Page 1

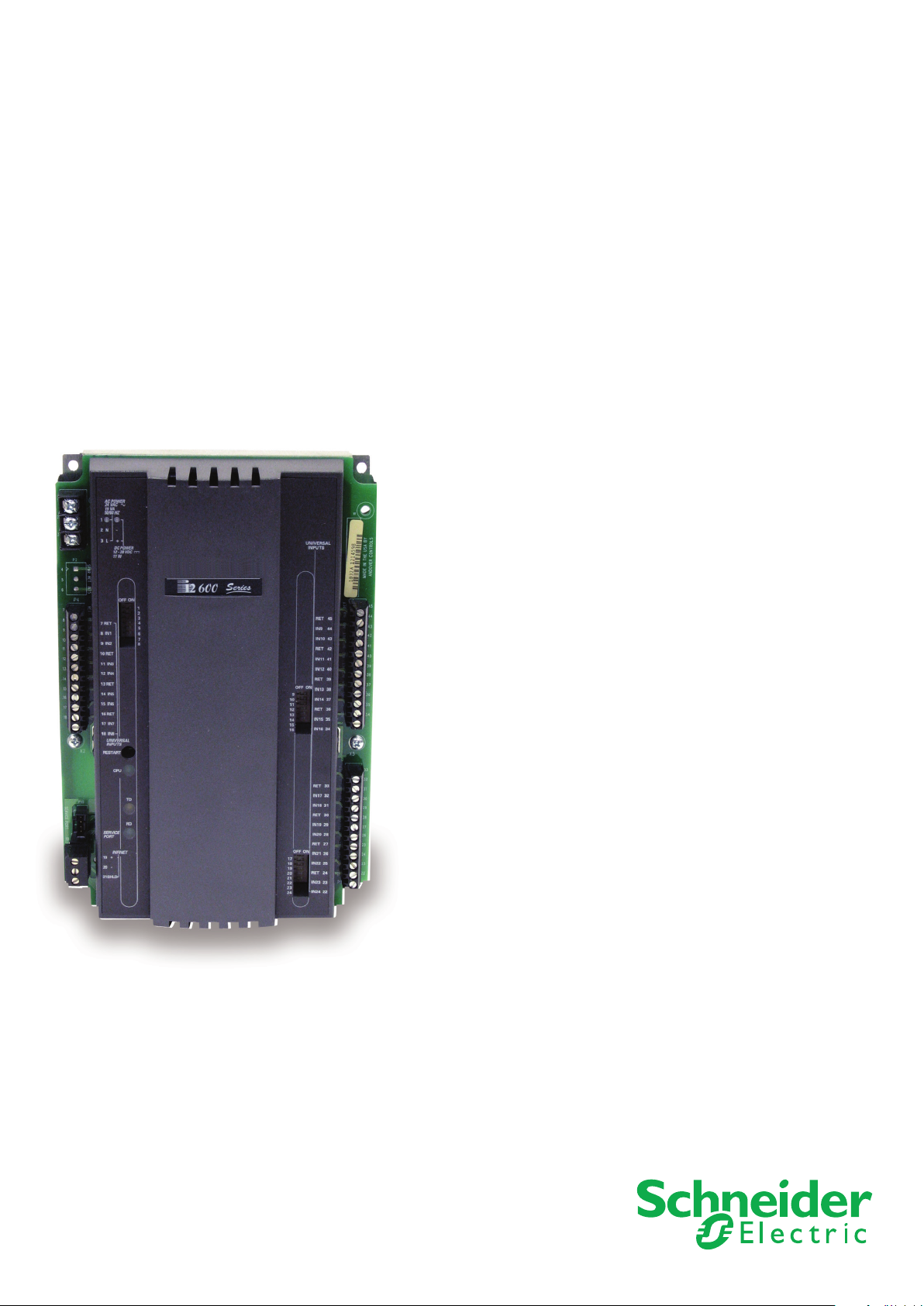

Andover ContinuumTM

Infinet II

i2600 Series Local

The i2600 Series controllers are designed for monitoring a small

or large concentration of input points from a single controller.

Page 2

Andover Continuum Infi net II i2600

Series Local Controllers

Features

PRODUCT AT A GLANCE

• Comp act, C ost-Effe ctive I nput

Moni toring Control ler

• Powerful , Flexib le Syst em Cont roller for

the Most Demanding Applications

• Idea l for Monito ring Small or Large Grou ps of

Inputs in a Concentrated Area

• Univ ersal I nputs C an be C onfigu red as a

Supe rvised Input for M onitori ng Open Wires

or Short Circuits

• Non-Vola tile Fl ash Mem ory Prov ides U tmost

Reli ability — Stor es Both Applic ation P rogram

and Operating System

• Local, Extended Storage of Log Data

• Local, On-Board Service Port

02

Choose the i2600 model with the

input confi guration that matches

your application:

• The i2608, with eight universal inputs, is

designed for stand-alone equipment monitoring

for a small concentration of input points. This

controller is also confi gurable for supervised input

monitoring to determine broken wire detection or

shorts. The i2608 is ideal for security applications

(motion detection, glass break detection,

intrusion detection) or traditional control

applications (e.g. temperature, humidity).

•

The i2624 provides the same functionality as

the i2608 and in the same small footprint of

the i2608, but with three times the number of

input points (24) for monitoring various device

signals. With the small footprint and high point

count, the i2624 is ideal for large concentration

of inputs, reducing the number of controllers

required in the system, and decreasing cost,

complexity, and maintenance requirements.

The i2600 Series also features Flash memory,

increased user memory, and a fast (32-bit) processor

for faster scan times, with plenty of memory available

for data logging of your critical data.

The i2600 Series communicates with the entire

Andover Continuum Infi net RS-485 fi eld bus (i.e.

both Andover Continuum Infi net and Andover

Continuum Infi net II controllers) and is compatible

with the Continuum CyberStation front-end. Up to

254 Andover In net devices can be networked to

any Andover Continuum network controller.

Schneider Electric

SDS-I2600-A4.BU.N.EN.

11.2007.0.00.CC

Page 3

Andover Continuum Infinet II i2600

Series Local Controllers

03

Features

(continued)

Increased Reliability with Flash Memory

The i2600’s non-volatile Flash memory stores your

operating system and application programs, so that

in the event of a power loss, your application will

be restored when power is returned. In addition,

the Flash memory allows for easy upgrades of

your operating system via software downloads,

eliminating the need to swap out proms.

The i2600 Series controllers include an onboard battery to safeguard your runtime data —

protecting all point data and log data from being

lost if power is removed.

Inputs

The input conguration on the i2600 Series

consists of eight (or twenty-four) full range, 10-bit

universal inputs that accept voltage (0-5VDC),

digital (on/off), counter signals (up to 4Hz),

temperature signals, or supervised alarm circuits

for security applications or broken wire detection.

Dimensional Drawings

1

3

4

Software Capabilities

The dynamic memory of a i2600 controller can

be allocated for any combination of programs,

scheduling, alarming, and data logging using

the powerful Andover Continuum Plain English

programming language.

Our object-oriented Plain English language with

intuitive keywords provides an easy method to tailor

the controller to meet your exact requirements.

Programs are entered into the i2600 using the

Andover Continuum CyberStation. Programs are then

stored and executed by the i2600 controllers.

Programming multiple i2600 Series controllers

is inherently easy with Plain English. A complete

copy of one i2600 controller’s programs can be

loaded directly into other i2600 controllers without

changing any point names or programs.

TM

2

Schneider Electric

SDS-I2600-A4.BU.N.EN.

11.2007.0.00.CC

Page 4

Andover Continuum Infinet II i2600

Series Local Controllers

04

Features

(continued)

Optional Wireless Andover Continuum

Infinet

The i2600 Andover Continuum Innet controllers

can also communicate using a wireless mesh

network. Simply plug Andover Continuum Wireless

Adapters into the service ports of these controllers

with wireless compatible firmware to create a

wireless mesh network that sends and receives

Andover Continuum Infinet messages.

Dimensional Drawings

1

Power Drawing

2

Communi cations

Drawing

Sc

hneider Electric

SDS-I2600-A4.BU.N.EN.11.2007.0.00.CC

3

i2608 an d i2624

Input Drawing

i2624

4

Page 5

05

Andover Continuum Infinet II i2600

Series Local Controllers

Specifications

i2600 Series Local Controllers

Electrical

Power

24VAC, 12-24VDC - auto sensing,

+10% -15%, 50/60 Hz

Power Consumption

25 VA

Overload Protection

Fused with 3 amp fuse. MOV protected

Software Real-Time Clock

Synchronized through Andover

Continuum Innet by network controller

Mechanical

Operating Environment

32°–120°F (0–49°C),

10–95% RH (non-condensing)

Size

9.03˝ H x 6.01˝ W x 2.14˝ D

(229 H x 153 W x 54 D) mm

Weight

1.19 lbs. (.54 kg)

Enclosure Type

UL Open class, IP 10.

Flammability rating of UL94-5V

Mounting

Panel mount

Battery

Battery Backup

Replaceable, non-rechargeable,

lithium battery. Provides 5 years typical

accumulated power failure backup of

RAM memory

Communications

Communications Interface

Through Andover Continuum Infinet

RS-485 field bus to network controller

Communications Speed

1200 to 19.2K baud

Bus Length

4,000 ft. (1,220m) standard for Andover

Continuum Innet, i2 Inlink module

allows extension to longer distances and

is required after every group of 32 units

on the network.

Bus Media

Andover Continuum Infinet:

twisted, shielded pair,

low capacitance cable

RS-485 port for implementing Wireless

Andover Continuum Infinet II

connection, including:

Standard service port, four-position

shrouded connector

Comm. Error Checking

International Standard CRC 16

Compatibility

Andover Continuum CyberStation

Version 1.5 or greater

05

Inputs

Inputs

i2608: 8 Universal inputs

i2624: 24 Universal inputs

Voltage (0-5.115 VDC); Temperature -30°F

to 230°F (-34°C to 110°C), Digital (on/off),

Counter (up to 4Hz at 50% duty cycle,

125 ms min. pulse width).

Supervised Alarm (single or double resistor).

Current input (0 - 20 mA) using external

250 ohm resistor

Input Voltage Range

0-5.115 volts DC

Input Impedance

10K ohm to 5.120V or 5M ohm

with pull-up resistor disabled

Input Resolution

5.0 mV

Input Accuracy

±15mV (±0.56°C from -23°C to +66°C or

±1°F from -10°F to +150°F)

hneider Electric

Sc

SDS-I2600-A4.BU.N.EN.11.2007.0.00.CC

Page 6

Andover Continuum Infinet II i2600

Series Local Controllers

06

Specifications

(continued)

i2600 Series Local Controllers

Connections

Power

3-position xed screw terminal connector

Inputs

Inputs 1-8 (both i2608 and i2624):

12-position xed screw terminal connector

i2624 only:

Inputs 9-16:

12-position xed screw terminal connector

Inputs 17-24:

12-positon xed screw terminal connector

Communications

3-position removable screw

terminal connector

Service Port

4-position shrouded connector

User LEDs/Switches

Status Indicator LEDs:

CPU CPU Active

TD Transmit Data

RD Receive Data

Switches

RESET

Input Pull-up Resistor Switch (per input)

General

Memory

128K SRAM, 1MB FLASH

Processor

Motorola 32-bit Coldre

Agency Listings

UL/CUL 916, FCC CFR 47 Part 15,

ICES-003, EN55022, AS/NZS 3548,

Class A, CE

Options

UL864, Smoke Control System Equipment,

UUKL (i2608-S, i2624-S)

Models

i2608

Innet II i2608 Local Controller

i2608-S

Innet II i2608 Local Controller with

Smoke-Control option

i2608-WL

Wireless Innet II i2608 Local Controller

i2624

Innet II i2624 Local Controller

i2624-S

Innet II i2624 Local Controller

with Smoke-Control option

i2624-WL

Wireless Innet II i2624 Local Controller

All brand names, trademarks and registered trademarks are the property of their respective owners. Information contained within this document is subject to change

without notice.

On October 1st, 2009, TAC became the Buildings Business of its parent company Schneider Electric. This document reflects the visual identity of Schneider Electric,

however there remains references to TAC as a corporate brand in the body copy. As each document is updated, the body copy will be changed to reflect appropriate

corporate brand changes.

hneider Electric

Sc

SDS-I2600-A4.BU.N.EN.11.2007.0.00.CC

November 2007 pdw

© 2007-20 09 Schneider Electric. All rights reserved.

Loading...

Loading...