Sony MHC-V11 Service Manual

MHC-V11

SERVICE MANUAL

Ver. 1.2 2016.05

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC

DISTORTION:

(The United States model only)

Left/Right Channel:

With 3ohms loads, both channels

driven, from 120

30watts per channel minimum

RMS power, with no more than

0.7% total harmonic distortion from

250milliwatts to rated output.

10,000Hz; rated

–

Speaker section

Speaker system:

Tweeter + Woofer

Tweeter L/R:

50 mm (2in), c one type

Woofer:

200 mm (7 in),

cone type

Inputs

AUDIO/PARTY CHAIN IN L/R:

Voltage 2 V, impedance 10kilohms

MIC 1, MIC 2:

Sensitivity 1 mV, impedance

10kilohms

Outputs

AUDIO/PARTY CHAIN OUT L/R:

V V, impedance 600 ohmsoltage 2

Disc player section

System:

Compact disc and digital audio

system

Laser Diode Properties

Emission Duration: Continuous

Laser Output*: Less than 44.6μW

* This output is the value

measurement at a distance of

200mm from the objective lens

surface on the Optical Pick-up Block

with 7mm aperture.

USB section

(USB) port:

Type A, maximum current 1 A

Supported audio formats (MP3

discs and USB devices only)

Supported bit rate:

MP3 (MPEG1 Audio Layer- 3): 32kbps

320kbps, VBR

WMA*: 32kbps

Sampling frequencies:

MP3 (MPEG1 Audio Layer-3):

32/44.1/48 kHz

WMA*: 44.1 kHz

* USB devices only

192kbps, VBR

Tuner section

FM stereo

FM superheterodyne tuner

Antenna:

FM lead antenna

FM tuner section:

Tuning range:

North American model: 87.5MHz –

108.0MHz (100kHz step)

Other models: 87.5MHz – 108.0MHz

(50kHz step)

BLUETOOTH section

Communication system:

BLUETOOTH Standard version 3.0

Output:

BLUETOOTH Standard Power Class 2

Maximum communication range:

Line of sight approx. 10 m (33 feet)

Frequency band:

2.4 GHz band (2.4000 GHz –

2.4835 GHz)

Modulation method:

FHSS (Freq Hopping Spread

Spectrum)

Compatible BLUETOOTH proles

A2DP (Advanced Audio Distribution

Prole)

AVRCP (Audio Video Remote Control

Prole)

SPP (Serial Port Prole)

Supported codecs:

SBC (Sub Band Codec)

AAC (Advanced Audio Coding)

LDAC

2)

:

1)

US Model

Canadian Model

AEP Model

UK Model

Australian Model

Model Name Using Similar Mechanism NEW

Mechanism Type TDL-5W

1)

The actual range will vary depending

on factors such as obstacles between

devices, magnetic elds around a

microwave oven, static electricity,

reception sensitivity, antenna’s

performance, operating system, software

application, etc.

2)

BL UETOOTH standard proles indicate the

purpose of BLUETOOTH communication

between devices.

General

Power requirements:

North American model: AC 120V ,

60 Hz

Other models: AC 120V

50/60Hz

Power consumption:

45 W

Standby power consumption (at the

Standby Mode):

When BLUETOOTH standby mode is

set to o: 0.5 W (eco mode)

When BLUETOOTH standby mode is

set to on: 2.8 W (all wireless network

ports on)

Dimensions (W/H/D) (Approx.):

290 mm × 600 mm × 265 mm

Mass (Approx.):

Quantity of the system:

1 piece

Supplied accessories:

Remote control (1)

R03 (size AAA) batteries* (2)

RU model:

* Рекомендуемый срок годности

указан на о трицательной стороне

батарейки.

FM lead antenna (1)

AC power cord (1)

AC plug adaptor* (1) (E4, LA, SP6)

(supplied only for certain areas)

* This plug adaptor is not for the use

in Chile, Paraguay and Uruguay. Use

this plug adaptor in the countries

where it is necessary.

240V ,

RU model (RUSSIAN):

Условия хранения:

Товары сохраняют в упакованном

виде в темных, сухих, чистых,

хорошо вентилируемых

помещениях, изолированных от

мест хранения кислот и щелочей.

Температура хранения: от -10°C

до + 45°C

Относительная влажность

хранения:

от 30% до 70%

Рабочая температура: от 5°C до

35°C

Рабочая относительная

влажность:

от 30% до 70%

RU model (UKRAINIAN):

Умови зберігання:

Продукцію зберігають в

упакованому виді в темних, сухих,

чистих, добре вентильованих

приміщеннях, ізольованих від

місць зберігання кислот і лугів.

Температура зберігання:

від -10°C до + 45°C

Відносна вологість зберігання:

від 30% до 70%

Робоча температура:

від 5°C до 35°C

Робоча відносна вологість:

від 30% до 70%

Design and specications are subject to

change without notice.

HOME AUDIO SYSTEM

E Model

9-896-262-03

2016E33-1

2016.05

©

Sony Video & Sound Products Inc.

Published by Sony Techno Create Corporation

MHC-V11

T

T

Ver. 1.2

License and Trademark

Notice

• MPEG Layer-3 audio coding

technology and patents licensed

from Fraunhofer IIS and Thomson.

• Windows Media is either a registered

trademark or trademark of Microsoft

Corporation in the United States

and/or other countries.

• This product is protected by

certain intellectual property rights

of Microsoft Corporation. Use or

distribution of such technology

outside of this product is prohibited

without a license from Microsoft or

an authorized Microsoft subsidiary.

• The BLUETOOTH® word mark and

logos are registered trademarks

owned by Bluetooth SIG, Inc. and

any use of such marks by Sony

Corporation is under license. Other

trademarks and trade names are

those of their respective owners.

• The N Mark is a trademark or

registered trademark of NFC Forum,

Inc. in the United States and in other

countries.

• Android™ is a trademark of Google

Inc.

• Google Play™ is a trademark of

Google Inc.

• LDAC™ and LDAC logo are

trademarks of Sony Corporation.

• Apple, the Apple logo, iPhone, and

iPod touch are trademarks of Apple

Inc., registered in the U.S. and other

countries. App Store is a service

mark of Apple Inc.

• “Made for iPod” and “Made for

iPhone” mean that an electronic

accessory has been designed to

connect specically to iPod or

iPhone, respectively, and has been

certied by the developer to meet

Apple performance standards. Apple

is not responsible for the operation

of this device or its compliance with

safety and regulatory standards.

Please note that the use of this

accessory with iPod or iPhone may

aect wireless performance.

• All other trademarks and registered

trademarks are of their respective

holders. In this manual,

marks are not specied.

CAUTION

The use of optical instruments with this

product will increase eye hazard.

TM

and

®

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

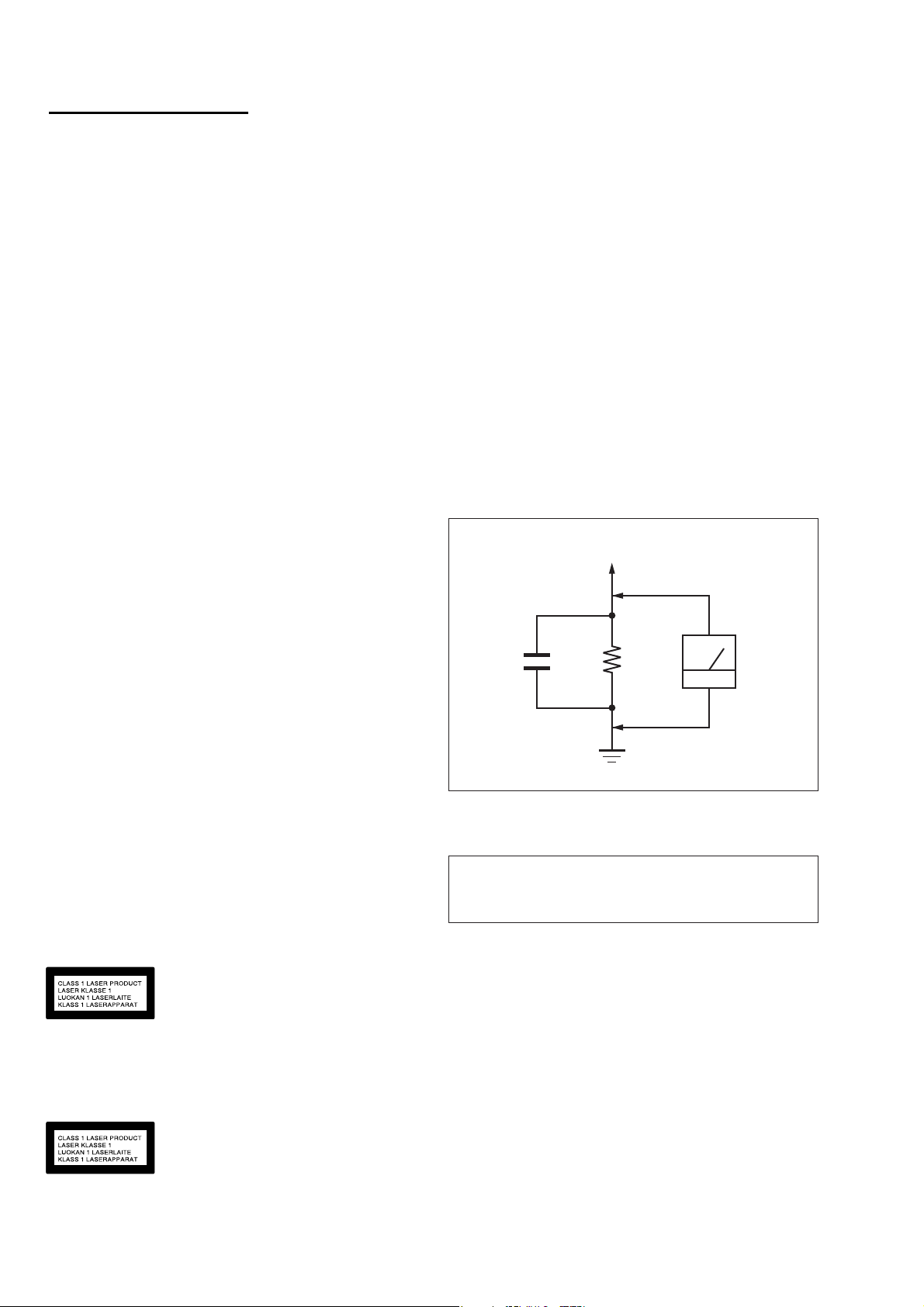

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

AC

1.5 kΩ0.15 μF

voltmeter

(0.75 V)

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specifi ed herein may result in hazardous radia-

tion exposure.

