Page 1

User Manual

Safe Torque Off Option (Series B)

for PowerFlex 40P and PowerFlex 70

Enhanced Control AC Drives

Catalog Number 20A-DG01

Topi c Pag e

General Description 2

What Is the DriveGuard Safe Torque Off Option? 2

Certifications and Compliance 3

CE Certification 4

Certified Equipment 5

Important Safety Considerations 5

Safe State 6

Safety Category 3 / PL (d) Performance Definition 6

Stop Category Definitions 7

Performance Level and Safety Integrity Level (SIL) CL2 7

PFD and PFH Definitions 7

PFD and PFH Data 8

Functional Proof Tests 9

Contact Information if Safety Option Failure Occurs 9

Installation and Wiring 10

Pre-Installation Instructions 10

EMC Considerations 11

DriveGuard Safe Torque Off Option Installation 11

Wirin g 15

Veri fy Ope ration 16

Description of Operation 18

PowerFlex 40P Safe Torque Off Operation 18

PowerFlex 70 Safe Torque Off Operation 19

Connection Examples 20

Original Instructions

Page 2

General Description

IMPORTANT

General Description

The DriveGuard Safe Torque Off option, when used with PowerFlex 40P or

PowerFlex 70 drives together with other safety components, provides a safety

function which inhibits torque generation in the motor(s) powered by the

drive. When used with PowerFlex 40P or PowerFlex 70 drive, the DriveGuard

Safe Torque Off option has been certified to meet the requirements for SIL 2

according to EN/IEC 61800-5-2 and IEC 61508, and PL d and Category 3

according to EN ISO 13849-1. The DriveGuard Safe Torque Off option is

just one component in a safety control system. Components in the system

must be chosen and applied appropriately to achieve the desired level of

safeguarding.

What Is the DriveGuard Safe Torque Off Option?

The DriveGuard Safe Torque Off option:

• Provides the “Safe torque off (STO)” function defined in EN/IEC

61800-5-2.

• Blocks gate firing signals from reaching the IGBT output power devices

of the drive. This prevents the IGBT’s from switching in the sequence

necessary to generate torque in the connected motor.

• Can be used in combination with other safety devices to fulfill the

requirements of a system “safe torque off” function which satisfies

Category 3 / PL (d) according to EN ISO 13849-1 and SIL CL 2

according to EN/IEC 62061, IEC 61508, and EN/IEC 61800-5-2.

This option is suitable for performing only mechanical work on the drive system or

affected area of a machine. It does NOT disconnect or isolate the drive power output

to the motor.

This option should not be used as a control for normal starting and/or stopping the

drive.

2 Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012

Page 3

General Description

ATTENTION: Electrical Shock Hazard. Verify that all sources of AC and DC power are

de-energized and locked out or tagged out in accordance with the requirements of

ANSI/NFPA 70E, Part II.

ATTENTION: To avoid an electric shock hazard, verify that the voltage on the bus

capacitors has discharged before performing any work on the drive. Measure the DC bus

voltage at the +DC and -DC terminals or test points (refer to your drive’s User Manual for

locations). The voltage must be zero.

ATTENTION: In Safe Torque Off mode, hazardous voltages may still be present at the

motor. To avoid an electric shock hazard, disconnect power to the motor and verify that

the voltage is zero before performing any work on the motor.

ATTENTION: In the event of the failure of two output IGBT's in the drive, when the

DriveGuard Safe Torque Off option has controlled the drive outputs to the off state, the

drive may provide energy for up to 180° of rotation in a 2-pole motor before torque

production in the motor ceases.

Certifications and Compliance

TUV Rheinland EC Type Examination Certification

TUV Rheinland has certified the DriveGuard Safe Torque Off option, when

used in a PF70 or PF40P drive, is compliant with the requirements for

machines defined in Annex I of the EC Directive 2006/42/EC, and that it

complies with the requirements of the relevant standards listed below.

• EN ISO 13849-1:2008 Safety of machinery - Safety related parts of

control systems - Part 1: General principles for design

(DriveGuard Safe Torque Off option + drive achieves Category 3 / PL

(d))

• EN/IEC 61800-5-2:2007 Adjustable speed electrical power drive systems

- Part 5-2 Safety requirements - Functional

(DriveGuard Safe Torque Off option + drive achieves SIL CL 2)

• EN/IEC 62061:2005 Safety of machinery - Functional safety of

safety-related electrical, electronic and programmable electronic control

systems

• IEC 61508 Part 1-7:1998 and 2000 Functional safety of electrical/

electronic/programmable electronic safety-related systems - Parts 1-7

TUV also certifies that the DriveGuard Safe Torque Off option may be used

in applications up to Category 3 / PL (d) according to EN ISO 13849-1 and

SIL 2 according to EN/IEC 62061 / IEC 61508 / EN/IEC 61800-5-2.

TUV Rheinland certificate 01/205/0665/09 may be found at:

www.rockwellautomation.com/products/certification/

Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012 3

Page 4

General Description

CE Certification

LV Directive 2006/95/EC

Rockwell Automation declares the PF40P and PF70 drives compliant with

the CE LV Directive as demonstrated by compliance with the requirements of

EN 50178 Electronic equipment for use in power installations. The

DriveGuard Safe Torque Off Option Kit is not within the scope of the Low

Voltage Directive.

EMC Directive 2004/108/EC

Rockwell Automation declares the PF40P (240V, 480V), PF70 (240V, 400V,

480V), and DriveGuard Safe Torque Off option compliant with the CE

EMC Directive as demonstrated by compliance with the requirements of EN

61800-3 Adjustable speed electrical power drive systems Part 3: EMC

requirements and specific test methods.

Machinery Directive 2006/42/EC

TUV Rheinland, Notified Body Identification Number 0035, certifies the

DriveGuard Safe Torque Off option compliant with the CE Machinery

Directive as demonstrated by compliance with the requirements of EN ISO

13849-1, EN ISO 13849-2, EN/IEC 61800-5-2, and EN/IEC 62061.

