Page 1

PowerFlex 1769-SM2

Compact I/O DSI/Modbus

Communications Module

Firmware Version 1.xxx

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application, Installation

and Maintenance of Solid State Controls (Publication SGI-1.1 available from your

local Rockwell Automation sales office or online at http://

www.rockwellautomation.com/literature) describes some important differences

between solid state equipment and hard-wired electromechanical devices. Because

of this difference, and also because of the wide variety of uses for solid state

equipment, all persons responsible for applying this equipment must satisfy

themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with any

particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written

permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of safety

considerations.

WARNING: Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment, which may

!

!

lead to personal injury or death, property damage, or economic loss.

Important: Identifies information that is critical for successful application and

!

!

Allen-Bradley, PowerFlex, DriveExplorer, DriveExecutive, DriveTools SP, CompactLogix, MicroLogix, DSI, RSNetWorx for

DeviceNet, and ControlFLASH are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

understanding of the product.

ATTENTION: Identifies information about practices or circumstances

that can lead to personal injury or death, property damage, or economic

loss. Attentions help you identify a hazard, avoid a hazard, and

recognize the consequences.

Shock Hazard labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that dangerous voltage may be present.

Burn Hazard labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that surfaces may be at dangerous

temperatures.

Page 3

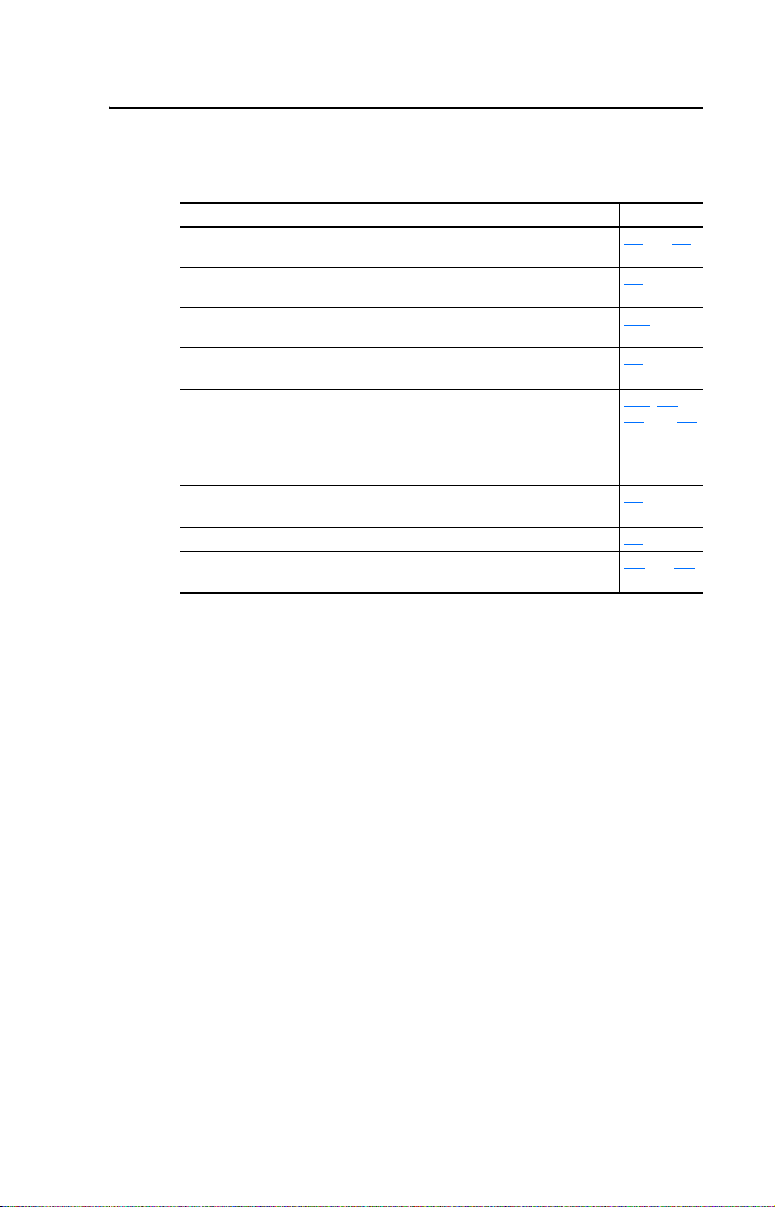

Summary of Changes

The information below summarizes the changes made to this manual

since version 1769-UM013B-EN-P (January 2006):

Description Page(s)

Changed Figures 1.3 and 1.4 to correctly show the wiring of the RJ45

daisy-chained connectors.

In the “Compatible Products” section, added the PowerFlex 4M and

PowerFlex 40P drives.

Moved the Module Start-Up Status Indication table from Chapter 1 to

Chapter 2 after the “Applying Power” section.

Added the subsection “Special Case—Data Entry for 2 Stop Bits

Communication.”

Changed module Parameters 15 - [RTU Parity 1], 30 - [RTU Parity 2], and

45 - [RTU Parity 3] per 1769-SM2 firmware v2.001 update. The parameter

numbers remain the same but the parameter names changed from [RTU

Parity x] to [RTU Format x]. Also, in addition to parity (None, Even or Odd),

the parameter function changed to include choice of stop bits (1 or 2).

In the “Using Reference/Feedback” section, revised table to include

PowerFlex 4M and PowerFlex 40P drives.

Added the new section “Using RSLinx Classic” to Chapter 8. 8-2

Updated the Logic Command word and Logic Status word information to

include data for all PowerFlex 4-Class drives.

and 1-5

1-4

1-6

2-15

3-8

3-17

, B-3,

B-5, and B-7

4-4

D-1 and D-2

Page 4

soc-ii

Page 5

Preface About This Manual

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Rockwell Automation Support. . . . . . . . . . . . . . . . . . . . . . . . P-2

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . P-3

Chapter 1 Getting Started

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Single Mode vs. Multi-Drive Mode. . . . . . . . . . . . . . . . . . . . 1-3

Compatible Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Chapter 2 Installing the Module

Preparing for an Installation. . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Removing Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Setting the Configuration Mode Switch. . . . . . . . . . . . . . . . . 2-3

Setting the Operating Mode Switch (Single/Multi-Drive). . . 2-4

Assembling the Module to the Controller . . . . . . . . . . . . . . . 2-5

Mounting the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Replacing the Module within a System . . . . . . . . . . . . . . . . . 2-9

Connecting Drive(s) to the Module . . . . . . . . . . . . . . . . . . . 2-10

Grounding the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Network Cable Strain Relief . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Viewing Start-Up Status Indicators . . . . . . . . . . . . . . . . . . . 2-15

Table of Contents

Chapter 3 Configuring the Module

Determining I/O Image Size . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Configuration Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Configuration Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Controller Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Parameter Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Using the Optional, External PowerFlex 4-Class HIM . . . . 3-13

Setting the I/O Configuration (Multi-Drive Mode Only). . . 3-14

Setting an Idle Action (Single and Multi-Drive Mode) . . . . 3-15

Setting Drive Node Addresses (Multi-Drive Mode Only). . 3-16

Configuring the Modbus RTU Master Parameters. . . . . . . . 3-17

Resetting the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Viewing the Module Status Using Parameters. . . . . . . . . . . 3-21

Flash Updating the Module . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Page 6

ii Table of Contents

Chapter 4 Understanding the I/O Image

Module Control Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Module Status Word. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Using Logic Command/Status . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Using Reference/Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Chapter 5 Understanding Explicit Messaging

Formatting Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Modbus RTU Master Operation Messages . . . . . . . . . . . . . . 5-9

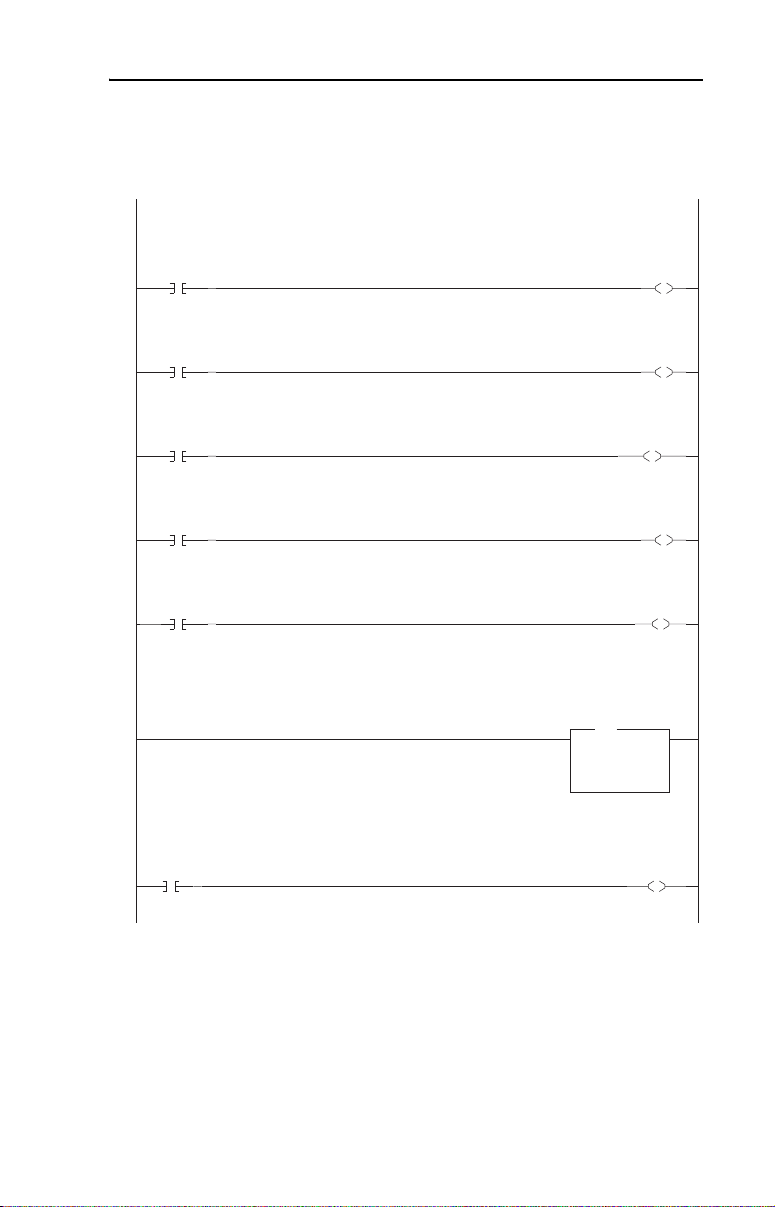

Chapter 6 MicroLogix 1500 Example Ladder Programs

Single Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Multi-Drive Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

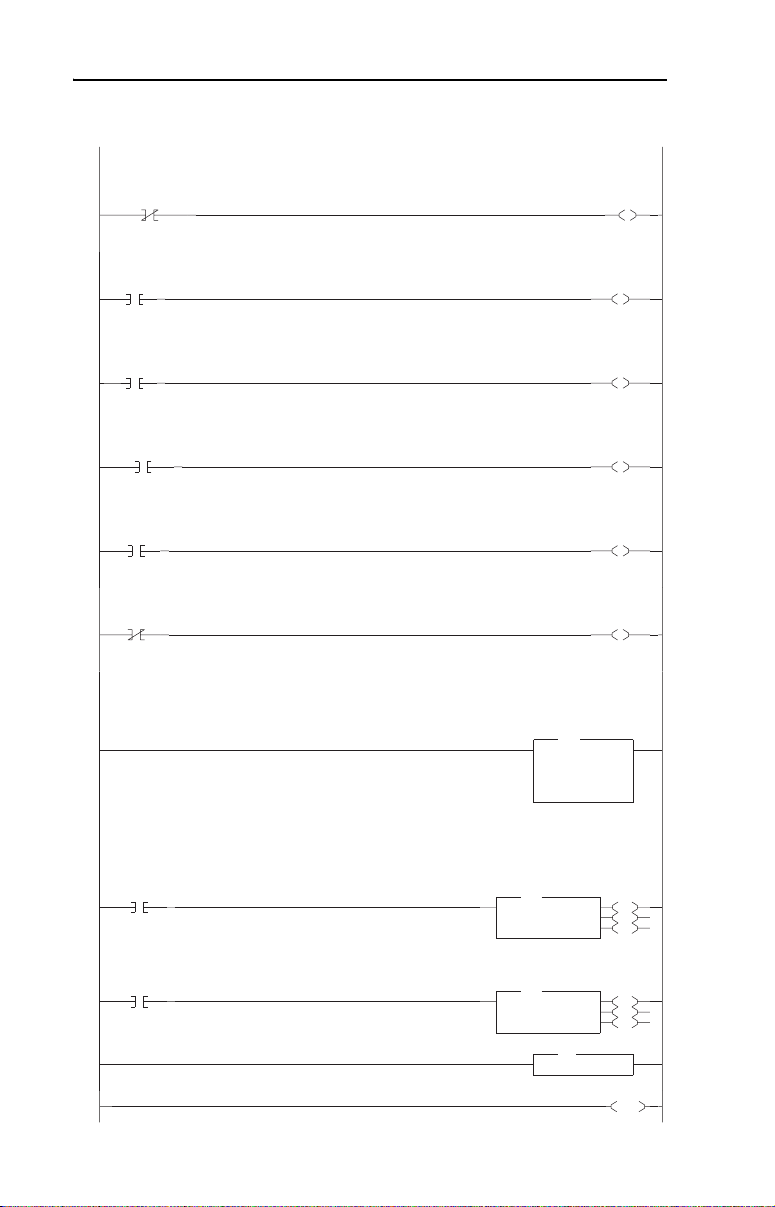

Chapter 7 CompactLogix Example Ladder Programs

Single Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Multi-Drive Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Chapter 8 ControlLogix w/1769-ADN DeviceNet Example Ladder

Program

Single Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Using RSLinx Classic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Using RSNetWorx for DeviceNet . . . . . . . . . . . . . . . . . . . . . 8-3

Setting Up the 1769-ADN . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Registering the 1769-SM2 EDS File . . . . . . . . . . . . . . . . . . . 8-8

PowerFlex 40 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

1769-SM2 Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

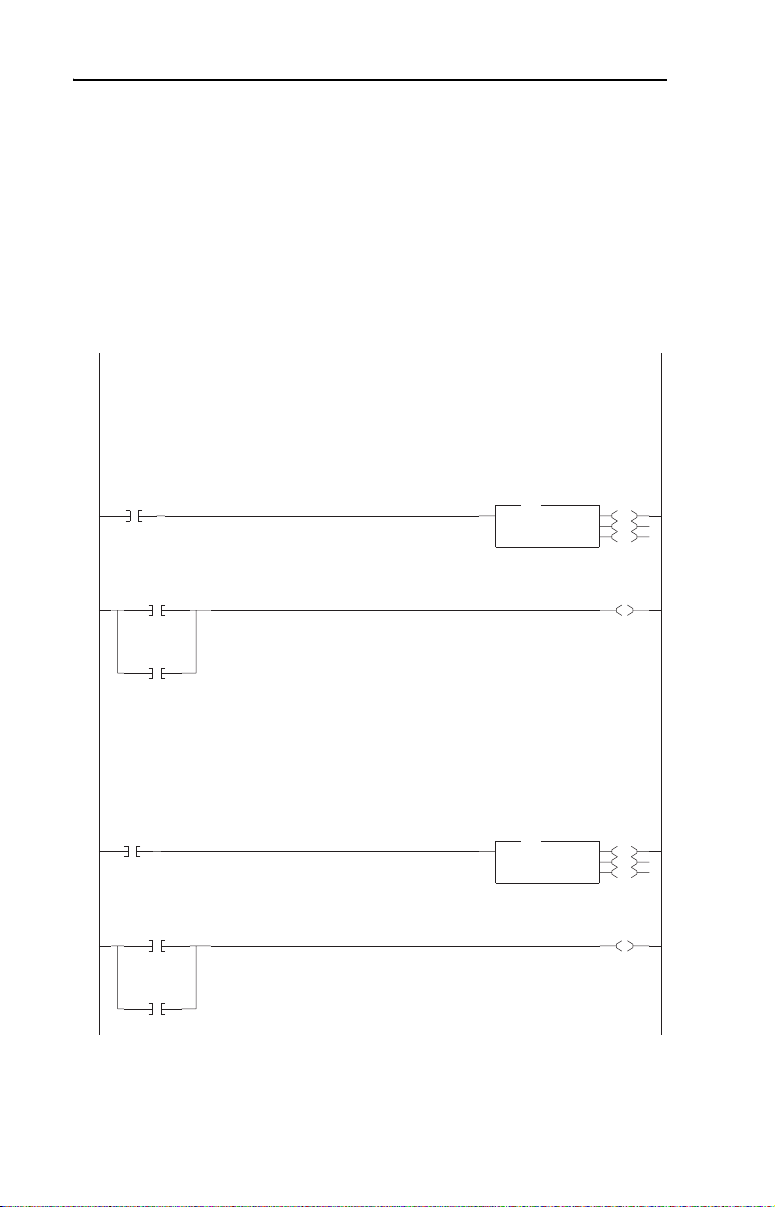

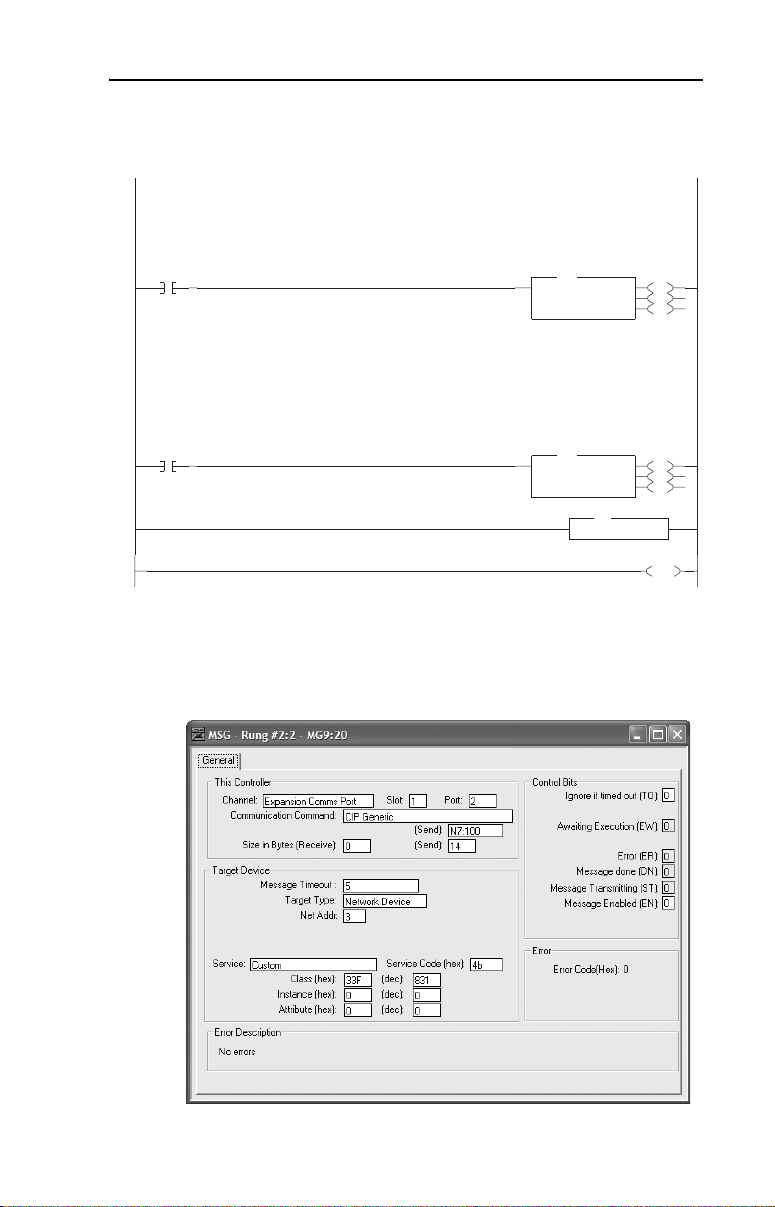

ControlLogix w/1769-ADN Example Program. . . . . . . . . . 8-13

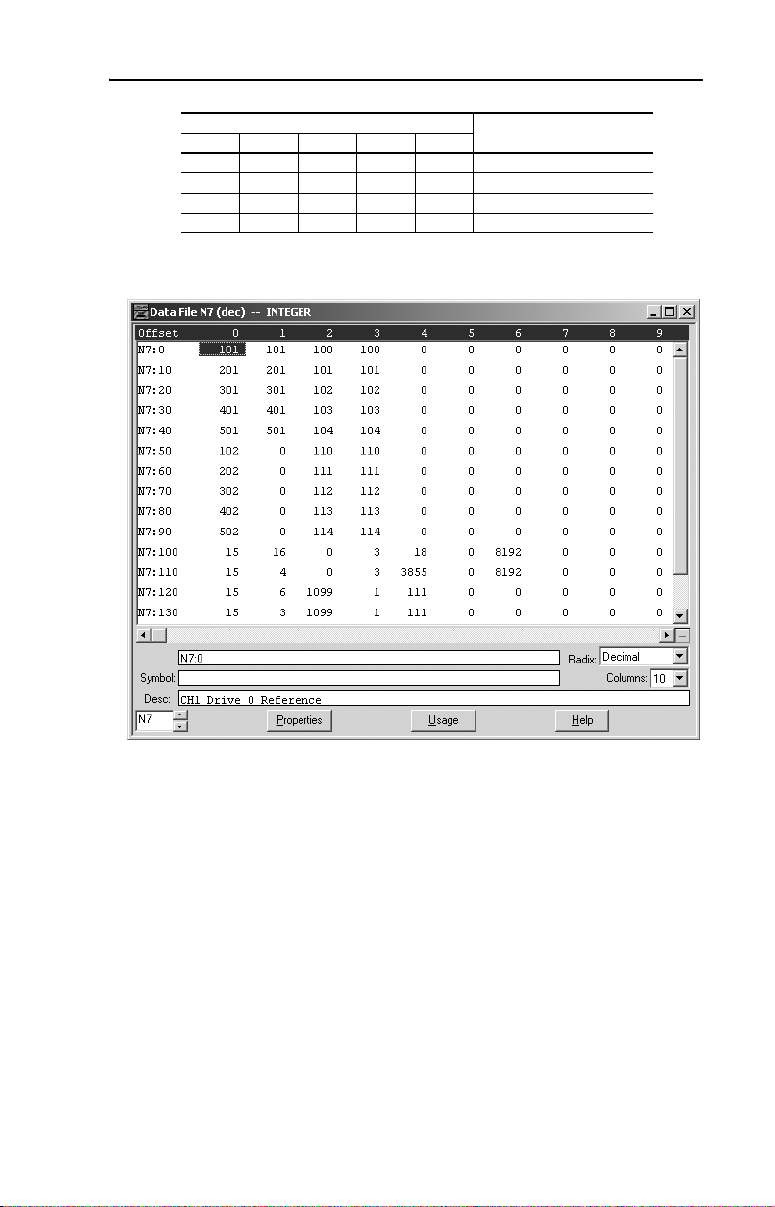

Example Program Data Table . . . . . . . . . . . . . . . . . . . . . . . 8-21

Chapter 9 Troubleshooting

Locating the Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . 9-1

MODULE Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

CH1…CH3 Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Viewing Module Diagnostic Items. . . . . . . . . . . . . . . . . . . . . 9-4

