SEW-Eurodrive MOVIDRIVE MDX60B, MOVIDRIVE MDX61B, INTERBUS DFI11B User Manual

MOVIDRIVE® MDX61B

Edition

INTERBUS DFI11B Fieldbus Interface

03/2004

Manual

1126 3717 / EN

SEW-EURODRIVE

1 Important Notes...................................................................................................... 4

2 Introduction ............................................................................................................ 5

3 Assembly / Installation Instructions..................................................................... 7

3.1 Installing the DFI11B option card................................................................... 7

3.2 Connection and terminal description of the DFI11B option............................ 9

3.3 Pin assignment ............................................................................................ 10

3.4 Shielding and routing bus cables................................................................. 11

3.5 Setting the DIP switches.............................................................................. 11

3.6 Display elements.......................................................................................... 14

I

00

4.1 Startup of the drive inverter.......................................................................... 16

4.2 Configuring the INTERBUS system............................................................. 18

4.3 Testing the PCP connection ........................................................................ 24

5 The PCP Interface................................................................................................. 26

5.1 Basic structure ............................................................................................. 26

5.2 PCP services ............................................................................................... 27

5.3 Parameters in the object list......................................................................... 29

5.4 Return codes for parameter setting.............................................................. 35

6 Application Examples.......................................................................................... 37

6.1 Control via process data ..............................................................................37

6.2 Setting parameters via the PCP interface.................................................... 37

6.3 Presentation of coding examples................................................................. 38

6.4 Process of a parameterization sequence..................................................... 38

6.5 Reading a drive parameter........................................................................... 39

6.6 Writing a drive parameter............................................................................. 40

4 Project Planning and Startup.............................................................................. 16

®

6.7 Writing IPOS variables/parameters via MOVILINK

6.8 Reading IPOS variables/parameters via MOVILINK

parameter channel.....41

®

parameter channel... 41

6.9 Writing IPOS variables/parameters using the download parameter block... 43

kVA

i

n

f

Hz

P

7 Technical Data...................................................................................................... 44

7.1 DFI11B option.............................................................................................. 44

8 Index...................................................................................................................... 45

Manual – MOVIDRIVE® MDX61B INTERBUS DFI11B Fieldbus Interface

3

1

Important Notes

1 Important Notes

Handbuch

• This manual does not replace the detailed operating instructions!

• Only electrical specialists are allowed to perform installation and startup

observing relevant accident prevention regulations and the MOVIDRIVE

MDX60B/61B operating instructions!

Documentation

Bus systems

• Read through this manual carefully before you start installation and startup of

MOVIDRIVE

• This manual assumes that the user has access to and is familiar with the

MOVIDRIVE

manual.

• In this manual, cross references are marked with "→". For example, (→ Sec. X.X)

means: Further information can be found in section X.X of this manual.

• A requirement of fault-free operation and fulfillment of any rights to claim under

guarantee is that you observe the information in the documentation.

General safety notes on bus systems:

This communication system allows you to adjust the MOVIDRIVE

specific application very accurately. As with all bus systems, there is a danger of

invisible, external (as far as the inverter is concerned) modifications to the parameters

which give rise to changes in the inverter’s behavior. This may result in unexpected (not

uncontrolled) system behavior.

®

drive inverters with the INTERBUS DFI11B option card.

®

documentation, in particular the MOVIDRIVE ® MDX60B/61B system

®

drive inverter to your

®

Safety and

warning notes

Always observe the safety and warning instructions in this publication!

Electrical hazard

Possible consequences: Severe or fatal injuries.

Hazard

Possible consequences: Severe or fatal injuries.

Hazardous situation

Possible consequences: Slight or minor injuries.

Harmful situation

Possible consequences: Damage to the unit and the

environment.

Tips and useful information.

4

Manual – MOVIDRIVE® MDX61B INTERBUS DFI11B Fieldbus Interface

2 Introduction

Introduction

2

Contents of this

manual

Additional

documentation

MOVIDRIVE® and

INTERBUS

This user manual describes how to install the INTERBUS DFI11B option card in the

MOVIDRIVE

INTERBUS fieldbus system.

It also contains an explanation of all settings on the fieldbus option card and connection

variants with INTERBUS in the form of small startup examples.

For a simple and effective connection of MOVIDRIVE® to the INTERBUS fieldbus

system, you should request the following publications from SEW-EURODRIVE about

the fieldbus technology in addition to this manual:

•MOVIDRIVE

•MOVIDRIVE

The manual for the MOVIDRIVE

and their coding. It also explains the whole range of control concepts and application

options in the form of small examples.

The parameter list is a list of all drive inverter parameters that can be read and written

via various communication interfaces such as RS-485, SBus and even the fieldbus

interface.

The MOVIDRIVE® drive inverter together with the DFI11B option and its highperformance universal fieldbus interface enable the connection to master

programmable controllers via the open and standardized INTERBUS fieldbus system.

®

MDX61B drive inverter and how to start up MOVIDRIVE® with the

®

Fieldbus Unit Profile manual

®

MDX60/61B system manual

®

fieldbus unit profile describes the fieldbus parameters

Unit profile

Drive parameters

READ/WRITE

The performance of the inverter (also referred to as the unit profile) that forms the basis

for INTERBUS operation, is fieldbus-independent and, therefore, uniform. This allows

the user to develop fieldbus-independent drive applications. This makes it much easier

to change to other bus systems, such as PROFIBUS (DFP 21B option) or DeviceNet

(DFD 21B option).

MOVIDRIVE® offers digital access to all drive parameters and functions via the

INTERBUS interface. The drive inverter is controlled via the fast, cyclical process data.

