Page 1

kÉï=~ë=çÑW=

NMKOMMR

H

`OHI=`PHI=`QHI=`RHI=jN

pЙкобЕЙ=j~ем~д===== =

bеЦдблЬ

IMPORTANT:

• In case of faults which you are unable to eliminate with the help

of this manual, please contact our Customer Service Center.

• It is essential that you take this Service Manual along with you

on every customer call.

Furthermore, you must always have the spare parts list and wiring diagrams with you as well.

You can order additional copies of this Service Manual under the

• order number 58 77 977 from our department DZL 1 in Bensheim.

See reverse side of manual for address.

Page 2

Page 3

kÉï=~ë=çÑW=

NMKOMMR

H

`OHI=`PHI=`QHI=`RHI=jN

pЙкобЕЙ=j~ем~д===== =

bеЦдблЬ

`O

H

H

`P

H

`Q

H

`R

jN

H

Page 4

Page 5

Contents

1 Important information..................................................................................................... 1 – 1

1.1 Technical data ...................................................................................................... 1 – 2

1.2 Warning and safety information............................................................................ 1 – 2

1.3 Symbols................................................................................................................ 1 – 2

1.4 Abbreviations........................................................................................................ 1 – 3

1.5 Minimum configuration ......................................................................................... 1 – 4

1.6 Where to save user-specific data in the C2

+

, C3+, C4+, C5+, M1+...................... 1 – 4

2 Overview of modules and PCBs.................................................................................... 2 – 1

3 Points to observe during assembly................................................................................ 3 – 1

3.1 Patient chair ......................................................................................................... 3 – 2

3.2 Protective ground / electronic ground................................................................... 3 – 2

3.3 MV1 / AD3 ............................................................................................................ 3 – 2

3.4 Connecting the water Unit/assistant element: ...................................................... 3 – 2

3.5 Assistant element: ................................................................................................ 3 – 3

bеЦдблЬ

4 What happens after switch-on? ..................................................................................... 4 – 1

4.1 Sequence of events.............................................................................................. 4 – 2

4.2 Checking the CAN BUS ....................................................................................... 4 – 5

4.3 CAN BUS wiring diagram ..................................................................................... 4 – 8

5 Description of the functions of ... ................................................................................... 5 – 1

5.1 Control panel / PCB AP........................................................................................ 5 – 2

5.2 Chair control/PCB CJ ........................................................................................... 5 – 3

6 How it works ... .............................................................................................................. 6 – 1

6.1 ... Water supply .................................................................................................... 6 – 2

6.2 ... Tumbler filling ................................................................................................... 6 – 2

6.3 ... Cuspidor flushing.............................................................................................. 6 – 2

6.4 ... Motor SL / EL1 ................................................................................................ 6 – 4

6.5 ... highspeed handpiece ....................................................................................... 6 – 6

6.6 ... ultrasound......................................................................................................... 6 – 8

6.7 ... Sprayvit ............................................................................................................ 6 – 9

6.8 ... Polylight in the assistant element ..................................................................... 6 – 9

6.9 ... Polylight Mini LED in the assistant/dentist element.......................................... 6 – 9

6.10 ... X-ray image viewer........................................................................................... 6 – 10

7 Points to observe when changing the ........................................................................... 7 – 1

7.1 …ADX/CJ board Serial No.

7.2 ... ADX PCB in the dentist element ...................................................................... 7 – 3

7.3 ... Water heating voltage for Sprayvit ................................................................... 7 – 3

7.4 ... PCB HP in the assistant element ..................................................................... 7 – 3

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

≥ 70,000 .................................................................. 7 – 3

I

Page 6

Contents

8 Service LEDs................................................................................................................. 8 – 1

9 Option list....................................................................................................................... 9 – 1

10 Reading out service codes ... ........................................................................................ 10 – 1

10.1 on the display of the dentist element.................................................................... 10 – 2

10.2 ... using a notebook link to the C2

+

, C3+, C4+, C5+, M1+..................................... 10 – 3

11 Service code listings...................................................................................................... 11 – 1

11.1 Service messages of the connection box (AK) ................................................... 11 – 2

11.1.1 Software version: 1.6 - 5.8, revision date 08.2004

11.2 Service messages of the dentist element (AE) ................................................... 11 – 6

11.2.1 Software version: 1.5 - 2.37/3.37, revision date 01.2005

11.3 Service messages of the dentist panel (AP) ....................................................... 11 – 14

11.3.1 C2+– C5+: Software version: 1.7 - 5.8, revision date 08.2004

11.4 Service messages of the assistant element (HE) ................................................ 11 – 15

11.4.1 Software version: 1.4 - 2.3, revision date 10.2004

11.5 Service messages of the water unit (WE) ............................................................ 11 – 19

11.5.1 Software version: 1. - 3.2, revision date 08.2005

+

M1

: Software version 10.3 , revision date 08.2004

II D 3370.076.01.06.02 10.2005

58 77 977 D 3370

Page 7

1 Important information

C2+, C3+, C4+, C5+, M1

+

Page 8

1 Important information

C2

+

C3

+

C4

+

1.1 Technical data

Model designation C2+, C3+, C4+, C5+, M1+, M1

+

Power supply 230V AC 50Hz,

115V AC 50/60Hz

Nominal current 4.5A at 230V

9.5A at 115V

Main unit fuse for 230V AC: T 6.3A H , 250V AC, Order No. 10 77 452

for 100/115 V AC: T 10A H, 250V AC, Order No. 10 77 460

1.2 Warning and safety information

Caution! Prior to opening the unit, connecting a measuring instrument or replacing

parts: Switch the unit OFF.

Protective ground connection The building water supply is at protective ground potential and must not touch

the fuse box of the chair.

Warning! If there is a protective ground contact, the patient or user may be exposed to

tension in the event of a fault - risk of electric shock!

Operational reliability To ensure operational reliability, the use of mobile telephones in the practice

or hospital area must be prohibited.

Troubleshooting: If you encounter difficulties, search in the error catalog first and proceed

according to the instructions given there.

C2

C3

C4

M1

1.3 Symbols

C2+ dentist element

+

+

C3

dentist element

+

+

C4

dentist element

+

+

C5

dentist element

+

C5

+

M1

dentist element

+

1 – 2 D 3370.076.01.06.02 10.2005

58 77 977 D 3370

Page 9

1 Important information

Assistant element

Patient chair

Water unit

1.4 Abbreviations

Dent. el. Dentist element

AK Connection box

COM Serial interface

EMC Electromagnetic compatibility

PCB Printed circuit board

FS Foot switch

FT Foot button

GND Ground

Ass. el. Assistant element

HW Hardware

KL Holder

L Cable

LCD Liquid Crystal Display

LED Light Emitting Diode

PC Personal Computer

S Switch

SDI Sirona Dental Interface (electrical, pneumatic, hydraulic plug connection)

ST Patient chair

SW Software

T Transformer

TR Support arm

VAC AC voltage

VDC DC voltage

WE Water unit

X Connector

+V

Galvanically isolated voltage

iso

bеЦдблЬ

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

1 – 3

Page 10

1 Important information

1.5 Minimum configuration

Component PCB Hardware

version

Software version

C2

+

Software version

+

+

C3

/C4

Software version

C5

+

Software version

M1

Dentist element ADX - 2.19 2.23 2.29 2.30

Dentist element AL - 4.0 4.0 4.0 4.0

Assistant element HC - 2.1 2.2 2.2 2.2

Water unit WE - 3.0 3.1 3.1 3.1

For PC networking PCB Hardware

version

Software version

C2

+

Software version

+

+

C3

/C4

Software version

C5

+

Software version

M1

Connection box CJ - 5.3 5.5 5.7 5.7

Dentist element AP - 5.2 5.4 5.7 10.2

1.6 Where to save user-specific data in the

Board

(Part no., designation)

Dentist element

(42 00 221, ADX)

+

C2

, C3+, C4+, C5+, M1

Stored settings Default value

Mode dialog:

Language (Engl., D, I, F, E)

Pressure indication (bar/PSI)

Cursor control (On/Off)

Foot switch mode (On/Off - adjustable)

Purge time (60 sec. to 120 sec.)

Service mode / Start - Stop)

Max. light voltage per instrument

+

-

English

PSI

ON

adjustable

120 sec.

STOP

3.6V

+

+

Cooling air for electric motor

Saline pump (holders 2, 3, 4, 5, 6, Off) C2

+

/M1

Saline pump (holders 2, 3, 4, 5, Off) C3+/C4+/C5

SIVISION (On/Off)

+

+

100% of input pressure

OFF

OFF

OFF

Instrument parameters:

Instrument light (On/Off)

Spray (On/Off)

OFF

High-speed handpiece: ON

Electric motor: OFF

(not programmable)

Direction of rotation (CW/CCW)

US: ON

CW

(storable, but is set to the default value the next time the

treatment center is turned on for safety reasons)

US intensity

Highspeed handpiece intensity

Intensity of electric motor 1

Intensity of electric motor 2

HF intensity

20

3.5 ±0.1 bar

40,000 rpm

20,000 rpm

20

Miscellaneous:

Sprayvit ventilation (Yes/No) NO

1 – 4 D 3370.076.01.06.02 10.2005

58 77 977 D 3370

Page 11

1 Important information

Board

(Part no., designation)

Assistant element

(42 00 650, ass. el.)

