Page 1

Clamshell Grill

Models C832 & C834

Place this chapter in the Grill section

of the Equipment Manual.

Manufactured exclusively for

McDonald's® by

Taylor Company

750 N. Blackhawk Blvd.

Rockton, IL 61072

McDonald's Hotline:

(877-435-7623)

service@taylor-company.com

Table of Contents

Introduction Page 1.....................................................

Safety Page 1..........................................................

Parts Identification/Function Page 4.......................................

Important to the Operator Page 15.........................................

Equipment Set Up Procedures Page 17.....................................

Menu Screens Page 21...................................................

Daily Cleaning Procedures Page 28........................................

Troubleshooting Guide Page 45............................................

Limited Warranty on Equipment Page 48....................................

Limited Warranty on Parts Page 50.........................................

Ordering/Service Information Page 53......................................

Non-Scheduled Maintenance Page 54......................................

System Set-up Page 54...................................................

Menu Items Page 59.....................................................

Auto Leveling Page 67....................................................

Warranty

Warranty information is contained in this Equipment Manual. Refer to the warranty information listed in the Limited

Warranty on Equipment and Limited Warranty on Parts sections and to the warranty classifications listed in the Parts

Identification/Function section when service is performed on your machine.

It is recommended that the operator take the necessary time to carefully read through the complete warranty information.

Thoroughly understand your warranty protection before you begin operation.

For any questions pertaining to the Taylor Warranty, please contact Taylor Company, Rockton, Illinois 61072.

This manual is for the exclusive use of licensees and employees of McDonald's Corporation.

E2010 McDonald's Corporation

All Rights Reserved

January, 2010 (Original Publication)

(Updated May, 2016)

EM SD11

The United States of America

Printed in

Page 2

INTRODUCTION

The Models C832 and C834 have two

independent upper platens. These grills

provide automatic leveling of the platens.

The grills are capable of cooking a variety of

products and feature two cooking options,

AUTO and MANUAL.

AUTO Option: The grills automatically detect

the product placed on the grill plate (menu

items that are cooked using the upper platen,

only) and set the appropriate cooking

parameters.

MANUAL Option: After the operator selects

the desired product to be cooked, the grills

automatically set the appropriate cooking

parameters.

These grills provide all the features of a flat

grill, as well as the advantages of two-sided

cooking.

All repairs must be performed by an

authorized Taylor service agent. The main

power supplies to the grill must be

disconnected prior to performing any repairs.

These grills are designed for indoor use

only.

Note: Only instructions originating from the

factory or its authorized translation

representative(s) are considered to be the

original set of instructions.

This appliance is to be used only by

trained personnel. It is not intended for use by

children or people with reduced physical,

sensory, or mental capabilities, or lack of

experience and knowledge, unless given

supervision or instruction concerning the use

of the appliance by a person responsible for

their safety. Children should be supervised to

ensure that they do not play with the

appliance.

DO NOT install the unit in an area

where a water jet could be used. DO NOT use

a water jet to clean or rinse the grill. Failure to

follow this instruction may result in serious

electrical shock. In addition, water may collect

inside the grill and destroy electrical

components and cause injury from hot steam.

DO NOT operate the grill unless it is

properly grounded. Failure to comply may

result in equipment damage or personal injury.

This unit is provided with an equipotential

grounding lug that is to be properly attached to

the rear of the frame by the authorized

installer. The installation location is marked by

the equipotential bonding symbol (5021 of IEC

604171) on both the removable panel and the

equipment's frame.

SAFETY

Always follow these safety precautions when

operating the grill:

DO NOT operate the grill without

reading this operator's manual. Failure to

comply may result in equipment damage or

personal injury. This manual should be kept in

a safe place for future reference.

S DO NOT operate the unit unless it is

properly grounded.

S DO NOT operate the unit with larger

fuses than specified on the data label.

S All repairs must be performed by an

authorized Taylor service technician.

S The main power supplies to the

machine must be disconnected prior to

performing any repairs.

S For Cord Connected Units: Only Taylor

authorized service technicians or

licensed electricians may install a plug

or replacement cord on these units.

130826

1

Page 3

S Stationary appliances which are not

equipped with a power cord and a plug

or other device to disconnect the

appliance from the power source must

have an all-pole disconnecting device

with a contact gap of at least 3 mm

installed in the external installation.

S Appliances that are permanently

connected to fixed wiring and for which

leakage currents may exceed 10 mA,

particularly when disconnected or not

used for long periods, or during initial

installation, shall have protective

devices such as a GFI, to protect

against the leakage of current, installed

by the authorized personnel to the

local codes.

S Supply cords used with this unit shall

be oilresistant, sheathed flexible cable

not lighter than ordinary

polychloroprene or other equivalent

synthetic elastomersheathed cord

(Code designation 60245 IEC 57)

installed with the proper cord

anchorage to relieve conductors from

strain, including twisting, at the

terminals and protect the insulation of

the conductors from abrasion.

If the supply cord is damaged, it must

be replaced by an authorized Taylor

service technician in order to avoid a

hazard.

Failure to follow these instructions may result

in personal injury, equipment damage, or poor

grill performance.

WARNING: Improper installation, adjust

ment, alteration, service or maintenance

can cause property damage, injury or

death. Read the installation, operating

and maintenance instructions thoroughly

before installing or servicing this equip

ment.

S This appliance must be isolated from

all combustible construction and

materials including, but not limited to;

walls, partitions, furniture, floors,

curtains, paper, boxes, and

decorations. Failure to comply may

result in fire and cause destruction and

severe injury.

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors or liquids in the vicinity

of this or any other appliance.

S DO NOT obstruct the ventilation

openings at the rear of this appliance.

S DO NOT obstruct the flow of air in and

around the grill.

S DO NOT operate the grill unless all

service panels and access doors are

attached with screws. Failure to comply

may result in personal injury from gas

or electrical components.

USE EXTREME CAUTION while

setting up, operating, and cleaning the grill.

Avoid coming in contact with the hot grill

surfaces or with the hot grease. Failure to

comply will result in burn injuries.

2

130826

Page 4

S The grill must be placed on a level

surface.

S To ensure thorough cleaning, the grill

must be pulled away from the wall.

When returning the grill to its original

position, use extreme caution to

smoothly and slowly roll the grill

backward into place.

Failure to follow these instructions may cause

the grill to tip and can result in severe

equipment damage or personal injury.

NOISE LEVEL: Airborne noise emission does

not exceed 70 dB(A) when measured at a

distance of 1.0 meter from the surface of the

machine and at a height of 1.6 meters from

the floor.

These instructions are valid only if the country

code symbol appears on the appliance. If the

symbol does not appear on the appliance,

refer to the technical instructions which give

the necessary instructions for adapting the

appliance to the utilization conditions of that

country.

NOTICE all warning labels that have

been attached to the grill to further point out

safety precautions to the operator.

HAZARD COMMUNICATION STANDARD

(HCS) - The procedure(s) in this manual

include the use of chemical products.

These chemical products will be

highlighted with bold faced letters followed

by the abbreviation (HCS) in the text

portion of the procedure. See the Hazard

Communication Standard (HCS) manual for

the appropriate Material Safety Data

Sheet(s) (MSDS).

This piece of equipment is made in America

and has American sizes on hardware. All

metric conversions are approximate and vary

in size.

If the crossed out wheeled bin symbol

is affixed to this product, it signifies that this

product is compliant with the EU Directive as

well as other similar legislation in effect after

August 13, 2005. Therefore, it must be

collected separately after its use is completed,

and cannot be disposed as unsorted municipal

waste.

The user is responsible for returning the

product to the appropriate collection facility, as

specified by your local code.

For additional information regarding applicable

local laws, please contact the municipal facility

and/or local distributor.