This process data channel offers the opportunity to initiate various drive functions such

as enable, controller inhibit, normal stop, rapid stop, and to specify setpoint values such

as setpoint speed, integrator time for acceleration/ramp down.

At the same time you can also use this channel to read back actual values from the drive

inverter, such as actual speed, current, unit status, fault number or reference signals.

While the process data exchange generally occurs cyclically, the drive parameters can

be read or written only acyclically via the READ and WRITE services. This parameter

data exchange enables you to implement applications in which all the important drive

parameters are stored in the master programmable controller, so that there is no need

to make manual parameter settings on the drive inverter itself.

Manual – MOVIDRIVE® MDX61B INTERBUS DFI11B Fieldbus Interface

5

2

Introduction

Startup

Monitoring

functions

Diagnostics

Generally, the INTERBUS DFI11B option card has been designed so that all

INTERBUS-specific settings, such as process data length and baud rate can be made

using the hardware switch on the option card. This manual setting means the drive

inverter can be integrated into the INTERBUS system and switched on quickly.

The parameter setting process can be performed automatically by the higher-level

INTERBUS master (parameter download). This forward-looking variant shortens the

system startup time and simplifies the documentation of your application program

because all the important drive parameters can now be stored directly in your control

program.

The use of a fieldbus system requires additional drive system monitoring such as time

monitoring of the fieldbus (fieldbus timeout) or even special emergency stop concepts.

The MOVIDRIVE

®

monitoring functions can be customized to your application. You can

determine, for instance, which of the drive inverter’s fault responses should be triggered

in the event of a bus error. A rapid stop is useful for many applications, although this can

also be achieved by 'freezing' the last setpoint values so the drive continues operating

with the most recently valid setpoint values (for example, conveyor belt). As the

functions of the control terminals are still active in fieldbus operation, you can still

implement fieldbus-independent emergency stop concepts via the terminals of the drive

inverter.

The MOVIDRIVE® drive inverter offers numerous diagnostic options for startup and

service.

For example, you can use the integrated fieldbus monitor to control both setpoint values

sent from the higher-level controller as well as the actual values. The MOVITOOLS

software package offers a convenient diagnostic option that allows for a detailed display

of fieldbus and device state information in addition to the settings of all drive parameters

(including fieldbus parameters).

®

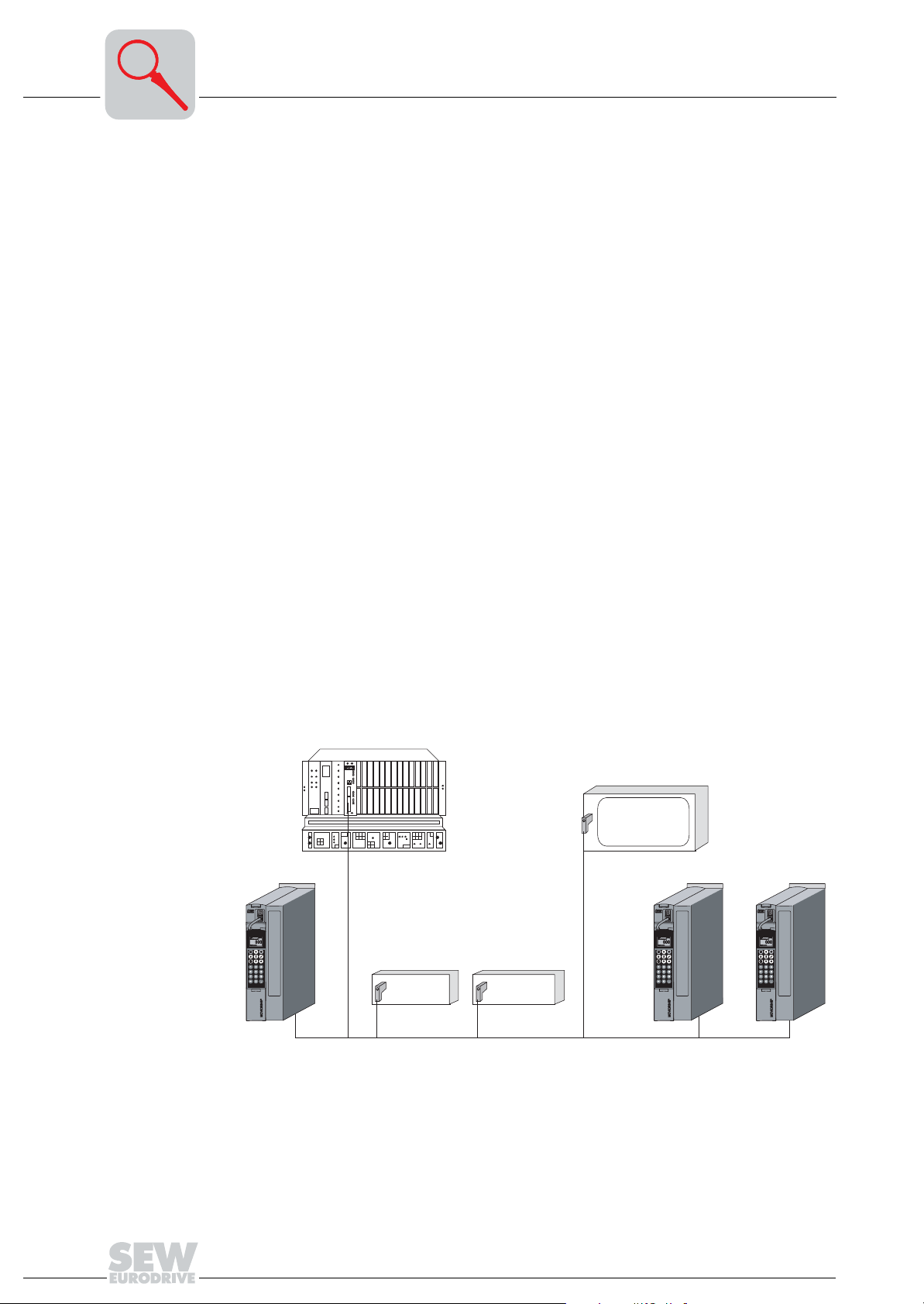

[1]

INTERBUS Master

Digital I/O Analog I/O

INTERBUS

Figure 1: INTERBUS with MOVIDRIVE® MDX61B

6

Manual – MOVIDRIVE® MDX61B INTERBUS DFI11B Fieldbus Interface

53568AXX

Assembly / Installation Instructions

Installing the DFI11B option card

3 Assembly / Installation Instructions

3.1 Installing the DFI11B option card

• Option cards can only be installed and removed for MOVIDRIVE® MDX61B

sizes 1 to 6.