For customers in Europe

his appliance is classied as a CLASS 1

LASER product. This marking is located

on the rear exterior.

For customers in the United Arab

Emirates

his product is classied as a Class 1

Laser product under IEC 60825-1:2007.

This label is located on rear surface of

the product.

2

SAFETY-RELATED COMPONENT WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE

PAR DES PIÈCES SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU DANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

SECTION 1

SERVICING NOTES

MHC-V11

TABLE OF CONTENTS

1. SERVICING NOTES ............................................. 3

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 5

2-2. Left Side Cover, Right Side Cover ................................. 6

2-3. Top Cover Block ............................................................. 7

2-4. Main Volume Knob, MIC Volume Knob ........................ 8

2-5. CONTROL Board ........................................................... 9

2-6. Top Cover Assy, NFC Board .......................................... 9

2-7. Loader (CDM1) .............................................................. 10

2-8. BT Board ......................................................................... 11

2-9. Chassis Block .................................................................. 12

2-10. Front Panel Block ........................................................... 13

2-11. Tweeter Unit Wire ........................................................... 14

2-12. Tweeter Unit (SP2, SP3) ................................................. 15

2-13. LED A Board, LED B Board .......................................... 16

2-14. Woofer Unit (SP1) .......................................................... 17

2-15. Loader Block ................................................................... 18

2-16. MAIN Board ................................................................... 19

2-17. PSU Board ...................................................................... 19

3. TEST MODE ............................................................ 20

4. ELECTRICAL CHECKS ...................................... 21

The SERVICING NOTES contains important information for

servicing. Be sure to read this section before repairing the

unit.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body .

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The fl exible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc refl ective surface by the objective lens in the optical

pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

5. DIAGRAMS

5-1. Block Diagram - OVERALL Section - ........................... 22

5-2. Block Diagram - POWER SUPPLY Section - ................ 23

5-3. Printed Wiring Board - MAIN Board - ........................... 25

5-4. Schematic Diagram - MAIN Board (1/9) - ..................... 26

5-5. Schematic Diagram - MAIN Board (2/9) - ..................... 27

5-6. Schematic Diagram - MAIN Board (3/9) - ..................... 28

5-7. Schematic Diagram - MAIN Board (4/9) - ..................... 29

5-8. Schematic Diagram - MAIN Board (5/9) - ..................... 30

5-9. Schematic Diagram - MAIN Board (6/9) - ..................... 31

5-10. Schematic Diagram - MAIN Board (7/9) - ..................... 32

5-11. Schematic Diagram - MAIN Board (8/9) - ..................... 33

5-12. Schematic Diagram - MAIN Board (9/9) - ..................... 34

5-13. Printed Wiring Board - BT Board - ................................. 35

5-14. Schematic Diagram - BT Board - ................................... 35

5-15. Printed Wiring Board - NFC Board - ............................... 35

5-16. Schematic Diagram - NFC Board - ................................. 35

5-17. Printed Wiring Board - KARAOKE (MIC) Board - ....... 36

5-18. Schematic Diagram - KARAOKE (MIC) Board - .......... 36

5-19. Printed Wiring Board - LED A Board - .......................... 37

5-20. Schematic Diagram - LED A Board - ............................. 37

5-21. Printed Wiring Board - LED B Board - .......................... 37

5-22. Schematic Diagram - LED B Board - ............................. 37

5-23. Printed Wiring Board - CONTROL Board - ................... 38

5-24. Schematic Diagram - CONTROL Board - ...................... 39

5-25. Printed Wiring Board - PSU Board - .............................. 40

5-26. Schematic Diagram - PSU Board - ................................. 41

6. EXPLODED VIEWS

6-1. Side Cover Section .......................................................... 47

6-2. Top Cover Section........................................................... 48

6-3. Woofer Unit Section ....................................................... 49

6-4. Front Panel Section ......................................................... 50

6-5. Main Section ................................................................... 51

7. ACCESSORIES ........................................................ 52

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

REPAIRING THE BOARDS

When each boards installed in this unit are defective, replace the

mounted board.

Individual electrical parts that mounted on the each boards cannot

be replaced.

Printed wiring board and schematic diagram that have been described on this service manual are for reference.

NOTE OF REPLACING THE BT BOARD OR THE NFC

BOARD

When replacing the BT board or the NFC board, be sure to replace

the BT board and the NFC board simultaneously.

The BT board or the NFC board cannot replace with single.

Among the repair parts, the BT board and the NFC board is supplied as one unit.

TEST DISCS

Use following TEST DISC (for CD) when this unit confi rms the

operation and checks it.

Part No. Description

3-702-101-01 DISC (YEDS-18), TEST

4-225-203-01 DISC (PATD-012), TEST

3

MHC-V11

Ver. 1.2

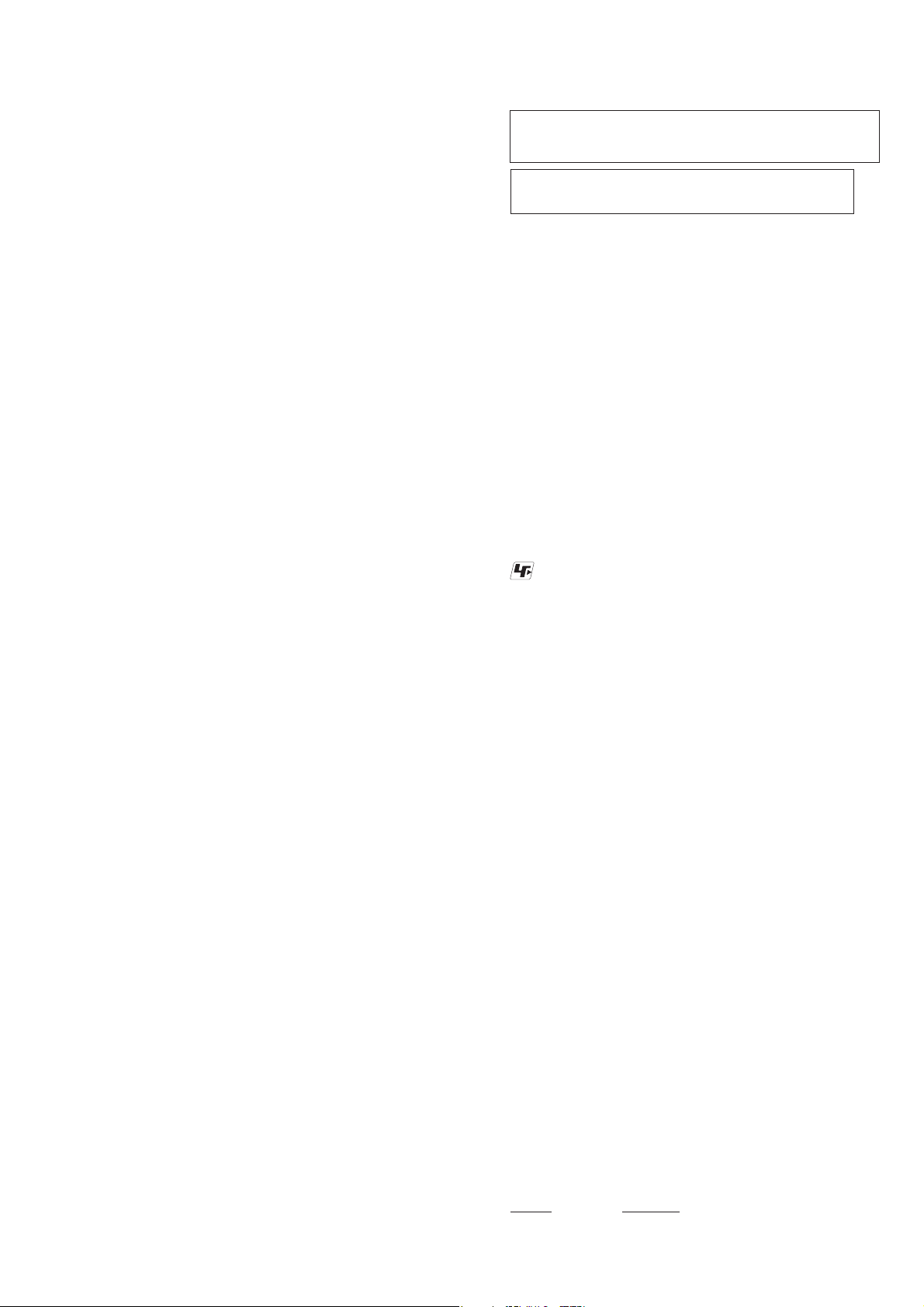

MODEL IDENTIFICATION

Distinguish by Part No. and destination code on the rear side of the main unit.

MODEL NUMBER LABEL

US, CND, RU, E4, LA, SP6, AR, TH

Part No.

Destination code

AEP, UK, E93, AUS

– Rear view –

Part No.

Destination code

Destination Part No. Destination code

US, CND models (UC2)

AEP, UK, AUS models (CEL, CEK, AU1)

RU, E4, SP6 models (RU1, E4, SP6)

E93 model (E93)

TH model (TH1)

AR model (AR2)

LA model (LA9)

4-589-649-0[]

4-589-650-0[]

4-589-651-0[]

4-589-652-0[]

4-589-653-0[]

4-589-655-0[]

4-589-656-0[]

UC2

CEL/CEK/AU1

E4/E12/RU1/SP6

E93

TH1

AR2

LA9

DESTINATION ABBREVIATIONS

The following abbreviations for model destinations are used in this service manual.