3

Page 5

PARTS IDENTIFICATION/FUNCTION

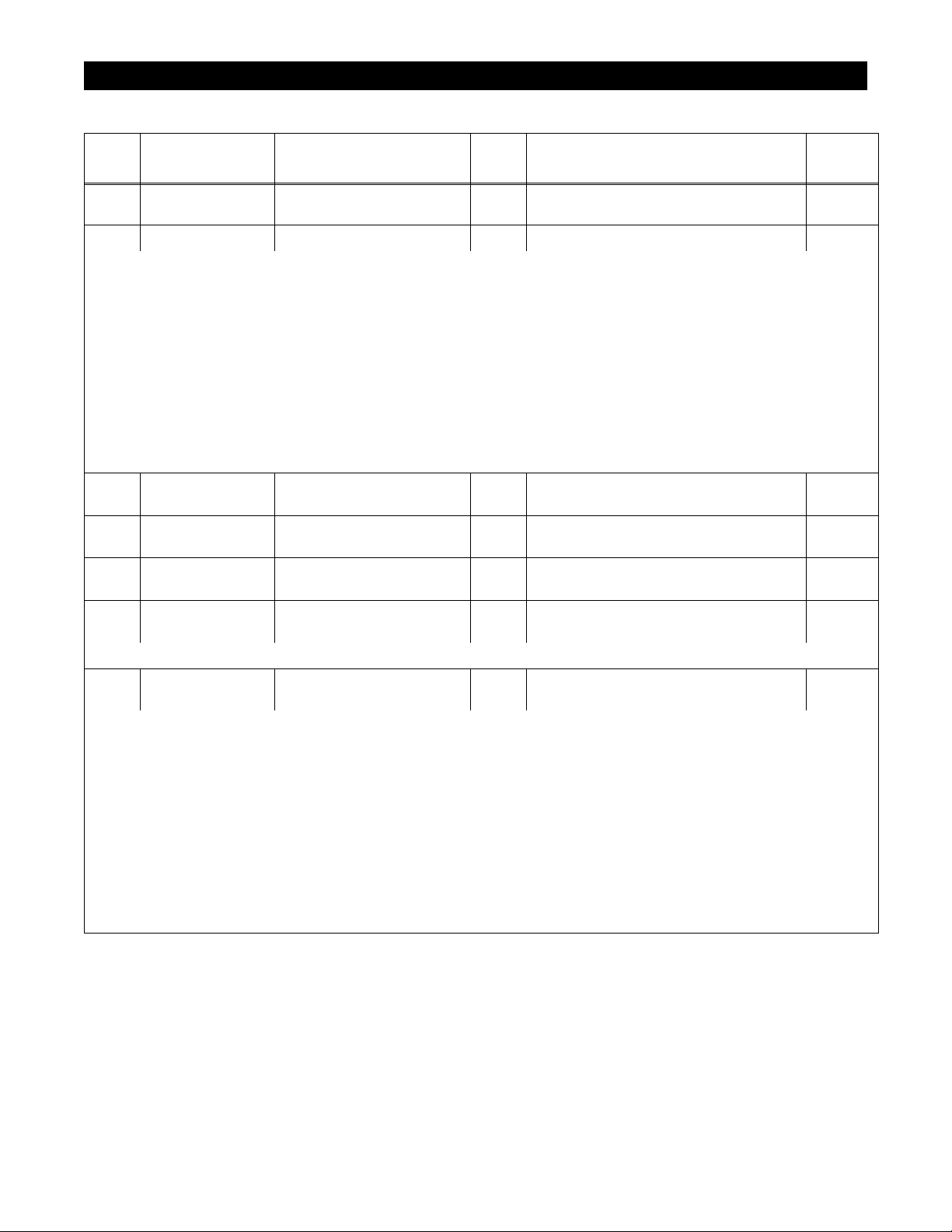

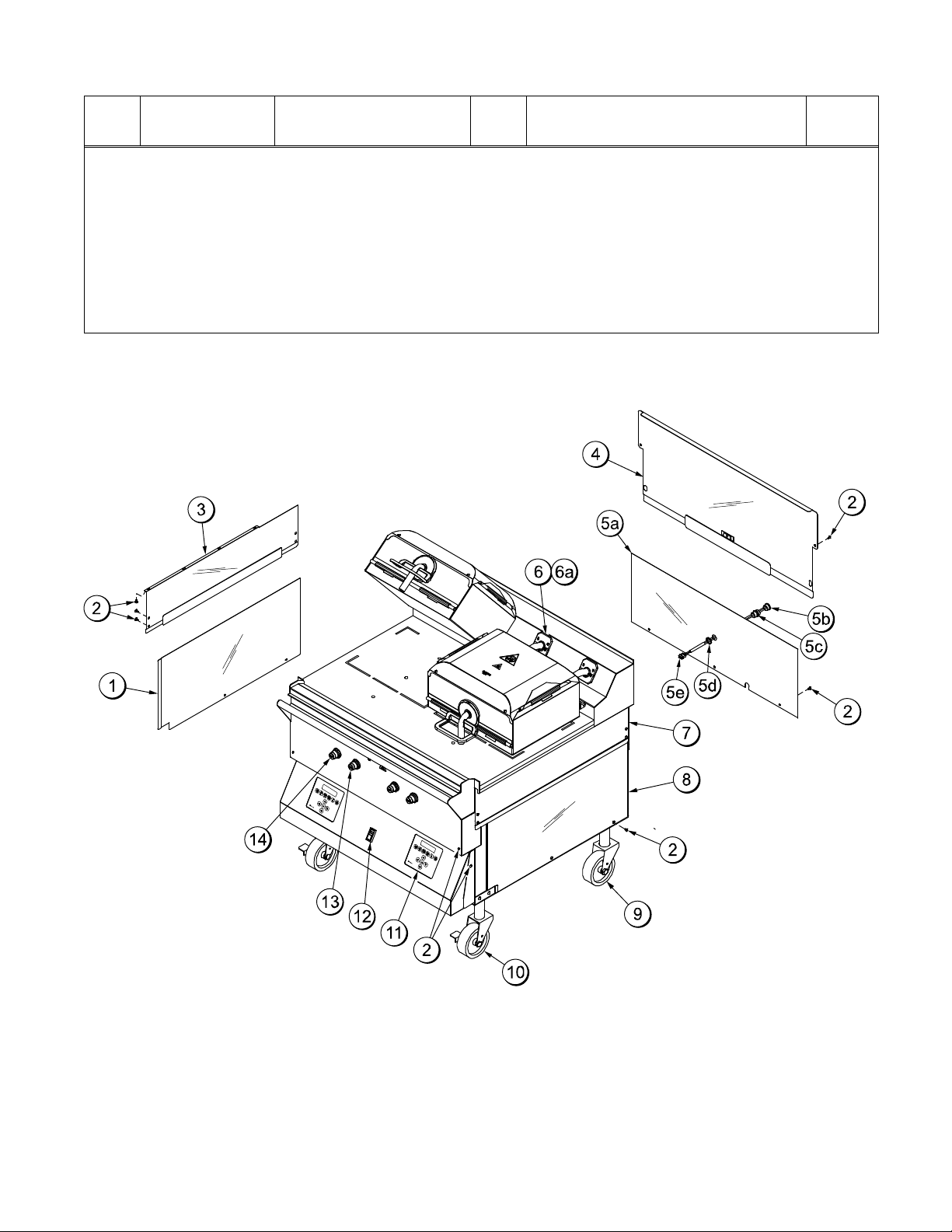

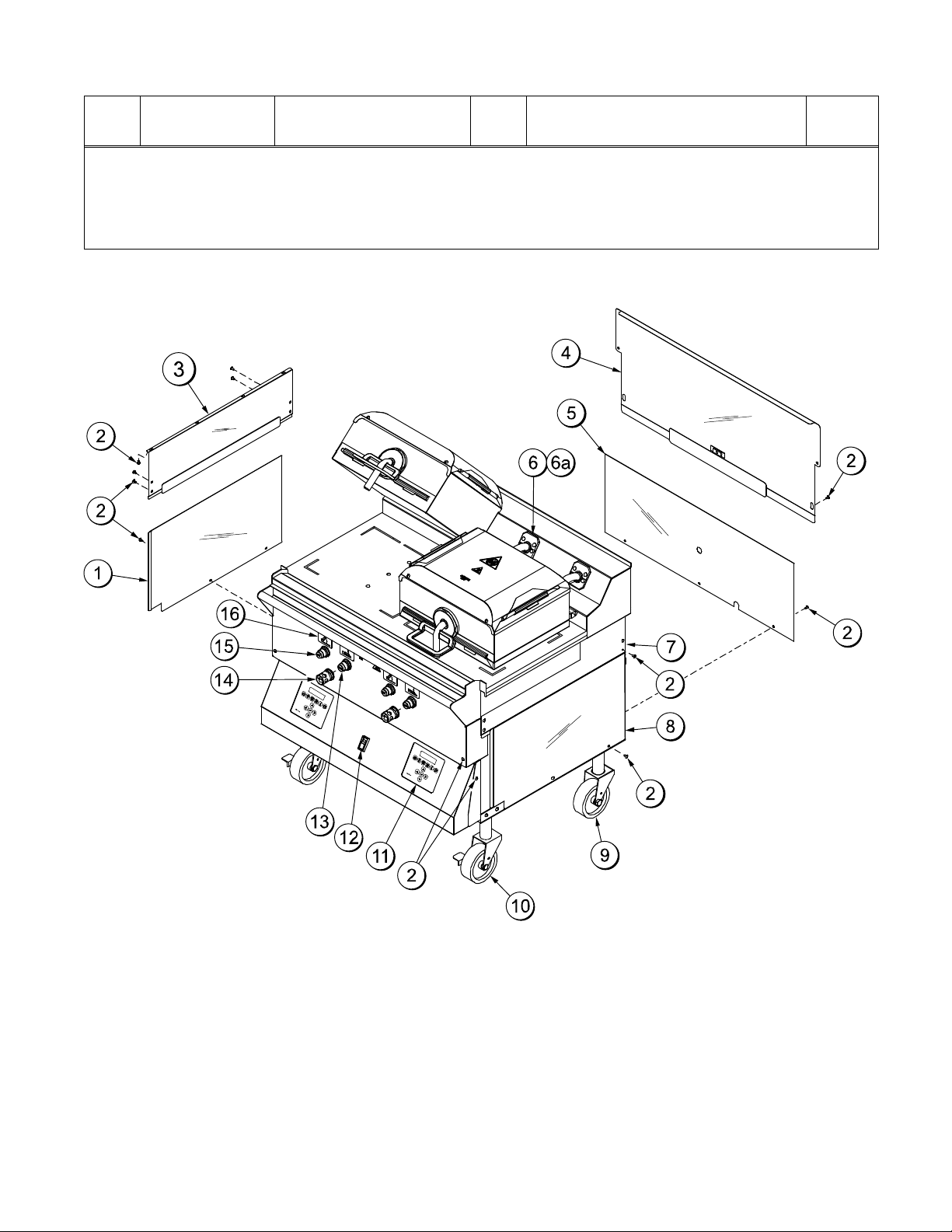

C832 Exploded View (See Figure 1.)

ITEM

PART NO. DESCRIPTION QTY. FUNCTION WARR.

CLASS

1 072967 Panel-Side Left 1 Provides access to internal com

ponents for service and cleaning.

2 024298 Screw-10-32 X 3/8 23 Secures the panel to the frame. 000

3 X72962 Panel A.Side Left

(Upper)

4 X72951 Panel A.Back Service

(Upper)

5 X72958-SER

(Includes

Panel A.Back Panel

(Lower)

5a-5e)

1 Provides access to internal com

ponents for service and cleaning.

1 Provides access to internal com

ponents for service and cleaning.

1 Provides access to internal com

ponents for service and cleaning.

Has a two speed fan connector

built into the panel.

5a 072959 Panel-Back Two Speed

Fan

1 Provides access to internal com

ponents. Has a two speed fan

connector built into the panel.

5b 053889 Cap-Protective Plastic

7/8 THD

1 Protects the plug on the end of

the back panel harness.

5c X74158 Harness A.-Back Pnl 1 Connects to the internal harness

in the grill for the 2 speed fan.

5d 078327 Nut-Locking Conduit

1/2”

1 Secures the back panel harness

connector to the panel.

5e 044823 Connector-Mate Lock 1 Connects the back panel harness

to the internal wire harness.

6 X78330SER Kit A.Grease Shield 2 Prevents grease migration. 103

6a 078329 Fastener-Snap 16 Fastens grease shields to rear

shroud of grill.

7 X72965 Panel A.Side Right

(Upper)

8 072968 PanelSide Right

(Lower)

1 Provides access to internal com

ponents for service and cleaning.

1 Provides access to internal com

ponents for service and cleaning.

9 078377 Caster5” 75/8 Stem 2 Allows grill mobility. 103

10 073240 CasterGrill 5” Swivel

2 Prevents grill movement. 103

w/Lock

11 X72491SER ControlDisplay 2 Controls all functions of the grill. 103

12 076989WP SwitchRockerDPST

10A (Fan Interlock)

1 Activates power to the grill and the

exhaust fans.

103

103

103

103

103

000

103

000

103

000

103

103

103

4

100804

Page 6

C832 Exploded View

ITEM

PART NO. DESCRIPTION QTY. FUNCTION WARR.

13 076012 ButtonOperatorBlack

(Standby)

14 076011 ButtonOperatorRed

(Raise)

2 Activates the cook cycle, keeps

the upper platen in the closed po

sition, and displays the message

“STANDBY” on the control. When

pressed twice within five seconds,

the upper platen will automatically

lower into the Standby position.

2 Cancels the Standby mode, raises

the upper platen, and deactivates

the Cook cycle.

CLASS

000

000

Figure 1

5

101018

Page 7

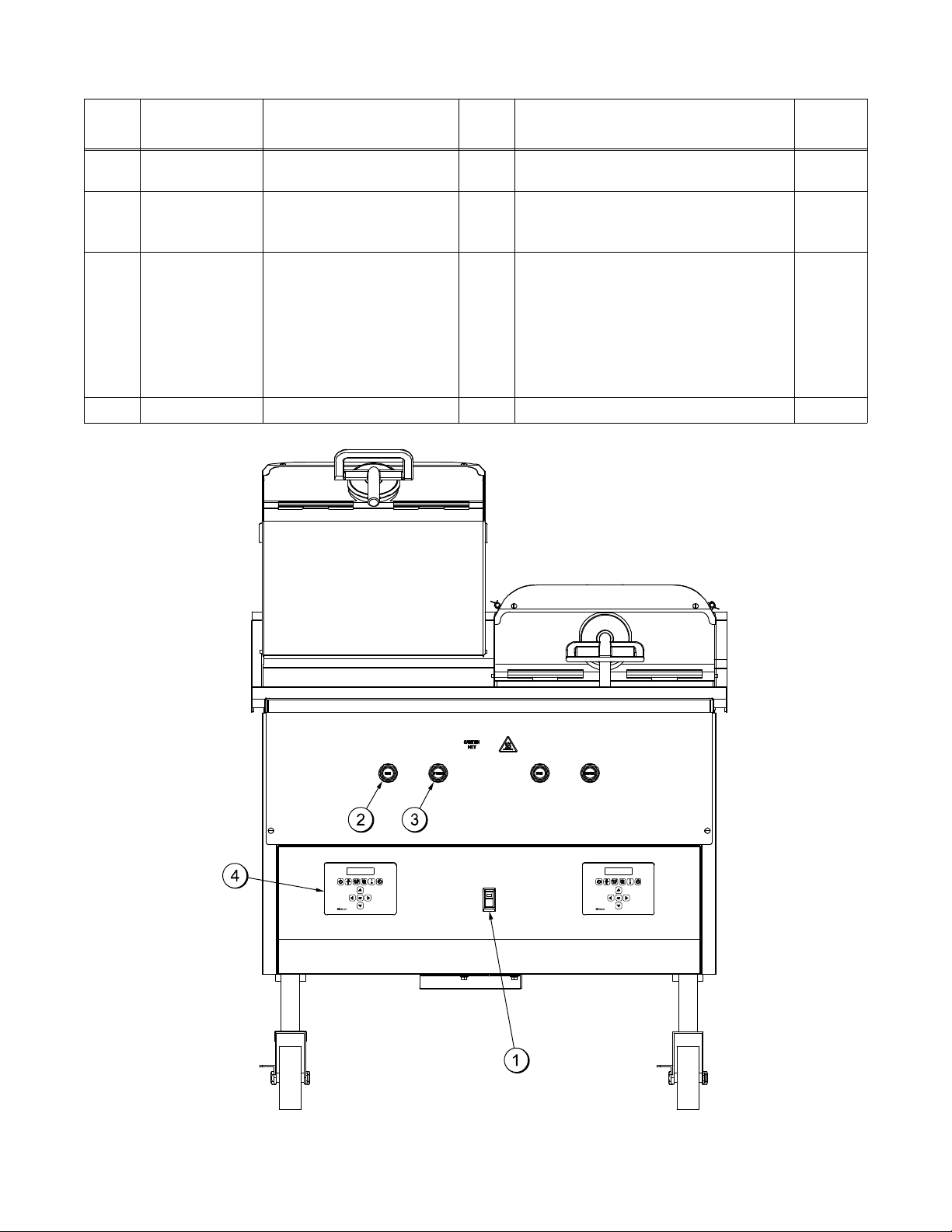

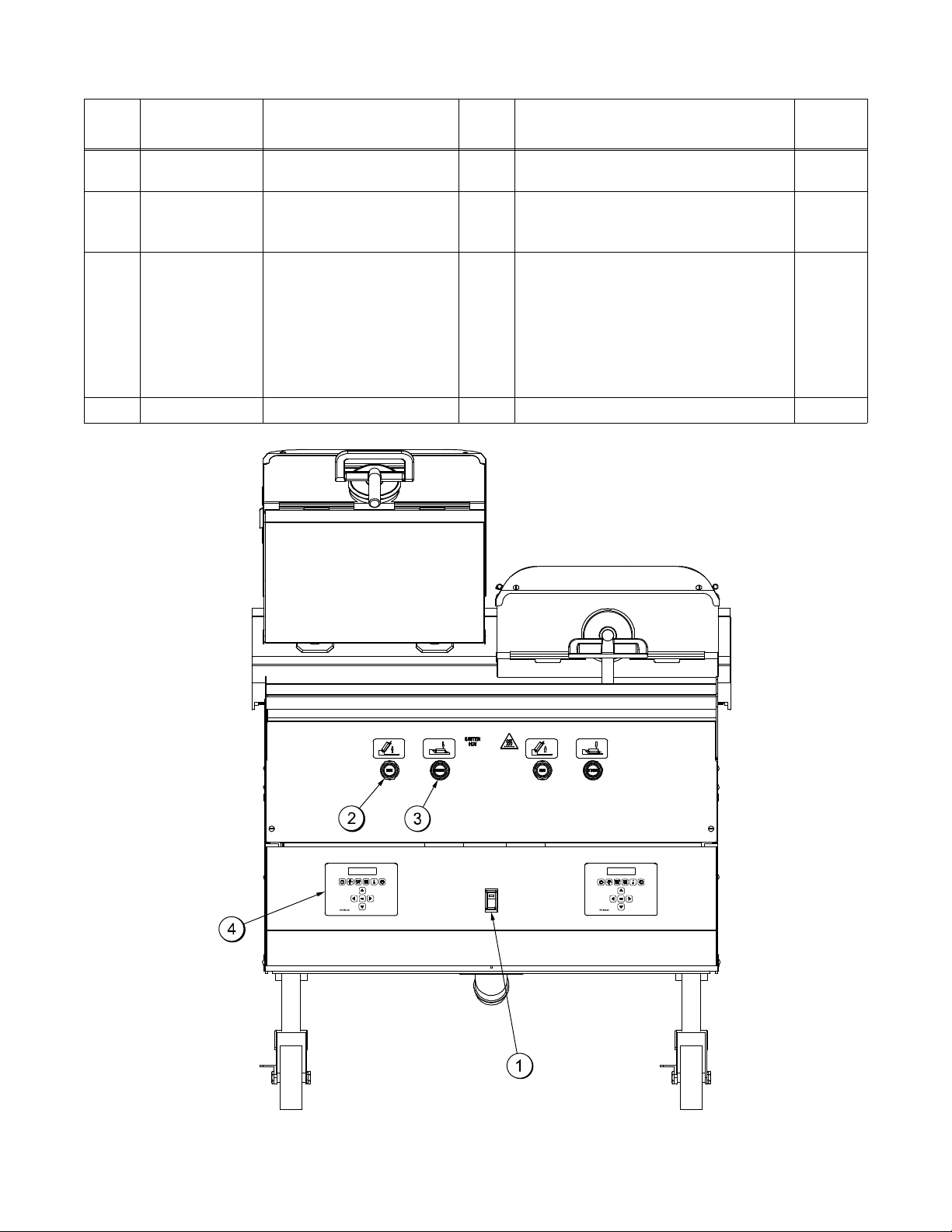

C832 Front View

ITEM

1 076989-WP Switch-Rocker-DPST

2 076011 Button-Operator-Red

PART NO. DESCRIPTION QTY. FUNCTION WARR.

1 Activates power to the grill and the

10A (Fan Interlock)

exhaust fans.

2 Cancels the Standby mode, raises

(Raise)

the upper platen, and deactivates

the Cook cycle.

3 076012 Button-Operator-Black

(Standby)

2 Activates the cook cycle, keeps

the upper platen in the closed

position, and displays the

message “STANDBY” on the

control. When pressed twice

within five seconds, the upper

platen will automatically lower into

the Standby position.