• Only SEW-EURODRIVE engineers can install or remove option cards for

MOVIDRIVE

®

MDX61B size 0.

3

Before you begin

The DFI11B option card must be plugged into the fieldbus slot.

Observe the following notes before installing or removing an option card:

• De-energize the inverter. Switch off the DC 24 V and the supply voltage.

• Take appropriate measures to protect the option card from electrostatic charge (use

discharge strap, conductive shoes, etc.) before touching it.

• Before installing the option card, remove the keypad and the front cover.

• After installing the option card, replace the front cover and the keypad.

• Keep the option card in its original packaging. Do not remove the option card from

the packaging until immediately before you are ready to install it.

• Hold the option card by its edges only. Do not touch any components.

Manual – MOVIDRIVE® MDX61B INTERBUS DFI11B Fieldbus Interface

7

3

Installing and

removing the

option card

Assembly / Installation Instructions

Installing the DFI11B option card

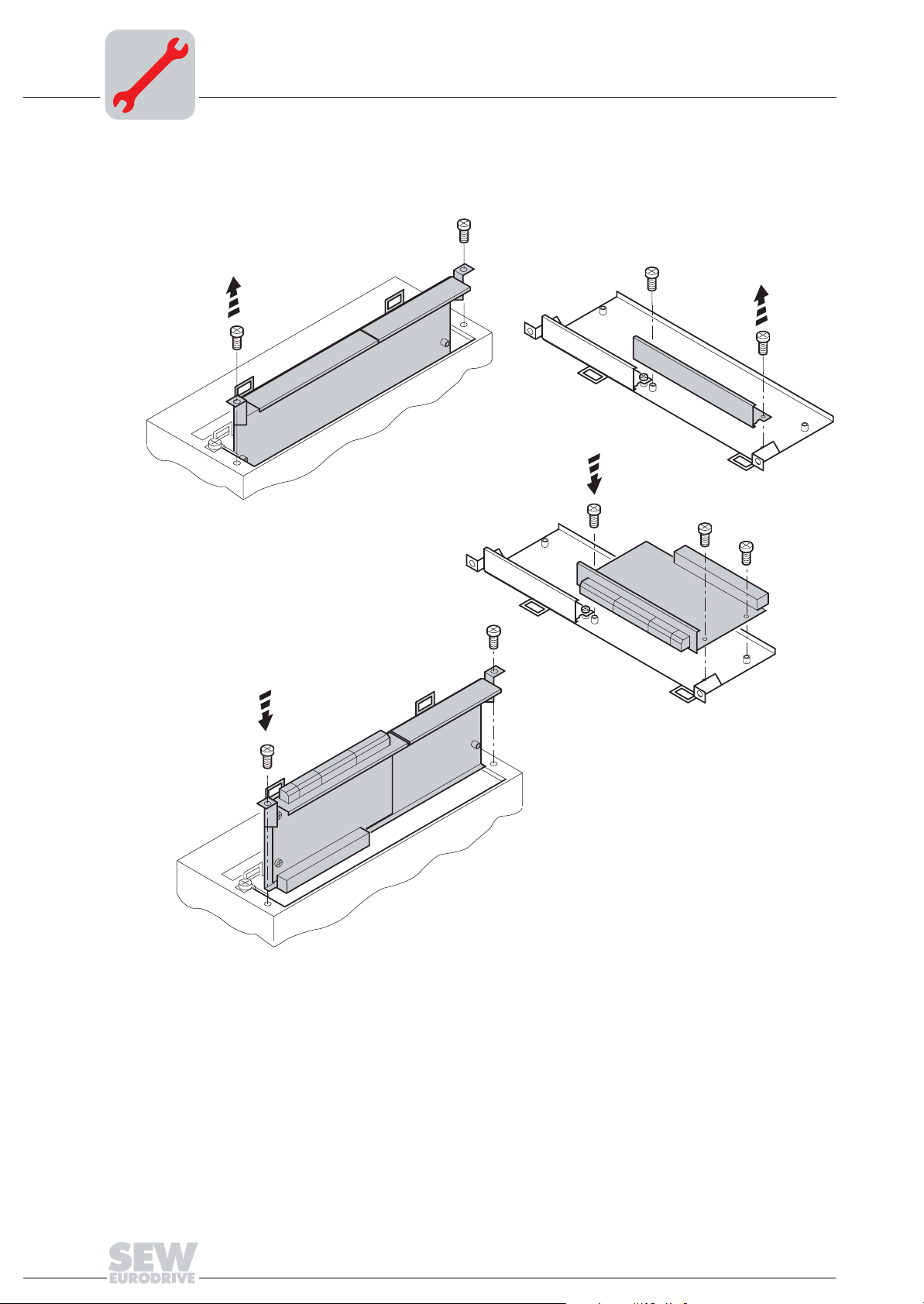

2.

1.

3.

4.

