Page 1

AllenBradley

Classic 1785 PLC5

Programmable

User

Controllers

(1785LT,

L

T2, LT3, L

Manual

T4)

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance and

safety requirements, including any applicable laws, regulations, codes,

and standards.

The illustrations, charts, sample programs, and layout examples shown in

this guide are intended solely for purposes of example. Since there are

many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intellectual property liability) for actual use based on the

examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application,

Installation, and Maintenance of Solid State Control (available from your

local Allen-Bradley office), describes some important differences between

solid-state equipment and electromechanical devices that should be taken

into consideration when applying products such as those described in

this publication.

Reproduction of the contents of this copyrighted publication, in whole

or in part, without written permission of Allen-Bradley Company, Inc.,

is prohibited.

Throughout this manual we use notes to make you aware of

safety considerations:

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death,

property damage, or economic loss.

Attention statements help you to:

identify a hazard

avoid the hazard

recognize the consequences

Important: Identifies information that is critical for successful application

and understanding of the product.

Page 3

Summary of Changes

Summary of Changes

This manual has been revised to cover only Classic PLC-5 programmable

controllers: PLC-5/10, -5/12, -5/15, and -5/25.

It has also been revised to include the accompanying design worksheets

that were formerly available as a separate publication: 1785-5.2. This

separate publication is no longer available; see Appendix B for these

worksheets.

For information about Enhanced and Ethernet PLC-5 processors, see the

Enhanced and Ethernet PLC-5 Programmable Controllers User Manual,

publication 1785-6.5.12.

i

Page 4

Table of Contents

Summary of Changes

Classic PLC5 Programmable Controllers

Purpose

Manual Organization

How to Use this Manual

of this Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Understanding Your System 11. . . . . . . . . . . . . . . . . . . . . . .

Using this Chapter 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Understanding the Terms Used in this Chapter 11

Designing Systems 12

Preparing Your Functional Specification 13

Introducing Classic PLC5 Processor Modules 15

Using the Classic PLC5 Processor as a Remote I/O Scanner 18

Using the Classic PLC5 Processor as a Remote I/O Adapter 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . .

. . . .

Choosing Hardware 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Selecting

Selecting I/O Adapter Modules 24

Selecting

Selecting an Operator Interface 26

Choosing a Classic PLC5 Processor for Your Application 29

Selecting Power Supplies 29

Selecting Memory Modules 213

Selecting a Replacement Battery 213

Selecting

Selecting a PLC5 Processor Backup System 214

Selecting Link Terminators 215

Connecting a Programming Terminal to a Processor Module 215

Choosing Cables 215

Objectives

I/O Modules

I/O Chassis

Complementary I/O

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

213. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . .

iii

iii

iv

iv

i

Placing System Hardware 31. . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Determining the Proper Environment 31

Protecting Your Processor 34

Avoiding Electrostatic Damage 34

Laying

Planning

Laying Out the Backpanel Spacing 36

Grounding

Objectives

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

Out Y

our Cable Raceway 34. . . . . . . . . . . . . . . . . . . . . . . . .

Cabling

. . . . . . . . . . . . . . . . . . . . . . .

Configuration

31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contentsii

Assigning Addressing Modes, Racks, and Groups 41. . . . . .

Chapter

Placing

Understanding the Terms Used in this Chapter 42

Choosing the Addressing Mode 43

Assigning Racks 49

Addressing

Choosing

Chapter

Identifying Classic PLC5 Processor Channels/Connectors 51

Configuring

Configuring a DH+ Link 53

Connecting a DH+ Link to Data Highway 510

Choosing Programming Terminal Connection 510

Objectives

I/O Modules in Chassis

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Complementary I/O

Communication

Objectives

Communication for Y

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

41. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

412. . . . . . . . . . . . . . . . . . . . . . . . . .

51. . . . . . . . . . . . . . . . . . . . . . . . .

51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . .

our Processor 53. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

Planning Your System Programs 61. . . . . . . . . . . . . . . . . . . .

Chapter

Planning Application Programs 61

Using SFCs with PLC5 Processors 61

Preparing the Programs for Your Application 63

Addressing Data T

Using the Processor Status File 69

Objectives

able Files

61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

67. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Interrupt Routines 71. . . . . . . . . . . . . . . . . . . . . . .

Chapter

Using Programming Features 71

Writing

Understanding ProcessorDetected Major Faults 711

Objectives

a Fault Routine

71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

Transferring Discrete and BlockTransfer Data 81. . . . . . . . .

Chapter

Transferring Data Using Adapter Mode 81

Programming Discrete Transfer in Adapter Mode 84

Programming Block Transfer in Adapter Mode 87

Transferring Data Using Scanner Mode 816

Programming Discrete Transfer in Scanner Mode 816

Programming Block Transfer in Scanner Mode 817

Programming Considerations 821

Objectives

81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

Table of Contents iii

Calculating

Chapter

Introduction to Classic PLC5 Processor Scanning 91

I/O ScanningDiscrete and Block Transfer 95

Instruction Timing and Memory Requirements 97

Program Constants 913

Direct and Indirect Elements 913

Program T

Objectives

iming 91. . . . . . . . . . . . . . . . . . . . . . . .

91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximizing System Performance 101. . . . . . . . . . . . . . . . . . . .

Chapter

Components of Throughput 101

Input and Output Modules Delay 101

I/O Backplane Transfer 102

Remote

Processor Time 106

Calculating Throughput 106

Objectives

I/O Scan T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ime 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Switch Settings A1. . . . . . . . . . . . . . . . . . . . . . . . .

Chassis Backplane with Classic PLC5 Processor A1. . . . . . . . . . . . .

Chassis Backplane with Adapter Module A2

Chassis Configuration Plug for Power Supply A3

Remote I/O Adapter Module 1771ASB Series C without

Complementary I/O

Remote I/O Adapter Module 1771ASB Series C with

Complementary I/O

SW1 A7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AdapterMode ProcessorsSW2 in a PLC5 or Scanner Module A8

AdapterMode ProcessorsSW2 in a PLC2/20, 2/30,

or Sub I/O Scanner Module System A9

AdapterMode ProcessorsSW2 in a PLC3 or PLC5/250

System with 8Word Groups A10

AdapterMode ProcessorsSW2 in a PLC3 or PLC5/250

System with 4Word Groups A11

SW3 A12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

A4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. .

. . . . . . . . . . . . . . . . . . . .

Design Worksheets B1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions Used in These Worksheets B1. . . . . . . . . . . . . . . . . . .

Prepare

Determine Control Strategy B4

Identify Chassis Locations B6

Select Module T

Total

Assign I/O Modules to Chassis and Assign Addresses B10

Select Adapter Modules B12

Place System Hardware B14

a Functional Specification

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ypes and List I/O Points

I/O Module Requirements

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B2. . . . . . . . . . . . . . . . . . . . . . . .

B7. . . . . . . . . . . . . . . . . . . .

B9. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

Page 7

Table of Contentsiv

Configure

Determine Communication Requirements B17

Select a Classic PLC5 Processor B21

Select Power Supplies B23

Choose a Programming Terminal B24

Select Programming T

Select Operator Interface B26

Develop Programming Specifications B28

Switch Settings

erminal Configuration

B15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

B25. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

Page 8

Preface

Classic PLC5 Programmable Controllers

How to Use

Your Documentation

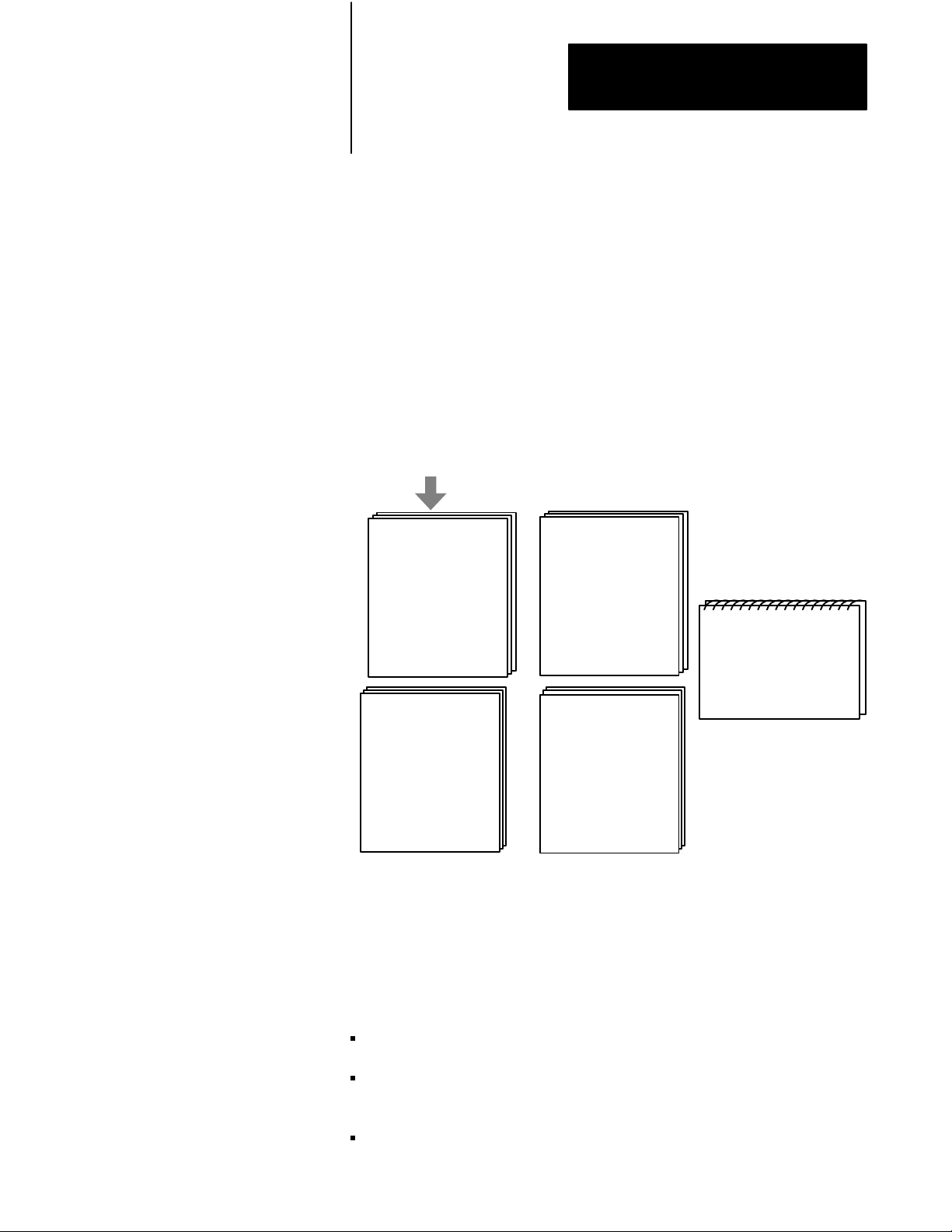

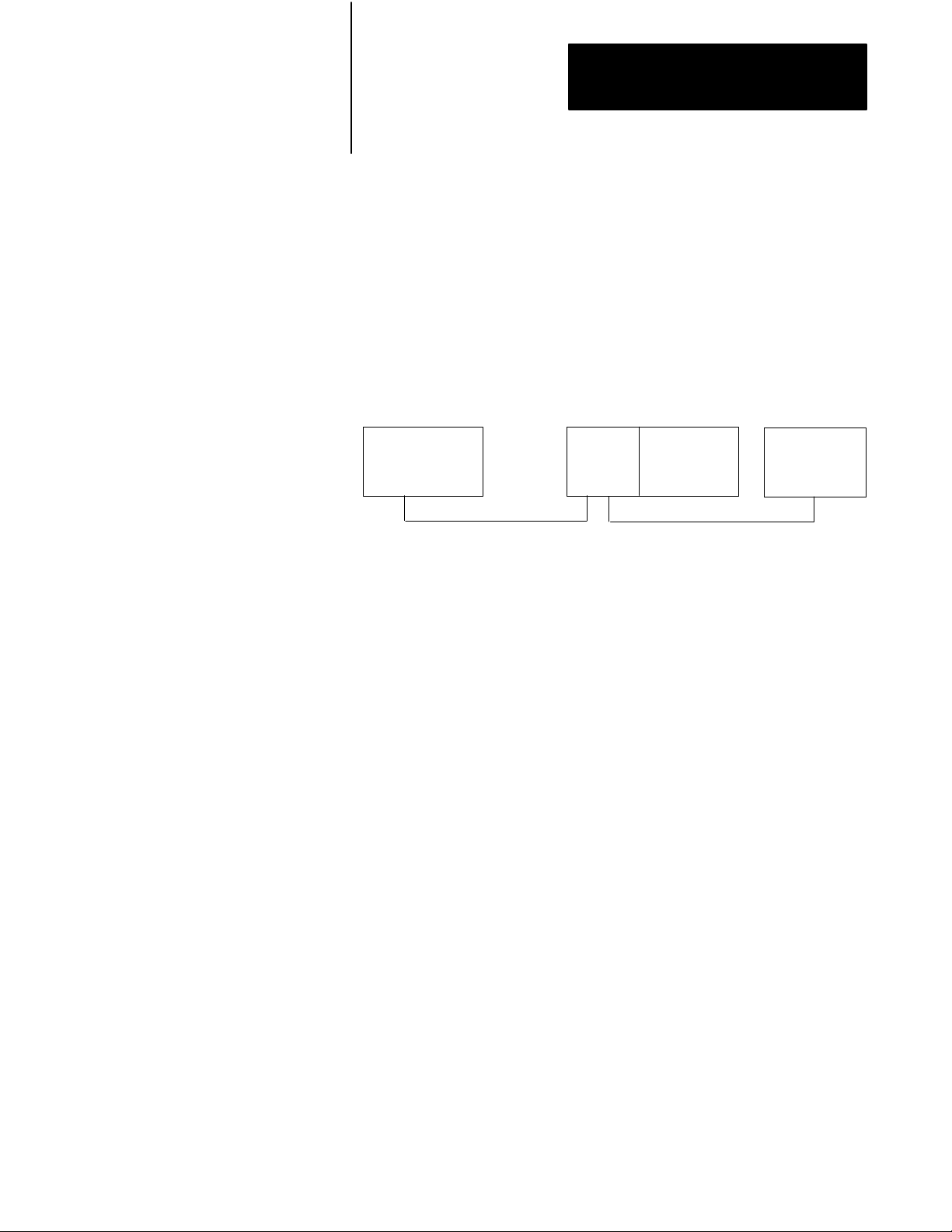

Your Classic PLC-5 Programmable Controllers documentation is organized

into manuals according to the tasks you perform. This organization lets

you easily find the information you want without reading through

information that is not related to your current task. The arrow in Figure 1

points to the book you are currently using.

Figure 1

Classic

PLC5 Programmable Controllers Documentation Library

Classic 1785 PLC5

Programmable Controllers

User Manual

Explanation of processor

functionality, system

design, and programming

considerations and worksheets

17856.2.1

6200 or AI Series Software

Classic 1785 PLC5

Programmable Controllers

Hardware Installation

How to install and set

switches for chassis,

PLC5 processor, how

to wire and ground

your system

17856.6.1

Instruction Set

Reference

Instruction execution,

parameters, status

bits and examples

1785 PLC5

Programmable Controllers

Quick Reference

Quick access to switches,

status bits, indicators,

instructions, SW screens

17857.1

Purpose

of this Manual

17856.1

For more information on 1785 PLC-5 programmable controllers or the

above publications, contact your local Allen-Bradley sales office,

distributor, or system integrator.