Viewing and Clearing Events. . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Appendix A Specifications

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Regulatory Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

DSI Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Page 7

Table of Contents iii

Appendix B Module Parameters

About Parameter Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Appendix C CIP/DSI Objects

CIP Identity Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

CIP Parameter Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

DSI Device Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

DSI Parameter Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-10

DSI Fault Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-14

DSI Diagnostic Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-16

Appendix D PowerFlex 4-Class Drives Logic Command/Status

Words

Logic Command Word. . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Logic Status Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Glossary

Index

Page 8

iv Table of Contents

Page 9

Preface

About This Manual

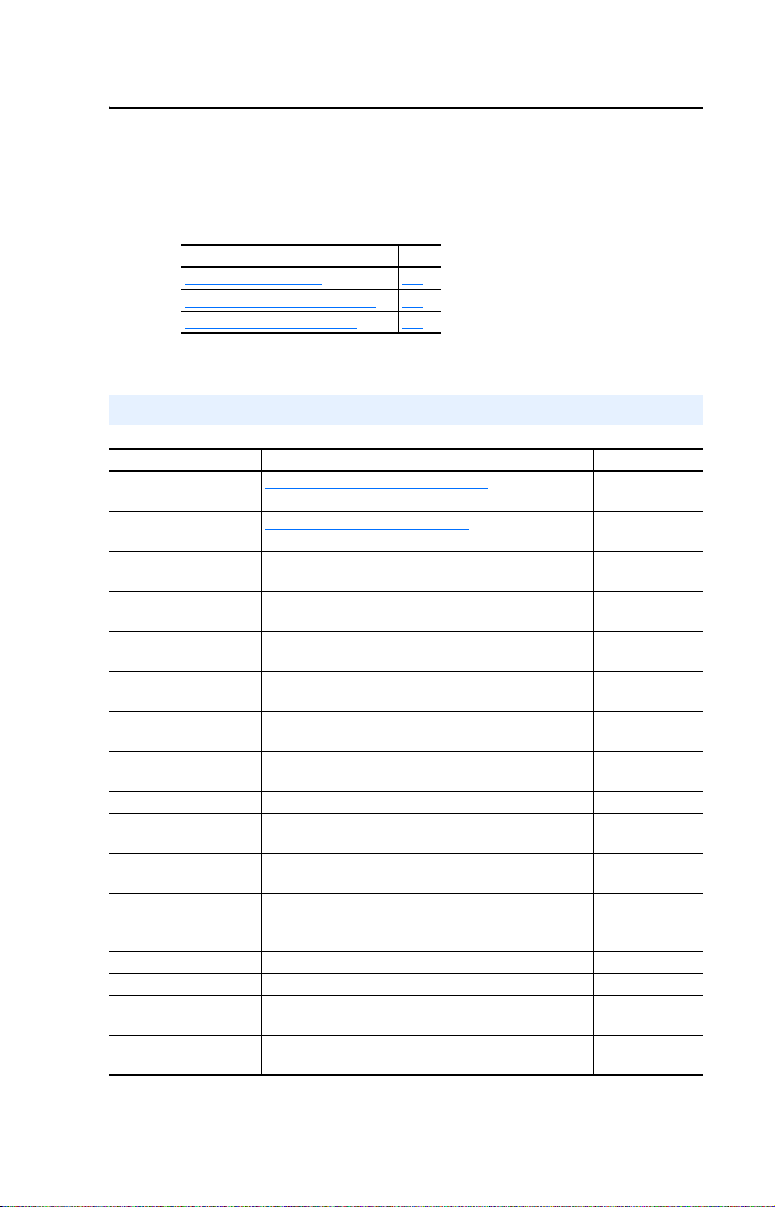

Topic Page

Related Documentation

Conventions Used in this Manual P-3

Rockwell Automation Support P-2

Related Documentation

For: Refer to: Publication

DriveExplorer™ http://www.ab.com/drives/driveexplorer

DriveTools™ SP

(includes DriveExecutive)

PowerFlex 4-Class HIM

(22-HIM-A3 / -C2S)

PowerFlex

PowerFlex

PowerFlex

PowerFlex

PowerFlex

RSLinx

RSLogix™ 500

RSLogix™ 5000

RSNetWorx™ for

DeviceNet

MicroLogix™ 1500 MicroLogix 1500 Programmable Controllers User Manual

CompactLogix™ CompactLogix System User Manual 1769-UM007

ControlLogix

Modbus RTU

Specification

PowerFlex 7-Class Drive

Connectivity

(1)

®

4 Drive PowerFlex 4 User Manual

®

4M Drive PowerFlex 4M User Manual

®

40 Drive PowerFlex 40 User Manual

®

40P Drive PowerFlex 40P User Manual

®

400 Drive PowerFlex 400 User Manual

®

Classic Getting Results with RSLinx Guide, and online help

®

The online help is installed with the software.

DriveExplorer online help

http://www.ab.com/drives/drivetools

DriveExecutive online help

HIM Quick Reference 22HIM-QR001

PowerFlex 4 Quick Start

PowerFlex 4M Quick Start

PowerFlex 40 Quick Start

PowerFlex 40P Quick Start

PowerFlex 400 Quick Start

RSLogix 500 Getting Results Guide, and online help

RSLogix 5000 Getting Results Guide, and online help

RSNetWorx for DeviceNet Getting Results Guide, and

online help

MicroLogix 1200 and MicroLogix 1500 Programmable

ControlLogix Gateway System User Manual 1756-6.5.13

Modbus – ida.org —

20-COMM-H RS-485 HVAC Adapter User Manual 20COMM-UM009

(1)

Controllers Reference Manual

P-1

(1)

(1)

, and

, and

—

—

22A-UM001

22A-QS-001

22F-UM001

22F-QS-001

22B-UM001

22B-QS-001

22D-UM001

22D-QS-001

22C-UM001

22C-QS-001

(1)

LINX-GR001

(1)

LG500-GR002

(1)

9399-RLD300GR

DNET-GR001

1764-UM001

1762-RM001

Page 10

P-2 About This Manual

You can view or download publications at http://

literature.rockwellautomation.com. To order paper copies of technical

documentation, contact your local Rockwell Automation distributor or

sales representative.

To find your local Rockwell Automation distributor or sales

representative, visit www.rockwellautomation.com/locations

For information such as firmware updates or answers to drive-related

questions, go to the Drives Service & Support web site at www.ab.com/

support/abdrives and click on the “Downloads” or “Knowledgebase” link.

Rockwell Automation Support

Rockwell Automation, Inc. offers support services worldwide, with over

75 sales/support offices, over 500 authorized distributors, and over 250

authorized systems integrators located through the United States alone.

In addition, Rockwell Automation, Inc. representatives are in every

major country in the world.

Local Support

.

Contact your local Rockwell Automation, Inc. representative for:

• Sales and order support

• Product technical training

• Warranty support

• Support service agreements

Technical Assistance

For technical assistance, please review the information in Chapter 9,

Troubleshooting, first. If you still have problems, then access the

Allen-Bradley Technical Support web site at www.ab.com/support/

abdrives or contact Rockwell Automation, Inc.

Page 11

About This Manual P-3

Conventions Used in this Manual

The following conventions are used throughout this manual:

• Parameter names are shown in the format Parameter xx - [*]. The

xx represents the parameter number. The * represents the parameter

name. For example Parameter 01 - [Config Mode].

• Menu commands are shown in bold type face and follow the format

Menu > Command. For example, if you read “Select File > Open,”

you should click the File menu and then click the Open command.

• RSNetWorx for DeviceNet (version 4.01) and RSLinx (version 2.41)

were used for the screen shots in this manual. Different versions of

the software may differ in appearance and procedures.

• The firmware release is displayed as FRN X.xxx. The “FRN”

signifies Firmware Release Number. The “X” is the major release

number. The “xxx” is the minor update number. This manual is for

Firmware release 1.xxx.

Page 12

P-4 About This Manual

Notes:

Page 13

Chapter 1

Getting Started

The 1769-SM2 Compact I/O to DSI module provides a Compact I/O

connection for PowerFlex 4-Class drives. It can be used with a

MicroLogix 1500, CompactLogix, or a remote 1769-based adapter such

as the 1769-ADN.

Topic Page Topic Page

Components

Features 1-2 Safety Precautions 1-7

Single Mode vs. Multi-Drive Mode 1-3 Quick Start 1-9

Compatible Products 1-6 Status Indicators 1-10

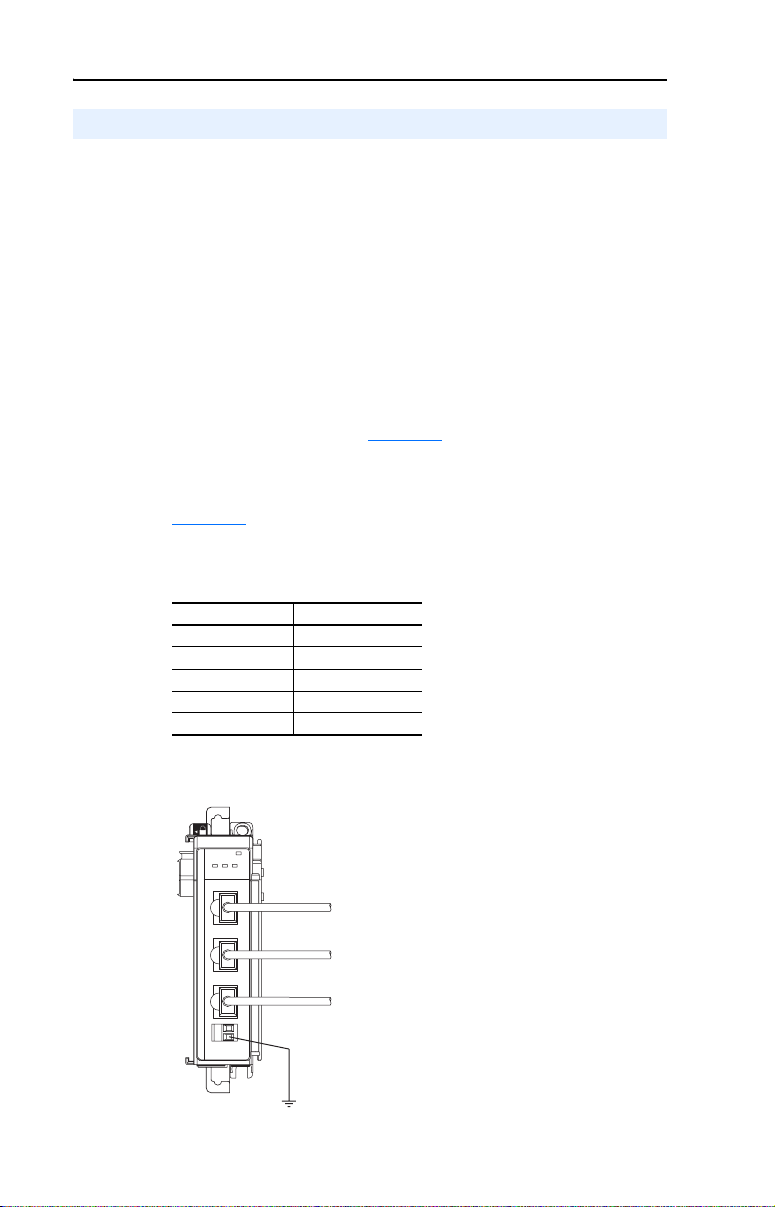

Components

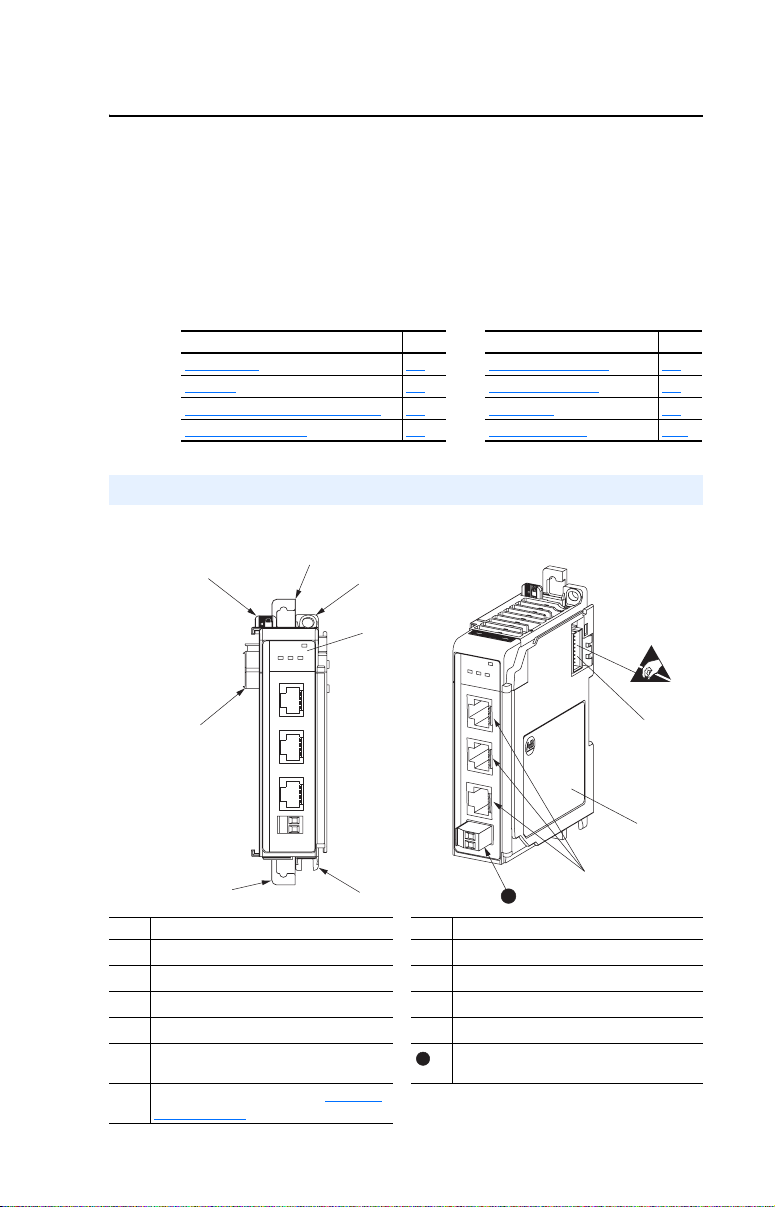

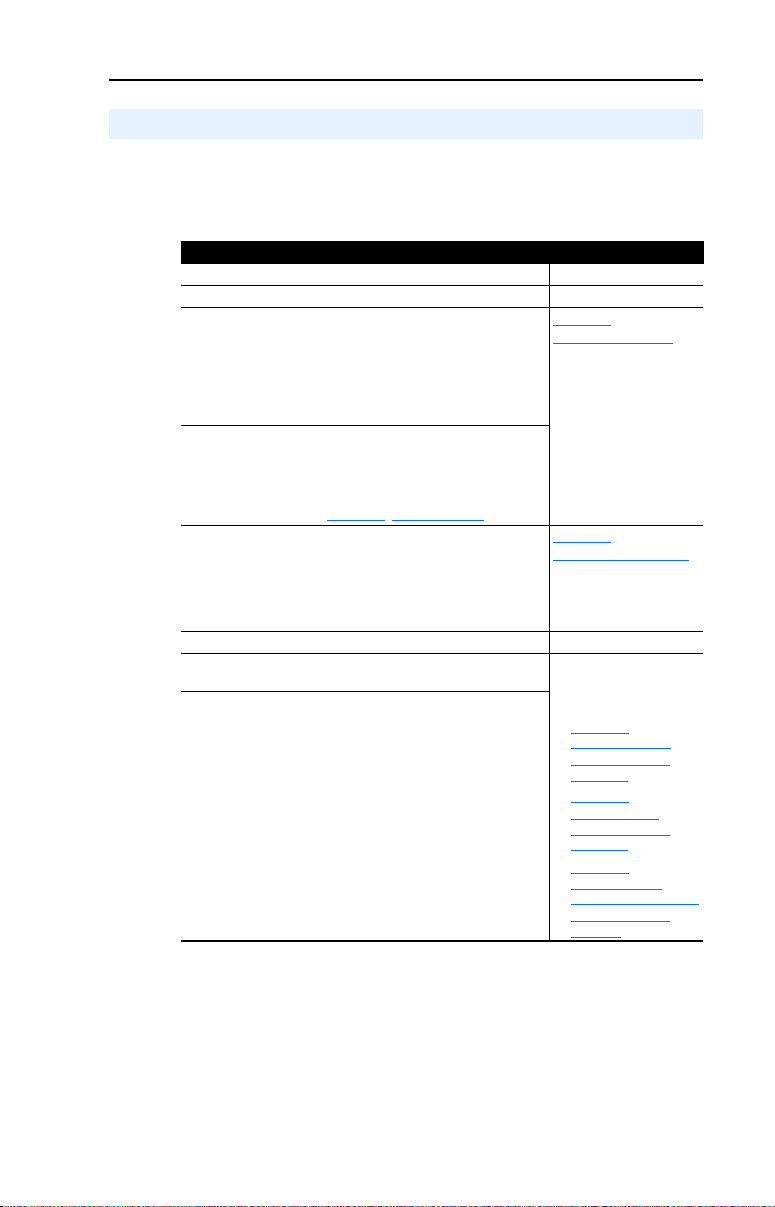

Figure 1.1 Components of the Module

➊

➋

1-1 Required Equipment 1-6

➍

MODULE

CH1

CH2 CH3

DSI

C

H

1

➐

C

H

2

C

H

3

➏

MODULE

C

H

1

C

H

2

C

H

3

I

S

D

C

H

1

C

H

2

C

H

3

➌

Item Part Item Part

Bus lever (with locking function)

➊

Upper DIN rail latch

➋

Lower DIN rail latch

➌

Upper panel mounting tab

➍

Lower panel mounting tab Terminal block for network communication

➎

Module status indicators (see Chapter 9,

➏

Troubleshooting

for details).

➎

➐

➑

➒

➓

11

11

Movable bus connector with female pins

Bus connector with male pins

Nameplate label

DSI connectors

shielding and earth ground wire.

➓

➑

➒

Page 14

1-2 Getting Started

Features

The 1769-SM2 Compact I/O to DSI module features include:

• Three Compact I/O connection channels for PowerFlex 4-Class

drives. Up to 3 drives can be connected in Single mode (1 per

channel) and up to 15 drives can be connected in Multi-Drive mode

(5 per channel). Any channel in Multi-Drive mode can also be

configured to operate as a Modbus RTU Master, allowing

connectivity to a maximum of 31 other Modbus RTU Slave devices,

such as PowerFlex 7-Class drives with 20-COMM-H RS485 HVAC

adapters.

• Use as expansion I/O on MicroLogix 1500 and CompactLogix

controllers or with a remote 1769-based adapter. It receives the

required power from the Compact I/O backplane.

• Parameter-configurable I/O, including Logic Command/Reference

and Logic Status/Feedback for each connected drive.

• Explicit messaging (parameter read/write, etc.) support for:

– MicroLogix 1500 LRP Series C systems when used with

RSLogix 500 v6.30 (or higher)

– Enhanced CompactLogix processors, such as the -L31, -L32E,

and -L35E

Explicit messaging is NOT available for CompactLogix -L20 and

-L30 processors, or 1769-ADN DeviceNet adapters.

• User-defined fault actions to determine how the module and

connected drives respond to controllers in idle mode (Idle Action).

• Bi-color (red/green) status indicators to report the status of the

module and channel communications.

• Compatibility with various configuration tools to configure the

module and connected drive(s). The tools include an optional,

external PowerFlex 4-Class HIM (22-HIM-A3 or 22-HIM-C2S), and

drive-configuration software such as DriveExplorer v3.01 (or higher)

or DriveExecutive v4.01 (or higher).

Page 15

Getting Started 1-3

Single Mode vs. Multi-Drive Mode

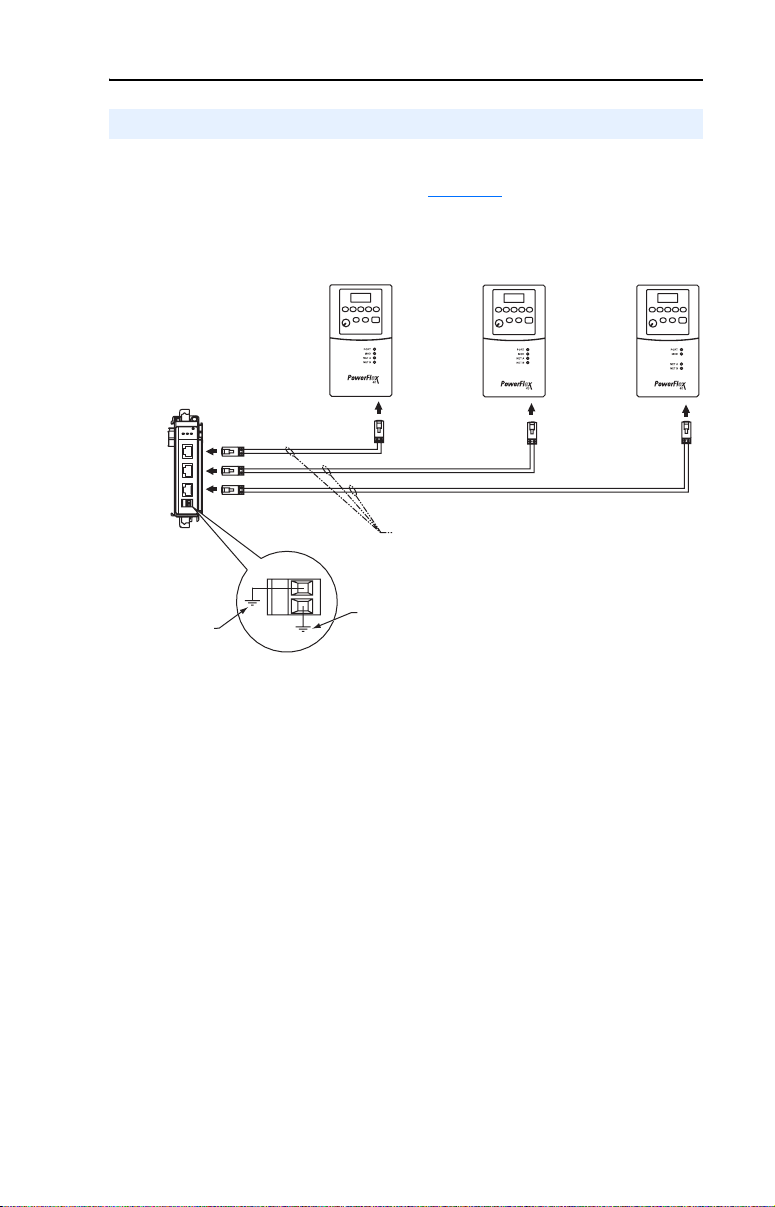

Single mode is a one-to-one connection, where a channel is connected to

a single PowerFlex 4-Class drive (Figure 1.2

Figure 1.2 Single Mode Wiring Example

1769-SM2

CH1

CH2

CH3

Module

MODULE

CH1

CH2 CH3

C

H

1

C

H

2

C

H

3

AK-U0-RJ45-TB2P

Terminal Block

Connector

22-RJ45CBL-C20 Cable, or User-Supplied Wire

(recommend Belden No. 3105A or equivalent)

with AK-U0-RJ45-TB2P terminal block connectors

AK-U0-RJ45-TB2P

).