• Abbreviations

AR : Argentina model

AUS : Australian model

CND : Canadian model

E4 : Middle East area (Bahrain, Lebanon, Libya, Oman, Pakistan, Qatar, Syria, Yemen) and African (Algeria, Angola, Egypt, Ethiopia,

E93 : Middle East area (Iraq, Kuwait, Saudi Arabia, UAE) and African (Kenya, Nigeria, Tanzania) models

LA : Latin American (Except Brazilian and Argentina) model

RU : Russian model

SP6 : South East Asian area (Except Indian, Thai) model

TH : Thai model

Morocco, Tunisia) models

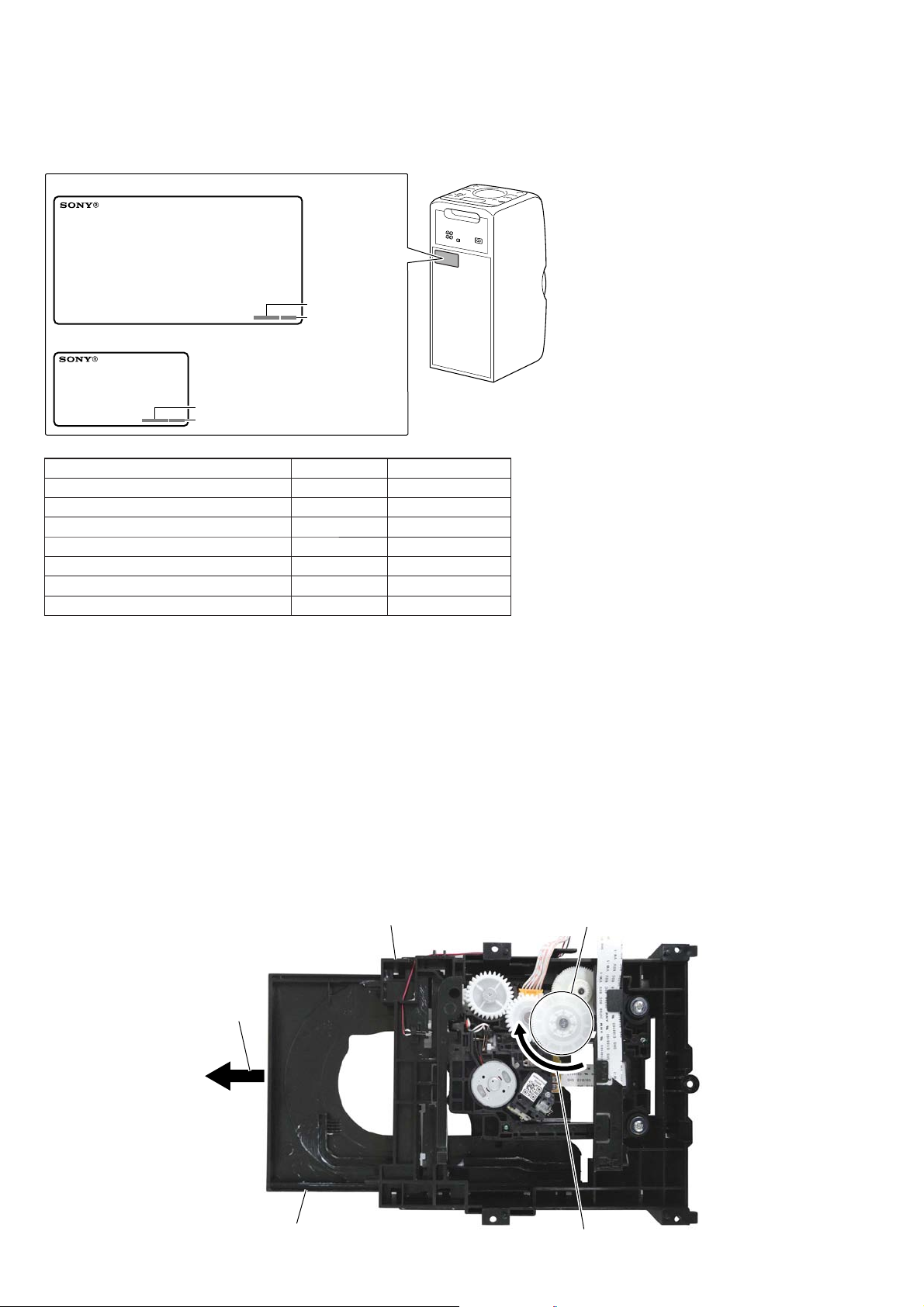

HOW TO OPEN THE TRAY WHEN POWER SWITCH TURN OFF

Note: Refer to “2. DISASSEMBLY” to remove the loader (CDM1) from the unit.

loader (CDM1)

2 Draw out the tray.

gear

tray

– Bottom view –

1 Rotate the gear in the

direction of the arrow.

4

DISASSEMBLY

• This set can be disassembled in the order shown below.

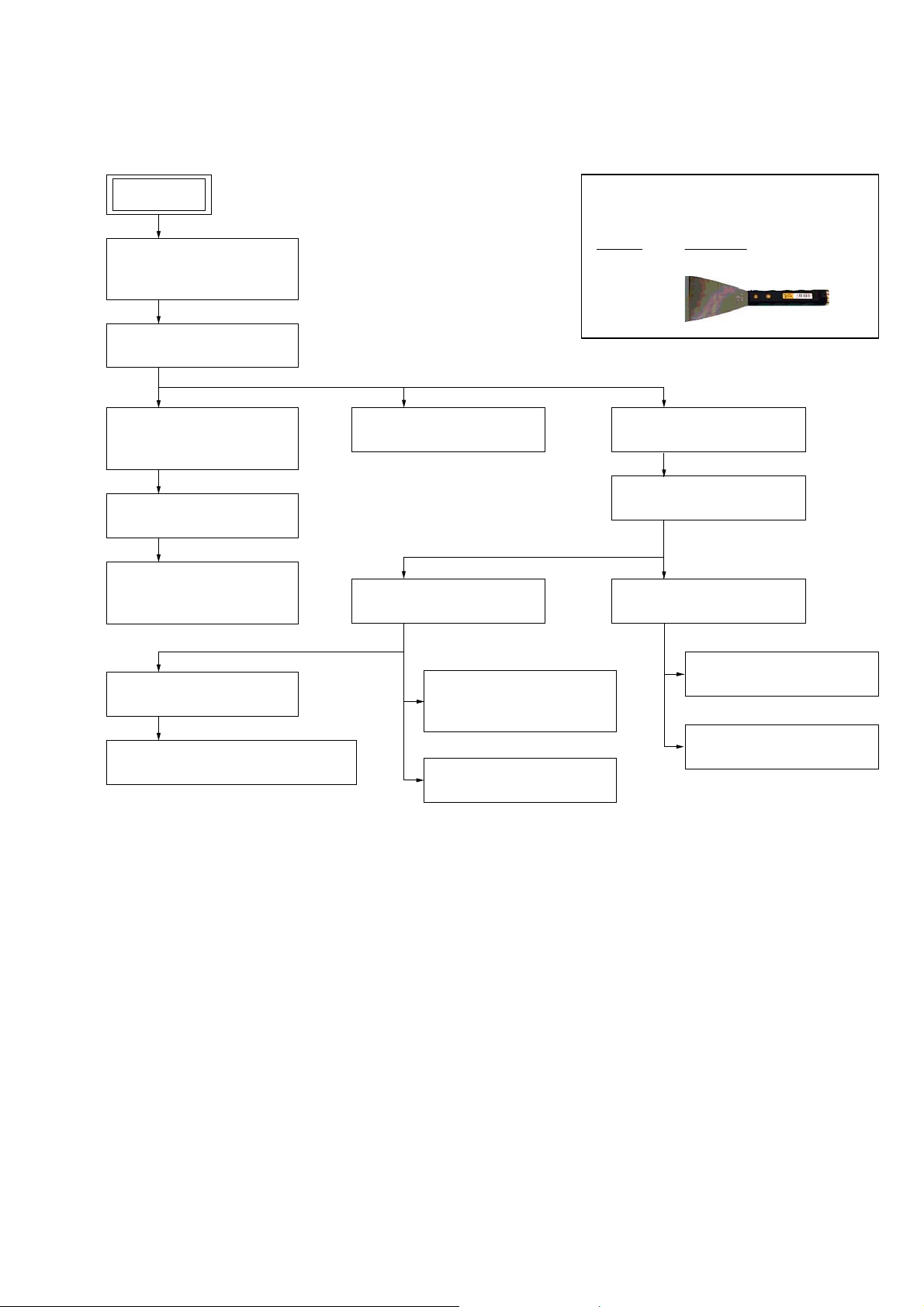

2-1. DISASSEMBLY FLOW

SET

SECTION 2

MHC-V11

JIG

When disassembling the unit, use the following

jig for speaker removal.

2-2. LEFT SIDE COVER,

RIGHT SIDE COVER

(Page 6)

2-3. TOP COVER BLOCK

(Page 7)

2-4. MAIN VOLUME KNOB,

MIC VOLUME KNOB

(Page 8)

2-5. CONTROL BOARD

(Page 9)

2-6. TOP COVER ASSY,

NFC BOARD

(Page 9)

2-11. TWEETER UNIT WIRE

(Page 14)

2-12. TWEETER UNIT (SP2, SP3)

(Page 15)

2-7. LOADER (CDM1)

(Page 10)

2-10. FRONT PANEL BLOCK

(Page 13)

2-13. LED A BOARD,

LED B BOARD

(Page 16)

2-14. WOOFER UNIT (SP1)

(Page 17)

Part No. Description

J-2501-238-A JIG FOR SPEAKER REMOVAL

2-8. BT BOARD

(Page 11)

2-9. CHASSIS BLOCK

(Page 12)

2-15. LOADER BLOCK

(Page 18)

2-16. MAIN BOARD

(Page 19)

2-17. PSU BOARD

(Page 19)

5

MHC-V11

Note: Follow the disassembly procedure in the numerical order given.

