Drive Technology \ Drive Automation \ System Integration \ Services

Operating Instructions

*23507268_1217*

MAXOLUTION® System Solution

Automated Guided Vehicle

MAXO-MTS-T005-P-00-B04-04-C-VR0-A-00

Edition 12/2017 23507268/EN

SEW-EURODRIVE—Driving the world

Table of contents

Table of contents

1 General information.................................................................................................................. 5

1.1 About this documentation ...............................................................................................5

1.2 Structure of the safety notes ...........................................................................................5

1.3 Rights to claim under limited warranty ............................................................................6

1.4 Exclusion of liability.........................................................................................................7

1.5 Other applicable documentation ..................................................................................... 7

1.6 Product names and trademarks......................................................................................7

1.7 Copyright notice ..............................................................................................................7

2 Safety notes .............................................................................................................................. 8

2.1 Preliminary information ................................................................................................... 8

2.2 Working on the system solution ......................................................................................8

2.3 Target group ...................................................................................................................8

2.4 Designated use ...............................................................................................................9

2.5 Functional safety...........................................................................................................10

2.6 Bus systems..................................................................................................................10

2.7 Transport.......................................................................................................................11

2.8 Electrical installation .....................................................................................................11

2.9 Startup and operation ...................................................................................................11

2.10 Inspection and maintenance ......................................................................................... 12

2.11 Storage .........................................................................................................................12

3 Vehicle ..................................................................................................................................... 13

3.1 Type designation...........................................................................................................13

3.2 Short designations ........................................................................................................ 13

3.3 Nameplates...................................................................................................................14

3.4 Structure .......................................................................................................................15

3.5 Detailed drawings .........................................................................................................19

3.6 Functional principle .......................................................................................................20

3.7 Caution signs on the vehicle .........................................................................................21

3.8 Load handling device interfaces ...................................................................................21

4 Warning and safety devices .................................................................................................. 23

4.1 Safety concept .............................................................................................................. 23

4.2 Safety functions ............................................................................................................23

4.3 Safety laser scanner ..................................................................................................... 24

4.4 Emergency stop button .................................................................................................25

4.5 Optical and acoustic warning signals............................................................................26

4.6 Key switch.....................................................................................................................27

5 Operation................................................................................................................................. 28

5.1 Notes on safe operation................................................................................................28

5.2 Operating modes of the vehicle .................................................................................... 29

5.3 Control elements on the vehicle....................................................................................30

5.4 Switching on the vehicle ...............................................................................................30

23507268/EN – 12/2017

5.5 Switching off the vehicle ...............................................................................................30

5.6 DOP operator panel ......................................................................................................30

Operating Instructions – Automated Guided Vehicle

3

Table of contents

6 Maintenance............................................................................................................................ 40

6.1 Inspection and maintenance work ................................................................................40

6.2 Failures ......................................................................................................................... 43

6.3 Status and error messages...........................................................................................44

6.4 Replacing the battery ....................................................................................................46

6.5 Transport.......................................................................................................................48

6.6 Spare parts ...................................................................................................................49

6.7 Electronics Service .......................................................................................................49

7 Technical data......................................................................................................................... 51

7.1 Ambient conditions........................................................................................................51

7.2 Vehicle .......................................................................................................................... 51

7.3 Startup parameters ....................................................................................................... 52

7.4 Dimension sheets .........................................................................................................55

8 MAXOLUTION® Competence Center ..................................................................................... 56

Operating Instructions – Automated Guided Vehicle

4

23507268/EN – 12/2017

1 General information

1.1 About this documentation

The current version of the documentation is the original.

This documentation is an integral part of the product. The documentation is written for

all employees who assemble, install, start up, and service this product.

Make sure this documentation is accessible and legible. Ensure that persons responsible for the machinery and its operation as well as persons who work on the product

independently have read through the documentation carefully and understood it. If you

are unclear about any of the information in this documentation or require further information, contact SEW‑EURODRIVE.

1.2 Structure of the safety notes

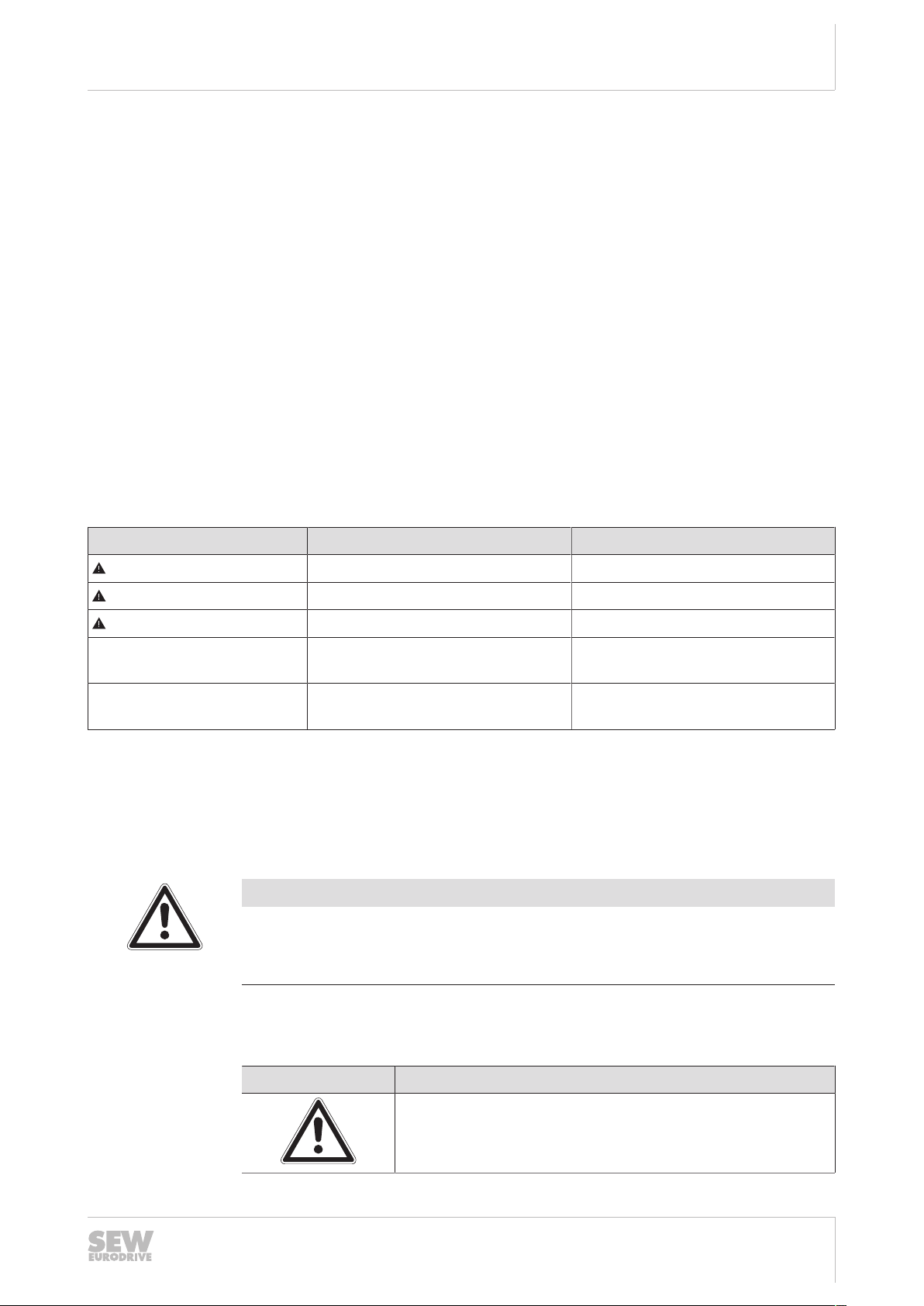

1.2.1 Meaning of signal words

The following table shows the grading and meaning of the signal words for safety

notes.

General information

About this documentation

1

Signal word Meaning Consequences if disregarded

DANGER Imminent hazard Severe or fatal injuries

WARNING Possible dangerous situation Severe or fatal injuries

CAUTION Possible dangerous situation Minor injuries

NOTICE Possible damage to property Damage to the product or its envir-

onment

INFORMATION Useful information or tip: Simplifies

handling of the product.

1.2.2 Structure of section-related safety notes

Section-related safety notes do not apply to a specific action but to several actions

pertaining to one subject. The hazard symbols used either indicate a general hazard

or a specific hazard.

This is the formal structure of a safety note for a specific section:

SIGNAL WORD

Type and source of hazard.

Possible consequence(s) if disregarded.

• Measure(s) to prevent the hazard.