UL Certification

The PF40P, PF70, and DriveGuard Safe Torque Off option have been listed

with UL as compliant with UL 508C.

Canadian Certification

The PF40P, PF70, and DriveGuard Safe Torque Off option have been listed

(CuL) as compliant with C22.2 No 14.

Australian C-tick Certification

Rockwell Automation declares the PF40P (240V, 480V), PF70 (240V, 400V,

480V), and DriveGuard Safe Torque Off option compliant with the

Australian Radiocommunications Act of 1992, the Radiocommunications

(Electromagnetic Compatibility) Standard of 2008, and the

Radiocommunications Labelling (Electromagnetic Compatibility) Notice of

2008 as demonstrated by compliance with IEC 61800-3 Adjustable speed

electrical power drive systems Part 3: EMC requirements and specific test

methods.

4 Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012

Page 5

General Description

IMPORTANT

Certified Equipment

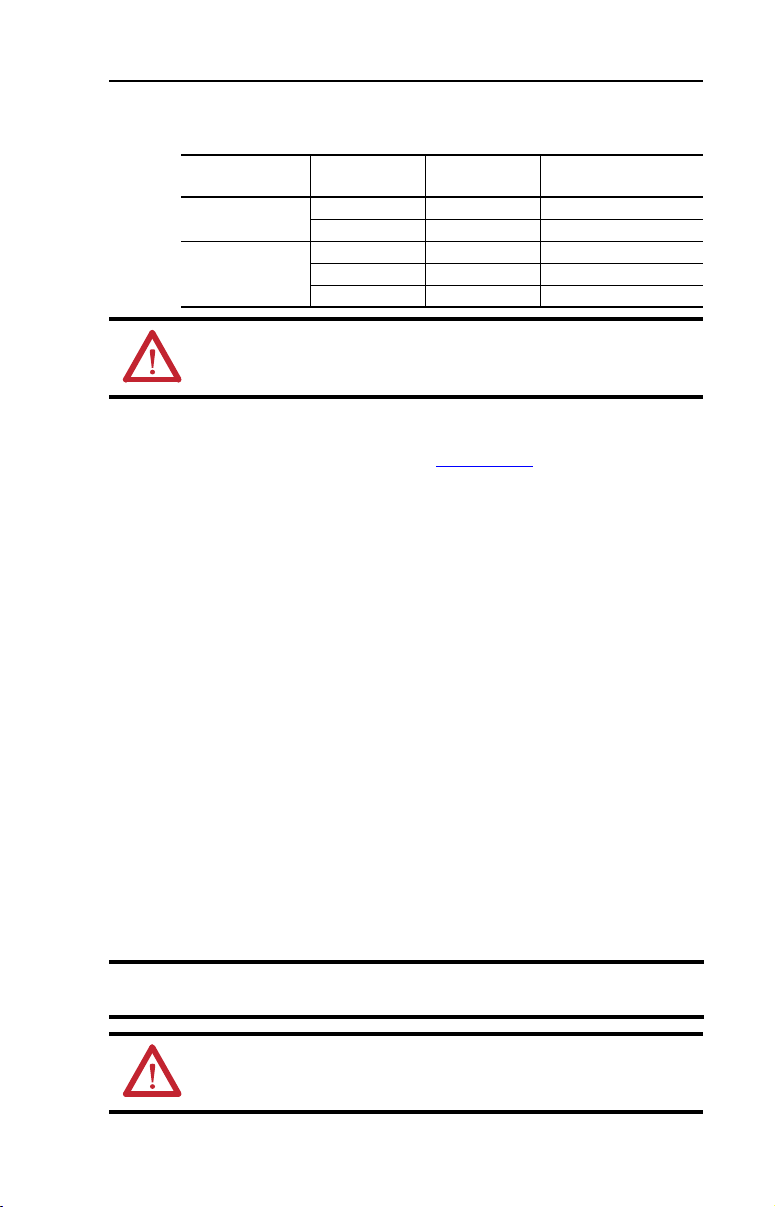

Drive Rating TUV Certified DriveGuard Safe Torque Off

Function

PowerFlex 40P 240V ✔ Series B or greater

480V ✔ Series B or greater

PowerFlex 70 Enhanced

Control

ATTENTION: Hazard of injury exists due to electric shock. Only install a Series B or

greater DriveGuard Safe Torque Off option in a PowerFlex 40P Drive.

240V ✔ Series A or greater

400V ✔ Series A or greater

480V ✔ Series A or greater

Certifications Online

See the Product Certifications link at http://ab.com for Declarations of

Conformity, Certificates, and other certifications details.

Important Safety Considerations

The system user is responsible for:

• the set-up, safety rating, and validation of any sensors or actuators

connected to the system.

• completing a system-level risk assessment and reassessing the system any

time a change is made.

• certification of the system to the desired safety performance level.

• project management and proof testing.

• programming the application software and the safety option

configurations in accordance with the information in this manual.

• access control to the system, including password handling.

• analyzing all configuration settings and choosing the proper setting to

achieve the required safety rating.

When applying Functional Safety, restrict access to qualified, authorized personnel

who are trained and experienced.

ATTENTION: When designing your system, consider how personnel will exit the

machine if the door locks while they are in the machine. Additional safeguarding

devices may be required for your specific application.

Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012 5

Page 6

General Description

Safe State

The DriveGuard Safe Torque Off option is intended for use in safety-related

applications where the de-energized state is the safe state. All of the examples

in the Description of Operation section are based on achieving the

de-energization as the safe state.

Safety Category 3 / PL (d) Performance Definition

To achieve Safety Category 3 / PL (d) according to EN ISO 13849-1, the

safety-related parts have to be designed such that:

• the safety-related parts of machine control systems and/or their protective

equipment, as well as their components, shall be designed, constructed,

selected, assembled, and combined in accordance with relevant standards

so that they can withstand expected conditions.

