Sanyo MCO-19M UV Installation Manual

INSTRUCTION MANUAL

Multi Gas Incubator

MCO-19M(UVH) MCO-19M(UV)

MCO-19M

CONTENTS

INTRODUCTION |

P. 3 |

PRECAUTIONS FOR SAFE OPERATION |

P. 4 |

LABELS ON THE INCUBATOR |

P. 8 |

ENVIRONMENTAL CONDITIONS |

P. 8 |

INCUBATOR COMPONENTS |

P. 9 |

Control panel and keypad |

P. 12 |

Remote alarm terminals |

P. 13 |

INSTALLATION SITE |

P. 14 |

INSTALLATION |

P. 15 |

Connection of CO2 gas cylinder |

P. 16 |

Connection of N2 (or O2) gas cylinder |

P. 17 |

Connection of gas injection nozzle |

P. 18 |

Using the inner door and gastight split doors |

P. 18 |

PREVENTING CONTAMINATION |

P. 19 |

PRECAUTIONS FOR CULTURES |

P. 20 |

Using the unlock key |

P. 21 |

CORRECT OPERATION |

P. 21 |

LCD PANEL |

P. 22 |

BASIC OPERATIONS ON CONTROL PANEL |

P. 24 |

BASIC PARAMETERS |

|

Setting the chamber temperature, CO2 and CO2 density |

P. 25 |

Setting the key lock |

P. 26 |

Releasing the key lock |

P. 27 |

Setting the key lock password |

P. 28 |

Automatic N2 (or O2) gas cylinder changeover |

P. 30 |

Setting the upper limit alarm temperature |

P. 32 |

ALARM PARAMETERS |

P. 33 |

UV LAMP PARAMETERS |

P. 34 |

Using the UV lamp |

P. 34 |

Precautions when using the UV lamp |

P. 35 |

Setting the UV lamp ON period |

P. 36 |

Lighting the UV lamp for 24 hours |

P. 37 |

OTHER PARAMETERS |

|

Setting the date, time, and log interval |

P. 38 |

Initial settings (LCD/DAQ parameters) |

P. 40 |

DISPLAYING THE LOG |

P. 41 |

Transferring data |

P. 43 |

WATER LEVEL SENSOR |

P. 44 |

ROUTINE MAINTENANCE |

|

Cleaning the chamber and inner attachments |

P. 45 |

Filling the humidifying pan |

P. 48 |

H2O2 DECONTAMINATION |

P. 49 |

H2O2 decontamination |

P. 51 |

Precautions when handling H2O2 decontamination reagent |

P. 54 |

ALARMS, SAFETY, AND SELF-DIAGNOSIS |

P. 55 |

CALIBRATION |

|

Temperature/CO2/O2 calibration |

P. 58 |

TROUBLESHOOTING |

P. 60 |

DISPOSING OF THE MULTI-GAS INCUBATOR |

P. 62 |

AUTOMATIC CO2 CYLINDER CHANGEOVER |

P. 67 |

AUTOMATIC CO2 AND O2 DENSITY CALIBRATION |

P. 69 |

STACKING INCUBATORS |

P. 72 |

1

CONTENTS

SPECIFICATIONS |

P. 74 |

PERFORMANCE |

P. 75 |

SAFETY CHECK SHEET |

P. 76 |

2

INTRODUCTION

■Read this manual carefully before using the Product and follow the instructions for safety operation.

■Sanyo disavows any responsibility for safety if the Product is used for other than the intended use or used with any procedures other than those given in this manual.

■Keep this manual in a suitable place so that it can be referred to as necessary.

■The contents of this manual are subject to change without notice for improvement of performance or functions.

■Contact a Sanyo sales representative or agent if any page of the manual is lost or the page order is incorrect.

■Contact a Sanyo sales representative or agent if any point in this manual is unclear or if there are any inaccuracies.

■No part of this manual may be reproduced in any form without the expressed written permission of Sanyo.

CAUTION

CAUTION

SANYO guarantees the product under certain warranty conditions. SANYO in no way shall be responsible for any loss of content or damage of content.

3

PRECAUTIONS FOR SAFE OPERATION

It is imperative that the user complies with this manual as it contains important safety advice.

Items and procedures are described so that you can use this unit correctly and safely. If the precautions advised are followed, this will prevent possible injury to the user and any other person.

Precautions are illustrated in the following way:

WARNING

WARNING

Failure to observe WARNING signs could result in a hazard to personnel possibly resulting in serious injury or death.

CAUTION

CAUTION

Failure to observe CAUTION signs could result in injury to personnel and damage to the unit and associated property.

Symbol shows;

this symbol means caution.

this symbol means caution.

this symbol means an action is prohibited.

this symbol means an action is prohibited.

this symbol means an instruction must be followed.

this symbol means an instruction must be followed.

Be sure to keep this manual in a place accessible to users of this unit.

< Label on the unit >

This mark is labeled on the cover in which the electrical components of high voltage are enclosed to prevent the electric shock.

