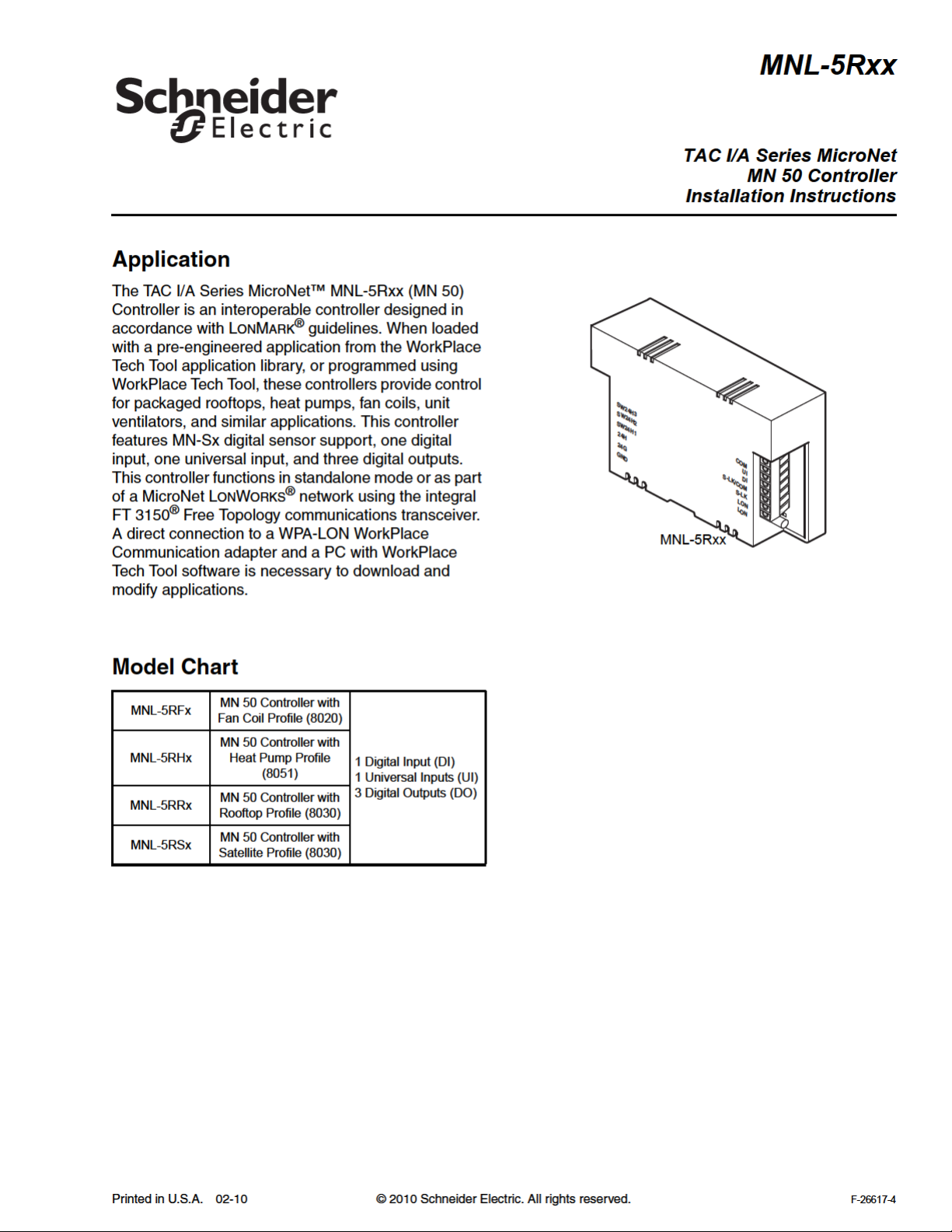

Schneider Electric MNL-5Rxx Installation Instructions

Applicable Documentation

F-Number Description Audience Purpose

– Application Engineers

– Installers

– Service Personnel

– Start-up Technicians

– Application engineers

– Installers

– Start-up technicians

– Service personnel

– Application Engineers

– Installers

– Service Personnel

– Start-up Technicians

– Application Engineers

– Installers

– Service Personnel

– Start-up Technicians

– Application Engineers

– Installers

– Service Personnel

– Start-up Technicians

– Application Engineers

– Installers

– Service Personnel

Provides step-by-step installation and checkout procedures for TAC

I/A Series MicroNet MN-Sx Series Sensors. Also contains

instructions for sensor operation.

Provides an overview of the TAC I/A Series MicroNet System. It

includes brief descriptions of the hardware and software components,

and how they may be combined to create MicroNet networks and

stand-alone systems.

Provides engineering and technical information for applying and

using all aspects of WorkPlace Tech Tool.

Provides engineering and technical information to assist in

designing a complete MicroNet controller system using different

architectures, components, and software.

Provides step-by-step instructions for using WorkPlace Tech Tool.

Offers guidelines for avoiding equipment damage associated with

improperly wiring devices of varying rectifier types. Contains

instructions for identifying device rectifier type, guidelines for

correctly powering devices of varying rectifier types, and examples

illustrating proper power wiring techniques.

F-26277

F-26303

F-27254

F-26507

F-27255

F-26363

TAC I/A Series MicroNet

MN-Sx Series Sensors

General Instructions

TAC I/A Series MicroNet

System Overview

WorkPlace Tech Tool 4.0

Engineering Guide

TAC I/A Series MicroNet

Systems Engineering

Guide

WorkPlace Tech Tool 4.0

User’s Guide

EN-206 Guidelines for

Powering Multiple FullWave and Half-Wave

Rectifier Devices from a

Common Transformer

Installation

Inspection Inspect carton for damage. If damaged, notify carrier immediately. Inspect controllers for

damage upon receipt.

Requirements

(These items not provided)

• Installer must be a qualified technician

• Job wiring diagrams

• To o ls :

– Digital Volt-ohm meter (DVM)

– Drill and bits for mounting screw

– Static protection wrist strap

• MNA-FLO-1 enclosure for connecting to conduit (optional)

• Class 2 power transformer supplying a nominal 24 VAC (20.4 to 30 VAC) with a

minimum rating of 12 VA, 50/60 Hz per controller, plus Digital Output (DO). Each DO

can be up to an additional 24VA maximum. In European Community, transformer must

conform to EN 60742

• Terminators:

– One LON-TERM1 terminator required for each free topology segment

– Two LON-TERM2 terminators required for each bus topology segment

• Two #10 sheet metal screws

2 © 2010 Schneider Electric. All rights reserved.

F-26617-4

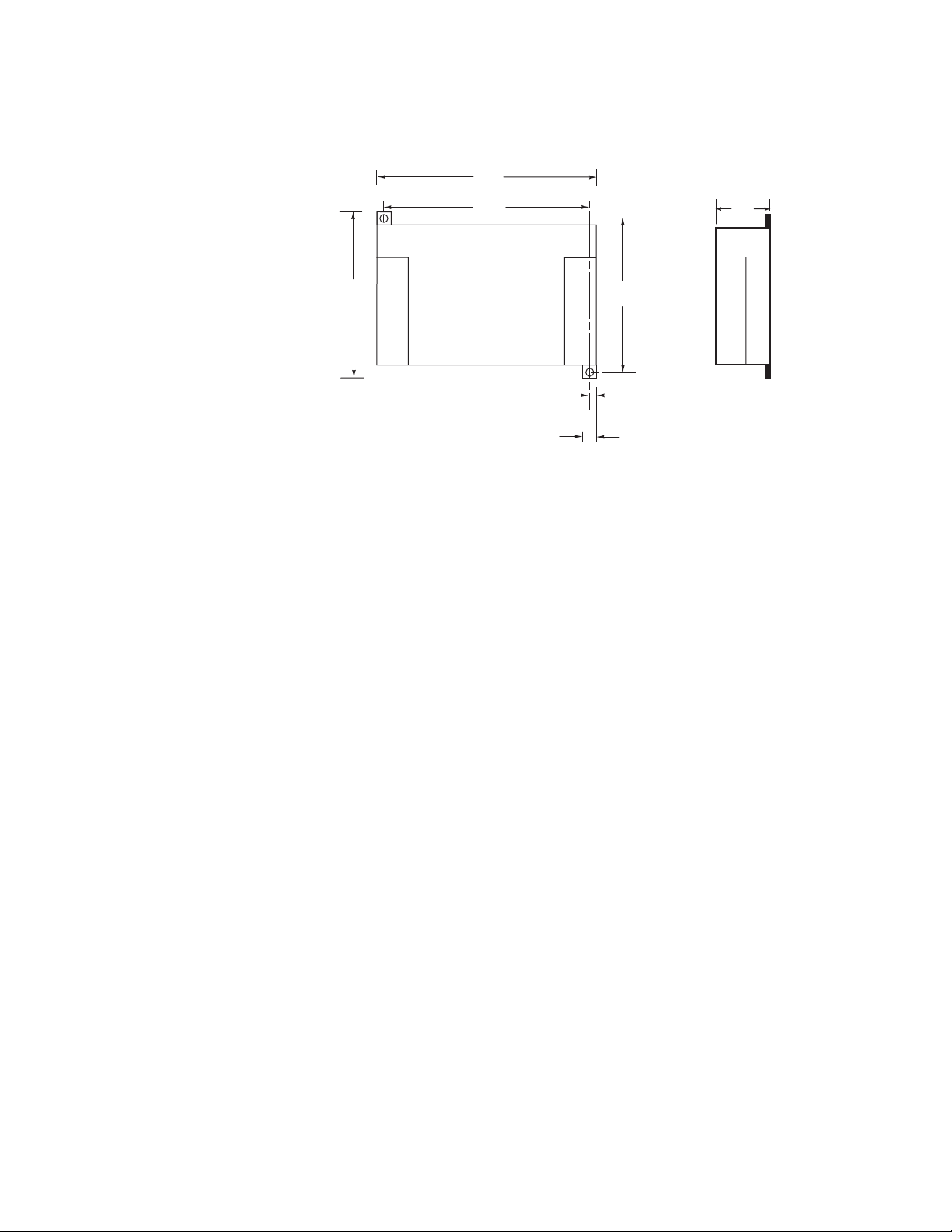

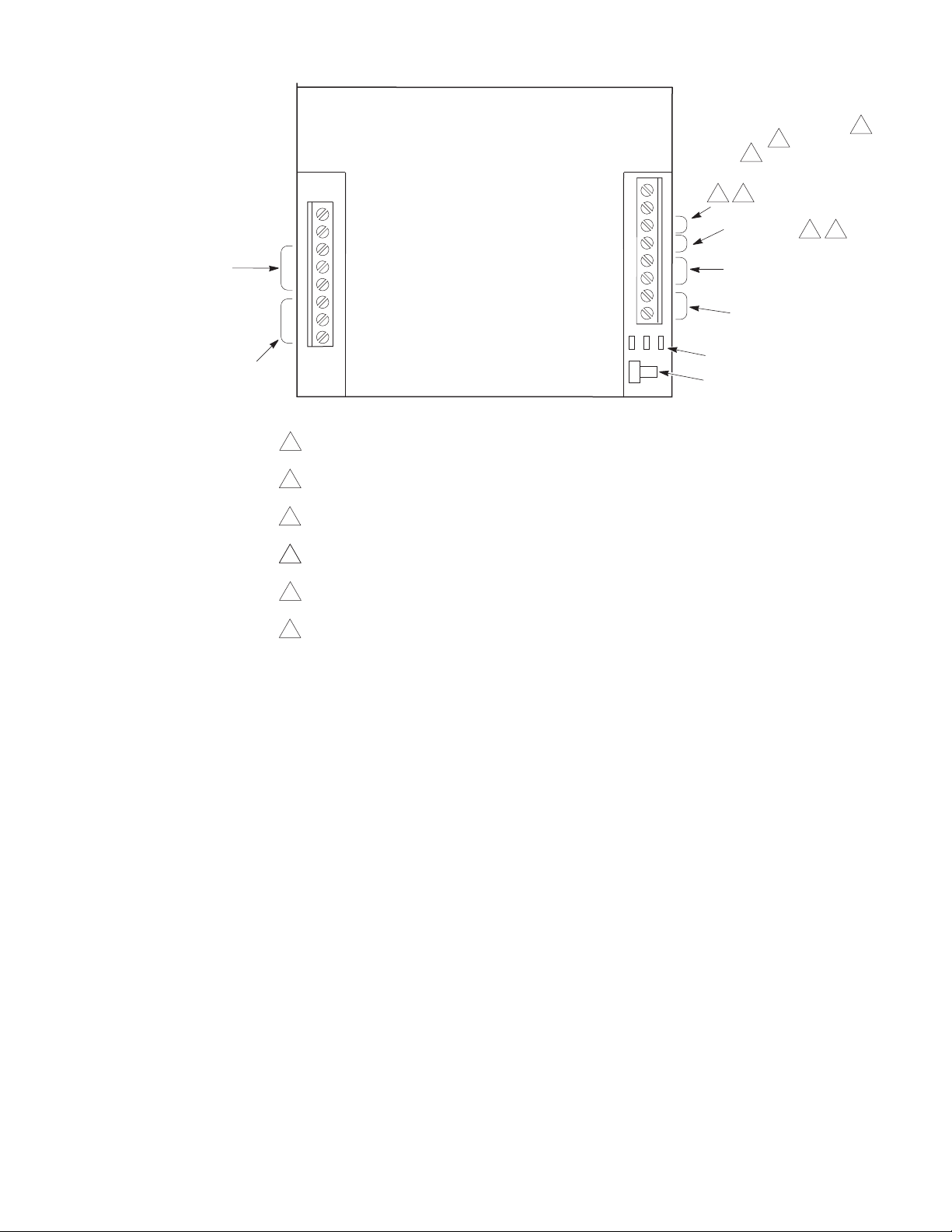

Mounting

MN 50 controllers can be mounted in any direction and on any plane. Mounting dimensions

are shown in Figure-1

5

(127)

4-19/32

(118)

1-19/32

(41)

Wiring

4-13/32

(112)

4

(102)

3/16

(5)

3/8

(10)

Dimensions shown

are in inches (mm).

Figure-1 Mounting Dimensions.

The following electrical connections can be made to TAC I/A Series MicroNet MN 50

controllers:

• Sensor Link (S-Link) connection to a TAC I/A Series MicroNet Sensor (MN-Sx)

• MicroNet LONWORKS network (LON

®

) connection

• LONWORKS network connection from controller to a TAC I/A Series MicroNet Sensor

• I/O connections including:

– One Universal Input (UI)

– One Digital Input (DI)

– Three Digital Outputs (DO)

• Power connection to a 24 VAC nominal Class 2 (EN 60742) power source and earth

ground.

See Figure-2 for wiring terminal information.

4 © 2010 Schneider Electric. All rights reserved.

F-26617-4

Universal Input

0 to 5 Vdc

0 to 20mA

10K Thermistor

1K Balco

1K Platinum

Digital Input (Dry

Contact)

S-Link

Supports one

TAC I/A Series

MN-Sx Sensor

L

ONWORKS Network

Communications

FT 3150 Transceiver

Service Pin Button

AC Power

24 Vac, 50/60 Hz

Class 2

12 VA per Controller

plus DO Loads

Digital Outputs

24 Vac, Class 2,

24 VA per output

Pilot Duty

Form A

Single Pole, Single Throw

Normally Open Relay

Digital Input

Dry Contact

Controller LEDs

COM

UI

DI

S-LK/COM

S-LK

LON

LON

SW24H3

SW24H2

SW24H1

24H

24G(COM)

GND

5

Applications which use a 10K Thermistor Sensor (non-850 series) universal input require

an 11K ohms shunt resistor kit, AD-8969-206. Install resistor across universal input and common.

4

Applications which use 0 to 20 mA analog inputs require a 250 ohms shunt resistor kit,

AD-8969-202. Install resistor across universal input and common.

To detect a closed switch, maximum resistance must be less than 300 ohms.

To detect an open switch, minimum resistance must be greater than 1.5K ohms.

1

2

Input signals of 1 to 11 Vdc must be converted to 0.45 to 5 Vdc with a voltage

divider, AD-8961-220.

3

6

To detect an open switch, minimum resistance must be greater than 100K ohms.

2

1

6

1

4

3

5

Figure-2 MN 50 Terminal Connections.

F-26617-4

© 2010 Schneider Electric. All rights reserved. 5

Loading...

Loading...