Models C819 & C821

Auto Lift Grills

Original Operating Instructions

073946-M

5/10/11 (Original Publication)

(Updated 10/14/11)

Complete this page for quick reference when service is required:

Taylor Distributor:

Address:

Phone:

Service:

Parts:

Date of Installation:

Information found on data plate:

Model Number:

Serial Number:

Electrical Specs: Voltage Cycle

Phase

Maximum Fuse Size: Amps

Minimum Wire Ampacity: Amps

Part Number:

E May, 2011 Taylor

All rights reserved.

073946-M

The word Taylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

Taylor Company

750 N. Blackhawk Blvd.

Rockton, IL 61072

Table of Contents

Section 1 To th e Installer 1............................................

Installer Safety 1........................................................

Site Preparation 1.......................................................

Electrical Connections 1.................................................

Installation 2...........................................................

Section 2 To the Operator 3...........................................

Section 3 Safety 4....................................................

Section 4 Operator Parts Id entification 7...............................

C819 7................................................................

C821 8................................................................

Accessories 9..........................................................

Section 5 Important: To the Operator 10.................................

Section 6 Operating Procedures 11.....................................

Daily Opening Procedures 11..............................................

Loading Store Menu Items To USB 18......................................

Table of Contents Models C819 & C821

Table of Contents - Page 2

Loading Menu Items From USB 19.........................................

Operating Procedures 21.................................................

Daily Cleaning Procedures 23.............................................

Section 7 Troubleshooting Guide 31....................................

Section 8 Parts List 35.................................................

Wiring Diagrams 44......................................................

Note: Continuing research results in steady improvements; therefore, information

in this manual is subject to change without notice.

Note: Only instructions originating from the factory or its authorized translation

representative(s) are considered to be the original set of in structions.

E May, 2011 Taylor (Original Publication)

(Updated October, 2011)

All rights reserved.

073946-M

The word Taylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

Models C819 & C821 Table of Contents

Taylor Company

750 N. Blackhawk Blvd.

Rockton, IL 61072

Section 1 To the Installer

The following are general installation instructions.

For complete installation details, please see the

checkout card.

cause severe injuries.

This unit has many sharp edges that can

Installer Safety

In all areas of the world, equipment should

be installed in accordance with existing local codes.

Please contact your local authorities if you have any

questions.

Care should be taken to ensure that all basic safety

practices are followed during the installation and

servicing activities related to the installation and

service of Taylor equipment.

S Only Taylor authorized service personnel

should perform installation and repairs on

the equipment.

S Authorized service personnel should consult

OSHA Standard 29CFRI910.147 or the

applicable code of the local area for the

industry standards on lockout/tagout

procedures before beginning any installation

or repairs.

S Authorized service personnel must ensure

that the proper PPE is available and worn

when required during installation and

service.

S Authorized service personnel must remove

all metal jewelry, rings, and watches before

working on electrical equipment.

The main power supply(s) to the equipment

must be disconnected prior to performing any

repairs. Failure to follow this instruction may result in

personal injury or death from electrical shock or

hazardous moving parts as well as poor

performance or damage to the equipment.

Site Preparation

Review the area where the unit will be installed

before uncrating the unit. Make sure all possible

hazards to the user or the equipment have been

addressed.

Electrical Connections

The grill is supplied with one power cord. Check the

data plate on the grill for voltage, cycle, phase and

electrical specifications.

For proper power connections, refer to the wiring

diagram provided inside the left side panel, attached

to the gas manifold assembly. The power connection

is located behind the access line cover on the front

of the grill.

In the United States, this equipment is intended to

be installed in accordance with the National

Electrical Code (NEC), ANSI/NFPA 70-1987. The

purpose of the NEC code is the practical

safeguarding of persons and property from hazards

arising from the use of electricity. This code contains

provisions considered necessary for safety.

Compliance therewith and proper maintenance will

result in an installation essentially free from hazard!

In all other areas of the world, equipment should be

installed in accordance with the existing local codes.

Please contact your local authorities.

The Proper Wire Size and Branch Circuit

Overcurrent Device shall be selected according to

the data label information and in accordance with

CEC Part I 2006, Section 14-100(e)(i).

Note:Allrepairsmustbeperformedbyan

authorized Taylor Service Technician.

Models C819 & C821 To the Installer

1

FOLLOW YOUR LOCAL ELECTRICAL CODES!

CAUTION: THIS EQUIPMENT MUST BE

PROPERLY GROUNDED! FAILURE TO DO SO

CAN RESULT IN SEVERE PERSONAL INJURY

FROM ELECTRICAL SHOCK!

This unit is provided with an equipotential

grounding lug that is to be properly attached to the

rear of the frame by the authorized installer. The

installation location is marked by the equipotential

bonding symbol (5021 of IEC 60417-1) on both the

removable panel and the equipment's frame.

S Stationary appliances which are not

equipped with a power cord and a plug or

another device to disconnect the appliance

from the power source must have an all-pole

disconnecting device with a contact gap of

at least 3 mm installed in the external

installation.

S Appliances that are permanently connected

to fixed wiring and for which leakage

currents may exceed 10 mA, particularly

when disconnected or not used for long

periods, or during initial installation, shall

have protective devices such as a GFI to

protect against the leakage of current and

be installed by the authorized personnel to

the local codes.

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable, not

lighter than ordinary polychloroprene or

other equivalent synthetic

elastomer-sheathed cord (Code designation

60245 IEC 57) installed with the proper cord

anchorage to relieve conductors from strain,

including twisting, at the terminals and

protect the insulation of the conductors from

abrasion.

Installation

WARNING: Improper installation, adjustment,

alteration, service, or maintenance can cause

property damage, injury or death. Read the

installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

This machine is designed for indoor use only.

DO NOT installthemachineinanarea

where a water jet could be used to clean or rinse the

machine. Failure to follow this instruction may result

in serious electrical shock.

This grill must be installed on a level

surface. Failure to comply may result in personal

injury or equipment damage.

Installation of Cab le Kit

If the unit is permanently connected, the Cable Kit

must be installed. Flexible conduit must be used

when installing the appliance.

Ventilation and Clearance

To ensure proper operation of this appliance, it must

be installed so that the products of combustion are

efficiently removed.

After set up, do not store anything on top of

the grill. Failure to follow this instruction may result

in a fire hazard.

Grease Disposal Container

If the grill is not factory-equipped with grease

disposal containers, the store is required to provide

appropriate grease disposal containers in

accordance with NSF Standard 4 requirements.

2

Models C819 & C821To the Installer

Section 2 To the Operator

The grill you have purchased has been carefully

engineered and manufactured to provide

dependable operation.

This grill, when properly operated and maintained,

will produce a consistent quality product. Like all

mechanical products, it will require cleaning and

maintenance. A minimum amount of care and

attention is necessary if the operating procedures in

this manual are followed closely.

This Operator's Manual should be read before

operating or performing any maintenance on your

equipment.

It is strongly recommended that all personnel

responsible for the equipment's operation and

cleaning review these procedures for proper training

and assurance that no misunderstandings exist.

In the event you should require technical assistance,

please contact your local authorized Taylor

Distributor.

Note: Warranty is valid only if the parts are

authorized Taylor parts, purchased from an

authorized Taylor Distributor, and the required

service work is provided by an authorized Taylor

service technician. Taylor reserves the right to deny

warranty claims on equipment or parts if

non-approved parts or refrigerant were installed in

the machine, system modifications were performed

beyond factory recommendations, or it is determined

that the failure was caused by neglect or abuse.

Note: Constant research results in steady

improvements; therefore, information in this

manual is subject to change without notice.

If the crossed out wheeled bin symbol is

affixed to this product, it signifies that this product is

compliant with the EU Directive as well as other

similar legislation in effect after August 13, 2005.

Therefore, it must be collected separately after its

use is completed and cannot be disposed as

unsorted municipal waste.

The user is responsible for returning the product to

the appropriate collection facility as specified by your

local code.

For additional information regarding applicable local

laws, please contact the municipal facility and/or

local distributor.

Models C819 & C821 To the Operator

3

Section 3 Safety

We, at Taylor Company, are concerned about the

safety of the operator when he or she comes in

contact with the grill and its parts. Taylor has gone

to extreme efforts to design and manufacture built-in

safety features to protect both you and the service

technician. As an example, warning labels have

been attached to the grill to further point out safety

precautions to the operator.

IMPORTANT - Failure to adhere to the

following safety precautions may result in

severe personal injury or death. Failure to

comply with these warnings may damage the

machine and its components. Component

damage will result in part replacement expense

and service repair expense.

To Operate Safely:

DO NOT operate the grill without reading

this Operator's Manual. This manual should be kept

in a safe place for future reference.

S Stationary appliances which are not

equipped with a power cord and a plug or

other device to disconnect the appliance

from the power source must have an all-pole

disconnecting device with a contact gap of

at least 3 mm installed in the external

installation.

S Appliances that are permanently connected

to fixed wiring and for which leakage

currents may exceed 10 mA, particularly

when disconnected or not used for long

periods, or during initial installation, shall

have protective devices such as a GFI to

protect against the leakage of current and

be installed by the authorized personnel to

the local codes.

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable, not

lighter than ordinary polychloroprene or

other equivalent synthetic

elastomer-sheathed cord, (Code designation

60245 IEC 57), installed with the proper

cord anchorage to relieve conductors from

strain, including twisting, at the terminals

and protect the insulation of the conductors

from abrasion.

Per IEC 60335-1 and its part 2 standards, “This

appliance is to be used only by trained personnel. It

is not intended for use by children or people with

reduced physical, sensory, or mental capabilities, or

lack of experience and knowledge, unless given

supervision or instruction concerning the use of the

appliance by a person responsible for their safety.”

Failure to follow the instructions below may

result in severe injury or death from electrocution:

S DO NOT operate the grill unless it is

properly grounded.

S DO NOT operate the grill with larger fuses

than specified on the data label.

S DO NOT operate the grill unless all service

panels and access doors are attached with

screws.

IMPORTANT: DO NOT use a water jet or

spray excessive water on or anywhere near the

grill. Failure to follow this instruction may result in

serious electrical shock and cause permanent

electrical and mechanical damage to internal parts.

Failure to follow this instruction may result in:

S serious electrical shock

S burns from hot steam

S liquid collecting inside the grill and

destroying electrical components

4

Models C819 & C821Safety

This appliance must be isolated from all

combustible construction and materials including,

but not limited to: walls, partitions, furniture, floors,

curtains, paper, boxes, and decorations. Failure to

comply may result in a fire and cause destruction

and severe injury.

FORYOURSAFETY

Do not store or use gasoline or other

flammable vapors or liquids in the vicinity of

this or any other appliance.

USE EXTREME CAUTION while setting up,

operating, and cleaning the grill.

S Avoid coming in contact with hot grill

surfaces or with hot grease.

S DO NOT prepare or remove product without

proper equipment.

S DO NOT allow untrained personnel to

operate this grill.

Failure to follow these instructions can result in burn

injuries.

Take caution to protect eyes, lungs, and all

parts of the body from potential harm when using

any chemical cleaner. Failure to follow this

instruction may result in a chemical burn.

DO NOT use any abrasives or cleaners

other than approved foodservice cleaners and

degreasers. Failure to comply may cause illness to

the consumer and may also damage grill surfaces.

For thorough cleaning, the grill must be

pulled away from the wall. Before moving the grill,

remove the grease cans. Turn off the gas at the

quick connect shut-off valve on the flexible hose.