This manual is intended to help you design a Classic PLC-5 programmable

controller system. Use this manual to assist you in:

selecting the proper hardware components for your system

determining the important features of classic PLC-5 processors and how

to use those features

planning your classic PLC-5 system layout

iii

Page 9

Preface

Manual Organization

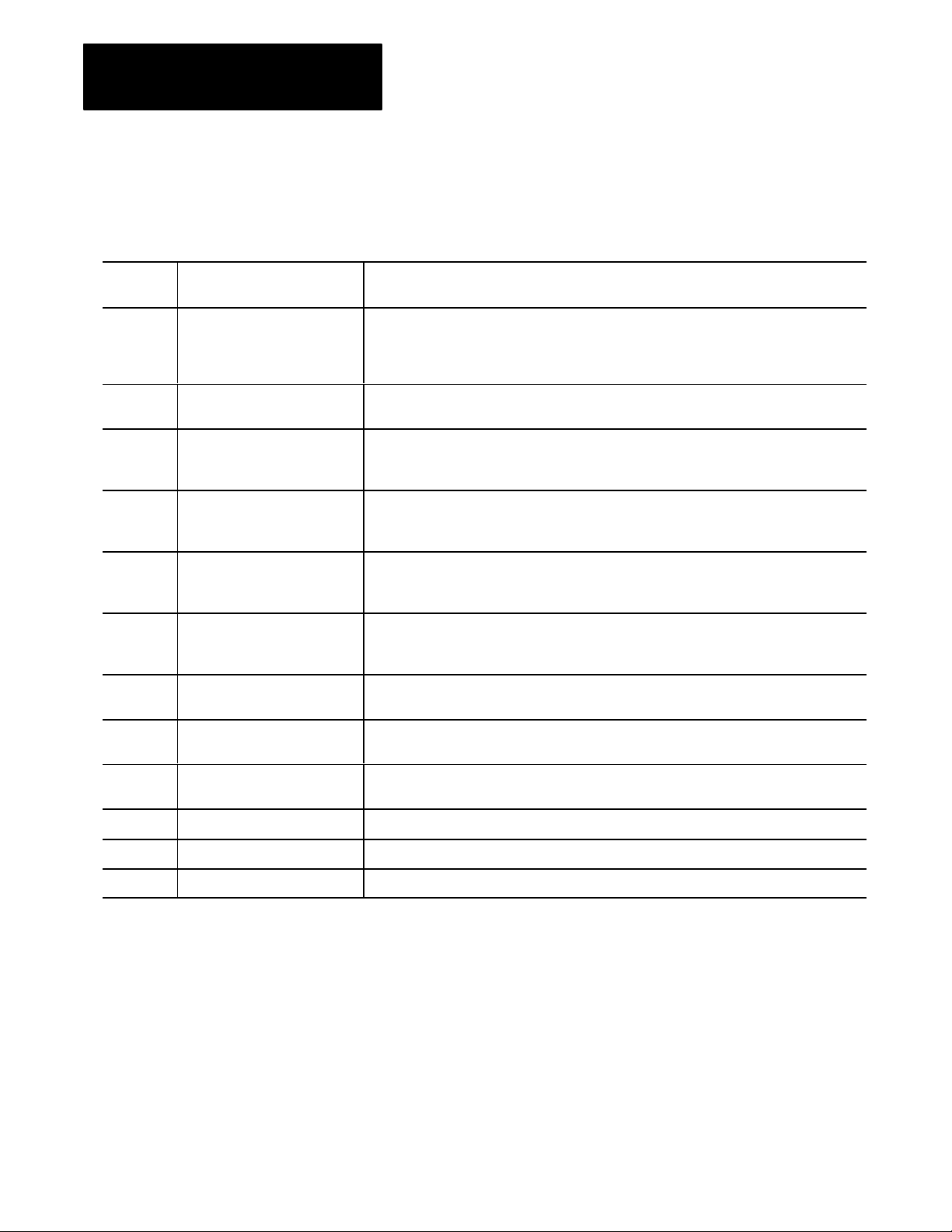

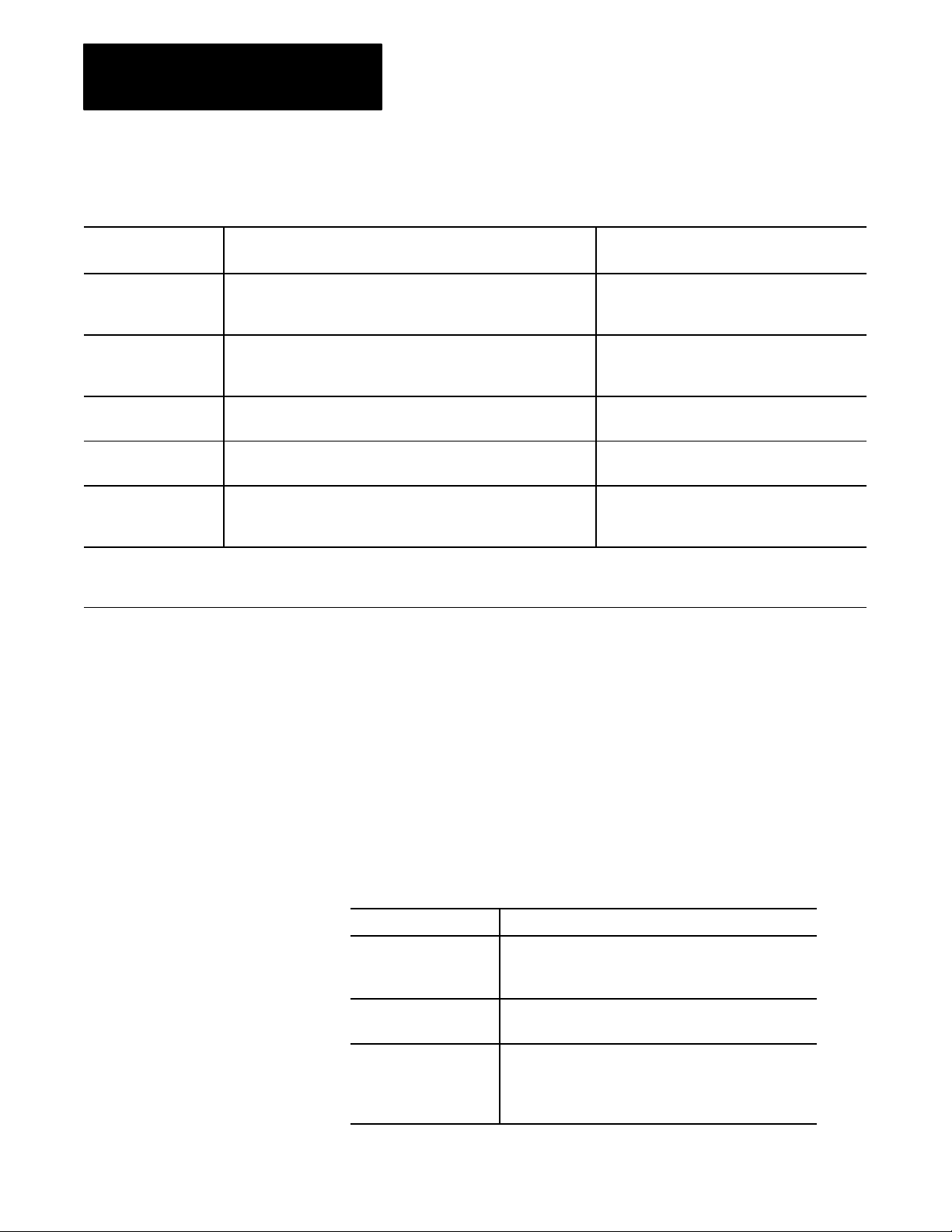

Chapter

/

Appendix

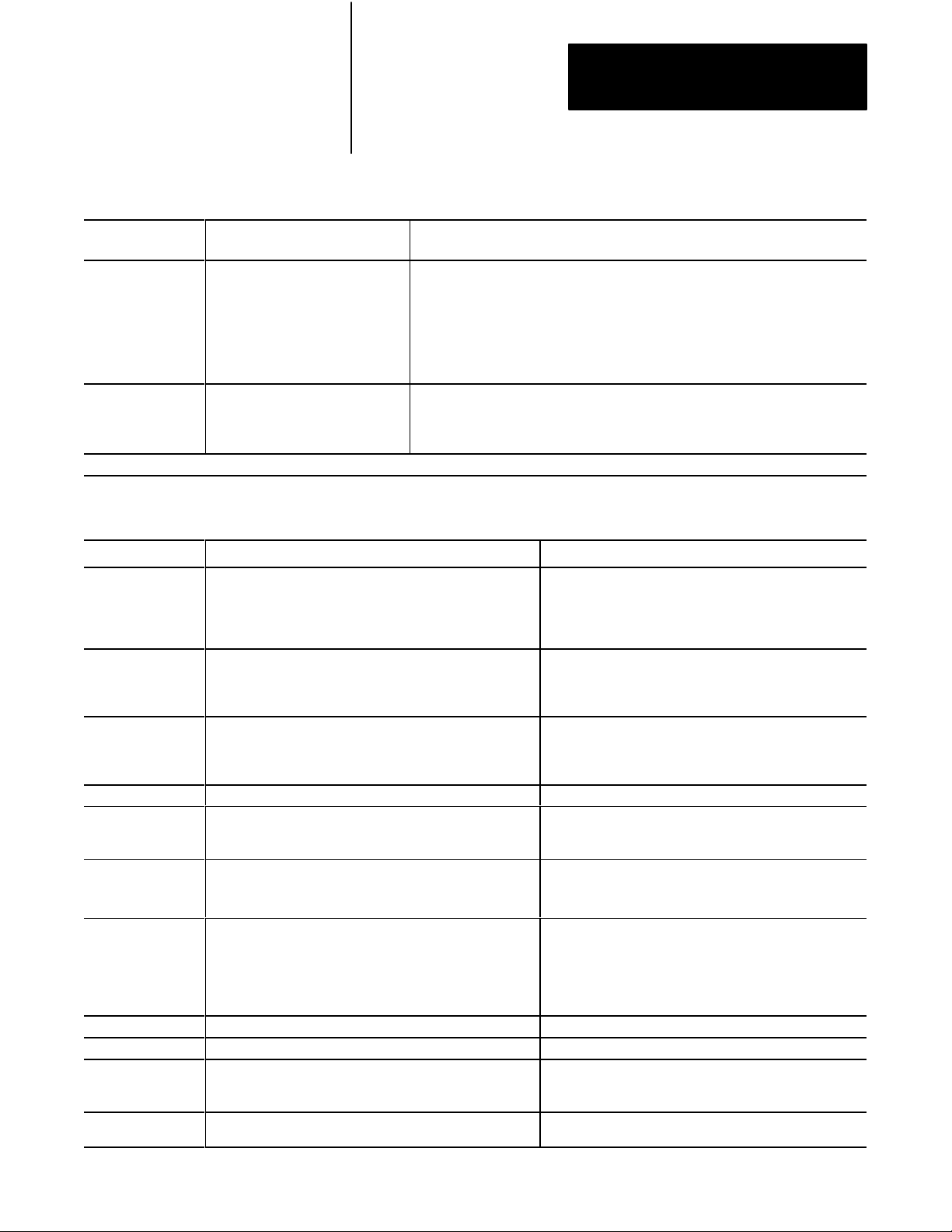

1 Understanding Your System Provides an overview of Classic PLC5 processors in different system configurations. Provides

2 Choosing Hardware Provides information on your hardware choices when you design a Classic PLC5 processor

3 Placing System Hardware Describes proper environment, Classic PLC5 processor protection, and prevention of

4 Assigning Addressing Mode,

Rack, and Groups

5 Choosing Communication Identifies each Classic 5 processor channel/connector, and explains how to configure your

6 Planning Your System Programs Explains the use of sequential function charts (SFCs). Provides guidelines and examples for

This manual has ten chapters and two appendices. The following table

lists each chapter or appendix with its corresponding title and a brief

overview of the topics covered in it.

Title Topics Covered

an introduction to Classic PLC5 processors and their primary features and configurations. Also

provides information on using a Classic PLC5 processor as a remote I/O scanner or a remote

I/O adapter.

system.

electrostatic damage for your Classic PLC5 programmable controller system. Also covers

raceway and cable layout, backpanel spacing, and grounding configurations.

Describes the I/O addressing modes that you can choose for your chassis. Explains how you

assign group and rack numbers to your I/O chassis. Also covers how you configure

complementary I/O by assigning rack and group addresses.

Classic PLC5 processor. Provides additional information about the Data Highway Plust

(DH+t) link, programming software, and programmingterminal connections.

preparing system programs. Provides a map of data table files and methods to address the

data table files. Explains how to use the processor status file.

7 Selecting Interrupt Routines Summarizes the conditions for which you would choose fault routines for your application.

Provides a definition of fault routines.

8 Transferring Discrete and

BlockTransfer Data

9 Calculating Program Timing Provides an overview of processor scan timing. Lists execution times and memory

10 Maximizing System Performance Explains how to calculate throughput, and provides methods for optimizing I/O scan time.

A Selecting Switch Settings Describes the switch settings for configuring a Classic PLC5 programmable controller system.

B Design Worksheets Provides worksheets to help the designer plan the system and the installer to install the system.

How to Use this Manual

Explains how your CLassic PLC5 processor transfers discrete and blocktransfer data in both

scanner and adapter modes.

requirements for bit and word instructions as well as file instructions.

