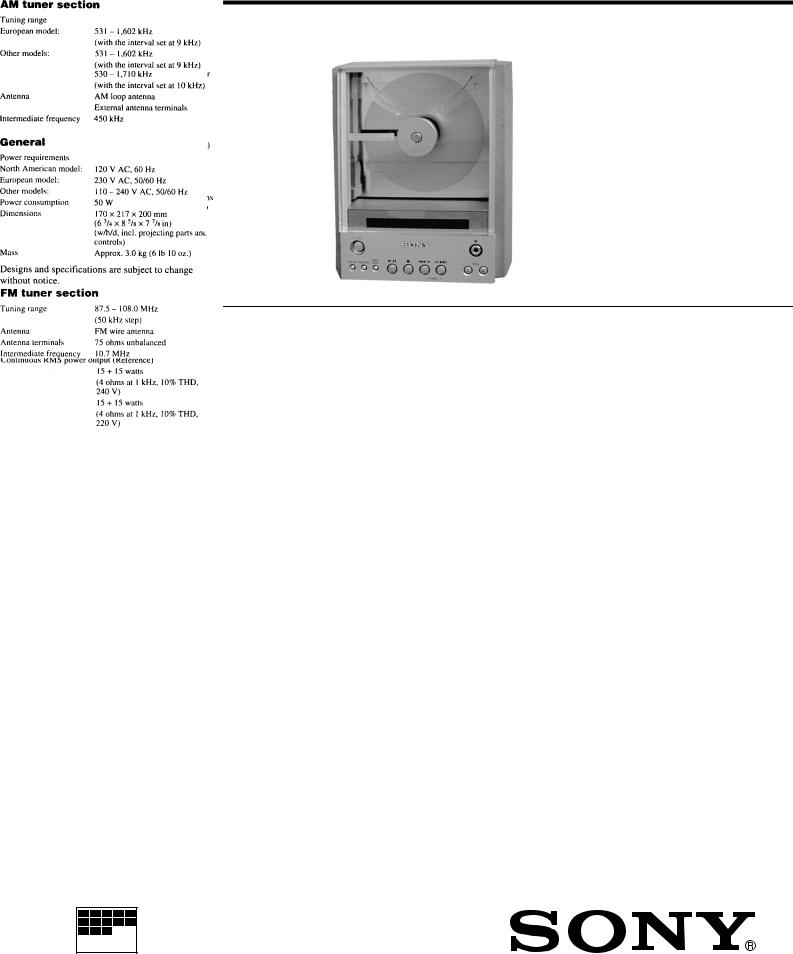

Sony HCD-EX1 Service manual

HCD-EX1

SERVICE MANUAL

HCD-EX1 is the amplifier, CD and tuner section in CMT-EX1.

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Tourist Model

Model Name Using Similar Mechanism |

NEW |

|

|

Mechanism Type |

CDM-60 |

|

|

Base Unit Type |

KSM-770ACA/S-NP |

|

|

Optical Pick-up Type |

KSS-770A/S-N1 |

|

|

SPECIFICATIONS

COMPACT COMPONENT SYSTEM

MICROFILM

1

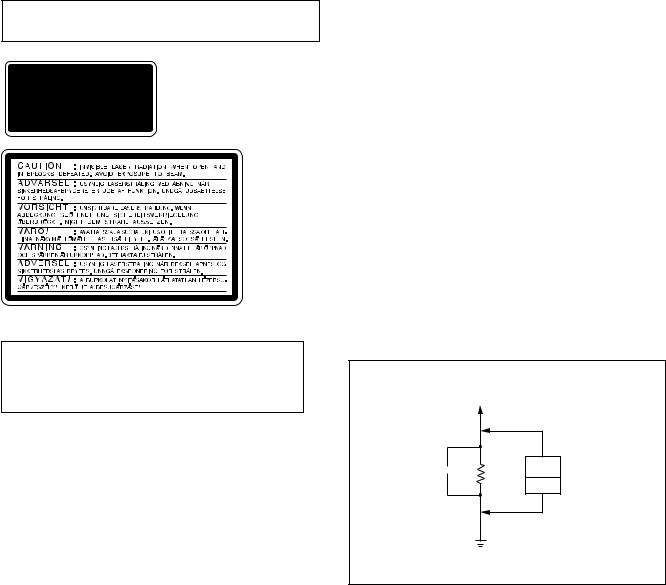

Laser component in this product is capable of emitting radiation exceeding the limit for Class 1.