Meaning of the hazard symbols

The hazard symbols in the safety notes have the following meaning:

Hazard symbol Meaning

23507268/EN – 12/2017

General hazard

Operating Instructions – Automated Guided Vehicle

5

General information

Rights to claim under limited warranty

1

Hazard symbol Meaning

Warning of dangerous electrical voltage

Warning of hot surfaces

Warning of risk of crushing

Warning of suspended load

Warning of automatic start-up

No access to persons with pacemakers

Do not ride on vehicle

1.2.3 Structure of embedded safety notes

Embedded safety notes are directly integrated into the instructions just before the description of the dangerous action.

This is the formal structure of an embedded safety note:

SIGNAL WORD Type and source of hazard. Possible consequence(s) if disreg-

arded. Measure(s) to prevent the hazard.

1.3 Rights to claim under limited warranty

Read the information in this documentation. This is essential for fault-free operation

and fulfillment of any rights to claim under limited warranty. Read the documentation

before you start working with the product.

Operating Instructions – Automated Guided Vehicle

6

23507268/EN – 12/2017

1.4 Exclusion of liability

Read the information in this documentation, otherwise safe operation is impossible.

You must comply with the information contained in this documentation to achieve the

specified product characteristics and performance features. SEW‑EURODRIVE assumes no liability for injury to persons or damage to equipment or property resulting

from non-observance of these operating instructions. In such cases,

SEW‑EURODRIVE assumes no liability for defects.

1.5 Other applicable documentation

Observe the corresponding documentation for all further components.

1.6 Product names and trademarks

The brands and product names in this documentation are trademarks or registered

trademarks of their respective titleholders.

General information

Exclusion of liability

1

1.7 Copyright notice

©2017SEW‑EURODRIVE. All rights reserved. Unauthorized reproduction, modification, distribution or any other use of the whole or any part of this documentation is

strictly prohibited.

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

7

Safety notes

Preliminary information

2

2 Safety notes

2.1 Preliminary information

The following basic safety notes must be read carefully to prevent injury to persons

and damage to property.

The safety notes refer to the use of the system solution described in this document.

This document does not replace the detailed documentation of the products and software used. You therefore have to observe the documentation of the products and software used.

Ensure that all safety notes are observed.

2.2 Working on the system solution

Make sure that all work steps described in this documentation are only performed by

qualified specialists.

Observe the following:

• National and regional safety and accident prevention regulations

• Personal protective equipment, e.g. safety shoes

• Caution signs on the products

• All system-specific specifications and conditions

The system solution may only be operated in systems equipped with the required

monitoring and protection devices.

2.3 Target group

Operation The product must only be operated by qualified personnel. Qualified personnel in this

context are persons who have the following qualifications:

• Appropriate instruction

• Knowledge of this documentation and all other referenced documentation

• Participation in a product training for the system solution

Specialist for

mechanical work

Specialist for electrotechnical work

Any mechanical work may only be performed by adequately qualified specialists. Specialists in the context of this documentation are persons familiar with the design,

mechanical installation, troubleshooting, and maintenance of the product who possess

the following qualifications:

• Qualification in the mechanical area in accordance with the national regulations

• Familiarity with this documentation

Any electrotechnical work may only be performed by electrically skilled persons with a

suitable education. Electrically skilled persons in the context of this documentation are

persons familiar with electrical installation, startup, troubleshooting, and maintenance

of the product who possess the following qualifications:

• Qualification in the electrotechnical area in accordance with the national regulations

• Familiarity with this documentation

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

8

Safety notes

Designated use

Software specialist Any work with the software may only be performed by adequately qualified personnel.

Qualified personnel in this context are persons who have the following qualifications:

• Appropriate instruction

• Knowledge of this documentation and other applicable documentation

• Participation in a product training for the software and the products operated with

it.

Additional qualification

Instructed persons All work in the areas of transportation, storage, operation and waste disposal must be

In addition to that, these persons must be familiar with the valid safety regulations and

laws, as well as with the requirements of the standards, directives, and laws specified

in this documentation. The persons must have the express authorization of the company to operate, program, parameterize, label, and ground units, systems, and circuits

in accordance with the standards of safety technology.

carried out by persons who are trained appropriately. The purpose of the instruction is

that the persons are capable of performing the required tasks and work steps in a safe

and correct manner.

2

2.4 Designated use

The system solution consists of one or several vehicles. The vehicle is designed for

material transport within industrial and commercial systems using an active or passive

load handling device.

The system solution is intended for integration in electrical systems and machines in

covered industrial use.

In case of installation in electrical systems or machines, startup of the system solution

is prohibited until it is determined that the system or machine meets the requirements

stipulated in the valid laws and directives.

The standards included in the declaration of conformity are applied for the system

solution.

Persons in the system

Restrictions Adhere to the following restrictions:

23507268/EN – 12/2017

Observe the following notes regarding the protection of persons:

• Instruct employees and visitors on how to act when accessing the system.

• The vehicle always takes priority to forklifts or other industrial trucks.

• Entering the hazardous areas is not permitted.

• Access to the closed off areas is only permitted to trained personnel.

• The system solution must only be used indoors and outside of potentially explosive

areas.

• Do not operate the system solution in environments containing harmful substances

(e.g. oils, acids, gases, vapors, dusts, radiation).

• Operate the system solution in a dry environment. Remove liquids from the floor.

• Do not operate the system solution in environments with conductive dirt.

• The vehicles are only suitable for transporting materials using the designated carriers.

• Transporting persons or animals is not permitted.

• Make sure that there are no obstacles on the track and that no objects protrude in

the track.

• Obstacles on the floor must have a minimum height of 200mm to be detected by

the safety laser scanner (risk of collision).

Operating Instructions – Automated Guided Vehicle

9

Safety notes

Functional safety

2

2.5 Functional safety

• Moving obstacles are detected. However, it is possible that the vehicle may not

come to a stop in due time. The braking distance is dimensioned for standing

obstacles.

• Do not step into the travel range of the vehicle.

• Keep a distance to the vehicle during load transfer (risk of crushing).

• Do not reach or walk into the pivoting/curved area of the vehicle.

• Adhere to the technical data, e.g. the maximum permitted total weight.

• Make sure no undetectable staircases, loading bays, or gaps in the floor are within

the range of the vehicle. Fence off areas that cannot be detected.

• Make sure the specified functional and safely test is completed before you start the

vehicle.

• Observe the travel range of adjacent systems.

• Operation is only permitted when the notes on safe operation are adhered to.

2.5.1 Safety-relevant conditions

To ensure that the emergency stop buttons can be used in case of danger, observe

the following notes:

• Do not block or cover the emergency stop buttons.

• Use the emergency stop buttons only in case of danger.

• Replace defective emergency stop buttons immediately.

2.5.2 Validation

The purpose of the validation is to confirm the specification and conformity of the drive

solution described in this document within the overall specification for the safety requirements of the machine/plant.

The validation must confirm that every safety-related component of the different safety

functions fulfills the required safety guidelines.

The validation process comprises the analysis and tests in accordance with a validation plan. Consult the various standards (e.g. ISO 13849-1) and corresponding resources.

If safety-relevant components and/or software is modified, the system/machine must

be validated again.

2.6 Bus systems

10

Operating Instructions – Automated Guided Vehicle

A bus system makes it possible to adapt electronic drive components to the particulars

of the machinery within wide limits. There is a risk that a change of parameters that

cannot be detected externally may result in unexpected (but not uncontrolled) system

behavior and may have a negative impact on operational safety, system availability, or

data security.

Especially in Ethernet-based networked systems and with engineering interfaces,

make sure that unauthorized access is prevented.

Use IT‑specific safety standards to increase access protection to the ports. For a port

overview, refer to the respective technical data of the device in use.

23507268/EN – 12/2017

Safety notes

Transport

2.7 Transport

Observe the following information to avoid damage to the product:

Before transport • Before you lift the product, read the safety notes on transport.

• Always use suitable, sufficiently rated handling equipment.

• Observe the ambient conditions of the components included in the product in the

SEW‑EURODRIVE documentation or in the documentation of the respective

manufacturer for third-party components.

During transport • Ensure that the product is not subject to mechanical impact during transportation.

After transport • Inspect the shipment for eventual damage as soon as you receive the delivery. In-

form the shipping company immediately about any damage. Do not startup any

device if it has been damaged during transport.

• Remove transport protection prior to startup.

2.8 Electrical installation

2

Ensure that all of the required covers are correctly attached after carrying out the electrical installation.

Make sure that preventive measures and protection devices comply with the applicable regulations (e.g. EN60204-1 or EN61800-5-1).