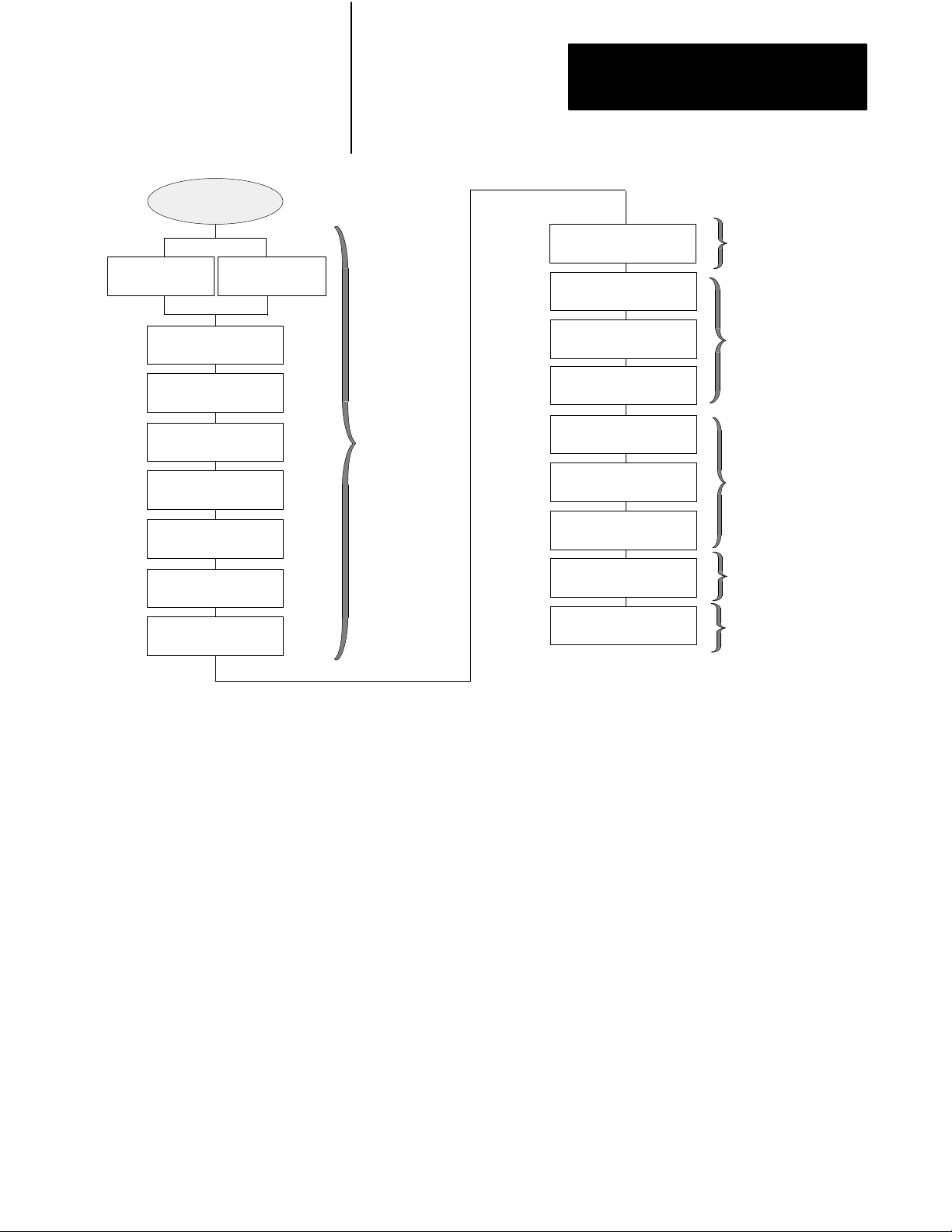

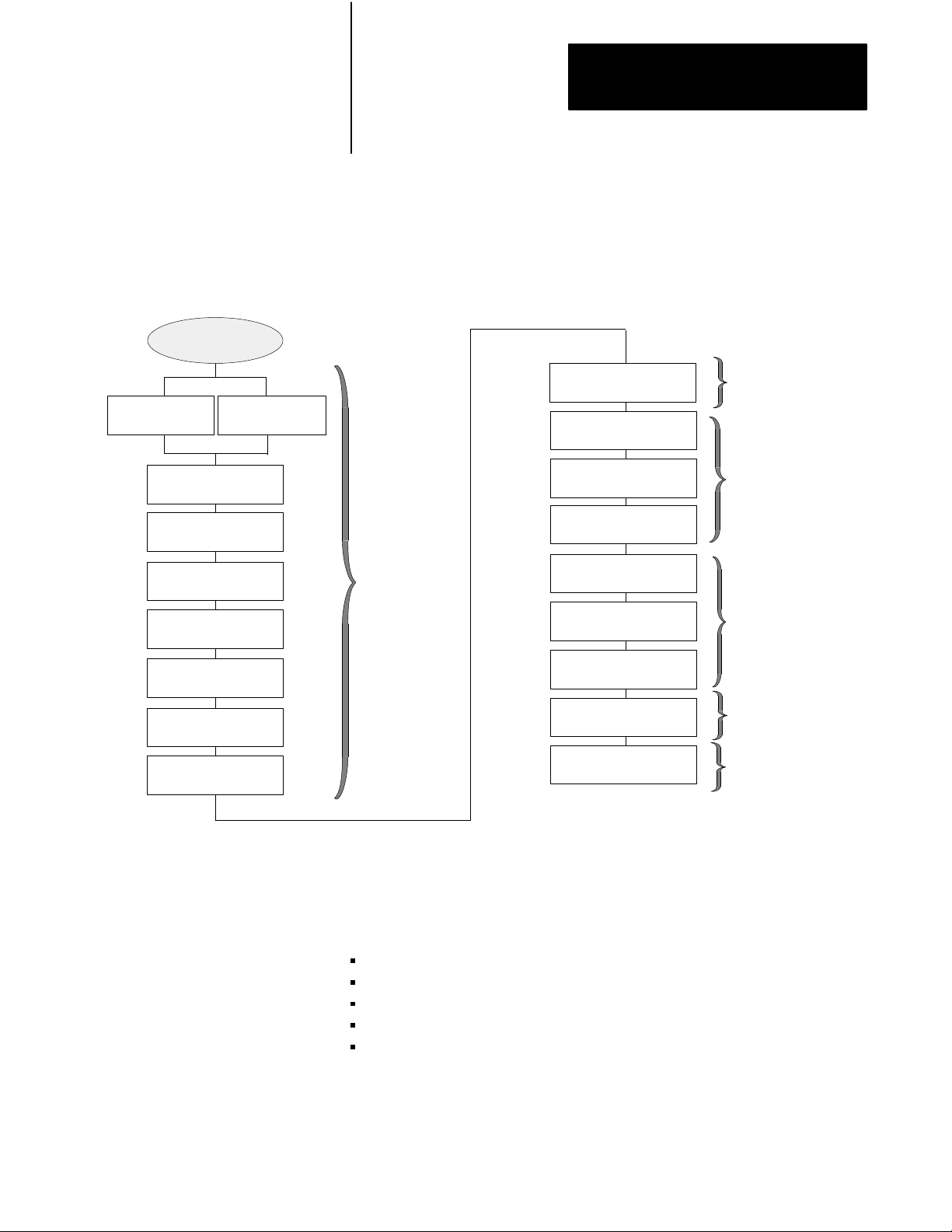

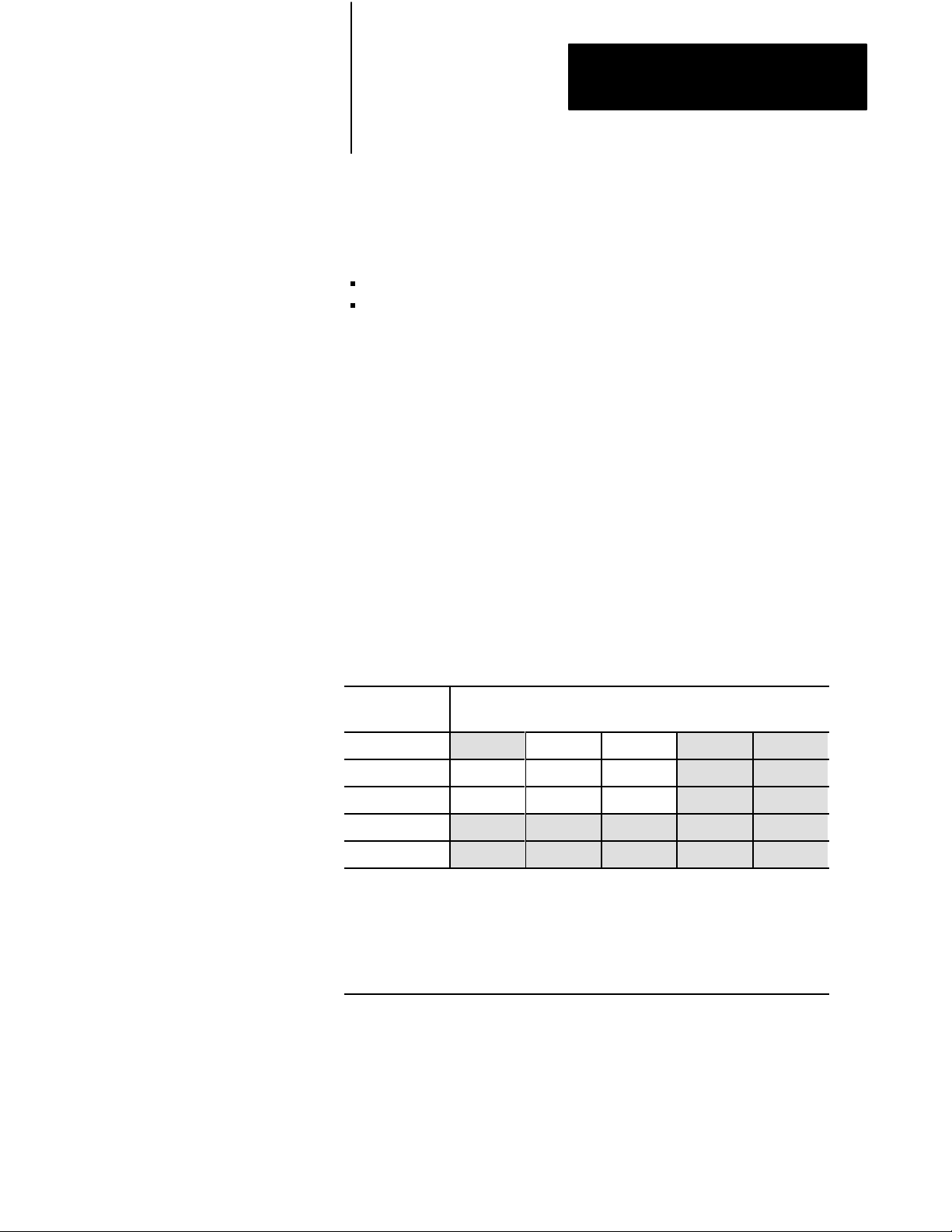

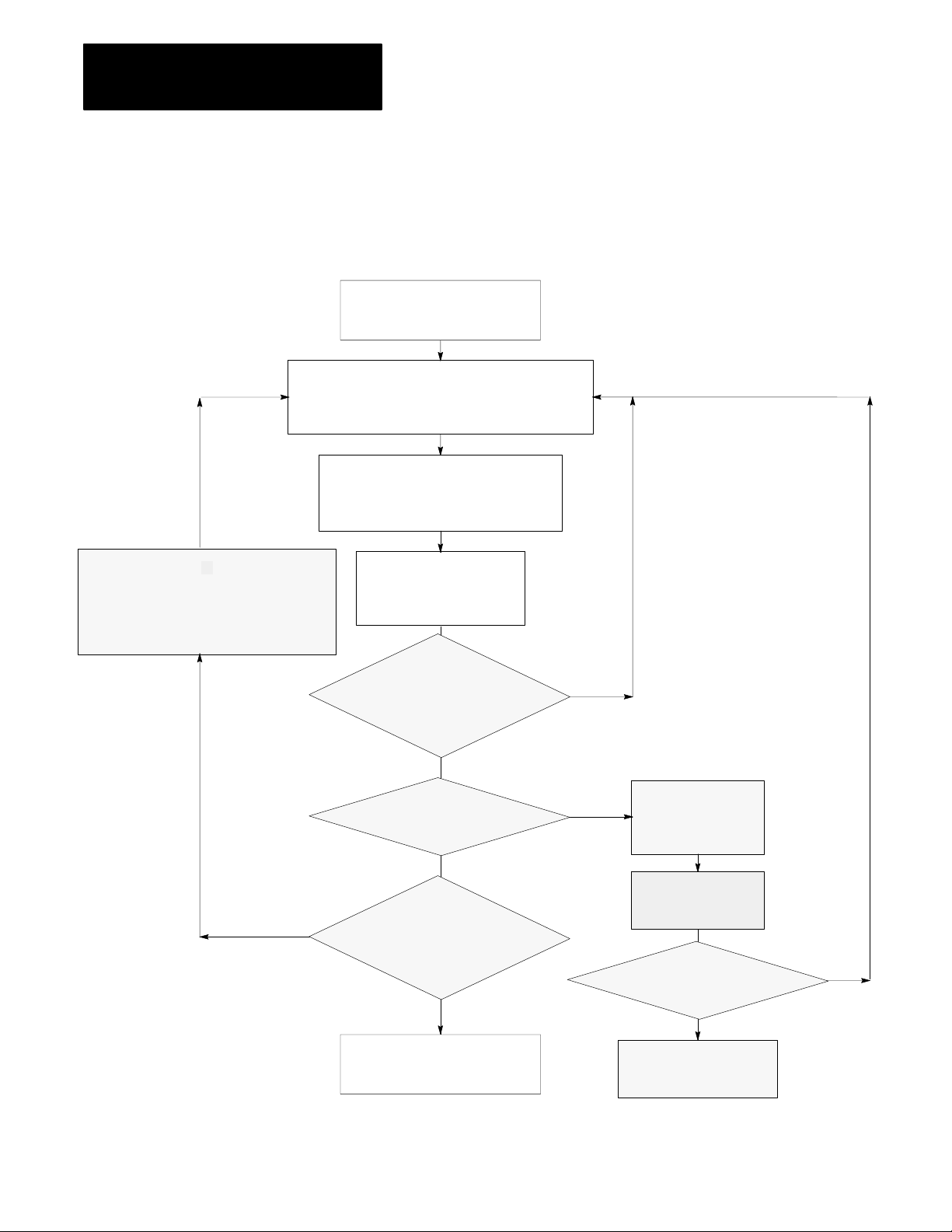

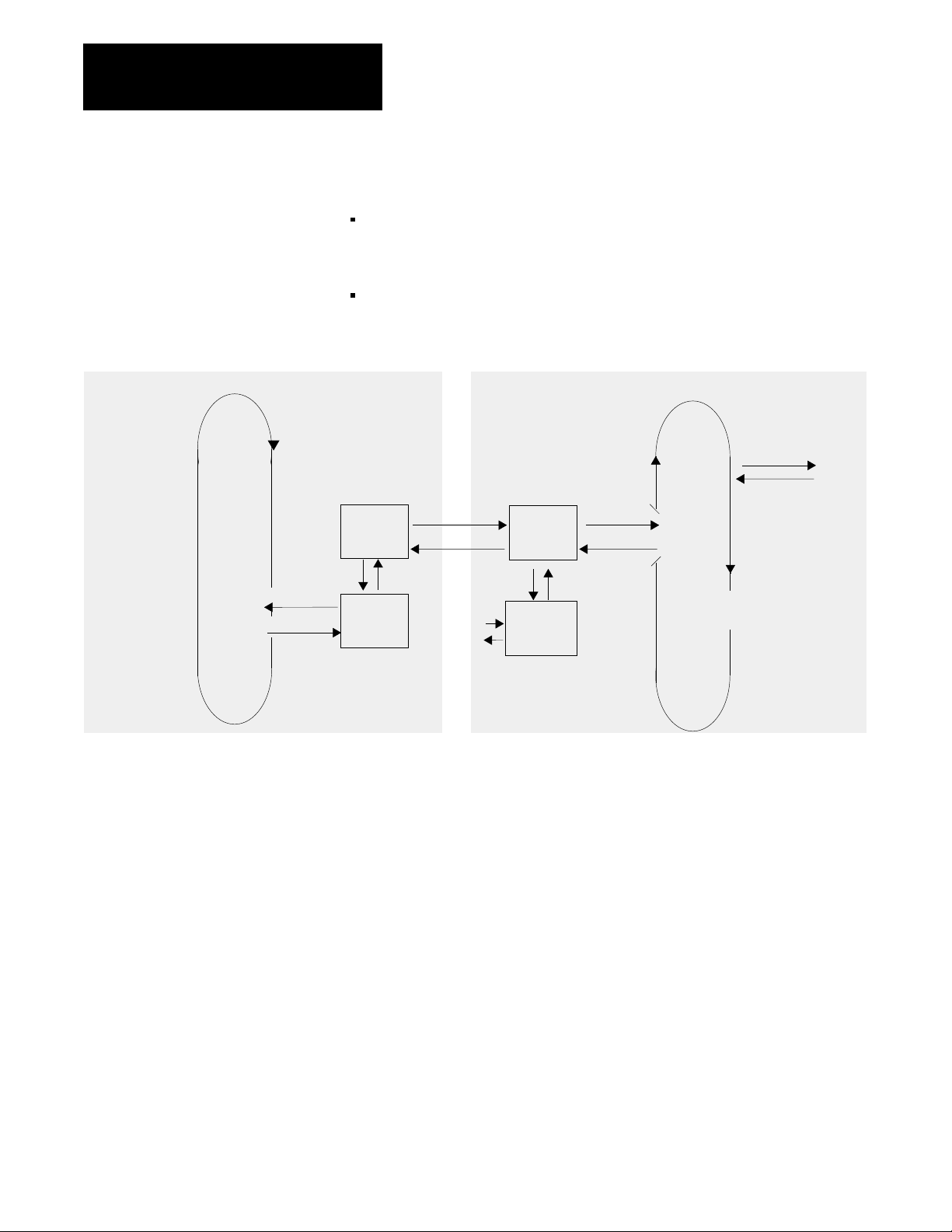

The following flow chart demonstrates a thought process that you can use

when you plan your Classic PLC-5 programmable controller system.

iv

Page 10

System Design

Determined

Select I/O

modules, terminals

Place

hardware

Preface

Assign

addressing

Configure processor

communication

Assigning

Addressing Mode,

Racks, and Groups

Select adapter modules

Select I/O chassis

Select power supply

Select PLC5 processor

Select batteries and

memory modules

Complementary I/O

selected?

Backup system

selected?

Choosing

Hardware

and

Placing

System

Hardware

Configure Data

Highway Plus

Select programming

software

Design SFCs

Data table layout and

processor status

Use fault routines

Transfer data in adapter

and scanner modes

I/O update and ladder

program scan times

Choosing

Communication

Planning Your

System Programs

Transferring

Discrete and

Block Data

Calculating

Program Timing

and Maximizing

System

Performance

Since your decisions cannot always be made as a part of a strictly linear

process, you can choose to complete tasks in parallel. When you select

your I/O modules, for example, you can also begin to lay out and address

your modules. Consult chapter 3, “Placing System Hardware,” to

determine environmental requirements, enclosures needed, cable layout,

and grounding requirements for your chassis and I/O links. Also, you can

choose to assess block-transfer timing when you determine where you will

place your block-transfer modules (in the processor-resident local I/O

chassis, extended-local I/O chassis, or remote I/O chassis).

v

Page 11

Chapter

Understanding Your System

1

Using this Chapter

Understanding the Terms

Used in this Chapter

If you want to read about: Go to page:

Terms used in this chapter 11

Designing systems 12

Preparing your functional specification 13

Identifying Classic PLC5 processor features 15

Using the Classic PLC5 processor as a remote I/O scanner 18

Using the Classic PLC5 processor as a remote I/O adapter 19

Become familiar with the following terms and their definitions.

Term Definition

Processorresident

local I/O chassis

Processorresident

local I/O

Remote I/O link a serial communication link between a PLC5 processor port in scanner

the I/O chassis in which the PLC5 processor is installed

I/O modules located in the same chassis as the PLC5 processor

mode and an adapter as well as I/O modules that are located remotely

from the PLC5 processor

Remote I/O chassis the hardware enclosure that contains an adapter and I/O modules that

are located remotely on a serial communication link to a PLC5

processor in scanner mode

Discretetransfer data data (words) transferred to/from a discrete I/O module

Blocktransfer data data transferred, in blocks of data up to 64 words, to/from a block

transfer I/O module (for example, an analog module)

1-1

Page 12

Chapter 1

Understanding Your System

Designing

Centralized

Systems

control

is a

hierarchical system where control

over an entire process is

concentrated in one processor

Distributed

control

is a system in

which control and management

functions are spread throughout a

plant. Multiple processors handle

the control and management

functions and use a Data

Highway

or a bus system

for communication.

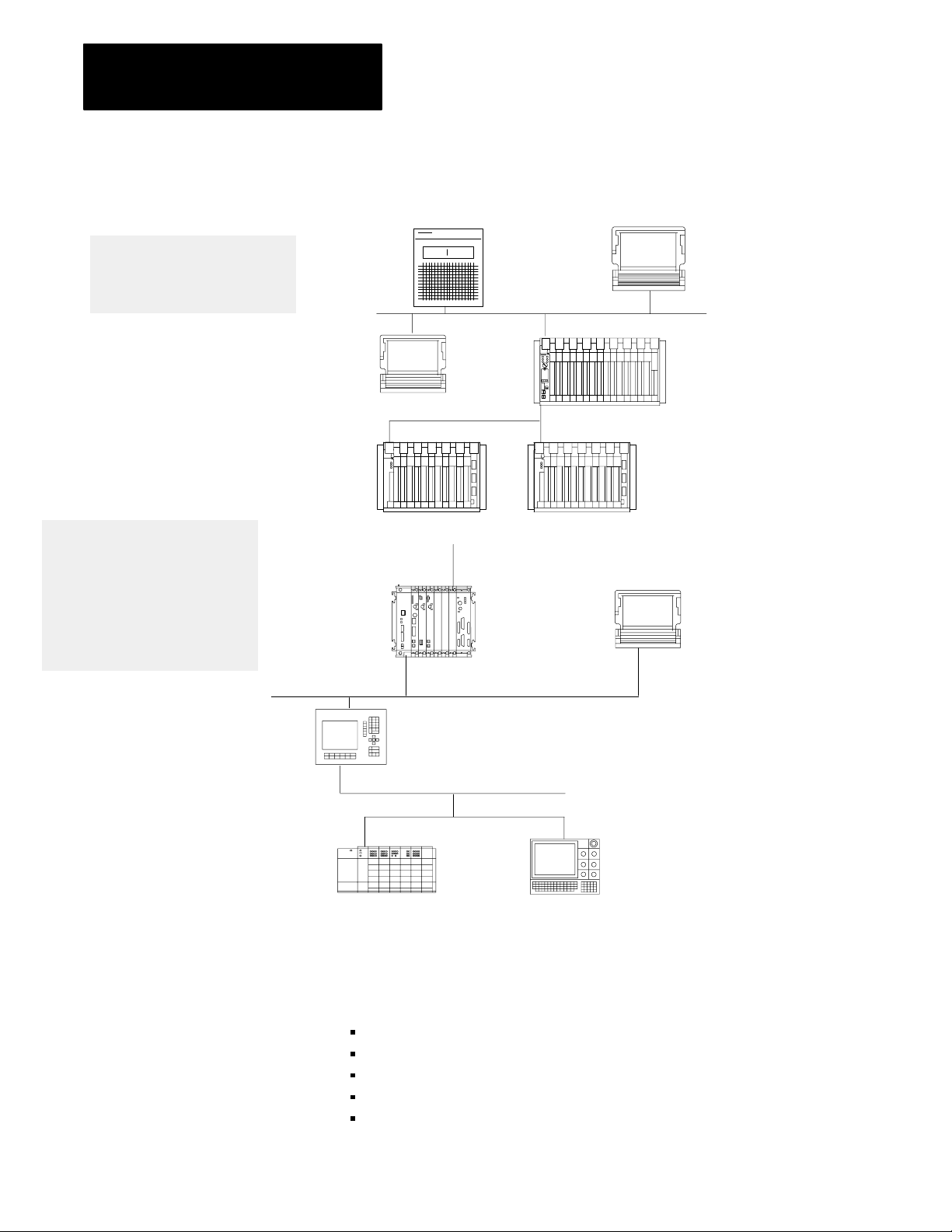

You can use Classic PLC-5 processors in a system that is designed for

centralized control or in a system that is designed for distributed control.

