

21), and the wiring from the terminal plug to the sensor. When the control has this

error the melting system is shut down.

090 BROWN SENSOR (or SLAB SENSOR 072) – OPEN CIRCUIT

Check the wiring to the 090 brown temperature sensor (black and brown wires,

terminals 19 & 22) or the Slab Sensor 072 (terminals 19 & 22). When the control has

this error, the melting system is shut down.

090 BROWN SENSOR (or SLAB SENSOR 072) – SHORT CIRCUIT

Check the wiring to the 090 brown temperature sensor (black and brown wires,

terminals 19 & 22) or the Slab Sensor 072 (terminals 19 & 22). When the control has

this error, the melting system is shut down.

WATER DETECTION CIRCUIT – OPEN CIRCUIT

Check the 090 water detection circuit (black and blue wires, terminals

19 & 20) according to brochure D 090. When the control has this error, the melting

system can only be operated using a remote enable signal.

WATER DETECTION CIRCUIT – SHORT CIRCUIT

Check the 090 water detection circuit (black and blue wires, terminals

19 & 20) according to brochure D 090. When the control has this error, the melting

system can only be operated using a remote enable signal.

INTERNAL CONTROL SENSOR – OPEN OR SHORT CIRCUIT

The control has an internal temperature sensor which monitors the temperature

inside the enclosure. If this sensor develops either an open or short circuit, the

control continues to operate normally. This sensor is not field repairable.

INTERNAL CONTROL SENSOR – ENCLOSURE OVERHEATED

This error message is displayed if the enclosure overheats. The 120 V ac variable

speed output stops but the 4 - 20 mA and floating outputs are unaffected. Make sure

the ambient temperature is less than 104°F (40°C).

090 SENSOR – HEATER MALFUNCTION

Check the 090 heater circuit (red and black wires, terminals

18 & 19) according to brochure D 090. Make sure the yellow and brown wires are

not reversed. When the control has this error, the melting system can only be

operated using a remote enable signal. If this error persists contact your local

tekmar representative.

090 SENSOR - HEATER SHORT CIRCUIT

If the red and black wires on the 090 Sensor are shorted together, the power supply

itself is shorted. When this occurs, the control continuously cycles through the start

of the power up routine. This fault should be repaired immediately or damage to the

control could result.

OUTSIDE

°F°

C

11

Page 12

Snow Detector & Melting Control 662

Literature — D 662, A 662’s, D 001, D 070, E 021.

Control — Microprocessor PID control; This is not a safety (limit) control.

Packaged weight — 4.1 lb. (1900 g), Enclosure A, blue modified PPO plastic

Dimensions — 6-5/8” H x 7-9/16” W x 2-13/16” D (170 x 193 x 72 mm)

Approvals — CSA NRTL/C, meets ICES & FCC regulations for EMI/RFI.

Floating / Variable Speed / 4-20 mA

Min. Boiler Return

∆

T Max

CWCO

Motor Speed

Temperature display

— Off, 55 to 150°F (Off, 13 to 66°C)

— 10 to 50°F (6 to 28°C)

— Off, -22 to 25°F (Off, -30 to -4°C)

— 30 to 230 seconds

— Fahrenheit / Celsius

Ambient conditions — Indoor use only, 30 to 105°F (0 to 40°C), < 90% RH non-

Power — 120 V (ac) ±10% 50/60 Hz 300 VA

condensing.

System Pumps — 120 V (ac) 6 A 1/3 hp, pilot duty 240 VA 2 A

Variable Pump — 120 V (ac) 50/60 Hz 2.2 A 1/6 hp, internally fused

Mix Relays — 24 V (ac) 10 A, pilot duty 48 VA 2 A

Other Relays — 120 V (ac) 10 A 1/3 hp, pilot duty 240 VA 2 A

Sensors included — NTC thermistor, 10 kΩ @ 77°F (25°C ±0.2°C) ß=3892

Outdoor Sensor 070, Slab Sensor 072, & 3 of Universal Sensor 071

Optional devices — tekmar Type #: 011, 031, 090, 091.

Detection of Snow/Ice — Down to -20°F (-29°C) in calm air with 500 feet (150 m) of 18

AWG wire to Snow/Ice Sensor 090.

Surface, Melting

Surface, Idling

Water Sensitivity

Maximum Supply

— 34 to 44°F (1 to 7°C)

— Off, 24 to 35°F (Off, -5 to 2°C)

— 20 to 80%

— 100 to 200°F (38 to 93°C)

OUTSIDE

FC

Slab

Supply

Actual ∆T

Target ∆T

The Snow/Ice Sensor is installed in a

hostile environment. It should be cleaned

3

2

4

Warning

and checked on a regular basis.

5

Power

N

Snow Detector & Melting Control 662

Floating / Variable Speed / 4-20 mA

Use Nº 20 AWG or larger copper conductors rated for at least 75°C / 300V

1

Melt

Item

6

Com

Pmp

L

To change between

°F and °C, press and

hold for 1 sec.

78

P1

Pmp

Pmp

Usage (∆T x hrs)

Boiler Return

9

10

P2

Var

Pmp

% Output

1112131415

Boiler

Power

Remote

WWCO

Melting

Water

Maximum

Supply

Pump 1

Opening

Boiler

Warning

1000Ω

Com

4-20

4-20

Mix

+ –

NRTL /C

LR 58223

16

17

Cls

Opn

Mix

Mix

Power

System Pumps

Variable Pump

Mix Relays

Other Relays

Made in Canada by

tekmar Control Systems Ltd.