2.9 Startup and operation

Do not deactivate monitoring and protection devices even for a test run. When in

doubt, switch off the unit whenever changes occur in relation to normal mode (e.g. increased temperatures, noise, oscillation). Determine the cause. It may be necessary

to contact SEW‑EURODRIVE.

Where required, systems with these devices integrated must be equipped with additional monitoring and protection devices in accordance with the applicable safety regulations, e.g. the legislation governing technical equipment, accident prevention regulations, etc.

Additional preventive measures may be required for applications with increased hazard potential. You must check the functionality of protection devices each time you

change the configuration.

Do not touch live components or power connections immediately after disconnecting

the device from the voltage supply because some capacitors may still be charged. Observe the corresponding minimum switch-off time on the device labels and in the component documentation.

For further information on separating the power supply, refer to chapter Disconnecting

the power supply.

When the unit is switched on, dangerous voltages are present at all power connections as well as at any connected cables and motor terminals. This also applies even

when the unit is inhibited and the motor is at standstill.

The fact that the operation LED and other display elements are no longer illuminated

does not indicate that the device has been disconnected from the supply system and

no longer carries any voltage.

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

11

Safety notes

Inspection and maintenance

2

Mechanical blocking or internal safety functions of the unit can cause a motor standstill. Eliminating the cause of the problem or performing a reset may result in the drive

re-starting automatically. If, for safety reasons, this is not permitted for the drive-controlled machine, first disconnect the device from the supply system and discharge it

completely. Only then, start troubleshooting.

Electric arcs may damage electrical components. Do not disconnect power connections during operation. Do not connect power connections during operation.

2.10 Inspection and maintenance

Carry out maintenance and repair work only on a secured and de-energized machine/

system. Ensure a de-energized state of the machine/system before you start working

on it. Ensure a de-energized state for the entire time you work on the system.

2.11 Storage

Observe the following instructions when shutting down or storing the product:

• Make sure that the product is not subject to mechanical impact during storage.

• In case of extended storage, connect the product to the relevant supply voltage for

at least 8hours every 2years.

• Observe the note of the manufacturer regarding the shelf life of the energy storage

device in the vehicle.

• To avoid damage to the wheels, move the vehicles at least 2times a year or store

the vehicle without load being applied to the wheels.

Adhere to the notes on storage temperature:

• In chapter "Technical Data".

• In the manufacturer documentation if third-party components are installed.

12

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

3 Vehicle

3.1 Type designation

The type designation of the vehicle contains the following data:

MAXO MAXOLUTION® system solution

-

MTS Mobile transport system

-

T 3-wheel drive

005 Load capacity 500kg

-

P Standardized platform

-

00 No load handling device

Vehicle

Type designation

3

-

B04 Lead crystal battery bundle 48V

-

04 DC link voltage DC48V

-

C Energy supply with contact

-

V Optical navigation

R Navigation via RFID transponder

-

A Vehicle software AGVbasic

-

00 Version

3.2 Short designations

The following short designations are used in this documentation:

23507268/EN – 12/2017

Component Short designation

MAXO-MTS-T005-P-00-B04-04-C-VR0-A-00 Vehicle

Operating Instructions – Automated Guided Vehicle

13

Vehicle

D-76646 Bruchsal

Made in Germany

Ernst-Blickle-Str. 42

Typ:

S#:

Leergewicht:

Max. Zuladung:

Max. Geschw.:

MAXOLUTION®-Projekt-Nr.:

Versorgungsspg.:

[1] [3] [4][2]

[5]

[6]

D-76646 Bruchsal

Made in Germany

Ernst-Blickle-Str. 42

Typ:

S#:

Batterien Anzahl / Gewicht:

Spannung Batteriesatz:

Batterie Typ:

Fahrerloses Transportfahrzeug

Kapazität Batteriesatz:

[1] [2]

[3]

[4]

Nameplates

3

3.3 Nameplates

3.3.1 Main nameplate

The main nameplate lists information about the product. The following figure shows an

example of a main nameplate:

9007219191538955

[1] Type designation

[2] Serial number

[3] Data matrix code

[4] CE marking

[5] Technical data, such as no-load weight, max. velocity, max. payload, and sup-

ply voltage

[6] MAXOLUTION® project no.

3.3.2 Battery nameplate

The nameplate contains information on the battery. The following figure shows an example of a nameplate:

[1] Type designation

[2] Serial number

[3] Technical data, such as number and weight of the batteries, battery type,

[4] Designation of the system solution

20099741835

voltage of the battery set, and capacitance of the battery set.

14

Operating Instructions – Automated Guided Vehicle

23507268/EN – 12/2017

3.4 Structure

[2]

[1]

[3]

[2]

[3]

[4]

[3]

[5]

[1]

[1]

3.4.1 Vehicle structure

Vehicle

Structure

3

[1] Load handling device module (project-specific)

[2] Energy module

[3] Technology module

3.4.2 Front of the vehicle

No. Component Function

[1] Caution signs Warning about hazards.

[2] WLAN antenna Communication with the higher-level controller.

9007220061939595

18014418711452299

[3] Emergency stop button Stopping the vehicle in case of emergency.

[4] Safety laser scanner Detecting persons and objects.

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

15

Vehicle

[9]

[2]

[3]

[1]

[5]

[4]

[6]

[3]

[2][1] [4]

[8]

[3]

[3]

[7]

[10]

Structure

3

No. Component Function

[5] Attachment point for the

vehicle

3.4.3 Bottom of the vehicle

Transporting the vehicle.

No. Component Function

[1] Travel drive Driving the drive wheel

[2] Drive wheel Moving the vehicle

[3] LED lights Optical display of the vehicle status

[4] Auxiliary wheel Vehicle stability

[5] Safety laser scanner Recognition of persons in the direction of travel

[6] Read head Optical track guidance

[7] Read/write head Reading and writing the RFID transponder.

Distance read/write head (center) to the central axis of the vehicle: 175mm

Distance read/write head (center) to the front edge of the vehicle: 735mm

[8] Positive terminal char-

ging contact

[9] Read head (optional) Optical track guidance

[10] Negative terminal char-

ging contact

Charging the battery. The positive terminal is on the left in the direction of

travel.

Only required for vehicles with reverse motion.

Charging the battery. The negative terminal is on the right in the direction of

travel.

18014418711455755

16

Operating Instructions – Automated Guided Vehicle

23507268/EN – 12/2017

3.4.4 Back of the vehicle

[1] [2] [4][3]

[7]

[5] [6][6]

[8]

No. Component Function

Vehicle

Structure

9007219456717067

3

[1] Multi-function button Flashing green lighted pushbutton

[2] Acknowledgment button Flashing blue lighted pushbutton

[3] Emergency stop button Stopping the vehicle in case of emergency

[4] Key switch Keyswitch mode

DANGER!Danger due to safety functions that can be bypassed via

keyswitch. Serious injuries.

Do not bypass safety functions in normal operation!

[5] WLAN antenna Communication with the higher-level controller

[6] Attachment point for the

vehicle

[7] DOP operator terminal Operating and display element for manual mode and diagnostics

[8] Safety switching strip

(optional)

Transporting the vehicle

Safety measure to avoid crushing.

Only required for vehicles with reverse motion.

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

17

Vehicle

[1]

[3]

[4]

[5]

[2]

Structure

3

3.4.5 Vehicle backside – drawer

No. Component Function

[1] I/O module I/O system of the MOVI‑PLC

[2] Safety relays Safe brake control

[3] MOVISAFE® UCS

safety controller

[4] MOVI‑PLC

[5] WLAN client Communication of the vehicle with the logistics controller

®

Processing the signals of all safety components on the vehicle.