Water unit

42 00 627,

(

WE Air Water Sep.)

(42 00 619, WE)

Stored settings Default value

Mode dialog:

-------------------miscellaneous:

SPRAYVIT ventilation (Yes/No) NO

Mode dialog:

Tumbler filling with

S program (On/Off)

Cuspidor flushing with

S program (On/Off)

SIROLUX U-POS

(Sirolux switched on if dentist element is in place)

Miscellaneous:

Tumbler filling time

(2, 4, 6, 8, 10 sec.)

Flushing time

(20, 40, 60, 90, 150, 300, 360, 420 sec.)

SIROLUX intensity

(20, 40, 80, 90, 100%)

Suction intensity (4 levels)

OFF

ON

OFF

6 sec.

60 sec.

80%

100%

bеЦдблЬ

Chair

connection box

(58 63 480, CJ)

Dentist panel

(33 17 091, AP)

SIROLUX status with chair programs:

Program S (On/Off)

Program 0 (On/Off)

Program 1 (On/Off)

Program 2 (On/Off)

Mode dialog:

# key (switch/button)

Miscellaneous:

Chair programs 0, S, 1, 2, for users A and B;

(Position of: lift, backrest, travel track, tilting part)

User (A/B)

The dentist panel is not used for saving any data!

OFF

OFF

ON

ON

Switch

Factory program

A

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

1 – 5

Page 12

Page 13

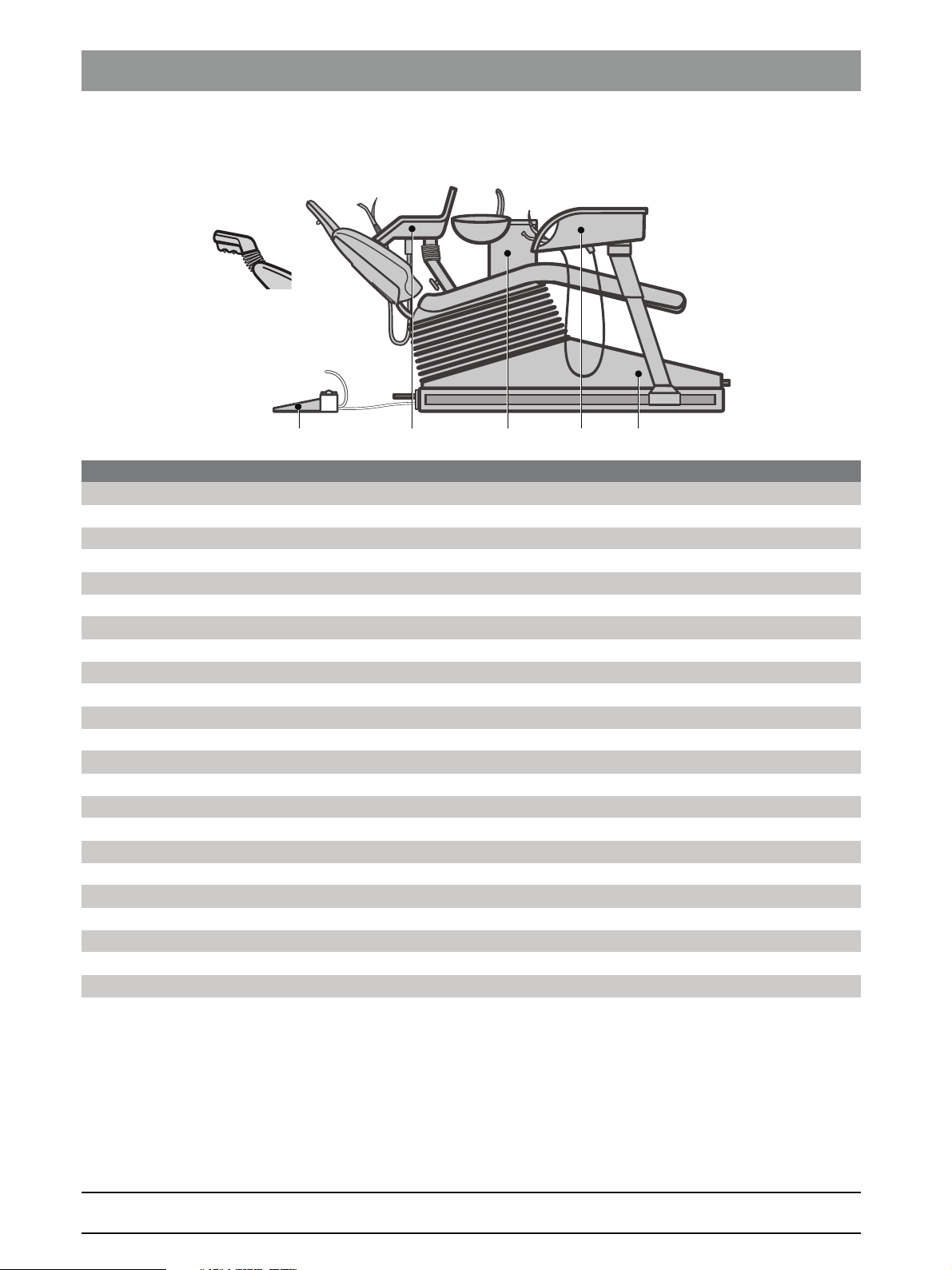

2 Overview of modules

and PCBs

C2+, C3+, C4+, C5+, M1

+

Page 14

2 Overview of modules and PCBs

H

`O

Component PCB / module

Dentist element (AE) AP = Control panel

ADX = Control PCB

AL = SIRONA motor SL module

AU = SIROSON module

HF = HF module

PL = Polylux

MI = Mini LED

CC = IR PCB

STAEHEFS WE

Assistant element (HE) HEP = Control panel

HC = Control PCB

HP = Power supply PCB

HI = Flexible PCB

PL = POLYLUX

MI = Mini LED

Water unit (WE) WE = Control PCB

Patient chair (ST) DI = SIROLUX

CJ = Control ST

CF = Fuse PCB

SR = Relay PCB

CK = Hand switch PCB

SL = Wiring PCB

KS = 4-way foot control

Foot switch (FS) CFS = Foot switch PCB

2 – 2 D 3370.076.01.06.02 10.2005

58 77 977 D 3370

Page 15

`P

H

Component PCB / module

Dentist element (AE) AP = Control panel

ADX = Control PCB

AL = SIRONA motor SL module

AU = SIROSON module

CC = IR PCB

2 Overview of modules and PCBs

bеЦдблЬ

STAEAss. FS WE

Assistant element (HE)

Water unit (WE) WE = Control PCB

Patient chair (ST) DI = SIROLUX

HEP = Control panel

HC = Control PCB

HP = Power supply PCB

RK = IR PCB

PL = Polylux

MI = Mini LED

CJ = Control ST

CF = Fuse PCB

SR = Relay PCB

SL = Wiring PCB

CK = Hand switch PCB

KS = 4-way foot control

Foot switch (FS) CFS = Foot switch PCB

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

2 – 3

Page 16

2 Overview of modules and PCBs

H

`Q

Component PCB / module

Dentist element (AE) AP = Control panel

ADX = Control PCB

AL = SIRONA motor SL module

AU = SIROSON module

CC = IR PCB

STAEAss. FS WE

Assistant element (HE) HEP = Control panel

HC = Control PCB

HP = Power supply PCB

RK = IR PCB

PL = POLYLUX

MI = Mini LED

Water unit (WE) WE = Control PCB

Patient chair (ST) DI = SIROLUX

CJ = Control ST

CF = Fuse PCB

SR = Relay PCB

SL = Wiring PCB

CK = Hand switch PCB

KS = 4-way foot control

Foot switch (FS) CFS = Foot switch PCB

2 – 4 D 3370.076.01.06.02 10.2005

58 77 977 D 3370

Page 17

`R

2 Overview of modules and PCBs

H

bеЦдблЬ

FS

Component PCB / module

Dentist element (AE) AP = Control panel

ADX = Control PCB

AL = SIRONA motor SL module

AU = SIROSON module

CC = IR PCB

Assistant element (HE) HEP = Control panel

HC = Control PCB

HP = Power supply PCB

RK = IR PCB

PL = POLYLUX

MI = Mini LED

Water unit (WE) WE = Control PCB

WV = WE and video interface

DI = SIROLUX

Patient chair (ST) CJ = Control ST

CF = Fuse PCB

SR = Relay PCB

SL = Wiring PCB

CK = Hand switch PCB

KS = 4-way foot control

WE

STAEAss.

Foot switch (FS) CFS = Foot switch PCB

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

2 – 5

Page 18

2 Overview of modules and PCBs

H

jN

FS

Component PCB / module

Dentist element (AE) AP = Control panel

ADX = Control PCB

AL = SIRONA motor SL module

AU = SIROSON module

HF = HF module

PL = Polylux

MI = Mini LED

CC = IR PCB

Assistant element (HE) HEP = Control panel

HC = Control PCB

HP = Power supply PCB

HI = Flexible PCB

PL = POLYLUX

MI = Mini LED

Water unit (WE) WE = Control PCB

Patient chair (ST) DI = SIROLUX

CJ = Control ST

CF = Fuse PCB

SR = Relay PCB

CK = Hand switch PCB

SL = Wiring PCB

KS = 4-way foot control

WEAss.

