Page 1

OPERATOR'S

MANUAL

Model 811, 813, 819, 821 Series

Auto Lift Gas Grills

Original Operating Instructions

073625-M

9/15/10 (Original Publication)

(Updated 9/4/14)

Page 2

Complete this page for quick reference when service is required:

Taylor Distributor:

Address:

Phone:

Service:

Parts:

Date of Installation:

Information found on data plate:

Model Number:

Serial Number:

Electrical Specs: Voltage Cycle

Phase

Maximum Fuse Size: Amps

Minimum Wire Ampacity: Amps

Part Number:

E 2010 Carrier Commercial Refrigeration, Inc.

073625-M

Any unauthorized reproduction, disclosure, or distribution of copies by any person of any portion of this work may

be a violation of Copyright Law of the United States of America and other countries, could result in the awarding

of Statutory Damages of up to $250,000 (17 USC 504) for infringement, and may result in further civil and criminal

penalties. All rights reserved.

Taylor Company

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072

Page 3

Table of Contents

Section 1 To th e Installer 1............................................

Installer Safety 1........................................................

Site Preparation 1.......................................................

Electrical Connections 1.................................................

Installation 2...........................................................

Section 2 To the Operator 3...........................................

Section 3 Safety 4....................................................

Section 4 Operator Parts Id entification 7...............................

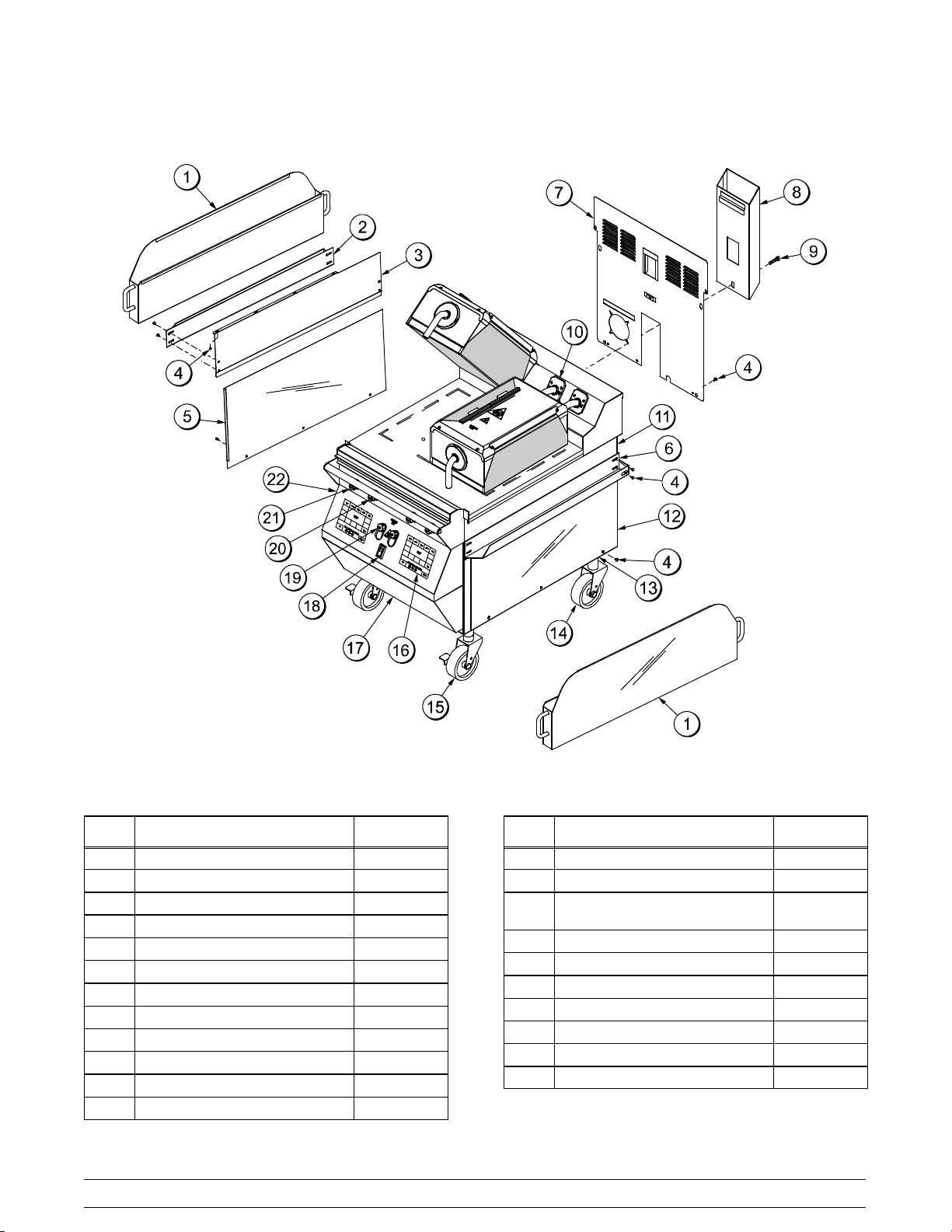

C811 Exploded View 7..................................................

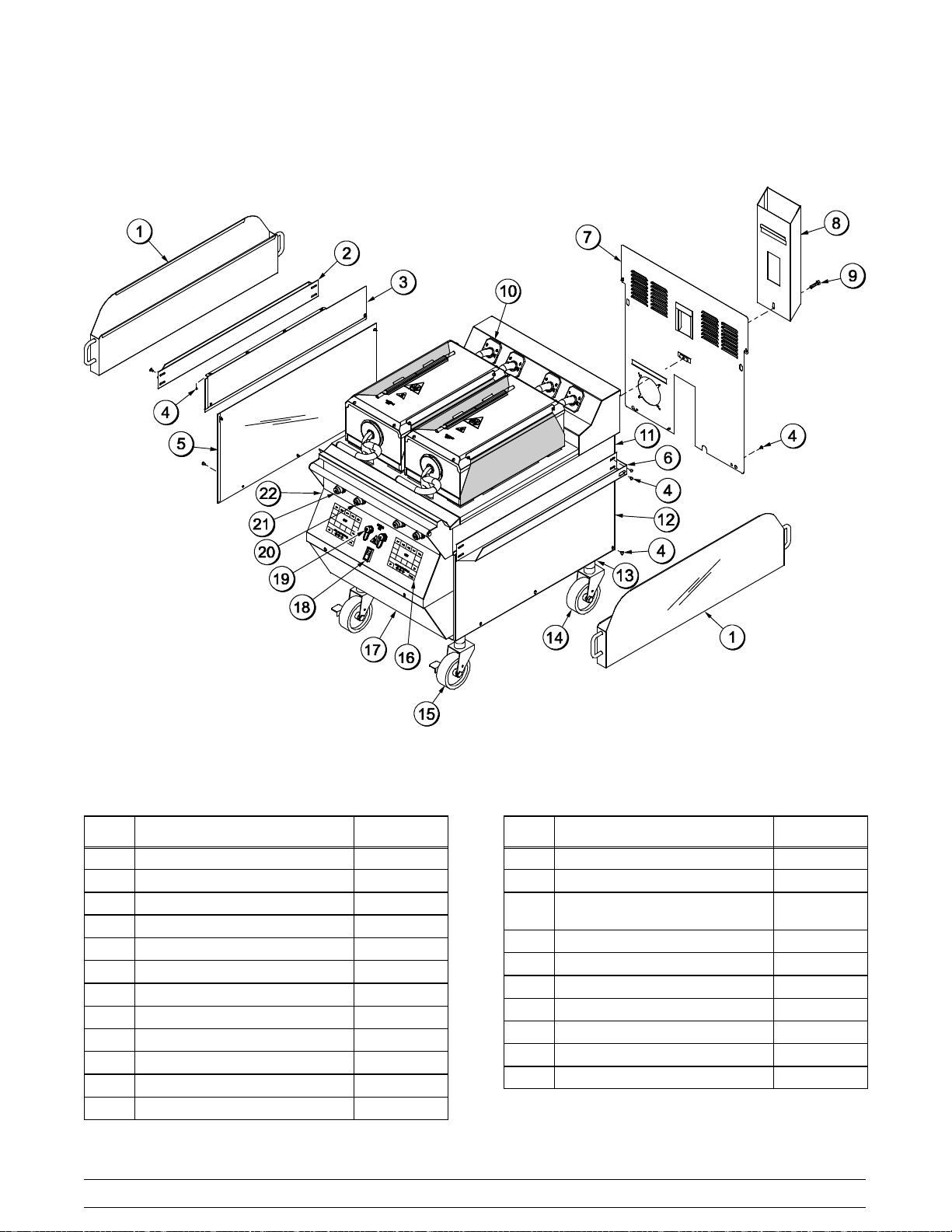

L811 Exploded View 8...................................................

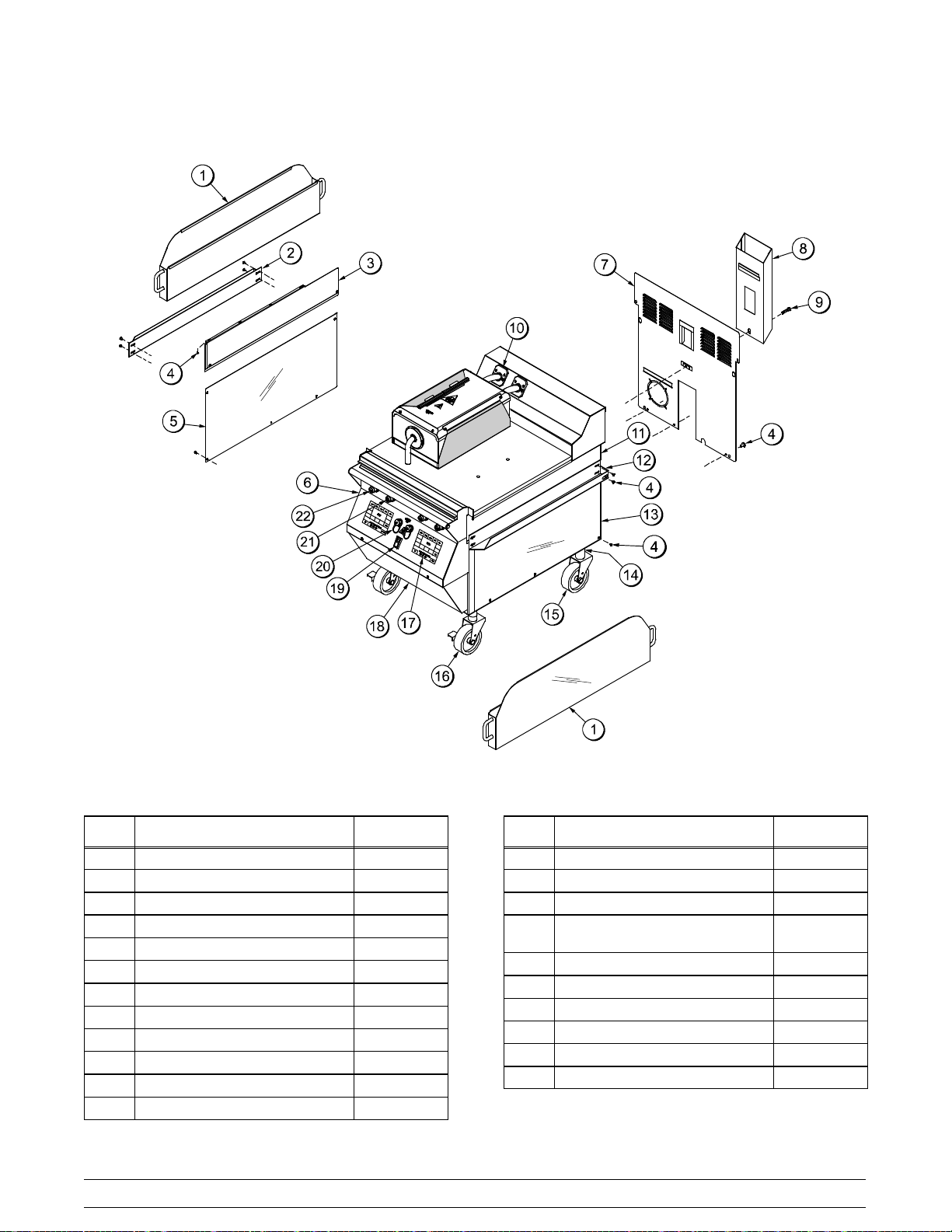

C813 Exploded View 9..................................................

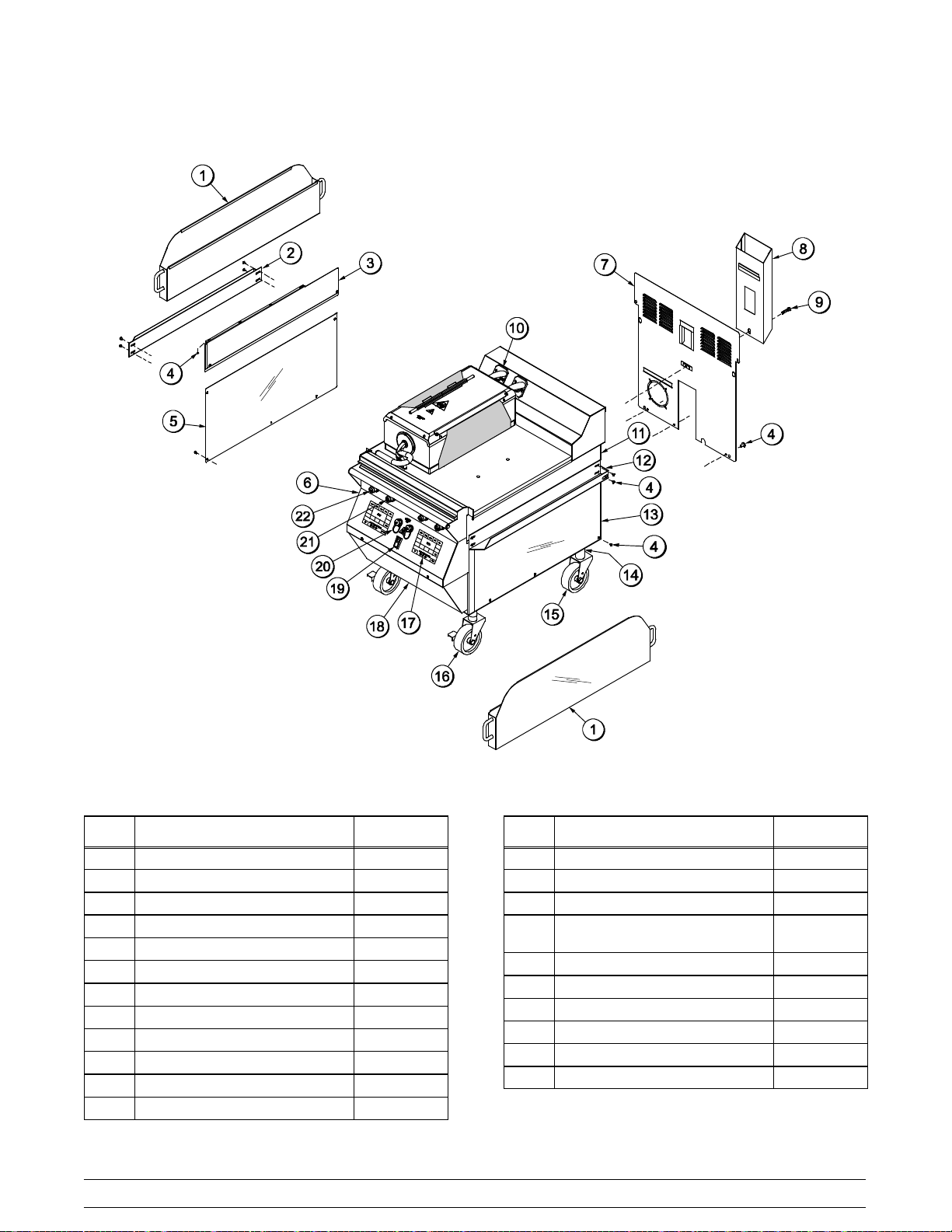

L813 Exploded View 10...................................................

C819 Exploded View 11..................................................

L819 Exploded View 12...................................................

