SEW-Eurodrive MOVIDRIVE compact MCF, MOVIDRIVE Series, MOVIDRIVE compact MCS_4A, MOVIDRIVE compact MCV, MOVIDRIVE MD_60A User Manual

Edition

MOVIDRIVE® Serial Communication

11/2001

Manual

1053 1610 / EN

SEW-EURODRIVE

Contents

1 Important Notes...................................................................................................... 4

2 Introduction ............................................................................................................ 5

2.1 Overview of serial interfaces.......................................................................... 5

2.2 Technical data................................................................................................ 8

2.3 MOVILINK® and system bus......................................................................... 9

3 Installation ............................................................................................................ 12

3.1 System bus (SBus) installation .............................. .... ... ... ... .... ..................... 12

3.2 RS-485 interface installation ........................................................................ 14

3.3 RS-232 interface installation ........................................................................ 16

4 RS-485 Communication....................................................................................... 17

4.1 Telegrams.................................................................................................... 17

4.2 Addressing and transmission proces s ....................... .................................. 20

4.3 Data contents and PDU types...................................................................... 29

P6..

P60.

P600

5 System Bus (SBus) .............................................................................................. 37

5.1 Slave data exchange via MOVILINK® ......................................................... 37

5.2 Setting parameters via the CAN bus............................................................ 42

5.3 Master data exchange via MOVILINK®....................................................... 47

5.4 Master/slave operation via the SBus............................................................ 50

5.5 Data exchange via variable telegrams......................................................... 51

5.6 Project planning example for SBus............................................ ... ... ... ......... 62

6 Operation and Service.......................... ... ... ... ............................................. .... ... .. 64

6.1 Startup problems with the SBus................................................................... 64

6.2 Return codes for parameter setting.............................................................. 65

7 Parameter List .................................................................................... .................. 67

7.1 Explanation of the table header .................................... ... ............................ 67

7.2 Complete parameter list, sorted by parameter numbers.............................. 68

7.3 Quantity and conversion index................................................................ ..... 84

8 Index...................................................................................................................... 87

MOVIDRIVE® Serial Communication

3

1

1 Important Notes

• This manual does not replace the detailed operating instructions!

• Installation and startup only by trained personnel observing applicable

accident prevention regulations and the MOVIDRIVE

®

operating instructions!

Documentation • Read through this manual carefully before you commence installation and startup of

MOVIDRIVE

®

drive inverters with a serial communications link (RS-232, RS-485,

system bus).

• This manual assumes that the user has access to and is familiar with the

MOVIDRIVE

®

documentation, in particular the MOVIDRIVE® system manual.

• In this manual, cross references are marked with "→". For example, (→ Sec. X.X)

means: Further information can be found in section X.X of this manual.

• A requirement of fault-free operation and fulfillment of any rights to claim under

guarantee is that the documentation is observed.

Bus systems General safety notes on bus systems:

This communication system allows you to match the MOVIDRIVE

®

drive inverter to the

specifics of your application to a very high degree. As with all bus systems, there is a

danger of invisible, external (as far as the inverter is concerned) modifications to the

parameters which give rise to changes in the inverter behavior. This may result in

unexpected (not uncontrolled, though!) system behavior.

Safety and

Always follow the safety and warning instructions contained in this publication!

warning

instructions

Electrical hazard

Possible consequences: Severe or fatal injuries.

Hazard

Possible consequences: Severe or fatal injuries.

Hazardous situation

Possible consequences: Slight or minor injuries.

Harmful situation

Possible consequences: Damage to the unit and the

environment.

Tips and useful information.

4

MOVIDRIVE® Serial Communication

2 Introduction

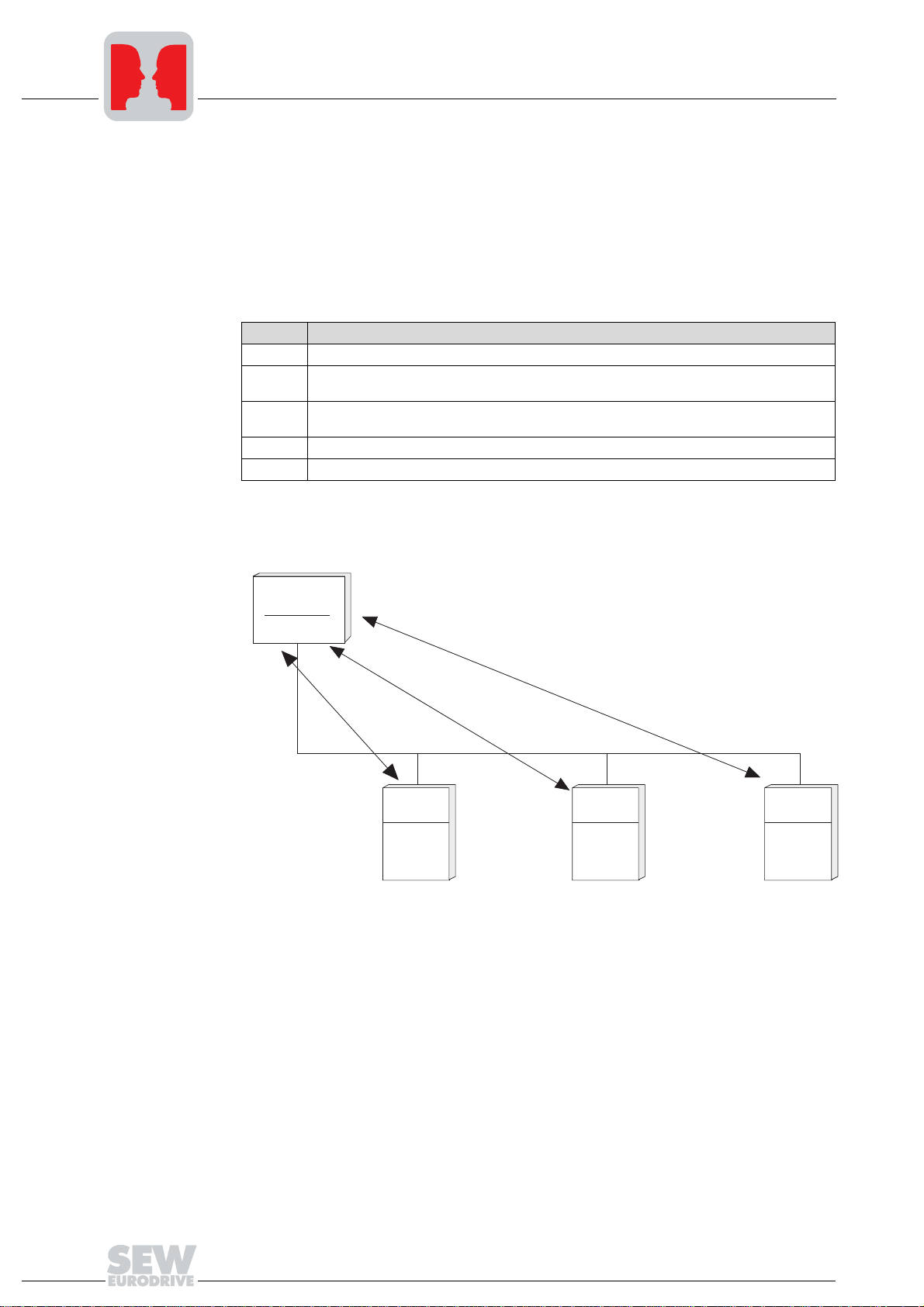

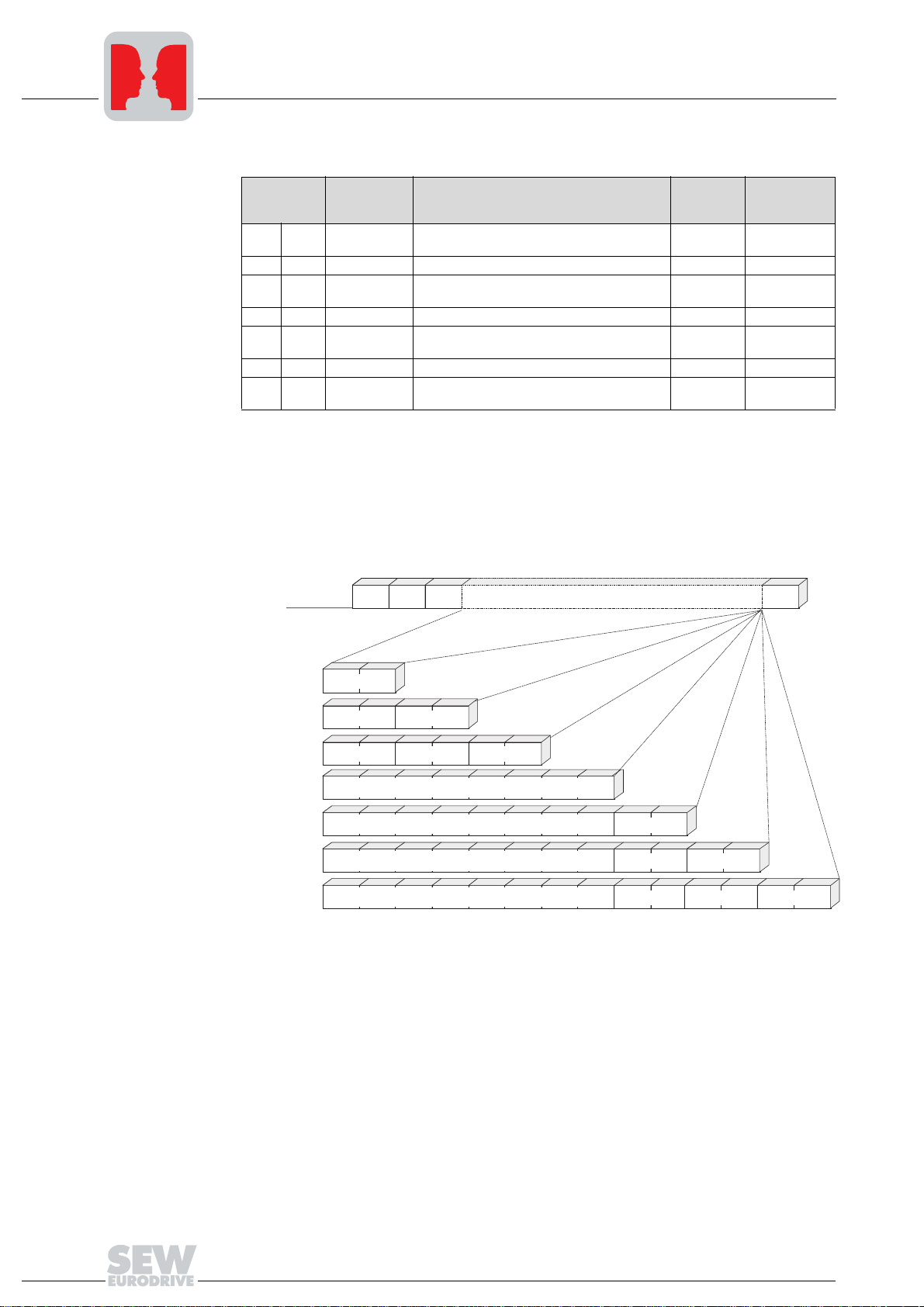

2.1 Overview of serial interfaces

The following serial interfaces are provided as standard with MOVIDRIVE® drive

inverters for serial communication:

1. System bus (SBus) = CAN bus to CAN specification 2.0, parts A and B.

2. RS-485 interface to EIA standard

Overview of serial interfaces

2

MOVIDRIVE

MD_60A

®

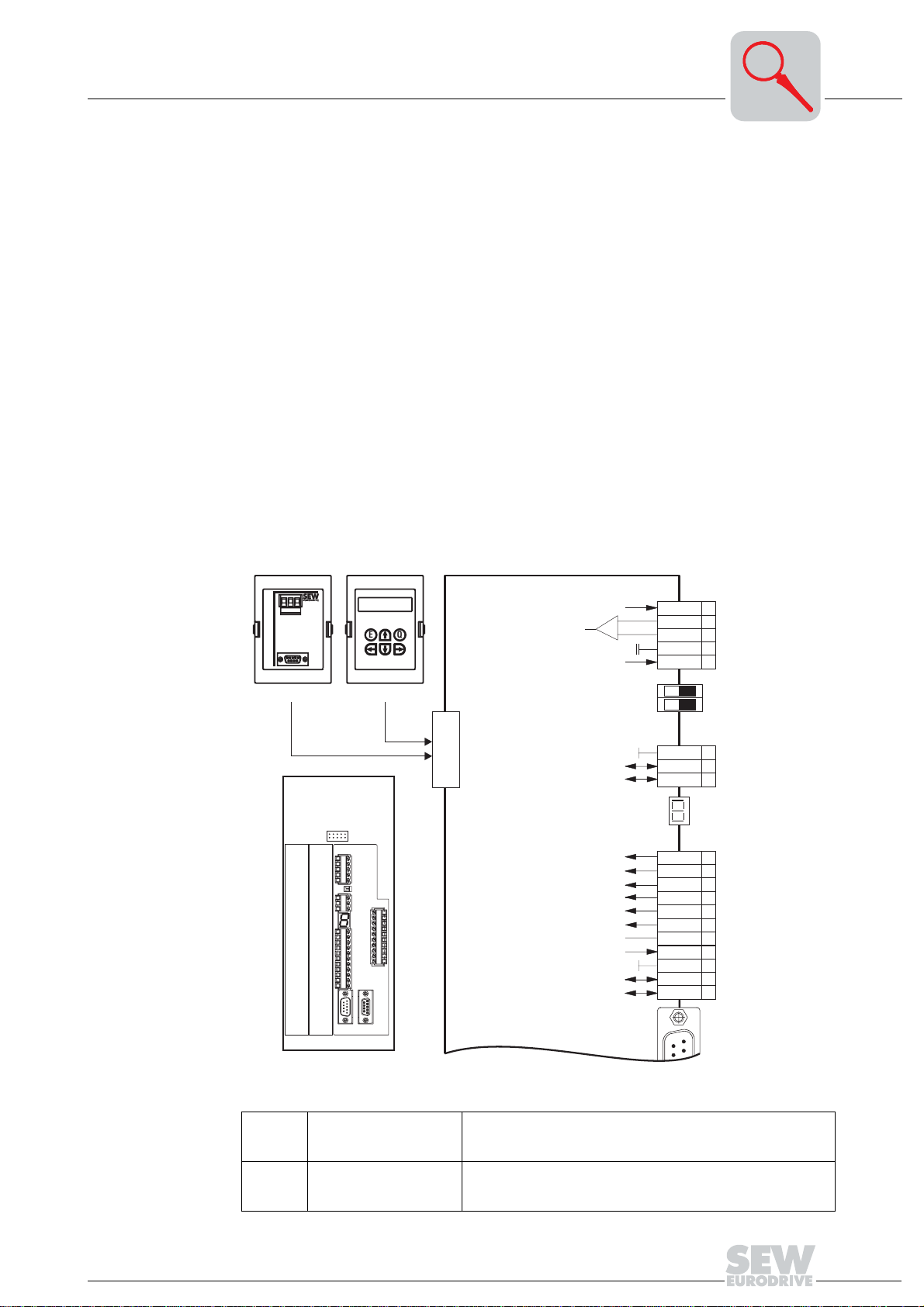

System bus (SBus):

The system bus (SBus) is routed to terminals X12:2/3 in MOVIDRIVE

®

MD_60A drive

inverters.