Powerflex 4-Class Drives

Terminal Block

Connector

AK-U0-RJ45-TB2P

Terminal Block

Connector

Earth Ground

Connection

Ground Wire Connection

(for network communication

shielding)

An additional DSI peripheral device, such as an external PowerFlex

4-Class HIM or Serial Converter module (22-SCM-232) with a software

tool, can be used with each drive. An AK-U0-RJ45-SC1 DSI Splitter

cable can be used to split the RJ45 connector on the drive into two RJ45

connectors.

Page 16

1-4 Getting Started

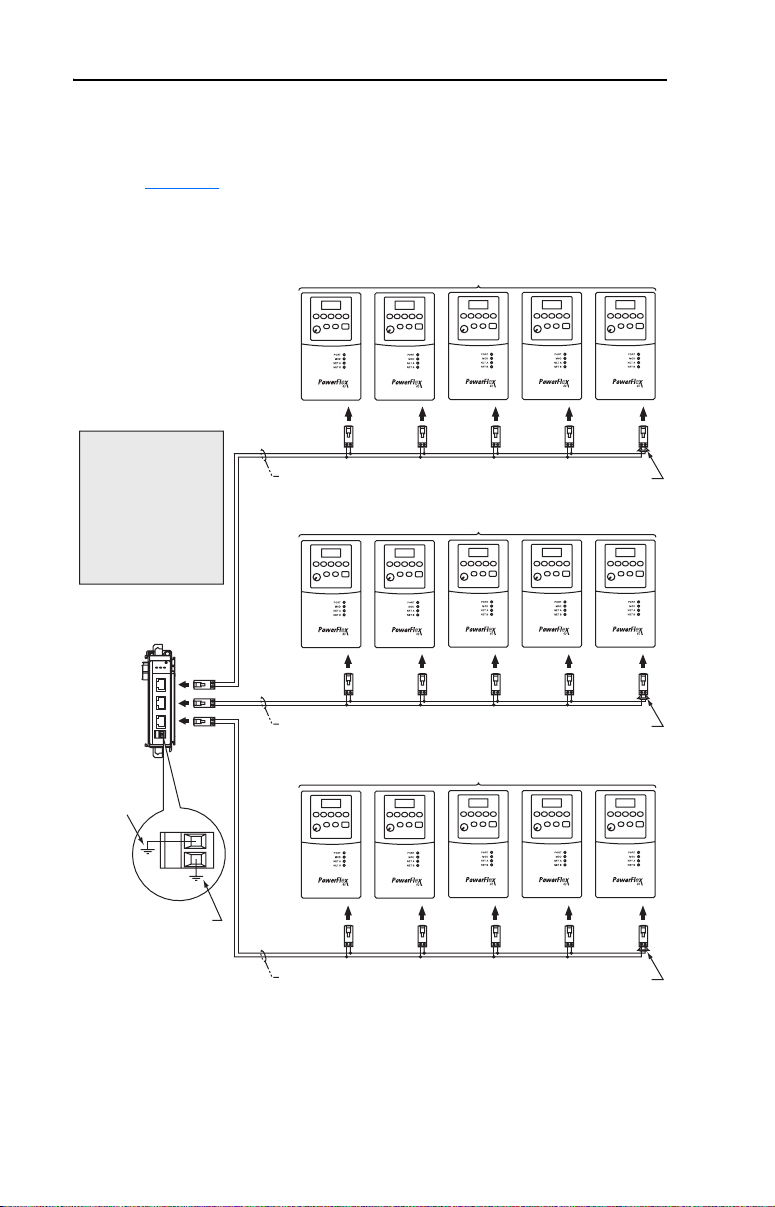

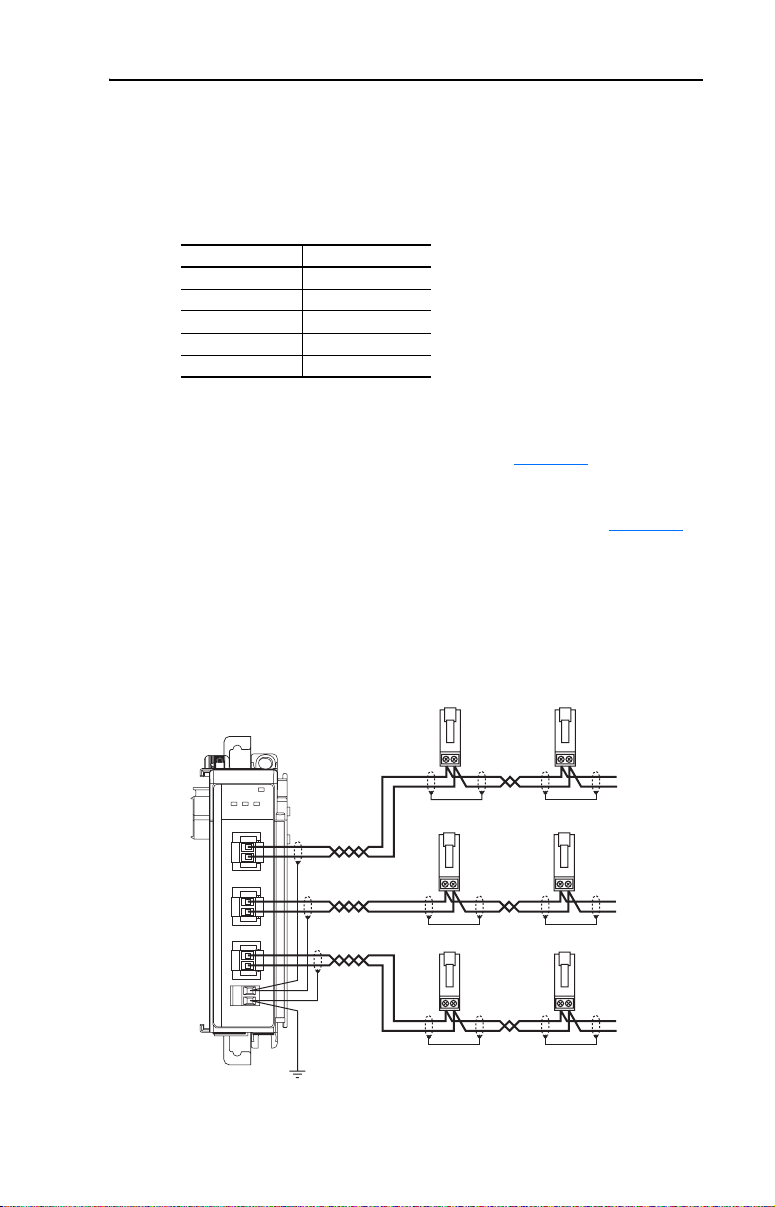

Multi-Drive mode enables increased connectivity, where one to five

PowerFlex 4-Class drives can be connected per channel. All of the drives

are daisy-chained to the 1769-SM2 module over RS-485 as shown in

Figure 1.3

Figure 1.3 Multi-Drive Mode Wiring Example

Wiring Tip:

The 1769-SM2 has an

integral terminating

resistor for each channel.

Thus, it is only necessary

to connect a terminating

resistor to the RJ45

terminal block at the last

drive on each channel.

1769-SM2

Module

MODULE

CH1

C

H

1

CH1

C

H

2

CH2

C

H

3

CH3

.

CH2 CH3

AK-U0-RJ45-TB2P

Terminal Block

Connectors

User-Supplied Wire (recommend

Belden No. 3105A or equivalent)

AK-U0-RJ45-TB2P

Terminal Block

Connectors

User-Supplied Wire (recommend

Belden No. 3105A or equivalent)

Up to 5 PowerFlex 4-Class drives

120 ohm, ¼ Watt

Terminating Resistor

Up to 5 PowerFlex 4-Class drives

120 ohm, ¼ Watt

Terminating Resistor

Earth Ground

Connection

Ground Wire Connection

(for network

communication

cable shielding)

AK-U0-RJ45-TB2P

Terminal Block

Connectors

User-Supplied Wire (recommend

Belden No. 3105A or equivalent)

Up to 5 PowerFlex 4-Class drives

120 ohm , ¼ Watt

Terminating Resistor

Page 17

Getting Started 1-5

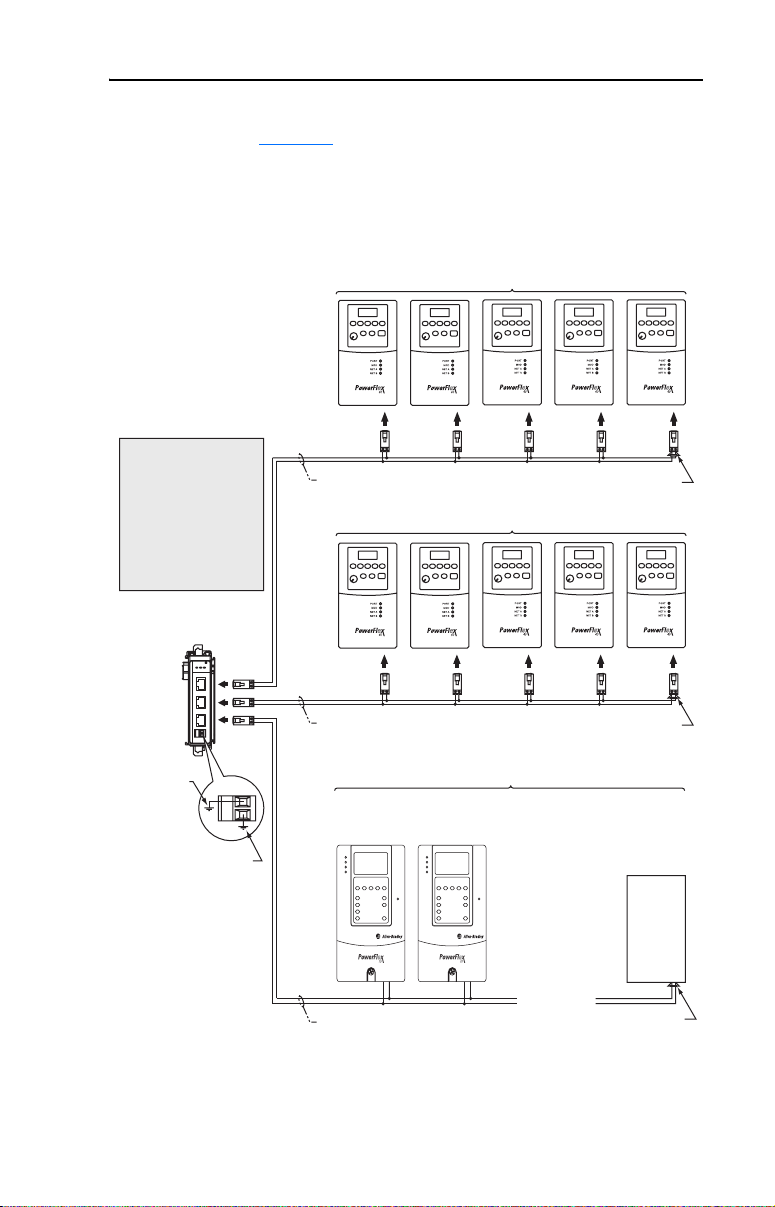

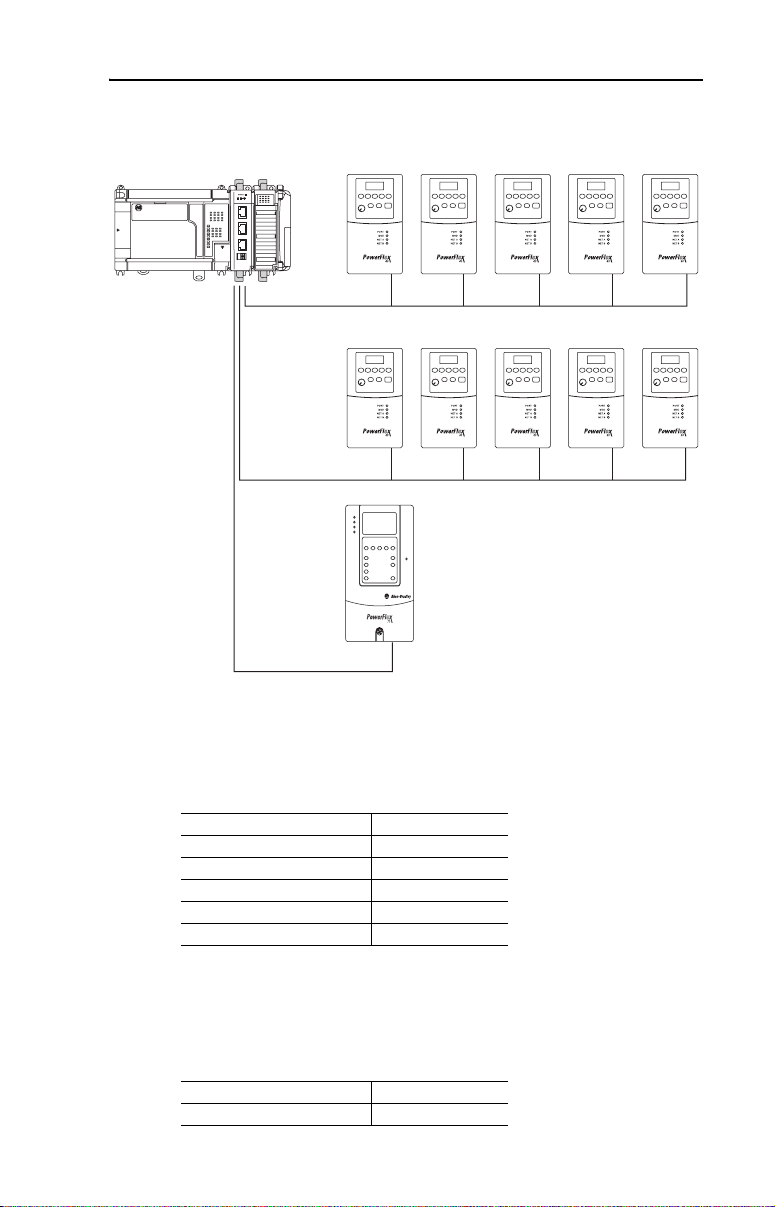

In Multi-Drive mode, any channel can be configured for “RTU Master”

operation (Figure 1.4). This enables connection of up to 31 RTU Slave

devices, such as PowerFlex 7-Class drives with 20-COMM-H RS485

HVAC adapters.

Figure 1.4 Multi-Drive Mode and Modbus RTU Master Mode Wiring Example

CH1 - Multi-Drive Mode (up to 5 PowerFlex 4-Class Drives)

AK-U0-RJ45-TB2P

Terminal Block

Wiring Tip:

The 1769-SM2 has an

integral terminating

resistor for each channel.

Thus, it is only necessary

to connect a terminating

resistor to the RJ45

terminal block at the last

drive on each channel.

CH1

CH2

CH3

1769-SM2

Module

MODULE

CH1

CH2 CH3

C

H

1

C

H

2

C

H

3

Connectors

User-Supplied Wire (recommend

Belden No. 3105A or equivalent)

CH2 - Multi-Drive Mode (up to 5 PowerFlex 4-Class Drives)

AK-U0-RJ45-TB2P

Terminal Block

Connectors

User-Supplied Wire (recommend

Belden No. 3105A or equivalent)

Terminating Resistor

Terminating Resistor

120 ohm, ¼ Watt

120 ohm, ¼ Watt

Earth Ground

Connection

Ground Wire Connection

(for network

communication

cable shielding)

CH3 - Modbus RTU Master Mode (up to 31 Devices)

PowerFlex 7-Class Drives

with 20-COMM-H RS485 HVAC

Communication Adapters

. . .

User-Supplied Wire (recommend

Belden No. 3105A or equivalent)

Terminating Resistor

Generic

Modbus RTU

Device

120 ohm, ¼ Watt

Page 18

1-6 Getting Started

Benefits of Multi-Drive mode include:

• Lower hardware costs. Only one 1769-SM2 is needed for up to five

PowerFlex 4-Class drives per channel (15 total).

• Controller can independently control, monitor, and read/write

parameters for all five drives on each channel (same functionality as

Single mode).

The trade-offs of Multi-Drive mode include:

• Since the RS-485 ports are used for daisy-chaining the drives,

additional DSI peripheral devices cannot be used with the drives.

This includes an optional, external PowerFlex 4-Class HIM

(22-HIM-A3 or 22-HIM-C2S) or a 22-SCM-232 Serial Converter

module with a software tool. The AK-U0-RJ45-SC1 DSI Splitter

cable cannot be used to add a second connection for a DSI peripheral

device.

Compatible Products

The 1769-SM2 module is compatible with Allen-Bradley PowerFlex

4-Class (Component class) drives and other products that support DSI.

At the time of publication, compatible products include:

• PowerFlex 4 drives

• PowerFlex 4M drives

• PowerFlex 40 drives

• PowerFlex 40P drives

• PowerFlex 400 drives

When the 1769-SM2 is used in Multi-Drive as a Modbus RTU Master,

other Modbus RTU Slave devices, such as PowerFlex 7-Class drives

with 20-COMM-H RS485 HVAC adapters, can also be connected.

Required Equipment

Equipment Shipped with the Module

When you unpack the module, verify that the package includes:

❑ One 1769-SM2 module

❑ This manual

Page 19

Getting Started 1-7

User-Supplied Equipment

To install and configure the 1769-SM2 module, you must supply:

❑ A small flathead screwdriver

❑ Communications cable 22-RJ45CBL-C20

- orAK-U0-RJ45-TB2P terminal block connectors (one for each

channel connection and one for each drive connection) and twisted

pair network wiring (Belden No. 3105A or equivalent)

❑ Configuration tool, such as:

– PowerFlex 4-Class HIM (22-HIM-A3 or 22-HIM-C2S)—

required to access module parameters if not using DriveExplorer

software or DriveExecutive software

– DriveExplorer (version 3.01 or higher)

– DriveExecutive stand-alone software (version 4.01 or higher) or

bundled with the DriveTools SP suite (version 4.01 or higher)

– RSNetWorx for DeviceNet

❑ Controller configuration software (such as RSLogix 500/5000)

Safety Precautions

Please read the following safety precautions carefully.

ATTENTION: Risk of injury or death exists. The PowerFlex drive

may contain high voltages that can cause injury or death. Remove all

!

power from the PowerFlex drive, and then verify power has been

removed before installing or removing the module.

ATTENTION: Risk of injury or equipment damage exists. Only

personnel familiar with drive and power products and the associated

!

machinery should plan or implement the installation, start-up,

configuration, and subsequent maintenance of the product using the

module. Failure to comply may result in injury and/or equipment

damage.

ATTENTION: Risk of injury or equipment damage exists. If the

module is transmitting control I/O to the drive, the drive may fault when

!

you reset the module. Determine how your drive will respond before

resetting the module.

ATTENTION: Risk of injury or equipment damage exists. When a

system is configured for the first time, there may be unintended or

!

incorrect machine motion. Disconnect the motor from the machine or

process during initial system testing.

Page 20

1-8 Getting Started

ATTENTION: Risk of injury or equipment damage exists.

Parameters 04 - [Idle Action 1], 19 - [Idle Action 2], and 34 - [Idle

!

Action 3] let you determine the action of the module and connected

drives if communications are disrupted. By default, these parameters

fault the drive. You can set these parameters so that the drive continues

to run. Precautions should be taken to ensure that the settings of these

parameters do not create a risk of injury or equipment damage. When

commissioning the drive, verify that your system responds correctly to

various situations (for example, a disconnected cable or a faulted

controller).

ATTENTION: Risk of injury or equipment damage exists. The

examples in this publication are intended solely for purposes of

!

example. There are many variables and requirements with any

application. Rockwell Automation, Inc. does not assume responsibility

or liability (to include intellectual property liability) for actual use of

the examples shown in this publication.

ATTENTION: This equipment is intended for use in a Pollution

Degree 2 industrial environment, in overvoltage Category II

!

applications (as defined in IEC publication 60664-1), at altitudes up to

2000 meters without derating.

This equipment is considered Group 1, Class A industrial equipment

according to IEC/CISPR Publication 11. Without appropriate

precautions, there may be potential difficulties ensuring

electromagnetic compatibility in other environments due to conducted

as well as radiated disturbance.

This equipment is supplied as “open type” equipment. It must be

mounted within an enclosure that is suitably designed for those specific

environmental conditions that will be present and appropriately

designed to prevent personal injury resulting from accessibility to live

parts. The interior of the enclosure must be accessible only by the use

of a tool. Subsequent sections of this publication may contain

additional information regarding specific enclosure type ratings that are

required to comply with certain product safety certifications.

See NEMA Standards publication 250 and IEC publication 60529, as

applicable, for explanations of the degrees of protection provided by

different types of enclosure. Also, see the appropriate sections in this

publication, as well as the Allen-Bradley publication 1770-4.1

(“Industrial Automation Wiring and Grounding Guidelines”), for

additional installation requirements pertaining to this equipment.

Page 21

Getting Started 1-9

Quick Start

This section is provided to help experienced users quickly start using the

1769-SM2 Compact I/O to DSI module. If you are unsure how to

complete a step, refer to the referenced chapter.

Step Action Refer to…

1 Review the safety precautions for the module. Throughout This Manual

2 Verify that the drive is properly installed. Drive User Manual

3 Install the module.

Verify that the controller is not powered. Connect the

module to the controller backplane bus. Then connect

the module to the drive(s) using communications cable

22-RJ45CBL-C20 or AK-U0-RJ45-TB2P terminal block

connectors and communications network wiring.

4 Apply power to the module.

The module receives power from the controller. Apply

power to the controller. The MODULE indicator should

be green or flashing green. If it flashes red, there is a

problem. Refer to Chapter

5 Configure the module for your application.

Set the following parameters for the module as required

by your application:

• I/O configuration.

• Fault actions.

6 Apply power to the drive. Drive User Manual

7 Configure the controller to communicate with the

module.

8 Create a ladder logic program.

Use a programming tool such as RSLogix to create a

ladder logic program that enables you to:

• Control the module and connected drive.

• Monitor or configure the drive using Explicit

Messages.

9, Troubleshooting.