C821 Exploded View 13..................................................

L821 Exploded View 14...................................................

Accessories 15..........................................................

Section 5 Important: To the Operator 16.................................

Model 811, 813, 819, 821 Series Table of Contents

Page 4

Table of Contents - Page 2

Section 6 Operating Procedures 17.....................................

Daily Opening Procedures 17..............................................

Loading Store Menu Items To USB 23......................................

Loading Menu Items From USB 24.........................................

Operating Procedures 27.................................................

Daily Cleaning Procedures 29.............................................

Section 7 Troubleshooting Guide 38....................................

Section 8 Limited Warranty on Equipment 43............................

Section 9 Limited Warranty on Parts 46.................................

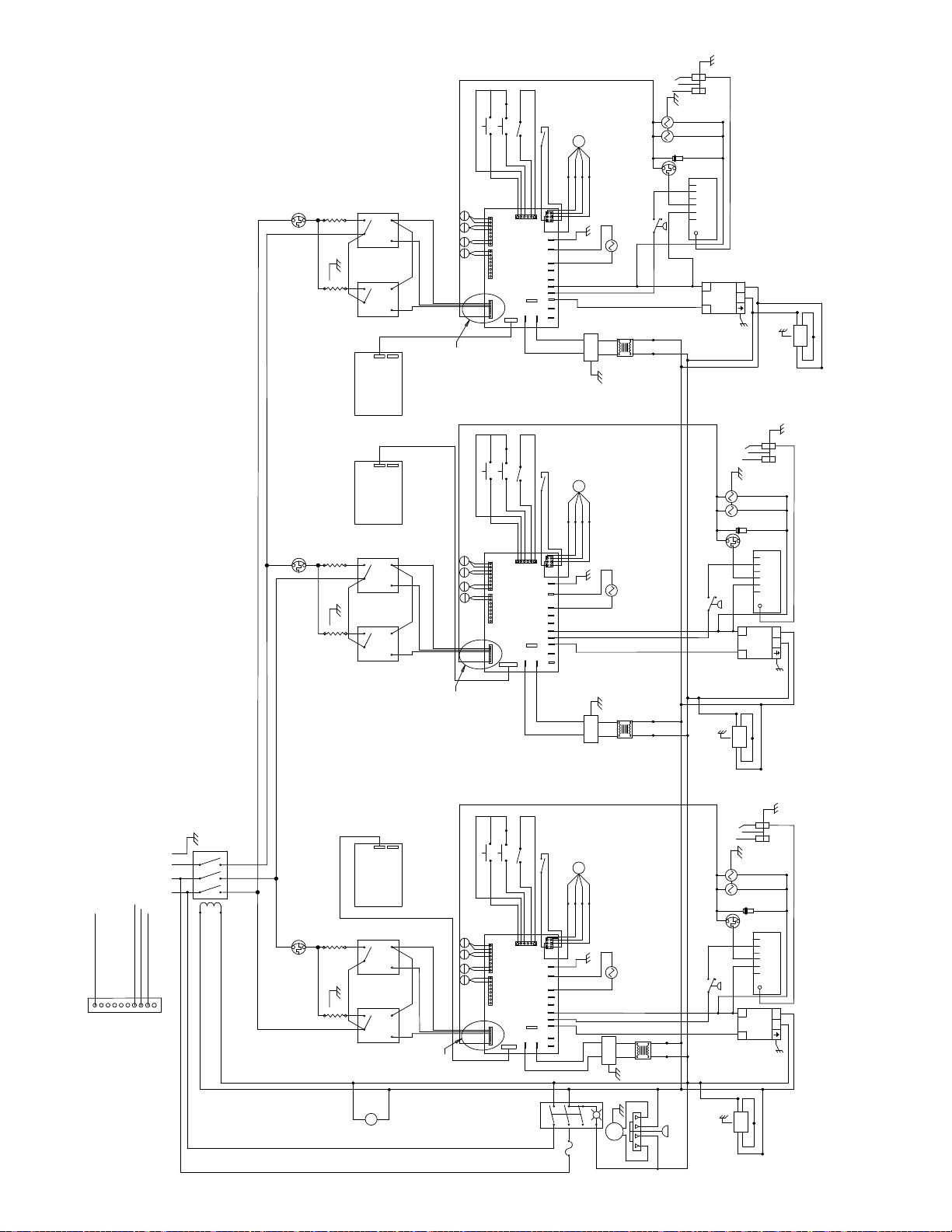

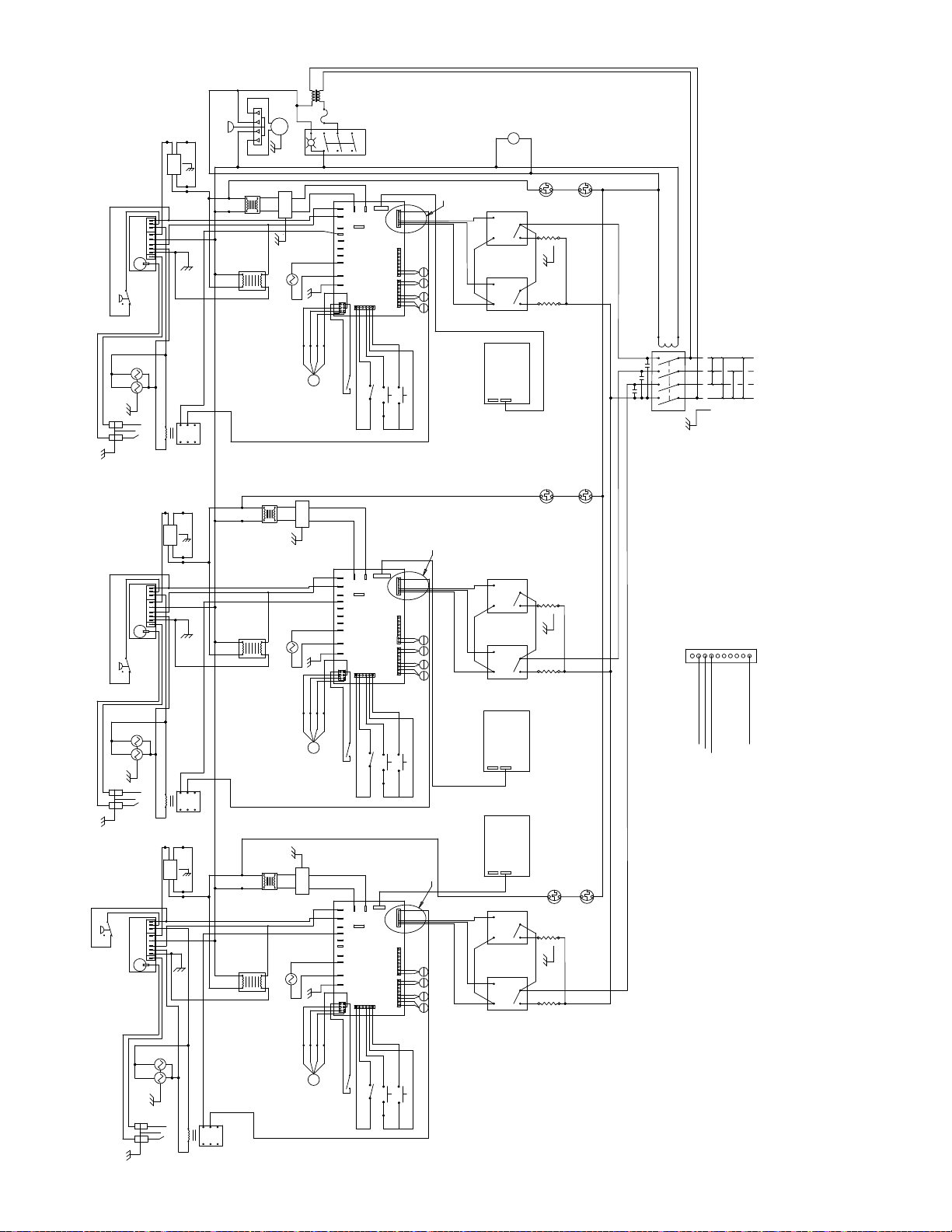

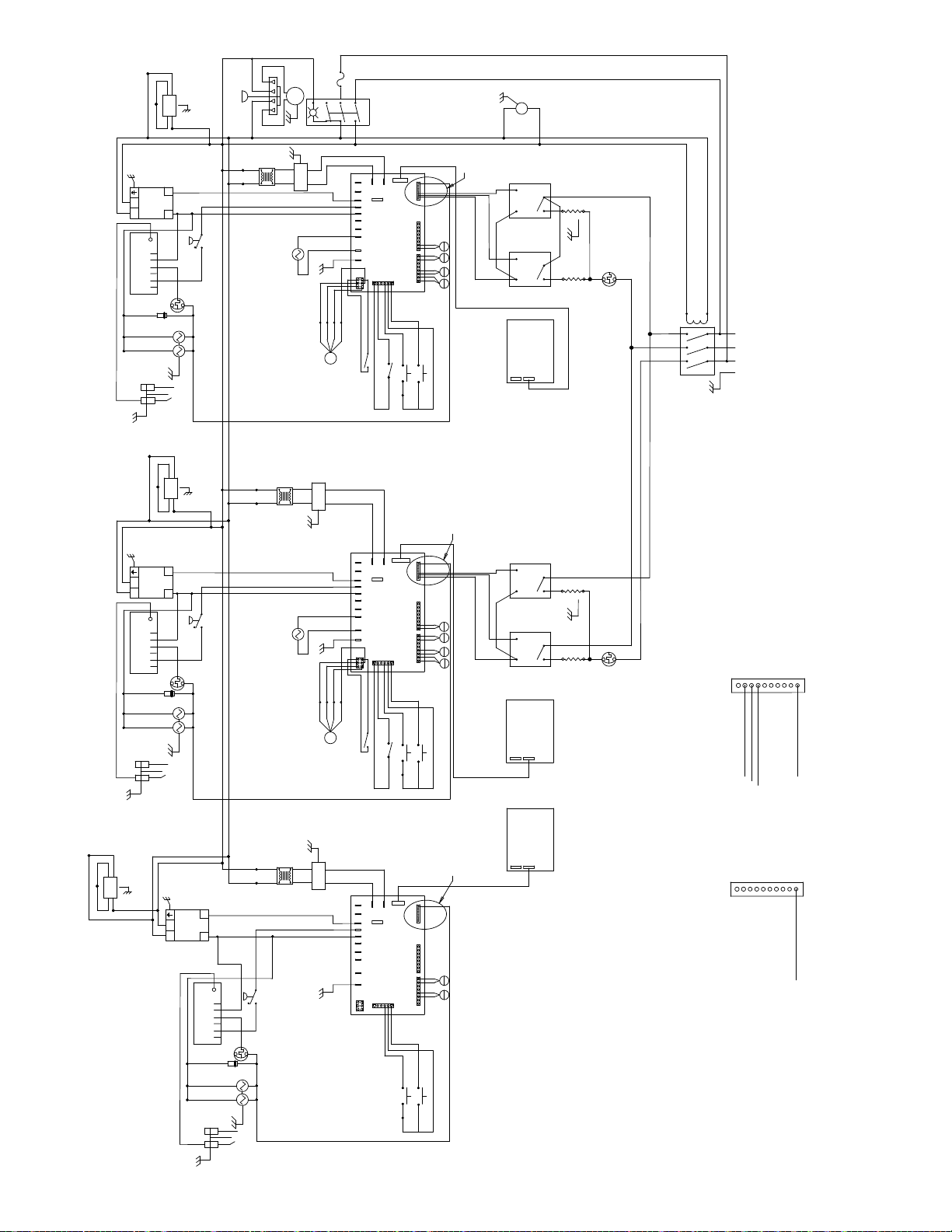

Wiring Diagrams 49......................................................

Note: Continuing research results in steady improvements; therefore, information

in this manual is subject to change without notice.

Note: Only instructions originating from the factory or its authorized translation

representative(s) are considered to be the original set of in structions.

E 2010 Carrier Commercial Refrigeration, Inc. (Original Publication)

(Updated August, 2014)

073625-M

Any unauthorized reproduction, disclosure, or distribution of copies by any person of any portion of this

work may be a violation of Copyright Law of the United States of America and other countries, could result

in the awarding of Statutory Damages of up to $250,000 (17 USC 504) for infringement, and may result

in further civil and criminal penalties.

All rights reserved.

Taylor Company

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072

Table of Contents Model 811, 813, 819, 821 Series

Page 5

Section 1 To the Installer

The following information has been included in the

manual as safety and regulatory guidelines. For

complete installation instructions, please see the

Installation Checklist.

cause severe injuries.

This unit has many sharp edges that can

Installer Safety

In all areas of the world, equipment should

be installed in accordance with existing local codes.

Please contact your local authorities if you have any

questions.

Care should be taken to ensure that all basic safety

practices are followed during the installation and

servicing activities related to the installation and

service of Taylor equipment.

S Only Taylor authorized service personnel

should perform installation and repairs on

the equipment.

S Authorized service personnel should consult

OSHA Standard 29CFRI910.147 or the

applicable code of the local area for the

industry standards on lockout/tagout

procedures before beginning any installation

or repairs.

S Authorized service personnel must ensure

that the proper PPE is available and worn

when required during installation and

service.

S Authorized service personnel must remove

all metal jewelry, rings, and watches before

working on electrical equipment.

The main power supply(s) to the equipment

must be disconnected prior to performing any

repairs. Failure to follow this instruction may result in

personal injury or death from electrical shock or

hazardous moving parts as well as poor

performance or damage to the equipment.

Site Preparation

Review the area where the unit will be installed

before uncrating the unit. Make sure all possible

hazards to the user or equipment have been

addressed.

Electrical Connections

The grill is supplied with one power cord. Check the

data plate on the grill for voltage, cycle, phase and

electrical specifications.

For proper power connections, refer to the wiring

diagram provided inside the left side panel, attached

to the gas manifold assembly. The power connection

is located behind the access line cover on the front

of the grill.

In the United States, this equipment is intended to

be installed in accordance with the National

Electrical Code (NEC), ANSI/NFPA 70-1987. The

purpose of the NEC code is the practical

safeguarding of persons and property from hazards

arising from the use of electricity. This code contains

provisions considered necessary for safety.

Compliance therewith and proper maintenance will

result in an installation essentially free from hazard!

In all other areas of the world, equipment should be

installed in accordance with the existing local codes.

Please contact your local authorities.

The Proper Wire Size and Branch Circuit

Overcurrent Device shall be selected according to

the data label information and in accordance with

CEC Part I 2006, Section 14-100(e)(i).

Note:Allrepairsmustbeperformedbyan

authorized Taylor Service Technician.

Model 811, 813, 819, 821 Series To the Installer

1

FOLLOW YOUR LOCAL ELECTRICAL CODES!

131205

Page 6

CAUTION: THIS EQUIPMENT MUST BE

PROPERLY GROUNDED! FAILURE TO DO SO

CAN RESULT IN SEVERE PERSONAL INJURY

FROM ELECTRICAL SHOCK!

This unit is provided with an equipotential

grounding lug that is to be properly attached to the

rear of the frame by the authorized installer. The

installation location is marked by the equipotential

bonding symbol (5021 of IEC 60417-1) on both the

removable panel and the equipment's frame.

Installation

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause

property damage, injury or death. Read the

installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

This machine is designed for indoor use only.

DO NOT installthemachineinanarea

where a water jet could be used to clean or rinse the

machine. Failure to follow this instruction may result

in serious electrical shock.

S Stationary appliances which are not

equipped with a power cord and a plug or

another device to disconnect the appliance

from the power source must have an all-pole

disconnecting device with a contact gap of

at least 3 mm installed in the external

installation.

S Appliances that are permanently connected

to fixed wiring and for which leakage

currents may exceed 10 mA, particularly

when disconnected or not used for long

periods, or during initial installation, shall

have protective devices such as a GFI, to

protect against the leakage of current,

installed by the authorized personnel to the

local codes.

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable not

lighter than ordinary polychloroprene or

other equivalent synthetic

elastomer-sheathed cord (Code designation

60245 IEC 57) installed with the proper cord

anchorage to relieve conductors from strain,

including twisting, at the terminals and

protect the insulation of the conductors from

abrasion.

