Sigma Spectrum Service manual

SERVICE MANUAL

SIGMA INTERNATIONAL

MODEL SPECTRUM

INFUSION PUMP

REVISION W |

August 2009 |

Additional copies of this Service Manual Are available from

SIGMA International, Inc.

711 Park Avenue, Medina, NY USA 14103-0756 (Latest revision will be sent unless otherwise specified)

SIGMA SPECTRUM INFUSION PUMP - SERVICE MANUAL |

|

Table of Contents |

|

SECTION 1: .................................................................................................................................... |

1 |

1.1 LIMITED WARRANTY............................................................................................................... |

1 |

1.2 SIGMA SPECTRUM INFUSION PUMP WARNINGS AND CAUTIONS .................................... |

3 |

1.3 SIGMA SPECTRUM CLEANING............................................................................................... |

5 |

Cleaning............................................................................................................................................................. |

5 |

1.4 SIGMA SPECTRUM INFUSION PUMP SPECIFICATIONS ...................................................... |

6 |

Applications........................................................................................................................................................ |

6 |

Administration Set.............................................................................................................................................. |

6 |

Performance ...................................................................................................................................................... |

6 |

Technical............................................................................................................................................................ |

8 |

Listings & Certifications...................................................................................................................................... |

9 |

1.5 PREVENTIVE MAINTENANCE ............................................................................................... |

10 |

Preventative Maintenance Schedule ............................................................................................................... |

10 |

Visual Inspection.............................................................................................................................................. |

10 |

Keyboard Test.................................................................................................................................................. |

11 |

Upstream (Proximal) Occlusion Sensor Test ................................................................................................... |

11 |

Downstream (Distal) Occlusion Sensor Test *................................................................................................. |

11 |

Air Detection Test * .......................................................................................................................................... |

12 |

Memory Test (this assumes you are starting from an all clear point) * ............................................................ |

12 |

Recommended Flow Rate Accuracy Test * ..................................................................................................... |

12 |

AC Power Adaptor Safety Analysis.................................................................................................................. |

12 |

Battery Capacity Test....................................................................................................................................... |

13 |

Preventative Maintenance Check Off Sheet .................................................................................................... |

14 |

1.6 DOWNLOADING THE HISTORY LOG.................................................................................... |

15 |

1.7 User Options - OPTIONS SCREEN........................................................................................ |

17 |

Alarm Settings ................................................................................................................................................. |

17 |

Display Settings .............................................................................................................................................. |

17 |

View Information ............................................................................................................................................. |

17 |

1.8 Biomed Options – OPTIONS SCREEN.................................................................................. |

19 |

Sensor Configuration ....................................................................................................................................... |

19 |

Calibration Menu .............................................................................................................................................. |

19 |

Pump Settings.................................................................................................................................................. |

20 |

Pump Testing ................................................................................................................................................... |

20 |

Update Software .............................................................................................................................................. |

20 |

Network Configuration ..................................................................................................................................... |

20 |

1.9 TROUBLESHOOTING GUIDE ................................................................................................ |

22 |

BATTERY CHARGER ERROR CODE DESCRIPTIONS ................................................................................ |

22 |

Spectrum "SYSTEM ERROR" CODE DESCRIPTIONS .................................................................................. |

22 |

1.10 SERVICE ............................................................................................................................... |

26 |

Return Authorization ........................................................................................................................................ |

26 |

Field Service .................................................................................................................................................... |

26 |

Battery Removal and Replacement ................................................................................................................. |

27 |

Wireless Battery Module Removal and Replacement...................................................................................... |

27 |

Battery Disposal ............................................................................................................................................... |

28 |

Section 2: Technical Drawings: .................................................................................................. |

29 |

Assembly, Spectrum Final 35700 .................................................................................................................... |

29 |

Assembly, Spectrum Final 35700 .................................................................................................................... |

30 |

I |

|

P/N 41019 Rev W

SIGMA SPECTRUM INFUSION PUMP - SERVICE MANUAL |

|

Front Case Assembly 35708............................................................................................................................ |

31 |

Front Case Assembly 35708............................................................................................................................ |

31 |

Assembly, Processor PCB 60087 .................................................................................................................... |

32 |

Assembly, Mechanism / Door 35703 ............................................................................................................... |

33 |

Assembly, Mechanism / Door 35703 ............................................................................................................... |

33 |

Assembly, Rear Case 35701 ........................................................................................................................... |

35 |

Assembly, Key Hole 35709 .............................................................................................................................. |

36 |

Assembly, Pole Clamp 35712.......................................................................................................................... |

37 |

Assembly, I/O PCB 60091 ............................................................................................................................... |

38 |

Assembly Power Cord 35714 .......................................................................................................................... |

39 |

Assembly, Wireless Battery Module 35083………………………………………………………………..………...40 |

|

Section 3: Theory of Operation................................................................................................... |

41 |

Case................................................................................................................................................................. |

42 |

Front Case Assembly.............................................................................................................................. |

42 |

Rear Case Assembly .............................................................................................................................. |

42 |

Battery Pack..................................................................................................................................................... |

42 |

Pole Clamp ...................................................................................................................................................... |

43 |

Tubing Channel/Pump Door ............................................................................................................................ |

43 |

Set Slide Clamp Sensor................................................................................................................................... |

43 |

Processing Architecture ................................................................................................................................... |

43 |

Pumping Mechanism ....................................................................................................................................... |

44 |

Physical Method...................................................................................................................................... |

44 |

Operation ................................................................................................................................................ |

44 |

Pumping Mechanism Assembly.............................................................................................................. |

44 |

Motor ................................................................................................................................................................ |