Vehicle controller

®

20811159691

18

Operating Instructions – Automated Guided Vehicle

23507268/EN – 12/2017

3.5 Detailed drawings

X32

X42

X11

X21

X12

X22

X13

X31

UCS12B

X6

DI 01 02 03 04

DO K1 K2 02 03

DI 05 06 07 08

DI 09 10 11 12

ENTER

STATUS

DI 13 14 P1 P2

X7

X8

1

6

5

1

6

5

9

XCS

XCD

/PS

RUN

SYSFault

X41

UCS23B

DI 01 02 03 04

DIO 03 04 05 06 DI 05 06 07 08

DI 09 10 11 12

STATUS

DIO 13 14 P1 P2

DIO 07 08 09 10

X35

X45

X36

X46

X15

X25

X16

X26

UCS23B

DI 01 02 03 04

DIO 03 04 05 06 DI 05 06 07 08

DI 09 10 11 12

STATUS

DIO 13 14 P1 P2

DIO 07 08 09 10

X35

X45

X36

X46

X15

X25

X16

X26

DHP11B

X30

2

2

2

2

0

1

2

3

2

2

2

4

5

6

[1]

[2]

[1]

[3]

[3]

[1]

[7]

[1]

[15]

[14]

[26]

[25]

[5]

[6]

[10]

[5]

[9]

[24]

[9]

[5]

[23]

[22]

[11]

[6]

[18]

[19]

[20]

[21]

[13]

[4]

[17]

[8]

[12]

[16]

3.5.1 Technology module

Vehicle

Detailed drawings

3

21477269771

[1] LED strip [10] Read/write head for RFID

[19] LED switch

transponder

[2] Safety switching strip [11] MOVI‑PLC

®

[20] Fuse

[3] Motor CMP ELVCD [12] Safety relays [21] OCC11C bus coupler

[4] Energy module interface [13] Relay [22] Access Point

[5] Emergency off button [14] MOVISAFE® UCS23B [23] DOP operator terminal

[6] WLAN antenna [15] MOVISAFE® UCS12B/PS [24] Multi-function button

[7] Safety laser scanner [16] Relay [25] Key switch

[8] Charging contacts [17] Horn [26] Acknowledgment button

[9] Optical track guidance with

[18] MOVI‑PLC® I/O system

PGV data matrix positioning

system

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

19

Vehicle

A

[2]

[3]

[4]

[6]

[1]

[5]

Functional principle

3

3.5.2 Energy module

[1] Measuring transducer [4] Technology module interface

[2] Batteries [5] DC/DC converter

[3] Load handling device module inter-

face

3.6 Functional principle

3.6.1 Information

The following pages illustrate all options. Observe the information applicable to your

vehicle according to the type code.

3.6.2 Control and communication

The vehicle communicates with the higher-level controller (logistics controller) using

the WLAN infrastructure. The software transferring the travel order to the vehicle is installed on the logistics controller.

After having received a travel task, the vehicle warns persons close to it before it

starts its travel by means of warning and safety measures.

The vehicle transmits operating data of the vehicle to the logistics controller.

21483207051

[6] Relay

3.6.3 Energy supply

3.6.4 Navigation

Optical

20

Operating Instructions – Automated Guided Vehicle

The vehicle is supplied with energy by batteries. The batteries are charged via charging contacts.

The track guidance is realized optically via a read head and via track marks glued to

the floor.

23507268/EN – 12/2017

3.6.5 Referencing

RFID

The positioning is realized using RFID transponders and a read/write head. The read/

write head detects the RFID transponders embedded in the floor and uses them to determine the position.

Data matrix code

The positioning is realized using a data matrix positioning system. The read head for

optical track guidance detects the data matrix code and thus determines the absolute

vehicle position in the system.

3.6.6 Service and diagnostics

Status and commands of the vehicle can be read using the DOP operator panel. Furthermore, the DOP operator panel shows further information regarding faults.

You can control the vehicle manually in the operating mode "manual mode". Use the

DOP operator panel to switch to the operating mode "manual operation". For further

information on the operating modes, refer to chapter "Operation".

Vehicle

Caution signs on the vehicle

3

3.7 Caution signs on the vehicle

Caution signs waring about potential hazards must be attached to multiple areas on

the vehicle. Ensure that the following hazard symbol for identifying hazardous areas

are complete and legible:

Hazard symbol Meaning

Warning of injury to the hand

Do not ride on vehicle

3.8 Load handling device interfaces

The following interfaces can be routed from the energy module to the outside to the

load handling device:

Voltage

23507268/EN – 12/2017

Terminal Function

3X9.1 DC48V

3X3.10 2A, DC24V, 48W

Housing DC0V (DC24V + DC48V)

Operating Instructions – Automated Guided Vehicle

21

Vehicle

Load handling device interfaces

3

CANBus

Terminal Function

3X3.1 CAN ground

3X3.2 CAN high

3X3.3 CAN low

Safe inputs/outputs

Terminal Function

3X0.1 – 3X0.8 DI 1 – 8 (8 inputs)

3X0.9 – 3X0.12 DIO 1 – 4 (4 inputs/outputs)

3X0.13 – 3X0.14 DO 2 (2 outputs)

Emergency stop button

Terminal Function

3X3.4 P1 (pulse 1)

3X3.5 P2 (pulse 2)

3X3.6 P1 output

3X3.7 P1 input

3X3.8 P2 output

3X3.9 P2 input

22

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

4 Warning and safety devices

4.1 Safety concept

INFORMATION

Do not perform any changes to the safety concept. Changes require a new validation

and a new conformity procedure.

The safety concept of the system solution is based on the principle of functional safety

and is realized using the following safety technology:

• Safety laser scanner

• Emergency stop button

• Optical and acoustic warning signals

The machine/system manufacture is responsible for performing a risk assessment and

the resulting construction measures, such as for example:

• Putting up safety fences at the travel section

• Attaching warning signs to hazardous areas

Warning and safety devices

Safety concept

4

4.2 Safety functions

Application Safety function Description

Monitoring the maximum velocity

Speed-dependent safety

zone switchover

Safety zone switchover by

the vehicle controller

Monitoring the direction of

movement

Indicating the direction of

travel

Restart after emergency

stop

SLS (Safely Limited

Speed)

SCA (Safe Cam) The safety zones of the safety laser scanner are

SCA (Safe Cam) The controller can perform safety zone switchovers.

SDI – Safe Direction In order to switch the safety zones in the direction of

– When the vehicle moves, the direction of travel is in-

The speed of the vehicle is monitored. If the defined

maximum travel speed is exceeded, the enable of the

drive is revoked.

switched depending on the actual vehicle speed of the

vehicle.

This is necessary to travel underneath trestles, for example. For this reason, it cannot be ensured that the

safety zones are activated for speeds below 0.3m/s.

movement, the direction of movement I monitored (forward and backward).

If no protection device for backward motion is installed

(safety switching strip), backward motion is safely prevented.

dicated by optical displays in the direction of travel.

An acoustic signal indicates if the vehicle is started

again after an STO.

Safe standstill

Safe brake control

23507268/EN – 12/2017

SS2c (Safe Stop 2),

SOS (Safe Operating Stop)

SBC (Safe Brake

Control), STO (Safe

Torque Off)

If the systems for person detection trip, the SS2c

safety function is activated and the safe operational

stop (SOS) is monitored. If the safety functions SS2c

or SOS are violated, an STO is trigged and safe brake

control is activated.

Operating Instructions – Automated Guided Vehicle

23

Warning and safety devices

[1]

[2]

[3]

Safety laser scanner

4

Application Safety function Description

Emergency stop SS2c (Safe Stop 2)

SBC (Safe Brake

Control), STO (Safe

Torque Off)

Safety switching strip evaluation

Emergency stop

SBC (Safe Brake

Control), STO (Safe

Torque Off)

4.3 Safety laser scanner

Basic functional

principle

The safety laser scanner is a device for protecting persons and systems. The safety

laser scanner monitors the route of the vehicle and detects obstacles in areas that are

defined as hazardous.

The scan field of the safety laser scanner is a two-dimensional layer. The scan field is

generated in the vehicle environment through an opening in the vehicle cover and is

positioned in a specific height. Objects above or below this scan field cannot be detected.

The monitored area is defined in so-called zone sets. A zone set consists of one or

several warning and safety zones.

Depending on the travel speed, the applicable zone set is activated automatically.

The following specifications depend on the safety requirements of the application:

• Number and position of used safety laser scanners at the vehicle.

• Number, shape, and dimensions of the warning and safety zones.

• Reaction in case of violations to warning or safety zones.

The width of the scan field is always 250mm from the edge of the vehicle. The length

of the scan field is variable.

Several emergency stop buttons allow for switching off

all travel, conveying, and hoist movements.

The safety switching strip is used for switching off

movements.

24

INFORMATION

The specifications are defined at the project start and must not be changed afterwards.

The following figure depicts the example of assembly variants for a vehicle, as well as

the resulting warning and safety zones.

[1] Warning zone

[2] Safety zone

[3] Travel direction

Operating Instructions – Automated Guided Vehicle

20740427531

23507268/EN – 12/2017

Warning and safety devices

For further information, refer to the following documentation:

• Operating instructions of the safety laser scanner

Emergency stop button

4

Warning zone

breach

Safety zone

breach

If a safety laser scanner recognizes an obstacle in the warning zone, the vehicle

speed is reduced.

If the safety zone of the safety laser scanner is breached, an emergency stop of the

vehicle is triggered. The vehicle is decelerated with the rapid stop ramp until standstill.

If the vehicle does not reach standstill within a defined time, the brake of the travel

drive is activated and the vehicle is brought to a complete stop.

During standstill, the vehicle is monitored by the safety function "Safe Operational

Stop (SOS)".