RS-485 interface:

The RS-485 interface is routed to the TERMINAL option slot and, in parallel, to terminals

X13:10/11 in MOVIDRIVE

®

MD_60A drive inverters.

Either the "DBG11A keypad" or the "USS21A serial interface" can be connected to the

TERMINAL option slot.

0V5 - +

RS485

RS232

USS21A

EQ

DBG11A

CONTROL

TERMINAL

SBusHigh

SBusLow

X11:

1

+

-

REF1

AI11

AI12

AGND

REF2

ON OFF

2

3

4

5

S 11

S 12

X12:

DGND

1

SC11

2

SC12

3

MOVIDRIVE

Fig. 1: Serial interfaces on MOVIDRIVE® MD_60A

X12:1

X12:2

X12:3

X13:10

X13:11

®

Serial Communication

TERMINAL

CONTROL

OPTION2

OPTION1

DGND: Ref. potential

SBus high

SBus low

ST11: RS-485+

ST12: RS-485-

X13:

DIØØ

1

DIØ1

2

DIØ2

3

DIØ3

4

DIØ4

5

DIØ5

6

DCOM

7

VO24

8

DGND

RS-485+

RS-485-

ST11

ST12

9

10

11

X14:

1

6

05274AXX

CAN bus to CAN specification 2.0, parts A and B, transmission

technology to ISO 11898, max. 64 stations, terminating resistor

(120 Ω) can be activated using DIP switches

EIA standard, 9600 baud, max. 32 stations

Max. cable length 200 m (660 ft) in total

Dynamic terminating resistor with fixed installation

5

2

Overview of serial interfaces

MOVIDRIVE®

compact

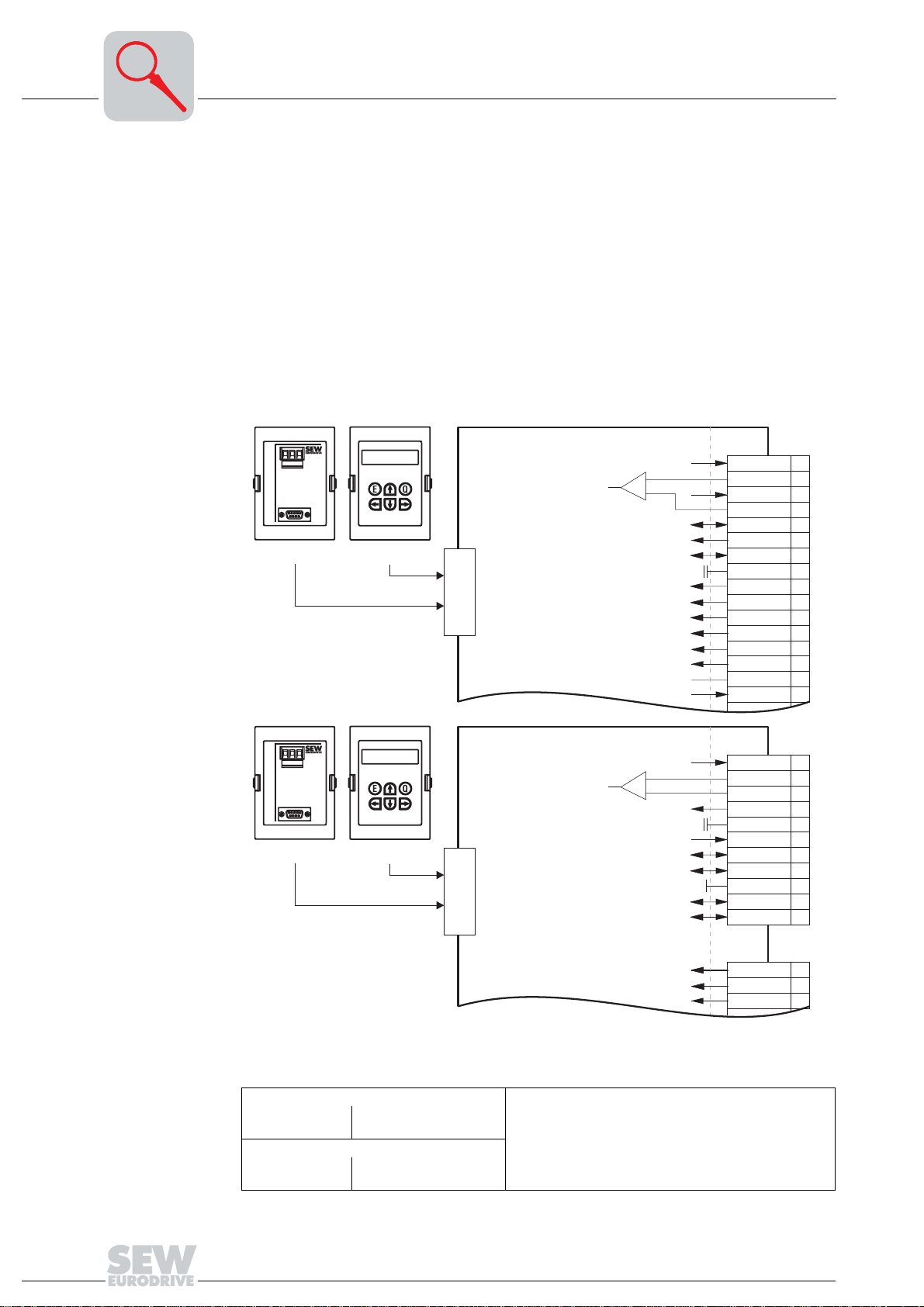

System bus (SBus):

• The system bus (SBus) is routed to terminals X10:5/7 in MOVIDRIVE

®

compact

MCF/MCV/MCS4_A drive inverters.

• The system bus (SBus) is routed to terminals X10:7/8 and X10:10/11 in

MOVIDRIVE

®

compact MCH4_A drive inverters. Terminals X10:7 and X10:10 are

electrically connected, as are terminals X10:8 and X10:11.

RS-485 interface:

The RS-485 interface is routed to the TERMINAL option slot in MOVIDRIVE

®

compact

drive inverters.

Either the "DBG11A keypad" or the "USS21A serial interface" can be connected to the

TERMINAL option slot.

0V5 - +

RS485

RS232

USS21A

EQ

DBG11A

MCF/MCV/MCS4_A

+

-

SBusHigh

SBusLow

TERMINAL

X10:

AGND

DCOM

REF1

AI11

REF2

AI12

SC11

AI21

SC12

DIØØ

DIØ1

DIØ2

DIØ3

DIØ4

DIØ5

VO24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

MCH4_A

0V5 - +

RS485

RS232

USS21A

EQ

DBG11A

TERMINAL

+

-

SBusHigh

SBusLow

SBusHigh

SBusLow

Fig. 2: Serial interfaces on MOVIDRIVE® compact

* Only use these terminals if S12 = OFF; connect terminating equipment to SC11/SC12.

MOVIDRIVE

X10:5

X10:7

MOVIDRIVE

X10:7/10

X10:8/11

®

compact MCF/MCV/MCS4_A

SBus high

SBus low

®

compact MCF/MCV/MCS4_A

SBus high

SBus low

CAN bus to CAN specification 2.0, parts A and B

Transmission system to ISO 11898

max. 64 stations

Terminating resistor (120 Ω) can be activated using

DIP switches

X10:

AGND

DGND

SC21*

SC22*

X11:

REF1

AI11

AI12

AI21

REF2

SC11

SC12

DIØØ

DIØ1

DIØ2

05275AXX

1

2

3

4

5

6

7

8

9

10

11

1

2

3

6

MOVIDRIVE® Serial Communication

Overview of serial interfaces

2

USS21A (RS-232

and RS-485)

Startup, operation and service are possible from the PC via the serial interface. The

SEW MOVITOOLS software is used for this purpose. It is also possible to transfer

parameter settings to several MOVIDRIVE

MOVIDRIVE

®

can be equipped with isolated RS-232 and RS-485 interfaces. The RS-

®

drive inverters via PC.

232 interface is configured as a 9-pin sub D female connector (EIA standard) and the

RS-485 interface as a terminal connection. The interfaces are accommodated in a

housing for plugging onto the inverter (TERMINAL option slot). The option can be

plugged on during operation. The transmission rate of both interfaces is 9600 baud.

DBG11A and USS21A are connected to the same inverter slot (TERMINAL) and cannot

be used at the same time.

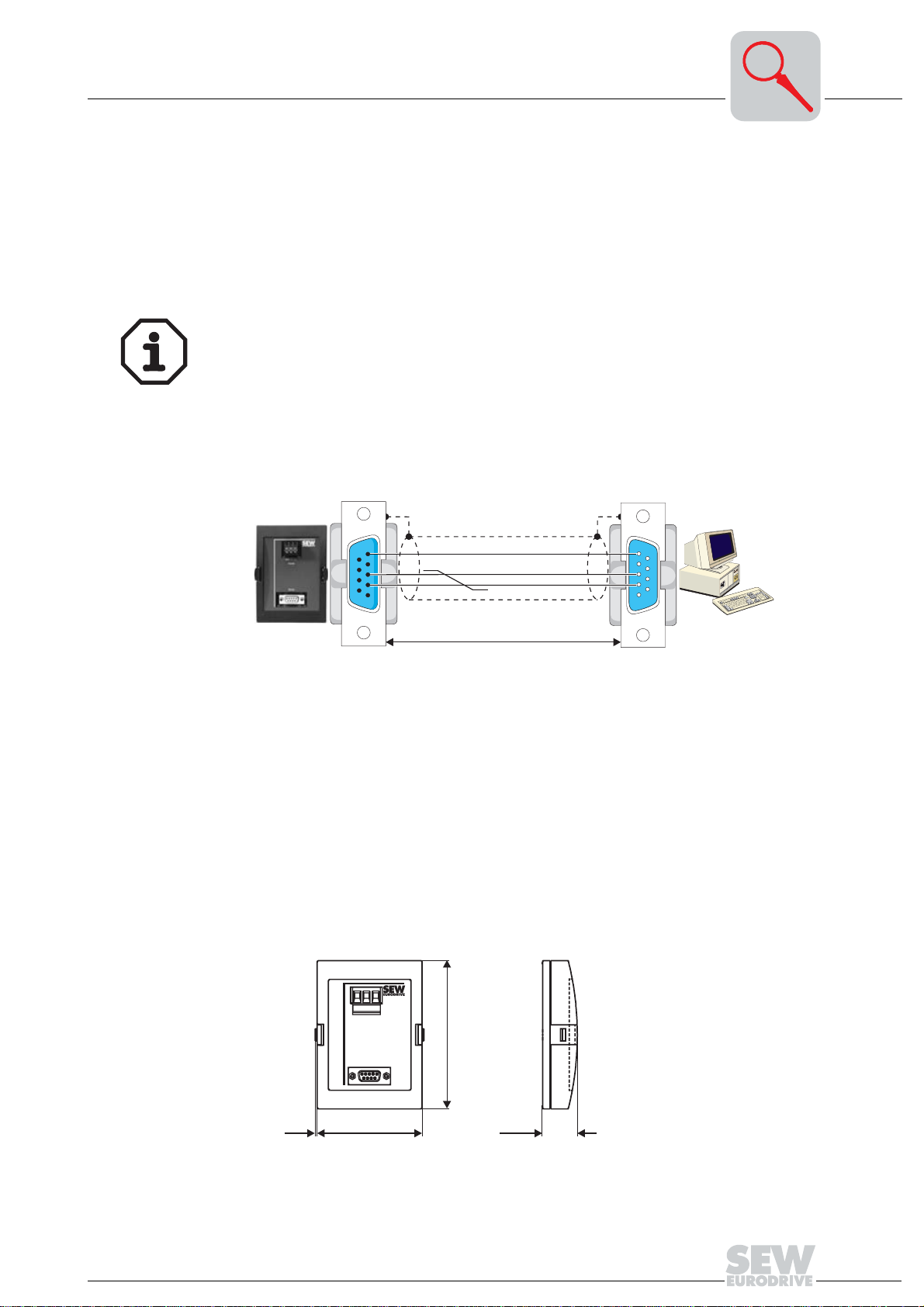

RS-232 interface Use a commercially available serial interface cable (shielded!) for connecting a PC to

MOVIDRIVE

®

with the USS21A option.