44 |

Motor Drive ............................................................................................................................................. |

44 |

Motor and Gear Drive ............................................................................................................................. |

44 |

Fluid Temperature............................................................................................................................................ |

44 |

Upstream Sensors ........................................................................................................................................... |

45 |

Optical tube sensor ................................................................................................................................. |

45 |

Proximal Occlusion Detection ................................................................................................................. |

45 |

Air Sensor ............................................................................................................................................... |

45 |

Downstream Sensors....................................................................................................................................... |

45 |

Set loading .............................................................................................................................................. |

45 |

Distal Occlusion Detection ...................................................................................................................... |

45 |

Audible Alarm Device and System................................................................................................................... |

46 |

Electronic Components .................................................................................................................................... |

46 |

AC Power Adaptor / Charger .................................................................................................................. |

46 |

Display .................................................................................................................................................... |

46 |

I/O Board................................................................................................................................................. |

46 |

Processor Board ..................................................................................................................................... |

47 |

Flex Circuits ............................................................................................................................................ |

47 |

Ultrasonic Flex ............................................................................................................................... |

47 |

Upper Aux Flex .............................................................................................................................. |

47 |

Lower Aux Flex .............................................................................................................................. |

47 |

Force Sensor Flex ......................................................................................................................... |

47 |

Backflex ......................................................................................................................................... |

47 |

Keypad.................................................................................................................................................... |

47 |

Rear Case Connector ............................................................................................................................. |

48 |

Power / Charging Cord .................................................................................................................. |

48 |

Digital Data Port............................................................................................................................. |

48 |

Appendix A – General Specifications............................................................................................. |

49 |

Appendix B – System Block Diagram ............................................................................................ |

50 |

Appendix C – Wireless Networking ................................................................................................ |

49 |

II

P/N 41019 Rev W

SIGMA SPECTRUM INFUSION PUMP - SERVICE MANUAL

SECTION 1:

1.1 LIMITED WARRANTY

SIGMA SPECTRUM INFUSION PUMP LIMITED WARRANTY

SIGMA International warrants, to the original purchaser, the SPECTRUM Infusion Pump (hereinafter Pump) to be free from defects in material and workmanship under normal use and service for one year from the date of purchase. SIGMA’s obligation under this limited warranty shall be limited to repair or replacement of Pumps, which, upon SIGMA’s examination, are found defective in material or workmanship under normal use and service within one year from the date of purchase by the original purchaser. The repair or replacement of any Pump under this limited warranty shall not extend the term of this limited warranty beyond the original term as set forth in this paragraph.

Qualified, trained service personnel must perform all repairs qualifying under this limited warranty. In the event that any Pump is found to be defective during the aforesaid warranty period, the purchaser shall notify SIGMA in writing of any claimed defect within thirty days after such claimed defect is discovered. The Pump claimed to be defective must then be promptly delivered to SIGMA or its designated representative for inspection and repair or replacement, if necessary. Pumps returned to SIGMA must be properly packaged and sent to SIGMA with postage and handling prepaid. Severe pump damage may result if SIGMA shipping cartons and inserts are not used. Shipping cartons and inserts are available at no charge from SIGMA.

This limited warranty shall not apply to defective conditions or damage caused, in whole or in part, by negligence, fluid spills, dropped Pumps, misuse, abuse, improper installation, improper cleaning, alteration, or damage caused by improper shipment to SIGMA. If, after inspection, SIGMA is unable to identify a problem, SIGMA reserves the right to invoice the purchaser for such inspection.

THIS LIMITED WARRANTY IS THE SOLE AND ENTIRE WARRANTY PERTAINING TO THE PUMP AND IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES OF ANY NATURE WHATSOEVER WHETHER EXPRESS, IMPLIED OR ARISING BY OPERATION OF LAW, TRADE, USAGE OR COURSE OF DEALING, INCLUDING, BUT NOT LIMITED TO, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. ANY AFFIRMATION OF FACT OR PROMISE MADE BY SIGMA SHALL NOT BE DEEMED TO CREATE AN EXPRESS WARRANTY THAT THE PUMP SHALL CONFORM TO THE AFFIRMATION OR PROMISE; ANY DESCRIPTION OF THE PUMP IS FOR THE SOLE PURPOSE OF IDENTIFYING IT AND SHALL NOT BE DEEMED TO CREATE AN EXPRESS WARRANTY THAT THE PUMP SHALL CONFORM TO SUCH DESCRIPTION; ANY SAMPLE OR MODEL IS FOR ILLUSTRATIVE PURPOSES ONLY AND SHALL NOT BE DEEMED TO CREATE AN EXPRESS WARRANTY THAT THE PUMP SHALL CONFORM TO SUCH SAMPLE OR MODEL; AND NO AFFIRMATION, PROMISE, DESCRIPTION SAMPLE OR MODEL SHALL BE DEEMED TO BE PART OF THE PURCHASE OF THE PUMP. THE PURCHASER EXPRESSLY ACKNOWLEDGES THAT THIS LIMITED WARRANTY CONSTITUTES THE PURCHASERS SOLE AND EXCLUSIVE REMEDY WITH RESPECT TO ANY CLAIM OF THE PURCHASER ARISING OR RESULTING DIRECTLY OR INDIRECTLY FROM THE USE OF THE PUMP. IN NO EVENT SHALL SIGMA BE LIABLE HEREUNDER FOR AN AMOUNT THAT EXCEEDS THE PURCHASE PRICE OF THE PUMP. NO PERSON, FIRM OR CORPORATION IS AUTHORIZED TO ASSUME FOR SIGMA ANY LIABILITY IN CONNECTION WITH THE SALE OF THE PUMP.

