Sigma C4 User Manual

SIGMA SYSTEMS

MODELS C4 & CC-3.5

PROGRAMMABLE TEMPERATURE CONTROLLER / INTERFACE

OPERATING & PROGRAMMING MANUAL

Firmware Version 7.5.2

Manual Revision 4

June 3, 1999

SIGMA SYSTEMS CORPORATION

1817 John Towers

San Diego, California 92116 USA

TEL: (619) 258-3700 |

WWW.SigmaSystems.Com |

FAX: (619/258-3712) |

C4 Manual Rev 7.5.2

Copyright 1997, 1998

Sigma Systems Corporation

1817 John Towers

El Cajon, California 92020 USA

All rights reserved

The manual may be reproduced, in whole, or in part, solely for the purposes of use and training for the use, of Sigma Systems equipment, or as required to assist in the sale of new Sigma Systems equipment. No modification of the content is permitted.

C4 Manual Rev 7.5.2

TABLE OF CONTENTS

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Models C4 & CC-3.5 Explained . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 1.2 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 Custom Features / Interchangeability WARNING . . . . . . . . . . . . . . . . . . 11 1.4 Release 7.5.2 Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 1.5 C4 vs. CC-3 Differences (What’s New) . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5.1 Hardware & Stability Improvements . . . . . . . . . . . . . . . . . . . . . 12 1.5.2 Hardware Change (EEPROM replaces BBSRAM) . . . . . . . . . . 12

1.5.3 Firmware Uploads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 1.5.4 Forced Start from PROM Firmware . . . . . . . . . . . . . . . . . . . . . 13 1.5.5 Front Panel Information Display at Startup . . . . . . . . . . . . . . . . 13

1.5.6 Temperature Out of Range Shutdown . . . . . . . . . . . . . . . . . . . 13 1.5.7 Internal Error Shutdown Conditions . . . . . . . . . . . . . . . . . . . . . 14 1.5.8 Fahrenheit Temperature Scale Supported . . . . . . . . . . . . . . . . 14 1.5.9 Temperature Probe Correction (Calibration) . . . . . . . . . . . . . . . 14 1.5.10 “Bumpless” Temperature Control . . . . . . . . . . . . . . . . . . . . . . 14

1.5.11 Intelligent 2 Probe Control (Probe Averaging) . . . . . . . . . . . . 15

1.5.12 Default Setup Parameters Restore . . . . . . . . . . . . . . . . . . . . . 16 1.5.13 Program Mode Step Insert & Delete . . . . . . . . . . . . . . . . . . . . 16 1.5.14 Program Mode Any Step Points to Step 100 . . . . . . . . . . . . . 16 1.5.15 Program Mode Safer Program Clear . . . . . . . . . . . . . . . . . . . 16

1.5.16 Program Mode Run Time Program Pre-check . . . . . . . . . . . . 16

1.5.17 Remote Mode EIA-232 Baud Rate Improvement . . . . . . . . . . 16 1.5.18 Remote Mode EIA-232 Port Initialization . . . . . . . . . . . . . . . . 17 1.5.19 Remote Mode Fault Tolerant Parser . . . . . . . . . . . . . . 17 1.5.20 Remote Mode System Information Queries . . . . . . . . . . . . . . 17

1.5.21 Remote Mode Operation Information Queries . . . . . . . . . . . . 17

1.5.22 Remote Mode Setup Parameter Commands . . . . . . . . . . . . . 18 1.5.23 Remote Mode IEEE-488 (GPIB) Monitoring . . . . . . . . . . . . . . 18 1.5.24 Setup Mode Easier Parameter Access . . . . . . . . . . . . . . . . . . 18

2. PHYSICAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

||

2.1 |

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

|

|

2.1.1 |

Digital LED Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

|

2.1.2 |

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

|

2.1.3 Mode Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

|

|

2.1.4 |

Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

21 |

2.2 |

Rear Panel Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

|

3. GENERAL OPERATION & ERROR CONDITIONS . . . . . . . . . . . . . . . . . . . . . . 23 3.1 Startup Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 3.1.1 Model Number and Firmware Version Number Display . . . . . . 23 3.1.2 Temperature Range Display . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.3 Serial Number Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

C4 Manual Rev 7.5.2 |

3 |

3.2 Updating Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2.1 Upgrading Firmware by PROM Replacement . . . . . . . . . . . . . . 25 3.2.2 Upgrading Firmware by Uploading through C4 Serial Port . . . . 25

Making the physical connection for upload . . . . . . . . . . . . . . . . 26 Running the upload software on the PC . . . . . . . . . . . . . . . . . . 26 Starting the upload on the C4 . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3 Restoring Setup Parameters to Default Values . . . . . . . . . . . . . . . . . . . . 27 3.4 Fahrenheit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.5 System Operating (Temperature) Range . . . . . . . . . . . . . . . . . . . . . . . . 29 3.6 Probe Out of Range Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 3.6.1 Effect of Probe Correction on Out of Range Shutdown . . . . . . . 30

3.6.2 Probe Out of Range Shutdown Reported in Error/Status String

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.6.3 Clearing a Probe Out of Range Shutdown . . . . . . . . . . . . . . . . 30 3.7 Internal Error Shutdown Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.7.1 Watchdog Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 3.7.2 Memory signature checking . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 3.7.3 Setup parameter integrity checking . . . . . . . . . . . . . . . . . . . . . . 32

3.8 Software Probe Correction (Calibration) . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.9 Status and Error Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.10 Fail-safe System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4. INTELLIGENT 2 PROBE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

35 |

|

4.1 |

How Intelligent 2 Probe Control functions . . . . . . . . . . . . . . . . . . . . . . . . |

36 |

4.2 |

Preparing for Intelligent 2 Probe Control . . . . . . . . . . . . . . . . . . . . . . . . |

