SATO S8424, S8408, S8412 User Manual

S8408/S8412/S8424

PRINTERS

OPERATOR MANUAL

PN: 9001160B

SATO America, Inc.

10350A Nations Ford Road

Charlotte, NC 28273

Main Phone: (704) 644.1650

Technical Support Hotline: (704) 644.1660

Technical Support Fax: (704) 644.1661

E-Mail: satosales@satoamerica.com

techsupport@satoamerica.com

www.satoamerica.com

WARNING

THE EQUIPMENT REFERENCED IN THIS DOCUMENT COMPLIES WITH THE REQUIREMENTS IN PART 15 OF FCC RULES FOR A CLASS B COMPUTING DEVICE. OPERATION OF THIS EQUIPMENT IN A RESIDENTIAL AREA MAY CAUSE UNACCEPTABLE INTERFERENCE TO RADIO AND TV RECEPTION.

PN: 9001160B

TABLE OF CONTENTS

INTRODUCTION

About This Manual |

1-2 |

General Description |

1-3 |

Control Features |

1-5 |

TECHNICAL DATA

Physical Characteristics |

2-2 |

Power |

2-2 |

Enviromental |

2-2 |

Processing |

2-2 |

Command |

2-2 |

Interface Modules |

2-2 |

Regulatory Approvals |

2-2 |

2-3 |

|

Media |

2-3 |

Ribbon |

2-3 |

Sensing |

2-4 |

Character Font Capabilities |

2-4 |

Barcode Capabilities |

2-5 |

INSTALLATION

Unpacking & Parts Identification |

3-2 |

Printer Installation |

3-3 |

Printer Loading |

3-5 |

Operational Mode Selection |

3-8 |

Interface Selection |

3-9 |

RS232C High-Speed Serial Interface |

3-10 |

IEEE1284 Parallel Interface |

3-12 |

Universal Serial BUS (USB) Adapter |

3-13 |

Local Area Network (LAN) Ethernet |

3-14 |

802.11G Wireless |

3-15 |

All Interfaces |

3-17 |

Accessories Installation |

3-25 |

Interface |

3-25 |

Remote Operator Panel |

3-26 |

S8400 Series Operator Manual |

PN: 9001160B |

PRINTER CONFIGURATION

Printer Configuration |

4-2 |

Configuration Modes |

4-3 |

User Mode |

4-3 |

Advanced Mode |

4-4 |

Parallel Interface Mode |

4-5 |

Serial Interface Mode |

4-6 |

Local Area Network (LAN) Interface Mode |

4-7 |

Universal Serial BUS (USB) Interface Mode |

4-8 |

Centronics Interface Mode |

4-9 |

Wireless LAN (Local Area Network) Interface Mode |

4-10 |

Service Mode |

4-11 |

Factory Mode |

4-12 |

Work Shift Mode |

4-13 |

Hidden Mode |

4-14 |

Download Mode |

4-15 |

Boot Download Mode |

4-16 |

Print Cancel Mode |

4-17 |

Default Settings Mode |

4-18 |

Test Print Mode |

4-19 |

Hex Dump Mode |

4-20 |

CF (Compact Flash) Card Mode |

4-21 |

Stand Alone Mode |

4-22 |

Menu Definition Tables |

4-23 |

TROUBLESHOOTING

Error Signal Troubleshooting |

5-2 |

Warning Signal Troubleshooting |

5-6 |

Troubleshooting Table |

5-7 |

Interface Troubleshooting |

5-9 |

Parallel Interface |

5-9 |

RS232 Serial Interface |

5-9 |

Universal Serial Bus (USB) Interface |

5-9 |

LAN Ethernet Interface |

5-10 |

802.11g Interface |

5-10 |

Centronics Interface |

5-10 |

Test Print Troubleshooting |

5-11 |

Hex Dump Mode |

5-11 |

Test Label Printing |

5-11 |

Sample Test Label |

5-11 |

S8400 Series Operator Manual |

PN: 9001160B |

MAINTENANCE

Cleaning Procedures |

6-2 |

Replacement Procedures |

6-3 |

Print Head |

6-3 |

Platen Rollers |

6-4 |

Interface Board |

6-5 |

Fan Filter |

6-6 |

Adjustment Procedures |

6-7 |

Label Sensor Positioning |

6-7 |

Print Head Pressure |

6-8 |

Print Head Alignmnent |

6-9 |

Ribbon Guide Alignment |

6-10 |

Media Pressure Roller Balance |

6-11 |

Ribbon Cassette Belt Tensioning |

6-12 |

Print Head Balance |

6-13 |

Eye-Mark/Paper-End Sensor Sensitivity |

6-14 |

Gap Sensor Sensitivity |

6-15 |

Operational Adjustments |

6-16 |

Pitch |

6-16 |

Offset |

6-16 |

Darkness |

6-16 |

APPENDIX

Ready/Busy timing Charts |

7-2 |

X-On/X-Off Timing Charts |

7-3 |

Session Connect/Disconnect Diagram |

7-4 |

Printer Dimensions (Standard w/Cassette) |

7-5 |

Printer Dimensions (Opposite w/Cassette) |

7-8 |

Printer Dimensions (Standard Direct Load) |

7-11 |

Printer Dimensions (Opposite Direct Load) |

7-14 |

Glossary |

7-17 |

S8400 Series Operator Manual |

PN: 9001160B |

INTRODUCTION

•About This Manual

•General Description

•Control Features

S8400 Series Operator Manual |

1-1 |

PN: 9001160B |

Unit 1: Introduction

ABOUT THIS MANUAL

This manual is laid out consistent with the product discussed and provides all of the information required for general printer configuration, operation, troubleshooting, and maintenance. For specialized programming, refer to the Programming Reference document.

Step-by step maintenance instructions are provided with typical problems and solutions. Become familiar with each unit and section before installing and maintaining the printer.

This manual also incorporates the use of special information boxes. Examples of these boxes and the type of information provided in each, are below.

WARNING: PROVIDES INFORMATION THAT, IF UNHEEDED, MAY RESULT IN

PERSONAL INJURY.

CAUTION: PROVIDES INFORMATION THAT, IF UNHEEDED, MAY RESULT IN

EQUIPMENT DAMAGE.

ATTENTION: Provides information that is deemed of special importance but will not result in personal injury or product damage if unheeded.

NOTE: Provides helpful hints to assist in performing the tasks at hand.

NOTE: Provides helpful hints to assist in performing the tasks at hand.

LCD DISPLAY: Provides the specific display that should be visible on the LCD at that point.

A comprehensive Table Of Contents provided at the front of this manual facilitates rapid movement within. The contents identify the different Units, Chapters, and some Sections. Each references the page number of their commencement.

The pages of this manual have embedded headers and footers to assist the user in identifying his or her exact position within the manual. The header provides the unit number followed by its name. The footer identifies the product on the left, the page number in the center, and the manual’s part number to the right side of the page.

Page enumeration is two-part with each separated by a hyphen. The first character set references the Unit and the second identifies the page number within that unit. Page numbers begin with the numeral one (1) at the beginning of a new unit and ascend sequentially.

ATTENTION: The illustrations and graphics provided in this manual may display components, assemblies, and purchase options that may not be present on idividual printers. However, where those instances arise, they are not revalent to the topic discussed.

S8400 Series Operator Manual |

1-2 |

PN: 9001160B |

Unit 1: Introduction

GENERAL DESCRIPTION

The S8400 series print engines are specifically designed for use in high-volume, automated print/apply labeling applications demanding unparalleled reliability and around the clock operation. These print engines offer four-inch wide printing ability and are available in 203, 305, and 609 dpi print resolution. However, more compelling is their user-friendly design and application flexability.

These OEM print engines follow the design concepts and principles of SATO’s previous, market leading, industrial print engines. The S8400 series can physically and electronically replace any of SATO’s previous S-type OEM print engines. Additionally, this printer utilizes the same SATO Barcode Printing Language (SBPL) as drives all current SATO OEM print engines.

The S8400 series print engine is available with many options, including quick-change ribbon cassette, ribbon saver, and RFID capability.