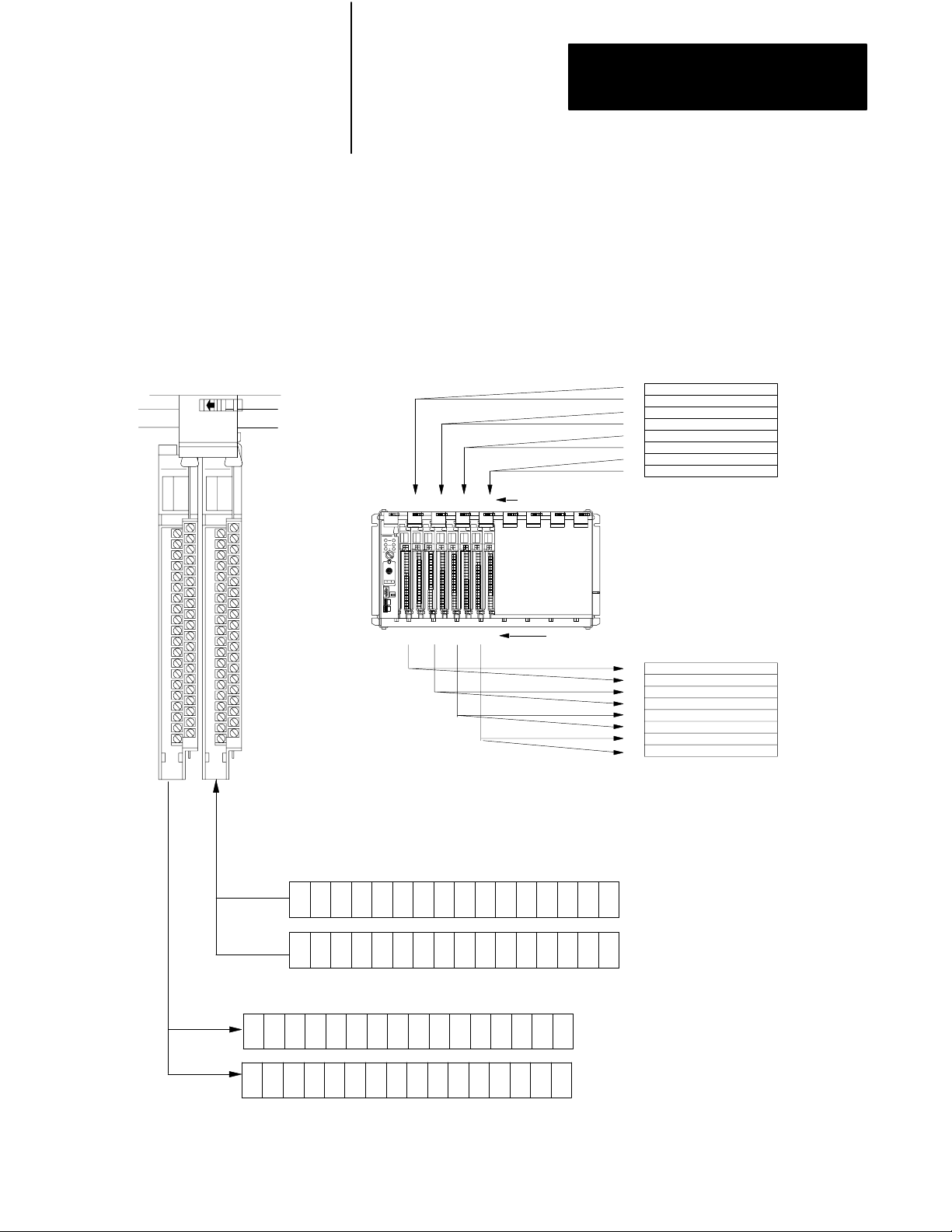

HP 9000

or VAX

Host

.

Programming

Terminal with

ControlView

Software

Remote I/O Link

Chassis with Chassis with

1771ASB

Remote I/O

Adapter

r

6200 VMS

INTERCHANGE

Software

Pyramid

Integrator

To DECnet

DH+ Link

Classic PLC5

Processor

1771ASB

Remote I/O

Adapter

Programming

Terminal

Programming Terminal

ControlView

INTERCHANGE

Software

DH+ Link

PanelView

Operator

Terminal

SLC 5/01 Processor

7slot Modular System

with 1747DCM Module

Remote I/O Link

Series 8600

CNC with

Remote I/O

Consider the following items as general guidelines when designing

your system.

Will your processor(s) be used in a centralized or distributed system?

What type of process(es) will be controlled by the PLC-5 system?

What processes will be controlled together?

What are the environmental and safety concerns?

What is the flow and functionality of your system?

18084

1-2

Page 13

System Design

Determined

Select I/O

modules, terminals

Place

hardware

Chapter 1

Understanding Your System

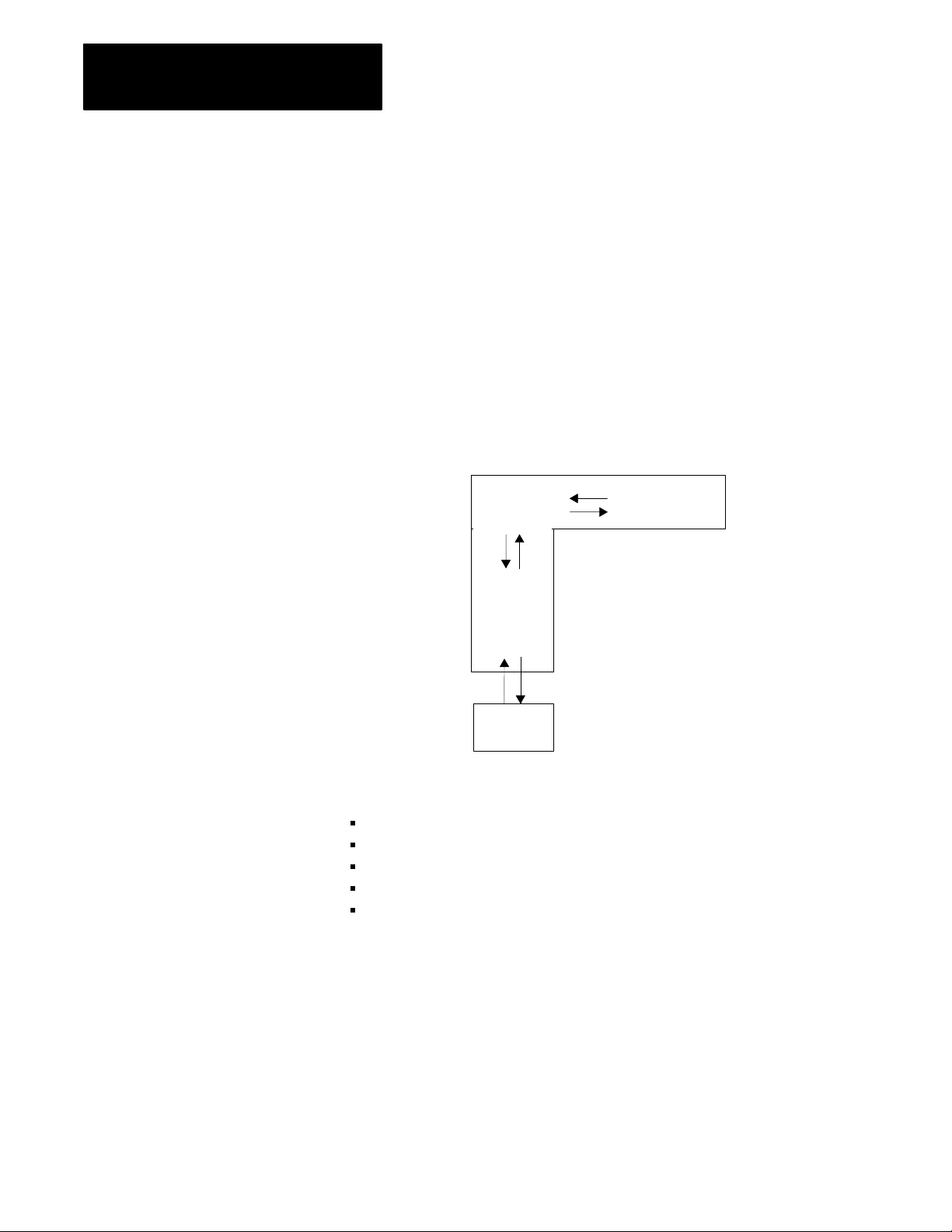

Determine the general criteria for your system. Use the chapters that

follow to guide you through the criteria and choices for selecting the major

Classic PLC-5 programmable controller system elements, as shown in

Figure 1.1.

Figure 1.1

Processor System Design Flow

PLC5

Assign

addressing

Configure processor

communication

Assigning

Addressing Mode,

Racks, and Groups

Select adapter modules

Select I/O chassis

Select power supply

Select Classic PLC5

processor

Select batteries and

memory modules

Complementary I/O

selected?

Backup system

selected?

Preparing Your

Functional Specification

Choosing

Hardware

and

Placing

System

Hardware

Configure Data

Highway Plus

Select programming

software

Design SFCs

Data table layout and

processor status

Use fault routines

Transfer data in adapter

and scanner modes

I/O update and ladder

program scan times

Choosing

Communication

Planning Your

System Programs

Transferring

Discrete and

Block Data

Calculating

Program Timing

and Maximizing

System

Performance

We recommend that you first develop a specification that defines your

hardware selection and your programming application. The specification

is a conceptual view of your system. Use it to determine your:

control strategy

hardware selection, layout, and addressing

sequential function chart (SFC)

special programming features

ladder-logic requirements

1-3

Page 14

Chapter 1

Understanding Your System

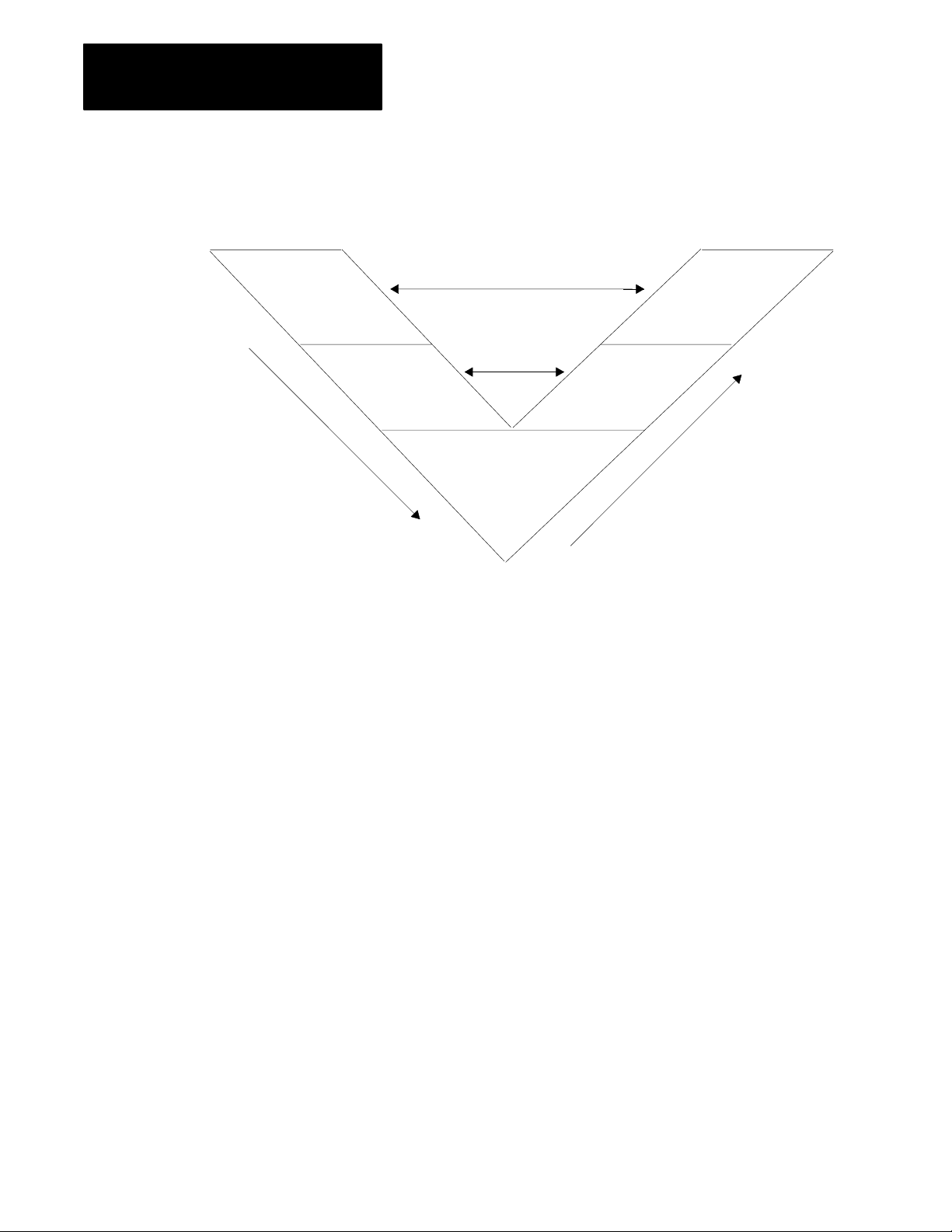

Figure 1.2 illustrates a program-development model that you can use.

Figure 1.2

ProgramDevelopment

Functional

Specification

(General Conception)

Model

Acceptance

Signoff

Detailed

Anaylsis

Program

Development

Testing

This model allows for the interaction of activities at the different levels.

Each section represents an activity that you perform. Prepare a functional

specification to start; then, prepare the detailed analysis.

Based on the detailed analysis, you can also develop your programs, enter

your programs, and test them. When testing is complete, you are ready to

implement the programs in your application. The detailed analysis can be

used as the basis for developing your testing procedures and requirements.

Because the functional specification is well thought out, it can be used as

the program sign-off document.

Functional Specification Content

1-4

The functional specification represents a very general view of your process

or a description of operation. Identify the events and the overall order in

which they must occur. Identify the equipment that you will need for your

process/operation. Generally indicate the layout of your system. If your

application requires a distributed control system, for example, indicate

where you will need remote I/O links. Also, you can have a process that is

located close to your processor. The process can require faster update time

than that provided by a remote I/O link, so you can select an extendedlocal I/O link for that process.

Important: Choose a communication rate for your remote I/O link at

which every device on the link can communicate.

Page 15

Chapter 1

Understanding Your System

The program-development portion of your functional specification can be

in any form: written statement; flowchart; or rough-draft MCPs, SFCs,

and subroutines. Use the form that is most familiar to you. We

recommend, however, that you generate rough-draft SFCs and subroutines

so that you have a better correspondence between your beginning diagrams

and your finished program.

Detailed Analysis

In this phase, you identify the logic needed to plan your programs. This

includes inputs, outputs, specific actions, and transitions between actions

(i.e., the bit-level details needed to write your program).

Program Development

Introducing

Classic PLC5

Processor Modules

You enter the programs either offline into your computer or online into a

processor. In the next phase, you test the programs that you have entered.

Once testing is complete, your resulting programs should match your

functional specification.

Checking for Completeness

When you complete the functional specification and the detailed analysis,

review them and check for missing or incomplete information such as:

input conditions

safety conditions

startup or emergency shutdown routines

alarms and alarm handling

fault detection and fault handling

message display of fault conditions

abnormal operating conditions

The following is a list of the PLC-5 processors and their catalog numbers.

Processor Catalog Number

PLC5/10t

PLC5/12t

PLC5/15t

PLC5/25t

1785LT4

1785LT3

1785LT

1785LT2

For information on other PLC-5 processors (Enhanced, Ethernet, or

ControlNet), see your Allen-Bradley representative.

1-5

Page 16

Chapter 1

Understanding Your System

Classic PLC5 Family Processor Features

From the family of PLC-5 processors, you can choose the processor(s)

that you need for your application. Features common to all Classic PLC-5

processors are:

same physical dimensions

use of the left-most slot in the 1771 I/O chassis

can use any 1771 I/O module in the processor-resident local I/O chassis

with up to 32 points per module

same programming software and programming terminals

same base set of instructions

ladder programs and SFCs can be used by any of the PLC-5 processors

Check with your Allen-Bradley sales office or distributor if you have

questions regarding any of the features of your PLC-5 processor.

Subprogram Calls

Use a subroutine to store recurring sections of program logic that can be

accessed from multiple program files. A subroutine saves memory

because you program repetitive logic only once. The JSR instruction

directs the processor to go to a separate subroutine file within the logic

processor, scan that subroutine file once, and return to the point

of departure.

For detailed information about how you generate and use subroutines, see

your programming software documentation set.

Sequential Function Charts

Use SFCs as a sequence-control language to control and display the state

of a control process. Instead of one long ladder program for your

application, divide the logic into steps and transitions. A step corresponds

to a control task; a transition corresponds to a condition that must occur

before the programmable controller can perform the next control task. The

display of these steps and transitions lets you see what state the machine

process is in at a given time.

1-6

For detailed information about how you generate and use SFCs, see you

programming software.

Ladder Logic Programs

A main program file can be an SFC file numbered 1-999; it can also be a

ladder-logic file program numbered 2-999 in any program file.

Page 17

Chapter 1

Understanding Your System

Consider using this technique:

SFC

Ladder Logic

If you are:

• defining the order of events in a sequential process

• more familiar with ladder logic than with programming

languages such as BASIC

• performing diagnostics

• programming discrete control

For detailed information about how you use ladder logic, see your

programming software documentation.