Figure 2: Installing an option card in MOVIDRIVE® MDX61B sizes 1 to 6

1. Remove the two retaining screws holding the card retaining bracket. Evenly pull the

card retaining bracket out from the slot (do not twist!).

2. Remove the two retaining screws of the black cover plate on the card retaining

bracket. Remove the black cover plate.

3. Position the option card onto the retaining bracket so that the three retaining screws

fit into the corresponding holes on the card retaining bracket.

4. Insert the retaining bracket with installed option card into the slot, pressing slightly so

it is seated properly. Secure the card retaining bracket with the two retaining screws.

5. To remove the option card, follow the instructions in reverse order.

53001AXX

8

Manual – MOVIDRIVE® MDX61B INTERBUS DFI11B Fieldbus Interface

Assembly / Installation Instructions

Connection and terminal description of the DFI11B option

3.2 Connection and terminal description of the DFI11B option

3

Part number

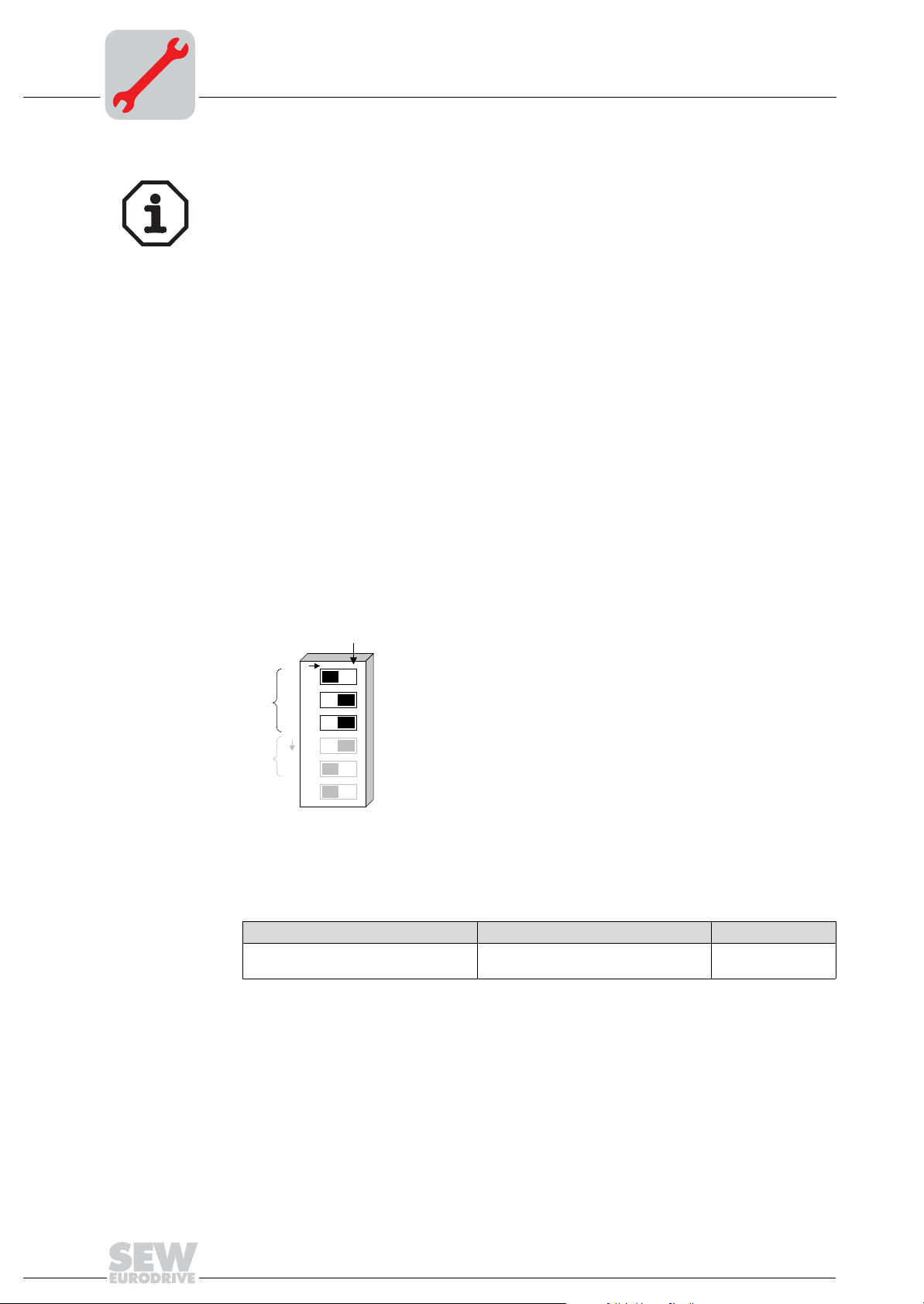

Front view of

DFI11B

DFI 11B

01

0

2

1

2

2

2

1

22M4

0,5M

U

L

RC

BA

RD

TR

X30X31

INTERBUS interface type DFI11B option: 824 309 3

The "INTERBUS interface type DFI11B" option is only possible in conjunction with

MOVIDRIVE

®

MDX61B, not with MDX60B.

The DFI11B option must be plugged into the fieldbus slot.

