Page 1

Installation Instructions

Compact I/O DeviceNet Scanner Module

(Cat. No. 1769-SDN)

Inside...

For More Information.............................................................................. 2

European Communities (EC) Directive Compliance ................................ 3

Hazardous Location Considerations ....................................................... 4

Environnements dangereux .................................................................... 4

Module Description ................................................................................ 5

Module Installation................................................................................. 6

System Planning ..................................................................................... 8

System Assembly.................................................................................... 9

System Mounting.................................................................................. 10

Replacing the Scanner Module within a System ................................. 13

Field Wiring Connections ...................................................................... 14

Scanner Module Power-Up ................................................................... 15

Configuring the 1769-SDN on DeviceNet............................................. 16

Data Organization................................................................................. 17

Diagnostic Indicators ............................................................................ 18

Error Codes............................................................................................ 19

Specifications ....................................................................................... 21

Publication 1769-IN060C-EN-P - May 2002

Page 2

2 Compact I/O DeviceNet Scanner Module

TIP

For More Information

For Refer to this Document Pub. No.

A more detailed description of how to use

your DeviceNet Scanner Module

Detailed information on planning,

mounting, wiring, and troubleshooting your

CompactLogix System.

Detailed information on planning,

mounting, wiring, and troubleshooting your

MicroLogix 1500 System.

DeviceNet network planning information. DeviceNet Cable System Planning and

More information on proper wiring and

grounding techniques.

If you would like a manual, you can:

• download a free electronic version from the internet:

www.theautomationbookstore.com

• purchase a printed manual by:

– contacting your local distributor or Rockwell Automation representative

– visiting www.theautomationbookstore.com and placing your order

– calling 1.800.963.9548 (USA/Canada)

or 001.330.725.1574 (Outside USA/Canada)

Compact I/O DeviceNet Scanner

Module User Manual

CompactLogix System User Manual 1769-UM007C-EN-P

MicroLogix 1500 Programmable

Controllers User Manual

Installation Manual

Industrial Automation Wiring and

Grounding Guidelines

1769-UM009A-EN-P

1764-UM001A-US-P

DN-6.7.2

1770-4.1

Translated versions of these Installation Instructions are

available electronically. Obtain a translated version of this

publication at www.theautomationbookstore.com.

Publication 1769-IN060C-EN-P - May 2002

Page 3

Compact I/O DeviceNet Scanner Module 3

European Communities (EC) Directive Compliance

This product carries the CE mark and is approved for installation within the

European Union and EEA regions. It has been designed and tested to meet the

following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC Electromagnetic

Compatibility (EMC) by applying the following standards, in whole or in part,

documented in a technical construction file:

• EN 50081-2 EMC — Generic Emission Standard, Part 2 — Industrial

Environment

• EN 50082-2 EMC — Generic Immunity Standard, Part 2 — Industrial

Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage, by

applying the safety requirements of EN 61131-2 Programmable Controllers, Part 2 Equipment Requirements and Tests. For specific information required by

EN 61131-2, see the appropriate sections in this publication, as well as the

Allen-Bradley publication Industrial Automation Wiring and Grounding Guidelines

For Noise Immunity, publication 1770-4.1. and the Automation Systems Catalog,

B111.

This equipment is classified as open equipment and must be mounted in an

enclosure during operation to provide safety protection.

Publication 1769-IN060C-EN-P - May 2002

Page 4

4 Compact I/O DeviceNet Scanner Module

WARNING

!

AVERTISSEMENT

!

Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or

non-hazardous locations only. The following WARNING statement applies to use in

hazardous locations.

EXPLOSION HAZARD

• Substitution of components may impair suitability for Class

I, Division 2.

• Do not replace components or disconnect equipment

unless power has been switched off or the area is known

to be non-hazardous.

• Do not connect or disconnect components unless power

has been switched off or the area is known to be

non-hazardous.

• This product must be installed in an enclosure. All cables

connected to the product must remain in the enclosure or

be protected by conduit or other means.

• All wiring must comply with N.E.C. article 501-4(b).

Environnements dangereux

Cet équipement est conçu pour être utilisé dans des environnements de Classe 1,

Division 2, Groupes A, B, C, D ou non dangereux. La mise en garde suivante

s’applique à une utilisation dans des environnements dangereux.

Publication 1769-IN060C-EN-P - May 2002

DANGER D’EXPLOSION

• La substitution de composants peut rendre cet équipement

impropre à une utilisation en environnement de Classe 1,

Division 2.