Important: 1:1 cabling

USS21A

5

55

3

33

22

2

GND (ground)

TxD

RxD

5

55

3

33

2

22

PC COM 1-4

Fig. 3: Connection cable USS21A – PC

RS-485 interface A maximum of 16 MOVIDRIVE

(max. total cable length 200 m (660 ft)) via the RS-485 interface of the USS21A.

Dynamic terminating resistors are permanently installed, so do not connect any external

terminating resistors.

Unit addresses 0 – 99 are permitted with multipoint connections. In this case, the "peerto-peer connection" must not be selected in MOVITOOLS. The communications

address in MOVITOOLS and the RS-485 address of the MOVIDRIVE

be identical.

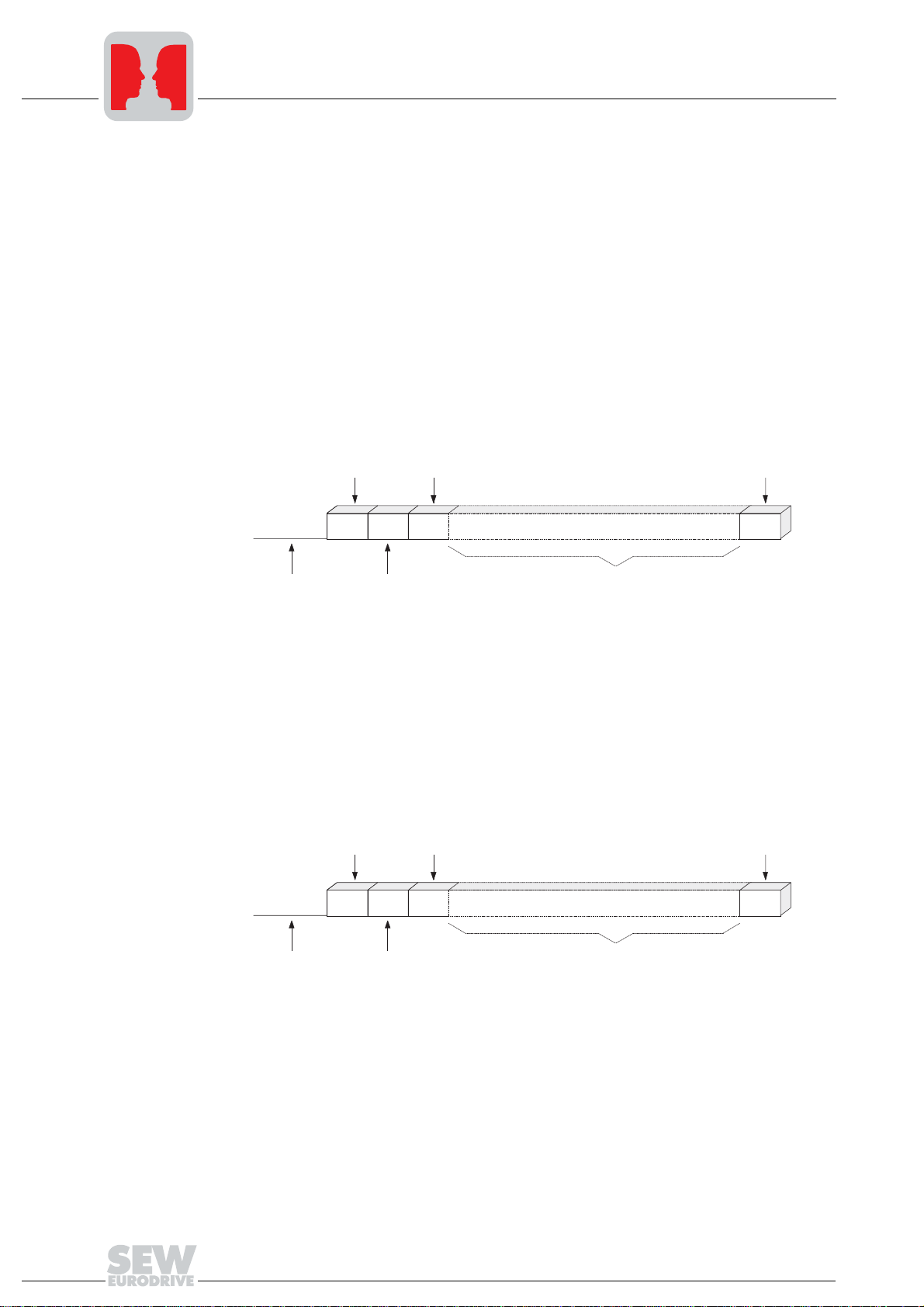

Dimensions

0V5 - +

RS485

RS232

max. 5 m (16.5 ft)

9-pin sub D connector (female)9-pin sub D connector (male)

02399AEN

®

units can be networked for communications purposes

®

unit (P810) must

120 (4.72)

MOVIDRIVE

1.5 (0.06)

Fig. 4: USS21A dimensions in mm (in)

®

Serial Communication

85 (3.35)

28.5 (1.12)

01003BXX

7

2

2.2 Technical data

System bus

(SBus)

Technical data

Standard CAN specification 2.0 parts A and B

Baud rate either 125, 250, 500 or 1000 kbaud, factory setting 500 kbaud

ID range 3 – 1020

Address can be set with parameter P813: 0 – 63

Number of process

data words

Line length depending on the baud rate, max. 320 m

Number of stations max. 64

fixed setting: 3 PD

Co

RS-485 interface

RS-232 interface

Only when P816 "SBus baud rate" = 1000 kbaud:

Do not combine MOVIDRIVE

®

compact MCH42A units with other MOVIDRIVE® units in

the same system bus combination.

The units are allowed to be mixed at baud rates ≠ 1000 kbaud.

Standard RS-485

Baud rate 9.6 kbaud

Start bits 1 start bit

Stop bits 1 stop bit

Data bits 8 data bits

Parity 1 parity bit, supplementing to even parity

Line length 200 m between two stations

Number of stations 1 master and max. 31 slaves

Standard DIN 66020 (V.24)

Baud rate 9.6 kbaud

Start bits 1 start bit

Stop bits 1 stop bit

Data bits 8 data bits

Parity 1 parity bit, supplementing to even parity

Line length max. 5 m

Number of stations 1 master + 1 slave (peer-to-peer connection)

8

MOVIDRIVE® Serial Communication

MOVILINK® and system bus

2

2.3 MOVILINK

MOVILINK®

protocol

®

and system bus

This document provides a detailed description of the MOVILINK® serial interface

protocol for the RS-485 interfaces of MOVIDRIVE

®

drive inverters. You can control the

inverter and set its parameters via the RS-485 interface.

However, please bear in mind that this communications variant is a proprietary

communication system for low-end applications.

The low speed of transmission and the significant time and effort needed to implement

the various automation systems mean that SEW recommends the following fieldbus

systems as the professional method of linking SEW inverters to machine control

systems:

• PROFIBUS-DP

• INTERBUS

• INTERBUS with fiber optic cable

•CAN

• CANopen

• DeviceNet

These fieldbus systems are supported by SEW and by all well-known manufacturers of

automation systems.

The MOVILINK

MOVIDRIVE

®

protocol for serial interfaces in the new SEW range of inverters,

®

and MOVIMOT®, enables you to set up a serial bus connection between

a higher-level master and several SEW inverters. For example, masters may take the

form of programmable logic controllers, PCs or even SEW inverters with PLC functions

plus®

(IPOS

). Generally speaking, the SEW inverters function as slaves in the bus

system.

The MOVILINK

®

protocol allows both of the following applications to be implemented:

automation tasks such as control and parameter setting of the drives by means of

cyclical data exchange, startup and visualization tasks.

Features The principal features of the MOVILINK

• Support for the master/slave structure via RS-485 with one master (single master)

and at most 31 slave stations (SEW inverters).

• Support for peer-to-peer connection via RS-232.

• User-friendly implementation of the protocol in a simple and reliable telegram

structure with fixed telegram lengths and a unique start identifier

• Data interface to the basic unit in accordance with the MOVILINK

means the user data sent to the drive are transmitted to the inverter in the same way

as via the other communications interfaces (PROFIBUS, INTERBUS, CAN,

CANopen, DeviceNet, etc.).

• Access to all drive parameters and functions, i.e. it can be used for startup, service,

diagnosis, visualization and automation tasks

• Startup and diagnostic tools on the basis of MOVILINK

SHELL and MOVITOOLS/SCOPE).

®

protocol are:

®

profile. This

®

for PC (e.g. MOVITOOLS/

MOVIDRIVE

®

Serial Communication

9

2

MOVILINK® and system bus

System bus

(SBus)

The SBus is a CAN bus in accordance with the CAN specification 2.0, parts A and B. It

supports all services in the SEW MOVILINK

plus®

IPOS

variables via the SBus independently of the profile.

®

unit profile. In addition, you can exchange

The unit behavior of the inverter which forms the basis of CAN operation is referred to

as the unit profile. It is independent of any particular fieldbus and is therefore a uniform

feature. This provides you, the user, with the opportunity of developing applications

regardless of the fieldbus.

MOVIDRIVE

®

offers digital access to all drive parameters and functions via the SBus.

The drive inverter is controlled via high-speed process data. These process data

telegrams let the user enter setpoints, such as the setpoint speed, ramp generator time

for acceleration/deceleration, etc. and trigger various drive functions such as enable,

control inhibit, normal stop, rapid stop, etc. You can also use these telegrams to read

back actual values from the drive inverter, such as the actual speed, current, unit status,

error number and reference signals.

The exchange of parameter data via the MOVILINK

®

parameter channel lets you create

applications in which all important drive parameters are stored in the programmable

master controller. This means there is no need to manually set the parameters on the

drive inverter itself, which is frequently a rather time-consuming task. IPOS

plus®

provides the MOVLNK command for the exchange of parameter data and process data

with other MOVILINK

via IPOS

plus®

and control other units.

®

stations. As a result, MOVIDRIVE® can operate as the master

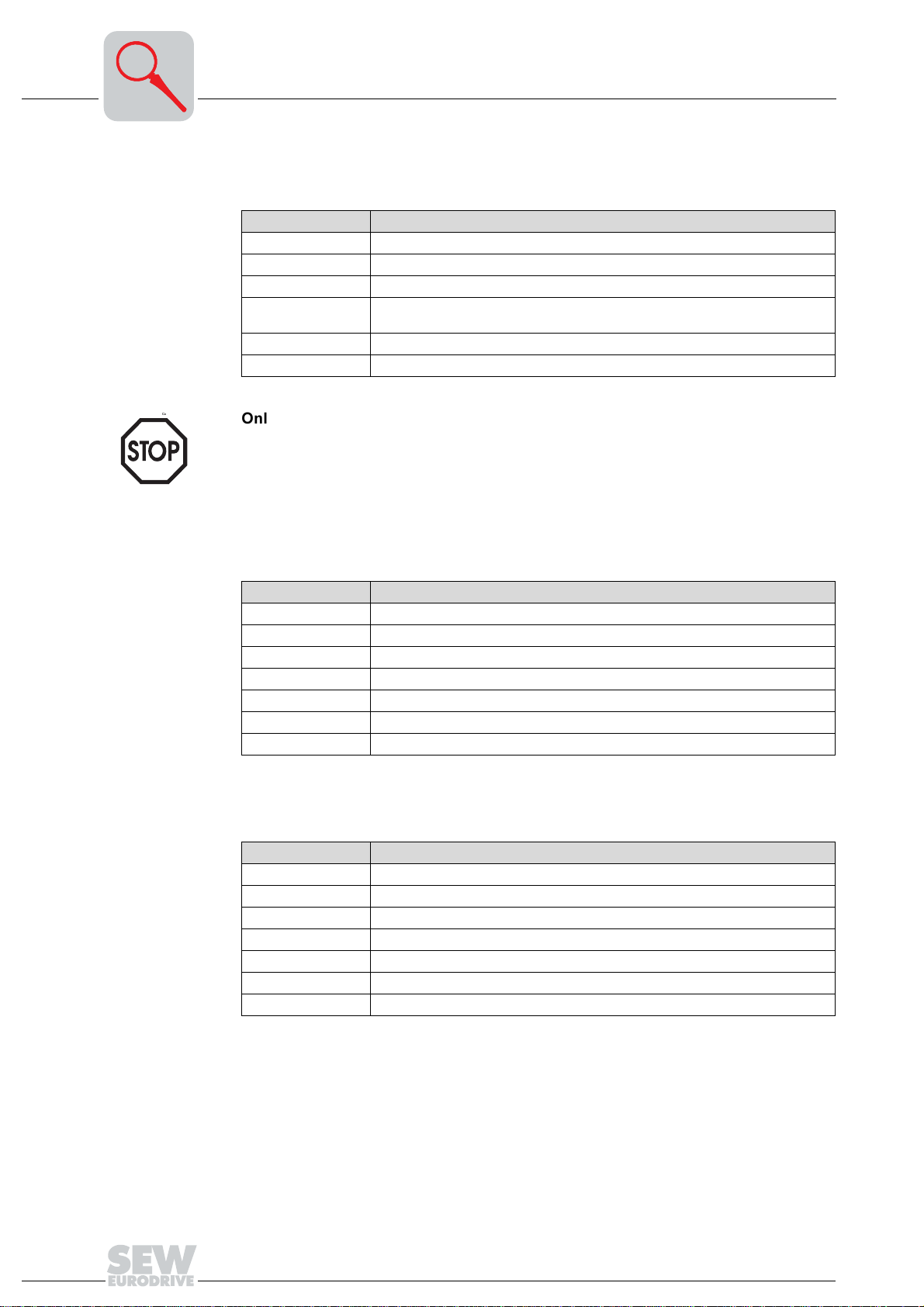

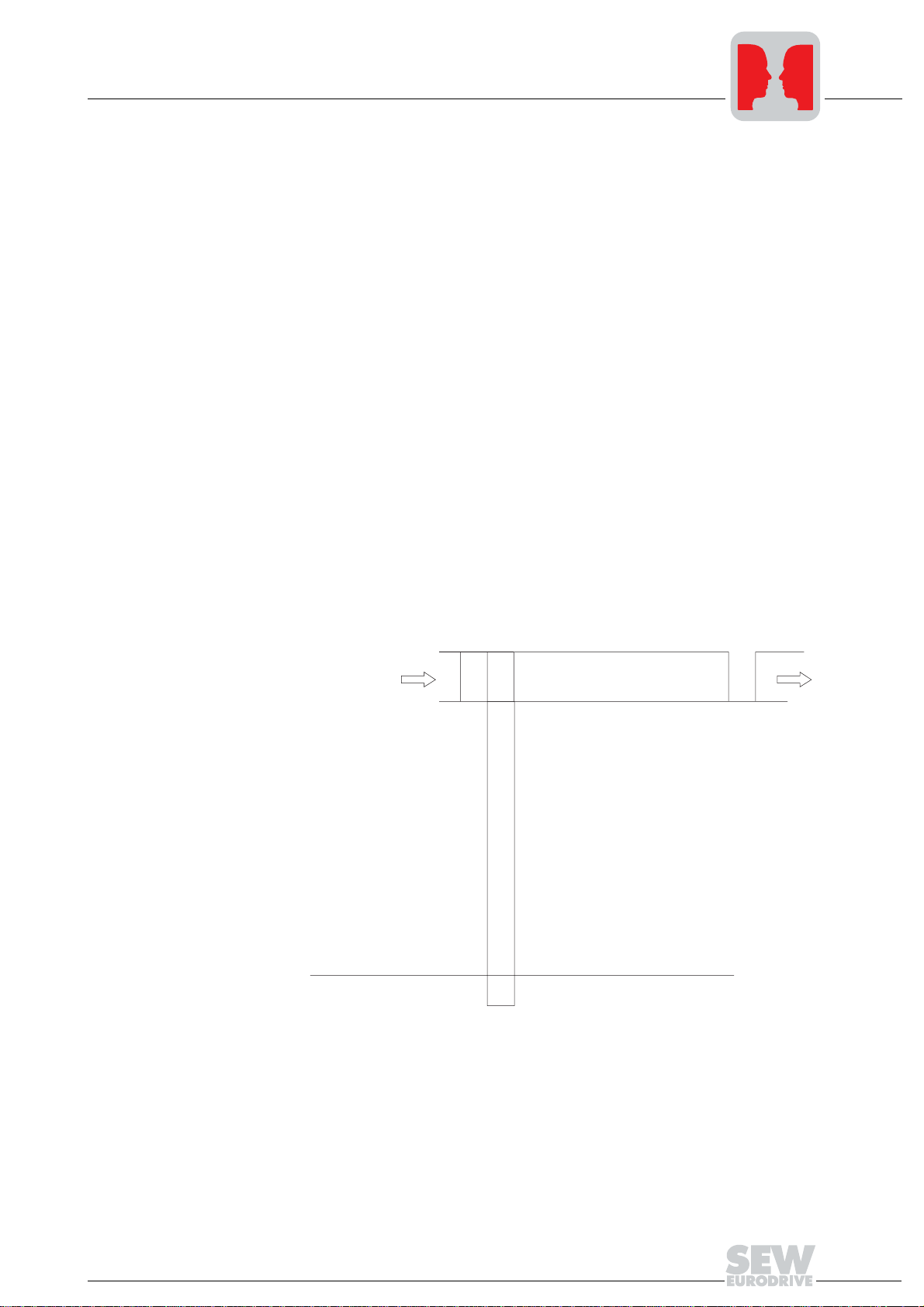

The process data and the drive parameters can be sent to a synchronization telegram

synchronously or asynchronously.

®

Parameter

PD1 PD2 PD3

PD2

PD1 PD2 PD3

PD3

Q

E

02244BEN

plus®

IPOS

Q

E

plus®

IPOS

Max. 8 data bytes = 2 variables, each 32 bit

Fig. 5: Variants of SBus communication

PD1

System bus (SBus)

MOVILINK protocol

Variable exchange

Using the SBus requires additional monitoring functions such as time monitoring (SBus

timeout delay) or special emergency-off concepts. You can adapt the monitoring

functions of MOVIDRIVE

®

specifically to your application. You can determine which

error response the drive inverter should trigger in the event of a timeout. A rapid stop is

a good idea for many applications, although this can also be achieved by "freezing" the

last setpoints so the drive continues operating with the most recently valid setpoints (e.g.

conveyor belt). You can still implement emergency-off concepts which are independent

of the bus and use the terminals of the drive inverter because the functions of the control

terminals are still active when the SBus is in operation.

10

MOVIDRIVE® Serial Communication

MOVILINK® and system bus

The MOVIDRIVE® drive inverter offers you numerous diagnostic options for startup and

service purposes. An easy-to-use diagnostics tool is provided in the MOVITOOLS/

SHELL PC software. This software makes it possible to call up a detailed display of the

bus and unit status as well as setting all drive parameters.

2

Variable telegrams Not only does the cyclical and acyclical variable exchange function create an interface

via which variables can be exchanged between several MOVIDRIVE

possible to implement partial functions for specific profiles in external units. These

external units may support the CANopen or DeviceNet protocol.

®

units, it is also

MOVIDRIVE

®

Serial Communication

11

3

System bus (SBus) installation

3 Installation

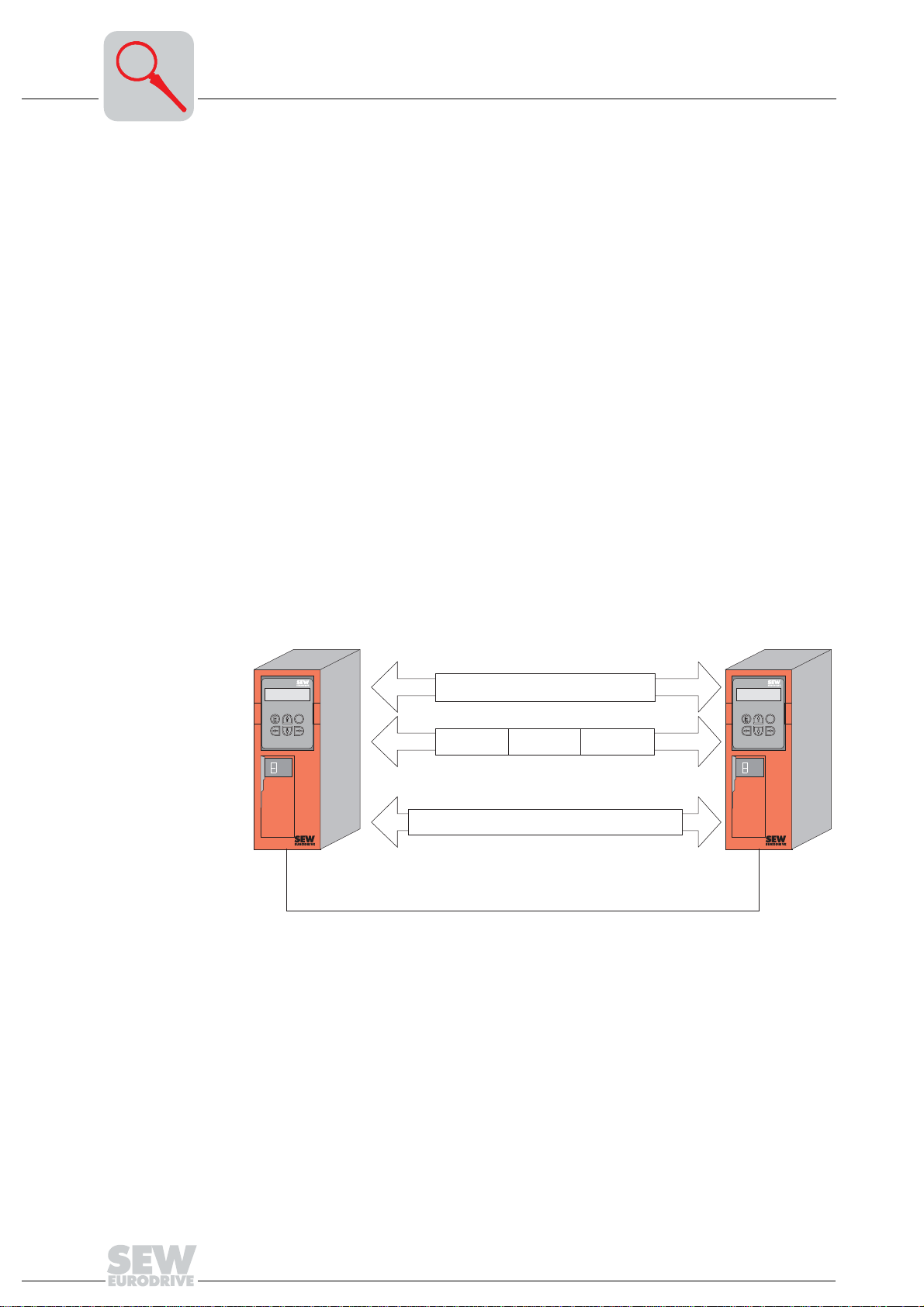

3.1 System bus (SBus) installation

Only when P816 "SBus baud rate" = 1000 kbaud:

Do not combine MOVIDRIVE

the same system bus combination.

The units are allowed to be mixed at baud rates ≠ 1000 kbaud.

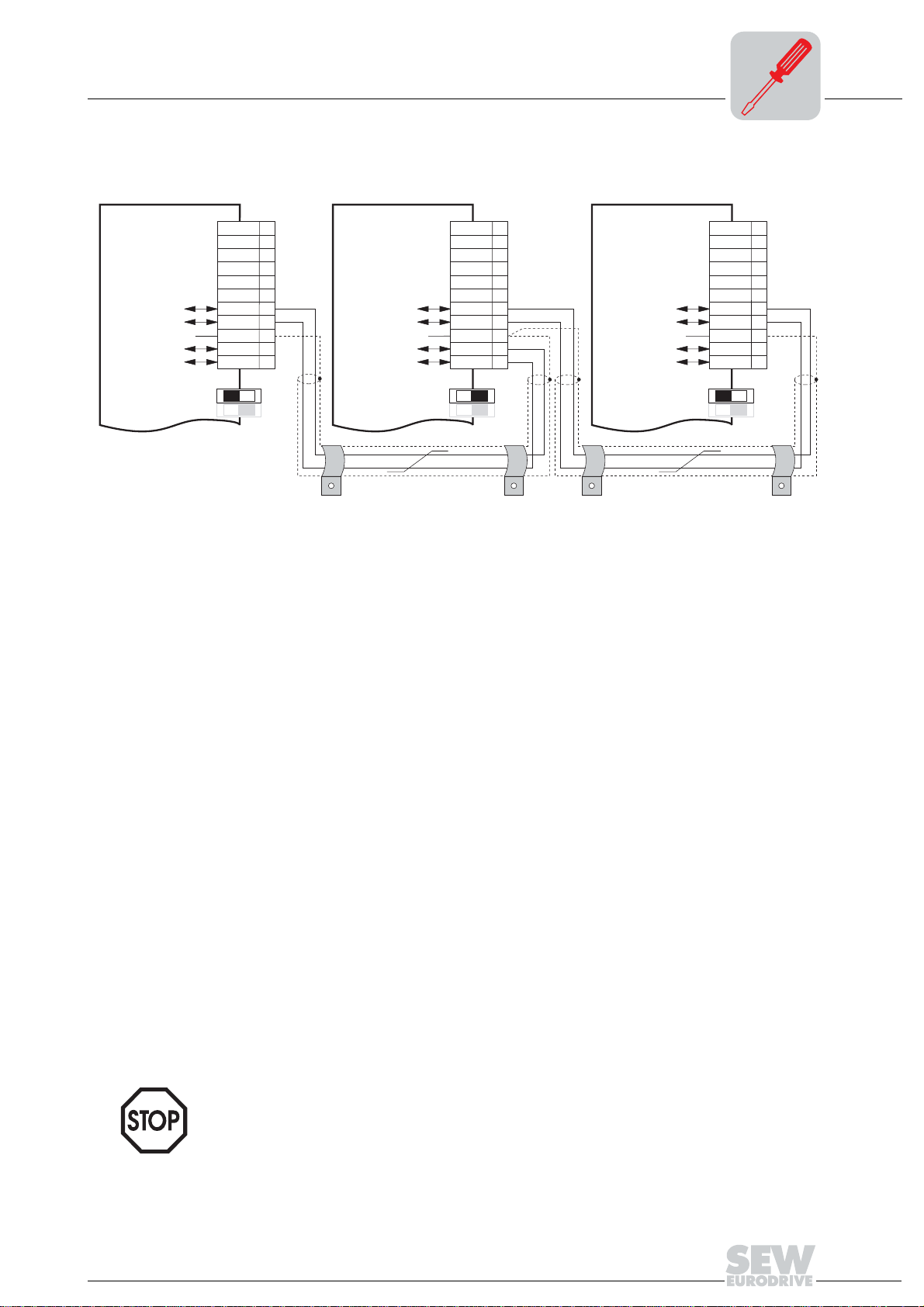

MOVIDRIVE® MD_60A

®

compact MCH42A units with other MOVIDRIVE® units in

Controlunit Controlunit Controlunit

Terminating resistor

Systembus

ref.potential

Systembushigh Systembushigh Systembushigh

Systembuslow Systembuslow Systembuslow

X11:

System bus

X12:

REF1

AI11

AI12

AGND

REF2

ON OFF

DGND

SC11

SC12

1

2

3

4

5

S 11

S 12

1

2

3

X11:

System bus

Terminating resistor

Systembus

ref.potential

X12:

REF1

AI11

AI12

AGND

REF2

ON OFF

DGND

SC11

SC12

1

2

3

4

5

S 11

S 12

1

2

3

Terminating resistor

Systembus

ref.potential

쵰쵰쵰쵰

Fig. 6: System bus connection MOVIDRIVE® MD_60A

MOVIDRIVE

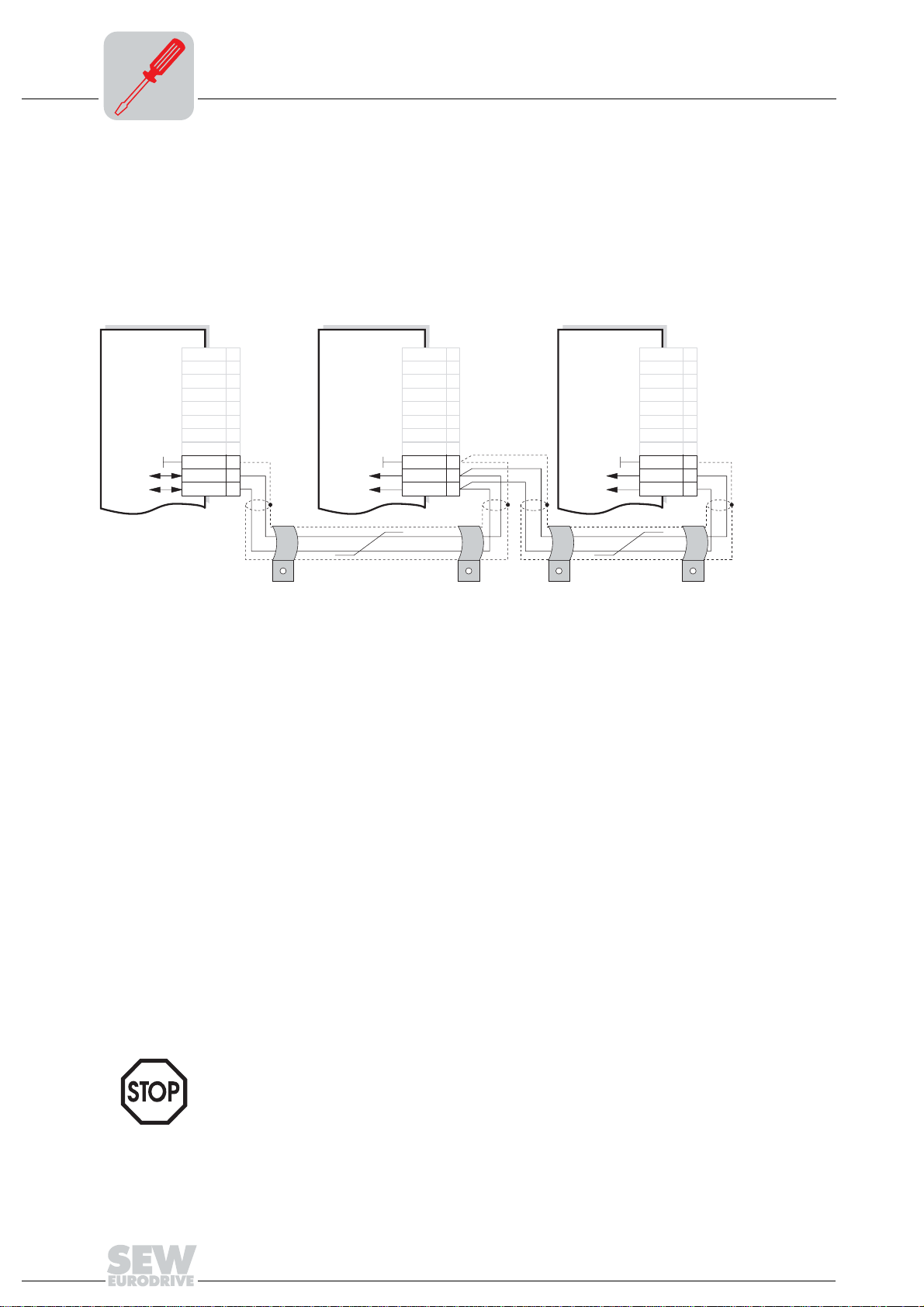

®

compact MCF/MCV/MCS4_A

Controlunit Controlunit Controlunit

X10: X10: X10:

SC11

SC12

1

2

3

4

5

6

7

1

2

3

4

SC11

SC12

5

6

7

Systembushigh Systembushigh Systembushigh

Systembuslow Systembuslow Systembuslow

02205BEN

X11:

System bus

X12:

SC11

SC12

REF1

AI11

AI12

AGND

REF2

ON OFF

DGND

SC11

SC12

1

2

3

4

5

6

7

1

2

3

4

5

S 11

S 12

1

2

3

Reference

potential

System bus

Terminating resistor

DGND

17 17 17

ON OFF ON OFF ON OFF

S 12

S 11

Reference

potential

System bus

Terminating resistor

DGND

쵰쵰쵰쵰

Fig. 7: System bus connection MOVIDRIVE® compact MCF/MCV/MCS4_A

12

Reference

potential

System bus

S 12

S 11 S 11

Terminating resistor

02411AEN

DGND

S 12

MOVIDRIVE® Serial Communication

System bus (SBus) installation

MOVIDRIVE® compact MCHS4_A

Controlunit Controlunit Controlunit

X10: X10: X10:

1

2

3

4

5

6

Systembushigh Systembushigh Systembushigh

Systembuslow Systembuslow Systembuslow

Referencepotential

Systembushigh Systembushigh Systembushigh

Systembuslow Systembuslow Systembuslow

System bus

Terminating resistor

ON OFF ON OFF ON OFF

7

SC11

8

SC12

9

DGND

10

SC21

11

SC22

S 12 S 12 S 12

S 11 S 11 S 11

Referencepotential

System bus

Terminating resistor

쵰쵰쵰 쵰

SC11

SC12

DGND

SC21

SC22

10

11

1

2

3

4

5

6

7

8

9

Referencepotential

Terminating resistor

System bus

SC11

SC12

DGND

SC21

SC22

3

1

2

3

4

5

6

7

8

9

10

11

Fig. 8: System bus connection MOVIDRIVE® compact MCH4_A

05210AEN

SBus MCH4_A: Connect the terminating equipment to SC11/SC12. SC21/SC22 are only active when S12 = OFF.

Cable

specification

• Use a 2-core twisted and shielded copper cable (data transmission cable with shield

comprising copper braiding). The cable must meet the following specifications:

– Conductor cross section 0.75 mm

2

(AWG 18)

– Cable resistance 120 Ω at 1 MHz

– Capacitance per unit length ≤ 40 pF/m (12 pF/ft) at 1 kHz

Suitable cables are CAN bus or DeviceNet cables, for example.

Shield contact • Connect the shield at either end to the electronics shield clamp of the inverter or the

master control and ensure the shield is connected over a large area. Also connect

the ends of the shield to DGND.

Line length • The permitted total line length depends on the baud rate setting of the SBus (P816):

– 125 kbaud → 320 m (1056 ft)

– 250 kbaud → 160 m (528 ft)

– 500 kbaud → 80 m (264 ft)

– 1000 kbaud → 40 m (132 ft)

Terminating

resistor

MOVIDRIVE

®

• Switch on the system bus terminating resistor (S12 = ON) at the start and finish of

the system bus connection. Switch off the terminating resistor on the other units

(S12 = OFF).

• There must not be any potential displacement between the units which are

connected together using the SBus. Take suitable measures to avoid a potential

displacement, e.g. by connecting the unit ground connectors using a separate lead.

Serial Communication

13

3

RS-485 interface installation

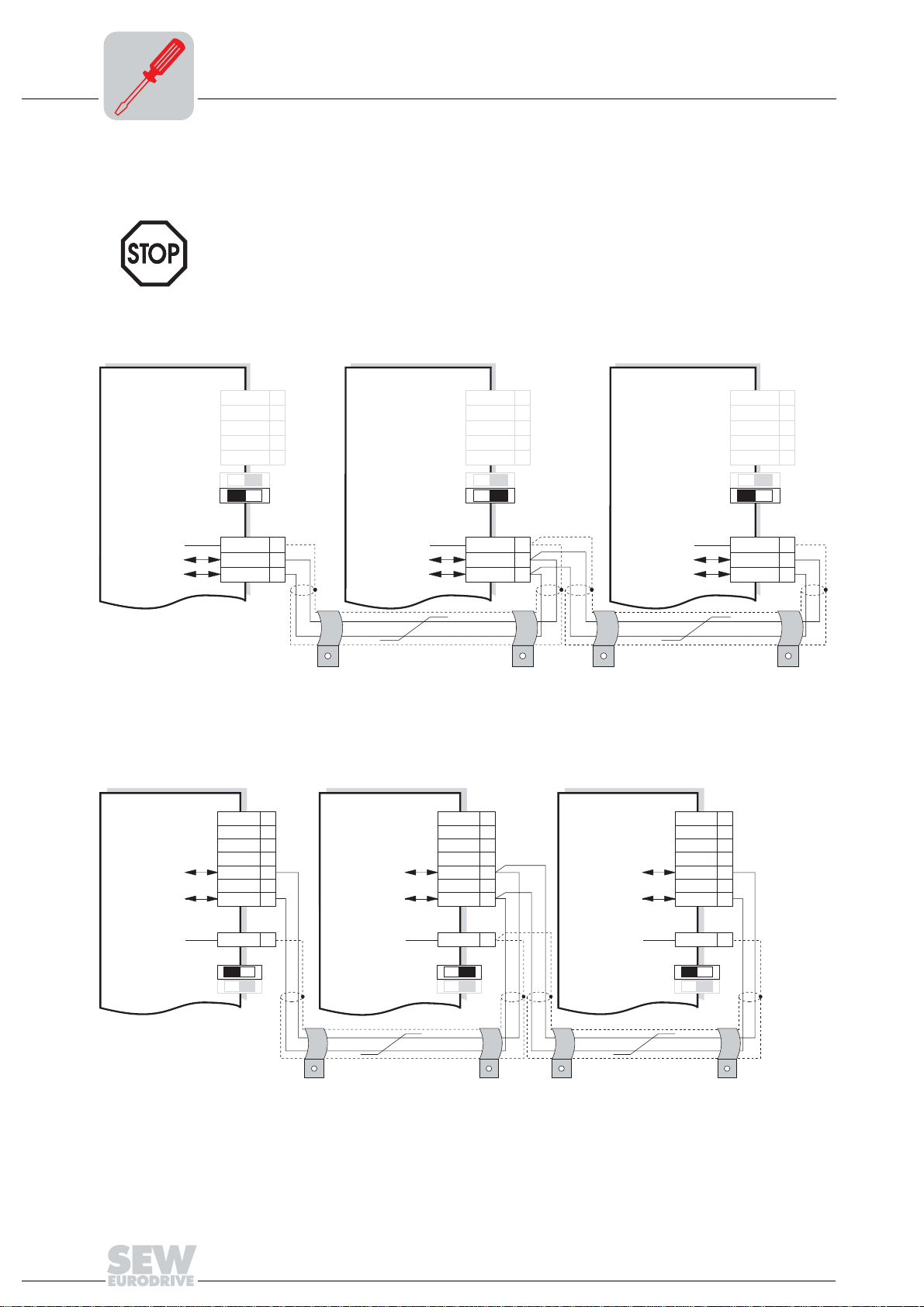

3.2 RS-485 interface installation

MOVIDRIVE®

MD_60A

The RS-485 interface is routed to terminals X13:10/11 and, in parallel, to the TERMINAL

option slot. The RS-485 interface can only be accessed via the TERMINAL option slot

when the "serial interface type USS21A" option is attached.

RS-485 connection via terminals X13:10/11

Controlunit Controlunit Controlunit

X13: X13: X13:

DIØØ

1

DIØ1

2

DIØ2

3

DIØ3

4

DIØ4

5

DIØ5

6

DCOM

7

VO24

8

DGND

RS-485+ RS-485+ RS-485 +

RS-485- RS-485- RS-485-

ST11

ST12

9

10

11

DIØØ

DIØ1

DIØ2

DIØ3

DIØ4

DIØ5

DCOM

VO24

DGND

ST11

ST12

1

2

3

4

5

6

7

8

9

10

11

쵰쵰쵰쵰

Fig. 9: RS-485 connection via X13:10/11

02206AEN

DIØØ

DIØ1

DIØ2

DIØ3

DIØ4

DIØ5

DCOM

VO24

DGND

ST11

ST12

1

2

3

4

5

6

7

8

9

10

11

Cable specification • Use a 2-core twisted and shielded copper cable (data transmission cable with shield

comprising copper braiding). The cable must meet the following specifications:

– Conductor cross section 0.5 – 0.75 mm

2

(AWG 20 – 18)

– Cable resistance 100 – 150 Ω at 1 MHz

– Capacitance per unit length ≤ 40 pF/m (12 pF/ft) at 1 kHz

The following cable is suitable, for example:

– BELDEN (www.belden.com), data cable type 3105A

Shield contact • Connect the shield at either end to the electronics shield clamp of the inverter or the

machine control and ensure the shield is connected over a large area. Also connect

the ends of the shield to DGND.

Line length • The permitted total line length is 200 m (660 ft).

Terminating

resistor

• Dynamic terminating resistors are fitted. Do not connect any external terminating

resistors!

• There must not be any potential displacement between the units which are

connected via RS-485. Take suitable measures to avoid a potential displacement,

e.g. by connecting the unit ground connectors using a separate lead.

14

MOVIDRIVE® Serial Communication

RS-485 interface installation

3

USS21A serial

interface

• With MOVIDRIVE® MD_60A drive inverters, the RS-485 interface can also be

accessed using the "serial interface type USS21A" option.

• With MOVIDRIVE

®

compact drive inverters, the RS-485 interface can only be

accessed using the "serial interface type USS21A" option.

RS-485 connection

via USS21A

USS21A USS21A

++

--

0V5 0V5

1

2

3

1

2

3

쵰쵰 쵰쵰

Fig. 10: RS-485 interface of the USS21A

00997CXX

Cable specification • Use a 2-core twisted and shielded copper cable (data transmission cable with shield

comprising copper braiding). The cable must meet the following specifications:

– Conductor cross section 0.5 – 0.75 mm

2

(AWG 20 – 18)

– Cable resistance 100 – 150 Ω at 1 MHz

– Capacitance per unit length ≤ 40 pF/m (12 pF/ft) at 1 kHz

The following cable is suitable, for example:

– BELDEN (www.belden.com), data cable type 3105A

Shield contact • Connect the shield at either end to the electronics shield clamp of the inverter and

ensure the shield is connected over a large area. Also connect the ends of the shield

to DGND.

EIA standard • Max. transmission rate 9600 baud

• Max. 32 stations (each unit with USS21A counts as two stations)

• Max. cable length 200 m (660 ft) in total

• Dynamic terminating resistor with fixed installation

MOVIDRIVE

®

Serial Communication

15

3

RS-232 interface installation

3.3 RS-232 interface installation

With MOVIDRIVE® MD_60A and MOVIDRIVE® compact, the RS-232 interface can only

be accessed using the "serial interface type USS21A" option.

RS-232

connection

• Use a shielded standard interface cable for connecting to the RS-232 interface.

Important: 1:1 cabling

USS21A

5

55

3

33

22

2

Fig. 11: PC connection via RS-232

GND (ground)

TxD

RxD

max. 5 m (16.5 ft)

5

55

3

33

2

22

9-pin sub D connector (female)9-pin sub D connector (male)

PC COM 1-4

02399AENdf

16

MOVIDRIVE® Serial Communication

Telegra ms

4 RS-485 Communication

4.1 Telegrams

Telegram traffic Both cyclical and acyclical data exchange are used in drive engineering. Cyclical

telegrams via the serial interface are used in automation applications, particularly for

drive control. The master station must ensure cyclical data exchange in this case.

4

Cyclical data

exchange

Acyclical data

exchange

Cyclical data exchange is used predominantly for controlling the inverters via the serial

interface. In this process, the master continuously sends telegrams containing setpoints

(request telegrams) to an inverter (slave) and then waits for a response telegram with

actual values from the inverter. After a request telegram has been sent to an inverter,

the master expects the response telegram within a defined length of time (response

delay time). The inverter only sends back a response telegram if it has received a

request telegram sent to its slave address without any errors. The inverter monitors

whether the data communication fails during the cyclical data exchange. If

communication does fail, the inverter triggers a timeout response if it does not receive a

new request telegram from the master within an adjustable time.

MOVILINK

even during cyclical communication without changing the type of telegram.

Acyclical data exchange is principally used for startup and diagnostics. The inverter

does not monitor the communications link in this case. The master can send telegrams

to the inverter at irregular intervals in acyclical mode.

®

also offers the opportunity to perform acyclical service and diagnostic tasks

MOVIDRIVE

®

Serial Communication

17

4

Telegrams

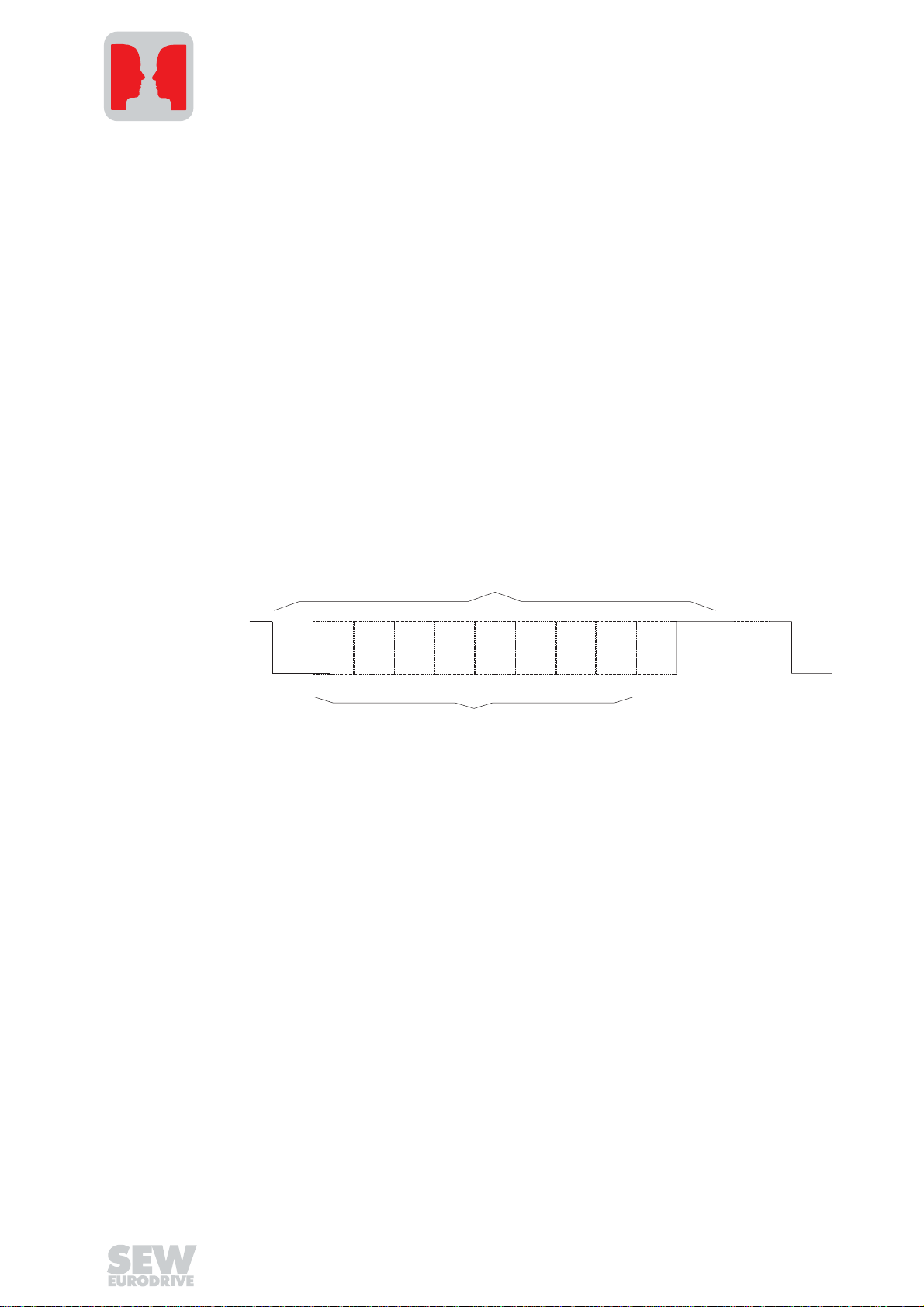

Telegram

structure

Request telegram

structure

The entire data exchange is performed using only two types of telegram. It involves the

master sending a request containing data to the inverter, in the form of a request

telegram. The inverter answers with a response telegram. When word information (16bit) is sent within the user data, the high byte is always sent first and the low byte last.

In the case of double word information (32-bit), the high word is sent first and the low

word last. Coding of the user data is not part of the protocol. The content of the user data

is explained in detail in the MOVIDRIVE

®

Fieldbus Unit Profile manual.

Fig. 12 shows the structure of the request telegram which the master sends to the

inverter. Each telegram starts with an idle time on the bus, referred to as the start pause,

followed by a start character. Different start characters are used so that it is possible to

clearly differentiate between request and response telegrams. The request telegram

starts with the start character SD1 = 02

, followed by the slave address and the PDU

hex

type.

Start delimiter 1

02 hex

....Idle...

Start pause Slave address Protocol data unit

SD1

ADR

PDU type

TYP

Block check character

PDU BCC

Response

telegram structure

Fig. 12: Structure of the request telegram

01485BEN

Fig. 13 shows the structure of the response telegram by means of which the inverter

(slave) responds to a request sent by the master. In turn, each response telegram starts

with a start pause, followed by a start character. The response telegram starts with the

start character SD2 = 1D

, followed by the slave address and the PDU type so that it

hex

is possible to clearly differentiate between request and response telegrams.

Start delimiter 2

02 hex

....Idle...

Start pause Slave address Protocol data unit

Fig. 13: Structure of the response telegram

SD2

ADR

PDU type

TYP

Block check character

PDU BCC

01487BEN

18

MOVIDRIVE® Serial Communication

Telegra ms

Start pause (idle) The master must observe a start pause of at least 3.44 ms before sending the start

character SD1 (02

telegram. This pause prevents the bit combination 02

user data, from being erroneously interpreted as the start character. As a result, the start

pause forms part of the start character. After it has received a valid request telegram,

the inverter waits for an idle time of at least 3.44 ms before sending back the response

telegram with the start character SD2 (1D

the start character of a response telegram as well. In case the transmission of a valid

request telegram is canceled by the master, a new request telegram cannot be sent until

at least two start pauses (6.88 ms) have elapsed.

) so that the inverter can definitively identify the start of a request

hex

). This enables the master to clearly identify

hex

, which may also occur in the

hex

4

Start character

(SD1 / SD2)

The start character and the preceding start pause detect the commencement and the

data direction of a new telegram. The following table shows the allocation of the start

character to the data direction.

SD1 02

SD2 1D

hex

hex

Request telegram Master → inverter

Response telegram Inverter → master

MOVIDRIVE

®

Serial Communication

19

4

Addressing and transmission process

4.2 Addressing and transmission process

Address byte

(ADR)

Individual

addressing

The address byte always specifies the slave address regardless of the data direction.

Therefore, the ADR character in a request telegram specifies the address of the inverter

which is to receive the request. In the opposite direction, the master can tell from which

inverter the response telegram was sent. Generally speaking, there is only one master

in the system. This means the master is not addressed. In addition to individual

addressing, the MOVILINK

®

protocol also offers further addressing options. The

following table shows the address areas and what they mean.

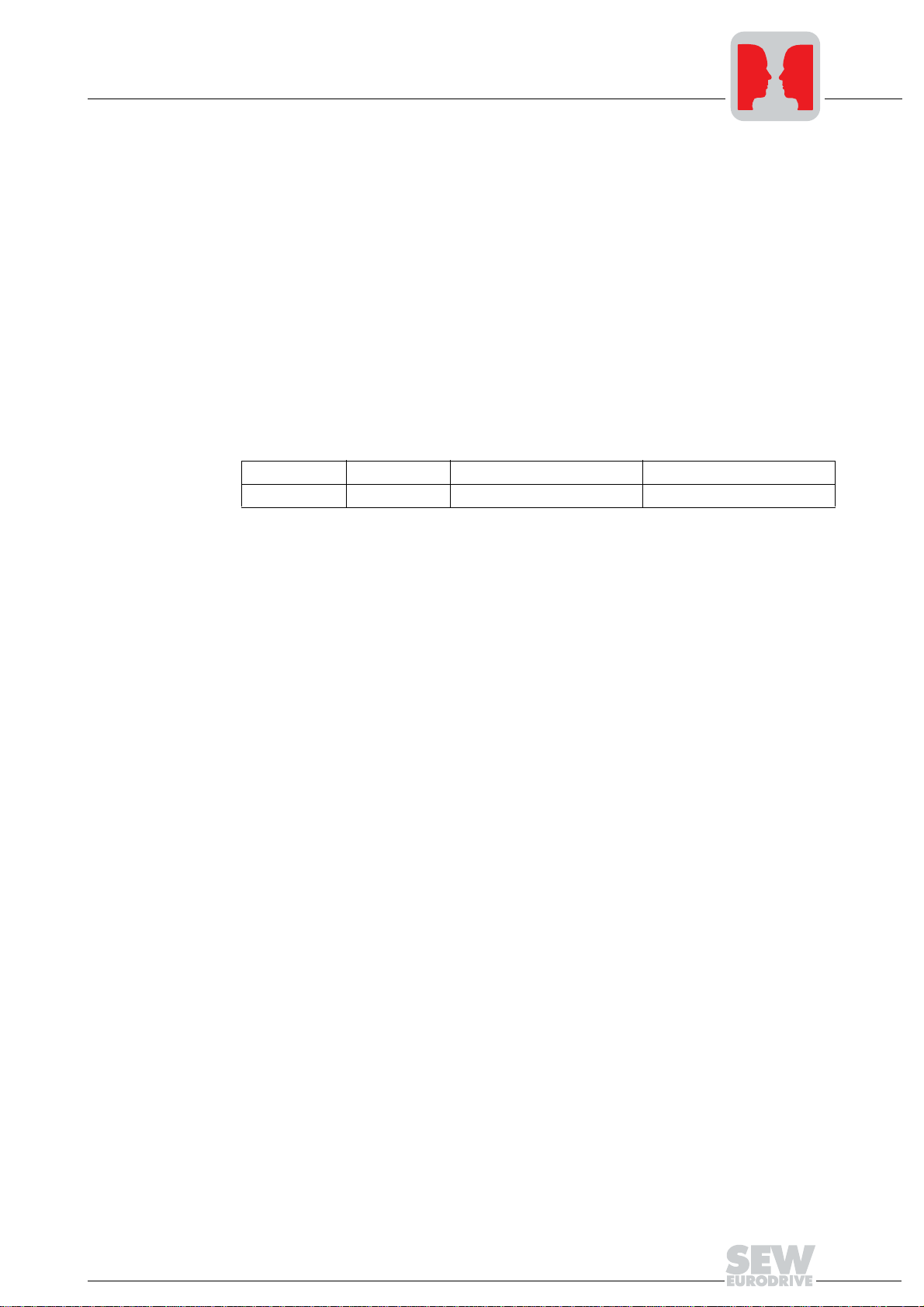

ADR Meaning

0 – 99 Individual addressing within an RS-485 bus

100 –

199

253

254 Universal address for peer-to-peer communication

255 Broadcast address

Group addressing (multicast)

Special case of group address 100: Means "Not assigned to any group", i.e. ineffective

plus®

Local address: Only effective in conjunction with IPOS

command. For communication within the unit.

as master and the MOVILINK

Each inverter can be addressed directly via addresses 0 – 99. Each request telegram

from the master is answered by a response telegram from the inverter.

Master

Request to ADR 1

Response from ADR 1

Request to ADR 3

Response from ADR 3

Request to ADR 12

Response from ADR 12

Slave SlaveSlave

Inverter Inverter

ADR: 1 ADR: 3

Fig. 14: Individual addressing via unit address 232/485

Inverter

ADR: 12

01488BEN

20

MOVIDRIVE® Serial Communication

Addressing and transmission process

4

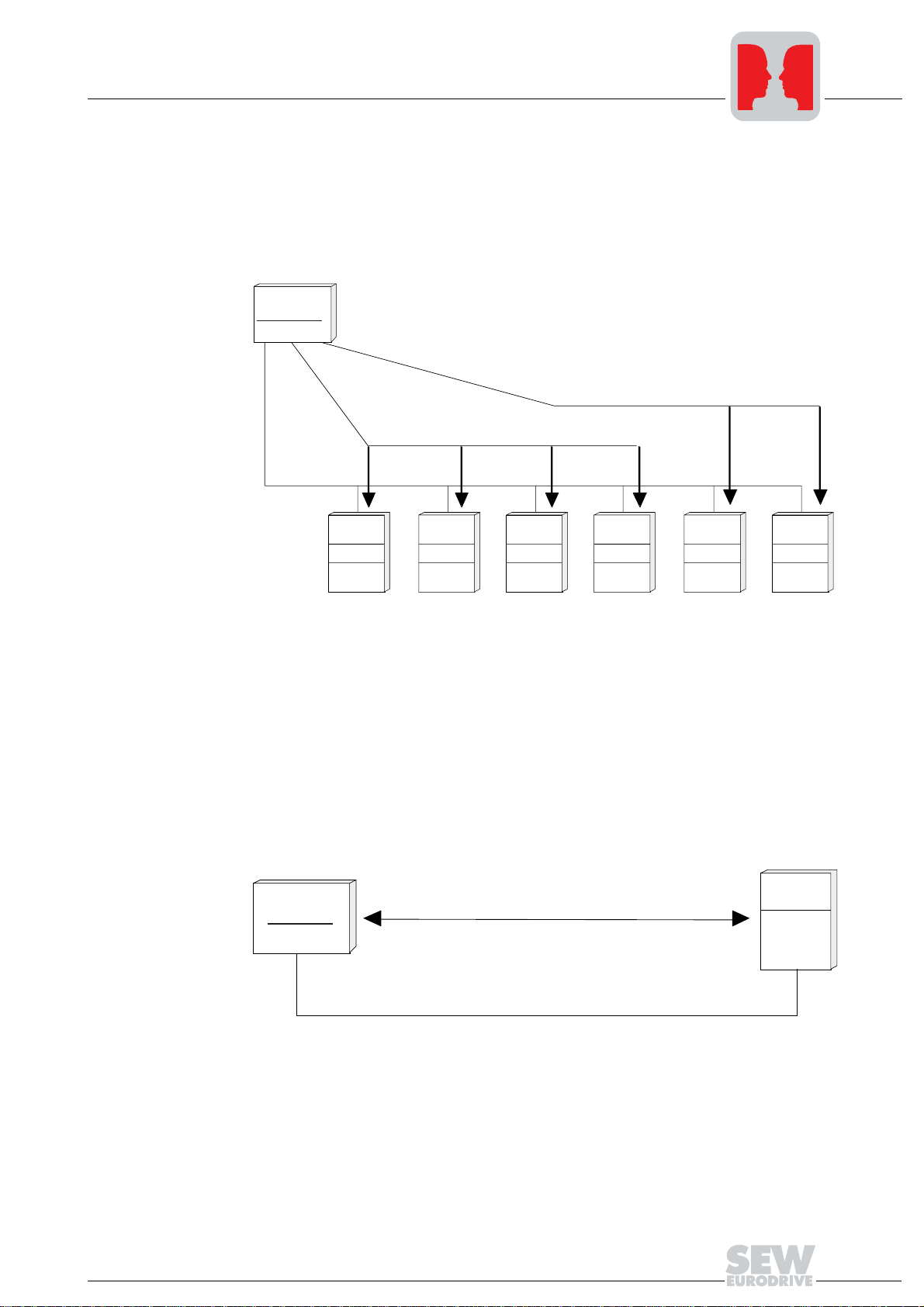

Group addressing

(multicast)

Each inverter possesses an adjustable group address in addtion to its individual

address. This setup enables the user to form groups with various stations and then

address the individual stations in a group simultaneously using the group address. No

response telegram is sent back to the master in the case of group addressing. This

means it is not possible to request data from the inverter. Also, there is no response

when data are written. You can create up to 99 groups.

Master

Request telegram to group adr. 102

Request telegram to group adr. 101

Slave Slave Slave Slave Slave Slave

Inveter

ADR: 1 ADR: 2 ADR: 3 ADR: 4 ADR: 5 ADR: 6

Group

adr.: 101

Inverter Inverter

Group

adr.: 101

Group

adr.: 101

Inverter

Group

adr.: 101

Inverter

Group

adr: 102

Inverter

Group

adr.: 102

Universal

addressing for

peer-to-peer

connection

Fig. 15: Addressing individual groups

01489BEN

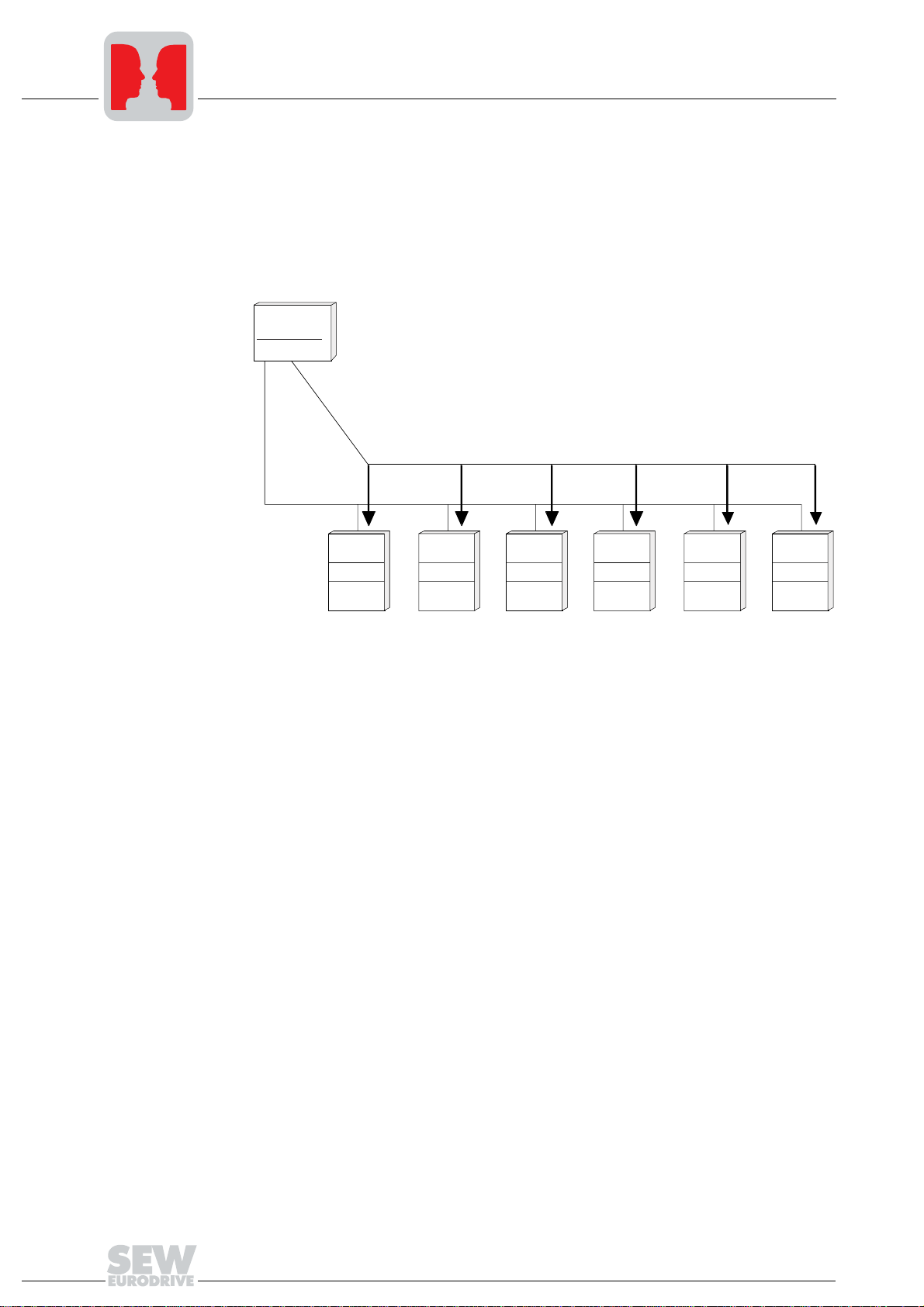

Every inverter can be addressed via the universal address 254 regardless of the

individual address which has been set for it. The advantage of this method is that peerto-peer connections can be established via the RS-232 interface without necessarily

knowing the currently set individual address. Every inverter station is addressed with

this universal address, which means this method must not be used in multipoint

connections (e.g. RS-485 bus). Otherwise, there would be data collisions on the bus

because every inverter would send a response telegram after receiving the request

telegram.

Slave

Master

Fig. 16: Addressing in peer-to-peer connections with universal address 254

Request telegram via universal adr. 254

Response telegram from slave

Inverter

ADR: 1

01490BEN

MOVIDRIVE

®

Serial Communication

21

4

Addressing and transmission process

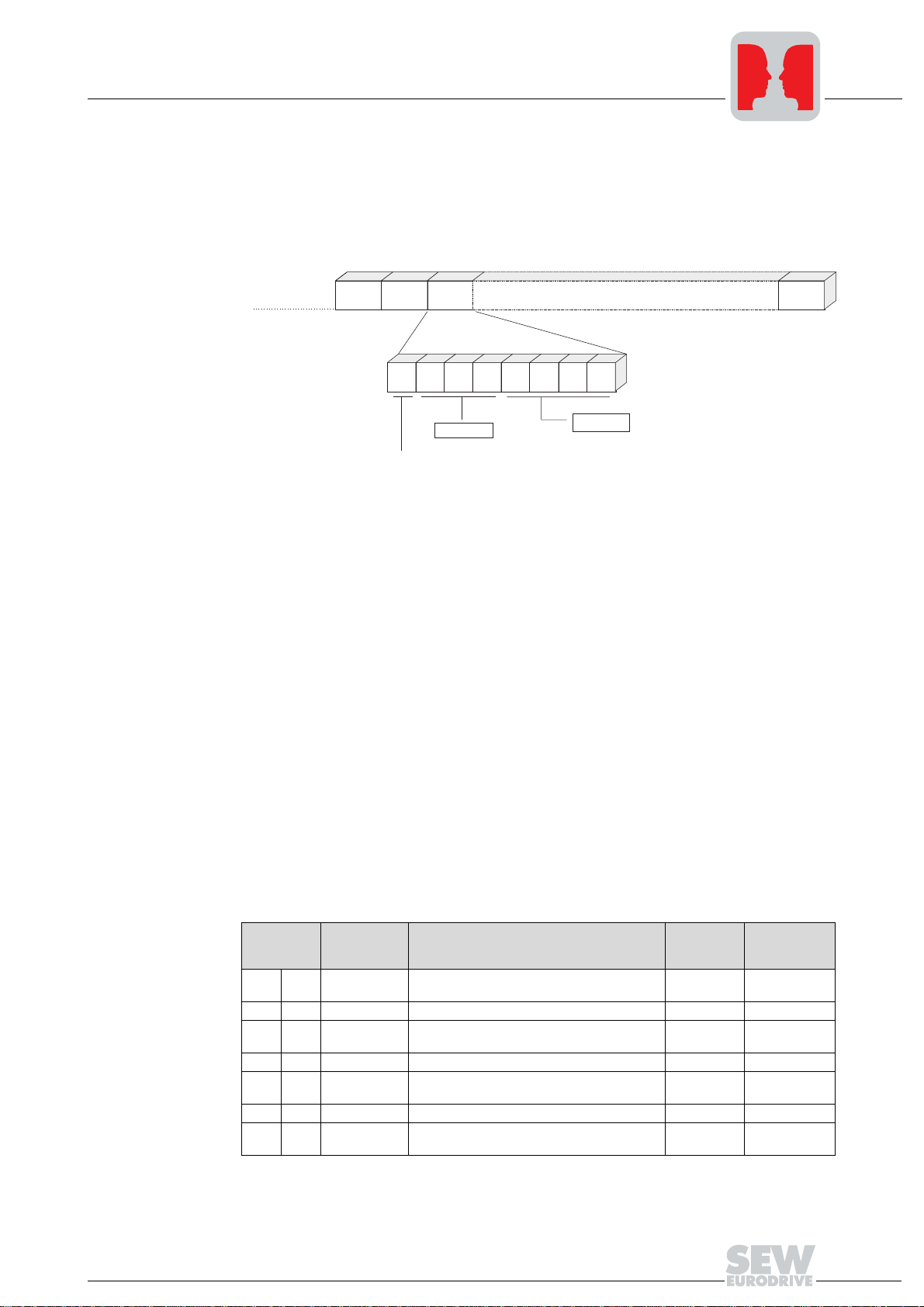

Broadcast address The broadcast address 255 permits a broadcast to all inverter stations. The request

telegram sent out by the master to broadcast address 255 is received by all inverters,

but they do not reply. Consequently, this addressing variant is predominantly used for

transferring setpoints. The master can send broadcast telegrams with a minimum time

interval of 25 ms, i.e. an idle time of at least 25 ms must be observed between the last

character sent in a request telegram (BCC) and the start of a new request telegram

(SD1).