4 X72491-SER Control-Display 2 Controls all functions of the grill. 103

CLASS

103

000

000

Figure 2

6

101018

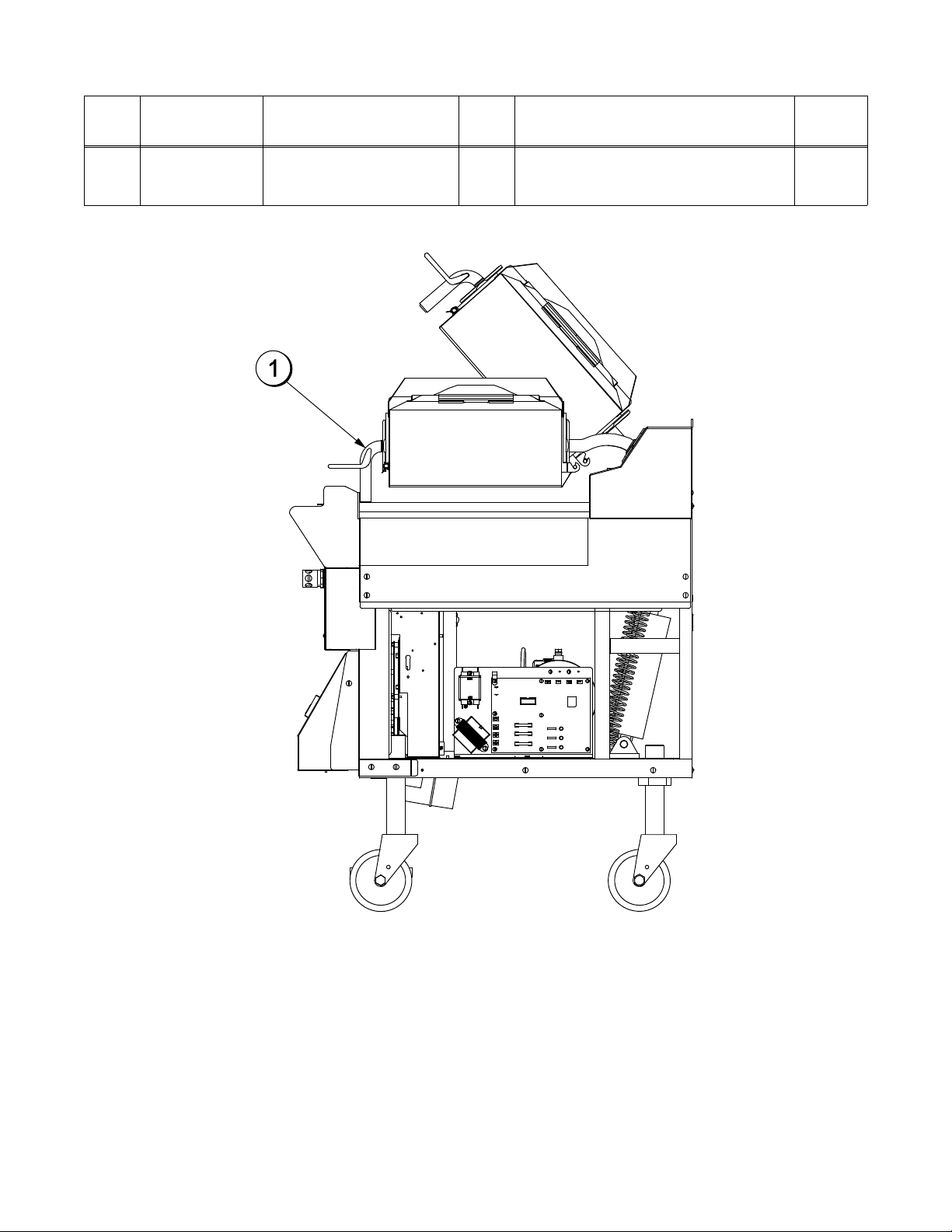

Page 8

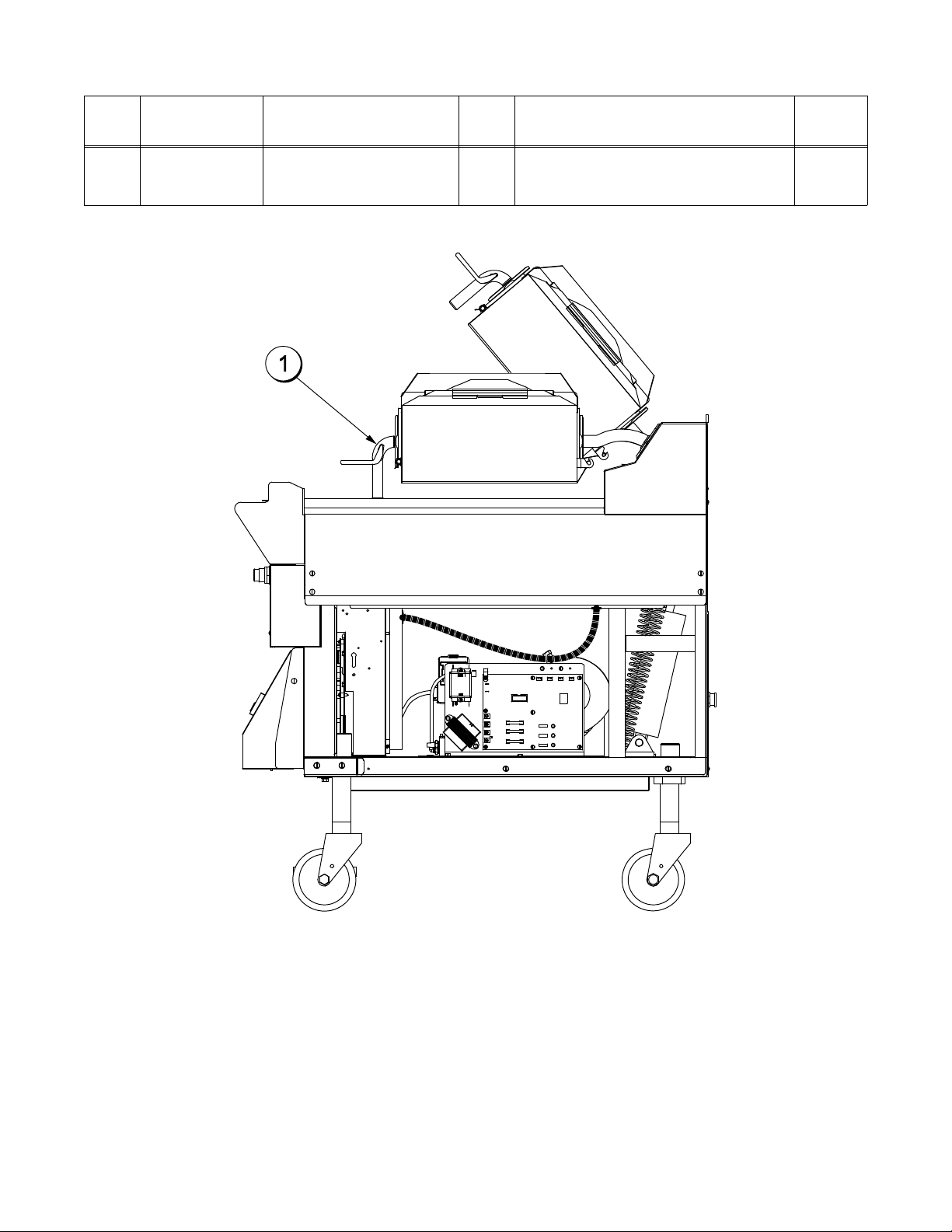

C832 Right Side View

ITEM

PART NO. DESCRIPTION QTY. FUNCTION WARR.

1 072472 Handle-Platen 2 The handle sits solidly on the

lower cook surface when the

platen is lowered.

CLASS

103

Figure 3

7

Page 9

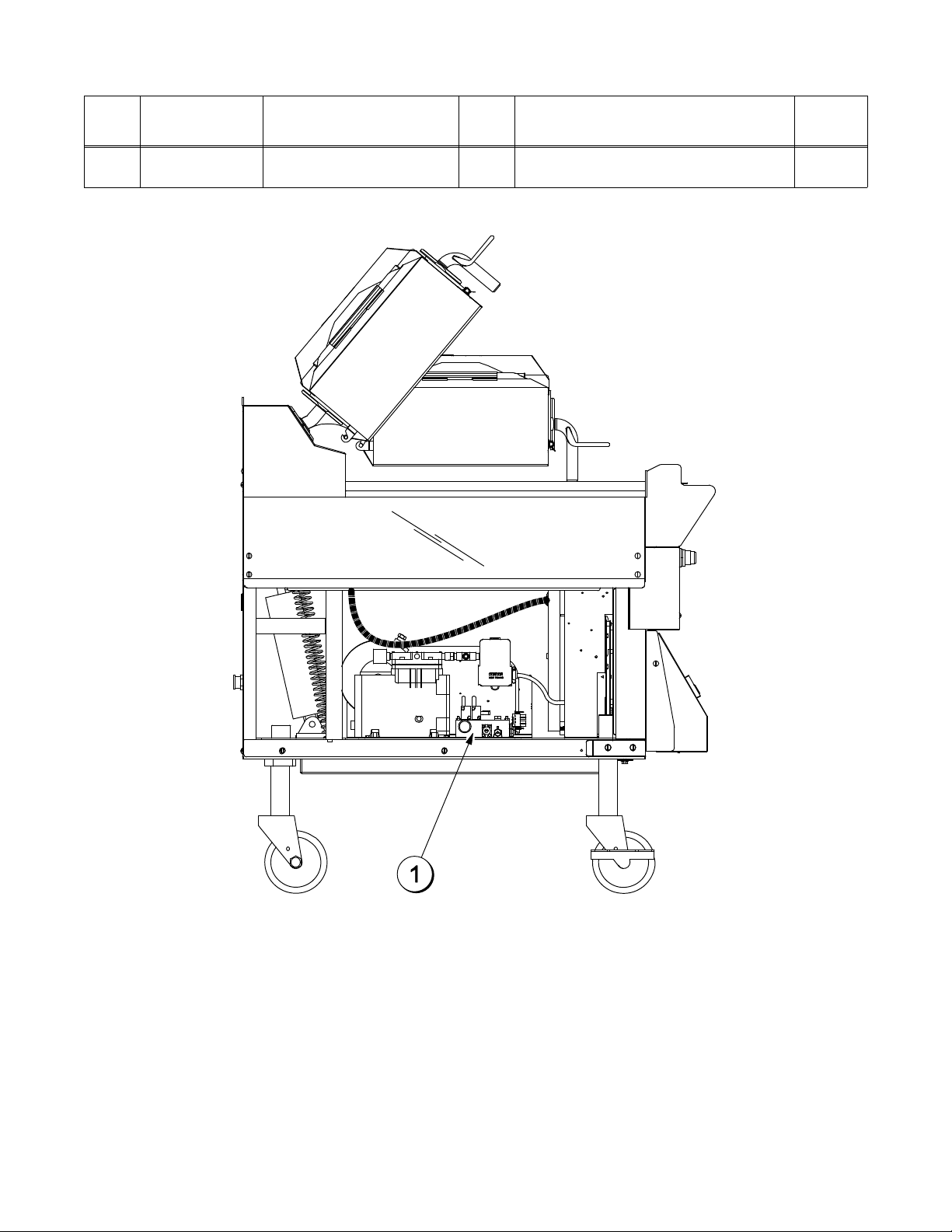

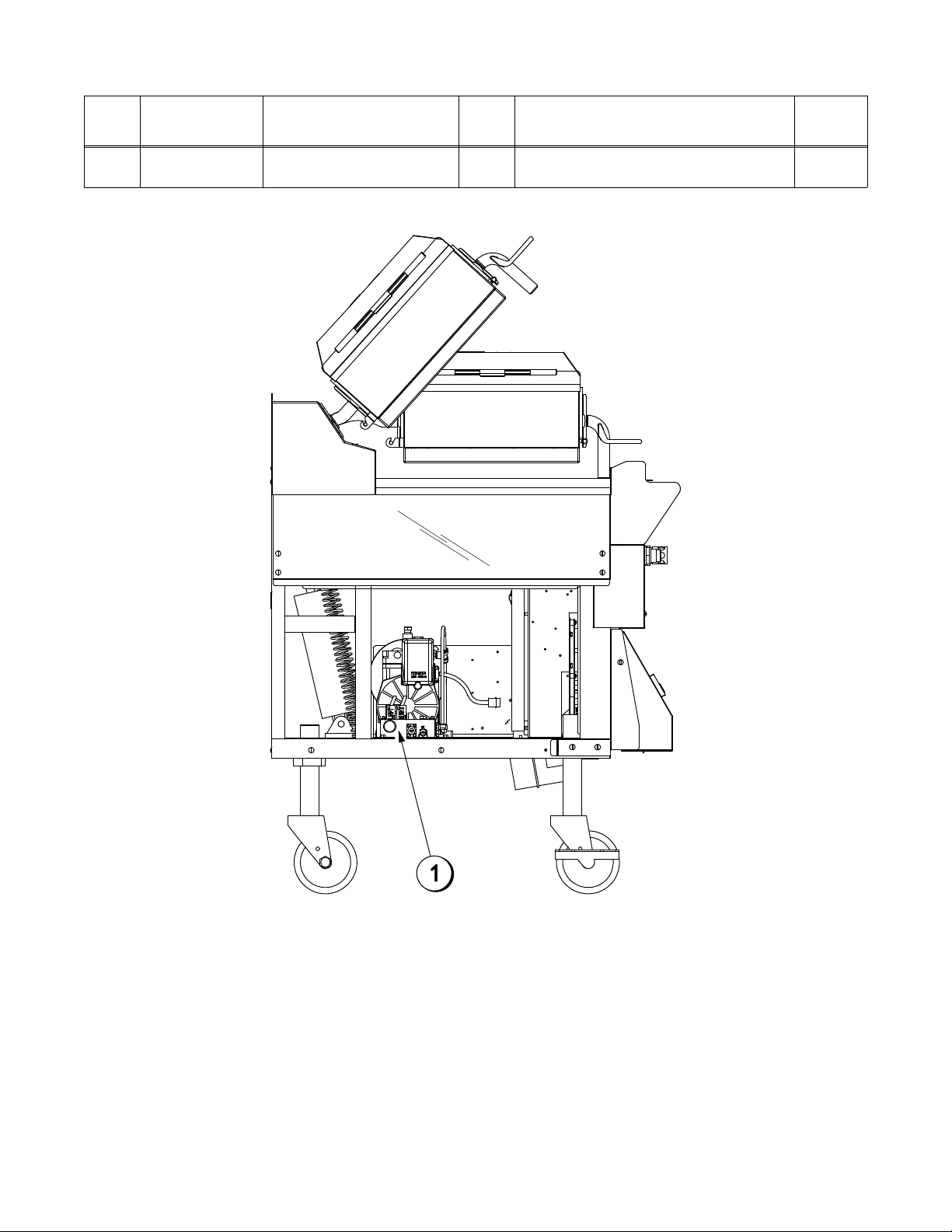

C832 Left Side View

ITEM

PART NO. DESCRIPTION QTY. FUNCTION WARR.

1 073129 Manifold A. 1 Regulates air pressure for platen

operation.

CLASS

103

Figure 4

8

Page 10

C834 Exploded View (See Figure 5.)

ITEM

PART NO. DESCRIPTION QTY. FUNCTION WARR.