• Ne pas remplacer de composants ou déconnecter

l'équipement sans s'être assuré que l'alimentation est

coupée et que l'environnement est classé non dangereux.

• Ne pas connecter ou déconnecter des composants sans

s'être assuré que l'alimentation est coupée ou que

l'environnement est classé non dangereux.

• Ce produit doit être installé dans une armoire.

Page 5

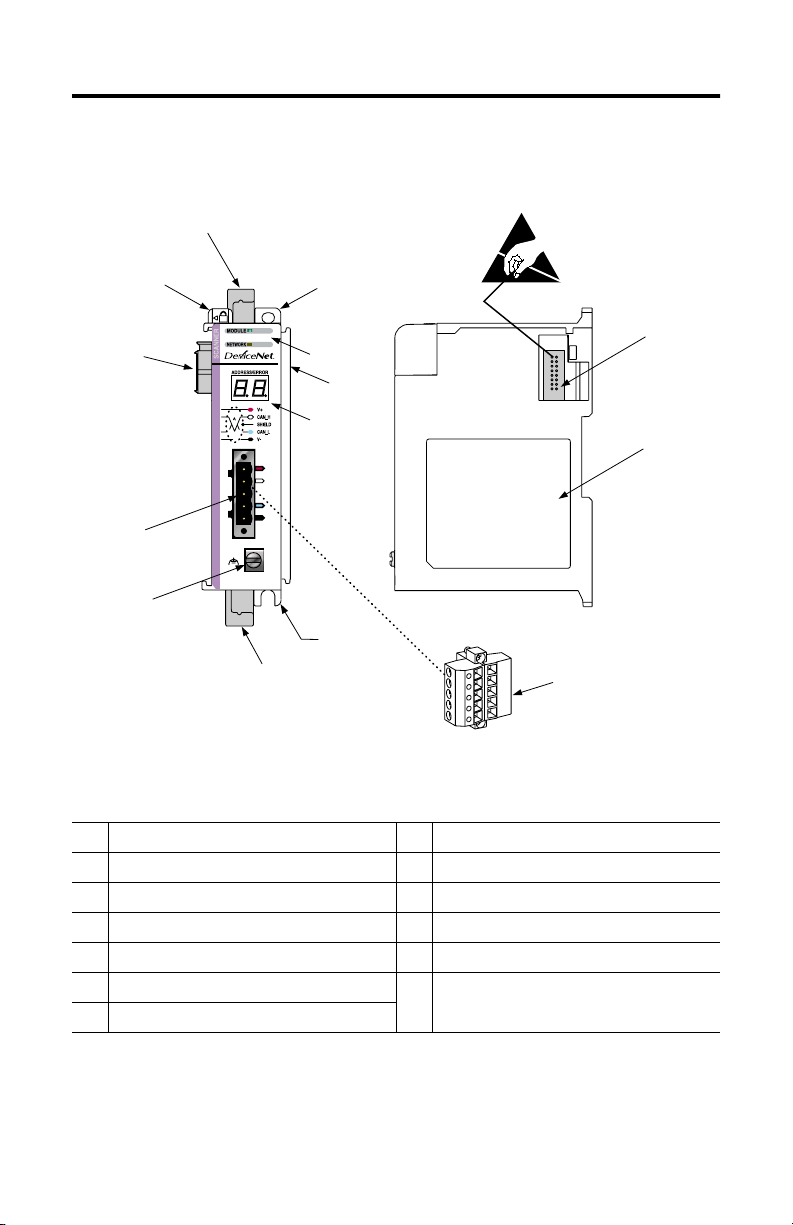

Module Description

2A

Compact I/O DeviceNet Scanner Module 5

1

8A

3A

4

8B

5

7A

6

3B

2B

7B

Table A

1 bus lever (with locking function) 6 grounding screw

2A upper DIN rail latch 7A DeviceNet mating male receptacle

2B lower DIN rail latch 7B removable DeviceNet female connector

3A upper panel mounting tab 8A movable bus connector with female pins

3B lower panel mounting tab 8B bus connector with male pins

4 Module and Network status LEDs 9 nameplate label

5 Address and Error numeric displays

8B

9

Publication 1769-IN060C-EN-P - May 2002

Page 6

6 Compact I/O DeviceNet Scanner Module

ATTENTION

!

