Sanyo MCO-40AIC, MCO-20AIC Manual

Large Capacity |

Incubators |

MCO-20AIC |

Cell Culture CO2 |

MCO-40AIC |

|

|

|

The industry’s most complete cell culture solution

for applications requiring larger flexible volume.

Provides a stable cell culture environment, ranging from 7.6 to 15.2 cu.ft., for specific temperature and CO2 control with continuous contamination control.

www.sanyobiomedical.com

General Features & Benefits

The SANYO Large Capacity Cell Culture CO2 incubator is designed for a wide array of demanding and highly regulated applications in the biomedical, pharmaceutical, medical research and clinical laboratory. Representing years of research, development and component testing, the Cell Culture CO2 incubator incorporates a collective of mutually functional systems and design attributes to offer a holistic solution to cell culture protocols, from the most sophisticated to more familiar and conventional processes.

Large Capacity CO2 Incubator |

MCO-20AIC |

MCO-40AIC |

SafeCell™ UV Decontamination |

Standard |

Standard |

Single Beam, IR CO2 Sensor |

Standard |

Standard |

|

|

|

Decontamination

•Active Background Contamination Control™ fights contamination while cell culture protocols are in process.

The patented SafeCell™ UV system scrubs interior airflow to destroy airborne and humidity pan contaminants.

Exclusive InCu SaFe™ copper-enriched stainless steel interior surfaces assure constant germicidal protection.

Control and Monitoring

•Control and information center includes central mounted touchpad and digital display.

•Precise PID logic controls adjust to all temperature setpoints and alarm parameters.

CO2 Control

SANYO proprietary single-beam (IR) CO2 sensor delivers precise CO2 control, quick recovery following door openings, and auto sampling with no moving parts.

•Ceramic based infrared system that is maintenance free

•Continuous zero calibration is standard.

Temperature and Humidity Control

•The patented Direct Heat and Air™ jacketsystem manages setpoint temperature through multiple, variable warming points under microprocessor control.

•The humidity pan is easy to fill, easy to clean; the automatic optical sensor advises of low water level.

Cabinet Design

•High volume, low profile cabinets are stackable with field-reversible doors.

•Interior components and adjustable shelves are configured for easy access.

MCO-40AIC

Interior components and adjustable shelves are configured for easy access, in situ sterilization and flexible arrangement for a variety of applications.

Model MCO-20AIC is designed for use with a variety of standard

cell culture vessels and protocols. Four adjustable shelves are included, standard; maximum shelf capacity is 15 shelves.

2

Contamination Control

Active Background Contamination Control

At the base of the plenum, an isolated beam of high intensity, ozone-free UV light destroys

contaminants in the air and in the water pan, away from cell cultures, not simply collected in a HEPA filter. Plenum components isolate UV light to protect cell cultures, while

the UV process continues in the background as programmed without downtime. Airborne contaminants are eliminated by an automatic 5 minute UV cycle (programmable 0 - 30 minutes). Trace contaminants which attach to walls, shelves and plenum components are destroyed by the germicidal properties of the inCuSaFe™ copper-enriched stainless steel surfaces.