ST

AE

Foot switch (FS) CFS = Foot switch PCB

58 77 977 D 3370

2 – 6 D 3370.076.01.06.02 10.2005

Page 19

3 Points to observe during assembly

C2+, C3+, C4+, C5+, M1

+

Page 20

3 Points to observe during assembly

AD3

MV1

3.1 Patient chair

The patient chair can be moved without dentist element only if the

4-way foot control is installed.

3.2 Protective ground / electronic

A

ground

An equipotential bonding conductor must not be connected. If

present, isolate it!!

Measure the protective ground against electronic ground.

Measure continuity from A to B:

The continuity tester must not beep.

Assistant element

Water unit

Dentist element

X2.1 = gray

X2.2 = pink

X3.1 = gray

X3.2 = pink

X1.1 = gray

X1.2 = pink

A meter must show a reading of ∞ Ω.

B

3.3 MV1 / AD3

During assembly, decide whether the MV1 (version with disinfection system) or pressure reducer AD3 (version without disinfection system) is to be installed (see installation instructions).

3.4 Connecting the water Unit/assis-

tant element:

The 16V supply cables must be connected according to the color

coding to terminals X1, X2 and X3 on PCB CF in the connection

box.

58 77 977D 3370

3 – 2 D 3370.076.01.06.02 10.2005

Page 21

3 Points to observe during assembly

3.5 Assistant element:

The 16VAC and 24VAC cables are interconnected at the neutral conductors. If the conductors are switched, there will be

a short-circuit and fuse F 13 on PCB CF will blow. If no

medium time-lag fuse is fitted, PCB HP in the assistant element may be destroyed.

bеЦдблЬ

General Ensure proper installation of hoses and cables, do not allow them to be

crushed.

If hoses are interchanged, water will penetrate into the air supply system. This

may result in a failure of solenoid valves.

Crushed hoses and cables may cause failures on the entire treatment center.

Check the position of cables and media hoses before tightening any nuts.

EMC installation work EMC work that has not been performed correctly may result in faults which

are difficult to detect later on.

When all the installation work has been completed, measure the contact

resistance between protective ground and electronic ground (see 3.2 or

installation instructions).

3

58 77 977D 3370

D 3370.076.01.06.02 10.2005

3 – 3

Page 22

Page 23

4 What happens after switch-on?

C2+, C3+, C4+, C5+, M1

+

Page 24

4 What happens after switch-on?

BAR

BAR

50

50

PSI

PSI

BAR

BAR

50

50

PSI

PSI

BAR

BAR

50

50

PSI

PSI

BAR

BAR

50

50

PSI

PSI

4.1 Sequence of events

The unit transformer T1 is supplied with power via the unit main

switch S1.

The transformer supplies a voltage of 25VAC which is then rectified.

This results in a DC voltage (approx. + 35VDC).

S1

T1

READY

"READY" indicates that the treatment center is ready to

operate. This does not mean, however, that the treatment

center self-tests have been completed without errors.

Components AE, HE, WE and the chair (AK) are now supplied with + 35VDC

via fuse PCB CF, i.e., the required voltages (e.g., + 5V for logic, + 24V for

solenoid valves) are generated on the PCBs in the different components.

The 16VAC and 24VAC voltages in the unit are used primarily to power the

SPRAYVIT, water heater, camera supply and the halogen Polylight.

When the supply voltages are applied to the different components, the software on the PCBs powers up (boot procedure).

A self-test is performed on the treatment center in this phase, and is audible

(for example, solenoid valves respond and relays trip).

Current is measured to detect whether any of the components (solenoid

valve, relay, or motor) has 1. a short-circuit, 2. an open circuit.

These evaluations are written into the service info memory of the individual

components AE, HE, WE and chair (AK).

CAUTION

A message relating to an open circuit does not necessarily indicate a fault. If

an open circuit is detected and the component is nevertheless functioning

completely, the current measurement is only out of tolerance.

When the self-test has been completed, the LCD indicates READY.

The clock is also displayed

i

NOTE

The clock chip is located on PCB CJ in the connection box (chair).

If the clock is functioning properly, CAN communication between the components is generally in order.

The software recognizes ...: :

1. ... whether the treatment center is in a sanitation mode.

This signal comes from the water unit, PCB WE, via CAN communication.

CJ

If this is the case, it must be terminated or properly interrupted.

Interrupt sanitizing by simultaneously pressing the SPRAY ON/OFF and

CHIP BLOWER keys, AP SW version 5.4 and higher press intensity

R

R

I

I

S

S

BA

BA

P

P

5

5

0

0

R

R

I

I

S

S

BA

BA

P

P

5

5

0

0

1

R

R

I

I

S

S

BA

BA

P

P

5

5

0

0

R

R

I

I

S

S

BA

BA

P

P

5

5

0

0

Intensity key 1

SW version 5.4 and higher

in the AP

key for 3 sec. (assistant element:press the SAN key for 3 sec.).

SAN

58 77 977 D 3370

4 – 2 D 3370.076.01.06.02 10.2005

Page 25

4 What happens after switch-on?

. 2. ... whether the instrument configuration at the instrument

P21

R297

X30

ADX

flanges has changed since the last power ON.

This is detected by the different instrument hoses and their

coding.

If it is determined during power-up that the instrument configuration differs from the stored configuration (on the ADX PCB),

the instrument values will be set as follows:

– Highspeed handpiece to full power

– 1. Motor to 40,000 rpm

– 2. Motor to 20,000 rpm

HP

– Ultrasound to 20

CAUTION

The heater and the light in the SPRAYVIT remain turned off during

HC

initial start-up.

The water pump must execute at least 20 strokes before the heating and light are enabled. This applies to the SPRAYVIT both in

the dentist element and in the assistant element.

If the ADX PCBs in the dentist element and HC are replaced, the

pump must execute an additional 20 strokes.

When the self-test has been completed, the individual components can communicate with each other via a data bus system.

This system is called: "CAN BUS"

bеЦдблЬ

4

PCB

CJ

Jumper

plugs

must

be

present

PCB

WE

PCB

CJ

CAN BUS, data communication between PCBs C2+,C3+, C4+,

+

M1

,

PCB

HF

Option

C2

M1

PCB

ADX

+

+

PCB

AP

PCB

ADX

PCB

HF

Option

C2

M1

PCB

CJ

+

l

+

PCB

HC

PCB

CJ

Jumper

plugs

must

be

present

PCB

CJ

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

4 – 3

Page 26

4 What happens after switch-on?

CAN BUS, data communication between PCBs C5

The four components chair, dentist element, assistant element and water

unit are interconnected via a CAN serial interface.

The individual CAN drivers (transmitters and receivers for data communication) are arranged in the following order:

Chair = board CJ

Water unit = board WE

Assistant element = board HF

Dentist element = board ADX

Dentist element = board AP

Assistant element = board HC

+

The individual signals - for example, cuspidor flushing, tumbler filling, instrument motor ON and clock time - are transferred and relayed from component

to component via this system.

4 – 4 D 3370.076.01.06.02 10.2005

58 77 977 D 3370

Page 27

4 What happens after switch-on?

L

BAR

BAR

5050

PSI

PSI

BARBAR

50

PSI

PSI

4.2 Checking the CAN BUS

Is the clock running ?

If not, check whether the CAN connections are crushed, and

check for short-circuits and loose pins on the connectors.

CJ

505050

i

NOTE

Tip: The clock chip is situated on PCB CJ in the chair (connection

bеЦдблЬ

box).

4

I

I

S

S

BAR

BAR

P

P

Turn on SIROLUX FANTASTIC from the dentist side and from the

assistant side.

I

I

S

S

P

P

i

NOTE

Tip: In this way you check the CAN cabling and the functioning of

many PCBs.

The "Turn on SIROLUX" key information is passed from the dentist element panel (AP) to the connection box (CJ) and from there

on to the water unit (WE).

Here PCB WE drives the SIROLUX dimmer PCB.

It then turns the SIROLUX light on.

In addition, the relevant LEDs on the panels are activated by a

CAN message from the water unit.

Check the CAN BUS using the foot switch.

Move the chair with the cursor.

In this way you can test the section between foot switch, chair (connection

box) and panel.

i

NOTE

Information: You can move the chair with the 4-way foot control.

Tip:The 4-way foot control is not connected to the CAN; the chair also moves

when communication is no longer possible.

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

4 – 5

Page 28

4 What happens after switch-on?

PCB

CJ

Jumper

plugs

must

be

present

PCB

WE

PCB

CJ

60

Ω

+

OK

Measurements on the CAN bus system, C2+ – C4+, M1

1.

120

Ω

PCB

HF

Option

C2

M1

PCB

ADX

+

+

PCB

AP

PCB

ADX

PCB

HF

Option

C2

M1

PCB

CJ

+

+

PCB

HC

PCB

CJ

Jumper

plugs

must

be

present

If the functions of the dentist and assistant elements cannot be triggered, this

is indicative of an open circuit in the CAN BUS system.

Turn the unit OFF.

1. Measure Ω:

PCB

CJ

If you measure approx. 60Ω between X34.1B and X34.2B,

the CAN circuit is OK.

If you measure approx. 120Ω between X34.1B and X34.2B,

the CAN circuit is open-circuited.

2. Locate the open circuit.

Measure the CAN_High and CAN_LOW circuits one after the other.

e.g.: Measure CAN_High between X33.2B and X34.2A

– If you read approx. 2 -3

Ω, this circuit is OK.