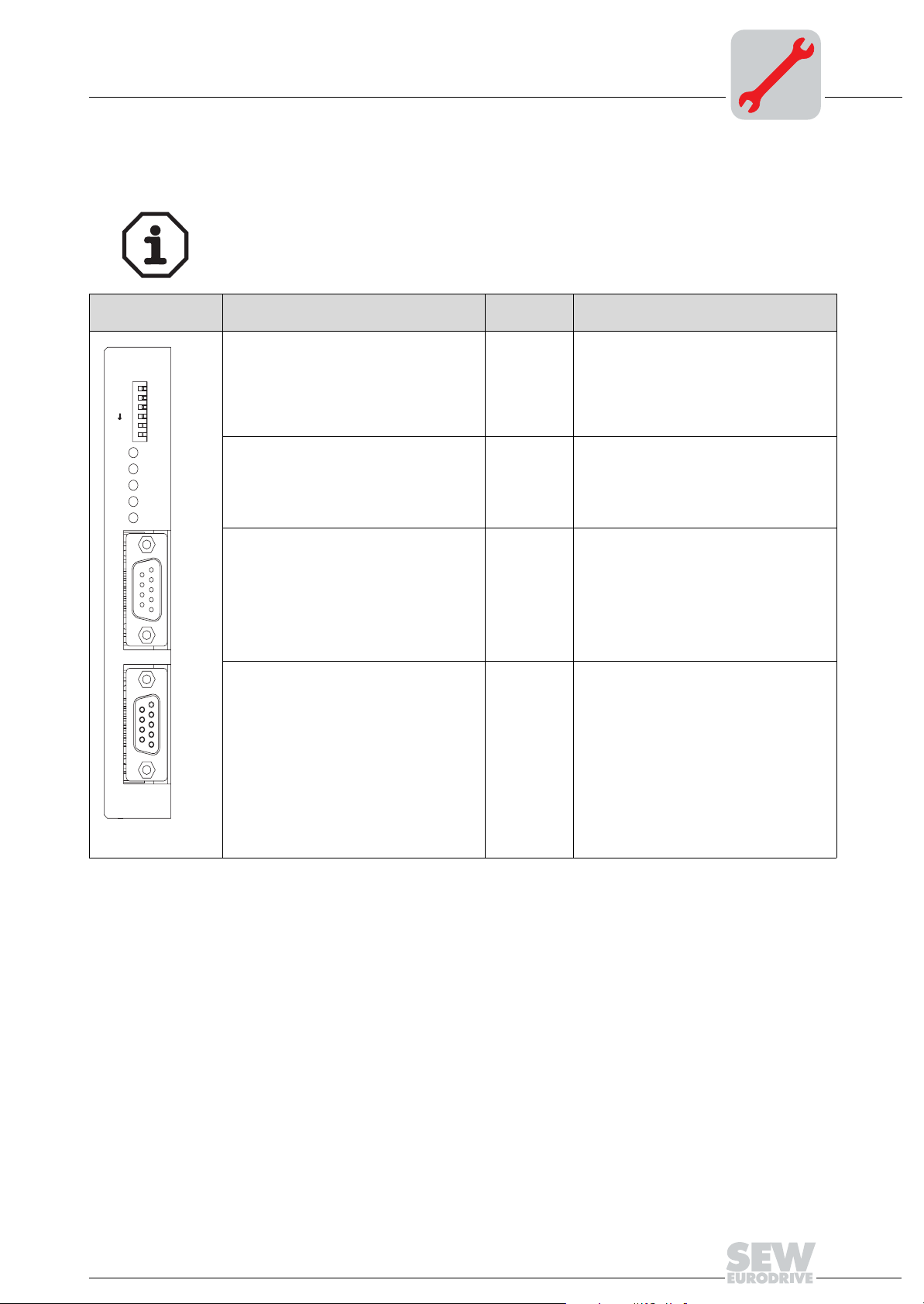

Description

Six (6) DIP switches for setting the

process data length, PCP length and baud

rate

U

= Logic voltage (green = OK)

L

RC = Remote cable check (green = OK)

BA = Bus active (green = OK)

RD = Remote bus disabled (orange = OK)

TR = Transmit (green = PCP active)

X30: INTERBUS interface

incoming

X31: INTERBUS interface

outgoing

DIP switch

Terminal

0

2

2

, 21, 2

1, 2, 4

2M / 0,5M

X30:1

X30:2

X30:3

X30:4

X30:5

X30:6

X30:7

X30:8

X30:9

X31:1

X31:2

X31:3

X31:4

X31:5

X31:6

X31:7

X31:8

X31:9

Function

Number of process data (1 to 6 words)

Number of PCP words (1, 2 or 4 words)

Baud rate:

0 = 2 MBaud

1 = 0.5 MBaud

The INTERBUS LEDs display the current

status of the fieldbus interface and the

INTERBUS system:

DO

DI

COM

N.C.

N.C.

/DO

/DI

N.C.

N.C.

DO

DI

COM

N.C.

Jumper to X31:9

/DO

/DI

N.C.

Jumper to X31:5

52287AXX

Manual – MOVIDRIVE® MDX61B INTERBUS DFI11B Fieldbus Interface

9

3

3.3 Pin assignment

Assembly / Installation Instructions

Pin assignment

Connection to the INTERBUS network is realized using a 9-pin sub D coupling for the

incoming remote bus and a 9-pin sub D plug for the outgoing remote bus according to

IEC 61158. The following figures show the connection assignment of the 9-pole Sub D

coupling/plug for the incoming and outgoing remote bus as well as the signal wire colors

of the bus cable used for the INTERBUS.

[1]

[2]

GN

YE

PK

GY

BN

[3]

6

/DO

1

DO

7

/DI

2

DI

3

COM

5

691

52296AXX

Figure 3: Assignment of 9-pin sub D coupling of the incoming remote bus cable

GN = Green BN = Brown

YE = Yellow [1] 9-pin sub D coupling

PK = Pink [2] Signal cable, twisted

GY = Gray [3] Conductive, wide area connection is necessary between the

plug housing and the shield

[1]

[2]

10

6

1

6

9

5

/DO

DO

/DI

DI

COM

1

7

2

3

5

9

GN

YE

PK

GY

BN

[3]

52297AXX

Figure 4: Assignment of 9-pin sub D plug of the outgoing remote bus cable

GN = Green BN = Brown

YE = Yellow [1] 9-pole sub D connector

PK = Pink [2] Signal line, twisted

GY = Gray [3] Conductive, wide area connection is necessary between the

plug housing and the shield

As a rule, the DFI11B option is connected to the INTERBUS system using the 2-wire

remote bus with a 6-core shielded cable with twisted signal wire pairs.

