Page 1

Model SK-FFT

Fire Fighters Telephone

Installation and

Operations Manual

Document 54711

08/12/13 Rev:

54711:B1 ECN 13-0704

B1

Page 2

Page 3

Installation Procedure

Installation Precautions - Adherence to the following will aid in problem-free

installation with long-term reliability: WARNING - Several different sources of power

can be connected to the fire alarm control panel. Disconnect all sources of power

before servicing. Control unit and associated equipment may be damaged by

removing and/or inserting cards, modules, or interconnecting cables while the unit is

energized. Do not attempt to install, service, or operate this unit until manuals are

read and understood. CAUTION - System Re-acceptance Test after Software

Changes: To ensure proper system operation, this product must be tested in

accordance with NFPA 72 after any programming operation or change in site-specific

software. Re-acceptance testing is required after any change, addition or deletion of

system components, or after any modification, repair or adjustment to system

hardware or wiring. All components, circuits, system operations, or software functions

known to be affected by a change must be 100% tested. In addition, to ensure that

other operations are not inadvertently affected, at least 10% of initiating devices that

are not directly affected by the change, up to a maximum of 50 devices, must also be

tested and proper system operation verified. This system meets NFPA requirements

for operation within the range of 0°C-49°C (32°F-120°F) or humidity within the range

of 10%-93% at 30°C (86°F) noncondensing. However, the useful life of the system's

standby batteries and the electronic components may be adversely affected by

extreme temperature ranges and humidity. Therefore, it is recommended that this

system and its peripherals be installed in an environment with a normal room

temperature of 15-27º C/60-80º F. Verify that wire sizes are adequate for all

initiating and indicating device loops. Most devices cannot tolerate more than a 10%

I.R. drop from the specified device voltage. Like all solid state electronic devices,

this system may operate erratically or can be damaged when subjected to lightning

induced transients. Although no system is completely immune from lightning

transients and interference, proper grounding will reduce susceptibility. Overhead or

outside aerial wiring is not recommended, due to an increased susceptibility to

nearby lightning strikes. Consult with the Technical Services Department if any

problems are anticipated or encountered. Remove DC power prior to removing or

inserting circuit boards. Failure to do so can damage circuits. Remove all electronic

assemblies prior to any drilling, filing, reaming, or punching of the enclosure. When

possible, make all cable entries from the sides or rear. Before making modifications,

verify that they will not interfere with battery, transformer, or printed circuit board

location. Do not tighten screw terminals more than 9 in-lbs. Over-tightening may

damage threads, resulting in reduced terminal contact pressure and difficulty with

screw terminal removal. Fire alarm control panels contain static-sensitive

components. Always ground yourself with a proper wrist strap before handling any

circuits so that static charges are removed from the body. Use static suppressive

packaging to protect electronic assemblies removed from the unit.

Follow the instructions in the installation, operating, and programming manuals.

Page 4

These instructions must be followed to avoid damage to the control panel and

associated equipment. FACP (Fire Alarm Control Panel) operation and reliability

depend upon proper installation.

Equipment used in the system may not be technically compatible with the control. It

is essential to use only equipment listed for service with your control panel.

Telephone lines needed to transmit alarm signals from a premise to a central

monitoring station may be out of service or temporarily disabled. The most common

cause of fire alarm malfunctions, however, is inadequate maintenance. All devices

and system wiring should be tested and maintained by professional fire alarm

installers following written procedures supplied with each device. System inspection

and testing should be scheduled monthly or as required by national and/or local fire

codes. Adequate written records of all inspections should be kept.

Page 5

Contents

Section 1

Overview ...................................................................................................................................................... 1-1

1.1 Features ...................................................................................................................................1-1

1.2 Optional Accessories ................................................................................................................1-2

1.3 Agency Requirements ..............................................................................................................1-2

1.4 About This Manual ...................................................................................................................1-2

1.5 How to Contact Silent Knight ....................................................................................................1-2

Section 2

Before you Begin Installing ................................................................................................ 2-1

2.1 Environmental Specifications ...................................................................................................2-1

2.2 Preventing Water Damage .......................................................................................................2-1

2.2.1 Removing the SK-FFT Assembly from the Housing ..........................................................2-1

2.3 SK-FFT Board Layout ..............................................................................................................2-2

2.4 Electrical Specifications ............................................................................................................2-4

2.4.1 Power Requirements .........................................................................................................2-4

2.4.2 Current Ratings ..................................................................................................................2-4

2.5 Wiring Specifications ................................................................................................................2-5

2.6 Wire Routing .............................................................................................................................2-6

Section 3

Installation ................................................................................................................................................. 3-1

3.1 Mounting the Cabinet ...............................................................................................................3-1

3.1.1 Surface Mounting ...............................................................................................................3-1

3.1.2 Flush Mounting ..................................................................................................................3-2

3.1.2.1 Cabinet Door and Dead Front Removal ...................................................................3-3

3.2 Installing the Fire Fighter’s Hand Set .......................................................................................3-4

3.3 FFT-24 Installation ...................................................................................................................3-5

3.4 Installing the SK-FFT ................................................................................................................3-7

3.5 Operating Power ......................................................................................................................3-7

3.6 DIP switch settings on SK-FFT ................................................................................................3-8

3.6.1 DIP Switch ........................................................................................................................3-8

3.7 SK-FFT Fire Fighter Telephone Module Connection ...............................................................3-9

3.8 FFT-FPJ Installation ...............................................................................................................3-10

3.9 Installation of FFT-STS ..........................................................................................................3-11

3.9.1 Assembly of Units with Coiled Cord Handsets .................................................................3-11

Section 4

SLC Device Installation ............................................................................................................ 4-1

4.1 List of SLC Devices ..................................................................................................................4-1

54711 1

Page 6

4.2 Maximum Number of Devices ..................................................................................................4-1

4.3 Wiring Requirements for SLC Device .......................................................................................4-2

4.3.1 Wiring SLC in Style 4 (Class B) Configuration ...................................................................4-2

4.3.2 Wiring SLC Devices in Style 6 & 7 (Class A)

Configuration ......................................................................................................................4-4

4.4 Addressing SK-Minimon SLC Devices .....................................................................................4-5

Section 5

Audio Phone Circuit Installation .................................................................................. 5-1

5.1 List of Devices ..........................................................................................................................5-1

5.2 Maximum Number of Devices .................................................................................................5-1

5.3 Wiring Requirements for the Audio Telephone Circuit .............................................................5-1

5.3.1 Single Phone Jack Audio Circuit in Class B Configuration ................................................5-1

5.3.2 Single Phone Jack Audio Circuit in Class A Configuration ................................................5-3

5.3.3 Multi-Phone Jack Audio Circuit in Class B Configuration ..................................................5-4

5.3.4 Multi-Phone Jack Audio Circuit in Class A Configuration ..................................................5-5

5.3.5 Telephone Jack Only Audio Circuit ....................................................................................5-6

Section 6

System Operation ............................................................................................................................ 6-1

6.1 Key Switch Operations .............................................................................................................6-1

6.1.1 JumpStart Key Switch (on inside of FFT dead front panel). ..............................................6-1

6.1.2 Accept Key Switch (on inside of FFT dead front panel). ....................................................6-1

6.1.3 Answer Switch ..................................................................................................................6-1

6.1.4 Silence Switch ....................................................................................................................6-1

6.2 LED Operations ........................................................................................................................6-2

6.2.1 Power Status LED ..............................................................................................................6-2