– If you read ∞, both this circuit and CAN_LOW are open-circuited.

– If you read approx. 240

Ω, this circuit is open-circuited and the

CAN_LOW circuit is OK!

If an open circuit is found, it is now possible to individually check the

nodes on PCB CJ in order to locate the open circuit.

MeasureX33.2B > X34.2B >>> If there is an open circuit, then:

measure X33.2B > X31.2B >>> If no open circuit can be measured here,

i.e. you measure approx. 2 - 3

Ω, then the open circuit must be located in

the connection to the assistant element!

At this point it is highly probable that the open circuit can be easily located by

simply checking the cables and connectors, since the number of possible

errors is greatly reduced.

4 – 6 D 3370.076.01.06.02 10.2005

58 77 977 D 3370

Page 29

4 What happens after switch-on?

PCB

CJ

Jumper

plugs

must

be

present

Measurements on the CAN bus system, C5

+

60

Ω

OK

1.

120

Ω

Jumper

plugs

must

be

present

If the functions of the dentist and assistant elements cannot be triggered, this

is indicative of an open circuit in the CAN BUS system.

Turn the unit OFF.

1. Measure Ω:

If you measure approx. 60Ω between X34.1B and X34.2B,

the CAN circuit is OK.

If you measure approx. 120Ω between X34.1B and X34.2B,

the CAN circuit is open-circuited.

2. Locate the open circuit.

Jumper

plugs

must

be

present

bеЦдблЬ

4

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

Measure the CAN_High and CAN_LOW circuits one after the other.

e.g.: Measure CAN_High between X33.2B and X34.2A

– If you read approx. 2 -3

Ω, this circuit is OK.

– If you read ∞, both this circuit and CAN_LOW are open-circuited.

– If you read approx. 240Ω, this circuit is open-circuited and the

CAN_LOW circuit is OK!

If an open circuit is found, it is now possible to individually check the

nodes on PCB CJ in order to locate the open circuit.

MeasureX33.2B > X34.2B >>> If there is an open circuit, then:

measure X33.2B > X31.2B >>> If no open circuit can be measured here,

i.e. you measure approx. 2 - 3

Ω, then the open circuit must be located in

the connection to the assistant element!

At this point it is highly probable that the open circuit can be easily located by

simply checking the cables and connectors, since the number of possible

errors is greatly reduced.

4 – 7

Page 30

4 What happens after switch-on?

4.3 CAN BUS wiring diagram

CAN-HI

CANController

CAN-LO

PCB

CJ

120Ω

PCB

CJ

4.3.1 C2+ – C4+/M1

CAN-HI OUT CAN-HI OUT

X33.1B X5.1B

120Ω

120Ω

CAN-LO OUT CAN-LO OUT

X33.2A X5.2A

CAN-HI IN CAN-HI IN

X33.1A X5.1A

CAN-LO IN CAN-LO IN

Jumper

Board

WE

Jumper

Board

WE

X32.2B X3.2A X1.2AX2.2B X23.2AX2.2B

CAN-HI OUT CAN-HI IN CAN-HI INCAN-HI OUT

X32.1B X3.1A X1.1AX2.1B X23.1AX2.1B

CAN-LO OUT CAN-LO IN CAN-LO INCAN-LOOUT

X32.2A X3.2B X1.2BX2.2A X23.2BX2.2A

CAN-HI IN CAN-HI OUT CAN-HI OUTCAN-HI IN

X32.1A X3.1B X1.1BX2.1A X23.1BX2.1A

CAN-LO IN CAN-LO OUT CAN-LO OUTCAN-LO IN

CAN-HI OUT CAN-HI OUT

X31.2B X10.2

CAN-LO OUT CAN-LO OUT

X31.1B X10.4

CAN-HI IN CAN-HI IN

X31.2A X10.1

CAN-LO IN CAN-LO IN

X31.1A X10.3

CAN-HI OUT

X34.2B

CAN-LO OUT

X34.1B

CAN-HI IN

X34.2A

CAN-LO IN

X34.1A

Jumper

X33

X33.2B

X33.1B

X33.2A

X33.1A

X32.2B

X32.1B

X32.2A X5.2B X19.2A

X32.1A X5.1B X19.1A

X5.2A X20.2B X2.5 X23.2BX20.4 X2.2A X1.2A

X5.1A X20.1B X2.3 X23.1BX20.2 X2.1A X1.1A

PCB

WE

Jumper

Board

CJ

CAN-HI OUT

CAN-LO OUT

CAN-HI IN

CAN-LO IN

CAN-HI OUT

CAN-LO OUT

CAN-HI IN

CAN-LO IN

X20.2A X2.4 X23.2AX20.5 X2.2B X1.2B

X20.1A X2.2 X23.1AX20.3 X2.1B X1.1B

X19.2B

X19.1B

CAN-HIX33.2B X5.2B

CAN-LO

X19.2B

X19.1B

X19.2A

X19.1A

X20.2B

X20.1B

X20.2A

X20.1A

CAN-HI CAN-HI

CAN-LO CAN-LO

CAN-HI

CAN-LO

4.3.2 C5

Jumper

X19

CANController

PCB

WE

PCB

HF

CANController

PCB

HC

CANController

PCB

WV

+

CAN-HI

CAN-

CAN-LO

PCB

ADX

CANController

PCB

AP

Controller

+

PCB

ADX

PCB

AP

X31.2B X10.1

X31.1B X10.3

X31.2A X10.2

X31.1A X10.4

120Ω

X34.2B

X34.1B

X34.2A

X34.1A

Jumper

X33

PCB

HC

58 77 977 D 3370

4 – 8 D 3370.076.01.06.02 10.2005

Page 31

PCB

CJ

120Ω

120Ω

X33.2B

X33.1B

Jumper

X33

X33.2A

X33.1A

X32.2B

X32.1B

X32.2A X5.2B X19.2A

X32.1A X5.1B X19.1A

X31.2B

X31.1B

X31.2A

X31.1A

X34.2B

X34.1B

X34.2A

X34.1A

X5.2A X20.2B X2.5 X23.2BX20.4 X2.2A X1.2A

X5.1A X20.1B X2.3 X23.1BX20.2 X2.1A X1.1A

X20.2A X2.4 X23.2AX20.5

X20.1A X2.2 X23.1AX20.3

PCB

WE

X19.2B

X19.1B

Jumper

X31

Jumper

X33

4.3.3 C5+ Tur n

PCB

WV

X10.1

X10.3

X10.2

X10.4

PCB

HC

4 What happens after switch-on?

X2.2B X1.2B

X2.1B X1.1B

PCB

ADX

PCB

AP

bеЦдблЬ

4

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

4 – 9

Page 32

Page 33

5 Description of the functions of ...

C2+, C3+, C4+, C5+, M1

+

Page 34

5 Description of the functions of ...

AMALG

DESINF

AMALG

DESINF

40

20

0.2

rpm

x1000

AMALG

DESINF

AMALG

DESINF

C

5.1 Control panel / PCB AP

The panel control PCB [AP] in the C2+, C3+, C4+, C5+, M1+ and

+

forwards the request to operate from the panel to the relevant

M1

components via the CAN cable.

Green LEDs on keys: The green LEDs are status LEDs. The status (ON, OFF, FLASH-

ING) is signaled back by the components concerned to the panel

via the CAN cable. If the function is not activated, search locally

in the respective components. It is possible that an interlock is

active or that the option corresponding to the function has not

been installed.

Exception: The LEDs of the manual chair adjustment keys are

addressed directly by the panel.

Yellow cursor LEDs: The yellow cursor LEDs indicate the location of the cursor posi-

tioned with the help of the foot switch.

This cursor control can be deactivated in the Mode dialog.

Key click: Every key actuation on the panel and foot switch (exceptions: 4-

way foot control and keys on the tilting part) is confirmed by a key click.

This key click is generated on the panel.

If a key click is generated in response to a key operation, it can be assumed

that the keyboard is in order.

+

C2

M1

C4

A

+

A

+

–

Mode

+

RPM

–

+

–

Mode

A

+

–

Mode

+

C3

A

100

50

1

A/B

x1000

5 – 2 D 3370.076.01.06.02 10.2005

RPM

SS1100

–

+

–

Mode

22

40

100

30

0.2

rpm x 1000

0.2

rpm x 1000

0.2

rpmx1000

75

20

50

10

25

40

20

100

40

30

75

20

50

10

25

1

100

50

1

A/B

1

A/B

0

A/B

RPM

–

RPM

S10

2

SS1100

22

2

1

S

58 77 977 D 3370

Page 35

5 Description of the functions of ...

Self-test program: You can change the PCB to a self-test mode. When the operating voltage is

turned on, the plus and minus keys must be pressed simultaneously.

z All display elements are visible.

z The hardware version is shown on the display.

z The cursor LEDs flash continuously in quick succession.

z The LEDs on the keys light up when the relevant key is pressed and the

beeper generates a key click. There are no function LEDs for Mode, Plus

and Minus. Here, the value of the 7-segment display is incremented on

the display.

z Identification of the system: C2+, C3+, C4+, C5+ or M1+.

z The "service" LED flashes.

The test mode is terminated by turning off the operating voltage.