1

P/N 41019 Rev W

SIGMA SPECTRUM INFUSION PUMP - SERVICE MANUAL

SIGMA SPECTRUM BATTERY PACK LIMITED WARRANTY

SIGMA International warrants, to the original purchaser, the SPECTRUM Infusion Pump Battery Pack (hereinafter Battery) to be free from defects in material and workmanship under normal use and service for one year from the date of purchase. SIGMA’s obligation under this limited warranty shall be replacement of Batteries, which, upon SIGMA’s examination, are found defective in material or workmanship under normal use and service within one year from the date of purchase by the original purchaser. The replacement of any Battery under this limited warranty shall not extend the term of this limited warranty beyond the original term as set forth in this paragraph.

During the aforesaid warranty period, a Battery shall be capable of accepting a full charge, as indicated by a full charge icon and maintaining the specified battery capacity as outlined in section 1.5.

It is normal for battery capacity to decrease over the life of the battery. Beyond the aforesaid warranty period, batteries may exhibit a normal decrease in capacity, depending upon age and usage. If batteries exhibit decreased capacity, they may need to be replaced.

Replacement batteries, purchased separately from SIGMA, International will be subject to the aforesaid one-year warranty.

In the event that any Battery is found to be defective during the aforesaid warranty period, the purchaser shall notify SIGMA in writing of any claimed defect within thirty days after such claimed defect is discovered. The Battery claimed to be defective must then be promptly delivered to SIGMA or its designated representative for inspection and replacement, if necessary. Batteries returned to SIGMA must be properly packaged and sent to SIGMA with postage and handling prepaid.

This limited warranty shall not apply to defective conditions or damage caused, in whole or in part, by negligence, fluid spills, dropped Pumps or Batteries, misuse, abuse, improper installation, improper cleaning, alteration, or damage caused by improper shipment to SIGMA. If, after inspection, SIGMA is unable to identify a problem, SIGMA reserves the right to invoice the purchaser for such inspection.

THIS LIMITED WARRANTY IS THE SOLE AND ENTIRE WARRANTY PERTAINING TO THE PUMP AND IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES OF ANY NATURE WHATSOEVER WHETHER EXPRESS, IMPLIED OR ARISING BY OPERATION OF LAW, TRADE, USAGE OR COURSE OF DEALING, INCLUDING, BUT NOT LIMITED TO, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. ANY AFFIRMATION OF FACT OR PROMISE MADE BY SIGMA SHALL NOT BE DEEMED TO CREATE AN EXPRESS WARRANTY THAT THE PUMP SHALL CONFORM TO THE AFFIRMATION OR PROMISE; ANY DESCRIPTION OF THE PUMP IS FOR THE SOLE PURPOSE OF IDENTIFYING IT AND SHALL NOT BE DEEMED TO CREATE AN EXPRESS WARRANTY THAT THE PUMP SHALL CONFORM TO SUCH DESCRIPTION; ANY SAMPLE OR MODEL IS FOR ILLUSTRATIVE PURPOSES ONLY AND SHALL NOT BE DEEMED TO CREATE AN EXPRESS WARRANTY THAT THE PUMP SHALL CONFORM TO SUCH SAMPLE OR MODEL; AND NO AFFIRMATION, PROMISE, DESCRIPTION SAMPLE OR MODEL SHALL BE DEEMED TO BE PART OF THE PURCHASE OF THE PUMP. THE PURCHASER EXPRESSLY ACKNOWLEDGES THAT THIS LIMITED WARRANTY CONSTITUTES THE PURCHASERS SOLE AND EXCLUSIVE REMEDY WITH RESPECT TO ANY CLAIM OF THE PURCHASER ARISING OR RESULTING DIRECTLY OR INDIRECTLY FROM THE USE OF THE PUMP. IN NO EVENT SHALL SIGMA BE LIABLE HEREUNDER FOR AN AMOUNT THAT EXCEEDS THE PURCHASE PRICE OF THE PUMP. NO PERSON, FIRM OR CORPORATION IS AUTHORIZED TO ASSUME FOR SIGMA ANY LIABILITY IN CONNECTION WITH THE SALE OF THE PUMP.

2

P/N 41019 Rev W

SIGMA SPECTRUM INFUSION PUMP - SERVICE MANUAL

1.2 SIGMA SPECTRUM INFUSION PUMP WARNINGS AND CAUTIONS

Definitions:

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate personal injury or property damage. This word is used to also alert against unsafe practices.

NOTE: |

Additional information to clarify or strengthen wording. |

Warnings:

–THIS EQUIPMENT IS NOT SUITABLE FOR USE IN THE PRESENCE OF A FLAMMABLE ANAESTHETIC MIXTURE WITH AIR OR OXYGEN OR NITROUS OXIDE.

–LITHIUM BATTERY (SIGMA P/N 55071)

(LOCATION: BT1 ON PCBA P/N 60087)

DANGER OF EXPLOSION IF THE BATTERY IS INCORRECTLY REPLACED. REPLACE ONLY WITH THE SAME OR EQUIVALENT TYPE RECOMMENDED BY SIGMA. REFERENCE SIGMA OPERATOR’S MANUAL FOR DISPOSAL INSTRUCTIONS.

–DO NOT SHORT CIRCUIT THE BATTERY TERMINALS, DISASSEMBLE OR MODIFY BATTERY PACKS.

–DO NOT DISPOSED OF BATTERIES OR BATTERY PACKS IN FIRE

–ANY PUMP THAT HAS BEEN DROPPED OR IS OTHERWISE VISIBLY DAMAGED MUST NOT BE USED. Discontinue use immediately and refer to a qualified Service Technician for inspection and repair prior to further use.