This appliance is classified as a CLASS 1 LASER product. The CLASS 1 LASER PRODUCT MARKING is located on the rear exterior.

This caution label is located inside the unit.

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

•Never reuse a disconnected chip component.

•Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of soldering iron around 270˚C during repairing.

•Do not touch the soldering iron on the same conductor of the circuit board (within 3 times).

•Be careful not to apply force on the conductor when soldering or unsoldering.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK !OR DOTTED LINE WITH MARK !ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws, and all other exposed metal parts for AC leakage. Check leakage as described below.

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and from all exposed metal parts to any exposed metal part having a return to chassis, must not exceed 0.5 mA (500 microampers). Leakage current can be measured by any one of three methods.

1.A commercial leakage tester, such as the Simpson 229 or RCA WT-540A. Follow the manufacturers’ instructions to use these instruments.

2.A battery-operated AC milliammeter. The Data Precision 245 digital multimeter is suitable for this job.

3.Measuring the voltage drop across a resistor by means of a VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate low-voltage scale. The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

AC 0.15µF  1.5kΩ

1.5kΩ  voltmeter

voltmeter

(0.75V)

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

ATTENTION AU COMPOSANT AYANT RAPPORT À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE !SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

2

TABLE OF CONTENTS |

|

1. SERVICING NOTE .......................................................... |

4 |

2. GENERAL .......................................................................... |

7 |

3. DISASSEMBLY |

|

3-1. Back Cover and Case ............................................................ |

9 |

3-2. Panel Board and Stabilizer .................................................... |

9 |

3-3. AMP Block ......................................................................... |

10 |

3-4. CD Block ............................................................................ |

10 |

3-5. Motor ASSY and CAM ....................................................... |

11 |

3-6. Base Unit ............................................................................. |

11 |

3-7. Main Board and Power Board ............................................ |

12 |

4. ELECTRICAL ADJUSTMENT .............................. |

13 |

5. DIAGRAMS |

|

5-1. Circuit Boards Location ...................................................... |

14 |

5-2. Printed Wiring Board – Main Section – .............................. |

16 |

5-3. Schematic Diagram – Main (1/3) Section – ........................ |

18 |

5-4. Schematic Diagram – Main (2/3) Section – ........................ |

19 |

5-5. Schematic Diagram – Main (3/3) Section – ........................ |

20 |

5-6. Printed Wiring Board – LED/Loading/SW Section – ......... |

21 |

5-7. Schematic Diagram |

|

– LED/Loading/SW Section Section – ............................... |

21 |

5-8. Printed Wiring Board – AMP Section – .............................. |

22 |

5-9. Schematic Diagram – AMP Section – ................................. |

23 |

5-10. Printed Wiring Board – Panel Section – ........................... |

24 |

5-11. Schematic Diagram – Panel Section – ............................. |

25 |

5-12. Printed Wiring Board – Power Section – ......................... |

26 |

5-13. Printed Wiring Board – Power Section – ......................... |

27 |

5-14. Printed Wiring Board – REG Section – ............................ |

28 |

5-15. Schematic Diagram – REG Section – .............................. |

29 |

5-16. IC Block Diagrams ........................................................... |

30 |

5-17. IC Pin Functions ............................................................... |

32 |

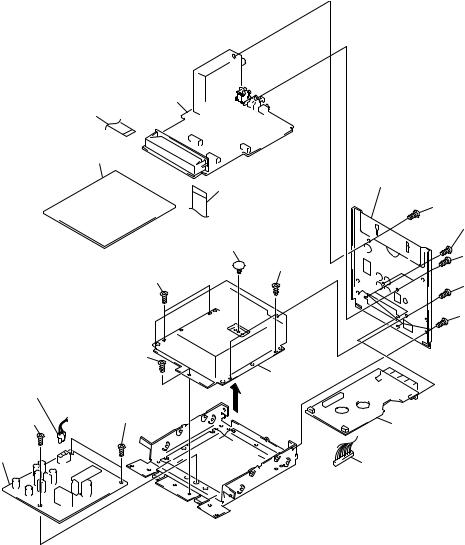

6. EXPLODED VIEWS |

|

6-1. Front and Case Section ....................................................... |

36 |

6-2. Chassis Section ................................................................... |

37 |

6-3. Mechanism Section ............................................................. |

38 |

6-4. Base Unit Section ................................................................ |

39 |

7. ELECTRICAL PARTS LIST ................................. |

40 |

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated by the charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also use the procedure in the printed matter which is included in the repair parts.