Module Installation

The 1769-SDN module is suitable for use in an industrial environment when

installed in accordance with these instructions. Specifically, this equipment is

intended for use in clean, dry environments (Pollution Degree 2

circuits not exceeding Over Voltage Category II

(2)

(IEC 60664-1).

Prevent Electrostatic Discharge

Electrostatic discharge can damage integrated circuits or

semiconductors if you touch bus connector pins. Follow these

guidelines when you handle the module:

• Touch a grounded object to discharge static potential.

• Wear an approved wrist-strap grounding device.

• Do not touch the bus connector or connector pins.

• Do not touch circuit components inside the module.

• If available, use a static-safe work station.

• When not in use, keep the module in its static-shield box.

(1)

) and with

(3)

(1)

Pollution Degree 2 is an environment where, normally, only non-conductive pollution occurs except that occasionally a

temporary conductivity caused by condensation shall be expected.

(2)

Over Voltage Category II is the load level section of the electrical distribution system. At this level transient voltages are

controlled and do not exceed the impulse voltage capability of the product’s insulation.

(3)

Pollution Degree 2 and Over Voltage Category II are International Electrotechnical Commission (IEC) designations.

Publication 1769-IN060C-EN-P - May 2002

Page 7

Remove Power

ATTENTION

!

Compact I/O DeviceNet Scanner Module 7

Remove power before removing or inserting this module. When

you remove or insert a module with power applied, an

electrical arc may occur. An electrical arc can cause personal

injury or property damage by:

• sending an erroneous signal to your system’s field devices,

causing unintended machine motion

• causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on both the

module and its mating connector. Worn contacts may create

electrical resistance.

Publication 1769-IN060C-EN-P - May 2002

Page 8

8 Compact I/O DeviceNet Scanner Module

System Planning

Consider the following when planning your system:

• The scanner can communicate with up to 63 DeviceNet devices.

• The scanner, as a master, can own up to 63 slave I/O nodes.

• The scanner can simultaneously be a master and be a slave owned by

another DeviceNet master.

• A 1769-ECR (right end cap) or 1769-ECL (left end cap) is required to

terminate the end of the Compact I/O bus.

• Each bank of Compact I/O must have its own power supply (a MicroLogix

1500 acts as the power supply for modules directly connected to it).

• A Compact I/O power supply, or MicroLogix 1500 Base Unit, has limits in

the amount of +5V dc and +24V dc current it can supply to modules in its

I/O bank. These limits depend on the catalog number (e.g. 1769-PA2) of the

supply. A bank of modules must not exceed the current limits of the I/O

bank power supply or MicroLogix 1500 Base Unit.

Refer to the Compact 1769 Expansion I/O Power Supplies Installation

Instructions, publication 1769-5.14 or the MicroLogix 1500 User Manual,

publication 1764-UM001A-EN-P.

• The scanner has a distance rating of four, therefore the scanner must be

within four modules of the I/O bank’s power supply.

• Determine the DeviceNet baud rate based on standard DeviceNet

considerations.

• Consider the number of words of I/O data the host controller supports.

For more information on planning your DeviceNet network, refer to the DeviceNet

Cable System Planning and Installation Manual, publication DN-6.7.2.

Publication 1769-IN060C-EN-P - May 2002

Page 9

Compact I/O DeviceNet Scanner Module 9

ATTENTION

!

System Assembly

The module can be attached to an adjacent controller, power supply, or I/O

module. For mounting instructions, see “Panel Mounting” on page 10, or “DIN Rail

Mounting” on page 12. To work with a system that is already mounted, see

“Replacing a Single Module within a System” on page 13.

The following procedure shows you how to assemble the Compact I/O system.

A

C

1. Disconnect power.

2. Check that the bus lever of the module (A) is in the unlocked (fully right)

position.

3. Use the upper and lower tongue-and-groove slots (B) to secure the modules

together.

4. Move the module back along the tongue-and-groove slots until the bus

connectors (C) line up with each other.

5. Use your fingers or a small screw driver to push the bus lever back slightly

to clear the positioning tab (D).

6. Move the module’s bus lever fully to the left (E) until it clicks. Ensure it is

locked firmly in place.

B

B

D

E

G

F

When attaching I/O modules, it is very important that the

bus connectors are securely locked together to ensure

proper electrical connection.

Publication 1769-IN060C-EN-P - May 2002

Page 10

10 Compact I/O DeviceNet Scanner Module

ATTENTION

!