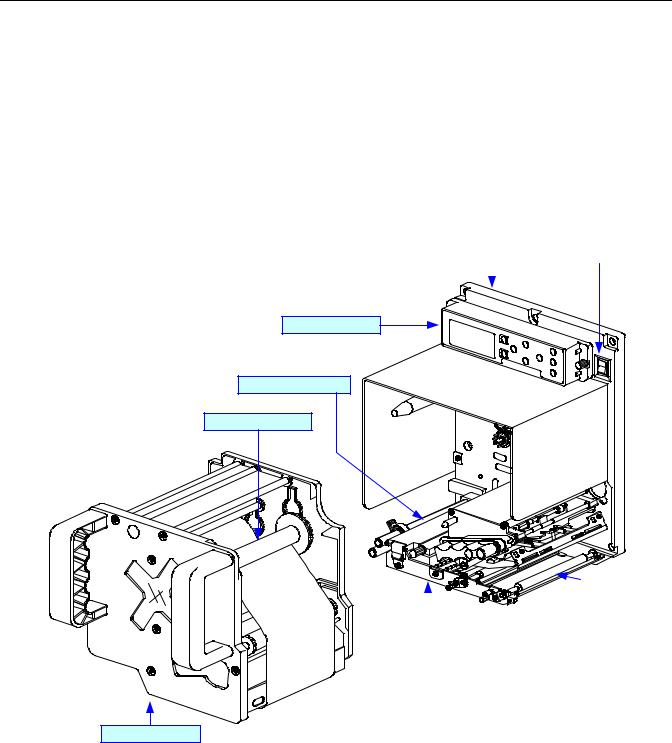

Center Frame |

|

Power Switch |

|

|

|

|

|

Operator Panel

Label Sensor Assy

Ribbon Spindle x2

|

|

|

|

|

|

|

|

|

|

Chassis |

|

Platen Roller x3 |

||

Ribbon Cassette

Figure 1-1a, Primary Components

S8400 Series Operator Manual |

1-3 |

PN: 9001160B |

Unit 1: Introduction

Front Housing Cover |

|

Rear Housing Covers |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ribbon Supply Spindle

Ribbon Rewind Spindle

Media Guide |

|

|

Ribbon Roller x2 |

Printer Chassis |

Ribbon Guide |

|

|

Label Sensor Adjustment Knob |

Head Pressure Knob |

Head Balance |

Print Head Latch |

Figure 1-1b, Primary Components

S8400 Series Operator Manual |

1-4 |

PN: 9001160B |

Unit 1: Introduction

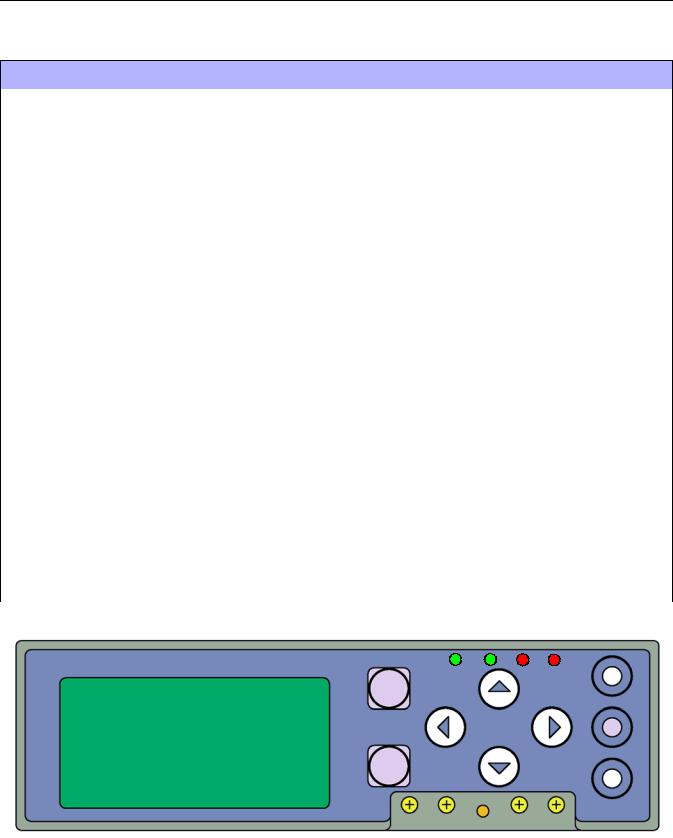

CONTROL FEATURES

This chapter identifies the interactive control features of the printer. These functions are defined generally here. More specific explanations will be found throughout this manual on how to use them.

OPERATOR PANEL FEATURES

LED |

DEFINITION |

|

|

POWER |

Illuminates green when the printer is powered on. Terminates when powered off. |

|

|

ONLINE |

Illuminates green when the printer is in an online state. Terminates when the printer goes offline. |

|

|

LABEL |

Off = Normal state. |

|

Red Constant = When a Label Error has occurred. |

|

|

RIBBON |

Off = Normal state. |

|

Red Flashing = Ribbon supply is low. |

|

Red Constant = When a Ribbon Error has occurred. |

|

|

KEYS |

DEFINITION |

|

|

POWER |

Removes power supply at its entry to the printer. |

|

|

LINE |

Moves the printer from an online to offline state and vise-versa. Has other special functions as |

|

identified in flow charts throughout this manual as applicable. |

|

|

FEED |

Advances the label media when pressed. Has other special functions as identified in flow charts |

|

throughout this manual as applicable. |

|

|

FUNCTION |

Pressing steps the LCD back to a previous menu. Has other special functions as identified in flow |

|

charts throughout this manual as applicable. |

|

|

ENTER |

Used to select a menu option and to advance the menu screen accordingly. Has other special |

|

functions as identified in flow charts throughout this manual as applicable. |

|

|

CANCEL |

Pressing steps the LCD back to a previous menu. Has other special functions as identified in flow |

|

charts throughout this manual as applicable. |

|

|

ARROWS |

Allows the operator to scroll through various menus and menu options. Has other special |