As soon as the obstacle is removed from the safety zone of the safety laser scanner,

the vehicle sends an optical signal and starts moving again after a waiting time of

2seconds.

4.4 Emergency stop button

Emergency stop buttons are installed at the vehicle in positions that are easy to reach,

so that the vehicle can be manually stopped in hazardous situations. If you push the

emergency stop button, the vehicle will be brought to standstill in a controlled way.

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

25

Warning and safety devices

Optical and acoustic warning signals

4

4.4.1 Starting the vehicle after an emergency stop

To restart the vehicle in automatic mode after an emergency stop, proceed as follows:

ü The hazardous situation is eliminated.

1. Unlock the activated emergency stop button.

ð The acknowledgment key (blue) is flashing.

2. Press the acknowledgment key (blue) on the vehicle.

ð The emergency stop has been acknowledged.

ð The vehicle is ready for operation again.

ð The vehicle gives a warning signal and automatically restarts after a waiting time

of 2seconds.

ð The vehicle resumes the last pending travel command.

4.5 Optical and acoustic warning signals

4.5.1 LED lights

The LED lights have the following meaning:

Lighting State

Green/

white

Blue The right and left side are illuminated in

Yellow The right or left side is flashing yellow. The vehicle turns in the direction of the LED light.

Green light The vehicle is supplied with energy by the energy

storage unit.

White light The energy storage unit of the vehicle is charged.

One side illuminated in green or white. The vehicle travels in the direction of the LED light.

One side flashes green or white. Startup warning

The lights on the vehicle sides are flashing in green or white around the vehicle

circumference, in clockwise or counterclockwise direction.

The vehicle is illuminated in white at the

front and the back.

blue.

The right and left side are flashing yellow.

The vehicle is illuminated in green or

white at the front and the back.

The vehicle rotates in the direction of the LED light.

The vehicle stands still and the energy storage unit

is charged.

The vehicle is in the station.

The vehicle is in manual mode and travels in the

direction of the green or white LED lights.

26

All sides illuminated yellow. The safety laser scanner or emergency stop has

been triggered.

All sides flashing yellow. The keyswitch has been activated.

Red All sides illuminated red. A fault at the vehicle occurred.

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

4.5.2 Horn

The vehicle is equipped with a horn, to warn persons near the vehicle. After the

vehicle has been reset in the event of emergency stop or actuation of the safety

switching strip, the vehicle gives an acoustic warning signal and starts moving again

after a waiting time of 2seconds.

4.6 Key switch

4.6.1 Using keyswitches

Certain safety functions of the vehicle can be jumpered using the keyswitch.

1. DANGER!No monitoring due to jumpered safety functions. Severe or fatal in-

juries. Use is only permitted for trained persons.

Turn the keyswitch to position1.

ð The acknowledgment key (blue) is flashing.

2. Press the acknowledgment key (blue).

ð The existing safety laser scanner is not active.

Warning and safety devices

Key switch

4

ð The travel speed is safely limited (max. 0.1m/s).

ð The emergency stop safety function remains active.

4.6.2 Resetting time monitoring

To prevent unauthorized use, manual mode is limited to a maximum time of 120s. To

restart the time monitoring of the safety controller, proceed as follows:

1. Turn the keyswitch to position0.

2. Turn the keyswitch to position1.

ð The acknowledgment key (blue) is flashing.

3. Press the acknowledgment key (blue).

ð The time monitoring has been restarted.

4.6.3 No longer use keyswitch

1. Turn the key to position 0.

ð The safety laser scanners are active again.

2. Remove the key to prevent unauthorized use.

3. Press the acknowledgment key (blue) on the vehicle.

ð The emergency stop has been acknowledged.

23507268/EN – 12/2017

ð The vehicle is ready for operation again.

ð If automatic mode has been activated previously, the vehicle gives a warning sig-

nal and automatically restarts after a waiting time of 2seconds.

Operating Instructions – Automated Guided Vehicle

27

Operation

Notes on safe operation

5

5 Operation

5.1 Notes on safe operation

WARNING

Risk of crushing if persons are present in the assembly areas when the vehicle

enters.

Severe or fatal injuries.

• Do not sit or stand in the vehicle entry area.

WARNING

An insufficient stopping distance may lead to collision, e.g. due to entering the safety

zone from the side.

Severe or fatal injuries.

ü The vehicle takes the stopping distance to stop. The stopping distance depends

on the speed.

• To ensure that the stopping distance is sufficient and to prevent a collision, do

not enter the safety zone of the safety laser scanner from the side.

• Do not move toward the vehicle against the travel direction.

CAUTION

Risk due to tilting of the vehicle because the center of gravity is too high.

Serious injuries.

• Always adhere to the maximum permitted weight of the transported goods (see

chapter "Technical data").

• Adhere to the maximum center of gravity of the loading (project-specific).

• Make sure the weight is distributed evenly and centered.

• Use the vehicle exclusively in accordance with the intended use.

CAUTION

Risk if the load falls down if it shifts.

Serious injuries.

• Make sure the weight is distributed evenly and centered.

• Ensure that the load does not protrude on any side.

• Secure the load.

• Make sure the load carrier is in flawless condition.

• Make sure no parts of the stationary system protrude via the outer edge of the

vehicle.

28

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

CAUTION

Danger due to insufficient floor quality.

Serious injuries.

• Operate the vehicle only on floors that ensure sufficient traction of the vehicle.

• Keep the travel section clean and dry.

NOTICE

Risk of collision with obstacles that the safety laser scanner does not detect.

Damage to the vehicle and/or parts of the system.

• Remove all obstacles from the travel section.

• Especially flat objects that cannot be detected by the safety laser scanner.

5.2 Operating modes of the vehicle

Operation

Operating modes of the vehicle

5

5.2.1 Automatic mode

After the system was started up the vehicle automatically is in the operating mode

"Automatic mode".

In "Automatic mode" the logistics controller coordinates travel orders during operation,

and ensures the priority rules. In addition, travel orders can be transferred to the

vehicle using the control elements.

5.2.2 Manual mode

The DOP operator panel can be used to interrupt the automatic mode and manually

operate the vehicle functions.

5.2.3 Keyswitch mode

Risk of crushing due to limited safety zone in keyswitch mode.

Risk of injury.

• Keyswitch mode must only be executed by especially trained personnel (e.g.

Use the keyswitch to start the keyswitch mode. Note that this jumpers some safety

functions (e.g. safety laser scanners).

CAUTION

maintenance staff).

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

29

Operation

Control elements on the vehicle

5

5.3 Control elements on the vehicle

The control elements may have various functions assigned, depending on the operating mode and location of the vehicle within the track.

5.3.1 Multi-function button

The multi-function button (green) has the following functions:

• Switching the vehicle on and off.

• Starting the vehicle movement after an emergency stop has been acknowledged

(in automatic mode).

• Sending the vehicle to the next station (in automatic mode).

5.3.2 Acknowledgment button

In automatic mode, the acknowledgment (blue) has the following functions:

• Acknowledgment of pending vehicle faults at the safety module.

5.4 Switching on the vehicle

ü The vehicle is switched off or in "Standby".

1. Press the multi-function button for 3 seconds, until the LED at the DOP operator

panel lights up.

ð The vehicle is ready for operation.

ð If the vehicle is in automatic mode and an order is pending, the vehicle will start

moving.

5.5 Switching off the vehicle

ü The vehicle is not in a charging station, or the charging station is switched off.

1. Push an emergency stop button at the vehicle.

2. Press the multi-function button for 5seconds until it stops blinking.

3. Release the multi-function button.

5.6 DOP operator panel

The DOP operator panel can be used to manually operate the vehicle functions and

components (e.g. hoist). Status and fault messages can be displayed for diagnostic

purposes.

Note that some functions are initiated via the DOP interface and completed via the

multi-function button.