7. Attach an end cap terminator (F) to the last module in the system by using

the tongue-and-groove slots as before.

8. Lock the end cap bus terminator (G).

IMPORTANT

A 1769-ECR or 1769-ECL right or left end cap must be used to

terminate the end of the serial communication bus.

System Mounting

During panel or DIN rail mounting of all devices, be sure that

all debris (metal chips, wire strands, etc.) is kept from falling

into the module. Debris that falls into the module could cause

damage on power up.

Minimum Spacing

Compact I/O

Top

Compact I/O

Bottom

Compact I/O

Compact I/O

Maintain spacing from

enclosure walls,

wireways, adjacent

equipment, etc. Allow 50

mm (2 in.) of space on all

sides for adequate

ventilation, as shown:

Allow at least 110 mm

(4.33 in.) of enclosure depth to accommodate the module and the DeviceNet

connector.

Side

Controller

Panel Mounting

Mount the module to a panel using two screws per module. Use M4 or #8 panhead

screws. Mounting screws are required on every module.

Publication 1769-IN060C-EN-P - May 2002

Side

Compact I/O

End Cap or Cable

Page 11

Compact I/O DeviceNet Scanner Module 11

Panel Mounting Using the Dimensional Drawing

NOTE: All dimensions are in mm (inches). Hole spacing tolerance: ±0.04 mm (0.016 in.).

Compact I/O with CompactLogix Controller and Power Supply

Mounting Hole

Dimension

132 mm (5.19 in)

122.6 mm (4.83 in)

59 mm

59 mm

(2.32 in)

(2.32 in)

(1.97 in)

40 mm

(1.58 in)

118 mm (4.65 in)

35 mm

(1.38 in)

35 mm

50 mm

(1.38 in)

DIN Rail

Center Line

Compact I/O with MicroLogix 1500 Base Unit and Processor

168 mm

Mounting Hole

Dimension

59 mm

(2.32 in)

(6.62 in)

147 mm

(5.79 in)

35 mm

(1.38 in)

70 mm

(2.76 in)

(1.38 in)

14.7 mm

(0.58 in)

35 mm

35 mm

(1.38 in)

35 mm

(1.38 in)

35 mm

(1.38 in)

35 mm

(1.38 in)

28.5 mm

(1.12 in)

147.4 mm (5.81 in)

28.5 mm

(1.12 in)

132 mm (5.19 in)

122.6 mm (4.83 in)

59 mm

(2.32 in)

118 mm (4.65 in)

DIN Rail

Center Line

13.5 mm

(0.53 in)

14.7 mm

(0.58 in)

Publication 1769-IN060C-EN-P - May 2002

147.4 mm (5.81 in)

Page 12

12 Compact I/O DeviceNet Scanner Module

Panel Mounting Procedure Using Modules as a Template

The following procedure allows you to use the assembled modules as a template

for drilling holes in the panel. Due to module mounting hole tolerance, it is

important to follow these procedures:

1. On a clean work surface, assemble no more than three modules.

2. Using the assembled modules as a template, carefully mark the center of all

module-mounting holes on the panel.

3. Return the assembled modules to the clean work surface, including any

previously mounted modules.

4. Drill and tap the mounting holes for the recommended M4 or #8 screw.

5. Place the modules back on the panel, and check for proper hole alignment.

6. Attach the modules to the panel using the mounting screws.

7. Repeat steps 1 to 6 for any remaining modules.

DIN Rail Mounting

The module can be mounted using the following DIN rails: 35 x 7.5 mm (EN 50 022

- 35 x 7.5) or 35 x 15 mm (EN 50 022 - 35 x 15).

Before mounting the module on a DIN rail, close the DIN rail latches. Press the DIN

rail mounting area of the module against the DIN rail. The latches will momentarily

open and lock into place. DIN rail mounting dimensions are shown below.

Dimension Height

B

A

C

Publication 1769-IN060C-EN-P - May 2002

A 118 mm

B 59 mm

C 59 mm

(4.65 in.)

(2.325 in.)

(2.325 in.)

Page 13

Compact I/O DeviceNet Scanner Module 13

TIP

Replacing the Scanner Module within a System

The scanner can be replaced while the system is mounted to a panel (or DIN rail).

1. Remove power. See important note on page 7.

2. Remove the DeviceNet cable from the scanner by removing the DeviceNet

connector.

3. Remove the upper and lower mounting screws from the scanner (or open

the DIN latches using a flat-blade screwdriver).