Disconnect the gas quick connector. Disconnect the

tether to the grill, which is located on the back panel

of the unit.

To return the grill to its original position, reverse the

steps. Use extreme caution to smoothly and slowly

roll the grill backward into place.

Failure to do so may cause the grill to tip and can

result in severe equipment damage or personal

injury.

DO NOT use cold water or ice to cool the

upper platen or the lower cook surface. Failure to

follow this instruction may result in:

S serious electrical shock

S burns from hot steam

S liquid collecting inside the grill and

destroying electrical components

S DO NOT obstruct the ventilation openings at

the rear of this appliance.

S DO NOT obstruct the flow of air in and

around the grill.

NOTICE all warning labels that have been

attached to the grill to further point out safety

precautions to the operator.

Models C819 & C821 Safety

5

This piece of equipment is made in America and has

American sizes on hardware. All metric conversions

are approximate and vary in size.

NOISE LEVEL: Airborne noise emission does not

exceed 70 dB(A) when measured at a distance of

1.0 meter from the surface of the machine and at a

height of 1.6 meters from the floor.

If the crossed out wheeled bin symbol is

affixed to this product, it signifies that this product is

compliant with the EU Directive as well as other

similar legislation in effect after August 13, 2005.

Therefore, it must be collected separately after its

use is completed, and cannot be disposed as

unsorted municipal waste.

These instructions are valid only if the country code

symbol appears on the appliance. If the symbol does

not appear on the appliance, refer to the technical

instructions which give the necessary instructions for

adapting the appliance to the utilization conditions of

that country.

The user is responsible for returning the product to

the appropriate collection facility, as specified by

your local code.

For additional information regarding applicable local

laws, please contact the municipal facility and/or

local distributor.

6

Models C819 & C821Safety

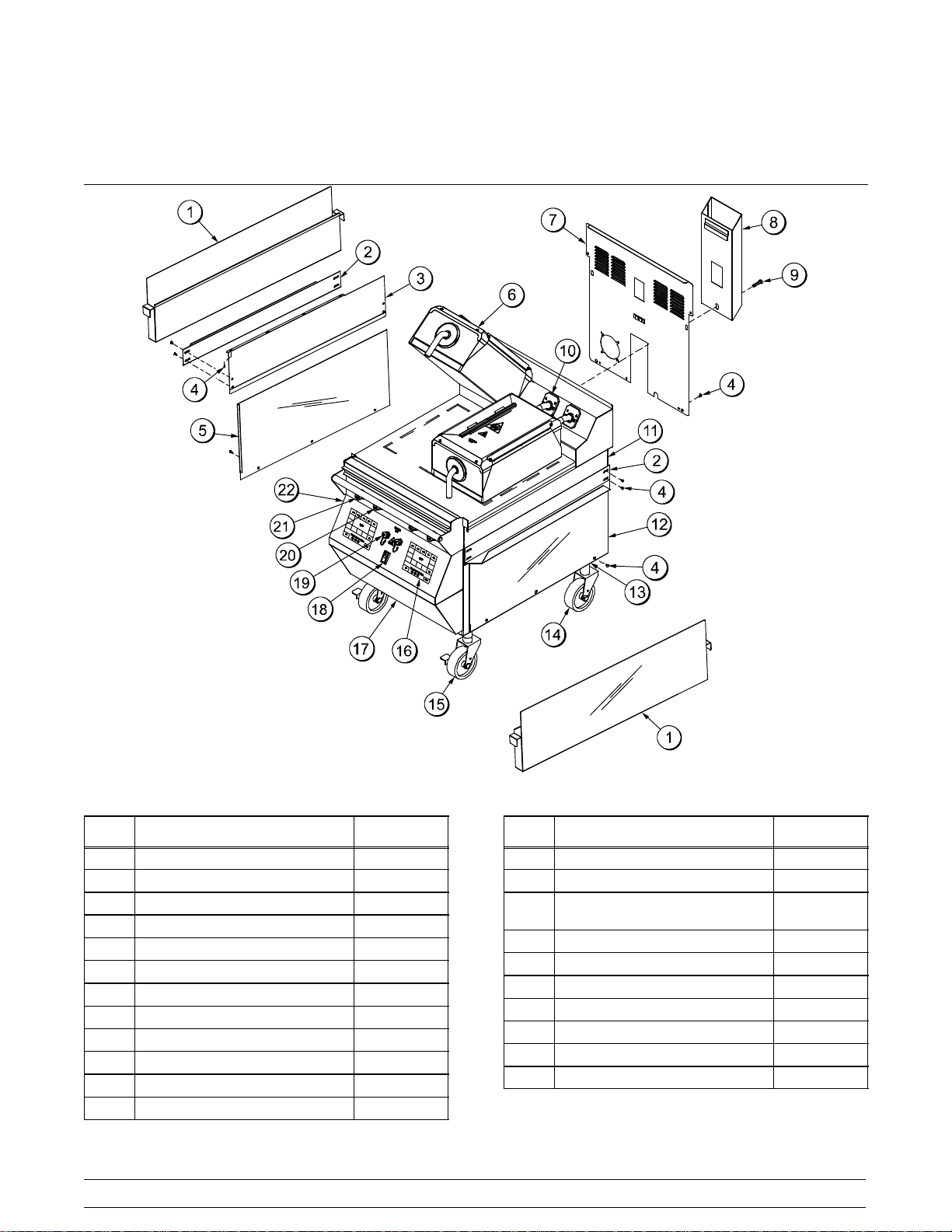

Section 4 Operator Parts Identification

C819

Figure 1

ITEM DESCRIPTION PART NO.

1 CAN A.-GREASE X73944

2 SLIDE-GREASE CAN 073293

3 PANEL-SIDE UPPER-LEFT 073990

4 SCREW-10-32X3/8SLTD TRUS 024298

5 PANEL-SIDE-LOWER-LEFT 073992

6 PLATEN A.-SERVICE X73741-23

7 PANEL A.-BACK SERVICE X69664

8 DEFLECTOR A.-FLUE X69657

9 SCREW-3/8-16X1-1/2 SERR 020129

10 KIT A.-GREASE SHIELD X78330-SER

11 PANEL-SIDE UPPER-RIGHT 073989

12 PANEL-SIDE-LOWER-RIGHT 073991

Models C819 & C821 Operator Parts Identification

ITEM DESCRIPTION PART NO.

13 NUT-JAM 1 1/2-12 STEEL 073594

14 CASTER-5" 7-5/8 STEM 078377

15 CASTER-GRILL 5" SWIVEL

W/LOCK

16 KIT A.-GRILL CONTROL X73474-SER

17 PANEL A.-FRONT-LOWER X69660

18 SWITCH-ROCKER-DPST-10A 076989-WP

19 PLUG A.-USB CABLE 073808

20 BUTTON-OPERATOR-BLACK 076012

21 BUTTON-OPERATOR-RED 076011

22 PANEL A.-LIGHT X69678

7

073240

110902

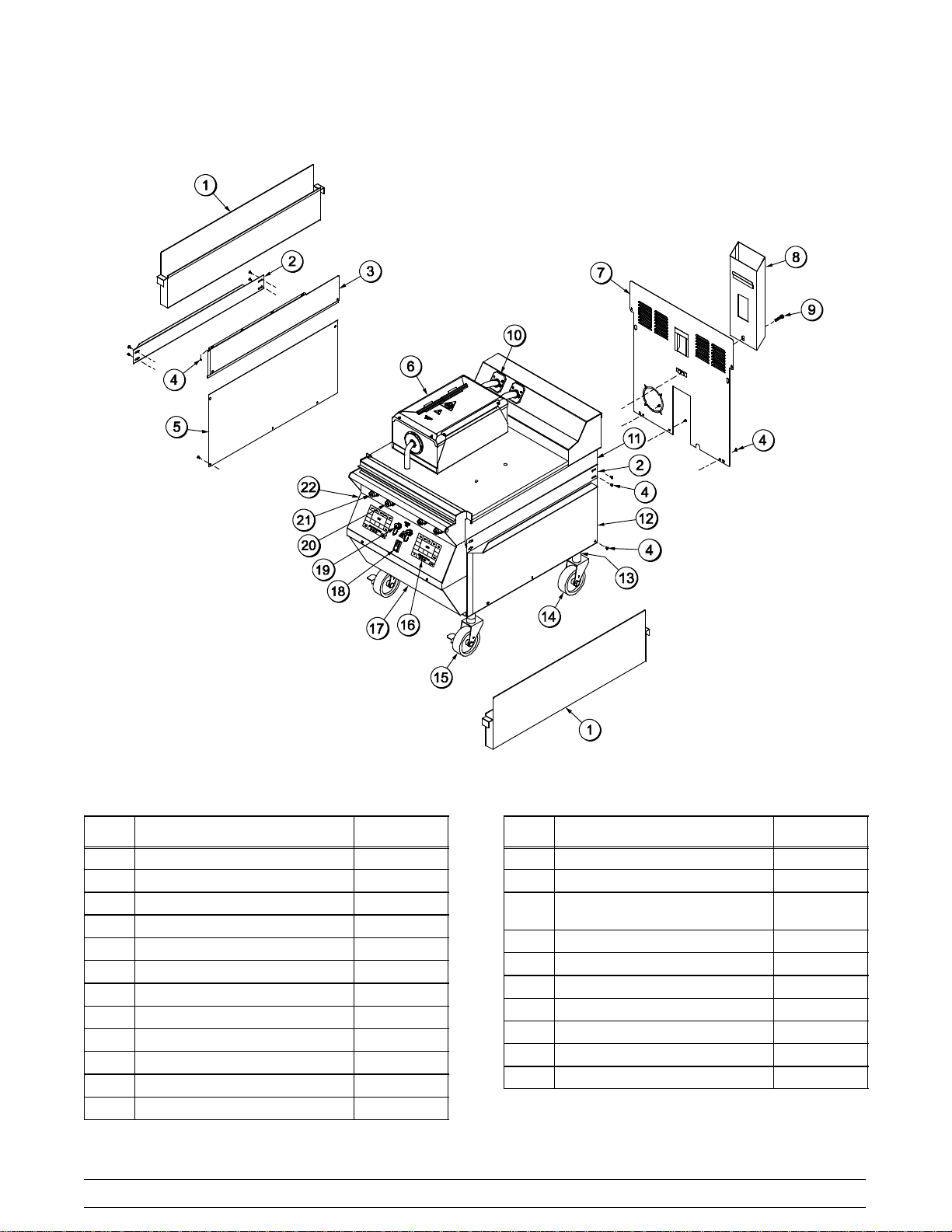

C821

ITEM DESCRIPTION PART NO.

1 CAN A.-GREASE X73944

2 SLIDE-GREASE CAN 073293

3 PANEL-SIDE UPPER-LEFT 073990

4 SCREW-10-32X3/8SLTD TRUS 024298

5 PANEL-SIDE-LOWER-LEFT 073992

6 PLATEN A.-SERVICE X73741-23

7 PANEL A.-BACK SERVICE X69664

8 DEFLECTOR A.-FLUE X69657

9 SCREW-3/8-16X1-1/2 SERR 020129

10 KIT A.-GREASE SHIELD X78330-SER

11 PANEL-SIDE UPPER-RIGHT 073989

12 PANEL-SIDE-LOWER-RIGHT 073991

110902

Figure 2

8

ITEM DESCRIPTION PART NO.