6.2.2 Answer ...............................................................................................................................6-2

6.2.3 Power .................................................................................................................................6-2

6.2.4 Local Handset Trouble .......................................................................................................6-2

6.2.5 Remote Handset Trouble ..................................................................................................6-2

6.2.6 General Trouble .................................................................................................................6-2

6.2.7 Status LEDs (on Inside of FFT dead front panel) ..............................................................6-3

6.2.8 Zone Active ........................................................................................................................6-4

6.2.9 Zone Trouble ......................................................................................................................6-4

6.3 JumpStart Operation ................................................................................................................6-5

Appendix A

Compatible Powering Devices ....................................................................................... A-1

Silent Knight Fire Product Warranty and Return Policy

Manufacturer Warranties and Limitation of Liability

Model SK-FFT Basic Operating Instructions

54711 2

Page 7

Section 1 Overview

An SK-FFT Fire Fighter Telephone System provides supervision, annunciation, and

control for local and remote telephone handsets. The SK-FFT with keypad, provides

indications of phone activation, and corresponding trouble conditions. Additionally, up

to 48 telephone circuits can be annunciated at the SK-FFT by connecting the FFT-24

zone expander.

1.1 Features

• One Form-C trouble relay:

System Trouble Relay - TB6

• SK-FFT Fire Fighter Telephone module for control and annunciation of up to 48

remote telephone jacks

• A maximum of 10 Fire Fighter Remote Handsets (FFT-RHS) can be used at one

time to communicate over the telephone circuit connected to the SK-FFT

• Fire Fighter Phone Jack (FFT-FPJ) provides a plug-in location for the FFT-RHS

• Single Telephone Station (FFT-STS)

• Fire Fighter Handset Cabinet (FFT-HSC) is used to store ten Fire Fighter

Handsets (FFT-RHS)

• System Status LEDs

• Supports a single FFT-24 zone expander

54711 1-1

Page 8

SK-FFT Installation and Operation Manual

1.2 Optional Accessories

This manual also contains information on how to install the following compatible

accessories with the FFT series equipment:

Model Number Description

FFT-24 24 Zone Expander

FFT-FPJ Remote Phone Jack

FFT-RHS Fire Fighters Remote Hand Set

FFT-HSC Fire Fighters Handset Cabinet

FFT-STSR Single Telephone Station Recessed

FFT-STSS Single Telephone Station Surface Mount

FFT-BGK Break Glass Kit for FFT-STS

SK-Minimon Addressable Mini-Monitor Module

SK-ISO SLC Line Isolation Module

1.3 Agency Requirements

The SK-FFT has the same requirements as the main control panel. These

requirements are listed in Silent Knight addressable FACP Installation Manuals.

Silent Knight Addressable FACP Installation Manuals can be found on Silent Knight’s

web site at www.silentknight.com.

1.4 About This Manual

This manual is intended to be a complete reference for all installation and operations

tasks for the SK-FFT. Silent Knight Installation Manuals can be found on Silent

Knight’s web site at www.silentknight.com.

Please let us know if the manual does not meet your needs in any way. We value

your feedback!

1.5 How to Contact Silent Knight

If you have a question or encounter a problem not covered in this manual, contact

Silent Knight Technical Support at 800-446-6444.

To order parts, contact Silent Knight Sales at 800-328-0103.

1-2 54711

Page 9

Overview

Limitations of Fire Alarm Systems

Requirements and recommendations for proper use of fire alarm systems including smoke detectors and other fire alarm devices:

• To keep your fire alarm system in excellent working order, ongoing maintenance is

required per the manufacturer’s recommendations and UL and NFPA standards.

At a minimum the requirements of Chapter 14 of NFPA 72, 2010 Edition shall be

followed. A maintenance agreement should be arranged through the local

manufacturer’s representative. Maintenance should be performed annually by

authorized personnel only.

The most common cause of an alarm system not functioning when a fire occurs is

inadequate maintenance. As such, the alarm system should be tested weekly to

make sure all sensors and transmitters are working properly.

54711 1-3

Page 10

SK-FFT Installation and Operation Manual

1-4 54711

Page 11

Section 2 Before you Begin Installing

This section of the manual is intended to help you plan your tasks to complete the

installation. Please read this section thoroughly, especially if you are installing a SKFFT for the first time.

2.1 Environmental Specifications

It is important to protect the SK-FFT control panel from water. To prevent water

damage, the following conditions should be AVOIDED when installing the units:

• Do not mount directly on exterior walls, especially masonry walls (condensation)

• Do not mount directly on exterior walls below grade (condensation)

• Protect from plumbing leaks

• Protect from splash caused by sprinkler system inspection ports

• Do not mount in areas with humidity-generating equipment (such as dryers,

production machinery)

When selecting a location to mount the SK-FFT, the unit should be mounted where it

will NOT be exposed to temperatures outside the range of 0°C- 49°C (32°F-120°F) or

humidity outside the range of 10% - 93% at 30°C (86°F) noncondensing.

2.2 Preventing Water Damage

Water damage to the fire fighters phone system can be caused by moisture entering

the cabinet through the conduits. Conduits that are installed to enter the top of the

cabinet are most likely to cause water problems. Installers should take reasonable

precautions to prevent water from entering the cabinet. Water damage is not covered

under warranty.

2.2.1 Removing the SK-FFT Assembly from the Housing

If it should ever be necessary to remove the control panel assembly from the cabinet

for repair, do so by removing the screws that hold the control panel in to the cabinet.

Do not attempt to disassemble the circuit boards.