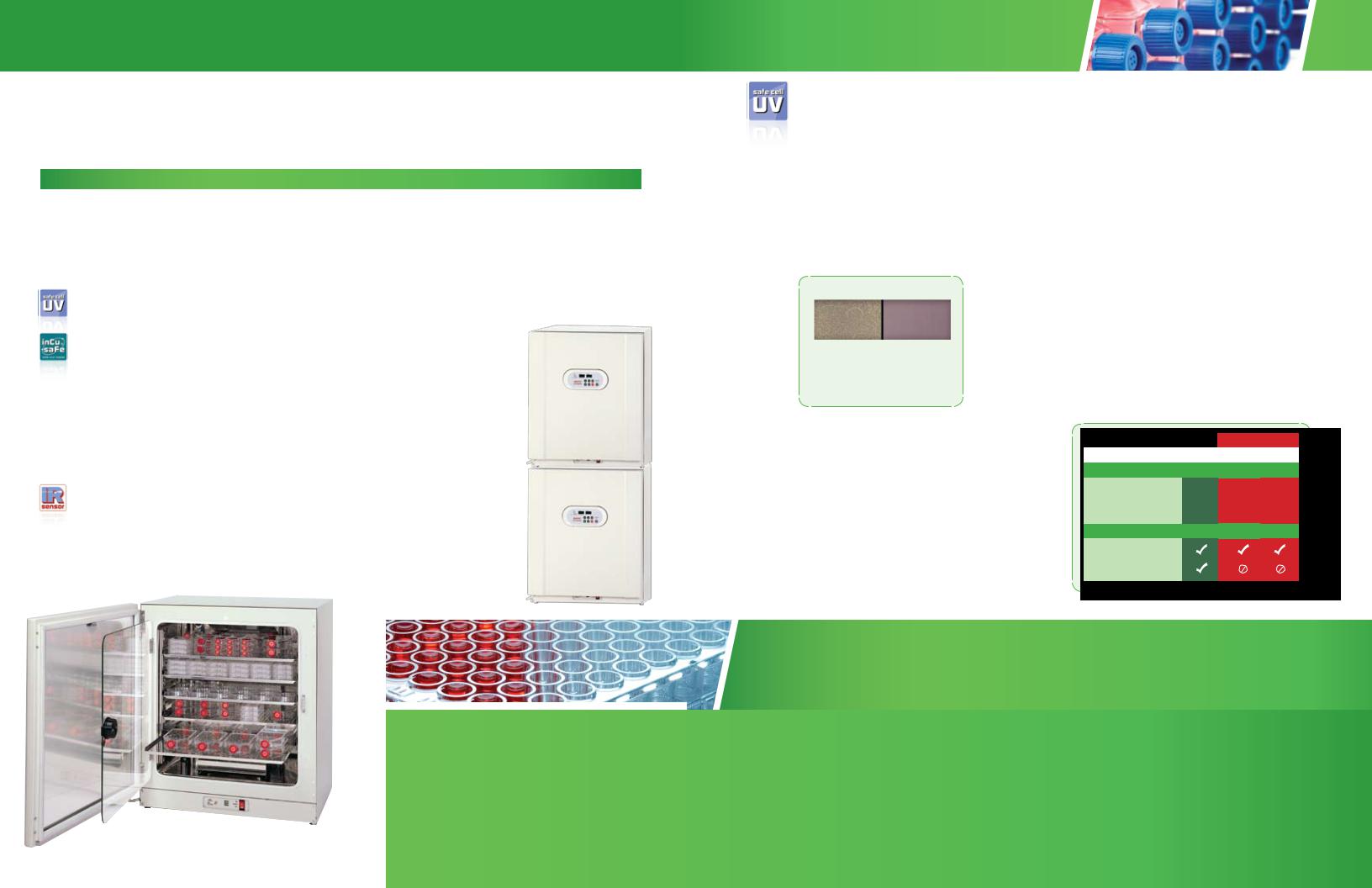

Humidifying Water Comparison

No exposure to UV |

Five-minute exposure to |

|

SafeCell™ UV |

Test results after three months confirm the efficacy of SANYO SafeCell™ UV protection on humidifying water after three months.

Other design factors which help mitigate contamination include condensation control, inner door gasket design and triple 0.3 micron filters for vent air and CO2 sensor sampling.

•The SafeCell™ UV air flow plenum promotes temperature uniformity through the chamber, shaped by natural and mechanical convection through and around the perforated shelves with gentle circulation through the plenum for UV sterilization and warm water humidification.

•Contaminants contained within the distilled water in the humidity pan are destroyed by UV.

•Sterile, humidified air is released from the lower plenum for vertical convection through and around the perforated shelves

•Interior air motion stops when the door is opened, minimizing movement of room air into the chamber.