4. On the scanner to be replaced and the right-side adjacent module (or end

cap if the scanner is the last module in the bank), move the bus levers to the

right (unlock) to disconnect the scanner from the adjacent modules.

5. Gently slide the disconnected scanner module forward.

If you feel excessive resistance, make sure that you disconnected the

scanner from the bus and that you removed both mounting screws (or

opened the DIN latches).

.

It may be necessary to rock the scanner slightly from

front to back to remove it, or, in a panel-mounted

system, to loosen the screws of adjacent modules.

6. Before installing the replacement scanner, be sure that the bus lever on the

right-side adjacent module is in the unlocked (fully right) position.

7. Slide the replacement scanner into the open slot.

8. Connect the scanner and modules together by locking (fully left) the bus

levers on the replacement scanner and the right-side adjacent module or end

cap.

9. Replace the mounting screws (or snap the scanner onto the DIN rail).

10. Replace the DeviceNet cable on the scanner by attaching the connector to

the scanner.

Publication 1769-IN060C-EN-P - May 2002

Page 14

14 Compact I/O DeviceNet Scanner Module

ATTENTION

!

11. Restore scanner configuration using RSNetWorx for DeviceNet.

IMPORTANT

Be sure that the new module has the same node address

and baud rate as the module that was replaced.

Field Wiring Connections

Grounding the Scanner Module

This product is intended to be mounted to a well-grounded mounting surface such

as a metal panel. Additional grounding connections from the scanner’s mounting

tabs or DIN rail (if used), are not required unless the mounting surface cannot be

grounded.

The grounding screw on the front of the scanner must be

connected to a suitable ground source when operating in

electrically noisy environments. Use a #14 AWG wire to make

this connection.

Refer to Industrial Automation Wiring and Grounding Guidelines, Allen-Bradley

publication 1770-4.1, for additional information.

Publication 1769-IN060C-EN-P - May 2002

Page 15

DeviceNet Wiring

Compact I/O DeviceNet Scanner Module 15

DeviceNet Connector

Grounding Screw

Use #14 AWG wire

to connect to panel

ground.

(1)

Connect

Red Wire V+

White Wire CAN High

Bare Wire Shield

Blue Wire CAN Low

Black Wire V-

To

1. Connect the DeviceNet cable to the removable connector as shown.

2. Insert the removable female connector into the mating male connector on

the DeviceNet scanner module.

3. Screw the removable connector to the scanner case with the upper and

lower mounting screws. Screw torque is 0.6 to 0.7 Nm (5 to 6 in-lbs).

IMPORTANT

If the 1769-SDN is the first or last device connected to the

DeviceNet network trunkline, be sure to add a termination resistor

(120Ω 1% ≥ ¼W resistor, Allen-Bradley part number 1485A-C2)

across the Blue (CAN Low) and White (CAN High) wires.

Scanner Module Power-Up

When power is applied via the Compact I/O bus, the scanner module goes through

a self test sequence. Upon successful completion of the self test, the scanner is

ready to communicate.

The default scanner settings are:

• baud rate = 125K

• node address = 63

Use your configuration software to change the baud rate and node address.

Publication 1769-IN060C-EN-P - May 2002

Page 16

16 Compact I/O DeviceNet Scanner Module

TIP

TIP

Configuring the 1769-SDN on DeviceNet

The 1769-SDN must be configured using a DeviceNet configuration tool. The

recommended configuration software is RSNetWorx for DeviceNet (version 3.00 or

higher).

If your RSNetWorx configuration software does not include the

required EDS (Electronic Data Sheet) file, it is available via

http://www.ab.com/networks/eds.

This configuration tool allows you to identify all of the devices (I/O modules,

power supplies, expansion cables, end caps) and their locations in your system.

The controller must be in the Run mode, or the scanner in the

Idle mode (bit 0 of the Module Command Array = 0), for the

scanner to accept the configuration information.

For more information, refer to the

Manual, publication 1769-UM009A-EN-P.

Publication 1769-IN060C-EN-P - May 2002

Compact I/O DeviceNet Scanner Module

User

Page 17

Compact I/O DeviceNet Scanner Module 17

Data Organization

The scanner uses the input and output data images to transfer data, status and

command information between the scanner and the controller. The basic structure

is shown below. Refer to the

Compact I/O DeviceNet Scanner Module

publication 1769-UM009A-EN-P, for more detailed information.