CLASS

1 074110 Panel-Side Left

(Lower)

1 Provides access to internal com

ponents for service and cleaning.

2 024298 Screw-10-32 X 3/8 23 Secures the panel to the frame. 000

3 X74126 Panel A.Side Left

(Upper)

4 X72951 Panel A.Back Service

(Upper)

5 072959 Panel-Back Two Speed

Fan

1 Provides access to internal com

ponents for service and cleaning.

1 Provides access to internal com

ponents for service and cleaning.

1 Provides access to internal com

ponents. Has a two speed fan

connector built into the panel.

6 X78330SER Kit A.Grease Shield 2 Prevents grease migration. 103

6a 078329 Fastener-Snap 16 Fastens grease shields to rear

shroud of grill.

7 X74127 Panel A.Side Right

(Upper)

8 074111 PanelSide Right

(Lower)

1 Provides access to internal com

ponents for service and cleaning.

1 Provides access to internal com

ponents for service and cleaning.

9 078377 Caster5” 75/8 Stem 2 Allows grill mobility. 103

10 073240 Caster5” 75/8 Stem

2 Prevents grill movement. 103

Locking

11 X72491SER ControlDisplay 2 Controls all functions of the grill. 103

12 076989WP SwitchRockerDPST

10A (Fan Interlock)

13 076012 ButtonOperatorBlack

(Standby)

1 Activates power to the grill and the

exhaust fans.

2 Activates the cook cycle, keeps

the upper platen in the closed po

sition, and displays the message

“STANDBY” on the control. When

pressed twice within five seconds,

the upper platen will automatically

lower into the Standby position.

14 075288 GuardLens 2 Prevents accidental activation of

the Standby Button.

103

103

103

103

000

103

103

103

000

103

9

100804

Page 11

C834 Exploded View

ITEM

PART NO. DESCRIPTION QTY. FUNCTION WARR.

15 076011 ButtonOperatorRed

(Raise)

16 075699SYM LabelControl Panel

International Symbols

2 Cancels the Standby mode, raises

the upper platen, and deactivates

the Cook cycle.

1

Visually describes the grill platen

Set

functions for standard operation.

CLASS

000

000

Figure 5

10

101018

Page 12

C834 Front View

ITEM

1 076989-WP Switch-Rocker-DPST

2 076011 Button-Operator-Red

PART NO. DESCRIPTION QTY. FUNCTION WARR.

1 Activates power to the grill and the

10A (Fan Interlock)

exhaust fans.

2 Cancels the Standby mode, raises

(Raise)

the upper platen, and deactivates

the Cook cycle.

3 076012 Button-Operator-Black

(Standby)

2 Activates the cook cycle, keeps

the upper platen in the closed

position, and displays the

message “STANDBY” on the

control. When pressed twice

within five seconds, the upper

platen will automatically lower into

the Standby position.

4 X72491-SER Control-Display 2 Controls all functions of the grill. 103

CLASS

103

000

000

Figure 6

11

101018

Page 13

C834 Right Side View

ITEM

PART NO. DESCRIPTION QTY. FUNCTION WARR.

1 072472 Handle-Platen 2 The handle sits solidly on the

lower cook surface when the

platen is lowered.

CLASS

103

Figure 7

12

Page 14

C834 Left Side View

ITEM

PART NO. DESCRIPTION QTY. FUNCTION WARR.

1 073129 Manifold A. 1 Regulates air pressure for platen

operation.

CLASS

103

Figure 8

13

Page 15

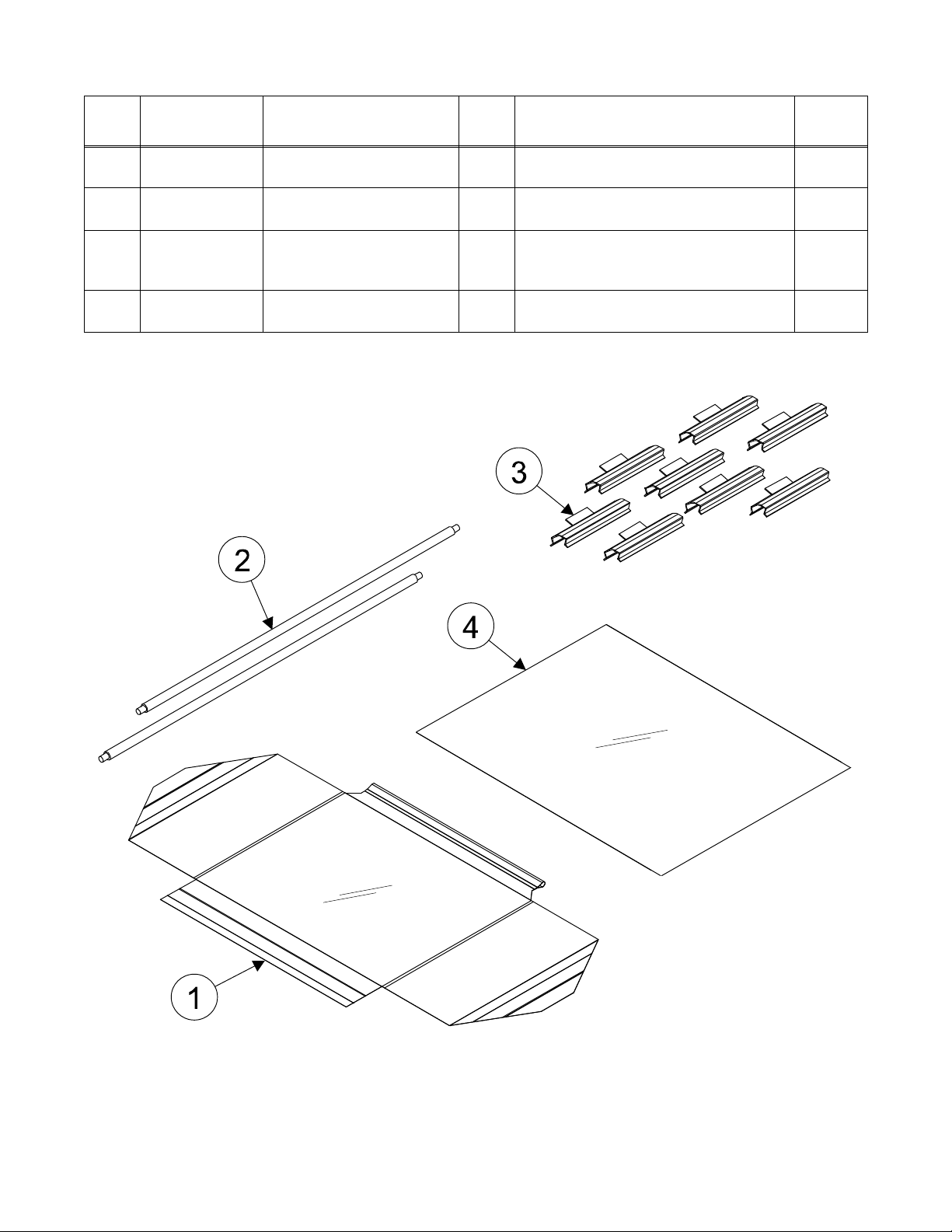

Accessories

ITEM

1 073317 Sheet-Release

PART NO. DESCRIPTION QTY. FUNCTION WARR.

1 Non-stick barrier used to protect

(Box of 6)

the upper platen.

2 076155 Rod-Release Material 2 Slides through the loop in the

release material sheet.

3 072673 Clip-Release Material

w/Tab

8 Secures the non-hemmed end of

the release sheet to the release

material bar.

*4 081432 Sheet-Lower Release

(Box of 12)

1 Non-stick barrier used to protect

the lower cook surface.

*For grill markets using lower release sheet, only.

CLASS

000

103

000

000

Figure 9

14

121102

Page 16

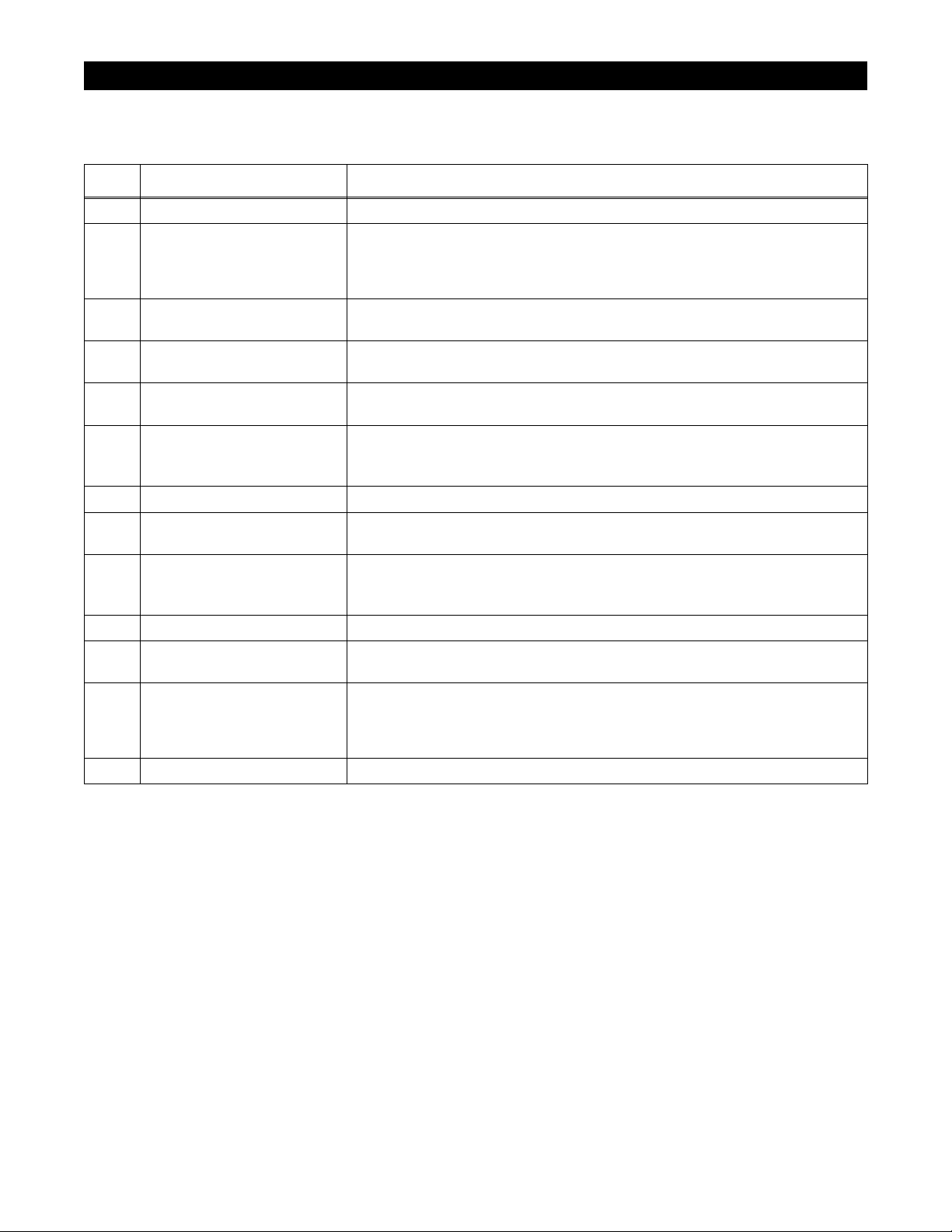

IMPORTANT TO THE OPERATOR

Important to the Operator Exploded View (See Figure 10.)

ITEM DESCRIPTION FUNCTION

1 Fan Interlock Switch This switch activates power to the grill and the exhaust fans.

2 ON/OFF Key This key is used to turn the controller on and off to start a

preheating mode and to auto-gap the platen. The key must be

pressed and held for three seconds to activate, in order to

prevent unintended operation.

3 AM/PM Key This key is used to toggle back and forth between the AM and PM

menu item lists.

4 MANUAL/AUTO Key This key is used to toggle back and forth between the Manual

and Auto modes.

5 Left Arrow Key This key is used to scroll through menu items when cooking in the

Manual mode. (Inactive in the Auto mode.)

6 Down Arrow Key While in the Menu mode, this key is used to decrease a numerical

value and to scroll through the characters when entering a new

menu item or modifying an old one. (Inactive in the Auto mode.)

7 OK Key This key is used to accept the information entered.

8 Right Arrow Key This key is used to scroll through menu items when cooking in the

Manual mode. (Inactive in the Auto mode.)

9 Up Arrow Key While in the Menu mode, this key is used to increase a numerical

value and to scroll through the characters when entering a new

menu item or modifying an old one. (Inactive in the Auto mode.)

10 Program Key This key is used to enter and exit the Programming mode.

11 Temperature Key When pressed and held for 3 seconds, this key will access the

Probe Calibration screen.

12 Cook Time Key This key is used to change the remove time of a specific menu

item. To change a specific cook time, the item must be selected in

the Manual mode. (Note: Press and hold the Cook Time key for

three seconds to activate.)

13 Liquid Crystal Display This screen displays menu options and information.

15

101018

Page 17

Important to the Operator

Symbol Definitions

To better communicate in the International

arena, the words on many of our operator

keys have been replaced by symbols to

indicate their functions. Your Taylor equipment

is designed with these International symbols.

The following chart identifies the symbol

definitions.