UV Decontamination vs. Heat Sterilization

Independent testing1 confirms that the UV decontamination technique employed by the SANYO incubator is equally effective against contamination as conventional high heat sterilization over a range of +90°C to +140°C. Whenever overnight or event sterilization of the SANYO incubator chamber is desired, all interior components are removed for autoclaving, exposing all interior surfaces to ultraviolet light. During normal operation when cells are being incubated within the chamber, the UV lamp is visibly isolated from the cell culture chamber by a plenum cover over the humidity pan, permitting UV decontamination of circulated, humidified air and humidity pan surface water to remain in process without damaging the cells.

1. A Comparative Analysis of Ultraviolet Light Decontamination vs. High Heat Sterilization in the Cell Culture CO2 Incubator, with the Use of Copper-Enriched Stainless Steel Construction to Achieve Active Background Contamination Control" H. Busujima; D. Mistry 2007

METHOD |

UV |

HIGH HEAT |

|

SANYO |

(+140˚C) (+90˚C) |

TEST RESULTS, MAXIMUM LOG REDUCTIONS

Bacteria |

> 4.5 |

> 4.5 |

> 4.5 |

Yeast |

> 2.9 |

> 2.9 |

> 2.9 |

Mold |

> 2.7 |

> 2.7 |

> 2.7 |

DECONTAMINATION OPTIONS

Overnight

Active Background

Contamination Control™

Ideal for Highly Regulated or Sensitive Applications

|

|

The combination of SANYO's CO2 incubator performance |

• Stem cell research |

functions permit use with confidence in high-value cell |

• Autologous tissue regeneration & regenerative medicine |

protocols among hard-to-grow cell lines, cells highly |

• In vitro fertilization2 |

sensitive to contamination, ultra-sensitive media and |

• Genomic and proteomic expression |

reagents, or protocols that require a strict isolation and |

• Esoteric plant and amphibian cell culture |

sterilization between processes.These include but are not |

• Hypersensitive and transgenic cell culture |

limited to: |

• Low media volume microplate work |

1. MCO-20AIC CO2 incubators have received U.S. Food and Drug Administration 510(k) clearance for in vitro fertilization applications in accordance with the FDA Safe Medical Devices Act of 1990 and the Medical Device Amendments of 1992. Reference: Number K013703. Regulation Number: 21 CFR 884-6120, Assisted Reproduction Accessories, Regulatory Class II, Product Code 85MOG, October 30, 2001

3

Control System

Microprocessor Based Controller

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Digital Temperature Display |

|

|

|

|

|

|

|

|

|

|

|

|

|

CO2 Inject Lamp |

|

|

|

|

|

|

|

|

|

|

|||||||||

SANYO expertise in electronic innovations applies to the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Multi-function display reads actual |

|

|

|

|

|

|

|

|

|

|

|

|

|

Indicates CO2 flow |

to chamber |

|

|

|

|

|

|

|

|

||||||||||||||||||

SANYO MCO-20AIC microprocessor control system. All |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

temperature in normal mode |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Digital CO2 Display Multi-function |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

incubator functions are managed by a fully integrated |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

display reads actual CO2 density in |

||||||||||||

controller which acquires and processes information from data |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heat ON Lamp |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

normal mode |

|

|

|

|

|

|

|||||||||||

entry, setpoints and alarm parameters. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indicates when Direct Heat, Air |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

• P.I.D. Proportional, integral and derivative controls supervise |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Jacket elements are powered |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Calibration Function Key |

|

|

|

|

|||||||||||||||

temperature, and other features for accurate, repeatable |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Accesses calibration |

|

|

|

|

|||||||||

performance. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UV Lamp |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

functions and UV lamp periods |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

• A range of setpoint, alarm and programmable inputs are |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indicates ultraviolet lamp ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

established through the use of function keys. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Audible Alarm Silence Key |

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

• Standard parameters are factory-set for quick start-up, and |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Silences alarm buzzer |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Door Open Lamp |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

all parameters may be changed as required. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gas Cylinder Supply Indicator |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Warns of inner or outer door ajar |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Optional) Indicates gas supply source |

|||||||||||||||||

• A remote alarm terminal mounted at the rear of the cabinet |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

can be connected to an external alarm system. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Low Water Lamp |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