The cover should be removed by a qualified engineer or a service personnel only.

WARNING

WARNING

As with any equipment that uses CO2 gas, there is a likelihood of oxygen depletion in the vicinity of the equipment. It is important that you assess the work site to ensure there is suitable and sufficient ventilation. If restricted ventilation is suspected, then other methods of ensuring a safe environment must be considered. These may include atmosphere monitoring and warning devices.

4

WARNING

WARNING

Do not use the unit outdoors. Current leakage or electric shock may result if the unit is exposed to rain water.

Only qualified engineers or service personnel should install the unit. The installation by unqualified personnel may cause electric shock or fire.

Install the unit on a sturdy floor and take an adequate precaution to prevent the unit from turning over. If the floor is not strong enough or the installation site is not adequate, this may result in injury from the unit falling or tipping over.

Never install the unit in a humid place or a place where it is likely to be splashed by water.

Deterioration of the insulation may result which could cause current leakage or electric shock.

Never install the unit in a flammable or volatile location. This may cause explosion or fire.

Never install the unit in a flammable or volatile location. This may cause explosion or fire.

Never install the unit where acid or corrosive gases are present as current leakage or electric shock may result due to corrosion.

Always ground (earth) the unit to prevent electric shock. If the power supply outlet is not grounded, it will be necessary to install a ground by qualified engineers.

Never ground the unit through a gas pipe, water main, telephone line or lightning rod. Such grounding may cause electric shock in the case of an incomplete circuit.

Connect the unit to a power source as indicated on the rating label attached to the unit. Use of any other voltage or frequency other than that on the rating label may cause fire or electric shock.

Never store volatile or flammable substances in this unit if the container cannot be sealed. These may cause explosion or fire.

Do not insert metal objects such as a pin or a wire into any vent, gap or any outlet on the unit.

This may cause electric shock or injury by accidental contact with moving parts.

Use this unit in safe area when treating the poison, harmful or radiate articles. Improper use may cause bad effect on your health or environment.

Turn off the power switch (if provided) and disconnect the power supply to the unit prior to any repair or maintenance of the unit in order to prevent electric shock or injury.

Do not touch any electrical parts (such as power supply plug) or operate switches with a wet hand. This may cause electric shock.

5

WARNING

WARNING

Ensure you do not inhale or consume medication or aerosols from around the unit at the time of maintenance. These may be harmful to your health.

Never splash water directly onto the unit as this may cause electric shock or short circuit.

Never splash water directly onto the unit as this may cause electric shock or short circuit.

Never put containers with liquid on the unit as this may cause electric shock or short circuit when the liquid is spilled.

Never bind, process, or step on the power supply cord, or never damage or break the power supply plug. A broken supply cord or plug may cause fire or electric shock.

Do not use the supply cord if its plug is loose. Such supply cord may cause fire or electric shock.

Do not use the supply cord if its plug is loose. Such supply cord may cause fire or electric shock.

Never disassemble, repair, or modify the unit yourself. Any such work carried out by an unauthorized person may result in fire, or electric shock or injury due to a malfunction.

Disconnect the power supply plug if there is something wrong with the unit. Continued

abnormal operation may cause electric shock or fire.

abnormal operation may cause electric shock or fire.

When removing the plug from the power supply outlet, grip the power supply plug, not the cord. Pulling the cord may result in electric shock or fire by short circuit.

Disconnect the power supply plug before moving the unit. Take care not to damage the power

cord. A damaged cord may cause electric shock or fire.

cord. A damaged cord may cause electric shock or fire.

Disconnect the power plug when the unit is not used for long periods. Keeping the connection

may cause electric shock, current leakage, or fire due to the deterioration of insulation.

may cause electric shock, current leakage, or fire due to the deterioration of insulation.

If the unit is to be stored unused in an unsupervised area for an extended period, ensure that children do not have access and that doors cannot be closed completely.

The disposal of the unit should be accomplished by appropriate personnel. Remove doors to prevent accidents such as suffocation.

Do not put the packing plastic bag within reach of children as suffocation may result.

Do not put the packing plastic bag within reach of children as suffocation may result.

Use the reagent specified by Sanyo for H2O2 decontamination. Using a different H2O2 solution may result in explosion or damage to the Incubator.

When performing H2O2 decontamination, securely close gastight split doors, inner door and outer door. Failure to do so may be harmful to health due to leakage of H2O2 gas.

During H2O2 decontamination, plug the access hole with the silicon cap that is provided. Failure to do so may be harmful to health due to leakage of H2O2 gas.

6

CAUTION

CAUTION

Use a dedicated power source (a dedicated circuit with a breaker) as indicated on the rating label attached to the unit. A branched circuit may cause fire resulting from abnormal heating.

Connect the power supply plug to the power source firmly after removing the dust on the plug.

A dusty plug or improper insertion may cause a heat or ignition.

Never store corrosive substances such as acid or alkali in this unit if the container cannot be sealed. These may cause corrosion of inner components or electric parts.