Manual – MOVIDRIVE® MDX61B INTERBUS DFI11B Fieldbus Interface

Assembly / Installation Instructions

The 2-wire remote bus chiefly comprises an RS-485 data out channel (signal wires "DO"

and "/DO") and the RS-485 data in channel (signal wires "DI" and "/DI").

3.4 Shielding and routing bus cables

The INTERBUS interface DFI11B supports RS-485 transmission technology and requires the cable type A to IEC 61158 specified as the physical medium for INTERBUS.

This cable must be a 6-core shielded and twisted pair cable.

Correct shielding of the bus cable attenuates electrical interference that may occur in

industrial environments. The following measures ensure the best possible shielding:

• Tighten the mounting screws on the connectors, modules and equipotential bonding

conductors by hand.

• Only use connectors with a metal housing or a metallized housing.

• Connect the shielding in the connector with the greatest possible surface area.

• Attach the shielding of the bus line on both sides.

• Do not route signal and bus cables parallel to power cables (motor leads). They must

be routed in separate cable ducts.

• Use metallic, grounded cable racks in industrial environments.

• Route the signal cable and the corresponding equipotential bonding in close proximity using the shortest way possible.

• Avoid using plug connectors to extend bus cables.

• Route the bus cables closely along existing grounding surfaces.

Shielding and routing bus cables

3

In case of fluctuations in the earth potential, a compensating current may flow via the

bilaterally connected shield that is also connected to the protective earth (PE). Make

sure you supply adequate equipotential bonding according to relevant VDE regulations

in such a case.

3.5 Setting the DIP switches

The six DIP switches S1 to S6 on the front side of the option are used for setting the

process data length, the PCP length and for selecting the baud rate.

ON

ON

1234

0

2

1

2

[1]

2

2

[2]

DIP switch assignment for DFI11B

[3]

56

PAC ER

2M

0.5M

1

42

[4]

03700AXX

[1] Number of process data (1 to 6 words)

[2] Number of PCP words (1, 2 or 4 words)

Baud rate: [3] OFF: 2 MBaud / [4] ON: 0.5 Mbaud

Setting shown in the figure:

Process data width: 2 PD

Number of PCP words: 1 PCP

Baud rate: 2 Mbaud

Manual – MOVIDRIVE® MDX61B INTERBUS DFI11B Fieldbus Interface

11

3

Assembly / Installation Instructions

Setting the DIP switches

Note

De-energize the drive inverter (mains and 24 V backup supply) every time before you

change the DIP switch settings. The settings of DIP switches S1-1 to S1-5 only become

effective during initialization of the drive inverter.

The drive inverter signals the "Microprocessor not ready" ID code (38 hex) if the DIP

switch settings are incorrect.

Setting the baud

rate

Setting the process data and

PCP length

The baud rate is selected using DIP switch S1-6. The selected baud rate takes effect

immediately and might therefore interrupt an existing data communication of the Interbus.

Up to six INTERBUS data words can be exchanged between the INTERBUS interface

and the DFI11B. These data words can be divided between the process data channel

and the PCP channel using DIP switches S1-1 to S1-5. Because of the restriction to six

data words, some settings cannot be reproduced on the Interbus.

The DFI11 signals the "Microprocessor not ready" ID code (38hex) if the setting is incorrect. The incorrect setting is indicated by the red TR LED. The following figure shows

the peripheral conditions for setting the process data and PCP lengths. The following

restrictions apply:

ON

ON

1234

0

2

1

6PD

2

2

2

[A]

56

PAC ER

1

42

12

2M

0.5M

ID: 03hex (3dez)

Figure 5: Settings for operating the DFI11B with 6 process data

[A]PCP setting ineffective!

Process data length in words PCP length ID code

6 PCP setting ineffective;

no PCP channel can be used

Manual – MOVIDRIVE® MDX61B INTERBUS DFI11B Fieldbus Interface

03hex (3dec)

03701AXX

Assembly / Installation Instructions

Setting the DIP switches

3

max.

5 DP

0 PCP

O

N

1

0

2

2

1

2

3

2

2

4

5

P

A

C

E

6

R

2M

ID: 38 hex (56 dez)

ON

0.5M

ON

O

N

1

0

2

max.

5 DP

1

1 PCP

42

2

1

2

3

2

2

4

5

P

A

C

E

6

R

0.5M

2M

max.

4 DP

1

2 PCP

42

ID: E3 hex (227 dez)

O

N

0

2

1

2

2

2

P

A

C

E

R

ID: E0 hex (224 dez)

ON

1

2

3

4

5

6

0.5M

2M

Figure 6: Examples for setting the PCP length and the maximum process data length

PCP length Maximum process data length ID code

1 word 5 words E3 hex (227dec)

2 words 4 words E0 hex (224dec)

4 words 2 words E1 hex (225dec)

If the max. length is exceeded or the setting is 0 or 7 PD

38 hex (56dec) = "Microprocessor not

ready"

All settings that have not been mentioned result in the "Microprocessor not ready" ID

code. The inverter then signals 0PD in parameter P090 "PD configuration" and indicates

that the setting is incorrect by means of the red TR LED on the DFI11B option card.

ON

O

N

1

0

2

max.

