Page 1

Com’X 510 Energy Server

User manual

DOCA0098EN-12

09/2020

www.schneider-electric.com

Page 2

Legal Information

The Schneider Electric brand and any trademarks of Schneider Electric SE and its

subsidiaries referred to in this guide are the property of Schneider Electric SE or its

subsidiaries. All other brands may be trademarks of their respective owners.

This guide and its content are protected under applicable copyright laws and

furnished for informational use only. No part of this guide may be reproduced or

transmitted in any form or by any means (electronic, mechanical, photocopying,

recording, or otherwise), for any purpose, without the prior written permission of

Schneider Electric.

Schneider Electric does not grant any right or license for commercial use of the guide

or its content, except for a non-exclusive and personal license to consult it on an "as

is" basis. Schneider Electric products and equipment should be installed, operated,

serviced, and maintained only by qualified personnel.

As standards, specifications, and designs change from time to time, information

contained in this guide may be subject to change without notice.

To the extent permitted by applicable law, no responsibility or liability is assumed by

Schneider Electric and its subsidiaries for any errors or omissions in the informational

content of this material or consequences arising out of or resulting from the use of the

information contained herein.

Page 3

Safety information

Important information

Read these instructions carefully and look at the equipment to become familiar

with the device before trying to install, operate, service, or maintain it. The

following special messages may appear throughout this manual or on the

equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety label indicates

that an electrical hazard exists which will result in personal injury if the

instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that accompany this symbol to avoid possible

injury or death.

Com’X 510 Energy Server

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Failure to follow these instructions will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE

NOTICE is used to address practices not related to physical injury.

Please note

Electrical equipment should be installed, operated, serviced and maintained only

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material. A qualified person is one who

has skills and knowledge related to the construction, installation, and operation of

electrical equipment and has received safety training to recognize and avoid the

hazards involved.

DOCA0098EN-12 3

Page 4

Com’X 510 Energy Server

Notice

FCC

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no

guarantee that the interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to

try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment to an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

The user is cautioned that any changes or modifications not expressly approved

by Schneider Electric could void the user’s authority to operate the equipment.

This digital apparatus complies with CAN ICES-3 (B) /NMB-3(B).

4 DOCA0098EN-12

Page 5

Table of Contents

Safety precautions ......................................................................................9

Com’X 510 Introduction ........................................................................... 11

Com’X 510 User Interface Access ......................................................... 14

Supported Web Browsers..........................................................................14

Start Up Your Com’X ................................................................................. 14

Accessing Through the Ethernet Port With Windows ................................... 14

Accessing Through Wi-Fi Access Point Mode With Windows ....................... 16

Logging In................................................................................................18

Changing the Password ............................................................................ 19

Com’X 510 Quickstart ..............................................................................23

Quickstart Overview.................................................................................. 23

Quickstart: Setting Up and Starting Data Logging........................................ 23

Quickstart: Viewing On-board Data ............................................................23

Quickstart: Setting Up Publication..............................................................23

Com’X 510 Energy Server

Accessing Through the Ethernet Port With Other Operating

Systems............................................................................................. 15

Accessing Through Wi-Fi Access Point Mode ....................................... 17

Com’X 510 Security..................................................................................25

Security overview ..................................................................................... 25

Security features on your device ................................................................25

Security Configuration Recommendations ..................................................28

Com’X 510 Settings.................................................................................. 30

Settings Overview.....................................................................................30

Date and Time Settings ............................................................................. 30

Configuring Date and Time .................................................................. 30

Network Settings ...................................................................................... 30

Network Configuration Options ............................................................31

Selecting a Network Configuration .......................................................31

Ethernet Port Settings .........................................................................32

GPRS/3G Settings.............................................................................. 34

Wi-Fi Settings ..................................................................................... 38

Proxy Settings ....................................................................................40

Contact Management..........................................................................41

Email Settings ....................................................................................42

Publication .........................................................................................44

Publication Identification Settings......................................................... 47

File Format of CSV Export ...................................................................47

Digital Service Platform Connection ...........................................................48

Wi-Fi Access Point Settings....................................................................... 49

Activating the Wi-Fi Access Point .........................................................49

Deactivating the Wi-FI ......................................................................... 49

Site Information ........................................................................................ 50

Configuring Site Information ................................................................ 50

Data Logging............................................................................................50

Defining the Logging Intervals.............................................................. 50

Security ................................................................................................... 50

Firewall Management................................................................................ 51

DOCA0098EN-12 5

Page 6

Com’X 510 Energy Server

Port Settings.......................................................................................51

Upstream Network Access...................................................................51

Configuring Firewall Settings ...............................................................51

Disabling DPWS and SSH services......................................................52

Disabling the Password Reset Button ...................................................52

Account Lockout Policy .......................................................................52

Configuring Account Lockout Policy ..................................................... 53

Disabling Account Lockout Policy.........................................................53

Warning Banner Overview ...................................................................53

Certificates...............................................................................................54

Uploading a New Certificate................................................................. 54

HTTPS Redirection ............................................................................. 54

User Management .................................................................................... 54

Group Settings .........................................................................................55

Creating a Group ................................................................................55

Modifying Group Settings .................................................................... 56

Deleting a Group.................................................................................56

Users.......................................................................................................56

Creating a User .................................................................................. 57

Modifying a User.................................................................................57

Deleting a User................................................................................... 57

Event Settings.......................................................................................... 58

Predefined Events ....................................................................................58

Custom Events.........................................................................................58

Creating a Custom Event ..........................................................................58

Editing or Deleting a Custom Event............................................................ 60

Copying an Event .....................................................................................60

Links ....................................................................................................... 60

Configuring Links...................................................................................... 60

Viewing Links ........................................................................................... 61

Custom Page Management....................................................................... 61

Adding a Custom Web Page......................................................................61

Deleting Custom Web Pages ..................................................................... 62

Downloading a Custom Page .................................................................... 62

Viewing a Custom Web Page .................................................................... 62

Com’X 510 Communications................................................................... 63

IPv4 Address Settings...............................................................................63

Modbus TCP Access.................................................................................65

Configuring Modbus TCP/IP Filtering .........................................................67

Modbus Serial Port ................................................................................... 68

Modbus Serial Port Settings................................................................. 68

Advanced Ethernet Settings ......................................................................69

ZigBee Network Settings...........................................................................70

Com’X 510 Device settings ..................................................................... 73

Device Settings Overview .........................................................................73

Common Properties..................................................................................74

Adding a Downstream Device....................................................................76

Modifying a Device ...................................................................................77

Disconnecting a Device.............................................................................77

Reconnecting a Device .............................................................................77

Replacing a Device................................................................................... 78

6 DOCA0098EN-12

Page 7

Com’X 510 Energy Server

Deleting a Device .....................................................................................78

Measurement and Metadata Exported Per Hosted Platform .........................79

Built-In Pulse Meters................................................................................. 80

Custom Pulse Meter............................................................................ 81

Resistance Temperature Detectors ............................................................81

Custom Analog Devices............................................................................81

Discovering Connected Devices ................................................................ 81

Adding a Modbus Device Manually ............................................................82

Connecting Devices to WT4200 Modbus Receiver ...................................... 83

Connecting Devices to Smartlink ...............................................................83

Built-in Ethernet Devices ...........................................................................84

Custom Ethernet Devices ....................................................................85

Discovering Zigbee Devices ......................................................................85

Com’X 510 Measurements...................................................................... 86

Viewing the Measurements Table .............................................................. 86

Com’X 510 Commissioning ..................................................................... 87

Commissioning Overview..........................................................................87

Starting the Data Logging..........................................................................87

Starting the Publication .............................................................................88

Com’X 510 Monitoring..............................................................................89

Monitoring Overview ................................................................................. 89

Real Time Data ........................................................................................ 89

Summary Device View .............................................................................. 89

Real Time Trending .................................................................................. 90

Dashboards .............................................................................................91

Historical Data Export ...............................................................................93

Custom Web Pages.................................................................................. 93

Com’X 510 Control ...................................................................................94

Device Resets.......................................................................................... 94

Resetting Device Parameters ..............................................................94

Setting Time on Devices............................................................................94

Com’X 510 Diagnostics............................................................................ 95

Diagnostics Overview ...............................................................................95

Statistics ..................................................................................................95

Read Device Registers .............................................................................97

Communications Check ............................................................................98

Com’X 510 Custom Library ..................................................................... 99

Custom Models ........................................................................................ 99

Custom Modbus Devices ........................................................................ 101

Custom Pulse Meter Model ..................................................................... 105

Custom KYZ Pulse Meter Model .............................................................. 106

Custom Main Meter Model ...................................................................... 107

Custom Contactor or Impulse Relay......................................................... 109

Custom Analog Sensor Model ................................................................. 110

Com’X 510 Maintenance ....................................................................... 112

Logs ...................................................................................................... 112

System Settings ..................................................................................... 112

Configuration Management ............................................................... 113

Save the Configuration...................................................................... 113

Restore a configuration ..................................................................... 114

DOCA0098EN-12 7

Page 8

Com’X 510 Energy Server

Upgrade Firmware.................................................................................. 116

Replacing the SD Card ........................................................................... 117

Enabling Remote Access ........................................................................ 118

Disabling Remote Access from Cloud Services......................................... 119

Restarting the Com’X from the Web Interface ........................................... 119

Product Replacement ............................................................................. 119

Resetting the Password Locally ............................................................... 119

Resetting to Factory Settings................................................................... 120

Checklist Before Leaving Customer Site............................................. 121

Com’X 510 Troubleshooting.................................................................. 122

Metering Device Troubleshooting............................................................. 122

Modbus Device Troubleshooting.............................................................. 123

Network Troubleshooting ........................................................................ 123

Com’X Troubleshooting........................................................................... 124

Certificate Authorities ............................................................................. 127

Modbus Register Mapping..................................................................... 130

8 DOCA0098EN-12

Page 9

Safety precautions Com’X 510 Energy Server

Safety precautions

Installation, wiring, testing and service must be performed in accordance with all

local and national electrical codes.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices. See NFPA 70E in the USA, CSA Z462 or

applicable local standards.