|

functions as identified in flow charts throughout this manual as applicable. |

|

|

POTENTIOMETERS |

DEFINITION |

|

|

VOLUME |

Allows volume control of the printer’s audible alarm. |

|

|

PITCH |

For adjusting the print position. |

|

|

OFFSET |

Adjusts the peel or dispense stop position. |

|

|

DARKNESS |

Adjusts the print density resulting in a lighter or darker print image. |

|

|

FUNCTION

LINE

ENTER

LCD DISPLAY

FEED |

CANCEL |

Figure 1-2, Operator Panel

S8400 Series Operator Manual |

1-5 |

PN: 9001160B |

TECHNICAL DATA

•Physical Characteristics

•Power

•Environmental

•Processing

•Command

•Interface Modules

•Regulatory Approvals

•Media

•Ribbon

•Sensing

•Character Font Capabilities

•Barcode Capabilities

S8400 Series Operator Manual |

2-1 |

PN: 9001160B |

|

|

Unit 2: Technical Data |

|

|

|

PHYSICAL CHARACTERISTICS |

|

|

|

|

|

Typical Width |

|

9.65 Inches (245mm) |

Typical Height |

|

11.81 Inches (300mm) |

Maximum Depth |

|

18.82 Inches (478mm) |

Standard Weight |

|

35.27 Pounds (16.0Kg) |

|

|

|

POWER |

|

|

|

|

|

Input Voltage |

|

100-240 Volts AC +/- 10%, 50/60 Hertz +/-5% |

Power Consumption |

|

220 Watts, 2.7 to 1.1 Amperes (operating) |

Accelleration Perfomance |

|

3.5G (Frequency: 10Hz or below, Vibration Time: within 5 minutes) |

|

|

|

ENVIRONMENTAL |

|

|

|

|

|

Operating Temperature |

|

41 to 104°F (5° to 40°C) |

Storage Temperature |

|

0 to 140°F (-20° to 60°C) |

Storage Humidity |

|

15 to 85% RH Non-Condensing |

Operating Humidity |

|

15 to 85% RH Non-Condensing |

|

|

|

PROCESSING |

|

|

|

|

|

CPU |

|

32 Bit RISC |

FLash ROM |

|

4 Megabytes |

SDRAM |

|

16 Megabytes |

FRAM |

|

32 Kilobytes |

Receive Buffer |

|

2.95 Megabytes |

SRAM (integrated calendar) |

|

8 Kilobytes |

|

|

|

COMMAND |

|

|

|

|

|

Standard |

|

SATO Barcode Printer Language (SBPL) |

|

|

|

INTERFACE MODULES |

|

|

|

|

|

Enhanced Parallel Port |

|

IEEE1284 (ECP Compatible) |

|

|

RS232C (9600 to 57,600 bps) - 25 Pin |

Serial Port |

|

RS422/485 (9600 to 57600 bps) |

|

|

RS232C - 9 Pin PCI |

Universal Serial Bus (USB) |

|

USB Adapter (12 Mbps) - PCI |

Local Area Network (LAN) |

|

10BASE-T/100BASE-TX Automatic Switching |

Wireless LAN |

|

802.11g Wireless |

|

|

|

REGULATORY |

|

|

|

|

|

Safety |

|

MET, NEMKO-GS, C-MET |

Radiant Noise |

|

FCC (Class B), EN 55022 (Class B) |

Efficiency |

|

International Energy Star |

Packaging Drop Test |

|

ISTA-2A |

|

|

|

S8400 Series Operator Manual |

2-2 |

PN: 9001160B |

|

Unit 2: Technical Data |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|||

Method |

|

Direct Thermal / Thermal Transfer |

|||||

Head Width |

|

|

4.09 Inches (104mm) |

|

|||

|

203 Dots Per Inch (8dpmm): 4 to 16 Inches Per Second (102-406mm/s) |

||||||

Maximum Speed |

305 Dots Per Inch (12dpmm): 4 to 14 Inches Per Second (102-356mm/s) |

||||||

|

609 Dots Per Inch (24dpmm): 2 to 6 Inches Per Second (51-152mm/s) |

||||||

|

|

|

203 Dots Per Inch (8dpmm) |

|

|||

Resolution |

|

|

305 Dots Per Inch (12dpmm) |

|

|||

|

|

|

609 Dots Per Inch (24dpmm) |

|

|||

|

203 Dots Per Inch (8dpmm): 4.09 x 98.4 Inches Wide (104mm W x 2500mm L) |

||||||

Maximum Printable Area |

305 Dots Pre Inch (12dpmm): 4.09 x 59.0 Inches Wide (104mm W x 1500mm L) |

||||||

|

609 Dots Per Inch (24dpmm): 4.09 x 15.7 Inches Wide (104mm W x 400mm L) |

||||||

|

|

|

|

|

|

|

|

MEDIA |

|

|

|

|

|

|

|

|

|

|

|

||||

Width |

Media Width: 0.394 to 5.039 Inches (10-128 mm) |

||||||

Media Width with Backing Paper: 0.5 to 5.1 Inches (13-131 mm) |

|||||||

|

|||||||

Length (Pitch) |

Media Length: 0.6 Inches (15 mm) (to printable area) |

||||||

Type |

Die-Cut Labels, Waste removed, Roll, 0.125 inch Gap or Eye-Mark |

||||||

Thickness |

|

0.002 to 0.012 Inches (0.05 - 0.31mm) |

|||||

|

Media Width (mm) |

|

Label Supply Load (grams) |

|

Liner Rewind Load (grams) |

||

|

13 to 18 |

|

|

< 250 |

|

< 150 |

|

|

|

|

|

|

|

|

|

|

18 to 28 |

|

|

< 400 |

|

< 300 |

|

Media Handling |

|

|

|

|

|

|

|

28 to 48 |

|

|

< 900 |

|

< 300 |

||

|

|

|

|

|

|

|

|

|

48 to 63 |

|

|

< 1,200 |

|

< 400 |

|

|

|

|

|

|

|

|

|

|

63 to 83 |

|

|

< 1,200 |

|

< 650 |

|

|

|

|

|

|

|

|

|

|

83 + |

|

|

< 1,400 |

|

< 800 |

|

|

|

|

|

|

|

|

|

RIBBON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Width |

|

Minimum: |

0.98 Inches (25mm) |

|

|||

|

Maximum: |

5.04 Inches (128mm) |

|||||

|

|

||||||

Length |

|

|

3280 Feet (1000m) |

|

|||

|

Ribbon Length (m) |

|

Ribbon Width (mm) |

|

Label Pitch (mm) |

||

Ribbon Handling |

1,000 |

|

|

76 |

|

60 + |

|

|

|

|

|

|

|

||

600 |

|

|

39.5 to 75 |

|

25 + |

||

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

450 |

|

|

< 39.5 |

|

< 25 |

|

Wound |

|

|

Face In / Face Out |

|

|||

Roll Diameter |

|

|

4.252 Inches (108mm) |

|

|||

Core Diameter |

|

1.01 +/-0.008 Inches (25.6mm +/-0.2mm) |

|||||

Color |

Black (standard), Other Tints (non-standard) |

||||||

|

|

|

|

|

|

|

|

S8400 Series Operator Manual |

2-3 |

PN: 9001160B |

|

|

Unit 2: Technical Data |

|

|

|

SENSING |

|

|

|

|

|

Gap |

|

Adjustable |

Reflective Eye-Mark |

|

Adjustable |

Ribbon Near End |

|

Enable/Disable |

Media Out |

|

Constant |

Cover-Open |

|

Constant |

Head-Open |

|

Constant |

|

|

|

CHARACTER FONT CAPABILITIES |