13 NUT-JAM 1 1/2-12 STEEL 073594

14 CASTER-5" 7-5/8 STEM 078377

15 CASTER-GRILL 5" SWIVEL

W/LOCK

16 KIT A.-GRILL CONTROL X73474-SER

17 PANEL A.-FRONT-LOWER X69660

18 SWITCH-ROCKER-DPST-10A 076989-WP

19 PLUG A.-USB CABLE 073808

20 BUTTON-OPERATOR-BLACK 076012

21 BUTTON-OPERATOR-RED 076011

22 PANEL A.-LIGHT X69678

073240

Models C819 & C821Operator Parts Identification

Accessories

Figure 3

ITEM DESCRIPTION PART NO.

1 SHEET-RELEASE (BOX 9) 073442

*2 RETAINER-SHEET RELEASE

(RETENTION BAR)

**3 CLIP-RELEASE MATERIAL

W/TAB

4 SCRAPER-TEFLON WIPER 075887

072845

072673

Models C819 & C821 Operator Parts Identification

ITEM DESCRIPTION PART NO.

5 STRIP-REPLACEMENT 075888

6 CLEANER-STERA SHEEN

(CASE OF 6, 1 QT. BOTTLES)

***7 HOLDER-CLEANING 073736

***8 PAD-CLEANING 073737

* SHOWN PER PLATEN

** SHOWN PER PLATEN

(NOTE: EXTRA CLIPS ARE SENT WITH GRILL)

*** SOLD SEPARATELY THROUGH YOUR LOCAL

DISTRIBUTOR

9

073160

110602

Section 5 Important: To the Operator

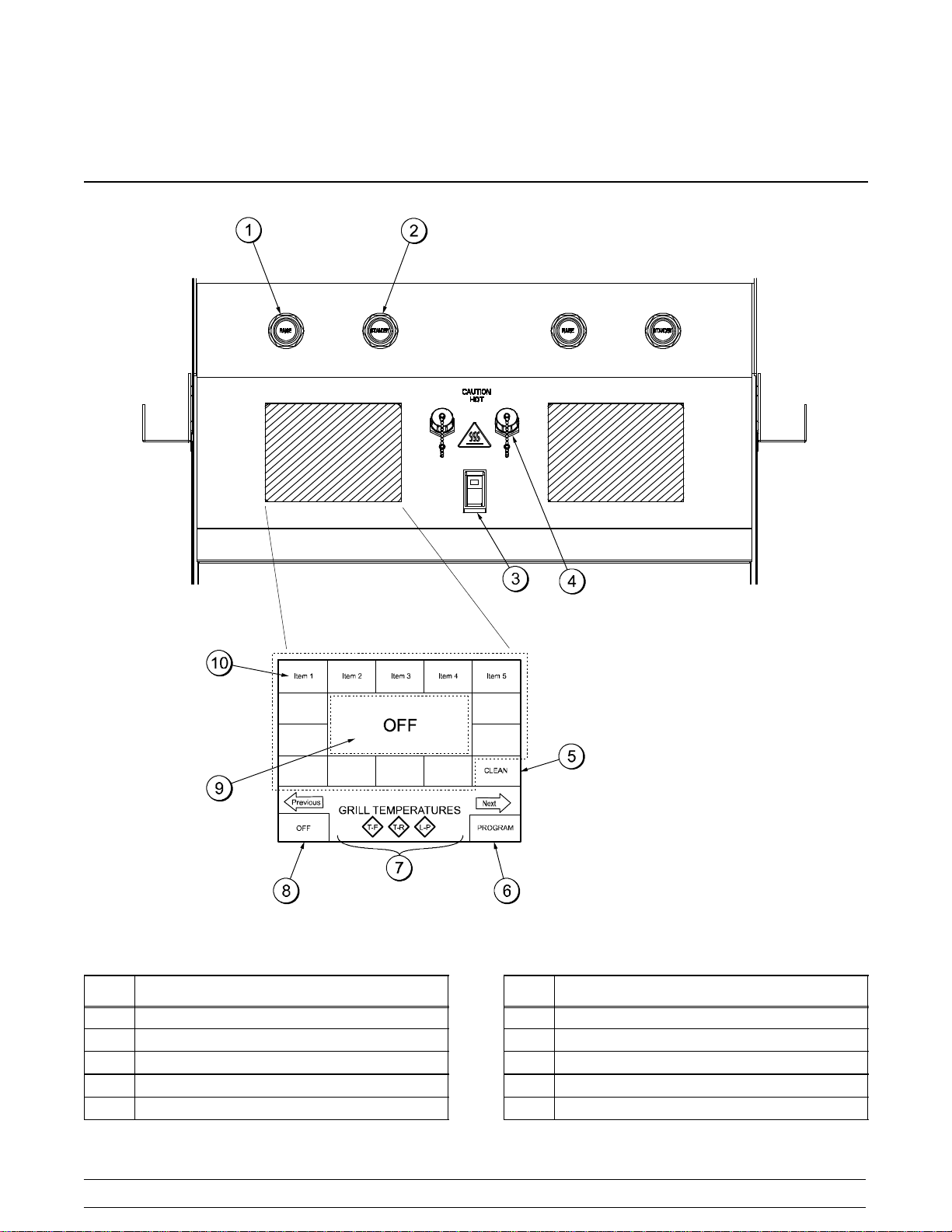

ITEM DESCRIPTION

1 RAISE BUTTON

2 STANDBY/COOK MODE BUTTON

3 MASTER POWER SWITCH

4 COVER A.-USB

5 CLEAN MODE KEY

Figure 4

10

ITEM DESCRIPTION

6 PROGRAM KEY

7 TEMPERATURE INDICATOR LIGHTS

8 POWER KEY

9 FUNCTION DISPLAY

10 MENU SELECT KEYS

Models C819 & C821Important: To the Operator

Section 6 Operating Procedures

The Models C819 and C821 are 24” (610 mm) grills.

The C819 is equipped with two independent 12”

(305 mm) upper platens and the Model C821 is

equipped with one independent 12” (305 mm) upper

platen.

These grills are capable of cooking a variety of

products and feature two cooking options. They

provide all the features of a flat grill as well as the

advantages of two-sided cooking.

Note: The two platen Model C819 has been

selected to illustrate the step-by-step procedures.

For grills equipped with less than two platens,

perform the following steps as appropriate for your

grill platen configuration.

Daily Opening Procedures

Before operating the grill, the release material

sheets must be installed on the upper platens. The

release material sheets are reversed and rotated on

a daily basis (black side vs. brown side.)

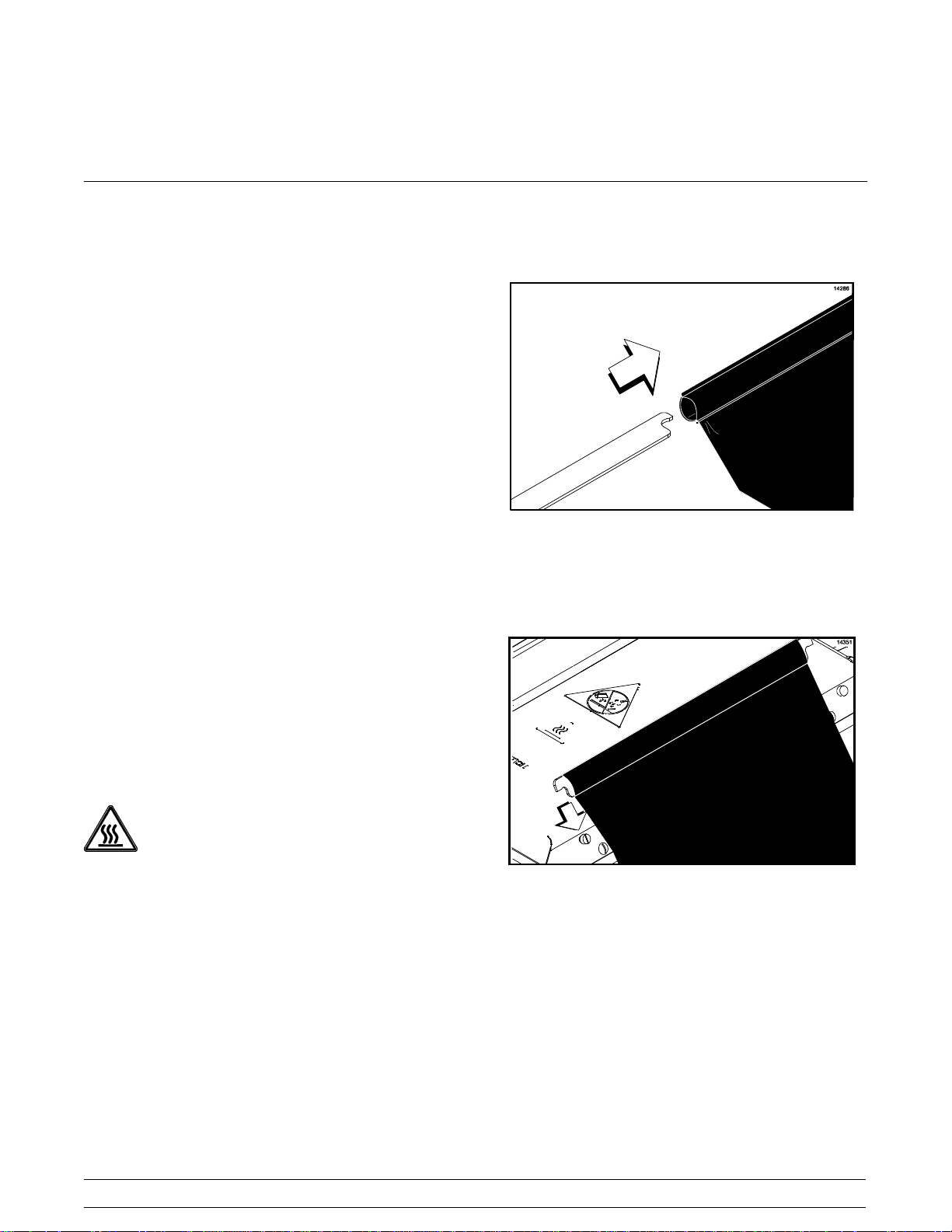

Step 1

Slide the release sheet retainer through the hemmed

end of the release material sheet.

Figure 5

Step 2

Hook the release sheet retainer on the release

material shoulder screws at the top of the upper

platen.

Perform the following steps for installing the release

material sheets:

CAUTION: Make sure the grill is COOL

before attempting to install or remove release

material sheets.

Models C819 & C821 Operating Procedures

11

Figure 6

110531

Step 3

Hold the non-hemmed end of the release material

sheet. Gently pull the sheet tight, wrapping it around

the platen in a side-to-side manner.

Step 5

Check the tightness of the release material sheet

against the upper platen.

Figure 7

Note: Check the alignment of the release material

sheet and make sure it fits smoothly over the upper

platen.

Step 4

Place the release material clips over the release

material sheet. Press them into place over the

release material bar at the top of the platen.

Figure 8

Figure 9

Note: Installing the release material sheets too

tightly may cause premature failure of the sheet.

Step 6

Repeat steps 1 through 5 for the remaining upper

platen.

Note: Temperature checks should only be

conducted with the release material sheets removed.

12

Models C819 & C821Operating Procedures

The release material must be replaced when:

Care of Release Material Sheets

S Cleaning procedures fail to remove all

buildup and product sticks to the release

material.

S A tear appears in the cooking area of the

release material, causing product to stick to

the release material.