54711 2-1

Page 12

SK-FFT Installation and Operation Manual

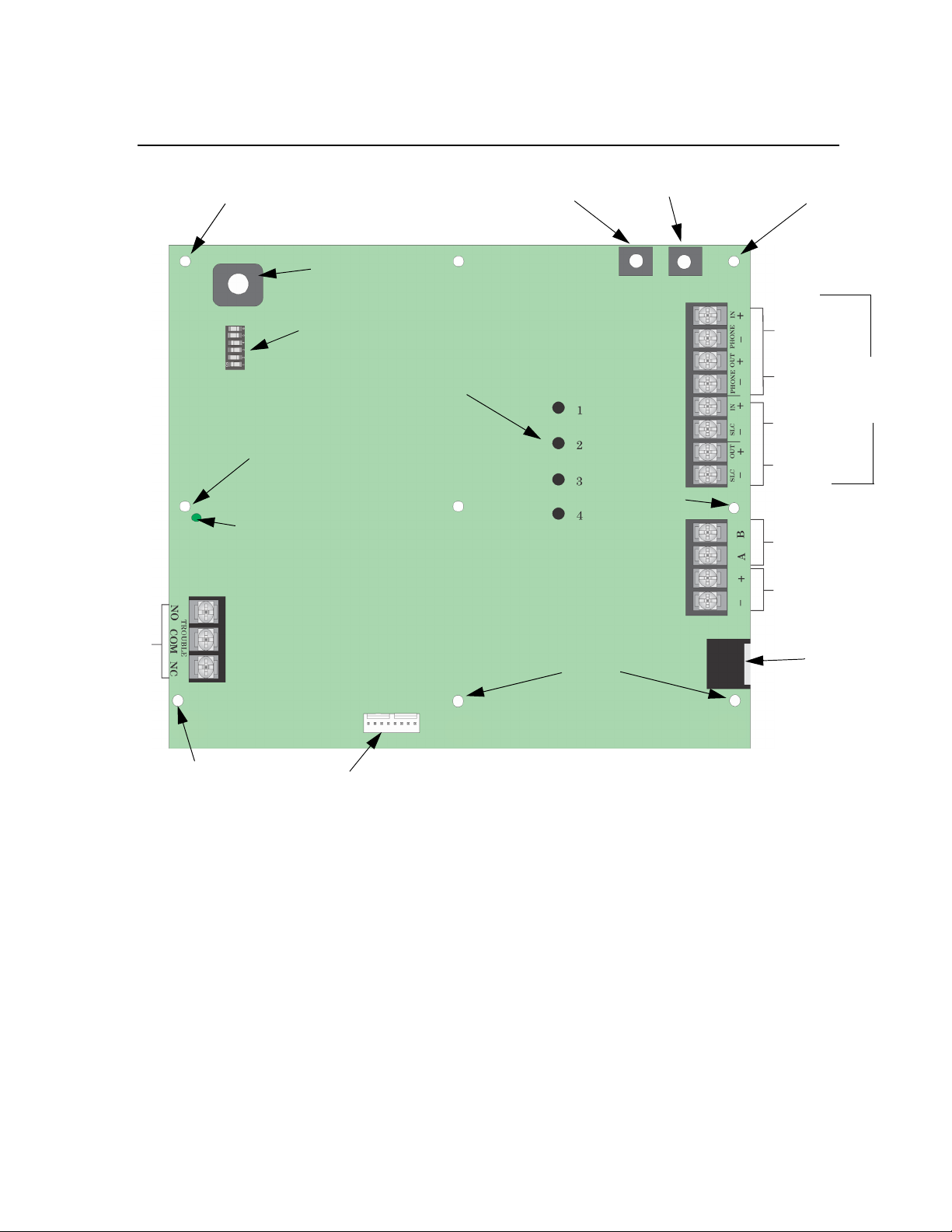

JumpStart

Accept

Connector for FFT-24

Status LED’s

Local

Handset

PZT

Phone In

Phone Out

SLC IN

SLC Out

Mounting

stud

Mounting stud

Supervised

Power

Limited

All circuits inherently

power limited except the

trouble relay

DIP Switch

Not

Used

DC

Power

Non Power

Limited

Mounting

stud

Mounting stud

Mounting stud

Mounting stud

Power Status

LED

2.3 SK-FFT Board Layout

Trouble

Relay

Figure 2-1 Back view of SK-FFT

Figure 2-1 shows the circuit board that attaches to the cabinet. If you should need to

remove the board assembly for repair, remove the seven mounting nuts which hold

the assembly in the cabinet. Then lift the control board out of the cabinet.

2-2 54711

Page 13

Before you Begin Installing

Active

(green)

Trouble

(amber)

Zone 1-

Zone 8

Zone 9 Zone 16

Answer LED

General Trouble LED

Zone 17 -

Zone 24

Zone 25

-Zone 32

Zone 33 Zone 40

Zone

41-

Zone 48

Active

(green)

Trouble

(amber

)

Figure 2-2 SK-FFT Front View

Figure 2-3 FFT-24 Expander Front View for Zone 25 - 48

54711 2-3

Page 14

SK-FFT Installation and Operation Manual

2.4 Electrical Specifications

2.4.1 Power Requirements

Voltage for the SK-FFT must be a power-limited, filtered, non resettable nominal 24

VDC source. The voltage source must be within the range of 17-29 VDC.