|

|

|

|

|

MATRIX FONTS |

|

|

|

|

|

XU |

|

5 dots W x 9 dots H (Helvetica) |

XS |

|

17 dots W x 17 dots H (Univers Condensed Bold) |

XM |

|

24 dots W x 24 dots H (Univers Condensed Bold) |

|

|

203dpi (8dots/mm): 15 dots W x 22 dots H |

OA Font (OCR-A) |

|

305dpi (12dots/mm): 22 dots W x 33 dots H |

|

|

609dpi (24dots/mm): 44 dots W x 66 dots H |

|

|

203dpi (8dots/mm): 20 dots W x 24 dots H |

OB Font (OCR-B) |

|

305dpi (12dots/mm): 30 dots W x 36 dots H |

|

|

609dpi (24dots/mm): 60 dots W x 72 dots H |

AUTO SMOOTHING FONTS |

|

|

|

|

|

XB |

|

48 dots W x 48 dots H (Univers Condensed Bold) |

XL |

|

48 dots W x 48 dots H (Sans Serif) |

VECTOR FONT |

|

|

|

|

|

|

|

Proportional or Fixed Spacing |

|

|

Font Size 50 x 50 dots to 999 x 999 dots |

|

|

Helvetica, 10 Font Variations |

AGFA RASTER FONTS |

|

|

|

|

|

A Font |

|

CG Times, 2 to 99 pt. (4-999 dots) |

B Font |

|

CG Triumvirate, 2 to 99 pt. (4-999 dots) |

DOWNLOADABLE FONTS |

|

|

|

|

|

|

|

Compact Flash Card required |

CHARACTER CONTROL |

|

|

|

|

|

|

|

Expansion up to 12 x in either the X or Y coordinates. |

|

|

Character Pitch Control |

|

|

Line Space Control |

|

|

Journal Print Facility |

|

|

0, 90, 180, and 270 Degree Rotation |

|

|

|

S8400 Series Operator Manual |

2-4 |

PN: 9001160B |

Unit 2: Technical Data

BAR CODE CAPABILTIES

|

UPC A/E |

|

|

EAN 8/13 |

|

|

Code 39 |

|

|

Code 93 |

|

|

Code 128 |

|

|

Interleaved 2 of 5 |

|

Linear Bar Codes |

Industrial 2 of 5 |

|

Matrix 2 of 5 |

||

|

||

|

Bookland |

|

|

RSS-14 |

|

|

MSI |

|

|

POSTNET |

|

|

UCC/EAN 128 |

|

|

NW-7 (Codabar) |

|

|

QR Code |

|

|

Data Matrix (ECC200) |

|

Two Dimemsional |

Maxi Code |

|

|

PDF417 |

|

|

Composite Symbology |

|

Bar Width Ratio |

1:2, 1:3, 2:5, User definable bar widths |

|

Bar Height |

4 to 999 dots, User progammable |

|

Rotation |

0, 90, 180, and 270 Degrees |

|

Sequential Numbering |

Sequential numbering of both numerics and bar codes |

|

Graphics |

Full dot addressable graphics, SATO Hex/Binary, BMP or PCX formats |

|

Form Overlay |

Form overlay for high-speed editing of complex formats |

|

|

|

S8400 Series Operator Manual |

2-5 |

PN: 9001160B |

INSTALLATION

•Unpacking & Parts Identification

•Printer Installation

•Printer Loading

•Operational Mode Selection

•Interface Selection

•Accessories Installation

S8400 Series Operator Manual |

3-1 |

PN: 9001160B |

Unit 3: Installation

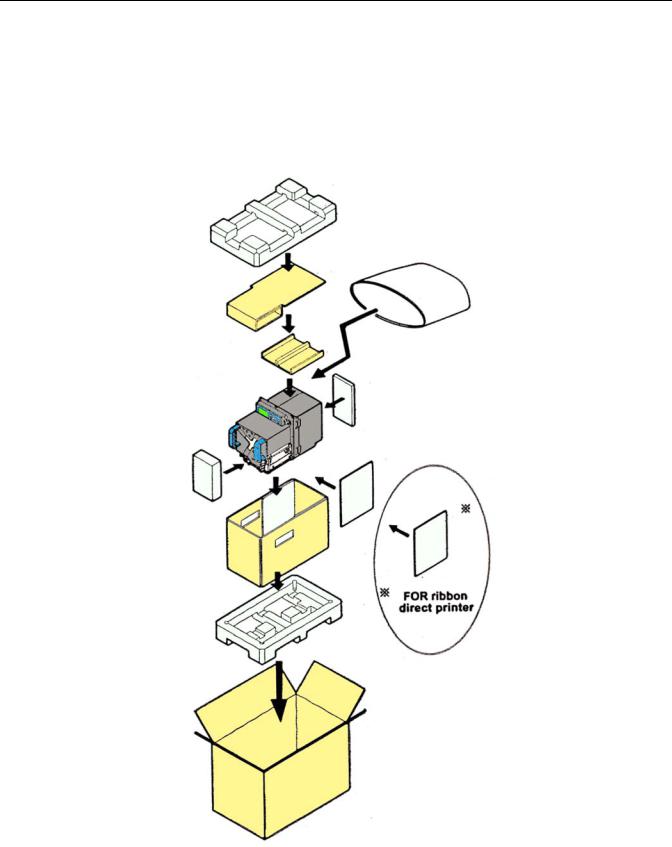

UNPACKING & PARTS IDENTIFICATION

Unpack the printer as directed in the folowing procedure.

1.Place the shipping container (box) upright on a stable, flat surface.

2.Open the box, remove any loose items and the first layer of packing material.

3.Carefully lift the printer and accessories from the box and place them on a stable, flat surface.

4.Remove the plastic covers from the packed items and visually inspect for physical damage.

5.Ensure all components are present as dictated on the Packing List.

6.Report damaged property to the shipping carrier.

Figure 3-1, Unpacking

S8400 Series Operator Manual |

3-2 |

PN: 9001160B |

Unit 3: Installation

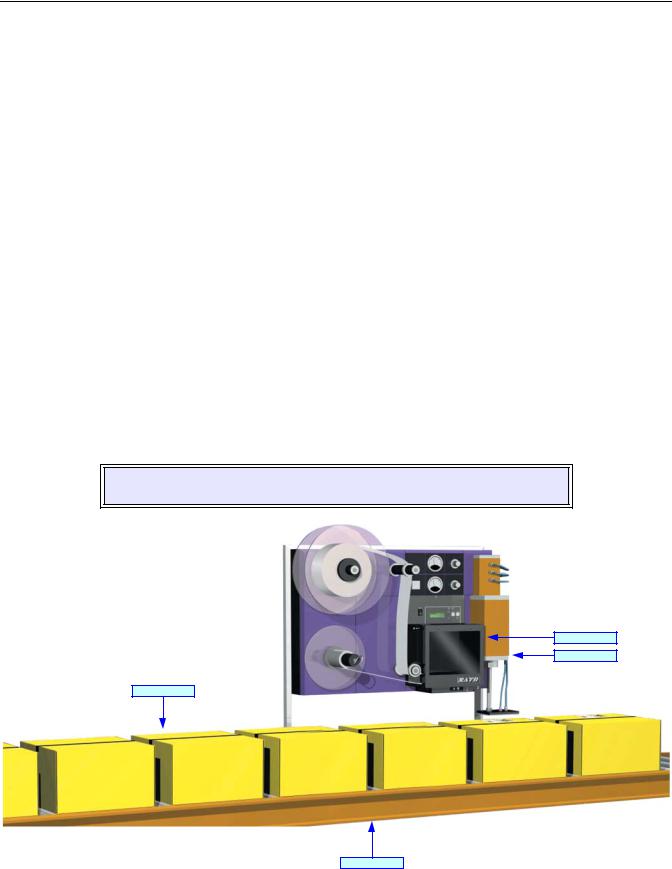

PRINTER INSTALLATION

This chapter provides guidance on how to station, connect, and load the printer once unpacked. Following printer setup, proceded to the next chapter for information on interface selection.

SITE LOCATION

•Stationed away from hazardous materials.

•Stationed within an enclosed structure that conforms to the printer’s enviromental requirements.

•Stationed within operational distance of the host based on interface specifications.

•Stationed to allow unimpeded access to the printer for operation, loading, and maintenance.

INSTALLATION REQUIREMENTS

The printer has five bores in its center frame for the purpose of mounting to a support structure. Refer to the following list of mounting requirements.

•The support structure must be firmly secured to the floor or production machinery.

•The support structure must be sturdy and stable so as to prevent unnecessary movement or vibration.

•The printer is to be mounted to the support structure using attaching hardware design to accommodate the printer’s weight, as well as, the prevailing operational and enviromental conditions within the facility.

•A power supply recepticle or junction box is to be properly secured within regulated proximity to the printer.

•The power supply is to be metered condusive to the printer’s design requirements.

•The printer must be installed so that its output side is within the designated distance and height relative to the applicator.

•Media supply dispensers must be mounted or placed with operational distance of the printer’s input side.

NOTE: Figures 3-2 and 3-3 are to be used as instructional displays only and are not to be literally interpretted as precise examples.

Printer

Applicator

Packaging

Production Line

Figure 3-2, Typical Printer/Applicator Process

S8400 Series Operator Manual |

3-3 |

PN: 9001160B |

Unit 3: Installation

Figure 3-3, Printer Mounting

Host Computer

Breaker Box

Applicator |

|

|

|

|

|

Printer |

|||

|

|

|

|

|

|

|

|

|

|

Interface Card

Interface Cable

Power Cord

EXT Interface

OR

Figure 3-4, Printer Connection

ATTENTION: Figure 3-4 displays the printer interfaced with a host computer. However, the printer may also be interfaced with a PLC, keyboard, scanner, etc.

S8400 Series Operator Manual |

3-4 |

PN: 9001160B |

Unit 3: Installation

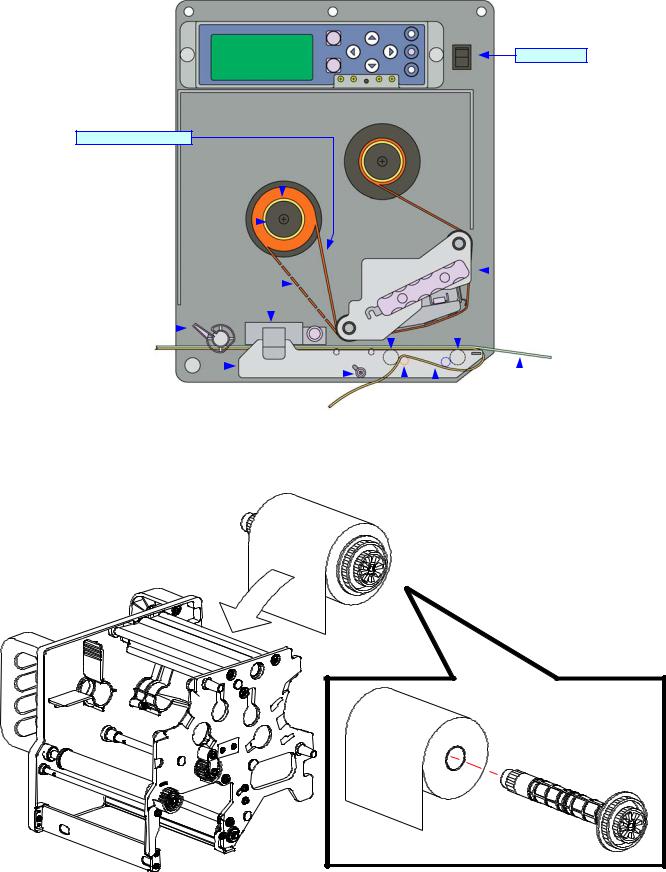

PRINTER LOADING

WARNING: AVOID PHYSICAL CONTACT WITH THE PRINT HEAD TO PREVENT

BURNED FINGERS/HANDS AND COMPONENT DAMAGE.

MEDIA SELECTION

The size and type of labels to be printed should have been taken into consideration before printer purchase. Ideally, the media width will be equal to, or just narrower than, the print head. Using media that does not cover the print head will allow the platen roller to tread upon its surface resulting in premature wear. The media edge will also wear a groove in the platen roller affecting print quality.

There are two types of media that may be used: thermal transfer and direct thermal. Thermal transfer media requires the use of ribbon stock for print application. In such a scenario, it is the ribbon stock (carbon paper) that contains the ink that will be transfered to the media.

Direct thermal media has thermally reactive material embedded within and is brought to the surface through heat penetration by print head contact. Only load ribbon stock into the printer if that media type is to be used.

MEDIA LOADING

To load label media, unlatch the print head and remove any remnants that may exist of the prior media supply. Feed the free end of the media from the printer’s left side, beneath the shaft of the media guide, between the upper and lower halves of the label sensor, across the top of all forthcoming rollers, and through to protrude six or more inches beyond the printer chassis.

Ensure the media is flush against the printer’s back side (toward the center wall) and then adjust the media guide inward until it almost makes contact with the media’s backing paper.

Remove all labels from the backing paper that extend beyond the printer chassis and relatch the print head.

Lift upward on the pressure roller release knob (purple) and allow the pressure roller plate to fall to a vertical position. Route the backing paper’s free end around the front of the printer chassis, beneath the front platen roller and onward between the second platen roller and the pressure roller. Pull the free end of the backing paper to remove all slack while lifting the pressure plate until latched. Refer to Figures 3-5 and 3-6 for visual assistance.

NOTE: Properly installed label media will be oriented so that the label side is upward and the backing paper is downward resting upon the printer chassis.

NOTE: Refer to the Printer Configuration unit of this manual for media configuration instructions and the Adjustment chapter of the Maintenance unit for label sensor adjustment instructions as necessary.

RIBBON LOADING

To load ribbon stock, unlatch the print head and remove exhausted ribbon stock if applicable. Insert an unused ribbon roll, with ribbon core, fully onto the ribbon supply boss (left) and an empty core onto the ribbon rewind boss (right). Route the ribbon’s free end around the print assembly and tape it to the blank core on the rewind boss. Rotate the core a couple of times while holding the boss stationary to take up take up slack. Refer to Figure 3-5 and Figure 3-6 for visual assistance.

NOTE: Properly installed ribbon stock will be oriented so that its dull, ink side is facing the printer chassis while the ribbon is dispensed and taken up on the right side of each roll. The non-ink side of the riibon stock is the shiniest of the two surfaces.

S8400 Series Operator Manual |

3-5 |

PN: 9001160B |

Unit 3: Installation

Power Switch

Ribbon Stock (wound face in)

Ribbon Core |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ribbon Boss |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Print Assembly |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ribbon Stock (wound face out) |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

||

Label Sensor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Media Guide |

|

|

|

|

|

|

|

|

|

Platen Rollers |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Printer Chassis |

|

Pressure Roller Release |

|

Pressure Roller |

|

Paper Backing |

|

Label Media |

|||||||

Figure 3-5, Ribbon & Media Loading

|

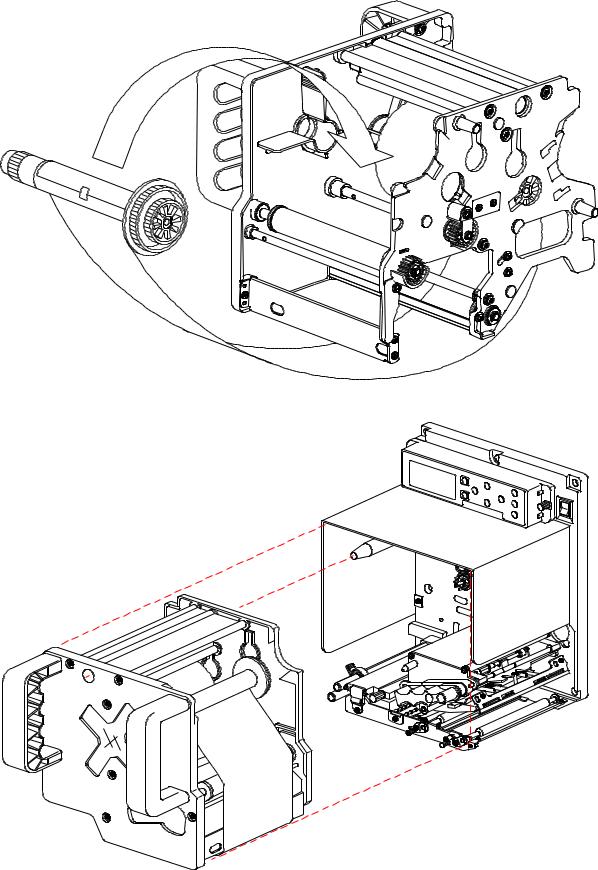

Figure 3-6a, Ribbon Cassette Loading |

|

S8400 Series Operator Manual |

3-6 |

PN: 9001160B |

Unit 3: Installation

Figure 3-6b, Ribbon Cassette Loading

Figure 3-6c, Ribbon Cassette Loading

S8400 Series Operator Manual 3-7 PN: 9001160B

Unit 3: Installation

OPERATIONAL MODE SELECTION

There are two modes of printer operation: Dispense or Continuous. The difference between the two is the way that the label and paper backing is ejected. Before printer configuration, one must determine which mode will be used. This chapter identifies and defines the functional differences between the two.

DISPENSE MODE

With this method of operation, after printing, the printer feeds the first (outermost) label so that it is fully extended out of the printer’s front for dispensing. Printing of the next label will not begin until the prior printed label has been removed. This mode of operation is specifically suited for the use of automated machinery to remove the printed and dispensed label to apply to packaging, etc.

Upon removal of the prior printed label, the printer repositions the media so that the next label in line may be printed, then prints. The before-mentioned cycle, repeats for each consecutive label.

Printer configuration for the backfeed function may be found in the Advanced Mode of the Configuration unit of this manual. Refer to the Table of Contents for the page number.

CONTINUOUS MODE

With this method of operation, the media remains in position for printing at all times. To do so, means that the previous printed label is never in proper position for dispensing and thusly, must be manually removed form the printer rather than through the application of automated machinery.

Printer configuration for Continuous mode of operation may be found in the Advanced Mode of the Configuration unit of this manual. Refer to the Table of Contents for the page number.

ATTENTION: Refer to the Printer Configuration unit of this manual to program the printer’s internal memory to suit individual needs using the printer’s integrated menu options. Refer to the Programming Reference document to remotely program the printer’s features and functions through a host system.

S8400 Series Operator Manual |

3-8 |

PN: 9001160B |

Unit 3: Installation

INTERFACE SELECTION

This unit presents the printer interface types and their specifications. These specifications include detailed information to assist in the selection of the most appropriate method for the printer to interface with the host. The five acceptable interface methods are:

•RS232C High-Speed Serial

•IEEE1284 Parallel

•Universal Serial Bus (USB)

•Local Area network (LAN) Ethernet

•802.11g Wireless

Following the selection of the desired interface, proceed to the next unit for instructions on how to configure the printer for that interface type.

WARNING: NEVER CONNECT OR DISCONNECT INTERFACE CABLES (OR USE

A SWITCH BOX) WITH POWER APPLIED TO EITHER THE HOST OR THE

PRINTER. THIS MAY CAUSE DAMAGE TO THE INTERFACE CIRCUITRY IN THE

PRINTER/HOST AND IS NOT COVERED BY WARRANTY.

NOTE: Some hosts monitor the Request-To-Send (RTS) signal (pin 4 of 25) to determine if the printer is ready to receive data. Since the printer does not generate this signal, the RTS line must be held true (high) in order to allow communication. This can be performed by connecting the RTS pin to the Clear-To-Send (CTS) signal (pin 5 of 25).

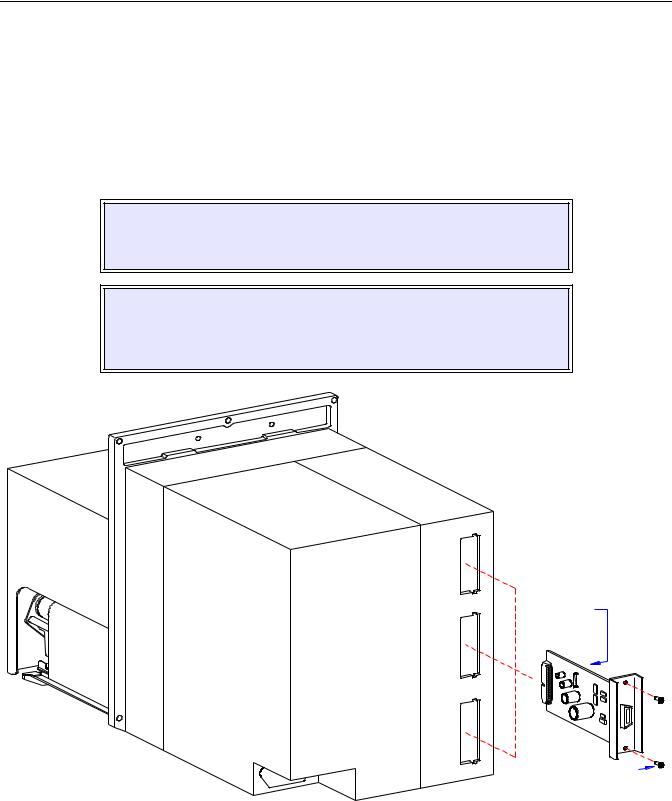

Interface Card

Screw x2

Figure 3-7, Interface Installation

S8400 Series Operator Manual |

3-9 |

PN: 9001160B |

Unit 3: Installation

RS232C HIGH-SPEED SERIAL INTERFACE

This High Speed Serial Interface is a Plug-In Interface Module that can be installed in the printer by the user.

|

INTERFACE SPECIFICATIONS |

|

|

Asynchronous ASCII |

Half-duplex communication |

|

Bi-Directional Communication |

|

|

Data Transmission Rate |

9600, 19200, 38400, 57600 bps |

|

|

Transmission Form |

Start, b1, b2, b3, b4, b5, b6, b7, b8, Stop (b8 will be omitted if using 7 bit oriented) |

|

|

Data Length |

7 or 8 bit (selectable) |

|

|

Stop Bit |

1 or 2 bit (selectable) |

|

|

Parity Bit |

ODD, EVEN, NONE (selectable) |

|

|

Codes Used |

ASC II Character Codes: 7 bits, Graphics: 8 bits |

|

|

Control Codes |

STX (02H), ETX (03H), ACK (06H), NAK (15H) |

|

|

Connector (Printer Side) |

DB-25S Male (equivalent), 9-pin Serial Interface (PCI) |

|

|

Cable Connector |

DB-25P Female (equivalent), 9-pin Serial Interface (PCI) |

|

|

Cable Length |

5 meters or less. |

|

|

Signal Levels |

High = +5V to +12V, Low = -5V to -12V |

|

|

Protocol |

Ready/Busy, X-On/X-Off, Protocol for Driver, Status4, Status5 |

|

|

|

|

|

|

DIPSWITCH SETTINGS |

|

|

|

|

|

|

|

SWITCH |

COMPONENT |

|

|

|

SETTINGS |

|

|

|

|

|

|

1 |

Data Bit |

ON |

|

7 Bits |

|

|

|

|

|

||

OFF |

|

8 Bits |

|||

|

|

|

|||

|

|

2 |

|

3 |

|

|

|

ON |

|

ON |

Reserved |

2 & 3 |

Parity |

|

|

|

|

ON |

|

OFF |

ODD |

||

|

|

|

|

|

|

|

|

OFF |

|

ON |

EVEN |

|

|

|

|

|

|

|

|

OFF |

|

OFF |

NONE |

4 |

Stop Bit |

ON |

|

2 Bits |

|

|

|

|

|

||

OFF |

|

1 Bit |

|||

|

|

|

|||

|

|

5 |

|

6 |

|

|

|

ON |

|

ON |

57600 bps |

5 & 6 |

Baud Rate |

|

|

|

|

ON |

|

OFF |

38400 bps |

||

|

|

|

|

|

|

|

|

OFF |

|

ON |

19200 bps |

|

|

|

|

|

|

|

|

OFF |

|

OFF |

9600 bps |

|

|

7 |

|

8 |

|

|

|

ON |

|

ON |

Reserved: Status2 & 3 (when compatible mode is OFF) |

7 & 8 |

Protocol |

|

|

|

|

ON |

|

OFF |

Protocol for Driver, Status5 |

||

|

|

|

|

|

|

|

|

OFF |

|

ON |

X-ON/X-OFF |

|

|

|

|

|

|

|

|

OFF |

|

OFF |

Ready/Busy |

|

|

|

|

|

|

S8400 Series Operator Manual |

3-10 |

PN: 9001160B |

|

|

Unit 3: Installation |

|

|

|

|

|

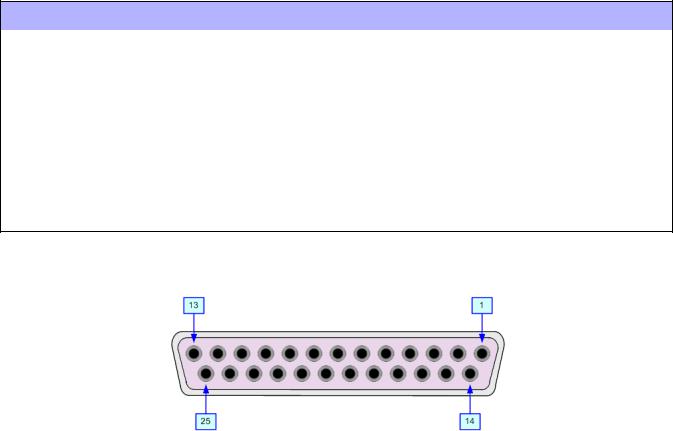

READY/BUSY INTERFACE SIGNALS |

|

|

|

PIN |

DIRECTION |

SIGNAL DEFINITION |

|

|

|

1 |

Reference |

FG (Frame Ground) |

2 |

To Host |

TD (Transmit Data) - Data from the printer to the host computer. Sends X-On/X-Off characters |

|

|

or status data (bi-directional protocols). |

3 |

To Printer |

RD (Receive Data) - Data to the printer from the host computer. |

4 |

To Host |

RTS (Request to Send) - Used with Ready/Busy flow control to indicate an error condition. |

|

|

RTS is high and remains high unless the print head is open (in this case, RTS would return to |

|

|

the high state after the print head is closed and the printer is placed back on-line) or an error |

|

|

condition occurs during printing (e.g., ribbon out, label out). |

5 |

To Printer |

CTS (Clear to Send) - When this line is high, the printer assumes that data is ready to be |

|

|

transmitted. The printer will not receive data when this line is low. If this line is not being used, |

|

|

it should be tied high (to pin 4). |

6 |

To Printer |

DSR (Data Set Ready) - When this line is high, the printer will be ready to receive data. This |

|

|

line must be high before data is transmitted. If this line is not being used, it should be tied high |

|

|

(to pin 20). |

7 |

Reference |

SG (Signal Ground) |

20 |

To Host |

DTR (Data Terminally Ready) - This signal applies to Ready/Busy flow control. The printer is |

|

|

ready to receive data when this pin is high. It goes low when the printer is off-line, either |

|

|

manually or due to an error condition, and while printing in the single job buffer mode. It will |

|

|

also go low when the data in the buffer reaches the buffer near full level. |

|

|

|

READY/BUSY CABLE REQUIREMENTS

DB9 |

DB25 |

HOST |

DIRECTION |

DB25 |

PRINTER |

|

|

|

|

|

|

1 |

1 |

FG (Frame Ground) |

Bi-Directional |

1 |

FG (Frame Ground) |

|

|

|

|

|

|

2 |

3 |

RD (Receive Data) |

To Host |

2 |

TD (Transmit Data) |

|

|

|

|

|

|

3 |

2 |

TD (Transmit Data) |

To Printer |

3 |

RD (Receive Data) |

|

|

|

|

|

|

8 |

5 |

CTS (Clear To Send) |

To Printer DB9-6 |

4 |

RTS (Request To Send) |

|

|

|

|

|

|

4 |

20 |

DTR (Data Terminal Ready) |

To Printer DB9-4 |

5 |

DSR (Data Set Ready) |

|

|

|

|

|

|

6 |

6 |

DSR* (Data Set Ready) |

To Host |

6 |

DTR (Data Terminal Ready) |

|

|

|

|

|

|

5 |

7 |

SG (Signal Ground) |

Bi-Directional |

7 |

SG (Signal Ground) |

|

|

|

|

|

|

* This connection at the host side of the interface would depend upon the pin that is being used as the Ready/Busy signal by the driving software. Typically, on a PC, it would be either CTS (pin5) or DSR (pin 6) on a DB-25 connector.

Figure 3-8, Serial Connector Pin Assignments

S8400 Series Operator Manual |

3-11 |

PN: 9001160B |

Unit 3: Installation

X-ON/X-OFF CABLE REQUIREMENTS

Communicates with the host to determine if the printer is ready to receive data by sending “XON” (HEX 11H) or “XOFF” (HEX 13H) code to the TD line. The single and multiple item buffers are switchable in the Interface Mode of the printer.

DB9 |

DB25 |

HOST |

DIRECTION |

DB25 |

PRINTER |

|

|

|

|

|

|

1 |

1 |

FG (Frame Ground) |

Bi-Directional |

1 |

FG (Frame Ground) |

|

|

|

|

|

|

2 |

3 |

RD (Receive Data) |

To Host |

2 |

TD (Transmit Data) |

|

|

|

|

|

|

3 |

2 |

TD (Transmit Data) |

To Printer |

3 |

RD (Receive Data) |

|

|

|

|

|

|

5 |

7 |

SG (Signal Ground) |

Bi-Directional |

7 |

SG (Signal Ground) |

|

|

|

|

|

|

NOTE: Depending on the host used, it may be required to loop CS and RS (maintaining at high-level) on the host side. For more information, refer to the host computer documentation.

NOTE: Refer to the Charts & Diagrams unit of this manual to view timing charts for

Ready/Busy and X-ON/X-OFF.

IEEE1284 PARALLEL INTERFACE

The parallel interface is a plug-in module that can be installed by the user and conforms to IEEE1284 specifications. It automatically detects the IEEE1284 signals and operates in the high speed mode. If the IEEE1284 signals are not detected, it will operate in the slower standard Centronics mode. For this reason, an interface cable and host interface conforming to the IEEE1284 specification must be present to fully utilize the speed capabilities. This interface also operates bi-directionally and can report the status of the printer back to the host.

|

SPECIFICATIONS |

|

|

Printer Connector |

AMP 57-40360 DDK (or equivalent) |

|

|

Cable Connector |

AMP 57-30360 DDK (or equivalent) |

|

|

Cable |

1.5 meter or less |

|

|

Signal Level |

High = +2.4V to +5.0V, Low = 0V to -0.4V |

|

|

Data Stream |

<ESC>A . . Job#1 . . <ESC>Z<ESC>A . . Job#n . . <ESC>Z |

|

|

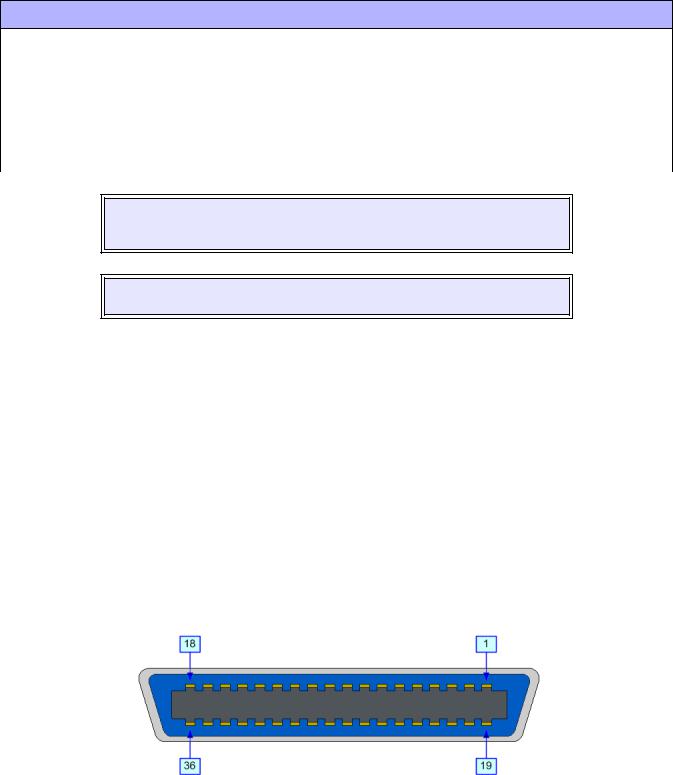

Figure 3-9, Parallel Connector Pin Assignments

S8400 Series Operator Manual |

3-12 |

PN: 9001160B |

Unit 3: Installation

PIN ASSIGNMENTS

PIN |

SIGNAL |

|

DIRECTION |

PIN |

SIGNAL |

|

DIRECTION |

|

|

|

|

|

|

|

|

1 |

Strobe |

|

To Printer |

19 |

Strobe Return |

|

Reference |

2 |

Data 1 |

|

To Printer |

20 |

Data 1 Return |

|

Reference |

3 |

Data 2 |

|

To Printer |

21 |

Data 2 Return |

|

Reference |

4 |

Data 3 |

|

To Printer |

22 |

Data 3 Return |

|

Reference |

5 |

Data 4 |

|

To Printer |

23 |

Data 4 Return |

|

Reference |

6 |

Data 5 |

|

To Printer |

24 |

Data 5 Return |

|

Reference |

7 |

Data 6 |

|

To Printer |

25 |

Data 6 Return |

|

Reference |

8 |

Data 7 |

|

To Printer |

26 |

Data 7 Return |

|

Reference |

9 |

Data 8 |

|

To Printer |

27 |

Data 8 Return |

|

Reference |

10 |

ACK |

|

To Host |

28 |

ACK Return |

|

Reference |

11 |

Busy |

|

To Host |

29 |

Busy Return |

|

Reference |

12 |

Ptr Error |

|

To Host |

30 |

PE Return |

|

Reference |

13 |

Select |

|

To Host |

31 |

INIT |

|

From Host |

14 |

AutoFD1 |

|

To Host |

32 |

Fault |

|

To Host |

15 |

Not Used |

|

33 |

|

Not Used |

||

16 |

Logic Gnd |

|

|

34 |

|

Not Used |

|

17 |

FG |

|

Frame Gnd |

35 |

|

Not Used |

|

18 |

+5V (z=24k ohm) |

|

To Host |

36 |

SelectIn1 |

|

From Host |

|

|

|

|

|

|

|

|

1 Signals required for ieee 1284 mode.

UNIVERSAL SERIAL BUS (USB)

The Universal Serial Bus (USB) interface is a Plug-In Interface Module that can be installed by the user. It requires a driver (shipped with each printer that has the interface installed) that must be loaded onto the PC and configured to support USB peripherals using Windows 2000 or above. Details for loading the USB driver are contained in the USB Interface Manual that is shipped with each printer with a USB Optional interface installed. Up to 127 devices may be connected to a USB port using powered hubs.

|

|

|

|

|

|

|

|

ATTENTION: This Interface Type Is Not Compatible With Windows 98 Or Windows |

|

|

|

|

|

Me. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SPECIFICATIONS |

|

|

|

|

|

|

|

|

Printer Connector |

USB Type B Plug |

|

|

||

|

|

|

|

||

Cable |

10 feet (3 m) maximum |

|

|

||

|

|

|

|

||

Host |

Windows 2000 or above with USB Port |

|

|

||

|

|

|

|

||

Power Supply |

BUS Power through cable |

|

|

||

|

|

|

|

||

Power Consumption |

+5 V at 80 ma |

|

|

||

|

|

|

|

|

|

S8400 Series Operator Manual |

3-13 |

PN: 9001160B |

Unit 3: Installation

LOCAL AREA NETWORK (LAN) ETHERNET

A Local Area Network (LAN) interface is an optional Plug-In Interface Module that can be installed by the user. It requires a driver shipped with each printer that has the interface installed. The driver that must be loaded onto the host computer and configured to run one of the supported network protocols using a 10Base-T or 100Base-TX LAN connection. Details for loading the LAN driver are contained in the LAN Interface Manual that is shipped with each printer with a LAN Optional interface installed.

|

SPECIFICATIONS |

|

|

Connector |

RJ-45 Receptacle |

|

|

Cable |

10/100BaseT Category 5 |

|

|

Cable Length |

100 meters or less |

|

|

Power Supply |

Powered from printer |

|

|

Protocol |

Status3 return |

|

Protocol for Driver (cyclic response mode) |

|

Protocol for Driver (ENQ response mode) |

|

Status5 return |

|

|

IP Address |

0.0.0.0 to 255.255.255.255 |

|

|

Subnet Mask |

0.0.0.0 to 255.255.255.255 |

|

|

Gateway Address |

0.0.0.0 to 255.255.255.255 |

|

|

|

DIPSWITCH SETTINGS |

|

|

SWITCH |

SETTING |

|

|

1 |

Reserved (setup prohibited). |

2 |

LAN board EEPROM initialization (configuration). |

3 |

Print configuration details on a label. |

4 |

Print a self-diagmosis of the board onto a label. |

|

|

|

SOFTWARE SPECIFICATIONS |

|

|

Corresponding Protocol |

TCP/IP |

|

|

Network Layer |

ARP, RARP, IP, ICMP |

|

|

Session Layer |

TCP, UDP |

|

|

Application Layer |

LPD, FTP, TELNET, BOOTP, DHCP |

|

|

NOTE: Print data can be sent by LPR and FTP of TCP/IP and dedicated socket protocol. Printer status is obtainable by dedicated socket protocol.

NOTE: In the TCP/IP protocol enviroment, LPD and FTP are provided for printing; TELNET for variable setup; ARP, RARP, and BOOTP/DHCP for address setup.

LPD protocol complies with RFC1179 and handles the list of logical printer name as queue name such as lp, sjis, euc. In addition, a banner page can be printed by a proper setup.

When sending the job by LPR, the transmission order of data file/control file within the job will not affect print operation. In addition, if the banner page is specified, it will be added to each data file. Job deletion by LPR is not available.

FTP protocol complies with RFC959 and handles the list of logical printer name as a transfer directory. File transfer to this directory executes print operation. It is possible to specify ASCII(A), Binary(I) and TENEX(L8) as transfer mode - although the mode difference is dependent on the client. A banner page may be printed with a proper setup.

TELNET Complies with RFC854. This operation consists of interactive menu form and enables change and reference of internal setup, and to display status. To change the setup, enter “root” user and password at the time of login. Default of root pasword is set as null (linefeed only).

S8400 Series Operator Manual |

3-14 |

PN: 9001160B |

Unit 3: Installation

802.11G WIRELESS

The wireless print server provides easy printer interface with 802.11g Wi-Fi compliant networks free of wired connections. Each printer is shipped with an integrated driver and interface installed. The driver must be loaded onto the host computer and configured to run one of the supported protocols.

|

SPECIFICATIONS |

|

|

Variable Data Rates |

54, 11, 5.5, 2 and 1 Mbps |

|

|

Frequency Band |

2.4 GHz ISM Band |

|

|

Wired Equivalent Privacy |

128 bit, 64 bit (compatible with 40bit), none (WPA) |

|

|

Sensitivity |

(typ, AAWGN, 8E-2 PER): -91dBm at 1Mbps, -88dBm at 2 Mdps, -87dBm at 5.5Mbps, - |

|

84dBm at 11Mbps. |

|

|

Range |

100m indoors, 300m outdoors (enviromentally dependent) |

|

|

Protocols |

TCP/IP, IPX/SPX, Direct Mode IPX/IP, DLC/LLC, NetBEUI, NetBIOS/IP |

|

|

Protocol |

Status3 return |

|

Protocol for Driver (cyclic response mode) |

|

Protocol for Driver (ENQ response mode) |

|

Status5 return |

|

|

IP Address |

0.0.0.0 to 255.255.255.255 |

|

|

Subnet Mask |

0.0.0.0 to 255.255.255.255 |

|

|

Gateway Address |

0.0.0.0 to 255.255.255.255 |

|

|

Communication Mode |

802.11 Ad hoc, Ad hoc, Infrastructure |

|

|

SSID |

Optional alphanumeric character string (up to 32 characters) |

|

|

Channels |

01 to 11 |

|

|

DIPSWITCH SETTINGS

The dipswitches serve to initialize the configuration saved on the Wireless-LAN board, print the configuration, and make a selfdiagnosis. To communicate with the host,set the communication mode by through switches 5 and 6, then set the remaining switches to the OFF position.

Print of configuration and self-diagnsis are operable only on the screen after turning on the printer. Ensure all switches are in the OFF position when operating the printer.

SWITCH |

|

SETTING |

|

|

|

|

|

1 |

OFF |

Normal operating setting. |

|

2 |

OFF |

Normal operating setting. |

|

|

|

||

ON |

Initialization/Reset to factory default upon power up. |

||

|

|||

3 |

OFF |

Normal operating setting. |

|

|

|

||

ON |

Configuration report upon power up - prints diagnostic report upon powering up. |

||

|

|||

4 |

OFF |

Wireless Mode setting. |

|

|

|||

ON |

|||

|

|

||

|

|

|

NOTE: The communication mode may be set within the printer’s Interface Mode. Go to [Communication] of the Interface Mode to enable setup by either the dipswitches or through the Interface Mode.

WIRELESS LAN SIGNAL STRENGTH

|

|

Off |

0 to 50% (weak) |

|

|

|

|

Network Port |

Link LED |

Blinking |

50 to 75% (medium) |

|

|

|

|

|

|

On |

75 to 100% (strong) |

|

|

|

|

S8400 Series Operator Manual |

3-15 |

PN: 9001160B |

Loading...

Loading...