Input Data Image

The input data image is transferred from the scanner module to the controller.

Word Description Data Type

0 to 63 Status Structure 64-word array

64 and 65 Module Status Register 2 words

66 to 245 Input Data Image 180-word array

Output Data Image

The output data image is transferred from the controller to the scanner module.

User Manual,

Word Description Data Type

0 and 1 Module Command Array 2-word array

2 to 181 Output Data Image 180-word array

The following table shows the bit descriptions for the Module Command Array.

Word Bit Operating Mode

0 0 1 = Run, 0 = Idle

1 1 = Fault

2 1 = Disable Network

3

4 1 = Reset

5 to 15

10 to 15

(1)

DO NOT manipulate Reserved Bits. Doing so may interfere with future compatibility.

Reserved

Reserved

Reserved

(1)

(1)

(1)

Publication 1769-IN060C-EN-P - May 2002

Page 18

18 Compact I/O DeviceNet Scanner Module

Diagnostic Indicators

Indicator Color/

Module Off No power applied to module. Apply power.

Network Off No module power, no network power, or

7-Segment

Numeric

Display

Status

Flashing

Green

Solid Green Normal operation. No action required.

Flashing

Red

Solid Red Unrecoverable fault Verify module connectors are properly

Flashing

Green

Solid Green Normal operation. Scan list is

Flashing

Red

Solid Red Critical network failure. Duplicate

Node

Address

and Status

Display

Indicates Recommended Action

No Bus Master (MicroLogix or

CompactLogix controller) present.

Recoverable Fault - Memory has been

erased or is being programmed.

communications are not occurring

between the module and the DeviceNet

network. (This may be an acceptable

condition.)

Device is operational. There are no

connections established with any of the

network devices.

configured. Module is not in Idle mode.

One or more of the devices that the

scanner is communicating with is in a

timed out state.

DeviceNet node address detected.

Indicates diagnostic information about the status of the module.

When the numeric display is showing 0 to 63, it is indicating the 1769-SDN

module’s DeviceNet node address.

When it shows 70 to 99, it indicates an Error Code for the displayed node address.

When it flashes alternating numbers, one is the Error Code (70 to 99), and the

other is the Node Number (0 to 63) that has generated the error.

See the list of Error Codes on page 19 for more information.

Verify module connectors are properly

seated. If they are, cycle power to the

controller. If this does not correct the

problem, replace the controller. If

replacing the controller does not

correct the problem, replace the

1769-SDN.

Complete flash update or start a new

update.

seated. If they are, verify that bus

terminator/end cap is installed. Cycle

power. If still faulted, replace the

module.

Verify module has power. Check that

the DeviceNet cable is securely

connected and the DeviceNet network

is powered. Verify that network power

is adequate (11 to 25V dc).

If the module is supposed to be

controlling DeviceNet slaves,

configure the module’s scan list.

No action required.

Monitor the status display, or the

module’s status field to determine

which slave device is offline.

Reset module. Change module’s node

address or change conflicting device’s

node address. If failure continues,

replace module.

Publication 1769-IN060C-EN-P - May 2002

Page 19

Compact I/O DeviceNet Scanner Module 19

Error Codes

The following table describes the Error Codes indicated by the 7-segment numeric

display.

Code

(decimal)

70 Duplicate Node Controller has Failed Duplicate

71 Illegal Scan

72 Slave Timeout One of the module’s slave devices

73 Electronic Key

75 No Messages

76 No Message

77 Slave Data Size

78 No Such

79 Transmit

80 In Idle Mode Module is in Idle mode. Put the controller into Run mode and

81 Scanner

Name Description Recommended Action

Change the module’s or conflicting

device’s network address (node

number) to an available one.

remove any illegal data.

Inspect the module’s slave devices and

verify the DeviceNet connections.

Make sure that the device at the

flashing node address matches the

desired electronic key (vendor, product

code, product type)

Verify the scan list is correctly

configured to scan slave devices. Verify

DeviceNet network connections.

None. There are other active devices on

the network, initiating messages, but

none of the messages are for the

module.

Either reconfigure the slave device, or

change the module’s scan list to match

the slave device.

Either add the device to the DeviceNet

network, or delete the device’s entry in

the scan list.

Make sure that the module is

connected to a valid network. Check for

disconnected cables.

enable the scanner Run bit (bit 0 of the

Module Command Array = 1). See page

17.

Check the FAULT value in the module

command array.

