Page 1

TALEA - ODEA

SERVICE

MANUAL

Revision 04 December 2012

All parts of this document are the property of Saeco International Group. All rights reserved. The manufacturer shall not accept responsibility for possible errors or omissions in this document. Any reproduction or use by

third parties is prohibited without the prior written approval of the manufacturer or through an agreement clause.

Page 2

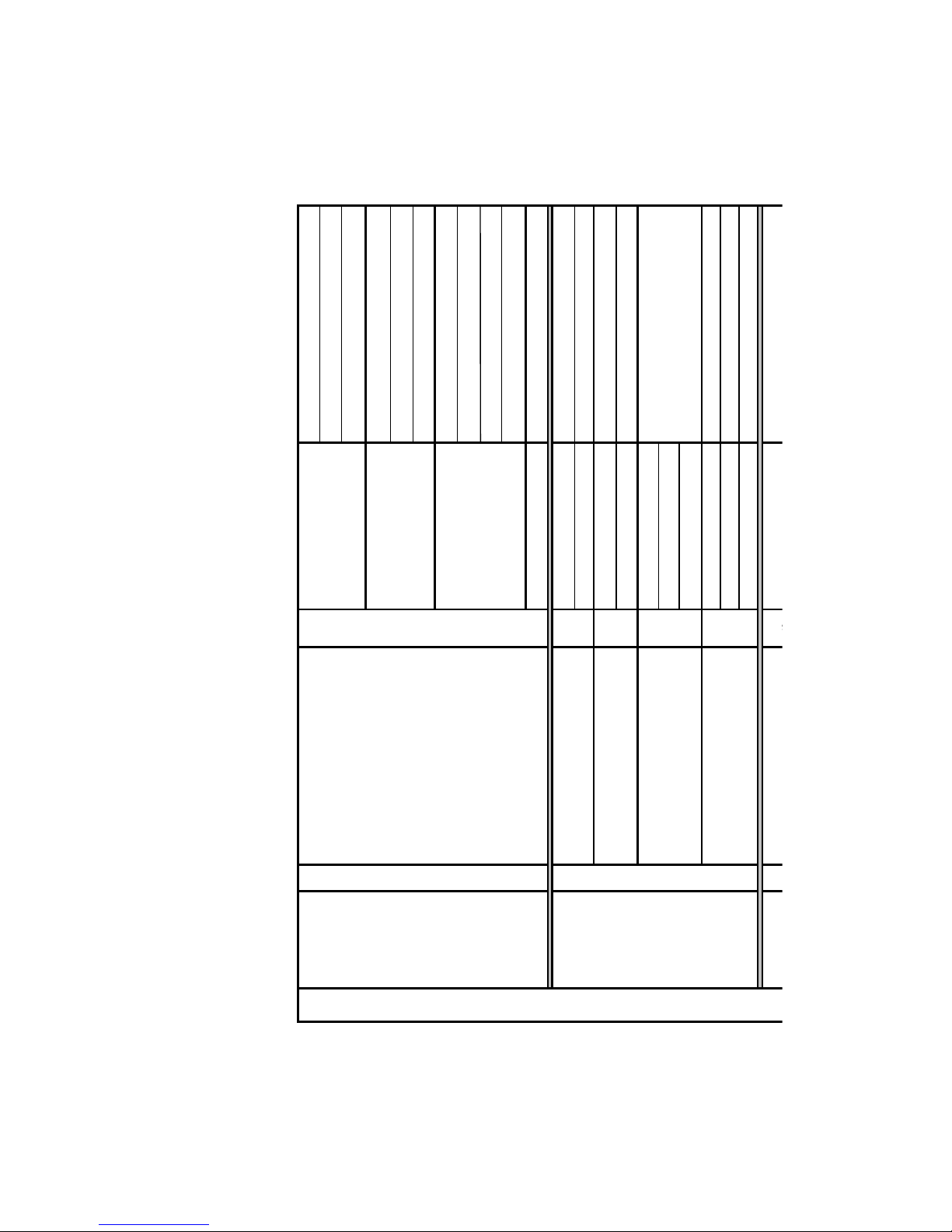

Saeco International Group Talea / Odea - Line

Page

1. Introduction

1.1 Documents required 1

1.2 Tools and resources 1

1.3 Materials 1

1.4 Safety precautions 1

1.5 Service Policy 2

1.6.1 External appliance components 3

1.6.2 Internal appliance components 4

2. Technical specifi cations 1

2.1 Technical specifi cations

2.2 Specifi cation for the measurement of the

coffee products temperature. 2

3. Operating

3.1 User interfaces 1

3.1.1 Odea Go 2

3.1.2 Odea Giro, Talea Giro 3

3.1.3 Talea Giro Plus 3

3.1.4 Talea Ring, Ring Plus 4

3.1.5 Talea Touch 8

3.2 Use, cleaning, maintenance 12

3.3 Messages - Troubleshooting 13

4. Functional principles

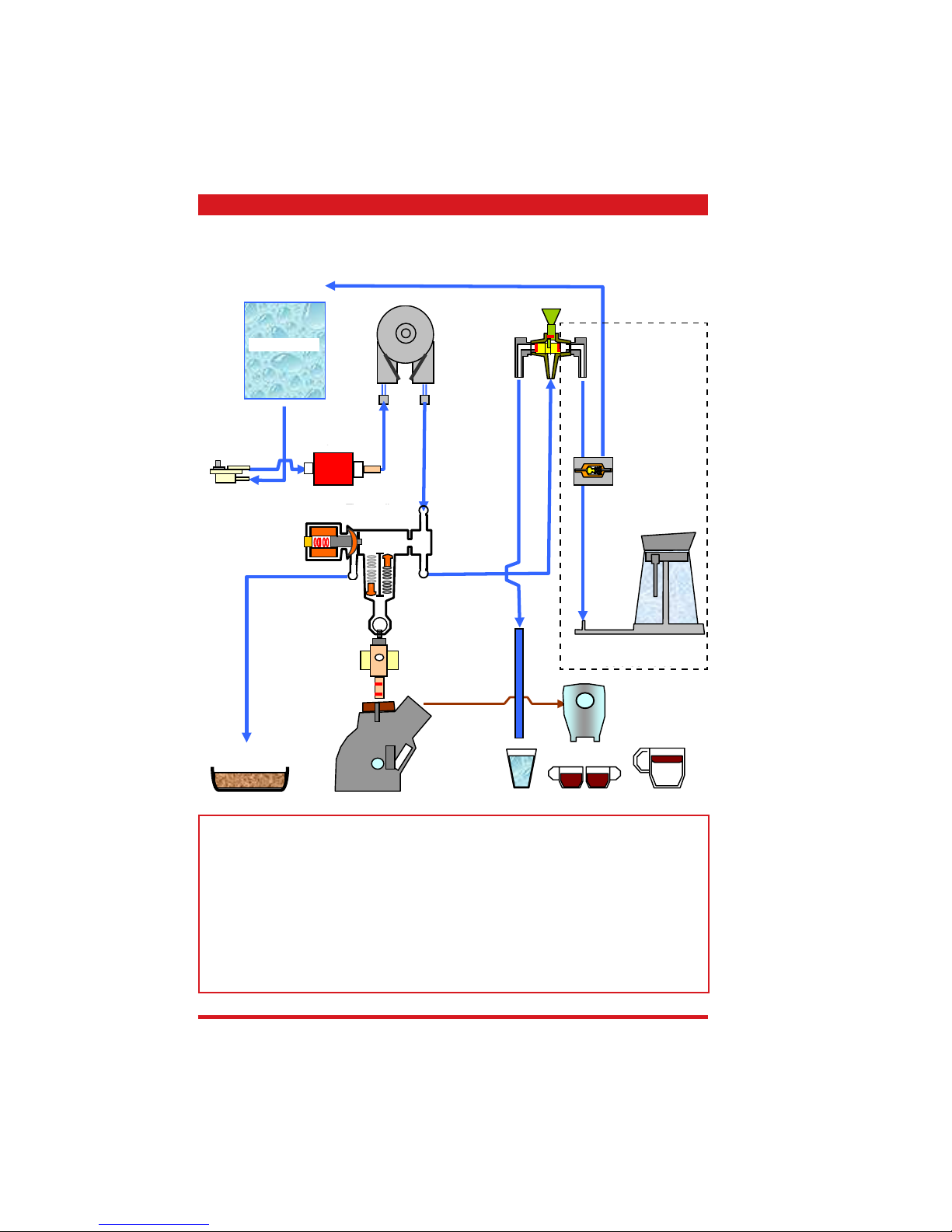

4.1.1 Odea Go water system 1

4.1.2 Talea, Odea Giro water system 2

4.2 Solenoid valve, multi-way valve 3

4.3 Hot water / steam faucet 4

4.4 Coffee cycle 5

4.5 Brewing unit’s gear mechanism 6

4.6 Temperature sensor (control) 6

4.7 SBS 7

4.8 Coffee grinder 8

4.9 Dosing quantity control, coffee grinder blockage when

machine is low on beans 8

4.10 Autodose (automatic dosing quantity control) 9

Table of contents

Page 3

Saeco International Group Talea / Odea - Line

Table of contents

Page

4. Functional principles

4.11 Water level detection of fresh water tank 10

4.12 Limescale fi lter 10

4.13 Water level detection of residual water tray 11

4.14 “Empty dreg drawer” message 11

4.15 Descaling request 12

4.16 Electronical confi guration (DIP-switch setting) 12

4.17 Cup lift 13

4.18 Milk Island 13

5. Service modality

5.1.1 Test mode - Talea Giro and Odea 1

5.1.2 Special function mode - Talea Giro and Odea 2

5.2.1 Test mode - Talea Ring and Ring Plus 3

5.2.2 Diagnosis menu - Talea Ring and Ring Plus 6

5.3.1 Test mode - Talea Touch 9

5.3.2 Diagnosis menu - Talea Touch 13

5.4 Error messages 17

6. Standard controls

6.1 Repair plan 1

6.2 Service plan 1

6.3 Final control 2

7. Disassembly

7.1 SBS / dispenser 1

7.2 Housing 1

7.3 Electronics 3

7.4 Boiler pin 3

7.5 Gear motor device 4

7.6 Boiler 5

Page 4

Saeco International Group Talea / Odea - Line

Table of contents

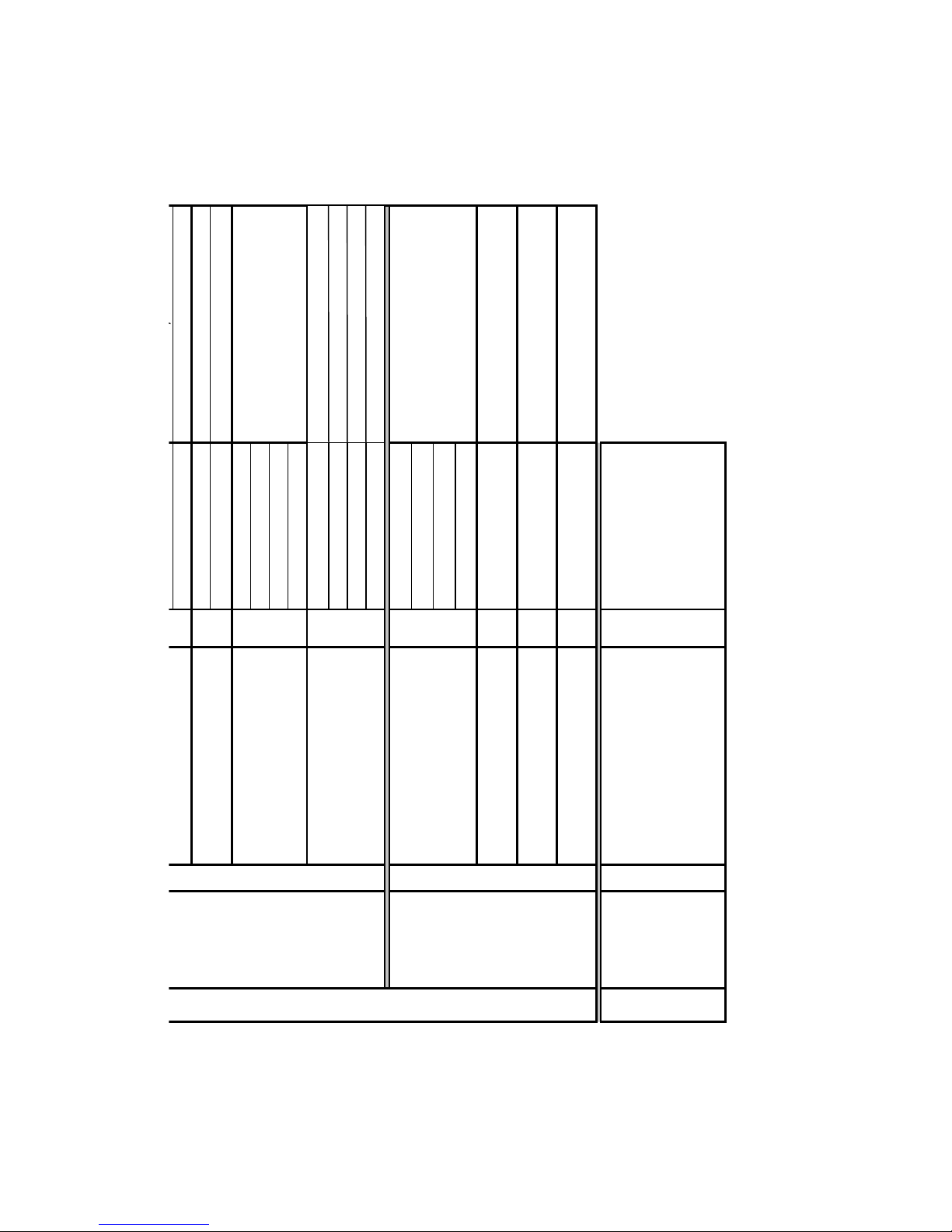

Page

7. Disassembly

7.7 Solenoid valve / multi-way valve 6

7.8 Pump 7

7.9 Hose connections (assembly) 7

7.10 Coffee grinder 9

7.11 Grinders 10

7.12 Adjustment of coffee grinder 11

7.13 Cup lift 12

8. Notes 1

9. Water system diagrams

Odea Go

Odea Giro Plus, Giro

Talea

10. Wiring diagrams

Odea Go

Odea Giro

Talea Giro Plus

Talea Ring

Talea Ring Plus

Talea Touch Plus

Page 5

Saeco International Group Talea / Odea - Line

CHAPTER 1

INTRODUCTION

Page 6

TALEA / ODEA - LINE 01 INTRODUCTION

Saeco International Group Page 1 / 4

1.1 Documents required

The following documents are needed for repair work:

• Instruction booklet for the related model

• Technical documentation for specifi c model (diagrams, exploded view, sympton cure and

service manual).

1.2 Tools and resources

As well as the standard equipment, the following is required:

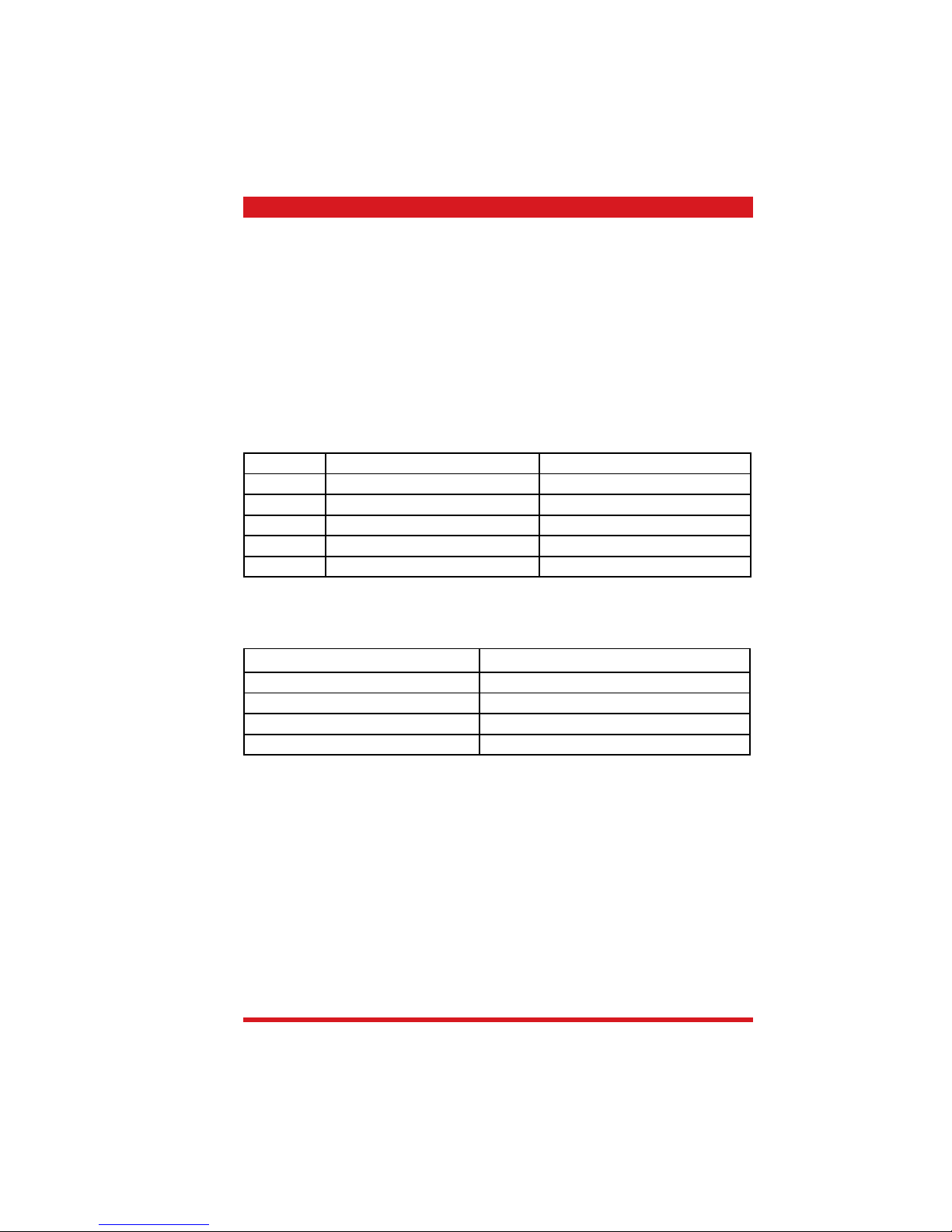

Pieces Description Comment

1 Special screwdriver Torx T 10

1 Pliers for Oetiker clamps

1 Tester CC - A - VDC

1 Digital temperature meter Temperature range > 150°C

1 SSC (Saeco Service Center) Interface for programming

1.3 Materials

Description Comment

Thermal conductance paste Temperature resistance > 200°C

Descaler Saeco descaler

Fat solvent Personal choice

Silicone grease Food-safe

1.4 Safety precautions

We recommend you consult this Service Manual of the machine before performing any maintenance work.

Observe all applicable standards relating to the repair of electrical appliances.

Always disconnect the power plug from the mains before beginning repair work.

Simply turning off the main machine power switch is not an adequate safety precaution.

This domestic appliance is rated as insulation class I.

On completion of the repair work, insulation and dielectric rigidity tests must be performed.

Page 7

Page 2 / 4 Saeco International Group

01 INTRODUCTION TALEA / ODEA - LINE

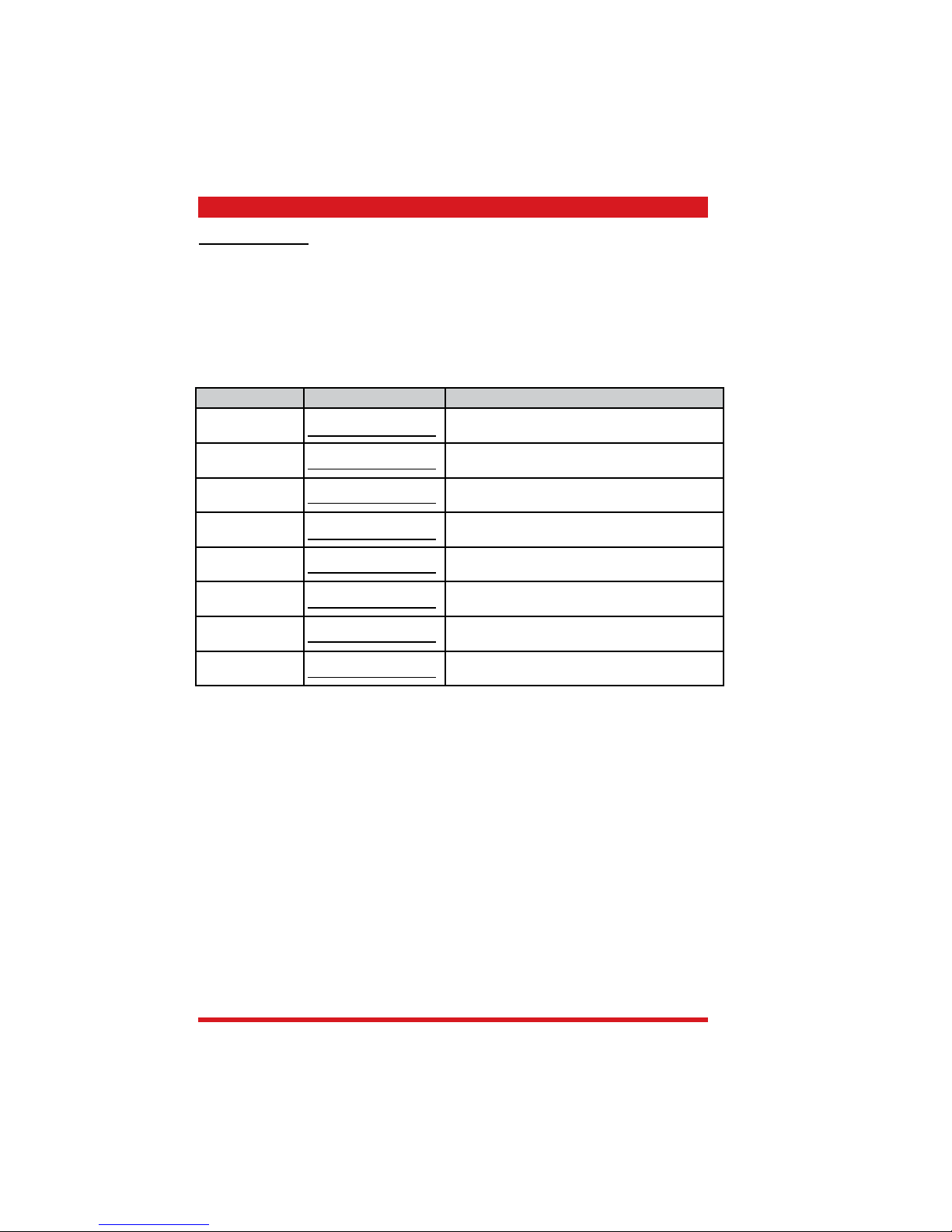

Components Assembly use Single components available

COFFEE

GRINDER

Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine or of the Coffee Grinder on website

BREWING UNIT Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine or of the Brewing unit on website

BOILER Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine on website

GEAR

MOTOR

Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine on website

FILTER

HOLDER

Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine on website

MILK

CARAFE

Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine on website

THERMAL

CARAFE

Only for OOW repairs

YES, to consult the specifi c exploded-view of the

Thermal Carafe on website

MILK ISLAND Only for OOW repairs

YES, to consult the specifi c exploded-view of the

Milk Island on website

List of principal assembly present in all our coffee machines

1.5 Service POLICY grid as used for coffee machine

For IN WARRANTY repairs is mandatory to use the single components (not the assembly) avail-

able in the exploded views of the coffee machines or of the specifi c components. If you fi nd the

information “SEE THE EXPLODED VIEW E........” in the assembly description fi eld, it means that

the single components of the assembly are available in the other pages of the exploded view. It’s

possible to use the assembly only if there is a specifi c Symptom Cure that include this possibility or

when the single components are not available for the order.

Page 8

TALEA / ODEA - LINE 01 INTRODUCTION

Saeco International Group Page 3 / 4

Button for lifting/lowering the drip

tray (motor controlled function,

with Touch/Ring Plus only)

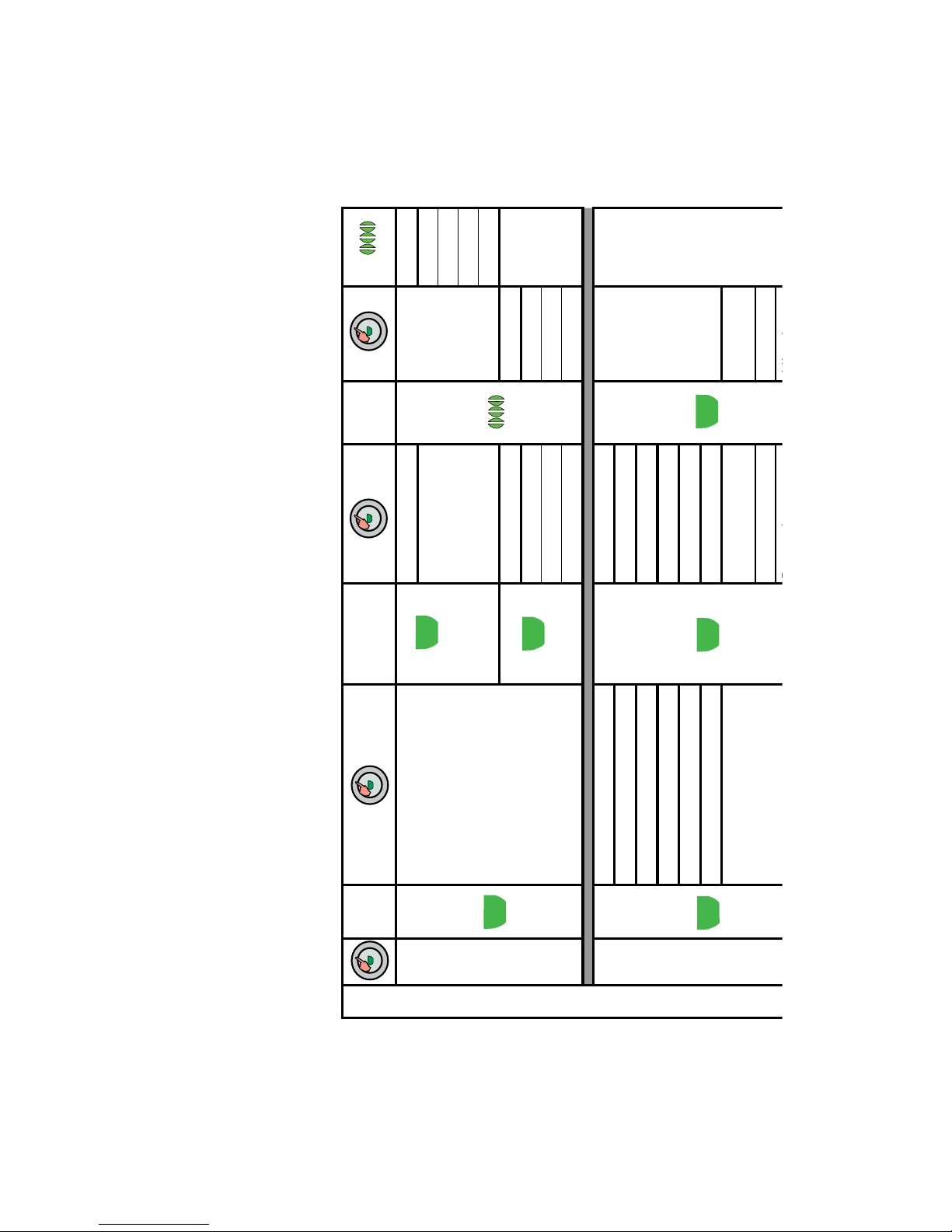

1.6.1. External appliance components

Coffee bean hopper

Coffee bean hopper

lid

Funnel for ground

coffee

Service door

Dreg drawer

Brewing unit

Residual water

Socket for power

cord

Milk Island connection

port

Water tank

Hot water / steam

wand

Cup warming surface

Control panel

Dispensing head

Drip tray + grill

Hot water / steam

knob

Main switch

Saeco Brewing System SBS

Page 9

Page 4 / 4 Saeco International Group

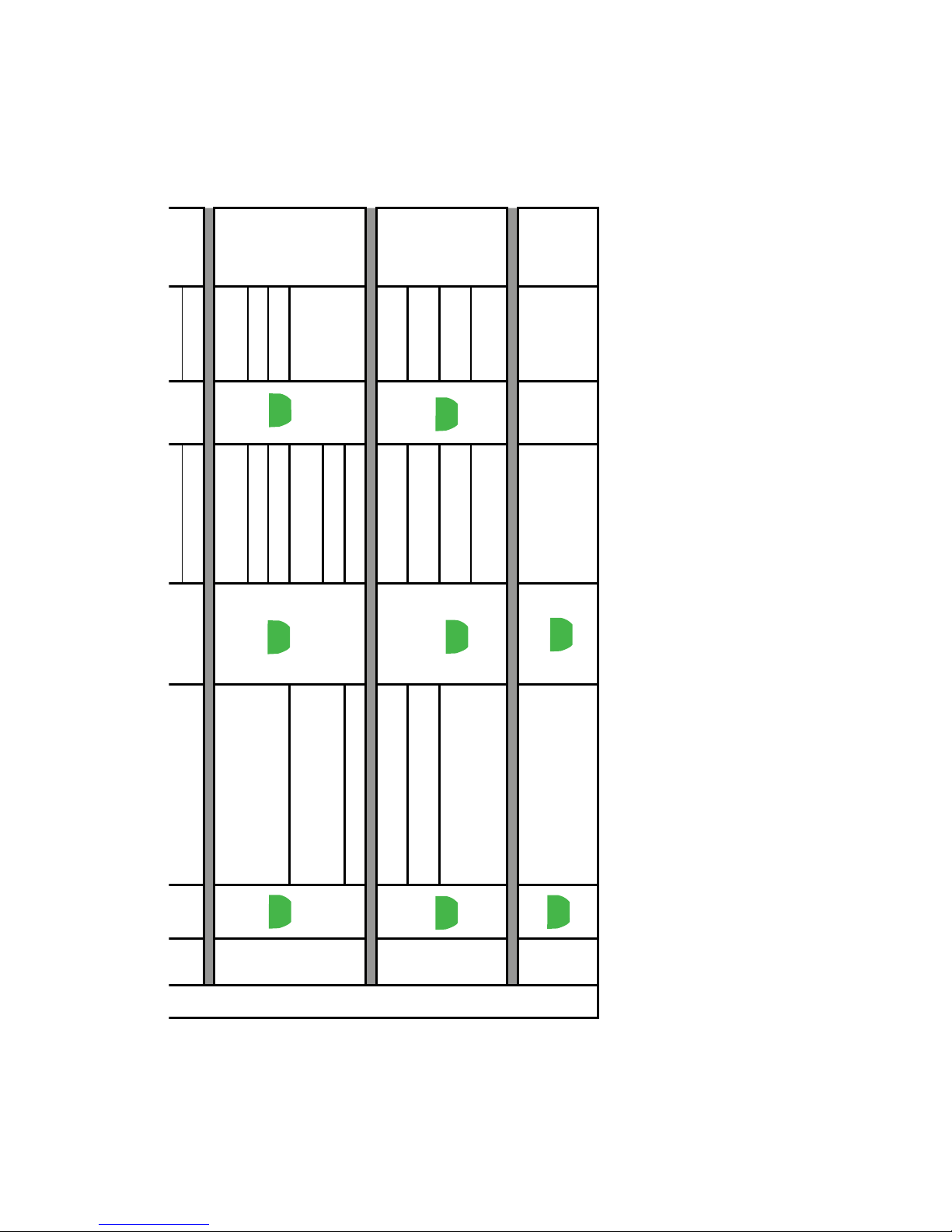

01 INTRODUCTION TALEA / ODEA - LINE

Pump

Unblocking

fi lter

Flowmetre

Boiler

Coffee grinder

Power board

Control

board

Electrical cup lift’s motor

*Touch/Ring Plus only

Multi-way valve (not odea Go)

1.6.2. Internal appliance components

Page 10

Saeco International Group Talea / Odea - Line

CHAPTER 2

TECHNICAL

SPECIFICATIONS

Page 11

Saeco International Group Page 2 / 2

TALEA / ODEA - LINE 02 TECHNICAL SPECIFICATIONS

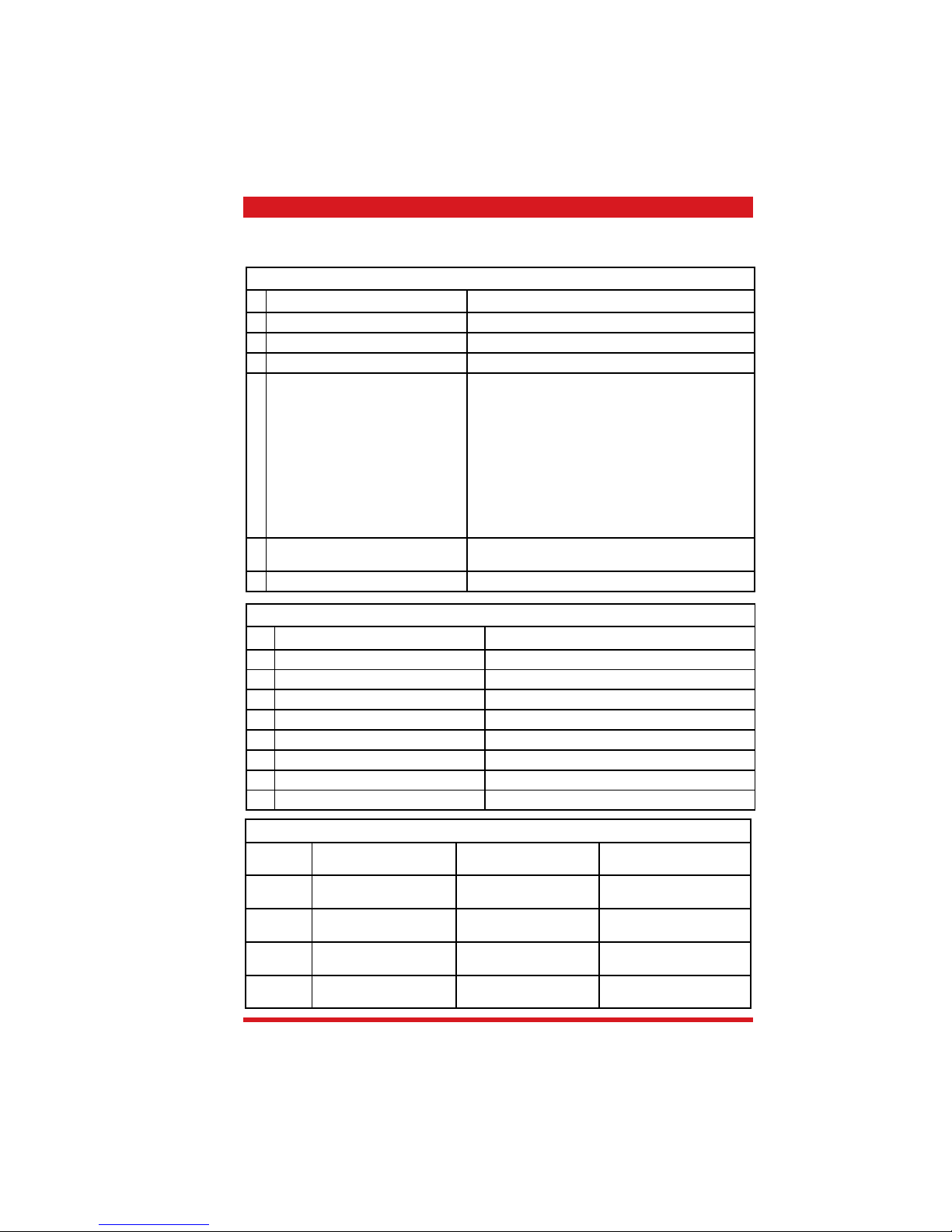

Connection values / power

consumption:

230 V~, 50/60 Hz, 1500 W

Temperature control: Temperature sensor (NTC, 20°C approx. 61 kOhm)

Safety equipment: 2 safety thermostats, can resist 175°C

Power output of stainless boiler: 1300 W - to dispense coffee, hot water and steam

Electrical cup lift

*Talea Touch and Ring Plus only

Stepping motor 24VDC

Tank water level and

residual water tray sensor

Capacitive sensor

Gear motor: DC motor with 2 rotating directions (24VDC)

Actively heated cup warmer:

*Talea Touch and Ring Plus only

PTC control

Pump: Ulka reciprocating piston type pump with thermal safety

100°C

48 W, 230V, 50 Hz, Type EP5 approx. 13-15 bar

Safety valve: Opens at approx. 18-20 bar

Water fi lter: in tank

Coffee grinder: DC motor with

ceramic grinders

Multi-way valve: 15 W

Coffee dose control Hall sensor - pulse control. Adjustable

coffee dosage from approx. 7 - 10.5 g set via program.

Power consumption: During heating phase - approx. 5.6 A

Dimensions: W x H x D in mm: 300/375/410

Weight: approx. 10 kg

Water tank capacity: approx. 1.7 l.

Coffee container fi lling capacity approx. 250g coffee beans

Dreg drawer capacity 14

Continuous-fl ow heater capacity: approx. 10 ccm

Water circuit fi lling time: approx. 15 seconds for fi rst fi lling cycle

Heating time: approx. 45 seconds

Grinding time: approx. 8-10 seconds

2.1. Technical specifi cations

Page 12

Page 3 / 2 Saeco International Group

02 TECHNICAL SPECIFICATIONS TALEA / ODEA - LINE

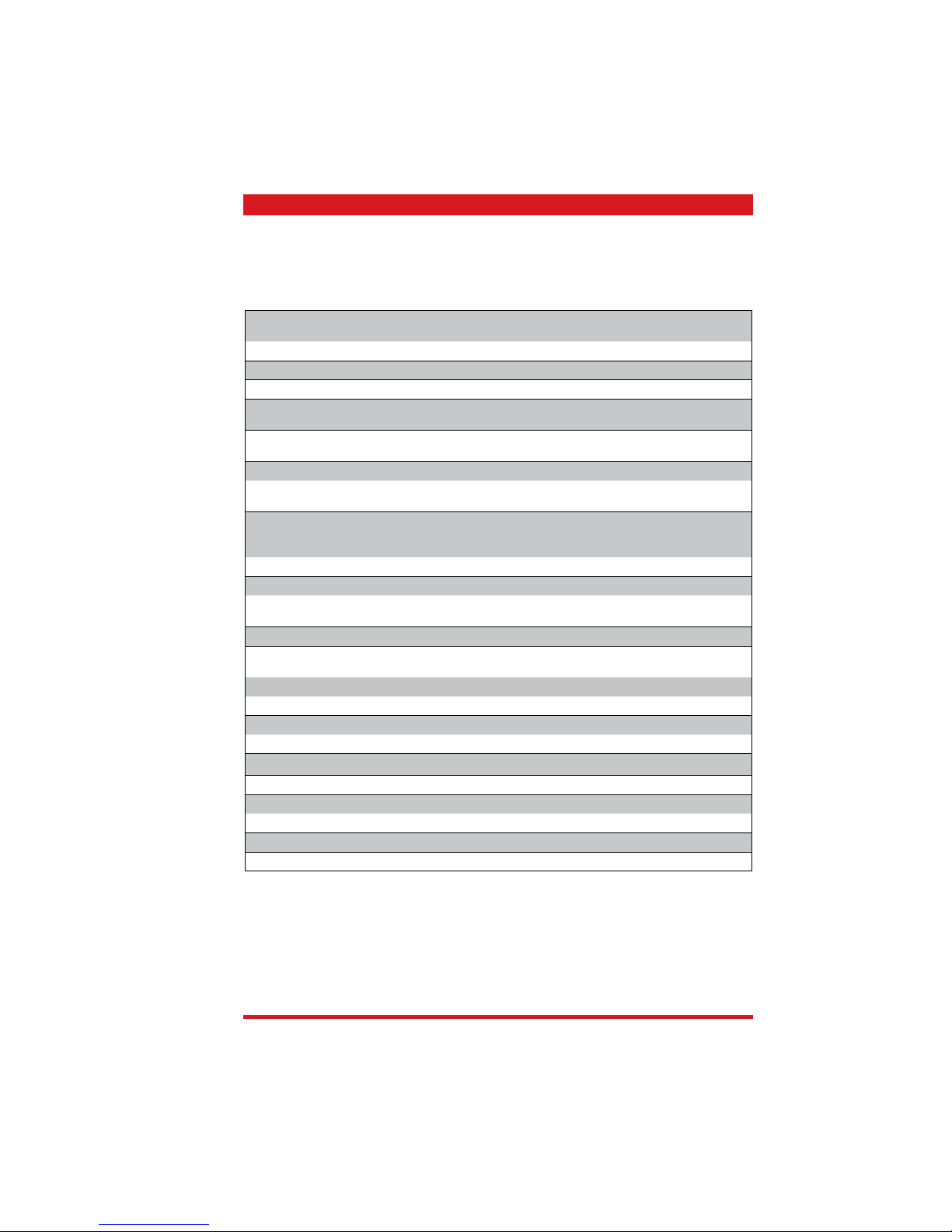

2.2. Specifi cation for the measurement of the coffee products temperature.

The temperature is infl uenced by the fl ow from the dispenser and stratifi cation of temperatures in the

glass. In order to consider these phenomena and to introduce measures that allow comparisons in controlled conditions, below guidelines must be followed:

Conditions:

a) Water temperature in tank: 23°C (+/-2°C).

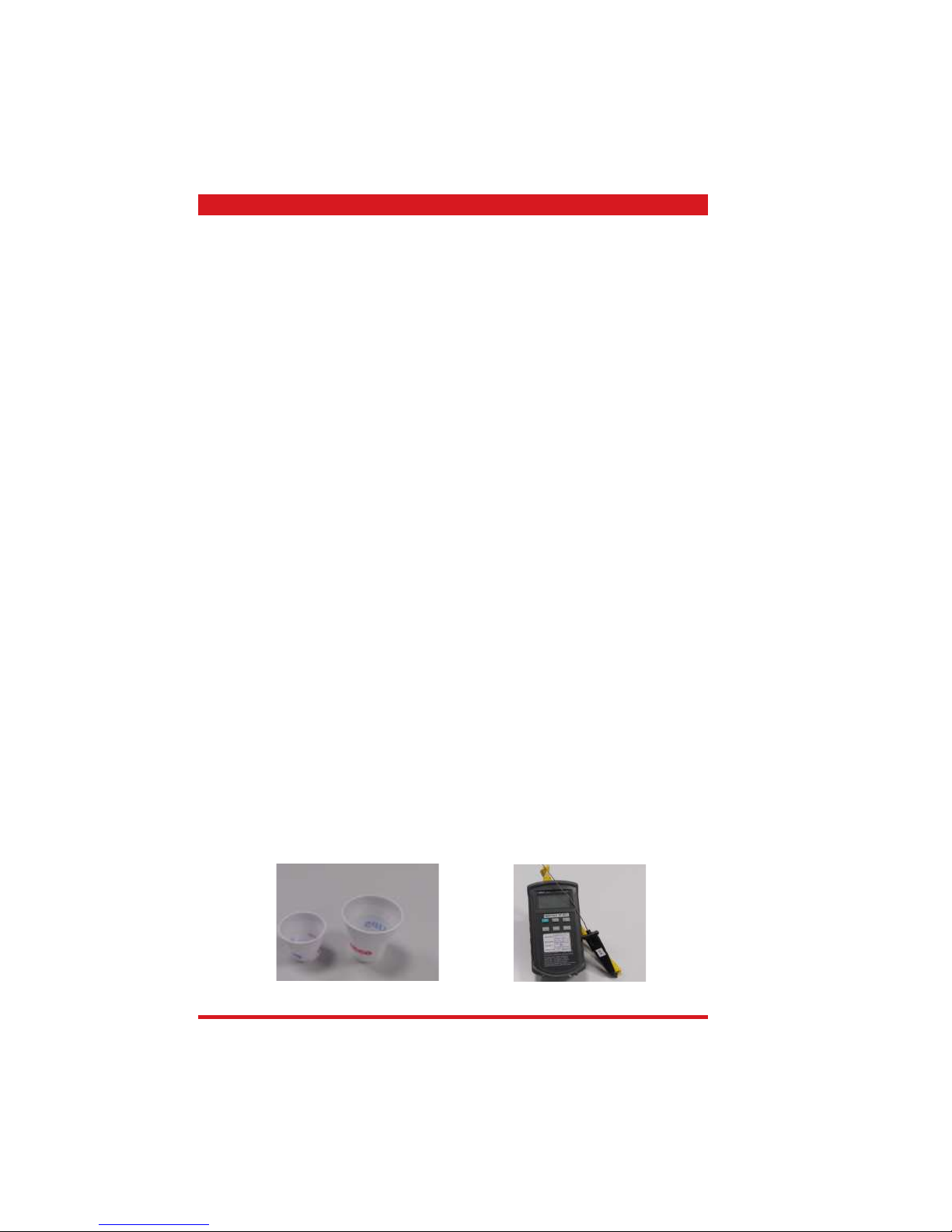

b) It must be used a plastic cup (see picture N°1).

c) It must be used a thermocouple thermometer (e.g. type K - see picture N°2).

d) The coffee machine is tested without any change of parameters or calibrations, which may

affect the temperature of products, so the measurement of temperature must be done with

machine in default factory setting.

Procedure:

1. The temperature must be measured in the cup, immediately after dispensing. Cup has to be

placed on a non-metal surface using a thermocouple thermometer.

2. The temperature in the cup is measured by immersing the probe of the thermometer up to

touch the bottom.The probe then must be moved in a circular motion for 5/6 rotations. At the

of the rotations, stop in the center of the cup.

3. The highest temperature measured during the rotations is the value we are searching for, and

that must be reported;

4. Test measurement: from end of dispensing to the end of rotations must be completed within 12

seconds.

Limits of acceptability

The acceptance limits are divided by features and products and are the following:

Espresso Coffee Italy Q.ty 25/40 gr.

Temperature of 1st product 69°C ≤ 85°C

Temperature of 2nd product 72°C ≤ 85°C

Coffee Q.ty 70/120 gr.

Temperature of 1st product 69°C ≤ 85°C

Temperature of 2nd product 72°C ≤ 85°C

Picture 1

Picture 2

Page 13

Saeco International Group Talea / Odea - Line

CHAPTER 3

OPERATING

Page 14

TALEA / ODEA - LINE 03 OPERATING

Saeco Internationa Group Page 1 / 13

and LEDs fl ashing alternately: turn off the appliance. Turn the appliance back on after 30 seconds and wait until the movements stop. Then turn the appliance off again. Remove the brewing unit and

clean thoroughly (see page 29). If the display reappears when you turn the machine back on, contact the

Service Centre.

Reset: Press the steam key for 10 seconds

3.1. User interfaces

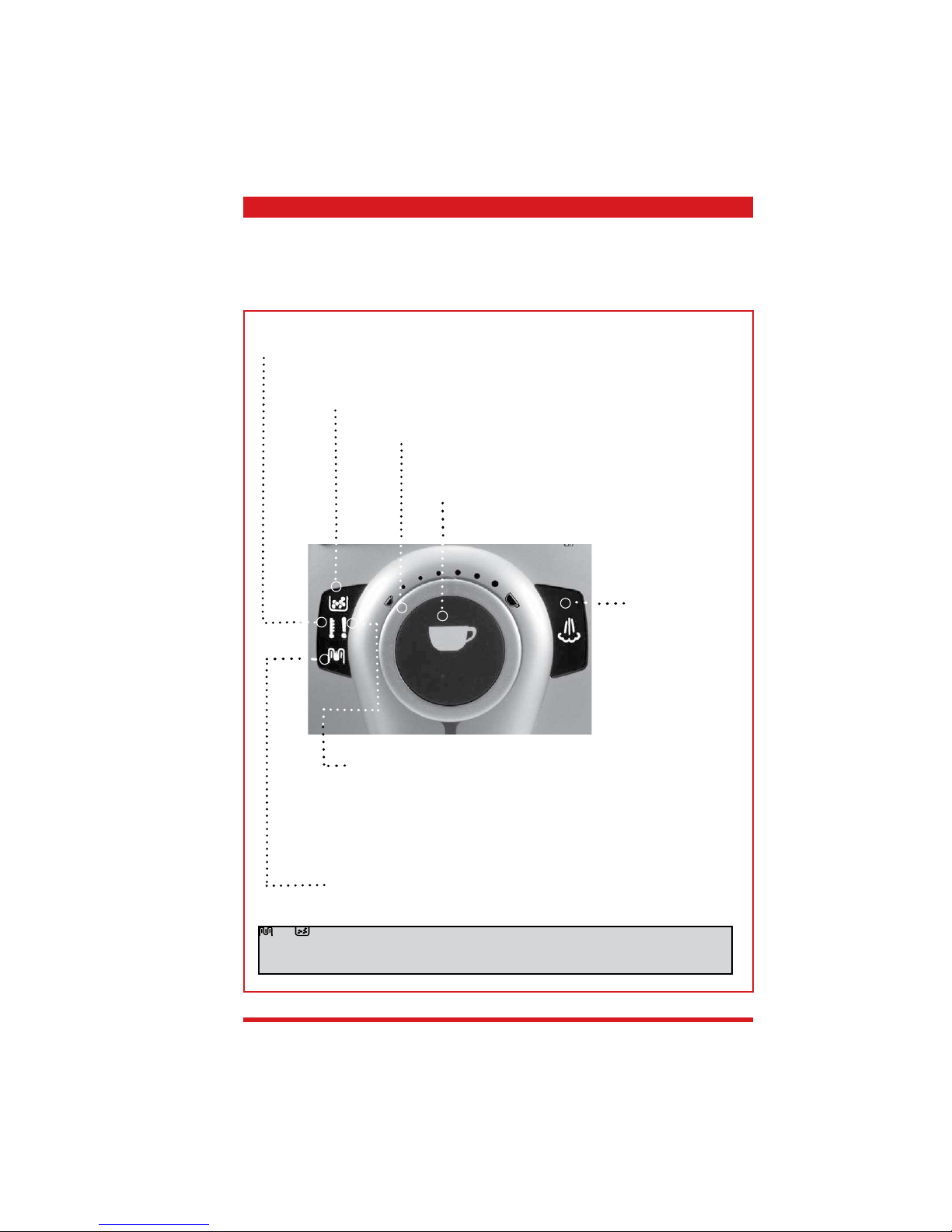

3.1.1 Odea Go

“Appliance ready” LED:

• Permanently on: The appliance is ready for use.

• Flashing: The appliance has to fi nish the heating-up phase.

“Empty dreg drawer” LED:

• Permanently on: Empty the dreg drawer. The appliance must be switched on for this procedure.

“Descaling” LED:

• Flashing: Start the descaling cycle.

Control to set how much coffee is dispensed into the cup.

Coffee dispensing key:

• Flashing slowly: 1 coffee selected (key pressed once).

• Flashing rapidly: 2 coffees selected (key pressed twice).

“Hot water” key:

• On: The appliance dis-

penses steam.

• Off: The appliance dis-

penses hot water.

Alarm LED:

• Permanently on (one or more causes): No coffee left, water tank is empty, empty the residual water

tray is full (in this case the dreg drawer also has to be emptied to prevent problems).

• Flashing slowly (one or more causes): Brewing unit is missing, dreg drawer has not been inserted,

coffee container cover has not been inserted, service door is open, rotary knob for opening the hot

water / steam is not in the right position.

• Flashing rapidly: Ventilate the water system.

Page 15

Page 2 / 13 Saeco International Group

03 OPERATING TALEA / ODEA - LINE

Reset: Press the hot water key for 10 seconds

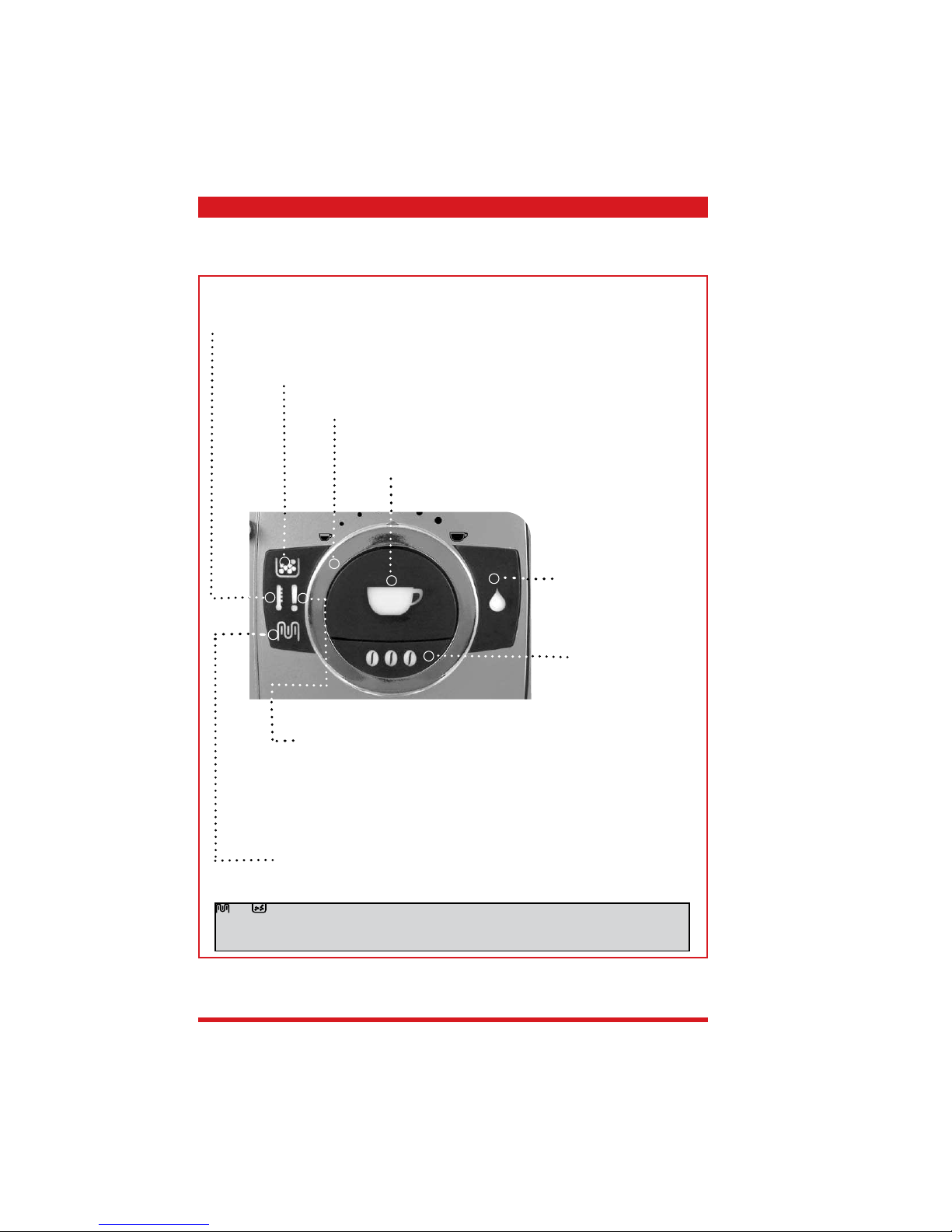

3.1.2 Odea Giro,Talea Giro

“Appliance ready” LED:

• Permanently on: The appliance is ready for use.

• Flashing: The appliance has to fi nish the heating-up phase.

“Empty dreg drawer” LED:

• Permanently on: Empty the dreg drawer. The appliance must be switched on for this procedure.

“Descaling” LED:

• Flashing: Start the descaling cycle.

Alarm LED:

• Permanently on (one or more causes): No coffee left, water tank is empty, the residual water tray is

full (in this case the dreg drawer also has to be emptied to prevent problems).

• Flashing slowly (one or more causes): Brewing unit is missing, dreg drawer has not been inserted,

coffee container cover has not been inserted, service door is open, rotary knob for opening the hot

water / steam is not in the right position.

• Flashing rapidly: Ventilate the water system.

Coffee dispensing key:

• Flashing slowly: 1 coffee selected (key pressed once).

• Flashing rapidly: 2 coffees selected (key pressed twice).

“Hot water” key:

• Off: The appliance dispenses

steam.

• On: The appliance dispenses hot

water.

Ground coffee quantity (Opti-dose)

key.

Control to set how much coffee is dispensed into the cup.

and LEDs fl ashing alternately: turn off the appliance. Turn the appliance back on after 30 seconds and wait until the movements stop. Then turn the appliance off again. Remove the brewing unit and

clean thoroughly (see page 29). If the display reappears when you turn the machine back on, contact the

Service Centre.

Page 16

TALEA / ODEA - LINE 03 OPERATING

Saeco Internationa Group Page 3 / 13

3.1.3 Talea Giro Plus

.

Reset: Press the hot water key for 10 seconds

“Appliance ready” LED:

• Permanently on: The appliance is ready for use.

• Flashing: The appliance has fi nished the heating-up phase.

“Empty dreg drawer” LED:

• Permanently on: empty the dreg drawer. The appliance must be switched on for this procedure.

“Descaling” LED:

• Flashing: Start the descaling cycle.

Alarm LED:

• Permanently on (one or more causes): No coffee left, water tank is empty, the residual water tray is full

(in this case the dreg drawer also has to be emptied to prevent problems).

• Flashing slowly (one or more causes): Brewing unit is missing, dreg drawer has not been inserted,

coffee container cover has not been inserted, service door is open, rotary knob for opening the hot water

/ steam is not in the right position.

• Flashing rapidly: Ventilate the water system.

Control to set how much coffee is dispensed into the cup.

Coffee dispensing key:

• Flashing slowly: 1 coffee selected (key pressed once).

• Flashing rapidly: 2 coffees selected (key pressed twice).

“Hot water” key:

• Off: The appliance dispenses

steam.

• On: The appliance dispenses

hot water.

“Descaling cycle” key

• On: Press for 3 seconds.

• Off: Press for 3 seconds.

Ground coffee quantity (Opti-dose) key.

and LEDs fl ashing alternately: turn off the appliance. Turn the appliance back on after 30 seconds and wait until the movements stop. Then turn the appliance off again. Remove the brewing unit and

clean thoroughly (see page 29). If the display reappears when you turn the machine back on, contact the

Service Centre.

Page 17

TALEA / ODEA - LINE 03 OPERATING

Saeco Internationa Group Page 4 / 13

,

.

Go to

customer

menu

Activate steam function

Switch to

hot water

Coffee start key

Press once for 1 coffee

Press twice for 2 coffees

Press down longer =

quantity programming

Coffee product

selection

Selection:

Powder coffee

mild aroma

medium aroma

strong aroma

Back to the previous

level

Turn to scroll through

the menu levels and

change the parameters

Reset factory parameters

To program the following parameters for each

product (Espresso, Coffee and Large Coffee):

Aroma

Prebrewing

Press to enter the

selected menu level

or to save changed

parameters

Customer programming menu

3.1.4 Talea Ring, Ring Plus

....... aroma

coffee time

1 beverage settings

Page 18

Page 5 / 13 Saeco International Group

03 OPERATING TALEA / ODEA - LINE

2.

Main menu levels

Dosage quantity

Temperature

Prebrewing

Language

Water hardness

Acoustic signal / alarm

Filter alarm

Rinsing

Cup warmer (Ring Plus)

Time setting (Ring Plus)

Aqua Prima

Descaling

Clean brewing unit

Switch-off time (standby)

Timer (switching time)

Restore settings (factory settings)

Cancel:

Press the menu key several times until

you see “cancel” in the display, then

confi rm with the start key

1 beverage settings

2 machine settings

3 maintenance

4 energy saving

5 special functions

Exit

Page 19

Menu key

1. Beverage settings

1.1.Espresso

1.2. Coffee

1.3. Large coffee

Short press

Cup capacity Aroma

+/-

mild

medium

strong

preground

Long press

Temperature Prebrew

low normal

medium long

high off

2. Machine settings

2.1 Language 8 languages

2.2 Water hardness 1,2,3,4

2.3 Signal alarms On/Off

2.4 Water fi lter alarm On/Off

2.5 Rinsing On/Off

2.6 Cup warmer ** On/Off

2.7 Clock setting **

Time setting

Hours -

Minutes

Time format 24hr - am/pm

Date setting dd/mm/yyyy

Customer menu table

Page 20

Menu key

Date setting dd/mm/yyyy

Date format dd/mm/yy

3. Maintenance

3.1 Water fi lter

Remaining water

quantity

Filter status On/Off

Activate fi lter Activate

3.2 Descaling

Remaining water

quantity

Carry out immediately

3.3 Clean brewing unit Carry out immediately

4. Energy saving

mode

4.1 Switch-off time 15 - 180 minutes

4.2 Timer setting ** On/Off

4.3 Monday - 4.9 Sunday **

Turn on Time

Turn off Time

5. Special

case

5.1 Restore settings immediately

Restore settings,

are you sure?

** Available with Ring Plus only

Page 21

TALEA / ODEA - LINE 03 OPERATING

Saeco Internationa Group Page 8 / 13

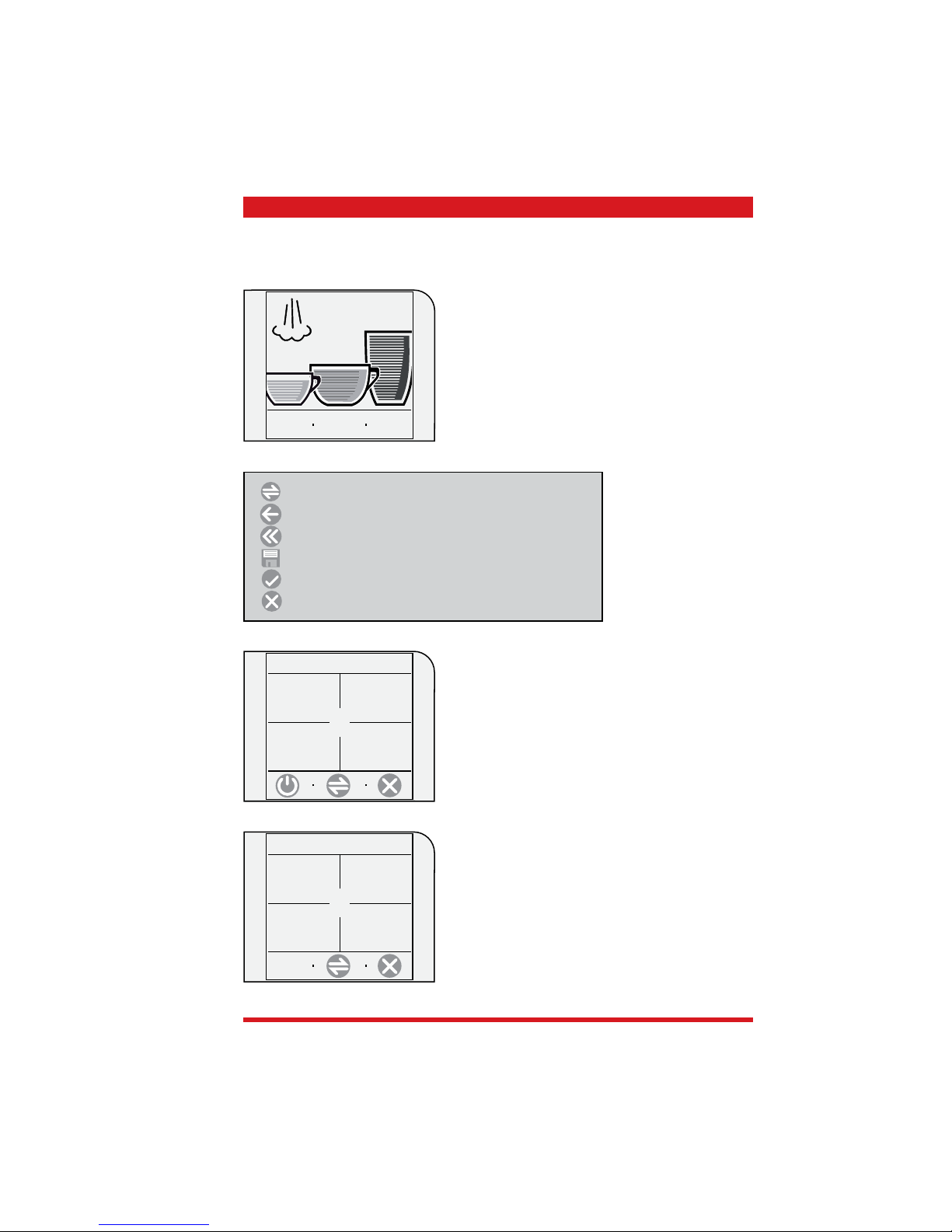

3.1.5 Talea Touch

To start:

Press the “go to menu” key

Beverage programming:

Keep the relevant beverage key pressed

show

text

8:30

24/06/06

go to

menu

beverage

settings

machine

settings

maintenance

settings

time/date

setting

beverage settings:

Espresso, Coffee and Large Coffee settings

machine settings:

Language, acoustic signals, cup warmer and water settings

time/date settings:

Time, clock timer and standby settings

maintenance settings:

Product counter, cleaning cycle, descaling cycle and

display lock

1. main menu

special

settings

special settings:

Factory settings

2. main menu

Scroll if menu point has several pages

Back to previous menu point

Back to main menu

Save

Confi rm (activate functions)

Exit menu

Page 22

Page 9 / 13 Saeco International Group

03 OPERATING TALEA / ODEA - LINE

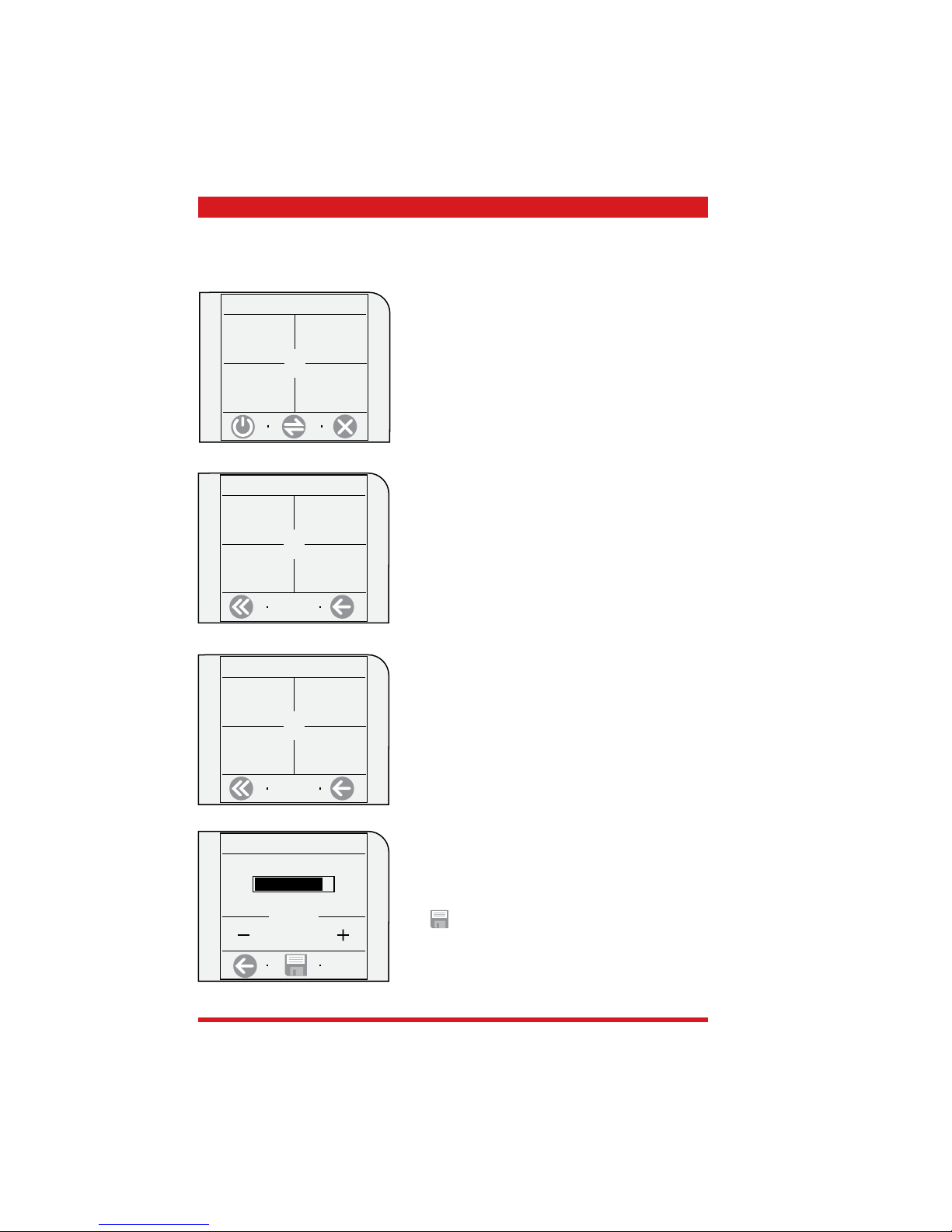

Example, water hardness setting

Press the “water settings” key

1.2 machine settings

water settings

cup - warming

surface

alert and

acoustic

setting

language &

display

.

1.2.4 water settings

water hardness

3/4

water fi lter

Off

rinse

On

Press the “Water hardness” key

3

1.2.4.3 water hardness

Carry out the settings with the +/- keys and save with

the

save key.

In the fi rst main menu, select “machine settings”

beverage

settings

machine

settings

maintenance

settings

time/date

setting

1. main menu

Page 23

1. Main menu

Beverage

settings

1.1. Beverage setting

Espresso

Coffee

Large coffee

1.1.1. Espresso/ 1.1.2.Coffe/1.1.3.Large

Coffee

Prebrewing

normal

strong

off

Temperature

low

medium

high

Aroma

mild

normal

strong

preground

Coffee capacity

+ / -

Machine

settings

1.2. Machine settings

Language & display

1.2.1.

Language

11 languages

Contrast + / -

Acoustic signals and alarms

1.2.2.

Machine ready

On/Off

Key tone

On/Off

Heated cup holder

1.2.3.

always on

always off

off in standby

Water settings

1.2.4.

Rinse On/Off

Aqua Prima On/Off

Water hardness 1,2,3,4

Time settings

1.3.1.

Current time

+ / -

Customer menu table

Page 24

1. Main menu

Clock settings

1.3. Clock settings

Time settings

1.3.1.

+ / -

Time format Select

Date settings

1.3.2.

Current date Year / Month / Day

Date format

Select

Standby setting

1.3.3.

after 15 minutes

after 30 minutes

after 1 hour

after 3 hours

Machine on/off

1.3.4.

Interval 1

Hours / Minutes

Interval 2 Hours / Minutes

Interval 3 Hours / Minutes

Day settings Select

Maintenance

settings

1.4. Maintenance settings

Product counter

1.4.1.

Espresso

Coffee

Large coffee

Reset

Cleaning cycle

1.4.2

Yes/no

Descaling cycle

1.4.3

Yes/no

Display lock

1.4.4

Release

2. Main menu

Special

settings

2.1. Special settings

Factory settings

2.1.1.

no/yes

Page 25

TALEA / ODEA - LINE 03 OPERATING

Saeco Internationa Group Page 12 / 13

3.2 Use, cleaning and maintenance

Cleaning and service

A Empty dreg drawer When message appears

B Empty drip tray When message appears

C Clean water tank Weekly

D Clean coffee bean hopper As necessary

E Clean housing As necessary

F Clean brewing unit 2 - 3 x weekly or after 50 coffees

H Carry out a descaling cycle When message appears

J Clean drip tray Weekly

K Clean brewing unit compartment Weekly

Descaling cycles

Hardness Water hardness Interval without lim-

scale fi lter

Interval with limscale

fi lter

1 Soft water

(up to 7ºdH)

approx. every 3 months /

120 litres

approx. every 6 months /

240 litres

2 Medium hard water

(7º-14ºdH)

approx. every 2 months /

90 litres

approx. every 4 months /

180 litres

3 Hard water

(15º-21ºdH)

approx. every 6 weeks /

60 litres

approx. every 3 months /

120 litres

4 Very hard water

(over 21ºdH)

approx. every 4 weeks /

30 litres

approx. every 6 weeks /

60 litres

Using the machine

1 Insert the limescale fi lter If available

2 Fill water tank

3 Fill bean hopper

4 Turn on the appliance

5 Carry out machine settings (machines

with display only)

Determine and set water hardness, activate limescale

fi lter

IMPORTANT: if the limescale fi lter is not inserted for

longer periods, the relevant setting must be set to "OFF"

otherwise the descaling interval calculated by the appliance is too long and this results in limescale building up

in the appliance.

Two settings must be programmed on models with ring

function:

1. Machine settings: 2.4 Alarm Filter ON/OFF

2. Maintenance / Aqua Prima: 3.1.2 Additional Filter ON/

OFF

6 Specify the product

(machines with display only)

Cup capacity, dosing quantity, prebrewing

7 Press the start key Press 1x for 1 coffee, press 2x for 2 coffees

Page 26

Page 13 / 13 Saeco International Group

03 OPERATING TALEA / ODEA - LINE

DISPLAY MESSAGE SHOWN INSTRUCTIONS FOR TROUBLESHOOTING

Turn machine off and on to solve the problem Turn the appliance off and then back on after 30

seconds to resolve the fault.

Call Service Centre The problem requires the intervention of the Service

Centre

Insert drip tray Insert the drip tray

Close coffee bean hopper lid The coffee bean hopper lid must be closed to

produce beverages.

Insert ground coffee This message is shown if the user selected the use of

this type of coffee when the products were specifi cally

programmed.

Insert brewing unit Insert the brewing unit in its intended location

Insert dreg drawer Insert the dreg drawer

Empty dreg drawer Remove the dreg drawer and empty.

NOTE: the dreg drawer must only be emptied when

the appliance is switched on. The drawer must

be removed for at least 5 seconds. If the drawer

is emptied when the appliance is switched off the

message is not reset.

Close side door Close the service door.

Fill water tank Fill the water tank

Empty residual water tray Empty residual water tray

Prime circuit Start the automatic water cycle fi lling The appliance

makes 5 attempts to fi ll the cycle automatically.

If these attempts fail, the Service Centre must be

informed about these ventilation attempts.

The descaling cycle did not run correctly. Repeat the operation as described in the appropriate

chapter in the instruction booklet

Replace Aqua Prima fi lter This message is only displayed if the fi lter control is

enabled (see notes in the instruction booklet)

The fi lter should be replaced in the following cases:

1) Over 60 litres of water have been dispensed for

drinks

2) 90 days have elapsed since installation

3) 20 days have elapsed since the coffee maker was

last used.

The cleaning cycle did not run correctly Repeat the operation as described in the relevant

chapter in the instruction booklet.

Descale appliance Carry out the descaling cycle

Standby Press the “ON” key

3.3 Messages - troubleshooting

Page 27

Saeco International Group Talea / Odea - Line

CHAPTER 4

FUNCTIONAL

PRINCIPLES

Page 28

Saeco Intrnational Group Page 1 / 14

TALEA / ODEA - LINE 04 FUNCTIONAL PRINCIPLES

4.1.1 Odea Go water system

Caldaia 1

Rubinetto

Gruppo

Pompa EP5

Serbatoio

Turbina

Perno Caldaia

con spillo

Valvola

sicurezza

Odea Go

• Conventional water system

• Flowmetre - cup capacity / ventilation display

• Reciprocating piston type pump (13 - 15 bar)

• Overpressure valve (opening pressure 18 - 20 bar).

• Boiler (= continuous-fl ow heater) 1300 W

• Valve pin (mechanical valve opener)

• Hot water / steam valve (switch between coffee / hot water, steam output)

Pump

Flowmetre

Water tank

Boiler

Hot water /

steam valve

Brewing unit

Valve pin

Overpressure

valve

Page 29

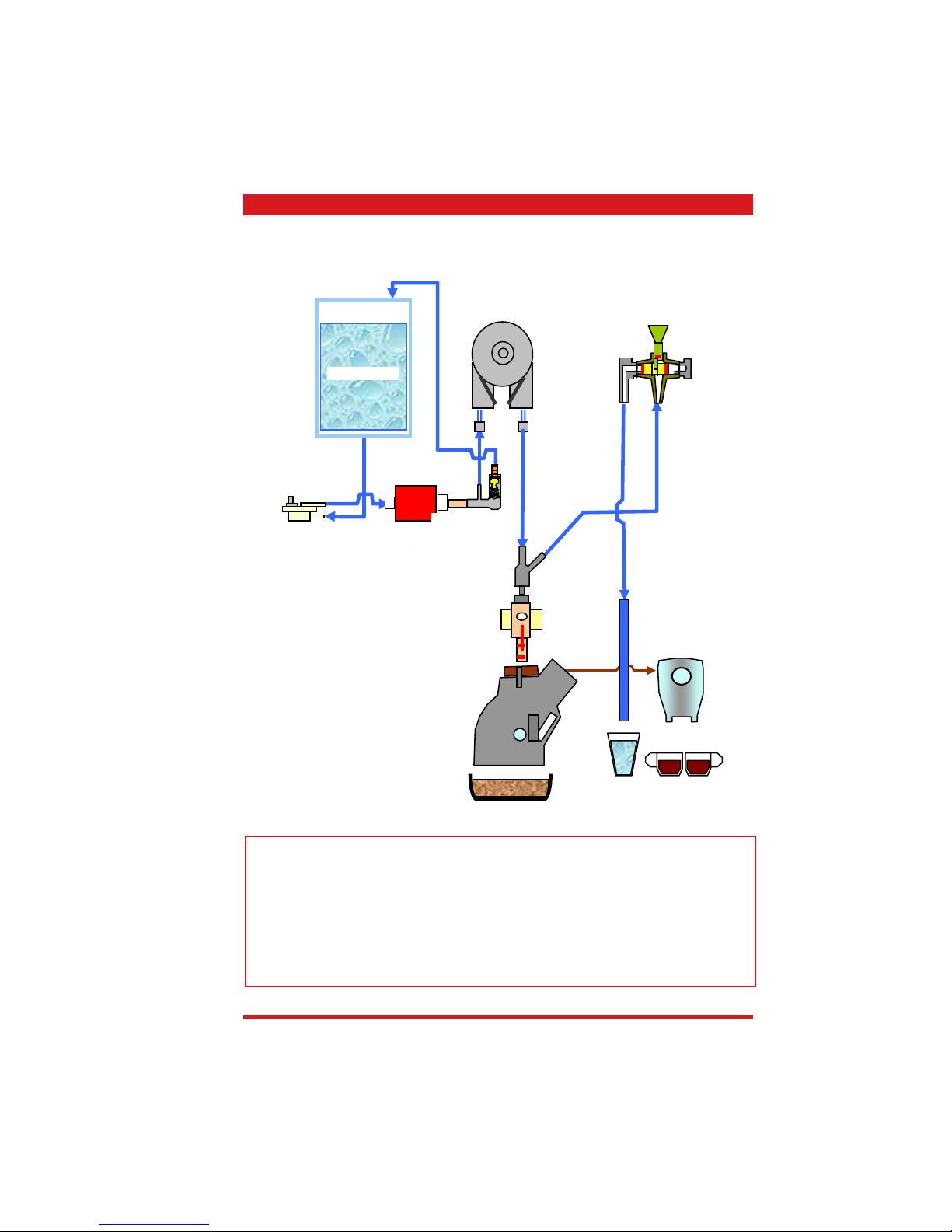

Page 2 / 14 Saeco Internationa Group

04 FUNCTIONAL PRINCIPLES TALEA / ODEA - LINE

Talea, Odea Giro

• The solenoid valve has several functions and these are described in the following paragraphs. A mechanical overpressure valve is integrated in the electrical valve which opens

at approx. 18 - 20 bar.

• When dispensing coffee and the hot water / steam valve is closed, the coffee valve opens

at approx. 4 bar and the water is pressed through the brewing unit.

• The overpressure valve in the steam pipe to the Milk Island protects the system against

damage caused by pressure, the steam state overpressure is fed back to the fresh water

tank.

• The multi-way valve opens selectively depending on the operating situation in the fl ow

direction (dispensing) or against the fl ow direction (pressure release).

Caldaia 1

Perno Caldaia

senza spillo

Sistema di

sicurezza

Milk Island

solo su Talea

Elettropilota

Valvola 3

4 bar

Valvola 2

4bar

Valvola 1

scarico

Rubinetto

Pompa EP5

Serbatoio

Turbina

Gruppo

4.1.2 Talea, Odea Giro water system

Electrical valve

Overpressure

valve (steam

pipe) Milk

Island

Pump

Water tank

Boiler

Hot water / steam valve

Pin without

valve

Brewing unit

Two-way valve

Flowmetre

Milk Island

Residual water tray

Valve pressure

reduction approx.

4 bar

Coffee valve

approx. 4 bar

Talea series only

Page 30

Saeco Intrnational Group Page 3 / 14

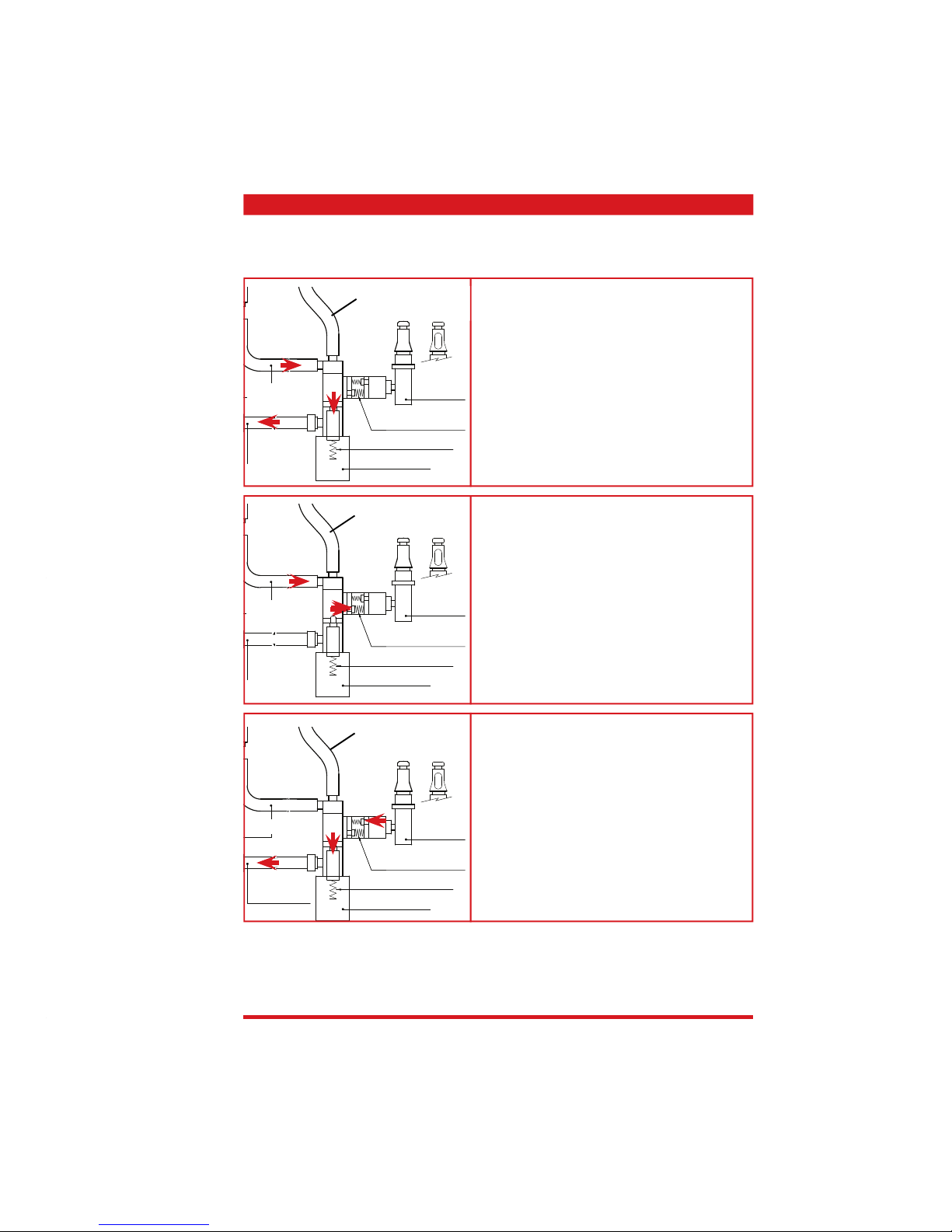

TALEA / ODEA - LINE 04 FUNCTIONAL PRINCIPLES

Brewing unit pressure reduction:

Before the brewing unit moves to the home

position after a brewing process, the electric

valve opens and the overpressure in the brewing chamber is released and escapes into the

residual water tray.

Wasserauslaufstutzen

Pin

3-5 bar coffee dispensing valve

Release valve

16-19 bar safety valve

4.2. Solenoid valve / multi-way valve

Wasserauslaufstutzen

Pin

3-5 bar coffee dispensing valve

Release valve

16-19 bar safety valve

Ventilation:

After the appliance is switched on, the electric

valve opens, the pump is activated and the

appliance is ventilated automatically.

Preheating the pipes:

If the coffee machine has not been used for

a while or after each heating-up phase, the

pump is activated during the grinding process.

The hot water enters via the pipes, the multiway valve, and the water channel into the

residual water tray.

When coffee is dispensed:

The same applies for when coffee is dispensed,

only the brewing unit is positioned in the

brewing position and is docked to the pin.

Wasserauslaufstutzen

Pin

3-5 bar coffee dispensing valve

Release valve

16-19 bar safety valve

from boiler

from boiler

to residual

water tray

to residual

water tray

to hot water /

steam valve

to hot water /

steam valve

from boiler

to residual

water tray

to hot water /

steam valve

18-20 bar safety valve

18-20 bar safety valve

18-20 bar safety valve

Page 31

Page 4 / 14 Saeco Internationa Group

04 FUNCTIONAL PRINCIPLES TALEA / ODEA - LINE

Hot water / steam faucet

The hot water / steam valve has 3 positions:

1. Middle position = closed

2. Hot water / steam

3. Milk Island (not with Odea)

The three hot water / steam valve positions

are monitored using three Hall sensors and a

magnet that is fi tted to the hot water / steam

valve axle.

Hot water /

steam

from boiler

to Milk Island

Hall sensors

Magnet

Pipe system pressure reduction:

The electrical valve opens to reduce the

pressure in the pipe system:

Each time hot water or steam is used

Each time milk is frothed with the Milk Island.

Wasserauslaufstutzen

Pin

3-5 bar coffee dispensing valve

Release valve

16-19 bar safety valve

Overpressure valve (safety valve):

As the multi-way valve already opens at 3 - 5

bar in the fl ow direction, it takes over the

overpressure function (1) when the brewing

unit is not in the brewing position. If the

brewing unit is positioned in the brewing

position in an overpressure situation and/or

the multi-way valve is blocked, the magnet

valve acts as an overpressure valve and opens

mechanically against the spring pressure at

16 - 19 bar (2).

Wasserauslaufstutzen

Pin

3-5 bar coffee dispensing valve

Release valve

16-19 bar safety valve

(1)

(2)

to hot water /

steam valve

to hot water /

steam valve

from boiler

from boiler

to residual

water tray

to residual

water tray

4.3. Hot water / steam faucet

18-20 bar safety valve

18-20 bar safety valve

Page 32

Saeco Intrnational Group Page 5 / 14

TALEA / ODEA - LINE 04 FUNCTIONAL PRINCIPLES

To turn on:

• When the main switch is activated, the gearing mechanism searches for its original position

and moves downwards into the Microswitch (MS) (with cam 1, see the following section).

The gear motor changes the direction of rotation, moves back up and stops approx. 1 - 2

mm after leaving the microswitch.

• The continuous-fl ow heater then starts to heat the water for approx. 45 seconds to reach

the operating temperature,

• 40 seconds of which is spent at full heating power and the rest is spent recycling the power.

Coffee cycle:

1. The coffee grinder starts the grinding process (pulse-controlled).

2. The gearing mechanism (brewing unit) moves to the brewing position.

3. Then the prebrewing begins (brief pumping activity, then a quick break).

4. Brewing procedure (length of the pumping activity, depending on the coffee quantity

selected).

5. The gearing mechanism moves to its original position (brew grounds are automatically

ejected).

4.4. Coffee cycle

Main switch ON START STOP

Timing

Coffee grinder

Pulse

(Dosage)

Heating

approx. 45

secs

Pump

*

Pump activity

(fl owmetre pulses)

according to cup

capacity

Gearing motor /

brewing unit

Status Warm-up phase Ready Coffee cycle

Note: * With prebrewing only

Status MS1

Status MS2

OFF ON

Gearing mechanism with 2 microswitches (MS)

Status MS

OFF ON

Gearing mechanism with single microswitch (MS)

Page 33

Page 6 / 14 Saeco Internationa Group

04 FUNCTIONAL PRINCIPLES TALEA / ODEA - LINE

With 2 microswitches

The gear is powered by a direct current motor

that engages in the smaller double toothed

gear using the worm gear drive. The brewing

unit is placed on the axis between the large

geared tooth and is moved by the change in

direction of the motor between the home and

brewing positions.

The end positions are monitored by the

switching pins and the corrisponding

microswitches.

Home position: MS1 / Pin 1

Brewing position: MS2 / Pin 2

When moving to the home position, pin 1

activates the MS1, the motor changes the

direction of rotation and the pin disactivates the

MS1.

The pin is positioned 2 mm away from the

switching point in its home position.

1

2

MS1

MS2

4.5. Brewing unit’s gear mechanism

Temperature sensor

An NTC is used as the temperature sensor:

If the NTC senses too high temperatures,

electronics decreases boiler’s temperature that

is controlled by the resistance’s voltage.

Resistance values and the corrisponding

temperatures: see table

4.6. Temperature sensor (control)

Single micro

The function is the same as with 2 microswitches. However, here a toothed gear with

continuous pin is used and a single microswitch takes over the monitoring of both end

positions.

Important: during the movement between the

brewing and home position, the microswitch

is not activated (does not move onto the pin),

but both ends of the pin switch the microswitch in their fi nal positions.

Home position: Pin 1

Brewing position: Pin 2

MS

1

2

T (°C) R (kΩ) ΔR (+/- %)

20 61.465 8.6

50 17.599 5.9

75 7.214 4.1

80 6.121 3.7

85 5.213 3.4

90 4.459 3.1

100 3.3 2.5

125 1.653 3.9

150 0.893 5.1

Page 34

Saeco Intrnational Group Page 7 / 14

TALEA / ODEA - LINE 04 FUNCTIONAL PRINCIPLES

SBS - Saeco Brewing System - principle

Controlling the fl ow speed that then infl uences

the contact time between the coffee and water,

changes the extraction and therefore the taste

intensity and strength of the coffee.

• Slower fl ow: strong extraction

• Rapid fl ow: weaker extraction

SBS / dispensing valve

Turning the SBS control knob creates a back

pressure in the brewing unit where the fl ow

speed is regulated using a controllable cream

valve.

Cream valve control

High fl ow (slow extraction)

The coffee can fl ow much easier when the

SBS valve is open. The pressure applied to the

membrane remains comparatively low and with

the support of spring, the membrane almost

stays in its original position and the control

needle is not pulled into the opening - the fl ow

remains unchanged.

Cream valve control

Low fl ow (strong extraction)

The coffee can only dispense inadequately with

a throttled SBS valve - a back pressure forms,

forcing the membrane to the side and pushing

it against the spring force.

In the next stage, the valve needle is pulled

into the opening that, in turn, reduces the

fl ow.

4.7. SBS

Page 35

Page 8 / 14 Saeco Internationa Group

04 FUNCTIONAL PRINCIPLES TALEA / ODEA - LINE

Ceramic coffee grinder

The coffee grinder is driven by a direct current

motor (1) using a worm gear (2).

The worm (2) drives a plastic gear wheel (3)

where the lower ceramic disc (4) and the

copper pre-draw worm (5) is driven at the

bottom.

Two magnets (6) are built into the drive gear.

A Hall sensor is mounted on the bottom side

of the housing that sends 2 pulses to the

electronics using two magnets per rotation.

4.8. Coffee grinder

4.9. Dosing quantity control, coffee grinder blockage when machine is

low on beans

Low bean quantity

If the machine is low on beans, it is detected

from the speed difference (frequency Hall

sensor pulses) of the grinder between its idle

state and the bean grinding process.

If no beans are found in the grinder (idle

state), the speed and therefore the frequency

of the pulses is higher - small

t1 = “Beans low” message.

If beans are in the grinder, this results in a

reduced grinding speed due to the resistance

that is generated by the beans in the grinding

process and therefore, a greater

t2 = no message displayed.

t3 and t4 = This measurement is carried

out when the grinding process slows

down at the end.

Dosing quantity control

The dosing quantity is controlled using

the recorded pulses (number of rotations

proportional to the choose of aroma, mild,

medium and strong).

Coffee grinder blockage

If external objects enter the grinder, the

electronics detects the blockage from the missing

fl ow and stops the grinder.

with beans n=50%

without beans

n=50%

with beans

n=100%

without beans

n=100%

t

t

t

t

V

t4

t3

t2

t1

6

4

2

3

1

Page 36

Saeco Intrnational Group Page 9 / 14

TALEA / ODEA - LINE 04 FUNCTIONAL PRINCIPLES

Autodose

The appliances are fi tted with an automatic dosage quantity adjustment from the following

software versions:

Type Software version with autodose

Talea Touch ≥ V.01.08.14

Talea Ring Plus / Ring ≥ V.02.00.08

Talea Giro e Odea Giro / Go ≥ V01.02.01

Function:

The coffee machine adjusts automatically the average coffee dose with an algorithm based on

three informations that it detects via the electronic board:

1. Number of grinding pulses performed during the grinding,

2. Maximum of average values of the current consumption of the gear device during the coffee

pressing,

3. Aroma selected by the customer.

The algorithm compares the maximum of the average values of the gear device’s current consumption with the range defi ned to the selected aroma fuction in order to adjust the number of

grinding pulses for the next coffee.

If the value of the current consumption is less than the minimum of the range defi ned for the

aroma in question, the grinding pulses will be increased by 2.

If the value of the current consumption is more than the maximum of the range defi ned for the

aroma in question, the grinding pulses will be decreased by 4.

If the value of the current consumption is within the range defi ned for the “Exceeded stress”,

the coffee will be brewed and the grinding pulses will be decreased by 10.

If the value of the current consumption is within the range defi ned for the “Ejection”, the coffee

cake will be ejected and the grinding pulses will be decreased by 10.

In the customer has selected “coffee powder” as the aroma, no adjustment will be done.

This guarantees that, regardless of the coffee type used, the grinding level setting

or possible wear to the grinding disc always remains constant when dosing.

Important:

The machine monitors in the area of the fi elds shown in green (A,B,C) during normal operation.

This area is normally only left when changing the type of coffee (new bean type / fat content,

new blend). Therefore when changing the type of coffee, a few dispenses may be subject to

under or over dosage (until the controller has compensated for the change).

Caution: In case of overdosage, dry coffee may be ejected several times as a result.

This is not a fault and can occur during fi rst use or after a service.

Setting/status

Current

consumption

Pulses corrected in the next

grinding process

Area Exceeded by Defi cient by

A mild aroma 200 - 300 mA -4 +2

B medium aroma 301 - 450 mA -4 +2

C strong aroma 451 - 600 mA -4 +2

D Stress 601 - 800 mA -4

E Exceeded stress 801 - 1,000 mA -10

F Ejection of dry coffee > 1,000 mA -10

4.10. Autodose - automatic dosing quantity control

Page 37

Page 10 / 14 Saeco Internationa Group

04 FUNCTIONAL PRINCIPLES TALEA / ODEA - LINE

“Low water” message (water reserve)

Function:

The water level is monitored using a capacitive sensor. This is fi tted on the side of the machine at the

height level of the lower third of the water tank.

When the sensor communicates to the electronics

that there is no water in the tank at its level, there

is still a water reserve of 200 fl owmetre pulses

remaining for the current dispensing that will be

completed.

If a drink cycle ends after the sensor has been

triggered (in the reserve) then the message "Water

low" continues to be displayed also the next time

you request a drink.

Fresh water

tank

4.11. Water level detection of fresh water tank

Limescale fi lter Intenza (Brita)

Function:

• Reduction or delay of limescale deposits.

• Improved quality of water.

• Optimum taste due to the ideal water hardness.

Life span / descaling performance:

• - 10° dH

• 60 litres

• 2 months

To achieve the best possible consistency in the

operating mode over the total life span, the water is

blended using a 3 stage bypass (A, B, C) depending

on the degree of hardness. See the small picture.

Bypass

4.12. Limescale fi lter

200 imp

Sensor

Page 38

Saeco Intrnational Group Page 11 / 14

TALEA / ODEA - LINE 04 FUNCTIONAL PRINCIPLES

“Empty dreg drawer” message:

The following destinations are stored in the diagnosis menu for the message, "Empty dreg

drawer":

• Grounds limit (maximum dregs)

• Actual grounds (dreg counter)

• Grounds warning

Grounds limit is programmed to 13 cycles as standard. The counter "actual grounds" takes

over this value when you empty the dreg drawer and deducts one of these values with each

cycle.

If the value is 0, "Empty dreg drawer" appears (a request of dispensing is no longer

possible). If the last order was a double cup function, the programming allows another 14th

use and then displays "Empty dreg drawer".

If the counter “actual grounds” reaches a value of "grounds warning" during the process

(e.g. "3"), the advanced notice "Empty dreg drawer" appears on appliances with a display

(coffee can still be dispensed).

When the dreg drawer is emptied, the counter "actual grounds" will be reseted (after 5

seconds).

4.14. “Empty dreg drawer” message

“Empty residual water tray” message

Function:

The residual water level is monitored using a

capacitive sensor. The sensor is positioned approx.

half way up the upper edge of the residual water

tray. To ensure the best possible use of holding

capacity, the sensor is positioned in the area of a

shaft where its upper edge overlaps the sensor.

Therefore, the residual water tray fi lls up to the

upper edge of the shaft and the overfl ow in the

shaft triggers the sensor and therefore displays to

empty residual water tray.

Exception:

Odea: from 2008 production, the Odea series is no

longer fi tted with a residual water sensor.

The capacity is calculated by the electronics,

depending on the dispensing situation (coffee,

steam, hot water, rinsing).

Residual water tray

Switching level

sensor

Total

capacity

Sensor

4.13. Water level detection of residual water tray

Page 39

Page 12 / 14 Saeco Internationa Group

04 FUNCTIONAL PRINCIPLES TALEA / ODEA - LINE

ODEA GO

ODEA GIRO

TALEA GIRO

Function:

Only one electric function is used with appliances in

the Odea and Talea series (without display).

When changing the electronics, the dip-switch position must be checked and altered if necessary.

“Descaling with limescale fi lter”

message

(appliances that have a display only)

The water hardness is set in the usual way

by determining the regional water hardness.

(1, 2, 3, 4).

Filter off:

The appliance determines the amount of

water that fl ows through the fl owmetre and

shows the Display "Descaling" according to

the pre-specifi ed quantity of water set via

the hardness setting.

Filter on:

If the function limescale fi lter / Aqua Prima

is turned on in the customer menu, only

every 2nd fl owmetre pulse is counted when

determining the fi rst descaling interval.

The descaling interval is doubled.

“Change limescale fi lter / Aqua Prima”

message

(appliances that have a display only)

Function:

The electronics use the fl owmetre pulses to

count the amount of water that has fl owed

through and, after 60 litres, shows the

“Change fi lter” message.

360°

1 rev

Number of

pulses

Filter

on

Filter

off

Flowmetre pulses

4.15. Descaling request

4.16. Electronical confi guration (DIP - switch settings)

On

On

On

Page 40

Saeco Intrnational Group Page 13 / 14

TALEA / ODEA - LINE 04 FUNCTIONAL PRINCIPLES

Electrical cup lift

(Talea Touch and Ring Plus only)

Operation:

The cup lift is activated via two capacitive

sensors located on the front part of the cup

holder.

The lower sensor (1) activates the upwards

function.

The upper sensor (2) the downwards

function.

Function:

The sensors control an inching motor (3) in

different rotating directions.

A spindle (4) where the bottom end is

attached fl ush with the cup plate (5), gets

turned by the direction of motion of the

motor: lifting or lowering.

The end positions are monitored by two

microswitches: upper end switch (6) and

lower end switch (7).

1

3

5

6

7

4

2

4.17. Cup lift

Milk Island

(Talea series only / optional)

Function:

The function of the Milk Island is based on

the Venturi principle in combination with a

Vernay valve.

1. The steam fl owing into the Venturi

valve produces a high subpressure that

absorbs the milk.

2. In turn, the milk generates a

subpressure when fl owing past the

Vernay valve that sucks air in via the

Vernay valve.

3. The milk is frothed using this air.

4. The milk froth and the steam make

contact in the Venturi nozzle and the

milk froth is heated up.

Milk

Milk

froth

Venturi

valve

Steam

Air

Vernay

valve

Hot milk froth

4.18. Milk Island

Page 41

Page 14 / 14 Saeco Internationa Group

04 FUNCTIONAL PRINCIPLES TALEA / ODEA - LINE

Electrical

connection to the

machine

Hydraulic connection

on the appliance for the

incoming steam supply

Pushbutton for connecting

and disconnecting the Milk

Island to/from the machine

Escaping steam

LED to show ca-

rafe is installed

Clamp for fi xing the

Milk Island to the

machine

To dismantle,

unscrew the screws

marked in the il-

lustration

Cappucinatore cover

Cappucinatore valve cover

Vernay valve

Insertion for the Cappucinatore

valve cover

Cappucinatore

Carafe handle

Carafe milk suction tube

Carafe steam dispenser hose

Upper part of the carafe

2

1

3

4

5

6

7

8

9

Caution: if the base station of the Milk Island is removed from the coffee machine, it is absolutely

necessary to apply the lock on the bottom of the machine!

2

2

1

9

8

7

5

4

3

6

Page 42

Saeco International Group Talea / Odea - Line

CHAPTER 5

SERVICE MODALITY

Page 43

Saeco International Group Page 1 / 17

TALEA / ODEA - LINE 05 SERVICE MODALITY

5.1.1. Test mode - Talea Giro and Odea

• Press the hot water key (steam key on the Odea Go) and turn the appliance on at the same

time. Keep the hot water key or the steam key pressed until all four LEDs fl ash in the follow-

ing sequence

(anticlockwise)

Function Signal Display

Hot water / steam valve (open) lit

Microswitch of brewing unit not activated (missing) fl ashing

Dreg drawer’s reed switch (missing) fl ashing

Reed switch for doors (open) fl ashing

Bean hopper cover’s reed switch (missing) fl ashing

Flowmetre pulses

(when the pump is active)

fl ashing

Microswitch of milk carafe presence

(hot water / steam valve closed)

lit

Water tank’s sensor (no water) lit

Residual water tray’s sensor (full) lit

X

X

X

X

X

X

X

X + hot water /

steam valve open

Rotary knob to

set cup capacity

Function

Display

Electrical valve

Coffee grinder

Letting steam out

with new software

Heating

Brewing unit

(home position

gear microswitches

activated)

Pump fl owmetre

pulses

Brewing unit

(brewing position

gear microswitch)

Dosing quantity setting for coffee quantity test in test mode.

=90 pulses =100 pulses

=110 pulses

Odea Go only

not with

Odea Go

Messages / Errors

Page 44

Page 2 / 17 Saeco Internationa Group

05 SERVICE MODALITY TALEA / ODEA - LINE

• Press the start key and turn the appliance on at the same time. Keep the start key pressed

until all four LEDs fl ash in the following sequence

(clockwise)

The following functions are no longer available with those appliances that are

installed with the automatic dosing regulation.

5.1.2. Special function mode - Talea Giro and Odea

Rotary knob to

set cup capacity

Key

Function Display Comment

Let steam out

(approx. 2 min / hot

water / steam valve open)

Flashing in

clockwise

sequence)

Press the key to reduce

the dosing quantity

pulses by 5 pulses each

(setting range 60 - 150)

standard 80 -100

The LED lights

up when the key

is pressed.

If the value is at

the minimum,

the LED no

longer lights

up or fl ashes

when pressed

(depending on

the model)

Press the key to increase

the dosing quantity

pulses by 5 pulses each

time.

(setting range 60 - 150)

standard 80 -100

The LED lights

up when the key

is pressed.

If the value is at

the maximum,

the LED no

longer lights

up or fl ashes

when pressed

(depending on

the model)

Odea Go only

Odea Go only

Odea Go only

Odea Go only

Function Status Signal Display

Brewing unit present - microswitch Switch not on lit

Dreg drawer sensor Sensor not on lit

Hot water / steam valve sensor Sensor not on lit

Bean hopper cover sensor Sensor not on lit

Messages / Errors

Page 45

Saeco International Group Page 3 / 17

TALEA / ODEA - LINE 05 SERVICE MODALITY

Function level/display Key Function Display/description

*Test* M0 Key check / time / software version / mains frequency

* Test* M0 (12345) time

Ver.00.00.00 50/60Hz

Steam

Hot water

Aroma

Menu

Coffee/Start

Keypad check 1: Steam key OK

2: Hot water key OK

3: Aroma key OK

4: Menu key OK

5: Coffee/Start key OK

*Test* M1 Sensor/microswitch test (can only be carried out manually)

*Test* M1 time

Inputs(123456789ABCDEFGH)

Sensor/

microswitch test

1: Brewing unit microswitch

2: Brewing position gearing

mechanism micro

3: Home position of gearing

mechanism micro

4: Flowmetre (Hall sensor)

5: Water tank sensor (capacitive)

6: Door switch (reed sensor)

7: Dreg tray (reed sensor)

8: Bean cover (reed sensor)

9: Coffee grinder (Hall sensor)

A: Drip tray sensor (capacitive)

B: Hot water / steam valve Sensor

pos. Milk Island

C: Hot water / steam valve Sensor

pos. Water/steam

D: Milk Island (adapter) detected

E: Carafe microswitch

F: Cup lift, bottom end switch

G: Cup lift, top end switch

H: Hot water / steam valve Sensor

pos. closed

*Test* M2 Test: Brewing unit test (power input / microswitch)

*Test* M2 (6712) mA going

to work xxx

Menu Brewing unit up

Brewing position microswitch 2

xxx Power consumption of gear motor

*Test* M2 (6713) mA going to

home xxx

Aroma Brewing unit

down

Home position microswitch 3

xxx Power consumption of gear motor

5.2.1 Test mode - Talea Ring and Ring Plus

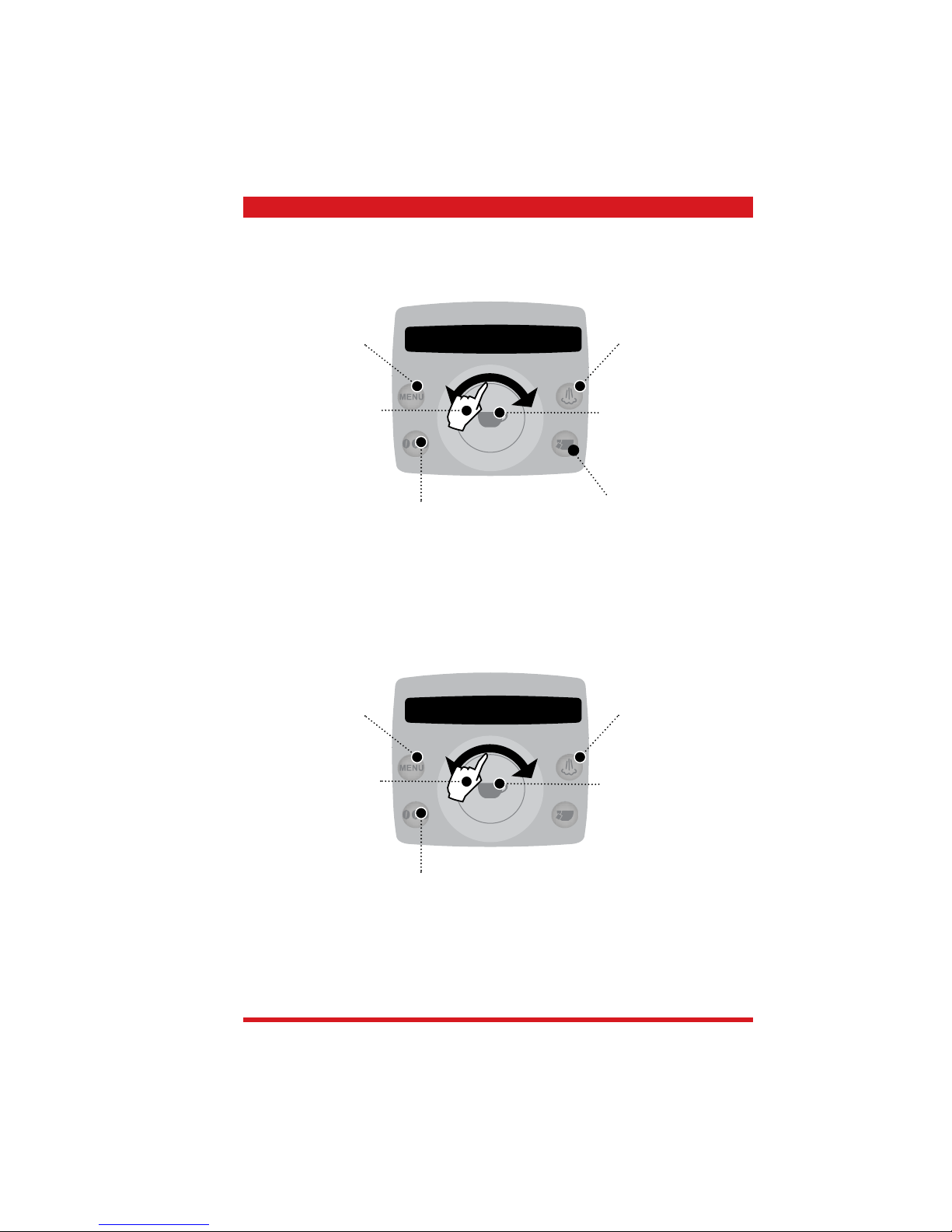

Getting started with test mode:

• Turn on the appliance.

• Keep the menu key pressed for approx.

2 seconds until "Cancel" appears in the

display.

• Then press the aroma, steam, menu and hot

water keys in that order (1,2,3,4).

Navigation:

• Use the ring function to move through the

menu levels.

• Activate each function with the relevant key.

• Adjust with the ring.

• Save with the coffee/start key.

EXIT

MENU

1

2

3

4

Page 46

Page 4 / 17 Saeco Internationa Group

05 SERVICE MODALITY TALEA / ODEA - LINE

Function level/display Key Function Display/description

*Test* M3 Test: El.valve/Adjust,Test Dosage quantity/Pump

Flowmeter

*Test* M3 xx yy

z (8)

Menu Elctronic valve z: Ev Brew (the electro valve

opens)

8: Sensor bean cover (closed)

*Test* M3

Setup Aroma (imp) tt

Enter: Coffee

Adjust: Ring

Store: Coffee

Dosage quantity start position

tt: 60 - 150 dosage quantity start

position

(From Version 02.00.08

autodose)

*Test* M3 xx yy

u (8)

Aroma Dosage quantity

for the grinder

test

u: 1 = mild start position -10%

u: 2 = medium start position

u: 3 = strong start position +10%

*Test* M3 (F) xx yy

Grinder (8) vv ww

Steam Grinder on Grinds the dosage quantity

resulting from the start position

and u (1,2,3)

vv: Number of pulses

ww: Pulses/sec.

F: Failed (low on beans)

S: Successful (beans detected)

xx: Factory parameters

yy: Factory parameters

*Test* M3 xx yy

Flowmetre (pulses/s) ff

Hot water Pump on ff: Number of pulses/sec (approx.

14-17)

*Test* M4 Test: Continuous-fl ow heater / cup warmer /

temperature display

*Test* M4 4

Cup Heater

Menu Cup warmer Cup warmer heats up

- No temperature display

4: Key test (menu key)

*Test* M4 3

Heater

Aroma Continuous-fl ow

heater

Continuous-fl ow heater heats up

Temperature quantity with hot

water key

3: Key test (Aroma key)

*Test* M4 2

Boiler temperature tt

Hot water Temp. display tt: Boiler temperature

2: Key test (hot water key)

*Test* M4 2

Boiler Temperature tt

Hot water /

steam valve Valve open +

coffee key

Let steam out

tt: Boiler temperature

Heats up to 110°C after completing

the display pass!!

*Test* M5 Test: Cup lift (Ring Plus only)

*Test* M5 4 (67)

Cuplift Position

Menu Upwards

movement

G: Upper end switch activated

4: Key test (menu key)

6: Cup lift UP sensor

7: Cup lift DOWN sensor

*Test* M5 3 (67)

Cuplift Position

Aroma Downwards

movement

F: Bottom end switch activated

3: Key test (Aroma key)

6: Cup lift UP sensor

7: Cup lift DOWN sensor

*Test* M6 Adjustment: LCD Contrast

*Test* M6 time

LCD Contrast xx%

Coffee Adjustment (ring) xx: 0 - 100

Page 47

Saeco International Group Page 5 / 17

TALEA / ODEA - LINE 05 SERVICE MODALITY

Function level/display Key Function Display/description

*Test* M7 Adjustment: LCD backlight

*Test* M7 time

LCD backlight xx%

Coffee Adjustment (ring) xx: 0 - 100

*Test* M8 Autotest

*Test* M8 time

*Self test*

Coffee Autotest • Gearing mechanism test

• Grinder test

• Cup lift test

• Heater and sensor test

At the end of the tests, an acoustic

signal tells you if the tests were

successful or not.

• 2 acoustic signals - passed test

• 10 acoustic signals - failed test

If the test was not successful, the

relevant error message is shown on

the display.

*Test* M9 Exit

*Test* M9 time

Exit

Coffee Exit test mode

Page 48

Page 6 / 17 Saeco Internationa Group

05 SERVICE MODALITY TALEA / ODEA - LINE

Menu Address Parameters Comment

1. Product counters

1.1 Total Products

N°

Total amount of coffee used since

production

1.2 Total N° of Espresso

N°

Total quantity of espresso used since

production

1.3 Total ml of Espresso

ml

Amount of water used in ml for the

Espresso program since production

1.4 Total N° of Coffee

N°

Number of coffees since production

1.5 Total ml of Coffee

ml

Amount of water used in ml for the

Coffee program since production

1.6 Total N° of L.Coffee

N°

Number of long coffees used since

production

1.7 Total ml of L.Coffee

ml

Amount of water used in ml for the

Long Coffee program since production

1.8 Total N° of Water

N°

Number of hot water deliveries since

production

1.9 Total ml of Water

ml

Amount of water used in ml for the Hot

Water program since production

2. Totalcounters

2.1 Water S.L Descale

N°

Current descaling counter counts the

amount of water fl owed through since

the last descaling

2.2 Water s. 1 Descale

ml

Last descaling interval

2.3 Water s. 2 Descale

ml

2. Last descaling interval

2.4 Water s. 3 Descale

ml

3. Last descaling interval

2.5 Water S. Production

ml

Total amount of water in ml for all

drinks made since production

2.6 Descaling N°

N°

Number of descaling processes carried

out since production

2.7 B.U Cleanings N°

N°

Number of cleaning cycles carried out

since production

2.8 Water Filters N°

N°

Number of water fi lter resets carried

out

5.2.2. Diagnosis menu - Talea Ring and Ring Plus

Getting started:

• Keep the menu key pressed for approx. 2 seconds until “Cancel” appears in the display.

• Then press the menu key, steam key, aroma and hot water key in that order.

Page 49

Saeco International Group Page 7 / 17

TALEA / ODEA - LINE 05 SERVICE MODALITY

Menu Address Parameters Comment

3. Errors

3.1 Errors

List

List Error memory (20)

3.2 Clear all

NO

No/Yes Reset error memory

4. Products Settings

4.1 Espresso Settings

4.2 Coffee Settings

4.3. Coffee Settings

4.1(2,3).1 Product Qty

(pulses)165

Stored number of pulses for the

cup capacity

4.1(2,3).2 Aroma

(1,2,3)

Aroma setting (1 mild, 2 medium,

3 strong)

4.1(2,3).3 Prebrewing

(1,2)

Prebrewing (0: off, 1: normal, 2:

long)

4.1(2,3).4 Temperature °C

°C

95 - 105 Can be changed by +/- 3

°C in the customer menu

5. System settings

5.1 Fw Version

v.3.00.05"

5.2 Fw Boot Version

v.05

5.3 Setup Aroma

(pulses) N°

60 -150

(autodose from V.2.00.08)

A dosage quantity adjustment

should be carried out here up to

V.2.00.08. From V.2.00.08, the

value is corrected automatically by

the autodose function, depending

on the type of coffee or degree of

grinding.

5.4 Temp. Standby

°C 65

50 - 80 Temperature level of the heater in

standby

5.5 Temp. Cup

°C 78

70 - 85 Temperature control (brewing

temperature)

5.6 Standby timeout

180

15 - 180 Selected standby time from the

customer menu

5.7 Flowrate (l/h)

15

10 - 20 Flow speed during hot water

dispensing

5.8 Language

Select

11 languages Language setting (from the

customer menu)

5.9 Water Hardness

3

1 - 4 Water hardness setting (from the

customer menu)

5.10 LCD Backlight

50

0 - 100 Setting for the display’s backlight

5.11 LCD Contrast

50

0 - 100 Contrast setting (brightness of the

lettering) in the display

Page 50

Page 8 / 17 Saeco Internationa Group

05 SERVICE MODALITY TALEA / ODEA - LINE

Menu Address Parameters Comment

5. System settings

5.12 Grounds Limit

13

5 -25 Dreg stop (number of cycles until

the message “Empty dreg drawer”

appears

5.13 Grounds Left

N°

1 - 13 Number of remaining uses until

the message

“Empty dreg drawer” (counts the

uses from 13 downwards)

5.14 Grounds Warning

8

1 - 13 If the value in Grounds Left and

Grounds Warning are identical,

(e. g. 3), the message empty

dreg drawer appears (after 10

uses since the last reset the

dreg drawer can be emptied

but does not have to be (if the

drawer is emptied, the Grounds

Left counter is reset [set to 13

Grounds Limit]). The dreg drawer

must be emptied at Grounds left

= 0

5.15 Cup Warm Power

0

0,1 Cup warmer 0: Off, 1: On

Page 51

Saeco International Group Page 9 / 17

TALEA / ODEA - LINE 05 SERVICE MODALITY

5.3.1 Test mode - Talea Touch

Function group t.1 - Brewing unit

Function group t.0 - software version

t.0

software version

next

CPU_V01.04.09

*

* *

4

2

3

1

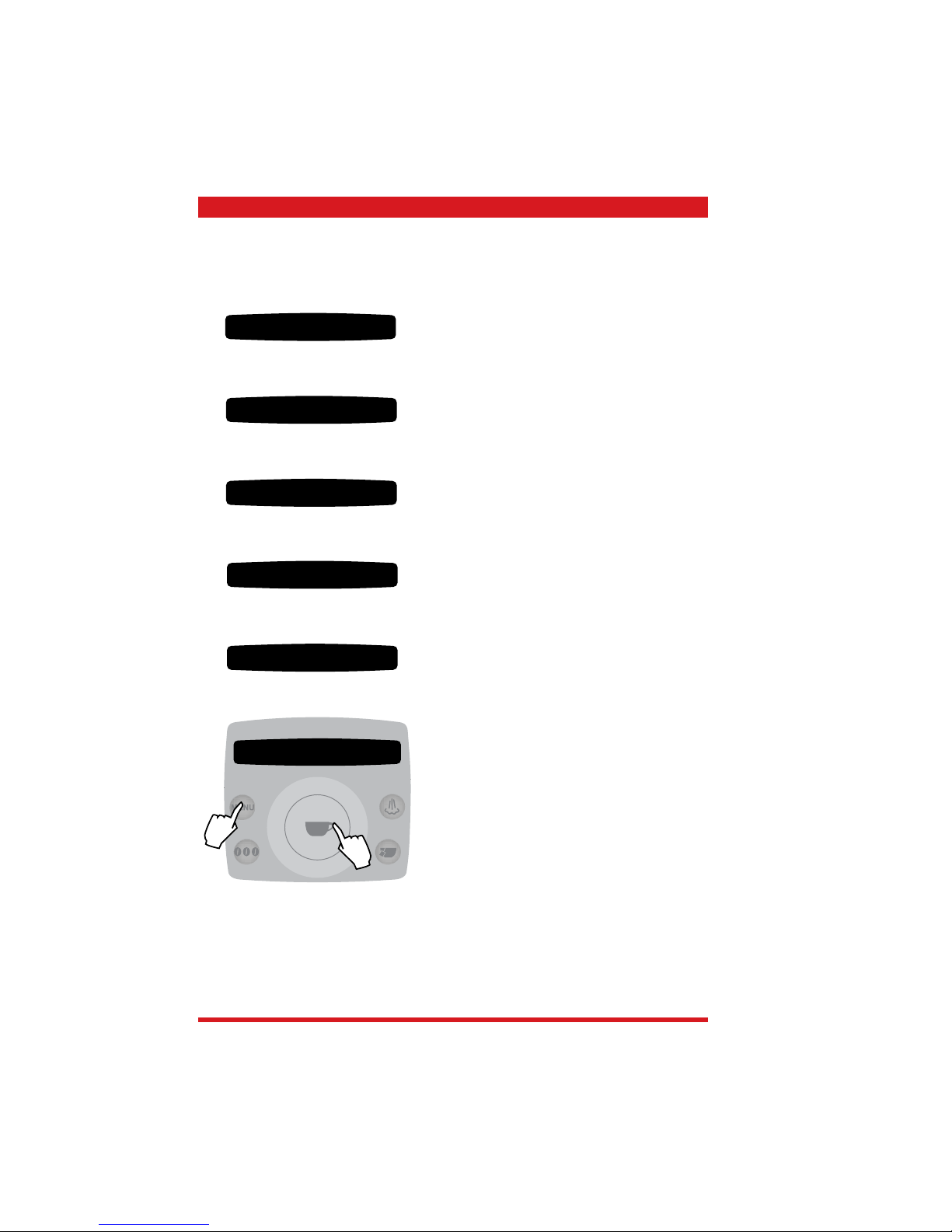

Getting started with test mode:

• Turn on the appliance (wait for hourglass to appear).

• Within 3 seconds, type in an X in the corner of the display

in the sequence shown (beginning at the bottom right).

Navigation:

• Use the "next" key to move through the menu levels.

• You can use the three keys on the lower edge of the display to start up to three functions for each menu level.

t.1 - Brewing unit

next

bu_current (mA) = 3

bu_home = OFF

bu_work = ON

bu_present = ON

bu_dregdrawer = ON

bu_door = ON

bu go

home

bu go

work

bu

stop

Displays the current CPU software version.

bu_current (mA)

bu_home:

bu_work

bu_present:

bu_dregdrawer:

bu_door:

bu go home:

bu go work:

bu stop:

Power consumption in mA

ON - Microswitch (original position)

Gearing mechanism activated

ON - Microswitch (brew position)

Gearing mechanism activated

ON - Microswitch brewing unit

(inserted) activated

ON - Dreg drawer reed switch

ON - Reed switch for doors

Brewing unit moves to original position

Brewing unit moves to brewing

position

Stop brewing unit

Page 52

Page 10 / 17 Saeco Internationa Group

05 SERVICE MODALITY TALEA / ODEA - LINE

Function group t.4 - Grinder

Function group t.3 - Water/steam system

Function group t.2 - Heater

fl ow_metre(p/s):

driptray_sens:

waterlevel_sens:

knob_milk:

knob_water/steam

knob_closed:

milkisland present:

carafe present:

valve:

pump water:

*:

Flowmetre pulses (12-17)

ON - Residual water tray full

ON - Water tank full

ON - Hot water / steam valve in pos.

Milk Island

ON - Hot water / steam valve in pos.

hot water/steam

ON - Hot water / steam valve in pos.

closed

ON - Milk Island adapter detected

ON - Carafe microswitch activated

Magnet valve activation

Pump activation

no function

boiler_temp (C°)

cup heater:

boiler:

*:

Temperature recorded by the

temperature sensor.

Cup warmer heats up

Continuous-fl ow heater heats up

no function

pulses_counter:

delay_time (msec)

bean_door:

bean_alarm:

grinder:

*:

bean_test:

Coffee grinder pulses (Hall sensor)

Coffee grinder pulse msec/pulse

ON - Reed sensor bean cover

activated

ON - Beans low (speed exceeded)

Coffee grinder activation

no function

The machine starts grinding and the

relevant message is shown next to

bean_alarm (ON/OFF)

t.2 -

heating unit

next

boiler_temp (C°) =79.8

cup

heater

Boiler

*

t.3

-

hydraulic circuit

next

fl ow_meter (p/s) = 0

driptray_sens = OFF

waterlevel_sens = ON

knob_milk = OFF

knob_water&steam = ON

knob_closed = OFF

Milk Island present = OFF

caraffe present = OFF

valve

pump

water

*

t.4 -

grinder unit

next

pulses_counter = 0

delay_time (msec) = 0

bean_door = ON

bean_alarm = OFF

grinder

* bean

test

Page 53

Saeco International Group Page 11 / 17

TALEA / ODEA - LINE 05 SERVICE MODALITY

Function group t.5 - Cup lift

Function group t.6 - Dosing

t.5 -

cup lift

next

upper_switch = OFF

lower_switch = OFF

key_up = OFF

key_down = OFF

cup_lift

up

cup_lift

down

*

t.6 -

grinder dose

next

mild dose = 81

medium dose = 90

strong dose = 99

mild medium strong

value

up

value

down

value

test

Function group t.7 - Dreg counter

t.7 -

dreg counter

next

max dreg counter = 13

current dreg counter = 9

value

up

value

down

*

max dreg counter:

current dreg count

value up:

value down:

*:

Maximum number of cycles until

“Empty dreg drawer” message

appears

Running dreg counter

increase the number of cycles

reduce the number of cycles

no function

mild dose

medium dose

strong dose

mild

medium

strong

value up:

value down:

value test:

= medium dose -10% (fi x)

Range 60 - 150 (value up/down)

= medium dose +10% (fi x)

Setting for the dosing quantity test

Setting for the dosing quantity test

Setting for the dosing quantity test

Brewing unit moves to original position

Brewing unit moves to brewing position

Stop brewing unit

upper_switch:

lower_switch:

key_up:

key_down:

cup_lift up:

cup_lift down:

*:

ON - Microswitch cup lift (top end

position)

ON - Microswitch cup lift (bottom end

position)

ON - Cup lift sensor UP activated

ON - Cup lift sensor DOWN activated

Cup lift moves upwards

Cup lift moves downwards

no function

Page 54

Page 12 / 17 Saeco Internationa Group

05 SERVICE MODALITY TALEA / ODEA - LINE

Function group t.8 - Let steam out

Function group t.8 - Let steam out

Function group t.8 - Let steam out

t.8 -

steam out

next

boiler_temp (C°)

start

* *

t.8 -

steam out

next

boiler_temp (C°)

open knob to water & steam

start

* *

t.8 -

steam out

next

boiler_temp (C°) = 105.9

counter = 7.4

pass..

start

* *

boiler_temp (C°):

start:

*:

*:

current boiler temperature

Starts the steam out procedure

no function

no function

boiler_temp (C°):

open knob to w/st:

start:

*:

*:

current boiler temperature

Instruction to open hot water / steam

valve

Starts the steam out procedure

no function

no function

boiler_temp (C°):

counter:

pass:

start:

*:

*:

heats up to approx. 110 (C°)

counts from 10 to 0 (steam out time)

Steam out procedure completed

Starts the steam out procedure

no function

no function

Page 55

Menu level

Comment

1 2 3 4 5 6

Counters

D1.1.counters

Water counters

D1.1.1. total counters

Water s. prod. Amount of water since fi rst use

Descaling cycles

since last DS. +/- Water since the last descaling

since sec. last DS. Water 2. last descaling

since third. last DS. Water 3. last descaling

n° of DS. Cycles Number of descaling cycles carried out

Water fi lter

water since last fi lter

reset

+/- Water since fi lter reset

water fi lters since prod.

Number of fi lters changed = number of

fi lter initialisations

Cleaning cycles

n° of cleaning cycles Cleaning cycles carried out Brewing unit

water since last

cleaning

+/- Water since the last cleaning cycle

error counters

D1.1.2A. error counters

current error

error since prod. Errors since production

error since last

service

Error since last service

error log Error list (see list)

5.3.2 Diagnosis menu - Talea Touch

Getting started:

• Turn on the appliance and within the fi rst 3 seconds after the hourglass appears, touch the display in the corner with your fi nger in the following sequence

(top left, top right, bottom left, bottom right = Z)

Page 56

D1. Diagnostics menu

error counters

D1.1.2A. error counters

error log Error list (see list)

reset errors last

service

yes / no Delete errors

reset error log yes / no Delete errors

product

counters

D1.1.3. product

counters

espresso Product counters

coffee Product counters

long coffee Product counters

product total Product counters

Settings

Product settings

D1.2.1A Product settings

beverage

settings

espresso

coffee

long coffee

prebrewing

medium

Prebrewing settingstrong

off

temperature

low

Coffee temperature in the cupmedium

high

aroma

mild

Dosing quantity coffeemedium

strong

preground

coffee volume +/- Cup capacity

rinse

prebrewing no function No function

temperature

low

Coffee temperature for rinsingmedium

high

aroma no function No function

coffee volume +/- Amount of water for rinsing

Page 57

Menu level Comments / conversion

D1. Diagnostics menu

1 2 3 4 5 6

Product settings

D1.2.1A Product settings

time/date settings

set clock

current time h/min Programming current time

time format 24hr - am/pm Program. 12 / 24 hour display

date settings

current date yy/mm/dd Program. Date Year/Month/Day

date format select (3) Program. Date format

standby setting

15 min Standby 15 min after use

30 min Standby 30 min after use

1h Standby 1 hour after use

3h Standby 3 hours after use

machine on/off

interval 1 h/min Switching time 1 (ON/OFF time)

interval 2 h/min Switching time 2 (ON/OFF time)

interval 3 h/min Switching time 3 (ON/OFF time)

week day setting

Monday-

Sunday

Allocation of the switching time/

day

maintenance setting Product counters

D1.2.1B

Special settings Factory settings Initialise factory settings

Page 58

D1. Diagnostics menu

Settings

system settings

D1.2.2A. System setting

grounds settings

grounds limit (13) Maximum dregs

actual grounds

+/- (counts from 13

upwards)

+/- (1-26) Dreg counter

warning grounds (8) +/- (1-13)

If this value is the same as the

dreg counter then “empty dreg

drawer” appears