If the supply cord is damaged, it must be

replaced by an authorized Taylor service

technician in order to avoid a hazard.

This grill must be installed on a level

surface. Failure to comply may result in personal

injury or equipment damage.

Installation of Cab le Kit

If the unit is permanently connected, the Cable Kit

must be installed. Flexible conduit must be used

when installing the appliance.

Ventilation and Clearance

To ensure proper operation of this appliance, it must

be installed so that the products of combustion are

efficiently removed.

After set up, do not store anything on top of

the grill. Failure to follow this instruction may result

in a fire hazard.

Grease Disposal Container

If the grill is not factory-equipped with grease

disposal containers, the store is required to provide

appropriate grease disposal containers in

accordance with NSF Standard 4 requirements.

2

Model 811, 813, 819, 821 SeriesTo the Installer

Page 7

Section 2 To the Operator

The Taylor grills included in this manual consist of

the base model numbers 811, 813, 819, and 821.

Prefix letters were added to the base model

numbers to denote minor design differences:

C = Standard Platen Length (17.5” / 445 mm)

L = Longer Platen Length (21” / 533 mm)

G = Grooved Option

The models 811 and 813 are 36” (914 mm) grills.

The 811 is equipped with three upper platens and

the 813 is equipped with two upper platens.

The models 819 and 821 are 24” (610 mm) grills.

The 819 is equipped with two upper platens and the

model 821 is equipped with one upper platen.

These grills are capable of cooking a variety of

products and feature two cooking options. They

provide all the features of a flat grill as well as the

advantages of two-sided cooking.

The grill you have purchased has been carefully

engineered and manufactured to provide

dependable operation. When properly operated and

maintained, it will produce a consistent quality

product. Like all mechanical products, it will require

cleaning and maintenance. A minimum amount of

care and attention is necessary if the operating

procedures in this manual are followed closely.

This Operator's Manual should be read before

operating or performing any maintenance on your

equipment.

It is strongly recommended that all personnel

responsible for the equipment's operation and

cleaning review these procedures for proper training

and assurance that no misunderstandings exist.

Note: Your Taylor warranty is valid only if the parts

are authorized Taylor parts, purchased from the

local authorized Taylor Distributor, and only if all

required service work is provided by an authorized

Taylor service technician. Taylor reserves the right

to deny warranty claims on units or parts if

non-Taylor approved parts or incorrect refrigerant

were installed in the unit, system modifications were

performed beyond factory recommendations, or it is

determined that the failure was caused by abuse,

misuse, neglect, or failure to follow all operating

instructions. For full details of your Taylor Warranty,

please see the Limited Warranty section in this

manual.

Note: Constant research results in steady

improvements; therefore, information in this

manual is subject to change without notice.

If the crossed out wheeled bin symbol is

affixed to this product, it signifies that this product is

compliant with the EU Directive as well as other

similar legislation in effect after August 13, 2005.

Therefore, it must be collected separately after its

use is completed, and cannot be disposed as

unsorted municipal waste.

The user is responsible for returning the product to

the appropriate collection facility, as specified by

your local code.

In the event you should require technical assistance,

please contact your local authorized Taylor

Distributor.

Model 811, 813, 819, 821 Series To the Operator

For additional information regarding applicable local

laws, please contact the municipal facility and/or

local distributor.

131205

3

Page 8

Section 3 Safety

We, at Taylor Company, are concerned about the

safety of the operator when he or she comes in

contact with the grill and its parts. Taylor has gone

to extreme efforts to design and manufacture built-in

safety features to protect both you and the service

technician. As an example, warning labels have

been attached to the grill to further point out safety

precautions to the operator.

IMPORTANT - Failure to adhere to the

following safety precautions may result in

severe personal injury or death. Failure to

comply with these warnings may damage the

machine and its components. Component

damage will result in part replacement expense

and service repair expense.

To Op erate Safely:

DO NOT operate the grill without reading

this operator's manual. This manual should be kept

in a safe place for future reference.

This appliance is to be used only by trained

personnel. It is not intended for use by children or

people with reduced physical, sensory, or mental

capabilities, or lack of experience and knowledge,

unless given supervision or instruction concerning

the use of the appliance by a person responsible for

their safety. Children should be supervised to ensure

that they do not play with the appliance.

Failure to follow the instructions below may

result in severe injury or death from electrocution:

S DO NOT operate the grill unless it is

properly grounded.

S DO NOT operate the grill with larger fuses

than specified on data label.

S DO NOT operate the grill unless all service

panels and access doors are attached with

screws.

S All repairs must be performed by an

authorized Taylor service technician.

S The main power supplies to the grill must be

disconnected prior to performing any

repairs.

S For Cord Connected Units: Only Taylor

authorized service technicians or licensed

electricians may install a plug or

replacement cord on these units.

S Stationary appliances which are not

equipped with a power cord and a plug or

other device to disconnect the appliance

from the power source must have an all-pole

disconnecting device with a contact gap of

at least 3 mm installed in the external

installation.

S Appliances that are permanently connected

to fixed wiring and for which leakage

currents may exceed 10 mA, particularly

when disconnected or not used for long

periods, or during initial installation, shall

have protective devices such as a GFI, to

protect against the leakage of current,

installed by the authorized personnel to the

local codes.

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable not

lighter than ordinary polychloroprene or

other equivalent synthetic elastomersheathed cord, (Code designation 60245

IEC 57), installed with the proper cord

anchorage to relieve conductors from strain,

including twisting, at the terminals and

protect the insulation of the conductors from

abrasion.

If the supply cord is damaged, it must be

replaced by the manufacturer, its service

agent, or similarly qualified person, in order

to avoid a hazard.

130415

4

Model 811, 813, 819, 821 SeriesSafety

Page 9

IMPORTANT: DO NOT use a water jet or

spray excessive water on or anywhere near the

grill. Failure to follow this instruction may result in

serious electrical shock and cause permanent

electrical and mechanical damage to internal parts.

Failure to follow this instruction may result in:

DO NOT use cold water or ice to cool the

upper platen or the lower cook surface. Failure to

follow this instruction may result in:

S serious electrical shock

S serious electrical shock

S burns from hot steam

S liquid collecting inside the grill and

destroying electrical components

This appliance must be isolated from all

combustible construction and materials including,

but not limited to; walls, partitions, furniture, floors,

curtains, paper, boxes, and decorations. Failure to

comply may result in fire and cause destruction and

severe injury.

FORYOURSAFETY

Do not store or use gasoline or other

flammable vapors or liquids in the vicinity of

this or any other appliance.

S burns from hot steam

S liquid collecting inside the grill and

destroying electrical components

Take caution to protect eyes, lungs, and all

parts of the body from potential harm when using

any chemical cleaner. Failure to follow this

instruction may result in a chemical burn.

DO NOT use any abrasives or cleaners

other than approved food service cleaners and

degreasers. Failure to comply may cause illness to

the consumer and may also damage grill surfaces.

This grill must be installed on a level

surface. Failure to comply may result in personal

injury or equipment damage.

For thorough cleaning, the grill must be

pulled away from the wall. Before moving the grill,

USE EXTREME CAUTION while setting up,

operating, and cleaning the grill.

S Avoid coming in contact with hot grill

surfaces or with hot grease.

S DO NOT prepare or remove product without

proper equipment.

S DO NOT allow untrained personnel to

operate this grill.

Failure to follow these instructions can result in burn

injuries.

Model 811, 813, 819, 821 Series Safety

remove the grease cans. Turn off the gas at the

quick connect shut-off valve on the flexible hose.

Disconnect the gas quick connector. Disconnect the

tether to the grill, located on the back panel of the

unit.

To return the grill to its original position, reverse the

steps. Use extreme caution to smoothly and slowly

roll the grill backward into place.

Failure to do so may cause the grill to tip and can

result in severe equipment damage or personal

injury.

5

Page 10

Cleaning and sanitizing schedules are

governed by your state or local regulatory agencies

and must be followed accordingly. Please refer to

the cleaning section of this manual for the proper

procedure to clean this unit.

Access to the service area of the unit is

restricted to persons having knowledge and practical

experience with the appliance, in particular as far as

safety and hygiene are concerned.

S DO NOT obstruct the ventilation openings at

the rear of this appliance.

S DO NOT obstruct the flow of air in and

around the grill.

NOTICE all warning labels that have been

attached to the grill to further point out safety

precautions to the operator.

This piece of equipment is made in America and has

American sizes on hardware. All metric conversions

are approximate and vary in size.

NOISE LEVEL: Airborne noise emission does not

exceed 70 dB(A) when measured at a distance of

1.0 meter from the surface of the machine and at a

height of 1.6 meters from the floor.

These instructions are valid only if the country code

symbol appears on the appliance. If the symbol does

not appear on the appliance, refer to the technical

instructions which give the necessary instructions for

adapting the appliance to the utilization conditions of

that country.

130304

6

Model 811, 813, 819, 821 SeriesSafety

Page 11

Section 4 Operator Parts Identification

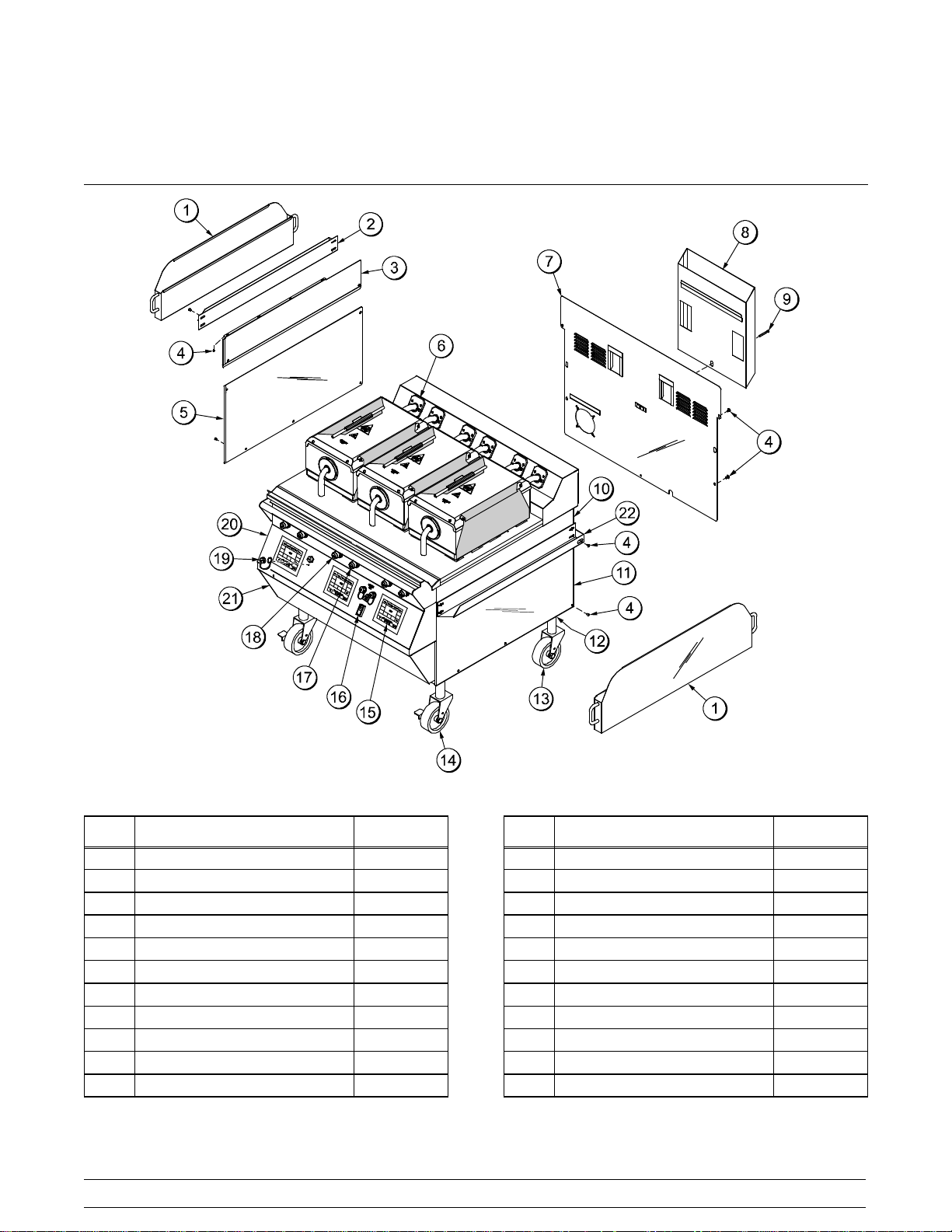

C811 Exploded View

Figure 1

ITEM DESCRIPTION PART NO.

1 CAN A.-GREASE X80925

2 SLIDE-GREASE CAN LEFT 069936

3 PANEL-SIDE-UPPER *LEFT 073990

4 SCREW-10-32X3/8SLTD TRUS 024298

5 PANEL-SIDE-LOWER*LEFT 073992

*6 KIT A.-GREASE SHIELD X78330-SER

7 PANEL A.-BACK SERVICE X73993

8 DEFLECTOR A.-FLUE X69555

9 SCREW-3/8-16X34SERR HWH 017328

10 PANEL-SIDE-UPPER*RIGHT 073989

11 PANEL-SIDE-LOWER*RIGHT 073991

Model 811, 813, 819, 821 Series Operator Parts Identification

ITEM DESCRIPTION PART NO.

12 NUT-JAM 1-1/2-12 (2 PCS) 073594

13 CASTER-5" 7-5/8 STEM 078377

14 CASTER-GRILL 5” SWIVEL LOC 073240

15 KIT A.-GRILL CONTROL GEN X73474-SER

16 SWITCH-ROCKER-DPST-10A 076989-WP

17 BUTTON-OPERATOR-BLACK 076012

18 BUTTON-OPERATOR-RED 076011

19 COVER A.-USB WATERPROOF 068583

20 PANEL A.-FRONT UPPER X69550

21 PANEL A.-FRONT-LOWER X73979

22 SLIDE-GREASE CAN RIGHT 069935

*NOTE: 1 KIT PER PLATEN

121003

7

Page 12

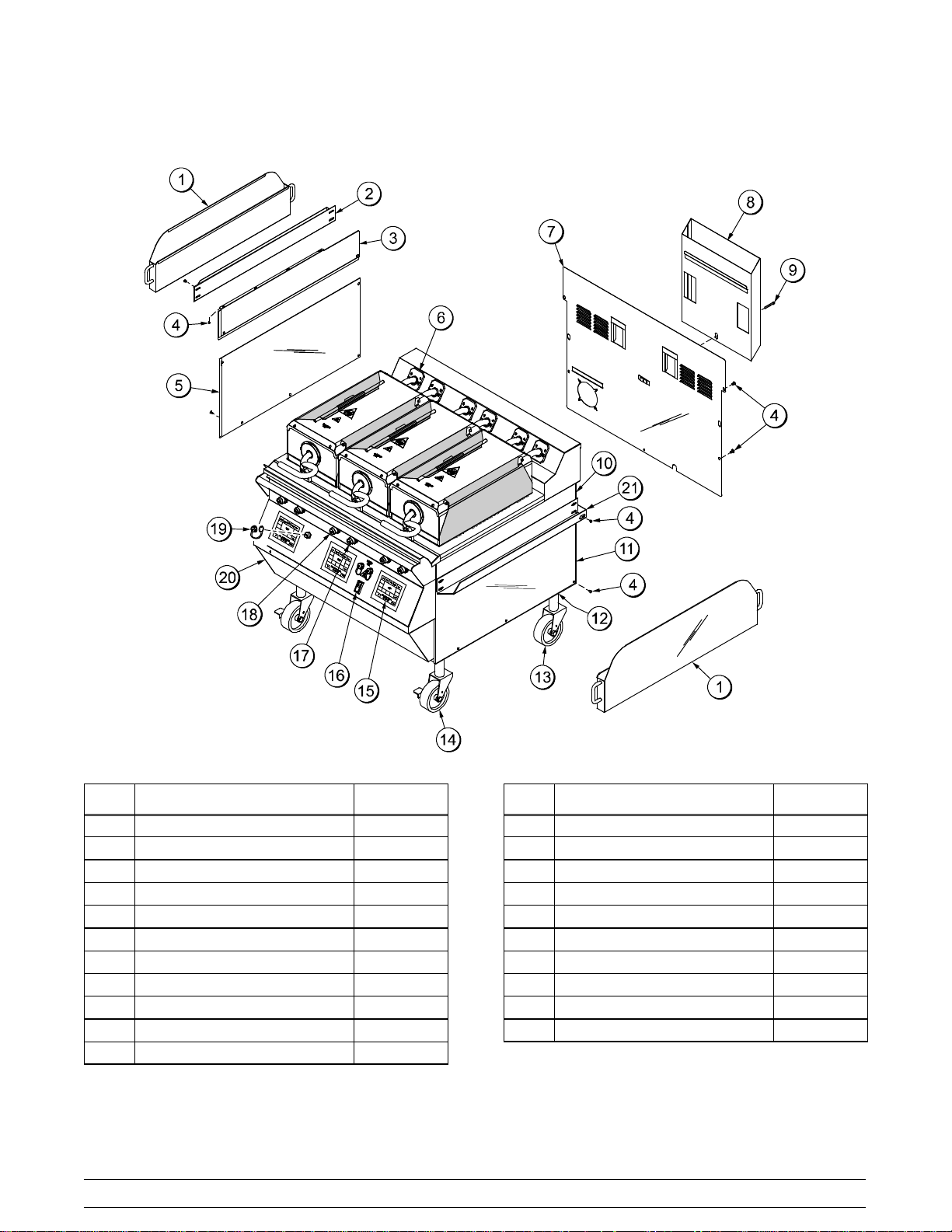

L811 Exploded View

ITEM DESCRIPTION PART NO.