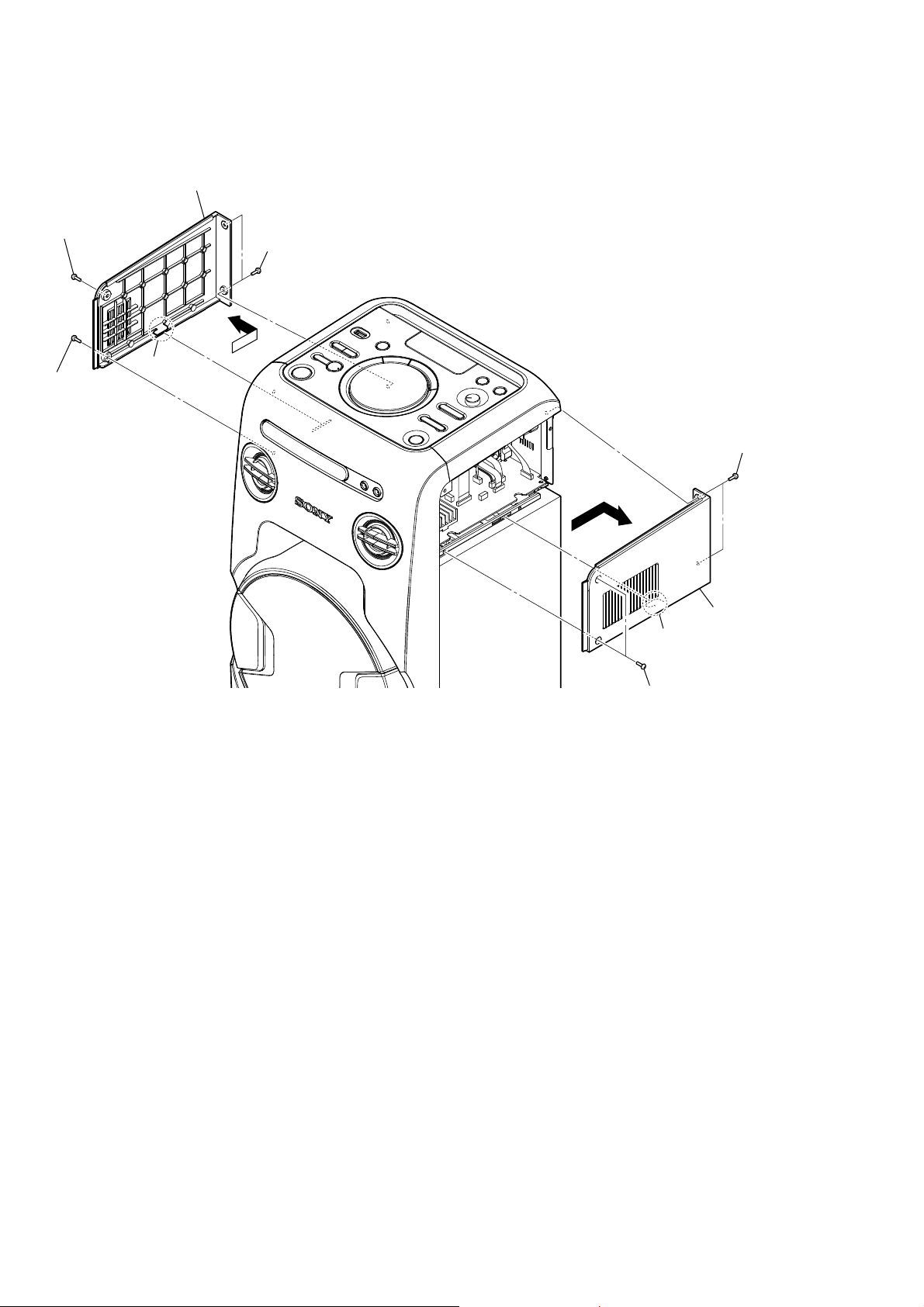

2-2. LEFT SIDE COVER, RIGHT SIDE COVER

4 right side cover

1 screw

1 screw

2 two screws

3 claw

2 two screws

4 left side cover

3 claw

1 two screws

6

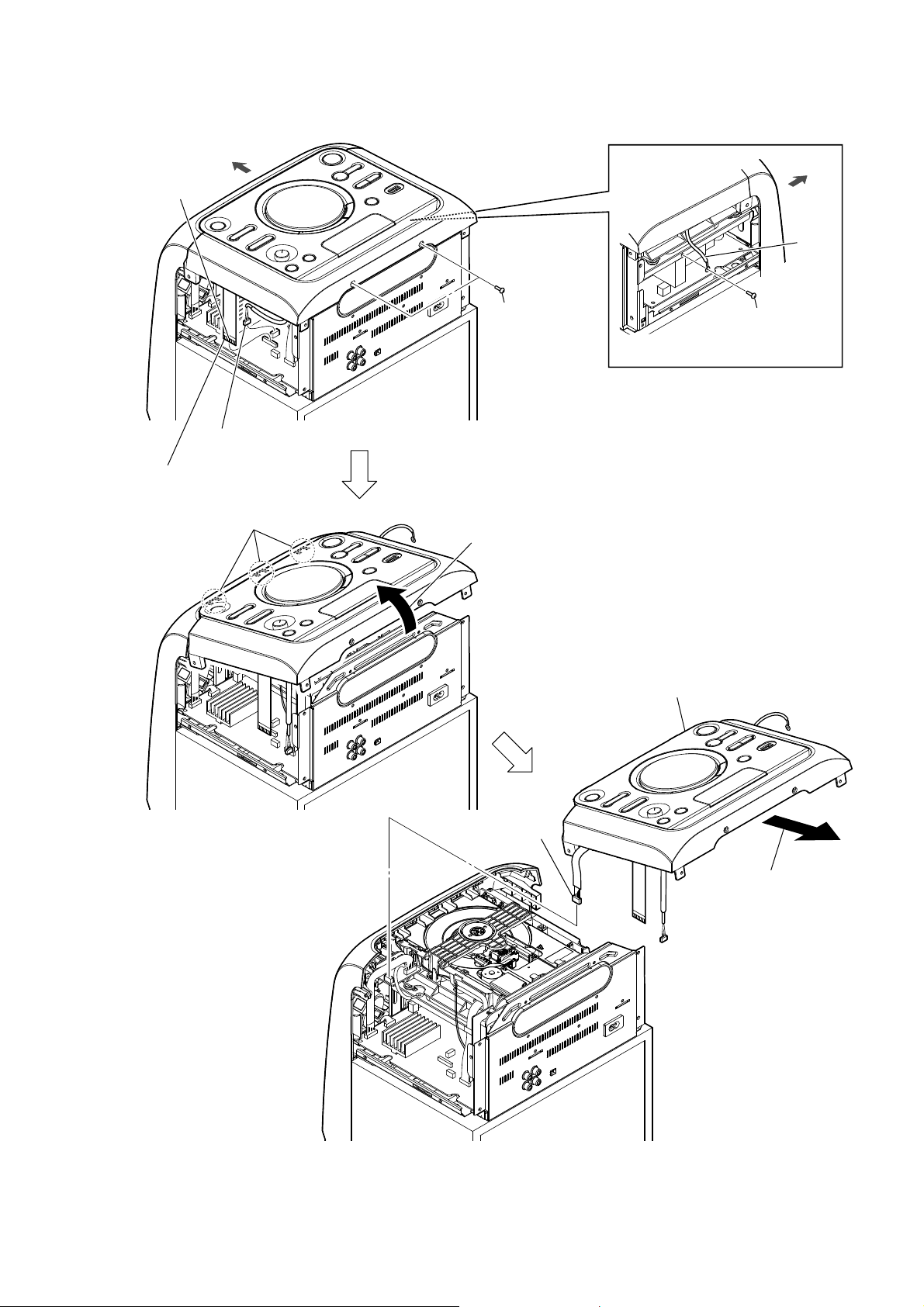

2-3. TOP COVER BLOCK

MHC-V11

This side is the

terminal side.

1 FFC (20P)

(XP10)

6 three claws

front side

2 connector (4P)

(XP7)

3 two screws

Lift up the top cover block

5

in the direction of the arrow.

front side

wire

4 screw

– Left view –

8 connector (5P)

(XP6)

9 top cover block

7 Remove the top cover

block in the direction

of the arrow.