= ON/OFF

= AM/PM

Figure 10

= PROGRAM

= TEMPERATURE

= TIME

101018

16

Page 18

EQUIPMENT SET-UP PROCEDURES

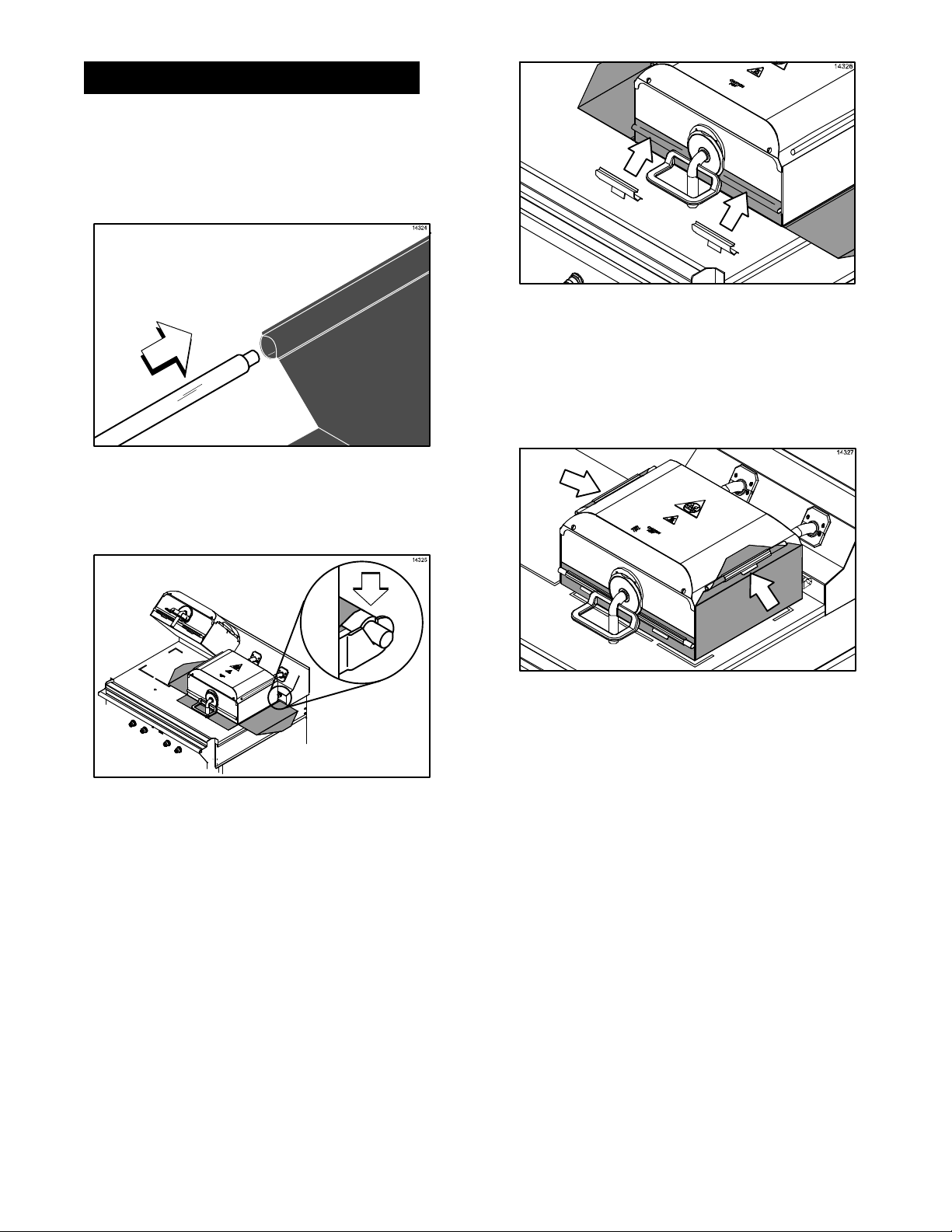

Installing Upper Platen Release Sheets

1. Slide the release material retention bar

through the loop in the release sheet.

(See Figure 11.)

Figure 11

2. Engage the material retention bar into the

hooks provided on the platen.

(See Figure 12.)

Figure 13

4. Carefully wrap the release sheet side

flaps over the cover rails and secure the

sheet with locking clips. (See Figure 14.)

Figure 12

3. Center the release sheet on the bar. Pull

it tightly over the release material bar

located in the front of the platen. Secure

the sheet with two locking clips.

(See Figure 13.)

Figure 14

IMPORTANT! Do not crease the release

sheet. This will greatly reduce the life

of the sheet.

5. Make sure the release sheets are tight

across the upper platen surface.

6. Repeat these steps for the other upper

platen.

17

Page 19

Installing Lower Release Sheets

(Grills Using Lower Release Sheets)

Note: The following steps pertain to grill

markets using lower release sheets, only. If

lower release sheets are not used, proceed to

“Start-Up of the Grill” on page 20.

WARNING! Upper release sheets

cannot be used on the lower grill surface. Poor

quality and potential food safety issues will

occur.

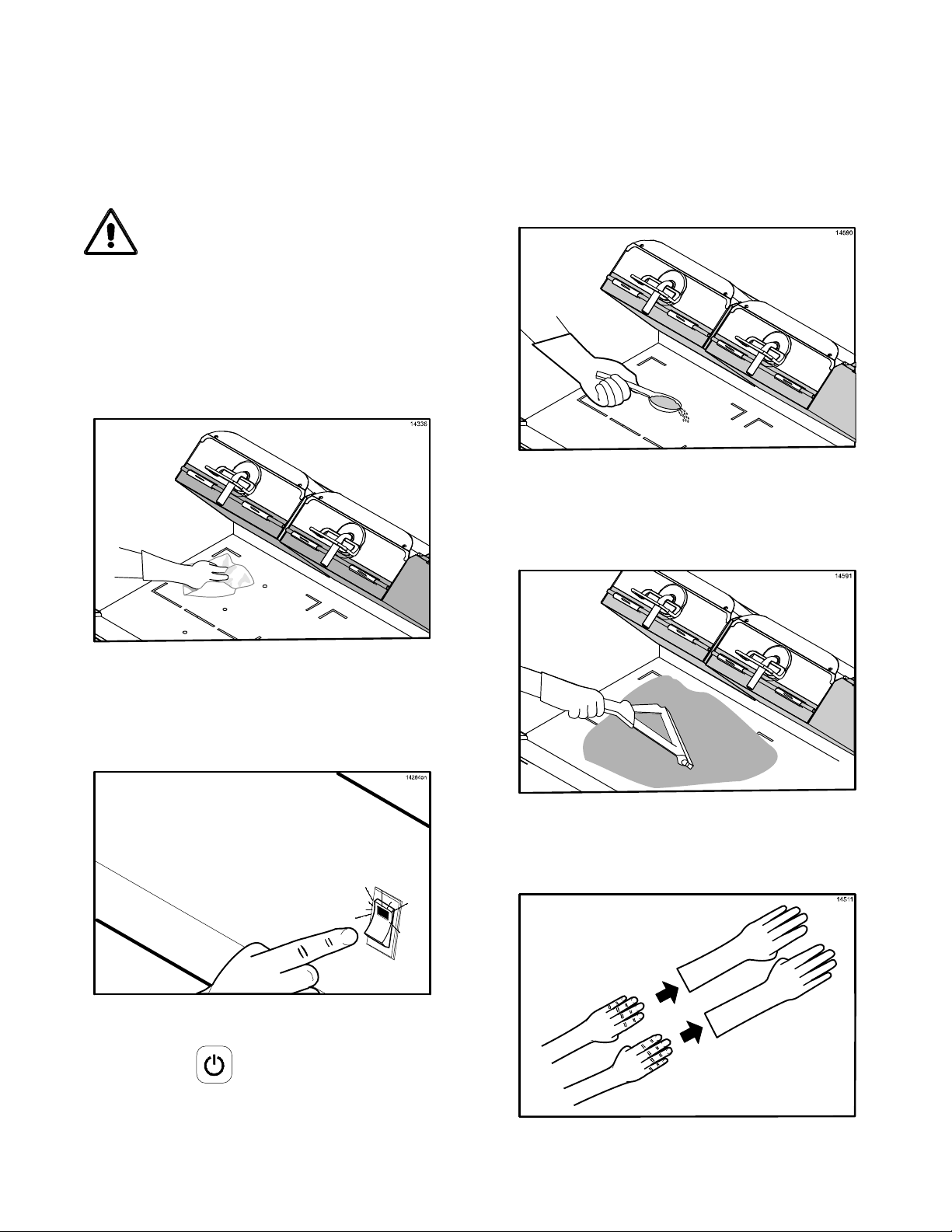

1. Clean the grill with a sanitizer-soaked grill

cloth to remove any debris on the grill.

(See Figure 15.)

4. The screen will then display, “CLEAN

GRILL SURFACES,” followed by “CLOSE

PLATEN FOR AUTO LEVELING.”

5. Using a sundae spoon, distribute two level

spoonfuls of soy adhesion flakes over a

warm 3 ft. (1 m.) grill surface, allowing the

flakes to melt. (See Figure 17.)

Figure 17

6. Using a clean squeegee, spread the

flakes on the cooking zone.

(See Figure 18.)

Figure 15

2. Place the fan interlock switch in the ON

position. The controller will display the

message “OFF”. (See Figure 16.)

Figure 16

3. Press the key for 3 - 5 seconds. “AM

TOO COOL” and “AM FOLDED EGGS CLAM” will be displayed on the control

screen.

Figure 18

7. Put on heat-resistant gloves.

(See Figure 19.)

Figure 19

18

121102

Page 20

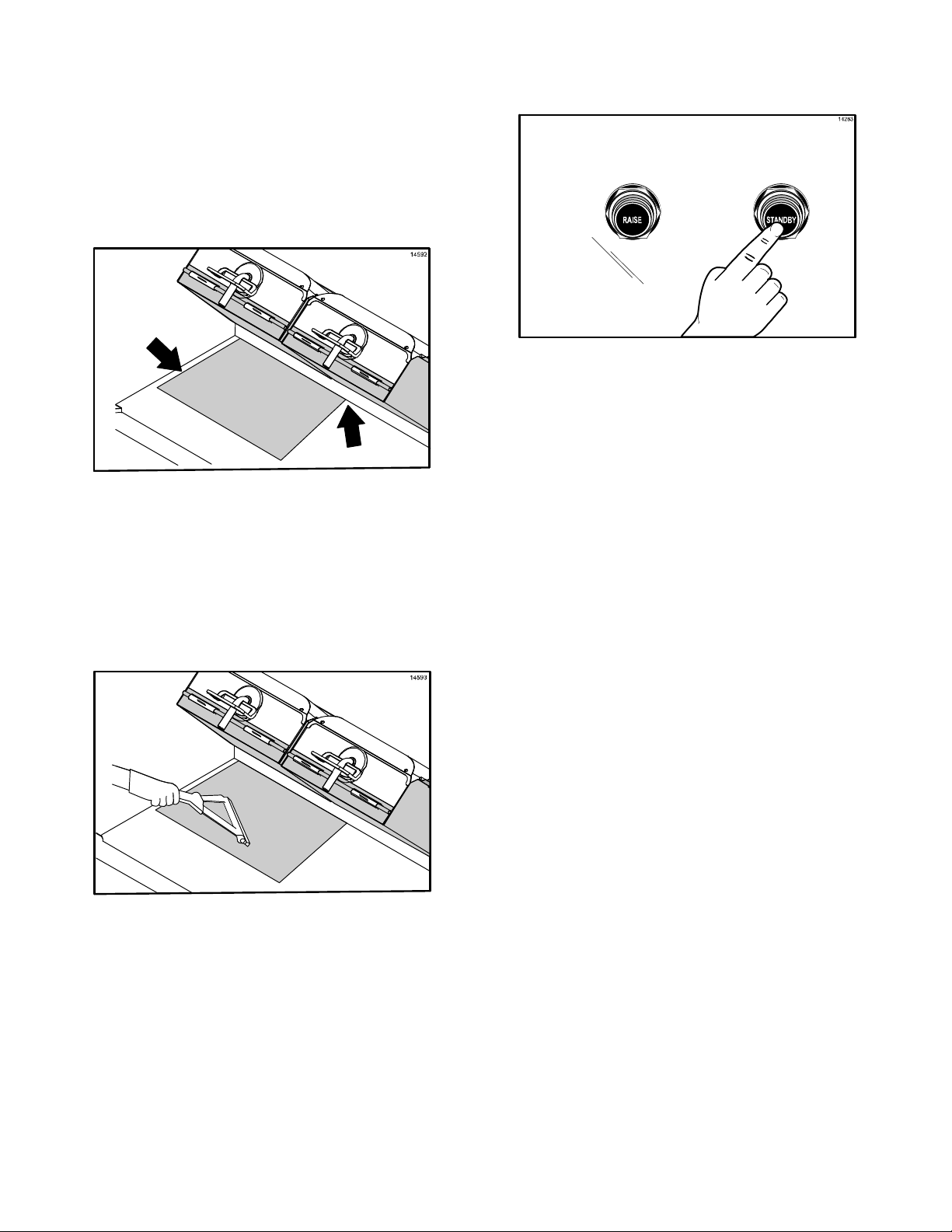

8. With the longest side of the lower release

sheet facing the back of the grill, hold the

release sheet about one inch from the

end of each side. Align the back edge of

the release sheet with the back splash

and the side edge of the grill.

(See Figure 20.)

11. Press the Standby button to close the

platen. (See Figure 22.)

Figure 22

12. After the platen has closed, the grill will

start heating up to the proper

temperature. The control will display the

following message until the grill has

reached the proper temperature, ”TOO

COOL FOR AUTO LEVELING”.

Figure 20

9. Using the grill squeegee, gently squeegee

out air bubbles, making sure not to crease

or fold the release sheet. (See Figure 21.)

Figure 21

13. When the grill has reached the proper

temperature, the screen will display,

“PLEASE WAIT FOR AUTO LEVELING”.

14. When the Auto Leveling is complete, the

upper platen will raise. The screen will

display the product that had been

selected.

The release sheet must be changed when:

S Product sticks to the release sheet.

S Carbon builds up, causing problems in

taste or appearance.

S There is a tear in the release sheet in

the cooking area.

S The release material substance is worn

from the release sheet.

Note: Reverse the cooking side of the release

sheets on a daily basis.

10. Repeat the last 2 steps for the other

half of the grill surface. The release

sheets will overlap about 1” (25 mm) in

the middle.

Note: When properly applied, the release

sheet will lay flat, with only a few small air

bubbles.

Care of Release Sheets

S DO NOT fold or crease.

S DO NOT touch with any sharp object or

abrasive.

S DO NOT hose with hot water or soak in

water.

S DO NOT place under other objects.

121101

19

Page 21

Start-Up of the Grill

IMPORTANT: The lower grill plate and the

upper platen MUST BE CLEAN before starting

these procedures.

Note: Grills that use lower release sheets

require start up of grill before installation of

lower release sheets. (See page 18.)