2 DP

1

4 PCP

42

2

1

2

3

2

2

4

5

P

A

C

E

6

R

2M

1

42

0.5M

ID: E1 hex (225 dez)

53597AXX

Manual – MOVIDRIVE® MDX61B INTERBUS DFI11B Fieldbus Interface

13

3

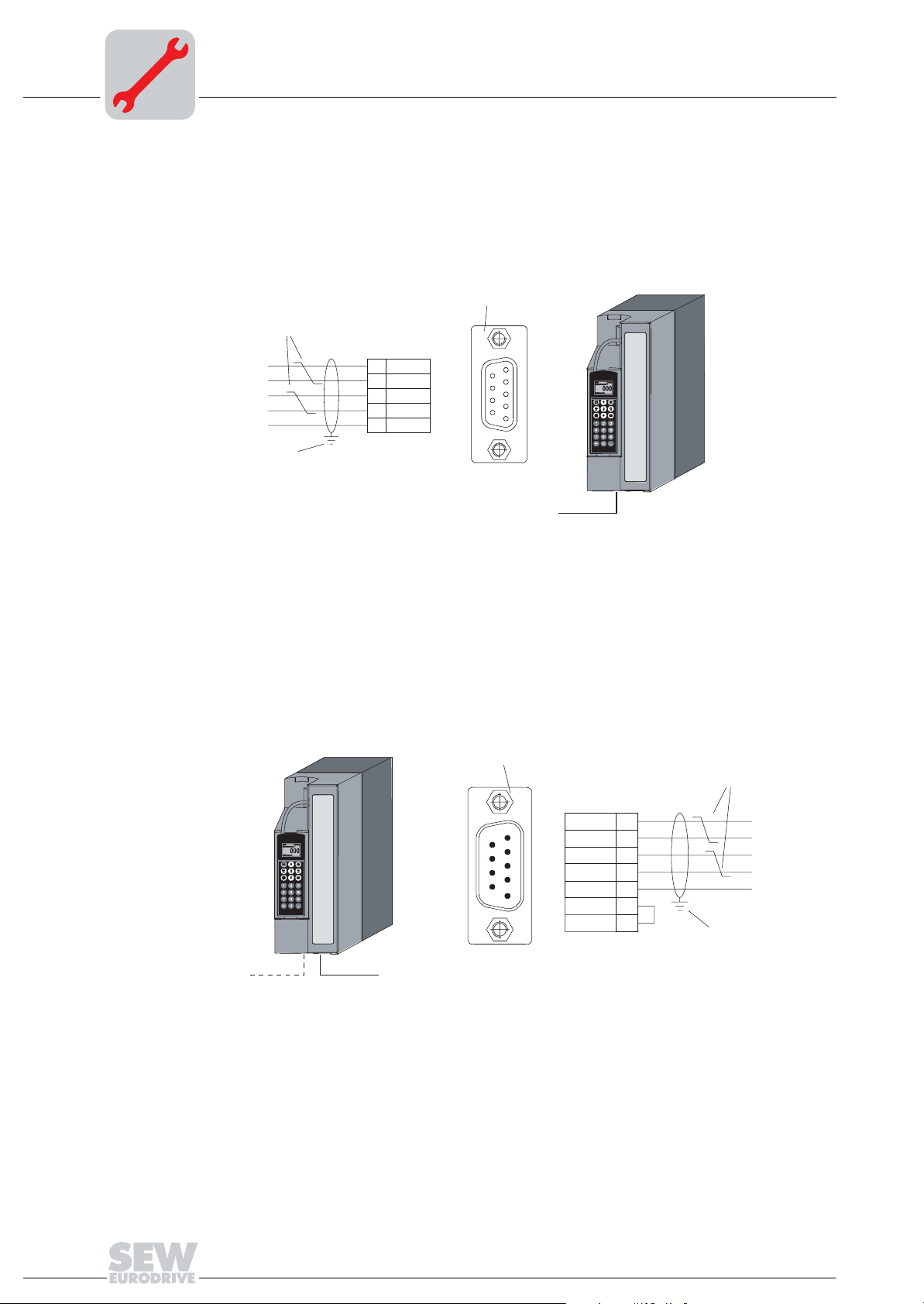

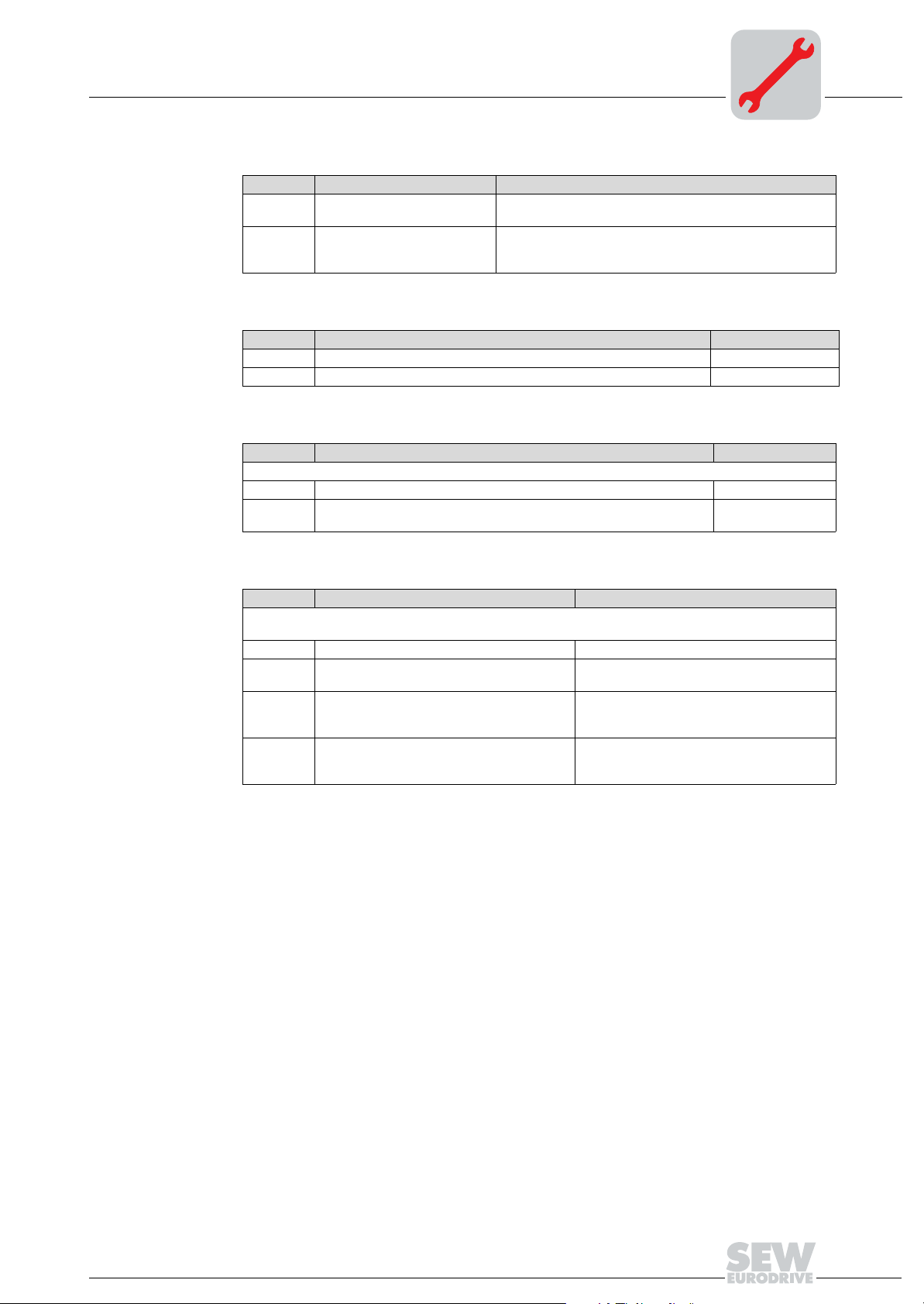

3.6 Display elements

Assembly / Installation Instructions

Display elements

INTERBUS LEDs

The INTERBUS interface DFI11B option card has five LEDs for diagnosing the INTERBUS system. These LEDs indicate the current status of the DFI1B and the INTERBUS

system.

U

L

RC Remote Cable Check (green = OK)

BA Bus Active (green = OK)

RD Remote Bus Disabled (red = OFF)

TR Transmit (green = PCP active)

Logic Voltage (green = OK)

The following figure shows frequently occurring LED patterns of the diagnostic LEDs.

The following tables provide a detailed description of the LEDs.

yellow

U

L

OFF

RC

OFF

BA

orange

RD

yellow flash, OFF

TR TR TR TRTR

U

RC

BA

RD

green

L

U

OFF

RC

OFF

BA

orange

RD

red OFF OFFOFF / PCP: green

green

L

green

green flash

orange

U

RC

BA

RD

green

L

green

green

OFF

U

CC

BA

RD

green

L

green flash

OFF

orange

[A] [B] [C] [D] [E]

Figure 7: Frequently occurring LED patterns

06515AEN

[A] Inverter power-on (INTERBUS not yet active)

[B] Incorrect DIP switch setting (INTERBUS not yet active)

[C] Initialization phase of the INTERBUS system

[D] Correct INTERBUS operation

[E] Incorrectly set baud rate

LED UL "U Logic"

(green)

LED RC "Remote

Cable Check"

(green)

State Meaning Fault correction

On Supply voltage applied to bus

electronics

Off Supply voltage for bus

electronics missing

State Meaning Fault correction

On Incoming remote bus

connection OK

Off Incoming remote bus

connection not OK

-