7

MHC-V11

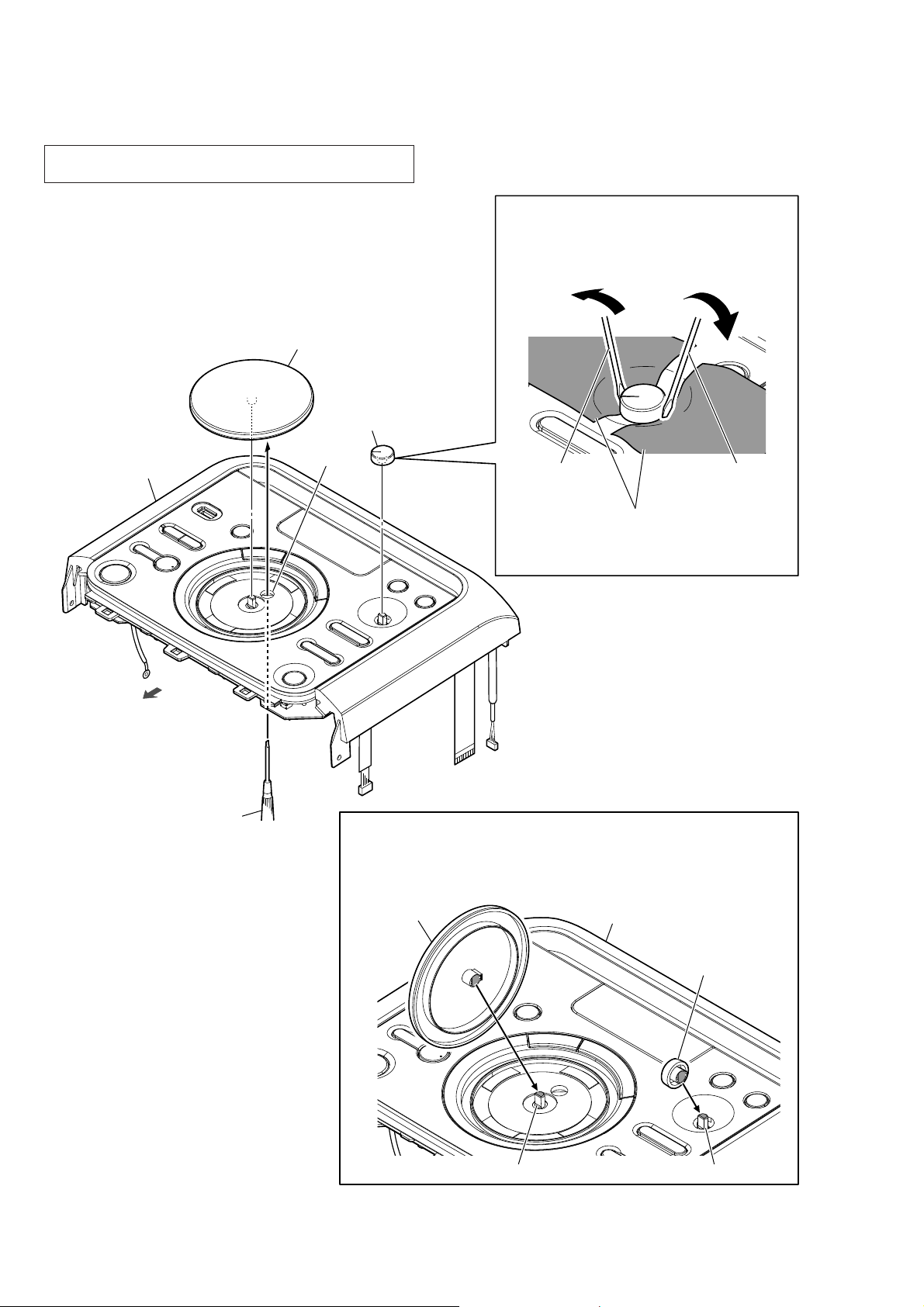

2-4. MAIN VOLUME KNOB, MIC VOLUME KNOB

Note 1: The MIC volume knob can be removed even without remov-

ing the main volume knob.

2 main volume knob

4 MIC volume knob

3 Insert a flathead screwdriver at both sides of

the MIC volume knob and lift at the same time.

Note 2: When using a flathead screwdriver, work

carefully so that you do not damage the

MIC volume knob and top cover block.

top cover block

front side

Push the main volume knob

1

by a flathead screwdriver.

hole

How to install the volume knob

When installing the volume knob to the rotary encoder, align the directions

of the D-shaped tip of the rotary encoder and the D-shaped notch at the

inner side of the volume knob.

flathead

screwdriver

Place soft pieces of cloth between

Note 3:

the MIC volume knob and the top

cover block to avoid damaging

the top cover block.

flathead

screwdriver

main volume knob

rotary encoder

top cover block

MIC volume knob

rotary encoder

8

2-5. CONTROL BOARD

MHC-V11

1 seven screws

top cover block

5 CONTROL board

1 seven screws

1 four screws

This side is

the terminal side.

4 FFC (20P)

(XP1)

3 connector (2P)

(XP2)

rear side

2-6. TOP COVER ASSY, NFC BOARD

Note: When replacing the NFC board, be sure to replace the BT board

and the NFC board simultaneously. The NFC board cannot replace with single. Among the repair parts, the BT board and the

NFC board is supplied as one unit.

top cover assy

3

top side

Lift up the CONTROL board block

2

in the direction of the arrow.

5 NFC board

4 connector (2P)

(XP15)

1 two claws

rear side

2 Peel the NFC board block

off of the adhesive sheet.

top side

9

MHC-V11

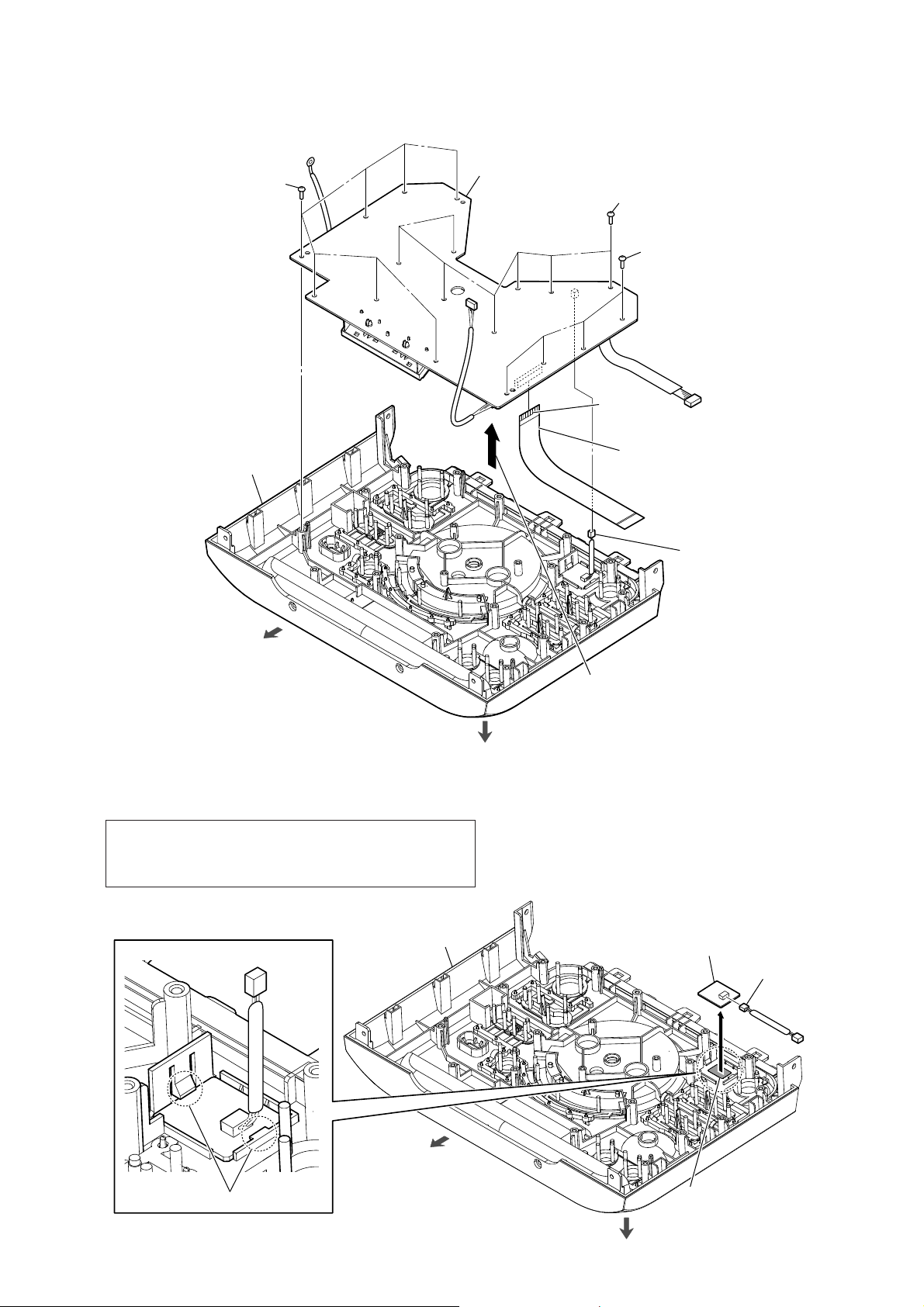

2-7. LOADER (CDM1)

5 two screws

5 two screws

1 cushion

3 connector (6P)

(XP5)

2 FFC (24P)

(XP4)

The opposite side is

the terminal side.

WireVHWWLQJ

loader (CDM1)

three hooks

cushion

6 loader (CDM1)

4 connector (2P)

(XP6)

front side

–5LJKWYLHZ–

MAIN board

10

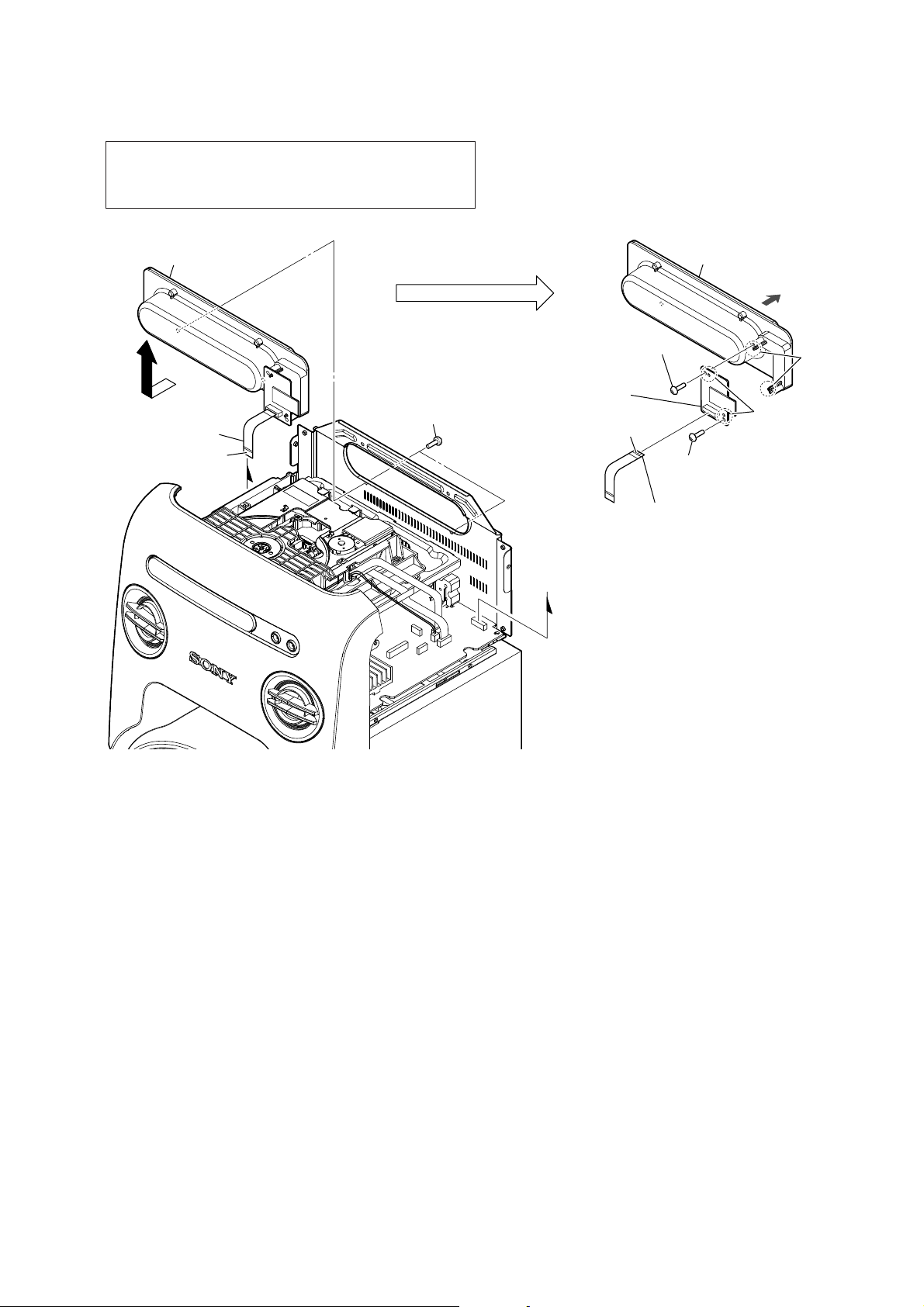

2-8. BT BOARD

Note 1: When replacing the BT board, be sure to replace the BT board

and the NFC board simultaneously. The BT board cannot replace with single. Among the repair parts, the BT board and

the NFC board is supplied as one unit.

MHC-V11

3 handle block

1 FFC (24P)

(XP35)

The opposite side is

the terminal side.

A

2 two screws

5 screw

7 BT board

Note 2:

board, align the two holes

and the two bosses.

When installing the BT

This side is the terminal side.

A

6 handle

rear side

two bosses

two holes

5 screw

4 FFC (24P)

(XP1)

11

MHC-V11

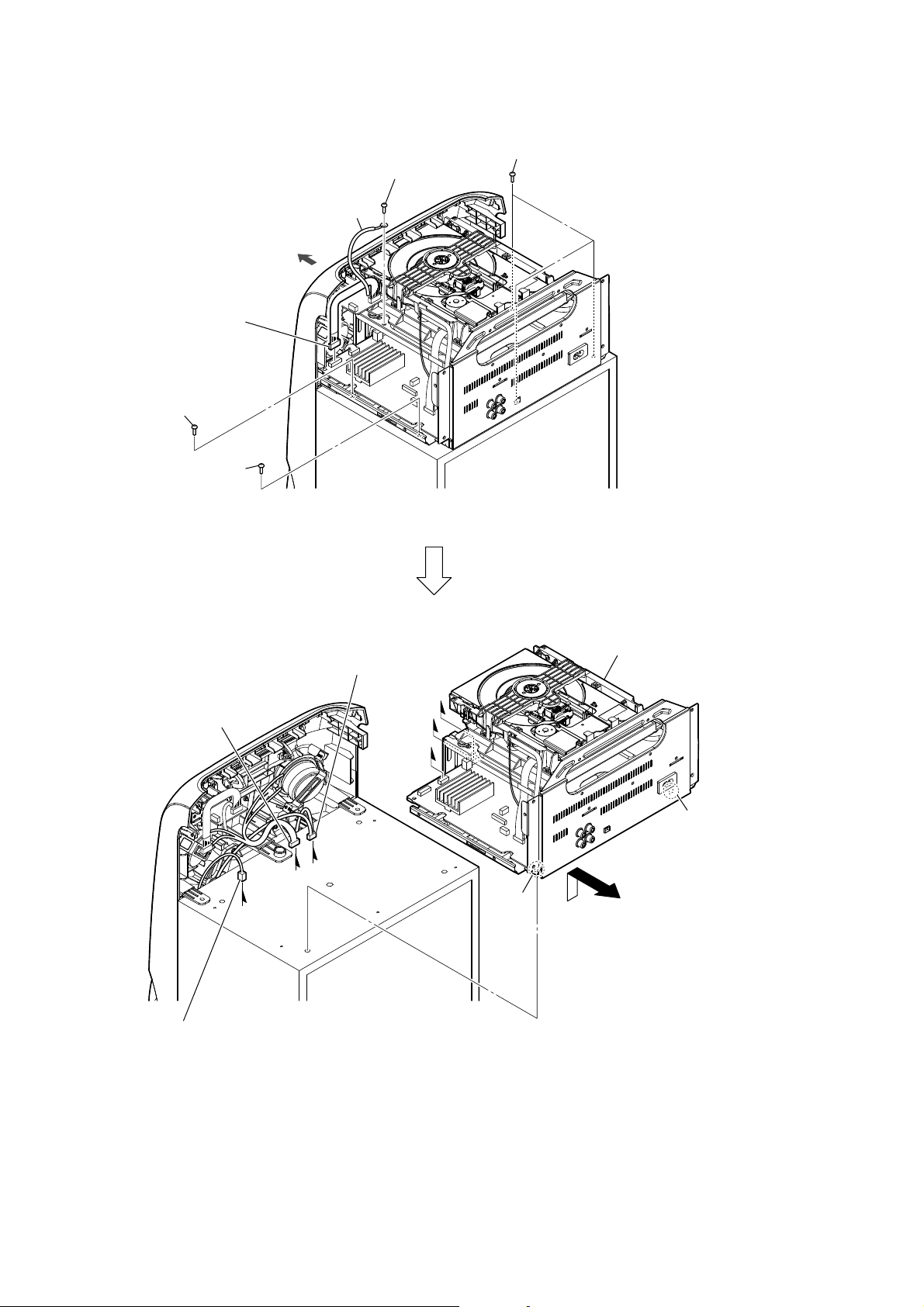

2-9. CHASSIS BLOCK

1 connector (7P)

(XP11)

3 screw

3 screw

3 three screws

2 screw

wire

front side

6 connector (4P)

(XP13)

A

5 connector (2P)

(XP14)

7 connector (4P)

(XP9)

C

B

8 chassis block

C

A

B

4 rib

4 rib

12

2-10. FRONT PANEL BLOCK

4 All bosses are removed while

moving jig in the direction of

the arrow, and front panel block

is removed.

3 Insert the jig into the space and

slowly remove the front panel block.

Note 1: When using a jig, please work

carefully so as not to damage

the front panel block and

speaker cabinet.

2 Insert a flathead screwdriver

in two notches at bottom of

the unit, and lift the front

panel block a little.

1 screw

1 screw

bottom side

MHC-V11

total eleven bosses

1 three

screws

speaker cabinet

4 All bosses are removed while

moving jig in the direction of

the arrow, and front panel block

is removed.

3 Insert the jig into the space and

slowly remove the front panel block.

Note 1: When using a jig, please work

carefully so as not to damage

the front panel block and

speaker cabinet.

5 front panel block

Note 2: When installing the front panel block,

remove the used bond and use a new

bond to fix the front panel block.

13

MHC-V11

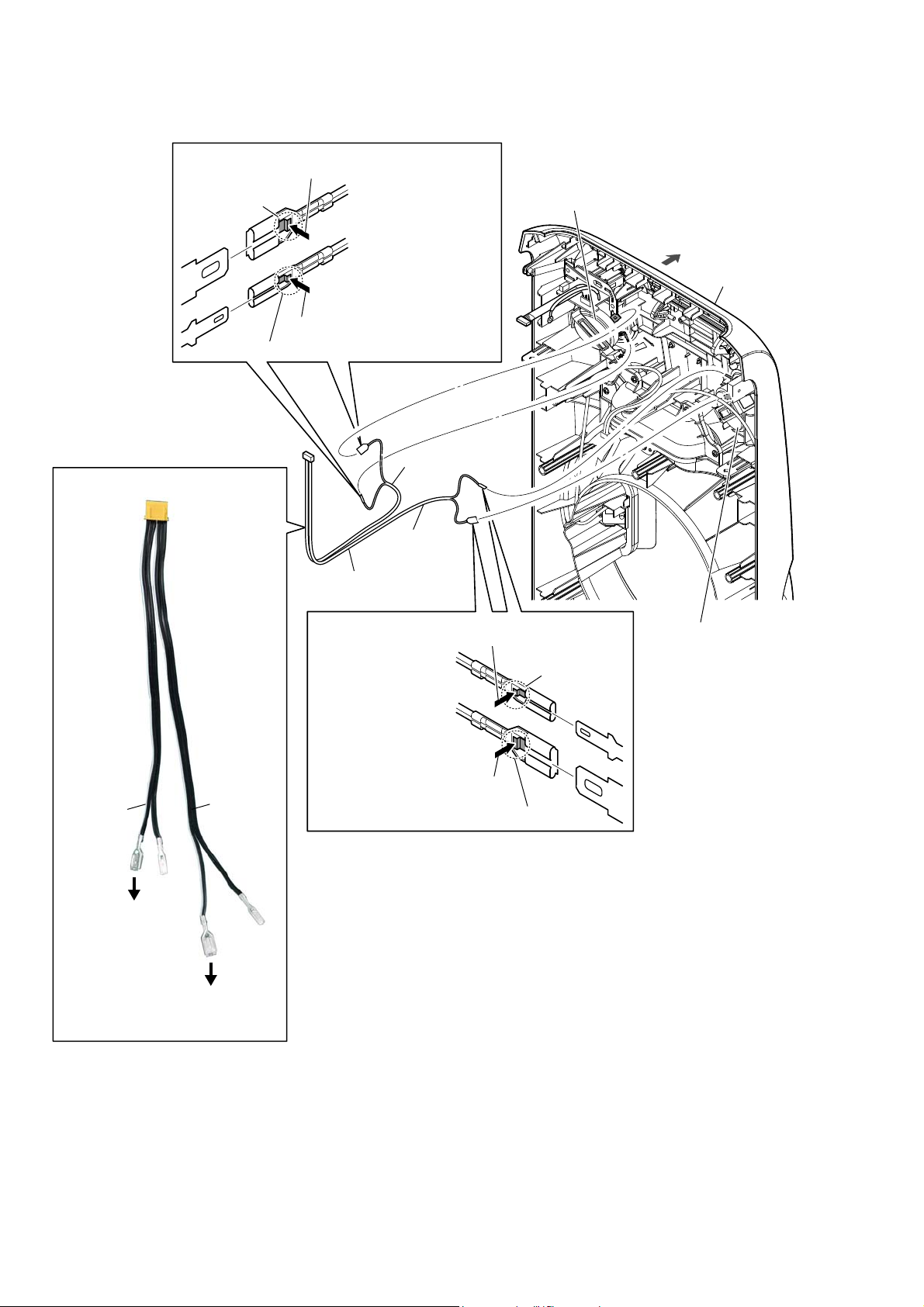

2-11. TWEETER UNIT WIRE

protrusion

protrusion

7ZHHWHUXQLWZLUHVHWWLQJ

1 Push the protrusion, and remove

the terminal (wide side).

tweeter unit (R-ch)

(SP3)

front side

front panel block

1 Push the protrusion, and remove

the terminal (narrow side).

short wire

short wire

tweeter unit

to

(R-ch)

long wire

long wire

2 tweeter unit wire

1 Push the protrusion, and remove

the terminal (narrow side).

1 Push the protrusion, and remove

the terminal (wide side).

tweeter unit (L-ch)

(SP2)

protrusion

protrusion

14

to

tweeter unit

(L-ch)

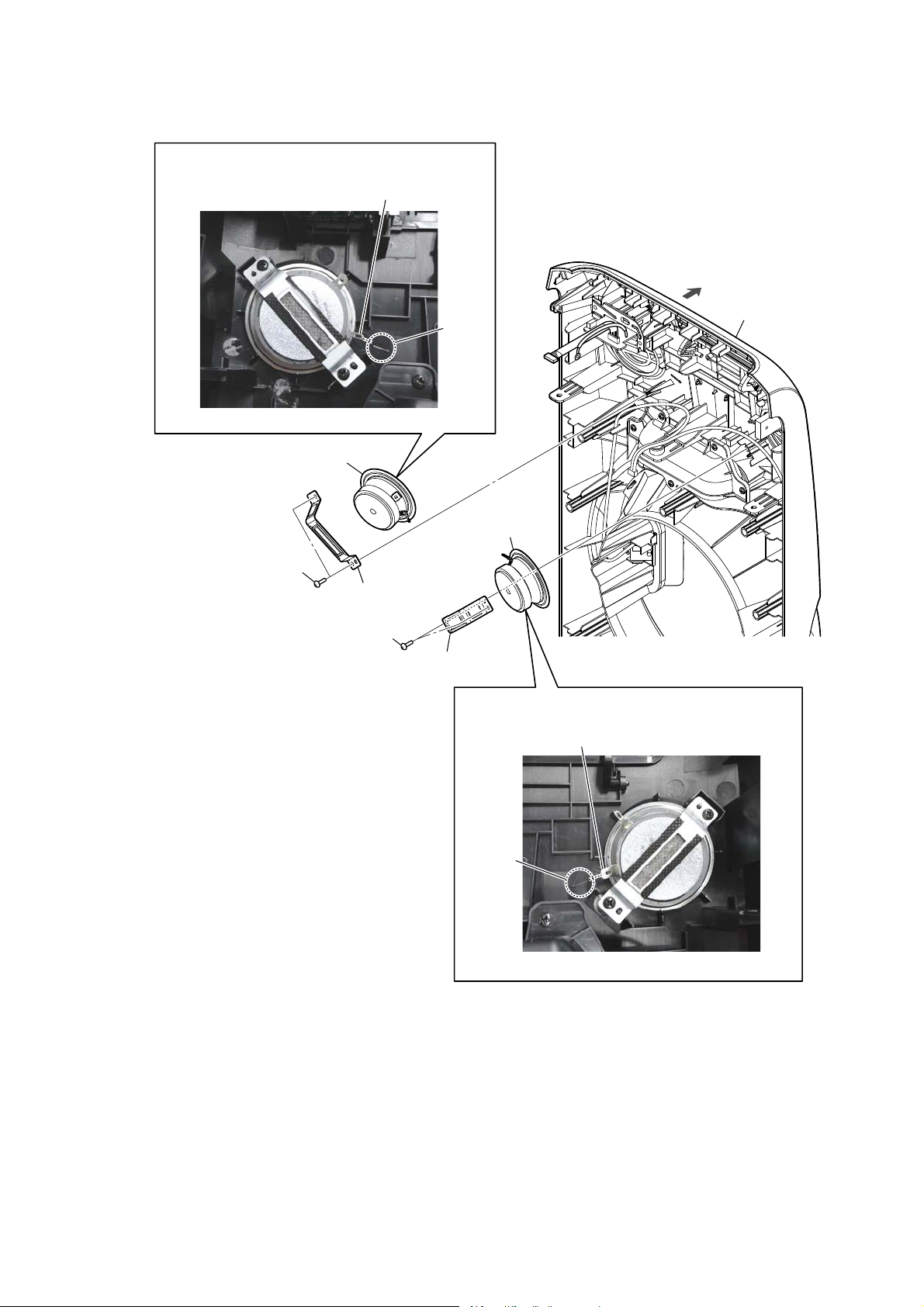

2-12. TWEETER UNIT (SP2, SP3)

,nVtallation Girection Ior tKe tweeter Xnit 5cK 63

Install so that the terminal (narrow side) of the tweeter

unit aligns with the direction of the arrow.

MHC-V11

front side

– Front panel block rear view –

3 tweeter unit (R-ch)

(SP3)

1 two screws

2 bracket

1 two screws

arrow

front panel block

3 tweeter unit (L-ch)

(SP2)

2 bracket

,nVtallation Girection Ior tKe tweeter Xnit /cK 63

Install so that the terminal (wide side) of the tweeter

unit aligns with the direction of the arrow.

arrow

– Front panel block rear view –

15

MHC-V11

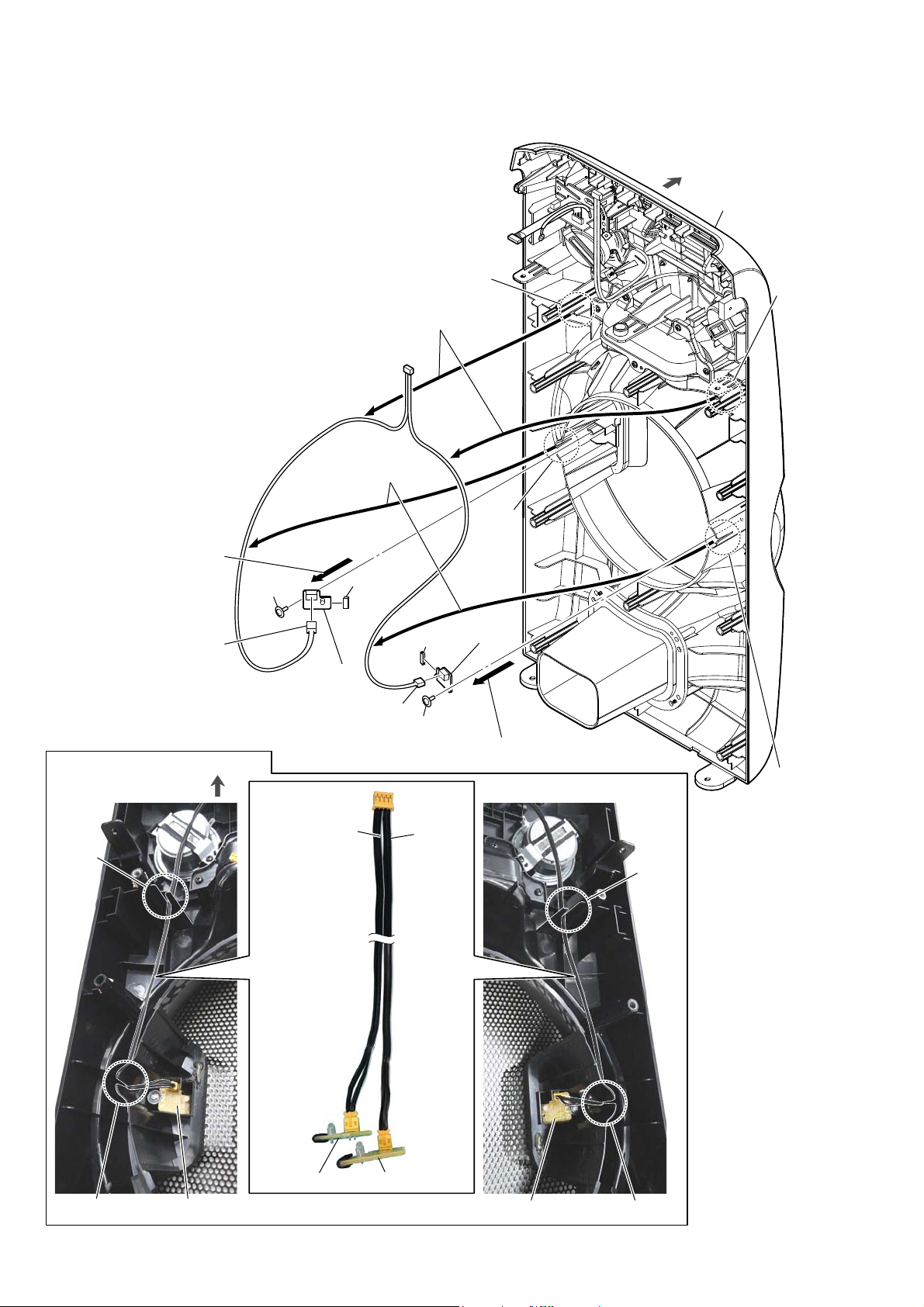

2-13. LED A BOARD, LED B BOARD

front side

front panel block

3 Remove the LED B board

block in the direction of

the arrow.