30

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

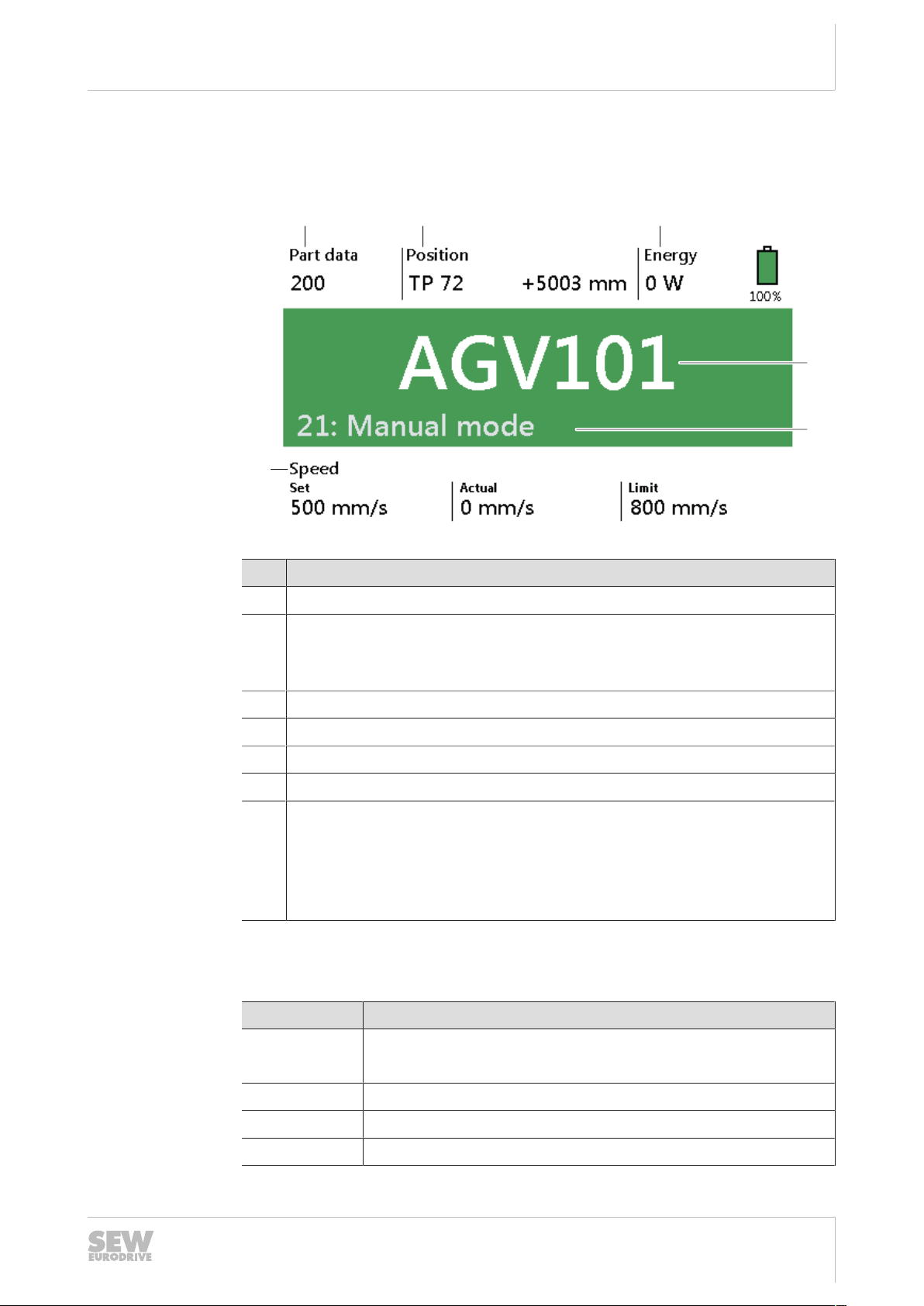

5.6.1 Initial screen

[5]

[4]

[1]

[3][2]

[6]

Operation

DOP operator panel

If the power supply of the vehicle is switched on, the DOP interface shows important

status information of the vehicle:

5

No. Meaning

[1] Currently selected part data

[2] Current position

[3] Current power rating of the vehicle

[4] Charging state of the battery

[5] Name of the vehicle

[6] Status and error messages

[7] Speed

Meaning of the background colors

The background colors have the following meaning:

Color Meaning

21228349067

• Address of the last successfully read transponder/data matrix code

• Distance (mm) that the vehicle travelled after the last position was read.

• Setpoint: Setpoint speed according to the settings in manual mode or automatic mode

• Actual: Current speed

• Limit: Maximum speed according to the settings in the safety controller

23507268/EN – 12/2017

Gray Software not ready.

No communication to the DOP operator panel.

Purple Timeout to higher-level controller

Green The vehicle is ready for operation.

Blue The vehicle has stopped at the target position in automatic mode.

Operating Instructions – Automated Guided Vehicle

31

Operation

[1]

[2]

[3][4][5]

DOP operator panel

5

5.6.2 Menu and navigation bar

Tap onto the initial screen to switch to the menu level. A window opens with the menu

and the navigation bar:

Color Meaning

Yellow The safety controller has stopped the vehicle (e.g. caused by

safety zone breach or emergency stop).

Red The vehicle is not ready to move due to a fault.

21283259915

No. Meaning

[1] Buttons to selected operating modes/functions

[2] The control elements in the navigation bar vary depending on the operating

level:

• On all levels:

Navigation buttons [3] and [5]

• Menu level (top level):

Language selection [4]

• Levels of the operating modes/functions (submenu):

Buttons for submenus (if available) and display of the current operating

mode/function

[3] Back to initial screen

[4] Select one of the following languages:

• English

• English

• French

[5] Back to the last operating level

32

Operating Instructions – Automated Guided Vehicle

23507268/EN – 12/2017

5.6.3 Automatic mode

[6]

[5]

[4]

[3]

[1]

[2]

In the "automatic mode" menu item, the following elements are available:

Operation

DOP operator panel

21286286603

5

Changing parameters

No. Meaning

[1] Information on the used program.

[2] Part data

[3] Current velocity

[4] Resume automatic mode

[5] To identify the position, the following values are displayed:

• Last transponder: Address of the last successfully read transponder/data

matrix code

• Distance: Distance (mm) that the vehicle travelled after the last position

was read.

[6] To change parameters, deactivate automatic mode, see chapter "Changing

parameters".

To change parameters, switch off automatic mode. The following procedure requires

the vehicle to remain at standstill after the automatic mode is switched off.

If the vehicle moves, changing parameters requires a special authorization (expert

mode) that is only granted to trained employees of SEW‑EURODRIVE and is therefore not described in this documentation.

1. Click the [Deactivate automatic mode] button.

ð The designation on the button changes to [Activate automatic mode]. The

vehicle stops.

23507268/EN – 12/2017

2. Click on the edit box of a parameter (e.g. Cmd).

ð A screen keyboard is displayed.

3. Enter a value. Apply the value using the enter key.

ð After the value has been changed successfully, the value "0" will be displayed

for the parameter "Cmd".

4. Reactivate the automatic mode.

Operating Instructions – Automated Guided Vehicle

33

Operation

[4]

[2]

[1]

[3]

[5]

DOP operator panel

5

5.6.4 Manual mode

In the "manual mode" menu item, the following elements are available:

9007219365621131

No. Meaning

[1] Select the track direction:

• CCW

• Straight forward

• CW

The selection must correspond to the track guidance ([2] or [4]) for the vehicle

to move in the desired direction of travel.

[2] Select the speed of the travel drive:

• Slow

• Fast

[3] Select the available track guidance (forwards):

• No track guidance: Vehicle travels without track guidance.

• Optical track guidance: Vehicle travels along an optical track.

[4] Specify the direction of travel of the travel drive:

• Turning (CCW/CW)

• Forward/reverse

[5] Select the available track guidance (backwards):

• No track guidance: Vehicle travels without track guidance.

• Optical track guidance: Vehicle travels along an optical track.

Executing travel commands

34

Operating Instructions – Automated Guided Vehicle

Proceed as follows:

1. Select the desired manual mode function.

ð Selected elements are highlighted in green on the software interface.

ð The multi-function button at the back of the vehicle flashes if you execute the

function by pushing the button (start and stop).

23507268/EN – 12/2017

ð The multi-function button is lit if you execute the function by continuously push-

[2]

[1]

ing the button.

2. Push the multi-function button (push and hold) to execute the travel command.

Measure when leaving track guidance

If the vehicle leaves track guidance unintentionally, proceed as follows:

ü Error number "110" displayed, background color is red.

ü The vehicle is in automatic mode.

1. Switch to manual mode.

2. Execute travel commands in manual mode to return to the track.

3. DANGER!

Switch to automatic mode.

ð The vehicle continues in automatic mode after a warning signal.

5.6.5 Diagnostics

Operation

DOP operator panel

5

In the "diagnostics" menu item, the following elements are available:

No. Meaning

[1] Button for selecting a submenu.

[2] Button for performing the following functions:

• Reset fault.

• Restarting the vehicle controller.

• Shut down the vehicle controller. DC24V supply is switched off.

9007219335920779

Meaning of the status LEDs

23507268/EN – 12/2017

The following table shows the meaning of the status LEDs if diagnostics information is

displayed:

Color Meaning

Gray No communication to the component.

Operating Instructions – Automated Guided Vehicle

35

Operation

[4]

[2]

[1]

[5]

[3]

DOP operator panel

5

Status

Color Meaning

Green Fault-free communication to component.

Red A fault occurred at the component.