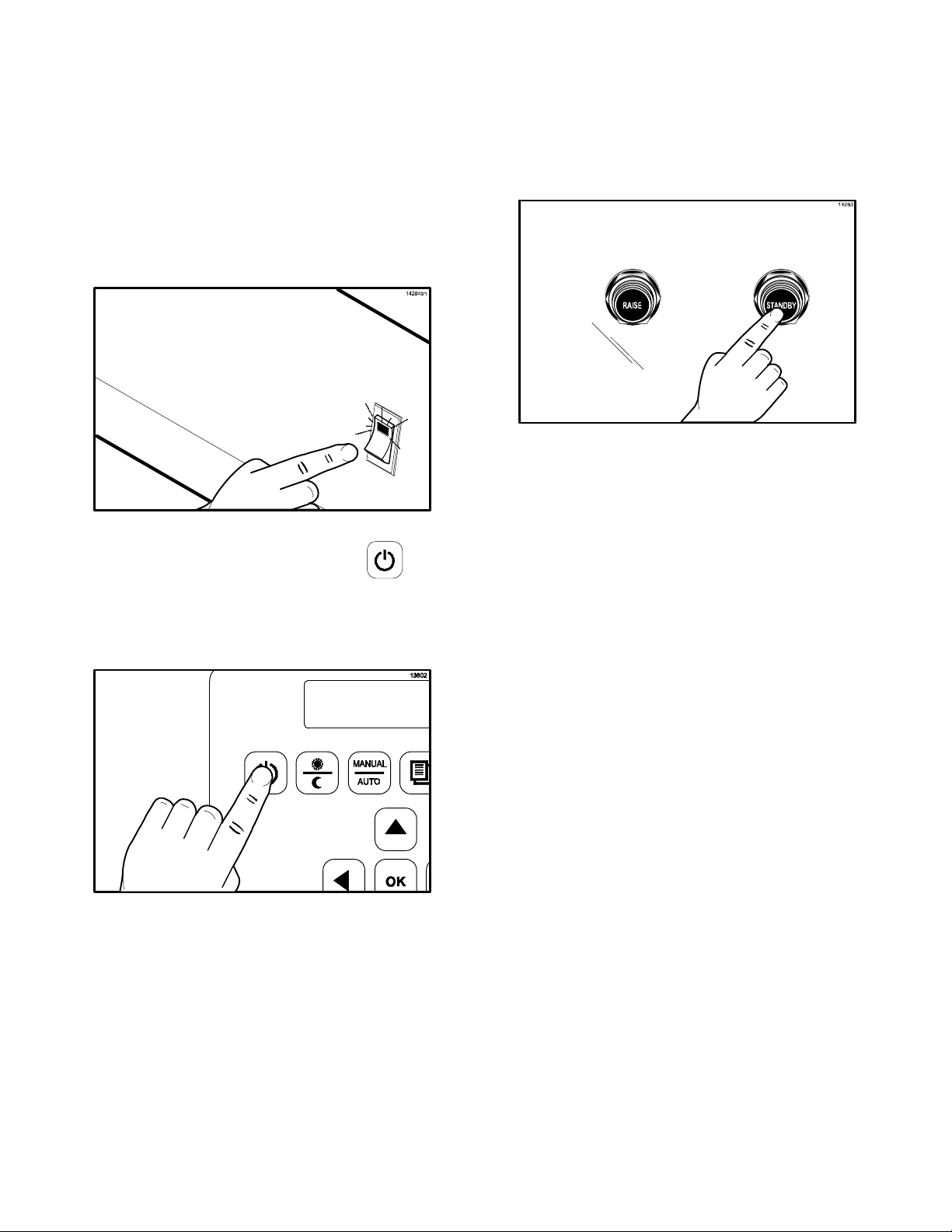

1. Place the fan interlock switch in the ON

position. The controller will display the

message “OFF”. (See Figure 23.)

Figure 23

2. Heat up the grill by pressing the key

for 3 - 5 seconds. “AM TOO COOL” and

“AM FOLDED EGGS - CLAM” will be

displayed on the control screen.

(See Figure 24.)

3. The control will first display, “CLEAN

GRILL SURFACES” and then display,

“CLOSE PLATEN FOR AUTO

LEVELING.”

4. Press the Standby button to close the

platen. (See Figure 25.)

Figure 25

5. After the platen has closed, the grill will

start heating up to the proper

temperature. The control will display the

following message until the grill has

reached the proper temperature, ”TOO

COOL FOR AUTO LEVELING”.

6. When the grill has reached the proper

temperature, the screen will display,

“PLEASE WAIT FOR AUTO LEVELING”.

7. When the Auto Leveling is complete, the

upper platen will raise. The screen will

display the product that had been

selected.

Figure 24

20

Page 22

MENU SCREENS

Manager Menu - Passcode Access

Limited access to menu screens is available

through the Operator Menu or the Manager

Menu. In order to enter the Operator Menu or

the Manager Menu, individual passcodes must

be entered.

Operator Menu - Passcode Access

The Operator Menu gives limited MENU and

SYSTEM SETUP access. Access to this menu

is intended for day to day operations

(whomever is responsible for Beef Integrity).

To enter the Operator Menu, press the

key to display “PROGRAMMING.” Press the

key to display the passcode entry

screen. Enter the Operator Menu passcode by

pressing the keys in this order:

The Manager Menu gives access to all MENU

items and limited SYSTEM SETUP access. To

access the Manager Menu, press the

key to display “PROGRAMMING.” Press the

key to display the passcode entry

screen. Enter the Manager Menu passcode by

pressing the keys in this order:

All MENU items will be visible, including “ADD

ITEM”. All parameters are available for each

menu item.

S REMOVE IN GAP

S STAGE 1 TIME

All menu items will be visible, except “ADD

ITEM”. The following parameters are available

for each menu item:

S AM/PM

S REMOVE IN

S REMOVE ALARM

S MUST REMOVE IN

S PREP BREAD IN

S PREP ALARM

The following SYSTEM SETUP parameters

will be available:

S PROBE CALIBRATION

S TEMPERATURE DISPLAY

S AUTO CLOSE

S SPEAKER VOLUME

S STATE 1 GAP

S TOP TEMPERATURE

S BOTTOM TEMPERATURE

S AUTO SELECTION

S AUTO GAP

The following SYSTEM SETUP parameters

will be available, in addition to those available

in the Operator Menu.

S AUTO PROD MELT TIME

S GATEWAY ENABLE

S DATE

S TIME

S 24 HOUR STORE

S AUTO IDLE TOP TEMP

S AUTO IDLE BOTTOM TEMP

S TOO COOL DELAY

S STANDBY ALERT

140908

21

Page 23

Product Selection

The

key allows the operator to cook in

either the AUTO mode or in the MANUAL

mode.

AUTO Mode

In the AUTO mode, the grill automatically

detects the product that is placed on the lower

grill plate and sets the appropriate cooking

parameters. The AUTO option is only

available for clam items.

Note: In “MENU ITEMS”, the AUTO

SELECTION parameter must be set to

“YES”.

MANUAL Mode

In the MANUAL mode, the operator selects

the desired product to be cooked.

To select a product using the MANUAL item

option, perform the following steps.

Patty Placement

Placement procedures of meat products must

be followed on the grill. Meat must be placed

on the lower grill plate, two patties at a time,

from front to back, per the patty placement

guide on page 23. When the cook cycle is

complete, the upper platen will raise.

The patties must be removed immediately

after the upper platen has been raised to the

OPEN position and the meat has been

seasoned. Remove the patties, one at a time,

from front to back and right to left, per the

patty placement guide on page 23.

The maximum amount of meat patties to be

cooked on each side of the grill is as follows.

S 8 regular (10:1) patties

S 6 quarter pound (4:1) patties

S 4 Angus patties

S 8 sausage patties

S 6 circular bacon

The following chart is to be used as the patty

placement guide.

1. Press the

key. “AM” will be

displayed on the control screen. If “PM” is

desired, press the

key one more

time.

2. Use the

or keys to scroll

through the various product menu

selections. Continue this process until the

desired product is displayed. The product

that is displayed will be selected.

22

Page 24

Models C832 & C834

IntelliGapt Grill

10:1, 4:1, Sausage, Circular Bacon, and

Patty Placement Guide

Figure 26

Note: Patty placement procedures for International Markets may differ. Follow the recommendations

of your local McDonald's authorities.

23

121221

Page 25

Standby Procedures

Whenever the grill is idle and product is not

being cooked, the upper platen must be

placed in the STANDBY position.

1. To place the upper platen in the

STANDBY position, press the STANDBY

button twice from the open position.

(See Figure 27.)

Cleaning After Each Run of Product

(Grills Using Lower Release Sheets)

Note: This manual contains separate

procedures for grills that use lower release

sheets and for grills that do not use lower

release sheets. Use the appropriate

procedures for your grill.

If your grill does not

use lower release

sheets, go to page 25.

1. Squeegee the lower release sheet from

front to back. (See Figure 29.)

Figure 27

2. To raise the upper platen to the OPEN

position to resume cooking, press the

RAISE button. (See Figure 28.)

Figure 28

Note: If the grill remains idle for 5 continuous

minutes without being placed in STANDBY, a

tone will sound and the display will flash “PUT

GRILL IN STANDBY”.

Figure 29

2. Squeegee the upper release sheet from

top to bottom. (See Figure 30.)

Figure 30

CAUTION: NEVER USE FORCE TO

RAISE THE UPPER PLATEN. DAMAGE TO

COMPONENTS WILL RESULT. USE ONLY

THE RAISE BUTTON TO OPEN THE UPPER

PLATEN!

3. Push the residue into the grease trough.

Note: Do not use excessive pressure when

wiping the release sheet with the squeegee.

Using excessive pressure can scratch or tear

the release sheet.

121101

24

Page 26

4. Carefully squeegee the air bubbles from

center to side, making sure the release

sheet does not become folded or creased.

5. Wipe the squeegee with a sanitizersoaked grill cloth.

6. Wipe the top platens and grill surface 4

times an hour with a sanitizer-soaked grill

cloth.

7. As needed during operation, use a

sanitizer-soaked grill cloth to clean the

back splash plate and the bullnose areas.

CAUTION: THE UPPER PLATENS

AND LOWER COOK SURFACE ARE HOT!

TO PREVENT BURN INJURIES, USE

EXTREME CAUTION WHEN WIPING THE

RELEASE MATERIAL SHEETS.

Cleaning After Each Run of Product

(Grills Not

Using Lower Release Sheets)

Note: This manual contains separate

procedures for grills that use lower release

sheets and for grills that do not use lower

release sheets. Use the appropriate

procedures for your grill.

2. Use the wiper squeegee to clean the

release sheet on the upper platen. Use a

diagonal motion to clean the sheet. Hold

the handle at a slight upward angle, with

the wiper end facing downward.

(See Figure 32.)

Figure 32

Note: Do not use excessive pressure when

wiping the release sheet with the squeegee.

Using excessive pressure can scratch or tear

the release sheet.

3. Using the wiper squeegee, push the

grease at the rear of the lower grill plate

into the grease can. Do not use the grill

scraper for this step. (See Figure 33.)

If your grill uses lower release sheets, go to

page 24.

1. Using the grill scraper, scrape the grease

on the lower grill plate from front to back.

Do not scrape across the rear of the

lower grill plate with the grill scraper.

(See Figure 31.)

Figure 31

Figure 33

4. Use the grill cloth to clean the back splash

plate and the bullnose areas, as needed

during operation.

Note: To increase the life of the release

sheet, wipe it with a damp, folded grill cloth a

minimum of four times every hour.

CAUTION: THE UPPER PLATEN

SURFACE IS VERY HOT! TO PREVENT

BURN INJURIES, USE EXTREME CAUTION

WHEN WIPING THE RELEASE MATERIAL

SHEET.

25

121102

Page 27

To Cook in the Flat Grill Mode

1. To select a flat grill menu item, press the

To Transition From Breakfast to Lunch

1. If the grill is in the AM AUTO Mode, press

the

key to select PM.

key.

2. Press the

key for the Manual Mode.

The display may show “TOO COOL” or

“TOO HOT”, until the grill reaches the set

temperatures.

3. Use the

or keys to scroll to the

flat grill menu item.

4. After placing product in the prescribed

method, press the STANDBY button to

start the cook cycle. (See Figure 34.)

2. If the grill is set to a certain breakfast item

in the Manual Mode, press the

key

to select PM.

3. The display may show “TOO COOL” or

“TOO HOT”, until the grill reaches the set

temperatures.

To Display the Current Temperatures

Note: The actual temperatures may be

displayed at any time, including during a cook

cycle.

1. Press the

key. A series of screens

will display. The first screen will display as

follows.

Top Bck (AM/PM) Top Frt

Figure 34

5. Perform the functions that appear on the

display (i.e., sear, turn). Pressing the

RAISE button will cancel the cook cycle.

6. When the cook cycle is complete, the

display will flash the message “REMOVE”

and an audible alert will sound. Remove

the product per the prescribed method.

Back Cntr Frt

2. The next display will show the actual

temperatures, per the following example.

426 Now/Deg F 425

348 350 349

Note: Pressing the key once and the

key five times will keep the temperatures

on the screen until the

key is pressed.

26

Page 28

3. The next display will show the set point

temperatures, per the following example.

425 Set/Deg F 425

350 350 350

4. The display will then return to the selected

menu item.

To Change Product Cook Times

Probe Calibration

For grill markets that use lower release

material sheets, probe calibration is performed

with the release sheets installed. For grill

markets that do not use lower release material

sheets, probe calibration is performed without

the lower release sheets installed.

Thermocouple probes are located from front to

rear on the lower grill plates and upper

platens. Measurements should be taken from

front to back and left to right on all model grills.

See Figures 35 and 36 below, which identify

the probe locations.

Model C832

1. Press the

key to put the grill into the

Manual Mode.

2. Scroll to the menu item that requires a

change to the cook time by pressing the

or keys.

3. Press and hold the

key for 3-5

seconds.

4. Use the

and the

key to increase the time

key to decrease the time.

Each press of the key changes the time

by one second.

Figure 35

Model C834

5. Press the

key to save the changes.

To Change a Menu Item

See “Product Selection” on page 22.

Figure 36

160505

27

Page 29

1. Press the key to put the grill into the

Manual Mode.

2. Press and hold the

key for three

seconds.

3. Place a pyrometer surface probe on the

selected heat zone as shown in

Figures 35 and 36.

4. If the displayed temperature on the

controller is more than 5°F/3°C different

from the pyrometer surface probe display:

Press the

temperature or press the

key to increase the

key to

decrease the temperature to match the

displayed temperatures.

Note: The set of numbers that follow the

zone name represent the previous

calibration adjustment.

DAILY CLEANING PROCEDURES

Grills Using Lower Release Sheets

Note: This manual contains separate

procedures for grills that use lower release

sheets and for grills that do not use lower

release sheets. Use the appropriate

procedures for your grill.

If your grill does not

use lower release

sheets, go to page 36.

S CAUTION: Never use cold water or

ice to cool the upper platen or the

lower grill plate.

S Never use grill screens on the upper

platen or the lower grill plate.

S Never allow the grill scraper or

abrasive cleaning materials to come

in contact with the release sheet.

1. Raise the upper platen to the OPEN

position by pressing the red RAISE key.

(See Figure 37.)

5. To calibrate the next zone, use the

key to move to the next zone.

6. Once calibration is complete, press the

key to save all changes.

Figure 37

CAUTION: NEVER USE FORCE TO

RAISE THE UPPER PLATEN. DAMAGE TO

COMPONENTS MAY RESULT. USE ONLY

THE RAISE KEY TO OPEN THE UPPER

PLATEN!

28

121102

Page 30

2. Press the key until the message

“CLEANING” is displayed

3. Press the

key.

When the cook surfaces reach the proper

temperature for cleaning, an alarm will

sound and the message “READY TO

CLEAN” will be displayed.

4. Press the key to cancel the alarm.

SHEETS ARE VERY HOT. TO PREVENT

BURN INJURIES, USE EXTREME CARE.

8. Wipe the exposed surface of the upper

and lower release sheets with a clean,

sanitizer-soaked grill cloth.

(See Figure 40.)

5. Press the

key again and the

message “OFF” will display.

6. Put on heat-resistant gloves.

(See Figure 38.)

Figure 38

7. Remove, empty, and reinstall the grease

pans. (See Figure 39.)

Figure 40

9. Open one packet of McD Hi-Temp Grill

Cleaner (HTGC). Empty the contents into

a clean entrée base or stainless steel

pan. (See Figure 41.)