The flexible board is easily damaged and should be handled with care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION CHECK

Carry out the “S curve check” in “CD section adjustment” and check that the S curve waveform is output four times.

3

SECTION 1

SERVICING NOTE

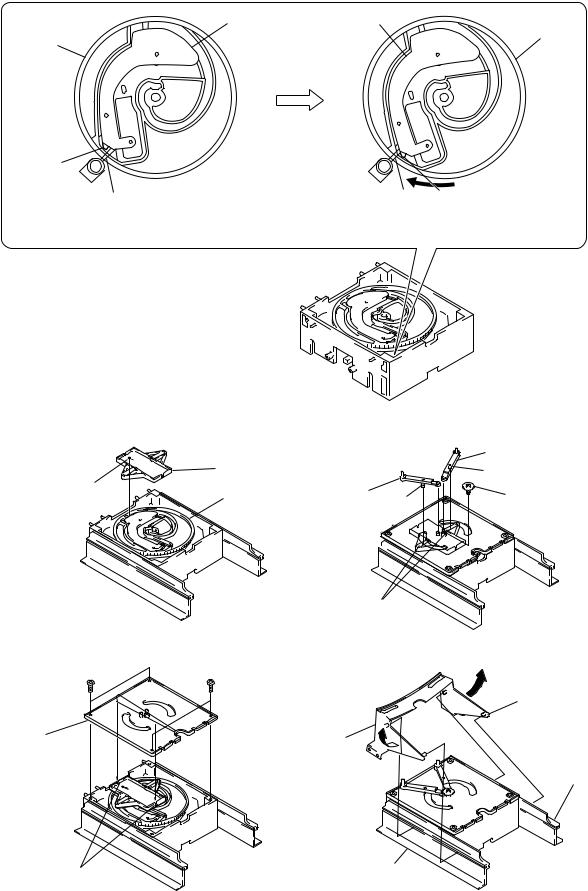

ADJUSTMENT OF CAM PHASE

Absorber |

Absorber |

Cam

Cam

Boss

SW lever |

SW lever Boss |

Insert the cam so that the boss touches the SW lever at the left shown in the figure.

Rotate the cam in the arrow direction, and adjust the phase until the boss touches the SW lever shown in the figure.

With the phase adjusted, attach the parts using the following procedure.

STEP1

Insert the boss of the slider (3) in the groove of the cam.

|

Slider (3) |

Boss |

Cam |

|

STEP2

Set the mecha cover to the groove on the slider (3) and attach.

Screw |

Screw |

|

(BVTP2.6x8) |

||

(BVTP2.6x8) |

||

|

STEP3

Insert the boss of the lever (1) in the hole of the slider (3) and attach.

|

|

Lever (1) |

|

|

Boss |

Lever (1) |

Boss |

Screw |

|

(PTTWH2.6x8) |

|

|

|

Hole of slider (3)

STEP4

While bending the slider (2) slightly in the arrow direction, insert it in the groove of the guides (L) and (R) and attach.

Boss (Four point)

Mecha cover |

Slider (2) |

Guide (L)

Groove of slider (3) |

Guide (R) |

|

4

Shipment Mode

• Mode for setting the state of the unit to the state at shipment. When returning the unit to the customer after completing servicing, set to the shipment mode.

Procedure :

Connect the power plug to the outlet while pressing the 1/u button.

Change-over of AM tuner Step between 9kHz and 10kHz.

• A step of AM channels can be changed over between 9kHz and 10kHz.

Procedure:

1.Press 1/u button to turn on the set ON.

2.Select the function “TUNER”, and press the TUNER/BAND button to select the BAND “AM”.

3.Press the 1/u button to turn on the set OFF.

4.Press 1/u button while pressing the )+/TUNING + button, and the display of liquid crystal indicator tube changes to “AM 9k STEP” or “AM 10k STEP”, and thus the channel step is changed over.

Switching the TAPE IN input level attenuate function ON/OFF

• The attenuate function of the line input level (TAPE IN) of this unit can be turned ON/OFF.

Procedure:

1.Press the 1/u button to turn ON the power.

2.Press the FUNCTION button and set the function to “TAPE”.

3.Press the 1/u button to turn OFF the power.