1 CAN A.-GREASE X80925

2 SLIDE-GREASE CAN LEFT 069936

3 PANEL-SIDE-UPPER *LEFT 073990

4 SCREW-10-32X3/8SLTD TRUS 024298

5 PANEL-SIDE-LOWER*LEFT 073992

*6 KIT A.-GREASE SHIELD X78330-SER

7 PANEL A.-BACK SERVICE X73993

8 DEFLECTOR A.-FLUE X69555

9 SCREW-3/8-16X34SERR HWH 017328

10 PANEL-SIDE-UPPER*RIGHT 073989

11 PANEL-SIDE-LOWER*RIGHT 073991

120907

Figure 2

8

ITEM DESCRIPTION PART NO.

12 NUT-JAM 1-1/2-12 (2 PCS) 073594

13 CASTER-5" 7-5/8 STEM 078377

14 CASTER-GRILL 5” SWIVEL LOC 073240

15 KIT A.-GRILL CONTROL GEN X73474-SER

16 SWITCH-ROCKER-DPST-10A 076989-WP

17 BUTTON-OPERATOR-BLACK 076012

18 BUTTON-OPERATOR-RED 076011

19 COVER A.-USB WATERPROOF 068583

20 PANEL A.-FRONT-LOWER X73979

21 SLIDE-GREASE CAN RIGHT 069935

*NOTE: 1 KIT PER PLATEN

Model 811, 813, 819, 821 SeriesOperator Parts Identification

Page 13

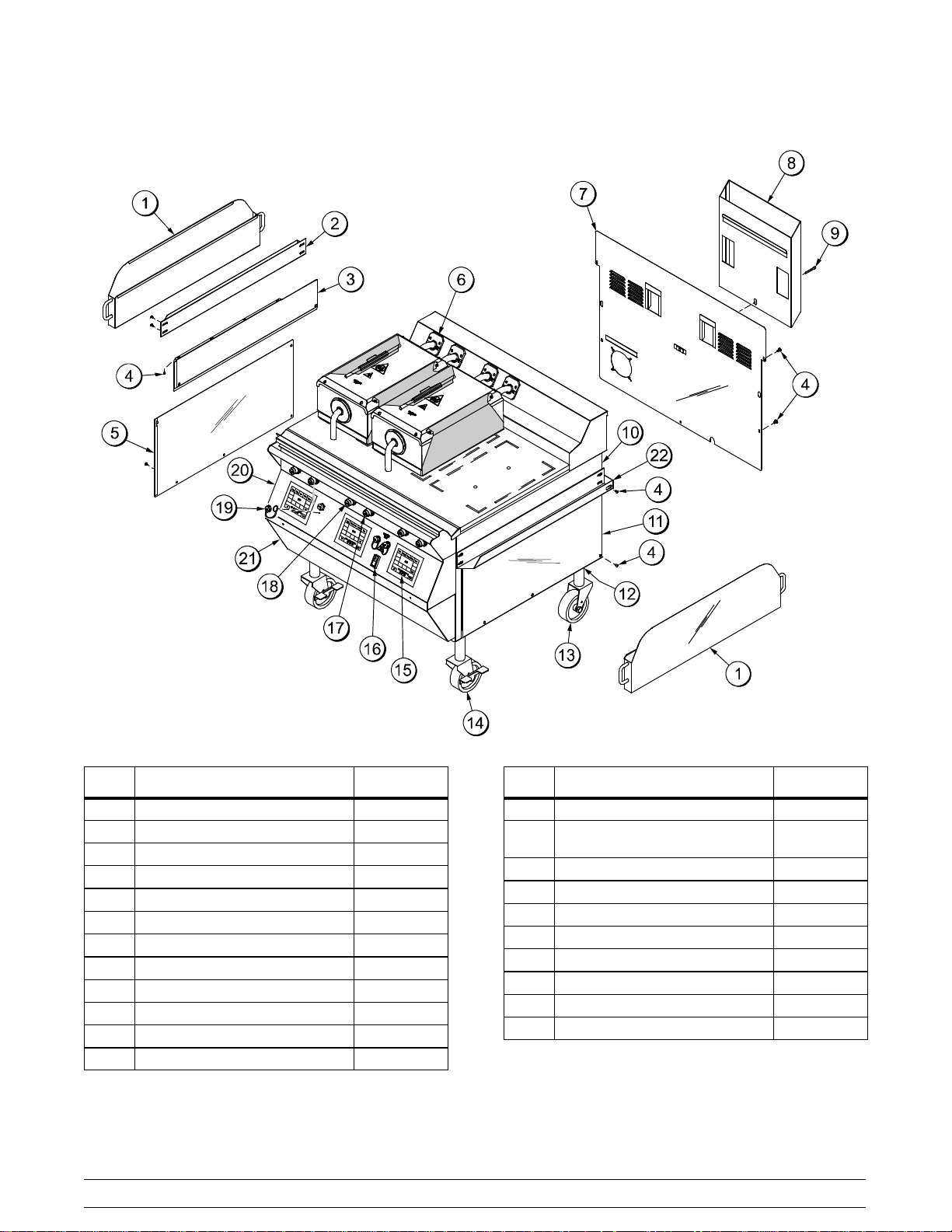

C813 Exploded View

Figure 3

ITEM DESCRIPTION PART NO.

1 CAN A.-GREASE X80925

2 SLIDE-GREASE CAN LEFT 069936

3 PANEL-SIDE-UPPER *LEFT 073990

4 SCREW-10-32X3/8SLTD TRUS 024298

5 PANEL-SIDE-LOWER-LEFT 073992

*6 KIT A.-GREASE SHIELD X78330-SER

7 PANEL A.-BACK SERVICE X73993

8 DEFLECTOR A.-FLUE X69555

9 SCREW-3/8-16X3/4 SERRATED 017328

10 PANEL-SIDE-UPPER*RIGHT 073989

11 PANEL-SIDE-LOWER-RIGHT 073991

12 NUT-JAM 1 1/2-12 STEEL 073594

Model 811, 813, 819, 821 Series Operator Parts Identification

ITEM DESCRIPTION PART NO.

13 CASTER-5" 7-5/8 STEM 078377

14 CASTER-GRILL 5" SWIVEL

W/LOCK

15 KIT A.-GRILL CONTROL GEN X73474-SER

16 SWITCH-ROCKER-DPST-10A 076989-WP

17 BUTTON-OPERATOR-BLACK 076012

18 BUTTON-OPERATOR-RED 076011

19 COVER A.-USB WATERPROOF 068583

20 PANEL A.-FRONT UPPER X69550

21 PANEL A.-FRONT-LOWER X73979

22 SLIDE-GREASE CAN RIGHT 069935

*NOTE: 1 KIT PER PLATEN

9

073240

121003

Page 14

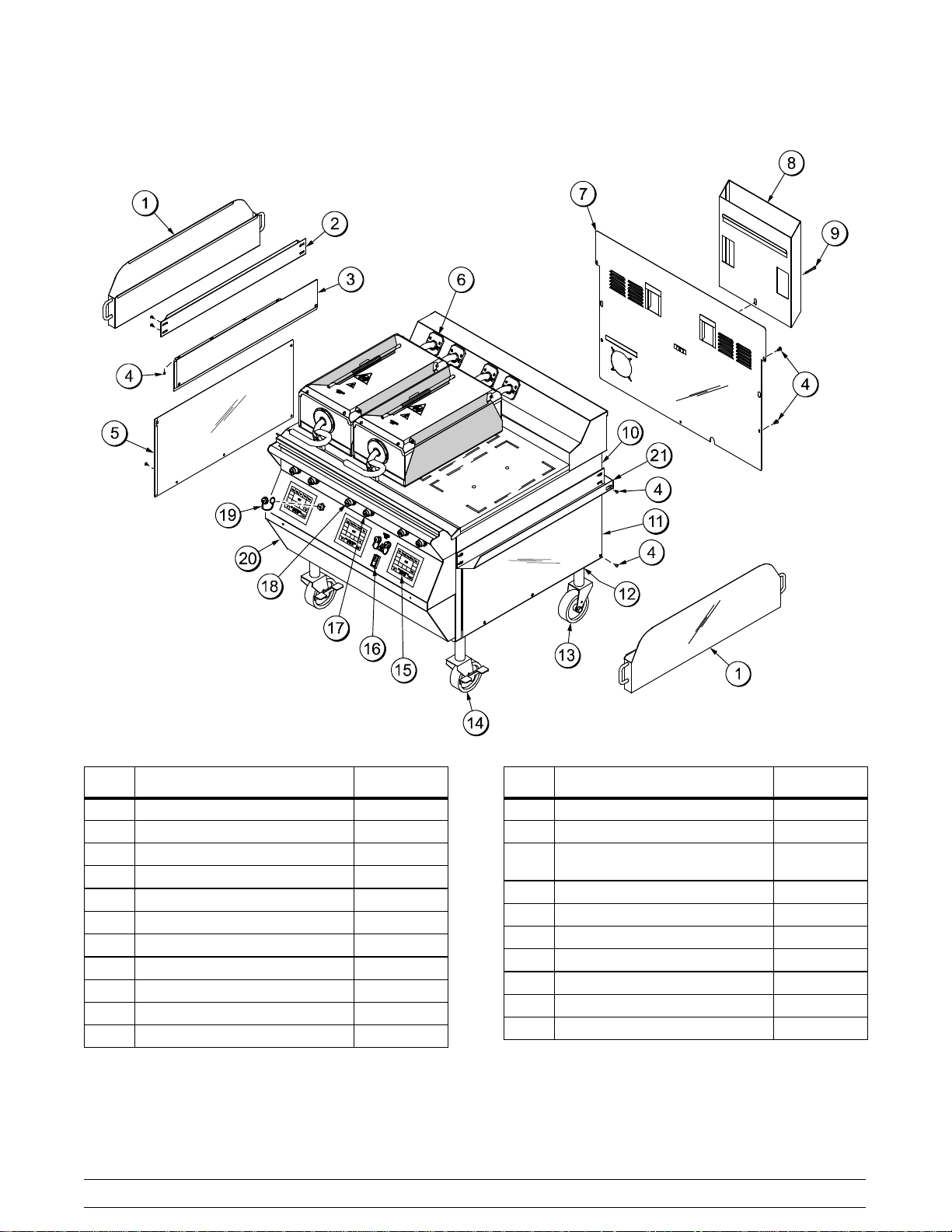

L813 Exploded View

ITEM DESCRIPTION PART NO.

1 CAN A.-GREASE X80925

2 SLIDE-GREASE CAN LEFT 069936

3 PANEL-SIDE-UPPER *LEFT 073990

4 SCREW-10-32X3/8SLTD TRUS 024298

5 PANEL-SIDE-LOWER-LEFT 073992

*6 KIT A.-GREASE SHIELD X78330-SER

7 PANEL A.-BACK SERVICE X73993

8 DEFLECTOR A.-FLUE X69555

9 SCREW-3/8-16X3/4 SERRATED 017328

10 PANEL-SIDE-UPPER*RIGHT 073989

11 PANEL-SIDE-LOWER-RIGHT 073991

120907

Figure 4

10

ITEM DESCRIPTION PART NO.

12 NUT-JAM 1 1/2-12 STEEL 073594

13 CASTER-5" 7-5/8 STEM 078377

14 CASTER-GRILL 5" SWIVEL

W/LOCK

15 KIT A.-GRILL CONTROL GEN X73474-SER

16 SWITCH-ROCKER-DPST-10A 076989-WP

17 BUTTON-OPERATOR-BLACK 076012

18 BUTTON-OPERATOR-RED 076011

19 COVER A.-USB WATERPROOF 068583

20 PANEL A.-FRONT-LOWER X73979

21 SLIDE-GREASE CAN RIGHT 069935

*NOTE: 1 KIT PER PLATEN

073240

Model 811, 813, 819, 821 SeriesOperator Parts Identification

Page 15

C819 Exploded View

Figure 5

ITEM DESCRIPTION PART NO.

1 CAN A.-GREASE X80925

2 SLIDE-GREASE CAN LEFT 069936

3 PANEL-SIDE UPPER-LEFT 073990

4 SCREW-10-32X3/8SLTD TRUS 024298

5 PANEL-SIDE-LOWER-LEFT 073992

6 SLIDE-GREASE CAN RIGHT 069935

7 PANEL A.-BACK SERVICE X69664

8 DEFLECTOR A.-FLUE X69657

9 SCREW-3/8-16X1-1/2 SERR 020129

*10 KIT A.-GREASE SHIELD X78330-SER

11 PANEL-SIDE UPPER-RIGHT 073989

12 PANEL-SIDE-LOWER-RIGHT 073991

Model 811, 813, 819, 821 Series Operator Parts Identification

ITEM DESCRIPTION PART NO.

13 NUT-JAM 1 1/2-12 STEEL 073594

14 CASTER-5" 7-5/8 STEM 078377

15 CASTER-GRILL 5" SWIVEL

W/LOCK

16 KIT A.-GRILL CONTROL X73474-SER

17 PANEL A.-FRONT-LOWER X69660

18 SWITCH-ROCKER-DPST-10A 076989-WP

19 COVER A.-USB WATERPROOF 068583

20 BUTTON-OPERATOR-BLACK 076012

21 BUTTON-OPERATOR-RED 076011

22 PANEL A.-LIGHT X80626

*NOTE: 1 KIT PER PLATEN

11

073240

121106

Page 16

L819 Exploded View

ITEM DESCRIPTION PART NO.

1 CAN A.-GREASE X80925

2 SLIDE-GREASE CAN LEFT 069936

3 PANEL-SIDE UPPER-LEFT 073990

4 SCREW-10-32X3/8SLTD TRUS 024298

5 PANEL-SIDE-LOWER-LEFT 073992

6 SLIDE-GREASE CAN RIGHT 069935

7 PANEL A.-BACK SERVICE X69664

8 DEFLECTOR A.-FLUE X69657

9 SCREW-3/8-16X1-1/2 SERR 020129

*10 KIT A.-GREASE SHIELD X78330-SER

11 PANEL-SIDE UPPER-RIGHT 073989

12 PANEL-SIDE-LOWER-RIGHT 073991

130316

Figure 6

12

ITEM DESCRIPTION PART NO.