Figure 41

10. Dip a clean, sanitizer-soaked grill cloth

into the grill cleaner. Do not saturate the

cloth. (See Figure 42.)

Figure 39

CAUTION: THE UPPER PLATENS,

LOWER COOK SURFACE AND RELEASE

Figure 42

121102

29

Page 31

11. Use the grill cloth dampened with grill

cleaner to clean the exposed surfaces of

the upper and lower release sheets.

(See Figure 43.)

Figure 43

12. Remove the release sheet locking clips,

the bars, and the upper and lower release

sheets. Wash and rinse the clips and bars

in the 3-compartment sink. If necessary,

soak them in a hot solution of SolidSense

APSC to remove carbon accumulation.

(See Figure 44.)

14. Dip the Kay Grill Cleaning Pad Holder into

the grill cleaner. (See Figure 45.)

Figure 45

IMPORTANT: DO NOT scrub while applying

the grill cleaner in the following steps:

15. Spread a light coating of the grill cleaner

over the entire lower grill surface, using

front to back strokes. Allow the product to

remain on the grill while spreading across

all surfaces. (See Figure 46.)

Figure 44

13. Place all release sheets flat on the

release sheet storage tray. DO NOT fold,

crease, or place them on sharp objects.

DO NOT clean them in the 3-compartment

sink.

Figure 46

Note: Allowing the grill cleaner to sit on

the grill surfaces will require less effort

and time to scrub heavy soil buildup and

achieve a clean grill.

121102

30

Page 32

16. Apply McD Hi-Temp Grill Cleaner

(HTGC) to the front side of the platens,

starting from the right platen to the left

platen. (See Figure 47.)

Figure 47

17. Apply the grill cleaner to the platen

surfaces, starting from the right platen to

the left platen. (See Figure 48.)

19. Apply the grill cleaner to the outer edges

of the right and left platens.

(See Figure 50.)

Figure 50

20. Press the black STANDBY button to lower

the right platen.

Figure 48

18. Apply the grill cleaner to the back side of

the platens, from the right platen to the

left platen. (See Figure 49.)

Figure 49

21. Apply grill cleaner to the inner edges of

the right and left platens. (See Figure 51.)

Figure 51

22. Press the red RAISE button to raise the

right platen.

31

Page 33

23. Using the Kay Grill Cleaning Pad Holder,

scrub the front side of the platens from

the right platen to the left platen. (See

Figure 52.)

26. Scrub the outer edges of the right and left

platens. (See Figure 55.)

Figure 55

Figure 52

Note: Scrub all areas containing visible

soil accumulation until the soil liquefies.

24. Scrub the platen surfaces, starting from

the right platen to the left platen.

(See Figure 53.)

Figure 53

25. Scrub the back side of the platens from

the right platen to the left platen.

(See Figure 54.)

27. Press the black STANDBY button to lower

the right platen.

28. Scrub the inner edges of the right and left

platens. (See Figure 56.)

Figure 56

29. Press the red RAISE button to raise the

right platen.

Figure 54

32

Page 34

30. Rinse all areas of the platen surfaces with

a clean, sanitizer-soaked grill cloth,

starting from the right platen to the left

platen. Lower and raise the platens as

needed to gain access to the sides of the

platens. (See Figure 57.)

Figure 57

31. Rinse the lower grill surface with a clean,

sanitizer-soaked grill cloth.

(See Figure 58.)

32. Clean the surrounding areas such as the

hood, bull nose, and back splash, with a

clean, sanitizer-soaked grill cloth.

(See Figure 59.)

Figure 59

Note: The rear of the upper platen, as

well as the tubular arm, can easily be

wiped from the front of the unit. If cleaning

is performed on a daily basis, there

should be no carbon build-up.

33. One at a time, place the upper and lower

release sheets on the lower grill surface.

Wipe both sides of each release sheet

with a clean, sanitizer-soaked grill cloth.

(See Figure 60.)

Figure 58

Figure 60

121102

33

Page 35

34. Re-install the upper release sheets.

Secure the sheets with the locking clips

and bars. (See Figure 61.)

Figure 61

Note: Reverse the cooking side of the

release sheets on a daily basis (example:

black side on odd days; grey or brown

side on even days).

35. Wipe the lower grill surface with a clean,

sanitizer-soaked grill cloth. Repeat until

surface is clean. (See Figure 62.)

37. Wash and rinse the grease pans in the

3-compartment sink.

38. Re-install the grease pans.

(See Figure 64.)

Figure 64

39. Press the key for 3 - 5 seconds. “AM

TOO COOL” and “AM FOLDED EGGS CLAM” will be displayed on the control

screen.

Figure 62

36. Remove and empty the grease pans.

(See Figure 63.)

40. The screen will then display, “CLEAN

GRILL SURFACES,” followed by “CLOSE

PLATEN FOR AUTO LEVELING.”

41. Using a sundae spoon, distribute two level

spoonfuls of soy adhesion flakes over a

warm 3 ft. (1 m.) lower grill surface,

allowing the flakes to melt.

(See Figure 65.)

Figure 63

Figure 65

130117

34

Page 36

42. Using a clean squeegee, spread the

flakes on the cooking zone.

(See Figure 66.)

44. Gently squeegee the air bubbles and

wrinkles out of each release sheet. Do not

crease or fold the release sheets.

(See Figure 68.)

Figure 68

Figure 66

43. With the longest side of the lower release

sheet facing the back of the grill, hold the

release sheet about one inch from the

end of each side. Align the back edge of

the release sheet with the back splash

and the side edge of the grill.

(See Figure 67.)

Figure 67

Note: Reverse the cooking side of the

release sheets on a daily basis (example:

black side on odd days; grey or brown

side on even days).

45. Repeat the last 2 steps for the other

half of the grill surface. The release

sheets will overlap about 1” (25 mm) in

the middle.

46. Leave the upper platens in the OPEN

position overnight.

47. Place the fan interlock switch in the OFF

position. (See Figure 69.)

Figure 69

48. After the grill cleaning pad has cooled,

remove it from the pad holder. Wash and

rinse it thoroughly at the 3-compartment

sink. Turn the grill pad over and re-install

it on the holder.

49. Wash, rinse, and sanitize all utensils and

tools used to clean the grill at the

3-compartment sink.

35

121102

Page 37

Cleaning Procedure - 24 Hour Stores Only

(Grills Using Lower Release Sheets)

DAILY CLEANING PROCEDURES

1. Clean the grill using the Daily Cleaning

Procedures on pages 28 - 35,

steps 1 - 45.

2. After the grill pad has cooled, remove,

wash, and rinse it thoroughly at the

3-compartment sink. Turn the grill pad

over and re-install on the grill pad holder.

3. Wash, rinse, and sanitize all utensils and

tools used to clean the grill at the

3-compartment sink.

4. Place the fan interlock switch in the OFF

position. Wait 10 seconds and then place

the switch back in the ON position. The

display will read “OFF”.

5. Press the Standby button to close the

platen.

6. After the platen has closed, the control will

display “GRILL TOO COOL FOR AUTO

LEVELING” until the grill reaches the

proper temperature. When the proper

temperature is reached, the platen will

self-level and open when completed. The

grill will be in the AM Manual mode.

Grills Not Using Lower Release Sheets

IMPORTANT: This manual contains separate

procedures for grills that use lower release

sheets and for grills that do not use lower

release sheets. Use the procedures

appropriate for your grill.

If your grill uses lower release sheets, go to

page 28.

S CAUTION: Never use cold water or

ice to cool the upper platen or the

lower grill plate.

S Never use grill screens on the upper

platen or the lower grill plate.

S Never allow the grill scraper or

abrasive cleaning materials to come

in contact with the release sheet.

1. Raise the upper platen to the OPEN

position by pressing the red RAISE key.

(See Figure 70.)

7. The grill is now ready to use.

Figure 70

CAUTION: NEVER USE FORCE TO

RAISE THE UPPER PLATEN. DAMAGE TO

COMPONENTS MAY RESULT. USE ONLY

THE RAISE KEY TO OPEN THE UPPER

PLATEN!

36

101018

Page 38

2. Press the key until the message

“CLEANING” is displayed

7. Wipe the exposed surface of the release

sheets with a clean, sanitizer-soaked grill

cloth. (See Figure 72.)

3. Press the

key.

When the cook surfaces reach the proper

temperature for cleaning, an alarm will

sound and the message “READY TO

CLEAN” will be displayed.

4. Press the

5. Press the

key to cancel the alarm.

key again and the

message “OFF” will display.

6. Put on heat-resistant gloves.

(See Figure 71.)

Figure 72

8. Remove the release sheet locking clips,

the bars, and the upper and lower release

sheets. Wash and rinse the clips and bars

in the 3-compartment sink. If necessary,

soak them in a hot solution of SolidSense

APSC to remove carbon accumulation.

(See Figure 73.)

Figure 71

CAUTION: THE UPPER PLATEN

SURFACE AND RELEASE SHEETS ARE

VERY HOT. TO PREVENT BURN INJURIES,

USE EXTREME CARE.

Figure 73

37

Page 39

9. Set the release sheets aside on a clean,

flat surface until further cleaning is

performed. Do not fold, crease, or place

them on sharp objects. (See Figure 74.)

12. Remove, empty, and reinstall the grease

pans. (See Figure 77.)

Figure 77

Figure 74

10. Scrape the lower grill surface with the grill

scraper, in a front to back direction.

(See Figure 75.)

Figure 75

11. Use the grill squeegee to push residual

grease into the grease pans.

(See Figure 76.)

13. Open one packet of McD Hi-Temp Grill

Cleaner (HTGC). Empty the contents into

an entrée base or stainless steel pan.

(See Figure 78.)

Figure 78

14. Dip the Kay Grill Cleaning Pad Holder into

the grill cleaner. (See Figure 79.)

Figure 76

Figure 79

IMPORTANT: DO NOT scrub while applying

the grill cleaner in the following steps:

38

Page 40

15. Apply McD Hi-Temp Grill Cleaner

(HTGC) to the front side of the platens,

starting from the right platen to the left

platen. (See Figure 80.)

Figure 80

17. Apply the grill cleaner to the back side of

the platens, from the right platen to the

left platen. (See Figure 82.)

Figure 82

18. Apply the grill cleaner to the outer edges

of the right and left platens.

(See Figure 83.)

DO NOT USE METAL SCRAPERS,

ABRASIVE PADS, SCREENS OR WIRE

BRUSHES ON THE UPPER PLATENS.

DAMAGE TO COMPONENTS MAY RESULT.

16. Apply the grill cleaner to the platen

surfaces, starting from the right platen to

the left platen. (See Figure 81.)

Figure 83

19. Press the black STANDBY button to lower

the right platen.

20. Apply grill cleaner to the inner edges of

the right and left platens. (See Figure 84.)

Figure 81

Figure 84

39

Page 41

21. Press the red RAISE button to raise the

right platen.

22. Using the Kay Grill Cleaning Pad Holder,

scrub the front side of the platens from

the right platen to the left platen.

(See Figure 85.)

Figure 85

23. Scrub the platen surfaces, starting from

the right platen to the left platen.

(See Figure 86.)

25. Scrub the outer edges of the right and left

platens. (See Figure 88.)

Figure 88

26. Press the black STANDBY button to lower

the right platen.

27. Scrub the inner edges of the right and left

platens. (See Figure 89.)

Figure 86

24. Scrub the back side of the platens from

the right platen to the left platen.

(See Figure 87.)

Figure 87

Figure 89

28. Press the red RAISE button to raise the

right platen.

29. Rinse the front, side, and back of the

platen surfaces with a clean,

sanitizer-soaked grill cloth, starting from

the right to the left platen.

(See Figure 90.)

Figure 90

40

Page 42

30. Press the black STANDBY button to lower

the right platen.

31. Rinse the inner edges of both platens with

a clean, sanitizer-soaked grill cloth.

(See Figure 91.)

Figure 91

32. Press the red RAISE button to raise the

platen.

33. Wipe the back of the upper grill platen

with a clean, sanitizer-soaked grill cloth.

(See Figure 92.)

35. Spread a light coating of the grill cleaner

over the entire lower grill surface, using

front to back strokes. Do not scrub while

applying product. (See Figure 94.)

Figure 94

36. Use the cleaning pad holder to lightly

scrub the lower grill surfaces until all soil

has been liquified by the grill cleaner. For

stubborn soils, apply additional grill

cleaner and lightly scrub. (See Figure 95.)

Figure 92

34. Pour the remaining McD Hi-Temp Grill

Cleaner (HTGC) onto the lower grill

surface. (See Figure 93.)

Figure 93

Figure 95

Note: The rear of the upper platen, as

well as the tubular arm, can easily be

wiped from the front of the unit. If cleaning

is performed on a daily basis, there

should be no carbon build-up.

41

Page 43

37. Pour a small amount of lukewarm water

on a clean, sanitizer-soaked grill cloth

while holding it over the bottom grill

surface. Wipe the lower grill surface until

all residue is removed. (See Figure 96.)

40. Re-install the release sheets. Secure the

sheets with the locking clips and bars.

(See Figure 99.)

Figure 99

Figure 96

38. Place the upper platen release sheets flat

on the lower grill surface. Gently clean

both sides of the sheets with the Kay Grill

Cleaning Pad Holder. (See Figure 97.)

Figure 97

39. Rinse both sides of the release sheets

with a clean, sanitizer-soaked grill cloth.

(See Figure 98.)

Note: Reverse the cooking side of the

release sheets on a daily basis (example:

black side on odd days; grey or brown

side on even days).

41. Wipe the lower grill surface with a clean,

sanitizer-soaked grill cloth. Repeat until

no visible soil remains. (See Figure 100.)

Figure 100

42. Remove and empty the grease pans.

(See Figure 101.)

Figure 98

Figure 101

42

Page 44

43. Wash and rinse the grease pans in the

3-compartment sink.

44. Re-install the grease pans.

(See Figure 102.)

Cleaning Procedure - 24 Hour Stores Only

(Grills Not

Using Lower Release Sheets)

1. Clean the grill using the Daily Cleaning

Procedures on pages 28 - 43,

steps 1 - 46.

2. After the grill pad has cooled, remove,

wash, and rinse it thoroughly at the

3-compartment sink. Turn the grill pad

over and re-install on the grill pad holder.

Figure 102

45. Wipe the remaining grill surfaces with a

clean sanitizer-soaked grill cloth.

46. Apply a light coat of fryer cooking oil to

the entire lower grill surface.

47. Leave the upper platens in the OPEN

position overnight.

48. Place the fan interlock switch in the OFF

position. (See Figure 103.)

Figure 103

49. After the grill pad has cooled, remove,

wash, and rinse it thoroughly at the

3-compartment sink. Turn the grill pad

over and re-install on the grill pad holder.

50. Wash, rinse, and sanitize all utensils and

tools used to clean the grill at the

3-compartment sink.

3. Wash, rinse, and sanitize all utensils and

tools used to clean the grill at the

3-compartment sink.