DO NOT:

S DO NOT fold or crease.

Figure 11

S DO NOT touch with sharp objects, grill

scrapers, or abrasive pads.

S DO NOT place under other equipment or

objects.

S DO NOT hot-hose or soak in water.

Figure 10

Note: It is not necessary to change the release

material if small pin holes develop on the sheet.

CAUTION: The upper platen surface and

release material are very hot. To prevent burn

injuries, wear heat-resistant gloves when

replacing release material.

DO:

S DO clean with a squeegee after each run of

product.

S DO wipe with a clean, sanitizer-soaked grill

cloth a minimum of 4 times per hour and

more often during peak periods.

S DO clean daily on both sides, using an

approved high temperature grill cleaner and

the grill cleaning pad and holder identified on

page 9.

110602

Models C819 & C821 Operating Procedures

13

Start Up of the Grill

IMPORTANT! Clean the release

sheets using the grill cleaning pad and

holder identified on page 9 ONLY. Using any

other pad and holder will damage the

release sheets.

Figure 12

Note: Contact your local Taylor Distributor to

purchase the grill cleaning pad and holder.

(See page 9.)

S DO rinse to remove cleaner and allow to dry

onaflatsurface.

S DO rotate the release material daily and

re-install on opposite side than previously

used (black side vs. brown side).

IMPORTANT! The lower grill surface and the

upper platen MUST BE CLEAN before starting

these procedures.

Step 1

Place the power switch in the ON position.

Figure 13

The control will display the word “INITIALIZATION”

for five seconds and then enter the OFF mode. The

control will now display the word “OFF”. The

temperature indicators will not be illuminated. A tone

will sound for 20 seconds. This tone can be stopped

immediately by touching the raise button, the

standby button, or anywhere on the display screen.

110602

14

Figure 14

Models C819 & C821Operating Procedures

Step 2

Touch a menu key on the control to start the grill.

The grill will start heating up to the proper

temperature. The control will display the selected

menu item and indicate “BOTTOM TOO COOL” and

“TOP TOO COOL”. The grill temperature indicators

will be illuminated in amber.

Figure 15

Note: If an ignition failure fault occurs upon start up,

press the center of the control. The control will

display “OFF”. Refer to problem #2, items a, b, and c

of the Gas Grill Troubleshooting Guide on page 34.

After five minutes has elapsed, press the menu key

again. If the ignition failure fault was not resolved,

please call your authorized service technician.

When the grill is at the proper temperature, the

temperature statements will no longer display and

the temperature indicators will be illuminated in

green.

Figure 16

Figure 17

Models C819 & C821 Operating Procedures

15

Programming Menu Items

To enter the Program Mode, the grill control must be

in the OFF or IDLE mode.

Step 1

Press and hold the PROGRAM key for

approximately five seconds to enter the Program

Mode.

Step 3

The PROGRAM MODE screen will appear.

Figure 20

UNITS Key

The UNITS key is used to select either English or

metric units of measure. The UNITS key toggles

between F and C with each key press.

Figure 18

Step 2

The PASSWORD screen will appear. Enter the

following password: STORE1.PresstheOKkey.

Figure 19

ADJUST VOLUME Key

The ADJUST VOLUME key displays the current

volume. To increase or decrease the volume, use

the UP and DOWN arrow keys.

Figure 21

16

Models C819 & C821Operating Procedures

MENU EDIT Key

The MENU EDIT key is used to program a menu

item. When the MENU EDIT key is pressed, the

following screen will display.

Figure 22

If there is more than one screen of menu items,

press the Previous or Next arrow keys to access the

other menu items.

Press the menu item key to be programmed. The

following screen will display.

To edit a menu item, press the menu item key to

bring up a virtual keyboard. Type in the desired

name (up to 8 characters per line) and then press

the “X” key to return to the previous screen.

Figure 24

ACTIVE: YES or NO. This key displays the current

selection. Pressing the key toggles to the opposite

selection. Selecting YES will display the menu item

on the main display screen.

TOP TEMP: This key displays the current set point

temperature for the platen. To increase or decrease

the temperature, use the UP and DOWN arrow keys.

BOTTOM TEMP: This key displays the current set

point temperature for the lower grill surface. To

increase or decrease the temperature, use the UP

and DOWN arrow keys.

Note: When setting the temperatures for a given

item, the limits are 150°F to 450°F (66°C to 232°C)

for the upper platen and 150°F to 400°F (66°C to

204°C) for the lower grill surface. If the temperatures

are set lower or higher than the temperature limits,

the set point at the control will default to 150°F and

450°F (66°C and 232°C), respectively.

CLAM/FLAT: This key displays the current setting

(CLAM or FLAT) associated with that function.

Pressing the key toggles the mode to the opposite

selection.

GAP: This key is only active if CLAM has been

selected. The key displays the platen gap (in inches

or mm) associated with the FUNCTION. To increase

or decrease the gap setting, use the UP and DOWN

Figure 23

Models C819 & C821 Operating Procedures

arrow keys.

17

MULTIPLE TIMING FUNCTIONS: There is one

timing function for clam items and a maximum of 3

timing functions for each flat menu item. Each

function has a set of parameters associated with it.

The function currently associated with the menu item

is displayed. Pressing either function 1, function 2, or

function 3 will bring up the next function in the list.

The functions provided are:

S REMOVE IN

S TURN IN

S SEAR IN

ALARM AUTO/MANUAL: This key displays the

current status of the alarm mode. Pressing the key

toggles the mode to the opposite selection.

If ALARM AUTO is selected, the alarm will

automatically stop after five seconds has elapsed.

Selecting ALARM MANUAL requires the operator to

manually stop the alarm by touching the raise

button, the standby button, or anywhere on the

display screen.

XXX SECONDS: This key displays the time

associated with that menu item in seconds. To

increase or decrease the seconds setting, use the

UP and DOWN arrow keys.

VIEW HELP Key

The View Help key is not functional at this time

(future development).

Loading Store Menu Items To USB

ThesameUSBflashdrivethatwasusedtoload

softwareintothegrillcanbeusedtoperformthis

procedure.

Step 1

Remove the USB cable cap from the USB connector

to access the USB port.

Note: Grills built prior to serial number M1035495

will require the front control panel be lowered to

access the control display boards.

Step 2

Insert the USB flash drive into the USB port.

Step 3

Press and hold the PROGRAM key for 5 seconds to

enter the Program Mode.

Upon completion of all programming selections,

save the selections by pressing the OK key. To

return to the main display screen without saving the

programming selections, press the X key.

SERVICE CONTACT INFORMATION Key

Press the SERVICE CONTACT INFORMATION key

to view the programmed service contact information.

Figure 26

Step 4

Enter the Operator Password “STORE1” and press

the OK key.

110603

Figure 25

18

Figure 27

Models C819 & C821Operating Procedures

Step 5

Press the MENU EDIT key.

Figure 28

Step 6

Press the STORE MENU TO USB key.

Loading Menu Items From USB

Once the proper software is loaded on the USB flash

drive, the next control board can be programmed

from the USB flash drive.

Step 1

Repeat Steps 1 through 5 from “Loading Store Menu

Items to USB.”

Step 2

Press the LOAD MENU FROM USB key.

Step 3

The control can display up to 5 different menu

options loaded on the USB flash drive. Select the

key for the correct menu to load. The control will

display “DONE” at the bottom of the screen when

the menu is loaded.

Step 4

Remove the USB flash drive from the USB port and

reinstall the USB cable cap on the USB connector.

Note: Grills built prior to serial number M1035495

will require the front control panel be reinstalled.

Figure 29

Step 7

Enter a file name (up to 8 characters) to save the

menu items, using the keyboard displayed on the

control. Press the OK key. The menu items are

saved to the USB flash drive.

Step 8

Remove the USB flash drive from the USB port and

reinstall the USB cable cap on the USB connector.

Note: Grills built prior to serial number M1035495

will require the front control panel be reinstalled.

Step 5

To load menu items from the USB flash drive to

another control board, repeat these software loading

procedures.

110603

Models C819 & C821 Operating Procedures

19

Patty Placement

Placement procedures of meat products must be

followed on the grill. Meat must be placed on the

lower grill surface from front to back. When the cook

cycle is complete, the upper platen will raise.

Note: It is very important that all patties be

removed from the lower grill surface in the same

sequence that they were placed before cooking.

Patties must be removed immediately after the

upper platen has been raised to the OPEN position

and after the meat has been seasoned.

Patties are generally placed two at a time from front to back of grill and right to left. The removal order of the

patties is shown in the diagram by the number shown in the center of each patty.

20

Models C819 & C821Operating Procedures

Operating Procedures

Cooking Product

Step 1

Select the menu item to be cooked. The grill is at the

correct temperature if the control does not display

any temperature statements and the grill

temperature indicators are green.

Step 2

Quickly place the product on the lower grill surface,

from front to back.

During the cooking cycle, the display will show the

name of the current menu item, “REMOVE IN”, and

the time remaining until the product should be

removed.

Figure 31

Step 3

Press the STANDBY button once.

Figure 30

The display reads “MOVING DOWN” as the platen

lowers to the cook surface.

At the end of the cook cycle, the control will display

“DONE”, a tone will sound, and the platen will

automatically raise.

Figure 32

Note: To cancel a cook cycle at any time, press the

RAISE button. A tone will sound and the display will

read “CANCEL” for five seconds and then enter an

IDLE mode.

Models C819 & C821 Operating Procedures

21

Standby Procedures

Menu Parameters

Whenever the grill is idle and product is not being

cooked, the upper platen must be placed in the

STANDBY position.

Step 1

To place the upper platen in the STANDBY position,

press the STANDBY button twice from the open

position.

Figure 33

The control will display “GOING TO STANDBY” and

then change to display “STANDBY”.

Step 2

To raise the upper platen to the OPEN position and

resume cooking, press the RAISE button.

To view the settings and actual temperatures for the

current item, press and hold the menu item key a

minimum of 5 seconds. The screen will display the

cook time, gap setting, temperature set points and

actual temperature readings for each zone for that

menu item.

Figure 35

If a key is not pressed for 20 seconds, the grill

control will return to the normal display. Pushing the

“X” key will bring the display back to the main display

page.

Cleaning After Each Run of Product

Figure 34

CAUTION: Never use force to raise the

upper platen. Damage to components may

result. Only use the RAISE button to open the

upper platen!

Step 1

Using the grill scraper, scrape the grease on the

lower grill surface from front to back. Do not scrape

across the rear of the lower grill surface with the grill

scraper.

Figure 36

22

Models C819 & C821Operating Procedures

Step 2

Use the wiper squeegee to clean the release

material sheet on the upper platen. Use a diagonal

motion to clean the sheet. Hold the handle at a slight

upward angle, with the wiper end facing downward.

Figure 37

Note: Do not use excessive pressure when wiping

the release material sheet. Using excessive

pressure can scratch or tear the sheet.

Step 3

Using the wiper squeegee, push the grease at the

rear of the lower grill surface into the grease can.

DO NOT use the grill scraper for this step.

CAUTION: The upper platen surface is

very HOT! To prevent burn injuries, use extreme

caution when wiping the release material sheet.

Daily Cleaning Procedures

Step 1

Raise the upper platen to the OPEN position by

pressing the red RAISE button.

Figure 38

Step 4

Use the grill cloth to clean the back splash plate and

the bullnose areas as needed during operation.