• well tried safety principles shall be applied.

• a single fault in any of its parts does not lead to a loss of safety function.

• some but not all faults will be detected.

• the accumulation of undetected faults can lead to loss of safety function.

• short circuits in the external wiring of the safety inputs is not one of the

faults that can be detected by the system, therefore, according to EN ISO

13849-2, these cables must be installed so as to be protected against

external damage by cable ducting or armor.

• whenever reasonably practical a single fault shall be detected at or before

the next demand of the safety function.

• the average diagnostic coverage of the safety-related parts of the control

system shall be low.

• the mean time to dangerous failure of each of the redundant channels

shall be low to high.

6 Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012

Page 7

General Description

IMPORTANT

Stop Category Definitions

The selection of a stop category for each stop function must be determined by

a risk assessment.

• Stop Category 0 is achieved with immediate removal of power to the

actuator, resulting in an uncontrolled coast to stop. See “Description of

Operation” Example 1 on page 20

• Stop Category 1 is achieved with power available to the machine actuators

to achieve the stop. Power is removed from the actuators when the stop is

achieved. See “Description of Operation” Example 2 on page 21

When designing the machine application, timing and distance should be considered

for a coast to stop (Stop Category 0 or Safe Torque Off). For more information

regarding stop categories, refer to EN/IEC 60204-1.

.

.

Performance Level and Safety Integrity Level (SIL) CL2

For safety-related control systems, Performance Level (PL), according to EN

ISO 13849-1, and SIL levels, according to IEC 61508 and EN/IEC 62061,

include a rating of the system’s ability to perform its safety functions. All of

the safety-related components of the control system must be included in both

a risk assessment and the determination of the achieved levels.

Refer to the EN ISO 13849-1, IEC 61508, and EN/IEC 62061 standards for

complete information on requirements for PL and SIL determination.

PFD and PFH Definitions

Safety-related systems can be classified as operating in either a Low Demand

mode, or in a High Demand/Continuous mode.

• Low Demand mode: where the frequency of demands for operation made

on a safety-related system is no greater than one per year or no greater

than twice the proof-test frequency.

• High Demand/Continuous mode: where the frequency of demands for

operation made on a safety-related system is greater than once per year or

greater than twice the proof test interval.

Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012 7

Page 8

General Description

The SIL value for a low demand safety-related system is directly related to

order-of-magnitude ranges of its average probability of failure to satisfactorily

perform its safety function on demand or, simply, average probability of

failure on demand (PFD). The SIL value for a High Demand/Continuous

mode safety-related system is directly related to the probability of a dangerous

failure occurring per hour (PFH).

PFD and PFH Data

These PFD and PFH calculations are based on the equations from Part 6 of

IEC 61508 and show worst-case values.

This table provides data for a 20-year proof test interval and demonstrates the

worst-case effect of various configuration changes on the data.

PowerFlex 40P PFD and PFH for 20-year Proof Test Interval

Attribute Test Result

PFD 1.74E-05

PFH 2.0E-10

SFF 81%

PowerFlex 70 PFD and PFH for 20-year Proof Test Interval

Attribute Test Result

PFD 3.4E-05

PFH 3.9E-10

SFF 81%

Terminology

Abbreviation Full Term Definition

PFD Probability of

PFH Probability of

SFF Safe Failure Fraction The sum of safe failures plus the sum of dangerous detected

8 Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012

Failure on Demand

Failure per Hour

The average probability of a system to fail to perform its

design function on demand.

The probability of a system to have a dangerous failure occur

per hour.

failures divided by the sum of all failures.

Page 9

General Description

IMPORTANT

Functional Proof Tests

The functional safety standards require that functional proof tests be

performed on the equipment used in the system. Proof tests are performed at

user-defined intervals and are dependent upon PFD and PFH values.

Your specific application determines the time frame for the proof test interval.

Contact Information if Safety Option Failure Occurs

If you experience a failure with any safety-certified device, contact your local

Rockwell Automation distributor. With this contact, you can:

• return the device to Rockwell Automation so the failure is appropriately

logged for the catalog number affected and a record is made of the failure.

• request a failure analysis (if necessary) to determine the probable cause of

the failure.

Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012 9

Page 10

Installation and Wiring

Installation and Wiring

Pre-Installation Instructions

Installation must be in accordance with the following steps and must be

carried out by competent personnel. The DriveGuard Safe Torque Off option

is intended to be part of the safety related control system of a machine. Before

installation, a risk assessment should be performed that compares the

DriveGuard Safe Torque Off option specifications and all foreseeable

operational and environmental characteristics of the machine to which it is to

be fitted.

In no case should be DriveGuard Safe Torque Off option be used in a

PowerFlex 40P or PowerFlex 70 drive where the maximum surrounding air

temperature, shock, or vibration specifications of the drive are exceeded.

PowerFlex 70 Maximum Surrounding Air Temperature

PowerFlex 40P Maximum Surrounding Air Temperature

Both Drives Shock: 15 g peak for 11 ms duration (±1.0 ms)

without derating:

IP20, NEMA/UL Type 1:

Flange Mount:

IP66, NEMA/UL Type 4X/12:

without derating:

IP20, Open Type:

IP30, NEMA 1, UL Type 1:

Flange and Plate Mount:

Vibration: 0.152 mm (0.006 in.) displacement, 1 g peak

0…50 °C (32…122 °F)

0…50 °C (32…122 °F)

0…40 °C (32…104 °F)

-10…50 °C (14…122 °F)

-10…40 °C (14…104 °F)

Heatsink: -10…40 °C (14…104 °F)

Drive: -10…50 °C (14…122 °F)

A safety analysis of the machine section controlled by the drive is required to

determine how often the safety function should be tested for proper

operation during the life of the machine.

ATTENTION: The following information is merely a guide for proper installation.

Rockwell Automation, Inc. cannot assume responsibility for the compliance or the

noncompliance to any code, national, local or otherwise for the proper installation of

this equipment. A hazard of personal injury and/or equipment damage exists if codes

are ignored during installation.

10 Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012

Page 11

Installation and Wiring

EMC Considerations

The DriveGuard Safe Torque Off option and PF40P and PF70 drives may be

installed in an industrial electromagnetic environment which is consistent

with the “Second Environment” described in IEC 61800-3 and where the

EMC requirements documented in the PF40P and PF70 Installation manuals

have been satisfied. Important installation requirements include:

• All motor output, control (I/O) and signal wiring for the drive and

DriveGuard Safe Torque Off option must be shielded cable

• Grounding (earthing ) must conform to the requirements described in the

drive user manuals

DriveGuard Safe Torque Off Option Installation

PowerFlex 40P Drives

1. Remove all power to the drive.

ATTENTION: To avoid an electric shock hazard, verify that the voltage on the bus

capacitors has discharged before performing any work on the drive. Measure the DC bus

voltage at the +DC and -DC terminals or test points (refer to your drive’s User Manual for

locations). The voltage must be zero.

Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012 11

Page 12

Installation and Wiring

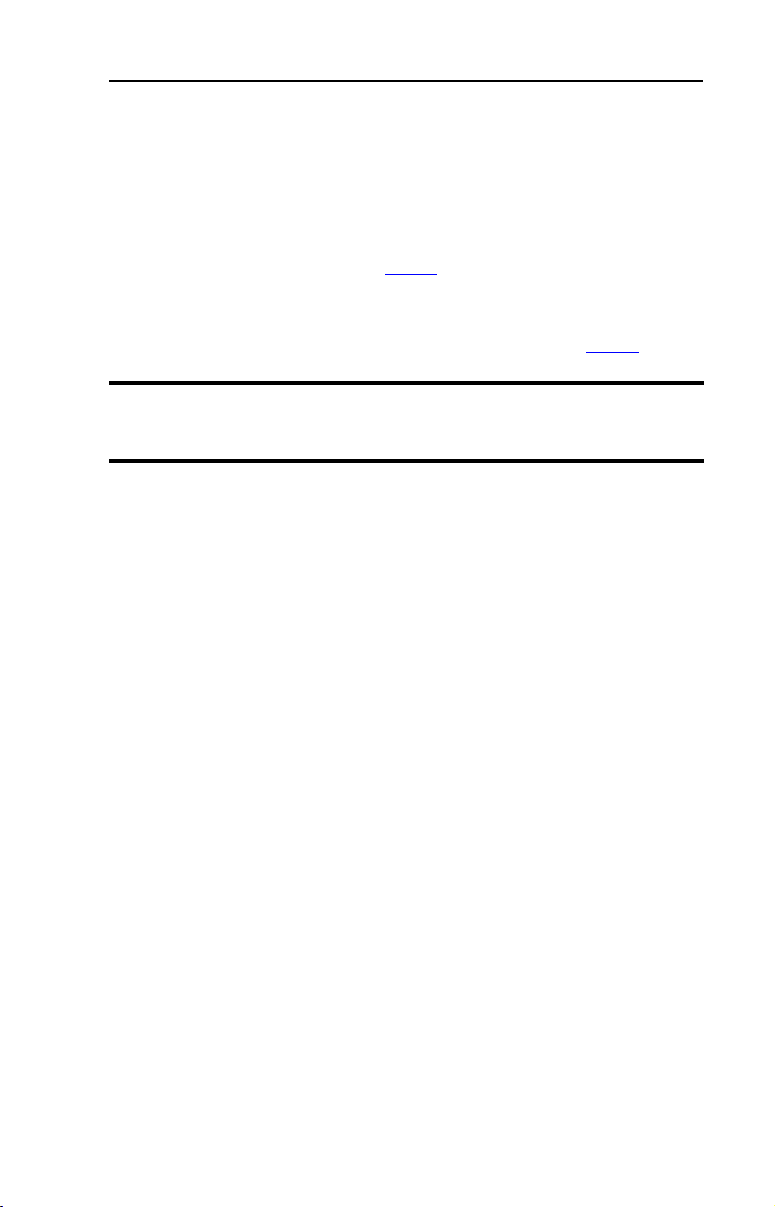

2. Remove the protective plug covering the PowerFlex 40P Safe Torque

Off connector shown in Figure 1.

Figure 1 - PowerFlex 40P Protective Plug

3. Remove the PowerFlex 40P Safe Torque Off connection jumper

shown in Figure 2.

Figure 2 - PowerFlex 40P Safe Torque Off Connection Jumper Location

12 Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012

Page 13

Installation and Wiring

IMPORTANT

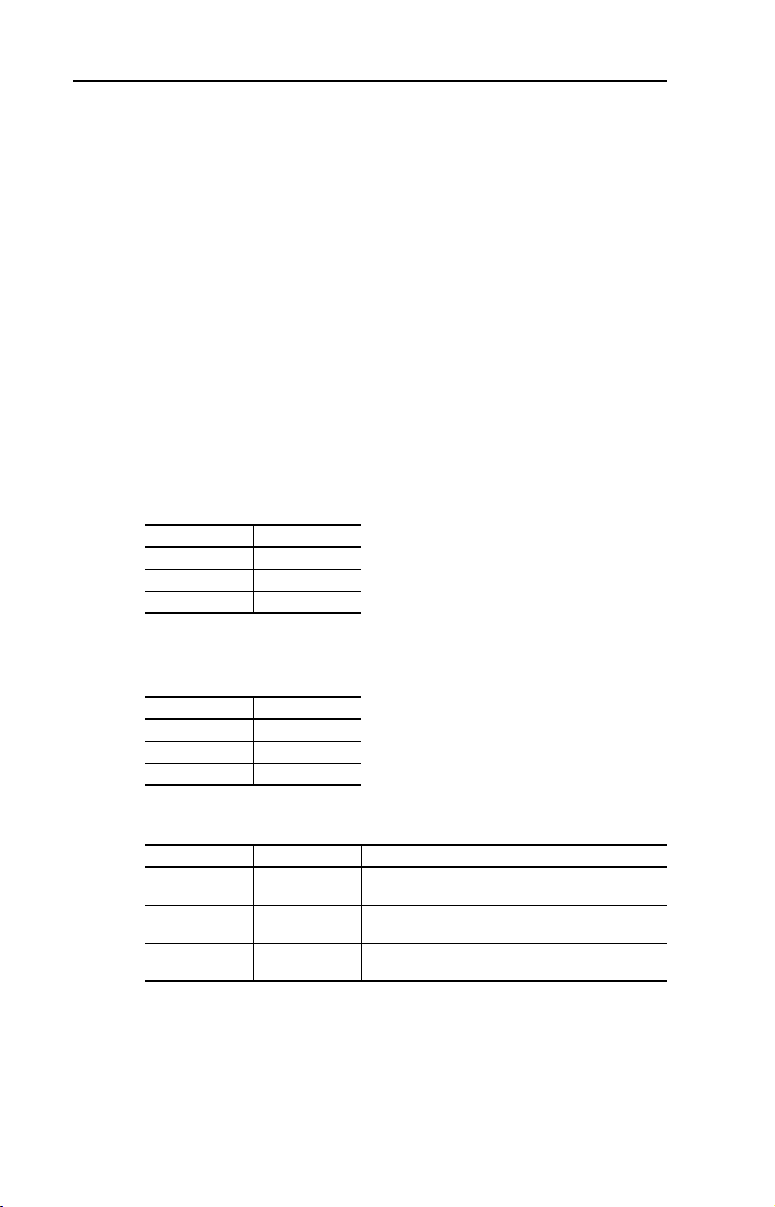

4. Remove the PowerFlex 40P Hardware Enable jump er shown in Figure

3.

Figure 3 - PowerFlex 40P Hardware Enable Jumper Location

The PowerFlex 40P hardware enable jumper must be removed when using the

DriveGuard Safe Torque Off option. Failure to remove the jumper will cause the drive

to fault when a start command is issued.

5. Plug the DriveGuard Safe Torque Off option (Series B or greater) into

the PowerFlex 40P four pin Safe Torque Off connector as shown in

Figure 4.

Figure 4 - PowerFlex 40P Safe Torque Off Connector

0.8…1.1 N•m

(7…10 lb•in)

6. Tighten screw to 0.8…1.1 N•m (7…10 lb•in).

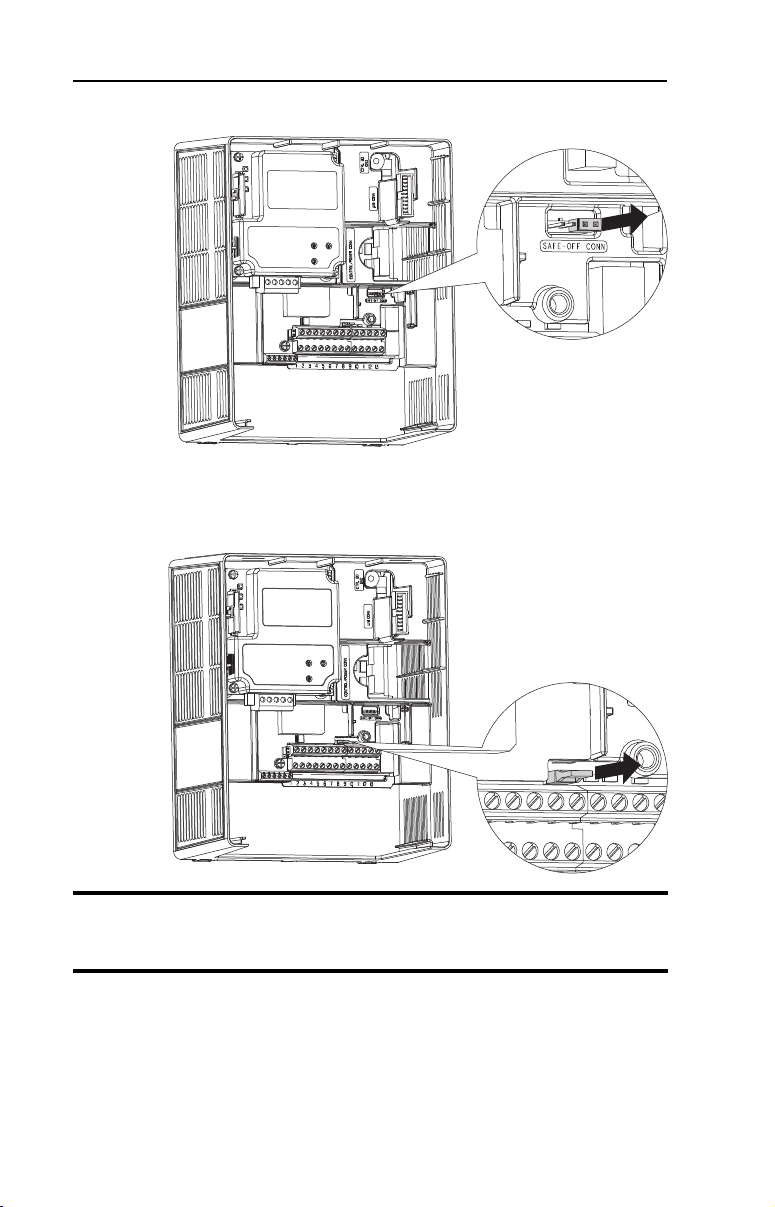

PowerFlex 70 Enhanced Control Drives

1. Remove the PowerFlex 70 Safe Torque Off Connection jumper as

shown in Figure 5.

Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012 13

Page 14

Installation and Wiring

IMPORTANT

Figure 5 - PowerFlex 70 Safe Torque Off Connection Jumper Location (Typical)

2. Remove the PowerFlex 70 Hardware Enable jumper as shown in

Figure 6.

Figure 6 - PowerFlex 70 Hardware Enable Jumper Location (Typical)

The PowerFlex 70 hardware enable jumper must be removed when using the

DriveGuard Safe Torque Off option. Failure to remove the jumper will cause the drive

to fault when a start command is issued.

3. Plug the DriveGuard Safe Torque Off option (Series A or greater)

into the PowerFlex 70 four pin connector as shown in Figure 7.

14 Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012

Page 15

Figure 7 - PowerFlex 70 Safe Torque Off Connector

0.8…1.1 N•m

(7…10 lb•in)

4. Tighten screw to 0.8…1.1 N•m (7…10 lb•in).

Wiring

Important points to remember about wiring:

•Always use copper wire.

Installation and Wiring

• Wire with an insulation rating of 600V or greater is recommended.

• Control wires should be separated from power wires by at least 0.3 meters

(1 foot).

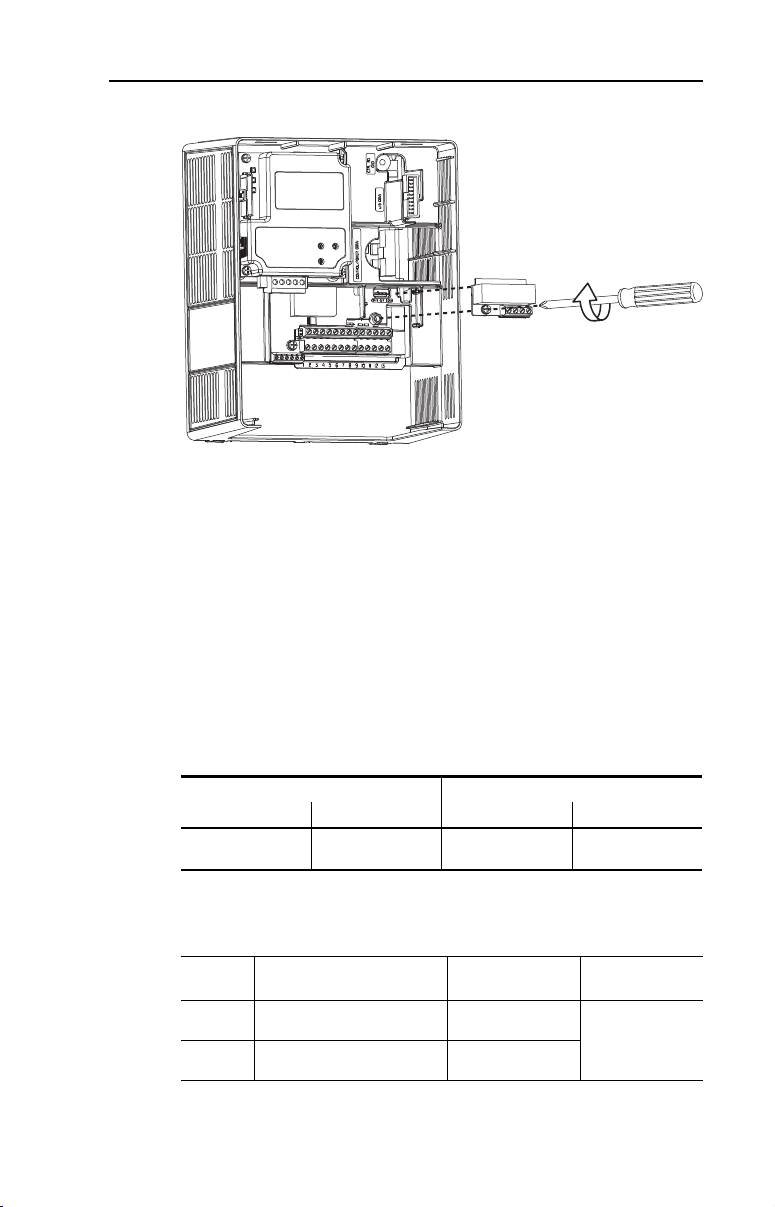

DriveGuard Safe Torque Off Option Terminal Block Specifications

Wire Size Range

Maximum Minimum Maximum Recommended

1.5 mm

(16 AWG)

(1) Maximum / minimum that the terminal block will accept - these are not recommendations.

(1)

2

0.14 mm

(26 AWG)

2

Tor que

0.25 N•m

(2.2 lb•in)

0.22 N•m

(1.9 lb•in)

Wire Types

Wire Type(s) Description Minimum Insulation

Unshielded Per US NEC or applicable national or

Shielded Multi- conductor shielded cable such

local code

as Belden 8770 (or equiv.)

—300V,

2

(18 AWG),

0.750 mm

3 conductor, shielded.

Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012 15

Rating

60 degrees C

(140 degrees F)

Page 16

Installation and Wiring

1234

DriveGuard Safe Torque Off Option Terminal Description

Verify Operation

Test the safety function for proper operation after the initial installation of

the DriveGuard Safe Torque Off option. Retest the safety function at the

intervals determined by the safety analysis described on page 10

Verify that both safety channels are functioning according to the Table 4 or

Tab le 5.

No. Signal Description

1 Monitor - N.C. Normally closed contacts for monitoring

2 Common - N.C.

3 +24V DC Connections for user supplied power to

424V Common

relay status.

Maximum Resistive Load:

250V AC / 30V DC / 50 VA / 60 Watts

Maximum Inductive Load:

250V AC / 30V DC / 25 VA / 30 Watts

energize coil.

33.3 mA typical, 55 mA maximum.

.

16 Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012

Page 17

PowerFlex 40P Channel Operation and Verification

Safety Fun ction Status Drive In

Safe State

Safe Torque Off Option

Ter min als 3 & 4

PowerFlex 40P

Enable Input

Safe Torque Off Option

Monitor Contact

Ter min als 1 & 2

PowerFlex 40P

[Control In Status]

Param . 13, Bit 2

PowerFlex 40P

Comms Stat us Word

8448, Bit 0

Safe Torque Off

(1)

Output

Relay N.O.

Dig Output States

(1) Must set A055 [Relay Out Sel], A058 or A061 [Opto Outx Sel] to option 25 “Safe-Off ”.

No Power Applied Power Applied No Power Applied Power Applied

No Power Applied No Power Applied Power Applied Power Applied

Closed Open Closed Open

Value = 0Value = 0Value = 1Value = 1

Value = 0Value = 0Value = 0Value = 1

Closed Open Ope n Open

Drive In

Stopped State

Safety Channel Operation

Description For Verification

Drive In

Stopped State

PowerFlex 70 Channel Operation and Verification

Safety Fun ction Status Drive In

Safe State

Safe Torque Off Option

Ter min als 3 & 4

PowerFlex 7 0

Enable Input

Safe Torque Off Option

Monitor Contact

Ter min als 1 & 2

PowerFlex 7 0

Drive Inhibits

Param. 214, Bit 2

(1) A Start/Run command will cause an F111 “Enable Hardware” fault.

No Power Applied Power Applied No Power Applied Power Applied

No Power Applied No Power Applied Power Applied Power Applied

Closed Open Closed Open

Value = 1 Value = 1 Value = 0 Value = 0

Drive In

Stopped State

Safety Channel Operation

Description For Verification

(1)

Drive In

Stopped State

Installation and Wiring

Drive Able

To R un

Drive Able

To Ru n

Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012 17

Page 18

Description of Operation

IMPORTANT

+24V DC

PowerFlex 40P

AC Drive

Stop

Start

AC Line

Input Power

Common

Enable

M

Gate Control

From Microcontroller

Gate Control

Circuit

Safety

Channel

Safety

Channel

1

2

3

4

Safe O Option

Description of Operation

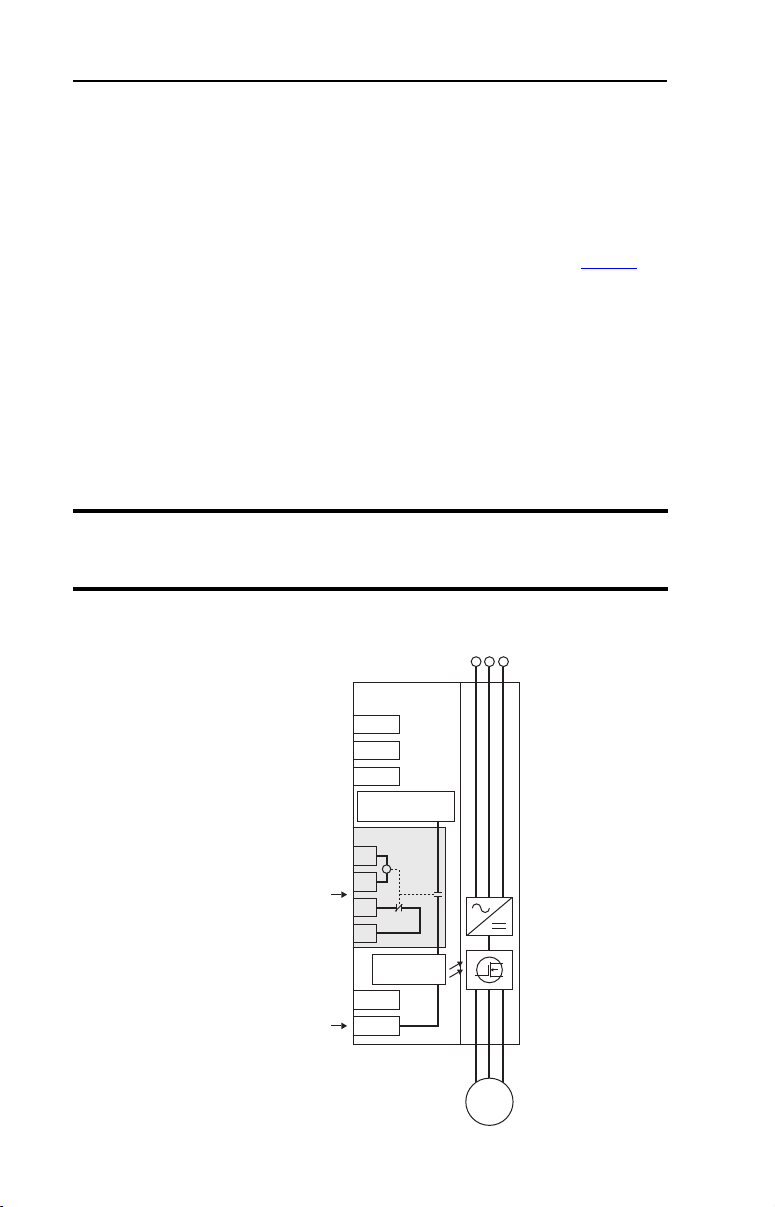

PowerFlex 40P Safe Torque Off Operation

The DriveGuard Safe Torque Off option for PowerFlex 40P (see Figure 8)

disables the drive’s output IGBT’s by breaking the link with the drive

microcontroller. When used in combination with a second safety channel (the

Enable input), the system satisfies the requirements of EN ISO 13849-1,

Category 3 / PL (d) for Safe Torque Off and helps protect against restart.

Under normal drive operation, the Safe Torque Off relay is energized, the

enable input is energized, and the drive is able to run. If either inputs is

de-energized, the gate control circuit is disabled. To meet EN ISO 13849-1,

Category 3 / PL (d) operation, both safety channels must be de-energized.

Refer to the following examples for details.

By itself, the Safe Torque Off option initiates a coast-to-stop action. Additional

protective measures will need to be applied when an application requires a change

to the stop action.

Figure 8 - PowerFlex 40P Drive Safe Torque Off Circuitry

18 Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012

Page 19

Description of Operation

IMPORTANT

+24V DC

PowerFlex 70

AC Drive

Stop

Start

AC Line

Input Power

Common

Enable

M

Gate Control

Power Supply

Gate Control

Circuit

Safety

Channel

Safety

Channel

1

2

3

4

Safe O Option

PowerFlex 70 Safe Torque Off Operation

The PowerFlex 70 DriveGuard Safe Torque Off option (see Figure 9) disables

the drive’s output IGBT’s by disconnecting the gate control power supply.

When used in combination with a second safety channel (the Enable input),

the system satisfies the requirements of EN ISO 13849-1, Category 3 / PL (d)

for Safe Torque Off and helps protect against restart.

Under normal drive operation, the Safe Torque Off relay is energized, the

enable input is energized, and gate control power is available to the gate

control circuit. If either of these inputs is de-energized, the gate control circuit

is disabled. To meet EN ISO 13849-1, Category 3 / PL (d) operation, both

safety channels must be de-energized. Refer to the following examples for

details.

By itself, the Safe Torque Off option initiates a coast-to-stop action. Additional

protective measures will need to be applied when an application requires a change

to the stop action.

Figure 9 - PowerFlex 70 Drive Safe Torque Off Circuitry

Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012 19

Page 20

Description of Operation

Stop

Start

A1

S21 S13 31 13 23 X1

A2

+24V DC

Common

+24V DC

S22 S14 32 14 24 X2

Minotaur

MSR9T

GuardMaster

Trojan

Gate

+24V DC

PowerFlex

AC Drive

Stop

Start

AC Line

Input Power

Common

Enable *

M

1

2

3

4

Safe O Option

*Important: The dri ve Enable digital

input is a solid state circuit. The safety

outputs on safety module must not be

configured for Pulsed/Safety Pulse Test.

Connection Examples

Example 1 - Safe Torque Off Connection with Coast-to-Stop Action, Dual Channel

Figure 10 - Stop Category 0 – Coast

Circuit Status

Circuit shown with guard door closed and system ready for normal drive

operation.

Operating Principle

This is a dual channel system with monitoring of the Safe Torque Off circuit

and drive. Opening the guard door will switch the input circuits (S13-S14 &

S21-S22) to the Minotaur monitoring safety relay unit. The output circuits

(13-14 & 23-24) will cause the Safe Torque Off option and drive Enable

circuit to trip and the motor will coast to stop. To restart the drive, the

Minotaur safety relay must first be reset followed by a valid start command to

the drive.

Fault Detection

A single fault detected on the Minotaur safety input circuits will result in the

lock-out of the system at the next operation and will not cause loss of the

safety function.

If the Safe Torque Off option sticks ON, the motor will stop on command

due to the enable input. The system cannot be reset when this fault condition

20 Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012

exists.

Page 21

Description of Operation

+24V DC

Common

+24V DC

GuardMaster

Trojan

Stop

Start

A1 S21 S11 S52 S12

A2 X1 X2

13 23

14 24

S33Y2S34

Y1X3

37 47 57

38 48 58X4

S22

Y39 Y40

Minotaur

MSR138DP

Gate

+24V DC

PowerFlex

AC Drive

Stop

Start

AC Line

Input Power

Common

Enable *

M

1

2

3

4

Safe O Option

*Important: The drive Enable digital

input is a solid state circuit. The safety

outputs on safety module must not be

configured for Pulsed/Safety Pulse Test.

Example 2 - Safe Torque Off Connection with Controlled Stop Action, Dual Channel

Figure 11 - Stop Category 1 – Controlled

Circuit Status

Circuit shown with guard door closed and system ready for normal drive

operation.

Operating Principle

This is a dual channel system with monitoring of the Safe Torque Off circuit

and drive. Opening the guard door will switch the input circuits (S11-S12 &

S21-S22) to the Minotaur monitoring safety relay unit. The output circuits

(13-14) issue a Stop command to the drive and cause a controlled

deceleration. After the programmed delay, the timed output circuits (47-48 &

57-58) will cause the Safe Torque Off option and the drive Enable circuit to

trip. If the motor is rotating when the trip occurs, it will coast to stop. To

restart the drive, the Minotaur safety relay must first be reset followed by a

valid start command to the drive.

Fault Detection

A single fault detected on the Minotaur safety input circuits will result in the

lock-out of the system at the next operation and will not cause loss of the

safety function.

If the Safe Torque Off option sticks ON, the motor will stop on command

due to the enable input. The system cannot be reset when this fault condition

exists.

Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012 21

Page 22

Description of Operation

Notes:

22 Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012

Page 23

Notes:

Description of Operation

Rockwell Automation Publication PFLEX-UM003B-EN-P - July 2012 23

Page 24

*PN-163523*

PN-163523

www.rockwellautomation.com

Americas: Rockwell Automation, 1201 South Second Street,

Milwaukee, WI 53204-2496 USA,

Tel:

(1) 414.382.2000, Fax: (1) 414.382.4444

Europe

/

Middle East/Africa: Rockwell Automati

on,

Pegasus Park, De Kleetlaan 12a,

1831 Diegem, Belgium,

Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

Asia Pacific: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

Power, Control and Information Solutions Headquarters

U.S. Allen-Bradley Drives Technical Support

Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, Email: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

Publication PFLEX-UM003B-EN-P – July 2012

Supersedes PFLEX-UM003A-EN-P – June 2006 Copyright © 20 12 Rockwell Automation, Inc. All rights reserved. Printed in USA.

Loading...

Loading...