Chapter

2,

Installing the Module

3,

Chapter

Configuring the Module

Depending on the type of

controller and 1769-SM2

operating mode:

• Chapter

• Chapter 7,

• Chapter 8,

6,

MicroLogix 1500

Example Ladder

Programs

CompactLogix

Example Ladder

Programs

ControlLogix w/

1769-ADN DeviceNet

Example Ladder

Program

Page 22

1-10 Getting Started

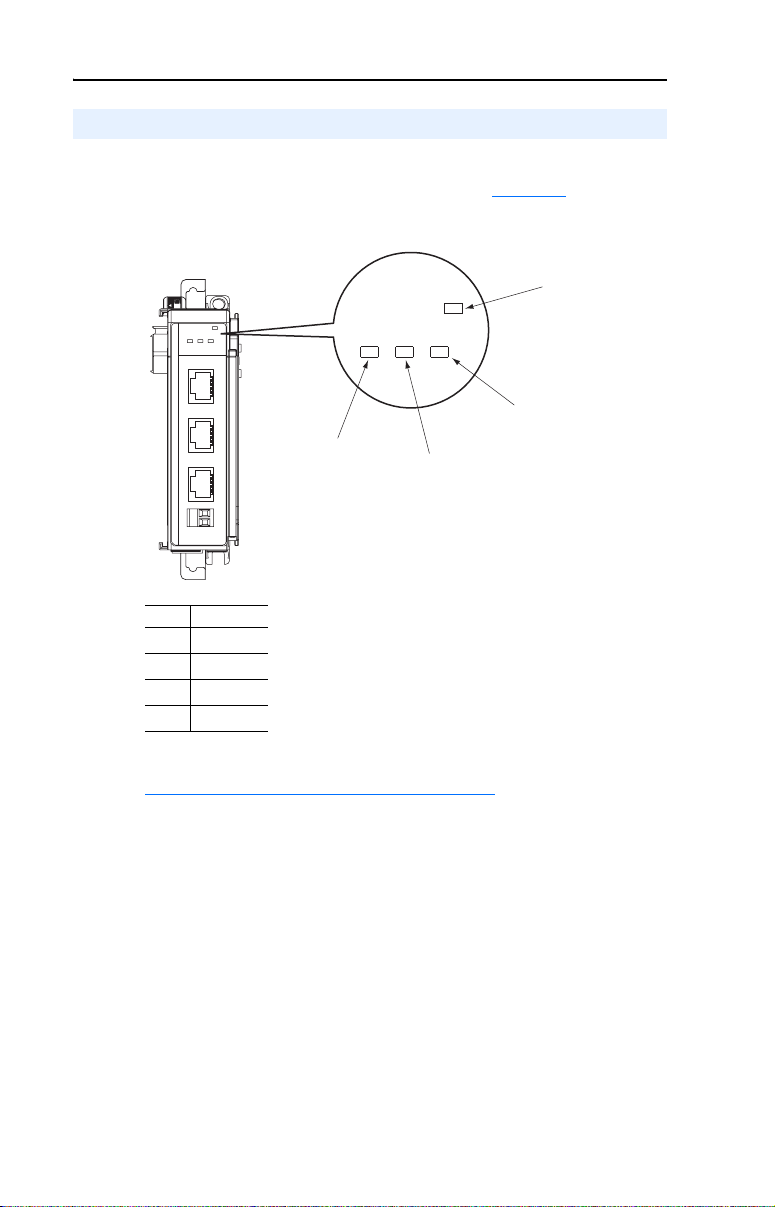

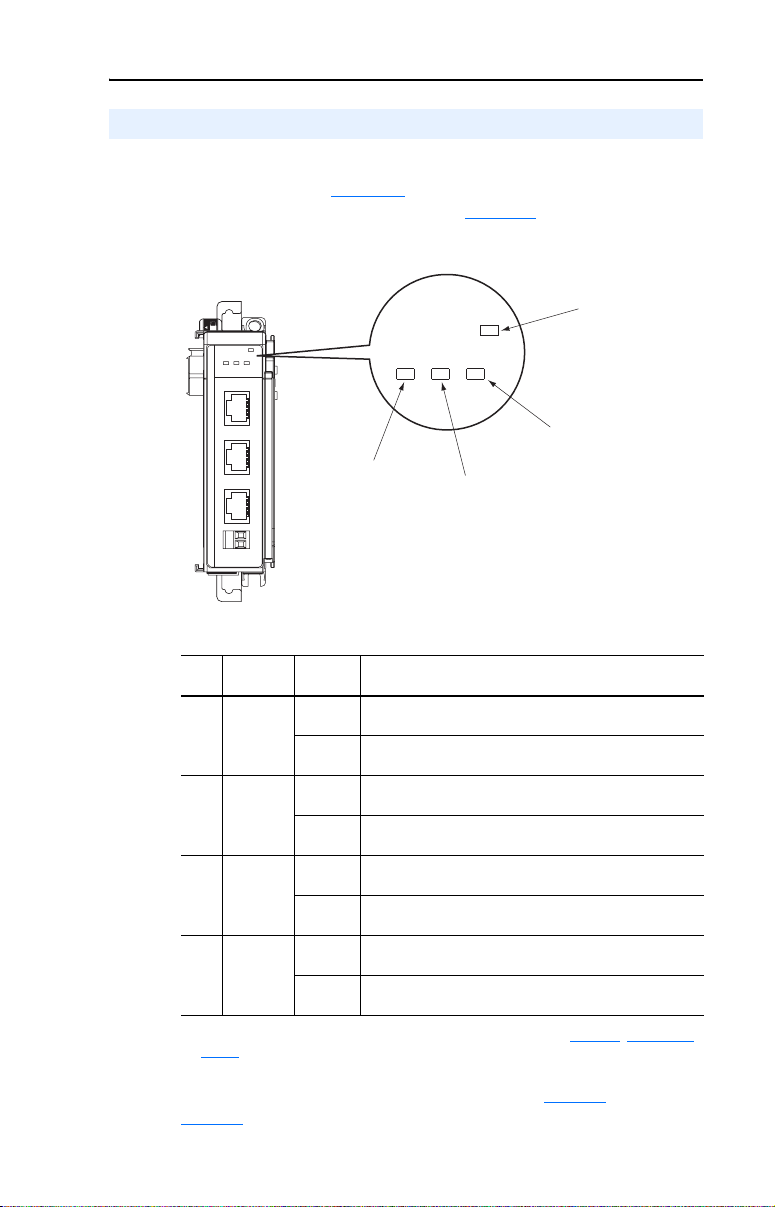

Status Indicators

The module uses four status indicators to report its operating status.

They can be viewed on the front of the module (Figure 1.5

Figure 1.5 Status Indicators

MODULE

CH1

CH2 CH3

DSI

C

H

1

C

H

2

C

H

3

Item Name

MODULE

➊

CH1

➋

CH2

➌

CH3

➍

).

➊

MODULE

CH1

CH2

CH3

➋

➍

➌

After installing the module and applying power to the drive(s), refer to

Viewing Start-Up Status Indicators

status indications and their descriptions.

on page 2-15 for possible start-up

Page 23

Chapter 2

Installing the Module

This chapter provides instructions for installing the 1769-SM2 as an

expansion I/O module on MicroLogix 1500 and CompactLogix

controllers, or with a remote 1769-based adapter.

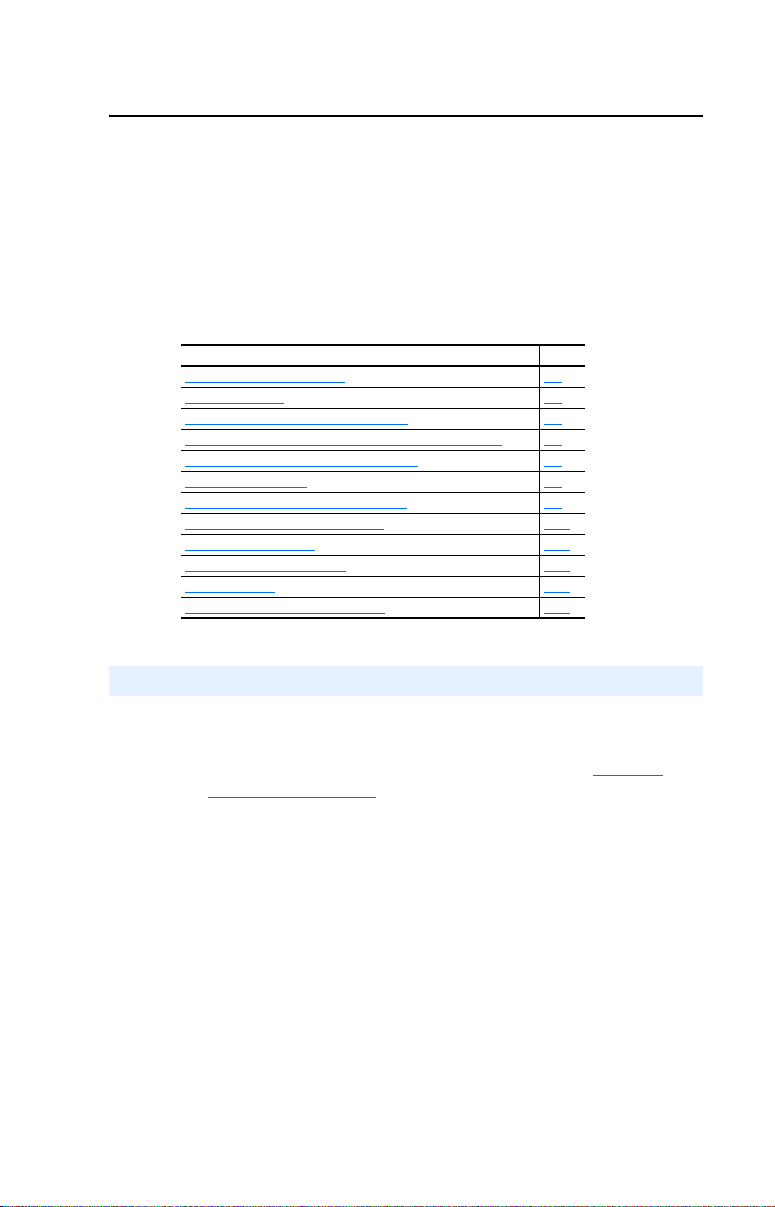

Topic Page

Preparing for an Installation

Removing Power 2-2

Setting the Configuration Mode Switch 2-3

Setting the Operating Mode Switch (Single/Multi-Drive) 2-4

Assembling the Module to the Controller 2-5

Mounting the Module 2-6

Replacing the Module within a System 2-9

Connecting Drive(s) to the Module 2-10

Grounding the Module 2-12

Network Cable Strain Relief 2-14

Applying Power 2-14

Viewing Start-Up Status Indicators 2-15

2-1

Preparing for an Installation

Consider the following when installing the 1769-SM2 module:

• Verify that you have all required equipment. Refer to Required

Equipment on page 1-6.

• A MicroLogix 1500 Base Unit or Compact I/O power supply has

limits in the amount of +5V dc and +24V dc current it can supply to

modules in its I/O bank. These limits depend on the catalog number

(e.g. 1769-PA2) of the power supply. A bank of modules must not

exceed the current limits of the MicroLogix 1500 Base Unit or I/O

bank power supply.

Refer to the MicroLogix 1500 User Manual (publication

1764-UM001) or the Compact 1769 Expansion I/O Power Supplies

Installation Instructions (publication 1769-5.14).

• The module has a distance rating of four. Therefore, the module must

be within four modules of the I/O bank’s power supply.

Page 24

2-2 Installing the Module

ATTENTION: Risk of equipment damage exists. The 1769-SM2

module contains ESD (Electrostatic Discharge) sensitive parts that can

!

be damaged if you do not follow ESD control procedures. Static control

precautions are required when handling the module. If you are

unfamiliar with static control procedures, refer to Guarding Against

Electrostatic Damage (publication 8000-4.5.2).

Removing Power

ATTENTION: Risk of equipment damage exists. Remove power

before installing or removing the 1769-SM2 module. When you install

!

or remove the module with power applied, an electrical arc may occur.

An electrical arc can cause personal injury or equipment damage by:

• Sending an erroneous signal to your system’s field devices, causing

unintended machine motion.

• Causing an explosion in a hazardous environment.

Electrical arcing causes excessive wear to contacts on both the module

and its mating connector. Worn contacts may create electrical

resistance.

Page 25

Installing the Module 2-3

Setting the Configuration Mode Switch

Before installing the module, make sure its Configuration Mode Switch

is correctly set. See Configuration Methods on page 3-3 for details on

the Controller and Parameter configuration modes. Then set the

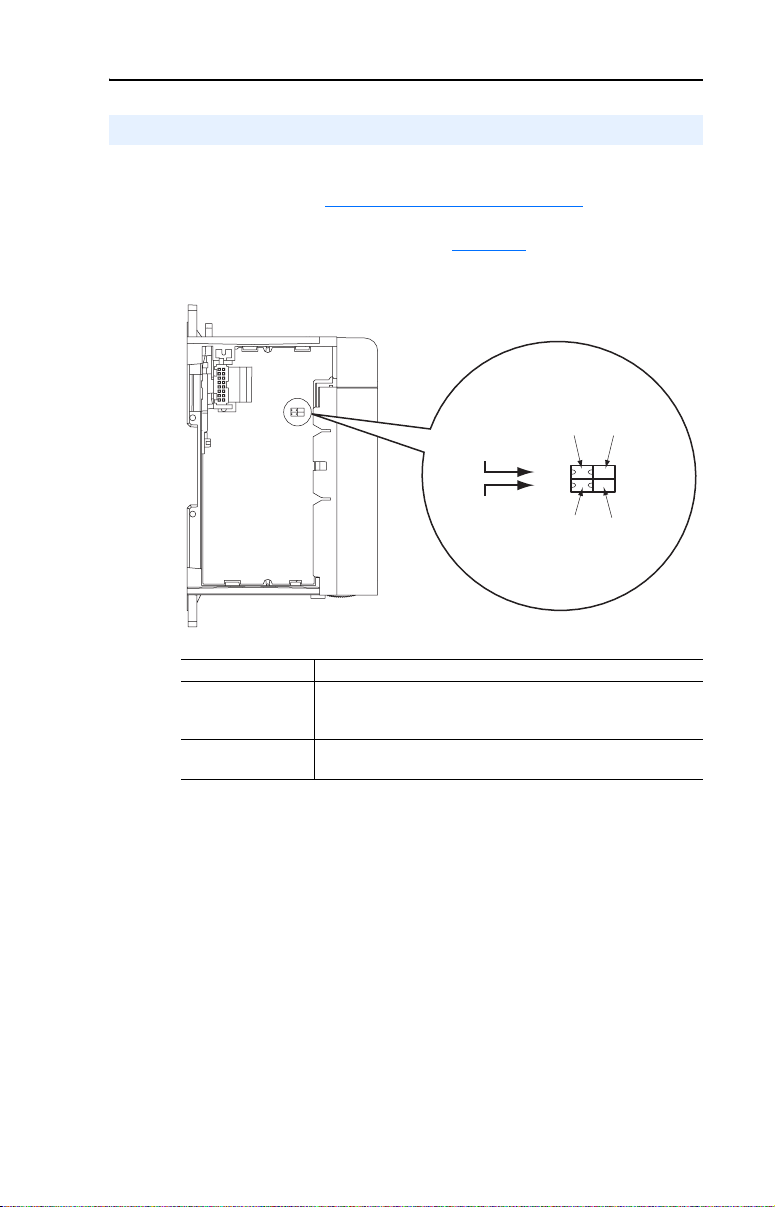

Configuration Mode Switch (SW1 in Figure 2.1

Figure 2.1 Configuration Mode and Single/Multi-Drive Operation Switch Locations

) for your application.

SW1 Setting Description

CONT (Controller)

back position

PARAM (Parameter)

front position

Default setting—The 1769-SM2 module uses the configuration

data downloaded from the controller on power-up and when the

controller is placed in run mode.

The 1769-SM2 module uses its internal parameter settings to

configure the module.

Configuration

Mode Switch

(SW1)

Operating

Mode Switch

(SW2)

(Controller

Position)

CONT PARAM

(Single

Position)

(Parameter

Position)

1X 5X

(Multi-Drive

Position)

Page 26

2-4 Installing the Module

Setting the Operating Mode Switch (Single/Multi-Drive)

Before installing the module, set its Operating Mode Switch (SW2 in

Figure 2.1) for Single or Multi-Drive operation. All channels (CH1,

CH2, and CH3) will operate in the selected mode.

SW2 Setting Description

1X (Single mode)

back position

5X (Multi-Drive mode)

front position

Default setting — sets the 1769-SM2 module for Single mode

using a single drive connection (one drive per channel).

Important: In Single mode, only one drive can be connected per

channel. Connections to multiple drives must be removed since

all powered and connected hosts will respond to any message

sent by the module.

Sets the 1769-SM2 module for Multi-Drive mode using up to five

PowerFlex 4-Class drives per channel.

In Multi-Drive mode, DSI peripherals such as the 22-HIM-A3 /

-C2S Human Interface Module, 22-SCM-232 serial converter, etc.

CANNOT be used. They will not operate with the 1769-SM2

module or drives.

The specific number of drives used in Multi-Drive mode for each

channel and a unique address for each drive must be configured

using 1769-SM2 module parameters. For instructions, see

Setting the I/O Configuration (Multi-Drive Mode Only)

page 3-14 and Setting Drive Node Addresses (Multi-Drive Mode

Only) on page 3-16.

NOTE: In Multi-Drive mode, each channel can be independently

configured for Modbus RTU Master operation by setting the

respective channel’s [DSI I/O Cfg] parameter to “5” (RTU Master).

This enables up to 31 RTU slave devices, such as PowerFlex

7-Class drives with 20-COMM-H RS485 HVAC adapters to be

connected to that channel.

on

Important: A new switch setting is recognized only when power is

applied to the module, or the module is reset. If you change

a setting, cycle power or reset the module.

The Configuration Mode Switch (SW1) and Operating Mode Switch

(SW2) settings can be verified by respectively viewing module

Parameters 01 - [Config Mode] and 02 - [DSI Mode] using an

optional, external PowerFlex 4-Class HIM, DriveExplorer software or

DriveExecutive software.

Page 27

Installing the Module 2-5

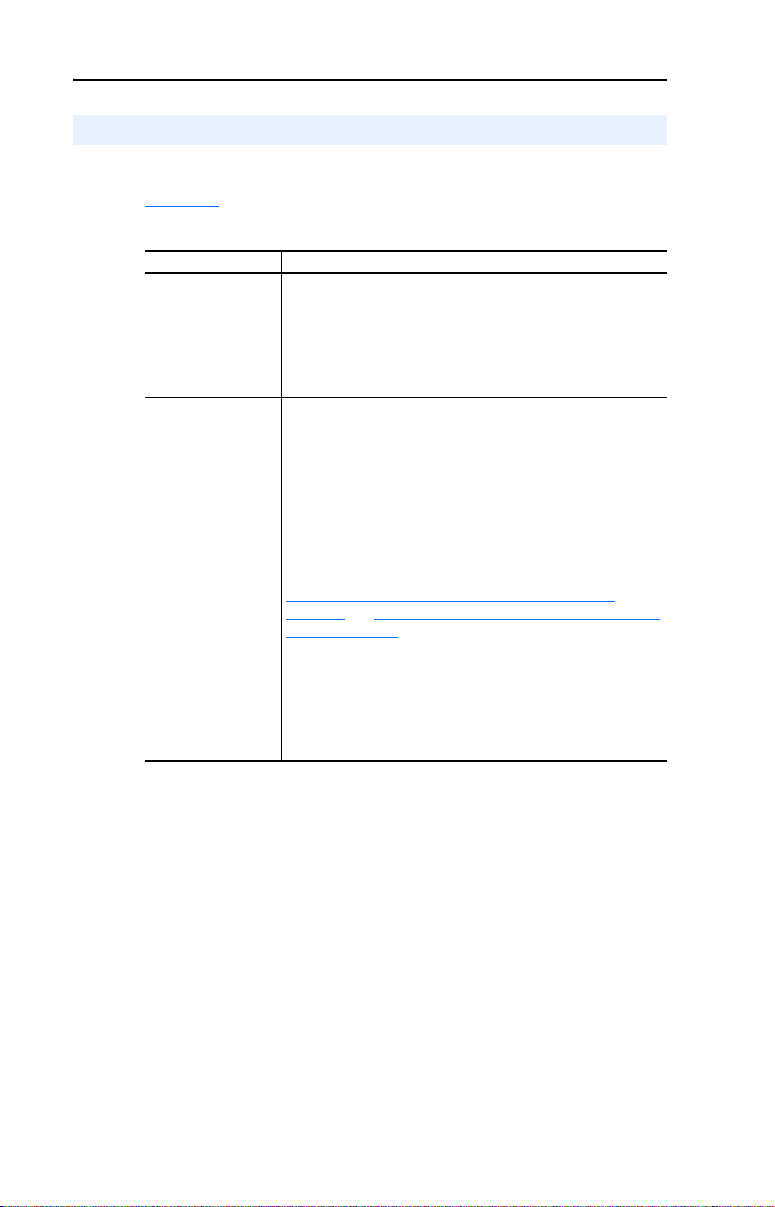

Assembling the Module to the Controller

The 1769-SM2 module can be attached to adjacent controller modules

before or after mounting. For mounting instructions, see Panel

Mounting on page 2-6 or DIN Rail Mounting on page 2-8. To work with

a system that is already mounted, see Replacing the Module within a

System on page 2-9.

Figure 2.2 and the following procedure describes how to assemble the

Compact I/O system.

Figure 2.2 Assembling 1769-SM2 Module to Compact I/O System

A

C

B

D

E

B

F

1. Disconnect power.

2. Check that the bus lever (A) of the 1769-SM2 module is in the

unlocked (fully right) position.

3. Use the upper and lower tongue-and-groove slots (B) to secure the

modules together.

4. Move the 1769-SM2 module back along the tongue-and-groove slots

until the bus connectors (C) line up with each other.

5. Use your fingers or a small screwdriver to push the bus lever back

slightly to clear the positioning tab (D).

6. Move the 1769-SM2 module’s bus lever fully to the left (E) until it

clicks. Ensure it is locked firmly in place.

G

ATTENTION: Risk of equipment damage exists. When attaching the

1769-SM2 module to a Compact I/O system, it is very important that

!

the bus connectors are securely locked together to ensure proper

electrical connection. Failure to do this may cause an electrical arc,

which can cause personal injury or equipment damage.

Page 28

2-6 Installing the Module

7. Attach an end cap terminator (F) to the last module in the system by

using the tongue-and-groove slots as before.

8. Lock the end cap bus terminator (G).

Important: A 1769-ECR or 1769-ECL right or left end cap must be

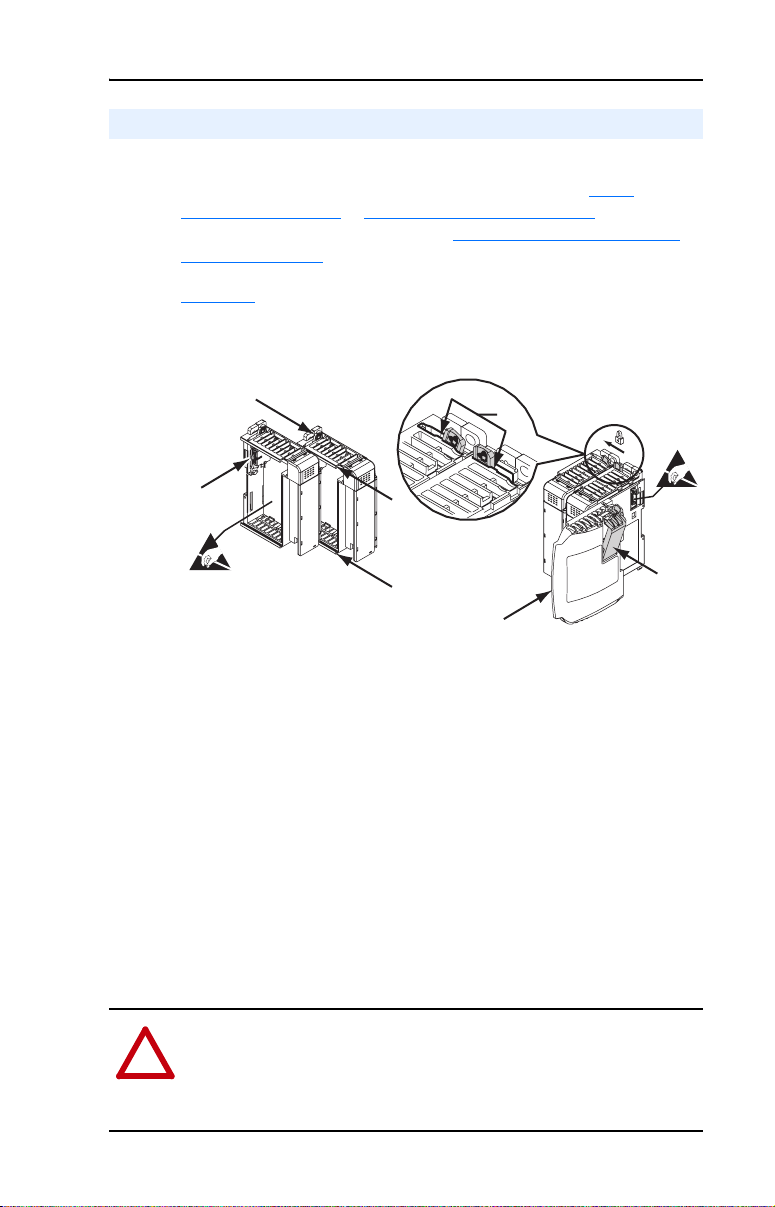

Mounting the Module

ATTENTION: Risk of equipment damage exists. During panel or

DIN rail mounting of all devices, be sure that all debris (metal chips,

!

wire strands, etc.) is kept from falling into the 1769-SM2 module.