–USE ONLY IV ADMINISTRATION SETS THAT ARE LISTED ON SIGMA COMPATIBLE SET LISTING (see Operator’s Manual for listing).

NOTE: Use of any other sets will result in malfunction or inaccurate delivery.

–DO NOT USE IF ROOM OR PUMP TEMPERATURE IS BELOW 15°C (60°F) OR ABOVE 32°C (90°F).

Cautions:

–Federal (USA) law restricts this device to sale by or on the order of a physician or other licensed practitioner.

–Operate only on the AC Line voltage for which the AC Power Adaptor is marked.

–The AC Power Adaptor should be plugged in during storage to maintain proper battery charge level.

–Disconnect from AC power source and remove the battery pack prior to servicing this pump.

–Routine cleaning and periodic maintenance is needed to assure that the pump remains safe and functional. Refer to Section 1.3, Cleaning and Maintenance, and Section 1.5, Preventative Maintenance.

–Solution spills should be cleaned up, as soon as possible, using a damp cloth or sponge. Dry thoroughly before use. The upstream and downstream sensors tube channel must be kept clean and dry at all times during pump operation. Do not use hard or sharp objects to clean sensor

3

P/N 41019 Rev W

SIGMA SPECTRUM INFUSION PUMP - SERVICE MANUAL

tube channel areas. Failure to comply with this requirement may cause the pump to fail. Refer to Section 1.3, Cleaning and Maintenance.

–Static sensitive electronics used in SIGMA infusion pumps may be damaged by electrostatic discharge. Service technicians must follow proper ESD procedures when working on pumps. Refer to MIL-STD-1686 for protective handling procedures.

–Do not use a pen or any other sharp object to actuate the keyboard switches. Replace torn or punctured membranes immediately, to assure solutions won't internally damage the membrane switch and prevent proper operation of the SIGMA SPECTRUM. (Replacement should only be performed by authorized personnel).

–If using filter set, use only filter sets which state specifically in the Operator’s Manual instructions that they may be used with pumps.

Notes:

NOTE:

For a list of serviceable parts, call the SIGMA Service Coordinator

4

P/N 41019 Rev W

SIGMA SPECTRUM INFUSION PUMP - SERVICE MANUAL

1.3 SIGMA SPECTRUM CLEANING

1.Caution Always press STOP then OFF and unplug the A.C. Power Adaptor before cleaning.

2.Caution DO NOT sterilize by autoclaving, ETO gas or spraying. DO NOT immerse any part of the pump. DO NOT use abrasive cleaners.

3.Caution DO NOT use phenolic based cleaners or disinfectants, extended use may cause damage to the keyboard, case and any other plastic component of the SIGMA SPECTRUM.

4.Clean exterior surfaces with pump in upright position. Apply cleaners with a dampened cloth per manufacture's instruction and dilution ratios. DO NOT use spray or aerosol cleaners. A lint free, foam-tipped swab (Chemtronics Foamtip or Qosmedix® precision foam tip for example) may be used in the Tube Channel.

5.Visually inspect the tubing channel and remove any foreign material. An obstructed set tubing channel could cause accidental free flow.

6.Subsequent disinfecting is recommended using the same application technique. Disinfectants should remain on the pump surface in an even, but not dripping, film for the manufactures' recommended contact time. Wipe dry or air-dry after completion of contact time period before pump reuse.

7.Dispose of all cleaning/ disinfectant materials per federal, state and local regulations for infectious waste disposal.

Cleaning

This pump is designed to be transportable and is recommended to be cleaned and disinfected in accordance with approved facility protocol for multiple patients’ usage. A listing of compatible solutions is provided. Turn the pump off and unplug the AC Power Adaptor from the AC power source. Place the pump in an upright position (Keyhole release upward). Apply solutions with a dampened cloth per the manufacturers’ instructions using appropriate dilution ratio. Disinfectants should remain on the pump’s surface in an even, but not dripping film for the manufacturers’ recommended contact time. Open the pump’s door using a clean I.V. set with respective slide clamp for the Keyhole match associated with the tubing manufacturer’s type of the pump. Clean the speaker vent, power supply connector, door release Keyhole and pumping channel areas with the soft swabs as required. Apply solutions sparingly to the swabs and wipe down the necessary areas. DO NOT use rigid cleaning instruments or spray solutions directly on the pump. For severe solution spills or contaminated pump product it is recommended that the Battery Pack be removed. The Battery Pack1., 2. / cavity area of the pump may be cleaned by wiping down these regions with a dampened cloth as described previously. Dispose of all cleaning materials (including the slide clamp if it is not to be cleaned and disinfected) as required per facility protocol / biohazard policy.

Examples of Compatible Cleaners:

(Refer to DOC 11318 for Complete Listing)

1 10% solution of bleach and water

2 Up to 90% Isopropyl alcohol1

3Caltech Industries Dispatch®

4 Steris TBQ® and Steris Germicidal Surface Wipes, Product Number 1608-GS

5Metrex Cavicide® and Cavi WipesTM

6May be others. Contact SIGMA for additional information

1.Alcohols are flammable and should not be use for battery cleaning / disinfection. Always use alcohol in a well-ventilated area.

2.When cleaning the Battery Pack, care should be taken to prevent shorting of the pack’s exposed terminals.

3.Do not sterilize this device by autoclaving or ETO gas.

4.Do not immerse any part of this device.

5.Do not use phenolic based cleaners / disinfectants.

5

P/N 41019 Rev W

SIGMA SPECTRUM INFUSION PUMP - SERVICE MANUAL

1.4 SIGMA SPECTRUM INFUSION PUMP SPECIFICATIONS

Applications

-Large and small volume parenterals

-Neonatal

Administration Set

Compatible with standard gravity IV sets supplied by Hospira® and several other companies, (consult SIGMA for a complete list of compatible standard IV sets).

Performance

See Appendix A for additional specifications.

Downstream occlusion time to alarm for occlusion pressures adjusted to LOW (6 psi), MEDIUM (13 psi), and HIGH (19 psi) *:

RATE |

LOW(6psi) |

MEDIUM(13psi) |

HIGH(19psi) |

5 mL/hr |

<5 min. |

<10 min. |

<20 min |

100 mL/hr |

<15 sec. |

<20 sec. |

<40 sec. |

Max. Bolus |

0.25 mL |

0.50 mL |

0.80 mL |

*With Occlusion 45 inches below the pump and alarm set to LOW, MEDIUM or HIGH.

Trip pressure specifications for downstream occlusions are:

Pressure Setting |

Nominal Value (psi) |

Tolerance (psi) |

Low |

6 |

±4 |

Medium |

13 |

±6 |

High |

19 |

±9 |

All safety related sensing systems are automatically checked for proper operation periodically during set up and pump running conditions. Faults are identified by SYSTEM ERROR codes.

Effect of Fluid Container Height1.

The performance of the infusion pump will be influenced by the forces of gravity on the fluid being administered to the patient. When a fluid container is positioned above or below the patient’s administration site, pressure forces associated with the fluid’s head-height (distance measured from the center of the pumping mechanism to the top of the fluid in the source container) will cause deviations in the nominal specification for device flow rate accuracy. The nominal head-height used for the flow rate and graphical presentation is 24” (61 cm). e.g. The deviation from the nominal flow rate accuracy from +24” to -20” (-51 cm) head-height has an influence of a possible -4% in flow rate accuracy when the flow rate is set to 25 mL/hr.

1. Note: Liquid container must be vented or a collapsible bag.

Bolus Accuracy

The SIGMA Spectrum IV Pump may have an optional bolus mode of operation. This feature allows the user to perform a BOLUS SETUP action. To utilize this feature the pump must be programmed with either a specific rate or a specific amount to be delivered in a certain amount of time.

If the pump is currently operating in mL/hr delivery mode, the bolus rate value is entered in mL/hr and the volume is entered in milliliter (mL). If the pump is operating in a non-mL/hr delivery mode (for example mcg/kg/min), the bolus amount would be entered in mcg/kg however the ML/HR soft key may be pressed in the setup screen to enter the bolus information in mL/hr format.

In either mode, the time is entered in minutes and seconds (min:sec). Limits are placed on the minimum and maximum amount of time for the bolus delivery. The limit constraints are contained within the software of the Spectrum pump and are necessary to control the maximum or minimum flow rate of the bolus infusion.

6

P/N 41019 Rev W

SIGMA SPECTRUM INFUSION PUMP - SERVICE MANUAL

The accuracy of the bolus volume is dependent up the resultant flow rate that is obtained from the calculation of volume to be delivered in the time requested. For example if the maximum bolus volume is 300 mL, the maximum flow rate is obtained with a bolus time of 18:02 (min:sec) or a flow rate of approximately 999 mL/hr. Using this maximum bolus volume, and delivering the volume in the shortest amount of time, the mean value of 302 mL ± 5% may be expected. Whereas using a minimum bolus volume (.5 mL), and delivering the volume in a reasonably short amount of time (1 minute), the mean value of .52 mL ±16% may be expected.

7

P/N 41019 Rev W

SIGMA SPECTRUM INFUSION PUMP - SERVICE MANUAL

Technical

See Appendix A for Additional technical specifications.

•Type of pump - Volumetric infusion pump.

•Operating Principle - Linear peristaltic

• Patient leakage: < 15 micro amps, normal condition; < 50 micro amps, single fault condition.

•Battery: Type: 7.2-volt battery pack consisting of (2) 3.6V/1.8 Ampere-hr rechargeable Lithium Ion, or 7.2-volt battery pack consisting of (2) 3.7V/1.75 Ampere-hr rechargeable Lithium Ion.

•Pump operating time on battery power is at least 8 hours at 125ml/hr with the backlight on.* With the optional Wireless Battery Module the specification is at least 4 hours under the same conditions with the wireless interface operating.*

•Computer interface: RS232 port on the back panel and IrDA on front panel. Since the systems pumps may be connected to vary widely, users should consult with SIGMA's Service Department for specific instructions. Users without sufficient electronic background and knowledge of both the SIGMA Spectrum infusion pump and outside devices it may be connected to should never attempt such a connection. To do so otherwise can result in severe damage to the pump.

-Alarms:

-Air-In-Line

-Downstream Occlusion

-Upstream Occlusion

-Door Open, Door Not Latched

-Low and Depleted Battery

-AC Applied / Removed

-Battery Not Detected

-Infusion Complete

-Secondary Complete

-Secondary Delivery

-Primary Delivery

-User Inactivity

-Unload Set Caution

-System Errors

-Incomplete Titration Entry

-Slide Clamp Closed

8

P/N 41019 Rev W

SIGMA SPECTRUM INFUSION PUMP - SERVICE MANUAL

Listings & Certifications

Standard |

Version |

Description |

UL 60601-1 |

2003 |

UL Standard for Safety Medical Electrical |

|

|

Equipment, Part 1: General Requirements for |

|

|

Safety First Edition |

CAN/CSA C22.2 NO 601.1-M90 |

1990 |

Medical Electrical Equipment – Part 1: General |

|

|

Requirements for Safety General Instruction No 1: |

|

|

with UL60601-1 Supplement I |

IEC 60601-2-24 |

1998-02 |

Medical Electrical Equipment – Part 2 –24: |

|

|

Particular Requirements for Safety of Infusion |

|

|

Pumps and Controllers First Edition |

EN 60601-1 |

1990 |

Medical Electrical Equipment Part 1: General |

|

|

Requirements for Safety Includes Amendments + |

|

|

A1(93) + A2(95) |

FCC Section 15C |

N/A |

FCC approved wireless transmitter/receiver module |

ID: MCQ-50M879 |

|

(Wireless Battery Module Only – SIGMA P/N |

|

|

35083) |

FCC Section 15C |

N/A |

FCC approved wireless transmitter/receiver module |

ID: MCQ-50M1538 |

|

(Wireless Battery Module Only – SIGMA P/N |

|

|

35162) |

See the SIGMA Spectrum Operator’s Manual (P/N 41018) for specific Flow Rate Accuracy (Trumpet Curve) information and Electromagnetic compatibility compliance levels.

NRTL – Intertek Testing Services NA Inc.

Reference Control Number 3063464

9

P/N 41019 Rev W

SIGMA SPECTRUM INFUSION PUMP - SERVICE MANUAL

1.5 PREVENTIVE MAINTENANCE

PURPOSE

The purpose of this procedure is to provide a guideline for the Preventative Maintenance of the SIGMA SPECTRUM IV pump.

SCOPE

The guidelines are to ensure that the SIGMA SPECTRUM IV pump is operating within the specified parameters set forth by SIGMA International, Inc.

REFERENCES

Preventative maintenance check off sheet (attached at the end of this section).

EQUIPMENT

1.SIGMA SPECTRUM Infusion Pump

2.IV set of the brand specified on the pump label

NOTE: If the pump is being accuracy tested following a clinical problem, it is essential to test with an IV set of the same catalog number and lot number as that in use when the problem occurred.

3.IV container (250, 500 or 1000 mL) to be used as pumping source.

4.Collection vessel used should be a class “A” graduate during a volumetric test.

5.Any collection vessel may be used if during a gravimetric test (output is weighed).

6.Pressure gauge.

7.Electronic balance scale with 0.1 gram readability (only for gravimetric flow rate testing).

DOCUMENTATION

After each operation in this procedure, the findings may be recorded on the Preventative maintenance check off sheet attached at the end of this section.

PROCEDURE

ALL TESTING AND EVALUATIONS SHALL REQUIRE FLUID AND AIR TEMPERATURE OF 72±2°F.

NOTE: The brand of IV sets being tested must be compatible with the pump under test. The proper IV set calibration is listed on the label located on the top of the pump.

NOTE: Sections identified with * may be utilized as an incoming test procedure.

Preventative Maintenance Schedule

1.Preventative maintenance is recommended a minimum of once annually on all pumps in service.

2.Preventative maintenance should be performed after any user facility maintenance.

3.Preventative maintenance test should also be carried out whenever a pump is dropped, or suspected of having been otherwise damaged.

Visual Inspection

1.Inspect the pump for visual evidence of damage and or defects to exterior components (i.e. case, keypad and door).

2.The IV set tube channel must be free of foreign materials and dry for both testing and use.

10

P/N 41019 Rev W

SIGMA SPECTRUM INFUSION PUMP - SERVICE MANUAL

3.Any evidence of damage to or repair of these parts is reason to run the preventative maintenance checks.

4.Verify legibility of all labels.

5.Replace labels as necessary.

Keypad Test

The Model Spectrum keypad and display may be checked for proper operation as follows (The 1,2,3, 5 and BASIC key will be verified during subsequent testing):

1.Press the “ON/OFF” key to turn the unit on and observe that the displays indicate the SIGMA Spectrum logo, followed by the “Select Care Area” screen, press BASIC, OK.

2.Press OK to select mL/hr then push the “4”, and “6” keys and observe the “Rate mL/hr” field to be “46”.

3.Press the “clear” soft key and verify that the rate field is cleared to 0.

4.Enter “7”, “8”, and “9” keys and observe the “Rate mL/hr” field to be “789”.

5.Push “clear” soft key and enter “.”, “0” keys and observe the “Rate mL/hr” field to be “0.0”

6.Push “clear” soft key, and press the “▼” key until the ’value given’ field is highlighted.

7.Press the left soft key “clr all” and verify that the display menu changes to the “Clear Program Yes/No?” screen, press Yes then the “Care Area Selection” screen will appear

Upstream (Proximal) Occlusion Sensor Test

NOTE: Confirm test failures with a new unused IV set.

1.Press BASIC, OK.

2.Set the flow Rate to 100 mL /hr. Press OK.

3.Set VTBI (volume to be infused) to 13.3 mL. Press OK.

4.Occlude IV set 12” above the pump with a pair of hemostats.

5.Push the “RUN / STOP” key to start the pump.

Note: Pumps with v6.00.00 and later software versions will display a CHECK FLOW screen once the pump is started. For purposes of this test, press ‘yes’ to proceed to the normal RUN screen.

6.The pump may indicate BAG NEAR EMPTY <30 MIN REMAIN. Press the “OK” key to silence this alarm.

7.Verify the pump goes into “UPSTREAM OCCLUSION” alarm prior to infusion complete message.

8.Release the occlusion and restart the pump.

Downstream (Distal) Occlusion Sensor Test *

NOTE: The IV line and gauge must be free of air. The test fixture must consist of only compatible IV tubing as specified on the label at the top of the pump. Softer tubing between the pump and the gauge, or air in the line can result in inaccurate results.