Backup System

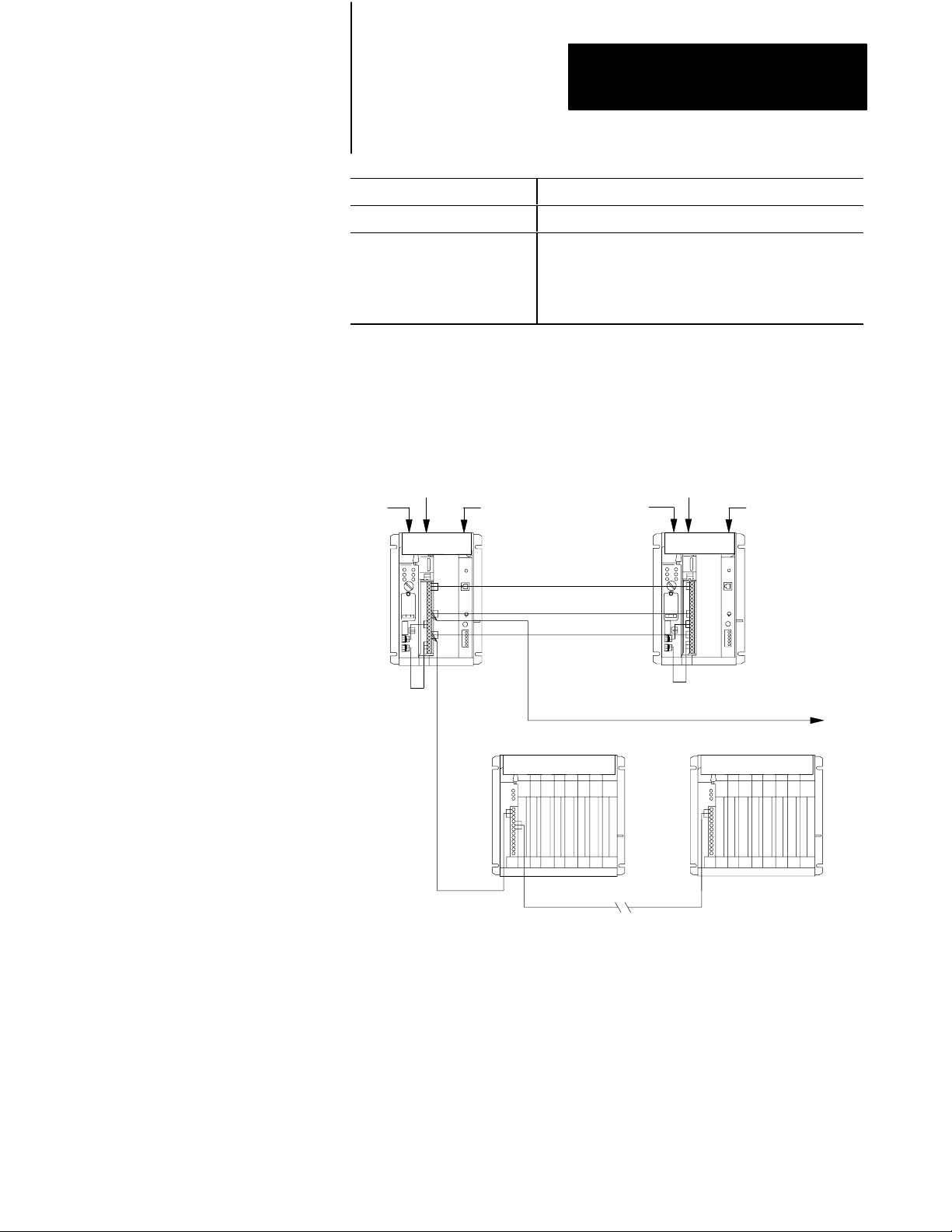

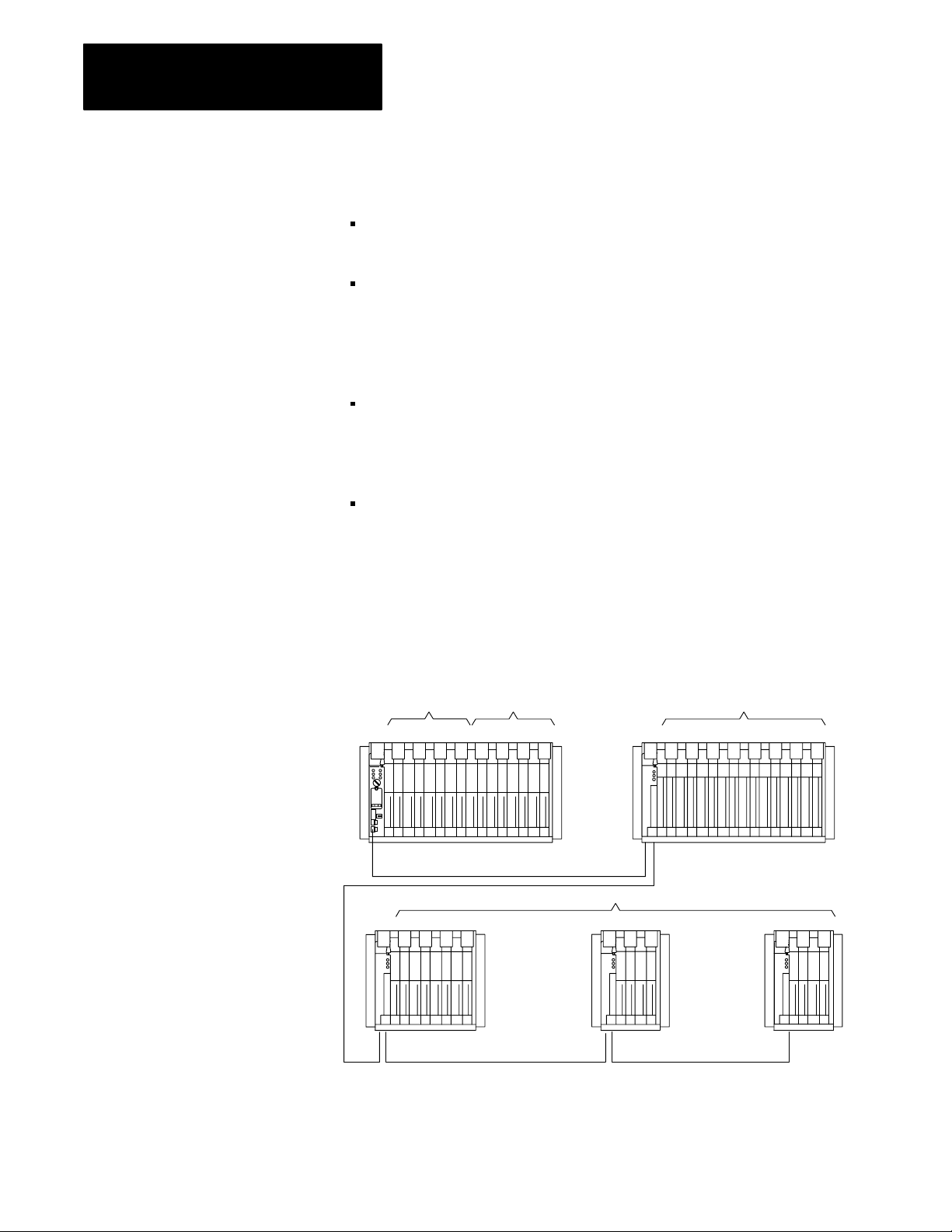

The following diagram shows a typical PLC-5 backup system:

Local I/O Chassis

1785BCM Module

PLC5

Processor

1771P4S

Power Supply

HSSL

DH+ Link

Remote I/O Link

Local I/O Chassis

1785BCM Module

PLC5

Processor

1771P4S

Power Supply

DH+ LInk

Remote I/O Chassis Remote I/O Chassis

Remote I/O Link

18691

In a PLC-5 backup system configuration, one system controls the operation

of remote I/O and DH+ communications. This system is referred to as the

“primary system.” The other system is ready to take control of the remote

I/O and DH+ communications in the event of a fault in the primary system.

This is referred to as the “secondary system.”

See chapter 2, “Choosing Hardware,” to select backup system hardware.

See the PLC-5 Backup Communication Module User Manual, publication

1785-6.5.4, for more information on configuring a PLC-5 backup system.

1-7

Page 18

Chapter 1

Understanding Your System

Using the Classic PLC5

Processor as a Remote I/O

Scanner

Use scanner mode whenever you want a Classic PLC-5 processor to scan

and control remote I/O link(s). The scanner-mode processor also acts as a

supervisory processor for other processors that are in adapter mode.

The scanner-mode processor scans the processor memory file to read

inputs and control outputs. The scanner-mode processor transfers

discrete-transfer data and block-transfer data to/from the processor-resident

local rack as well as to/from modules in remote I/O racks.

A PLC-5 processor scans processor-resident local I/O synchronously to the

program scan. A PLC-5 processor scans remote I/O asynchronously to the

program scan, but the processor updates the input/output image data table

from the remote I/O buffer(s) synchronously to the program scan. This

occurs at the end of each program scan.

ProcessorResident

Local I/O Scan

Synchronous to

Program Scan

ScannerMode

PLC5

Processor

Input

Output

Remote

I/O

Buffer

Input

Output

Processor

Resident

I/O

Remote I/O

Scan

Asynchronous to

Program Scan

OutputInput

Remote I/O

Link

The scanner-mode PLC-5 processor can also:

gather data from node adapter devices in remote I/O racks

process I/O data from 8-, 16-, or 32-point I/O modules

address I/O in 2-, 1-, or 1/2-slot I/O groups

support a complementary I/O configuration

support block transfer in any I/O chassis

Configure the PLC-5/15 or -5/25 processor for scanner mode by setting

switch assembly SW1.

1-8

Page 19

Chapter 1

Understanding Your System

Using the Classic PLC5

Processor

as a Remote I/O Adapter

Use a Classic PLC-5 processor (except the PLC-5/10 processor) in adapter

mode when you need predictable, real-time exchange of data between a

distributed control PLC-5 processor and a supervisory processor. You

connect the processors via the remote I/O link (see Figure 1.3). You can

monitor status between the supervisory processor and the adapter-mode

PLC-5 processor at a consistent rate (i.e., the transmission rate of the

remote I/O link is unaffected by programming terminals and other

non-control-related communications).

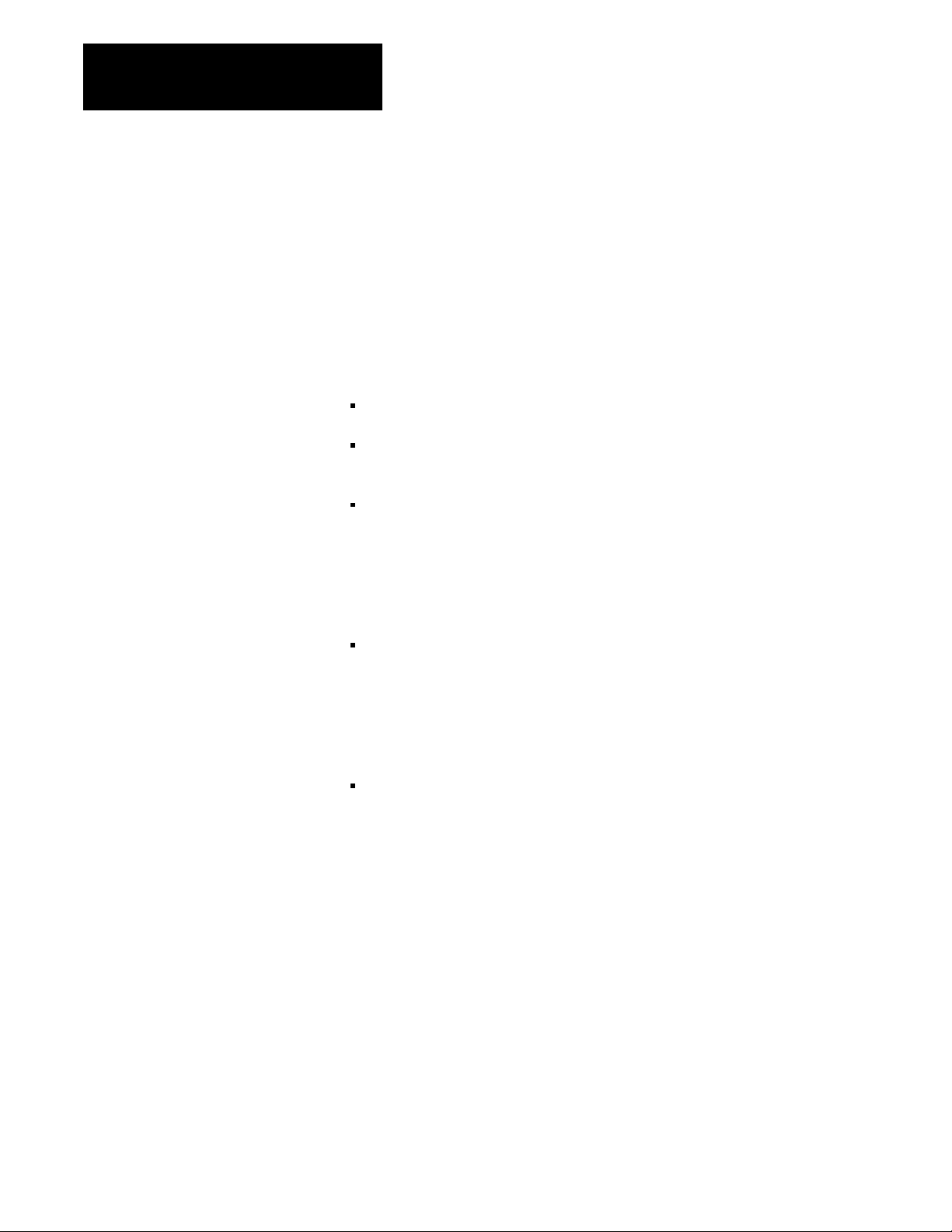

Figure 1.3

AdapterMode

Supervisory

Processor

1

The following programmable controllers can operate as supervisory processors:

PLC2/20t and PLC2/30t processors

PLC3t and PLC3/10t processors

PLC5/11, 5/15, 5/20, 5/25, and 5/30 processors as well as PLC5/VMEt processors

PLC5/40, 5/40L, 5/60, 5/60L, and 5/80 processors as well as PLC5/40BVt and

PLC5/40LVt processors

PLC5/20Et, 5/40Et

PLC5/250t

2

All PLC5 family processors, except the PLC5/10, can operate as remote I/O adapter modules.

Communication

1

Remote I/O Link

PLC5

Processor

in Adapter

2

Mode

1771

I/O

Remote I/O Link

DL40

Message

Display

The PLC-5 processor in adapter mode acts as a remote station to the

supervisory processor. The adapter-mode PLC-5 processor can monitor

and control its processor-resident local I/O while communicating with the

supervisory processor via a remote I/O link.

The supervisory processor communicates with the PLC-5/12, -5/15, or

-5/25 adapter with either eight or four I/O image table words.

A PLC-5 processor transfers I/O data and status data using discrete

transfers and block transfers. You can also use block-transfer instructions

to communicate information between a supervisory processor and an

adapter-mode processor. The maximum capacity per block transfer is

64 words.

1-9

Page 20

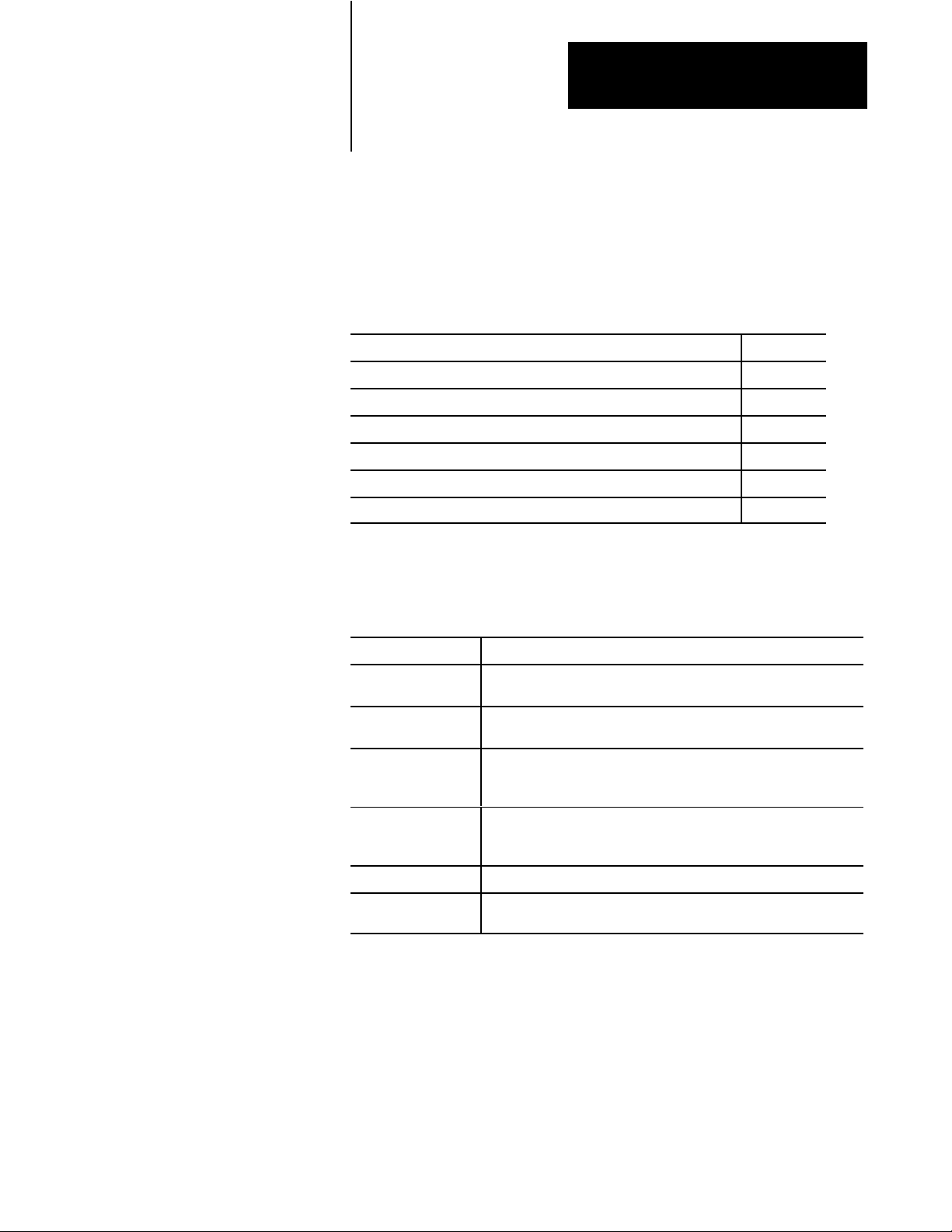

Choosing Hardware

Chapter

2

Chapter

Objectives

Selecting I/O Modules

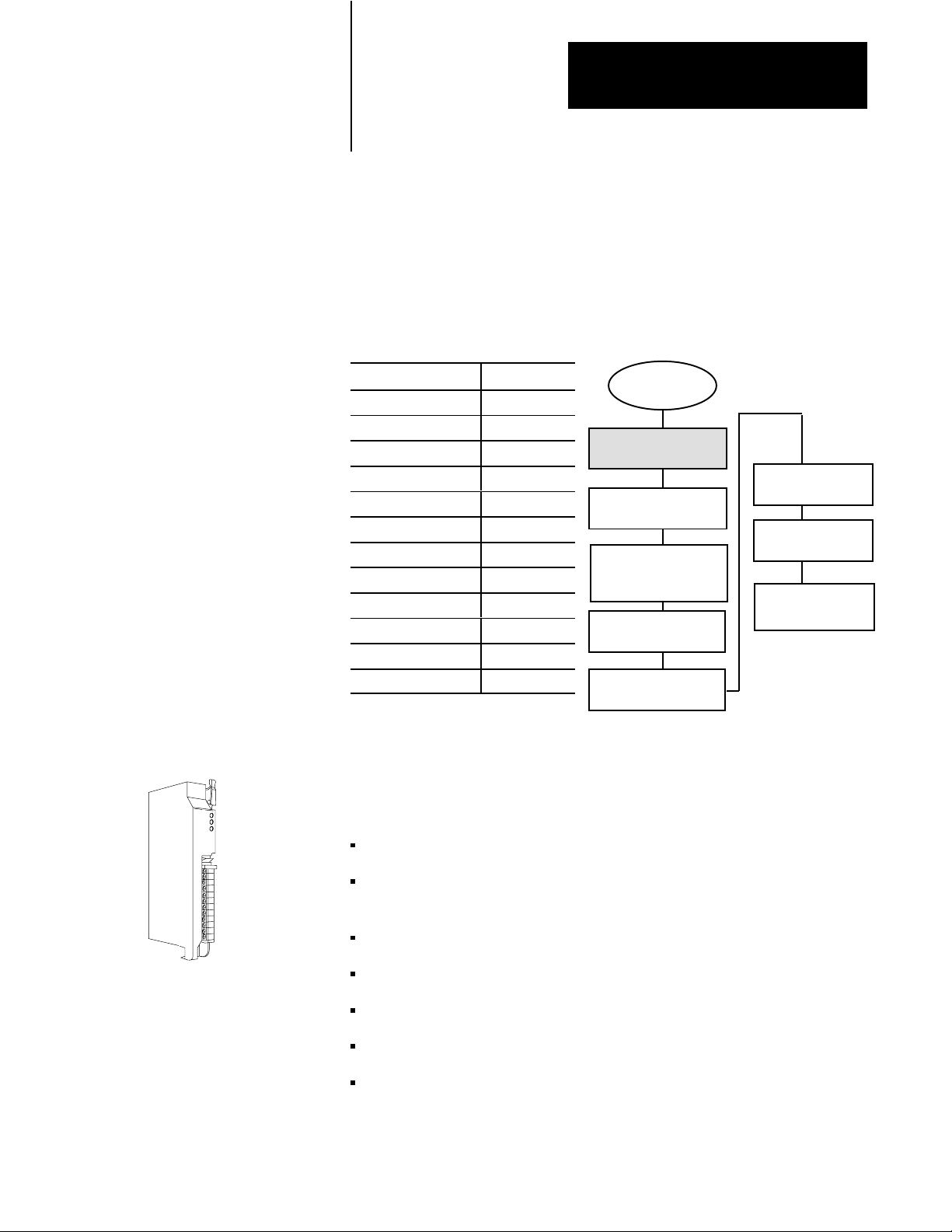

Use this chapter to guide you in the selection of system hardware for

your application.