Service LEDs: z Green LEDs must light up in normal operating mode.

z Yellow LEDs can light up.

z Red LEDs light up in the event of a fault or safety problem.

LEDs:

Software update:

+5V +5V power supply present (green)

Service Flashes while the self-test program is running.

Lights up if the X-ray image viewer output is activated.

Reset The Reset LED lights up briefly when the unit is turned on.

Software can be updated by replacing external memory J2.

bеЦдблЬ

5

Clock: The clock is located on PCB CJ in the chair and is transmitted to the panel via

the CAN cable.

5.2 Chair control/PCB CJ

Board CJ basically contains the following functional units:

z Powerful controller

z CAN communication

CJ

z Battery-backed real-time clock (RTC)

z Nonvolatile data memory

z Control of 3 DC motors

z Control of 2 AC motors

z Solenoid valve control

z Proportional valve control (currently not available)

z Relay PCB control

z LED control

z Digital inputs

z Safety switches

z Limit switch

z Analog inputs

z Sivision control

z RS232

z HE support arm safety switch

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

5 – 3

Page 36

5 Description of the functions of ...

Power supply PCB CJ always requires two power supplies:

approx. 35VDC and 115VAC.

Other voltages are derived from the 35V supply voltage.

5V, 600mA (short-circuit-proof) digital logic

24V, 5A (short-circuit-proof) power electronics

5Vref, 20mA (short-circuit-proof) external potentiometers

5.5V, 100mA RS232 and Sivision (with optical isolation)

A 4.0V reference voltage is made available at the analog input of the controller. This reference voltage is required for diagnostic purposes and for electronic control.

There are three green LEDs (+35V, +24V and +5V) for power supply monitoring.

The 115VAC voltage is required for driving the lift and backrest motors. The

AC voltage is fed to the solid-state relays via a safety relay.

The freedom of movement of the motors is restricted by the potentiometers

and limit switches. In addition, there are other safety switches which can interrupt the chair movement immediately. If a safety switch is active, the motor is

blocked in a certain direction of travel.

The cuspidor safety switch is a special case. If this safety switch is active, the

115VAC are turned off by means of the safety relay and the red LED (115V

relay) lights up. The two motors (lift and backrest) are blocked.

Controller At the heart of the circuit is a powerful 16-bit controller (C167CS). The con-

troller controls and regulates the complete range of functions on PCB CJ.

The external oscillator frequency is 5MHz. A PLL boosts the operating frequency internally to 20MHz.

The reset signal is generated by a reset chip. If the voltage drops below

4.63V, reset is activated. The red RESET LED lights up during reset. When

the controller has finished booting, the LED is switched off. There is a reset

button on PCB CJ. This button can be actuated at any time to generate a

reset.

The controller features a monitoring unit, known as watchdog. If the watchdog

timer is not reset within a fixed timeout, the unit triggers a reset. This reset

changes the on-chip I/O to the reset state. For monitoring the watchdog control, an external port (P3.2) is toggled every time the watchdog is reset.

The controller features an internal CAN controller. The CAN bus forms a network within the treatment center. All PCBs are connected to the CAN bus.

Information can thus be exchanged between any two components via the

CAN bus. The beginning and end of the CAN bus are located on PCB CJ.

A terminating resistance of 120 ohms is defined at either end of the CAN

cable. 60 ohms are then measured during operation.

The DC motors (headrest motors and travel track) are driven with a PWM via

the controller. The direction of rotation is determined by switching a relay.

There are LEDs fitted at the output stages that indicate the direction of movement.

5 – 4 D 3370.076.01.06.02 10.2005

58 77 977 D 3370

Page 37

5 Description of the functions of ...

i

NOTE

Both conventional solenoid valves and proportional valves can be fitted on the

solenoid valve block.

A coding resistor in the MV cable enables electronics/software to decide which

type of control must be used.

Currently not available.

The foot switch, 4-way foot control and controls on the headrest are coded. If

a part is fitted while the unit is running, the configuration is updated immediately.

The yellow USER LED lights up when a switch is operated.

There is an RTC (real-time clock) on PCB CJ. The time on the treatment center is set by PCB AP.

Non-volatile data (such as error memory and chair parameters) are stored in

the battery-buffered SRAM.

There is a resistor network on the PCB for identifying the hardware status.

Battery The battery is a lithium type battery (Sonnenschein, type SL-350). These bat-

teries are characterized by their high capacitance at a very low self-discharge

rate. The battery voltage (VBAT) is 3.6V. When the unit is switched off, the

battery supplies the RTC and the 32KB SRAM. Battery life: > 10 years.

bеЦдблЬ

5

Requirement: Customer Service can recognize the production date of the battery to substi-

tute the PCB or change the battery, as necessary.

Safety switches Chair safety switches:

The safety switches inhibit the respective hazardous directions of chair

movement by means of hardware.

There are three safety switches associated with the chair:

Headrest SS (headrest HR), backrest SS (backrest BR) and toeboard SS

(toeboard TB).

Cuspidor safety switch:

When the cuspidor is swung in, the lift and backrest motors are blocked.

+

HE support arm safety switch, C3

The chair motors are blocked during lifting or lowering of the support arm.

/C4+/C5+/M1+:

Emergency Stop The movement stop of the lift and backrest motors can be activated by the

EMERGENCY STOP signal.

The motorized chair movement is completely disabled.

If the emergency stop is active, the red EMERGENCY STOP LED lights up.

Diagnostics When the supply voltage is applied, the green LEDs light up:

z +35VDC supply voltage (approx.)

z +24VDC supply voltage

z +5VDC supply voltage

The states of all inputs are indicated on PCB CJ by means of three LEDs: SS

LED (all safety switches), LIMITS LED (all limit switches) and USER LED (all

switches).

The error states of the outputs, relays, and solenoid and proportional valves

are indicated by the D-ERROR (drive error) LED.

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

5 – 5

Page 38

5 Description of the functions of ...

Red LEDs The LEDs light up only in the event of a fault or safety problem.

Reset LED System status: RSTOUT. The LED lights up while the reset button is held

down.

SS LED Permanently on while at least one of the following signals is active: SS TB,

SS BR, SS HR, SS1 bowl, SS2 HE support arm C3+/C4+/C5+/M1+.

D-Error LED The LED can light up (depending on the operating status of the system).

Switched to statically "on" by the software in case of a driver stage error

involving one of the following actuators:

MV1, MV16, MV35, EXT relay, CALL relay, SUCTION relay, bowl MV, MVP1,

MVP2, MVP3.

Definition of error cases:

EMERGENCY STOP LED

a) A channel to which an actuator is connected does not switch on (error

in driver stage or overcurrent cutout)

b) A channel to which an actuator is connected does not switch off

c) A channel to which no actuator is connected receives an enable

request

Permanently on when EMERGENCY STOP becomes active.

115V RELAY LED Permanently on when 115V relay is switched off because of safety switch.

The AC motors are blocked.

SERVICE LED Switched by software, any indication.

LIMITS LED Permanently on while at least one of the following signals is active:

z LS-LIFT up

z LS-LIFT down

z LS-BR incline

z LS-BR recline

z LS-HR up

z LS-HR down

USER LED Permanently on while at least one of the following signals is active:

z Headrest switch signal

z Foot switch signal or

z 4-way foot control signal

Motor activation is signaled by two yellow LEDs for each function.

z LIFT up and LIFT down LED (lift motor)

z BR incline and recline LED (backrest motor)

z HR output and input LED (headrest extension motor)

z HR incline and recline LED (headrest incline/recline motor)

z TRACK forward and backward LED (travel track motor)

z CLUTCH LED (travel track clutch)

5 – 6 D 3370.076.01.06.02 10.2005

58 77 977 D 3370

Page 39

C2+, C3+, C4+, C5+, M1+

6 How it works ...

Page 40

6 How it works ...

BAR

BAR

5050

PSI

PSI

BAR

BAR

50

PSI

PSI

6.1 ... Water supply

Level sensor DS31, which is located in the mixing tank, sends a

signal to PCB WE in the water unit when the water reaches a low

level and indicates this by means of LED V76.

After the "Low water level" signal has been detected by PCB WE,

pump P performs a precisely defined number of strokes after a

load has been activated. PCB WE then generates a CAN data

signal, which is received by PCB CJ in the chair. MV1 opens and

water flows into the mixing tank. PCB WE then registers the time

that elapses until DS31 is reactivated and calculates the time until

the tank is filled. When the time has elapsed, PCB WE sends a

CAN data signal to PCB CJ, and MV1 closes.

6.2 ... Tumbler filling

R

R

I

I

S

S

BA

BA

P

P

board of the dentist element (PCB AP) or assistant element (PCB

HEP).

The key signal generates a CAN data signal in the dentist ele-

The tumbler filling function is activated on the membrane key-

A

ment (PCB AP) and in the assistant element (PCB HC), which is

sent to PCB WE, where it activates the tumbler filling function,

with MV34 opening for the programmed time interval.

The opening time is stored on PCB WE.

When the time has elapsed or when the tumbler filling key is

pressed again, MV34 closes.

If the tumbler filling key is pressed for more than 3 seconds, the

settings dialog for the tumbler filling time appears.

6.3 ... Cuspidor flushing

R

R

I

I

S

S

BA

BA

P

P

505050

The cuspidor flushing function is activated on the membrane keyboard of the dentist element (PCB AP) or assistant element (PCB

HEP).