4. |

While pressing the |

p |

button, press the |

1/u |

button to turn ON the power. |

5. |

After “POWER ON” is displayed, “ATT ON” and “ATT OFF” are displayed, and the attenuate function can be switched ON/OFF. |

||||

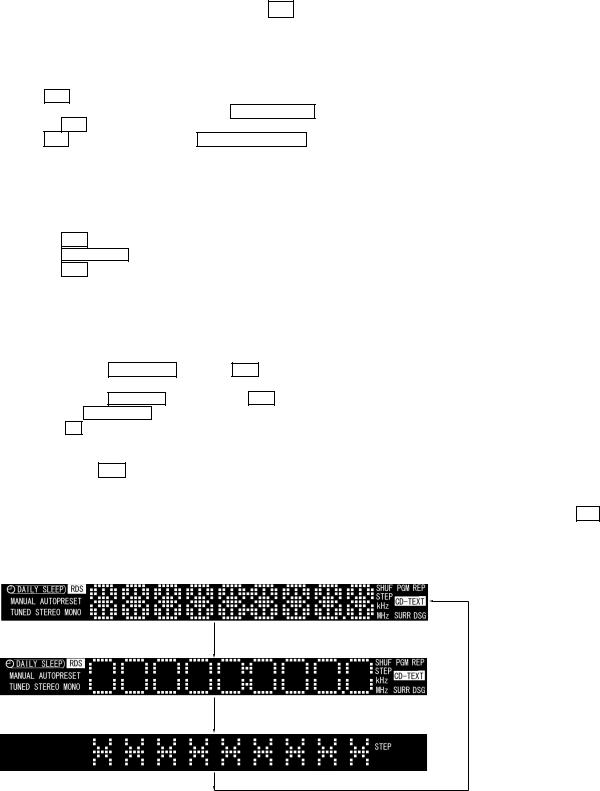

LCD All Lit and Key Check Mode

Procedure:

1. While pressing the FUNCTION button and ^ button, connect the power plug to the outlet.

2.When the test mode is set, the characters “STEP” are displayed on the LCD.

3.While pressing the DISPLAY button, press the ^ button. The whole LCD lights up.

4.Each time the FUNCTION button is pressed, the display switches between all lit npartial lighting 1 npartial lighting 2 nall lit.

5.When the p button is pressed, “KEY 0” is displayed and the key check mode is set.

6.Each time the button is pressed, the counter counts up. Buttons once pressed will not be counted when pressed again. When all buttons have been pressed, “KEY OK” is displayed.

7.To end, press the 1/u button to turn OFF the power, and disconnect the power plug from the outlet.

Note:

Pressing buttons other than those specified in steps 4 and 5 displays modes not used in servicing. In such cases, press the 1/u button to exit the mode, and repeat from step 3 again.

All lit

Partial lighting 1

Partial lighting 2

5

Displaying the CD Text

• This unit is equipped with a simple CD text display function.

The text is displayed only for the first 20 songs. As it will not be displayed from the 21st song, do not suspect a fault. In some cases, special characters may not be displayed or may be substituted by other characters. This is not a fault.

Aging Mode

• The aging mode automatically repeats the operations of the CD.

When an error occurs:

Aging stops

When no error occurs:

Aging is performed repeatedly.

Procedure:

1. |

Set any CD. (One with a short playback time of the final track is recommended.) |

||||||||

2. |

While pressing the |

FUNCTION |

button and |

^ |

button, connect the power plug to the outlet. |

||||

3. |

When the test mode is set, the characters “STEP” is displayed on the LCD. |

||||||||

4. |

When the |

^ |

button is pressed while pressing the |

DISPLAY |

button, “AGING” will be displayed, and aging is performed in the |

||||

|

following sequence. While aging is performed, “REP” will be displayed blinking. |

||||||||

5.Pressing the DISPLAY button during aging displays the cycle number (@ CY where @ is the number of agings).

6.To end aging, press the 1/u button, turn OFF the power, and disconnect the power plug from the outlet.