13 NUT-JAM 1 1/2-12 STEEL 073594

14 CASTER-5" 7-5/8 STEM 078377

15 CASTER-GRILL 5" SWIVEL

W/LOCK

16 KIT A.-GRILL CONTROL X73474-SER

17 PANEL A.-FRONT-LOWER X69660

18 SWITCH-ROCKER-DPST-10A 076989-WP

19 COVER A.-USB WATERPROOF 068583

20 BUTTON-OPERATOR-BLACK 076012

21 BUTTON-OPERATOR-RED 076011

22 PANEL A.-LIGHT X80626

*NOTE: 1 KIT PER PLATEN

073240

Model 811, 813, 819, 821 SeriesOperator Parts Identification

Page 17

C821 Exploded View

Figure 7

ITEM DESCRIPTION PART NO.

1 CAN A.-GREASE X80925

2 SLIDE-GREASE CAN LEFT 069936

3 PANEL-SIDE UPPER-LEFT 073990

4 SCREW-10-32X3/8SLTD TRUS 024298

5 PANEL-SIDE-LOWER-LEFT 073992

6 PANEL A.-LIGHT X80626

7 PANEL A.-BACK SERVICE X69664

8 DEFLECTOR A.-FLUE X69657

9 SCREW-3/8-16X1-1/2 SERR 020129

*10 KIT A.-GREASE SHIELD X78330-SER

11 PANEL-SIDE UPPER-RIGHT 073989

12 SLIDE-GREASE CAN RIGHT 069935

Model 811, 813, 819, 821 Series Operator Parts Identification

ITEM DESCRIPTION PART NO.

13 PANEL-SIDE-LOWER-RIGHT 073991

14 NUT-JAM 1 1/2-12 STEEL 073594

15 CASTER-5" 7-5/8 STEM 078377

16 CASTER-GRILL 5" SWIVEL

W/LOCK

17 KIT A.-GRILL CONTROL X73474-SER

18 PANEL A.-FRONT-LOWER X69660

19 SWITCH-ROCKER-DPST-10A 076989-WP

20 COVER A.-USB WATERPROOF 068583

21 BUTTON-OPERATOR-BLACK 076012

22 BUTTON-OPERATOR-RED 076011

*NOTE: 1 KIT PER PLATEN

13

073240

121106

Page 18

L821 Exploded View

ITEM DESCRIPTION PART NO.

1 CAN A.-GREASE X80925

2 SLIDE-GREASE CAN LEFT 069936

3 PANEL-SIDE UPPER-LEFT 073990

4 SCREW-10-32X3/8SLTD TRUS 024298

5 PANEL-SIDE-LOWER-LEFT 073992

6 PANEL A.-LIGHT X80626

7 PANEL A.-BACK SERVICE X69664

8 DEFLECTOR A.-FLUE X69657

9 SCREW-3/8-16X1-1/2 SERR 020129

*10 KIT A.-GREASE SHIELD X78330-SER

11 PANEL-SIDE UPPER-RIGHT 073989

12 SLIDE-GREASE CAN RIGHT 069935

130318

Figure 8

14

ITEM DESCRIPTION PART NO.

13 PANEL-SIDE-LOWER-RIGHT 073991

14 NUT-JAM 1 1/2-12 STEEL 073594

15 CASTER-5" 7-5/8 STEM 078377

16 CASTER-GRILL 5" SWIVEL

W/LOCK

17 KIT A.-GRILL CONTROL X73474-SER

18 PANEL A.-FRONT-LOWER X69660

19 SWITCH-ROCKER-DPST-10A 076989-WP

20 COVER A.-USB WATERPROOF 068583

21 BUTTON-OPERATOR-BLACK 076012

22 BUTTON-OPERATOR-RED 076011

*NOTE: 1 KIT PER PLATEN

073240

Model 811, 813, 819, 821 SeriesOperator Parts Identification

Page 19

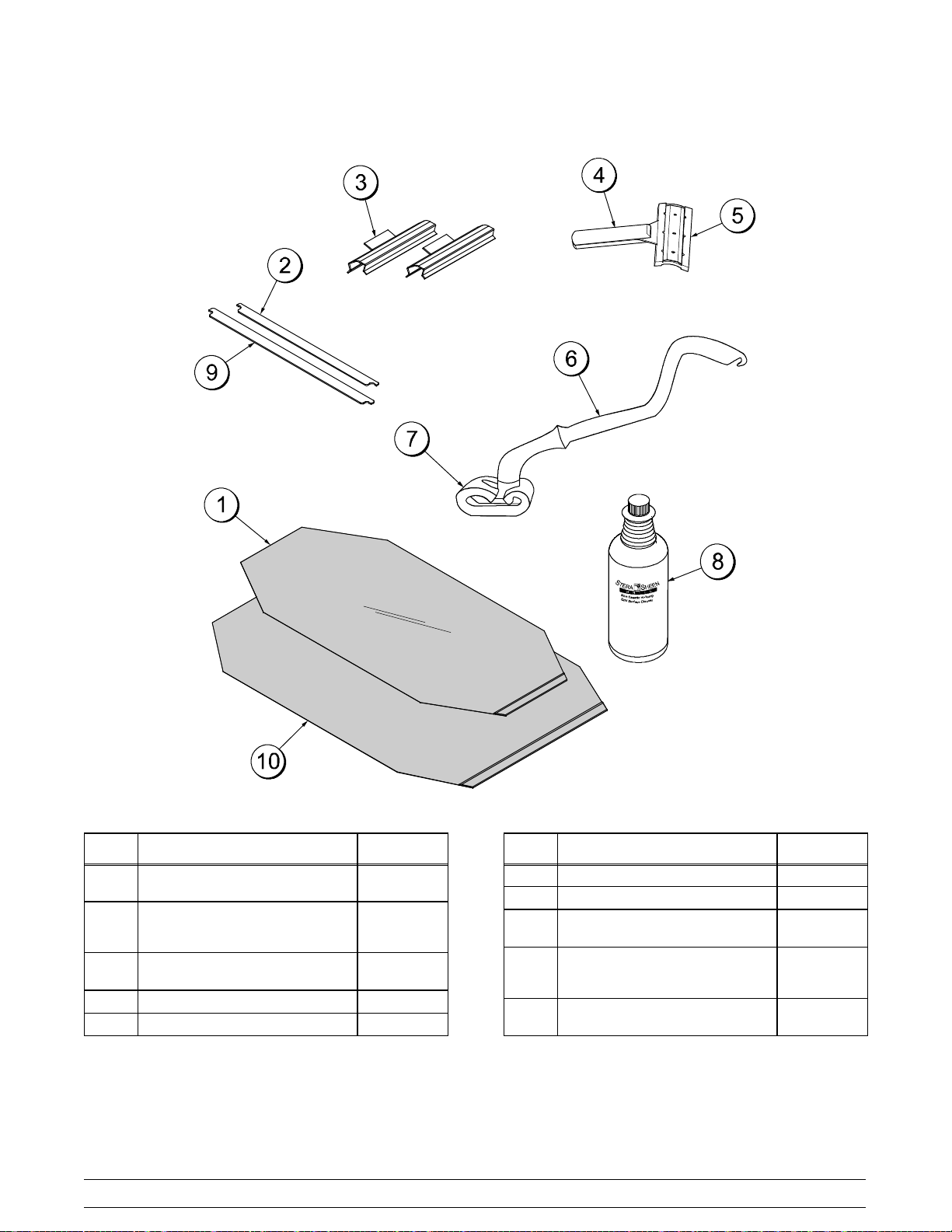

Accessories

Figure 9

ITEM DESCRIPTION PART NO.

1 SHEET-RELEASE - BOX OF 9

(C811, C813, C819, C821)

*2 RETAINER-SHEET RELEASE

(RETENTION BAR) (C811,

C813, C819, C821)

**3 CLIP-RELEASE MATERIAL

W/TAB

4 SCRAPER-TEFLON WIPER 075887

5 STRIP-REPLACEMENT 075888

073442

072845

072673

Model 811, 813, 819, 821 Series Operator Parts Identification

ITEM DESCRIPTION PART NO.

***6 HOLDER-CLEANING 073736

***7 PAD-CLEANING 073737

8 CLEANER-STERA SHEEN

(CASE OF 6, 1 QT. BOTTLES)

*9 RETAINER-SHEET RELEASE

(RETENTION BAR) (L811, L813,

L819, L821)

10 SHEET-RELEASE -BOX OF 9

(L811, L813, L819, L821)

* SHOWN PER PLATEN

** SHOWN PER PLATEN

(NOTE: EXTRA CLIPS ARE SENT WITH GRILL)

*** SOLD SEPARATELY THROUGH YOUR LOCAL

DISTRIBUTOR

15

073160

080594

080595

120720

Page 20

Section 5 Important: To the Operator

Note: The Model 811 three platen grill has been selected for illustration purposes.

Figure 10

ITEM DESCRIPTION

1 RAISE BUTTON

2 STANDBY/COOK MODE BUTTON

3 USB COVER/CONNECTION

4 POWER SWITCH

5 CLEAN MODE KEY

120604

ITEM DESCRIPTION

6 PROGRAM KEY

7 TEMPERATURE INDICATOR LIGHTS

8 POWER KEY

9 FUNCTION DISPLAY

10 MENU SELECT KEYS

16

Model 811, 813, 819, 821 SeriesImportant: To the Operator

Page 21

Section 6 Operating Procedures

The three platen Model L811 has been selected to

illustrate the step-by-step procedures. For grills

equipped with less than three platens, perform the

following steps as appropriate for your grill platen

configuration.

Daily Opening Procedures

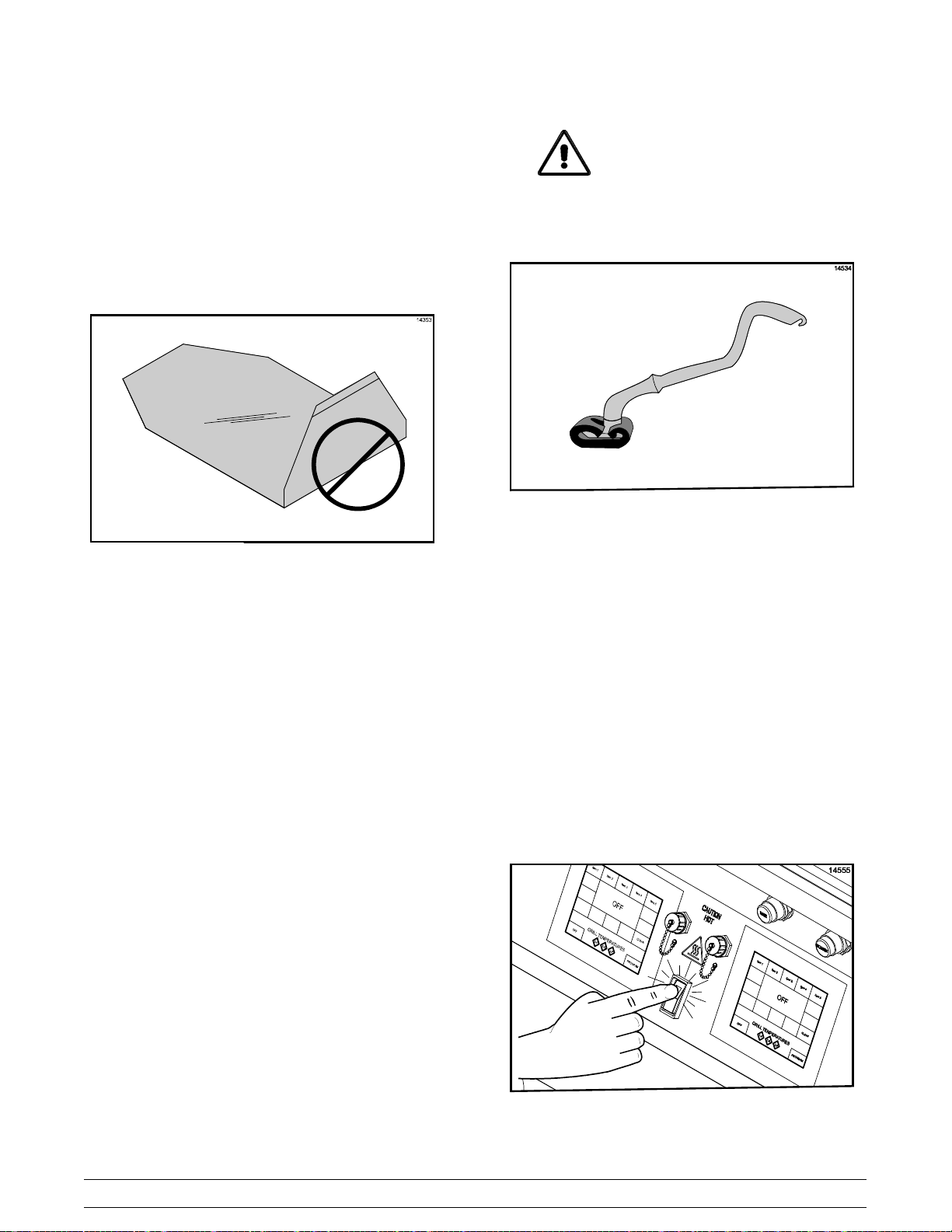

Before operating the grill, the release sheets must

be installed on the upper platens. The release

sheets are reversed and rotated on a daily basis

(black side vs. gray side.)

Perform the following steps for installing release

sheets:

CAUTION: Make sure the grill is COOL

before attempting to install or remove release

sheets.

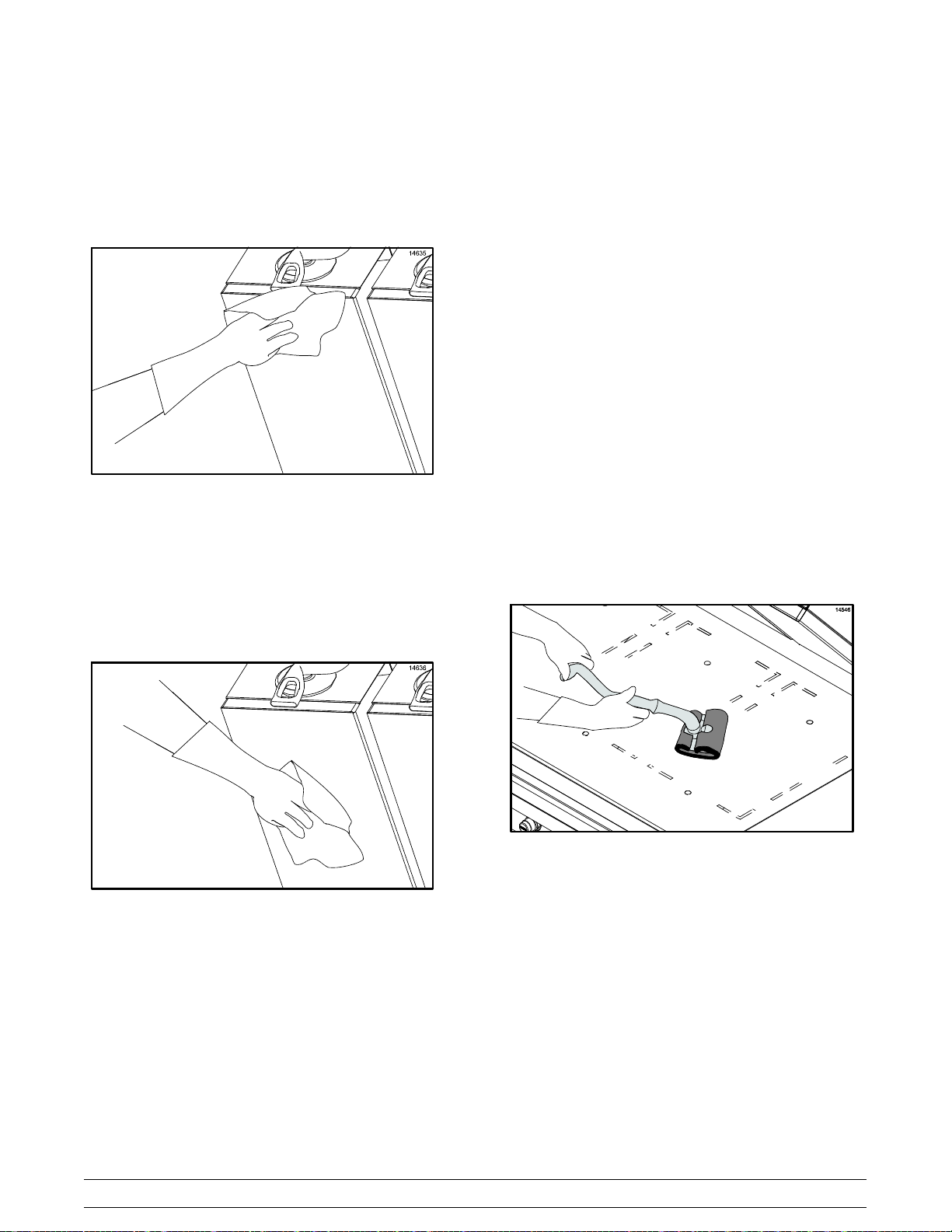

Step 1

Slide the release sheet retainer through the hemmed

end of the release sheet.