Master

Request telegram to all slaves via broadcast adr. 255

Slave Slave Slave Slave Slave Slave

Inveter

Inverter Inverter

ADR: 1 ADR: 2 ADR: 3 ADR: 4 ADR: 5 ADR: 6

Group

adr.: 101

Group

adr.: 101

Fig. 17: Addressing individual groups

Group

adr.: 101

Inverter

Group

adr.: 101

Inverter

Group

adr: 102

Inverter

Group

adr.: 102

01491BEN

22

MOVIDRIVE® Serial Communication

Addressing and transmission process

Structure and

length of user

data

PDU type (TYP) The TYP byte describes the structure and the length of the user data which succeed it

(protocol data unit or PDU). Fig. 18 shows the structure of the type byte.

...Idle... SD1 ADR TYP PDU BCC

Bit: 7 6 5 4 3 2 1 0

4

reserved

transmission variant

0: cyclical

1: acyclical

PDU type

01492BEN

Fig. 18: Structure of the TYP byte

Bit 7 of the TYP byte is used to differentiate between cyclical or acyclical transmission

of user data. A request telegram with the cyclical transmission variant signals to the

inverter that the data sent by the master will be updated cyclically. Consequently, a

response monitoring function can be activated in the inverter. This means a timeout

response is triggered if the inverter does not receive a new cyclical request telegram

within an adjustable timeout delay.

The following tables show the PDU types for cyclical and acyclical transmission.

However, not all PDU types are supported (depending on the type of inverter). The

special PDU types are not significant for general serial communication, and are thus not

included in the operator documentation. The length of the telegram depends on the

related PDU type and is always calculated as follows:

Telegram length = PDU length + 4.

CYCLICAL

transmission

MOVIDRIVE

PDU types in CYCLICAL transmission:

TYP byte PDU name Description

00

hex0dec

01

hex1dec

02

hex2dec

03

hex3dec

04

hex4dec

05

hex5dec

06

hex6dec

®

Serial Communication

PDU length

in bytes

PAR A M + 1 P D

1PD 1 process data word 2 6

PAR A M + 2 P D

2PD 2 process data words 4 8

PAR A M + 3 P D

3PD 3 process data words 6 10

PAR A M + 0 P D

8 bytes parameter channel + 1 process data

word

8 bytes parameter channel + 2 process data

words

8 bytes parameter channel +3 process data

words

8 bytes parameter channel without process

data

10 14

12 16

14 18

812

Tel egr am

length in

bytes

23

4

Addressing and transmission process

ACYCLICAL

transmission

PDU types in ACYCLICAL transmission:

TYP byte PDU name Description

80

81

82

83

84

85

86

hex

hex

hex

hex

hex

hex

hex

128

129

130

131

132

133

134

PAR A M + 1 P D

dec

dec

PAR A M + 2 P D

dec

dec

PAR A M + 3 P D

dec

dec

PAR A M + 0 P D

dec

1PD 1 process word 2 6

2PD 2 process data words 4 8

3PD 3 process data words 6 10

8 bytes parameter channel + 1 process data

word

8 bytes parameter channel + 2 process data

words

8 bytes parameter channel +3 process data

words

8 bytes parameter channel without process

data

The standard PDU types are made up of the MOVILINK

process data channel. Please refer to the MOVIDRIVE

®

Fieldbus Unit Profile for coding

PDU length

in bytes

10 14

12 16

14 18

812

®

parameter channel and a

Tel egra m

length in

bytes

of the parameter channel and the process data.

Fig. 19 shows the structure of a request telegram with the standard PDU types. The

corresponding response telegram has the same structure, except for the start character

SD2.

...Idle... SD1 ADR TYP PDU BCC

TYP 1/129

TYP 3/131

TYP 5/133

TYP 6/134

TYP 0/128

TYP 2/130

TYP 4/132

PD1

PD1

PD1

PD2

PD2

8 byte parameter channel

8 byte parameter channel

8 byte parameter channel

8 byte parameter channel

PD3

PD1

PD1

PD1

Fig. 19: Structure of the request telegram with the standard PDU types

PD2

PD2

PD3

01493BEN

24

MOVIDRIVE® Serial Communication

Block check

character BCC

Transmission

reliability

Addressing and transmission process

The transmission reliability of the MOVILINK

of character parity and block parity. This involves setting the parity bit for each character

of the telegram in such a way that the number of binary ones, including the parity bit, is

even. This means supplementing by the parity bit results in even character parity.

Block parity offers extra security. In this case, the telegram is supplemented by an

additional block check character (BCC). Each single bit of the block check character is

set in such a way that the telegram character is set to even parity again for all equivalent

information bits. Block parity is implemented in the program structure by an EXOR logic

operation of all telegram characters. The result is transmitted at the end of the telegram

in the BCC. The block check character itself is also safeguarded by means of even

character parity.

®

protocol is improved by the combination

4

Creating the block

check character

By way of example, the following table shows how the block check character is created

for a PDU type 5 cyclical telegram with 3 process data words. The EXOR logic operation

on the characters SD1 – PD3

results in the value 57

low

as the block check character

hex

BCC. This BCC is sent as the last character in the telegram. Once the receiver has

received the individual characters, it performs a character parity check. Following this

step, the block check character is created from the received characters SD1 – PD3

low

in accordance with the procedure below. The telegram has been correctly transmitted if

the calculated and received BCCs are identical and there is no character parity error.

Otherwise, a transmission error has occurred.

SD1: 02 hex

ADR: 01 hex

TYP: 05 hex

PD1 high: 00 hex

PD1 low: 06 hex

PD2 high: 3A hex

PD2 low: 98 hex

PD3 high: 01 hex

PD3 low: F4 hex

Stop

Parity

1

1

0

0

0

0

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

1

1

0

0

0

0

1

0

0

1

EXOR

0

EXOR

0

EXOR

0

EXOR

0

EXOR

1

EXOR

1

EXOR

0

EXOR

1

0

0

0

0

1

0

0

0

0

1

1

0

1

0

1

0

0

1

0

0

0

0

1

0

1

0

0

0

0

0

Start

0

1

1

0

0

0

0

1

0

MOVIDRIVE

calculated BCC:

Fig. 20: Creating the block check character BCC

®

Serial Communication

57 hex

1

1

01494BEN

1

1

0

1

0

1

0

25

4

Addressing and transmission process

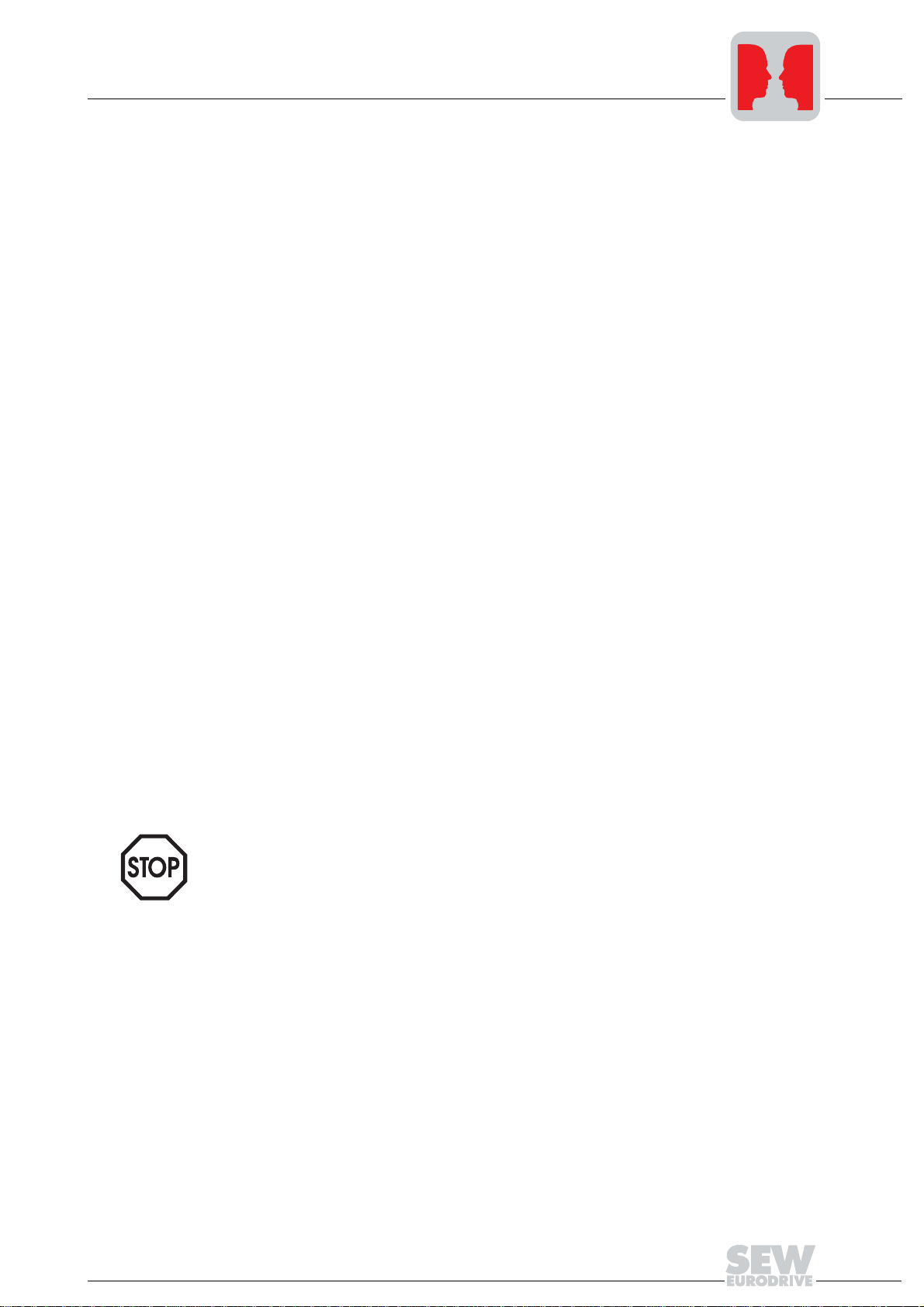

Transmission

process

Character frame Each character in the MOVILINK

An asynchronous serial transmission procedure is used. This is supported by the UART

components of digital technology which are generally and commonly employed. This

means the MOVILINK

modules.

structure:

• 1 start bit

• 8 data bits

• 1 parity bit, supplementing to even parity

• 1 stop bit

Each transmitted character starts with a start bit (always logical 0). This is followed by 8

data bits and the parity bit. The parity bit is set in such a way that the number of logical

ones in the data bits, including the parity bit, is an even number. The character is

completed by a stop bit which is always set to the logical level 1. This level remains on

the transmission medium until a new start bit signals the start of a new character

transmission.

®

protocol can be implemented on almost all controls and master

11 bit character frame

®

protocol consists of 11 bits and has the following

01234567

Start

LSB MSB even

Fig. 21: Character frame

8 data bits

Stop

Parity

Start

01495BEN

26

MOVIDRIVE® Serial Communication

Addressing and transmission process

4

Transmission

rate and

transmission

mechanisms

Response delay

time of the master

Character delay

time

RS-485 timeout

delay of the

inverter

The transmission rate is 9600 baud. The communication link is monitored by the master

and the inverter themselves. The master monitors the response delay time; the inverter

monitors the receipt of cyclical request telegrams from the master.

A response delay time is generally programmed on the higher-level master system. The

response delay time is the time interval between the last character in the request

telegram (BCC) being sent and the start of the response telegram (SD2). The maximum

permitted response delay time is 50 ms. There has been a transmission error if the

inverter does not respond within this time. Check the interface cable or the coding of the

transmitted request telegram. For application reasons, the request telegram should now

be repeated again or the next inverter should be addressed.

The time gap between the transmission of the characters in a request telegram must be

shorter than the start pause. Otherwise, the inverter might interpret a character it

receives containing 02

hex

or 1D

as a start character.

hex

The maximum permitted time interval between two cyclical request telegrams is set in

MOVIDRIVE

®

using parameter P812 "RS485 timeout delay". A valid request telegram

must be received within this time interval. Otherwise, the inverter triggers an RS-485

timeout error and performs a defined error response.

The MOVIDRIVE

®

is kept in a safe status until the first request telegram is received once

the power is switched on or an error has been performed. "t" (= timeout active) appears

on the 7-segment display of an enabled inverter; the enable setting does not have any

effect. The enable takes effect once the telegram has been received and the drive starts

moving.

If the inverter is controlled via the RS-485 interface (P100 "Setpoint source" = RS-485 /

P101 "Control signal source" = RS-485) and an error response involving a warning has

been programmed, the process data most recently received take effect following an RS485 timeout and re-establishment of communication.

MOVIDRIVE

The RS-485 timeout acts jointly on both RS-485 interfaces. Timeout monitoring of the

second interface is ineffective when the DBG11A keypad is connected, because the

DBG11A continuously sends request telegrams to the inverter, thereby triggering the

timeout mechanism.

®

Serial Communication

27

4

Addressing and transmission process

Processing the

request/response

telegrams

The inverter only processes request telegrams which have been received without errors

and are correctly addressed. The following reception errors can be recognized:

• Parity error

• Character frame error

• Character delay time exceeded with request telegram

• Address incorrect

• PDU type incorrect

• BCC incorrect

• Response delay time elapsed (master)

• → Possible send repeat

• RS-485 timeout occurred (inverter)

• → Triggering timeout response

The inverter does not respond to incorrectly received request telegrams! These

reception errors have to be evaluated on the master end in order to safeguard data

transmission.

28

MOVIDRIVE® Serial Communication

Loading...

Loading...