Check the setting when starting up of operation after power failure or turning off of power switch. The stored items may be damaged due to the change of setting.

Be careful not to tip over the unit during movement to prevent damage or injury.

Be careful not to tip over the unit during movement to prevent damage or injury.

Prepare a safety check sheet when you request any repair or maintenance for the safety of service personnel.

Wear rubber gloves when handling the H2O2 reagent. Direct contact with the H2O2 reagent may result in inflammation of the skin.

H2O2 decontamination can be performed only for the chamber and chamber attachments with standard specifications, and not for any other objects.

Perform H2O2 decontamination with the chamber attachments arranged as specified by Sanyo.

Arranging them in a different way may result in insufficient decontamination.

After H2O2 decontamination has been completed, wear rubber gloves and use a non-woven cloth to wipe off the residual H2O2 fluid from the bottom of the chamber, any objects that were decontaminated, and the bottoms of ducts.

7

LABELS ON THE INCUBATOR

Warning and caution labels are attached to the Incubator. The following table describes the labels.

This label is attached to covers that access high-voltage electrical components to prevent electric shock. Only a qualified engineer or service personnel should be allowed to open these covers.

This symbol indicates an ultraviolet light (UV) caution.

This symbol indicates that caution is required. Refer to product documentation for details.

This symbol indicates a hot surface.

This symbol indicates an earth.

This symbol means “ON” for a power switch.

This symbol means “OFF” for a power switch.

ENVIRONMENTAL CONDITIONS

This equipment is designed to be safe at least under the following conditions (based on the IEC 61010-1):

■Indoor use;

■Altitude up to 2000 m;

■Ambient temperature 5oC to 40oC

■Maximum relative humidity 80% for temperature up to 31oC decreasing linearly to 50% relative humidity at 40oC;

■Mains supply voltage fluctuations not to exceed ±10% of the nominal voltage;

■Other supply voltage fluctuations as stated by the manufacturer;

■Transient overvoltages according to Installation Categories (Overvoltage Categories) II; For mains supply the minimum and normal category is II;

■Pollution degree 2 in accordance with IEC 60664.

8

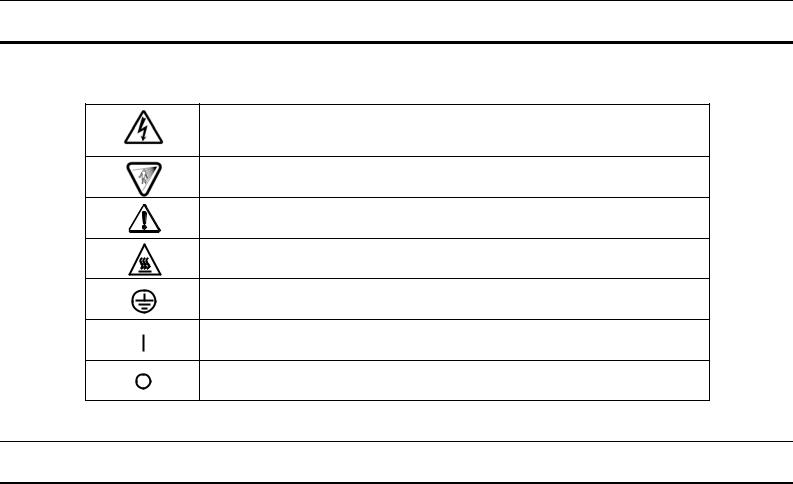

INCUBATOR COMPONENTS

Handles |

6 |

3 2 |

13 |

9 |

10(inside) |

|

|

5 |

1 |

7 |

|

|

|

8 |

16, 17(inside)

For MCO-19M(UVH)/19M(UV) or

when MCO-19UVS is installed.

Handles

24 12 11 15 14 25 4

For MCO-19M(UVH)/19M(UV) or |

19 |

|

|

when MCO-19UVS is installed. |

|

|

21 |

18 |

22 |

|

23 |

|

20 |

Rear Right Side |

Rear Left Side |

9

1.Outer door: The outer door is held to the frame with a magnetic seal. A door heater is installed in the door panel. The door opening is reversible. Contact a Sanyo representative or agent to change the door hinge from left to right or vice versa.

2.Inner door: Open when take the trays out or clean inside.

3.Gastight split door: Made of tempered glass, however avoid excessive impact on the glass.

4.Leveling feet: The leveling feet can be turned to adjust the height. Adjust the feet so that the Incubator is level.

5.Trays: Set trays at the same level as each gastight split door. Open a inner door when take the tray out.

6.Tray supports: The tray supports can be removed by lifting the front side and pulling toward you.

7.Side supports: The right and left side supports can be removed for disinfection. Refer to page 45.

8.Duct: The duct for the path for circulating air. It is removable.

9.Fan cover: The fan cover serves as the inlet for circulating air. It is removable.

10.Fan (inside the duct): The fan is made from polypropylene resin. It can be disinfected in an autoclave.

11.Sample air outlet: The sample air outlet also functions as an internal gas outlet. Normally, cover this outlet with the sample air outlet cap.

12.Sample air outlet cap: Always attach this cap except when using the sample air outlet.

13.Door switch: Detects the door opening/closing and stops the circulating fan and electromagnetic valve for CO2 and N2/O2 when door is open. UV lamp is also deactivated by door opening*.

14.Humidifying pan: Fill the humidifying pan with sterile distilled water. Install the pan properly so that it can be covered with the pan cover.

15.Humidifying pan cover: The cover prevents UV light entering the chamber. When filling the pan, lift the front side and take out the pan. Refer to page 48 for details.

16.UV lamp*: This Sanyo UV lamp does not generate ozone. Never look directly at the UV light. For replacement, contact a Sanyo representative or agent.

17.Water level sensor for humidifying pan: This sensor detects the water level in the humidifying pan. Refer to page 44 for details.

18.Remote alarm terminals: Refer to page 13.

19.Access port: Place the silicon caps on the port both outside and inside when the port is not being used.

20.Power switch: This is the main switch for the Incubator. It also functions as an overcurrent breaker.

21.Glow starter*: The glow started if for the UV lamp (model FG-7P)

22.Connecting port A/B for CO2 gas pipe: When the optional MCO-21GC Automatic CO2 Cylinder Changeover System is installed, both ports A and B are available. If the MCO-21GC is not installed, only

port A is available. Refer to page 16 for gas cylinder connection. Ensure that the gas pressure is set at 0.03 MPaG (0.3 kgf/cm2G, 4.3 psiG). Refer to page 67 for automatic CO2 cylinder changeover.

10

23.Connecting port A/B for N2/O2 gas pipe: Refer to page 17 for gas cylinder connection. Ensure that the gas pressure is set at 0.05 MPaG (0.5 kgf/cm2G, 7.1 psiG). Refer to page 30 for automatic N2 (or O2) gas cylinder changeover.

24.Attachment location for electric key: This is the attachment location for the electric key included in the optional Component H2O2 Decontamination Kit (MCO-HL). This kit must be attached to perform H2O2 decontamination. Refer to the installation procedure for MCO-HL for details.

25.Gas injection nozzle

* MCO-19M(UVH)/19M(UV) or when an optional UV System Kit (MCO-19UVS) is installed.*

11

Control panel and keypad

LCD panel

2

10

1

3

4

7

9

8

5 |

|

|

6 |

||

1. Upper limit regulator:

This regulator is used to set the upper temperature limit.

2. OVERHEAT indicator:

This indicator lights when the chamber temperature reaches the upper limit.

3. MENU Key:

Press this key to access the menu.

4. Contrast knob:

Turn this knob to adjust the contrast of the LCD.

5. BUZZER Key:

Press this key to silence the buzzer.

Note: It is not possible to silence the buzzer for an upper limit temperature alarm.

6. CE Key:

Press this key to clear the entered value when entering a setting.

7.Cursor Keys (Up, Down, Left, and Right): Use these keys to move the cursor on the LCD panel.

8.ENTER Key:

Press this key to select a menu command. When entering a setting, pressing this key to move to the next parameter.

9.Numeric Keys

10.H2O2 Key:

Press this key to start H2O2 decontamination. Refer to page 49 for details.

The following optional components must be installed to perform decontamination.

UV Lamp Add-on Kit (MCO-19UVS) (This is provided as standard equipment for the MCO-19M(UV).)H2O2 Decontamination Kit (MCO-HL)

H2O2 Generator (MCO-HP)

12

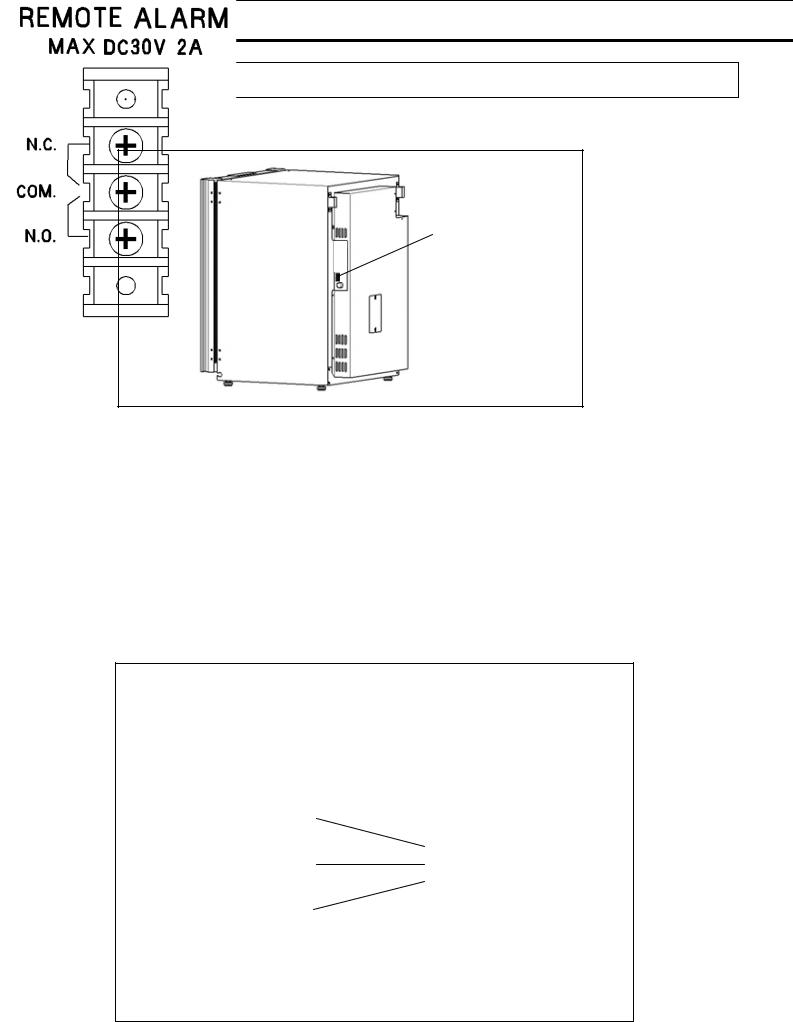

Remote alarm terminal

The remote alarm terminal is located at the rear right side of the incubator.

Remote alarm terminal

The alarm is outputted from this terminal. Contact capacity is DC 30 V, 2 A.

Contact output:

|

between COM. and N.O. |

between COM. and N.C. |

At normal |

Open |

Close |

At abnormal |

Close |

Open |

Note:

The alarm is actuated when the power cord is disconnected from the outlet or the power switch is OFF.

• The remote alarm cannot be stopped by pressing the alarm buzzer stop key (BUZZER) since the remote alarm is not conjunct with the alarm buzzer stop key (BUZZER).

Remote alarm terminal

13

INSTALLATION SITE

For correct operation of the Incubator, install it in a location with the following conditions.

WARNING

WARNING

When using CO2 gas for control, make sure that there is adequate ventilation. Using CO2 gas in a small room without adequate ventilation may cause gas poisoning or oxygen deprivation. In addition, when opening the Incubator doors, do not directly inhale the air in the chamber.

Si l’appareil est utilisé dans un evdroit restreint, le niveau de la densite CO2 de l’air peut s’élever et peut être nocif aux humains. Evitez d’aspirer l’air provenant de l’inérieur de l’appareil quand vous ouverz la porte.

z Normal air environment

Install the Incubator in an environment with normal air. z Do not expose to direct sunlight

Do not install the Incubator in a location where it will be exposed to direct sunlight. If the Incubator is operated in direct sunlight, performance will be adversely affected.

z Separate from heat sources

Do not install the Incubator near significant heat sources, such as heaters, boilers, ovens, or autoclaves. Heat will adversely affect the performance of the Incubator.

z Ambient temperature at least 5°C lower than set temperature

The control temperature of the Incubator is at least 5°C higher than the ambient temperature. For example, if the chamber is controlled at 37°C, the ambient temperature must normally be no more than 32°C. Do not allow the ambient temperature to become too high.

z Strong and level floor

Select a site with a strong and level floor. If the floor is uneven or the installation is not level, the Incubator will be unstable and this may cause accident or injury. To avoid vibration and noise, always make sure that the installation is stable. An unstable surface may result in vibration or noise.

WARNING

WARNING

Install the Incubator at a location that can support the weight. If the floor is not strong enough or if the installation is insufficient, the Incubator may fall over and cause injury.

Always make sure that the floor is strong, even, and level, and that the Incubator will not tip over. An insufficient installation may result in injury due to water leakage or the Incubator falling over.

z Low humidity

Select a site with a relative humidity of 80% or lower. Using the Incubator in high humidity may result in current leakage or electric shock.

WARNING

WARNING

Do not use the Incubator outdoors. If the Incubator is exposed to rain water, it may result in current leakage or electric shock.

Never install the Incubator in a moist location, such as near a sink or water line, or where it is likely to be exposed to water. In addition, do not install it near water or steam pipes. Moisture can cause the insulation to deteriorate, which may result in current leakage or electric shock.

z No inflammable or corrosive gas

Never install the Incubator in a location where it will be exposed to inflammable or corrosive gas. Doing so may result in explosion or fire. In addition, insulation may deteriorate due to corrosion of protective casing, resulting in current leakage or electric shock.

z No falling objects

Do not install the Incubator in a location where there is the possibility of objects falling from above. Doing so may result in damage or accident.

14

INSTALLATION

1. Remove the packing tape and clean up.

Remove all the tape that is securing the doors and inner attachments. Open the doors for ventilation. If the outer panels are dirty, dampen a cloth with a diluted neutral detergent and wipe them. (Using an undiluted solution may damage the plastic. Follow the diluting instructions for the detergent that is used.)

Wipe off the residual detergent with a wet cloth and then wipe off any moisture.

WARNING

WARNING

Do not leave plastic wrapping bags within reach of children. If a bag is placed over a child’s head, it can block the mouth and nose and cause suffocation.

2. Adjust the leveling feet.

Adjust the leveling feet by turning them counterclockwise to level the Incubator. (See the illustration on the right.)

3. Ground the Incubator.

Ground the Incubator during installation to prevent electric shock in case the insulation is not sufficient. If there is no ground wire at the location, consult with qualified service personnel.

z When a ground must be installed

If a grounded 3-pole outlet is not available, then a ground must be installed. Consult with qualified service personnel.

WARNING

WARNING

To prevent electric shock, always ground the Incubator. If grounding is not possible, then have a ground installed by qualified personnel. If the Incubator is not grounded, it may result in electric shock.

Never connect the ground wire to a gas pipe, water pipe, lightning rod, or telephone ground wire.

Doing so may cause electric shock.

z Installing a ground fault circuit breaker

If using the Incubator in a location with moisture or humidity cannot be avoided, then it is recommended that a ground fault circuit breaker be installed in the power supply circuit (i.e., the power supply at the Incubator). Have the circuit breaker installed by qualified service personnel.

CAUTION

CAUTION

Do not climb on the Incubator or place objects on top of it. Doing so may damage it or cause it to fall over, resulting in injury. If it is to be stacked, refer to page 72 and stack it securely.

z When the Incubator is not in use

Empty the water from the humidifying pan and remove moisture from the chamber. Make sure that the chamber is completely dry before closing the doors. Failure to do so may result in damage.

z Before moving the Incubator

Before moving the Incubator, empty the water from the humidifying pan, disconnect the power supply plug from the outlet, and make sure that the cord will not be damaged. Failure to do so may result in electric shock or fire.

15

Connection of CO2 gas cylinder

WARNING

WARNING

When connecting a gas cylinder to the Incubator, confirm the gas type. Confirm that the connections are secure and that no gas will escape. Be sure to use the specified pressure. Using an incorrect gas or pressure may result in explosion or fire, or in gas poisoning or oxygen deprivation due to escaping gas.

Install the Incubator in a location with adequate ventilation. If adequate ventilation cannot be provided, then install an alarm system using CO2 and O2 densitometers.

1.Use a liquefied CO2 gas cylinder (at least 99.5% pure). The siphon (dip tube) type cannot be used.

2.Install the Gas Pressure Regulator (MCO-100L, purchased separately) specified by Sanyo on the CO2 gas cylinder. Otherwise, use a CO2 gas pressure regulator rated at 25 MPaG (250 kgf/cm2G, 3600 psiG) for the primary pressure, and 0.2 MPaG (2 kgf/cm2G, 30 psiG) for the secondary pressure.

3.Using the gas supply pipe that is provided, connect the CO2 gas pressure regulator to the CO2 gas pipe inlet (located at the lower left-hand side on the rear panel of the Incubator).

Note:

If CO2 is supplied to multiple CO2 Incubators from a single gas cylinder, a CO2 solid will be formed in the gas pressure regulator. The gas pressure regulator safety valve will operate, and there may an explosive sound.

When the MCO-21GC is not mounted

Using the gas supply pipe that is provided, connect the CO2 gas pressure regulator for the CO2 gas cylinder to CO2 gas pipe connection port A on the Incubator. After connecting the pipe, check to make sure that no gas is leaking.

When the MCO-21GC is mounted

Connect a pair of CO2 gas cylinders with CO2 gas pressure regulators independently. The gas supply line will be switched automatically. Connect the main cylinder to port A and the reserve cylinder to port B. After connecting the cylinders, check to make sure that no gas is leaking.

z For details on installing the optional automatic CO2 Cylinder Changeover System (MCO-21GC), refer to the MCO-21GC installation guide. For details on using the MCO-21GC, refer to page 67.

4. Set the CO2 gas on the secondary side to 0.03 MPaG (0.3 kgf/cm2G, 4.3 psiG) for gas injection. As the pressure increases, the CO2 gas concentration control range will increase. Excessive pressure may cause gas supply lines inside the Incubator to come loose, which may result in gas poisoning or oxygen deprivation due to the escaping of gas. If gas lines come loose, the Incubator must be repaired.

z The gas lines connected to the Incubator will degrade over time. If any deterioration or abnormalities are found during inspection, replace the lines immediately.

16

Connection of N2 (or O2 ) gas cylinder

WARNING

WARNING

Check the gas type and ensure that it is fit for the purpose. Make sure that all pipes are connected correctly and are not liable to become disconnected. Ensure that the gas pressure is set at the specified value. Improper connection of the gas pipe or use of incorrect gas pressure may result in leakage of gas. Elevated level of gas can be hazardous to health and may lead to asphyxiation and risk of death.

This incubator needs N2 or O2 gas depending on the setting of O2 density. The selection is as follows: When the setting of O2 density is less than 18%: N2 gas

When the setting of O2 density is more than 22%: O2 gas

O2 density in the atmosphere is about 20%. For the control of O2 density in the chamber, O2 gas is diluted by N2 gas when the setting of O2 density is less than that of the atmosphere. On the contrary, O2 gas is added when the setting of O2 density is more than that of the atmosphere.

1.Install a gas pressure regulator (optional accessory MCO-100L) on N2 or O2 gas cylinder. Or use a regulator rated at 25 MPaG (250 kgf/cm2G, 3600 psiG) on the primary side and 0.2 MPaG (2.0 kgf/cm2G,

30psiG) on the secondary side.

2.Using the gas tube provided, connect the pressure regulator to the connecting port A/B for N2/O2 gas pipe located at the rear left side of the incubator. Connect the main cylinder to the connecting port A for N2/O2 gas pipe and connect the sub-cylinder to the connecting port B for N2/O2 gas pipe so that the gas supply can be switched automatically when one gas cylinder is empty. Connect the same gas type to both connecting port A/B for N2/O2 gas pipe. Never connect N2 gas and O2 gas at the same time to the connecting port A/B for N2/O2 gas pipe respectively.

3.Set the N2 or O2 gas pressure on the secondary side to 0.05 MPaG (0.5 kgf/cm2G, 7.1 psiG) (at gas injection). The higher gas pressure makes control range of O2 density wider. In addition, excessive pressure may cause disconnection of internal pipes inside the incubator, which will result in leakage of N2 or O2 gas into the atmosphere. Elevated level of CO2 gas or O2 gas can be hazardous to health and may lead to asphyxiation and risk of death or fire by gas leakage. The repair of the incubator will be necessary if the internal pipe is disconnected.

4.Check that no gas is leaking at any point where the pipe connects with the gas regulator or the incubator.

z The gas lines connected to the Incubator will degrade over time. If any deterioration or abnormalities are found during inspection, replace the lines immediately.

WARNING

WARNING

O2 gas increases the susceptibility of substances to burn. Take care of the handling of flame in a room where the incubator is installed.

17

Connection of gas injection nozzle

In the case of control of O2 density in the chamber, connect the gas injection nozzle to the gas injection port by using the connecting pipe enclosed (inner diameter; 5 mm, outer diameter; 9 mm, length; 400 mm). This helps faster recovery of humidity after opening of the inner door.

Fill the humidifying pan with sterile distilled water so that the injection nozzle can be under the water level.

Gas injection nozzle

Using the inner door and gastight split doors

zTo effectively use gastight split doors, set three trays (standard equipment) at the same level as bottom side of each gastight split door.

At the same level as bottom side of each gastight split doors

18

PREVENTING CONTAMINATION

To prevent contamination of the chamber, select a suitable installation site.

z Avoid locations with high temperatures or humidity.

Avoid locations with high temperatures or humidity, because of a greater presence of microorganisms in the air.

z Avoid locations with passers-by or drafts.

Avoid locations near doors, air conditioners, fans, etc., where passers-by or drafts can facilitate the entry of microorganisms into the chamber.

z If possible, use a cleanroom.

To achieve a better culture, it is recommended that a cleanroom be used if one is available.

z Use clean containers.

The greatest cause of contamination is dirty containers for cultures. Be careful not to get containers or trays dirty when taking them in and out.

z Keep the chamber clean.

Wipe off any fingerprints. If water spills from the humidifying pan, or if the doors are left open for a long time, condensation may form on the inside of the doors. If that occurs, wipe off the condensation with a dry sterile gauze. In particular, clean and disinfect the chamber if the culture medium is spilled. For details, refer to Routine Maintenance on page 45.

z Use sterile distilled water in the humidifying pan.

Always use sterile distilled water in the humidifying pan. Do not use ultrapure water, because it may contain red rust-like suspended particles.

A water level alarm is displayed in the status display area on the control panel. Quickly refill the water in the pan when the water level alarm is displayed. Adding low-temperature water will significantly lower the temperature in the chamber. Clean the humidifying pan once a month.

z Keep the Incubator out of direct airflows from air conditioners or fans.

Cool airflow from an air conditioner may cause condensation and lead to possible contamination.

19

PRECAUTIONS FOR CULTURES

z Leave space between culture containers.

Always leave space for ventilation between culture containers (Petri dishes, flasks, etc.). Inadequate spacing may result in uneven temperature distribution and CO2 gas concentration.

z Do not place harmful materials in the chamber.

Never place samples that release acidic, alkali, or corrosive gas in the chamber. Doing so may cause damage resulting from discoloration or corrosion.

z Close the inner door and all gastight split doors.

Always close the inner door and all gastight split doors before closing the outer door. Failure to close the inner door or any gastight split door will adversely affect performance even if the outer door is closed.

z Open and close the doors gently.

Always open and close the doors gently. Closing the doors forcefully may cause spillage of the culture medium, incomplete closing, or damage to the gasket. Before opening the inner door, check through the glass to confirm that the UV lamp is OFF (if the MCO-19M(UVH)/19M(UV) or the optional MCO-19UVS is installed).

z Be careful when closing the outer door.

Use the handle when closing the outer door. Holding the door in other places may cause injury by getting fingers caught in the door. Do not lean on the outer door. Doing so may result in injury from the outer door coming loose or the Incubator falling over, or it may cause current leakage or electric shock.

zBe careful of the inside of the outer door.

The inside of the outer door may become hot.

zAvoid using excessive force on the inner door.

Do not put your hand on the glass, poke it with sharp objects, or apply strong force. Doing so may result in injury from breaking the glass.

z Check the cause of any alarm buzzer.

If an alarm buzzer sounds while the Incubator is in use, immediately check the cause of the alarm. For details on what may cause an alarm buzzer to sound, refer to page 55.

20

Using the Unlock Key

z Unlocking when power is interrupted

If power is interrupted to the MCO-19M(UVH)/19M(UV) with an MCO-HL installed, the outer door is electrically locked. To unlock the outer door while the power is interrupted, use the unlock key that is provided. To lock the outer door again, turn the unlock key to the lock direction while the door is open. After the door has been locked condition manually, then close the door.

Note:

The outer door cannot be locked by using the unlock key while the door is closed. Lock the door while it is open. Attempting to turn the unlock key while the door is closed may damage the electric lock system.

WARNING

WARNING

For the MCO-19M(UVH)/19M(UV) with an MCO-HL installed, the outer door is electrically locked during decontamination. The chamber is filled with H2O2 gas during decontamination. Do not unlock the door during decontamination.

CORRECT OPERATION

Use the following procedure to start trial operation or actual operation of the Incubator.

1.Install the Incubator correctly, referring to Installation on page 15.

2.Remove the packing materials from the chamber and inner attachments. Clean and disinfect the chamber and inner attachments, referring to Routine Maintenance on page 45.

3.Add approximately 1.5 L of sterile distilled water to the humidifying pan. (Refer to page 48.)

4.Turn ON the power supply switch on the left side of the rear panel of the Incubator.

Note:

The humidity in the Incubator chamber is adjusted to the optimum setting. To prevent condensation on the surface inside chamber and the inner door, there is a low-temperature area under the humidifying pan in the bottom of chamber to recondense evaporated moisture. Condensation may occur around the humidifying pan at the bottom of the chamber, but this does not indicate a problem.

21

LCD PANEL

The following display (called the Top Display) will appear when the power switch is turned ON. The default temperature is 37.0oC, the default CO2 density is 0% and the default O2 density is 20%. The date and time are preset at the factory. Refer to page 38 to change the date and time.

|

|

|

1 |

|

|

|

|

|

|

3 |

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

0 |

0 |

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

2 |

2 |

2 |

2 |

2 |

|

2 |

2 |

|

2 |

2 |

2 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

4 |

||||

|

1 |

2 |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

0 |

1 |

2 |

3 |

4 |

|

5 |

6 |

|

7 |

8 |

9 |

0 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

0 |

||||

|

1 |

T e mp 3 7 . 0 o C |

|

|

C O 2 |

|

|

5 . 0 % |

A |

B |

|

O 2 |

|

|

5 . 0 % |

A |

B |

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||

2 |

3 |

|

|

|

. |

|

|

|

|

|

|

|

|

|

|

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

. |

. |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

5 |

|

|

|

S t a t u s |

|

|

|

U V |

|

|

R H P A N |

|

|

|

|

|

D o o r : O p e n |

|

|

|

|

|||||||||||||||||

10 |

6 |

|

|

|

O K |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. Display of set value of temperature

The set value of chamber temperature is displayed.

2. Display of current temperature

The current chamber temperature is displayed.

3. Display of set value of CO2 density

The set value of the chamber CO2 density is displayed.

4. Display of current CO2 density

The current chamber CO2 density is displayed.

5. Display of current CO2 cylinder

A and B will be displayed if the optional Automatic CO2 Cylinder Changeover System (MCO-21GC) is installed. The port of the CO2 gas pipe that is currently supplying CO2 will be displayed in reverse video. Nothing will be displayed if the MCO-21GC is not installed.

6. Display of set value of O2 density

The set value of the chamber O2 density is displayed.

7. Display of current O2 density

The current chamber O2 density is displayed.

8. Display of current N2/O2 cylinder

The connecting port A/B for N2/O2 gas pipe that is currently supplying N2 or CO2 will be displayed in reverse video.

22

9. Status display field

Various status or alarms are displayed.

When UV lamp is lit: “UV” is displayed in reverse video. (If the MCO-19M(UVH)/19M(UV) or the optional MCO-19UVS is installed).

When humidifying water is low: “RH PAN” is displayed in reverse video and blinks.When the door is open: “Door: Open” is displayed in reverse video.

10. Message display field

A message is displayed when fault occurs. The message is displayed alternately in normal characters and reverse video. Refer to pages from 55 to 57 for alarm details. “OK” is displayed during normal operation.

23

Loading...

Loading...