Check that the connection unit is correctly seated and the

DC 24 V voltage supply for the inverter is present.

-

Check the incoming FO remote bus.

14

Manual – MOVIDRIVE® MDX61B INTERBUS DFI11B Fieldbus Interface

LED BA "Bus

Active" (green)

LED RD "Remote

Bus Disable" (red)

LED TR "Transmit" (green)

Assembly / Installation Instructions

Display elements

State Meaning Fault correction

On Data transfer active on

INTERBUS

Off No data transfer; INTERBUS

stopped

State Meaning Fault correction

On Outgoing remote bus switched off Off Outgoing remote bus not switched off -

State Meaning Fault correction

The color of the LED TR corresponds to the INTERBUS standard.

Off No PCP communication Green PCP communication active or INTERBUS startup (parameter access via

INTERBUS PCP channel)

-

Check the incoming remote bus cable. Use the diagnostic

display of the INTERBUS interface module (master) for

further fault localization

-

3

LED TR "Transmit" (yellow or red)

State Meaning Fault correction

The yellow or red LED TR indicates states within the system that usually do not occur during INTERBUS

operation.

Off or green Normal mode (see table for TR = green) Yellow

flashing

Steady red Incorrect DIP switch configuration selected, no

Flashing

red

Inverter in initialization phase -

INTERBUS operation possible.

Incorrect DIP switch configuration or INTERBUS interface defective, no INTERBUS

operation possible.

Check the settings of DIP switch S1. Correct

the DIP switch settings if necessary and switch

the unit on again.

Check the setting of DIP switches S1 to S6.

Contact SEW Electronics Service if the fault

persists although the setting is correct.

Manual – MOVIDRIVE® MDX61B INTERBUS DFI11B Fieldbus Interface

15

Loading...

Loading...