In the "status" menu item, the following elements are available:

21284733963

No. Meaning

[1] Displays the active settings for track guidance

[2] Status code/fault code of the vehicle. For further information about the codes,

refer to the documentation of the devices.

[3] Displays the current status of the drives

[4] Displays the current status of the batteries

[5] Displays the current status for:

• Availability of MOVITRANS® (optional)

• Multi-function button

• UCS safety module

• Transponder read head

• EKK energy interface

36

Operating Instructions – Automated Guided Vehicle

23507268/EN – 12/2017

Position

[3]

[2]

[1]

[4]

In the "position" menu item, the following elements are available:

Operation

DOP operator panel

5

21284851083

No. Meaning

[1] Displays the relative position:

• Last transponder: Address of the last successfully read transponder/data

matrix code

• Distance: Distance (mm) that the vehicle travelled after the last position

was read.

[2] Displays the absolute position in directions X and Y, as well as the rotation of

the vehicle.

• Displays the single track ID

[3]

• Virtual track ID: No. of the virtual track the vehicle travels on.

[4] Displays the area:

• Area ID: Can be set to a defined position in automatic mode.

• Position in track: traveled distance from Area ID in mm

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

37

Operation

[1]

[2]

[1] [2] [3] [4]

[7]

[5]

[6]

[8]

DOP operator panel

5

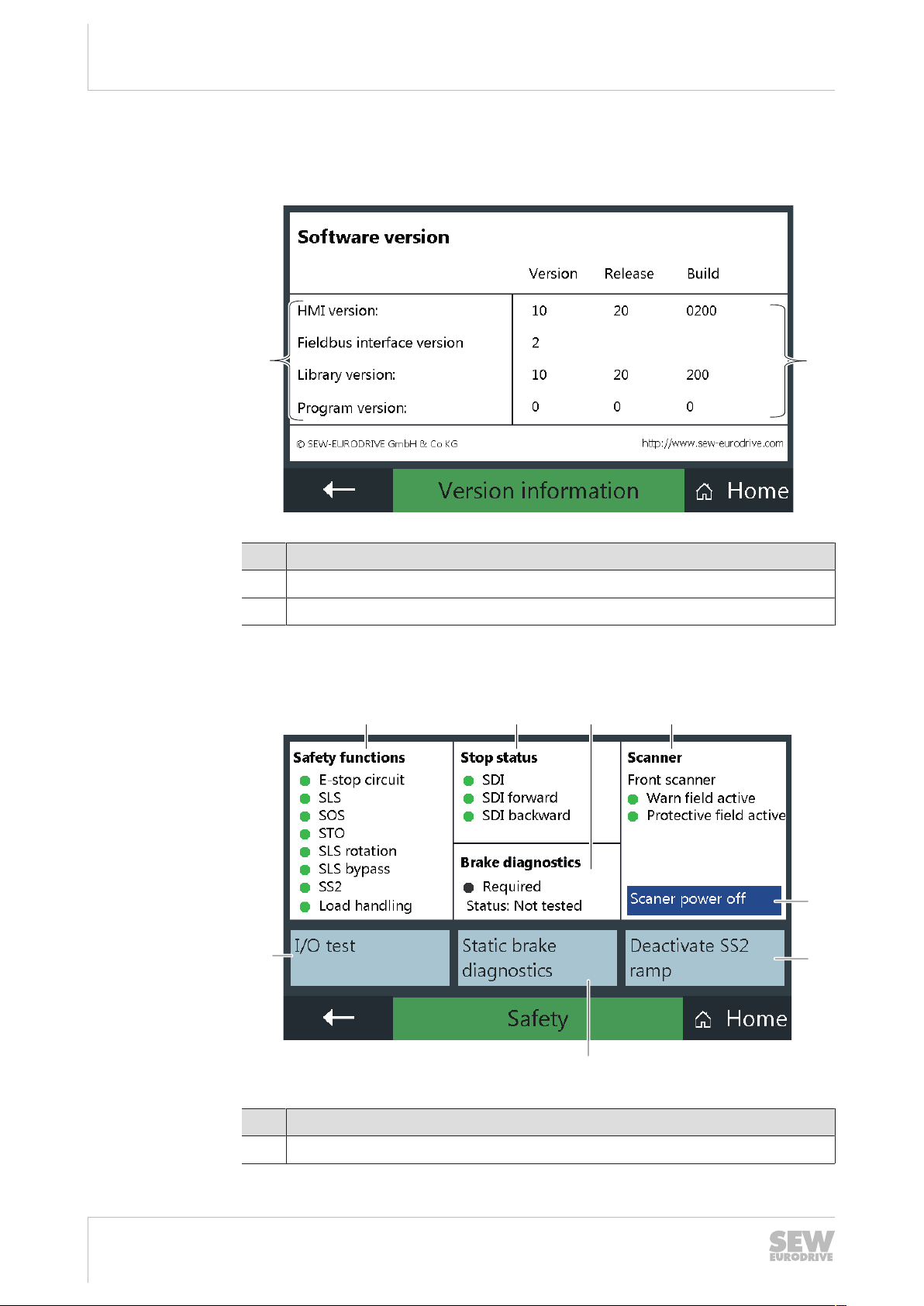

Version information

In the "Version information" menu item, the following elements are available:

No. Meaning

[1] Shows the used software products

[2] Software version

Safety

In the "Safety" menu item, the following elements are available:

21669909259

38

No. Meaning

[1] Displays the current status of the safety functions.

Operating Instructions – Automated Guided Vehicle

9007219329108107

23507268/EN – 12/2017

Operation

DOP operator panel

No. Meaning

[2] Displays the current status of the safety functions for stopping the vehicle in

hazardous situations.

[3] Displays if brake diagnostics is required:

• LED red: required.

• LED gray: not required.

Displays the current status of the brake diagnostics:

• Not tested

• OK

• Warning

• Failed

[4] Displays the current status of the safety laser scanner.

[5] Switch off scanner.

[6] Deactivate SS2 ramp.

This function is safety-relevant and may only be performed by qualified personnel (password-protected).

5

Brake diagnostics

[7] Start static brake diagnostics.

[8] Test inputs/outputs.

Brake diagnostics is started by the logic controller (project-specific deviations possible). Brake diagnostics is performed after every start and is repeated every 24hours.

If the brake diagnostics could not be performed in the defined time period or the test

was not passed, the travel speed of the vehicle is limited.

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

39

Maintenance

Inspection and maintenance work

6

6 Maintenance

6.1 Inspection and maintenance work

6.1.1 Requirements

Qualification requirements

The work steps at the system solution described in the following chapters may only be

performed by trained and authorized employees.

For this reason, SEW‑EURODRIVE demands that the following minimum qualification

requirements are met, according to the roles of the employees:

Role Qualification Working

Operator Participation in the basic train-

ing(L1) for system operators, or

in the training for advanced system operators(L2):

• By specialist from

SEW‑EURODRIVE

• Or by maintenance personnel of the operator trained

by SEW‑EURODRIVE

Maintenance staff Participation at a training for

maintenance personnel taught

by SEW‑EURODRIVE specialist.

The system solution was installed and taken into operation by SEW‑EURODRIVE employees. Companies wanting to re-install or expand the system solution must first consult SEW‑EURODRIVE.

Types of inspection and maintenance work

The product includes components that require inspection and maintenance. This

chapter provides an overview of the following inspection and maintenance work:

• Inspection work

Work that may be performed by the operating personnel.

• Inspection and maintenance work

Work that may only be performed by service engineers.

If stationary components fail, they can be replaced independently by the relevant specialists. The vehicle may only be completely replaced. If you are not sure which components you can install by yourself, the staff of SEW‑EURODRIVE will be glad to help.

Simple inspection and maintenance work, that is usually performed daily.

All inspection and maintenance

work included in the training.

40

Keeping purchased parts in stock

Third-party components used in this project have deviating replacement and repair

times than standard components by SEW‑EURODRIVE. The operator is responsible

of keeping sufficient numbers of spare parts in stock.

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

6.1.2 Inspection (operators)

The operator is responsible for the following inspection work:

1 day

Clean the vehicle cover.

Use teflon spray for dirt-repellent surfaces.

Check the caution signs at the vehicle for damages and dirt.

The safety notes attached to the vehicle must be complete and legible.

Check the operating and display elements for damages and dirt.

The check includes the following components:

• DOP operator terminal

• Buttons at the vehicle and carrier

Check the warning and safety devices for damages and dirt.

The check includes the following components:

• Safety laser scanner

• Safety switching strip (if installed)

• Emergency stop button

• LED lights

Maintenance

Inspection and maintenance work

6

Check the wheels for damage and wear.