37 |

4.3 |

Using Intelligent 2 Probe Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

38 |

5. LOCAL MODE ( Basic Operation ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 5.1 Displaying Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2 Displaying and Changing the Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3 Controlling to a Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 5.4 Compressor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6. PROGRAM MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 43 |

||

6.1 |

Description of a Program Step . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 43 |

|

|

6.1.1 Format of a Program Step . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 44 |

|

|

6.1.2 |

Maximizing Ramp Speed & Other Ramp Considerations |

. . . . . 45 |

6.2 |

Clearing Program Memory (Reinitializing program steps) . . . . . . . |

. . . . . 46 |

|

6.3 |

Displaying Program Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 46 |

|

6.4 |

Entering or Changing a Program Step . . . . . . . . . . . . . . . . . . . . . . |

. . . . 47 |

|

6.5 |

Insert Program Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 47 |

|

6.6 |

Delete Program step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 48 |

|

6.7 |

Running (Executing) a Program . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 48 |

|

|

6.7.1 |

Program Run Time Information/Considerations . . . . . . . . |

. . . . 49 |

|

6.7.2 |

Run Time Pre-read Errors . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 49 |

|

|

No Probe 2 Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 50 |

4 |

C4 Manual Rev 7.5.2 |

Invalid Loop Count Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Setpoint Out of Range Error . . . . . . . . . . . . . . . . . . . . . . . . . . 50 6.8 Special Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.8.1 Controlled Program Looping . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 6.8.2 External Compressor On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 6.8.3 External Compressor Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.8.4 Optional Aux/Power Control Port On . . . . . . . . . . . . . . . . . . . . 52 6.8.5 Optional Aux/Power Control Port Off . . . . . . . . . . . . . . . . . . . . 52

6.9 Common Programming Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 6.9.1 Step Numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 6.9.2 Changing Substep Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.9.3 Control Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7. REMOTE MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 7.1 EIA-232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2 IEEE-488 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 7.3 Command Summary (by functional group) . . . . . . . . . . . . . . . . . . . . . . . 56 7.4 System Information Queries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57 7.4.1 QV Query Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.4.2 QN Query Controller Serial Number . . . . . . . . . . . . . . . . . . . . . 57

7.4.3 QR Query Controller Temperature Range . . . . . . . . . . . . . . . . 58 7.4.4 QS Query Setpoint & Control Probe Number . . . . . . . . . . . . . . 58 7.4.5 QF, QFA Query Setup Parameter Value . . . . . . . . . . . . . . . . 59

7.5 Operation Information Queries & Commands . . . . . . . . . . . . . . . . . . . . 61

7.5.1 RS, RSA Request Status Byte . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.5.2 RE, REA Request Error Byte . . . . . . . . . . . . . . . . . . . . . . . . . . 61 7.5.3 QE, QEA Query Error/Status String . . . . . . . . . . . . . . . . . . . . . 62 7.5.4 QC Query Last Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64 7.5.5 ES Enable SRQ (Status Request Mode) . . . . . . . . . . . . . . . . . 64

7.5.6 DS Disable the SRQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.5.7 PT Read Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 7.6 Setup Parameter Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 7.6.1 SC Set Probe Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.6.2 WP Set PID Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.6.3 BF & BO Blower Off & Blower On Commands . . . . . . . . . . . . 68 7.6.4 SL Set UUT Temperature Limits . . . . . . . . . . . . . . . . . . . . . . . 69 7.6.5 SD Set UUT Temperature Differential Limits . . . . . . . . . . . . . . 69

7.6.6 UP Write Current Parameters to NV Memory . . . . . . . . . . . . . 69 7.7 System Operation Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.7.1 SI Select Immediate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 7.7.2 SP Select Program Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 7.7.3 PN Select Active (control) Probe . . . . . . . . . . . . . . . . . . . . . . . 70

7.7.4 GT, GTF Go To Temperature . . . . . . . . . . . . . . . . . . . . . . . . . 71 7.7.5 RA, RAF Ramp to Temperature . . . . . . . . . . . . . . . . . . . . . . . 71 7.7.6 DL Delay (Dwell Interval) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

7.7.7 CO & CF Turn the Refrigeration Port On . . . . . . . . . . . . . . . . . 72

C4 Manual Rev 7.5.2 |

5 |

7.7.8 TO & TF Turn Aux/Power Control Port On . . . . . . . . . . . . . . . . 72

7.7.9 QU Quit Controlling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.8 Error and Status Reporting - Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.8.1 Status Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.8.2 Error Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.8.3 Error/Status String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Error/Status String Bit Definitions . . . . . . . . . . . . . . . . . . . . . . . 77

8. SETUP MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79 8.1 Displaying the Field Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81 8.2 Changing the Value of a Setup Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.3 Two Probe Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82 8.4 Auto-start Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.5 Blower Shut-off Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83 8.6 Temperature Control Terms (PID) (Setup fields 0, 10, 11, 12) . . . . . . . . 83

8.7 Software Probe Correction (Calibration) . . . . . . . . . . . . . . . . . . . . . . . . . 83 Entering probe correction setup data . . . . . . . . . . . . . . . . . . . . 84

9. APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

9.1 Programming Examples & Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

9.1.1 Simple Local Program Example . . . . . . . . . . . . . . . . . . . . . . . . 87 9.1.2 Using shortcuts to shorten program entry time . . . . . . . . . . . . . 89 9.1.3 Local Program Example Using the Special Commands . . . . . . 91

9.2 Keeping More than One Program in Memory . . . . . . . . . . . . . . . . . . . . . 93

9.3 Sigma Systems C4 Programming Worksheet . . . . . . . . . . . . . . . . . . . . . 95

9.4 Sample Command Structure for IEEE-488 GPIB Operation . . . . . . . . . . 96 9.5 Installation and Use of TTL Outputs and Input . . . . . . . . . . . . . . . . . . . . 98 9.6 Field Calibration of Model C4 Controller . . . . . . . . . . . . . . . . . . . . . . . . . 99 9.7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

9.7.1 Servicing Considerations - Service WARNINGS . . . . . . . . . . . 101

9.7.2 Before you go any further... . . . . . . . . . . . . . . . . . . . . . . . . . . . 101 9.7.3 Diagnosing and Solving Hardware Problems . . . . . . . . . . . . . 101 9.7.4 Noise Immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

9.7.5 Diagnosing and Solving Local Mode Problems . . . . . . . . . . . . 102

Controller starts immediately in Local Mode . . . . . . . . . . . . . . 102 9.7.6 Diagnosing and Solving Program Mode Problems . . . . . . . . . 102 Hard Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Explicit Program End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103 Blowers Misbehaving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Program hangs on Ramp as Quickly as Possible step . . . . . . 103 9.7.7 Diagnosing and Solving Remote Mode Problems . . . . . . . . . . 103 EIA-232 Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

GPIB IEEE-488 Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . 104 9.7.8 Firmware Upload Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . 104 Starting the C4 from PROM based firmware . . . . . . . . . . . . . 105

COM port issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6 |

C4 Manual Rev 7.5.2 |

9.8 Temperature Control (PID) Tuning & Problems . . . . . . . . . . . . . . . . . . 105

Adjusting for changing needs . . . . . . . . . . . . . . . . . . . . . . . . . 106 The Proportional Term . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

The Integral Term . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107 The Differential Term . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108 9.9 Displayed Messages and Errors Table . . . . . . . . . . . . . . . . . . . . . . . . . 109

9.10 Technical Support, Repairs & Returns . . . . . . . . . . . . . . . . . . . . . . . . 110

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

111 |

C4 Manual Rev 7.5.2 |

7 |

8 |

C4 Manual Rev 7.5.2 |

1. INTRODUCTION

This manual describes the operating procedures for the Sigma Systems Models C4 & CC-3.5 Controllers, microprocessor based controllers and control communications interfaces for the family of Sigma Systems temperature chambers and thermal platforms.

1.1 Models C4 & CC-3.5 Explained

The models C4 & CC-3.5 controllers are successors to the model CC-3.

The model C4 is a completely redesigned controller that uses a completely different and more modern set of internal components with a new processor and completely new firmware. Model C4 controllers are only available as new products from Sigma Systems.

The model CC-3.5 is a hybrid upgrade controller that uses only the digital circuitry of the model C4. It is made by substituting the C4 digital p.c. board (known within Sigma Systems as the “CPU board”, or the “A” board) for the CC-3's “A” board. The upgrade from CC-3 to CC-3.5 also includes a few small modifications to other internal components. The power supply, power switching, analog, and front panel components of the CC-3 remain. Model CC-3.5 controllers are only available as the product of upgrading a CC-3 controller.

From a functional perspective, models C4 & CC-3.5 are identical because all of the functionality of the controllers is defined by the processor, bus interface components, and firmware... all of which are integral with the C4 “A” board. The C4 analog and front panel components that remain unique to the C4 (not included in the CC-3.5 upgrade from CC-3) provide slightly better accuracy and substantially better noise and static immunity.

For the balance of this manual, the term C4 will mean to include both the model C4 controller and the model CC-3.5 controller. In the event that there is a difference between the two models, that difference will be explicitly detailed.

C4 Manual Rev 7.5.2 |

9 |

1.2 General Description

Using the model C4, temperature control is available manually from the front panel, by use of user entered programs, or via remote control via either a EIA-232 or IEEE-488 GPIB. The controller has a precision temperature reading capability with a digital read-out. Two temperature probes can be connected to the controller allowing either probe or both probes to be the control probe(s) while either probe can be used to take measurements.

Two additional controlled device ports are available. They are intended for on/off control of a refrigeration compressor and an external load such as a device under test, or a main chamber or platform power relay. These ports normally are supplied as TTL level (low voltage) ports but are optionally available with solid state relays to control line voltage as in the case of units with mechanical refrigeration. The compressor control port may be toggled from the front panel at any time in the manual (LOCAL) mode. The compressor is designed to not cycle on and off with the temperature control function.

The controller operates in each of four modes:

Local |

Single Setpoint control from the front panel. Simple |

Mode |

Start/Stop functionality. |

|

|

|

Programmed control using programs entered, stored, and |

Program |

run from the front panel. 100 Temperature/Duration |

Mode |

Program steps available. Multiple programs may be stored |

|

and called as needed. |

|

Control via EIA-232 or IEEE-488 GPIB. The IEEE-488 |

|

interface implementation is a TALKER/LISTENER with |

Remote |

serial poll. Extended addressing and parallel poll |

Mode |

capabilities are not supported. The EIA-232 interface is |

|

fully configurable for baud rate, data bits, stop bits and |

|

parity. |

Setup |

Used to define and store operation and environment |

Mode |

variables that control how the C-4 behaves. |

10 |

C4 Manual Rev 7.5.2 |

1.3 Custom Features / Interchangeability WARNING

Each Sigma Systems C4 Controller has been custom configured for the chamber or platform with which it was supplied or for which it was specified. Many units include special wiring for custom control applications, precision fail-safe additions, non-standard voltages, external unit power control, etc. Units that may appear to be identical may be internally quite different. Do not interchange controllers between controlled devices (chambers and/or platforms) unless you are certain that the controllers have been identically constructed.

Failure to heed this warning voids your warranty, may cause unpredictable controlled device behavior that could cause damage to persons or property, pose a risk of fire, or cause other problems. If you must move controllers between controlled devices, please contact the Sigma technical support department for assistance and advice.

1.4 Release 7.5.2 Firmware

This manual is specifically written to cover the features of Release 7.5.2 firmware for the Sigma Systems Model C4 controller. The features of this release firmware are largely backward compatible with all CC-3 and earlier CC-3.5 & C4 firmware.

This release fixes a number of bugs found in the CC-3.5 interim release versions 6.8.6, 6.9.0, and 7.0.0. It also adds a number of new features. See Section 1.5.

Note: This release implements probe temperature correction on a per probe basis. Interim CC-3.5 releases implemented this feature on a global basis.

Sigma highly recommends that all users update to the latest firmware release. Contact Sigma Technical Support. See Section 9.10.

Note: This release is not available as an upload file for serial port firmware updating of your controller. Due to non-backward compatible change in the way some data is stored internally, this version must be installed using a PROM obtained from Sigma Systems.

C4 Manual Rev 7.5.2 |

11 |

1.5 C4 vs. CC-3 Differences (What’s New)

1.5.1 Hardware & Stability Improvements

The new C4 introduces a number of new improvements to make the controller faster and more reliable than its predecessor.

The C4 has a completely new digital processing board. The new board has a much faster processor, more memory, and a much faster IEEE-488 GPIB controller. Interrupts have been completely restructured to improve stability. The multilayer design is far more tolerant of both static and power line interference. There is now a watchdog timer to detect system lockups in the event that something does interfere with the system. The battery backed RAM has been replaced by an EEPROM. The Vactrol type isolation device in the failsafe circuit has been replaced. The C4 contains no components that have a time based failure mode.

The new firmware also monitors the state and integrity of internal memory. Critical system information is stored in multiple places so that minor errors due to uncontrollable transients or other causes can be repaired on the fly with no disruption in process control. Likewise, both the front panel display and the GPIB interface are monitored constantly to assure that their operation has not been compromised by static discharge or line transient. In the event of a problem, either device can be reset on the fly to allow operations to continue normally.

System integrity is further enhanced by a series of successive shutdown processes that monitor the integrity of the data coming from the sensor probes. In the event that any probe reports a temperature more than 20/C beyond the limits set in the controller, the controller will shut down all heating and cooling and display a warning message. Likewise, in the event that a sensor probe reports an extreme temperature, either hot or cold, the system will assume that a probe has become compromised by an open or shorted circuit and stop applying heat and cooling, shut down the system and display an appropriate warning message..

1.5.2 Hardware Change (EEPROM replaces BBSRAM)

All C4 controllers and CC-3.5 controllers converted after January 1998 have the battery backed static RAM (BBSRAM) replaced with an EEPROM. This change was implemented to reduce the possibility that the controller will require service. Although changing the BBSRAM when the battery died (about every 5-12 years) was a fairly simple matter, the necessity for doing so was found to be a nuisance as was diagnosing the need for the change. The BBSRAM or EEPROM provides the non volatile memory where the C4 stores both the setup parameter information and the user programs.

12 |

C4 Manual Rev 7.5.2 |

1.5.3 Firmware Uploads

When new firmware is available for your C4, you can easily upload it into the controller using the controller’s serial port. The procedure requires only a diskette bootable PC and a serial cable and takes only about ten minutes. Firmware updates, when available, may be obtained on diskette for a fee from Sigma Systems or for free by download from www.SigmaSystems.Com or ftp.SigmaSystems.Com. See Section 3.2.2

1.5.4 Forced Start from PROM Firmware

The controller can be started from the original firmware version that is stored in the PROM. Uploaded versions are stored in flash memory. If a firmware upload session should go astray somehow, this feature allows the controller to still operate. See Section 9.7.8.

1.5.5 Front Panel Information Display at Startup

The controller model is displayed at startup - See Section 3.1.1

The firmware version number is displayed at startup - See Section 3.1.1 The operating range may be displayed at startup - See Section 3.1.2 The controller serial number may be displayed - See Section 3.1.3

1.5.6 Temperature Out of Range Shutdown

The controller now stores the operational limits for itself, the controlled device (Sigma chamber or platform), and the unit under test (UUT). The operating temperature is checked against these limits, if it is too far outside these limits,. the system is shutdown with an appropriate error message displayed. See Section 3.5.

C4 Manual Rev 7.5.2 |

13 |

1.5.7 Internal Error Shutdown Conditions

The C4 monitors system health by keeping track of three additional areas; they are:

Processor health |

Tracked by watchdog timer |

Memory condition |

Checked at startup |

Setup parameter table |

Checked continuously as used |

Some detected internal errors can be repaired on the fly. If this is possible, the C4 will recover from the error and you will not know the error existed. If, however, the error is not repairable and the system must be shut down, an error message will be displayed to help you understand what happened and how to prevent or cope with it. See Section 3.7.

1.5.8 Fahrenheit Temperature Scale Supported

The controller will now operate in either Celsius /C or Fahrenheit /F mode. See Section 3.4.

1.5.9 Temperature Probe Correction (Calibration)

The C4 will allow you to enter data via the Setup mode that will correct anomalies in the temperature readings and control. Such adjustments are sometimes necessary to optimize accuracy at a particular temperature, or to compensate for differences between raw probe temperature data and actual temperatures. These differences can be the result of probe placement, effects of the unit under test on the temperature data, or other causes. See Section 3.8

1.5.10“Bumpless” Temperature Control

(Not in this release. Available in next release, without charge. Check the Sigma Systems FTP or WWW site for downloadable file.)

When the setpoint is changed, the PID control algorithm begins a new “search” for the right amount of heat and/or cooling to maintain the new setpoint. Normally, for each new setpoint, the PID routines begin the search anew... behaving as if the controller was just turned on. The controller will quickly determine that heat or cooling is called for, and while the chamber or platform advances toward the new Setpoint, the PID routine adjusts for the response to heat and cool and methodically settles the chamber or platform in on the new setpoint. For most setpoint changes, where the new and old setpoints are quite different, this is a fast, accurate and appropriate method of control.

14 |

C4 Manual Rev 7.5.2 |

However, when the change in the Setpoint is very small, this “start from the beginning” search routine can search over such a wide range that it will introduce a “bump” in the platform or chamber temperature that can exceed the amount of the Setpoint change. The C4 includes an intelligent PID routine that constrains the search appropriately for the change in Setpoint and thus eliminates the “PID bump”.

1.5.11Intelligent 2 Probe Control (Probe Averaging)

(Not in this release. Available in next release, without charge. Check the Sigma Systems FTP or WWW site for downloadable file.)

Intelligent 2 Probe Control allows the internal temperature of the unit under test (UUT) to be used in the temperature control algorithm. Both the primary probe, located in the chamber airstream or platform, and the secondary probe, typically located inside the UUT, are used to provide a chamber or platform response that can accelerate testing while respecting the absolute and relative limits of all the affected components.

Common single probe control strives to maintain the Setpoint temperature in the chamber airstream, or at the platform surface. If the UUT is massive, or is a poor thermal conductor, the internal temperature of the UUT can lag the chamber or platform temperature considerably. Conversely, using a second probe, buried inside the UUT, to control the temperature may achieve better UUT interior temperature control, but it will do so at the risk of extreme temperatures in the chamber or on the platform. If not carefully monitored, second probe only control can result substantial damage to the chamber or platform and UUT and risk operator injury.

Intelligent 2 Probe Control is designed to achieve the Setpoint temperature inside the UUT (probe 2) either as quickly as possible, or at a controlled ramp rate, while always respecting the limits of the controller, chamber or platform, and UUT. The user may specify the absolute limits of the exterior of the UUT as well as limit themal shock by specifying a dynamically changing “sliding scale” maximum temperature differential for the UUT skin to core temperature. Intelligent 2 Probe Control will maximize speed in achieving internal UUT Setpoint temperatures, while, at the same time, controlling the thermal stress on the UUT.

An in depth discussion of this feature can be found in Section 4.

1.5.12 Default Setup Parameters Restore

There is a procedure for erasing the current setup parameter table data and restoring it basic default values. See Section 3.3

C4 Manual Rev 7.5.2 |

15 |

1.5.13 Program Mode Step Insert & Delete

Program steps may now be deleted from or inserted into programs. See Sections 6.5 & 6.6.

1.5.14 Program Mode Any Step Points to Step 100

Any program step may now point to step 100 (program end) as the next step to execute.

1.5.15 Program Mode Safer Program Clear

Some deliberate delays have added to the key sequence to completely clear the program memory to lessen the likelihood that all of program memory will be erased by accident.

1.5.16 Program Mode Run Time Program Pre-check

When a program is run in Program Mode, the C4 pre-reads the program to look for run-time errors that it can report to you before starting. By pre-checking your program, errors are dealt with immediately rather than after the program has partially completed. The following items are checked:

Calls for probe 2 when only one probe is defined for the system Calls for setpoints that are not within the system operating range Loop counter numbers not within the range of 1 to 999 integer

See Section 6.7.2 for a full explanation.

1.5.17 Remote Mode EIA-232 Baud Rate Improvement

EIA-232 communications are now supported at 19,200 and 38,400 bps. See Section 8.

16 |

C4 Manual Rev 7.5.2 |

1.5.18 Remote Mode EIA-232 Port Initialization

The CC-3 required that to use the EIA-232 port, the port had to be initialized by switching the mode switch to SETUP before switching to REMOTE mode. The C4 eliminates this requirement. The EIA-232 port is initialized each time the remote switch is switched to REMOTE mode.

1.5.19 Remote Mode Fault Tolerant Parser

The C4 uses a very fault tolerant parser. Command strings received over either the EIA-232 or GPIB ports are converted to upper case, extra spaces and tabs are removed, commas are converted to spaces and line terminators are corrected if necessary. For this reason, programs that work properly with the C4 and not with a CC-3, that use only CC-3 commands, probably have syntax errors that the C4 parser corrects. See Section 9.7.7

1.5.20 Remote Mode System Information Queries |

|

|

QV |

Query Firmware Version . . . . . . . . . . . . . . . . |

. . . . . See Section 7.4.1 |

QN |

Query Serial Number . . . . . . . . . . . . . . . . . . . |

. . . . . See Section 7.4.2 |

QR |

Query Temperature Range . . . . . . . . . . . . . . . |

. . . . . See Section 7.4.3 |

QS |

Query Setpoint & Control Probe Number . . . |

. . . . . See Section 7.4.4 |

QF |

Query Setup Parameter Data (Binary Query) |

. . . . . See Section 7.4.5 |

QFA |

Query Setup Parameter Data (ASCII Query) |

. . . . . See Section 7.4.5 |

1.5.21 Remote Mode Operation Information Queries |

|

|

RSA |

Request Status Byte (ASCII Query) . . . . . . . . |

. . . . . See Section 7.5.1 |

REA |

Request Error Byte (ASCII Query) . . . . . . . . |

. . . . . See Section 7.5.2 |

QE |

Query Error/Status String (Binary Query) . . |

. . . . . See Section 7.5.3 |

QEA |

Query Error/Status String (ASCII Query) . . . |

. . . . . See Section 7.5.3 |

QC |

Query Last Command . . . . . . . . . . . . . . . . . . . |

. . . . . See Section 7.5.4 |

C4 Manual Rev 7.5.2 |

17 |

1.5.22 Remote Mode Setup Parameter Commands |

|

|

SC |

Set Correction (Calibration) for Probe . . . . . . . . . . . |

See Section 7.6.1 |

WP |

Set PID Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . |

See Section 7.6.2 |

BF |

Turn Blowers Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

See Section 7.6.3 |

BO |

Turn Blowers On . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

See Section 7.6.3 |

SL |

Set UUT Temperature Limits . . . . . . . . . . . . . . . . . . |

See Section 7.6.4 |

SD |

Set UUT Temperature Differential Limits . . . . . . . . |

See Section 7.6.5 |

UP |

Write SRAM Parameters to EEPROM . . . . . . . . . . . |

See Section 7.6.6 |

1.5.23 Remote Mode IEEE-488 (GPIB) Monitoring

The IEEE-488 bus controller is automatically reset if a problem is detected. No message to the user is generated as no data is typically lost in the process.

1.5.24 Setup Mode Easier Parameter Access

Setup parameters may now be accessed directly by number rather than having to scroll the entire list. If scrolling is used, there is now a backup key so the list can be scrolled in either direction. Likewise, for parameters that are chosen from a list, the list can be scrolled in either direction or the parameters can be keyed in directly without scrolling the list. See Section 8.1.

18 |

C4 Manual Rev 7.5.2 |

2. PHYSICAL DESCRIPTION

The SIGMA SYSTEMS Model C4 Controller fits into an area 3.5" x 5.5" x 9.5" long. Connection to the chamber or platform is made through an umbilical cable with a 12 pin connector that is standard for all SIGMA chambers and thermal platforms. Controllers destined for use with SIGMA thermal platforms have an additional 6 pin connector used for the sensor probe circuits. All C4 controllers have a 3 pin “pigtail” connector at the back of the controller for control of refrigeration via solid state relay. This feature was optional on CC-3 controllers and is thus not a consistent feature of CC-3.5 controllers.

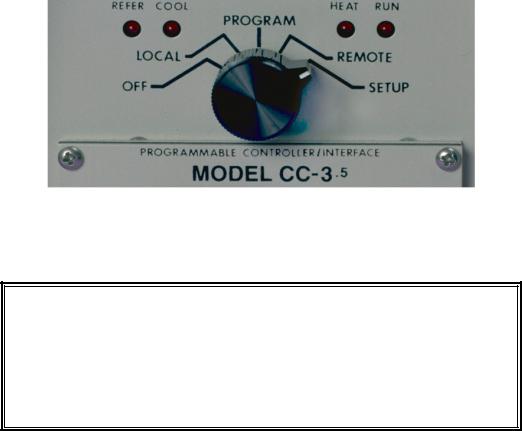

2.1 Front Panel

The front panel consists of four major parts: the LED digit display, the LED indicators, the mode switch and the keypad. The numbers in circles on the front panel guide the user through the steps for changing the temperature setting in the LOCAL (manual) mode of operation. See Section 5.

2.1.1 Digital LED Display

The Digital LED Display is a 7 digit display arranged in the following configuration:

***-****

The display is used for showing probe temperatures, setpoints, program steps, fail-safe status and setup information.

2.1.2 LED Indicators

Below the Digital LED Display are four discrete LED Indicators. These indicators are arranged in the following order:

REFER |

COOL |

HEAT |

RUN |

|

|

|

|

|

|

|

|

REFER indicator lights if power is applied to the refrigeration compressor control port (not all units are equipped with compressors).

C4 Manual Rev 7.5.2 |

19 |

COOL indicator lights when cooling is active, typically during the time the cryogenic valve is open on cryogenically cooled units.

HEAT indicator is pulsed along with the on and off function of the heaters. These indicators are active in all modes of operation.

RUN indicator shows whether the chamber temperature is being controlled.

2.1.3 Mode Switch

The Mode Switch is used to apply power to the chamber and to select the mode of operation. It is a 5 position rotary switch arranged as follows:

The OFF position removes the power from heating and cooling and compressor control circuits of both the controller and the chamber or thermal platform.

CAUTION: Placing the mode switch in the OFF position does not remove all power from either the controller or the chamber or thermal platform. Only the heating, cooling, and compressor control circuits are turned off. Full line voltage potential is still available in many places in both the controller and the chamber or platform. See servicing warnings and instructions in the appendix of this manual.

Moving the rotary switch changes the mode of operation of the chamber. The different modes are described in detail in separate sections of this manual. When the rotary mode switch is moved to a new position, other than OFF, the temperature control loop, if running, is turned off, heating and cooling are disabled but the chamber blowers will continue to run unless disabled via setup

20 |

C4 Manual Rev 7.5.2 |

parameter F15. Likewise, at the end of a local or remotely controlled program, chamber blowers will continue to run, but heating and cooling will be disabled. Note that a chamber in this condition, with blowers running, will exhibit some heating due to blower air friction. This effect is exaggerated in units equipped with high velocity blowers. Moving the rotary switch between OFF and LOCAL will maintain the last used setpoint for the next operation of the controller. See 6.3 for description of auto-start function.

2.1.4 Keyboard

The keyboard consists of 20 momentary contact keys. Certain keys are functional only in some of the modes of operation. With some keys, such as the Display Control, the function is different depending on the mode of operation. The Keyboard is arranged in the following configuration:

1 |

2 |

3 |

CLEAR |

START |

PROG |

STOP |

|||

|

|

|

|

|

4 |

5 |

6 |

REFER |

ENTER |

|

|

|

|

|

7 |

8 |

9 |

ADV |

DISP |

TEMP |

||||

|

|

|

|

|

. |

0 |

+ |

CLEAR |

DISP |

- |

ENTRY |

CNTL |

||

|

|

|

|

|

CLEAR PROG |

Clear program from memory |

START STOP |

Start/Stop temperature control |

REFER |

Toggle refrigeration compressor on or off * |

ENTER |

Enter/finalize current keyboard entry |

ADV |

Advance to next program step |

DISP TEMP |

Display temperature |

CLEAR ENTRY |

Clear current keyboard/display entry |

DISP CNTL |

Display control setpoint |

* = LOCAL MODE ONLY.

C4 Manual Rev 7.5.2 |

21 |

2.2 Rear Panel Connections

At the rear panel of the controller, a cable is provided to connect to the power, cooling solenoid, mechanical refrigeration and heaters of the chamber. In addition, a six lug screw terminal block (J1) is provided for eyelet terminal connection of the temperature probes and for connection of one additional optional device such as the Sigma PFS-2 Precision Fail Safe.

J1 TOP

ì

í

î

ï

ð

ñ

Probe 1 (Black lead)

Probe 2 (Black lead)

Chassis Ground (Probe shield)

(Chamber or platform ground, etc.)

Probe 1 & 2 return (Red or White lead)

Auxiliary device ground

12 VDC for Fail-Safe

Please observe all standard anti-static procedures when making connections to these points!

There is also an IEEE-488 (GPIB) connector, series 57 (metric threads), and an EIA-232 connector, female DB-25, for the remote modes of operation. Two TTL outputs and one TTL input are also available on J6. (See Section 9.5)

22 |

C4 Manual Rev 7.5.2 |

3. GENERAL OPERATION & ERROR CONDITIONS

3.1 Startup Displays

3.1.1 Model Number and Firmware Version Number Display

The C4 identifies itself upon power up. It will display the model number for 1 second, then the firmware version number for 2½ seconds as follows:

c3-5 |

rel |

7.5.2 |

c4 |

rel |

7.5.2 |

3.1.2 Temperature Range Display

Each C4 controller is set at the factory for use with a specific device (chamber or platform). Because the controlled device was made to specific thermal limit specifications, and because constraining the operating range of the controller improves it’s accuracy, the controller to be used with each device is set to operate only within the range appropriate for that device. The setting of an operating range involves a number of internal adjustments and calibrations and the loading of specific control tables for that range. This setting can only be changed by Sigma Systems service personnel. We recommend that each controller be kept with the device for which it was originally configured.

However, if you find that it is necessary to move a controller to another device, it is important that you check to be sure that the controller that is moved is configured to operate in the appropriate range for the device it is to control. As of November, 1998, controllers are supplied for five ranges as follows:

-100/C to 200/C |

-148/F to 392/F |

-100/C to 300/C |

-148/F to 572/F |

-100/C to 350/C |

-148/F to 662/F |

-175/C to 400/C |

-283/F to 752/F |

-195/C to 300/C |

-319/F to 572/F |

|

|

To check the internal range setting of your C4 controller, turn the mode switch from OFF to any other position. During the 2½ seconds that the firmware release number is shown on the display, rapidly press <DISP/TEMP> three times. The internal range setting will be displayed for 5 seconds following the version display. An example:

200 - 100c |

392 - 148f |

(Celsius mode) |

(Fahrenheit mode) |

C4 Manual Rev 7.5.2 |

23 |

3.1.3 Serial Number Display

The controller serial number can be displayed at startup by pressing <DISP/CTRL> while the model number (c3-5 or c4) is displayed. The serial number will be displayed in the format:

4-0 3276

The first digit (either a 3 or 4) indicates whether the controller is a CC-3.5 or C4,

and the 5 digits to the right of the dash is the sequential part of the number. There is no significance to the leftmost of the 5 sequential digits being separated from the other 4 digits. The separation is a limitation of the display. When recording or reporting serial numbers, please always use the 7 digit string, including the leftmost digit and the dash in this format: 4-03276.

When the serial number is displayed, the controller is not controlling. The number will remain on the display until the controller is turned off.

3.2 Updating Firmware

There are two methods of updating the firmware in the C4.

1. Physically replace the EEPROM that contains the firmware. (There is usually a charge for firmware EEPROMs)

.

2. Use a PC to upload the firmware through the C4 serial port. (Firmware and upload software are free from Sigma System’s internet sites, www.SigmaSystems.com or ftp.SigmaSystems.com)

Note: All firmware updates are available on EEPROM chips for physical installation. Not all updates are available as downloads from the Sigma Systems web site. The reason for this is that some firmware updates make changes in the basic data structures inside the C4. Because firmware loaded into the C4 through the serial port is stored separately, and in addition to, the EEPROM firmware, and because the C4 can be started from either resident version, the two versions must use compatible data structures. Thus, versions that will modify the data structures in the C4 may only be installed by changing the firmware EEPROM.

24 |

C4 Manual Rev 7.5.2 |

3.2.1 Upgrading Firmware by PROM Replacement

Before starting, be certain that you have a properly grounded antistatic surface and a grounding strap to prevent damaging the C4 components during disassembly and reassembly.

Remove the C4 from its cabinet or rack, then remove the EEPROM chip that contains the firmware and replace it with a new one containing the updated firmware. Firmware

EEPROMs are available from Sigma Systems. There is a charge for firmware EEPROMs.

The firmware EEPROM is located on the digital or “A” board, the same board that has the EIA-232 and GPIB connectors on the end. The location of the firmware EEPROM is shown by the triangle pointer. The EEPROM

socket is labeled U13. Make certain that the end of the EEPROM with the notch or notch mark is toward the inside, or center, of the board.

Note that it is possible to remove and replace the firmware EEPROM without disassembling the C4. If you lay the controller upside down, and look at the digital board from the bottom, the firmware EEPROM is the first large chip from the front of the controller. You will not be able to see the U13 label, but you can see the C32 label on the small capacitor located next to the firmware EEPROM socket. Using a small flat bladed screwdriver or chip removal tool, carefully pry the old EEPROM from it’s socket. Try to keep the chip as flat as possible while removing it to prevent damage to the pins or socket. When replacing, keep the replacement EEPROM flat to the socket, make sure all pins are started in their respective receivers in the socket, then press the chip firmly into place.

3.2.2 Upgrading Firmware by Uploading through C4 Serial Port

Note: CC-3.5 controllers with version 7.0.0 firmware or earlier have battery backed RAMS for non volatile storage. These units MUST have the BBRAM replaced with an EEPROM before newer firmware is installed.

C4 Manual Rev 7.5.2 |

25 |

Use a DOS bootable diskette and a PC type computer to load the new firmware through the C4's serial port. You can obtain the required diskette from Sigma Systems for a fee, or you can provide your own DOS bootable diskette and obtain the necessary files for the upload process from the Sigma Systems site on the Internet. The Internet address for this site is:

www.SigmaSystems.com

The download file, SSUPxxxx.EXE, may contain specific instructions that replace the instructions in the next paragraph. After downloading the file, copy it to an otherwise empty DOS bootable diskette and run SSUPxxxx.EXE. This file is a self extracting ZIP archive that will install all the files you need onto the diskette. Check for the presence of a README.TXT file on the diskette for instructions that supplement or supercede these instructions.

Making the physical connection for upload

To upload firmware to your C4, you will need to connect the C4 to a DOS bootable PC compatible computer using a straight-through, or modem type serial cable. The C4 is configured as DCE (Data Communications Equipment). Therefore, do NOT use a “null modem” type serial cable that has pins 2 & 3 crossed. Connect the cable to either COM1 or COM2 on the PC and to the female DB25 connector on the back of the C4.

Running the upload software on the PC

After you run the SSUPxxxx.EXE file on your DOS bootable diskette you are ready to run the software. Place the floppy in the “A” drive of the PC and turn on or reset the PC to allow it to boot from the floppy. Follow the instructions on the screen. Note that the menu will allow you to do successive uploads without restarting and will allow you to change serial ports as you do so. Users who will be uploading to a number of controllers in one session will find that this feature saves some time.

If the uploads are being done on a bench (as opposed to leaving the controller in it’s chamber or platform housing), be certain to follow all precautions about removing all power before removing the controller and about taking care to use proper anti-static procedures when handling the controller. Be certain that the bench has a properly grounded anti-static surface.

If you are going to upload firmware into many controllers successively in a bench environment, you can use a PC with two serial ports (COM1 and COM2) and two serial cables. You can then have the upload program alternate serial ports for the

26 |

C4 Manual Rev 7.5.2 |

uploads so that you can upload to one controller while connecting and disconnecting the other.

Starting the upload on the C4

When the PC is ready, turn the C4 controller on. During the 1 second display of the model number, rapidly press <CLEAR/PROG> three times. The display will read:

rs load

The firmware upload should begin immediately. The PC will indicate when the load is complete.

If you have difficulties, see the trouble shooting information in Section 9.7.8.

3.3 Restoring Setup Parameters to Default Values

Note: The default values are very generic. They are not the values that were likely in the controller when it was shipped from the factory. After completing this procedure, please check each value to make certain that it is appropriate.

To restore the default values to the setup parameter table, turn the controller off, then back on. During the 1 second in which the controller model is displayed, press <CLEAR/ENTRY> very quickly 3 times. The display should then read

su res

Press <ENTER> to confirm that you want restore the default values. (Any other key will abort the process). The display should then read

ee busy and then su done

Turn the controller off, then on again to resume operation with the new values. The first time the controller is turned back on after restoring the default setup

parameters, the display will show all res . The mode switch must then be

turned to SETUP. (You may see an ee busy display and model number

and/or firmware version number at this time.) The controller forces you to SETUP mode before it will function as a reminder that the default values have been loaded and that the parameters needed for your operation have not yet been set.

C4 Manual Rev 7.5.2 |

27 |

When you have set the necessary parameters for your needs, you are ready to go to LOCAL, PROGRAM, or REMOTE mode.

28 |

C4 Manual Rev 7.5.2 |

3.4 Fahrenheit Operation

The C4 can use either Celsius or Fahrenheit temperature scales. Celsius is the default mode. When the controller is operating in Celsius mode it’s behavior is identical to the model CC-3 controller. When the controller is operating in Fahrenheit mode, both the displays and the bus communications are different. These differences are intentional and designed to prevent errors that might arise from a user using setpoints in one scale while the controller is operating in the other scale. Note, however, that there is no difference in the Program mode programming operation of the C4 when operating in either Fahrenheit or Celsius mode. It is incumbent upon the user to notice the differences in the temperature displays and program accordingly.

To change the temperature scale, use SETUP mode (See Section 8) to access setup parameter F16. Select either of these field values:

0Celsius

1Fahrenheit

When in Fahrenheit mode, temperature displays have an “F” following the probe identifier on the left side of the display. Example:

p1f 102.4

Likewise, temperature inquires over the bus (PT command - See Section 7.5.7) will return a string with an “F” as the third byte in the string. The string will therefore be 1 byte longer than the string returned in Celsius mode. This difference was intentional as it requires a modification of the parsing routine that will assure that Celsius and Fahrenheit data are recognized properly. Thus, if the current probe 1 temperature is 86.7/F, the result of a Fahrenheit mode get temperature query for probe 1 (query command = PT1) would be

T1F 86.7<CR><LF>

If the temperature at probe 1 was 55.4/C, the same command in Celsius mode would return

T1 55.4<CR><LF>

During Remote mode operation, the C4 may be queried to determine the current temperature scale by using the QS, Query Setpoint, command. See Section 7.4.4.

C4 Manual Rev 7.5.2 |

29 |

3.5 System Operating (Temperature) Range

The C4 controller operates within the limits of the system devices. There are 3 pairs (low-high) of temperature limits that constrain the range of operations.

1.The range of the C4 as it is set at the factory

2The range of the controlled device (chamber or platform) as described by setup parameters F25 & F26.

3The range of the UUT (unit under test) as described by setup parameters F27 & F28.

Each of these ranges is characterized by a low limit and a high limit. The highest of the 3 low limits is the low temperature System Operation Limit. The lowest of the 3 high limits is the high temperature System Operation Limit. In other words, the controller will respect the most restrictive limits that are described by the combination of the 3 ranges listed above.

The low and high temperature System Operating Limits define the System Operating Range. The controller will not accept setpoints outside the System Operating Range and will report error conditions and stop controlling if the controlling probe(s) report a temperature too far outside that range.

Note: Probe 1 is always in the chamber airstream or platform and is always monitored for conformance with the System Operating Range. Probe 2 is monitored for conformance only if it is being used for control.

3.6 Probe Out of Range Shutdown

When the C4 is actively controlling the temperature of a chamber or platform, it frequently checks to be certain that the control temperature, as reported by any active control probe, is within the System Operating Range.

In the event that the temperature reported by the active control probe is more than 20/C, and less than 50/C, outside the controller’s System Operating Range, then the controller will presume that a “run away” condition exists. The controller will turn off all heating and cooling and stop controlling. Blowers will be left in the condition determined by setup parameter F15 (Blower shut-off mode). The controller display will show

p1 lo |

p1 hi |

30 |

C4 Manual Rev 7.5.2 |

Loading...

Loading...