NOTE: Confirm test failures with a new unused IV set.

1.Select CLR ALL, press YES. Select “Help” softkey.

2.Select OPTIONS, Biomed Configuration, and enter the password. Select Sensor Configuration. Verify that the DS Occlusion Auto Restart is set for “on” and verify US/Air Alarm Confirm is set for “on”.

3.Exit the BIOMED OPTION screen.

4.On the OPTIONS screen select User Settings. Select Alarm Settings verify DS Pressure Limit as “med” and exit the User Settings. Exit the OPTIONS screen.

5.Press OK to bypass the Help screen.

6.Select the BASIC key and press OK.

7.Set the Rate to 100 mL/hr and set the VTBI mL to 50 mL.

8.Connect a pressure gauge to the end of a fluid filled new IV set with a length of ≈ 48” of tubing between the pump and gauge.

9.Push the “RUN / STOP” key to start the pump.

Note: Pumps with v6.00.00 and later software versions will display a CHECK FLOW screen once the pump is started. For purposes of this test, press ‘yes’ to proceed to the normal RUN screen.

10.The pump may indicate BAG NEAR EMPTY <30 MIN REMAIN. Press the “OK” key to silence this alarm.

11.Verify the pump displays a “DOWNSTREAM OCCLUSION” alarm at a pressure within the 13psi ± 6 occlusion trip pressure setting.

11

P/N 41019 Rev W

SIGMA SPECTRUM INFUSION PUMP - SERVICE MANUAL

Air Detection Test *

NOTE: Confirm test failures with a new unused IV set.

1.Set VTBI limit to 50 mL. Press OK.

2.Push the “RUN / STOP” key.

Note: Pumps with v6.00.00 and later software versions will display a CHECK FLOW screen once the pump is started. For purposes of this test, press ‘yes’ to proceed to the normal RUN screen.

3.Introduce a 1” minimum air bubble into the IV set upstream from the pump.

4.Verify the pump goes into “AIR-IN-LINE” alarm. Press RUN/STOP.

Memory Test (this assumes you are starting from an all clear point) *

1.Turn the pump on. May ask New Patient Yes/No? Select No.

2.Push “BASIC” and “OK”, “OK”.

3.Set a parameter for “RATE” and “VTBI”.

4.Turn the pump off.

5.Turn the pump on and press No to the New Patient Yes/No screen. Verify the “RATE” and “VTBI” parameters were saved.

Recommended Flow Rate Accuracy Test *

NOTE: Confirm test failures with a new unused IV set.

1.Set the pump’s flow rate to 200 mL/hr.

2.Set the VTBI to 50 mL (length of test ≈ 15 min.) when using a gravimetric method.

3.Set the VTBI to 40 mL using a 50 mL Class A Graduate collection vessel when the volumetric test method is chosen. If a larger Class A Graduate is used a VTBI that is at least 80% of the collection vessel’s maximum capacity should be collected.

4.Hang the IV bag / container 24” above the pumping mechanism.

5.Connect a new IV set to the IV container and prime the set completely. Remove all air from the tubing, being sure the drip chamber is at least half full.

6.Load the set into the SIGMA Spectrum pump and close the door.

7.Place the end of the IV set in the collection vessel so that the fluid output end will not be below the fluid level that is to be collected. The set should be primed so that fluid is at the end of the IV set, but none has dripped into the graduate before starting the test.

8.Begin the test by pressing the “RUN” key. Allow the SIGMA Spectrum pump to run until it goes into infusion complete alarm.

Note: Pumps with v6.00.00 and later software versions will display a CHECK FLOW screen once the pump is started. For purposes of this test, press ‘yes’ to proceed to the normal RUN screen.

9.Press the “STOP” key to halt the KVO (keep vein open) rate once the pump goes into infusion complete.

10.If test is interrupted by any alarms except air, the test can be continued as long as the pump was observed by the tester to have not been in “STOP” for more than ten minutes.

11.Observe the actual volume collected either visually or weighed on the scale.

12.When measuring fluid level visually in the graduate, the level is read from the bottom of the fluid meniscus.

13.Acceptance criteria: collected volumes of ± 5%.

14.When measuring with the scale (gravimetric method):

15.Weigh the collection vessel and water using grams as the unit of measure.

16.Empty and dry the collection vessel.

17.Weigh the collection vessel. The difference between the two measured weights is equivalent to the volume delivered.

18.If the collection volume is within the range of ± 5%, the pump is properly calibrated. If not, return the pump to SIGMA International, Inc. for re-calibration.

AC Power Adaptor Safety Analysis

1.Inspect the SIGMA P/N 35714 AC Power Adaptor for signs of abuse such as cracks in the housing or bent AC main prongs.

2.Verify green LED is lit.

3.Inspect the low voltage supply cord from the AC power adaptor to the pump unit for signs of abuse such as cuts or exposed conductors.

12

P/N 41019 Rev W

SIGMA SPECTRUM INFUSION PUMP - SERVICE MANUAL

Battery Capacity Test

1.The storage capacity for the battery may be determined by running the Battery Capacity Test.

2.The pump must be connected to the AC power line for at least 12 hours prior to the test, to allow the battery to attain full charge. NOTE: If a Wireless Battery Module is installed the pump must be connected to the AC power line for at least 16 hours prior to the test.

3.The pump can be in use while the battery is charging.

4.Use an IV test set in a loop configuration, so that fluid is circulated around the loop.

5.Turn on the pump and load the IV set into the pump following the display prompts to assure that it is properly loaded. NOTE: If the IV set is not properly loaded the test results will be invalid.