The wheel lining is 22mm thick. If the lining is down to 19mm, replace the wheel.

Check the WLAN antenna for damages.

Defective WLAN antennas may cause communication problems.

Check the markings of the hazardous areas along the tracks.

Labels and markings on the floor must be complete, legible and visible.

Check the tracks for obstacles and remove them.

It is possible that work equipment (e.g. boxes or lifting carriages) were put down after

the operation has been interrupted.

Check if the tracks are clean.

Dirt on the tracks influences the travel/braking behavior.

Check if the track markings are clean and visible.

Dirty or damaged track markings influence the optical track guidance.

6.1.3 Inspection and maintenance (service engineers)

The service engineer performs the following inspection and maintenance works:

1 week

23507268/EN – 12/2017

Check the warning and safety devices for damages and dirt.

The check includes the following components:

• Safety laser scanner

• Safety switching strip (if installed)

• Emergency stop button

• LED lights

Operating Instructions – Automated Guided Vehicle

41

Maintenance

Inspection and maintenance work

6

1 week

Check if the vehicle is clean/contaminated and clean it.

Check the optical track for damages and replace it if necessary.

6months

Check the function of the safety devices and clean them.

The check and cleaning work includes the following components:

• Safety laser scanner

• Safety switching strip (if installed)

• Emergency stop button

• LED lights

Check the function of the sensors and clean them.

Check the drive wheels and auxiliary wheels for damage, such as pitting, cracks, or

wear. Check if the non-driven wheels run smoothly.

Visual inspection of motors and gear units.

6.1.4 Inspection and maintenance (SEW-EURODRIVE)

SEW‑EURODRIVE performs the following inspection and maintenance works:

1 year

Visually check the cabling and power supply chains (in drawer).

Clean the inside of the vehicle using a vacuum cleaner, and clean the electronic

components (using compressed air).

Inspection of entire drive: Check for running noise. Visual check of oil level.

Inspection of entire motor: Brake function and wear check. Check for running noise.

Clean the cooling air ducts.

Check the FS04 encoders for functional safety according to ENISO13849‑1.

Check the auxiliary wheels of the pivot bearings and lubricate them if necessary.

Check to see if the bearings and wheels run smoothly and for signs of wear. Replace

them if necessary.

Check the parameters/project data according to the project documentation.

Charge and discharge the batteries under supervision, then check the batteries.

Perform brake test on SS2 ramp.

3years

42

Replace auxiliary wheels (optional).

Replace drive wheels (optional).

Extensive maintenance of the travel drive: Replacing wear parts. Change the oil. Replace oil seal. Check the bearings for clearance and replace them if necessary.

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

6.2 Failures

Fault Possible cause Measure

Oil leaking from vehicle. Gear unit leaking. Contact

SEW‑EURODRIVE.

Maintenance

Failures

6

Touching the vehicle or the

load carriers might result in

electrostatic discharge.

Unusual noises at the

vehicle during travel.

Vehicle stops on the travel

section.

Vehicle swings during

travel.

Vehicle does not move. Emergency stop not un-

Static charge of the vehicle

due to insufficient electrical

discharge capacity of the

floor.

Gear unit or travel drive defective.

Safety controller detects an

error.

Drive wheels are worn or

dirty.

• Insufficient traction of

the drive wheels.

• Wheels aligned incorrectly.

locked or reset.

• Improve the electrical

discharge capacity of

the floor.

• Install ESD protection.

• Contact

SEW‑EURODRIVE.

Contact

SEW‑EURODRIVE.

• Eliminate cause of error

(e.g. unlock emergency

stop button).

• Acknowledge the error

using the acknowledgment key.

Check and clean the drive

wheels.

Contact

SEW‑EURODRIVE.

Unlock the emergency

stop. Reset the emergency

stop.

6.2.1 Acknowledging faults

Faults that were triggered by an activated safety function can be acknowledged directly at the vehicle using the acknowledgment button (blue).

23507268/EN – 12/2017

• There is an obstacle in

the safety zone of the

safety laser scanner

(safety zone violation).

• The protection devices

of the load handling

device has tripped.

• Safety controller detects an error.

• Brake, swivel caster, or

drives defective.

• Remove the obstacle.

• Check the protection

devices of the load

handling device.

Contact

SEW‑EURODRIVE.

Operating Instructions – Automated Guided Vehicle

43

Maintenance

Status and error messages

6

The following table lists measures to acknowledge a failure at the vehicle:

State Control element Measure

Fault present. Acknowledgment button (blue):

lights up

Fault eliminated. Acknowledgment button (blue):

flashing at 1Hz

INFORMATION

Faults that cannot be acknowledged.

In case of faults on the vehicle that cannot be acknowledged, the acknowledgment

button is lit permanently, despite pressing it.

• Contact SEW‑EURODRIVE.

Faults that were not triggered by an activated safety function can be acknowledged at

the vehicle using the operator panel DOP.

6.3 Status and error messages

The system solution can display different error messages. This chapter offers help for

troubleshooting.

Codes and meaning of the faults and status are displayed on the initial screen of the

operator panel.

Eliminate fault.

Unlock the emergency stop

button if it has been pushed

during a failure.

Press the acknowledgment

button to acknowledge the

measure.

6.3.1 Status reports

Code Meaning Description

001 Vehicle travels. Vehicle executes travel command.

002 Initialization Vehicle controller reboots.

003 Standby The vehicle is in energy-saving mode.

004 Motion pending. The vehicle will start moving soon.

011 "Single track" occupied. The higher-level controller prevents a vehicle

012 In station The vehicle is at the target position.

(If the vehicle does not move, check on the initial screen if the speed setpoint and the speed

limit are set ≠"0".)

The vehicle movement can be started using

the multi-function button or by a travel command of the higher-level controller.

from entering a reserved area ("Single track").

The number of the transfer station is displayed

after the "/" character.

23507268/EN – 12/2017

44

Operating Instructions – Automated Guided Vehicle

Code Meaning Description

Maintenance

Status and error messages

6

013 Stop due to higher-level

controller.

014 Waiting for command. The vehicle is in automatic mode and waits for

021 Manual mode The vehicle is in manual mode.

022 Target transponder

reached.

023 Waiting for travel com-

mand.

6.3.2 Error messages

Code Meaning Possible cause Measure

091 Safety function The internal monitoring function

of the safety controller (UCS) has

tripped.

092 Emergency stop The vehicle was stopped by the

safety controller due to an actuated emergency stop button.

The vehicle is stopped by the higher-level controller.

a command.

The vehicle has reached the target position.

The vehicle is in automatic mode and waits for

a travel command.

Contact SEW‑EURODRIVE.

• Eliminate the cause of the

error.

• Unlock the emergency stop

button.

• Acknowledge the fault using

the acknowledgment button.

093 Obstacle on the track Safety laser scanner detected

safety zone violation because of

an obstacle.

099 Application error Error in program sequence.

The special error code is displayed after the "/" character.

100 Left drive The inverter of the left/right travel

101 Right drive

103 Optical sensor Device and communication error Contact SEW‑EURODRIVE.

106 Transponder reader Device and communication error Contact SEW‑EURODRIVE.

107 Safety controller Device and communication error

drive signals an error.

The special error code is displayed after the "/" character.

• Remove the obstacle.

• If the obstacle cannot be removed, deactivate the safety

laser scanner using the keyswitch.

Contact SEW‑EURODRIVE.

• Eliminate the fault as described in the documentation

of the drive.

• Reset the error by clicking the

[Reset] button on the initial

screen.

• Eliminate the fault as described in the documentation

of the safety controller.

• Acknowledge the fault in the

software.

23507268/EN – 12/2017

Operating Instructions – Automated Guided Vehicle

45

Maintenance

[1]

Replacing the battery

6

Code Meaning Possible cause Measure

110 Track not detected The selected track sensor does

not detect a track.

111 DC link too low

112 Transponder distance The read value of the transpon-

113 Position window The vehicle stops after a travel

114 Invalid track guidance The selected track sensor is no

115 Battery service life The battery is at the end of its

116 I/O module Device and communication error Contact SEW‑EURODRIVE.

• DC48V voltage supply interrupted.

• Energy storage unit discharged.

der distance does no longer

match the configured value.

command but the position is outside the position window.

longer available.

service life.

• Position the vehicle on the

track correctly.

• Select the correct track

sensor.

• Look for damages or dirt on

the optical track.

Contact SEW‑EURODRIVE.

Contact SEW‑EURODRIVE.

Contact SEW‑EURODRIVE.

Contact SEW‑EURODRIVE.

Contact SEW‑EURODRIVE.

117 Brake diagnostics re-

quired

6.4 Replacing the battery

Proceed as follows: