Page 1

Modicon M221 Logic C ontroller

EIO0000003313 02/2020

Modicon M221 Logic

Controller

Hardware Guide

02/2020

EIO0000003313.01

www.schneider-electric.com

Page 2

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not

intended as a substitute for and is not to be used for determining suitability or reliability of these

products for specific user applications. It is the duty of any such user or integrator to perform the

appropriate and complete risk analysis, evaluation and testing of the products with respect to the

relevant specific application or use thereof. Neither Schneider Electric nor any of its affiliates or

subsidiaries shall be responsible or liable for misuse of the information contained herein. If you

have any suggestions for improvements or amendments or have found errors in this publication,

please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of

this document on any medium whatsoever without permission of Schneider Electric, given in

writing. You also agree not to establish any hypertext links to this document or its content.

Schneider Electric does not grant any right or license for the personal and noncommercial use of

the document or its content, except for a non-exclusive license to consult it on an "as is" basis, at

your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and

using this product. For reasons of safety and to help ensure compliance with documented system

data, only the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant

instructions must be followed.

Failure to use Schneider Electric software or approved software with our hardware products may

result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

2 EIO0000003313 02/2020

Page 3

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Part I Modicon M221 Logic Controller Introduction . . . . . .

Chapter 1 M221 General Overview . . . . . . . . . . . . . . . . . . . . . . . . . 19

TM221C Logic Controller Description . . . . . . . . . . . . . . . . . . . . . . . . .

TM221M Logic Controller Description . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . .

TMC2 Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3 Expansion Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM2 Expansion Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 M221 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Real Time Clock (RTC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Run/Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 M221 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

3.1 M221 Logic Controller General Rules for Implementing . . . . . . . . . . .

Environmental Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Certifications and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 M221 Logic Controller Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation and Maintenance Requirements . . . . . . . . . . . . . . . . . . . .

TM221C Logic Controller Mounting Positions and Clearances . . . . . .

TM221M Logic Controller Mounting Positions and Clearances. . . . . .

Top Hat Section Rail (DIN rail) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing and Removing the Controller with Expansions. . . . . . . . . . .

Direct Mounting on a Panel Surface . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 M221 Electrical Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Best Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Power Supply Characteristics and Wiring . . . . . . . . . . . . . . . . . . .

AC Power Supply Characteristics and Wiring . . . . . . . . . . . . . . . . . . .

Grounding the M221 System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17

20

25

30

34

36

45

49

54

61

65

69

72

80

81

85

86

87

90

93

96

100

104

106

107

114

119

122

EIO0000003313 02/2020 3

Page 4

Part II Modicon TM221C Logic Controller. . . . . . . . . . . . . .

127

Chapter 4 TM221C16R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

TM221C16R Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

129

Chapter 5 TM221CE16R. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

TM221CE16R Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

135

Chapter 6 TM221C16T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

TM221C16T Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

139

Chapter 7 TM221CE16T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

TM221CE16T Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

143

Chapter 8 TM221C16U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

TM221C16U Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

147

Chapter 9 TM221CE16U. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

TM221CE16U Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

151

Chapter 10 TM221C24R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

TM221C24R Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

157

Chapter 11 TM221CE24R. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

TM221CE24R Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

161

Chapter 12 TM221C24T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

TM221C24T Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

165

Chapter 13 TM221CE24T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

TM221CE24T Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

169

Chapter 14 TM221C24U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

TM221C24U Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

173

Chapter 15 TM221CE24U. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

TM221CE24U Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

179

Chapter 16 TM221C40R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

TM221C40R Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

185

Chapter 17 TM221CE40R. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

TM221CE40R Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

191

Chapter 18 TM221C40T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

TM221C40T Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

197

Chapter 19 TM221CE40T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

TM221CE40T Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

203

Chapter 20 TM221C40U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

TM221C40U Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

209

Chapter 21 TM221CE40U. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

TM221CE40U Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

215

4 EIO0000003313 02/2020

Page 5

Chapter 22 Embedded I/O Channels . . . . . . . . . . . . . . . . . . . . . . . . 221

Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regular and Fast Transistor Outputs . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part III Modicon TM221M Logic Controller. . . . . . . . . . . . . .

222

239

247

256

261

Chapter 23 TM221M16R / TM221M16RG . . . . . . . . . . . . . . . . . . . . 263

TM221M16R / TM221M16RG Presentation . . . . . . . . . . . . . . . . . . . .

TM221M16R / TM221M16RG Digital Inputs . . . . . . . . . . . . . . . . . . . .

TM221M16R / TM221M16RG Digital Outputs. . . . . . . . . . . . . . . . . . .

TM221M16R / TM221M16RG Analog Inputs . . . . . . . . . . . . . . . . . . .

264

268

272

276

Chapter 24 TM221ME16R / TM221ME16RG . . . . . . . . . . . . . . . . . . 281

TM221ME16R / TM221ME16RG Presentation . . . . . . . . . . . . . . . . . .

TM221ME16R / TM221ME16RG Digital Inputs. . . . . . . . . . . . . . . . . .

TM221ME16R / TM221ME16RG Digital Outputs . . . . . . . . . . . . . . . .

TM221ME16R / TM221ME16RG Analog Inputs . . . . . . . . . . . . . . . . .

282

287

291

295

Chapter 25 TM221M16T / TM221M16TG . . . . . . . . . . . . . . . . . . . . . 299

TM221M16T / TM221M16TG Presentation. . . . . . . . . . . . . . . . . . . . .

TM221M16T / TM221M16TG Digital Inputs . . . . . . . . . . . . . . . . . . . .

TM221M16T / TM221M16TG Digital Outputs . . . . . . . . . . . . . . . . . . .

TM221M16T / TM221M16TG Analog Inputs . . . . . . . . . . . . . . . . . . . .

300

304

309

314

Chapter 26 TM221ME16T / TM221ME16TG . . . . . . . . . . . . . . . . . . 319

TM221ME16T / TM221ME16TG Presentation . . . . . . . . . . . . . . . . . .

TM221ME16T / TM221ME16TG Digital Inputs . . . . . . . . . . . . . . . . . .

TM221ME16T / TM221ME16TG Digital Outputs. . . . . . . . . . . . . . . . .

TM221ME16T / TM221ME16TG Analog Inputs . . . . . . . . . . . . . . . . .

320

326

331

336

Chapter 27 TM221M32TK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

TM221M32TK Presentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM221M32TK Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM221M32TK Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM221M32TK Analog Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

342

346

351

356

Chapter 28 TM221ME32TK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

TM221ME32TK Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM221ME32TK Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM221ME32TK Digital Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM221ME32TK Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

362

367

372

377

EIO0000003313 02/2020 5

Page 6

Part IV Modicon M221 Logic Controller Communication . . .

381

Chapter 29 Integrated Communication Ports . . . . . . . . . . . . . . . . . . . 383

USB Mini-B Programming Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Line 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Line 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

384

386

389

393

Chapter 30 Connecting the M221 Logic Controller to a PC . . . . . . . . 397

Connecting the Controller to a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

397

401

407

6 EIO0000003313 02/2020

Page 7

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device

before trying to install, operate, service, or maintain it. The following special messages may appear

throughout this documentation or on the equipment to warn of potential hazards or to call attention

to information that clarifies or simplifies a procedure.

EIO0000003313 02/2020 7

Page 8

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material.

A qualified person is one who has skills and knowledge related to the construction and operation

of electrical equipment and its installation, and has received safety training to recognize and avoid

the hazards involved.

QUALIFICATION OF PERSONNEL

Only appropriately trained persons who are familiar with and understand the contents of this

manual and all other pertinent product documentation are authorized to work on and with this

product.

The qualified person must be able to detect possible hazards that may arise from parameterization,

modifying parameter values and generally from mechanical, electrical, or electronic equipment.

The qualified person must be familiar with the standards, provisions, and regulations for the

prevention of industrial accidents, which they must observe when designing and implementing the

system.

INTENDED USE

The products described or affected by this document, together with software, accessories, and

options, are programmable logic controllers (referred to herein as “logic controllers”), intended for

industrial use according to the instructions, directions, examples, and safety information contained

in the present document and other supporting documentation.

The product may only be used in compliance with all applicable safety regulations and directives,

the specified requirements, and the technical data.

Prior to using the product, you must perform a risk assessment in view of the planned application.

Based on the results, the appropriate safety-related measures must be implemented.

Since the product is used as a component in an overall machine or process, you must ensure the

safety of persons by means of the design of this overall system.

Operate the product only with the specified cables and accessories. Use only genuine accessories

and spare parts.

Any use other than the use explicitly permitted is prohibited and can result in unanticipated

hazards.

8 EIO0000003313 02/2020

Page 9

About the Book

At a Glance

Document Scope

Use this document to:

Install and operate your M221 Logic Controller.

Connect the M221 Logic Controller to a programming device equipped with EcoStruxure

Machine Expert - Basic software.

Interface the M221 Logic Controller with I/O expansion modules, HMI and other devices.

Familiarize yourself with the M221 Logic Controller features.

NOTE: Read and understand this document and all related documents

installing, operating, or maintaining your controller.

Validity Note

This document has been updated for the release of EcoStruxure

The technical characteristics of the devices described in this manual also appear online.

The characteristics that are presented in the present document should be the same as those

characteristics that appear online. In line with our policy of constant improvement, we may revise

content over time to improve clarity and accuracy. If you see a difference between the document

and online information, use the online information as your reference.

For product compliance and environmental information (RoHS, REACH, PEP, EOLI, etc.), go to

www.schneider-electric.com/green-premium

(see page 10)

TM

Machine Expert - Basic V1.1.

before

.

EIO0000003313 02/2020 9

Page 10

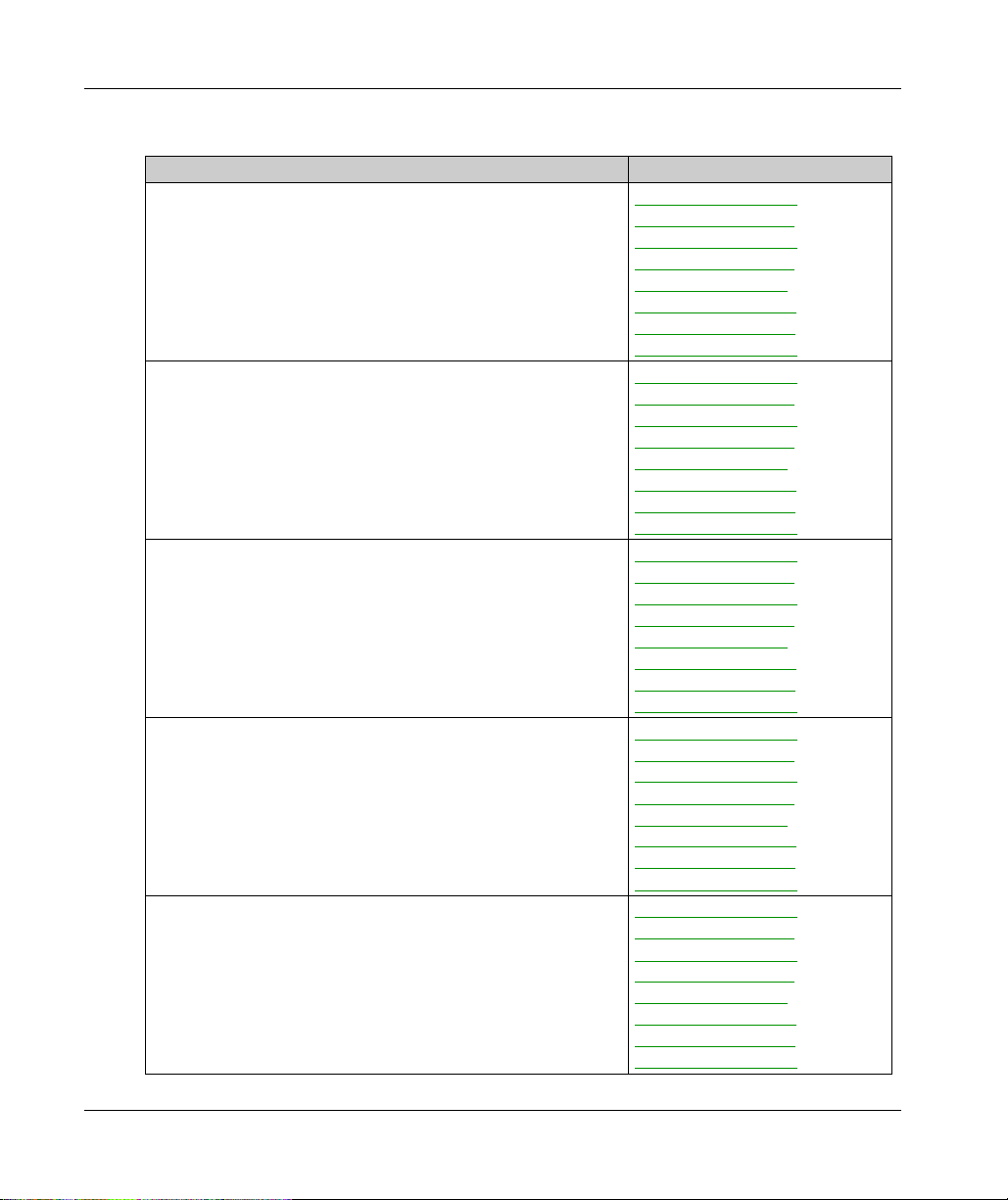

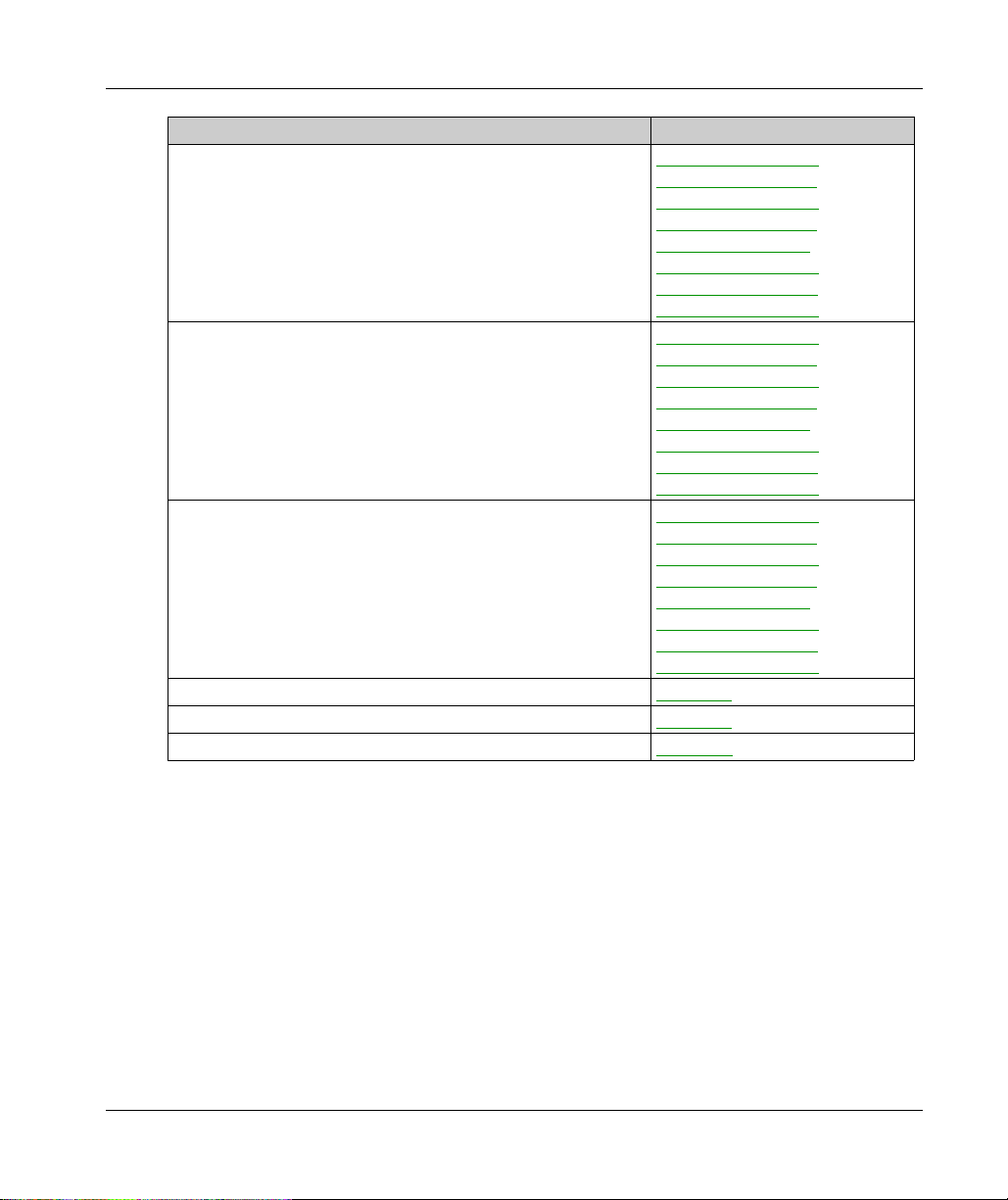

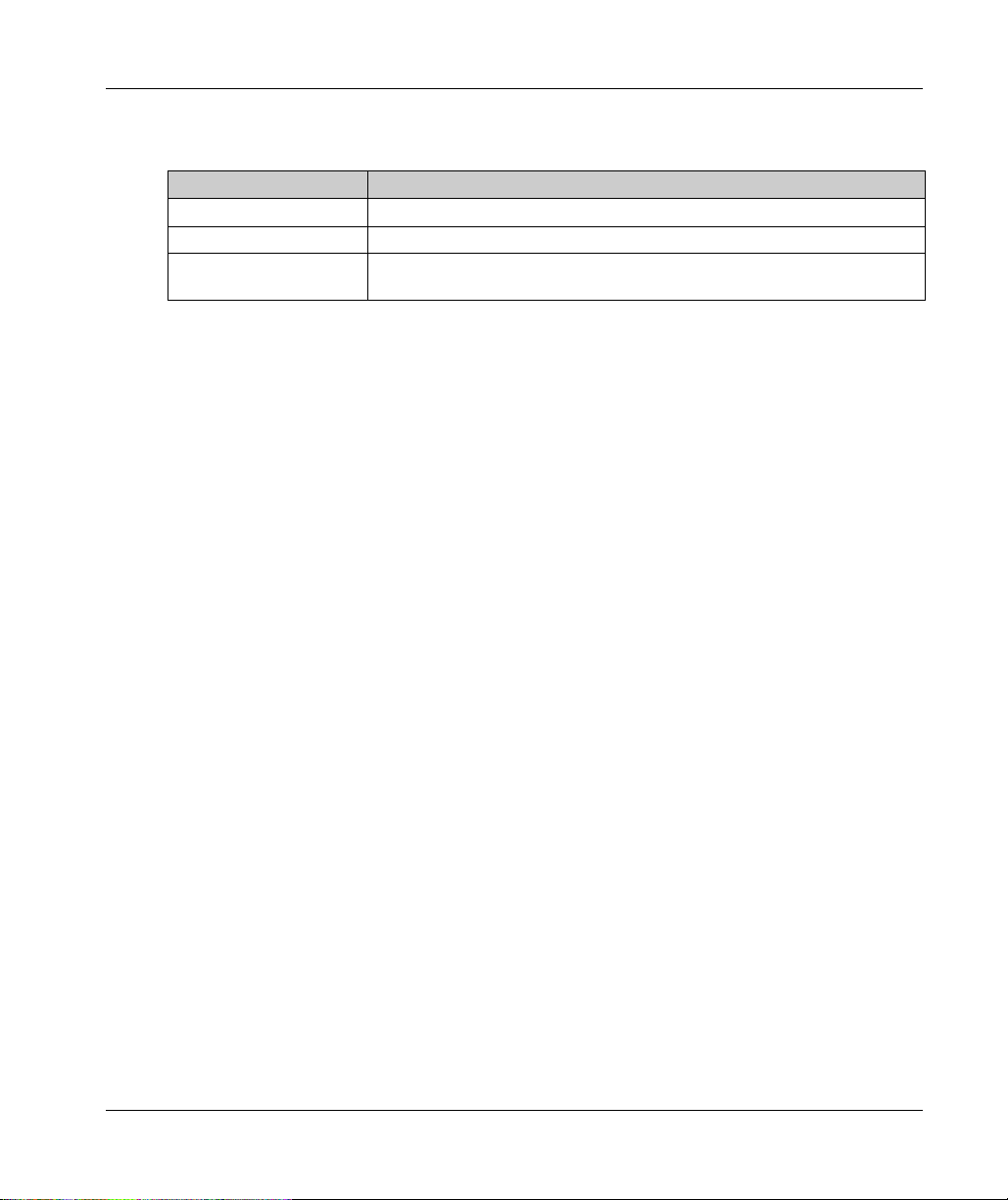

Related Documents

Title of Documentation Reference Number

Modicon M221 Logic Controller - Programming Guide

Modicon TMH2GDB Remote Graphic Display - User Guide

Modicon TMC2 Cartridges - Hardware Guide

Modicon TM3 Digital I/O Modules - Hardware Guide

Modicon TM3 Analog I/O Modules - Hardware Guide

EIO0000003297 (ENG)

EIO0000003298 (FRE)

EIO0000003299 (GER)

EIO0000003300 (SPA)

EIO0000003301 (ITA)

EIO0000003302 (CHS)

EIO0000003304 (TUR)

EIO0000003303 (POR)

EIO0000003321 (ENG)

EIO0000003322 (FRE)

EIO0000003323 (GER)

EIO0000003324 (SPA)

EIO0000003325 (ITA)

EIO0000003326 (CHS)

EIO0000003328 (TUR)

EIO0000003327 (POR)

EIO0000003337 (ENG)

EIO0000003338 (FRE)

EIO0000003339 (GER)

EIO0000003340 (SPA)

EIO0000003341 (ITA)

EIO0000003342 (CHS)

EIO0000003344 (TUR)

EIO0000003343 (POR)

EIO0000003125 (ENG)

EIO0000003126 (FRE)

EIO0000003127 (GER)

EIO0000003128 (SPA)

EIO0000003129 (ITA)

EIO0000003130 (CHS)

EIO0000003425 (TUR)

EIO0000003424 (POR)

EIO0000003131 (ENG)

EIO0000003132 (FRE)

EIO0000003133 (GER)

EIO0000003134 (SPA)

EIO0000003135 (ITA)

EIO0000003136 (CHS)

EIO0000003427 (TUR)

EIO0000003426 (POR)

10 EIO0000003313 02/2020

Page 11

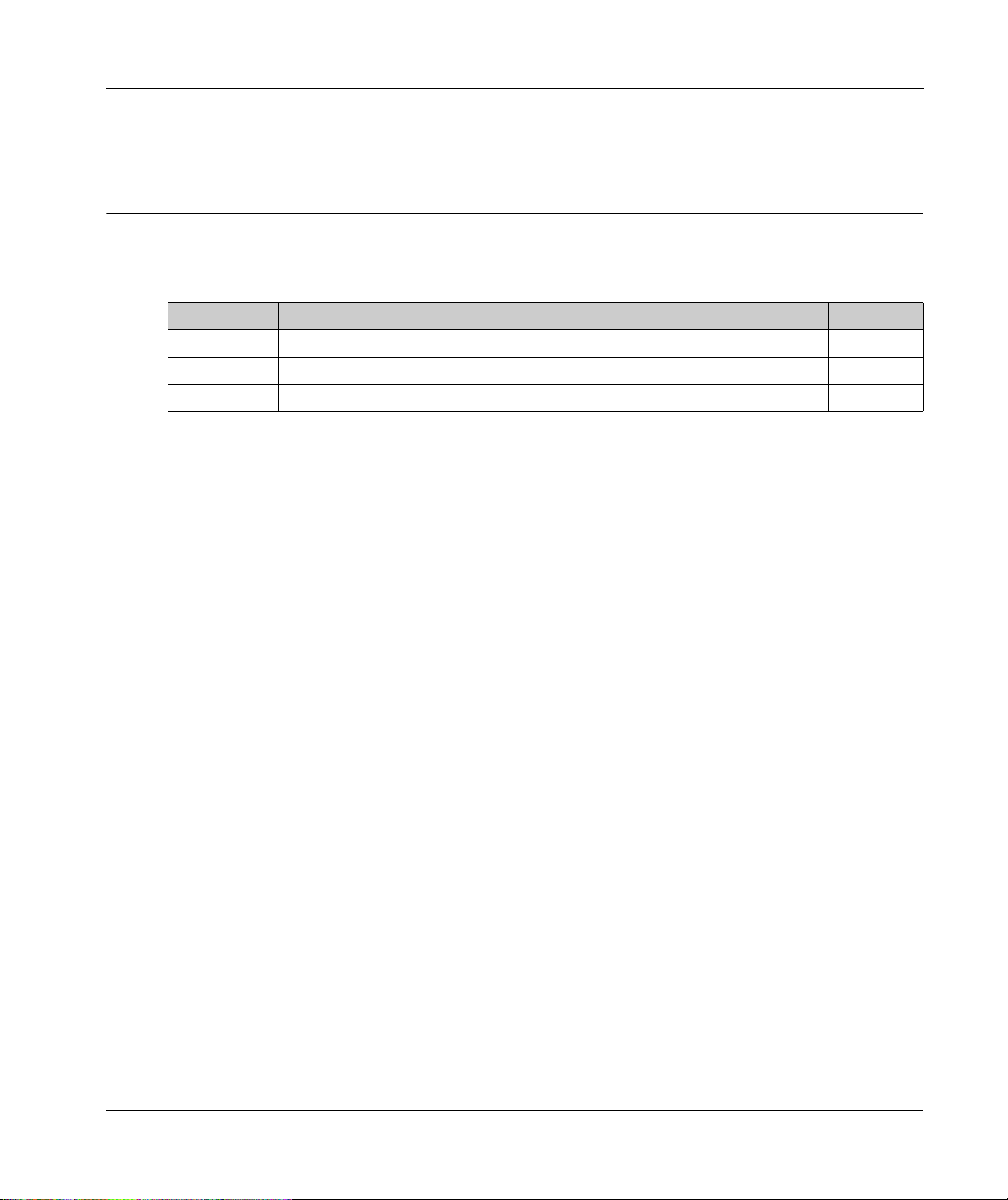

Title of Documentation Reference Number

Modicon TM3 Expert I/O Modules - Hardware Guide

EIO0000003137 (ENG)

EIO0000003138 (FRE)

EIO0000003139 (GER)

EIO0000003140 (SPA)

EIO0000003141 (ITA)

EIO0000003142 (CHS)

EIO0000003429 (TUR)

EIO0000003428 (POR)

Modicon TM3 Safety Modules - Hardware Guide

EIO0000003353 (ENG)

EIO0000003354 (FRE)

EIO0000003355 (GER)

EIO0000003356 (SPA)

EIO0000003357 (ITA)

EIO0000003358 (CHS)

EIO0000003360 (TUR)

EIO0000003359 (POR)

Modicon TM3 Transmitter and Receiver Modules - Hardware Guide

EIO0000003143 (ENG)

EIO0000003144 (FRE)

EIO0000003145 (GER)

EIO0000003146 (SPA)

EIO0000003147 (ITA)

EIO0000003148 (CHS)

EIO0000003431 (TUR)

EIO0000003430 (POR)

TM221C DC Logic Controller - Instruction Sheet

TM221C AC Logic Controller - Instruction Sheet

TM221M Logic Controller - Instruction Sheet

EAV48550

EAV58623

HRB59602

You can download these technical publications and other technical information from our website

at https://www.se.com/ww/en/download/ .

EIO0000003313 02/2020 11

Page 12

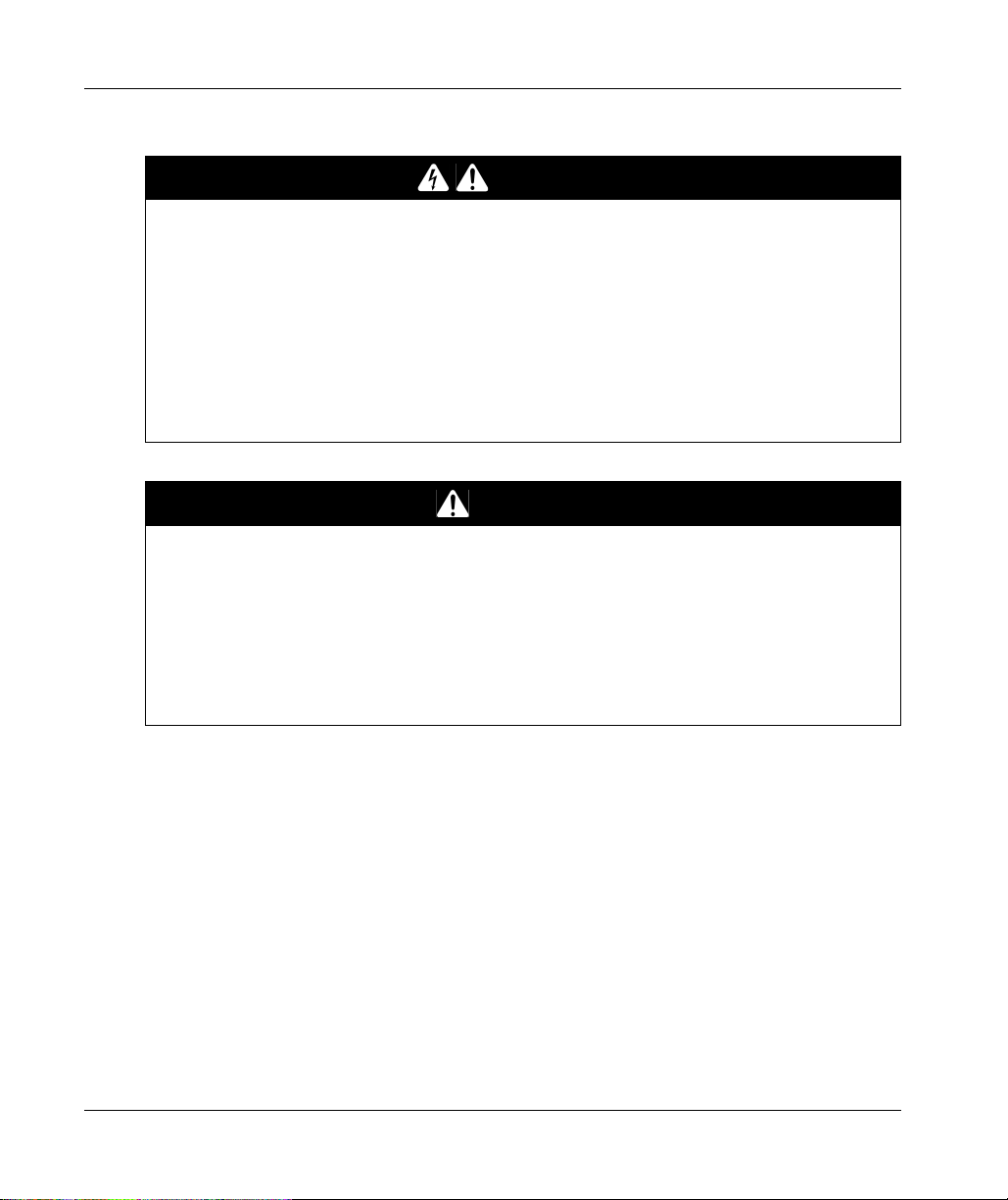

Product Related Information

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Disconnect all power from all equipment including connected devices prior to removing any

covers or doors, or installing or removing any accessories, hardware, cables, or wires except

under the specific conditions specified in the appropriate hardware guide for this equipment.

Always use a properly rated voltage sensing device to confirm the power is off where and when

indicated.

Replace and secure all covers, accessories, hardware, cables, and wires and confirm that a

proper ground connection exists before applying power to the unit.

Use only the specified voltage when operating this equipment and any associated products.

Failure to follow these instructions will result in death or serious injury.

POTENTIAL FOR EXPLOSION

Only use this equipment in non-hazardous locations, or in locations that comply with Class I,

Division 2, Groups A, B, C and D.

Do not substitute components which would impair compliance to Class I, Division 2.

Do not connect or disconnect equipment unless power has been removed or the location is

known to be non-hazardous.

Do not use the USB port(s), if so equipped, unless the location is known to be non-hazardous.

Failure to follow these instructions will result in death or serious injury.

DANGER

DANGER

12 EIO0000003313 02/2020

Page 13

WARNING

LOSS OF CONTROL

The designer of any control scheme must consider the potential failure modes of control paths

and, for certain critical control functions, provide a means to achieve a safe state during and

after a path failure. Examples of critical control functions are emergency stop and overtravel

stop, power outage and restart.

Separate or redundant control paths must be provided for critical control functions.

System control paths may include communication links. Consideration must be given to the

implications of unanticipated transmission delays or failures of the link.

Observe all accident prevention regulations and local safety guidelines.

Each implementation of this equipment must be individually and thoroughly tested for proper

1

operation before being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

1

For additional information, refer to NEMA ICS 1.1 (latest edition), "Safety Guidelines for the

Application, Installation, and Maintenance of Solid State Control" and to NEMA ICS 7.1 (latest

edition), "Safety Standards for Construction and Guide for Selection, Installation and Operation of

Adjustable-Speed Drive Systems" or their equivalent governing your particular location.

WARNING

UNINTENDED EQUIPMENT OPERATION

Only use software approved by Schneider Electric for use with this equipment.

Update your application program every time you change the physical hardware configuration.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000003313 02/2020 13

Page 14

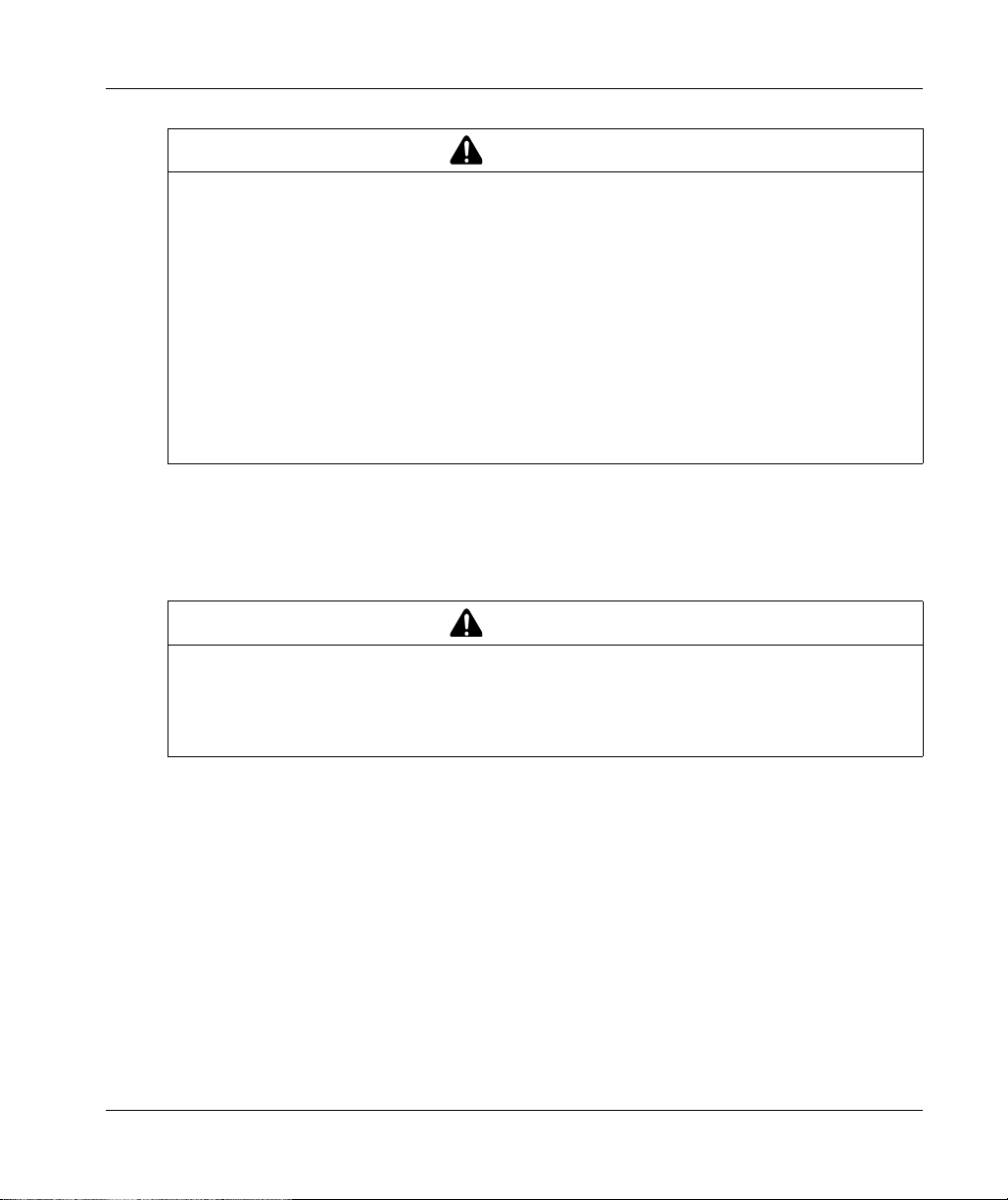

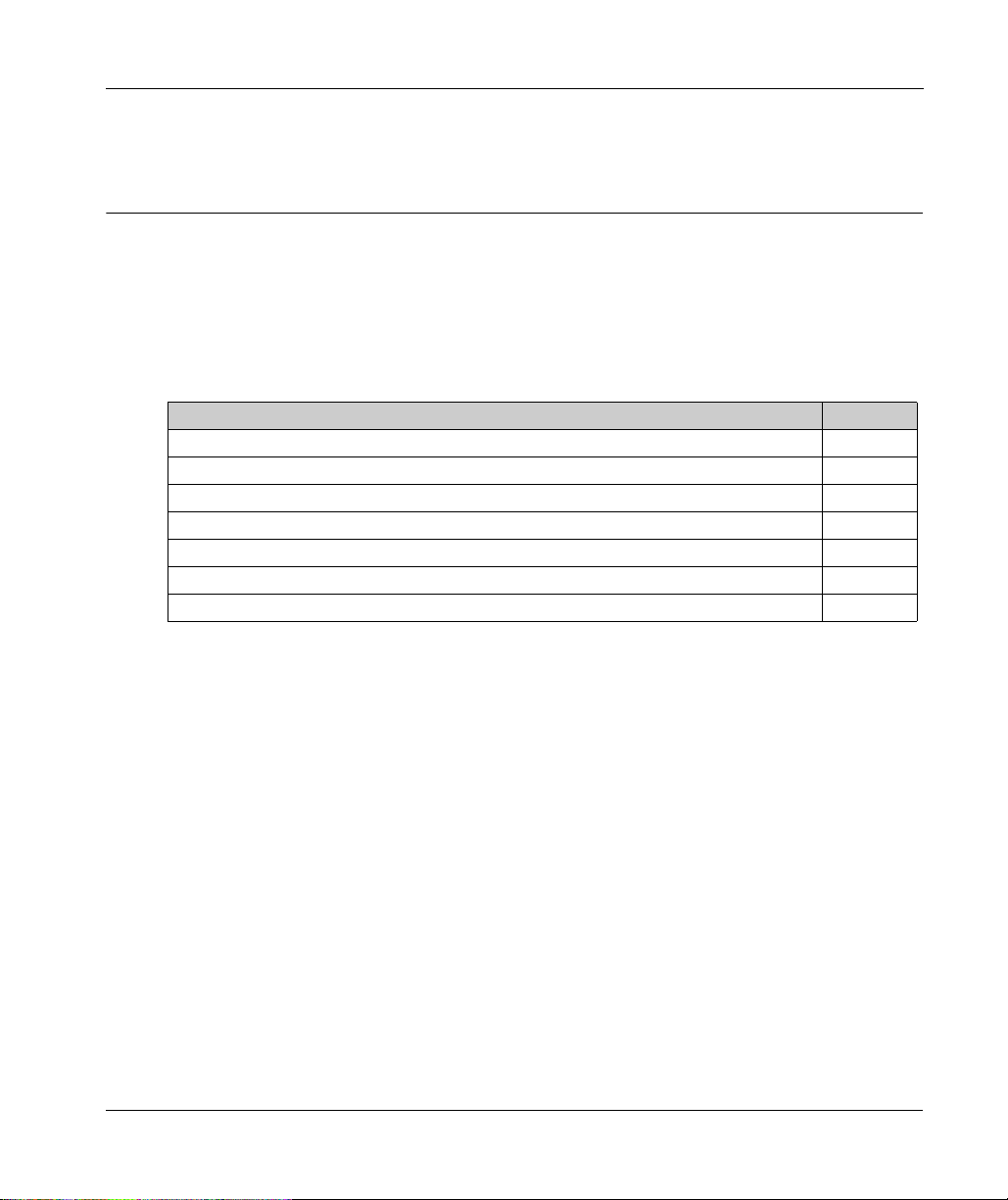

Terminology Derived from Standards

The technical terms, terminology, symbols and the corresponding descriptions in this manual, or

that appear in or on the products themselves, are generally derived from the terms or definitions

of international standards.

In the area of functional safety systems, drives and general automation, this may include, but is not

limited to, terms such as

safety, safety function, safe state, fault, fault reset, malfunction, failure

error, error message, dangerous

Among others, these standards include:

Standard Description

IEC 61131-2:2007 Programmable controllers, part 2: Equipment requirements and tests.

ISO 13849-1:2015 Safety of machinery: Safety related parts of control systems.

EN 61496-1:2013 Safety of machinery: Electro-sensitive protective equipment.

ISO 12100:2010 Safety of machinery - General principles for design - Risk assessment and risk

EN 60204-1:2006 Safety of machinery - Electrical equipment of machines - Part 1: General

ISO 14119:2013 Safety of machinery - Interlocking devices associated with guards - Principles

ISO 13850:2015 Safety of machinery - Emergency stop - Principles for design

IEC 62061:2015 Safety of machinery - Functional safety of safety-related electrical, electronic,

IEC 61508-1:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-2:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-3:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61784-3:2016 Industrial communication networks - Profiles - Part 3: Functional safety

2006/42/EC Machinery Directive

2014/30/EU Electromagnetic Compatibility Directive

2014/35/EU Low Voltage Directive

General principles for design.

Part 1: General requirements and tests.

reduction

requirements

for design and selection

and electronic programmable control systems

related systems: General requirements.

related systems: Requirements for electrical/electronic/programmable

electronic safety-related systems.

related systems: Software requirements.

fieldbuses - General rules and profile definitions.

,

, etc.

14 EIO0000003313 02/2020

Page 15

In addition, terms used in the present document may tangentially be used as they are derived from

other standards such as:

Standard Description

IEC 60034 series Rotating electrical machines

IEC 61800 series Adjustable speed electrical power drive systems

IEC 61158 series Digital data communications for measurement and control – Fieldbus for use in

industrial control systems

Finally, the term

hazards, and is defined as it is for a

2006/42/EC

(

zone of operation

) and

ISO 12100:2010

may be used in conjunction with the description of specific

hazard zone

or

danger zone

in the

Machinery Directive

.

NOTE: The aforementioned standards may or may not apply to the specific products cited in the

present documentation. For more information concerning the individual standards applicable to the

products described herein, see the characteristics tables for those product references.

EIO0000003313 02/2020 15

Page 16

16 EIO0000003313 02/2020

Page 17

Modicon M221 Logic Con troller

Modicon M221 Logic Con troller Introductio n

EIO0000003313 02/2020

Modicon M221 Logic Con troller Introductio n

Part I

Modicon M221 Logic Controller Introduction

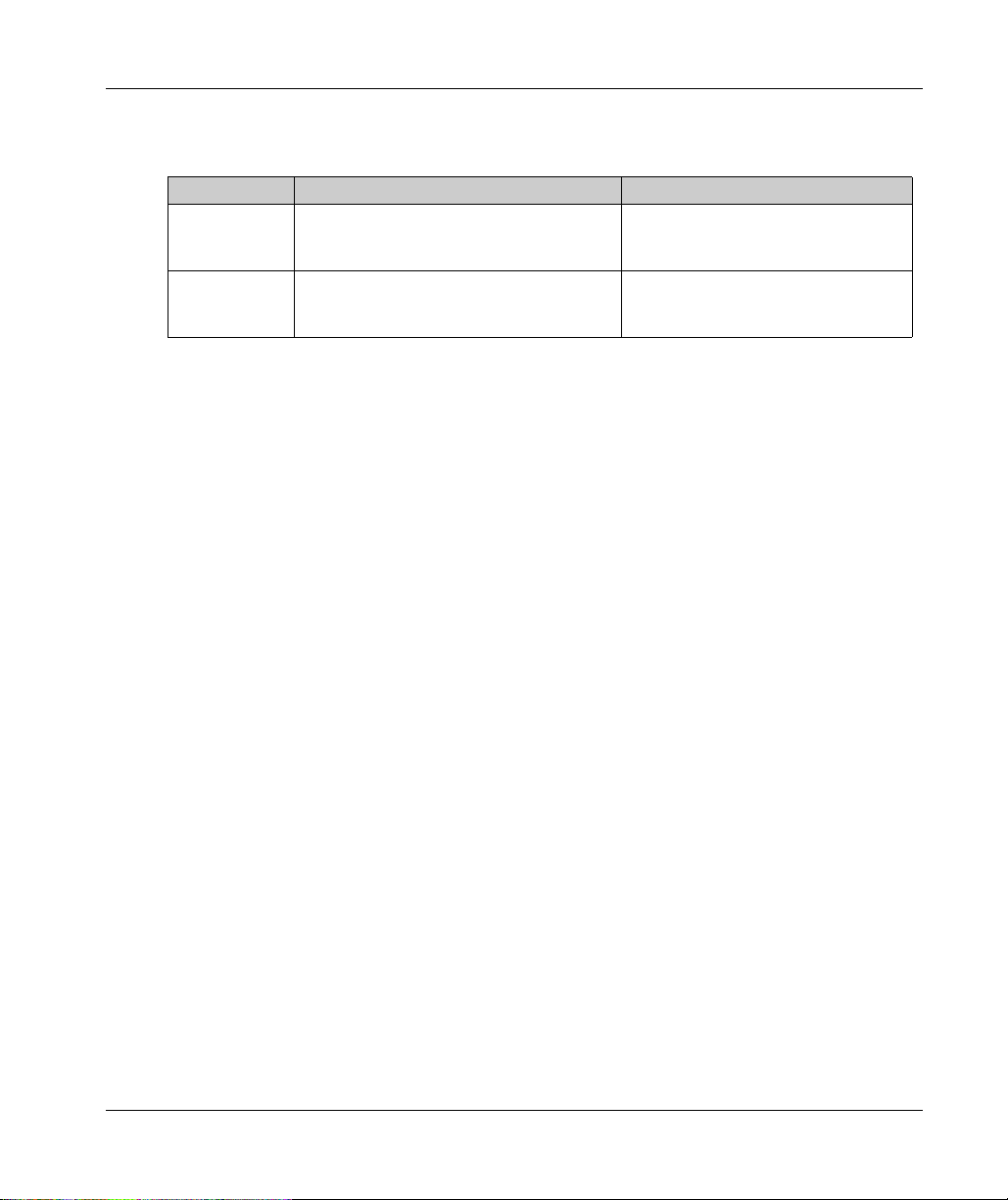

What Is in This Part?

This part contains the following chapters:

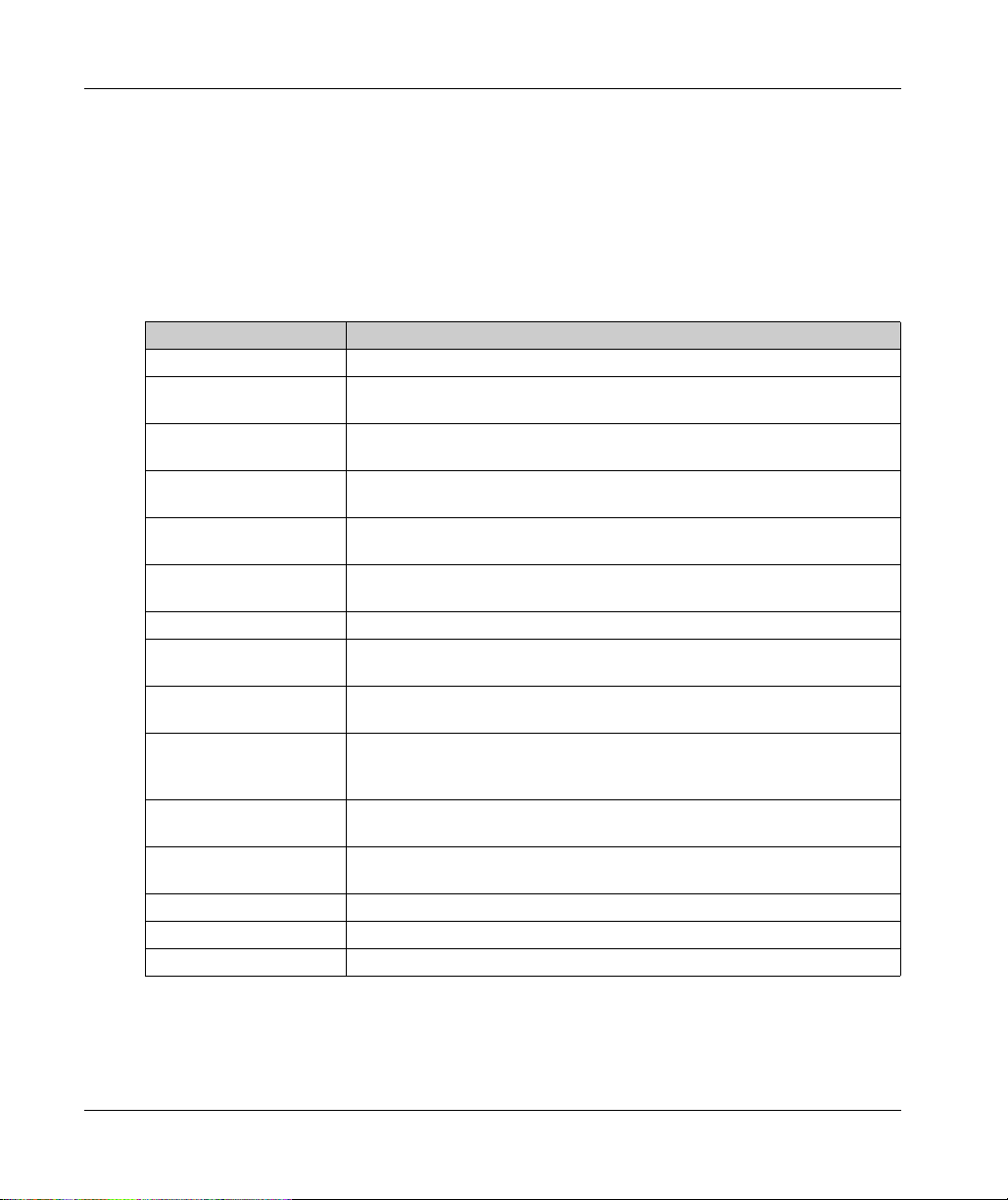

Chapter Chapter Name Page

1 M221 General Overview 19

2 M221 Features 53

3 M221 Installation 79

EIO0000003313 02/2020 17

Page 18

Modicon M221 Logic Controller Introduction

18

EIO0000003313 02/2020

Page 19

Modicon M221 Logic Con troller

M221 General Overview

EIO0000003313 02/2020

M221 General Overview

Chapter 1

M221 General Overview

Overview

This chapter provides general information about the M221 Logic Controller system architecture

and its components.

What Is in This Chapter?

This chapter contains the following topics:

TM221C Logic Controller Description 20

TM221M Logic Controller Description 25

Maximum Hardware Configuration 30

TMC2 Cartridges 34

TM3 Expansion Modules 36

TM2 Expansion Modules 45

Accessories 49

Topic Page

EIO0000003313 02/2020 19

Page 20

M221 General Overview

TM221C Logic Controller Description

Overview

The TM221C Logic Controller has various powerful features and can service a wide range of

applications.

Software configuration, programming, and commissioning are accomplished with the EcoStruxure

Machine Expert - Basic software described in the EcoStruxure Machine Expert - Basic Operating

(see EcoStruxure Machine Expert - Basic, Operating Guide)

Guide

- Programming Guide

Programming Languages

The M221 Logic Controller is configured and programmed with the EcoStruxure Machine Expert Basic software, which supports the following IEC 61131-3 programming languages:

IL: Instruction List

LD: Ladder Diagram

Grafcet (List)

Grafcet (SFC)

Power Supply

The power supply of the TM221C Logic Controller is 24 Vdc

(see page 119)

(see Modicon M221, Logic Controller, Programming Guide)

.

and the M221 Logic Controller

.

(see page 114)

or 100...240 Vac

Real Time Clock

The M221 Logic Controller includes a Real Time Clock (RTC) system

Run/Stop

The M221 Logic Controller can be operated externally by the following:

a hardware Run/Stop switch

a Run/Stop

configuration (for more information, refer to Configuring Digital Inputs

Logic Controller, Programming Guide)

EcoStruxure Machine Expert - Basic software (for more information, refer to Toolbar

(see EcoStruxure Machine Expert - Basic, Operating Guide)

a TMH2GDB Remote Graphic Display (for more information, refer to Controller State Menu

(see Modicon TMH2GDB, Remote Graphic Display, User Guide)

20

(see page 69)

(see page 54)

.

(seepage69)

operation by a dedicated digital input, defined in the software

(see Modicon M221,

.)

).

).

EIO0000003313 02/2020

Page 21

Memory

This table describes the different types of memory:

Memory Type Size Used to

RAM 512 Kbytes of RAM memory: 256 Kbytes for

Non-volatile 1.5 Mbytes, of which 256 Kbytes is used to

Embedded Inputs/Outputs

The following embedded I/O types are available, depending on the controller reference:

Regular inputs

Fast inputs associated with counters

Regular sink/source transistor outputs

Fast sink/source transistor outputs associated with pulse generators

Relay outputs

Analog inputs

Removable Storage

The M221 Logic Controllers include an embedded SD card slot

The Modicon M221 Logic Controller allows the following types of file management with an SD card:

Clone management

application, firmware, and post configuration (if it exists) of the logic controller

Firmware management

firmware to the logic controller, to a TMH2GDB Remote Graphic Display , or to TM3 expansion

modules

Application management

and restore the logic controller application, or copy it to another logic controller of the same

reference

Post configuration management

add, change, or delete the post configuration file of the logic controller

Error log management

delete the error log file of the logic controller

Memory management: back up and restore memory bits and words from a controller

internal variables and 256 Kbytes for

execute the application and contain data

application and data.

save the application

back up the application and data in case of

power outage.

(see page 72)

(see Modicon M221, Logic Controller, Programming Guide)

(see Modicon M221, Logic Controller, Programming Guide)

(see Modicon M221, Logic Controller, Programming Guide)

(see Modicon M221, Logic Controller, Programming Guide)

(see Modicon M221, Logic Controller, Programming Guide)

M221 General Overview

.

: back up the

: download

: back up

:

: back up or

Embedded Communication Features

The following types of communication ports are available depending on the controller reference:

Ethernet

USB Mini-B

Serial Line 1

EIO0000003313 02/2020 21

(seepage386)

(see page 384)

(see page 389)

Page 22

M221 General Overview

Remote Graphic Display

For more information, refer to the Modicon TMH2GDB Remote Graphic Display - User Guide.

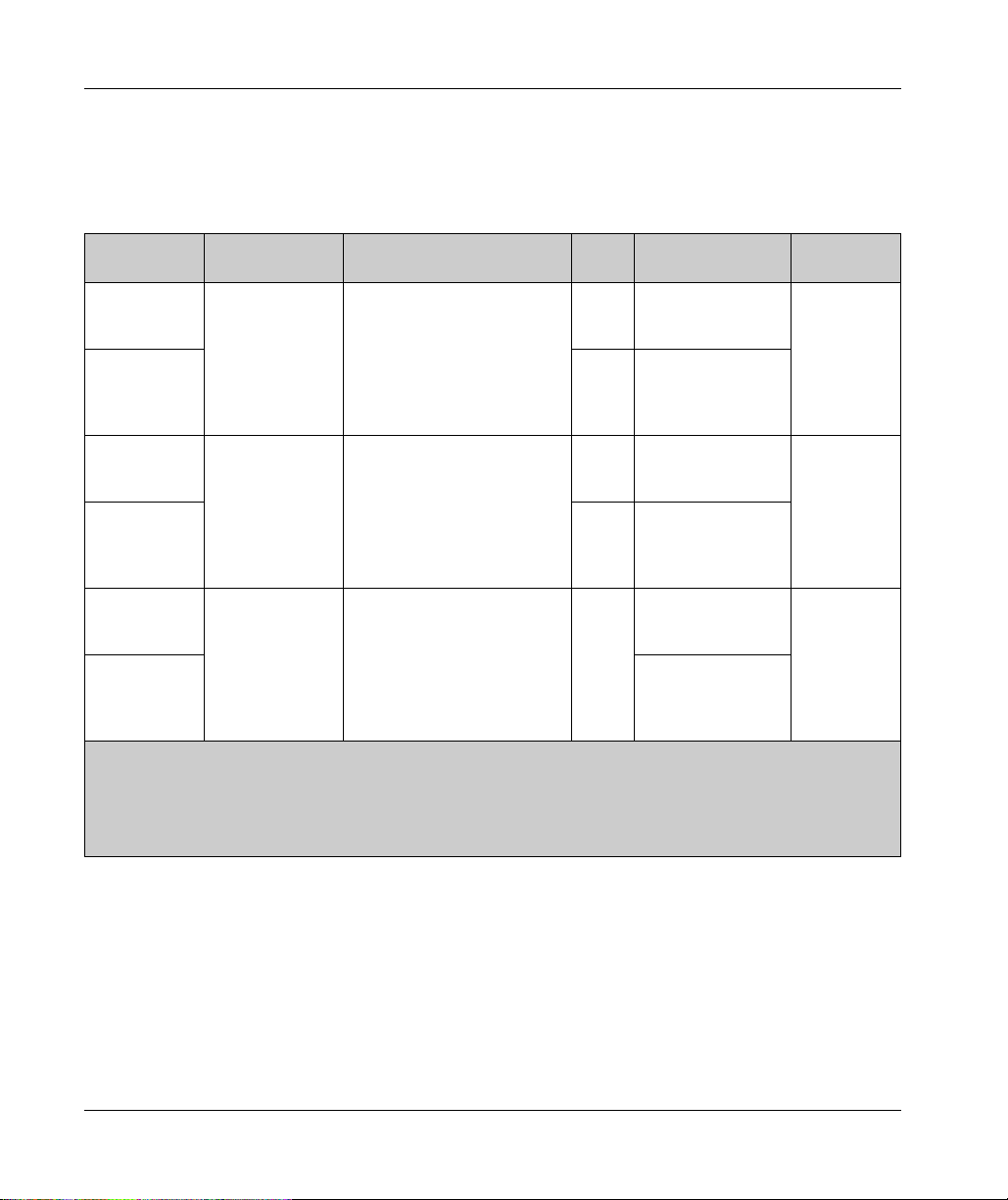

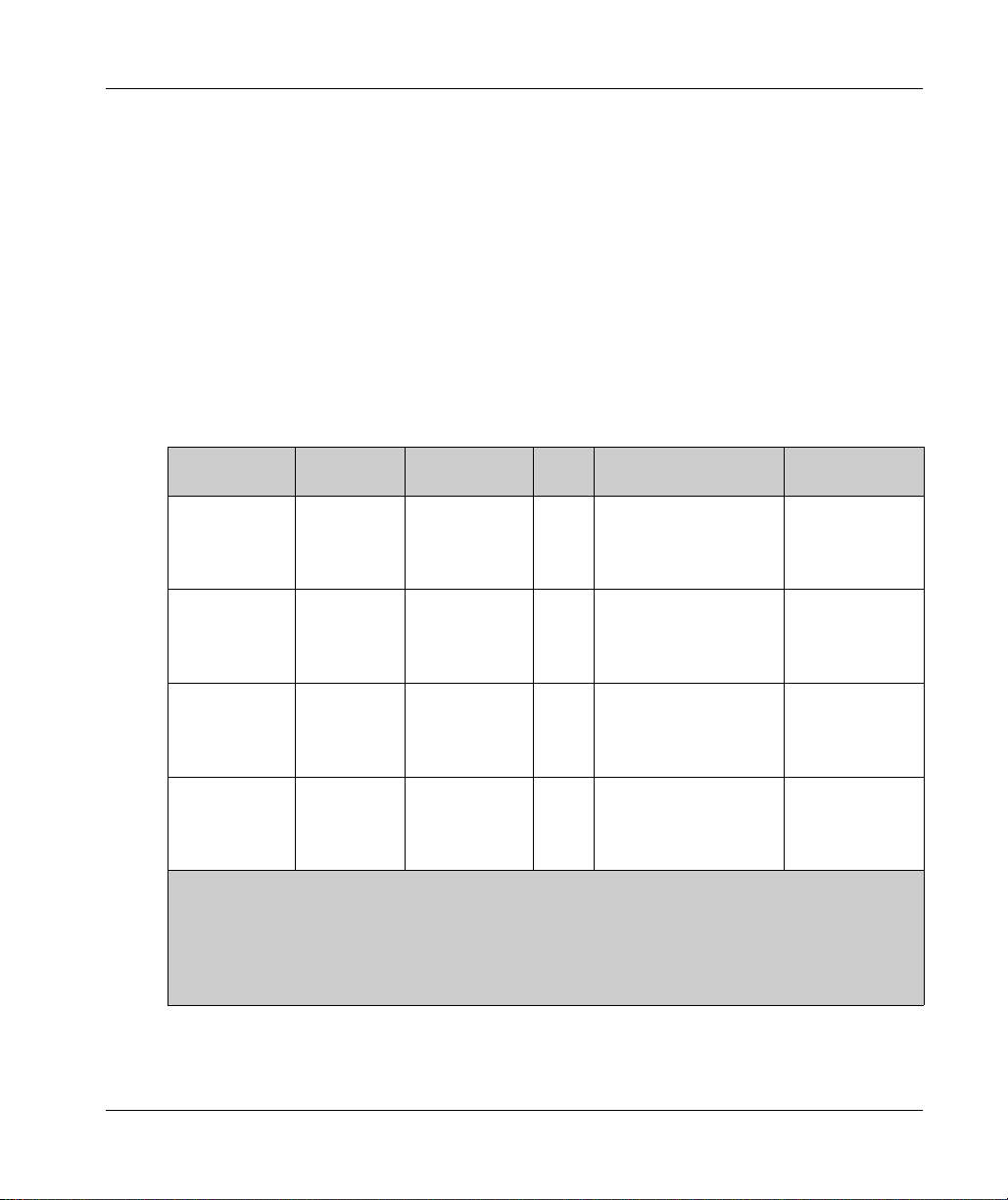

TM221C Logic Controller

Reference Digital Inputs Digital Outputs Analog

Inputs

TM221C16R

(see page 129)

TM221CE16R

5 regular inputs

4 fast inputs

(2)

(HSC)

(1)

7 relay outputs Yes 1 serial line port

Yes 1 serial line port

(see page 135)

Communication

Ports

1 USB programming

port

1 USB programming

Power Supply

100...240 Vac

port

1 Ethernet port

TM221C16T

(see page 139)

TM221CE16T

(see page 143)

5 regular inputs

4 fast inputs

(2)

(HSC)

(1)

Source outputs

5 regular transistor outputs

2 fast outputs

(PLS/PWM/PTO/FREQGEN)

Yes 1 serial line port

1 USB programming

port

(3)

Yes 1 serial line port

1 USB programming

24 Vdc

port

1 Ethernet port

TM221C16U

(see page 147)

TM221CE16U

(see page 151)

5 regular inputs

4 fast inputs

(2)

(HSC)

(1)

Sink outputs

5 regular transistor outputs

2 fast outputs

(PLS/PWM/PTO/FREQGEN)

Yes 1 serial line port

1 USB programming

port

(3)

1 serial line port

1 USB programming

24 Vdc

port

1 Ethernet port

NOTE: The TM221C Logic Controller uses removable screw terminal blocks.

(1) The regular inputs have a maximum frequency of 5 kHz.

(2) The fast inputs can be used either as regular inputs or as fast inputs for counting or event functions.

(3) The fast transistor outputs can be used either as regular transistor outputs, for PLS, PWM, PTO, or FREQGEN

functions, or reflex outputs for HSC.

22

EIO0000003313 02/2020

Page 23

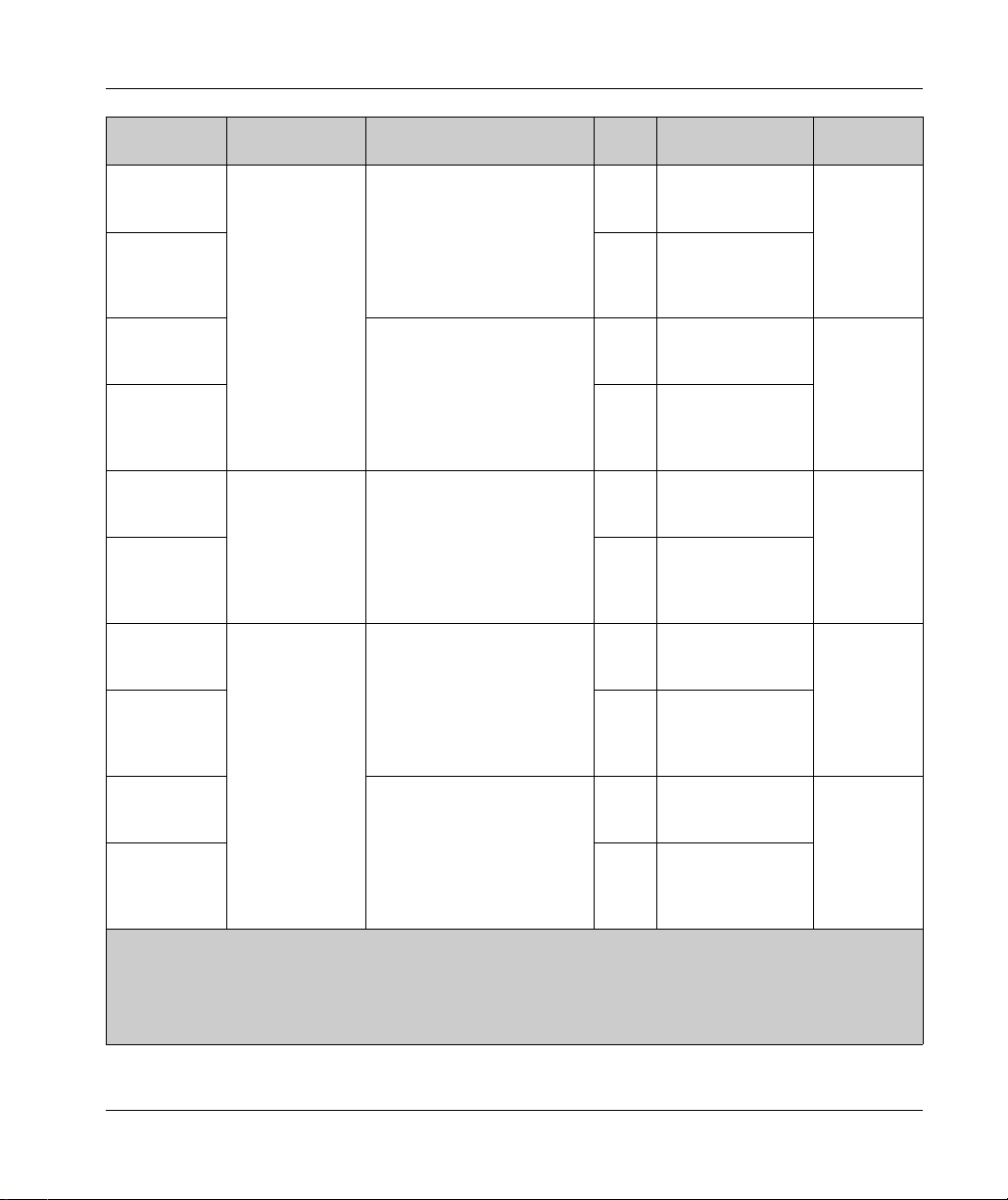

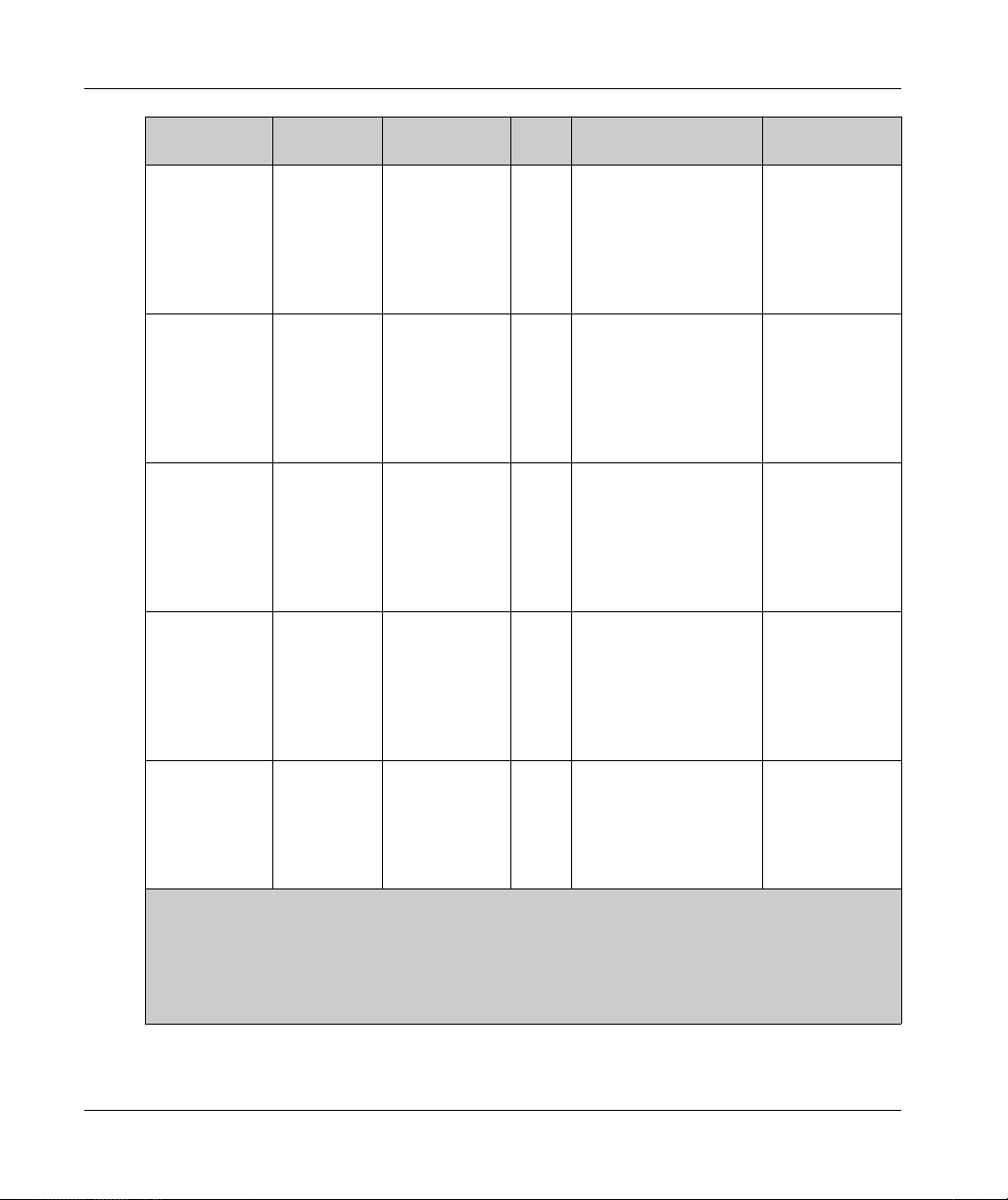

M221 General Overview

Reference Digital Inputs Digital Outputs Analog

Inputs

TM221C24R

(see page 157)

10 regular

(1)

inputs

10 relay outputs Yes 1 serial line port

4 fast inputs

TM221CE24R

(HSC)

Yes 1 serial line port

(2)

(see page 161)

Communication

Ports

1 USB programming

port

1 USB programming

Power Supply

100...240 Vac

port

1 Ethernet port

TM221C24T

(see page 165)

TM221CE24T

(see page 169)

Source outputs

8 regular transistor outputs

2 fast outputs

(PLS/PWM/PTO/FREQGEN)

Yes 1 serial line port

1 USB programming

port

(3)

Yes 1 serial line port

1 USB programming

24 Vdc

port

1 Ethernet port

TM221C24U

(see page 173)

TM221CE24U

(see page 179)

10 regular

inputs

4 fast inputs

(HSC)

(1)

8 regular transistor outputs

2 fast outputs

Sink outputs

(2)

(PLS/PWM/PTO/FREQGEN)

Yes 1 serial line port

1 USB programming

port

(3)

Yes 1 serial line port

1 USB programming

24 Vdc

port

1 Ethernet port

TM221C40R

(see page 185)

TM221CE40R

(see page 191)

20 regular

inputs

4 fast inputs

(HSC)

(1)

1 USB programming

port

16 relay outputs Yes 1 serial line port

(2)

Yes 1 serial line port

1 USB programming

100...240 Vac

port

1 Ethernet port

TM221C40T

(see page 197)

TM221CE40T

(see page 203)

Source outputs

14 regular transistor outputs

2 fast outputs

(PLS/PWM/PTO/FREQGEN)

Yes 1 serial line port

1 USB programming

port

(3)

Yes 1 serial line port

1 USB programming

24 Vdc

port

1 Ethernet port

NOTE: The TM221C Logic Controller uses removable screw terminal blocks.

(1) The regular inputs have a maximum frequency of 5 kHz.

(2) The fast inputs can be used either as regular inputs or as fast inputs for counting or event functions.

(3) The fast transistor outputs can be used either as regular transistor outputs, for PLS, PWM, PTO, or FREQGEN

functions, or reflex outputs for HSC.

EIO0000003313 02/2020 23

Page 24

M221 General Overview

Reference Digital Inputs Digital Outputs Analog

Inputs

TM221C40U

(see page 209)

TM221CE40U

20 regular

inputs

4 fast inputs

(HSC)

(1)

12 regular transistor outputs

Sink outputs

Yes 1 serial line port

4 fast outputs

(2)

(PLS/PWM/PTO/FREQGEN)

(3)

Yes 1 serial line port

(see page 215)

Communication

Ports

1 USB programming

port

1 USB programming

Power Supply

24 Vdc

port

1 Ethernet port

NOTE: The TM221C Logic Controller uses removable screw terminal blocks.

(1) The regular inputs have a maximum frequency of 5 kHz.

(2) The fast inputs can be used either as regular inputs or as fast inputs for counting or event functions.

(3) The fast transistor outputs can be used either as regular transistor outputs, for PLS, PWM, PTO, or FREQGEN

functions, or reflex outputs for HSC.

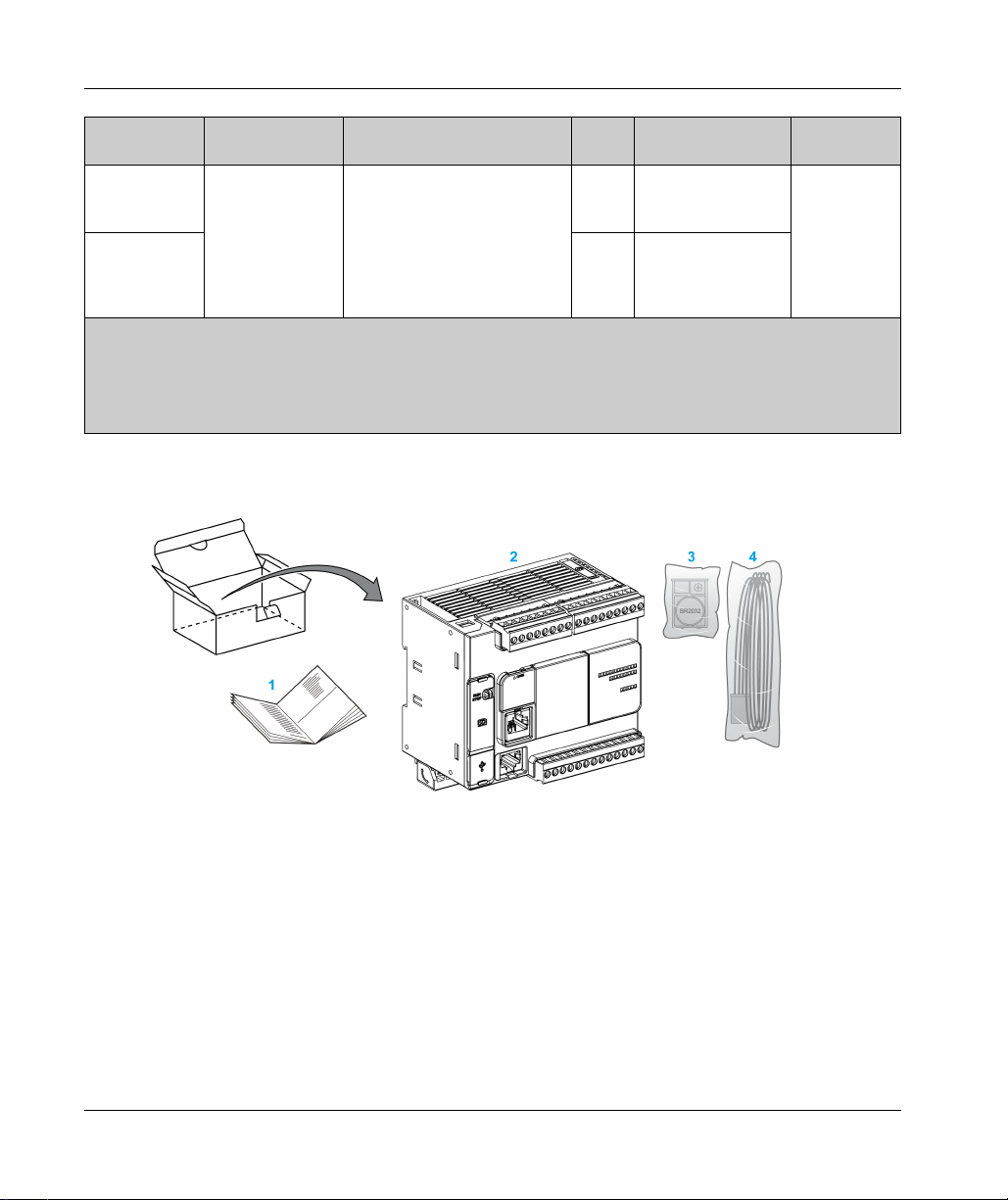

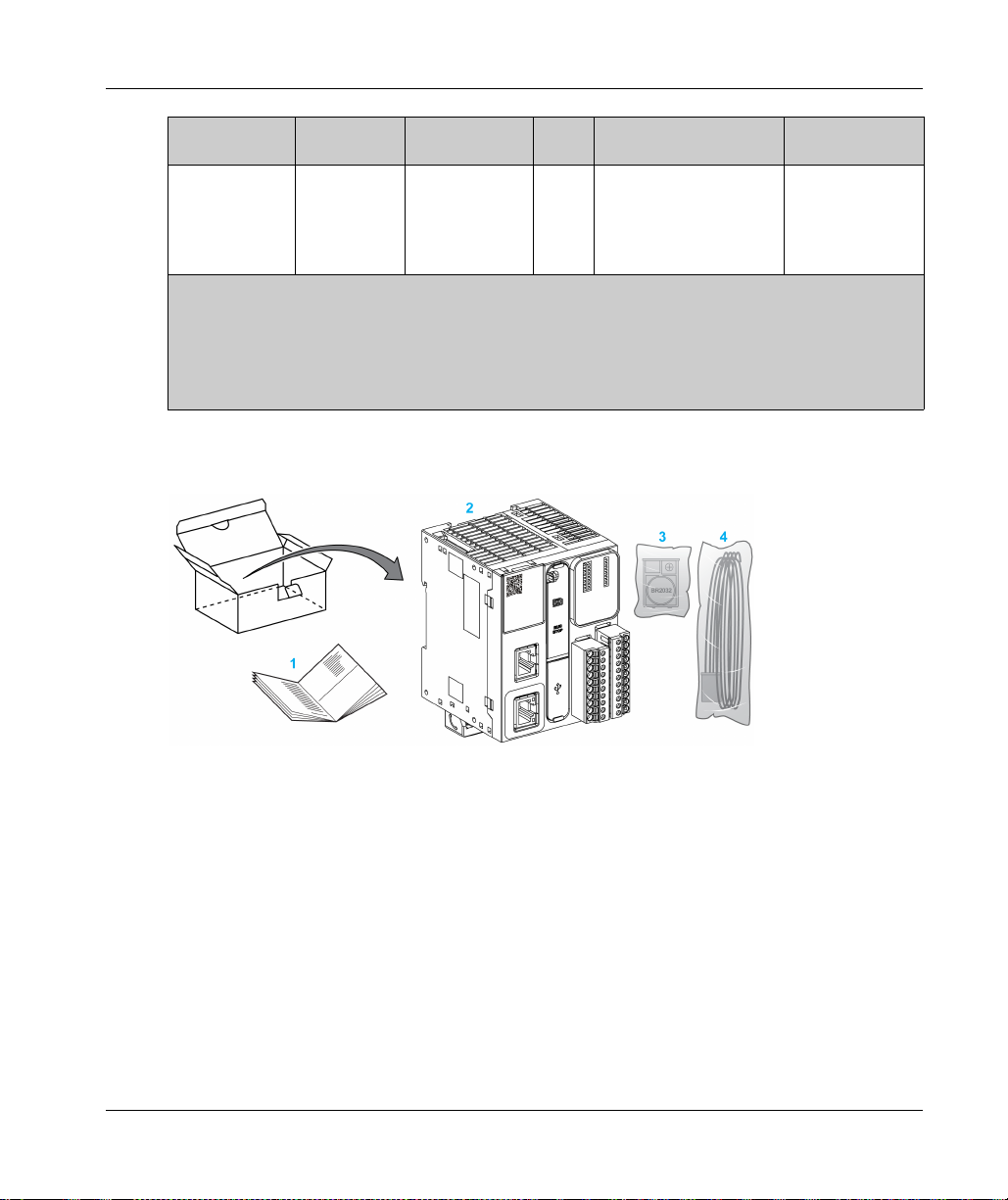

Delivery Content

The following figure presents the content of the delivery for a TM221C Logic Controller:

24

1 TM221C Logic Controller Instruction Sheet

2 TM221C Logic Controller

3 Battery holder with lithium carbon monofluoride battery, type Panasonic BR2032.

4 Analog cable

EIO0000003313 02/2020

Page 25

TM221M Logic Controller Description

Overview

The TM221M Logic Controller has various powerful features and can service a wide range of

applications.

Software configuration, programming, and commissioning are accomplished with the EcoStruxure

Machine Expert - Basic software described in the EcoStruxure Machine Expert - Basic Operating

(see EcoStruxure Machine Expert - Basic, Operating Guide)

Guide

- Programming Guide

Programming Languages

The M221 Logic Controller is configured and programmed with the EcoStruxure Machine Expert Basic software, which supports the following IEC 61131-3 programming languages:

IL: Instruction List

LD: Ladder Diagram

Grafcet (List)

Grafcet (SFC)

Power Supply

The power supply of the TM221M Logic Controller is 24 Vdc

(see Modicon M221, Logic Controller, Programming Guide)

M221 General Overview

and the M221 Logic Controller

.

(see page 114)

.

Real Time Clock

The M221 Logic Controller includes a Real Time Clock (RTC) system

(see page 54)

.

Run/Stop

The M221 Logic Controller can be operated externally by the following:

a hardware Run/Stop switch

a Run/Stop

(see page 69)

configuration (for more information, refer to Configuring Digital Inputs

Logic Controller, Programming Guide)

EcoStruxure Machine Expert - Basic software (for more information, refer to Toolbar

(see EcoStruxure Machine Expert - Basic, Operating Guide)

a TMH2GDB Remote Graphic Display (for more information, refer to Controller State Menu

(see Modicon TMH2GDB, Remote Graphic Display, User Guide)

EIO0000003313 02/2020 25

(seepage69)

operation by a dedicated digital input, defined in the software

(see Modicon M221,

)

).

).

Page 26

M221 General Overview

Memory

This table describes the different types of memory:

Memory Type Size Used to

RAM 512 Kbytes of RAM memory: 256 Kbytes for internal

Non-volatile 1.5 Mbytes, of which 256 Kbytes is used to back up the

Embedded Inputs/Outputs

The following embedded I/O types are available, depending on the controller reference:

Regular inputs

Fast inputs (HSC)

Regular transistor outputs

Fast transistor outputs (PLS/PWM/PTO/FREQGEN)

Relay outputs

Analog inputs

Removable Storage

The M221 Logic Controllers include an embedded SD card slot

The Modicon M221 Logic Controller allows the following types of file management with an SD card:

Clone management

application, firmware, and post configuration (if it exists) of the logic controller

Firmware management

firmware updates directly to the logic controller, and download firmware to a TMH2GDB Remote

Graphic Display

Application management

and restore the logic controller application, or copy it to another logic controller of the same

reference

Post configuration management

add, change, or delete the post configuration file of the logic controller

Error log management

delete the error log file of the logic controller

Memory management: backup/restore of memory bits and words from a controller

variables and 256 Kbytes for application and data.

application and data in case of power outage.

(see page 72)

(see Modicon M221, Logic Controller, Programming Guide)

(see Modicon M221, Logic Controller, Programming Guide)

(see Modicon M221, Logic Controller, Programming Guide)

(see Modicon M221, Logic Controller, Programming Guide)

(see Modicon M221, Logic Controller, Programming Guide)

execute the application and

contains data

save the application

.

: back up the

: download

: back up

:

: back up or

26

EIO0000003313 02/2020

Page 27

Embedded Communication Features

The following communication ports are available on the front panel of the controller, depending on

the controller reference:

Ethernet

USB Mini-B

SD Card

Serial Line 1

Serial Line 2

(seepage386)

(see page 384)

(see page 72)

(see page 389)

(see page 393)

Remote Graphic Display

For more information, refer to the Modicon TMH2GDB Remote Graphic Display - User Guide.

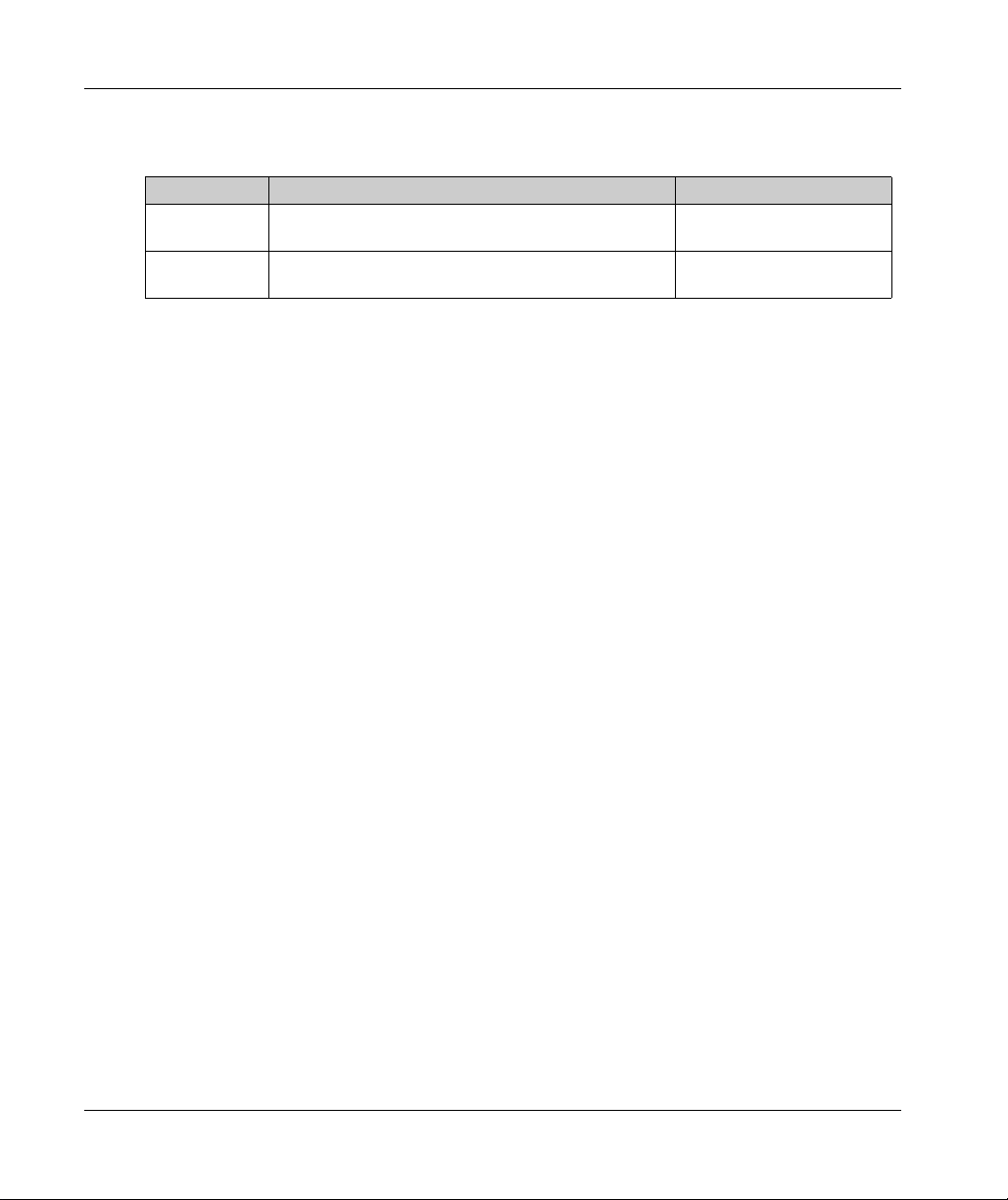

TM221M Logic Controller

M221 General Overview

Reference Digital Input Digital Output Analog

Communication Ports Terminal Type

Input

TM221M16R

(see page 263)

4 regular

(1)

inputs

8 relay outputs Yes 2 serial line ports

1 USB programming port

Removable screw

terminal blocks

4 fast inputs

(2)

(HSC)

TM221M16RG

(see page 263)

4 regular

(1)

inputs

8 relay outputs Yes 2 serial line ports

1 USB programming port

Removable spring

terminal blocks

4 fast inputs

(2)

(HSC)

TM221ME16R

(see page 281)

TM221ME16RG

(see page 281)

4 regular

(1)

inputs

4 fast inputs

(2)

(HSC)

4 regular

(1)

inputs

4 fast inputs

(2)

(HSC)

8 relay outputs Yes 1 serial line port

1 USB programming port

1 Ethernet port

8 relay outputs Yes 1 serial line port

1 USB programming port

1 Ethernet port

NOTE: The TM221M Logic Controller uses a 24 Vdc power supply

(see page 114)

Removable screw

terminal blocks

Removable spring

terminal blocks

.

(1) The regular inputs I2, I3, I4, and I5 have a maximum frequency of 5 kHz.

The other regular inputs have a maximum frequency of 100 Hz.

(2) The fast inputs can be used either as regular inputs or as fast inputs for counting or event functions.

(3) The fast transistor outputs can be used as regular transistor outputs, for PLS, PWM, PTO or FREQGEN

functions, or reflex outputs for HSC.

EIO0000003313 02/2020 27

Page 28

M221 General Overview

Reference Digital Input Digital Output Analog

Communication Ports Terminal Type

Input

TM221M16T

(see page 299)

4 regular

(1)

inputs

4 fast inputs

(2)

(HSC)

6 regular

transistor

outputs

2 fast transistor

outputs

Yes 2 serial line ports

1 USB programming port

Removable screw

terminal blocks

(PLS/PWM/PTO

(3)

Yes 2 serial line ports

1 USB programming port

Removable spring

terminal blocks

TM221M16TG

(see page 299)

4 regular

inputs

4 fast inputs

(HSC)

/FREQGEN)

6 regular

(1)

transistor

outputs

(2)

2 fast transistor

outputs

(PLS/PWM/PTO

(3)

Yes 1 serial line port

1 USB programming port

1 Ethernet port

Removable screw

terminal blocks

TM221ME16T

(see page 319)

4 regular

inputs

4 fast inputs

(HSC)

/FREQGEN)

6 regular

(1)

transistor

outputs

(2)

2 fast transistor

outputs

(PLS/PWM/PTO

(3)

Yes 1 serial line port

USB programming port

1 Ethernet port

Removable spring

terminal blocks

TM221ME16TG

(see page 319)

4 regular

(1)

inputs

4 fast inputs

(2)

(HSC)

/FREQGEN)

6 regular

transistor

outputs

2 fast transistor

outputs

(PLS/PWM/PTO

/FREQGEN)

TM221M32TK

(see page 341)

12 regular

inputs

4 fast inputs

(HSC)

(1)

transistor

outputs

14 regular

(2)

2 fast outputs

(PLS/PWM/PTO

/FREQGEN)

NOTE: The TM221M Logic Controller uses a 24 Vdc power supply

(3)

Yes 2 serial line ports

1 USB programming port

(3)

(see page 114)

HE10 (MIL 20)

connectors

.

(1) The regular inputs I2, I3, I4, and I5 have a maximum frequency of 5 kHz.

The other regular inputs have a maximum frequency of 100 Hz.

(2) The fast inputs can be used either as regular inputs or as fast inputs for counting or event functions.

(3) The fast transistor outputs can be used as regular transistor outputs, for PLS, PWM, PTO or FREQGEN

functions, or reflex outputs for HSC.

28

EIO0000003313 02/2020

Page 29

M221 General Overview

Reference Digital Input Digital Output Analog

TM221ME32TK

(see page 341)

NOTE: The TM221M Logic Controller uses a 24 Vdc power supply

(1) The regular inputs I2, I3, I4, and I5 have a maximum frequency of 5 kHz.

The other regular inputs have a maximum frequency of 100 Hz.

(2) The fast inputs can be used either as regular inputs or as fast inputs for counting or event functions.

(3) The fast transistor outputs can be used as regular transistor outputs, for PLS, PWM, PTO or FREQGEN

functions, or reflex outputs for HSC.

Delivery Content

The following figure presents the content of the delivery for a TM221M Logic Controller:

12 regular

inputs

4 fast inputs

(HSC)

Communication Ports Terminal Type

Input

(1)

outputs

2 fast outputs

14 regular

(2)

(PLS/PWM/PTO

/FREQGEN)

Yes 1 serial line port

1 USB programming port

1 Ethernet port

(3)

(see page 114)

HE10 (MIL 20)

connectors

.

1 TM221M Logic Controller Instruction Sheet

2 TM221M Logic Controller

3 Battery holder with lithium carbon monofluoride battery, type Panasonic BR2032.

4 Analog cable

EIO0000003313 02/2020 29

Page 30

M221 General Overview

Maximum Hardware Configuration

Introduction

The M221 Logic Controller is a control system that offers an all-in-one solution with optimized

configurations and an expandable architecture.

Local and Remote Configuration Principle

The following figure defines the local and remote configurations:

(1) Local configuration

(2) Remote configuration

M221 Logic Controller Local Configuration Architecture

Optimized local configuration and flexibility are provided by the association of:

M221 Logic Controller

TM3 expansion modules

TM2 expansion modules

Application requirements determine the architecture of your M221 Logic Controller configuration.

The following figure represents the components of a local configuration:

30

(B) Expansion modules (see maximum number of modules)

EIO0000003313 02/2020

Page 31

NOTE: You cannot mount a TM2 module before any TM3 module as indicated in the following

figure:

M221 Logic Controller Remote Configuration Architecture

Optimized remote configuration and flexibility are provided by the association of:

M221 Logic Controller

TM3 expansion modules

TM3 transmitter and receiver modules

Application requirements determine the architecture of your M221 Logic Controller configuration.

NOTE: You cannot use TM2 modules in configurations that include the TM3 transmitter and

receiver modules.

The following figure represents the components of a remote configuration:

M221 General Overview

(1) Logic controller and modules

(C) Expansion modules (7 maximum)

EIO0000003313 02/2020 31

Page 32

M221 General Overview

Maximum Number of Modules

The following table shows the maximum configuration supported:

References Maximum Type of Configuration

TM221C16•

TM221CE16•

TM221C24•

TM221CE24•

TM221C40•

TM221CE40•

TM221M16R•

TM221ME16R•

TM221M16T•

TM221ME16T•

TM221M32TK

TM221ME32TK

TM3XREC1 7 TM3 expansion modules Remote

NOTE: TM3 transmitter and receiver modules are not included in a count of the maximum number of

expansion modules.

NOTE: The configuration with its TM3 and TM2 expansion modules is validated by EcoStruxure

Machine Expert - Basic software in the Configuration window taking into account the total power

consumption of the installed modules.

NOTE: In some environments, the maximum configuration populated by high consumption

modules, coupled with the maximum distance allowable between the TM3 transmitter and receiver

modules, may present bus communication issues although the EcoStruxure Machine Expert Basic software allows for the configuration. In such a case you will need to analyze the

consumption of the modules chosen for your configuration, as well as the minimum cable distance

required by your application, and possibly seek to optimize your choices.

7 TM3 / TM2 expansion modules Local

32

EIO0000003313 02/2020

Page 33

Current Supplied to the I/O Bus

The following table shows the maximum current supplied by the controllers to the I/O Bus:

Reference IO Bus 5 Vdc IO Bus 24 Vdc

TM221C16R

TM221CE16R

TM221C16T

TM221CE16T

TM221C16U

TM221CE16U

TM221C24R

TM221CE24R

TM221C24T

TM221CE24T

TM221C24U

TM221CE24U

TM221C40R

TM221CE40R

TM221C40T

TM221CE40T

TM221C40U

TM221CE40U

TM221M16R•

TM221ME16R•

TM221M16T•

TM221ME16T•

TM221M32TK

TM221ME32TK

M221 General Overview

325 mA 120 mA

325 mA 148 mA

325 mA 148 mA

520 mA 160 mA

520 mA 200 mA

520 mA 200 mA

520 mA 240 mA

520 mA 304 mA

520 mA 304 mA

520 mA 460 mA

520 mA 492 mA

520 mA 484 mA

NOTE: Expansion modules consume current from the 5 Vdc and 24 Vdc supplied to the I/O Bus.

Therefore, the current delivered by the logic controller to the I/O Bus defines the maximum number

of expansion modules that can be connected to the I/O Bus (validated by EcoStruxure Machine

Expert - Basic software in the Configuration window).

EIO0000003313 02/2020 33

Page 34

M221 General Overview

TMC2 Cartridges

Overview

You can expand the number of I/Os or communication options of your Modicon TM221C Logic

Controller by adding TMC2 cartridges.

For more information, refer to the TMC2 Cartridges Hardware Guide.

TMC2 Standard Cartridges

The following table presents the general-purpose TMC2 cartridges with the corresponding channel

type, voltage/current range, and terminal type:

Reference Channels Channel Type Voltage

Current

TMC2AI2 2 Analog inputs

(voltage or current)

TMC2TI2 2 Analog temperature

inputs

TMC2AQ2V 2 Analog voltage

outputs

TMC2AQ2C 2 Analog current

outputs

(1)

TMC2SL1

(1) Only one serial line cartridge (TMC2SL1, TMC2CONV01) may be added to a logic controller.

1 Serial line RS232 or RS485 3.81 mm (0.15 in.)

0...10 Vdc

0...20 mA or 4...20 mA

Thermocouple type K, J,

R, S, B, E, T, N,C

3 wires RTD type Pt100,

Pt1000, Ni100, Ni1000

0...10 Vdc 3.81 mm (0.15 in.)

4...20 mA 3.81 mm (0.15 in.)

Terminal Type

3.81 mm (0.15 in.)

pitch, non-removable

screw terminal block

3.81 mm (0.15 in.)

pitch, non-removable

screw terminal block

pitch, non-removable

screw terminal block

pitch, non-removable

screw terminal block

pitch, non-removable

screw terminal block

34

EIO0000003313 02/2020

Page 35

TMC2 Application Cartridges

The following table presents the applicative TMC2 cartridges with the corresponding channel type,

voltage/current range, and terminal type:

M221 General Overview

Reference Channels Channel Type Voltage

Terminal Type

Current

TMC2HOIS01 2 Analog inputs

(voltage or current)

0...10 Vdc

0...20 mA or 4...20 mA

3.81 mm (0.15 in.)

pitch, non-removable

screw terminal block

TMC2PACK01 2 Analog inputs

(voltage or current)

0...10 Vdc

0...20 mA or 4...20 mA

3.81 mm (0.15 in.)

pitch, non-removable

screw terminal block

(1)

TMC2CONV01

1 Serial line RS232 or RS485 3.81 mm (0.15 in.)

pitch, non-removable

screw terminal block

(1) Only one serial line cartridge (TMC2SL1, TMC2CONV01) may be added to a logic controller.

EIO0000003313 02/2020 35

Page 36

M221 General Overview

TM3 Expansion Modules

Introduction

The range of TM3 expansion modules includes:

Digital modules, classified as follows:

Input modules

Output modules

Mixed input/output modules

Analog modules, classified as follows:

Input modules

Output modules

Mixed input/output modules

Expert modules

Safety modules

Transmitter and Receiver modules

For more information, refer to the following documents:

TM3 Digital I/O Modules Hardware Guide

TM3 Analog I/O Modules Hardware Guide

TM3 Expert I/O Modules Hardware Guide

TM3 Safety Modules Hardware Guide

TM3 Transmitter and Receiver Modules Hardware Guide

(see page 37)

(see page 40)

(see page 42)

(see page 43)

(see page 37)

(see page 39)

(see page 41)

(see page 42)

(seepage44)

36

EIO0000003313 02/2020

Page 37

TM3 Digital Input Modules

The following table shows the TM3 digital input expansion modules, with corresponding channel

type, nominal voltage/current, and terminal type:

M221 General Overview

Reference Channels Channel Type Voltage

TM3DI8A 8 Regular inputs 120 Vac

TM3DI8 8 Regular inputs 24 Vdc

TM3DI8G 8 Regular inputs 24 Vdc

TM3DI16 16 Regular inputs 24 Vdc

TM3DI16G 16 Regular inputs 24 Vdc

TM3DI16K 16 Regular inputs 24 Vdc

TM3DI32K 32 Regular inputs 24 Vdc

TM3 Digital Output Modules

The following table shows the TM3 digital output expansion modules, with corresponding channel

type, nominal voltage/current, and terminal type:

Reference Channels Channel Type Voltage

TM3DQ8R 8 Relay outputs 24 Vdc / 240 Vac

TM3DQ8RG 8 Relay outputs 24 Vdc / 240 Vac

TM3DQ8T 8 Regular transistor

TM3DQ8TG 8 Regular transistor

TM3DQ8U 8 Regular transistor

outputs (source)

outputs (source)

outputs (sink)

Terminal Type / Pitch

Current

Removable screw terminal block / 5.08 mm

7.5 mA

Removable screw terminal block / 5.08 mm

7mA

Removable spring terminal block / 5.08 mm

7mA

Removable screw terminal blocks / 3.81 mm

7mA

Removable spring terminal blocks / 3.81 mm

7mA

HE10 (MIL 20) connector

5mA

HE10 (MIL 20) connector

5mA

Current

7 A maximum per common line /

2 A maximum per output

7 A maximum per common line /

2 A maximum per output

24 Vdc

4 A maximum per common

line/0.5 A maximum per output

24 Vdc

4 A maximum per common

line/0.5 A maximum per output

24 Vdc

4 A maximum per common

line/0.5 A maximum per output

Terminal Type / Pitch

Removable screw

terminal block /

5.08 mm

Removable spring

terminal block /

5.08 mm

Removable screw

terminal block /

5.08 mm

Removable spring

terminal block /

5.08 mm

Removable screw

terminal block /

5.08 mm

EIO0000003313 02/2020 37

Page 38

M221 General Overview

Reference Channels Channel Type Voltage

Current

TM3DQ8UG 8 Regular transistor

outputs (sink)

24 Vdc

4 A maximum per common

line/0.5 A maximum per output

TM3DQ16R 16 Relay outputs 24 Vdc / 240 Vac

8 A maximum per common line /

2 A maximum per output

TM3DQ16RG 16 Relay outputs 24 Vdc / 240 Vac

8 A maximum per common line /

2 A maximum per output

TM3DQ16T 16 Regular transistor

outputs (source)

24 Vdc

8 A maximum per common line /

0.5 A maximum per output

TM3DQ16TG 16 Regular transistor

outputs (source)

24 Vdc

8 A maximum per common line /

0.5 A maximum per output

TM3DQ16U 16 Regular transistor

outputs (sink)

24 Vdc

8 A maximum per common line /

0.5 A maximum per output

TM3DQ16UG 16 Regular transistor

outputs (sink)

24 Vdc

8 A maximum per common line /

0.5 A maximum per output

TM3DQ16TK 16 Regular transistor

outputs (source)

24 Vdc

2 A maximum per common line /

0.1 A maximum per output

TM3DQ16UK 16 Regular transistor

outputs (sink)

24 Vdc

2 A maximum per common line /

0.1 A maximum per output

TM3DQ32TK 32 Regular transistor

outputs (source)

24 Vdc

2 A maximum per common line /

0.1 A maximum per output

TM3DQ32UK 32 Regular transistor

outputs (sink)

24 Vdc

2 A maximum per common line /

0.1 A maximum per output

Terminal Type / Pitch

Removable spring

terminal block /

5.08 mm

Removable screw

terminal blocks /

3.81 mm

Removable spring

terminal blocks /

3.81 mm

Removable screw

terminal blocks /

3.81 mm

Removable spring

terminal blocks /

3.81 mm

Removable screw

terminal blocks /

3.81 mm

Removable spring

terminal blocks /

3.81 mm

HE10 (MIL 20)

connector

HE10 (MIL 20)

connector

HE10 (MIL 20)

connectors

HE10 (MIL 20)

connectors

38

EIO0000003313 02/2020

Page 39

TM3 Digital Mixed Input/Output Modules

This following table shows the TM3 mixed I/O modules, with corresponding channel type, nominal

voltage/current, and terminal type:

M221 General Overview

Reference Channels Channel Type Voltage

Current

TM3DM8R 4 Regular inputs 24 Vdc

7mA

4 Relay outputs 24 Vdc / 240 Vac

7 A maximum per common line / 2 A

maximum per output

TM3DM8RG 4 Regular inputs 24 Vdc

7mA

4 Relay outputs 24 Vdc / 240 Vac

7 A maximum per common line / 2 A

maximum per output

TM3DM24R 16 Regular inputs 24 Vdc

7mA

8 Relay outputs 24 Vdc / 240 Vac

7 A maximum per common line / 2 A

maximum per output

TM3DM24RG 16 Regular inputs 24 Vdc

7mA

8 Relay outputs 24 Vdc / 240 Vac

7 A maximum per common line / 2 A

maximum per output

Terminal Type / Pitch

Removable screw

terminal block /

5.08 mm

Removable spring

terminal block /5.08 mm

Removable screw

terminal

blocks / 3.81 mm

Removable spring

terminal

blocks / 3.81 mm

EIO0000003313 02/2020 39

Page 40

M221 General Overview

TM3 Analog Input Modules

The following table shows the TM3 analog input expansion modules, with corresponding

resolution, channel type, nominal voltage/current, and terminal type:

Reference Resolution Channels Channel

Type

TM3AI2H 16 bit, or

15 bit + sign

TM3AI2HG 16 bit, or

15 bit + sign

TM3AI4 12 bit, or

11 bit + sign

TM3AI4G 12 bit, or

11 bit + sign

TM3AI8 12 bit, or

11 bit + sign

TM3AI8G 12 bit, or

11 bit + sign

TM3TI4 16 bit, or

15 bit + sign

2 inputs 0...10 Vdc

2 inputs 0...10 Vdc

4 inputs 0...10 Vdc

4 inputs 0...10 Vdc

8 inputs 0...10 Vdc

8 inputs 0...10 Vdc

4 inputs 0...10 Vdc

Mode Terminal Type / Pitch

Removable screw terminal block /

-10…+10 Vdc

0...20 mA

4...20 mA

-10…+10 Vdc

0...20 mA

4...20 mA

-10…+10 Vdc

0...20 mA

4...20 mA

-10…+10 Vdc

0...20 mA

4...20 mA

-10…+10 Vdc

0...20 mA

4...20 mA

0...20 mA

extended

4...20 mA

extended

-10…+10 Vdc

0...20 mA

4...20 mA

0...20 mA

extended

4...20 mA

extended

-10…+10 Vdc

0...20 mA

4...20 mA

Thermocouple

PT100/1000

NI100/1000

5.08 mm

Removable spring terminal block /

5.08 mm

Removable screw terminal block /

3.81 mm

Removable spring terminal blocks

/ 3.81 mm

Removable screw terminal block /

3.81 mm

Removable spring terminal blocks

/ 3.81 mm

Removable screw terminal block /

3.81 mm

40

EIO0000003313 02/2020

Page 41

M221 General Overview

Reference Resolution Channels Channel

TM3TI4G 16 bit, or

15 bit + sign

TM3TI4D 16 bit, or

15 bit + sign

TM3TI4DG 16 bit, or

15 bit + sign

TM3TI8T 16 bit, or

15 bit + sign

TM3TI8TG 16 bit, or

15 bit + sign

TM3 Analog Output Modules

The following table shows the TM3 analog output modules, with corresponding resolution, channel

type, nominal voltage/current, and terminal type:

Reference Resolution Channels Channel

TM3AQ2 12 bit, or

11 bit + sign

TM3AQ2G 12 bit, or

11 bit + sign

TM3AQ4 12 bit, or

11 bit + sign

TM3AQ4G 12 bit, or

11 bit + sign

Mode Terminal Type / Pitch

Type

4 inputs 0...10 Vdc

-10…+10 Vdc

0...20 mA

4...20 mA

Thermocouple

PT100/1000

NI100/1000

4 inputs Thermocouple Removable screw terminal block /

4 inputs Thermocouple Removable spring terminal blocks

8 inputs Thermocouple

NTC/PTC

Ohmmeter

8 inputs Thermocouple

NTC/PTC

Ohmmeter

Mode Terminal Type / Pitch

Type

2 outputs 0...10 Vdc

-10…+10 Vdc

0...20 mA

4...20 mA

2 outputs 0...10 Vdc

-10…+10 Vdc

0...20 mA

4...20 mA

4 outputs 0...10 Vdc

-10…+10 Vdc

0...20 mA

4...20 mA

4 outputs 0...10 Vdc

-10…+10 Vdc

0...20 mA

4...20 mA

Removable spring terminal blocks

/ 3.81 mm

3.81 mm

/ 3.81 mm

Removable screw terminal block /

3.81 mm

Removable spring terminal blocks

/ 3.81 mm

Removable screw

terminal block /

5.08 mm

Removable spring

terminal block /

5.08 mm

Removable screw

terminal block /

5.08 mm

Removable spring

terminal block /

5.08 mm

EIO0000003313 02/2020 41

Page 42

M221 General Overview

TM3 Analog Mixed Input/Output Modules

This following table shows the TM3 analog mixed I/O modules, with corresponding resolution,

channel type, nominal voltage/current, and terminal type:

Reference Resolution Channels Channel

Type

TM3AM6 12 bit, or

11 bit + sign

TM3AM6G 12 bit, or

11 bit + sign

TM3TM3 16 bit, or

15 bit + sign

12 bit, or

11 bit + sign

TM3TM3G 16 bit, or

15 bit + sign

12 bit, or

11 bit + sign

4 inputs 0...10 Vdc

2 outputs

4 inputs 0...10 Vdc

2 outputs

2 inputs 0...10 Vdc

1 outputs 0...10 Vdc

2 inputs 0...10 Vdc

1 outputs 0...10 Vdc

Mode Terminal Type / Pitch

Removable screw

-10...+10 Vdc

0...20 mA

4...20 mA

-10...+10 Vdc

0...20 mA

4...20 mA

-10...+10 Vdc

0...20 mA

4...20 mA

Thermocouple

PT100/1000

NI100/1000

-10...+10 Vdc

0...20 mA

4...20 mA

-10...+10 Vdc

0...20 mA

4...20 mA

Thermocouple

PT100/1000

NI100/1000

-10...+10 Vdc

0...20 mA

4...20 mA

terminal block /

3.81 mm

Removable spring

terminal block /

3.81 mm

Removable screw

terminal block /

5.08 mm

Removable spring

terminal block /

5.08 mm

TM3 Expert Module

The following table shows the TM3 expert expansion module, with corresponding terminal types:

Reference Description Terminal Type / Pitch

TM3XTYS4 TeSys module 4 front connectors RJ-45

42

1 removable power supply connector / 5.08 mm

EIO0000003313 02/2020

Page 43

TM3 Safety Modules

This table contains the TM3 safety modules

Guide)

, with the corresponding channel type, nominal voltage/current, and terminal type:

M221 General Overview

(see Modicon TM3, Safety Modules, Hardware

Reference Function

Category

TM3SAC5R 1 function,

up to

category 3

TM3SAC5RG 1 function,

up to

category 3

TM3SAF5R 1 function,

up to

category 4

TM3SAF5RG 1 function,

up to

category 4

TM3SAFL5R 2 functions,

up to

category 3

TM3SAFL5RG 2 functions,

up to

category 3

(1)

Depending on external wiring

(2)

Non-monitored start

Channels Channel type Voltage

Current

(1)

1 or 2

(2)

Start

3 in parallel Relay outputs

Safety input 24 Vdc

Input

100 mA maximum

24 Vdc / 230 Vac

Normally open

6 A maximum per

output

(1)

1 or 2

(2)

Start

3 in parallel Relay outputs

Safety input 24 Vdc

Input

100 mA maximum

24 Vdc / 230 Vac

Normally open

6 A maximum per

output

(1)

2

Start Input

3 in parallel Relay outputs

Safety inputs 24 Vdc

100 mA maximum

24 Vdc / 230 Vac

Normally open

6 A maximum per

output

(1)

2

Start Input

3 in parallel Relay outputs

Safety inputs 24 Vdc

100 mA maximum

24 Vdc / 230 Vac

Normally open

6 A maximum per

output

(1)

2

Start Input

3 in parallel Relay outputs

Safety inputs 24 Vdc

100 mA maximum

24 Vdc / 230 Vac

Normally open

6 A maximum per

output

(1)

2

Start Input

3 in parallel Relay outputs

Safety inputs 24 Vdc

100 mA maximum

24 Vdc / 230 Vac

Normally open

6 A maximum per

output

Terminal type

3.81 mm (0.15 in.) and

5.08 mm (0.20 in.),

removable screw

terminal block

3.81 mm (0.15 in.) and

5.08 mm (0.20 in.),

removable spring

terminal block

3.81 mm (0.15 in.) and

5.08 mm (0.20 in.),

removable screw

terminal block

3.81 mm (0.15 in.) and

5.08 mm (0.20 in.),

removable spring

terminal block

3.81 mm (0.15 in.) and

5.08 mm (0.20 in.),

removable screw

terminal block

3.81 mm (0.15 in.) and

5.08 mm (0.20 in.),

removable spring

terminal block

EIO0000003313 02/2020 43

Page 44

M221 General Overview

Reference Function

Channels Channel type Voltage

Category

TM3SAK6R 3 functions,

up to

category 4

(1)

1 or 2

Start Input

3 in parallel Relay outputs

TM3SAK6RG 3 functions,

up to

category 4

(1)

1 or 2

Start Input

3 in parallel Relay outputs

(1)

Depending on external wiring

(2)

Non-monitored start

TM3 Transmitter and Receiver Modules

The following table shows the TM3 transmitter and receiver expansion modules:

Reference Description Terminal Type / Pitch

TM3XTRA1 Data transmitter module for remote I/O 1 front connector RJ-45

TM3XREC1 Data receiver module for remote I/O 1 front connector RJ-45

Current

Safety inputs 24 Vdc

100 mA maximum

24 Vdc / 230 Vac

Normally open

6 A maximum per

output

Safety inputs 24 Vdc

100 mA maximum

24 Vdc / 230 Vac

Normally open

6 A maximum per

output

1 screw for functional ground connection

Power supply connector / 5.08 mm

Terminal type

3.81 mm (0.15 in.) and

5.08 mm (0.20 in.),

removable screw

terminal block

3.81 mm (0.15 in.) and

5.08 mm (0.20 in.),

removable spring

terminal block

44

EIO0000003313 02/2020

Page 45

TM2 Expansion Modules

Overview

You can expand the number of I/Os of your M221 Logic Controller by adding TM2 I/O expansion

modules.

The following types of electronic modules are supported:

TM2 digital I/O expansion modules

TM2 analog I/O expansion modules

For more information, refer to the following documents:

TM2 Digital I/O Expansion Modules Hardware Guide

TM2 Analog I/O Expansion Modules Hardware Guide

NOTE: TM2 modules can only be used in the local configuration, and only if there is no TM3

transmitter and receiver modules present in the configuration.

NOTE: It is prohibited to mount a TM2 module before any TM3 module. The TM2 modules must

be mounted and configured at the end of the local configuration.

TM2 Digital Input Expansion Modules

The following table shows the compatible TM2 digital input expansion modules with the

corresponding channel type, nominal voltage/current, and terminal type:

M221 General Overview

Reference Channels Channel Type Voltage

Current

TM2DAI8DT 8 Regular inputs 120 Vac

7.5 mA

TM2DDI8DT 8 Regular inputs 24 Vdc

7mA

TM2DDI16DT 16 Regular inputs 24 Vdc

7mA

TM2DDI16DK 16 Regular inputs 24 Vdc

5mA

TM2DDI32DK 32 Regular inputs 24 Vdc

5mA

EIO0000003313 02/2020 45

Terminal Type

Removable screw terminal block

Removable screw terminal block

Removable screw terminal block

HE10 (MIL 20) connector

HE10 (MIL 20) connector

Page 46

M221 General Overview

TM2 Digital Output Expansion Modules

The following table shows the compatible TM2 digital output expansion modules with the

corresponding channel type, nominal voltage/current, and terminal type:

Reference Channels Channel type Voltage

TM2DRA8RT 8 Relay outputs 30 Vdc / 240 Vac

TM2DRA16RT 16 Relay outputs 30 Vdc / 240 Vac

TM2DDO8UT 8 Regular transistor

outputs (sink)

TM2DDO8TT 8 Regular transistor

outputs (source)

TM2DDO16UK 16 Regular transistor

outputs (sink)

TM2DDO16TK 16 Regular transistor

outputs (source)

TM2DDO32UK 32 Regular transistor

outputs (sink)

TM2DDO32TK 32 Regular transistor

outputs (source)

TM2 Digital Mixed Input/Output Expansion Modules

The following table shows the compatible TM2 digital mixed I/O expansion modules with the

corresponding channel type, nominal voltage/current, and terminal type:

Reference Channels Channel type Voltage

TM2DMM8DRT 4 Regular inputs 24 Vdc

4 Relay outputs 24 Vdc / 240 Vac

TM2DMM24DRF 16 Regular inputs 24 Vdc

8 Relay outputs 24 Vdc / 240 Vac

Terminal type

Current

Removable screw terminal

2 A max

2 A max

24 Vdc

0.3 A max per output

24 Vdc

0.5 A max per output

24 Vdc

0.1 A max per output

24 Vdc

0.4 A max per output

24 Vdc

0.1 A max per output

24 Vdc

0.4 A max per output

Current

7mA

7 A maximum per common line /

2 A maximum per output

7 mA

7 A maximum per common line /

2 A maximum per output

block

Removable screw terminal

block

Removable screw terminal

block

Removable screw terminal

block

HE10 (MIL 20) connector

HE10 (MIL 20) connector

HE10 (MIL 20) connector

HE10 (MIL 20) connector

Terminal type

Removable screw

terminal block

Non-removable

spring terminal

block

46

EIO0000003313 02/2020

Page 47

TM2 Analog Input Expansion Modules

The following table shows the compatible TM2 analog input expansion modules with the

corresponding channel type, nominal voltage/current, and terminal type:

M221 General Overview

Reference Channels Channel type Voltage

TM2AMI2HT 2 High-level inputs 0...10 Vdc

TM2AMI2LT 2 Low-level inputs Thermocouple type

TM2AMI4LT 4 Analog inputs 0...10 Vdc

TM2AMI8HT 8 Analog inputs 0...20 mA

TM2ARI8HT 8 Analog inputs NTC / PTC Removable screw terminal block

TM2ARI8LRJ 8 Analog inputs PT100/1000 RJ11 connector

TM2ARI8LT 8 Analog inputs PT100/1000 Removable screw terminal block

TM2 Analog Output Expansion Modules

The following table shows the compatible TM2 analog output expansion modules with the

corresponding channel type, nominal voltage/current, and terminal type:

Reference Channels Channel type Voltage

TM2AMO1HT 1 Analog outputs 0...10 Vdc

TM2AVO2HT 2 Analog outputs +/- 10 Vdc Removable screw terminal block

Terminal Type

Current

Removable screw terminal block

4...20 mA

Removable screw terminal block

J,K,T

Removable screw terminal block

0...20 mA

PT100/1000

Ni100/1000

Removable screw terminal block

0...10 Vdc

Terminal Type

Current

Removable screw terminal block

4...20 mA

EIO0000003313 02/2020 47

Page 48

M221 General Overview

TM2 Analog Mixed Input/Output Expansion Modules

The following table shows the compatible TM2 analog mixed I/O expansion modules with the

corresponding channel type, nominal voltage/current, and terminal type:

Reference Channels Channel type Voltage

Current

TM2AMM3HT 2 Analog inputs 0...10 Vdc 4...20 mA Removable screw terminal block

1 Analog outputs 0...10 Vdc 4...20 mA

TM2AMM6HT 4 Analog inputs 0...10 Vdc 4...20 mA Removable screw terminal block

2 Analog outputs 0...10 Vdc 4...20 mA

TM2ALM3LT 2 Low-level inputs Thermo J,K,T, PT100 Removable screw terminal block

1 Analog outputs 0...10 Vdc 4...20 mA

Terminal Type

48

EIO0000003313 02/2020

Page 49

M221 General Overview

Accessories

Overview

This section describes the accessories, cables, and Telefast.

Accessories

Reference Description Use Quantity

TMASD1 SD Card

TMAT2MSET Set of 8 removable screw terminal

blocks:

4 x Removable screw terminal

4 x Removable screw terminal

TMAT2MSETG Set of 8 removable spring terminal

blocks:

4 x Removable spring terminal

4 x Removable spring terminal

TMAT2PSET Set of 5 removable screw terminal

block

AB1AB8P35 End brackets Help secure the logic controller or