Sequence during aging

Reads the TOC

Pauses

Accesses first track

Accesses last track

Plays last track

Eject disc (“OPEN” displayed)

Load disc (“CLOSE” displayed)

Displays number of cycles

Power OFF

Power ON

6

SECTION 2

GENERAL

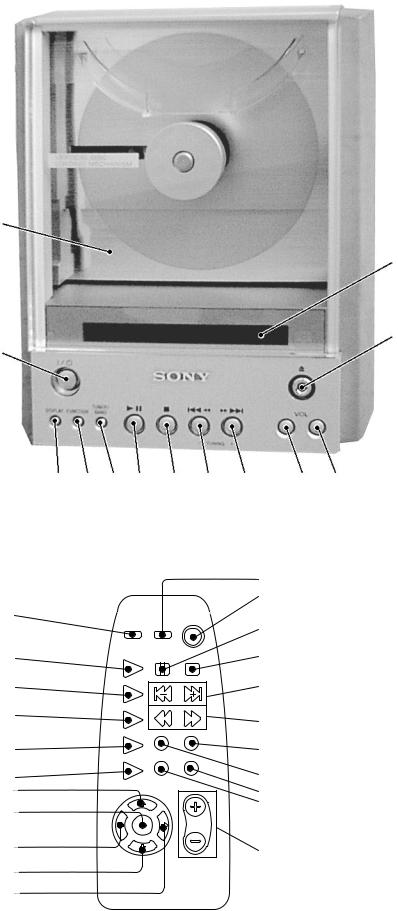

Front Panel

LOCATION OF PARTS AND CONTROLS

1 1/u(power) button

2 DISC tray

3 Display window

4 6button

5 VOLUME + button

6 VOLUME – button

7 )+/TUNING + button

8 =0/TUNING – button

9 p(stop) button

10 ^button

11 TUNER/BAND button

12 FUNCTION button

13 DISPLAY button

2

3

4

1

13 |

12 |

11 |

10 |

9 |

8 |

7 |

6 |

5 |

Remote |

|

|

|

12 |

|

|

13 |

|

1 |

14 |

|

|

||

2 |

15 |

|

3 |

16 |

|

4 |

17 |

|

|

||

5 |

18 |

|

6 |

19 |

|

20 |

||

7 |

||

8 |

21 |

|

|

||

9 |

22 |

|

|

||

10 |

|

|

11 |

|

1OPEN/CLOSE button

2CD ·button

3TUNER/BAND button

4FUNCTION button

5CD PLAY MODE button

6TUNING MODE button

7MEMORY button

8ENTER button

9TIMER SET button

10SLEEP button

11TIMER SELECT button

12DISPLAY button

131/u(power) button

14¸button

15¹button

16/±(AMS) TUNING +/– button

17º/‚button

18REPEAT button

19DSG button

20SURROUND button

21STEREO/MONO button

22VOLUME +/– button

• AMS is the abbreviation for Automatic Music Sensor.

7

This section is extracted from instruction manual.

8

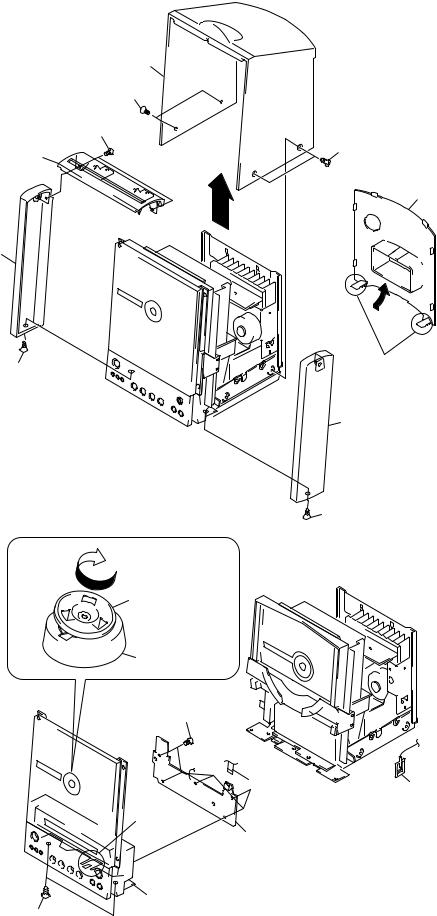

SECTION 3

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

3-1. BACK COVER AND CASE

5Case

4Two screws (KTP3x8)

6Two screws (BVTT3x5)

7Top panel |

3Two screws (KTP3x8) |

2 Rear cover

9Side ornamental

1Two claws

8Screw (KTP3x8)

!¡Side ornamental

3-2. PANEL BOARD AND STABILIZER |

0Screw (KTP3x8) |

Remove the stabilizer in the direction arrow.