Note: To increase the life of the release material

sheet, wipe it with a clean, sanitizer-soaked, folded

grill cloth a minimum of four times every hour.

Models C819 & C821 Operating Procedures

upper platen. Damage to components may

result. Only use the RAISE button to open the

upper platen!

23

CAUTION: Never use force to raise the

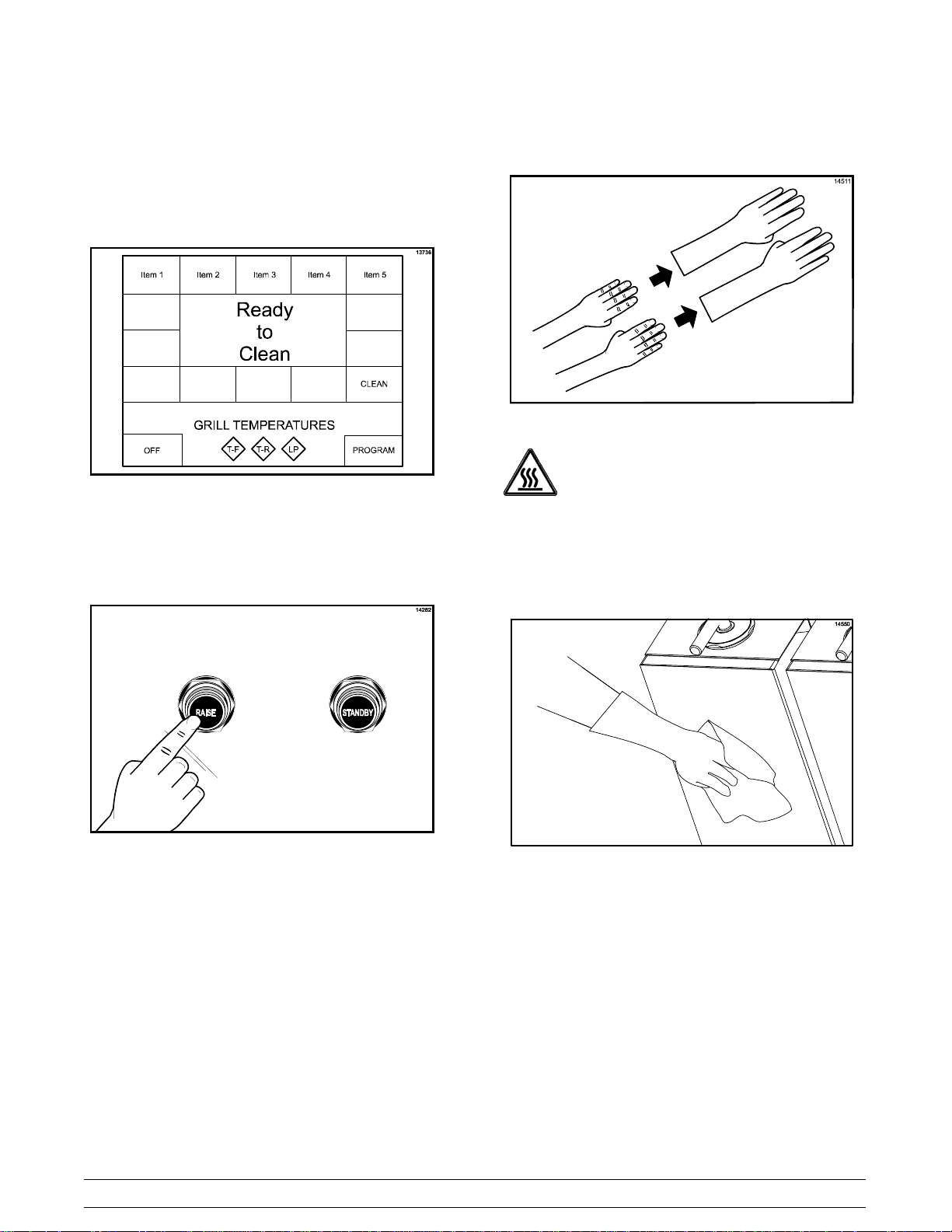

Step 2

Press the CLEAN key. When the cook surfaces

reach the proper temperature for cleaning, an alarm

will sound and the message “READY TO CLEAN”

will be displayed.

Figure 39

Step 3

Press the RAISE button to cancel the alarm.

Step 4

Put on heat-resistant gloves.

Figure 41

CAUTION: The upper platen surface and

release material sheets are very hot. To prevent

burn injuries, use extreme care.

Step 5

Wipe the exposed surface of the release material

sheets with a clean, sanitizer-soaked grill cloth.

Figure 40

24

Figure 42

Models C819 & C821Operating Procedures

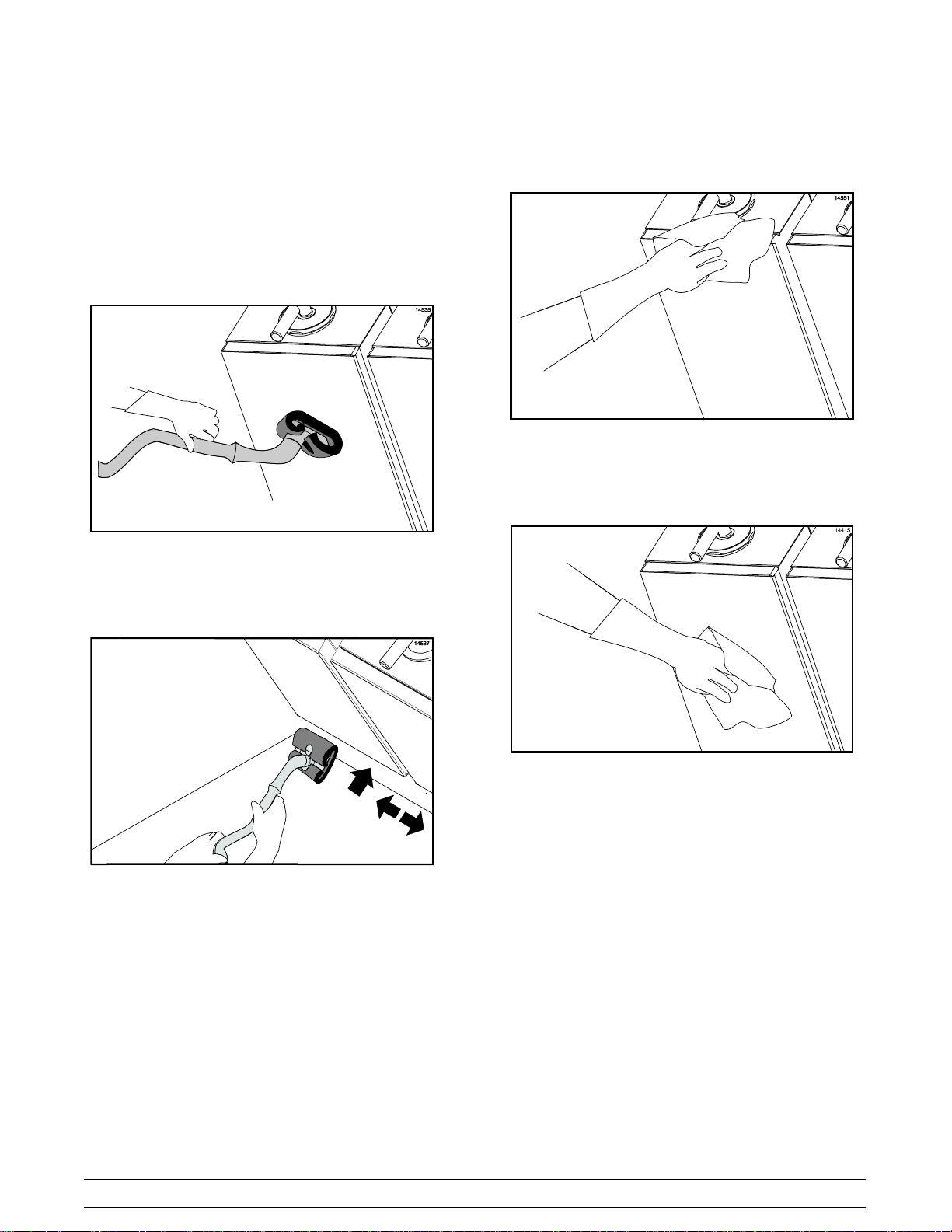

Step 6

Remove the release material clip, release sheet

retainer, and the release material sheet. Take these

parts to the sink to be washed and rinsed.

Figure 43

Step 7

Repeat steps 1 through 6 for the remaining upper

platen.

Step 10

Scrape the lower grill surface with the grill scraper,

from front to back.

Figure 45

Step 11

Use the wiper squeegee to push residual grease into

the grease cans.

Step 8

Wash and rinse the clips and retainers in the sink.

Set them aside for future use.

Step 9

Set the release material sheets aside on a clean, flat

surface next to the sink until further cleaning is

performed. DO NOT fold, crease, or place them on

sharp objects.

Figure 46

Step 12

Remove, empty, and reinstall the grease cans.

Figure 44

Models C819 & C821 Operating Procedures

25

Figure 47

Step 13

Using an approved high temperature grill cleaner,

pour approximately 3 oz. (90 ml) onto each 12” (305

mm) cook zone.

Figure 48

Step 14

Firmly attach the non-abrasive pad to the grill

cleaning pad holder.

IMPORTANT! Use the grill cleaning pad

and holder identified on page 9 ONLY. Using any

other pad and holder will damage the release

sheets.

DO NOT use metal scrapers, abrasive

pads, screens, or wire brushes. This could result

in damage to the components.

Step 17

Apply grill cleaner to the platen cook surfaces.

Figure 50

Step 18

Apply grill cleaner to the back side of the platens.

Step 15

Dip the pad into the grill cleaner.

IMPORTANT: DO NOT SCRUB while applying

grill cleaner in the following steps:

Step 16

Apply grill cleaner to the front side of the upper

platens.

Figure 49

Figure 51

Step 19

Apply grill cleaner to the outer edges of the platens.

Step 20

Press the STANDBY button to lower one of the

platens.

Step 21

Apply grill cleaner to the inner edges of the platens.

Step 22

Press the RAISE button to raise the lowered platen.

110602

26

Models C819 & C821Operating Procedures

Step 23

Lightly scrub the front side of the platens with the

non-abrasive pad until all soil has been liquified by

the grill cleaner. For stubborn soils, apply additional

grill cleaner and lightly scrub. Do not rinse the

platens at this time.

Step 24

Lightly scrub the platen cook surfaces.

Figure 52

Step 30

With a clean, sanitizer-soaked grill cloth, rinse the

front, sides, and back of the platen surfaces.

Figure 54

Step 31

With a clean, sanitizer-soaked grill cloth, rinse the

platen cook surfaces.

Step 25

Lightly scrub the back side of the platens.

Figure 53

Step 26

Lightly scrub the outer edges of the platens.

Step 27

Press the STANDBY button to lower one of the

platens.

Step 28

Lightly scrub the inner edges of the platens.

Step 29

Press the RAISE button to raise the lowered platen.

Figure 55

Step 32

Press the STANDBY button to lower one of the

platens.

Step 33

With a clean, sanitizer-soaked grill cloth, rinse the

inner edges of the platens.

Step 34

Press the RAISE button to raise the lowered platen.

Step 35

With a clean, sanitizer-soaked grill cloth, wipe the

exterior of the platens, especially behind the rear of

the platens (next to the arm assembly).

Step 36

Starting at the back of the lower grill, spread the

remaining grill cleaner over the entire surface. Do

not scrub while applying product.

110602

Models C819 & C821 Operating Procedures

27

Step 37

Lightly scrub the surface with the non-abrasive pad

until all soil has been liquified by the grill cleaner.

Figure 56

Step 38

Carefully pour warm water on the lower grill surface,

starting from the back to the front. Use the squeegee

to remove the cleaner from the grill surface.

Figure 57

Note: The rear of the upper platen, as well as the

tubular arm, can easily be wiped from the front of the

unit. If cleaning is performed on a daily basis, there

should be no carbon build-up.

IMPORTANT!

DO NOT use a jet of water to clean or rinse

the grill.

DO NOT use cold water or ice to cool the

upper platen or the lower cook surface.

Failure to follow these instructions may result in:

S serious electrical shock

S burns from hot steam

To avoid damaging the grill:

S Never use grill screens on the upper platen

or the lower grill surface

S Never use any abrasives or cleaners other

than the approved cleaner.

S Never allow the grill scraper or abrasive

cleaning materials to come in contact with

the release material.

Step 39

Pour a small amount of lukewarm water on a clean,

sanitizer-soaked grill cloth, while holding it over the

lower grill surface. Wipe the lower grill surface until

all residue is removed.

S liquid collecting inside the grill and

destroying electrical components

S damaged cook surfaces

110602

28

Figure 58

Models C819 & C821Operating Procedures

IMPORTANT! Step 40 must be performed

using the grill cleaning pad and holder

indentified on page 9, ONLY. Using any other pad

and holder will damage the release material sheets.

Note: Contact your local Taylor Distributor to

purchase the correct grill cleaning pad and holder.

(See page 9.)

Step 40

Place the release material sheets flat on the lower

grill surface. Gently clean both sides of the sheets

with an approved high temperature grill cleaner and

the grill cleaning pad and holder.

Step 43

Wipe the lower grill surface with a clean,

sanitizer-soaked grill cloth. Repeat until no visible

soil remains.

Step 44

Remove and empty the grease cans.

Figure 61

Step 45

Wash, rinse, and reinstall the grease cans.

Figure 59

Step 41

Rinse both sides of the release material sheets with

a clean, sanitizer-soaked grill cloth.

Figure 60

Step 42

Place the release material sheets on a clean,

sanitized, flat surface to air dry overnight.

24 Hour Stores Only:

Step 45

Re-install the release material sheets on the

opposite side than previously used. Secure the

sheets with the release material clips and retainers.

Start up the grill per the instructions starting on

page 11.

Figure 62

110602

Models C819 & C821 Operating Procedures

29

Non-24 Hour Stores Only:

Step 46

Wipe all areas with a clean, sanitizer-soaked grill

cloth.

Step 47

Wipe all exterior panels.

Step 48

Apply a light coat of vegetable oil to the entire lower

grill surface.

Step 49

Leave the upper platens in the OPEN position

overnight.

Step 50

Place the power switch in the OFF position.

Figure 63

Figure 64

30

Models C819 & C821Operating Procedures

Section 7 Troubleshooting Guide

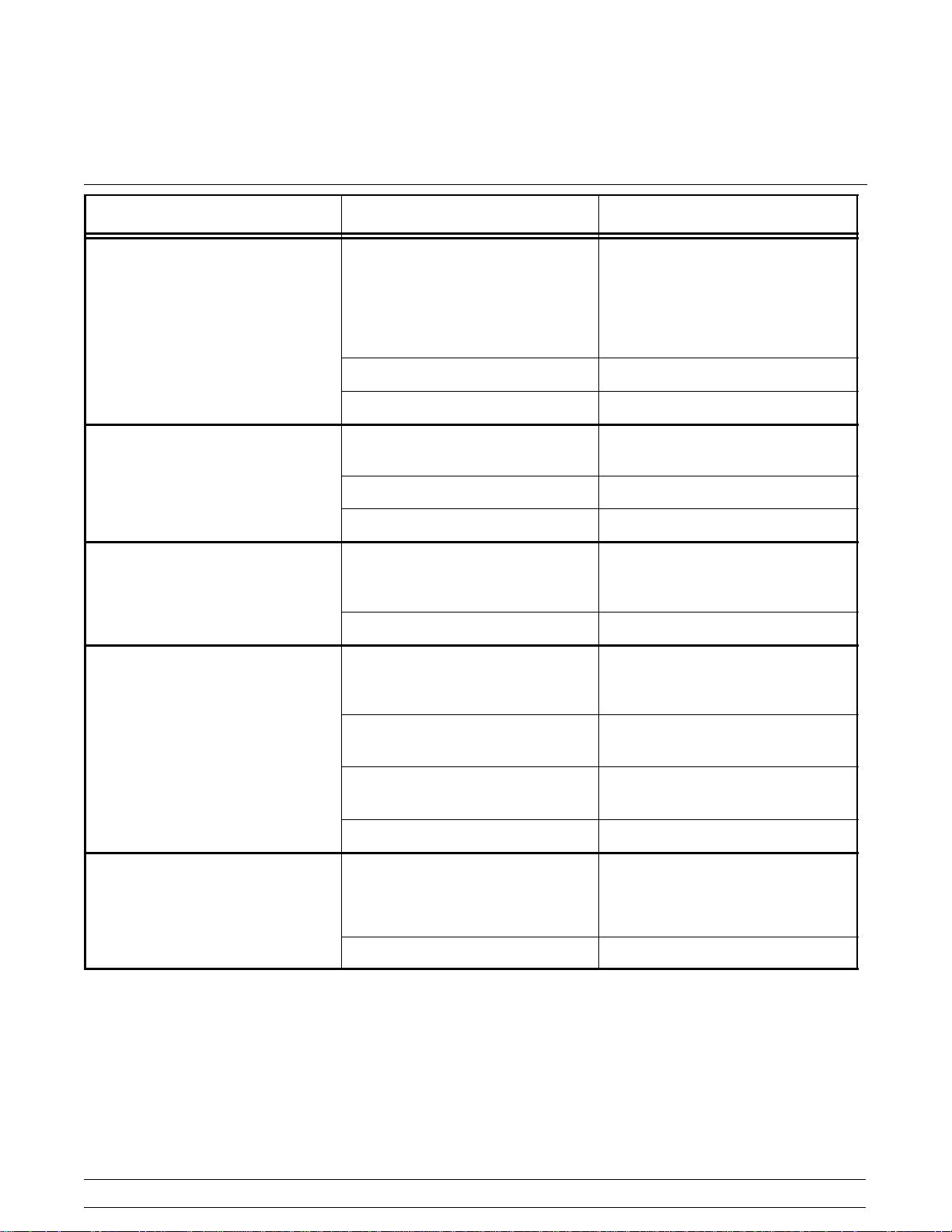

PROBLEM PROBABLE CAUSE REMEDY

1. One side of the grill will not

heat. The control will display

the message, “FAULTY

ELEMENT OR SHORTED

PROBE” after the TOO COOL

timer has elapsed.

2. One heat zone will not heat.

(Display reads “TOO COOL”.)

3. One of the heat zones is

overheating. (Display reads

“TOO HOT”.)

4. The grill will not turn on when

power switch is placed in the

ON position.

a. The heater is faulty. a. Call a service technician.

b. The high limit switch is faulty. b. Call a service technician.

c. The solid state relay is faulty. c. Call a service technician.

a. The interface board is faulty. a. Call a service technician.

b. The solid state relay is faulty. b. Call a service technician.

c. The control harness is faulty. c. Call a service technician.

a. The interface board is faulty. a. Call a service technician.

b. The solid state relay is faulty. b. Call a service technician.

a. The restaurant circuit breaker

has been tripped.

a. Reset the circuit breaker.

5. The upper platen will not stay

in the STANDBY mode, but will

stay in the COOK position.

b. The control cord is not

connected properly.

c. The fuse in the control box is

faulty.

d. The power switch is faulty. d. Call a service technician.

a. Incorrect use of the STANDBY

button.

b. Faulty wire connections. b. Call a service technician.

b. Reconnect the cord.

c. Call a service technician.

a. Press the STANDBY button

within five seconds of lowering

theplatenintotheCOOK

position.

Models C819 & C821 Troubleshooting Guide

31

PROBLEM PROBABLE CAUSE REMEDY

6. The upper platen will not stay

in the COOK or STANDBY

position.

7. The upper platen will not stay

in the COOK position, but will

stay in the STANDBY mode.

8. The upper platen opens too

rapidly.

9. The display reads “PLATEN

NOT LATCHED”.

a. Temperature is insufficient to

satisfy the indicator LED's.

b. The control harness is faulty. b. Call a service technician.

c. The interface board is faulty. c. Call a service technician.

d. The latch switch is faulty. d. Call a service technician.

e. The latch solenoid is faulty. e. Call a service technician.

f. The processor control is faulty. f. Call a service technician.

g. The pneumatic system is

faulty.

a. The processor control is not set

properly.

a. The orifice/check valve is

incorrect or missing.

a. The pneumatic system is

faulty.

a. Wait until the indicator LED's

turn green.

g. Call a service technician.

a. Call a service technician.

a. Call a service technician.

a. Call a service technician.

10. The display reads “UPPER

PLATEN STUCK”.

11. The platen will not lower to

preset gap height.

b. The latch switch is faulty. b. Call a service technician.

c. The latch solenoid is faulty. c. Call a service technician.

a. The arm bearings are dirty. a. Call a service technician.

b. The air cylinder is faulty. b. Call a service technician.

c. Plugged air lines to cylinders. c. Call a service technician.

a. Defective motors and cables. a. Call a service technician.

b. Defective motor interface

board.

c. Loose harness connections. c. Call a service technician.

d. Defective main display

controller.

b. Call a service technician.

d. Call a service technician.

32

Models C819 & C821Troubleshooting Guide

PROBLEM PROBABLE CAUSE REMEDY

12. The product is under-cooked

or overcooked.

13. The product is not cooking

evenly.

a. The release material sheet is

worn.

b. Incorrect cooking time. b. Reset the processor control for

c. Incorrect temperature. c. Adjust the processor control to

d. The upper platen or lower grill

surface is not clean and/or has

carbon build-up.

e. The preset gap height is

incorrect.

f. The heating zone is not

heating.

a. The upper platen or lower grill

surface is not clean and/or has

carbon build-up.

a. Replace the release material

sheet.

the correct time.

the proper setting.

d. Closing procedures must be

followed to properly clean the

upper platen and the lower grill

surface, and to remove carbon

build-up.

e. Call a service technician.

f. Call a service technician.

a. Closing procedures must be

followed to properly clean the

upper platen and the lower grill

surface, and to remove carbon

build-up.

14. The display reads “PROBE

OPEN”.

15. The display reads “HOME

SWITCH STUCK ON.”

b. Release material sheet is worn. b. Replace release material

sheet.

c. The platen is not level. c. Call a service technician.

d. The preset gap height is

incorrect.

e. Air pressure is not high

enough.

a. The thermocouple or the

thermocouple interface board

is faulty.

a. Defective motor control. a. Call a service technician.

b. Defective stepper motor. b. Call a service technician.

c. Defective stepper motor wire

harness.

d. Defective Home switch. d. Call a service technician.

d. Call a service technician.

e. Call a service technician.

a. Call a service technician.

c. Call a service technician.

Models C819 & C821 Troubleshooting Guide

33

PROBLEM PROBABLE CAUSE REMEDY

16. The display reads “HOME

SWITCH NOT SEEN.”

PROBLEM PROBABLE CAUSE REMEDY

1. The display reads “BLOWER

FAILURE”.

2. The burner will not light. The

display reads “IGNITION

FAILURE”.

a. Defective motor control. a. Call a service technician.

b. Defective stepper motor. b. Call a service technician.

c. Defective stepper motor wire

harness.

d. Defective Home switch. d. Call a service technician.

e. Broken platen cable. e. Call a service technician.

c. Call a service technician.

GAS ZONES ONLY

a. The blower is faulty. a. Call a service technician.

b. The pressure switch is faulty. b. Call a service technician.

a. The quick disconnect gas hose

is not fully engaged.

a. Re-engage the quick

disconnect.

3. The burner lights but will not

stay lit.

4. The burner lights but the zone

is cool or overheats.

b. The manual shutoff valve is in

the OFF position.

c. Air is in the gas hose. c. Wait 5 minutes before

d. The processor control is faulty. d. Call a service technician.

e. The spark ignition module is

faulty.

f. The gas solenoid is faulty. f. Call a service technician.

g. The electrode is faulty. g. Call a service technician.

h. The interface board is faulty. h. Call a service technician.

a. The electrode is faulty. a. Call a service technician.

b. Improper ground. b. Call a service technician.

a. The grill is out of calibration. a. Call a service technician.

b. The processor control is faulty. b. Call a service technician.

b. Turn the valve to the ON

position.

relighting.

e. Call a service technician.

c. The thermocouple is faulty. c. Call a service technician.

34

Models C819 & C821Troubleshooting Guide

Section 8 Parts List

REMARKS

WARR.

CLASS

C821

QTY.

C819

QTY.

PART

NUMBER

DESCRIPTION

+SEAL-ARM 079952 4 2 000

ACTUATOR-HOME SWITCH 079792 2 1 103

C81923N879 - 208V 60HZ 3PH - NATURAL GAS - CANADA & C82123NW39 - 208V 60HZ 3PH - NATURAL GAS - 1 PLATEN LEFT - ROHS COMPLIANT

+ Available Separately

ARM A.-TUBE *C845* X73031 2 1 103

Models C819 & C821

BACKSPLASH A. *C819* X69653 1 103

BACKSPLASH A. *C822* X69653-R 1 103

BAFFLE A.-COMBINATION X73937 1 1 103

BAFFLE A.-COMBINATION X73939 1 1 103

BAFFLE-INNER* L 073022 1 1 103

BAFFLE-INNER* R 073021 1 1 103

BAR A.-RELEASE MATERIAL X72843 2 1 103

+NUT-10-32 WHIZ FLANGE LOCKNUT 020983 10 5 000

+SCREW-SHOULDER 10-32X1/4X.125L 072849 4 2 000

BAR-BELLY *C820* 073540 1 1 103

BEARING-FLANGE 3/4 X 15/16 077042 8 4 000

35

BEARING .753 X 1.000 X 2.000 072541 4 2 000

BEARING 3/4 ID-SELF ALIGN 078730 4 2 103

BLOCK-CONTACT 1 NO *11/12/15 076013 4 4 103

BLOCK-TERMINAL 1P 073423 1 1 103

BLOCK-TERMINAL 2P .25 SPD-24X 073033 1 1 103

BLOCK-TERMINAL 3P 20A, 300V 051331 3 3 103

BULLNOSE A.-*C819* X69670 1 1 103

BURNER-I.R. 073334 2 2 103

+BRACKET-BURNER-SIDE 073010 4 4 103

+BRACKET-BURNER-SHORT 073016 4 4 103

BUSHING-FLG .627IDX.12WOILITE 052394 4 2 103

BUSHING-SNAP 11/16 ID X 7/8OD 010548 6 6 103

BUSHING-SNAP 1-3/8IDX 1-3/4OD 027712 4 4 103

BUSHING-SNAP 1-5/16IDX 1-1/2 017008 3 3 103

BUSHING-SNAP .391 ID X.500 OD 073910 2 2 103

BUTTON-OPERATOR-BLACK 076012 2 2 103

BUTTON-OPERATOR-RED 076011 2 2 103

111014

Parts List

CAN A.-GREASE X73944 2 2 103

WARR.

CLASS

C821

QTY.

C819

QTY.

PART

NUMBER

DESCRIPTION REMARKS

+SLIDE-GREASE CAN 073293 2 2 103

CARD-CHECKOUT GEN MKT INF GAP 073484 1 1 000

CABLE-PLATEN-F-REAR 073251 4 2 103

CABLE-PLATEN-FRONT 073252 4 2 103

CASTER-GRILL 5" SWIVEL W/LOCK 073240 2 2 103

CASTER-5" 7-5/8 STEM 078377 2 2 103

CLEANER-STERA SHEEN 6 1 QT/CS 073160 000 SAMPLE SENT WITH NEW EQUIPMENT

CLEVIS-ROD 1/2-20 THD 079777 2 1 000

+ Available Separately

Parts List Models C819 & C821

CLIP-RELEASE MATERIAL-W/TAB 072673 4 4 000

COMPRESSOR-AIR-230V SERV 032129SER2 1 1 ***

+ADAPTOR-1/4MPT X 1/4 OD TUBE 052563-2 2 2 103

+CROSS-1/4 FPT * 1.562 SQ 077339-M 1 1 103

+FITTING-SWIVELELBOW 1/4 OD 072695-6 1 1 103

+PLUG-HOLE 7/8 DIA. BLACK 010077 1 1 000

+PLUG-1/4 NPT-PARKER:VS219P-4 065156-6 1 1 103

36

+SWITCH-PRESSURE 240V,3HP 077879-C 1 1 103

+TEE-1/4OD X 1/4OD X 1/4OD TUBE 052562 1 1 103

+TUBE-TEFLON .188IDX.250OD R403022 10' 5' 000

+VALVE-CHECK 1/4MP 020959 1 1 103

CONTROL-GRILL TOUCH PAD------> SEE KIT A.-GRILL CONTROL - X73474-SER

+GASKET-CONTROL 072914 2 2 000

CONTROL-HI-LIMIT 450F RESET 070279 2 2 103

CONTROL-IGNITOR UTC X70301-02S 2 2 103

CONTROL-LIMIT W/SCREWS 078721 2 1 103

CONTROL-MOTOR X69621-SER 2 2 212

CONTROL-MOTOR -GRILL X73279-SER 212 REPLACED BY X69621-SER

CORD A.-POWER-250V-30A 4 WIRE 073668 1 1 103

+SHIELD-POWER CORD *C820* 073729 1 1 103

COVER A.-PLATEN X73256 2 1 103

COVER A.-USB WATERPROOF 073809 2 2 103

COVER-FRONT *C819* 073748 1 1 103

CROSS-1/4 FPT * 1.562 SQ 077339-M 1 1 103

CYLINDER-AIR 6IN STROKE C/C 079160 2 1 103

WARR.

CLASS

C821

QTY.

C819

QTY.

PART

NUMBER

DESCRIPTION REMARKS

DEFLECTOR A.-FLUE *C819* X69657 1 1 103

DIAGRAM-WIRING *C819* 073814-23 1 000

DIAGRAM-WIRING *C821* 069842-23 1 000

E-RING 1/4 BLACK PHOS 032190 4 4 000

E-RING-3/4STEEL 077046 8 4 000

+ Available Separately

Models C819 & C821

FAN-BLOWER 60CFM 120/230 VAC 079326-12 2 1 103

FASTENER-SNAP IN 1/4X15/16 078329 24 24 000

FILTER A.-*M22E*WHT/BLK X79256 2 1 103

FILTER-CORCOM 6EH1 040140-001 2 2 103

FITTING-1/4MPTX1/4OD TUBE 90DG 052560-2 5 5 103

FITTING-5/16X5/16X3/16 COMP 073911 2 2 103

FITTING-SWIVELELBOW 1/4 OD TB 072695-6 2 2 103

FITTING-DIFFUSER1/4 MPT 072695-8 1 1 103

FORM-QUALITY REPORT BY FAX 065712 1 1 000

FUSE-7 AMP MDQ-7 079837-070 1 1 000

37

+HOLDER-FUSE-15 A, 250 V 076299 1 1 103

GAUGE-130 PSI 1/8 MPT BACK MNT 072695-3 1 103

GASKET-BRAIDED-HITEMP R70113 10 000

GASKET-GORE-TEX .250 DIA 000 SEE SEALANT-GORE TEX R700033

GASKET-CONTROL *C842* 072914 2 2 000

GASKET-FRONT SHROUD *C819* 073753 1 1 000

GASKET-FRONT VIEW PORT 072985 2 2 000

GUIDE-PATTY PLACEMENT GEN MKT 073440 1 1 103

HANDLE-PLATEN 073250 2 1 103

HARNESS A.-COMP. VALVE X73703 1 103

HARNESS A.-COMP. VALVE *C820 X73703-R 1 103

HARNESS A.-MOTOR *C820* 073892 2 2 103

HARNESS-BLOWER 073608 2 2 103

HARNESS-COMPRESSOR 073422 1 103

HARNESS-FAN *C819* 069716 1 1 103

HARNESS-FAN *C819* 069717 1 1 103

HARNESS-HIGH LIMIT 073471-L 1 1 103

Parts List

HARNESS-HIGH LIMIT 073471-R 1 1 103

WARR.

CLASS

C821

QTY.

C819

QTY.

PART

NUMBER

DESCRIPTION REMARKS

CLIP-RELEASE MATERIAL-W/TAB 072673 4 4 000

RETAINER-SHEET RELEASE 072845 2 2 103

SCRAPER-TEFLON WIPER 075887 1 1 000

SCREW-10-32X3/8SLTD TRUSS 024298 9 9 000

SCREW-3/8-16X1 HEX HEAD CAP 001082 2 2 000

SHEET-RELEASE BOX(9) GEN MRK 073442 1 1 000

STRIP-REPLACEMENT 075888 1 1 000

WASHER-3/8 USS FLAT CR3 000653 2 2 000

SHIELD-GREASE 078285 4 2 103

KIT A.-GREASE SHIELD* X78330-SER 2 1 000

FASTENER-SNAP IN 1/4X15/16 078329 24 24 000

KIT A.-GRILL CONTROL-GEN MRKT X73474-SER 2 2 312

+GASKET-CONTROL 072914 2 2 000

LABEL-ELEC-CAUTION-CANADA 075484-CAN 1 1 000

+ORIFICE A.-IGNITOR 073826-003 2 2 103

+ORIFICE A.-IGNITOR 073826-005 2 2 103

+WIRE A.-IGNITOR*C845* X73147-12 2 2 103

HARNESS-IDC BOARD 073429-L 1 1 103

HARNESS-IDC BOARD 073429-R 1 1 103

HARNESS-IGNITION-GROUND * 069757 1 1 103

HARNESS-PCB/GR SWITCH 072529 2 2 103

HARNESS-RHT-GAS-DETECT *C 073731 1 103

HARNESS-SSR-LEFT 073095 1 1 103

HARNESS-SSR-RIGHT 073097 1 103

HARNESS-SWITCH 073728 1 1 103

HARNESS-TOUCH-CONTROL 073369 2 2 103

HOLDER-FUSE-15 A, 250 V 076299 1 1 103

HOSE ASSEMBLY-FLEXIBLE GAS 073941 1 1 103

HOSE-BEV.-.250IDX.438OD-100' R30317 5' 5' 000

IGNITOR-SPARK 073812 2 2 103

+ Available Separately

Parts List Models C819 & C821

38

KIT A.-3FT RESTRAIN CABLE 074948 1 1 103

KIT A.-ACCESSORY *C820* X73606 1 1 000

LABEL-INST-LIGHT 079567 1 1 000

WARR.

CLASS

C821

QTY.

C819

QTY.

PART

NUMBER

DESCRIPTION REMARKS

LABEL-INST-LIGHT*15E*FREN 079567-F 1 1 000

LABEL-NOTICE-CASTERS-CANADA 076389-CAN 1 1 000

LABEL-WARN-GAS GRILL-CANA 078075-CAN 1 1 000

LABEL-WARN-GRILL-MCD-SVC-CAN 072658-CAN 3 3 000

LENS-MICA 072986 2 2 000

+ Available Separately

Models C819 & C821

+GASKET-FRONT VIEW PORT 072985 2 2 000

MAN-OPER C819 073946-M 1 1 000

MAN-OPER C819 FRENCH CANADIA 073946FCM 1 1 000

MANIFOLD A.- AIR COMPRESSOR 073129 1 103

MANIFOLD A. 073129-R 1 103

CONNECTOR-MATE LOCK 4 CIR-PIN 500534 1 103

FITTING-DIFFUSER1/4 MPT 072695-8 1 1 103 COMPLETE A. - X73273-SER MOTOR A.-MOUNT

FITTING-SWIVELELBOW 1/4 OD 072695-5 2 1 103

FITTING-SWIVELELBOW 1/4 OD 072695-6 1 1 103

GAUGE-130 PSI 1/8 MPT BACK M 072695-3 1 1 103

39

PIN-.084 OD/14-20 AWG-STRIP 021624 1 103

PLUG-1/8 MP-NICKEL PLATED 020988 1 103

REGULATOR-PRESSURE 0-120 PSI 072695-2 1 1 103

VALVE-PRESSURE RELIEF 70 PSI 072695-4 1 1 103

VALVE-SOLENOID 3 WAY 12 VDC 072695-1 1 1 103

MANIFOLD A.-GAS *C819* X73872-02 1 1 103

ELBOW-3/8 MPT X 5/16 076370 2 2 103

ELBOW-3/8MPTX3/8FPT-BLACK 078890 1 1 103

FITTING-REDUCER-1/2FPT-3/8FP 077364 1 1 103

VALVE-GAS REDUNDANT 3-1/2 WC 079329-02 2 2 103

MOTOR-FAN 95.3 CFM 2700 RPM 062253-27 1 1 103

MOTOR-GEAR *M32/35* STEPPER V3 073247 2 1 103

+SCREW-SHOULDER 5/16 X 1 073249 4 2 103

+NUT-1/4-20 WHIZ FLANGE LOCK 017523 4 2 103

O-RING-1-3/16OD X .103W 052733-120 8 4 000

ORIFICE-HEX PLUG GAS-#40 076554-40 2 2 103

ORIFICE-HEX PLUG GAS-#53 076554-53 2 2 103

Parts List

PANEL A.-BACK SERVICE *C819* X73768 1 103

WARR.

CLASS

C821

QTY.

C819

QTY.

PART

NUMBER

DESCRIPTION REMARKS

PANEL A.-CONTROL UPPER *C819 X73816 2 103

PANEL A.-LIGHT *C819* X73881 1 103

PANEL A.-SIDE UPPER-LT X72962 1 103

PANEL A.-SIDE UPPER-RT X72965 1 103

PANEL-FRONT-LOWER *C819* 073902 1 103

PANEL-SIDE-LOWER-LEFT 073262 1 103

PANEL-SIDE-LOWER-RIGHT 073261 1 103

PANEL A.-BACK SERVICE- X69664 1 103

PANEL A.-FRONT-LOWER- X69660 1 103

PANEL A.-LIGHT *C819* X69678 1 103

PANEL-SIDE-LOWER-RIGHT 073991 1 103

PANEL-SIDE-LOWER-LEFT 073992 1 103

PANEL-SIDE UPPER-RT 073989 1 103

PANEL-SIDE UPPER-LT 073990 1 103

PIN-SPRING UPPER- 072542 2 000

PLATE A.-AIR SHUTTER SLIDE X79485 2 103

PLATE A.-DOOR HINGE-L X73569 1 103

PLATE A.-DOOR HINGE-R X73570 1 103

PLATEN A.-SERVICE *C820* 2600W X73741-23 2 1 212

PLUG A.-USB CABLE 073808 2 2 103

PLUG-HOLE 7/8 DIA. BLACK 010077 6 6 000

PLUG-HOLE 1-3/4 DIA. 027132 2 2 000

PLUG-HOLE 1-3/8 DIA.-BLACK 053361 1 1 000

PLUG-HOLE 3/8 DIA BLACK PLASTIC 050988 1 2 103

PULLEY-PLATEN CABLE 072662 4 2 103

PULLEY-PLATEN-LEFT 073248-L 2 1 103

PULLEY-PLATEN-RIGHT 073248-R 2 1 103

REGULATOR-PRESSURE 0-120 PSI 072695-2 1 1 103

RELAY-SS 25A NON-ALARM 240 V 074210-02 4 2 103

RELAY-3P-50A 208/240 COIL 051890-27 2 1 103

ROD-AIR SHUTTER ADJUST 073304 2 2 103

SCRAPER-TEFLON WIPER 075887 1 1 000

+ Available Separately

Parts List Models C819 & C821

40

+STRIP-REPLACEMENT 075888 1 1 000

WARR.

CLASS

C821

QTY.

C819

QTY.

PART

NUMBER

DESCRIPTION REMARKS

SCREW-1/4-20X3/8 SLTD ROUND 011694 15 30 000

SCREW-1/4-20X5/8 SERRATED HWH 017522 23 17 000

SCREW-10-24X1/2TORX TRUSS T20 002077 4 4 000

SCREW-10-32X1/2SERRATED HWH 020982 18 14 000

SCREW-10-32X1/2SLTD TRUSS 037734 20 10 000

+ Available Separately

Models C819 & C821

SCREW-10-32X3/8SLTD TRUSS 024298 31 22 000

SCREW-10-32X3/8UNSL HWH SERR 039381 14 16 000 SEE KIT A.-GREASE SHIELD

SCREW-10X3/8 SLOTTED HEX WSHR 015582 36 36 000

SCREW-6-32X3/8SLTD BINDER 002201 4 4 000

SCREW-6-32X5/8UNSLTD HWH 041363 12 12 000

SCREW-8X1/4 SLTD HEX WASHER 009894 4 4 000

SCREW-SHOULDER 4-40X.3755 SOC 058381 12 12 000

SCREW-SHOULDER 3/8X3-1/4 052010 8 4 103

SCREW-SHOULDER 10-32X1/4X.125L 072849 4 2 103

SCREW-SHOULDER 5/16 X 1 073249 4 2 103

41

+FASTENER-SNAP IN 1/4X15/16 078329 24 24 000

CLIP-RELEASE MATERIAL-W/TAB 072673 4 4 103

RETAINER-SHEET RELEASE (RETENTION BAR) 072845 4 2 000

SEALANT-GORE-TEX 1/4 UNCOMP. R700033 10' 6' 000

SEALANT-JOINT 1/2 IN TEADIT R70003 10' 5 000

SEAL-ARM 079952 4 2 000

SHEET-RELEASE BOX(9) GEN MRK 073442 1 1 000

SHIELD A.-HEAT X73597 2 2 103

SHIELD-COUPLING FRONT 072926 2 1 103

SHIELD-COUPLING REAR 072927 4 2 103

SHIELD-GREASE 078285 4 2 103 SEE - KIT A.-GREASE SHIELD X78330-SER

SHIELD-PLATE SHROUD 072465 6 3 103

SHIELD-PLATE SHROUD-OUTER 072466 6 3 103

SHIELD-PLATE TUBE 072467 6 3 103

SHIELD-PLATE TUBE INNER 072467-1 6 3 103

SHIELD-POWER CORD 073729 1 1 000

SHROUD A.-COMBINATION *C819* X73751 1 1 103

Parts List

SHROUD A.-PLATEN X72835 2 1 103

WARR.

CLASS

C821

QTY.

C819

QTY.

PART

NUMBER

DESCRIPTION REMARKS

SUPPLY-POWER-10W 12VDC 073336 2 2 103

SWITCH A.-LATCH X73775 2 2 103

SWITCH-SCREW TERMINAL 075780 2 2 103

SWITCH-HOME POSITION 073764 2 1 103

+ACTUATOR-HOME SWITCH 079792 2 1 103

SWITCH-PRESSURE 240V,3HP 077879-C 1 1 103

SWITCH-PRESSURE 074314 2 2 103

SWITCH-PUSHBUTTON-SPST 079442 2 103

SWITCH-ROCKER-DPST-10AMPIP65 076989-WP 1 1 103

SWITCH-SCREW TERMINAL 075780 2 2 103

TANK-ACCUMULATOR 10LB-NPT 078820 1 1 103 ACCUMULATOR A. *C820*

TEE-1/4OD X 1/4OD X 1/4OD TUBE 052562 1 1 103

THERMOCOUPLE K *M 15* 076222-K 4 4 103

42

THERMOCOUPLE-K TYPE SS BRAID 079622 4 2 103

TRANS.-100VA 120/208/240 PRI 079800 2 2 103

TRIM-CORNER-LEFT 073263 1 103

TRIM-CORNER- RIGHT 073264 1 103

TRIM-CORNER- FRONT-RIGHT 073973 1 103

TRIM-CORNER- FRONT-LEFT 073974 1 103

TRIM-CORNER-REAR-RIGHT 073987 1 103

TRIM-CORNER- REAR-LEFT 073988 1 103

TUBE A.-GAS BACK *C819* X73873 1 1 103

TUBE-.170ID X .250OD R403021 7' 7' 000

TUBE-NYLOBRADE 1/4ID X 7/16O 020568-20 1 1 000

TUBE-NYLOBRADE 1/4ID X 7/16O 020568-24 1 1 000

+CLAMP-HOSE 7/16-WIRE DICHROMAT 051742 2 2 000

TUBE-TEFLON .188IDX.250OD R403022 10' 6' 000

VALVE-CHECK W/#69 ORIFICE 078332 2 1 103

VALVE-CHECK 1/4MP 020959 1 1 103

VALVE-GAS REDUNDANT 3-1/2 WC 079329-02 2 2 103

+PIN-SPRING UPPER 072542 4 2 000

SPRING-EXTENSION LATCH 072617 8 4 000

+ Available Separately

Parts List Models C819 & C821

VALVE-PRESSURE RELIEF 70 PSI 072695-4 1 1 103

WARR.

CLASS

C821

QTY.

C819

QTY.

PART

NUMBER

DESCRIPTION REMARKS

+LENS-MICA 072986 2 2 000

+GASKET-FRONT VIEW PORT 072985 2 2 000

VALVE-SOLENOID 3 WAY 12 VDC 072695-1 2 1 103

VARISTOR A.-230VAC W/#10 SPADE X51733-C 2 2 103

WINDOW-FRONT VIEW PORT 073013 2 2 103

+ Available Separately

Models C819 & C821

WIRE A.-IGNITOR X73147-12 2 2 103

43

Parts List

C819

073814-23

9/11

C821

069842-23

9/11

Loading...

Loading...