The key signal generates a CAN data signal in the dentist element

(PCB AEP) and assistant element (PCB HC), which is sent to

PCB WE in the water unit. The amalgam separator starts up. A

CAN data signal to PCB CJ in the chair then activates MV35.

MV35 opens for the programmed time interval. The time interval

is stored on PCB WE. When the time has elapsed or when the

bowl flushing key is pressed again, MV35 closes. The flow can be

set by means of regulating inductor RD35.

Monitoring function of water monitor DN30.

If water monitor DN30 is activated for more than 12 seconds, cuspidor flushing is interrupted.

A CAN data signal to PCB CJ in the chair deactivates MV35. This

A

status is written to the error memory.

While cuspidor flushing is active, the LEDs of the corresponding

keys on both the dentist element panel and assistant element

panel light up, irrespective of the panel from which the function

was triggered.

If the bowl flushing key is pressed for more than 3 seconds, the

settings dialog for the bowl flushing time appears.

6 – 2 D 3370.076.01.06.02 10.2005

58 77 977 D 3370

Page 41

6 How it works ...

Connetion box / chair Water unit

MV1

Water

MV1

PCB

CJ

PCB

CJ

Inactive

Measurement of filling time

Level after a

certain number

of pump strokes

Water monitor

DN30

Mixing tank

with

level sensor

DS31

Pump P

RD35

filling time x tank volume

Full =

measured volume

Mixing tank

DS31 level sensor

LED

V76

PCB

WE

PCB

WE

bеЦдблЬ

6

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

6 – 3

Page 42

6 How it works ...

+

+

BAR

BAR

5050

PSI

PSI

BARBAR

50

PSI

PSI

6.4 ... Motor SL / EL1

A

–

A

NO COOLING AIR

–

Mode

Mode

Remove the motor from its holder.

RPM

The motor setting appears on the LC display of the dentist element

(only if PCB ADX in the dentist element detects that a Siromot module is

present).

The solenoid valve module (MV21.1 to 4) assigned to the motor is activated

(one of LEDs V69, V74, V79, V110 on PCB ADX lights up, depending on

which module is activated).

The relay for motor and instrument voltage assigned to the motor is activated

(one of LEDs V57, V60, V63 on PCB ADX lights up, depending on which relay

is activated).

Actuate foot switch S1.

PCB CJ in the connection box/chair then sends a CAN data signal to PCB

ADX in the dentist element and starts the motor.

PCB ADX then sends a CAN data signal to PCB CJ and turns on the cooling

air (MVP1) for the motor (if a proportional valve is installed, with the intensity

preset under MODE).

If there is a problem with the CAN data communication, or if the solenoid

RPM

valves are recognized as faulty, the motor is not started. In addition, the ADX

software queries the cooling air pressure using pressure sensor P21.

If a cooling air pressure of < 0.5 bar is detected, ADX turns off the motor function.

The motor menu remains on the display and the display shows the message

–

+

"NO COOLING AIR".

Spray preselection:

R

R

I

I

S

S

BA

BA

P

P

When the spray key is pressed (the LED of the corresponding key lights up),

a CAN data signal is generated on PCB AP in the dentist element and is sent

to PCB ADX. This in turn activates solenoid valve MVP3 for spray air on PCB

CJ via CAN (if the foot switch is active).

Instrument light preselection:

I

I

S

S

P

P

505050

When the light key is pressed (the LED of the corresponding key lights up),

the light supply is activated on PCB ADX (if the foot switch is active).

–

Mode

Motor functions:

ON/OFF - adjustable, can be adjusted in the Mode menu.

ON/OFF: The motor runs at the programmed speed when the foot

switch is operated.

Adjustable: The motor speed is controlled in proportion to the position of

the foot switch (gas pedal).

If the function is set as adjustable, boards CJ and ADX continuously exchange data on account of the foot switch position.

The motors obtain their supply voltage from the Siromot module, which is controlled by PCB ADX.

6 – 4 D 3370.076.01.06.02 10.2005

58 77 977 D 3370

Page 43

V30

Connection box / chair Dentist element

+

PCB

ADX

MV valves

PCB

CJ

P21

V63

K2

V69

V27

V74

V30

V60

K3

V89

V49

V98

V84

Modules, MV21.1 ... 4

V79

V110

V57

K4

6 How it works ...

PCB

AL

Electric motor

C2

C3

C4

M1

+

+

+

bеЦдблЬ

6

X32.2B H out

PCB

CJ

X6.3A X21.1 ... 6 X20 ... X14/15/16.2A/B- X17.1/2

S1

Foot switch

X32.1B L out

X32.2A H in

X32.1A L in

Air

MVP1

MVP2

MVP3

Solenoid

valves

Connection box /

CAN

Water

Cooling / driving air

Chip blower

Spray air

Water unit

chair

X2.2A H in

X2.1A L in

X2.2B H out

X2.1B L out

Module

MV21.1 ... 4

PCB

ADX

PCB

ADX

Voltage for:

motor,

light

CJ

Modules, MV21.1 ... 4

MV valves

Serial interface

Data exchange

0 - 24V -

Instrument hose

Dentist element

PCB

AL

Electric motor

PCB

AL

Electric motor

C5

+

PCB

CJ

Foot switch

Module

MV21.1 ... 4

PCB

ADX

Voltage for:

motor,

light

PCB

WV

Water

Cooling / driving air

Solenoid

valves

Chip blower

Spray air

Air

Serial interface

Data exchange

Instrument hose

PCB

AL

Electric motor

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

6 – 5

Page 44

6 How it works ...

+

BARBAR

5050

PSI

PSI

BAR

BAR

50

50

PSI

PSI

6.5 ... highspeed handpiece

A

Remove the highspeed handpiece from its holder.

The highspeed handpiece menu is displayed on the LC display of the dentist

element.

bar

The module assigned to the highspeed handpiece is not activated until the

foot switch is actuated (one of LEDs V69, V74, V79, V110 on PCB ADX lights

up, depending on which module is activated). Actuate foot switch S1. PCB CJ

in the connection box/chair then sends a CAN data signal to PCB ADX in the

dentist element and starts the highspeed handpiece function. Board ADX

then sends a CAN data signal to board CJ and turns on the driving air (MVP1).

I

I

S

S

P

P

Spray preselection:

When the spray key is pressed (the LED of the corresponding key lights up),

a CAN data signal is generated on PCB AEP in the dentist element and is sent

to PCB ADX. This in turn activates solenoid valve MVP3 for spray air on PCB

R

R

I

I

S

S

BA

BA

P

P

5

5

0

0

CJ via CAN (if the foot switch is active).

Instrument light preselection:

When the light key is pressed (the LED of the corresponding key lights up),

–

Mode

the light supply is activated on PCB ADX (if the foot switch is active).

i

NOTE

Highspeed handpiece functions:

Direct starter - variable, selectable in the Mode menu.

Direct starter:

The highspeed handpiece runs at the programmed intensity when the foot

switch is actuated.

Var iable:

The highspeed handpiece speed is controlled proportionally in relation to the

position of the foot switch (accelerator). For both functions, PCB ADX sends a

CAN data signal to PCB CJ for the preselected values of the proportional

valves.Currently not available.

6 – 6 D 3370.076.01.06.02 10.2005

58 77 977 D 3370

Page 45

V30

Connection box / chair Dentist element

PCB

ADX

MV valves

PCB

CJ

P21

V63

K2

V69

V27

V74

V30

V60

K3

V89

V49

V98

V84

Modules, MV21.1 ... 4

V79

V110

V57

K4

6 How it works ...

Highspeed handpiece

C2

C3

C4

+

+

+

bеЦдблЬ

6

X32.2B H out

PCB

CJ

X6.3A X21.1 ... 6 X20 ... X14/15/16.2A/B - X17.1/2

S1

Foot switch

X32.1B L out

X32.2A H in

X32.1A L in

Air

MVP1

MVP2

MVP3

Sole-

noid

Connection box /

CAN

Water

Cooling / driving air

Chip blower

Spray air

Water unit

chair

X2.2A H in

X2.1A L in

X2.2B H out

X2.1B L out

Module

MV21.1 ... 4

PCB

ADX

PCB

ADX

Voltage for:

light

CJ

Modules, MV21.1 ... 4

MV valves

Instrument hose

Dentist element

Highspeed hand-

piece

Highspeed handpiece

C5

+

PCB

CJ

Air

Foot switch

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

PCB

WV

Water

Solenoid

valves

Cooling / driving air

Chip blower

Spray air

Module

MV21.1 ... 4

PCB

ADX

Voltage for:

light

Instrument hose

Highspeed hand-

piece

6 – 7

Page 46

6 How it works ...

V30

BAR

BAR

5050

PSI

PSI

V30

ADX

K2

V49

V84

V63

V89

A

P21

V27

V98

V30

6.6 ... ultrasound

%

CJ

V69

V74

V60

K3

V79

V110

V57

K4

R

R

I

I

S

S

BA

BA

P

P

Remove the ultrasonic handpiece from its holder. The ultrasound menu

appears on the LC display (only if PCB ADX in the dentist element detects

that an ultrasound module is present).

Actuate foot switch S1.

PCB CJ in the connection box/chair then sends a CAN data signal to PCB

ADX in the dentist element and starts the ultrasound function.

Solenoid valves MV22 (water; LED V49 on PCB ADX lights up) and MV23

(air; LED V84 on PCB ADX lights up) are activated.

The resonant circuit, ultrasound module PCB AU and ultrasonic handpiece

are activated.

When the light key is pressed (the LED of the corresponding key lights up),

the light supply is activated on PCB ADX (if the foot switch is active).

Connection box / chair Dentist element

PCB

ADX

P21

V63

K2

V69

V27

V74

V30

V60

K3

V79

V110

V98

X20.6B

PCB

ADX

MV 23

V57

K4

X17.1/2

Voltage for:

light

MV 22

Cooling air for light

Serial interface

Data exchange

Voltage for:

ultrasound

Instrument hose

PCB

CJ

X32.2B H out

PCB

CJ

X6.3A X20.6A

X32.1B L out

X32.2A H in

X32.1A L in

CAN

Water

X2.2A H in

X2.1A L in

X2.2B H out

X2.1B L out

V89

V49

V84

Modules, MV22, MV23

X20.1A

X20.1B

S1

Air

Air

PCB

AU

X2

Ultrasound module

Ultrasonic handpiece

PCB

X2

AU

Ultrasonic

handpiece

Foot switch

58 77 977 D 3370

6 – 8 D 3370.076.01.06.02 10.2005

Page 47

6 How it works ...

V30

BAR

BAR

5050

PSI

PSI

L

BARBAR

50

50

PSI

PSI

L

BAR

BAR

50

50

PSI

PSI

ADX

K2

V49

V84

V63

V89

A

P21

V27

V98

V30

6.7 ... Sprayvit

Remove the SPRAYVIT from its holder.

Only the preselected user - A or B - appears on the LC display.

Solenoid valves MV24 (water; LED V89 on PCB ADX lights up)

and MV25 (air; LED V98 on PCB ADX lights up) are activated.

V69

V74

V60

K3

V79

V110

V57

K4

If instrument light is programmed, the LED of the corresponding key lights up.

If the water or air key is pressed lightly, the instrument light is turned on.

If the air key is pressed fully, voltage is applied to the heating cartridge in the

handpiece and the air is heated.

The heating voltage is switched via a relay on PCB ADX and indicated by LED

V30.

If the water key is pressed fully, voltage is applied to the heating cartridge in

the handpiece and the water is heated.

The heating voltage is switched via a relay on PCB ADX and indicated by LED

V27.

I

I

S

S

P

P

5

5

0

0

CAUTION

The heater and the light in the SPRAYVIT remain turned off during initial startup. To vent the water pipes, the water pump must have performed at least 20

strokes before the heater and the light are enabled. This applies to the

SPRAYVIT both in the dentist element and in the assistant element. When

R

R

I

I

S

S

BA

BA

P

P

PCBs ADX in the dentist element and HC in the assistant element are replaced, another 20 pump strokes must be executed.

bеЦдблЬ

6

6.8 ... Polylight in the assistant element

Remove the Polylight from its holder.

R

R

I

I

S

S

BA

BA

P

P

5

5

0

0

The Polylight is operated with 16VAC from the power supply.

A switch-on pulse via the light button (if fitted on the assistant element) switches on the electronics.

The same pulse deactivates the electronics the second time.

A checkback signal to the assistant element indicates whether the

Polylight is still active.

This signal is also used to turn off the heating voltage (SPRAYVIT and spray

water heater); this protects the system from overload. The fan is driven by

board PL.

6.9 ... Polylight Mini LED in the assistant/den-

tist element

As soon as the treatment center is switched on, the MINI LED DC/DC module

(MI) is supplied with a 35VDC voltage.

Located in the treatment center is a

DC/DC converter which generates

the 5VDC supply voltage for the MINI

LED handpiece from the 35VDC

voltage.

In contrast to all other treatment center instruments the MINI LED is not

detected by the software, and therefore is not indicated on the dentist

element display.

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

6 – 9

Page 48

6 How it works ...

BAR

BAR

50

50

PSIPSI

+

B

A

The complete control or control electronics of the MINI LED is located in

the MINI LED handpiece.

The operating mode is activated and selected via keys A (ON/OFF) and

B (operating mode) on the MINI LED handpiece.

6.10... X-ray image viewer

The X-ray image viewer is supplied with 12VDC from PCB ADX.

The ground conductor is looped through panel control AP (connector X3).

When the X-ray image viewer key is pressed, the ground conductor is switched through to the X-ray image viewer or switched off

again.

A yellow service LED (V52) lights up on PCB AP when the X-ray

image viewer is active (visible through lateral EPROM opening).

+

Using the X-ray image viewer key with the C2

R

R

BA

BA

5

5

0

0

+

or M1+, three different functions can be controlled simulta-

M1

neously:

1. The X-ray image viewer on the tray support arm,

controlled by PCB WE.

The PCB returns a status signal via the CAN bus.

This signal causes the AP controller

to activate the green LED on the X-ray image viewer key

when PCB WE has switched on the X-ray image viewer.

2. With a PC connection of the camera or second monitor function, an RS232

command is sent via the interface of board CJ to the PC, which can generate a WHITE SCREEN (factory setting). No status feedback signal is generated, i.e. the green LED on the X-ray image viewer key does not light up.

3. X-ray image viewer on the dentist element (only C2

Pressing the X-ray image viewer key always activates the output

of panel control AP.

No status feedback signal is generated, i.e. the green LED on the

X-ray image viewer key does not light up.

, C3+, C4+, C5+,

+

/C4+/C5+/M1+).

i

NOTE

If both an X-ray image viewer on the dentist element and a PC connection (or

a second monitor) are available, the WHITE SCREEN is not required.

The Mode dialog has an option WHITE SCREEN YES - NO (factory setting is

YES).

This item must be set to NO in order to ensure that no alternating states will

occur between the X-ray image viewerand the WHITE SCREEN.

–

Mode

6 – 10 D 3370.076.01.06.02 10.2005

58 77 977 D 3370

Page 49

7 Points to observe when

changing the ...

C2+, C3+, C4+, C5+, M1

+

Page 50

Page 51

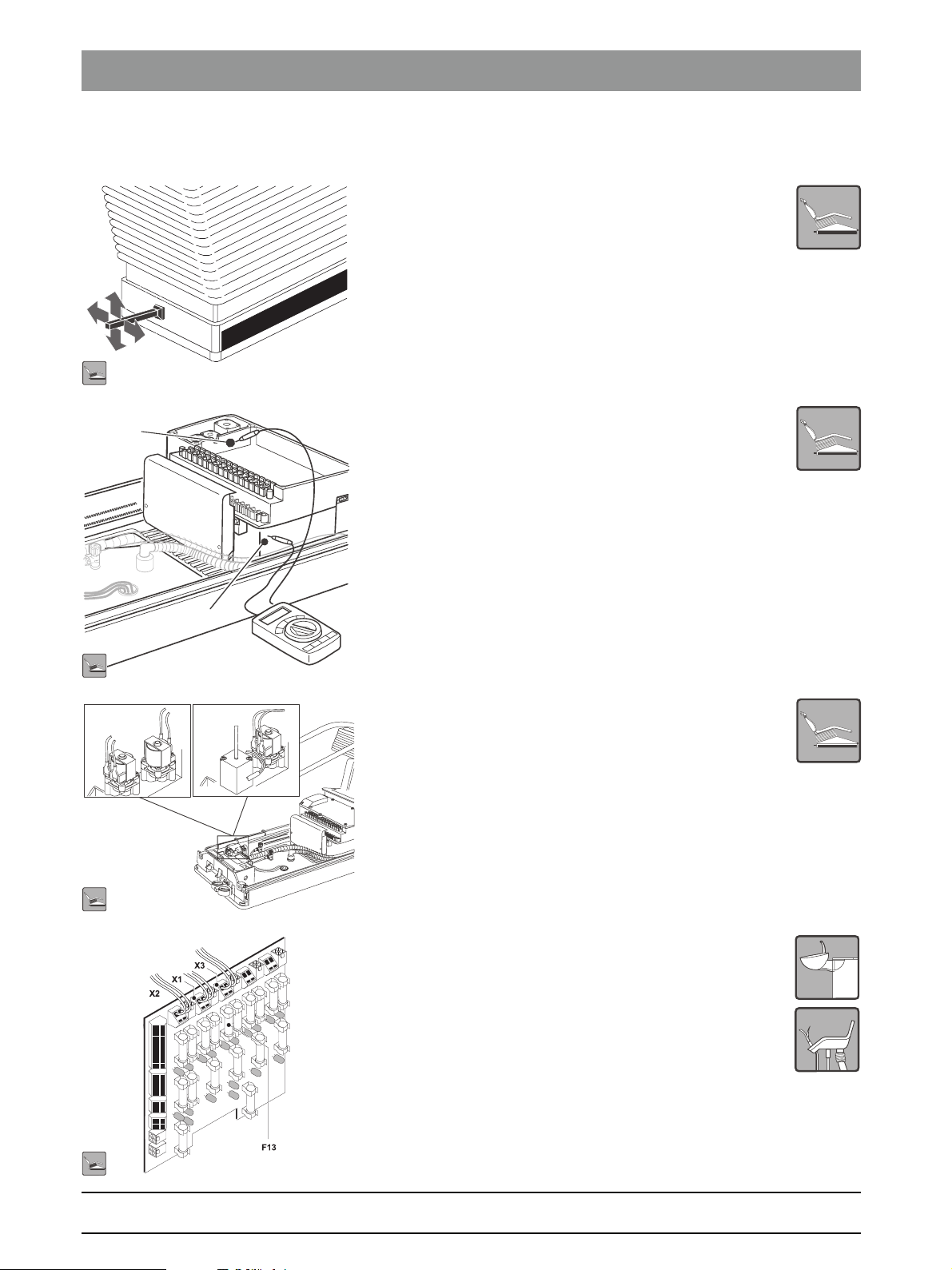

7 Points to observe when changing the ...

ADX

R297

HP

HC

7.1 …ADX/CJ board Serial No. ≥ 70,000

Install only the following no.

24V

X30

PCB Part No. Spare Part

No.

ADX 59 71 234 60 28 992 59 71 267

CJ 59 69 675 58 63 498 59 69 691

Repair Part No.

bеЦдблЬ

7

7.2 ... ADX PCB in the dentist element

A

P21

R297

X30

Set the air pressure indication / display for the highspeed

handpiece:

Remove highspeed handpiece

bar

Use resistor R297 to set the value 0.0 on the display, if necessary.

7.3 ... Water heating voltage for Sprayvit

16V

X30

The heating voltage (water) for the Sprayvit is factory-set to 24V on PCB

ADX.

You can reduce the heating voltage to 16V by resoldering the jumper at X30.

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

24V

JU1

16V

JU1

JU1

7.4 ... PCB HP in the assistant ele-

ment

Water heating voltage for Sprayvit:

The heating voltage (water) for the Sprayvit is factory-set to 24V on PCB HP.

You can reduce the heating voltage to 16V by resoldering the jumper at JU1.

7 – 3

Page 52

Page 53

C2+, C3+, C4+, C5+, M1+

8 Service LEDs

Page 54

8 Service LEDs

PCB LED Color Function

Dentist element

PC board

ADX

Dentist ele-

ment

PC board AP

V6

V12

V27

V30

V41

V49

V57

V60

V63

V69

V74

V79

V84

V89

V98

V110

V115

V116

V117

V134

V135

V138

V141

V145

V146

V50

V51

V52

YE

RD

YE

YE

RD

YE

YE

YE

YE

YE

YE

YE

YE

YE

YE

YE

GN

GN

GN

GN

GN

GN

YE

YE

YE

GN

RD

YE

NaCL pump ON

Fuse F1 for NaCL pump defective

Sprayvit water heater relay ON

Sprayvit air heater relay ON

Reset

MV22 US water

Holder relay K4 ON / motor voltage

Holder relay K3 ON / motor voltage

Holder relay K2 ON / motor voltage

MV21.1module solenoid valve, burr drive 1

MV21.2module solenoid valve, burr drive 2

MV21.3 module solenoid valve, burr drive 3

MV 23 solenoid valve, US air ON

MV 24 solenoid valve, Sprayvit water ON

MV 25 solenoid valve, Sprayvit air ON

MV21.4 module solenoid valve, drill drive 4 ON

+24V DC

+5V DC

+35V DC

+15V DC

+8V DC

+15V OP DC

Spray water heater ON

Polylight ON

Polylight fan ON

+5V

Reset, lights up briefly upon power up

X-ray image viewer output is switched through or flashes while the self-test

programm is running

Dentist element PCB

HF

Dentist ele-

ment

PC board AL

Dentist ele-

ment

PC board AU

V9

V23

V24

V25

V26

V27

V30

V31

V32

V34

V35

V1 RD BLx = flash code (e.g. BL1 = flashes once)

GN

GN

GN

GN

GN

RD

RD

GN

RD

LG

GN

HF output stage voltage

5V DC

Function check, flashes when software is OK

HF active

CAN monitoring, LED lights up in case of fault

Reset, lights up briefly during power up

Reset

RUN flashes 1-2 sec. > PCB in operation,

flashes ~ 3Hz foot switch in operation or FS signal active

BLx = flash code (e.g. BL1 = flashes once)

BL1: RAM error (internal RAM of microcontroller)

BL2: EPROM checksum error

BL3: PWM generator defective

BL4: 12V driver voltage outside of tolerance (+/-15%)

BL5: 32V operating voltage outside of tolerance (+/-15%)

BL6: One of the logical inputs or open collector outputs is defective

BL7: Flashes permanently, motor line open circuit (current below min.

level)

+32VDC

+8VDC

BL1: Handpiece not connected,

BL2: Oscillation frequency less than 27kHz,

BL3: Oscillation frequency exceeds 29kHz,

BL4: Bandwidth less than 8kHz,

BL5: Potentiometer not connected,

BL6: EPROM checksum error,

BL7: RAM in microprocessor defective

8 – 2 D 3370.076.01.06.02 10.2005

58 77 977 D 3370

Page 55

PCB LED Color Function

8 Service LEDs

Dentist element

PC board PL

Dentist element

PCB AKV

PCB LED Color Function

Patient chair

PC board CJ

V1

V39

V40

V106

V107

V110

V113

V114

V118

V120

V121

V122

V123

V200

V202

V203

V304

V401

V403

V405

V439

V440

V441

V442

V443

V444

V445

V446

V447

YE

YE

YE

GN

GN

GN

GN

YE

YE

YE

YE

YE

YE

YE

YE

YE

GN

YE

YE

YE

YE

YE

YE

YE

YE

YE

YE

YE

YE

+5V DC CPU supply

+12V DC

+5V DC supply voltage

+20V DC when supply voltage for AKV is present

+5V DC when supply voltage for digital circuitry is present

12V DC iso when camera is present

5V DC iso when power supply for camera electronics is present

Status Out when camera electronics report "CAMERA ACTIVE"

CamIn when power-on command for camera is sent by ADX

Contin1 when control sample signal 1 for camera is sent by ADX

Cont01 when control sample signal 1 is sent by AKV

Contin2, when control sample signal 2 for camera is sent by ADX

Cont02 when control sample signal 2 is sent by AKV

Tempsens when overtemperature protection is active

Lamp on for internal test purposes only

Power Lamp on, for internal test purposes only

Lamp+ when supply voltage for lamp and fan is active

Track backward

Track forward

Clutch travel track

HR recline

HR incline

HR in

HR out

BR incline

BR recline

Lift up

Lift down

Limits lights up when: LS Lift up, LS Lift down, LS HR inc, LS HR rec,

LS HR up, LS HR down

bеЦдблЬ

8

Patient chair

PC board CJ

V448

V449

V450

V451

V452

V453

V454

V455

V473

V474

YE

YE

RD

RD

RD

GN

GN

GN

RD

RD

Service, shows the programming mode

User Input lights up when:

headrest switch, unit foot switch, 4-way foot control

Emergency Stop

SS lights up when at least:

SS-TB, SS-BR, SS-HR, SS1_Bowl or EMERGENCY STOP is active.

D-Error is turned on with defect of:

MV1, MV16, MV35, Ext relay, Call relay, Suction rel., MV43, MVP1,

MVP2 and MVP3.

Fault scenarios:

A Actuator does not switch on, fault in driver stage or

overcurrent cutout

B Channel of an actuator does not switch off.

C Enable request to channel to which no actuator is connected.

+32V DC

+5V DC

+24V DC

LED lights up when:

115V RELAY is switched off when safety switches are active. Chair and

backrest motors are turned off.

Reset

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

8 – 3

Page 56

8 Service LEDs

PCB LED Color Function

Patient chair

PC board CF

PCB LED Color Function

Water

unit

PC board

WE

V16

V17

V18

V19

V20

V21

V22

V23

V24

V25

V28

V30

V32

V32

V35

V35

V36

V36

V40

V41

V69

V70

V71

V72/73

V74

V75

V76

V77/78

V79

V80

V82

V81/83

V84

V85

V86

V87

V88

V89 -91

V92

V101

V102

V103

V104

V105

V106

V107

V109

RD

RD

RD

RD

RD

RD

RD

RD

RD

RD

RD

RD

RD

RD

RD

RD

RD

RD

YE

YE

YE

YE

YE

YE

YE

YE

YE

YE

YE

YE

YE

YE

YE

YE

YE

YE

YE

YE

YE

RD

GN

GN

GN

GN

GN

GN

YE

WE F 1 35V DC

AE F 2 35V DC

HE F 3 35V DC

AK F 4 35V DC

NC F 5 35V DC

WE F 6 24V AC

AE F 7 24V AC

HE F 8 24V DC

AE F 12 16V AC

NC F 10 24V AC

HE F 13 16V AC

NC F 15 16V AC

WE F 11 16V AC

Sirolux F 18 24V AC

AK F 16 115V AC

115V AC F 16

115V AC F 17

AK F 17 115V AC

MV 33 Unit selector ON

Tumbler heater heating

Level switch DS 30, sep. tank empty

Safety switch S 3,

Amalgam rotor, tank closed

LED ON = no water, pressure switch DN 30

DS 33/34 reed contacts, water pump switch (flash alternately)

LED ON = disinfectant tank full, level switch DS 32

Not used

LED ON = water tank full, level switch DS 31

Not used

Tumbler filling/for S1 only

Cuspidor flushing/for S1 only

Vacuum active

Not used

Heater code recognition

MV 37 Solenoid valve of flow control valve

MV 40 Solenoid valve, water pump