4 connector (2P)

(XP4)

WireVeWWiQJ

top side

2 screw

1 Draw the cable out

of the groove.

1 Draw the cable out

of the groove.

5 cushion

5 cushion

6 LED B

board

4 connector (2P)

(XP3)

groove

2 screw

groove

groove

6 LED A

board

3 Remove the LED A board block

in the direction of the arrow.

groove

16

groove

groove

LED B board

white line

LED B board

–)rRQWSDQeOEORFNreDrYieZ–

LED A board

white line

LED A board

groove

groove

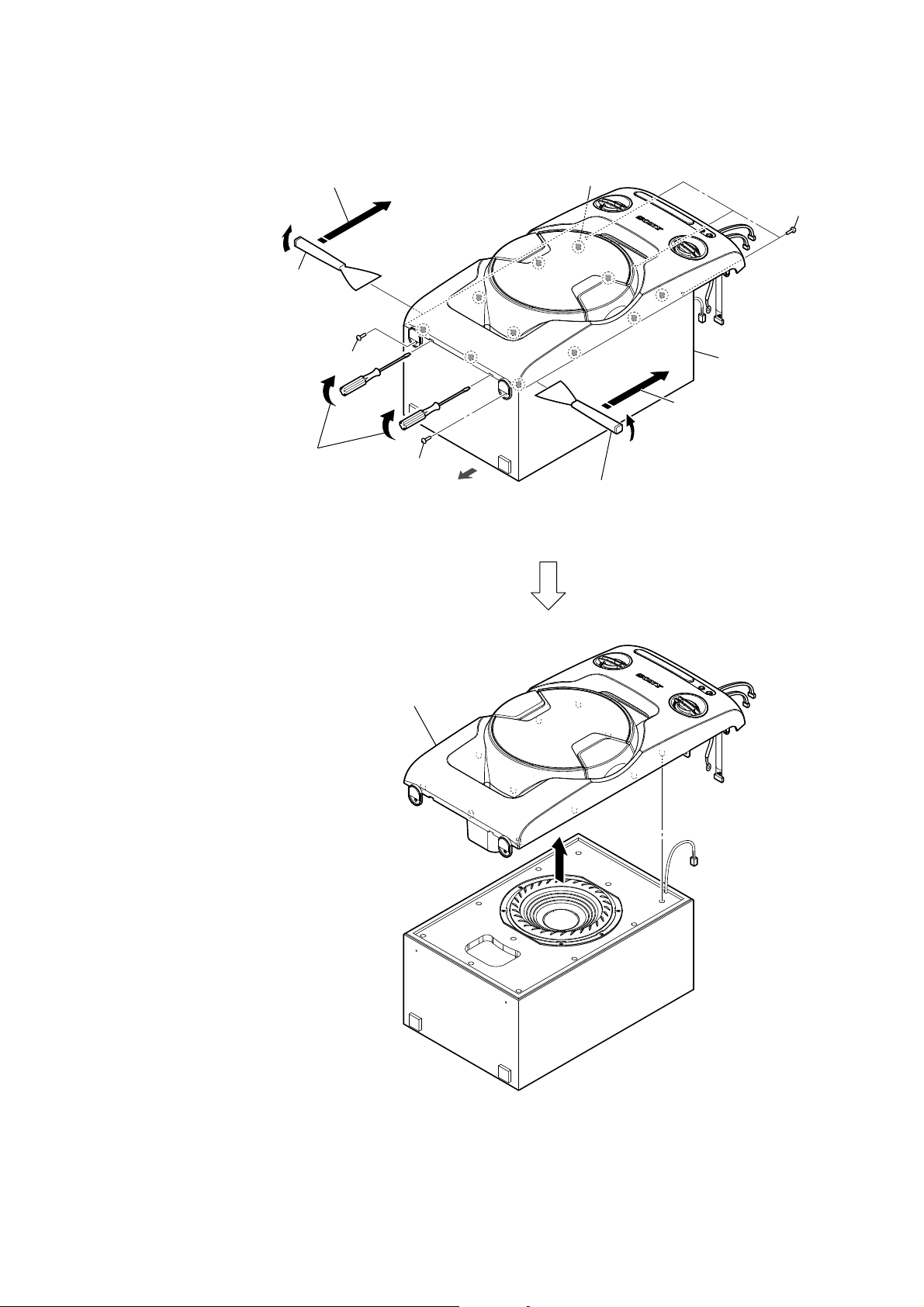

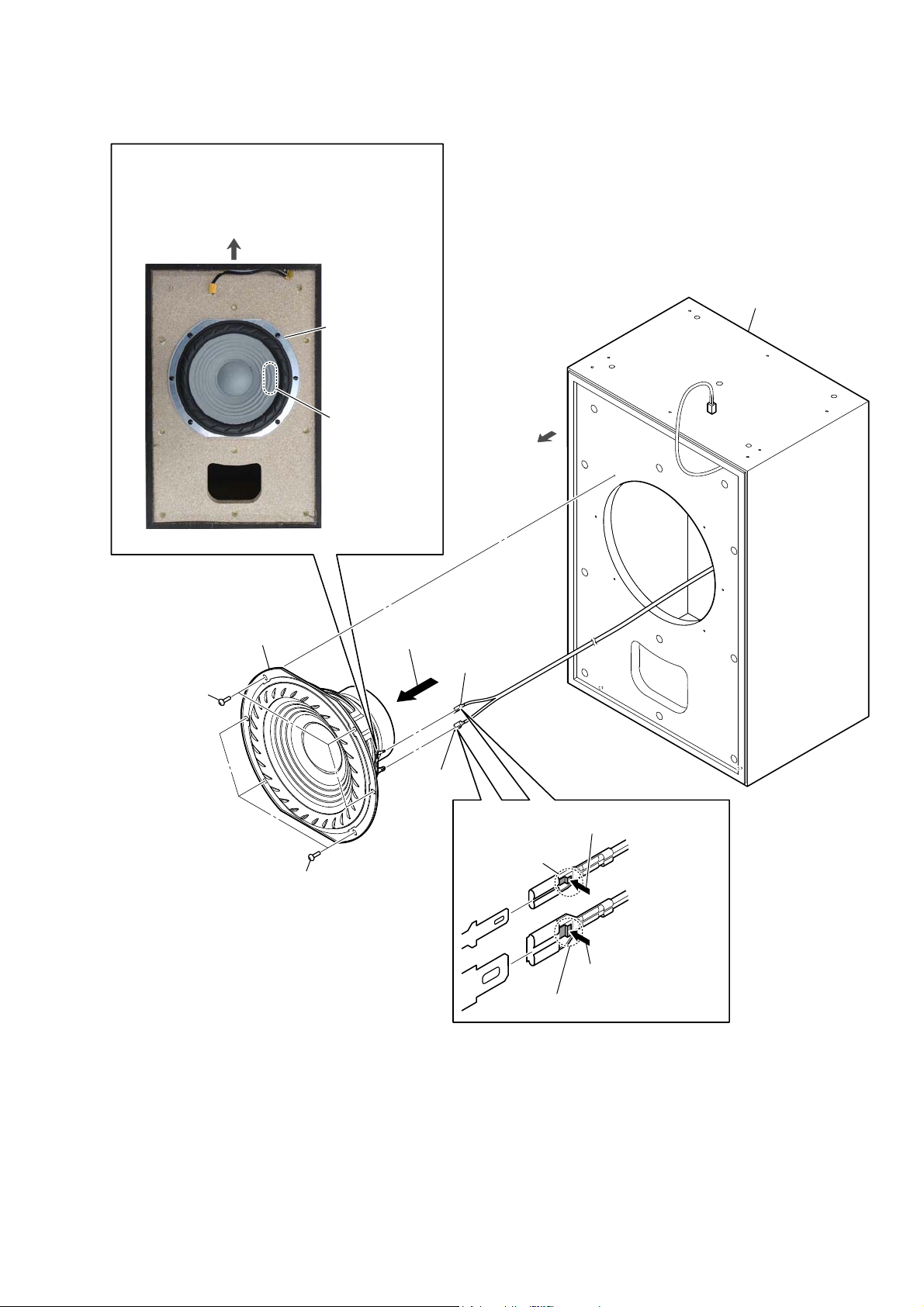

2-14. WOOFER UNIT (SP1)

,QVWDOODWLRQGLUHFWLRQIRUWKHZRRIHUXQLW63

When installing the woofer unit (SP1),

Note:

make the position of terminals as shown

in the figure below.

top side

woofer unit

(SP1)

terminal position

MHC-V11

speaker cabinet block

front side

– Speaker cabinet block front view –

4 woofer unit

(SP1)

1 three screws

1 three screws

Pull out the woofer unit block

2

in the direction of the arrow.

narrow side

wide side

3 Push the protrusion, and remove the

terminal (narrow side).

protrusion

protrusion

3 Push the protrusion,

and remove the

terminal (wide side).

17

Loading...

Loading...