Stabilizer

Stabiholder

6Five screws (BVTP2.6x8)

5Flat type wire |

1Remove the Earth clip |

|

(7 core) |

||

|

||

2Claw |

|

|

7PANEL board |

|

4Front panel assy

3Two screws (BVTT3x5)

9

3-3. AMP BLOCK

4Screw (BVTT3x5)

1Connector

AMP board: CN801

2Connector |

7AMP block |

AMP board: CN810 |

|

3Connector

AMP board: CN802

5Screw (BVTT3x5)

6Screw (BVTT3x5)

3-4. CD BLOCK

7CD block

6Connector

MAIN board: CN351

5Flat type wire (16 core)

2Screw (BVTT3x5)

4Connector

MAIN board: CN301

3Screw (BVTT3x5)

1Two screws (BVTT3x5)

10

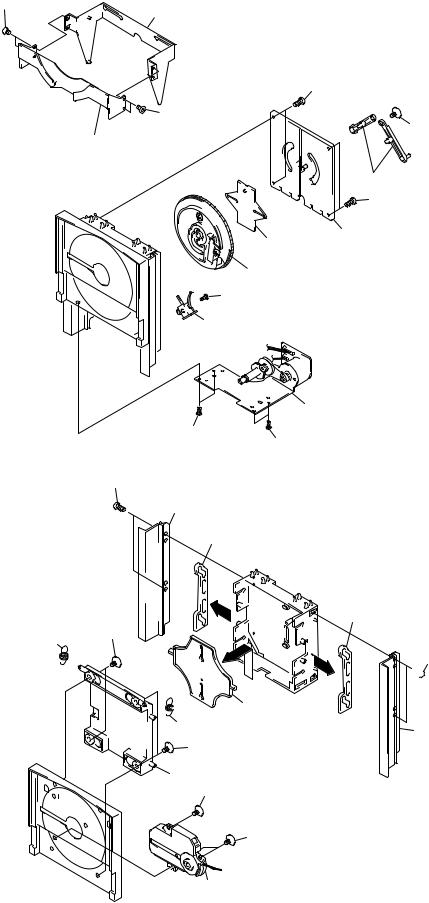

3-5. MOTOR ASSY AND CAM

Note: Adjustment of the phase is required in assembly.Refer to "Section 1. Servicing Note" for details.

4Two screws (2.4x6)

8Slider (2)

0Two screws (BVTP2.6x8)

5Two screws (2.4x6)

7Screws (PTPWH2.6x?)

6Diskholder

9Lever (1)

!¡Two screws (BVTP2.6x8)

!™Mecha cover

!£Slider (3)

!¢Cam

!°Screws (BTP2.6x8)

!§SW cam

3Motor assy

1Two screws (BVTP2.6x8)

2Two screws (BVTP2.6x8)

3-6. BASE UNIT

1Two screws (BVTP2.6x8)

2Guide (L)

5Slider (4)

|

9Two screws |

6Slider (4) |

|

|

|

8Coil spring |

(PTPWH2.6) |

|

|

|

3Two screws

(BVTP2.6x8)

(BVTP2.6x8)

7Slider (1)

0Coil spring

4Guide (R)

!¡Two screws (PTPWH2.6)

!™BU holder

!£Screws (PTPWH2.6)

!¢Two screws (PTPWH2.6)

!°Pick up assy

11

3-7. MAIN BOARD AND POWER BOARD

5Main board

4Flat type wire (7 core)

6Spacer

3Flat type wire

(13 core)

7Screw (PTPWH2.6) 9Two screws

8Two screws  (BVTT3x5) (BVTT3x5)

(BVTT3x5) (BVTT3x5)

|

0Screw (BVTT3x5) |

|

!™Sealed case |

@ºPower cord |

|

|

!ªTwo screws |

!•Screw (BVTT3x5) |

(BVTT3x5) |

@¡Power board

!¶Back panel

1Screw (BVTT3x5)

!¢Two screws (BVTP3x8)

2Two screws (BVTP3x8)

!¡Screw (BVTT3x5)

!§Three screws (BVTT3x5)

!°REG board

!£ Connector

POWER board: CN903

12

SECTION 4

ELECTRICAL ADJUSTMENT

Note:

1.CD Block is basically constructed to operate without adjustment. Therefore, check each item in order given.

2.Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3.Use an oscilloscope with more than 10MΩ impedance.

4.Clean the object lens by an applicator with neutral detergent when the signal level is low than specified value with the following checks.