6.Select the Help softkey, User Settings and select Display Settings, the Display Adjust and then select Backlight Level to “High”. Exit to the OPTIONS screen.

7.Select the Biomed Configuration so that the automatic monitoring of the battery capacity test can be selected. Enter the password and select Pump Testing.

8.Select option for “Battery Life Test”.

9.Follow the display instructions. Enter or verify 125 mL/hr for Rate and turn “Low batt alarm” and “Constant alarm” off.

10.Press the OK key and move the cursor to done press OK.

11.Be sure that the pump is unplugged and the “Current battery Level” indicates a fully charged battery (between 8.0V and 8.3V). If battery is fully charged, select “OK”.

12.The pump will run until the battery is depleted and will then power off.

13.After the battery is depleted, plug in the pump’s AC Power Adaptor and power the pump up or power the pump up with a fully charged battery.

14.When the pump is plugged in, it will display the time from the start of the test to depleted battery and it will also display time from low battery to depleted battery (in hr:min format).

15.Pass criteria for a used battery: ≥ 6 hours from “Start to dead” and ≥ 31 minutes from “Low to dead”. NOTE: If a Wireless Battery Module is installed, the pump used battery pass criteria is ≥ 3 hours from “Start to dead” and ≥ 31 minutes from “Low to dead”.

16.Pass criteria after installation of a new battery: ≥ 8 hours from “Start to dead” and ≥ 31 minutes from “Low to dead”. NOTE: If a Wireless Battery Module is installed, the pump new battery pass criteria is ≥ 4 hours from “Start to dead” and ≥ 31 minutes from “Low to dead”.

17.Less battery capacity indicates a battery reaching end of life.

18.See the Battery Removal and Replacement section of this manual for replacement. If a Wireless Battery Module is installed, see the Wireless Battery Module portion of the Battery Removal and Replacement section.

13

P/N 41019 Rev W

SIGMA SPECTRUM INFUSION PUMP - SERVICE MANUAL

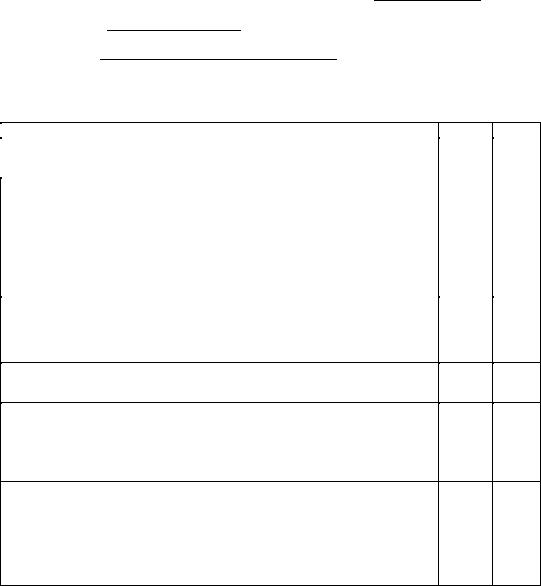

Serial Number: |

|

Date: |

Software Version:

Control Number:

Preventative Maintenance Check Off Sheet

TEST |

PASS FAIL |

VISUAL INSPECTION |

|

|

|

KEYBOARD TEST |

|

|

|

UPSTREAM (PROXIMAL) OCCLUSION SENSOR TEST |

|

|

|

AIR DETECTION TEST |

|

|

|

DOWNSTREAM (DISTAL) OCCLUSION SENSOR TEST |

|

______PSI |

OR ______mm/hg |

MEMORY TEST

FLOW RATE ACCURACY TEST

VOLUME OUTPUT ______mL

BATTERY CAPACITY TEST

TIME “Start to dead” = ______HRS ______MIN.

TIME “Low to dead” = ______HRS ______MIN.

14

P/N 41019 Rev W

SIGMA SPECTRUM INFUSION PUMP - SERVICE MANUAL

1.6 DOWNLOADING THE HISTORY LOG

PURPOSE

The purpose of this document is to provide instructions for the extraction of the history (event) log from a SIGMA Model Spectrum Infusion pump.

SCOPE

This procedure applies to the transfer of the history (event) log contents from a SIGMA Spectrum Infusion pump with V5.00.06 Operating Software to a PC via the IrDA port.

EQUIPMENT LIST

1.PC running Windows XP or Windows 2000 with enabled IrDA communications

2.Optional Equipment List (if IrDA-equipped PC is not available)

a.PC running Windows XP or Windows 2000 with SD Card Reader or,

b.USB External SD Card Reader/Writer, Ezonics™ or equivalent

c.SD Card, Kingston™ or equivalent, minimum size 512MB

d.PN 55098 – PDA, PalmOne™ Tungsten™ E2 or equivalent with a file transfer utility installed (McFile version 2.2sigma, or equivalent) for transferring data

REFERENCES

None.

DEFINITIONS

•PC – Personal Computer

•IrDA – Infrared Data Association defining a communications protocol for the short-range exchange of

data

•PDA – Personal Digital Assistant

•USB – Universal Serial Bus

•SD Card – Secure Digital Card (removable memory)

PROCEDURE

1.Access the “History Log” option of the Spectrum.

a.If the pump is running, press STOP and then press the ‘options’ softkey. Otherwise access the ‘options’ softkey from the ‘Need Help’ screen.

b.Select the ‘User Options’ menu item.

c.From the USER OPTIONS menu select the “View Information” menu item.

d.From the VIEW INFORMATION menu select the “History Log” menu item.

e.From the HISTORY LOG menu select the “Dump History Log” menu item.

f.Proceed to Step 6.2 or 6.3.

15

P/N 41019 Rev W

Loading...

Loading...