The MCO-20AIC control panel is center mounted in the outer |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Warns of low water level in |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gas Cylinder Switch Key |

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

humidity pan |

|

|

|

|

Set Function Key |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

door for easy access, even when incubators are stacked. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Optional) Allows manual switchover |

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

Microprocessor based controls manage all incubator functions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Overtemperature Setpoint |

|

|

Accesses setpoint mode |

|

|

|

|

|

|

|

|

|

from primary to secondary gas cylinder |

|||||||||||||||||||||||||

including setpoints, alarm parameters, UV lamp periods, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

programming, calibration and diagnostics. Extra-large digital |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Adjustment |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Numeric Shift Key |

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Digital Shift/Lock Key |

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

displays are easy to read. Tactile feedback touchpad data |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For manual adjustment of high |

|

|

|

|

|

|

|

Enter Key |

|

|

|

|

||||||||||||||||||||||||||

shift and entry keys simplify operation. When stacked, door |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

temperature limit |

|

|

|

|

|

Adjusts position in digital |

|

Adjusts digits in digital display |

Writes value to the controller |

|||||||||||||||||||||||||||

mounted controls remain easily accessible at eye level. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

display |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Overtemperature Warning Lamp |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indicates high temperature limit has |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

been reached normal mode |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

Start Incubation |

|

SafeCell UV on: |

|

SafeCell UV on: |

|

SafeCell UV on: |

|

SafeCell UV on: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SafeCell UV on: 5 min. |

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 min. after door |

|

5 min. after door |

|

5 min. after door |

|

5 min. after door |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(every 12 hours) |

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

opening |

|

opening |

|

opening |

|

|

|

|

opening |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Scrubs interior air flow |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Scrubs interior air |

|

Scrubs interior air |

|

Scrubs interior air |

|

Scrubs interior air |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

to destroy airborne |

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

flow to destroy |

|

flow to destroy |

|

flow to destroy |

|

flow to destroy |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

and humidity pan |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

airborne and |

|

airborne and |

|

airborne and |

|

airborne and |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

contaminants. |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

humidity pan |

|

humidity pan |

|

humidity pan |

|

humidity pan |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

SafeCell UV |

|

|

|

|

|

|

|

|

|

|

|

|

contaminants. |

|

contaminants. |

|

|

|

contaminants. |

|

|

|

contaminants. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

Active Background |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Contamination Control |

|

PREP: 15 min. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

(5 min. door openings) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

Before sterilization by UV lamp, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

remove all attachments |

(trays, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Start Cycle: 24 hours |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

tray supports, side supports, top |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

Follow keypad function code. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

duct, rear duct, humidifying pan, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

UV lamp is on for 24 hours. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

and pan cover with fan) in the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Finish. |

|

|||||||||||

SafeCell UV 24HR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

chamber. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shelves, humidity pan and plenum |

|

||||||||||

Decontamination |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

are returned to operating position. |

|

||||||||

Protocol |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

(24 Hours, total) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 min. |

30 min. |

|

45 min. |

1 |

|

|

2 |

3 |

4 |

5 |

|

|

6 |

7 |

|

|

8 |

|

9 |

|

|

10 |

|

11 |

12 |

13 |

|

14 |

15 |

|

16 |

17 |

|

18 |

|

19 |

|

20 |

21 |

22 |

|

23 |

|

24 |

|

|

|

|||||||||

Elapsed Time: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||

Conventional High Heat |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Decontamination |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

(24 Hours, total) |

|

|

|

Start Cycle: 90 min. |

|

|

|

|

|

|

|

|

Sterilize: 14 hours |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Finish. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

PREP: 15 min. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

Interior chamber elevates to high heat. |

|

|

|

|

|

|

Interior chamber remains at high heat. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Incubator must cool from high heat temperatures to near ambient. |

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

Remove interior components |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

4 |

|

|

|

sensitive to high heat. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Loading...

Loading...