To select: Go to page:

I/O modules 21

I/O adapters 24

Chassis 26

Operator interface 26

PLC5 processor 29

Power supplies 29

Memory modules 213

Batteries 213

Complementary I/O 213

Backup system 214

Termination resistor 215

Cables 215

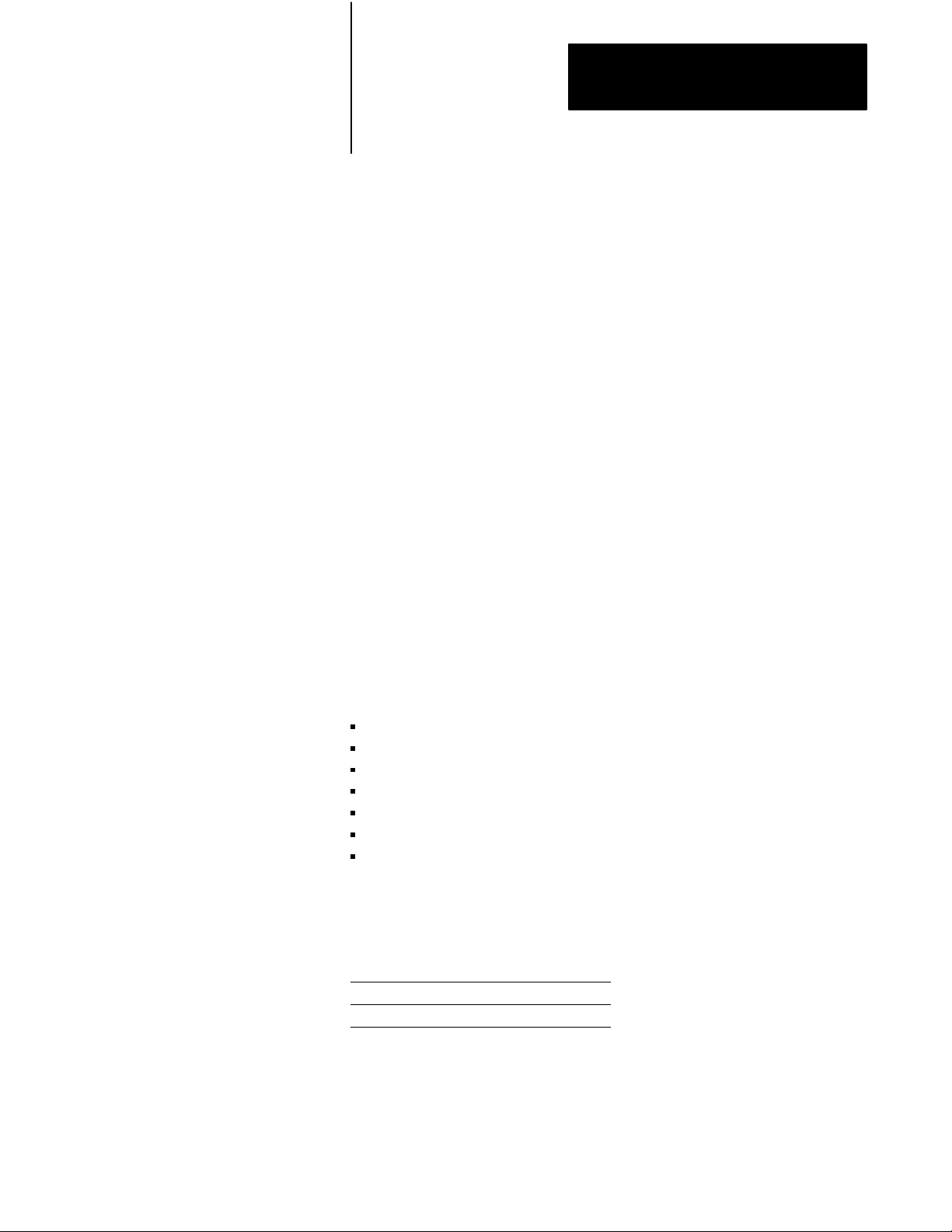

System Design

Determined

Choosing Hardware

Placing System

Hardware

Assigning Addressing

Mode, Racks,

and Groups

Choosing

Communication

Planning Your

System Programs

Selecting Interrupt

Routines

Transferring Discrete

and Block Data

Calculating Program

Timing

You select I/O modules to interface your PLC-5 processor with machines

or processes that you have previously determined.

Use the following list and Table 2.A as guidelines for selecting I/O

modules and/or operator control interface(s).

How much I/O is required to control the process(es)?

Where will you concentrate I/O points for portions of an entire process

(when an entire process is distributed over a large physical area)?

What type of I/O is required to control the process(es)?

What is the required voltage range for each I/O module?

What is the backplane current required for each I/O module?

What are the noise and distance limitations for each I/O module?

What isolation is required for each I/O module?

2-1

Page 21

Chapter 2

Choosing Hardware

Table 2.A

Guidelines

Choose this type of

I/O module:

Discrete input module

and block I/O module

Discrete output module

and block I/O module

Analog input module Temperature transducers, pressure transducers, load cell transducers,

Analog output module Analog valves, actuators, chart recorders, electric motor drives,

Specialty I/O modules Encoders, flow meters, I/O communication, ASCII, RF type devices,

1

A 1791 block I/O module is a remote I/O device that has a power supply, remote I/O adapter, signal conditioning circuitry, and I/O

connections. A block I/O module does not require a chassis mount. It is used to control concentrated discrete remote I/O such as control

panels, pilot lights, and status indications.

For these types of field devices or operations (examples): Explanation:

Selector switches, pushbuttons, photoelectric eyes, limit switches,

1

circuit breakers, proximity switches, level switches, motor starter

contacts, relay contacts, thumbwheel switches

Alarms, control relays, fans, lights, horns, valves, motor

1

starters, solenoids

humidity transducers, flow transducers, potentiometers

analog meters

weigh scales, barcode readers, tag readers, display devices

for Selecting I/O Modules

Important: Determine addressing in conjunction with I/O module

selection. The selection of addressing and the selection of I/O module

density are mutually dependent.

Input modules sense ON/OFF or OPENED/

CLOSED signals. Discrete signals can be either

ac or dc.

Output module signals interface with ON/OFF or

OPENED/CLOSED devices. Discrete signals can

be either ac or dc.

Convert continuous analog signals into input

values for PLC processor.

Interpret PLC processor output to analog signals

(generally through transducers) for field devices.

Are generally used for specific applications such

as position control, PID, and external device

communication.

Selecting I/O Module Density

The density of an I/O module is the number of processor input or output

image table bits to which it corresponds. A bidirectional module with 8

input bits and 8 output bits has a density of 8. Table 2.B provides

guidelines for selecting I/O module density.

Table 2.B

Guidelines

Choose this I/O density: If you:

8point I/O module

16point I/O module

32point I/O module

for Selecting I/O Module Density

• currently use 8point modules

• need integral, separatelyfused outputs

• want to minimize cost per module

• currently use 16point modules

• need separately fused outputs with a special wiring arm

• currently use 32point modules

• want to minimize number of modules

• want to minimize the space required for I/O chassis

• want to minimize cost per I/O point

2-2

Page 22

Chapter 2

Choosing Hardware

Master/Expander I/O Modules

Some I/O modules (called “masters”) communicate with their expanders

over the backplane. These master/expander combinations either:

can time-share the backplane, or

cannot time-share the backplane

For masters that can time-share the backplane, you can use two masters in

the same chassis. For a master/expander combination that cannot

time-share the backplane, you cannot put another master/expander

combination in the same I/O chassis.

Example: The stepper-controller module (cat. no. 1771-M1, part of a

1771-QA assembly) and the servo-controller module (cat. no. 1771-M3,

part of a 1771-QC assembly) always act as masters and cannot time-share

the backplane. Therefore, you cannot put a second master module in the

same chassis with either of these modules.

Table 2.C summarizes the compatibility of master modules within a single

I/O chassis.

Table 2.C

Compatibility

1st Master

Module

1771IX

1771IF

1771OF

1771M1

1771M3

1

2

of Master Modules within a Single I/O Chassis

2nd Master Module

1

1771IX

1

1

1

1771IF1 1771OF1 1771M1 1771M3

2

Valid

2

Valid

2

Valid

These

modules have been superseded by 1771IXE, IFE, and OFE master modules that

do not exhibit the master/expander conflict in a chassis as 1771IX, IF

modules shown in this table.

These are the only master combinations that you can use in a single I/O chassis. These

combinations are valid with or without the module'

M3 have expander modules). Y

chassis; you can use any other intelligent I/O modules not shown here with these masters.

2

Valid

2

Valid

ou can use a maximum of two masters in the same

2

Valid

2

Valid

2

Valid

s associated expanders (1771M1 and

, and OF master

Important: Density is not relevant to an expander module because it

communicates only with its master; an expander module does not

communicate directly with an adapter.

2-3

Page 23

Chapter 2

Remote I/O Adapter

I/O Density

Choosing Hardware

Selecting I/O Adapter

Modules

ASB

ALX

Select I/O adapter modules to interface your PLC-5 processor with I/O

modules. Use Table 2.D as a guide when you select I/O adapter modules.

Table 2.D

Guidelines

Choose: When your requirements are:

1771AS or 1771ASB

Remote I/O Adapter Module

(or 1771AM1, AM2 chassis

with integral power supply and

adapter module)

1771ALX ExtendedLocal I/O

Adapter Module

1

1771ASB

series C and later have 230.4 kbps communication rate in addition to 57.6 kbps and 1

for Selecting Adapter Modules

1

a remote I/O link with:

• 57.6 kbps with a distance of up to 10,000 cable feet or

• timing that isn't critical enough to place I/O modules in a processor local

I/O chassis or an extendedlocal I/O chassis

an extendedlocal I/O link with timing that is critical and all extendedlocal

I/O chassis are located within 100 ft of the processor.

17 71AS/ASB Remote I/O Adapter Modules

Table 2.E shows the I/O density per module and addressing modes you can

use with I/O chassis and remote I/O adapter modules.

Table 2.E

Chassis/Adapter Module Combinations

I/O

15.2 kbps.

Remote I/O Adapter I/O Density

Module Cat. No.

1771AS 8

1771ASB

Series A

1771ASB

Series B, C, and D

1771AM2 8

1

Conditional

adjacent slots (even/odd pair) of the I/O chassis beginning with slot 0. If you cannot pair the

modules this way

module placement; you must use an input module and an output module in two

, leave the adjacent slot empty

per Module

16

32

8

16

32

8

16

32

16

32

.

2Slot 1Slot 1/2Slot

Yes

1

No

Yes

1

No

Yes

1

No

Addressing

No

No

No

Yes

Yes

1

Yes

Yes

1

Yes

Yes

1

No

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Using the 1771-ASB Series C or D adapter module, you can choose one of

three communication rates: 57.6 kbps, 115.2 kbps, or 230.4 kbps.

2-4

Page 24

Chapter 2

Module C

I/O Density

Choosing Hardware

1771ALX ExtendedLocal I/O Adapter Module

Table 2.F shows the I/O density per module and addressing modes you can

use with I/O chassis and extended-local I/O adapter modules.

Table 2.F

Chassis/Extended Local I/O Adapter Module Combinations

I/O

at. No.

1771ALX

Series A

1

Conditional

module placement; you must use an input module and an output module in two adjacent slots (even/

odd pair) of the I/O chassis beginning with slot 0. If you cannot pair the modules this way

empty.

I/O Density

per Module

8

16

32

2Slot 1Slot 1/2Slot

Yes

1

No

Addressing

Yes

Yes

1

, leave the adjacent slot

Other Devices on an I/O Link

Other devices that you can use on a remote I/O link are:

PLC-5 processor in adapter mode

PLC-5/250 remote scanner in adapter mode

PLC interface module for digital ac and dc drives

remote I/O adapter for Bulletin 1336 drives

RediPANELt pushbutton and keypad modules

Datalinert

PanelView (see operator interface)

F30D option module (for T30 plant-floor terminal)

8600 or 9/SERIES CNC with remote I/O adapter option

CVIMt in adapter mode

Pro-Spect 6000 Fastening System with remote I/O adapter option

1747-DCM module (to SLC-500 rack)

1771-DCM module

1771-GMF robot (remote I/O interface module)

Yes

Yes

Yes

See the appropriate Allen-Bradley product catalog for more information on

these devices.

2-5

Page 25

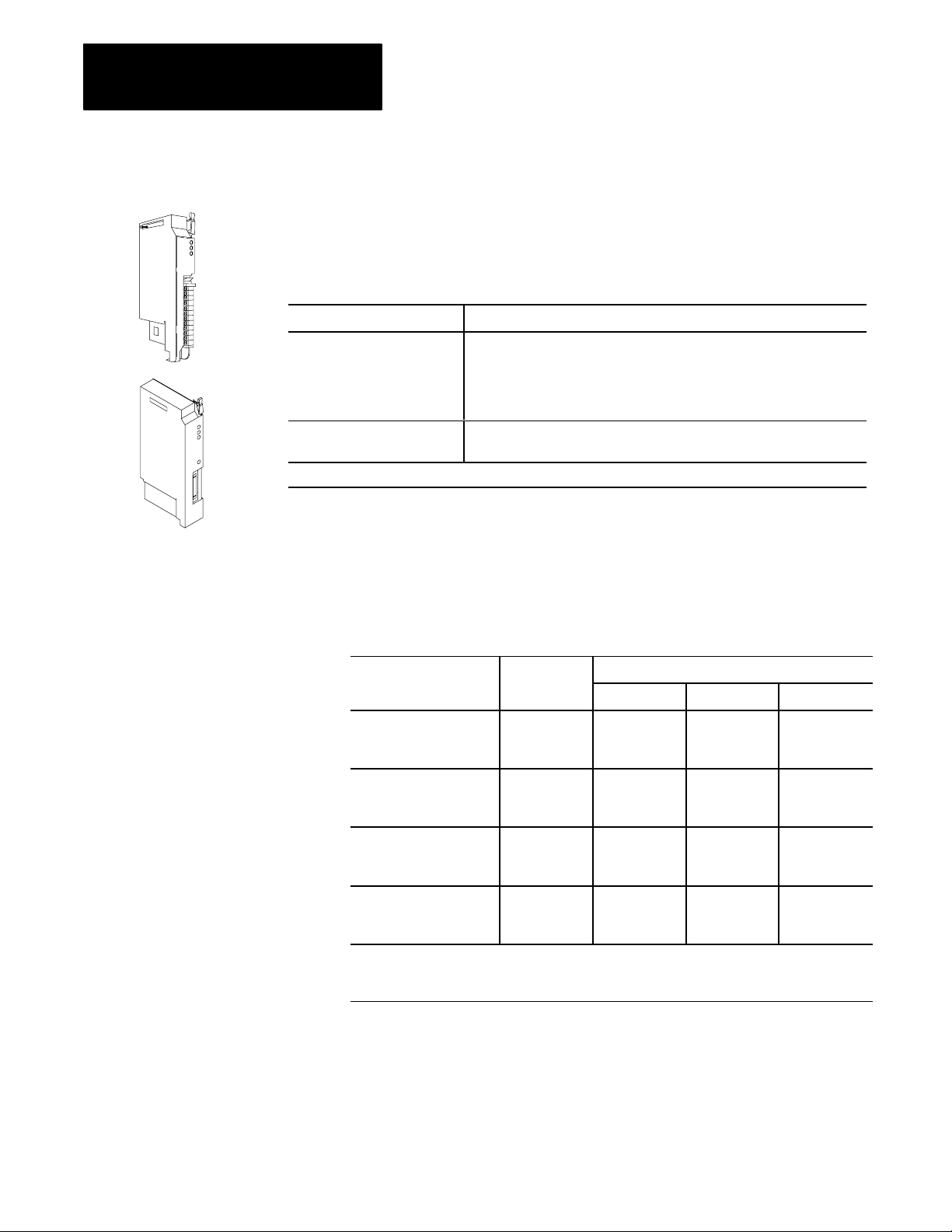

Chapter 2

Choosing Hardware

Selecting

I/O Chassis

4-Slot

1771A1B

An I/O chassis is a single, compact enclosure for the processor,

power-supply modules, remote and extended-local I/O adapter modules,

and I/O modules. The left-most slot of the I/O chassis is reserved for the

processor or adapter module. Consider the following when selecting

a chassis:

When you determine the maximum number of I/O in your application,

allow space for the I/O slots dedicated to power-supply modules,

communication modules, and other intelligent I/O modules.

You must use series B or later chassis with 16- and 32-point

I/O modules.

Allow space for future addition of I/O modules to chassis.

I/O chassis available are:

4-slot (1771-A1B)

8-slot (1771-A2B)

12-slot—rack mount (1771-A3B), panel mount (1771-A3B1)

16-slot (1771-A4B)

You can also choose a chassis with an integral power supply and remote

I/O adapter (show at left). The two types are:

1771AM1

1771AM2

Selecting an Operator

Interface

1-slot (1771-AM1)

2-slot (1771-AM2)

PanelView and ControlView are operator interface products or packages

that communicate with a PLC-5 processor. Use Table 2.G as a guideline

when selecting either PanelView or ControlView for your PLC-5

programmable controller system. Use Table 2.H for a comparison of

PanelView and ControlView features.

2-6

Page 26

Table 2.G

Guidelines

Chapter 2

Choosing Hardware

for Selecting an Operator Interface

Choose this

operator interface:

PanelView

1

For these types of

operations (examples):

Starts/stops, auto/manual operations,

setpoints, outputs, alarms

Explanation:

Used as an operator window to enter commands that make process adjustments such

as starts/stops and loop changes. Can also be used for alarming operations. Can

communicate with a single PLC5 processor on a remote I/O link. Has a fixed number

of devices and amount of data that it can handle. Has builtin error checking. Is an

industrialhardened CRT with pushbuttons, solid state memory and processor, and no

moving parts (i.e., disk drive).

Utilizes pass through, which is the ability to download/upload via DH+/remote I/O links.

ControlView

1

Refer

1

Store, display, and manipulate data

on process performance (i.e., trends,

process graphics, formulas, reports,

and journals)

to your local AllenBradley sales of

Used as an operator window that communicates with a PLC5 processor on Data

Highway Plus (DH+) link. Designed for use as an information link. Can communicate

to multiple PLC processors. ControlView is a software package that runs on an IBMr

DOSbased personal computer.

fice or AllenBradley distributor for more information on PanelV

iew and ControlV

iew.

Table 2.H

Comparison

of PanelV

Category PanelView ControlView

Communication with

PLC processor

Remote I/O

5 block transfers per terminal maximum (32 words per transfer)

1 discrete transfer per terminal (64 words maximum, one way)

This is 8 racks of transfer

Graphics Character graphics

Create screens with PanelBuilder software

Monochrome or color (8 of 16 colors displayed at a time)

Number of

Screens per

Terminal/Workstation

8 to 12 screens of medium complexity typical

200 objects maximum per screen

Limited by terminal memory size: 128 Kbytes

Data Capacity 200 objects maximum per screen 10,000 points maximum in database

Communication

Limited by blocktransfer and discretetransfer timing

Rate

Depends on PLC processor and remote I/O link size

Hardware Keypad or Touchscreen terminals, color or monochrome

AllenBradley, IBM, or compatible computer required for

PanelBuilder software

Programming PanelBuilder software

Menudriven with fillintheblank information entry

Use PanelBuilder to create application file that defines

screens, messages, alarms, then download application file to

PanelView terminal

Messages 496 maximum per terminal Not Applicable

Alarms 496 maximum per terminal 2000 points with Alarming option

Security 8 levels 16 levels with individual operator login capability

Options Remote serial port

EEPROM or EPROM memory

iew and ControlV

DH+ link

Data Highway

Data Highway II Native Mode

Pixel Graphics

Create screens with Mouse Grafix editor option or C Toolkit

EGA, VGA, or equivalent with 256K RAM

Monochrome or color monitor

Limited only by hard disk capacity

50 data entry locations per screen

50 tags per command list per screen

300 tags/points maximum per screen

8 scan classes, each with userconfigurable foreground and

background update times; limited by performance of Data

Highway, DH+, or Data Highway II link

AB, IBM, or compatible computer with 286 or 386

processor, math coprocessor, hard disk required at each

operator station

Create data base online via the menu. Menudriven,

fillintheblank information entry, or import data via the ASCII

import capability

Create screens with the mouse GRAFIX editor option or C

toolkit option

Individual objects with security

Screen lockout

Lots of software options

iew Features

2-7

Page 27

Chapter 2

Choosing Hardware

For more information on selecting and configuring PanelView, see:

PanelView Operator Terminal and PanelBuilder Development Software

User Manual, cat. no. 2711-ND002 version C, PN40061-139-01—

request latest revision

Replacing Node Adapter Firmware for PanelView Terminals Installation

Data, PN40062-236-01—request latest revision

For more information on selecting and configuring ControlView, see:

ControlView Core User Manual, publication 6190-6.5.1

ControlView Allen-Bradley Drivers User Manual,

publication 6190-6.5.5

ControlView Networking User Manual, publication 6190-6.5.9

Other Operator Interfaces

You can use the following as operator interfaces in your PLC-5

processor system:

RediPANEL pushbutton and keypad modules

Dataliner

1784-T47 and 1784-T53 programming terminals

See the appropriate Allen-Bradley product catalog for more information on

these operator interfaces.

2-8

Page 28

Chapter 2

Choosing Hardware

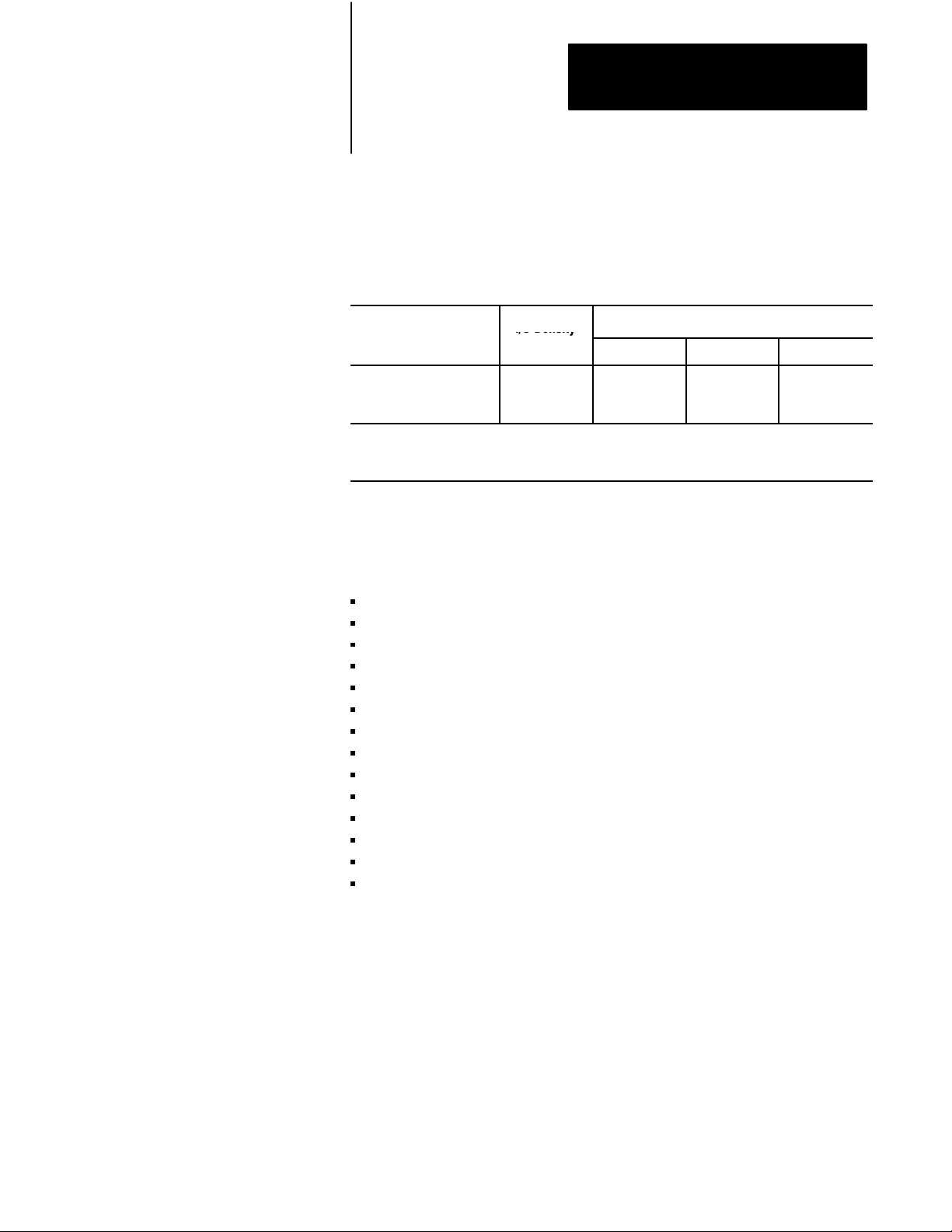

Choosing

a Classic PLC5

Processor for Your

Application

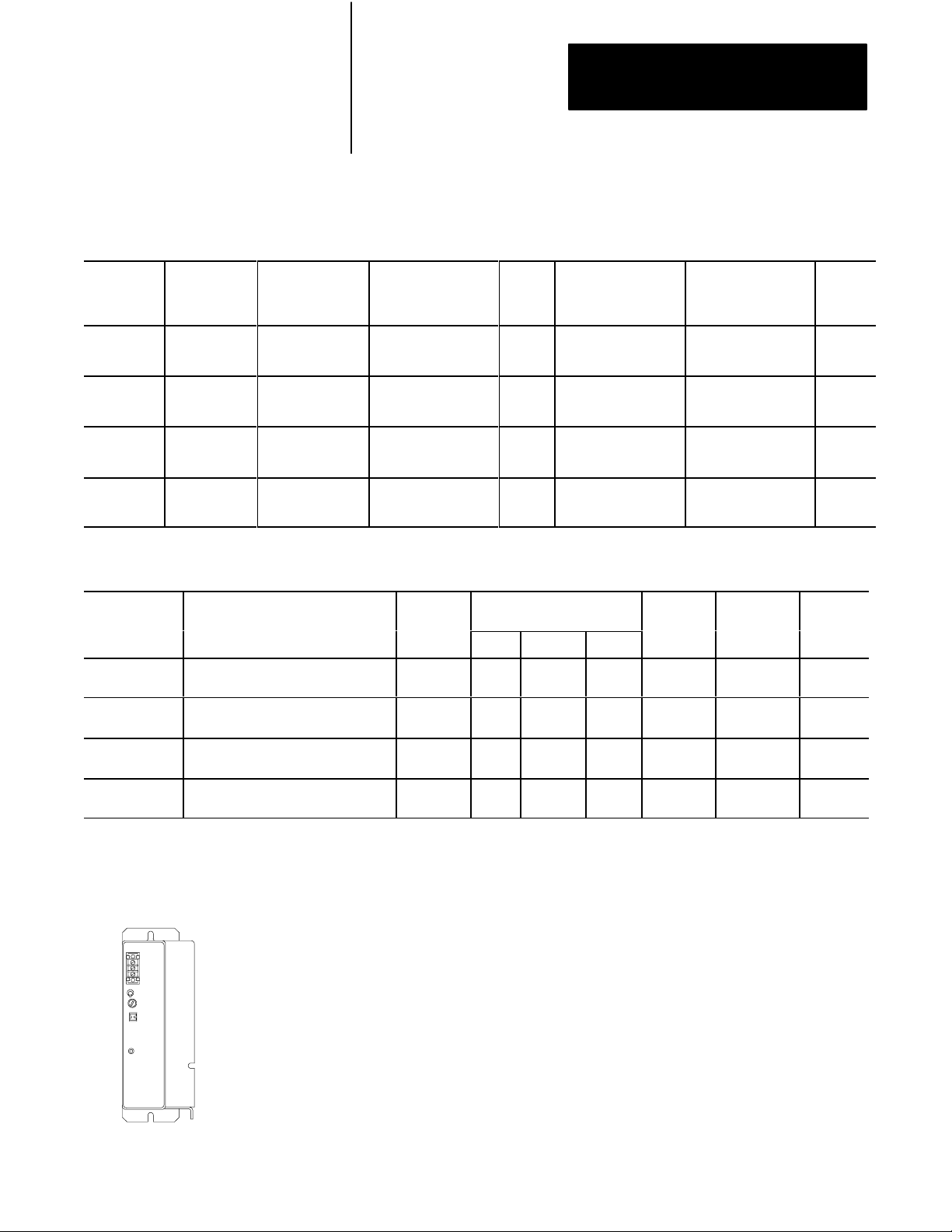

Processor/

No.

Cat.

PLC5/10

(1785LT4)

PLC5/12

(1785LT3)

PLC5/15

(1785LT)

PLC5/25

(1785LT2)

Processor/

Cat. No.

PLC5/10

(1785LT4)

PLC5/12

(1785LT3)

PLC5/15

(1785LT)

PLC5/25

(1785LT2)

Maximum User

Memory Words

6 K

6 K

6 K expandable

to 10 K or 14 K

13 K

expandable to

17 K or 21 K

Number of Remote I/O, ExtendedLocal

I/O, and DH+ Ports

•

1 DH+

•

1 DH+

•

1 Remote I/O (Adapter Only)

•1

DH+

•

1 Remote I/O (Adapter or Scanner)

•1

DH+

•

1 Remote I/O (Adapter or Scanner)

EEPROM Module

Memory (W

Module Number

8 K (1785MJ)

8 K (1785MJ)

8 K (1785MJ)

8 K (1785MJ) or

16 K (1785MK)

ords) &

Choose from the following PLC-5 processors.

Table 2.I

PLC5 Processor Selection ChartPart 1

Classic

Total I/O Maximum

(any mix)

•

512 (32I/O modules)

•

256 (16I/O modules)

•

128 (8I/O modules)

•

512 (32I/O modules)

•

256 (16I/O modules)

•

128 (8I/O modules)

•

512 (any mix) or

•

512 in + 512 out

(complementary)

•

1024 (any mix) or

•

1024 in + 1024 out

(complementary)

Table 2.J

PLC5 Processor Selection ChartPart 2

Classic

Maximum

Number of

I/O Racks

1 1 0 0 0 2.5A

4 1 0 0 0

4 13 0 12 0

8 17 0 16 0

Analog

I/O Max

256

256

512

1024

Maximum Number of I/O

Chassis

Total

Program Scan T

K W

2 ms (discrete logic)

8 ms (typical)

2 ms (discrete logic)

8 ms (typical)

2 ms (discrete logic)

8 ms (typical)

2 ms (discrete logic)

8 ms (typical)

Ext Local

ord

Remote

ime /

Number of

RS232/

422/ 423

ports

I/O Scan time/Rack

(in a single Chassis,

extlocal or remote)

N/A

•

10 ms @ 57.6 kbps

(remote)

•

10 ms @ 57.6 kbps

(remote)

•

10 ms @ 57.6 kbps

(remote)

Remote I/O

Transmission

1

Rates

57.6 kbps

57.6 kbps

57.6 kbps

Multiple

MCPs /

Quantity

No / 1

No / 1

No / 1

No / 1

Backplane

Current

Load

2.5A

2.5A

2.5A

Selecting Power Supplies

1771P7

Use the following steps as guidelines for selecting a power supply for a

chassis that contains a PLC-5 processor, a 1771-AS or -ASB remote I/O

adapter module, or a 1771-ALX extended-local I/O adapter module.

1. Determine the input voltage for the power supply.

2. Calculate the total backplane current draw for I/O modules by

adding together the backplane current draw for each I/O module in

that chassis.

2-9

Page 29

Chapter 2

Choosing Hardware

3. Add to the total of the I/O module backplane current draw either:

a. 3.3 Amps when the chassis will contain a PLC-5 processor

(maximum current draw for any PLC-5 processor) or

b. 1.2 Amps when the chassis will contain either a remote I/O

1771-AS or -ASB module or a 1771-ALX extended-local I/O

adapter module

4. If you leave slots available in your chassis for future expansion:

a. list backplane current draw for future I/O modules

b. add the total current draw for all expansion I/O modules to the

total calculated in step 3.

5. Determine whether the available space for the power supply is in the

chassis or mounted external to the chassis.

Choose your power supply from Table 2.K or Table 2.L using the input

voltage requirement and the total backplane current draw as determined in

the previous steps, 1 through 5.

See the Automation Products Catalog, publication AP100, for more

information on power supplies.

Powering a Chassis Containing a PLC5 Processor

Table 2.K lists the power-supply modules that you can use with a Classic

PLC-5 processor.

2-10

Page 30

Chapter 2

Power

Input

Output Current

Power Supply

Choosing Hardware

Table 2.K

Powering

Power

Input Output Current

Supply

1771P3 120V ac 3 6 11 11 chassis, 1slot

1771P4 120V ac 8 11 16 16 chassis, 2slot

1771P4S 120V ac 8 11 16 16

1771P4S1 100V ac 8 16

1771P4R 120V ac 8/16/24

1771P5 24V dc 8 16 chassis, 2slot

1771P6S 220V ac 8 16

1771P6S1 200V ac 8 16

1771P6R 220V ac 8/16/24

1771P7 120/220V ac 16

1771PS7 120/220V ac 16

1

See

publication 17712.136 for more information.

2

Y

ou cannot use an external power supply and a slotbased power supply module to power the same chassis;

they are not compatible.

Power

a Chassis Containing a Classic PLC5 processor

Output Current (in Amps) When Parallel with:

(in Amps)

P3 P4 P4S P4S1 P5 P6S P6S1

1

1

Power Supply

Location

chassis, 1slot

chassis, 1slot

2

external

2-11

Page 31

Chapter 2

Power

Input

Output Current

Power Supply

Choosing Hardware

Powering a Remote I/O Chassis Containing a 1771AS or 1771ASB or

an ExtendedLocal I/O Chassis Containing a 1771ALX

Table 2.L lists the power supply modules that you can use with a remote

I/O chassis or an extended-local I/O chassis.

Table 2.L

Powering

a Remote I/O Chassis (Containing a 1771AS or ASB)

or an ExtendedLocal I/O Chassis (Containing a 1771ALX)

Power

Input Output Current

Supply

Power

(in Amps)

1771P3 120V ac 3 6 11 11 chassis, 1slot

1771P4 120V ac 8 11 16 16 chassis, 2slot

1771P4S 120V ac 8 11 16 16

1771P4S1 100V ac 8 16

1771P4R 120V ac 8/16/24

1771P5 24V dc 8 16 chassis, 2slot

1771P6S 220V ac 8 16

1771P6S1 200V ac 8 16

1771P6R 220V ac 8/16/24

1771P1 120/220V ac 6.5

1771P2 120/220V ac 6.5

1771P7 120/220V ac 16

1771PS7 120/220V ac 16

Output Current (in Amps) When Parallel with:

P3 P4 P4S P4S1 P5 P6S P6S1

1

1

Power Supply

Location

chassis, 1slot

chassis, 1slot

2

external

2-12

1777P2 120/220V ac 9

1777P4 24V dc 9

1

See

publication 17712.136 for more information.

2

Y

ou cannot use an external power supply and a slotbased power supply module to power the same chassis;

they are not compatible.

Page 32

Chapter 2

Choosing Hardware

Selecting

Memory Modules

Selecting a Replacement

Battery

Select a memory module from Table 2.M for your PLC-5 processor.

Table 2.M

Processor Memory Modules

PLC5

Nonvolatile Memory Backup (EEPROM) RAM Memory (CMOS)

Words Catalog Number (and Processor) Words Catalog Number (and Processor)

8 K 1785MJ 4 K 1785MR (PLC5/15 and 5/25)

16 K 1785MK (PLC5/25) 8 K 1785MS (PLC5/15 and 5/25)

A battery ships with your PLC-5 processor. Select a replacement battery

using Table 2.N and Table 2.O. See the Allen-Bradley Guidelines for

Handling Lithium Batteries, publication ICCG-5.14, for more information.

Table 2.N

Processor

Processor Battery

PLC5/10, 5/12, 5/15,

and 5/25

1

The

their part number TL 5104 and type AEL/S.

Batteries

1770XY is a 3.6 V

1

1770XY, AA

lithium

olt AA size lithium thionyl chloride battery manufactured by T

Function

Retains the processor memory and the

memory in an optional CMOS RAM module

if the processor is not powered.

adiran as

Selecting

Complementary I/O

Table 2.O

Average

Battery Life

Battery Temperature Power Off 100%

1770XY

60° C

25° C

(Average)

329 days

2 years

Power Off 50%

(Average)

1.4 years

3.3 years

You configure complementary I/O by assigning an I/O rack number of one

I/O chassis (primary) to another I/O chassis (complementary). You

complement I/O functions in the primary chassis with opposite functions in

the complementary chassis. Use chapter 4, “Assigning Addressing Mode,

Racks, and Groups,” in conjunction with the following selection of

complementary I/O hardware.

2-13

Page 33

Chapter 2

Choosing Hardware

Use the following modules in either primary or complementary I/O chassis

opposite any type of module:

Communication Adapter Module (1771-KA2)

Communication Controller Module (1771-KE)

PLC-2 Family/RS-232-C Interface Module (1771-KG)

Fiber Optics Converter Module (1771-AF)

DH/DH+ Communication Adapter Module (1785-KA)

DH+/RS-232C Communications Interface Module (1785-KE)

Use the following modules in either primary or complementary I/O chassis

opposite any type of module. However, these modules do not work as

standalone modules; each one has an associated master module. Use care

when placing the master modules in the I/O chassis (refer to the paragraph

on Master/Expander I/O modules):

Analog Input Expander Module (1771-E1, -E2, -E3)

Analog Output Expander Module (1771-E4)

Servo (Encoder Feedback) Expander Module (1771-ES)

Pulse Output Expander Module (1771-OJ)

Selecting

a PLC5 Processor

Backup System

A PLC-5 processor backup system contains two of each of the following

hardware components:

Classic PLC-5 processor module

Processor Catalog Number

PLC5/15 1785LT Series B

PLC5/25 1785LT2

1785-BCM Series C Backup Control Module (for 2 channels)

1785-BEM Backup Expansion Module (for 2 additional channels)

Power supply

Local chassis

Important: The PLC-5 backup system does not back up I/O in the

processor-resident local chassis. Do not install I/O in the processorresident local chassis of a backed up system.

Refer to the PLC-5 Backup Communication Module User Manual,

publication 1785-6.5.4, for more information on configuring a PLC-5

processor backup system.

2-14

Page 34

Chapter 2

Choosing Hardware

Selecting Link Terminators

Connecting a

Programming Terminal to a

Processor Module

Terminate remote I/O links by setting switch assembly SW3. If you cannot

use an 82-Ohm terminator because of devices that you place on your I/O

link (see the table below for a list of these devices), you must use 150-Ohm

terminators. Using the higher resistance reduces the quantity of devices to

16 that you can place per remote I/O link. Also, this limits your

communication rates to 57.6 kbps and 115.2 kbps.

DH+ Network Terminator

Terminate your DH+ network with a 150-Ohm, 1/2-watt terminator.

If you have this processor: Terminate a DH+ link by:

PLC5/10, 5/12, 5/15, or 5/25 Setting switch assembly SW3 of the PLC5

processor (refer to your Classic 1785 PLC5 Family

Programmable Controllers Hardware Installation

Manual, publication 17856.6.1).

Connect the programming terminal directly to the processor through the

D-shell DH+ COMM INTFC connector on the front panel. You can also

connect the programming terminal remotely to a DH+ link through the

3-pin connector or at a remote station.

Choosing Cables

Select cables from the options listed below. See chapter 3, “Placing System

Hardware,” to determine the lengths that you will need for cables in

your system.

Remote I/O Link

Use Belden 9463 twinaxial cable (1770-CD) to connect your PLC-5

processor to remote I/O adapter modules.

Connect your I/O devices using:

single-conductor wire (analog and some discrete applications)

multi-conductor cable (analog and some discrete applications)

multi-conductor shielded cable (some specialty I/O modules and

low-voltage dc discrete modules)

2-15

Page 35

Chapter 2

PLC 5/10, 5/12, 5/15

1784 KT, KT2

1784 CP

Choosing Hardware

See the Classic 1785 PLC-5 Programmable Controllers Hardware

Installation Manual, publication 1785-6.6.1, and the installation data for

the I/O modules that you have selected for more information on I/O wiring.

Also, see Allen-Bradley Programmable Controller Wiring and Grounding

Guidelines, publication 1770-4.1, and Control, Communication and

Information Reference Guide, publication ICCG-1.2, for more information.

Programming Terminal

The cable that you use to connect a processor to a programming terminal

depends on the communication device used. Table 2.P lists the cables that

you need for different configurations.

Table 2.P

Cables

for Connecting a Classic PLC5 Processor and Programming

Terminal

If you have this device: With this

PLC5/10, 5/12, 5/15, 1784KT, KT2 1784CP

or 5/25

6160T60, 6160T70, 6121

IBM PC/AT (or compatible)

1784T47, 6123, 6124

IBM PC/XT (or compatible)

6120, 6122 1785KE 1784CYK

communication device:

,

1784KL, KL/B

1784KTK1 1784CP5

1784PCMK 1784PCM5

1785KE 1784CAK

1785KE 1784CXK

Use this cable:

You can also use a 1770-KF2/B communication interface to connect to a

PLC-5 processor. You build your own cables to connect your

programming terminal via the COM1 or COM2 serial ports to the

1770-KF2/B. For the cable pin assignments, see the Classic 1785 PLC-5

Programmable Controller Hardware Installation Manual, publication

1785-6.6.1.

2-16

Page 36

Chapter

Placing System Hardware

3

Chapter

Objectives

Determining the Proper

Environment

A well-planned layout is essential to the proper installation of your Classic

PLC-5 programmable controller system. Read this chapter for information

on placing hardware.

System Design

If you want to read about: Go to

page:

Proper environment 31

Protecting your system 34

Avoiding electrostatic damage 34

Planning your raceway layout 34

Planning your cabling 36

Grounding your system 37

Determined

Choosing Hardware

Placing System

Hardware

Assigning Addressing

Mode, Racks,

and Groups

Choosing

Communication

Planning Your

System Programs

Selecting Interrupt

Routines

Transferring Discrete

and Block Data

Calculating Program

Timing

Place the processor in an environment with conditions that fall within the

guidelines described in Table 3.A.

Table 3.A

Proper

Environmental Conditions For Y

Environmental Condition Acceptable Range

Operating temperature

Storage temperature

Relative humidity 5 to 95% (without condensation)

0 to 60° C (32 to 140° F)

40 to 85° C (40 to 185° F)

our Processor

Separate your programmable controller system from other equipment and

plant walls to allow for convection cooling. Convection cooling draws a

vertical column of air upward over the processor. This cooling air must

not exceed 60

If the air temperature exceeds 60

° C (140° F) at any point immediately below the processor.

° C, install fans that bring in filtered air or

recirculate internal air inside the enclosure, or install air-conditioning/heatexchanger units.

3-1

Page 37

Chapter 3

Placing System Hardware

To allow for proper convection cooling in enclosures containing a

processor-resident chassis and remote I/O chassis, follow these guidelines.

Minimum spacing requirements for a

processorresident chassis:

102mm

(4")

51mm(2")

Area reserved for disconnect.

transformer, control relays, motor

starters or other user devices.

(6")

51mm

(2")

Wiring Duct

153mm

153mm

(6")

• Mount the I/O chassis horizontally.

• Allow 153 mm (6 in) above and below the chassis.

• Allow 102 mm (4 in) on the sides of each chassis.

• Allow 51 mm (2 in) vertically and horizontally between

any chassis and the wiring duct or terminal strips.

• Leave any excess space at the top of the enclosure,

where the temperature is the highest.

102mm

(4")

13081

3-2

Page 38

153mm (6")

102mm

(4")

51mm (2")

51mm (2")

Area reserved for disconnect.

transformer, control relays,mot or

starters or other user devices.

153mm

(6")

Wiring Duct

Chapter 3

Placing System Hardware

Minimum spacing requirements for a remote

I/O chassis:

• Mount the I/O chassis horizontally.

• Allow 153 mm (6 in) above and below all

chassis. When you use more than one

chassis in the same area, allow 152.4 mm

(6 in) between each chassis.

• Allow 102 mm (4 in) on the sides of each

chassis. When you use more than one

chassis in the same area, allow 101.6 mm

(4 in) between each chassis.

• Allow 51 mm (2 in) vertically and

horizontally between any chassis and the

wiring duct or terminal strips.

• Leave any excess space at the top of

the enclosure, where the temperature is

the highest.

102mm

(4")

102mm

(4")

153mm (6")

Wiring Duct

18749

3-3

Page 39

Chapter 3

Placing System Hardware

Protecting Your Processor

Avoiding Electrostatic

Damage

You provide the enclosure for your processor system. This enclosure

protects your processor system from atmospheric contaminants such as oil,

moisture, dust, corrosive vapors, or other harmful airborne substances. To

help guard against EMI/RFI, we recommend a steel enclosure.

Mount the enclosure in a position where you can fully open the doors. You

need easy access to processor wiring and related components so that

troubleshooting is convenient.

When you choose the enclosure size, allow extra space for transformers,

fusing, disconnect switch, master control relay, and terminal strips.

ATTENTION: Under some conditions, electrostatic

discharge can degrade performance or damage the processor

module. Read and observe the following precautions to guard

against electrostatic damage.

Wear an approved wrist strap grounding device when

handling the processor module.

Laying Out Your

Cable Raceway

Touch a grounded object to discharge yourself before

handling the processor module.

Do not touch the backplane connector or connector pins.

When not handling the processor module, keep it in its

protective packaging.

The raceway layout of a system reflects where the different types of I/O

modules are placed in I/O chassis. Therefore, you should determine

I/O-module placement prior to any layout and routing of wires. When

planning your I/O-module placement, however, segregate the modules

based on the conductor categories published for each I/O module so that

you can follow these guidelines. These guidelines coincide with the

guidelines for “the installation of electrical equipment to minimize

electrical noise inputs to controllers from external sources” in IEEE

standard 518-1982.

3-4

Page 40

Chapter 3

Placing System Hardware

To plan a raceway layout, do the following:

categorize conductor cables

route conductor cables

Categorize Conductors

Segregate all wires and cables into categories as described in the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1. See

the installation data for each I/O module that you are using for information

about its classification.

Route Conductors

To guard against coupling noise from one conductor to another, follow the

general guidelines for routing cables described in the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1. You

should follow the safe grounding and wiring practices called out in the

National Electrical Code (NEC, published by the National Fire Protection

Association, in Quincy, Massachusetts), and local electrical codes.

Planning Cabling

DH+ Link Cabling

At a DH+ transmission rate of 57.6 kbps, do not exceed 3,048 cable-m

(10,000 cable-ft) for a trunkline cable length or 30.5 cable-m (100 cable-ft)

for a dropline cable length.

Remote I/O Link Cabling

Refer to Table 3.B for remote I/O link trunkline cable length restrictions.

Table 3.B

Maximum

Transmission Rate Maximum Cable Length

57.6 kbps 3,048 m (10,000 ft)

115.2 kbps 1,524 m (5000 ft)

230.4 kbps 762 m (2500 ft)

Important: All devices on the remote I/O link must be communicating at

the same transmission rate.

Cable Lengths per Communication Rate

3-5

Page 41

Chapter 3

Placing System Hardware

Laying Out the

Backpanel Spacing

1771A1B

1771A2B

1771A3B1

1771A4B

Power

Connector

193mm

(7.60")

Side

Use 6.35 mm (0.25 inch) mounting bolts to attach the I/O chassis to the

enclosure backpanel.

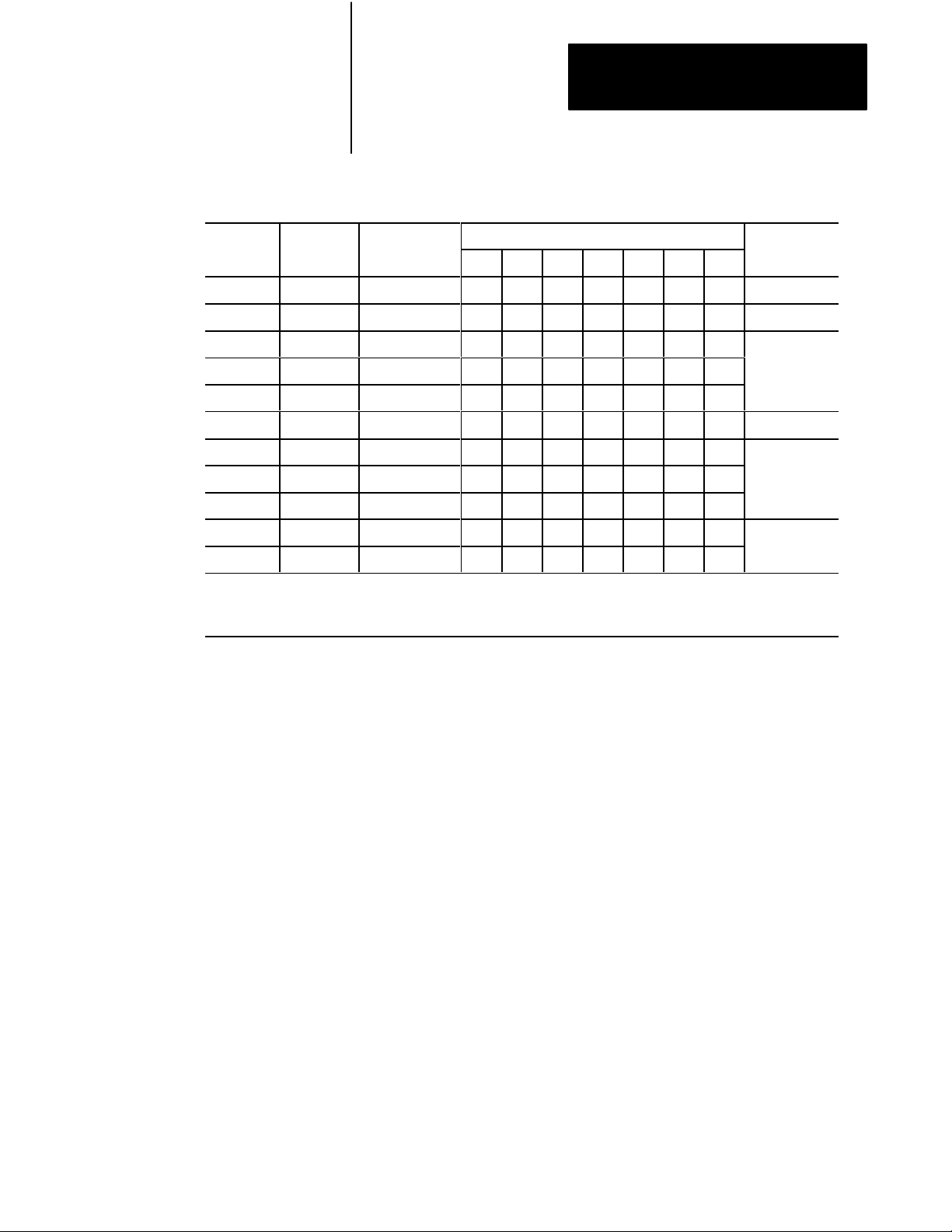

Figure 3.1

Chassis

1

Dimensions (Series B)

315mm

(12.41")

591mm

(23.25")

337mm

(13.25")

464mm

(18.25")

210mm

(8.25")

16slot 1771

12slot

8slot

4slot

254mm

(10")

1771A3B

217mm

(8.54")

Side

1

171mm

(6.75")

339mm

(13.53")

610mm

483mm

(19.01")

229mm

(9.01")

465mm

(18.31")

(24.01")

356mm

(14.01")

484mm

(19")

Front

1

Total