• Turn off all power supplying this device and the equipment in which it is

installed before working on the device or equipment.

• Always use a properly rated voltage sensing device to confirm that all power

is off.

• Treat communications and I/O wiring connected to multiple devices as

hazardous live until determined otherwise.

• Do not exceed the device’s ratings for maximum limits.

• Replace all devices, doors and covers before turning on power to this

equipment.

Failure to follow these instructions will result in death or serious injury.

WARNING

UNINTENDED OPERATION

• Do not use the software for critical control or protection applications where

human or equipment safety relies on the operation of the control action.

• Do not use the software to control time-critical functions because

communication delays can occur between the time a control is initiated and

when that action is applied.

• Do not use the software to control remote equipment without securing it with

an authorized access level, and without including a status object to provide

feedback about the status of the control operation.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

INACCURATE DATA RESULTS

• Do not incorrectly configure the software, as this can lead to inaccurate

reports and/or data results.

• Do not base your maintenance or service actions solely on messages and

information displayed by the software.

• Do not rely solely on data displayed in the software reports to determine if

the system is functioning correctly or meeting all applicable standards and

requirements.

• Do not use data displayed in the software as a substitute for proper

workplace practices or equipment maintenance.

Failure to follow these instructions can result in death, serious injury,

equipment damage, or permanent loss of data.

DOCA0098EN-12 9

Page 10

Com’X 510 Energy Server Safety precautions

WARNING

POTENTIAL COMPROMISE OF SYSTEM AVAILABILITY, INTEGRITY, AND

CONFIDENTIALITY

• Change default passwords to help prevent unauthorized access to device

settings and information.

• Disable unused ports/services and default accounts, where possible, to

minimize pathways for malicious attacks.

• Place networked devices behind multiple layers of cyber defenses (such as

firewalls, network segmentation, and network intrusion detection and

protection).

• Use cybersecurity best practices (for example: least privilege, separation of

duties) to help prevent unauthorized exposure, loss, modification of data and

logs, interruption of services, or unintended operation.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

10 DOCA0098EN-12

Page 11

Com’X 510 Introduction Com’X 510 Energy Server

Com’X 510 Introduction

Product Overview

The Com’X 510 energy server is a compact plug and play gateway and data

logger and is an essential part of an entry level energy management system.

Architecture

It collects and stores consumption of WAGES (Water, Air, Gas, Electricity, and

Steam) and environmental parameters such as temperature, humidity, and CO

levels in a building. The Com’X 510 provides access to reports such as on-board

device and circuit summary pages, as well as on-board data logging. Data can be

securely accessed in real time or transmitted as a report to an Internet database

server.

Data is ready to be processed once received by the server. Data is displayed as

web pages through energy management services provided by Schneider Electric,

such as EcoStruxure

support optimization of energy performance and cost management.

From a simple metering installation with one device to large metering systems, the

Com’X 510 collects data from any Modbus TCP/Modbus serial line gateways,

pulse meters, actuators, and analog sensors.

This graphic shows possible architectures of the Com’X 510:

™

Energy Operation and EcoStruxure™Facility Expert, to

2

Main Features

The main features of the Com’X 510 are:

• real-time data in easy to understand views

• dashboard view for historical reporting

• automatic discovery of connected Modbus devices

DOCA0098EN-12 11

Page 12

Com’X 510 Energy Server Com’X 510 Introduction

• connectivity to the cloud through three media: GPRS/3G, wired Ethernet, or

Wi-Fi Ethernet

• two Ethernet ports to separate upstream cloud connection from field device

network

• four supported transfer protocols: HTTP, HTTPS, FTP, and SMTP with proxy

management

• data logging

• data export with native connection to Schneider Electric service platforms

(such as Energy Operation) and with .csv file for other database servers

• gateway functionality Modbus TCP to Modbus RTU or Modbus ASCII

• setup through on-board web pages

• compliant with electrical switchboard environment (temperature,

electromagnetic compatibility)

• local backup of configuration parameters

• ZigBee Pro with EM4300 sensors

Com’X 510 for Entry-level Energy Management

The Com’X 510 supports real-time data views from many common device types,

providing several device-specific features.

Additional energy management capabilities include:

• View real-time and historical information from multiple locations through a

supported web browser.

• Select the logging intervals and topics you want logged.

• Automatically export selected logged data to your PC for additional analysis.

• Provide data and system security through password protection and controlled

access to individual web pages, as well as through Com’X 510 firewall

management.

• Perform simple control reset commands for supported devices (for example,

min/max and accumulated energy).

• Set date and time for connected devices that support set time commands.

Schneider Electric Digital Service Platform

The energy server can be associated with Schneider Electric Digital Service

Platform.

This platform allows you to:

• Remotely manage firmware upgrade, troubleshooting, and parameter

settings.

• Provide a SIM card with worldwide coverage, by using the EBXA-GPRS-SIM

option.

• Publish collected data to Schneider Electric energy management services.

NOTE: It is recommended to use external cellular router instead of EBXAGPRS-SIM option.

EcoStruxure™Facility Expert

EcoStruxure™Facility Expert allows you to outsource energy management and

maintenance, reducing your energy costs and increasing operating efficiency in

buildings.

12 DOCA0098EN-12

Page 13

Com’X 510 Introduction Com’X 510 Energy Server

EcoStruxure™Facility Expert is a cloud-based software application from

Schneider Electric to improve energy efficiency, and manage assets and

maintenance. EcoStruxure

™

Facility Expert is used for small and medium

buildings in industry, retail, public, and healthcare markets.

EcoStruxure

™

Facility Expert provides the following features:

• Support for data acquisition hardware: meters, gateways, and sensors.

• Cloud platform for data displays.

• Consulting service from Schneider Electric expert teams.

• A network of local partners to implement solutions.

Power Monitoring Expert

The Com’X can send data in comma-separated value (CSV) files to supervision

software such as Power Monitoring Expert (PME) or third-party supervision

software.

PME is a complete, interoperable, and scalable software package for power

management applications. The software collects and organizes data gathered

from the electrical network and presents it as meaningful, actionable information

through an intuitive Web interface. Share information with key stakeholders or

across your entire operation to influence behavioral changes that can save you

money.

Additional Resources

To find these and other resources, go to www.se.com and search for “Com’X.”

Document

Com’X Instruction Sheet 5406AD002

EBXA-GPRS/EBXA-GPRS-SIM Instruction

Sheet

EBXA-WIFI Instruction Sheet 253537634

Zigbee Instruction Sheet NHA2243500

Reference Number(s)

5406AD005

5406AD006

253537613

DOCA0098EN-12 13

Page 14

Com’X 510 Energy Server Com’X 510 User Interface Access

Com’X 510 User Interface Access

Supported Web Browsers

You can access the energy server using a variety of web browsers.

Browser Browser Version

Microsoft Edge 42.0 and above

Internet Explorer IE9 and above

Firefox 20.0 and above

Chrome 24.0 and above

Recommended Web Browsers

It is recommended to use Chrome for PC.

The following browsers are recommended for tablets:

Operating System

Windows 10 • Microsoft Edge

Windows 8 • Internet Explorer

iOS • Chrome

Android • Chrome

Start Up Your Com’X

The Com’X takes time to start up. Wait for the power LED to turn green before

performing any actions.

Once the Com’X is started, most configuration modifications are taken in account

without a reboot.

Reboot Cases

The Com’X requires a reboot in the following cases:

• Upgrading the firmware.

• Restoring a configuration.

• Changing the Ethernet network settings between 2 switched ports and 2

• Inserting a GPRS or 3G modem.

• Installing a Zigbee key.

Browser

• Firefox

• Safari

• Android browser

separate ports.

Accessing Through the Ethernet Port With Windows

Access the Com’X user interface for initial setup using Windows 10.

The default configuration for Com’X Ethernet port 2 is DHCP server.

14 DOCA0098EN-12

Page 15

Com’X 510 User Interface Access Com’X 510 Energy Server

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• This equipment must only be installed and serviced by qualified personnel.

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices. See NFPA 70E in the USA, CSA Z462 or

applicable local standards.

Failure to follow these instructions will result in death or serious injury.