CWCO

39°F

Idling

Maximum

∆T

Minimum

34 44

Melting

Return

Pump 2

Closing

Test

30°F

R

10

∆T Max.

Do not apply power here

18 19 202122 23

Brn

Blu

Yel

Blk

Red

Sen

Sen

Sen

Sen

Sen

120 V (ac) ±10% 50/60 Hz 300 VA

120 V (ac) 6 A 1/3 hp, pilot duty 240 VA 2 A

120 V (ac) 50/60 Hz 2.2 A 1/6 hp, internally fused

24 V (ac) 10 A, pilot duty 48 VA 2 A

120 V (ac) 10 A 1/3 hp, pilot duty 240 VA 2 A

Jan 98

1234567

29°F

24

Off 35

20 80

Idling

100 200

Max. Supply

-20

Off

CWCO

24 25

Bret

Rem

Sen

En

150°F

0°F

26

Com

Sen

Sensitivity

60

Off 150

Min. Boil Return

25

30

Motor Speed /

Pump Response

27 28

Ret

Sup

Sen

Sen

130 sec

Surface

50

Com

Sen

50 %

100°F

tekmar

011

tekmar

010

230

29

Out

Sen

The installer must ensure that this control and its wiring are shielded from strong sources of electromagnetic noise. Conversely, this electronic

control does not exceed Class B limits for radio noise emissions from digital apparatus as set out in the Radio Interference Regulations of

the Canadian Department of Communications. If this equipment does cause interference, the user is encouraged to try to correct the

interference by reorientating the receiving antenna and/or relocating the receiver with respect to this equipment. Le présent numérique

n'émete pas de bruits radioeléctriques dépassant les limites applicables aux appareils numériques de Classe B prescrites dans le réglement

sur le brouillace radioeléctrique édicté par le Ministére des Communications du Canada.

Limited Warranty and Product Return Procedure

Limited Warranty The liability of tekmar Control Systems Ltd. and tekmar

Control Systems, Inc. (“tekmar”) under this warranty is limited. The purchaser,

by taking receipt of the tekmar product (“product”), acknowledges receipt of

the terms of the warranty and acknowledges that it has read and

understands same.

tekmar warrants each tekmar product against defects in workmanship and materials, if the product is installed and used in compliance with tekmar's instructions. The

warranty period is for a period of twenty-four (24) months from the production date

if the product is not installed during that period, or twelve (12) months from the

documented date of installation if installed within twenty-four (24) months from the

production date.

The liability of tekmar under this warranty shall be limited to, at tekmar's sole discretion: the cost of parts and labor provided by tekmar to repair defects in materials

and/or workmanship of the defective product; or to the exchange of the defective

product for a replacement product; or to the granting of credit limited to the original

cost of the defective product, and such repair, exchange or credit shall be the sole

remedy available from tekmar, and, without limiting the foregoing in any way,

tekmar is not responsible, in contract, tort or strict product liability, for any

other losses, costs, expenses, inconveniences, or damages, whether direct, indirect, special, secondary, incidental or consequential, arising from ownership or use

of the product, or from defects in workmanship or materials, including any liability

for fundamental breach of contract.

This warranty applies only to those products returned to tekmar during the

warranty period. This warranty does not cover the cost of the parts or labor

to remove or transport the defective product, or to reinstall the repaired or

tekmar Control Systems Ltd., Canada

Control Systems

tekmar Control Systems, Inc., U.S.A.

Head Office: 4611 - 23rd Street

Vernon, B.C. Canada V1T 4K7

Tel. (250) 545-7749 Fax. (250) 545-0650

Web Site: www.tekmarcontrols.com

replacement product. Returned products that are not defective are not covered by this warranty.

This warranty does not apply if the product has been damaged by negligence

by persons other than tekmar, accident, fire, Act of God, abuse or misuse; or

has been damaged by modifications, alterations or attachments made subsequent to purchase which have not been authorized by tekmar; or if the

product was not installed in compliance with tekmar’s instructions and the

local codes and ordinances; or if due to defective installation of the product;

or if the product was not used in compliance with tekmar’s instructions.

This warranty is in lieu of all other warranties, express or implied, which the

Governing Law (being the law of British Columbia) allows parties to contractually exclude, including, without limitation, warranties of merchantability,

fitness for a particular purpose, durability or description of the product, its

non-infringement of any relevant patents or trademarks, and its compliance

with or non-violation of any applicable environmental, health or safety legislation; the term of any other warranty not hereby contractually excluded is

limited such that it shall not extend beyond twenty-four (24) months from the

production date, to the extent that such limitation is allowed by the Governing Law.

Product Return Procedure Products that are believed to have defects in work-

manship or materials must be returned, together with a written description of the

defect, to the tekmar representative for that territory. If the address of the representative is not known, please request it from tekmar at the telephone number

listed below

.

Product design, software and literature are Copyright © 1999 by:

tekmar Control Systems Ltd. and tekmar Control Systems, Inc.

12

All specifications are subject to change without notice.

Printed in Canada on recycled paper.

Loading...

Loading...