Step 2

Hook the release sheet retainer on the release sheet

shoulder screws at the top of the upper platen.

Figure 12

Step 3

Hold the non-hemmed end of the release sheet.

Gently pull the sheet tight, wrapping it around the

platen in a side-to-side manner.

Figure 13

Note: Check the alignment of the release sheet and

Figure 11

Model 811, 813, 819, 821 Series Operating Procedures

make sure it fits smoothly over the upper platen.

130206

17

Page 22

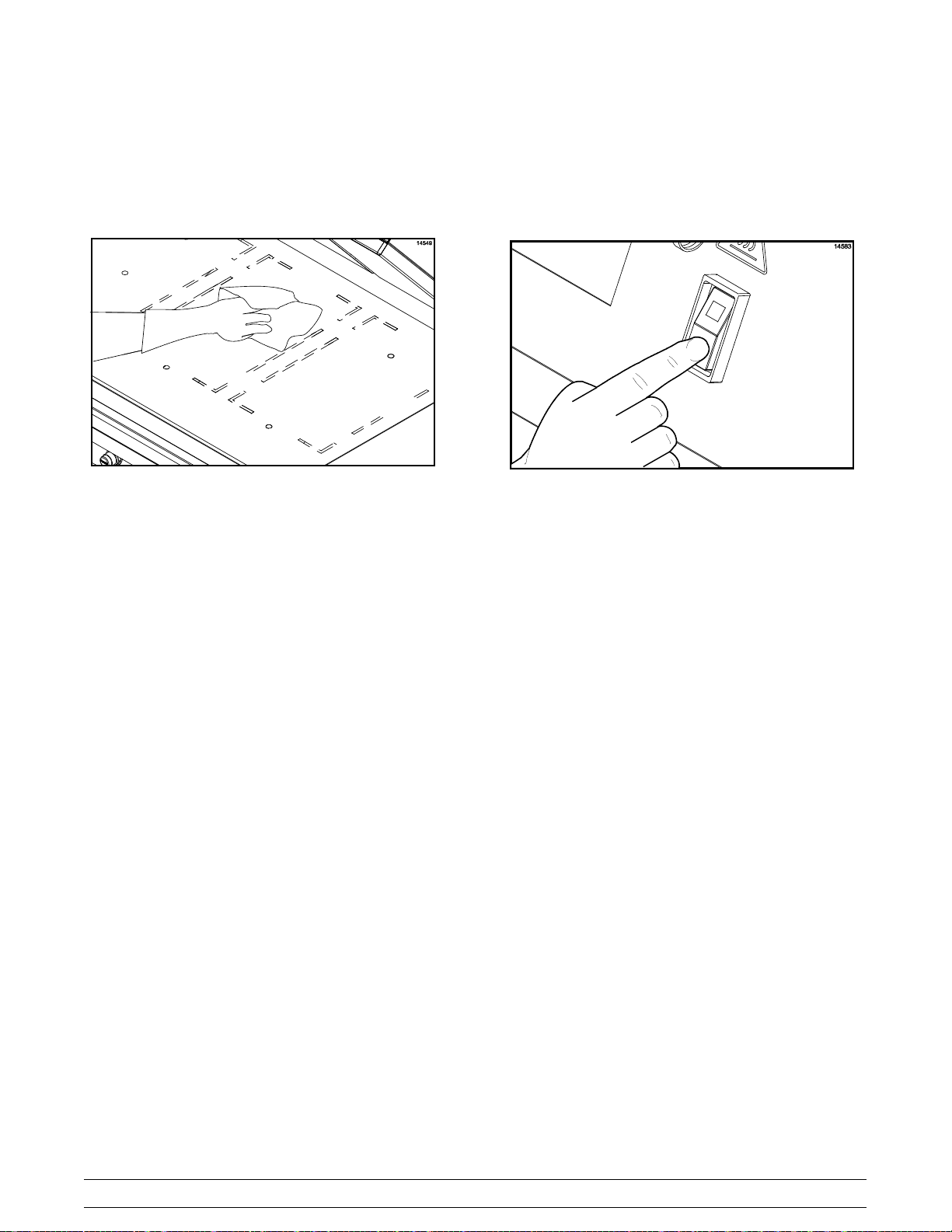

Step 4

Place the release sheet clips over the release sheet.

Press them into place over the release sheet bar at

the top of the platen.

Figure 14

Step 5

Check the tightness of the release sheet against the

upper platen.

Step 6

Repeat steps 1 through 5 for the remaining upper

platen(s).

Note: Temperature checks should only be

conducted with the release sheets removed.

Replace the release sheet when:

S Cleaning procedures fail to remove all

buildup and product sticks to the release

sheet.

S A tear appears in the cooking area of the

release sheet, causing product to stick to the

release sheet.

Figure 15

Note: Installing the release sheets too tightly may

cause p remature failure of the sheet.

Figure 16

CAUTION: The upper platen surface and

release sheet are very hot. To prevent burn

injuries, wear heat-resistant gloves when

replacing the release sheets.

Note: It is not necessary to change the release

sheet if small pin holes develop on the sheet.

130205

18

Model 811, 813, 819, 821 SeriesOperating Procedures

Page 23

Care of Release Sheets

DO NOT:

S DO NOT fold or crease.

Figure 17

S DO NOT touch with sharp objects, grill

scrapers, or abrasive pads.

S DO NOT place under other equipment or

objects.

IMPORTANT! Clean the release

sheets using the grill cleaning pad and

holder identified on page 15 ONLY. Using

any other pad and holder will damage the

release sheets.

Figure 18

Note: Contact your local Taylor Distributor to

purchase the correct grill cleaning pad and holder.

(See page 15.)

S DO rinsetoremovecleanerandallowtodry

onaflatsurface.

S DO rotate the release sheet daily and

re-install on opposite side than previously

used (black side vs. brown side).

StartUpoftheGrill

S DO NOT hot-hose or soak in water.

DO:

IMPORTANT! The lower grill surface and the

upper platen MUST BE CLEAN before starting

these procedures.

Step 1

Place the power switch in the ON position.

S DO clean with a squeegee after each run of

product.

S DO wipe with a clean, sanitizer-soaked grill

cloth a minimum of 4 times per hour and

more often during peak periods.

S DO clean daily on both sides, using an

approved high temperature grill cleaner and

the grill cleaning pad and holder identified

on page 15.

Model 811, 813, 819, 821 Series Operating Procedures

19

Figure 19

110602

Page 24

The control will display the word “INITIALIZATION”

for five seconds and then will enter the OFF mode,

displaying the message “OFF”. The temperature

indicators will not be illuminated. A tone will sound

for 2 0 seconds unless the operator touches the

display screen, raise button or the standby button.

Figure 20

Note: If an ignition failure fault occurs upon start up,

press the center of the control. The control will

display “OFF”. Refer to problem #2, items a, b, and c

of the Gas Grill Troubleshooting Guide on page 42.

After five minutes has elapsed, press the menu key

again. If the ignition failure fault was not resolved,

please call your authorized service technician.

Step 2

Touch a menu key on the control to start the grill.

The grill will start heating up to the proper

temperature. The control will display the selected

menu item and indicate “BOTTOM TOO COOL” and

“TOP TOO COOL”. The grill temperature indicators

will be illuminated in amber.

Figure 21

Figure 22

When the grill is at the proper temperature, the

temperature statements will no longer display and

the temperature indicators will be illuminated in

green.

Figure 23

20

Model 811, 813, 819, 821 SeriesOperating Procedures

Page 25

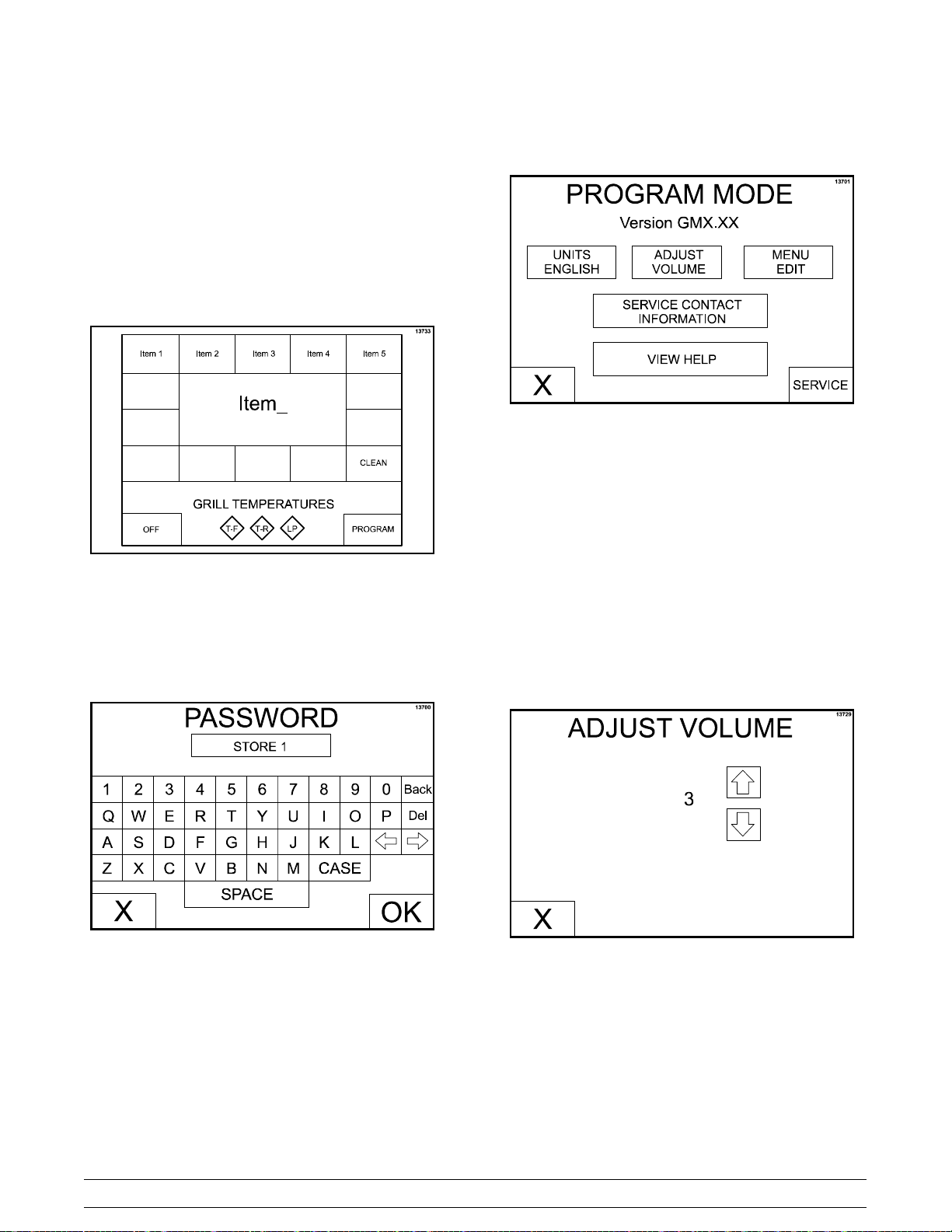

Programming Menu Items

To enter the Program Mode, the grill control must be

in the OFF or IDLE mode.

Step 1

Press and hold the PROGRAM key for

approximately five seconds to enter the Program

Mode.

Figure 24

Step 3

The PROGRAM MODE screen will appear.

Figure 26

UNITS Key

TheUNITSkeyisusedtoselecteitherEnglishor

metric units of measure. The UNITS key toggles

between F and C with each key press.

Step 2

The PASSWORD screen will appear. Enter the

Operator Password “STORE1” and press the OK

key.

Figure 25

ADJUST VOLUME Key

The ADJUST VOLUME key displays the current

volume. To increase or decrease the volume, use

the UP and DOWN arrow keys.

Figure 27

Model 811, 813, 819, 821 Series Operating Procedures

21

Page 26

MENU EDIT Key

The MENU EDIT key is used to program a menu

item. When the MENU EDIT key is pressed, the

following screen will display.

Figure 28

If there is more than one screen of menu items,

press the Previous or Next arrow keys to access the

other menu items.

Press the menu item key to be programmed. The

following screen will display.

To edit a menu item, press the menu item key to

bring up a virtual keyboard. Type in the desired

name (up to 8 characters per line) and then press

the “X” key to return to the previous screen.

Figure 30

ACTIVE: YES or NO. This key displays the current

selection. Pressing the key toggles to the opposite

selection. Selecting YES will display the menu item

on the main display screen.

TOP TEMP: This key displays the current set point

temperature for the platen. To increase or decrease

the temperature, use the UP and DOWN arrow keys.

BOTTOM TEMP: This key displays the current set

point temperature for the lower grill surface. To

increase or decrease the temperature, use t he UP

andDOWNarrowkeys.

Figure 29

Note: When setting the temperatures for a given

item, the limits are 150°F to 450°F (66°C to 232°C)

for the upper platen and 150°F to 400°F (66°C to

204°C) for the lower grill surface. If the temperatures

are set lower or higher than the temperature limits,

the set point at the control will default to 150°F and

450°F (66°C and 232°C) respectively.

CLAM/FLAT: This key displays the current setting

(CLAM or FLAT) associated with that function.

Pressing the key toggles the mode to the opposite

selection.

GAP: This key is only active if CLAM has been

selected. The key displays the platen gap (in inches

or mm) associated with the FUNCTION. To increase

or decrease the gap setting, use the UP and DOWN

arrow keys.

22

Model 811, 813, 819, 821 SeriesOperating Procedures

Page 27

MULTIPLE TIMING FUNCTIONS: There are four

timing functions for clam and flat menu items. Each

function has a set of parameters associated with it.

The functions currently associated with the menu

item are displayed. Pressing function 1, function 2,

or function 3 will bring up the next function in the list.

The functions provided are:

S REMOVE IN

S SEAR IN

S TURN IN

S SEAR/TURN IN

ALARM AUTO/MANUAL: Thiskeydisplaysthe

current status of the alarm mode. Pressing the key

toggles the mode to the opposite selection.

If ALARM AUTO is selected, the alarm will

automatically stop after five seconds has elapsed.

Selecting ALARM MANUAL requires the operator

touchanywhereonthedisplayscreenortheraiseor

standby buttons to stop the alarm.

XXX SECONDS: This key displays the time

associated with that menu item in seconds. To

increase or decrease the seconds setting, use the

UP and DOWN arrow keys.

Figure 31

VIEW HELP Key

The View Help key is not functional at this time

(future development).

LoadingStoreMenuItemsToUSB

ThesameUSBflashdrivethatwasusedtoload

softwareintothegrillcanbeusedtoperformthis

procedure.

Step 1

Remove the USB cable cap from the USB connector

to access the USB port.

GAP: Each timing function has an associated gap

setting. This setting can be changed selecting the

gap value. Then use the UP and DOWN arrow keys

to increase and decrease the gap value.

Upon completion of all programming selections,

save the selections by pressing the OK key. To

return to the main display screen without saving the

programming selections, press the X key.

SERVICE CONTACT INFORMATION Key

Press the SERVICE CONTACT INFORMATION key

to view the programmed service contact information.

Note: Grills built prior to serial number M1035495

will require the front control panel be lowered to

access the control display boards.

Step 2

Insert the USB flash drive into the USB port.

Step 3

Press and hold the PROGRAM key for 5 seconds to

enter the Program Mode.

Figure 32

140421

Model 811, 813, 819, 821 Series Operating Procedures

23

Page 28

Step 4

Enter the Operator Password “STORE1” and press

the OK key.

Step 7

Enter a file name (up to 8 characters) to save the

menu items, using the keyboard displayed on the

control. Press the OK key. The menu items are

saved to the USB flash drive.

Step 8

Remove the USB flash drive from the USB port and

reinstall the USB cable cap on the USB connector.

Note: Grills built prior to serial number M1035495

will require the front control panel be reinstalled.

Figure 33

Step 5

Press the MENU EDIT key.

Figure 34

Step 6

Press the STORE MENU TO USB key.

LoadingMenuItemsFromUSB

OncethepropersoftwareisloadedontheUSBflash

drive, the next control board can be programmed

from the USB flash drive.

Step 1

Repeat Steps 1 through 5 from “Loading Store Menu

Items to USB.”

Step 2

Press the LOAD MENU FROM USB key.

Step 3

The control can display up to 5 different menu

options loaded on the USB flash drive. Select the

key for the correct menu to load. The control will

display “DONE” at the bottom of the screen when

the menu is loaded.

Step 4

Remove the USB flash drive from the USB port and

reinstall the USB cable cap on the USB connector.

110603

Figure 35

Step 5

To load menu items from the USB flash drive to

another control board, repeat these software loading

procedures.

Note: Grills built prior to serial number M1035495

will require the front control panel be reinstalled.

24

Model 811, 813, 819, 821 SeriesOperating Procedures

Page 29

Patty Placement & Removal

Placement procedures of meat products must be

followed on the grill. The meat must be placed on

the lower grill surface from front to back. When the

cook cycle is complete, the upper platen will raise.

Note: It is very important that all patties be

removed from the lower grill surface in the same

sequence that they were placed before cooking.

L Series Grills (Longer PlatenVersion)

Patties must be removed immediately after the

upper platen has been raised to the OPEN position

and after the meat has been seasoned.

Patties are generally placed two at a time from front

to back of grill and right to left. The removal order of

the patties is shown in the diagrams by the number

shown in the center of each patty.

130312

Model 811, 813, 819, 821 Series Operating Procedures

25

Page 30

Patty Placement & Removal (continued)

C Series Grills (Shorter Platen Version)

130312

26

Model 811, 813, 819, 821 SeriesOperating Procedures

Page 31

Operating Procedures

Cooking Product

Step 1

Selectthemenuitemtobecooked.Thegrillisatthe

correct temperature if the control does not display

any temperature statements and the grill

temperature indicators are green.

Step 2

Quickly place the product on the lower grill surface,

from front to back.

During the cooking cycle, the display will show the

name of the current menu item, “REMOVE IN”, and

the time remaining until the product should be

removed.

Figure 37

Step 3

Press the STANDBY button once.

Figure 36

The d isplay reads “MOVING DOWN” as the platen

lowers to the cook surface.

At the end of the cook cycle, the control will display

“DONE”, a tone will sound, and the platen will

automatically raise.

Figure 38

Note: To cancel a cook cycle at any time, press the

RAISE button. A tone will sound and the display will

read “CANCEL” for five seconds and then enter an

IDLE mode.

Model 811, 813, 819, 821 Series Operating Procedures

27

Page 32

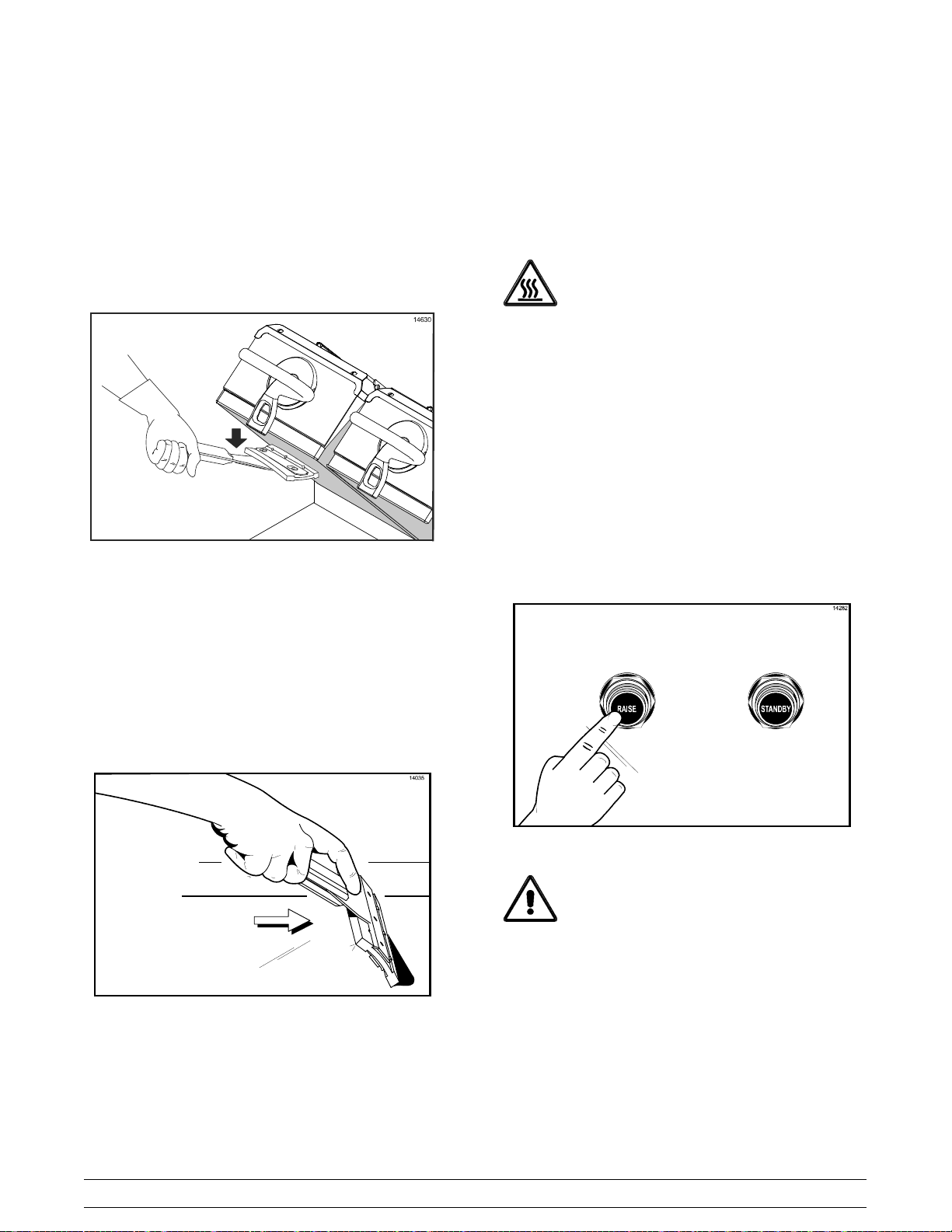

Standby Procedures

Menu Parameters

Whenever the grill is idle and product is not being

cooked,theupperplatenmustbeplacedinthe

STANDBY position.

Step 1

To place the upper platen in the STANDBY position,

press the STANDBY button twice from the open

position.

Figure 39

The control will display “GOING TO STANDBY” and

then change to display “STANDBY”.

To view the settings and actual temperatures for the

current item, press and hold the menu item key a

minimum of 5 seconds. The screen will display the

cook time, gap setting, temperature set points and

actual temperature readings for each zone for that

menu item.

Figure 41

If a key is not pressed for 20 seconds, the grill

control will return to the normal display. Pushing the

“X” key will bring the display back to the main display

page.

Step 2

To raise the upper platen to the OPEN position to

resume cooking, press the RAISE button.

Figure 40

CAUTION: Never use force to raise the

upper platen. Damage to components may

result. Only use the RAISE button to open the

upper platen!

Cleaning After Each Run of Product

Step 1

Using the grill scraper, scrape the grease on the

lower g rill surface from front to back. Do not scrape

across the rear of the lower grill surface with the grill

scraper.

Figure 42

28

Model 811, 813, 819, 821 SeriesOperating Procedures

Page 33

Step 2

Use the wiper squeegee to clean the r elease sheet

on the upper platen. Hold the handle at a slight

upward angle. Use a downward motion to clean the

sheet. (Note: Do not use excessive pressure when

wiping the release sheet with the squeegee, as this

can scratch or tear the release sheet.)

Figure 43

Step 4

Usethegrillclothtocleanthebacksplashplateand

the bullnose areas as needed during operation.

Note: To increase the life of the release sheet, wipe

it with a clean, sanitizer-soaked, folded grill cloth a

minimum of four times every hour.

CAUTION: The upper platen surface is

very HOT! To prevent burn injuries, use extreme

caution when wiping the release sheet.

Daily Cleaning Procedures

Note: The three platen Model L811 has been

selected to illustrate the step-by-step procedures.

For grills equipped with less than three platens,

perform the following steps as appropriate for your

grill platen configuration.

Step 1

Raise the upper platen to the OPEN position by

pressing the red RAISE button.

Step 3

Using the wiper squeegee, push the grease at the

rear of the lower grill surface into the grease can. Do

not use the grill scraper for this step.

Figure 44

CAUTION: Never use force to raise the

upper platen. Damage to components may

result. O nly use the RAISE button to open the

upper platen!

Note: DO NOT turn the power switch to the OFF

position while the platens are in the “down” position.

120127

Model 811, 813, 819, 821 Series Operating Procedures

29

Page 34

Step 2

Press the CLEAN key. When the cook surfaces

reach the proper temperature for cleaning, an alarm

will sound and the message “READY TO CLEAN”

will be displayed.

Figure 45

Step 3

Press the RAISE button to cancel the alarm.

Step 4

Put on heat-resistant gloves.

Figure 47

CAUTION: The upper platen surface and

release sheets are very hot. To prevent burn

injuries, use extreme care.

Step 5

Wipe the exposed surface of the release sheets with

a clean, sanitizer-soaked grill cloth.

130205

Figure 46

30

Figure 48

Model 811, 813, 819, 821 SeriesOperating Procedures

Page 35

Step 6

Remove the release sheet clip, release sheet

retainer, and the release sheet. Take these parts to

thesinktobewashedandrinsed.

Figure 49

Step 7

Repeat steps 1 through 6 for the remaining upper

platen(s).

Step 10

Scrape the lower grill surface with the grill scraper,

from front to back.

Figure 51

Step 11

Use the wiper squeegee to push residual grease into

the grease cans.

Step 8

Wash and rinse the clips and retainers in the sink.

Set them aside for future use.

Step 9

Set the release sheets aside on a clean, flat surface

next to the sink until further cleaning is performed.

DO NOT fold, crease, or place them on sharp

objects.

Figure 52

Step 12

Remove, empty, and reinstall the grease cans.

Figure 50

Model 811, 813, 819, 821 Series Operating Procedures

31

Figure 53

120524

Page 36

Step 13

Using a n approved high temperature grill cleaner,

pour approximately 3 oz. (90 ml) onto each 12”

(305 mm) cook zone.

Figure 54

Step 14

Firmly attach the non-abrasive pad to the grill

cleaning pad holder.

Step 17

Apply grill cleaner to the bottom of the platen

handles.

Figure 56

IMPORTANT! Use the grill cleaning pad

and holder identified on page 15 ONLY. Using

any other pad and holder will damage the release

sheets.

Step 15

Dip the pad into the grill cleaner.

IMPORTANT: DO NOT SCRUB while applying

grill cleaner in the following steps:

Step 16

Apply grill cleaner to the front side of the upper

platens.

DO NOT use metal scrapers, abrasive

pads, screens, or wire brushes. Damage to

components may result.

Step 18

Apply grill cleaner to the platen surfaces.

130201

Figure 55

32

Figure 57

Model 811, 813, 819, 821 SeriesOperating Procedures

Page 37

Step 19

Apply grill cleaner to the back side of the upper

platens.

Figure 58

Step 20

Apply grill cleaner to the outer edges of the right and

left platens.

Step 25

Lightly scrub the platen surfaces.

Figure 59

Step 26

Lightly scrub the back side of the upper platens.

Step 21

Press the STANDBY button twice to lower one of the

platens.

811 Only: Press the STANDBY button twice to lower

the center platen. Apply grill cleaner to both sides of

the center platen.

Step 22

Apply grill cleaner to the inner edges of the right and

left platens.

Step 23

Press the RAISE button to raise the lowered platen.

Step 24

Lightly scrub the front side of the platens and the

bottom of the platen handles with the non-abrasive

pad until all soil has been liquified by the grill

cleaner. For stubborn soils, apply additional grill

cleaner and lightly scrub. Do not rinse the platens

at this time.

Figure 60

Step 27

Lightly scrub the outer edges of the right and left

platens.

Step 28

Press the STANDBY button twice to lower one of the

platens.

811 Only: Press the STANDBY button twice to lower

the center platen. Lightly scrub both sides of the

center platen.

Step 29

Lightly scrub the inner edges of the right and left

platens.

Step 30

Press the RAISE button to raise the lowered platen.

Step 31

With a clean, sanitizer-soaked grill cloth, rinse the

front, sides, and back of the platen surfaces.

110610

Model 811, 813, 819, 821 Series Operating Procedures

33

Page 38

Step 32

With a clean, sanitizer-soaked grill cloth, rinse the

bottom of the platen handles, and the front, sides,

and back of the platen surfaces.

Figure 61

Step 33

With a clean, sanitizer-soaked grill cloth, rinse the

platen cook surfaces.

Step 34

Press the STANDBY button twice to lower one of the

platens.

811 Only: Press the STANDBY button twice to lower

the center platen. With a clean, sanitizer-soaked grill

cloth, rinse both sides of the center platen.

Step 35

With a clean, sanitizer-soaked grill cloth, rinse the

inner edges of the right and left platens.

Step 36

Press the RAISE button to raise the lowered platen.

Step 37

With a clean, sanitizer-soaked grill cloth, wipe the

exterior of all the platens, especially behind the rear

of the upper platens (next to the arm assembly).

Step 38

Starting at the back of the lower grill, spread the

remaining grill cleaner over the entire surface. Do

not scrub while applying product.

Step 39

Lightly scrub the surface with the non-abrasive pad

until all soil has been liquified by the grill cleaner.

130201

Figure 62

Figure 63

Note: The rear of the upper platen, as well as the

tubular arm, can easily be wiped from the front of the

unit. If cleaning is performed on a daily basis, there

should be no carbon build-up.

34

Model 811, 813, 819, 821 SeriesOperating Procedures

Page 39

IMPORTANT!

DO NOT use a jet of water to clean or rinse

the grill.

DO NOT use cold water or ice to cool the

upper platen or the lower cook surface.

Failure to follow these instructions may result in:

S serious electrical shock

S burns from hot steam

S liquid collecting inside the grill and

destroying electrical components

S damaged cook surfaces

Step 40

Carefully pour warm water on the lower grill surface,

starting from the back to the front. Use the squeegee

to remove the cleaner from the grill surface.

To avoid damaging the grill:

S Never use grill screens on the upper platen

or the lower grill surface.

S Never use any abrasives or cleaners other

than the approved cleaner.

S Never allow the grill scraper or the abrasive

cleaning materials to come in contact with

the release sheet.

Step 41

Pour a small amount of lukewarm water on a clean,

sanitizer-soaked grill cloth, while holding it over the

lower grill surface. Wipe the lower grill surface until

all residue is removed.

Figure 64

Figure 65

IMPORTANT! Step 42 must be performed

using the grill cleaning pad and holder identified

on page 15 ONLY. Using any other pad and holder

will damage the release sheet.

Note: Contact your local Taylor Distributor to

purchase the correct grill cleaning pad and holder.

(See page 15.)

Model 811, 813, 819, 821 Series Operating Procedures

35

Page 40

Step 42

Place the release sheets flat on the lower grill

surface. Gently clean both sides of the sheets with

an approved high temperature grill cleaner and the

grill cleaning pad and holder.

Figure 66

Step 43

Rinse both sides of the release sheets with a clean,

sanitizer-soaked grill cloth.

Step 46

Remove and empty the grease cans.

Figure 68

Step 47

Wash, rinse, and reinstall the grease cans.

Step 48

Wipe all areas with a clean, sanitizer-soaked grill

cloth.

Step 49

Wipe all exterior panels.

Figure 67

Step 44

Place the release sheets on a clean, sanitized, flat

surfacetoairdryovernight.

Step 45

Wipe the lower grill surface with a clean,

sanitizer-soaked grill cloth. Repeat until no visible

soil remains.

24 Hour Stores Only:

Re-install the release sheets on the opposite side

than previously used. Secure the sheets with the

release sheet clips and retainers. Start up the grill

per instructions starting on page 17.

Figure 69

130107

36

Model 811, 813, 819, 821 SeriesOperating Procedures

Page 41

Non-24 Hour Stores Only:

Step 50

Apply a light coat of vegetable oil to the entire lower

grill surface.

Step 51

Leave the upper platens in the OPEN position

overnight.

Step 52

Place the power switch in the OFF position.

Figure 70

Figure 71

120830

Model 811, 813, 819, 821 Series Operating Procedures

37

Page 42

Section 7 Troubleshooting Guide

PROBLEM PROBABLE CAUSE REMEDY

1. One side of the grill will not

heat. The control will display

the m essage, “PROBE

FAULT”.

2. One heat zone will not heat.

The display reads “TOO

COOL”.

3. One of the heat zones is

overheating. The display reads

“TOO HOT”.

a. One power connection is not

connected.

b. The restaurant circuit breaker

has tripped.

c. The contactor is faulty. c. Call a service technician.

d. The heater is faulty. d. Call a service technician.

e. The high limit switch is faulty. e. Call a service technician.

f. The solid state relay is faulty. f. Call a service technician.

a. The interface board is faulty. a. Call a service technician.

b. The solid state relay is faulty. b. Call a service technician.

c. The control harness is faulty. c. Call a service technician.

a. The interface board is faulty. a. Call a service technician.

a. Check the power connection.

b. Reset the restaurant circuit

breaker.

4. The grill will not turn on when

power switch is placed in the

ON position.

5. The upper platen will not stay

in the STANDBY mode, but will

stay in the COOK position.

120521

b. The solid state relay is faulty. b. Call a service technician.

a. The restaurant circuit breaker

has been tripped.

b. The control cord is not

connected properly.

c. The fuse in the control box is

faulty.

d. The power switch is faulty. d. Call a service technician.

a. Incorrect use of the STANDBY

button.

b. Faulty wire connections. b. Call a service technician.

a. Reset the circuit breaker.

b. Reconnect the cord.

c. Call a service technician.

a. Press STANDBY button within

five seconds of lowering the

platen into the COOK position.

38

Model 811, 813, 819, 821 SeriesTroubleshooting Guide

Page 43

PROBLEM PROBABLE CAUSE REMEDY

6. The upper platen will not stay

in the COOK or STANDBY

position.

7. The upper platen will not stay

in the COOK position, but will

stay in the STANDBY mode.

8. The upper platen opens too

rapidly.

a. Temperature is insufficient to

satisfy the indicator LED's.

b. The control harness is faulty. b. Call a service technician.

c. The interface board is faulty. c. Call a service technician.

d. The latch switch is faulty. d. Call a service technician.

e. The latch solenoid is faulty. e. Call a service technician.

f. The processor control is faulty. f. Call a service technician.

g. The pneumatic system is

faulty.

a. The product is out of

specification.

b. The processor control is not set

properly.

a. The orifice/check valve is

incorrect or missing.

a. Wait until the indicator LED's

turn green.

g. Call a service technician.

a. Product must be within

specification (proper thickness,

shape, etc.).

b. Call a service technician.

a. Call a service technician.

9. The display reads “PLATEN

NOT LATCHED”.

10. The display reads “UPPER

PLATEN STUCK”.

a. The pneumatic system is

faulty.

b. The latch switch is faulty. b. Call a service technician.

c. The latch solenoid is faulty. c. Call a service technician.

a. The arm bearings are dirty. a. Call a service technician.

b. The air cylinder is faulty. b. Call a service technician.

c. Plugged air lines to cylinders. c. Call a service technician.

a. Call a service technician.

120521

Model 811, 813, 819, 821 Series Troubleshooting Guide

39

Page 44

PROBLEM PROBABLE CAUSE REMEDY

11. The platen will not lower to

preset gap height.

12. The product is under-cooked

or overcooked.

a. Excessive carbon build-up on

the shields.

b. Defective motor interface

board.

c. Loose harness connections. c. Call a service technician.

d. Defective main display

controller.

e. Defective motors and cables. e. Call a service technician.

a. The release sheet is worn. a. Replace the release sheet.

b. Incorrect cooking time. b. Reset the processor control for

c. Incorrect temperature setting. c. Adjust the processor control to

d. The upper platen or lower grill

surface is not clean and/or has

carbon build-up.

a. Follow closing procedures to

properly clean and remove

carbon build-up from the

shields.

b. Call a service technician.

d. Call a service technician.

the correct time.

the proper setting.

d. Follow closing procedures to

properly clean the upper platen

and t he lower grill surface and

to remove carbon build-up.

e. There is a grease or carbon

build-up on the bottom of the

upper platen handles.

f. The preset gap height is

incorrect.

g. The heating zone is not

heating.

e. Follow closing procedures to

properly clean and remove

carbon build-up from the

bottom of the platen handles.

f. Call a service technician.

g. Call a service technician.

130201

40

Model 811, 813, 819, 821 SeriesTroubleshooting Guide

Page 45

PROBLEM PROBABLE CAUSE REMEDY

13. The product is not cooking

evenly.

14. The display reads “PROBE

OPEN” and displays the

specific zone.

a. The upper platen or lower grill

surface is not clean and/or has

carbon build-up.

b. There is a grease or carbon

build-up on the bottom of the

upper platen handles.

c. The release sheet is worn. c. Replace release sheet.

d. The product is out of

specification.

e. The platen is not level. e. Call a service technician.

f. The preset gap height is

incorrect.

g. Air pressure is not high

enough.

a. The thermocouple or the

thermocouple interface board

is faulty.

a. Follow closing procedures to

properly clean the upper platen

and t he lower grill surface and

to remove carbon build-up.

b. Follow closing procedures to

properly clean and remove

carbon build-up from the

bottom of the platen handles.

d. Product must be within

specification (proper thickness,

shape, etc.).

f. Call a service technician.

g. Call a service technician.

a. Call a service technician.

15. The display reads “HOME

SWITCH STUCK ON.”

16. The display reads “HOME

SWITCH NOT SEEN.”

a. Two sided cooking options are

blocked.

b. Defective stepper motor. b. Call a service technician.

c. Defective stepper motor wire

harness.

d. Defective home switch. d. Call a service technician.

e. Defective motor control. e. Call a service technician.

a. Defective motor control. a. Call a service technician.

b. Defective stepper motor. b. Call a service technician.

c. Defective stepper motor wire

harness.

d. Defective home switch. d. Call a service technician.

e. Broken platen cable. e. Call a service technician.

a. Turn the control off and then

back on to clear the fault.

c. Call a service technician.

c. Call a service technician.

130201

Model 811, 813, 819, 821 Series Troubleshooting Guide

41

Page 46

GAS ZONES ONLY

PROBLEM

1. The display reads “BLOWER

FAILURE”.

2. The burner will not light. The

display reads “IGNITION

FAILURE”.

PROBABLE CAUSE REMEDY

a. The blower is faulty. a. Call a service technician.

b. The pressure switch is faulty. b. Call a service technician.

a. The quick disconnect gas hose

is not fully engaged.

b. The manual shutoff valve is in

the OFF position.

c. Air is in the gas hose. c. Wait 5 minutes before

d. The processor control is faulty. d. Call a service technician.

e. The spark ignition module is

faulty.

f. The gas solenoid is faulty. f. Call a service technician.

g. The electrode is faulty. g. Call a service technician.

h. The interface board is faulty. h. Call a service technician.

a. Re-engage the quick

disconnect.

b. Turn the valve to the ON

position.

relighting.

e. Call a service technician.

3. The burner lights but will not

stay lit.

4. The burner lights but the zone

is cool or overheats.

a. The electrode is faulty. a. Call a service technician.

b. Improper ground. b. Call a service technician.

a. The grill is out of calibration. a. Call a service technician.

b. The processor control is faulty. b. Call a service technician.

c. The thermocouple is faulty. c. Call a service technician.

42

Model 811, 813, 819, 821 SeriesTroubleshooting Guide

Page 47

Section 8 Limited Warranty on Equipment

TAYLOR COMPANY LIMITED WARRANTY ON CROWN SERIES GRILLS

Taylor Company, a division of Carrier Commercial Refrigeration, Inc. (“Taylor”) is pleased to provide this limited

warranty on new Taylor-branded Crown Series g rill equipment available from Taylor to the market generally (the

“Product”) to the original purchaser only.

LIMITED WARRANTY

Taylor warrants the Product against failure due to defect in materials or workmanship under normal use and

service a s follows. All warranty periods begin on the date of original Product installation. If a part fails due to

defect during the applicable warranty period, T aylor, through an authorized Taylor distributor or service agency,

will provide a new or re-manufactured part, at Taylor’s option, to replace the failed defective part at no charge for

the part. Except as otherwise stated herein, these are Taylor’s exclusive obligations under this limited warranty for

a Product failure. This limited warranty is subject to all provisions, conditions, limitations and exclusions listed

below and on the reverse (if any) of this document.

Product

Taylor Crown Series Grills

1. If the date of original installation of the Product cannot be verified, then the limited warranty period begins

ninety (90) days from the date of Product manufacture (as indicated by the Product serial number). Proof of

purchasemayberequiredattimeofservice.

2. This limited warranty is valid only if the Product is installed and all required service work on the Product is

performed by an authorized Taylor distributor or service agency, and only if genuine, new Taylor parts are

used.

3. Installation, use, care, and maintenance must b e normal and in accordance with all instructions contained in

the T aylor Operator’s Manual.

4. Defective parts must be returned to the authorized Taylor distributor or service agency for credit.

This limited warranty does not

Air compressor (excluding tank, solenoid, pressure

switch, check valve, air cylinder, fittings, and airline)

The upper platen’s aluminum casting and shroud

only, and excluding all other upper platen

components, including those internal to the upper

platen

Microprocessor control Three (3) years

Partsnototherwiselistedinthistableorexcluded

below

LIMITED WARRANTY CONDITIONS

LIMITED WARRANTY EXCEPTIONS

cover:

Part Limited Warranty Period

Two (2) years

Two (2) years

One (1) year

1. Labor or other costs incurred for diagnosing, repairing, removing, installing, shipping, servicing or handling of

defective parts, replacement parts, or new Products.

2. Normal maintenance and cleaning as outlined in the Taylor Operator’s Manual, including cleaning of carbon

and grease buildup.

3. Required service, whether cleaning or general repairs, to return the Product’s cooking surface assemblies,

including the upper platen and lower plate, to an operational condition to achieve proper cooking or allow

proper assembly of release sheets and clips as a result of grease build-up on the cooking surfaces, including

but not limited to the platen and plate, sides of the shroud or top of the shroud.

131205

Model 811, 813, 819, 821 Series Limited Warranty on Equipment

43

Page 48

4. Replacement of the Product’s cooking surfaces, including the upper platen and lower plate, due to pitting or

corrosion (or in the case of the upper platen, due to loss of plating) as a result of damage due to the impact

of spatulas or other small wares used during the cooking process or as a result of the use of cleaners,

cleaning materials or cleaning processes not approved for use by Taylor.

5. Replacement of wear items designated as Class “000” parts in the Taylor Operator’s Manual, as well as any

release sheets and clips.

6. External hoses, electrical power supplies, and machine grounding.

7. Parts not supplied or designated by Taylor, or damages resulting from their use.

8. Return trips or waiting time required because a service technician is prevented from beginning warranty

service work promptly upon arrival.

9. Costs incurred to address food safety issues when the technician determines food safety standards are met

and the Product gaps are within specification.

10. Failure, damage or repairs due to faulty installation, misapplication, abuse, no or improper servicing,

unauthorized alteration or improper operation or use as indicated in the Taylor Operator’s Manual, including

but not limited to the failure to use proper assembly and cleaning techniques, tools, or approved cleaning

supplies .

11. Failure, damage or repairs due to theft, vandalism, wind, rain, flood, high water, water, lightning, earthquake

or any other natural disaster, fire, corrosive environments, insect or rodent infestation, or other casualty,

accident or condition beyond the reasonable control of Taylor; operation above or below the electrical or gas

specification of the Product; or components repaired or altered in any way so as, in the judgment of the

Manufacturer, to adversely affect performance, or normal wear or deterioration.

12. Any Product purchased over the Internet.

13. Failure to start due to voltage conditions, blown fuses, open circuit breakers, or damages due to the

inadequacy or interruption of electrical or gas service.

14. Electricity, gas or other fuel costs, or increases in electricity, gas or other fuel costs from any reason

whatsoever.

15. ANY SPECIAL, INDIRECT OR CONSEQUENTIAL PROPERTY OR COMMERCIAL DAMAGE OF ANY

NATURE WHATSOEVER. Some jurisdictions do not allow the exclusion of incidental or consequential

damages, so this limitation may not apply to you.

This limited warranty gives you specific legal rights, and you may also have other rights which vary from

jurisdiction to jurisdiction.

44

Model 811, 813, 819, 821 SeriesLimited Warranty on Equipment

Page 49

LIMITATION OF WARRANTY

THIS LIMITED WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, CONDITIONS

AND/OR REMEDIES UNDER THE LAW, INCLUDING ANY IMPLIED WARRANTIES OR CONDITIONS OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THE ORIGINAL OWNER'S SOLE

REMEDY WITH RESPECT TO ANY PRODUCTS SHALL BE REPAIR OR REPLACEMENT OF DEFECTIVE

COMPONENTS UNDER THE TERMS OF THIS LIMITED WARRANTY. ALL RIGHTS TO CONSEQUENTIAL

OR INCIDENTAL DAMAGES (INCLUDING CLAIMS FOR LOST SALES, LOST PROFITS, PRODUCT LOSS,

PROPERTY DAMAGES OR SERVICE EXPENSES) ARE EXPRESSLY EXCLUDED. THE EXPRESS

WARRANTIES MADE IN THIS LIMITED WARRANTY MAY NOT BE ALTERED, ENLARGED, OR CHANGED

BY ANY DISTRIBUTOR, DEALER, OR OTHER PERSON, WHATSOEVER.

LEGAL REMEDIES

The owner must notify Taylor in writing, by certified or registered letter to the following address, of any defect or

complaint with the Product, stating the defect or complaint and a specific request for repair, replacement, or other

correction of the Product under warranty, mailed at least thirty (30) days before pursuing a ny legal rights or

remedies.

Taylor Company

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072, U.S.A.

Model 811, 813, 819, 821 Series Limited Warranty on Equipment

45

Page 50

Section9 LimitedWarrantyonParts

TAYLOR COMPANY LIMITED WARRANTY ON TAYLOR GENUINE PARTS

Taylor Company, a division of Carrier Commercial Refrigeration, Inc. (“Taylor”) is pleased to provide this limited

warranty on new Taylor genuine replacement components and parts available from Taylor to the market generally

(the “Parts”) to the original purchaser only.

LIMITED WARRANTY

Taylor warrants the Parts against failure due to defect in materials or workmanship under normal use and service

as follows. All warranty periods begin on the date of original installation of the Part in the Taylor unit. If a Part fails

due to defect during the applicable warranty period, Taylor, through an authorized Taylor distributor or service

agency, will provide a new or re-manufactured Part, at Taylor’s option, to replace the failed defective Part at no

charge for the Part. Except as otherwise stated herein, these are Taylor’s exclusive obligations under this limited

warranty for a Part failure. This limited warranty is subject to all provisions, conditions, limitations and exclusions

listed below and on the reverse (if any) of this document.

Part's Warranty Class Code or Part

Class 103 Parts¹ Three (3) months

Class 212 Parts² Twelve (12) months

Class 512 Parts Twelve (12) months

Class 000 Parts No warranty

Taylor Part #072454 (Motor-24VDC *C832/C842*) Four (4) years

LIMITED WARRANTY CONDITIONS

1. If the date of original installation of the Part cannot be otherwise verified, proof of purchase may be required

at time of service.

2. This limited warranty is valid only if the Part is installed and all required service work in connection with the

Part is performed by an authorized Taylor distributor or service agency.