NOTICE

IP ADDRESS CONFLICT

Do not connect a Com'X Ethernet port to a local area network if it is configured

to DHCP server.

Failure to follow these instructions can result in impaired

communications.

1. Disconnect your local computer from all networks.

2. Connect an Ethernet cable from your local computer to the Ethernet port 2 of

the Com’X.

3. Open Windows Explorer on your local computer and click Network.

The Com’X appears in the list of devices.

4. Double-click the Com’X. The login page is opened automatically on your

default web browser.

NOTE: HTTPS is enabled by default on the Com’X configuration. The

Com’X has an autosigned security certificate. Therefore, connecting to

the energy server interface displays a security message. Before

accepting, confirm that communication with the energy server has been

established.

5. Type the username (default: admin) and the password (default: admin).

NOTE: The username and password are case-sensitive.

6. Click OK.

Related Topics

• Com’X 510 Troubleshooting

• Uploading a New Certificate

Accessing Through the Ethernet Port With Other Operating Systems

Access the Com’X user interface for initial setup using an operating system other

than Windows.

The default configuration for Com’X Ethernet port 2 is DHCP server.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• This equipment must only be installed and serviced by qualified personnel.

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices. See NFPA 70E in the USA, CSA Z462 or

applicable local standards.

Failure to follow these instructions will result in death or serious injury.

DOCA0098EN-12 15

Page 16

Com’X 510 Energy Server Com’X 510 User Interface Access

NOTICE

IP ADDRESS CONFLICT

Do not connect a Com'X Ethernet port to a local area network if it is configured

to DHCP server.

Failure to follow these instructions can result in impaired

communications.

1. Disconnect your local computer from all networks.

2. Connect an Ethernet cable from your local computer to the Ethernet port 2 of

the Com’X.

3. Open your web browser.

4. Type [10.25.1.1] in the address field and press Enter.

NOTE: HTTPS is enabled by default on the Com’X configuration. The

Com’X has an autosigned security certificate. Therefore, connecting to

the Com’X interface displays a security message. Before accepting,

confirm that communication with the Com’X has been established.

5. Type the username (default: admin) and the password (default: admin).

NOTE: The username and password are case-sensitive.

6. Click OK.

Related Topics

• Uploading a New Certificate

Accessing Through Wi-Fi Access Point Mode With Windows

You can access the energy server user interface through Wi-Fi Access Point

Mode using Windows.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• This equipment must only be installed and serviced by qualified personnel.

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices. See NFPA 70E in the USA, CSA Z462 or

applicable local standards.

Failure to follow these instructions will result in death or serious injury.

NOTICE

UNINTENDED EQUIPMENT OPERATION

Do not close the door of a metallic enclosure while using the Wi-Fi USB key.

Failure to follow these instructions can result in equipment damage.

1. Connect the Wi-Fi USB key to a USB port on the energy server.

2. Press the Wi-Fi button on the energy server.

The Wi-Fi button LED flashes green.

3. On your local computer, connect to the energy server wireless network using

the Windows Wireless Network configuration window.

4. Open Windows Explorer on your local computer and click Network. The

energy server appears in the list of devices.

16 DOCA0098EN-12

Page 17

Com’X 510 User Interface Access Com’X 510 Energy Server

5. Double-click the energy server and the login page opens automatically in your

default browser.

HTTPS is enabled by default on the energy server configuration. The energy

server has an autosigned security certificate. Therefore, connecting to the

energy server interface displays a security message. Before accepting,

confirm that communication with the energy server has been established.

6. Type the username (default: admin) and the password (default: admin).

The username and password are case-sensitive.

7. Click Ok.

Related Topics

• Com’X 510 Troubleshooting

• Uploading a New Certificate

Accessing Through Wi-Fi Access Point Mode

You can access the energy server user interface using Wi-Fi Access Point Mode

on operating systems other than Windows 7/Vista.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• This equipment must only be installed and serviced by qualified personnel.

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices. See NFPA 70E in the USA, CSA Z462 or

applicable local standards.

Failure to follow these instructions will result in death or serious injury.

NOTICE

UNINTENDED EQUIPMENT OPERATION

Do not close the door of a metallic enclosure while using the Wi-Fi USB key.

Failure to follow these instructions can result in equipment damage.

1. Connect the Wi-Fi USB key to a USB port on the energy server.

2. Press the Wi-Fi button on the energy server.

The Wi-Fi button LED flashes green.

3. On your local computer, connect to the energy server wireless network using

the Windows Wireless Network configuration window.

4. Open your browser.

5. Type [10.25.2.1] in the address field and press Enter.

HTTPS is enabled by default on the energy server configuration. The energy

server has an autosigned security certificate. Therefore, connecting to the

energy server interface displays a security message. Before accepting,

confirm that communication with the energy server has been established.

6. Type the username (default: admin) and the password (default: admin).

The username and password are case-sensitive.

DOCA0098EN-12 17

Page 18

Com’X 510 Energy Server Com’X 510 User Interface Access

7. Click Ok.

Related Topics

• Uploading a New Certificate

Logging In

You need to log in to access the energy server’s user interface.

If multiple sessions are opened, only the first session can be used to edit

parameters. Sessions opened after the first session are read-only.

1. Select your language.

2. Type the username and the password.

NOTE: The username and password are case-sensitive.

3. Click Connect to be logged in to the configuration web page.

NOTE: HTTPS is enabled by default on the Com’X configuration. The Com’X

has an autosigned security certificate. Therefore, connecting to the Com’X

interface displays a security message. Before accepting, confirm that

communication with the Com’X has been established.

Related Topics

• Uploading a New Certificate

Logging In for the First Time

There are special instructions when you log in to the user interface for the first

time.

The web server is a tool for reading and writing data. It controls the state of the

system, with full access to all data in your application. You will be prompted to

change your password the first time you log in to prevent unauthorized access to

the application.

UNAUTHORIZED DATA ACCESS

• Immediately change the default password to a new, secure password.

• Do not distribute the password to unauthorized or otherwise unqualified

Failure to follow these instructions can result in equipment damage.

A secure password should not be shared or distributed to unauthorized personnel.

The password should not contain any personal or obvious information.

NOTICE

personnel.

1. Log in as the default administrator.

Username and password: admin

2. Read the License Agreement completely.

NOTE: The Accept button will remain grayed until you scroll to the

bottom of the User License Agreement.

3. Accept the License Agreement.

18 DOCA0098EN-12

Page 19

Com’X 510 User Interface Access Com’X 510 Energy Server

4. Enter a new password.

It must contain:

• 8 characters

• 1 uppercase letter

• 1 numeric digit

• 1 special character

Changing the Password

You will need to change the password after the first login and will be directed

automatically to the username/password page.

1. Click the username/admin link

2. Enter the current password.

3. Enter a new password.

4. Confirm the new password.

5. Click OK.

User Session Timeout

The login session terminates after the configured Session Inactivity Time-out

interval for the user group.

Related Topics

• Group Settings

User Interface Overview

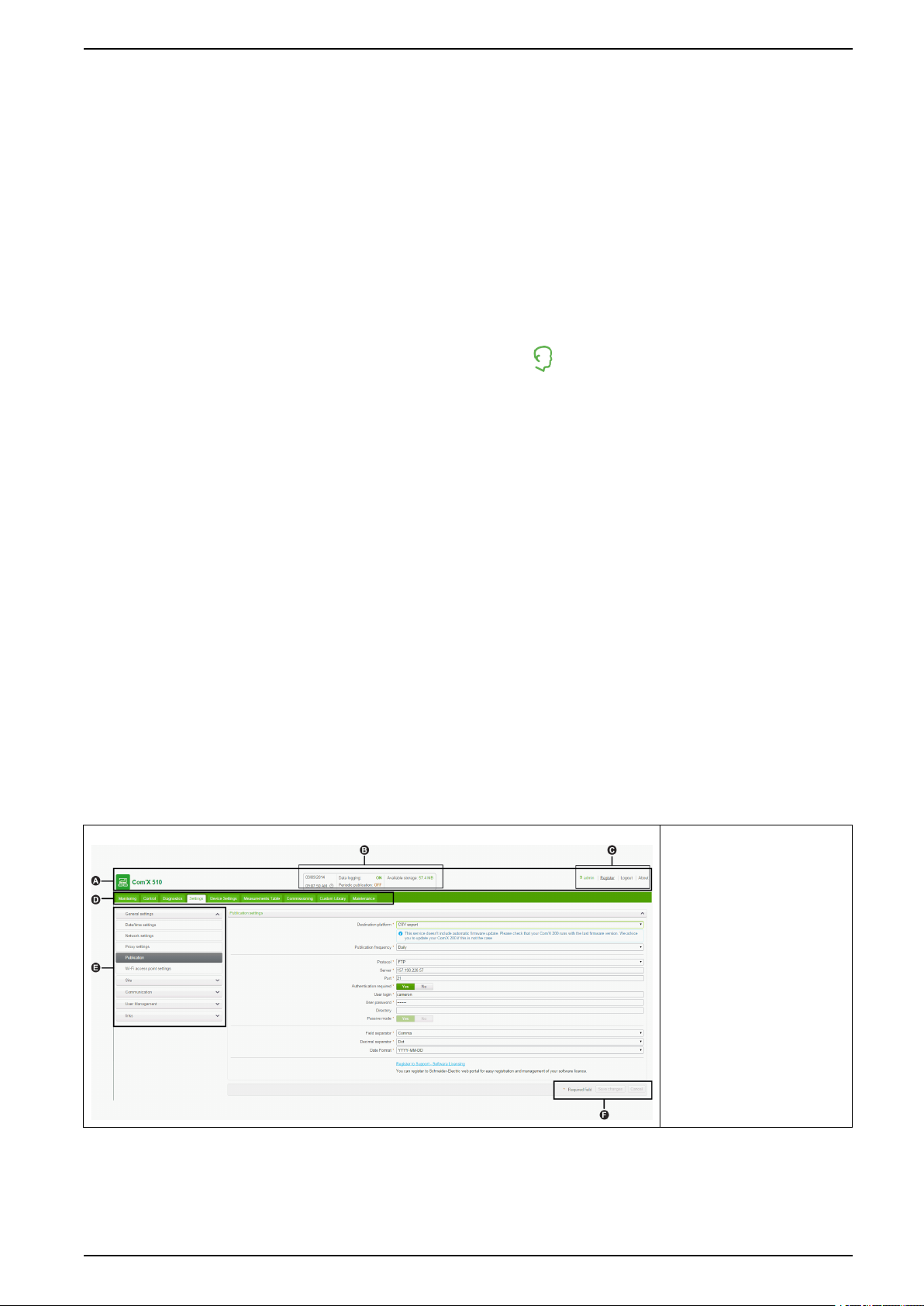

The web user interface allows you to commission your Com’X 510

This graphic shows the interface layout:

in the banner.

A. Banner

B. Gateway status

C. Generic information

D. Main tabs

E. Subtabs

F. Action buttons

Banner

The banner displays the following information at the top of all pages:

DOCA0098EN-12 19

Page 20

Com’X 510 Energy Server Com’X 510 User Interface Access

Main Tabs and Subtabs

Action Buttons

Status Data Logging: Displays status of data logging, which can be activated in

the Commissioning tab.

Periodic Publication: Displays publication status, which can be activated

in the Commissioning tab.

Available Storage: Shows available storage for data logging.

Generic Information Username/admin link: Displays the connected user.

About: Click to access information on your Com’X 510 and GPRS or 3G

modem (serial number and MAC address), IPv4 Ethernet ports, IPv6

address, and software versions.

Logout: To log out of the session, click Logout or close your browser. It is

recommended to log out of the Com’X 510 when not in use.

Time: Displays the time as set in the Date/Time Settings.

Subtabs display the submenus under the selected main tab. You can use your

web browser to bookmark each subtab of the Com’X 510 web interface.

The action buttons correspond to the selected tab and vary. This table describes

the interface buttons:

Icons

Button Action

Save changes Validates the modifications. Disabled when:

• there is no change in the web page.

• a mandatory field is left blank. The field is highlighted in

red.

• inappropriate characters are entered in a field. The field is

highlighted in red.

Cancel Cancels the modifications to return to the last saved settings.

Icon

* Fields marked with a red star are required fields.

Description

Indicates that the information necessary to complete the energy

server configuration and activation of data logging and

publication is unavailable for the tab.

Indicates the user that is logged in for the current session.

Contains information about configuration in the open menu.

Related Topics

• Configuring Date and Time

User Interface Features

The user interface organizes the features in main tabs and subtabs.

20 DOCA0098EN-12

Page 21

Com’X 510 User Interface Access Com’X 510 Energy Server

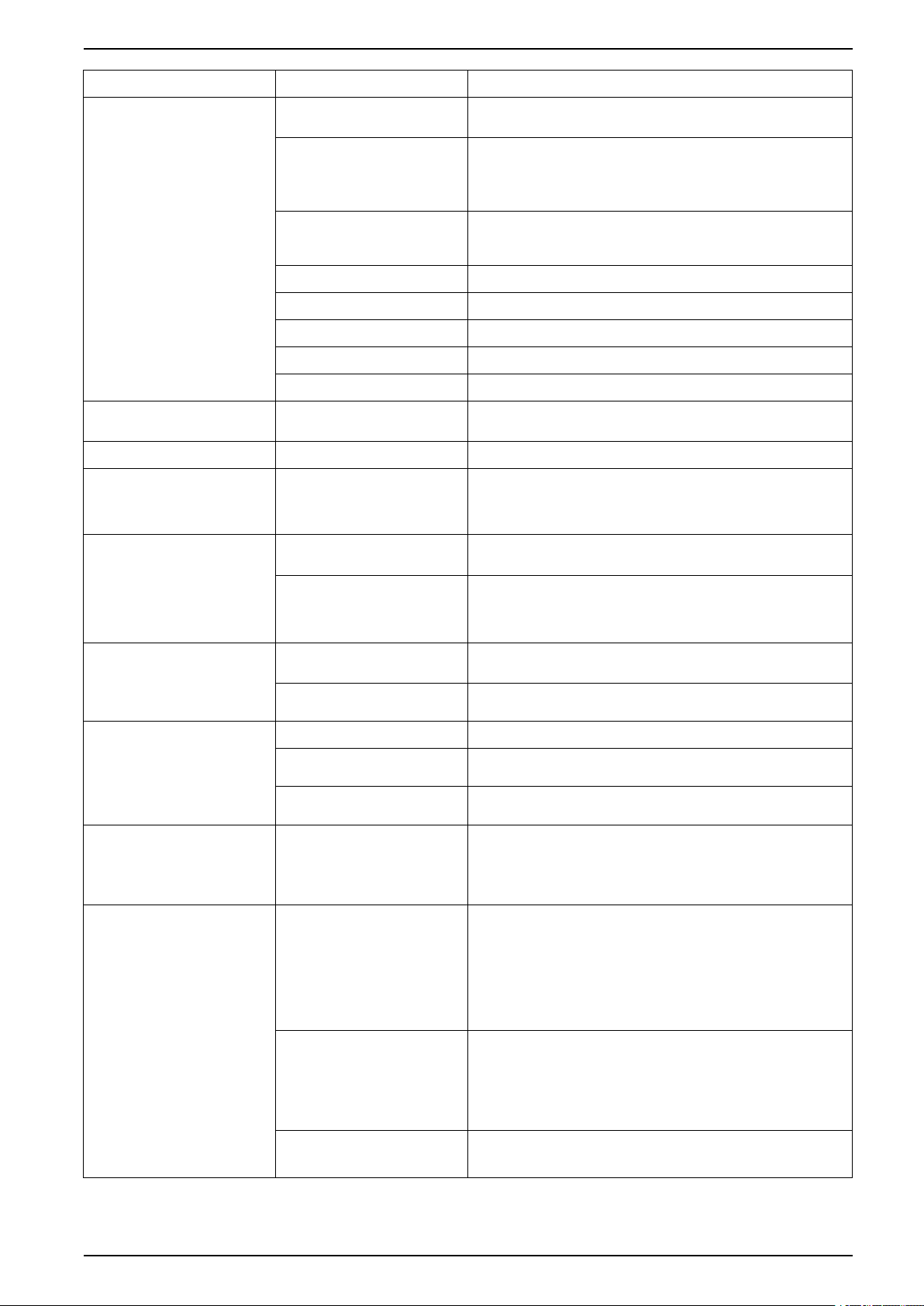

Main Tab Subtab

Settings General Settings Configures the date and time, network settings, proxy settings,

Site Settings • Contains the name of the site. This field is used by Energy

Communication Configures the Modbus serial port, Modbus gateway, TCP/IP

Security Update SSL certificate and firewall settings.

User Management Create and edit groups and users.

Links Configure file and URL documentation links.

Events Configure event settings and define custom events.

Custom Page Management Create and add custom web pages to the Com’X.

Device Settings

Measurements Table

Commissioning

–

–

–

Description

publication parameters, and Wi-Fi access point settings.

Operation.

• Configures the logging interval for each commodity and for

environmental parameters.

filtering, and advanced Ethernet settings. Setup and create a

ZigBee network.

Configures the metering architecture and the data to log and

publish.

Displays meters with metadata and data to be logged.

• Checks the system configuration.

• Starts or stops data logging.

• Starts, stops, or tests data publication.

Monitoring Real Time Data Provides basic readings of selected devices. Features include

Dashboards Provides graphical representation of energy consumption

Control Device Resets Allows execution of resets defined for the device, and displays the

Set Device Time Date and time resets are shown only when the device supports

Diagnostics Statistics Displays diagnostic data used to troubleshoot network problems.

Read Device Registers Allows users to read register data from local and remote Modbus

Communications Check Tests the communications health of Modbus devices configured on

Custom Library

Maintenance Logs Shows the date, time, and description of:

–

single device and summary views.

information aggregated over time for devices enabled for data

logging and provides trending information for other electrical

properties.

date and time each reset function was performed.

them.

devices connected to the Com’X.

the Com’X.

• Create a custom device model, new device model or based on

an existing custom device model in the library.

• Modify and delete custom models

• Import and export custom models.

• changes in the configuration

• errors detected during logging

• publication steps and status

• communication interruption with metering devices

• unsuccessful login attempts

System Settings • Allows you to back up and restore a Com’X configuration.

• Activates the remote access for Schneider Electric technical

support.

• Upgrades the Com’X firmware.

• Allows you to manually restart the Com’X.

Events • Provides log of all generated pre-defined events.

• Provides log of all pre-defined events to be published.

DOCA0098EN-12 21

Page 22

Com’X 510 Energy Server Com’X 510 User Interface Access

Related Topics

• Com’X 510 Settings

• Com’X 510 Communications

• Com’X 510 Device settings

• Com’X 510 Commissioning

• Com’X 510 Monitoring

• Com’X 510 Control

• Com’X 510 Custom Library

• Com’X 510 Diagnostics

• Com’X 510 Maintenance

22 DOCA0098EN-12

Page 23

Com’X 510 Quickstart Com’X 510 Energy Server

Com’X 510 Quickstart

Quickstart Overview

This chapter describes how to perform common tasks with the Com’X 510. For a

full description of the feature outlined in each, see the topics to which it points.

NOTE: Ensure your Com’X is running the latest firmware. Go to www.

schneider-electric.com/en/download/ to download the latest version of the

firmware.

Quickstart: Setting Up and Starting Data Logging

Below are the general tasks related to starting data logging. There may be

additional steps for publishing to a specific platform.

1. Add the downstream devices as in Adding a Downstream Device, page 76.

There are additional configuration tasks for each type of device:

– Devices That Can Connect to Digital Inputs

– Devices That Can Connect to Analog Inputs

– Modbus Devices

– Ethernet Device Configuration Parameters, page 84

2. Select the measurements to log as in Selecting Measurements to Log or

Publish, page 79

3. Define the logging intervals as in Defining the Logging Intervals, page 50

4. Start the data logging as in Starting the Data Logging, page 87.

Quickstart: Viewing On-board Data

You can view real time and logged data on the Com’X 510 without having to

connect to a hosted platform. Below are the steps for viewing on-board data.

1. Add the downstream devices as in Adding a Downstream Device, page 76.

There are additional configuration tasks for each type of device:

– Modbus Devices

– Ethernet Device Configuration Parameters, page 84

2. Complete the following steps to view an Energy dashboard or Historical

Trending. Skip to step 3 to view real time data.

a. Selecting Measurements to Log or Publish, page 79

b. Defining the Logging Intervals, page 50

c. Starting the Data Logging, page 87.

NOTE: The amount of data collected affects the ability to display certain

dashboard options, for example a year over year dashboard.

3. View real time data for one or more devices: Viewing Real Time Data for a

Single Device, page 89 or Viewing a Device Summary, page 90.

Quickstart: Setting Up Publication

The steps below are a summary of publishing options. Refer to the appropriate

sections for a full description of publishing per platform.

DOCA0098EN-12 23

Page 24

Com’X 510 Energy Server Com’X 510 Quickstart

1. Choose the platform and publication frequency as in Selecting Platform and

Publication Frequency, page 44. For each platform, see these related tasks:

– For a connection to a Schneider Electric subscribed service via Digital

™

Service Platform (for example, EcoStruxure

Facility Expert), see

Connection, page 48.

– For .csv export options, you may want to refer to File Format of CSV

Export, page 47.

2. Define the transfer protocol as in Define the Transfer Protocol, page 44

3. Start the publication as in Starting the Publication, page 88

24 DOCA0098EN-12

Page 25

Com’X 510 Security Com’X 510 Energy Server

Com’X 510 Security

Security overview

Your Schneider Electric product is equipped with security-enabling features.

These features arrive in a default state and can be configured for your installation

needs. Please note that disabling or modifying settings within the scope of these

individual features can impact the overall security robustness of the device and

ultimately the security posture of your network in either positive or negative ways.

Review the security intent and recommendations for the optimal use of your

device’s security features.

Products are hardened to increase security robustness. This is an ongoing

process consisting of secure development practices, inclusion of security features

and testing at our security test facilities. Following system hardening best

practices is also necessary to help ensure your overall system security.

See the Cybersecurity Hardening Best Practices white paper for suggested best

practices.

Security features on your device

Your device comes with security features that you can configure to help protect

against unauthorized configuration and access to your device’s data through its

user interfaces or communications.

User Management

User Management allows you to create user groups with configurable

permissions for Com’X features. You can restrict access to features by assigning

individual users to a group.

There are two default groups:

• administrator: Modification rights for all features; you cannot modify this

group.

• guest: Viewing rights for selected features. Only an administrator can modify

this group.

Only an administrator can add, modify, or remove users and groups.

Related Topics

• User Management

Password Requirements

The Com’X incorporates complex password requirements.

Each user is prompted to change their password the first time they log in to

prevent unauthorized access to the application. It is recommended to schedule

regular changes to your password.

Related Topics

• Logging In for the First Time

HTTPS Connection

Your connection to the Com’X web server is HTTPS by default.

DOCA0098EN-12 25

Page 26

Com’X 510 Energy Server Com’X 510 Security

The Com’X has a self-signed security certificate. Therefore, connecting to the

Com’X interface displays a security message. Before accepting, confirm that

communication with the Com’X has been established.

HTTPS Redirection is enabled by default. It is recommended to leave this setting

enabled to secure communications between PC and the Com’X.

HTTPS Proxy is supported in Settings > General Settings. The proxy address

and port number are provided by your network administrator, or you can retrieve

these values in the Internet Options of a PC connected to the LAN.

Related Topics

• Proxy Settings

• Uploading a New Certificate

Secure Data Export

Using a secure protocol when publishing data logs can help prevent interception

and corruption of data logs.

Secure publication options include:

• HTTPS when publishing data as a .csv file or publishing to Energy Operation.

• SMTP with connection security mode to TLS/SSL or STARTTLS when

publishing a .csv file over SMTP. The default mode is None.

• DSP (a Schneider Electric hosted platform)

Destination platform is not configured by default. If you are publishing to a

location other than DSP, you must configure the protocol in Settings > General

Settings > Publication, then Email Settings if using SMTP.

Firewall Management

Related Topics

• Define the Transfer Protocol

• Configuring the SMTP Server

Firewall management allows you to configure network access.

You can configure items such as:

• Enable or disable ports.

• Configure port numbers per interface (Eth1, Eth2, WiFi, GPRS/3G), except

where noted in Port Settings.

• Enable upstream network access.

• Enable Account Lockout policy.

Disabling unused ports (determined by your network selection in Settings >

General Settings > Network Settings) can help prevent unauthorized access.

Upstream Network Access

This feature allows downstream devices to access servers (such as DNS, SNTP,

and SMTP) on the upstream network.

Upstream Network Access is disabled by default. It is recommended to leave

this setting disabled unless it is required to publish data or send event messages

from downstream clients.

26 DOCA0098EN-12

Page 27

Com’X 510 Security Com’X 510 Energy Server

Account Lockout Policy

Account lockout feature disables a user account when the number of failed login

attempts exceeds the set limit within a predetermined time interval. You can

configure the following:

• Enable account lockout Account lockout policy is enabled by default. Select

No to disable this feature. It is recommended to keep the Account Lockout

feature enabled to secure the device from unauthorized access.

• Reset account lockout counter (number of attempts) determines the number

of invalid login attempts allowed before user account gets disabled. The

default is set to 10 attempts.

• Account lockout duration (minutes) determines amount of time user account

remains disabled. The default is set to 15 minutes.

Disabling Account Lockout Policy

NOTE: It is recommended to keep the Account Lockout enabled to better

secure the device from unauthorized access.

Related Topics

Communications

• Port Settings

• Selecting Measurements to Log or Publish

Ethernet Security

The Com’X supports two separate Ethernet networks for isolated device network,

for two separate infrastructure backbones, or for a switched network.

Wireless Security

Your Com’X wireless network can be secured with WPA2 (recommended),WPA,

or WEP.

Modbus TCP/IP Filtering

The Modbus TCP/IP filtering feature controls which IP addresses are allowed to

communicate with the Com’X and its downstream devices using Modbus TCP/IP.

Minimizing the number of IP address that can access the device reduces the

likelihood of unauthorized intrusions.

This feature is disabled by default. When enabled, the default access level is

Read for any Modbus TCP/IP client not in the filtered list. Setting the Default

Access field to None blocks all Modbus TCP/IP clients not in the filtered list.

It is recommended that you enable this feature, if your system architecture

permits.

Related Topics

• Configuring Modbus TCP/IP Filtering

Maintenance

Real-time access to maintenance logs allow you to check for excessive denied

accesses, unexpected firmware upgrades or unplanned backup restoration.

DOCA0098EN-12 27

Page 28

Com’X 510 Energy Server Com’X 510 Security

Configuration Backup

Configuration backup allows recovery of Com'X and device settings.

Firmware

Users can only install firmware signed by Schneider Electric.

Remote Access from Cloud Services

By default, a Com’X device connected to DSP can be accessed through remote

assistance. The Enable remote access from cloud option is enabled (ON) by

default. For security reasons it is recommended to disable this feature and enable

it only when remote access is required for technical support from Schneider

Electric.

Refer to Disabling Remote Access from Cloud Services, page 119 for additional

information.

Related Topics

• Logs

• Save the Configuration

• Restore a configuration

• Upgrade Firmware

Security Configuration Recommendations

There are some general security configuration recommendations for your device.

• Do not add more users than those who need access, and evaluate your

system needs before granting users access to critical pages, for example,

Firewall Management or Device Settings.

• Limit the number of IP addresses that have access to the Com’X.

• Do not use SHA1 certificates.

Recommended best practices for unsecure protocols

WARNING

POTENTIAL COMPROMISE OF SYSTEM AVAILABILITY, INTEGRITY, AND

CONFIDENTIALITY

• Change default passwords to help prevent unauthorized access to device

settings and information.

• Disable unused ports/services and default accounts, where possible, to

minimize pathways for malicious attacks.

• Place networked devices behind multiple layers of cyber defenses (such as

firewalls, network segmentation, and network intrusion detection and

protection).

• Use cybersecurity best practices (for example: least privilege, separation of

duties) to help prevent unauthorized exposure, loss, modification of data and

logs, interruption of services, or unintended operation.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

NOTE: Table below lists risks and best practices associated with unsecure

protocols. It is highly recommended to follow these best practices.

28 DOCA0098EN-12

Page 29

Com’X 510 Security Com’X 510 Energy Server

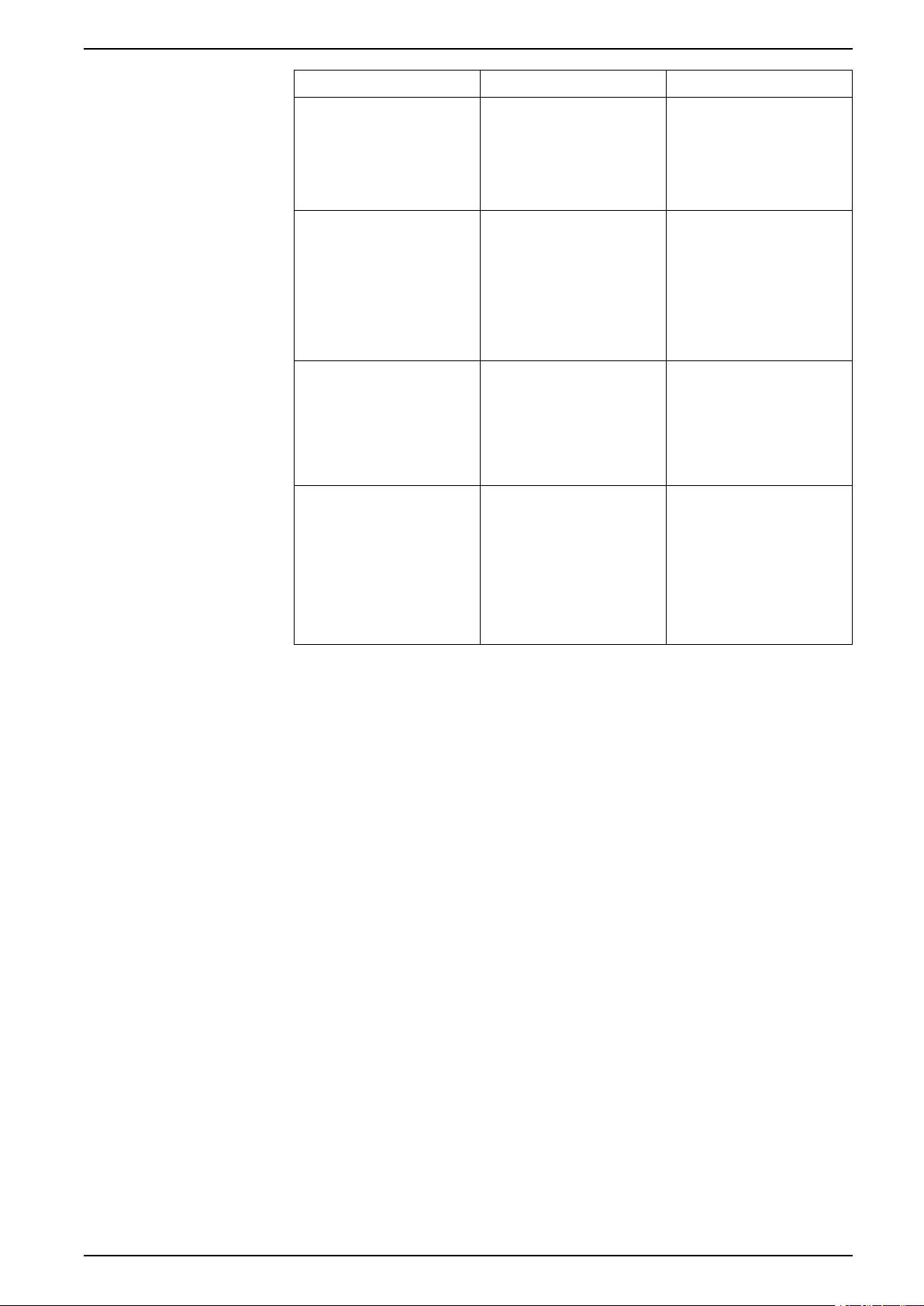

Unsecure protocols Risks Best Practices

SMTP • Threat of malware.

• Unauthorized access to

data.

• Threat of data leakage.

• Email contents

transferred in plain-text.

HTTP • Cross site scripting.

• Broken authentication

and session

management.

• Cross-site request

forgery.

• Eavesdropping and

tampering.

FTP • FTP brute force attack.

• Packet sniffing.

• Spoof attack.

• User credentials can be

compromised since all

authentication is done in

clear-text.

Modbus TCP/IP • Message interception.

• Information capture.

• Arbitrary command

issuance.

• Unauthorized users can

gather and /or tamper

device configurations.

For publication:

• Select SMTP with either

SSL/TLS or SMART TLS

configured for

publication.

For network configuration:

• Disable HTTP.

• Select HTTPS for

network connections.

For publication:

• Do not select HTTP.

• Select HTTPS with

authentication.

For publication:

• Do not use FTP.

• Select either HTTPS with

authentication, or SMTP

with either SSL/TLS or

SMART TLS configured

for publication.

For Modbus device

communications:

• Limit access to Modbus

Communications by use

of Modbus TCP/IP

Filtering.

• Disable the Modbus port

for each network

interface when not in

use.

DOCA0098EN-12 29

Page 30

Com’X 510 Energy Server Com’X 510 Settings

Com’X 510 Settings

Settings Overview

This section describes how to configure the general settings of the Com’X.

WARNING

INACCURATE DATA RESULTS

Do not incorrectly configure the software, as this can lead to inaccurate reports

and/or data results.

Failure to follow these instructions can result in death, serious injury,

equipment damage, or permanent loss of data.

Date and Time Settings

The Date/Time Settings subtab allows you to set the date and time by time zone

through SNTP or manually.

Configuring Date and Time

The time and date settings must be set to the current date and time before

enabling Schneider Electric Services on your Com’X.

Any manual changes on the date and time are overwritten by Digital Service

Platform. You can only edit the Timezone.

It is recommended that DST time zone is selected when using Energy Operation

to ensure consistent time stamping with the Com’X.

To set the date and time:

1. Click Settings > General Settings > Date/Time Settings.

2. Select the appropriate Timezone in the drop-down list. If a DST time zone is

3. Choose one of the following:

4. Click Save changes.

selected, the clock will automatically adjust for Daylight Saving Time.

a. Click the Today button to set the date and time automatically with the

date and time of your computer.

b. Manually enter the date and time in the date and time fields.

c. Select Yes for SNTP support, then enter an SNTP server address.

(Default: pool.ntp.org)

Network Settings

The Com’X offers several connection interfaces.

• Ethernet with two ports

• Wi-Fi

• GPRS or 3G for isolated sites or sites where the IT administrator does not

allow access to the network infrastructure.

The available interfaces are determined by the accessories connected to the

Com’X: GPRS or 3G modem or Wi-Fi USB key.

30 DOCA0098EN-12

Page 31

Com’X 510 Settings Com’X 510 Energy Server

Network Configuration Options

The Com’X features two Ethernet ports as well as a bay for a GPRS module or a

USB port for 3G modem.

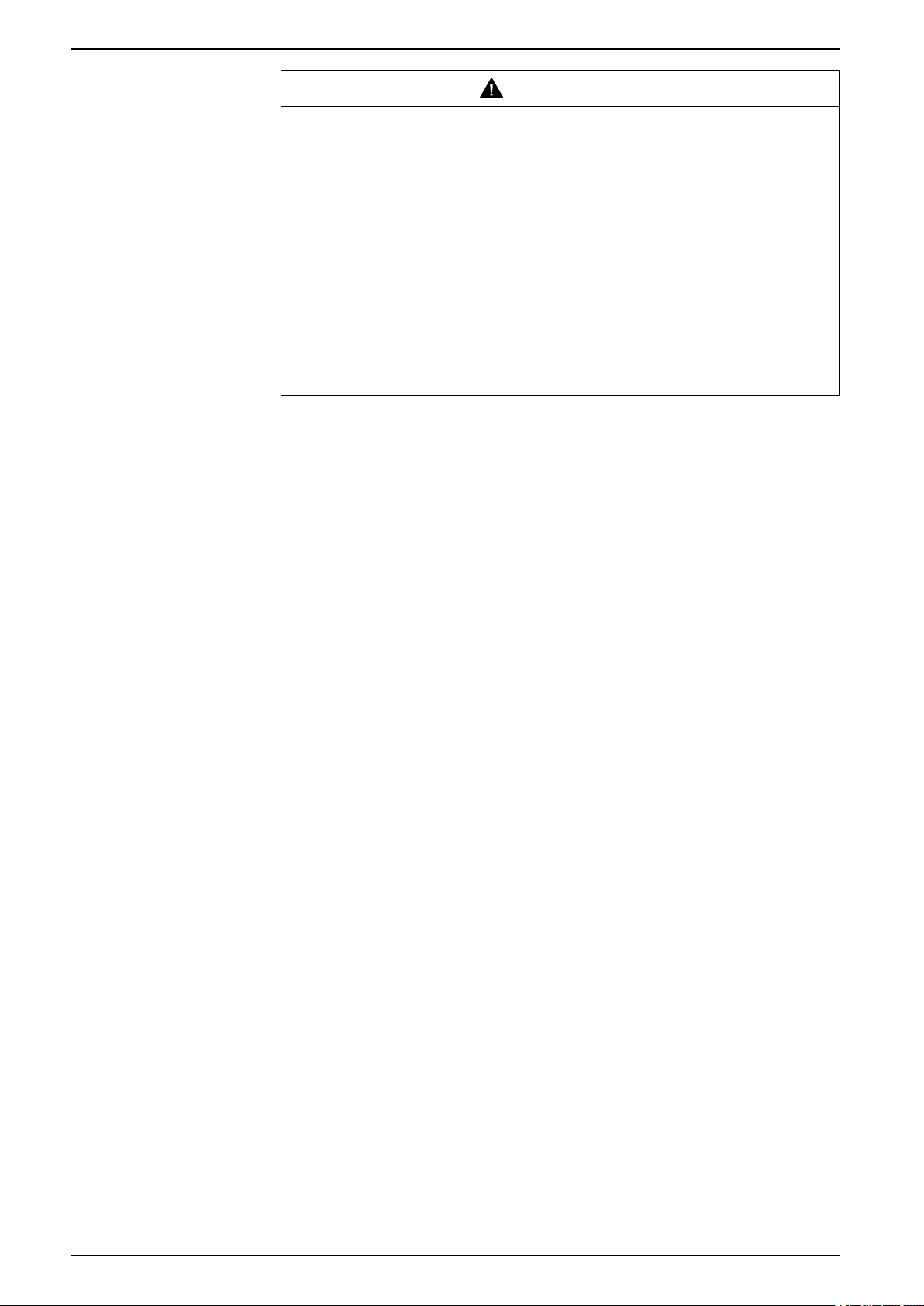

This table presents the network configuration options of the Com’X:

Port

Options

GPRS/3G only Configuration

GPRS/3G and

switched network

Wi-Fi only Configuration

Wi-Fi and

switched network

2 Switched Ports

(1 IP address for

both)

2 Separate Ports

(1 IP address for

each)

(1)

Preferred usage for this port.

(2)

Available only in Wi-Fi Access Point mode.

Ethernet Port 1 Ethernet Port 2 Wi-Fi GPRS/3G

(1)

(1)

Configuration

Configuration,

data collection,

and publishing

data collection,

and publishing

Configuration

Configuration

Configuration

and data

collection

Configuration and data collection Configuration

and data

collection

Configuration and data collection Configuration,

Configuration, data collection and

publishing

Configuration

and data

publishing

(1)

(1)

and data

collection

Configuration

and data

collection

Configuration

and data

collection

(2)

(2)

(2)

(2)

Data publishing

Data publishing

–

–

–

–

NOTE: It is recommended to use an external cellular router instead of the

above configurations.

With a GPRS or 3G Modem

The GPRS or 3G modem is used to publish data.

If you want to use Ethernet for data collection, configure the Com’X in GPRS/3G

and Switched network. Otherwise the Com’X must be configured as GPRS/3G

only.

When the Com’X is configured in GPRS/3G only, the Ethernet port 2 acts as a

DHCP server. This mode allows you to connect a PC for configuration.

NOTE: It is recommended to use an external cellular router instead of the

above configurations.

If a Wi-Fi module is installed, it can be used to establish a connection with a PC, a

tablet, or a smartphone to configure the system.

With a Wi-Fi Key

A Wi-Fi key can be used to publish data. If you want to use Ethernet for data

collection, configure the Com’X in Wi-Fi and switched network. Otherwise the

Com’X must be configured as Wi-Fi only.

Wired Ethernet

If the Com’X does not use a GPRS/3G modem or a Wi-Fi module for data

publishing, the two Ethernet ports can be configured separately.

Selecting a Network Configuration

Select the appropriate network configuration for your system.

DOCA0098EN-12 31

Page 32

Com’X 510 Energy Server Com’X 510 Settings

1. Click Settings > General Settings > Network Settings.

2. Select the network configuration in the Choose your network configuration

drop-down list.

3. If necessary, enter the parameters for each connection interface displayed.

Refer to the corresponding sections.

4. Click Save changes.

5. Wait for the Com’X to reboot.

The power LED turns green when the reboot is complete.

Related Topics

• GPRS/3G Settings

• Configuring Advanced Ethernet Settings

• Configuring a Wi-Fi Network

Reboot Cases

Changing some Com’X settings can cause an automatic reboot.

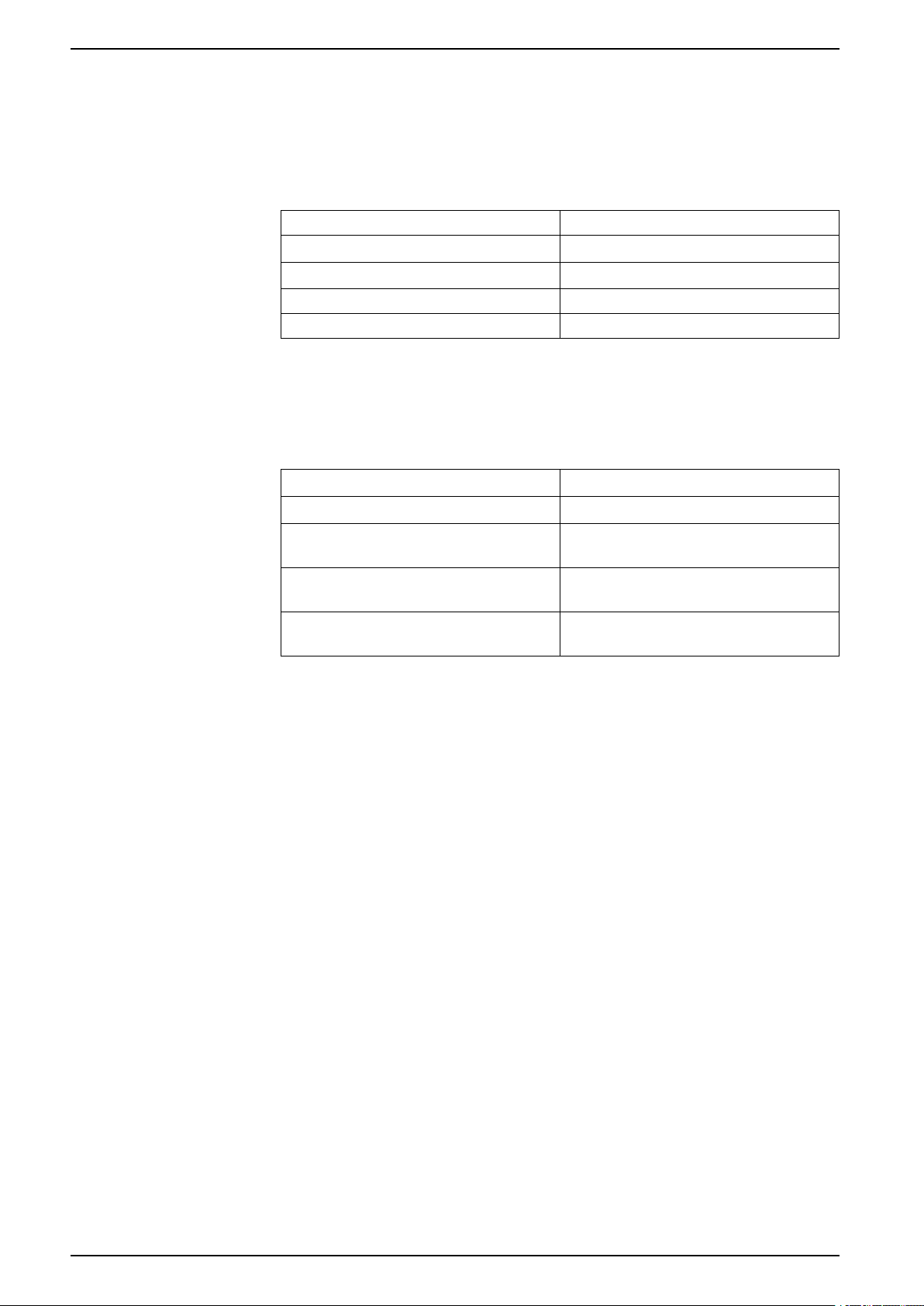

Initial Network Configuration New Network Configuration

2 separate ports • 2 switched ports

• GPRS/3G and 2 switched ports

• Wi-Fi and 2 switched ports

GPRS/3G only • 2 switched ports

• GPRS/3G and 2 switched ports

• Wi-Fi and 2 switched ports

Wi-Fi only • 2 switched ports

• GPRS/3G and 2 switched ports

• Wi-Fi and 2 switched ports

2 switched ports • 2 separate ports

• GPRS/3G only

• Wi-Fi only

GPRS/3G and 2 switched ports • 2 separate ports

• GPRS/3G only

• Wi-Fi only

Wi-Fi and 2 switched ports • 2 separate ports

• GPRS/3G only

• Wi-Fi only

NOTE: It is recommended to use an external cellular router instead of the

GPRS/3G configurations. Please refer to GPRS/3G Settings, page 34 to see a

list of recommended external 3G modems.

Ethernet Port Settings

Your Com’X has two Ethernet ports.

The Ethernet ports can be configured in two modes:

• Switch mode: two Ethernet ports share the same configuration.

• Upstream/downstream mode: two Ethernet ports are configured separately.

Switch Mode Configuration

This graphic illustrates the Ethernet port configuration in switch mode:

32 DOCA0098EN-12

Page 33

Com’X 510 Settings Com’X 510 Energy Server

In switch mode, both Ethernet ports have the same settings. Using two ports

simplifies wiring:

• one port can be connected to a switch in the local network.

• one port can be used to connect a PC for configuration operations or to

connect a data collection device locally with an Ethernet port.

Upstream/Downstream Mode Configuration

This graphic illustrates the Ethernet port configuration in upstream/downstream

mode:

DOCA0098EN-12 33

Page 34

Com’X 510 Energy Server Com’X 510 Settings

In upstream/downstream mode, the two Ethernet ports have different settings and

function independently:

• one port must be used for data publishing.

• one port must be used for data collection.

The port used for data publishing (eth1) can be configured in DHCP client mode or

static IPv4 address mode. The port used for data collection (eth2) can be

configured in DHCP client, static IPv4 address, or DHCP server.

Ethernet Configuration Settings

DHCP client: The IP address is automatically assigned to the Com’X. It is

recommended to have a fixed IP address, obtained by a DSL modem or by a

network administrator.

Static IPv4 address: Type the IP, subnetwork mask, and default gateway

addresses. Addresses are assigned to the Com’X by the IT administrator.

Related Topics

• IPv4 Address Settings

Configuring the Ethernet Ports

You can configure the Ethernet ports to as two separate ports.

1. Click Settings > General Settings > Network Settings.

2. Select the Choose your network configuration field.

NOTE: If you change the configuration of the Ethernet port you are

configuring through, you will be disconnected through the browser. Begin

a new browsing session to continue configuration.

3. Select 2 Separate Ports (1 IP address for each) in the drop-down list.

4. Select DHCP client and Static IPv4 address in the Configuration mode

drop-down list.

5. In the Ethernet configuration collapsible menu, enter the parameters in the

WAN network configuration (eth1) and LAN network configuration (eth2)

fields.

The Interface Status field changes to ACTIVE (if correctly wired).

6. In General network settings collapsible menu, type the addresses in the

Default gateway, Primary DNS server, and, if necessary, Secondary DNS

server fields.

Addresses are assigned to the Com’X by the IT administrator.

7. To enable ping replies, select Yes in General network settings > Reply to

ping.

Reply to ping is disabled by default.

8. Click Save changes.

GPRS/3G Settings

Cellular access can be added to the Com’X by installing a modem under the

cover.

This table illustrates GPRS/3G settings:

34 DOCA0098EN-12

Page 35

Com’X 510 Settings Com’X 510 Energy Server

GPRS/3G Only GPRS/3G and 2 Ethernet Switched Ports (1 IP Address for Both Ports)

Cellular network options depend on the modem that is connected.

GPRS/3G/4G and wireless transmissions are sensitive to local environmental

conditions, such as weather, network availability, and other GPRS/3G/4G devices.

You could incur increased communication costs in the event of low connectivity.

3G Modems

The following 3G modems have been tested and are compatible with the Com’X.

For each modem, refer to the manufacturer's documentation for technical

specifications and detailed installation instructions.

Manufacturer/Model Antenna Notes

MultiTech (rCell) External • Recommended

• Connected via an Ethernet cable.

• This modem must be mounted to the

enclosure. Refer to the manufacturer's

installation instructions.

Digi Routers External • Recommended

• Connected via an Ethernet cable.

• This modem must be mounted to the

enclosure. Refer to the manufacturer's

installation instructions.

MOXA (OnCell) External • Recommended

• Connected via an Ethernet cable.

• This modem must be mounted to the

enclosure. Refer to the manufacturer's

installation instructions.

eTIC External • Recommended

• Connected via an Ethernet cable.

• This modem must be mounted to the

enclosure. Refer to the manufacturer's

installation instructions.

DOCA0098EN-12 35

Page 36

Com’X 510 Energy Server Com’X 510 Settings

Related Topics

• Configuring Access Settings with EBXA-GPRS or a 3G Modem

• Configuring Access Settings with EBXA-GPRS-SIM Card

Installing a 3G Modem on the Com’X

You can install a 3G modem on the Com’X.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• This equipment must only be installed and serviced by qualified personnel.

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices. See NFPA 70E in the USA, CSA Z462 or

applicable local standards.

Failure to follow these instructions will result in death or serious injury.

1. Power off the Com’X.

2. Open the Com’X front door.

36 DOCA0098EN-12

Page 37

Com’X 510 Settings Com’X 510 Energy Server

3. Connect the 3G modem.

– For modems that mount inside the Com’X, connect the modem to the

internal USB port.

– For 3G modems that do not mount inside the Com’X front cover, break off

the tab to create an opening for the cable, then connect the modem cable

to the internal USB port.

4. Close the Com’X door as shown above.

5. Power on the Com’X. The Radio Modem LED flashes to show the modem

has been detected.

Configuring Access Settings with EBXA-GPRS-SIM Card

You can only use the EBXA GPRS SIM to publish data if you are exporting data to

Digital Service Platform.

The SIM card is embedded in the GPRS modem. The access settings of this

GPRS modem are set by the Com’X.

The reference EBXA-GPRS-SIM must be selected for this GPRS modem.

DOCA0098EN-12 37

Page 38

Com’X 510 Energy Server Com’X 510 Settings

NOTE: It is recommended to use an external cellular router instead of the

EBXA-GPRS-SIM. Please refer to GPRS/3G Settings, page 34 to see a list of

recommended external 3G modems.

Configuring Access Settings with EBXA-GPRS or a 3G Modem

You need to configure access settings when using an EBXA-GPRS or 3G modem.

Install the SIM card into the GPRS modem as described in the EBXA-GPRS/

EBXA-GPRS-SIM Instruction Sheet, reference 253537613. For 3G, install the

SIM card into the 3G modem as described in the manufacturer's installation

instructions.

The EBXA-GPR/3G modem requires:

• a mini SIM 2FF type card.

• a minimum 1 MB/month data export on the telecom contract.

A robust M2M SIM card is recommended rather than a standard SIM card.

NOTE: It is recommended to use an external cellular router instead of the

EBXA-GPRS. Please refer to GPRS/3G Settings, page 34 to see a list of

recommended external 3G modems.

1. Click Settings > General Settings > Network Settings.

Wi-Fi Settings

2. Select EBXA-GPRS/3G.

3. Type the APN, Username, Password, and PIN Code provided by the access

provider.

4. Click Save changes.

NOTE: The PIN code and the password of the SIM card cannot be changed

by the energy server.

This table illustrates Wi-Fi settings:

38 DOCA0098EN-12

Page 39

Com’X 510 Settings Com’X 510 Energy Server

Wi-Fi Only

Wi-Fi and 2 Ethernet Switched Ports (1 IP Address for Both

Ports)

Use any USB port for temporary access, for example, to configure the Com’X.

For permanent use, the Wi-Fi USB key must be installed outside the enclosure for

EMC reasons. Schneider Electric provides accessories to mount the Wi-Fi key

outside the enclosure.

NOTICE

UNINTENDED EQUIPMENT OPERATION

Do not install the Wi-Fi key inside a metallic enclosure.

Failure to follow these instructions can result in equipment damage.

The Com’X does not enable Point-to-Point connections with other Wi-Fi field

devices. Wi-Fi traffic is controlled by the Wi-Fi infrastructure of the site.

Related Topics

• Wi-Fi Access Point Settings

Configuring a Wi-Fi Network

You can configure your Com’X wireless network.