Debris that falls into the module could cause damage on power up.

Minimum Spacing

Maintain spacing from enclosure walls, wireways, adjacent equipment,

etc. Allow 50 mm (2 in.) of space on all sides for adequate ventilation as

shown:

used to terminate the end of the serial communication

bus.

To p

Side

Allow at least 140 mm (5.5 in.) of enclosure depth to accommodate the

1769-SM2 module.

Panel Mounting

Mount the 1769-SM2 module to a panel using two screws per module.

Use M4 or #8 panhead screws (not included). Mounting screws are

required on every module.

Controller

Compact I/O

Compact I/O

Compact I/O

Bottom

Compact I/O

Compact I/O

End Cap or Cable

Side

Page 29

Installing the Module 2-7

Panel Mounting Using the Dimensional Drawing

NOTE: All dimensions are in mm (inches). Hole spacing tolerance is

±0.4 mm (0.016 in.).

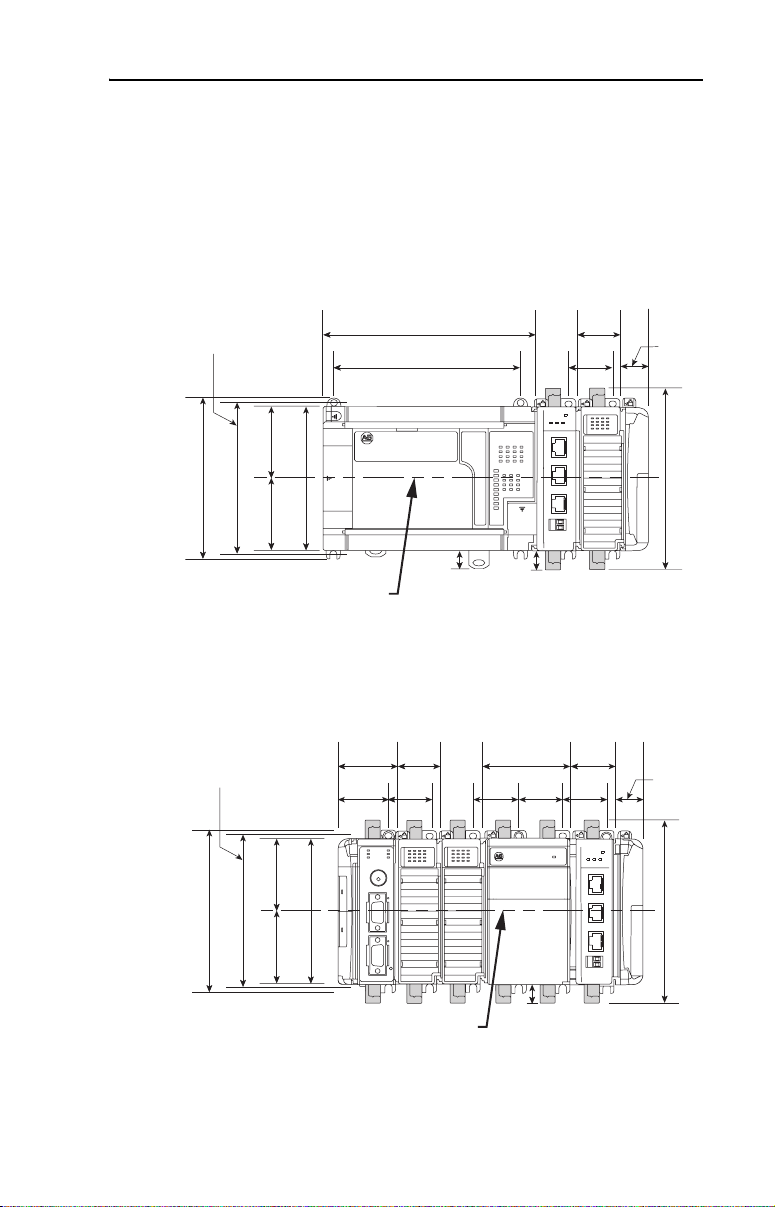

Figure 2.3 1769-SM2 Module with MicroLogix 1500 Base Unit and Processor

Mounting Hole

Dimension

132 mm (5.19 in)

122.6 mm (4.83 in)

59 mm

59 mm

(2.32 in)

(2.32 in)

118 mm (4.65 in)

168 mm

(6.62 in)

147 mm

(5.79 in)

ANport

PI / SC

D

C

H

1

C

H

2

C

H

3

DIN Rail

Center Line

13.5 mm

(0.53 in)

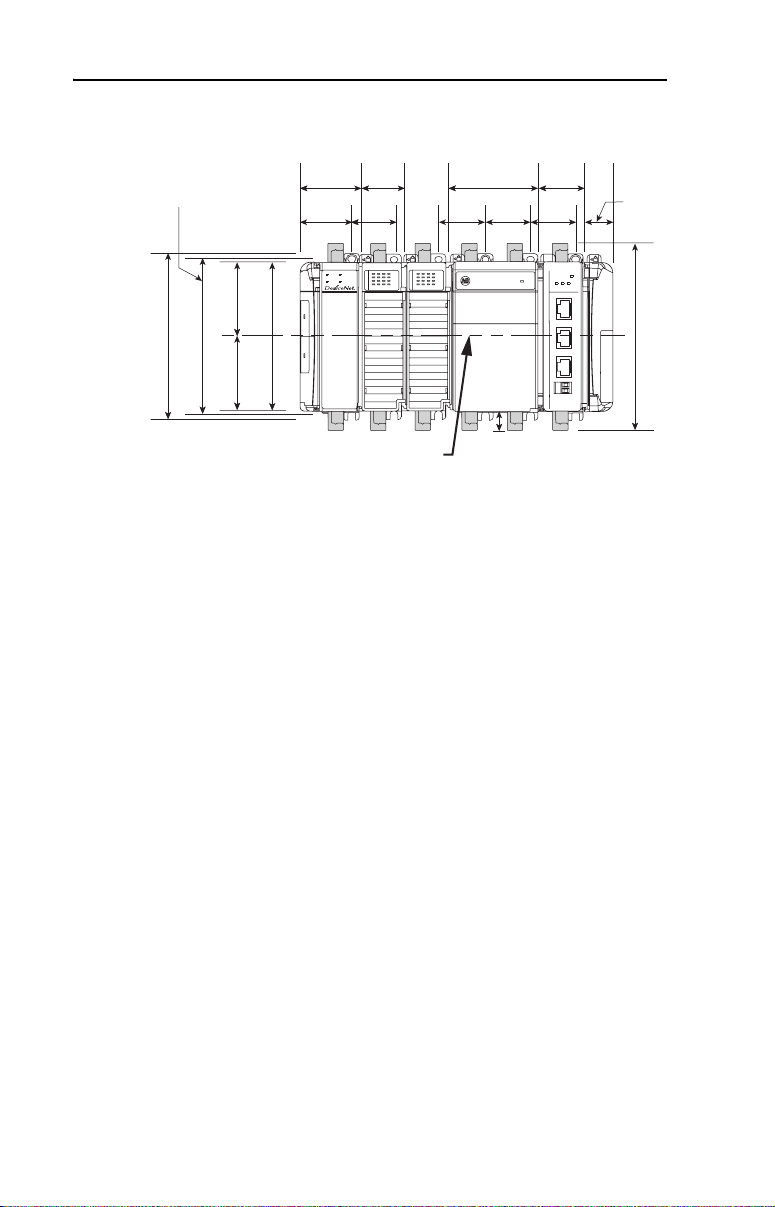

Figure 2.4 1769-SM2 Module with CompactLogix Controller

35 mm

Mounting Hole

Dimension

50 mm

(1.97 in)

40 mm

(1.58 in)

(1.38 in)

35 mm

(1.38 in)

(2.76 in)

35 mm

(1.38 in)

14.7 mm

(0.58 in)

70 mm

35 mm

(1.38 in)

59 mm

(2.32 in)

132 mm (5.19 in)

122.6 mm (4.83 in)

118 mm (4.65 in)

59 mm

(2.32 in)

CH1

MODULE

CH2

CH3

35 mm

(1.38 in)

35 mm

(1.38 in)

35 mm

(1.38 in)

35 mm

(1.38 in)

MODULE

ort

CH1

CH2

DPI / SCANp

C

H

1

C

H

2

C

H

3

28.5 mm

(1.12 in)

147.4 mm (5.81 in)

28.5 mm

(1.12 in)

CH3

147.4 mm (5.81 in)

DIN Rail

Center Line

14.7 mm

(0.58 in)

Page 30

2-8 Installing the Module

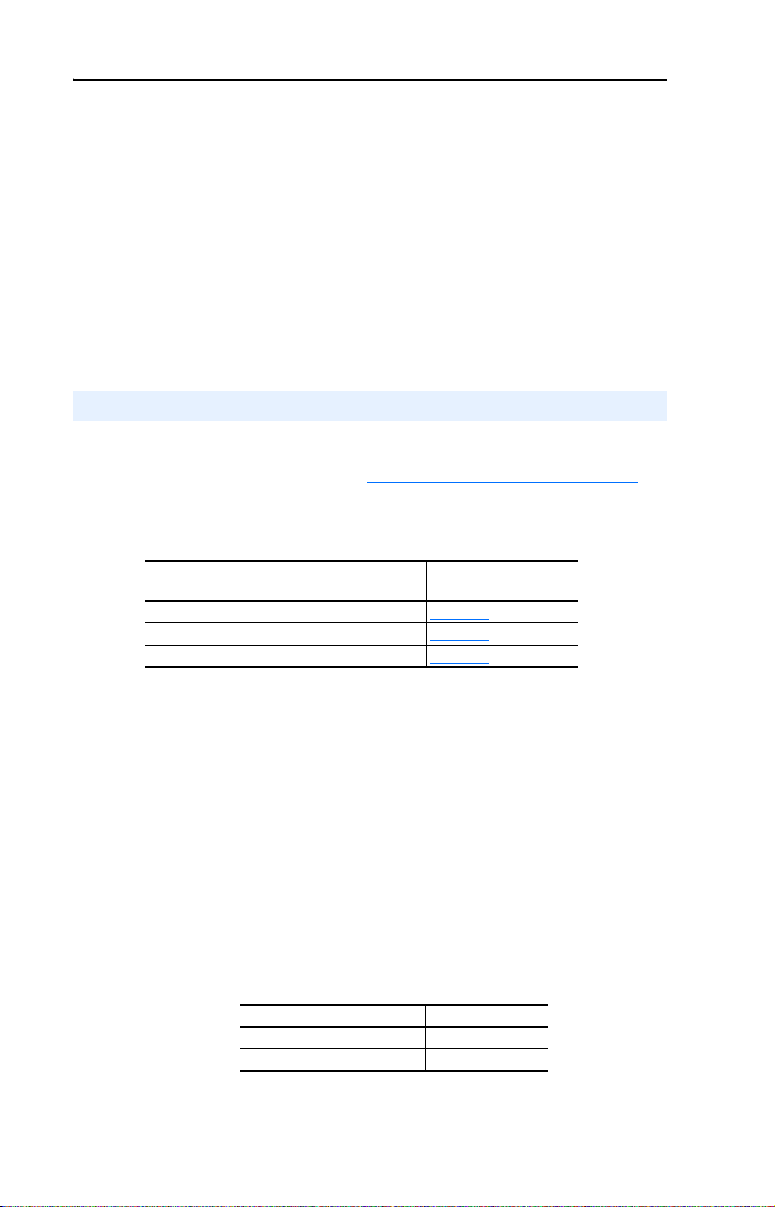

Figure 2.5 1769-SM2 Module with Remote 1769-Based Adapter

35 mm

(1.38 in)

35 mm

(1.38 in)

35 mm

(1.38 in)

port

CH1

N

A

C

I / S

P

D

C

H

1

C

H

2

C

H

3

28.5 mm

(1.12 in)

MODULE

CH2

CH3

147.4 mm (5.81 in)

Mounting Hole

Dimension

132 mm (5.19 in)

122.6 mm (4.83 in)

59 mm

59 mm

(2.32 in)

(2.32 in)

50 mm

(1.97 in)

40 mm

(1.58 in)

MS

IO

118 mm (4.65 in)

35 mm

(1.38 in)

35 mm

(1.38 in)

NS

DIAG

DIN Rail

Center Line

70 mm

(2.76 in)

35 mm

(1.38 in)

14.7 mm

(0.58 in)

Panel Mounting Procedure Using Module as a Template

The following procedure enables you to use the assembled modules as a

template for drilling holes in the panel. Due to module mounting hole

tolerance, it is important to follow these steps:

1. On a clean work surface, assemble no more than three modules.

2. Using the assembled modules as a template, carefully mark the

center of all module-mounting holes on the panel.

3. Return the assembled modules to the clean work surface, including

any previously mounted modules.

4. Drill and tap the mounting holes for the recommended M4 or #8

screw (not included).

5. Place the modules back on the panel, and check for proper hole

alignment.

6. Attach the modules to the panel using the mounting screws.

DIN Rail Mounting

The 1769-SM2 module can be mounted using these DIN rails:

• 35 x 7.5 mm (EN 50 022 - 35 x 7.5)

• 35 x 15 mm (EN 50 022 - 35 x 15)

When mounting the module to a DIN rail, make sure that the latches are

closed and properly securing the module.

Page 31

Installing the Module 2-9

Replacing the Module within a System

The 1769-SM2 module can be replaced while the system is mounted to a

panel (or DIN rail).

ATTENTION: Risk of equipment damage exists. Remove power

before installing or removing the 1769-SM2 module. When you install

!

or remove the module with power applied, an electrical arc may occur.

An electrical arc can cause personal injury or equipment damage by:

• Sending an erroneous signal to your system’s field devices, causing

unintended machine motion.

• Causing an explosion in a hazardous environment.

Electrical arcing causes excessive wear to contacts on both the module

and its mating connector. Worn contacts may create electrical

resistance.

1. Remove power.

2. Unplug the communications cable from each port (CH1, CH2, CH3)

on the 1769-SM2 module. Note each drive and the port to which it is

connected.

3. Remove the upper and lower mounting screws from the module (or

open the DIN latches using a flat-blade screwdriver).

4. On the right-side adjacent module, move its bus lever to the right

(unlock) to disconnect it from the module being removed.

5. Gently slide the disconnected 1769-SM2 module forward.

If you feel excessive resistance, make sure that you disconnected the

module from the bus and that you removed both mounting screws (or

opened the DIN latches).

TIP: It may be necessary to rock the module slightly from front to

back to remove it or, in a panel-mounted system, to loosen the screws

of adjacent modules.

6. Before installing the replacement 1769-SM2 module, be sure that the

bus lever on the right-side adjacent module is in the unlocked (fully

right) position.

7. Slide the replacement 1769-SM2 module into the open slot.

Page 32

2-10 Installing the Module

8. Connect the 1769-SM2 module and adjacent modules together by

locking (fully left) the bus levers on the 1769-SM2 module and the

right-side adjacent module.

9. Replace the mounting screws (or snap the module onto the DIN rail).

10. Plug the appropriate communications cable into its respective port on

the 1769-SM2 module.

11. Restore 1769-SM2 module configuration using an appropriate

configuration tool.

Connecting Drive(s) to the Module

NOTE: For Single or Multi-Drive mode, there is a maximum cable

distance limit per channel. See DSI Cable Requirements

more information.

For network wiring diagram examples, see the following figures:

1769-SM2 Operating Mode

Single mode (Default) Figure 1.2

Multi-Drive mode Figure 1.3

Multi-Drive mode with Modbus RTU Master Figure 1.4

on page A-2 for

Network Wiring

Diagram Example…

Single Mode

When the 1769-SM2 module is operated in Single drive mode, each

drive is directly connected to a channel port (CH1, CH2 or CH3) on the

module. Use either a 22-RJ45CBL-C20 communications cable for each

channel or AK-U0-RJ45-TB2P terminal block connectors and twisted

pair network wiring (Belden No. 3105A or equivalent).

Important: When connecting a drive to the channel port using

AK-U0-RJ45-TB2P terminal block connectors and twisted

pair network wiring, the following drive parameters MUST

be configured to the settings shown so that the 1769-SM2

module will communicate with the drive:

Drive Parameter Setting

A103 - [Comm Data Rate] “4” (19.2K)

A107 - [Comm Format] “0” (RTU 8-N-1)

Changes to these drive parameters require the drive to be

reset for the new settings to take effect.

Page 33

Installing the Module 2-11

When connecting a drive to the channel port using 22-RJ45CBL-C20

communications cable, the above drive parameters do not require

configuration because the drive senses that a DSI peripheral is connected

and it ignores these parameter settings.

Multi-Drive Mode

For Multi-Drive mode, each channel port MUST be connected to the

drives via daisy-chaining using AK-U0-RJ45-TB2P terminal block

connectors (one for the port connection and one for each drive

connection) and twisted pair network wiring (Belden No. 3105A or

equivalent). The 22-RJ45CBL-C20 communications cable and splitter

cables cannot be used.

Important: The following drive parameters MUST be configured to the

settings shown so that the 1769-SM2 module will

communicate with the drives:

Drive Parameter Setting

A103 - [Comm Data Rate] “4” (19.2K)

A104 - [Comm Node Addr] Value of Drive Addr x parameter in the

1769-SM2

A107 - [Comm Format] “0” (RTU 8-N-1)

Changes to these drive parameters require the drive to be

reset for the new settings to take effect.

Page 34

2-12 Installing the Module

Grounding the Module

The 1769-SM2 module is intended to be mounted to a well-grounded

mounting surface such as a metal panel. Additional grounding

connections from the module’s mounting tabs or DIN rail (if used) are

not required unless the mounting surface cannot be grounded. Refer to

Industrial Automation Wiring and Grounding Guidelines, publication

1770-4.1, for additional information.

Shielded Connector Grounding Requirements

When using the 22-RJ45CBL-20 cable, which has shielded connectors,

the shields are all grounded to the chassis terminal block on the

1769-SM2 module (item 11 in Figure 1.1

• Install a wire from the chassis terminal block on the 1769-SM2

module to a grounded, conductive surface (i.e. metal panel). See

Figure 2.6

• Remove the shield connection to chassis ground at the drive I/O

block shield terminal.

Drive Drive I/O Block

PowerFlex 4 Terminal 16

PowerFlex 4M Terminal 16

PowerFlex 40 Terminal 19

PowerFlex 40P Terminal 19

PowerFlex 400 Terminal 20

.

). However, the user must:

Figure 2.6 Shielded Connector Grounding Details

MODULE

CH1

CH2 CH3

DSI / Modbus RTU

C

H

1

C

H

2

C

H

3

To Drive 1

To Drive 2

To Drive 3

Page 35

Installing the Module 2-13

Unshielded Connector Grounding Requirements

When using twisted pair network wiring with unshielded

AK-U0-RJ45-TB2P connectors, ground the RJ45 socket on the drive by

connecting the drive chassis ground power terminal to the I/O block

shield terminal.

Drive Drive I/O Block

PowerFlex 4 Terminal 16

PowerFlex 4M Terminal 16

PowerFlex 40 Terminal 19

PowerFlex 40P Terminal 19

PowerFlex 400 Terminal 20

The 1769-SM2 module’s RJ45 connectors (CH1, CH2, and CH3), which

are electrically common, should be grounded by attaching a drain wire

from the 1769-SM2 terminal block (item 11 in Figure 1.1

conductive surface (i.e. metal panel). If shielded cable (not required) is

used, the cable shield should also be connected to the chassis by

attaching the cable shield to the 1769-SM2 terminal block (Figure 2.7

Good wiring practice dictates that the cable shield be terminated to the

chassis at only one point along the cable to prevent ground loops from

occurring. The chassis terminal block on the 1769-SM2 module is

provided as a convenient place for this termination.

) to a grounded,

).

Figure 2.7 Unshielded Connector Grounding Details

To Drive 1 To Drive 2

MODULE

CH1

CH2 CH3

To Drive 1 To Drive 2

To Drive 1 To Drive 2

DSI / Modbus RTU

C

H

1

C

H

2

C

H

3

. . .

. . .

. . .

Page 36

2-14 Installing the Module

Network Cable Strain Relief

Some type of strain relief should be provided for the communication

cables within 12 inches (305 mm) of the 1769-SM2 module. This may

include wireways, cable ties, panel mounted strain reliefs, or some other

appropriate strain relief device.

Applying Power

ATTENTION: Risk of equipment damage, injury, or death exists.

Unpredictable operation may occur if you fail to verify that parameter

!

settings are compatible with your application. Verify that settings are

compatible with your application before applying power to the drive.

1. Apply power to the controller. The status indicators can be viewed on

the front of the 1769-SM2 module after power has been applied.

2. Apply power to the drive(s). When you apply power to the

1769-SM2 module, controller, and drives for the first time, the status

indicators should be green after an initialization. If the status

indicators go red, there is a problem. Refer to Chapter 9

Troubleshooting.

,

Page 37

Installing the Module 2-15

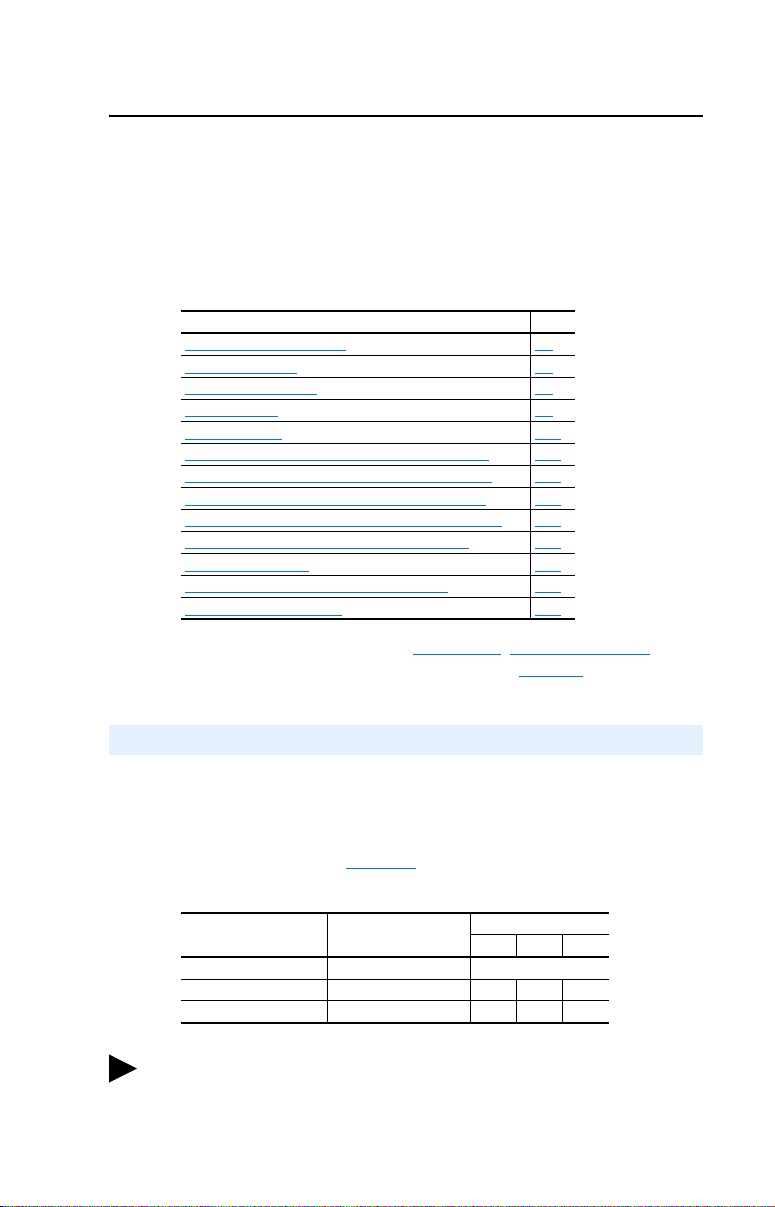

Viewing Start-Up Status Indicators

Status indicators for the communication module can be viewed on the

front of the module (Figure 2.8

start-up status indications are shown in Table 2.A.

Figure 2.8 Module Status Indictors

) after power has been applied. Possible

➊

MODULE

CH1

CH2 CH3

DSI

C

H

1

C

H

2

C

H

3

MODULE

CH1

CH2

CH3

➋

➍

➌

Table 2.A Module Start-Up Status Indications

Status

Item

Indicator

MODULE Green Normal Operation. The module has established

➊

CH1 Green Normal Operation. CH1 is operating and is transferring I/O

➋

CH2 Green Normal Operation. CH2 is operating and is transferring I/O

➌

CH3 Green Normal Operation. CH3 is operating and is transferring I/O

➍

(1)

If all status indicators are off, the module is not receiving power. Refer to Chapter 2, Installing the

Module, for instructions on installing the module.

Status

Flashing

Green

Flashing

Green

Flashing

Green

Flashing

Green

(1)

Description

communications with the controller.

The module is establishing communications with the

controller.

data between the controller and the drive(s).

Normal Operation. CH1 is operating but is not transferring

I/O data between the controller and the drive(s).

data between the controller and the drive(s).

Normal Operation. CH2 is operating but is not transferring

I/O data between the controller and the drive(s).

data between the controller and the drive(s).

Normal Operation. CH3 is operating but is not transferring

I/O data between the controller and the drive(s).

For more details on status indicator operation, see page 9-2 and

page 9-3.

Page 38

2-16 Installing the Module

Notes:

Page 39

Chapter 3

Configuring the Module

This chapter provides instructions and information for setting the

parameters in the 1769-SM2 module.

Topic Page

Determining I/O Image Size

Configuration Tools 3-2

Configuration Methods 3-3

Controller Mode 3-3

Parameter Mode 3-12

Using the Optional, External PowerFlex 4-Class HIM 3-13

Setting the I/O Configuration (Multi-Drive Mode Only) 3-14

Setting an Idle Action (Single and Multi-Drive Mode) 3-15

Setting Drive Node Addresses (Multi-Drive Mode Only) 3-16

Configuring the Modbus RTU Master Parameters 3-17

Resetting the Module 3-20

Viewing the Module Status Using Parameters 3-21

Flash Updating the Module 3-22

3-1

For a list of parameters, refer to Appendix

definitions of terms in this chapter, refer to the Glossary

Determining I/O Image Size

Single Mode

When the module is in Single mode, the I/O image is comprised of a

maximum of 7 words (Table 3.A

Table 3.A I/O Image Table for Single Mode

Output Image Input Image

Module Control Word Module Status Word 0

Logic Command Logic Status 1 3 5

Reference Feedback 2 4 6

TIP: When using Single mode, it is recommended to set the I/O size to

7 Input words and 7 Output words. This accommodates one drive per

channel, even if a channel is left unused for future use.

).

B, Module Parameters. For

.

Wor d

CH1 CH2 CH3

Page 40

3-2 Configuring the Module

Multi-Drive Mode

When the module is in Multi-Drive mode, the I/O image is comprised of

a maximum of 31 words (Table 3.B).

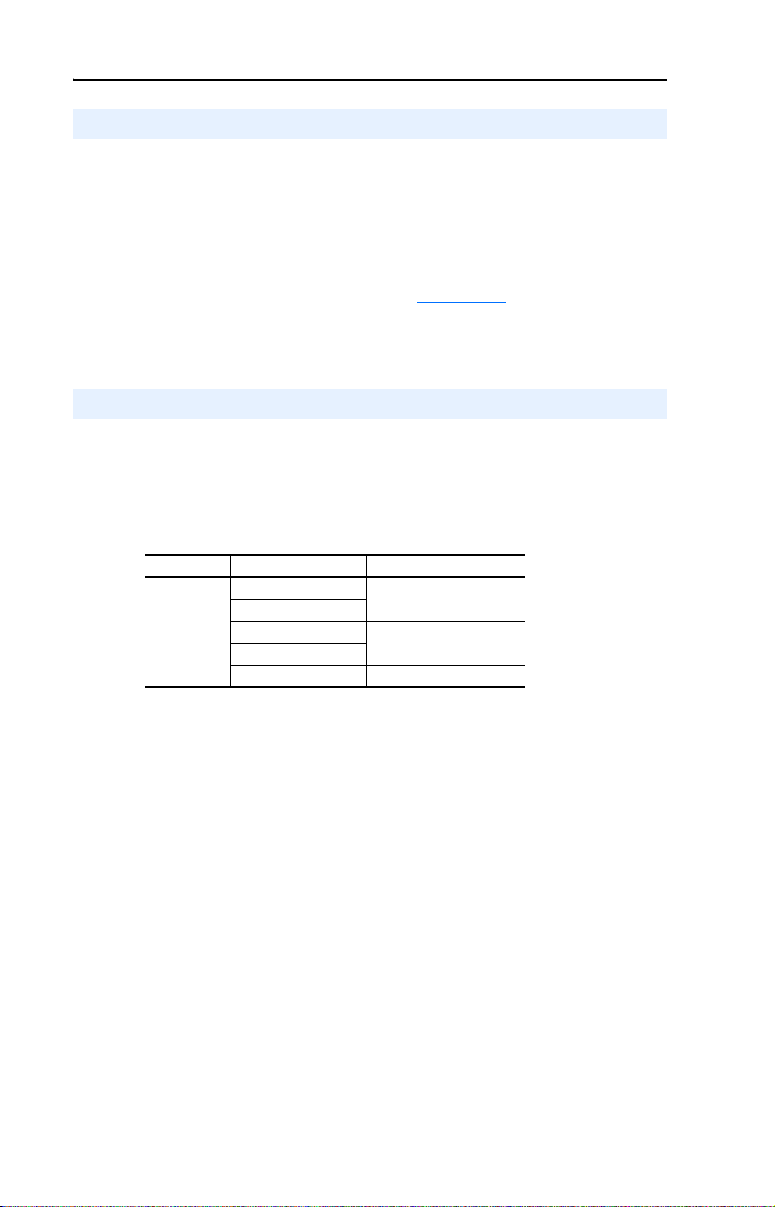

Table 3.B I/O Image Table for Multi-Drive Mode

Output Image Input Image

Module Control Word Module Status Word 0

Drive 0

Drive 1

Drive 2

Drive 3

Drive 4

TIP: When using Multi-Drive mode, it is recommended to set the I/O

size to 31 Input words and 31 Output words. This accommodates up to 5

drives per channel, even if a channel is left unused for future use.

Configure a smaller I/O size only if there is a limited amount of I/O

available on a controller.

Logic Command Logic Status 1 11 21

Reference Feedback 2 12 22

Logic Command Logic Status 3 13 23

Reference Feedback 4 14 24

Logic Command Logic Status 5 15 25

Reference Feedback 6 16 26

Logic Command Logic Status 7 17 27

Reference Feedback 8 18 28

Logic Command Logic Status 9 19 29

Reference Feedback 10 20 30

Word

CH1 CH2 CH3

For additional information on configuring the I/O image size, refer to

Chapter

4, Understanding the I/O Image.

Configuration Tools

The 1769-SM2 module stores parameters and other information in its

own non-volatile memory. You must, therefore, access the module to

view and edit its parameters. The following tools can be used to access

the module parameters:

Tool Refer to…

PowerFlex 4-Class HIM

(22-HIM-A3 or 22-HIM-C2S)

DriveExplorer Software

(version 3.01 or higher)

DriveExecutive Software

(version 4.01 or higher)

RSLogix 500 LG500-GR001

RSLogix 5000 9399-RLD300GR

RSNetWorx for DeviceNet DNET-GR001

Page 3-13

http://www.ab.com/drives/driveexplorer, or

DriveExplorer online help (installed with the software)

http://www.ab.com/drives/drivetools

DriveExecutive online help (installed with the software)

, or

Page 41

Configuring the Module 3-3

Configuration Methods

The 1769-SM2 module has two methods of configuration, which are

determined by the Configuration Mode Switch (SW1 in Figure 2.1

• Controller mode—The 1769-SM2 uses the configuration data

downloaded from the controller on power-up and when the controller

is placed in run mode. The data is configured using RSLogix 500,

RSLogix 5000 or RSNetWorx for DeviceNet.

• Parameter mode—The 1769-SM2 uses its internal parameter settings

to configure the module. The data is configured using an optional,

external PowerFlex 4-Class HIM, DriveExplorer, or DriveExecutive.

Only one method can be selected, and it is used for all three channels.

):

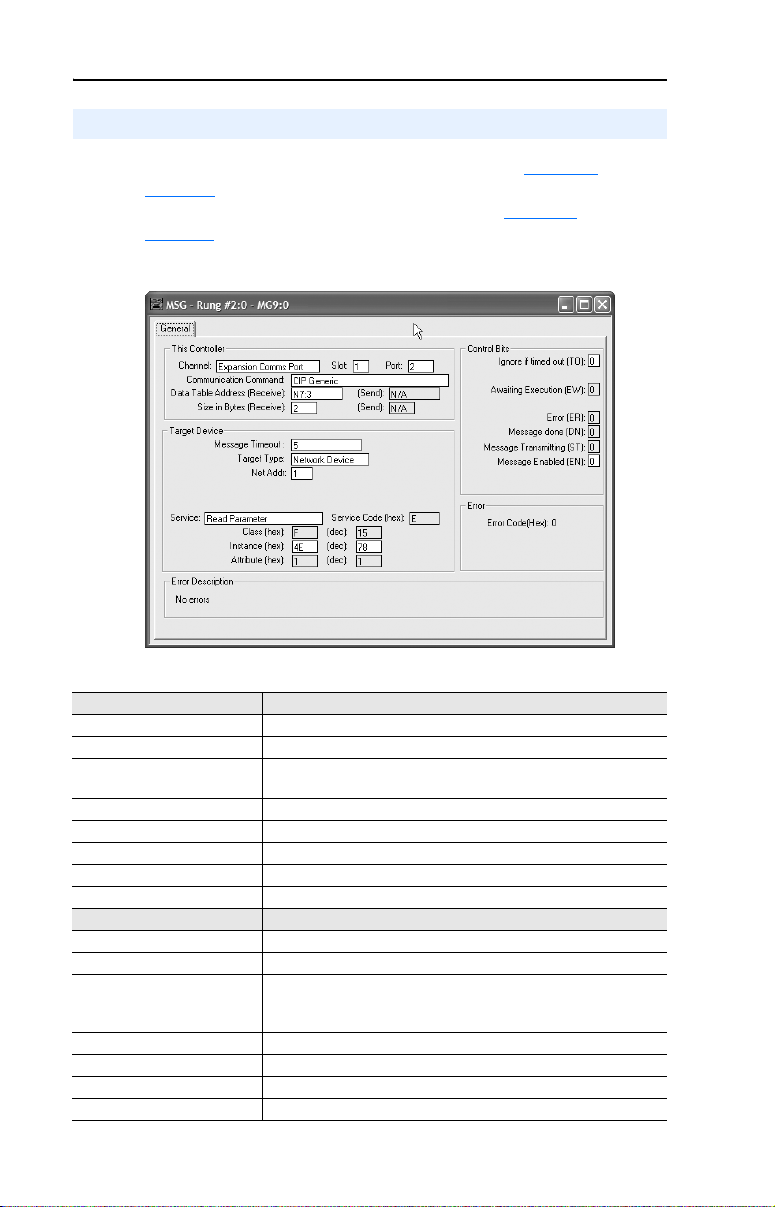

Controller Mode

When the Configuration Mode Switch (SW1 in Figure 2.1

default CONT (Controller) position, the 1769-SM2 uses the configuration

data downloaded from the controller on power-up and when the controller

is placed in run mode. Depending on the controller, configuration data is

allocated and entered using RSLogix500 or RSLogix 5000.

Configuration Data

The 1769-SM2 module contains a set of 42 words of configuration data

that is used to configure the module's behavior (Table 3.C). A software

tool, such as RSLogix 500, RSLogix 5000 or RSNetWorx for DeviceNet

is used to read/write the configuration data.

Table 3.C 1769-SM2 Module Configuration Data

Parameter Name CH1 CH2 CH3

Idle Action Word 0 Word 14 Word 28

Flt Cfg Logic Word 1 Word 15 Word 29

Flt Cfg Ref Word 2 Word 16 Word 30

DSI I/O Cfg Word 3 Word 17 Word 31

Drive 0 Addr Word 4 Word 18 Word 32

Drive 1 Addr Word 5 Word 19 Word 33

Drive 2 Addr Word 6 Word 20 Word 34

Drive 3 Addr Word 7 Word 21 Word 35

Drive 4 Addr Word 8 Word 22 Word 36

RTU Baud Rate Word 9 Word 23 Word 37

RTU Format Word 10 Word 24 Word 38

RTU Rx Delay Word 11 Word 25 Word 39

RTU Tx Delay Word 12 Word 26 Word 40

RTU Msg Timeout Word 13 Word 27 Word 41

) is in the

Page 42

3-4 Configuring the Module

The configuration data directly correlates to the module parameters.

Refer to Appendix B for more information.

Entering MicroLogix 1500 Configuration Data Using RSLogix 500 Before v6.30

Earlier versions of RSLogix 500 can be used, but the configuration data

must be entered in raw form in a Data Config table following the format

in Table 3.C

recommended for use with the 1769-SM2 because it contains a dedicated

I/O configuration window for the module to simplify the configuration

process. Version 6.30 is also required to perform explicit messaging,

such as parameter reads/writes.

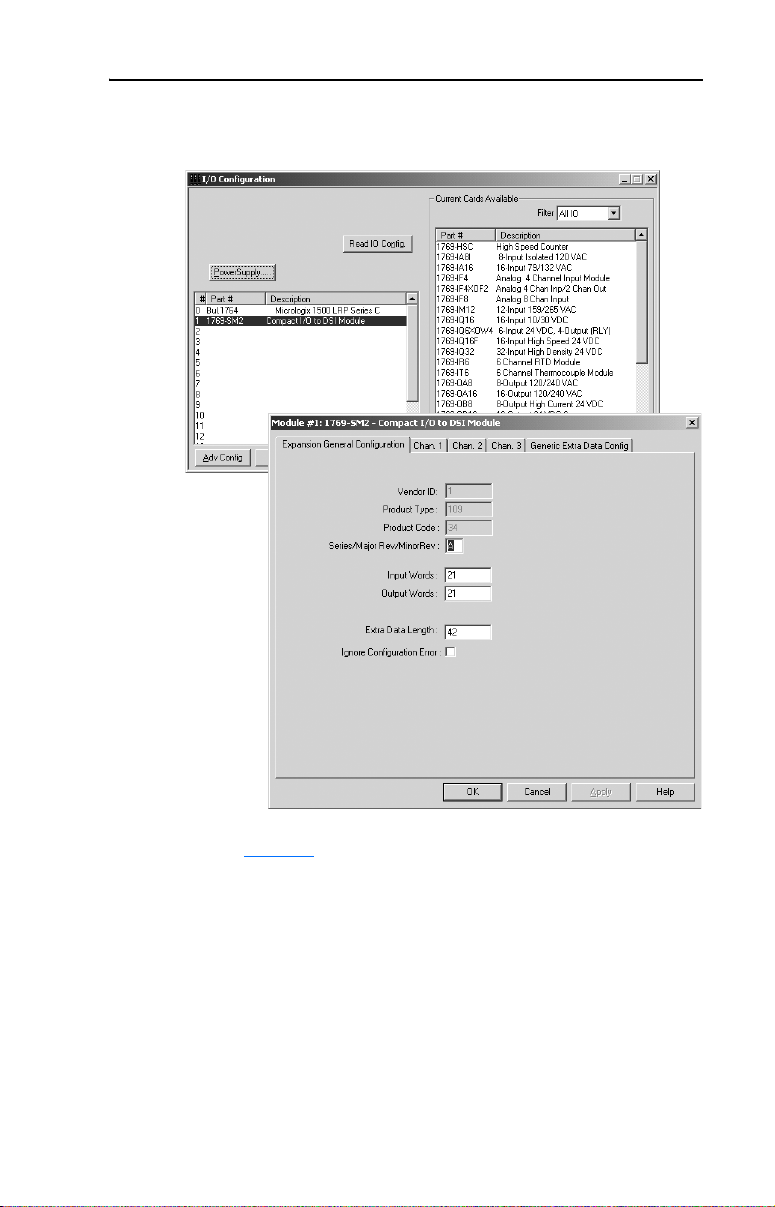

Entering MicroLogix 1500 Configuration Data Using RSLogix 500 v6.30 (or higher)

Allocate and enter the configuration data by performing these steps:

1. In the RSLogix 500 treeview, double-click on I/O Configuration to

open the I/O Configuration window. Double-click the 1769-SM2 in

the Current Cards Available list to add the module to the controller

system. Select the “1769-SM2” row and click the A

command button. The 1769-SM2 I/O Configuration window

(Figure 3.1

. However, RSLogix 500 v6.30 (or higher) is highly

) appears.

dv Config

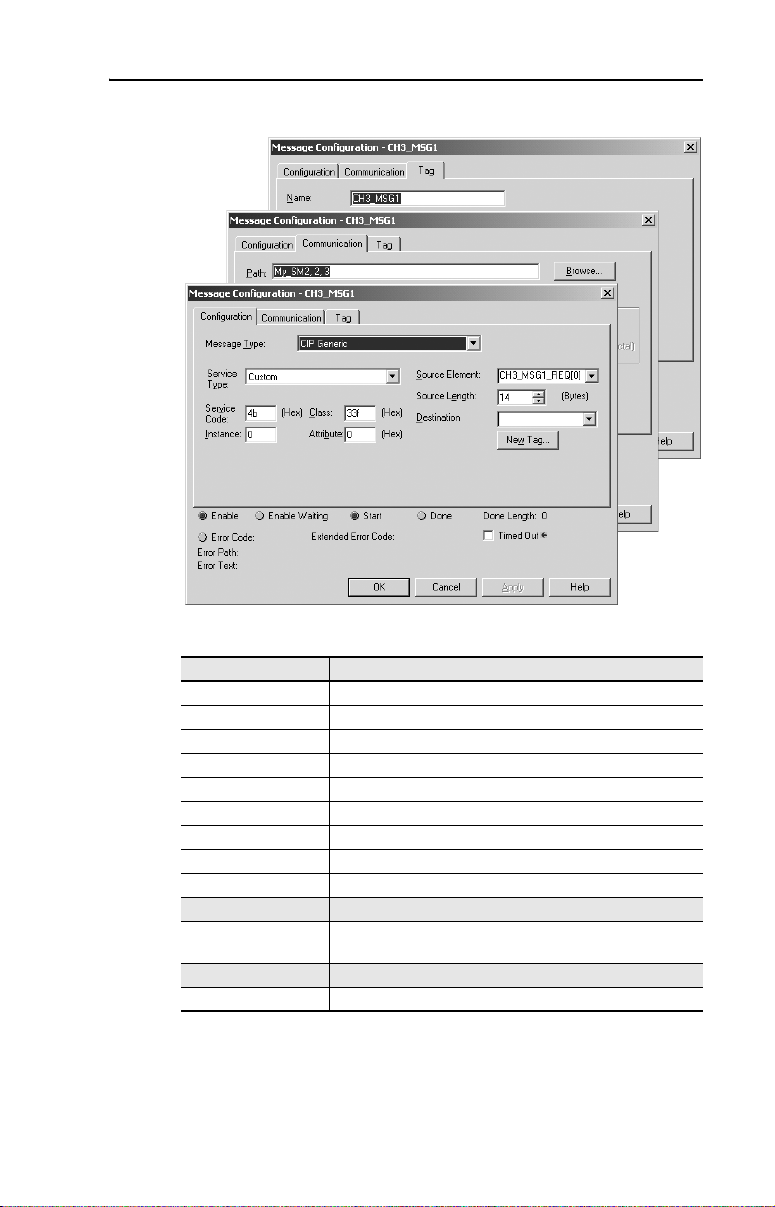

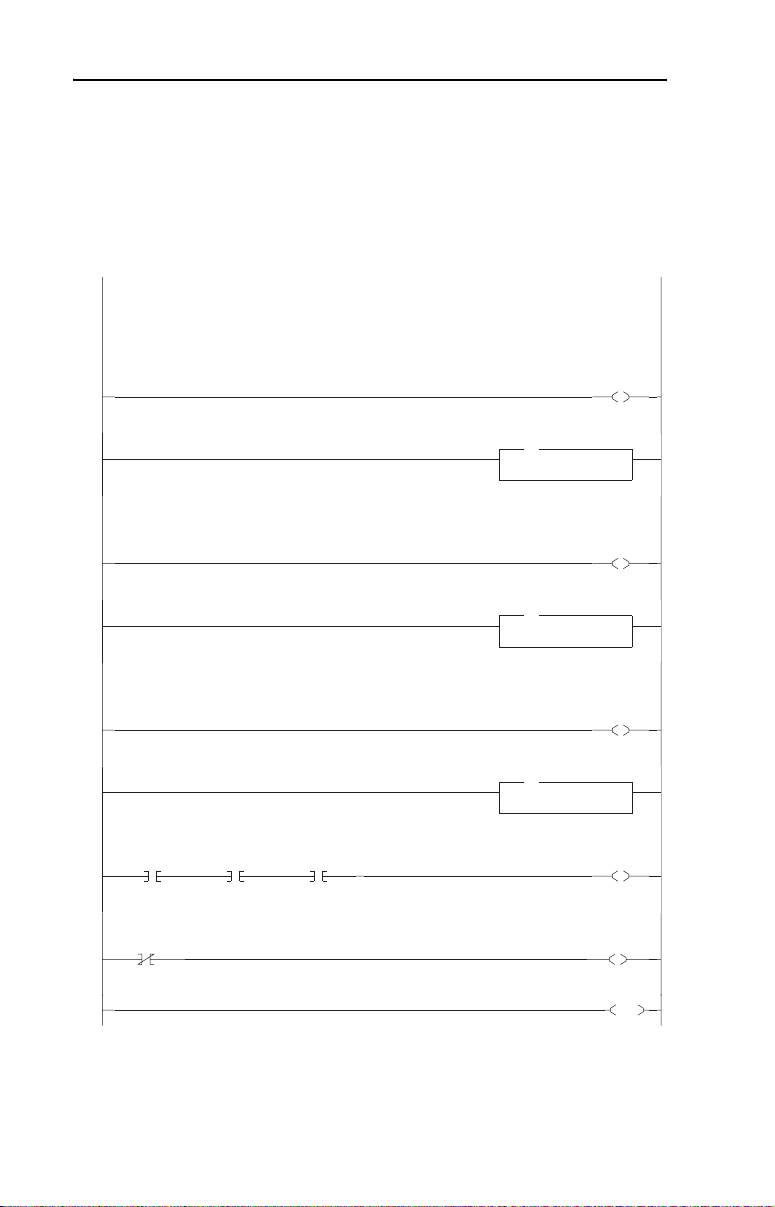

Figure 3.1 I/O Configuration Window and Expansion General Configuration Screen

Page 43

Configuring the Module 3-5

2. Enter the Series letter of the 1769-SM2, which can be determined by

checking the data nameplate label on the module (item 9 in

Figure 1.1

The I/O image of the module can be up to 31 words of Input and 31

words of Output, depending on the mode selected (Single or

Multi-Drive) and the number of drives connected. A Single mode

system with one drive on each channel requires 7 Input words and 7

Output words. A Multi-Drive mode system with five drives on each

channel requires 31 Input words and 31 Output words. See Table 3.A

or Table 3.B to determine the number of Input Words and Output

Words to enter for your system.

The Extra Data Length field can only be set to a size of 0 or 42. If the

controller will contain the configuration data for download to the

1769-SM2 module (Configuration Mode Switch SW1 set to CONT

position), set this value to 42. If the configuration data will be

contained in the 1769-SM2 parameters (Configuration Mode Switch

SW1 set to PARAM position), this value should be set to 0. See

Table 3.C

Figure 3.2 Expansion General Configuration Tab Screen

).

for descriptions of these configuration words.

Page 44

3-6 Configuring the Module

3. Click on the Chan. 1 tab (Figure 3.3) and set the I/O Config data

area accordingly. In this example, the 1769-SM2 is configured to

fault if the controller is switched to Program mode, and one drive is

connected at node address 100.

Figure 3.3 Chan. 1 Tab Data Example Screen

Important: When using Multi-Drive mode, the node addresses

entered in the Drive Addr x fields must match the

corresponding drive Parameter 104 - [Comm Node

Addr] value in the PowerFlex 4-Class drives so that the

1769-SM2 module will communicate with the drives.

Note that the DSI Fault Config settings can only be accessed if the

Idle Action is set to “Send Flt Cfg” (Figure 3.4

).

Page 45

Configuring the Module 3-7

Figure 3.4 Chan. 1 Tab Data Screen with Idle Action - Send Flt Cfg Enabled

4. For each additional channel being used, select its respective tab, set

the desired I/O configuration, and enable the appropriate idle action.

TIP: Alternatively, data can be entered on the Generic Extra Data

Config tab (shown in Figure 3.5 for identification purposes only).

However, with the easy-to-use Chan.1, Chan. 2, and Chan. 3 tabs, there

is no need to enter data on the Generic Extra Data Config tab. But as a

useful reference, this tab does show how the controller stores the data in

the configuration words.

Figure 3.5 Generic Extra Data Config Tab Screen

Page 46

3-8 Configuring the Module

See Table 3.C for descriptions of these configuration words.

5. Click OK when finished. The MicroLogix 1500 will download the

configuration data to the 1769-SM2 module when the controller is

placed in run mode.

Special Case— Data Entry for 2 Stop Bits Communication

The Chan.1, Chan. 2, and Chan 3 tabs do not allow settings that specify 2

stop bits communication in Modbus RTU operation. For this type of

configuration, you must use the Generic Extra Data Config tab to enter

the data by performing these steps:

1. To configure a specific 1769-SM2 module channel for 2 stop bits

communication, click on the Generic Extra Data Config tab.

2. On the Generic Extra Data Config tab screen, enter the appropriate

values from Table 3.D

Figure 3.6 Entering Data for 2 Stop Bits on Generic Extra Data Config Screen

in the offset addresses highlighted in Figure 3.6.

Table 3.D Entry Data for 2 Stop Bits Communication

1769-SM2 CH Offset Address Value Description

110 3

4

5

224 3

4

5

338 3

4

5

Sets CH1 for 8-N-2 format

Sets CH1 for 8-E-2 format

Sets CH1 for 8-O-2 format

Sets CH2 for 8-N-2 format

Sets CH2 for 8-E-2 format

Sets CH2 for 8-O-2 format

Sets CH3 for 8-N-2 format

Sets CH3 for 8-E-2 format

Sets CH3 for 8-O-2 format

Page 47

Configuring the Module 3-9

3. Click OK to apply the changes and close the screen. However, if you

click Apply or leave this tab to go to another tab, you may see this

message dialog box. If so, click Ye s to apply the changes.

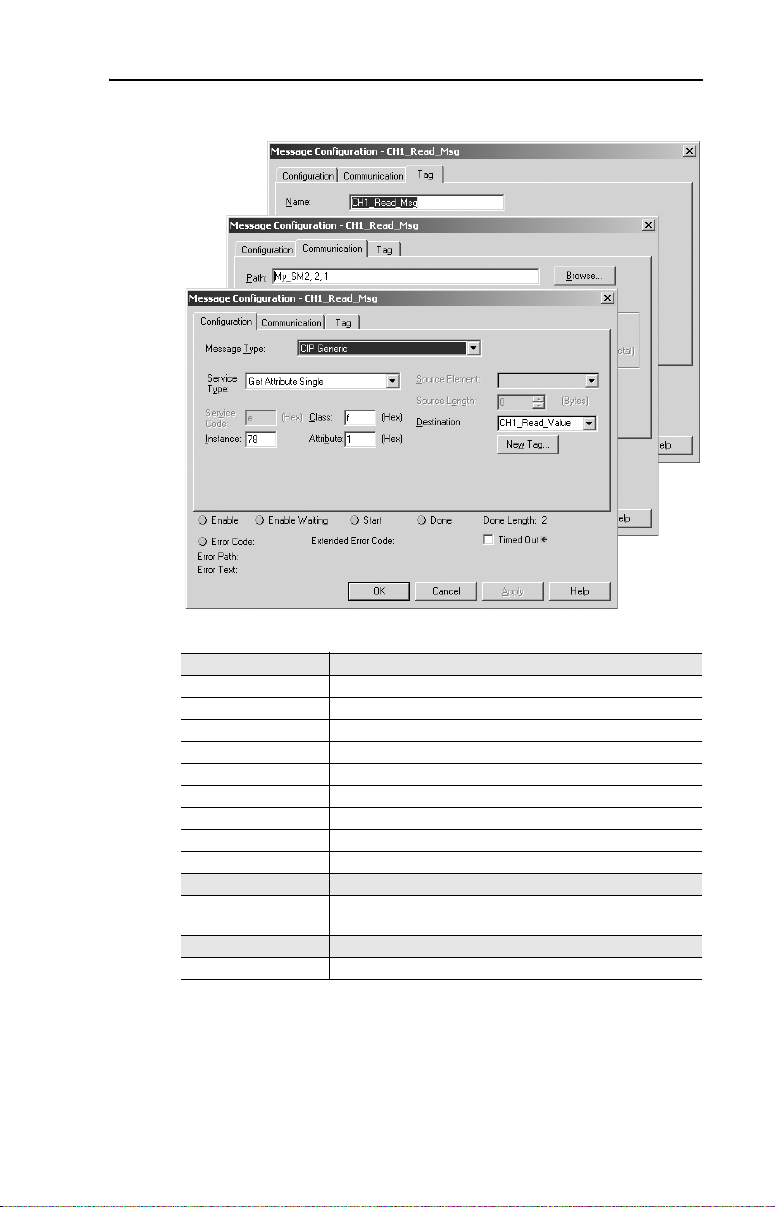

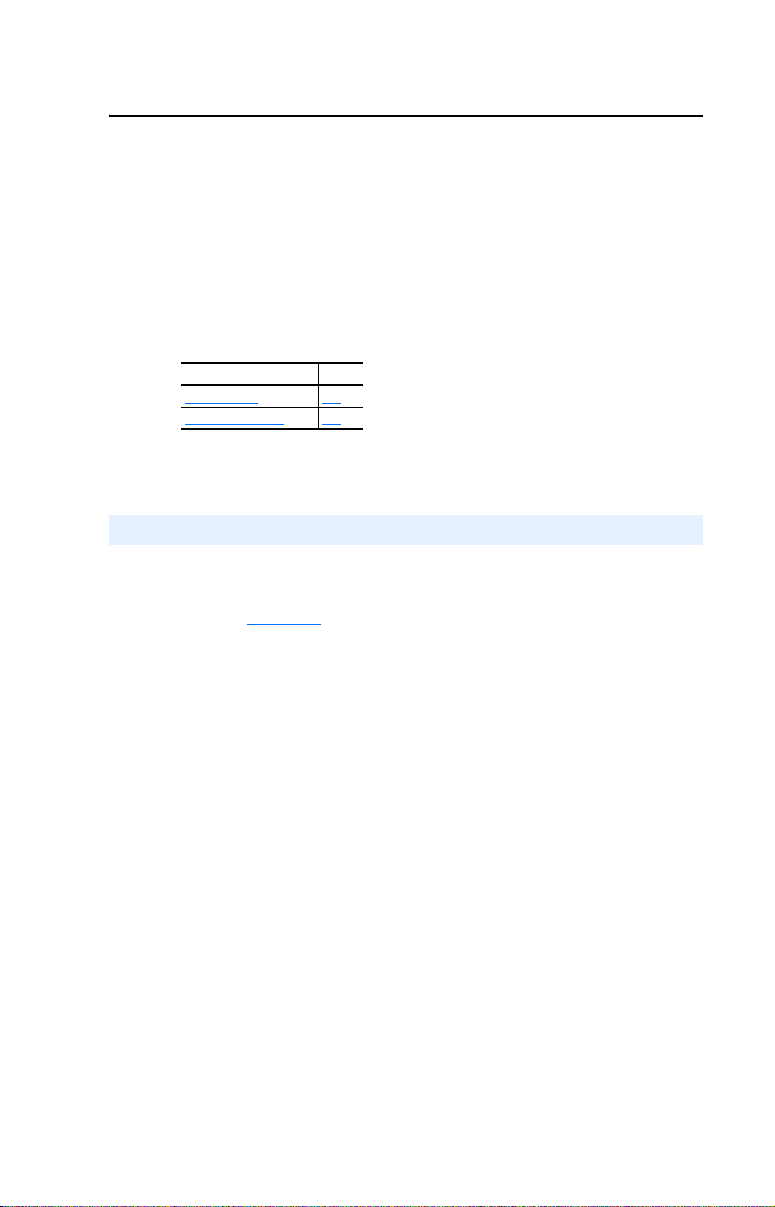

Entering CompactLogix Configuration Data Using RSLogix 5000 v10 (or higher)

Allocate and enter the configuration data by performing these steps:

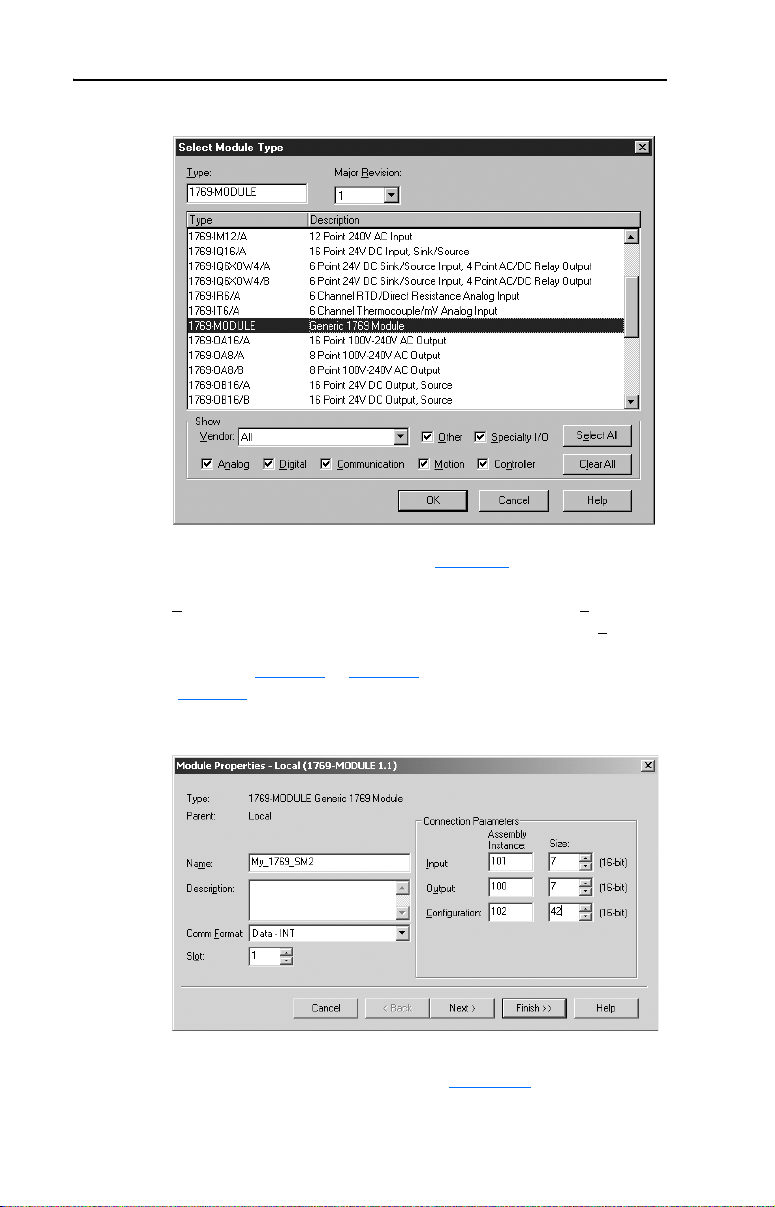

1. In the RSLogix 5000 treeview, right-click on CompactBus Local

and select New Module.

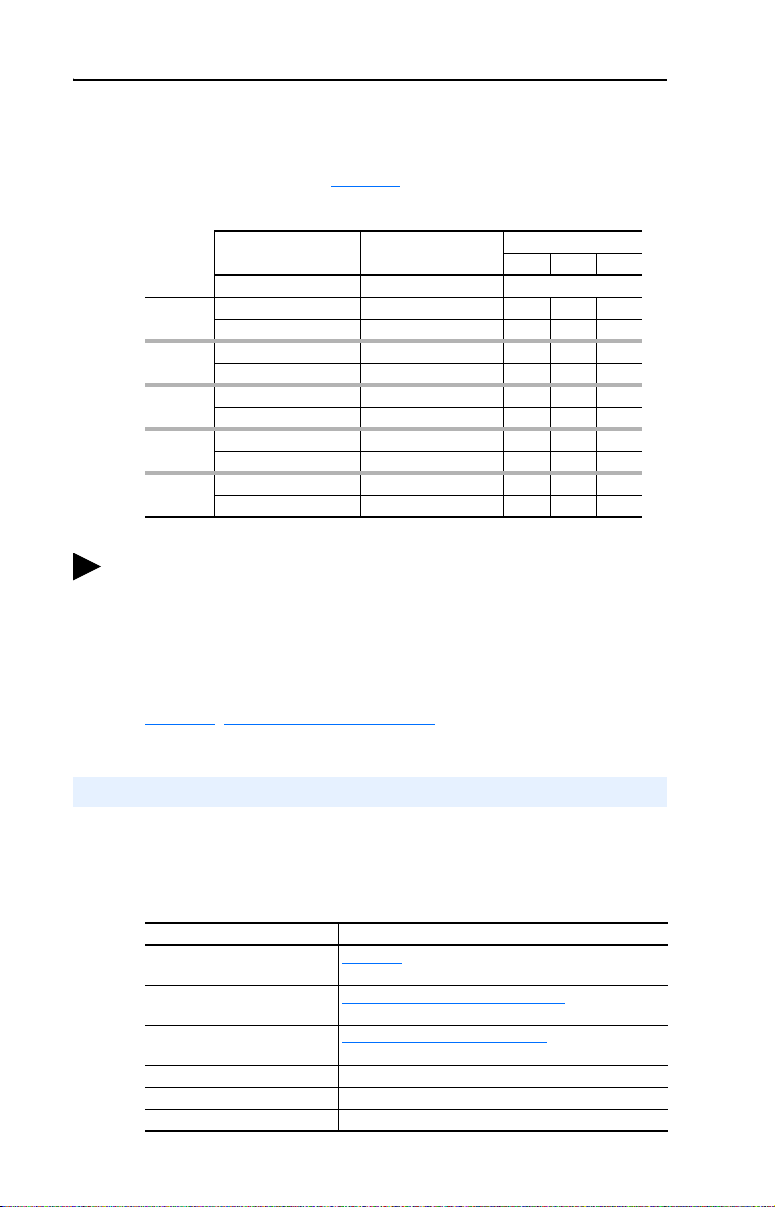

Figure 3.7 Treeview Window with New Module Inset Screen

2. After the Select Module Type screen (Figure 3.8) appears, select the

1769-MODULE and click OK.

Page 48

3-10 Configuring the Module

Figure 3.8 Select Module Type Screen

3. After the Module Properties screen (Figure 3.9) appears, enter a

name for the module, such as “My_1769_SM2.” Change the Comm

ormat to “Data - INT,” which will enable the entry of Output

F

Connection parameters (no longer grayed out). Enter the Slo

location of the 1769-SM2. Enter the desired Input and Output word

length (see Table 3.A or Table 3.B) and Configuration data size

(Table 3.C

). Click Next >.

t

Figure 3.9 Module Properties Screen

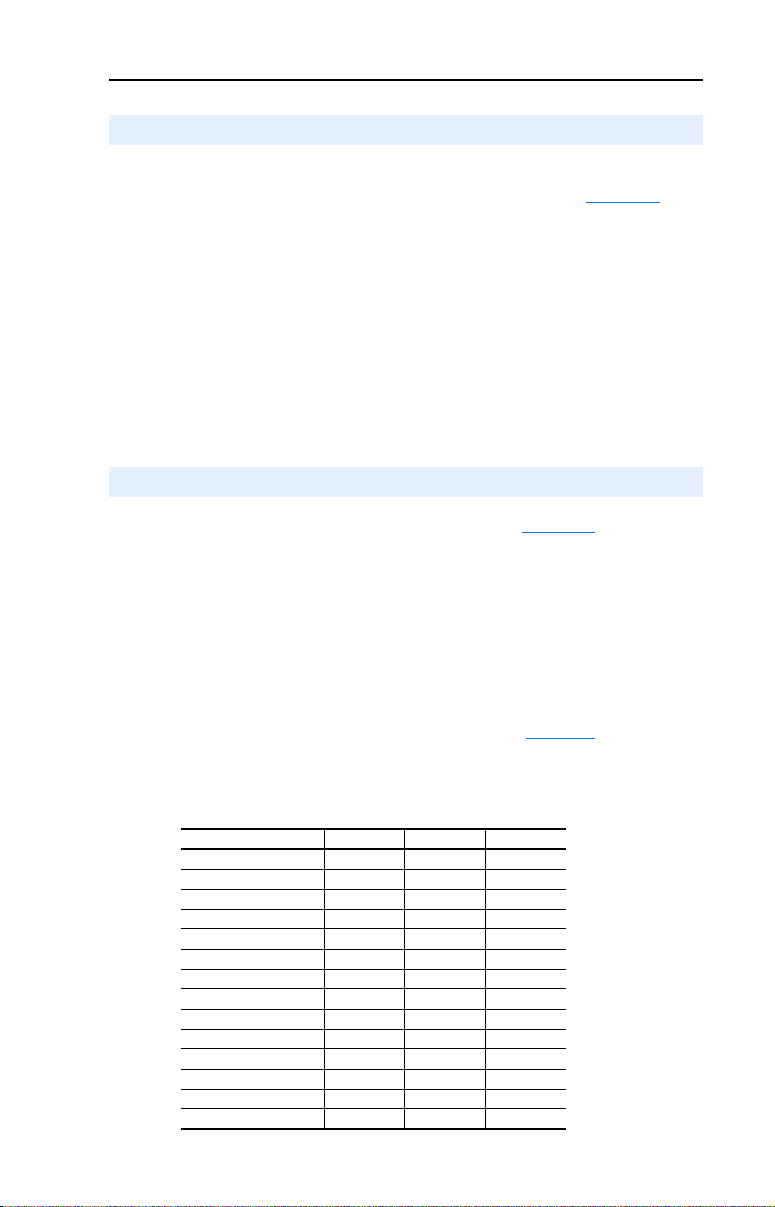

4. On the Module Properties last screen (Figure 3.10), click Finish >>.

Page 49

Configuring the Module 3-11

Figure 3.10 Module Properties Last Screen

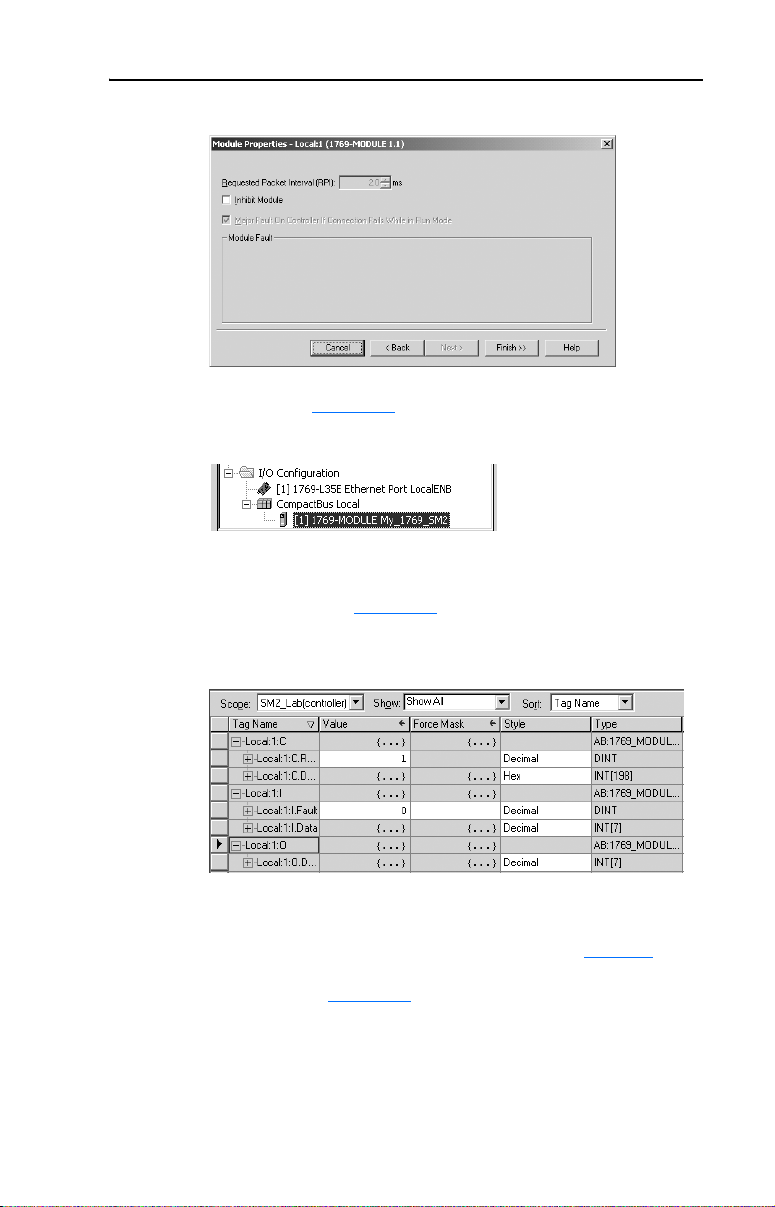

5. The treeview (Figure 3.11) now shows the 1769-MODULE.

Figure 3.11 RSLogix 5000 Treeview with Listed 1769-MODULE

6. Double-clicking on the Controller Tags or Program Tags in the

treeview will display the various tags, including the tags for the

1769-SM2 module (Figure 3.12). Click on the Monitor Tags tab at

the bottom of the window to enter the configuration data.

Figure 3.12 Controller Tags Screen

NOTE: RSLogix 5000 may create a data array that is much larger than

the 42 words previously specified when the module was configured. Use

words 0…41 and ignore all other words (42+). Refer to Table 3.C for

configuration data words and parameter descriptions. Also note that the

data entry format in Figure 3.12

format, click on the appropriate field in the “Style” column.

The CompactLogix will download the configuration data to the

1769-SM2 module on power-up.

is hexadecimal (16#). To change the

Page 50

3-12 Configuring the Module

Parameter Mode

When the Configuration Mode Switch (SW1 in Figure 2.1) is in the

PARAM (Parameter) position, the 1769-SM2 uses its internal parameter

settings to configure the module. If any configuration data is downloaded

by the controller, it will be ignored.

Important: When the Parameter mode is used, the configuration data

size in the controller should be set to “0.” See Controller

Mode on page 3-3 for more information.

Host PowerFlex 4-Class drives can use this feature since connected DSI

peripheral devices (optional, external PowerFlex 4-Class HIMs,

DriveExplorer with 22-SCM-232, etc.) can access the 1769-SM2 module

directly. However, the 1769-SM2 module must be set to Single mode for

these DSI peripherals to work with the module.

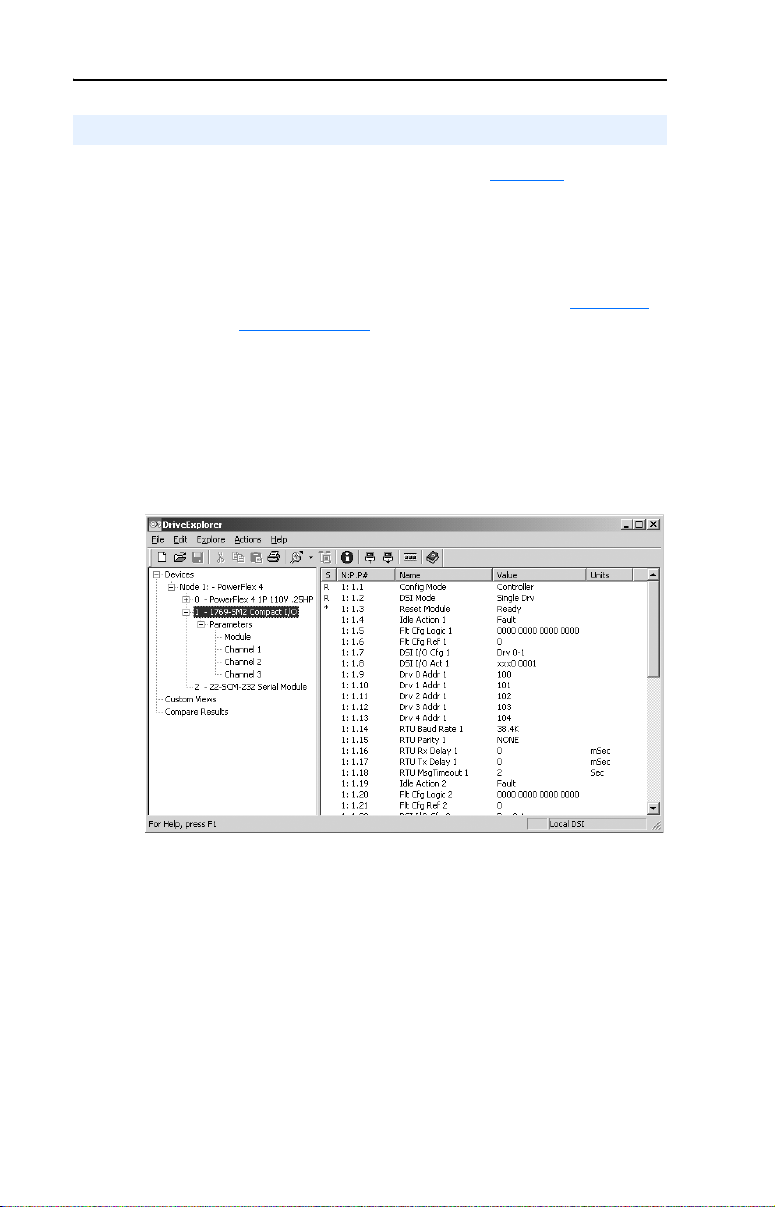

Figure 3.13 DriveExplorer Window with Mapped 1769-SM2 Compact I/O Module

Page 51

Configuring the Module 3-13

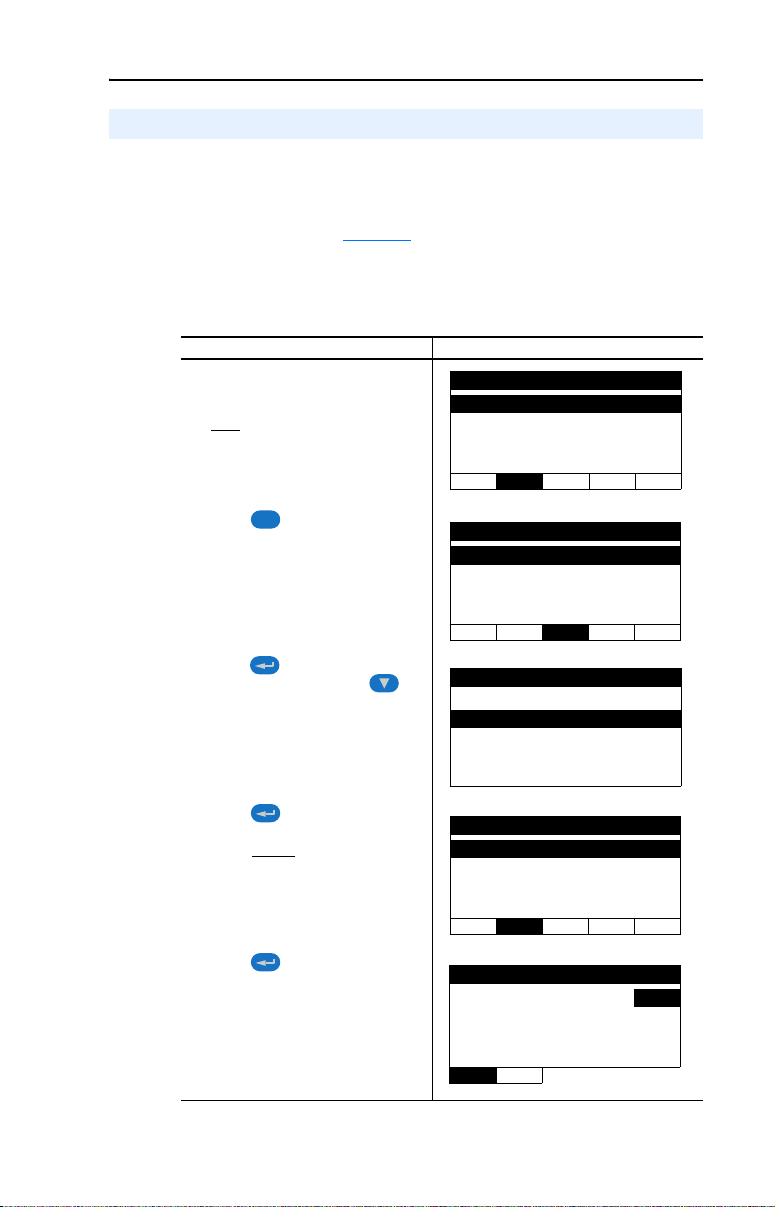

Using the Optional, External PowerFlex 4-Class HIM

When using the 1769-SM2 module in Single mode, the optional,

external PowerFlex 4-Class HIM (Human Interface Module) can be used

to access its parameters. Basic steps to access module parameters using

the HIM are shown in Table 3.E

to the PowerFlex 4-Class HIM Quick Reference (publication

22HIM-QR001).

Table 3.E Accessing Module Parameters Using the HIM (22-HIM-A3 or 22-HIM-C2S)

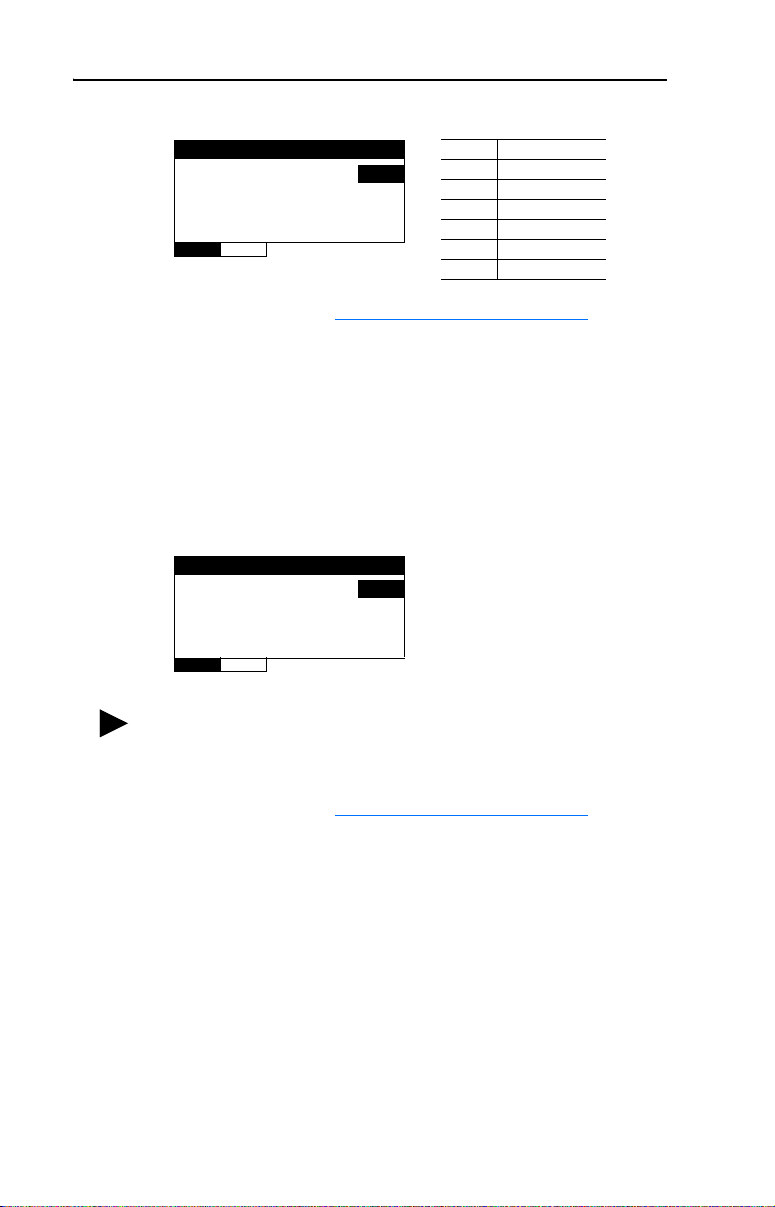

Step Example Screens

1. Power up the drive. Then plug the

external HIM into the bottom of the

drive. The Parameters menu for the

drive

will be displayed.

. For additional HIM information, refer

Parameters

Groups

Linear List

Changed Params

DIAG PA R A M DSEL MEM SEL

2. Press key once to display the

Sel

Device Select menu.

3. Press (Enter) key to display the

DSI Devices menu. Press

Arrow to scroll to 1769-SM2.

4. Press (Enter) key to select the

1769-SM2. The Parameters menu

for the module

5. Press (Enter) key to access

the parameters. Edit the module

parameters using the same

techniques that you use to edit drive

parameters.

will be displayed.

Device Select

DSI Devices

DIAG PARAM DSEL MEM SEL

DSI Devices

PowerFlex 4 0

1769-SM2

Parameters

Linear List

Changed Params

DIAG PA R A M DSEL MEM SEL

Mode RO

Parameter : #

0 = Controller

VAL UE LIMITS SEL

001

Page 52

3-14 Configuring the Module

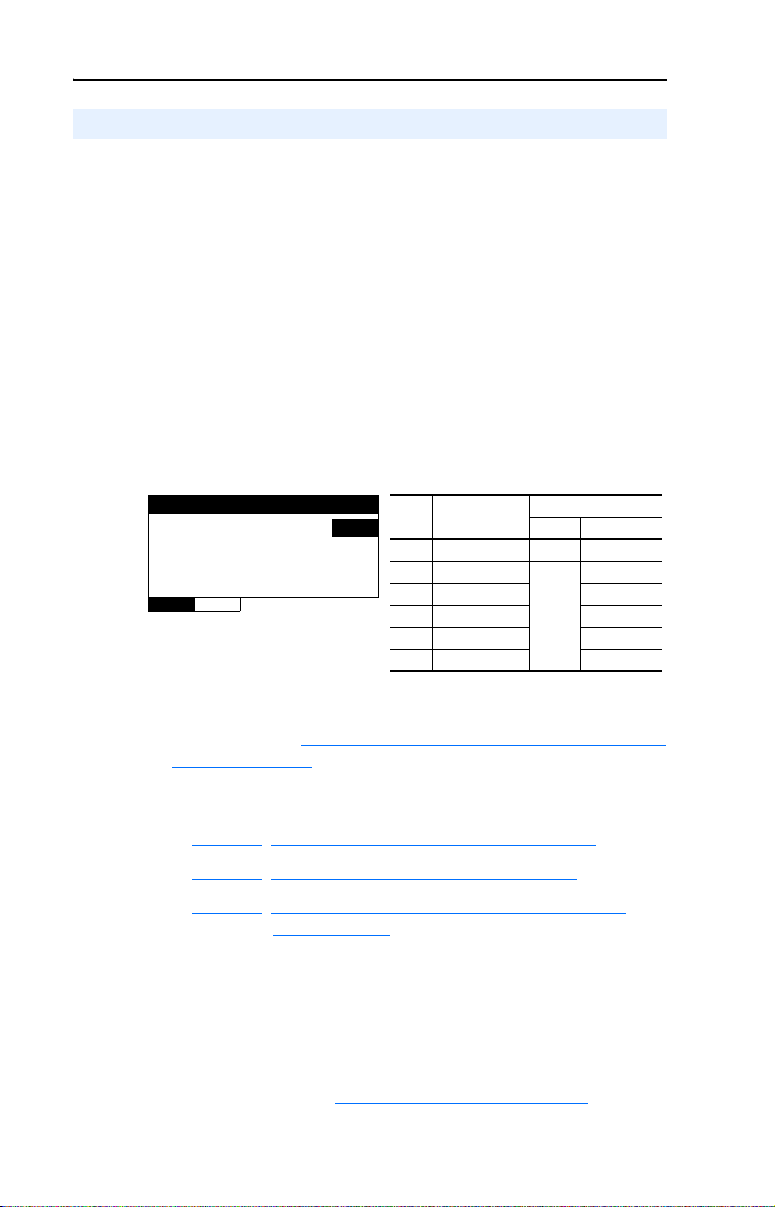

Setting the I/O Configuration (Multi-Drive Mode Only)

The I/O configuration sets the number of drives that are connected to

each channel. When the 1769-SM2 module is used in Single mode

(Operating Mode Switch SW2 set to “1X”), only one PowerFlex 4-Class

drive can be connected to each channel and module Parameters 07 -

[DSI I/O Cfg 1], 22 - [DSI I/O Cfg 2], and 37 - [DSI I/O Cfg 3] have no

effect. When the module is used in Multi-Drive mode (Operating Mode

Switch set to “5X”), up to five PowerFlex 4-Class drives can be

connected to each channel. When a channel is selected for Modbus RTU

Master operation, up to 31 devices can be connected.

1. Set the value in Parameters 07 - [DSI I/O Cfg 1], 22 - [DSI I/O Cfg

2], and 37 - [DSI I/O Cfg 3] to respectively configure each module

channel for the number of drives being used in Multi-Drive mode.

Figure 3.14 Example I/O Cfg Screen for CH1 Drive(s) in Multi-Drive Mode

DSI I/O Cfg 1

Parameter : #

Drives 0…4 4

VALU E LIMITS SEL

Each drive (Drive 0, Drive 1, etc.) on the node must be assigned a

node address [see Setting Drive Node Addresses (Multi-Drive Mode

Only) on page 3-16]. For more information on Multi-Drive mode and

RTU Master mode, refer to the Multi-Drive Mode section in the

chapter corresponding to your controller type:

• Chapter

• Chapter 7, CompactLogix Example Ladder Programs

• Chapter 8, ControlLogix w/1769-ADN DeviceNet Example

2. Configure the parameters in each enabled drive to accept the Logic

Command and Reference from the 1769-SM2 module. For example,

set PowerFlex 4/40/400 drive Parameters 36 - [Start Source] and 38 [Speed Reference] to “5” (Comm Port) so that the drive uses the

Reference from the 1769-SM2 module.

6, MicroLogix 1500 Example Ladder Programs

Ladder Program

007

Value Description

0 Drive 0 (Default) ✓✓

1Drives 0…1

2Drives 0…2 ✓

3Drives 0…3 ✓

4Drives 0…4 ✓

5 RTU Master ✓

Mode Switch Position

Single Multi-Drive

✓

Not Applicable

3. Reset the module (see Resetting the Module

on page 3-20).

Page 53

Configuring the Module 3-15

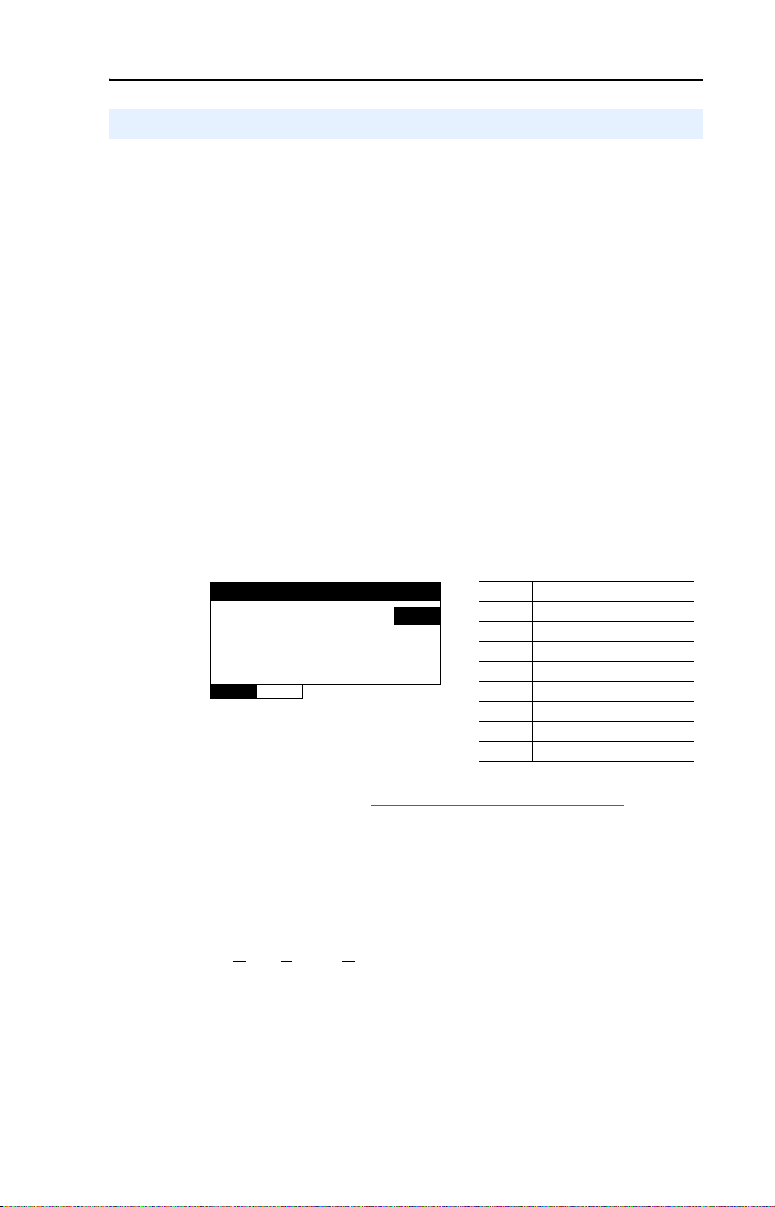

Setting an Idle Action (Single and Multi-Drive Mode)

By default, when the controller is idle, the drive responds by faulting

when using I/O from the 1769-SM2 module. You can respectively

configure a different response to an idle controller using Parameters 04

- [Idle Action 1], 19 - [Idle Action 2], and 34 - [Idle Action 3] for each

channel’s connected drives.

ATTENTION: Risk of injury or equipment damage exists.

Parameters 04 - [Idle Action 1], 19 - [Idle Action 2], and 34 - [Idle

!

Action 3] let you determine the action of each respective channel’s

connected PowerFlex 4-Class drives when the controller is idle. By

default, each parameter faults its respective channel’s drives. You can

set each parameter so that the respective channel’s drives continue to

run. Precautions should be taken to ensure that the settings of these

parameters do not create a hazard of injury or equipment damage.

Changing the Idle Action

Set the values of Parameters 04 - [Idle Action 1], 19 - [Idle Action 2],

and 34 - [Idle Action 3] to the desired responses:

Value Action Description

0 Fault (default) The drive(s) is faulted and stopped. (Default)

1 Stop The drive(s) is stopped, but not faulted.

2 Zero Data The drive(s) is sent 0 for Logic Command and Reference after a

3 Hold Last The drive(s) continues in its present state after a communications

4 Send Flt Cfg The drive(s) is sent the data that you set in the fault configuration

communications disruption. This does not command a stop.

disruption.

parameters. For:

CH1 drives, Parameters 05 - [Flt Cfg Logic 1] and 06 - [Flt Cfg Ref 1]

CH2 drives, Parameters 20 - [Flt Cfg Logic 2] and 21 - [Flt Cfg Ref 2]

CH3 drives, Parameters 35 - [Flt Cfg Logic 3] and 36 - [Flt Cfg Ref 3]

Figure 3.15 Example Idle Action HIM Screen for CH1 Drive(s)

Idle Action 1

Parameter: #

004

Fault 0