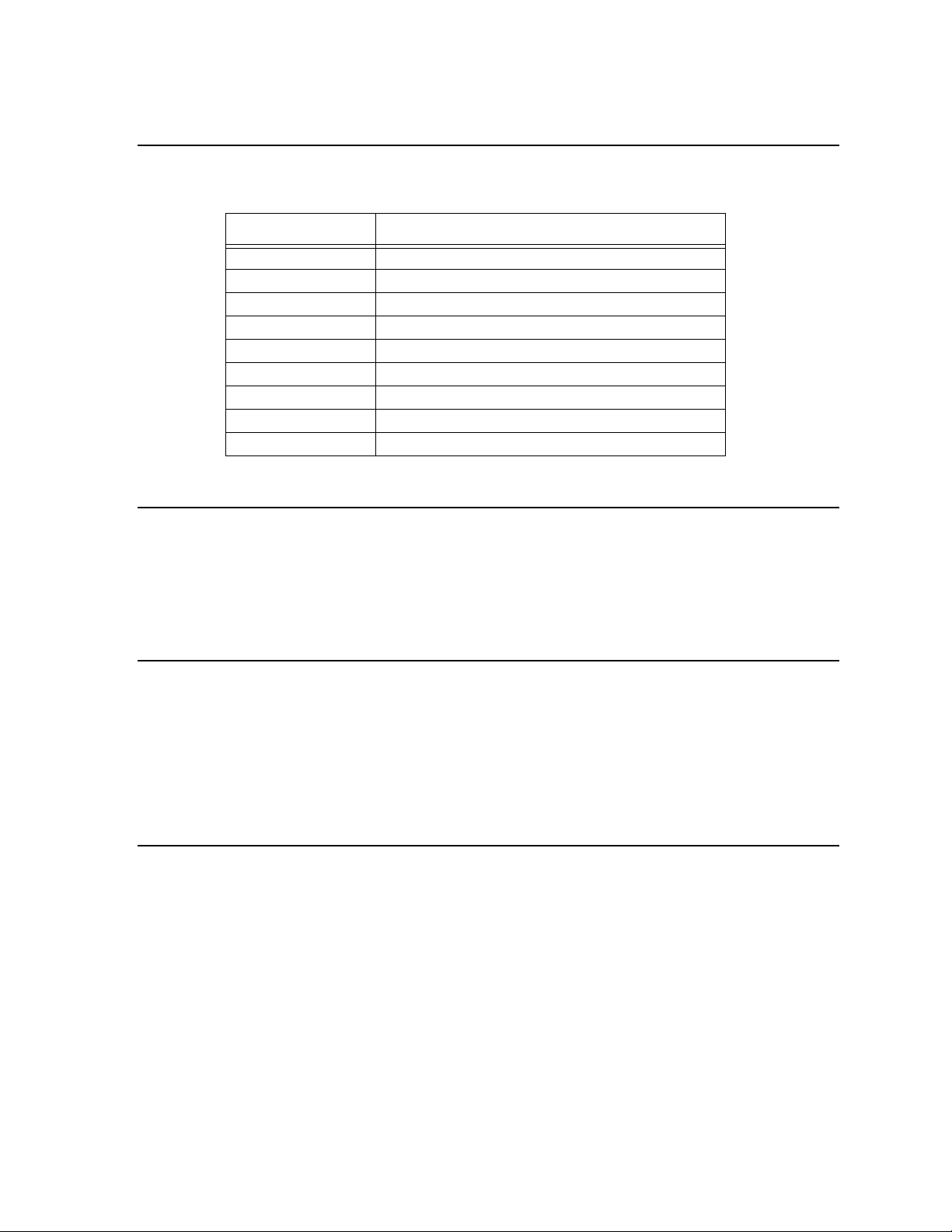

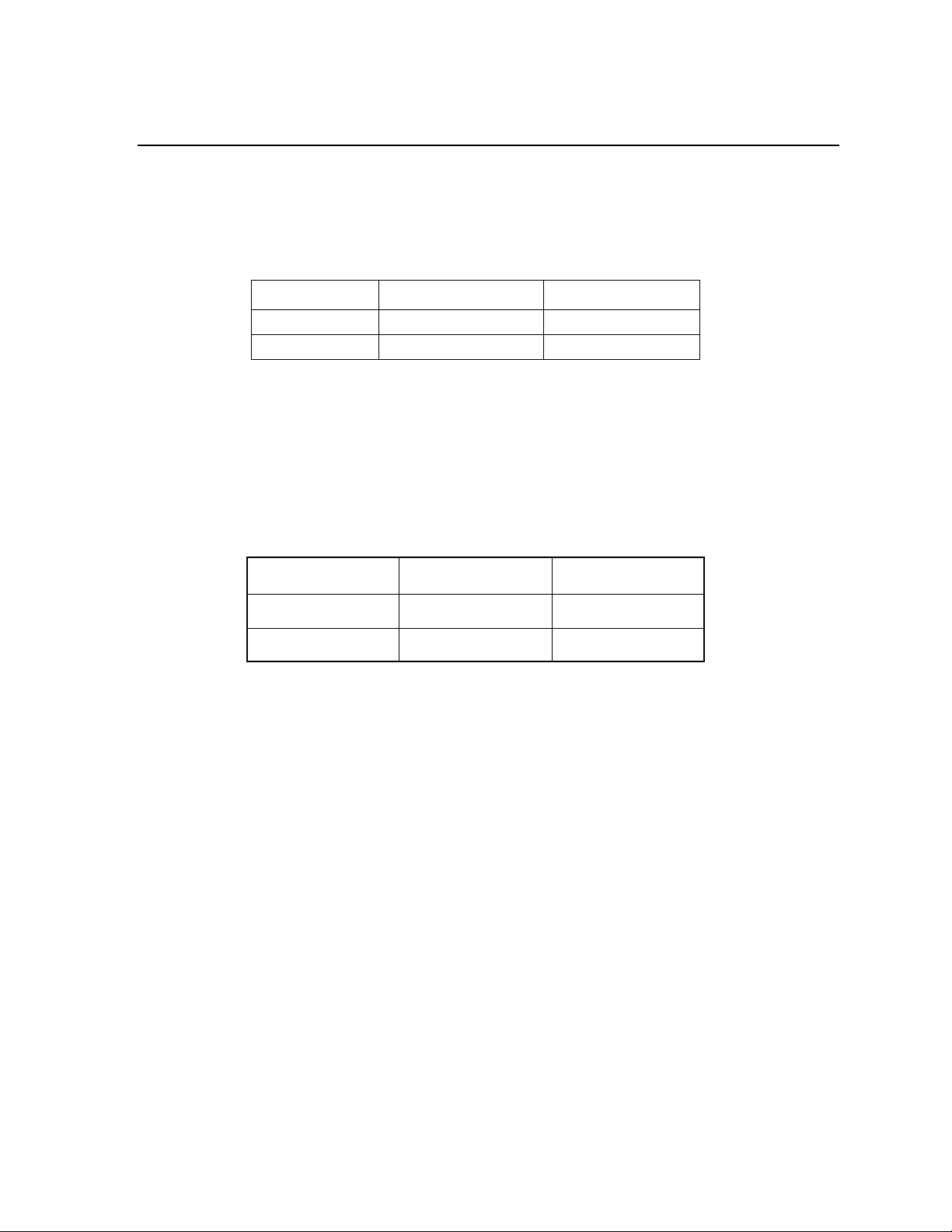

Table 2-1: Electrical Ratings

Circuits Voltage Current

SLC Circuits 32 V 150 mA

Audio Circuits 17 V 53 mA

2.4.2 Current Ratings

Maximum current ratings for determining backup battery requirements for alarm

(active) and standby conditions over the input voltage range of 17-29 VDC are shown

in Table 2-2.

Table 2-2: SK-FFT Current Draw

Active Standby

SK-FFT

FFT-24 25 mA 10 mA

230 mA 120 mA

2-4 54711

Page 15

Before you Begin Installing

2.5 Wiring Specifications

Induced noise (transfer of electrical energy from one wire to another) can interfere

with telephone communication or cause false alarms. To avoid induced noise, follow

these guidelines:

• Isolate input wiring from high current output and power wiring. Do not pull one

multi-conductor cable for the entire panel. Instead, separate the wiring as follows:

SLC loops Audio circuits

Relay circuit

• Do not pull wires from different groups through the same conduit. If you must run

them together, do so for as short a distance as possible or use shielded cable.

Twisted, shielded wire on the Audio Circuits is recommended for maximum

protection against EMI and AFI emissions and susceptibility. Connect the shield to

earth ground at the panel. You must route high and low voltages separately.

• Route the wiring around the inside perimeter of the cabinet. It should not cross the

circuit board where it could induce noise into the sensitive microelectronics or pick

up unwanted RF noise from the high speed circuits. See Figure 2-4 for an

example.

• High frequency noise, such as that produced by the inductive reactance of a

speaker or bell, can also be reduced by running the wire through ferrite shield

beads or by wrapping it around a ferrite toroid.

54711 2-5

Page 16

SK-FFT Installation and Operation Manual

Non-Power limited

Relay Circuit

Power Limited

Non power limited wiring

must be run separately from

power limited wiring

2.6 Wire Routing

You must follow power-limited wiring techniques, which include maintaining onequarter inch spacing between power-limited and non-power limited circuits and

separating high and low voltage circuits.

Figure 2-4 Wire Routing Example

2-6 54711

Page 17

Section 3

Bottom Mounting Holes

20"

26-½”

Installation

3.1 Mounting the Cabinet

Read the environmental specifications in Section 2.1 before mounting the SK-FFT

cabinet. This will ensure that you select a suitable location.

The cabinet can be surface or flush mounted. Do NOT flush-mount in a wall designed

as a fire break.

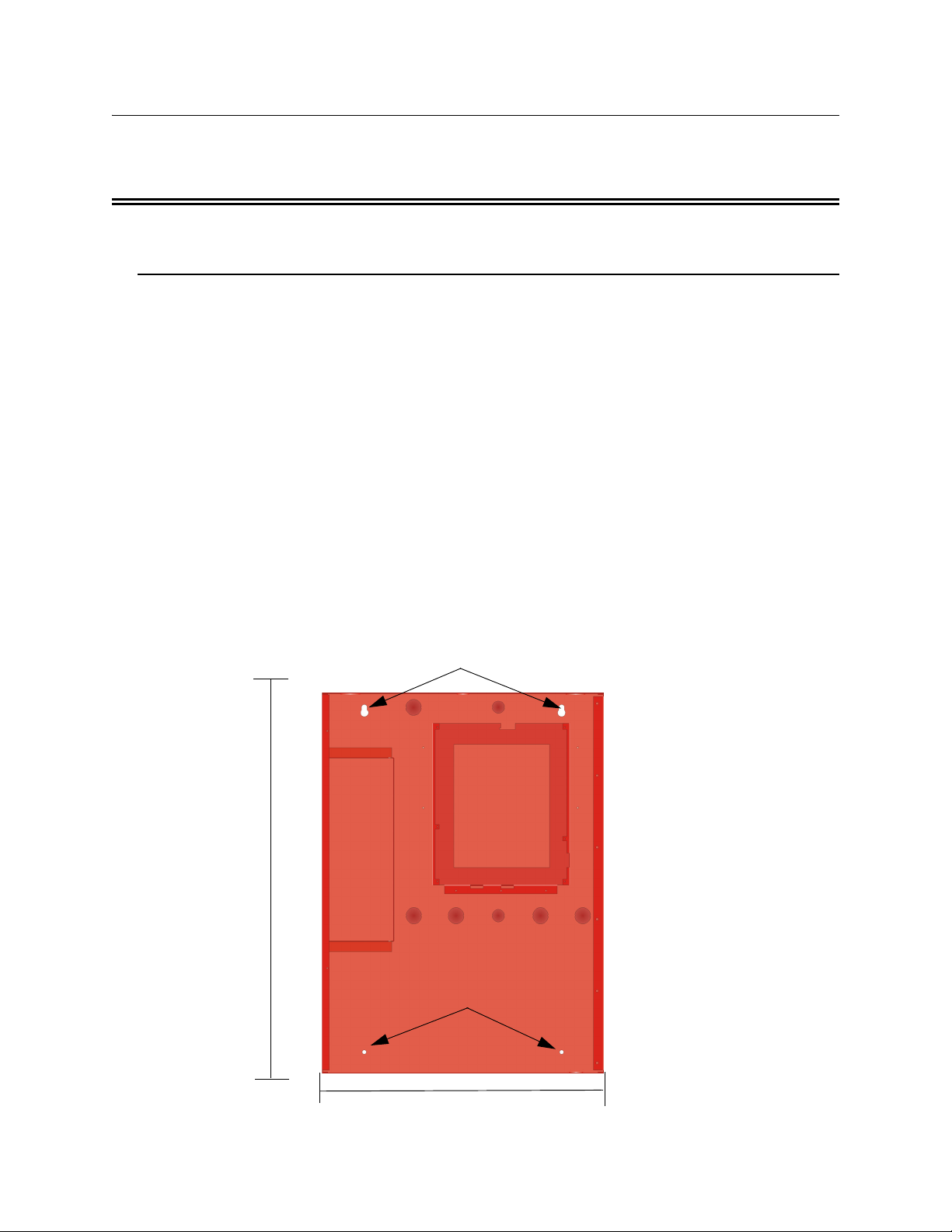

3.1.1 Surface Mounting

The Cabinet can be mounted on the wall surface by using the mounting holes in the

back of the cabinet (see Figure 3-1).

1. Insert two screws level with each other, 14" apart for the top cabinet key shaped

holes. See Figure 3-1.

2. Hang the cabinet onto the two screws. Tighten the screws down.

3. Insert two screws into the two bottom mounting holes and tighten them snug to the

cabinet.

Key Shaped Holes

Figure 3-1 Cabinet Mounting Holes

54711 3-1

Page 18

SK-FFT Installation and Operation Manual

Side View of Cabinet

Sheet Rock

Sheet Rock

Mounting

Studs

Cabinet

Mounting Hole

Trim Ring

Mounting

Hole

Cabinet

Mounting Hole

and Trim Ring

Trim Ring

1.5 to 1.75"

Trim Ring

Mounting

Hole

3.1.2 Flush Mounting

This section describes how to flush mount the cabinet into a wall. To recess mount

the cabinet you will need to have the optional trim ring P/N VIP-TR (ordered

separately).

Follow these steps to recess mount the cabinet:

1. Remove the cabinet door and the dead front panel.

2. Cut a recess hole 20-1/4” W x 26-3/4” H (51.44 cm W x 67.95 cm H). There

should be 1.5" to 1.75" of cabinet extruding from the wall, this should be measured

from either the top edge or bottom edge to the exterior side of the sheet rock. (See

Figure 3-2.)

Important!

Do not insert the cabinet deeper than recommend above. If the cabinet is mounted to deep you will

not be able to re-attach the door assembly.

3. Mount the cabinet to wall studs by inserting a screw through the cabinets side

mounting holes into the wall stud.

Figure 3-2 Detail of Flush Mounting with Trim Ring

3-2 54711

Page 19

Installation

Trim Ring

Cabinet

Cabinet Door

Dead

Front Panel

Dead Front

Panel Screws

Cabinet Door

Hex Nuts

4. Place the trim ring around the cabinet. See Figure 3-3.

Figure 3-3 Trim Ring Around cabinet

5. Secure the trim ring to the cabinet using the self-tapping sheet metal screws from

the inside of the cabinet into the trim ring.

6. Re-attach the cabinet door assembly.

3.1.2.1 Cabinet Door and Dead Front Removal

While installing the cabinet it may be necessary to remove the cabinet door and the

dead front panel. This section provides instructions on how to remove the door and

dead front panel.

1. Using a Phillips head screw driver, remove the six screws that hold the dead front

panel in place. See Figure 3-4.

Figure 3-4 Cabinet Door and Dead Front Panel Removal

2. Using a 1/4” Hex drive, remove the six Hex nuts that hold the cabinet door in

place. See Figure 3-4.

54711 3-3

Page 20

SK-FFT Installation and Operation Manual

Re-Attaching the Cabinet Door

To re-attach the cabinet door reverse the procedure in section 3.1.2.1.

3.2 Installing the Fire Fighter’s Hand Set

FFT Local Handset installation involves the following steps:

1. Insert phone cord through hole of dead front panel. See Figure 3-5.

Figure 3-5 Handset Cord Inserted Through Dead Front Panel Hole

2. Attach strain relief clip to the phone cord. The strain relief clip should have about 2

¾” of phone cord though it. See Figure 3-6.

Figure 3-6 Installing Strain Relief Clip

3. Push the strain into the hole in the dead front panel.

3-4 54711

Page 21

Installation

Mounting

Studs

Mounting

Studs

3.3 FFT-24 Installation

The FFT-24 expander board lets you add additional zones to the SK-FFT. To add

Zone 25 - Zone 48 to the SK-FFT, you must use FFT-24 expander board.

To install the FFT-24:

1. Open Cabinet door and dead front panel.

2. Remove power. See Appendix A for compatible powering devices.

3. Remove blank plate and discard.

4. Mount the FFT-24 on the six mounting studs located on the inside of the dead front

panel and secure using the nuts removed from the blank plate. See Figure 3-7.

54711 3-5

Figure 3-7 Mounting locations for the FFT-24

5. Connect one end of the wiring harness (P/N 130398 supplied) to the SK-FFT and

Page 22

SK-FFT Installation and Operation Manual

SK-FFT

the other end to the FFT-24 as shown in Figure 3-8.

Figure 3-8 Wire Harness Connection from SK-FFT to FFT-24 zones 25- 48

6. Restore power. See Section 3.5.

3-6 54711

Page 23

Installation

3.4 Installing the SK-FFT

SK-FFT installation involves the following steps:

• Make physical connection to any outputs that will power* the SK-FFT. (See

Section 3.5).

• Set the DIP switch ID for the SK-FFT (See Section 3.6.1).

*See Appendix A for compatible powering devices. Silent Knight Installation Manuals

can be found on Silent Knight’s web site at www.silentknight.com.

3.5 Operating Power

This section provides instructions to install the appropriate DC power source.

1. Connect the SK-FFT to the appropriate DC power source. See Section 2.4.1 for

power requirements. For compatible product see Table A-1.

2. Use the on-board DIP switch to assign the configuration setting to the SK-FFT.

(See Section 3.6.1).

54711 3-7

Page 24

SK-FFT Installation and Operation Manual

3.6 DIP switch settings on SK-FFT

This section describes how to configure the DIP switch setting on the SK-FFT.

1. Refer to Figure 2-1 for location of the DIP switches on the SK-FFT board.

2. Configure the SK-FFT module by adding it to the system through JumpStart

feature. See Section 6.3 for JumpStart Operation. Table 3-1 list possible DIP switch

configurations.

3.6.1 DIP Switch

Figure 3-9 DIP Switch

Table 3-1 SK-FFT DIP Switch Configurations

DIP Switch ON OFF

1

2 Trouble PZT Enabled Trouble PZT Disabled

3 SLC Class A Supervision SLC Class B Supervision

4 Phone Circuit Class A

5 First FFT-24 Expander

SLC Devices Installed SLC Devices not Installed

Phone Circuit Class B Supervision

Supervision

First FFT-24 Expander not Installed

Installed

3-8 54711

Page 25

Installation

To FFT - SLC

Terminal TB4

Connectors

or other SK-MM

The wiring between the

monitor module and FFT-FPJ

is supervised by the monitor

module. A 47K End-of-Line

resistor is built into

the FFT-

FPJ.

To FFT-Phone TB4 phone

In/Out + – connections or other

FFT-FPJ’s or FFT-STS’s

3.7 SK-FFT Fire Fighter Telephone Module

Connection

The SK-FFT provides connection for a single Class B or Class A telephone audio

circuit. See Section 4 and Section 5 for examples of audio zone configurations. A

monitor module can be used to monitor the connection of the Fire Fighter Telephone

remote handset (FFT-RHS) into the FFT-FPJ, which is then displayed on the SK-FFT

active zone LED during the JumpStart feature.

Figure 3-10 SK-FFT Connections

54711 3-9

Page 26

SK-FFT Installation and Operation Manual

3.8 FFT-FPJ Installation

The FFT-FPJ Firefighter Phone Jack mounts to a single-gang electrical box

(4" x 2-1/8" x 2-½") or, when the addressable mini-monitor module is installed with it,

a deep single-gang electrical box (4" x 2-1/8” x 3-¾”).

Connect the telephone audio loop between the FFT-FPJ and FFT as detailed in

Figure 3-12.

All circuits are power-limited and supervised.

Figure 3-11 FFT-FPJ (phone jack) and FFT-RHS (handset)

Figure 3-12 FFT to FFT-FPJ Connection

3-10 54711

Page 27

Installation

Contact EOL set

to Connected

*See Figure 3-14

for EOL example

3.9 Installation of FFT-STS

The Single Telephone Station comes in a series of parts. The telephone chassis,

backbox, breakglass kit and door with keylock are all ordered separately. Up to ten

remote handsets may be operated simultaneously.

3.9.1 Assembly of Units with Coiled Cord Handsets

The following assembly steps are for telephones with coiled cord handsets. These

steps must be accomplished once the enclosure has been mounted and the system

wiring is in place

1. Attach system wiring to the terminal strip on the telephone chassis assembly

2. Install 6-32 nut in backbox. Do not tighten.

3. Install telephone chassis assembly in backbox.

4. Install trim ring on backbox with 6-32 wing nuts. Do not tighten.

5. Install door assembly. Tighten wing nuts.

Figure 3-13 FFT-STS Telephone Connection

Figure 3-14 EOL Example

54711 3-11

Page 28

SK-FFT Installation and Operation Manual

3-12 54711

Page 29

SLC Device Installation

Section 4 SLC Device Installation

Caution!

To avoid the risk of electrical shock and damage to the unit, power should be

OFF at the control panel while installing or servicing.

4.1 List of SLC Devices

The following SLC device can be used with the Fire Fighters Phone. See the device

installation instructions for more information (packaged with the device).

Section/

SK Part Number Model Name/Description

Install Sheet

PN

SK-Minimon Mini Monitor Module I56-3444-000

SK-ISO Fault Isolator Module I56-3445-000

4.2 Maximum Number of Devices

The SK-FFT supports up to 48 SK-Minimon devices on one FFT system.

54711 4-1

Page 30

SK-FFT Installation and Operation Manual

4.3 Wiring Requirements for SLC Device

The following information applies to the SK-Minimon - Mini Monitor module.

4.3.1 Wiring SLC in Style 4 (Class B) Configuration

No special wire is required for addressable loops. The wire can be untwisted,

unshielded, solid or stranded as long as it meets the National Electric Code 760-51

requirements for power limited fire protective signaling cables. Wire distances are

computed using copper wire.

Maximum wiring resistance is 40 ohms to the farthest SLC device.

Maximum loop length depends on the wire gauge.

Wire Gauge Max. Distance

22 AWG 1200 feet

18 AWG 3100 feet

16 AWG 4900 feet

14 AWG 7900 feet

12 AWG 10,000 feet

4-2 54711

Page 31

SLC Device Installation

Figure 4-1 and Figure 4-2 show how length is determined for out and back tap T-Tap

style wiring.

Figure 4-1 Calculating wire run length for a simple out and back

When using T-taps, the total length of all taps and the main bus must not exceed

40,000 feet. This requirement must be met in addition to the maximum distance

requirements for the various wire gauges.

Figure 4-2 Calculating Wire Run Length for a T-tap

54711 4-3

Page 32

SK-FFT Installation and Operation Manual

4.3.2 Wiring SLC Devices in Style 6 & 7 (Class A)

Configuration

Figure 4-3 illustrates how to wire the SLC loop for Style 6 or Style 7 Class A

installations.

Note: Style 6 does not require the use of isolator modules.

Figure 4-3 Class A SLC Configuration

Note: No t-taps allowed on Class A SLC loops.

Caution

For proper system supervision do not use looped wire under terminals marked SLC + and –

of the SLC device connectors. Break wire runs to provide supervision of connections.

4-4 54711

Page 33

SLC Device Installation

Example 1: Device set to 10

Example 2: Device Set to 42

4.4 Addressing SK-Minimon SLC Devices

All SK-Minimon devices are addressed using the two rotary dials that appear on the

device board. Use the ONES rotary dial to set the ones place in a one or two digit

number, and use the TENS rotary dial to set the tens place in a two digit number.

SK-Minimon modules can be assigned any unique address from 1 to 48.

Example 1: To select device address 10, turn the ONES rotary dial to 0 and the

TENS rotary dial to 1 as shown in Figure 4-4.

Example 2: To select device address 42, turn the ONES rotary dial to 2 and the

TENS rotary dial to 4 as show in Figure 4-4.

Figure 4-4 SK-Minimon SLC Device Addressing using Rotary Dials

54711 4-5

Page 34

SK-FFT Installation and Operation Manual

4-6 54711

Page 35

Section 5 Audio Phone Circuit Installation

5.1 List of Devices

Part Number Description

FFT-FPJ Fire Fighters Telephone Jack

5.2 Maximum Number of Devices

The SK-FFT supports up to 48 zones. Each zone consists of one addressable

monitor module (SK-Minimon) and a minimum of one Fire Fighter Telephone Jack

(FFT-FPJ).

5.3 Wiring Requirements for the Audio Telephone

Circuit

The following information applies to the FFT-FPJ Fire Fighter Phone Jack.

5.3.1 Single Phone Jack Audio Circuit in Class B

Configuration

No special wire is required for the Audio Telephone Circuit. The wire can be

untwisted, unshielded, twisted or shielded as long as it meets the National Electric

code 760-51 requirements for power limited fire protective signaling cables.

54 Ohm maximum impedance - 12 to 18 AWG.

Twisted, shielded wire is recommended for maximum protection against EMI and AFI

emissions and susceptibility.

If using shielded cable, attach the shield to Grounding Stud below TB6 of the FFT.

Note: Do not ground shield on both ends.

54711 5-1

Page 36

SK-FFT Installation and Operation Manual

Contact EOL

Connected

(see Figure 5-2

for EOL

example)

Figure 5-1 illustrates single phone jack configuration wiring the audio circuit and SLC

for Class B Configuration. Audio circuits must be connected to FFT phone out

terminals for all Class B audio configurations.

Figure 5-1 Single Phone Jack Audio Circuit in Class B

Figure 5-2 EOL Example

5-2 54711

Page 37

Audio Phone Circuit

Contact EOL

Connected

5.3.2 Single Phone Jack Audio Circuit in Class A

Configuration

For wiring specifications see section 5.3.1.

Figure 5-3 illustrates phone jack audio circuit (Class A) and SLC for Style 6 & 7 (Class

A) configuration.

Figure 5-3 Single Phone Jack Audio Circuit in Class A

54711 5-3

Page 38

SK-FFT Installation and Operation Manual

5.3.3 Multi-Phone Jack Audio Circuit in Class B

Configuration

For wiring specifications see section 5.3.1.

Figure 5-4 illustrates how to wire the Multi-Phone Jack audio circuit (Class B) and

SLC for for Style 4 (Class B) configuration. In the Multi-Phone Jack configuration, the

maximum mini-monitor contact wiring resistance between to first and last FPJ must

be less that 100 ohms.

Figure 5-4 Multi-Phone Jack Audio Circuit in Class B

5-4 54711

Page 39

Audio Phone Circuit

5.3.4 Multi-Phone Jack Audio Circuit in Class A

Configuration

For wiring specifications see section 5.3.1.

Figure 5-5 illustrates how to wire the Multi-Phone Jack audio circuit (Class A) and

SLC for Style 6 & 7 (Class A) configuration. In the Multi-Phone Jack configuration, the

maximum Mini-Monitor Contact wiring resistance between to first and last FPJ must

be less that 100 ohms.

Figure 5-5 Multi-Phone jack Audio Circuit in Class A

54711 5-5

Page 40

SK-FFT Installation and Operation Manual

5.3.5 Telephone Jack Only Audio Circuit

The FFT can also be configured using only the Fire Fighters Phone Jack (FFT-FPJ).

In this configuration, the SK-Minimon module is not required for system operation. To

configure the FFT for Telephone Jack only, the DIP Switch position 1 must be off

(SLC Devices not Installed). See Table 3-1.

Audio wiring for this configuration is detailed below. See Figure 5-6 and Figure 5-7.

Figure 5-6 Telephone Jack Only Audio Circuit Class B

5-6 54711

Page 41

Audio Phone Circuit

Figure 5-7 Telephone Jack Only Audio Circuit Class A

54711 5-7

Page 42

SK-FFT Installation and Operation Manual

5-8 54711

Page 43

Section 6 System Operation

The operation of the SK-FFT Fire Fighter Telephone system allows audio

communication from 24 remote connections through remote handsets from a single

local handset. Up to 10 remote handset can be connected and communicating at one

time. Remote audio connections can be expanded to 48 with the optional FFT-24

zone expander.

6.1 Key Switch Operations

6.1.1 JumpStart Key Switch (on inside of FFT dead front

panel).

JumpStart key will cause the FFT to search the SLC loop for devices. The Active LED

(green) will then blink for each zone where a device was found. Press and hold the

Jumpstart Key for 2 seconds in order to initiate Jumpstart.

6.1.2 Accept Key Switch (on inside of FFT dead front

panel).

The Accept key is used after Jumpstart. It will save the current SLC device

configuration and re-initialize the FFT. If the user does not press the Accept key

within one minute after the JumpStart is complete, its configuration will be discarded

and the FFT will be restarted.

6.1.3 Answer Switch

When a Remote Handset is connected to one of the FFT-FPJ phone jacks, the

Answer LED will blink and the FFT's PZT will sound. Pressing the Answer Switch will

connect the local handset to the phone circuit, turn the answer LED on solid, and

silence the PZT. Communication between the local and remote handset is now

possible. Up to six remote handsets can be connected to the phone circuit

simultaneously. After the initial remote handset, the connection of additional handsets

does not cause the PZT to sound or the Answer LED to blink.

6.1.4 Silence Switch

The Silenced Switch is used to silence a system type trouble that has occurred in the

FFT system. Once pressed the PZT will silence.

54711 6-1

Page 44

SK-FFT Installation and Operation Manual

6.2 LED Operations

6.2.1 Power Status LED

The Power Status LED is located on the left side of the FFT board. On Power-UP the

Power Status LED will blink at a 50% on/off rate until FFT initialization is complete

(which takes approximately 20 seconds). Once initialization is complete the Power

Status LED will blink at a 10% on and 90% off rate.

No key input will be valid until the FFT completes its initialization.

6.2.2 Answer

When a Remote Handset connects to the audio channel the Answer LED will blink

and the PZT will sound. The operator at the FFT then picks up the local handset and

presses the Answer Switch which causes the Answer LED to remain on solid and the

PZT goes silent. Communication between the local and remote handset is now

established. Additional remote handsets can be attached to the audio connection

without any intervention at the FFT. Once the last remote handset has disconnected

from the FFT, the answer LED will go blank and the system will be back to normal.

6.2.3 Power

The Power LED indicates that 24 VDC is connected to the FFT.

6.2.4 Local Handset Trouble

The local handset trouble LED will activate and blink when there is a problem with the

local handset.

6.2.5 Remote Handset Trouble

The remote handset trouble LED will activate and blink when there is a problem with

the phone circuit.

6.2.6 General Trouble

The General Trouble LED will blink active when system troubles are detected. When

the Silence Key is pressed, the General Trouble LED will become constant. Once all

system troubles have been restored, the General Trouble LED will deactivate.

6-2 54711

Page 45

System Operation

6.2.7 Status LEDs (on Inside of FFT dead front panel)

LED 1 - SLC Supervision*

LED 2 - SLC Extra Point Detected

LED 3 - FFT-24 missing

LED 4 - Audio Circuit Supervision

Note: * Troubles that will turn LED on: SLC shorted, SLC Class A open trouble and wrong device type.

54711 6-3

Page 46

SK-FFT Installation and Operation Manual

Answer

LED

Active

(green)

Trouble

(amber)

6.2.8 Zone Active

Each zone has an Active LED (see Figure 6-1). The zone's Active LED will illuminate

when a remote handset is plugged into that zone. The LED will turn off when the

handset is removed from the zone.

6.2.9 Zone Trouble

Each zone has a Trouble LED (see Figure 6-1). The zone's Trouble LED will blink

when specific SLC issues occur such as a missing device or double address.

Pressing the Silence Key will cause the zone trouble LED to be on solid. Once the

zone trouble is corrected, the LED will turn off.

Figure 6-1 LED Operations

6-4 54711

Page 47

System Operation

6.3 JumpStart Operation

The JumpStart® feature will attempt to locate all SLC Mini-Monitor devices installed in

the system, indicate all devices found on the FFT and all FFT-24 Active LED's and

allow the user to accept the configuration, repeat the JumpStart or allow the

configuration to be discarded.

1. To perform the FFT Jumpstart press and hold the JumpStart button for 2 seconds.

2. The FFT will search for installed SLC devices and activate the Active LED’s of all

zone/point addresses found.

3. When the Jumpstart is complete, the first four status LED’s will blink. The user can

now press the ACCEPT key causing the FFT to save the configuration and

restart.

4. The user presses the JumpStart key again to repeat the SLC search process.

5. If the user does not press the Accept key within one minute after the JumpStart is

complete, its configuration will be discarded and the FFT will be restarted.

54711 6-5

Page 48

SK-FFT Installation and Operation Manual

6-6 54711

Page 49

Appendix A Compatible Powering Devices

A.1 Compatible Power Device

Table A-1 list the available Silent Knight compatible power devices used with SK-FFT.

Table A-1: Compatible Powering Devices

Model Manual PN

5820XL / 5820XL-EVS Addressable Fire Control Panel /

Emergency Voice System

5808 Addressable Fire Control Panel 151274

5700 Addressable Fire Control Panel 151295

5600 25-Point Addressable Fire Control Panel 151450

5895XL Power Supply 151142

151209 /

LS10061-001SK-E

54711 A-1

Page 50

SK-FFT Installation and Operation Manual

Notes:

A-2 54711

Page 51

Silent Knight Fire Product Warranty and Return Policy

General Terms and Conditions

• All new fire products manufactured by Silent Knight have a limited warranty period

of 36 months from the date of manufacture against defects in materials and

workmanship. See limited warranty statement for details.

• This limited warranty does not apply to those products that are damaged due to

misuse, abuse, negligence, exposure to adverse environmental conditions, or

have been modified in any manner whatsoever.

Repair and RMA Procedure

• All products that are returned to Silent Knight for credit or repair require a RMA

(Return Authorization) number. Call Silent Knight Customer Service at

800-328-0103 or 203-484-7161 between 8:00 A.M. and 5:00 P.M. EST, Monday

through Friday to obtain a return authorization number.

• Silent Knight Technical Support is available at 800-446-6444 between 8:00 A.M.

and 5:00 P.M. CST, Monday through Friday.

• All returns for credit are subject to inspection and testing at the factory before

actual determination is made to allow credit.

• RMA number must be prominently displayed on the outside of the shipping box.

See return address example under Advanced Replacement Policy.

• Included with each return should be: a packing slip that has the RMA number, a

content list, and a detailed description of the problem.

• All products returned to Silent Knight must be sent freight pre-paid. After product

is processed, Silent Knight will pay for shipping product back to customer via UPS

ground.

• Return the Silent Knight product circuit board only. Products that are returned in

cabinets will be charged an additional $50 to cover the extra shipping and

handling costs over board only returns. Do not return batteries. Silent Knight has

the authority to determine if a product is repairable. Products that are deemed unrepairable will be returned to the customer.

• Product that is returned that has a board date code more than 36 months from

date of manufacture will be repaired and the customer will be assessed the

standard Silent Knight repair charge for that model.

54711 3

Page 52

SK-FFT Installation and Operation Manual

Advanced Replacement Policy

• Silent Knight offers an option of advance replacement for fire product printed

circuit boards that fail during the first 6 months of the warranty period. These items

must be returned with transportation charges prepaid and must be accompanied

by a return authorization.

• For advance replacement of a defective board, contact your local Silent Knight

distributor or call Silent Knight at 800-328-0103 to obtain a RMA (Return

Authorization) number and request advanced replacement.

• A new or refurbished board will be shipped to the customer. The customer will

initially be billed for the replacement board but a credit will be issued after the

repairable board is received at Silent Knight. All returned products must comply

with the guidelines described under “General Terms and Conditions” and “Repair

and RMA Procedure”.

• The defective board must be returned within 30 days of shipment of replacement

board for customer to receive credit. No credit will be issued if the returned board

was damaged due to misuse or abuse.

• Repairs and returns should be sent to:

Silent Knight / Honeywell

Attn: Repair Department

12 Clintonville Road

Northford, CT 06472

USA

RA Number:___________________

4 54711

Page 53

Manufacturer Warranties and Limitation of Liability

Manufacturer Warranties. Subject to the limitations set forth herein, Manufacturer

warrants that the Products manufactured by it in its Northford, Connecticut facility and

sold by it to its authorized Distributors shall be free, under normal use and service,

from defects in material and workmanship for a period of thirty six months (36)

months from the date of manufacture (effective Jan. 1, 2009). The Products

manufactured and sold by Manufacturer are date stamped at the time of production.

Manufacturer does not warrant Products that are not manufactured by it in its

Northford, Connecticut facility but assigns to its Distributor, to extent possible, any

warranty offered by the manufacturer of such product. This warranty shall be void if a

Product is altered, service repaired by anyone other than Manufacturer or its

authorized Distributors. This warranty shall also be void if there is a failure to maintain

the Products and the systems in which they operate in proper working conditions.

MANUFACTURER MAKES NO FURTHER WARRANTIES, AND DISCLAIMS ANY

AND ALL OTHER WARRANTIES, EITHER EXPRESSED OR IMPLIED, WITH

RESPECT TO THE PRODUCTS,TRADEMARKS, PROGRAMS AND SERVICES

RENDERED BY MANUFACTURER INCLUDING WITHOUT LIMITATION,

INFRINGEMENT, TITLE, MERCHANTABILITY, OR FITNESS FOR ANY

PARTICULAR PURPOSE. MANUFACTURER SHALL NOT BE LIABLE FOR ANY

PERSONAL INJURY OR DEATH WHICH MAY ARISE IN THE COURSE OF, OR AS

A RESULT OF, PERSONAL, COMMERCIAL OR INDUSTRIAL USES OF ITS

PRODUCTS.

This document constitutes the only warranty made by Manufacturer with respect to its

products and replaces all previous warranties and is the only warranty made by

Manufacturer. No increase or alteration, written or verbal, of the obligation of this

warranty is authorized. Manufacturer does not represent that its products will prevent

any loss by fire or otherwise.

Warranty Claims. Manufacturer shall replace or repair, at Manufacturer's discretion,

each part returned by its authorized Distributor and acknowledged by Manufacturer to

be defective, provided that such part shall have been returned to Manufacturer with

all charges prepaid and the authorized Distributor has completed Manufacturer's

Return Material Authorization form. The replacement part shall come from

Manufacturer's stock and may be new or refurbished. THE FOREGOING IS

DISTRIBUTOR'S SOLE AND EXCLUSIVE REMEDY IN THE EVENT OF A

WARRANTY CLAIM.

Warn-HL-08-2009.fm

54711 5

Page 54

SK-FFT Installation and Operation Manual

6 54711

Page 55

Cut Along the Dotted Line

Model SK-FFT Basic Operating Instructions

These Instructions must be framed and displayed next to the SK-FFT

panel in accordance with NFPA 72 fire code for Local Protected Fire Alarm

Systems. Test the system in accordance to NFPA 72. Refer to Installation

Manual P/N 54711 for more information regarding this control panel.

Operation Task to Perform

Answer Call When Remote handset is connected to the FFT-FPJ, the Answer LED will

blink and PZT will sound.

Press key and PZT will silence. Answer LED will be on solid and

audio connection will be established between local and remote handset.

Silence Trouble

For Service call:

P/N 54713 Rev. A

Press key and PZT will silence. General Trouble LED will be on

solid.

ECN 11-0003

Page 56

Cut Along the Dotted Line

Page 57

Page 58

Silent Knight

12 Clintonville Road

Northford, CT 06472-1610

203-484-7161

Fax: 203-484-7118

www.silentknight.com

Loading...

Loading...