4. Place the fan interlock switch in the OFF

position. Wait 10 seconds and then place

the switch back in the ON position. The

display will read “OFF”.

5. Re-install the release sheets. Secure the

sheets with the locking clips and bars.

(See Figure 104.)

Figure 104

43

101018

Page 45

Note: Reverse the cooking side of the

release sheets on a daily basis (example:

black side on odd days; grey or brown

side on even days).

6. Press the

key for 3 - 5 seconds. “AM

TOO COOL” and “AM FOLDED EGGS FLAT” will be displayed on the control

screen.

8. Press the Standby button to close the

platen.

9. After the platen has closed, the control will

display “GRILL TOO COOL FOR AUTO

LEVELING” until the grill reaches the

proper temperature. When the proper

temperature is reached, the platen will

self-level and open when completed. The

grill will be in the AM Manual mode.

7. The screen will then display, “CLEAN

GRILL SURFACES,” followed by “CLOSE

PLATEN FOR AUTO LEVELING.”

10. The grill is now ready to use.

44

101018

Page 46

TROUBLESHOOTING GUIDE

WARNING: Inspection, testing, and

repair of electrical equipment should be

performed only by qualified service

personnel.

The grill should be disconnected

from all electricity when servicing, except

when electrical tests are required.

PROBLEM

One side of the grill will not

heat. (The control might display

PROBABLE CAUSE REMEDY

One power connection is not

connected.

the message “UPPER HEATER

FAILURE” or “LOWER

HEATER FAILURE”.)

The restaurant circuit breaker

has tripped.

The contactor is faulty. Call a service technician.

DANGER: Use extreme care during

electrical circuit tests. Live circuitry may

be exposed.

The grill must be pulled away from the

wall for thorough cleaning. When returning the

grill to its original position, use extreme

caution to smoothly and slowly roll the grill

backward into place. Failure to do so may

cause the grill to tip, and will cause severe

equipment damage or personal injury.

Check the power connection.

Reset the restaurant circuit

breaker.

The heater is faulty. Call a service technician.

The high limit switch is faulty. Call a service technician.

The solid state relay is faulty. Call a service technician.

One heat zone will not heat. The interface board is faulty. Call a service technician.

The solid state relay is faulty. Call a service technician.

The control harness is faulty. Call a service technician.

One of the heat zones is

The interface board is faulty. Call a service technician.

overheating. (The display reads

“TOO HOT”.)

The exhaust hood and grill will

not turn on when fan interlock

The solid state relay is faulty. Call a service technician.

The restaurant circuit breaker

has been tripped.

Reset the restaurant circuit

breaker.

switch is placed in the ON

position.

The fan interlock cord is not

Reconnect the cord.

connected properly.

The fan disconnect switch on

the roof is in the OFF position.

The fan interlock switch is

Place the switch in the ON

position.

Call a service technician.

faulty.

45

Page 47

PROBLEM PROBABLE CAUSE REMEDY

The exhaust hood alone does

not turn on when the fan

interlock switch is in the ON

position.

The grill alone will not turn on

when the fan interlock switch is

in the ON position.

The upper platen will not stay in

the COOK or STANDBY

position.

The fan interlock switch is

Call a service technician.

faulty.

Loose or broken wires. Call a service technician.

The ansul reset tripped. Press the ansul reset button.

The fan interlock switch is

Call a service technician.

faulty.

The fuse in the control box is

Call a service technician.

faulty.

The processor control is faulty. Call a service technician.

The control harness is faulty. Call a service technician.

The interface board is faulty. Call a service technician.

The latch switch is faulty. Call a service technician.

The latch solenoid is faulty. Call a service technician.

The upper platen will not stay in

the COOK position, but will stay

in the STANDBY mode.

The upper platen will not stay in

the STANDBY mode, but will

stay in the COOK position.

The upper platen opens too

rapidly.

The pneumatic system is faulty. Call a service technician.

The processor control is not set

Call a service technician.

properly.

Incorrect use of the STANDBY

button.

Press the STANDBY button

within five seconds of lowering

the platen into the COOK

position.

Faulty wire connections. Call a service technician.

The orifice/check valve is

Call a service technician.

incorrect or missing.

46

Page 48

PROBLEM PROBABLE CAUSE REMEDY

The product is under-cooked or

over-cooked.

The product is not cooking

evenly.

The release sheet is worn. Replace the release sheet.

Incorrect cooking time. Reset the processor control for

the correct time.

Incorrect temperature. Adjust the processor control to

the proper setting.

The upper platen or lower grill

surface is not clean and/or has

carbon build-up.

Daily cleaning procedures must

be followed to properly clean

the upper platen and the lower

grill surface and to remove

carbon build-up.

The preset gap height is

Call a service technician.

incorrect.

The heating zone is not

Call a service technician.

heating.

The upper platen or lower grill

surface is not clean and/or has

carbon build-up.

Daily cleaning procedures must

be followed to properly clean

the upper platen and the lower

grill surface and to remove

carbon build-up.

The release sheet is worn. Replace release sheet.

The platen is not level. Re-level the platen.

Air pressure is not high enough. Call a service technician.

The preset gap height is

Call a service technician.

incorrect.

The product is not recognized. The grill is not set in the Auto

Product Recognition mode.

Check the product for correct

settings.

The platen will not auto-level. Defective motors and cables. Call a service technician.

Defective motor interface

Call a service technician.

board.

Loose harness connections. Call a service technician.

Defective main display

Call a service technician.

controller.

The display reads “PROBE

OPEN”.

The thermocouple or the

thermocouple interface board is

Call a service technician.

faulty.

The display reads “UPPER

The arm bearings are dirty. Call a service technician.

PLATEN STUCK”.

The air cylinder is faulty. Call a service technician.

The automatic air drain will not

close.

Plugged air lines to cylinders. Call a service technician.

The solenoid is faulty. Call a service technician.

A wire is loose or broken. Call a service technician.

47

Page 49

LIMITED WARRANTY ON EQUIPMENT

TAYLOR COMPANY LIMITED WARRANTY ON INTELLIGAP GRILLS FOR MCDONALD’S

Taylor Company, a division of Carrier Commercial Refrigeration, Inc. (“Taylor”) is pleased to provide this

limited warranty on new Taylorbranded IntelliGap grill equipment available from Taylor (the “Product”)

to the original McDonald’s purchaser only.

LIMITED WARRANTY

Taylor warrants the Product against failure due to defect in materials or workmanship under normal use

and service as follows. All warranty periods begin on the date of original Product installation. If a part fails

due to defect during the applicable warranty period, Taylor, through an authorized Taylor distributor or

service agency, will provide a new or re-manufactured part, at Taylor’s option, to replace the failed

defective part at no charge for the part.

Product

Part Limited Warranty Period

Taylor IntelliGap Grills Parts not excluded below Two (2) years

In addition, during the two (2) year period commencing on the date of original installation of the Product,

Taylor will also provide, through an authorized Taylor distributor or service agency, all service needed to

replace the failed defective part at no charge for the service. This nocharge service shall not be available

for service performed by authorized McDonald’s service technicians. Local sales and use taxes may still

apply and will be charged accordingly.

Except as otherwise stated herein, these are Taylor’s exclusive obligations under this limited warranty for

a Product failure. This limited warranty is subject to all provisions, conditions, limitations and exclusions

listed below and on the reverse (if any) of this document.

LIMITED WARRANTY CONDITIONS

1. If the date of original installation of the Product cannot be verified, then the limited warranty period

begins ninety (90) days from the date of Product manufacture (as indicated by the Product serial

number). Proof of purchase may be required at time of service.

2. This limited warranty is valid only if the Product is installed and all required service work on the

Product is performed by an authorized Taylor distributor or service agency, and only if genuine,

new Taylor parts are used.

3. Installation, use, care, and maintenance must be normal and in accordance with all instructions

contained in the Equipment Manual.

4. Defective parts must be returned to the authorized Taylor distributor or service agency for credit.

LIMITED WARRANTY EXCEPTIONS

This limited warranty does not

cover:

1. Except as otherwise specifically set forth in this limited warranty, labor or other costs incurred for

diagnosing, repairing, removing, installing, shipping, servicing or handling of defective parts,

replacement parts, or new Products.

2. Normal maintenance and cleaning as outlined in the Equipment Manual, including cleaning of

carbon and grease buildup.

3. Required service, whether cleaning or general repairs, to return the Product’s cooking surface

assemblies, including the upper platen and lower plate, to an operational condition to achieve

proper cooking or allow proper assembly of release sheets and clips as a result of grease buildup

on the cooking surfaces, including but not limited to the platen and plate, sides of the shroud or

top of the shroud.

4. Replacement of the Product’s cooking surfaces, including the upper platen and lower plate, due

to pitting or corrosion (or in the case of the upper platen, due to loss of plating) as a result of

48

131126

Page 50

damage due to the impact of spatulas or other small wares used during the cooking process or as

a result of the use of cleaners, cleaning materials or cleaning processes not approved for use by

Taylor.

5. Replacement of wear items designated as Class “000” parts in the Equipment Manual, as well as

any release sheets and clips.

6. External hoses, electrical power supplies, and machine grounding.

7. Parts not supplied or designated by Taylor, or damages resulting from their use.

8. Return trips or waiting time required because a service technician is prevented from beginning

warranty service work promptly upon arrival.

9. Failure, damage or repairs due to faulty installation, misapplication, abuse, no or improper

servicing, unauthorized alteration or improper operation or use as indicated in the Equipment

Manual, including but not limited to the failure to use proper assembly and cleaning techniques,

tools, or approved cleaning supplies .

10. Failure, damage or repairs due to theft, vandalism, wind, rain, flood, high water, water, lightning,

earthquake or any other natural disaster, fire, corrosive environments, insect or rodent

infestation, or other casualty, accident or condition beyond the reasonable control of Taylor;

operation above or below the electrical or gas specification of the Product; or components

repaired or altered in any way so as, in the judgment of the Manufacturer, to adversely affect

performance, or normal wear or deterioration.

11. Any Product purchased over the Internet.

12. Failure to start due to voltage conditions, blown fuses, open circuit breakers, or damages due to

the inadequacy or interruption of electrical service.

13. Electricity, gas or other fuel costs, or increases in electricity, gas or other fuel costs from any

reason whatsoever.

14. ANY SPECIAL, INDIRECT OR CONSEQUENTIAL PROPERTY OR COMMERCIAL DAMAGE

OF ANY NATURE WHATSOEVER. Some jurisdictions do not allow the exclusion of incidental or

consequential damages, so this limitation may not apply to you.

This limited warranty gives you specific legal rights, and you may also have other rights which vary from

jurisdiction to jurisdiction.

LIMITATION OF WARRANTY

THIS LIMITED WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES,

CONDITIONS AND/OR REMEDIES UNDER THE LAW, INCLUDING ANY IMPLIED WARRANTIES OR

CONDITIONS OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THE

ORIGINAL OWNER'S SOLE REMEDY WITH RESPECT TO ANY PRODUCTS SHALL BE REPAIR OR

REPLACEMENT OF DEFECTIVE COMPONENTS UNDER THE TERMS OF THIS LIMITED

WARRANTY. ALL RIGHTS TO CONSEQUENTIAL OR INCIDENTAL DAMAGES (INCLUDING CLAIMS

FOR LOST SALES, LOST PROFITS, PRODUCT LOSS, PROPERTY DAMAGES OR SERVICE

EXPENSES) ARE EXPRESSLY EXCLUDED. THE EXPRESS WARRANTIES MADE IN THIS LIMITED

WARRANTY MAY NOT BE ALTERED, ENLARGED, OR CHANGED BY ANY DISTRIBUTOR,

DEALER, OR OTHER PERSON, WHATSOEVER.

LEGAL REMEDIES

The owner must notify Taylor in writing, by certified or registered letter to the following address, of any

defect or complaint with the Product, stating the defect or complaint and a specific request for repair,

replacement, or other correction of the Product under warranty, mailed at least thirty (30) days before

pursuing any legal rights or remedies.

Taylor Company

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072, USA

49

Page 51

LIMITED WARRANTY ON PARTS

TAYLOR COMPANY LIMITED WARRANTY ON TAYLOR GENUINE PARTS

Taylor Company, a division of Carrier Commercial Refrigeration, Inc. (“Taylor”) is pleased to provide this

limited warranty on new Taylor genuine replacement components and parts available from Taylor to the

market generally (the “Parts”) to the original purchaser only.

LIMITED WARRANTY

Taylor warrants the Parts against failure due to defect in materials or workmanship under normal use and

service as follows. All warranty periods begin on the date of original installation of the Part in the Taylor

unit. If a Part fails due to defect during the applicable warranty period, Taylor, through an authorized Taylor

distributor or service agency, will provide a new or re-manufactured Part, at Taylor’s option, to replace the

failed defective Part at no charge for the Part. Except as otherwise stated herein, these are Taylor’s

exclusive obligations under this limited warranty for a Part failure. This limited warranty is subject to all

provisions, conditions, limitations and exclusions listed below and on the reverse (if any) of this document.

Part's Warranty Class Code or Part

Limited Warranty Period

Class 103 Parts¹ Three (3) months

Class 212 Parts² Twelve (12) months

Class 512 Parts Twelve (12) months

Class 000 Parts No warranty

Taylor Part #072454 (Motor-24VDC *C832/C842*) Four (4) years

LIMITED WARRANTY CONDITIONS

1. If the date of original installation of the Part cannot be otherwise verified, proof of purchase may

be required at time of service.

2. This limited warranty is valid only if the Part is installed and all required service work in connection

with the Part is performed by an authorized Taylor distributor or service agency.

3. The limited warranty applies only to Parts remaining in use by their original owner at their original

installation location in the unit of original installation.

4. Installation, use, care, and maintenance must be normal and in accordance with all instructions

contained in the Taylor Operator’s Manual.

5. Defective Parts must be returned to the authorized Taylor distributor or service agency for credit.

6. This warranty is not intended to shorten the length of any warranty coverage provided pursuant to

a separate Taylor Limited Warranty on freezer or grill equipment.

7. The use of any refrigerant other than that specified for the unit in which the Part is installed will

void this limited warranty.

1, 2

Except that Taylor Part #032129SER2 (CompressorAir230V SERV) and Taylor Part #075506SER1

(CompressorAir115V 60HZ) shall have a limited warranty period of twelve (12) months when used in

Taylor freezer equipment and a limited warranty period of two (2) years when used in Taylor grill

equipment.

50

131126

Page 52

LIMITED WARRANTY EXCEPTIONS

This limited warranty does not

cover:

1. Labor or other costs incurred for diagnosing, repairing, removing, installing, shipping, servicing or

handling of defective Parts, replacement Parts, or new Parts.

2. Normal maintenance, cleaning and lubrication as outlined in the Taylor Operator’s Manual,

including cleaning of condensers or carbon and grease buildup.

3. Required service, whether cleaning or general repairs, to return the cooking surface assemblies,