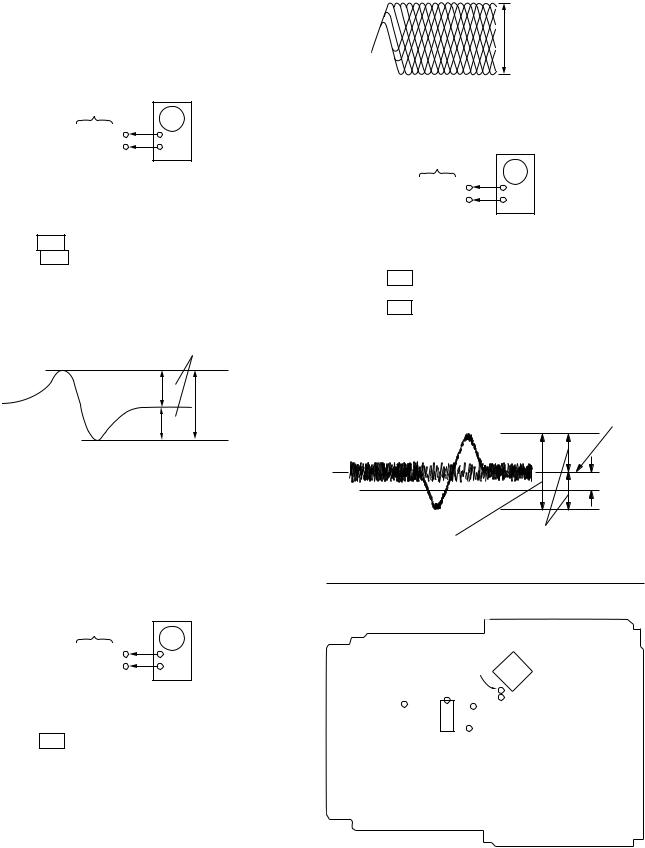

S Curve Check

|

oscilloscope |

MAIN board |

|

TP (FE) |

+ |

TP (VC) |

– |

Procedure :

1.Connect the oscilloscope to test points TP (FE) and TP (VC).

2.Connect TP (FEI) and TP (VC) of the MAIN board with lead wires.

3.Press the 1/u button to turn the set ON.

4.Press the ^ button, load and eject the disc (YEDS-18) to perform focus search.

5.Check the symmetry and peak to peak level of the oscilloscope waveform (S curve) at this time.

S-curve waveform

symmetry

A

Within 3.8 ± 1 Vp-p

B

6. After check, remove the lead wire connected in step 2.

Note: • Try to measure several times to make sure than the ratio of A : B or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the brightness to obtain best waveform.

Checking Location : MAIN board

RF Level Check

|

oscilloscope |

MAIN board |

|

TP (RF) |

+ |

TP (VC) |

– |

Procedure :

1.Connect oscilloscope to test point TP (RF) and TP (VC) on MAIN board.

2.Press the 1/u button to turn the set ON.

3.Put disc (YEDS-18) in and playback 5track.

4.Confirm that oscilloscope waveform is clear and check RF signal level is correct or not.

Note: Clear RF signal waveform means that the shape “ ◊” can be clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500ns

level : 1.2 ± 0.2 Vp-p

Checking Location : MAIN board

E-F Balance (1 Track Jump) check

|

oscilloscope |

MAIN board |

|

TP (TE) |

+ |

TP (VC) |

– |

Procedure:

1.Connect oscilloscope to test point TP (TE) and TP (VC) on MAIN board.

2.Press the 1/u button to turn the unit ON.

3.Put disc (YEDS-18) in to play the number five track.

4.Press the ^ button, to pause.

5.Check the level (B) of the oscilloscope's waveform and the DC voltage (A) of the center of the Traverse waveform.

Confirm the following:

•A/B x 100 = less then ± 22 (%)

•B = 1.3 ± +0.6–0.7 Vp-p

1 track jump waveform |

Center of the waveform |

B

A (DC voitage)

0V

Symmetry

level : 1.3 ± +0.6–0.7 Vp-p

Checking Location : MAIN board

[ MAIN BOARD ] — SIDE A —

TP

(FE) IC303

IC301 TP(RF)

TP TP (TE) (VC)

TP (FEI)

13

SECTION 5

DIAGRAMS

5-1. CIRCUIT BOARDS LOCATION

MAIN BOARD

LED BOARD

AMP BOARD

PANEL BOARD

REG BOARD

SW BOARD

POWER BOARD

LOADING BOARD

14

Loading...

Loading...