List Data

Mismatch

Received

For Scanner

Mismatch

Device

Failure

Faulted

Node Address Check. The node

address selected is already in use.

Illegal data in Scan List. Reconfigure the scan list table and

has stopped communicating.

The slave device Vendor ID key

parameter does not match the

slave’s configuration in the

module’s scan list.

No network traffic received by the

scanner. 10 seconds have elapsed

and no network traffic for the

module or for any other device have

been received by the module.

No direct network traffic for the

scanner detected. 10 seconds

elapsed and no DeviceNet input

being screened by the module has

been received.

The data being received from the

slave device does not match the

configuration in the scan list.

Slave device in scan list does not

exist.

The module has failed to transmit a

message.

The Scanner has stopped producing

and consuming I/O data. This

condition does not affect the

scanner’s system or messaging

modes.

Publication 1769-IN060C-EN-P - May 2002

Page 20

20 Compact I/O DeviceNet Scanner Module

Code

(decimal)

82 Fragmentation

83 Slave Init Error Slave device is returning error

84 Not Yet

85 Receive Buffer

86 Device Went

89 Auto Device

90 Disabled

91 Bus Off Bus off condition detected on

92 No DeviceNet

95 FLASH Update Flash Update In Progress None. DO NOT disconnect the module

98 Firmware

99 Hard Fault Cycle Power. Reflash module firmware.

Name Description Recommended Action

Error

Initialized

Overflow

Idle

Replacement

(ADR) Error

Network

Power

Corrupted

Error detected in sequence of

fragmented I/O messages from

device.

responses when the module

attempts to communicate with it.

Module has not completed its initial

attempt to establish

communications with its slaves.

Data size returned is larger than

expected.

Device is producing Idle state. Check the device configuration and

Slave device responded with an

error to the initialization data sent

to it by the scanner; or the

configuration table in the scanner’s

flash memory is not valid for a slave

node.

DeviceNet Port is Disabled Check for the disable being set in the

integral DeviceNet port.

No network power detected on

DeviceNet port.

Firmware is corrupted. Reflash module firmware. DO NOT

Check scan list table entry for slave

device to make sure that input and

output data lengths are correct. Check

slave device configuration.

Check slave device’s configuration.

Reboot slave device.

None. This code clears itself once the

module properly initializes all slave

devices on the network.

Configure the slave device for a smaller

data size.

slave node status.

Try the ADR download again. If it still

fails, try clearing the ADR flash by

downloading an empty ADR

configuration to the scanner and then

try the ADR configuration again.

module command array.

Check the DeviceNet connections and

physical media integrity. Check system

for failed slave devices or other

possible sources of network

interference. Check the Baud Rate.

Provide network power. Make sure the

module drop cable is providing the

proper power to the DeviceNet port.

from the network while a flash update

is in progress.

power cycle the module. Doing so may

cause the module to become

inoperable If the problem persists

contact Rockwell Automation Technical

Support.

Contact Rockwell Automation Technical

Support.

Publication 1769-IN060C-EN-P - May 2002

Page 21

Compact I/O DeviceNet Scanner Module 21

Specifications

General Specifications

Specification Value

Module Dimensions 118 mm (height) x 87 mm (depth) x 35 mm (width)

Approximate Shipping Weight

(with carton)

Storage Temperature -40°C to +85°C (-40°F to +185°F)

Operating Temperature 0°C to +60°C (32°F to +140°F)

Operating Humidity 5% to 95% non-condensing

Operating Altitude

Vibration Operating: 10 to 500 Hz, 5G, 0.030 inches maximum peak-to-peak

Shock Operating: 30G panel mounted (20G DIN rail mounted)

Agency Certification

Hazardous Environment Class Class I, Division 2, Hazardous Location, Groups A, B, C, D (UL 1604,

Radiated and Conducted Emissions EN50081-2 Class A

Electrical /EMC: The module has passed testing at the following levels:

ESD Immunity (IEC61000-4-2)

Radiated Immunity (IEC61000-4-3)

Fast Transient Burst (IEC61000-4-4)

Surge Immunity (IEC61000-4-5)

Conducted Immunity (IEC61000-4-6)

(1)

For operation above 2000 meters, consult the factory.

(2)

Conducted Immunity frequency range may be 150 kHz to 30 MHz if the Radiated Immunity frequency range is 30 MHz to

1000 MHz.

height including mounting tabs is 138 mm

4.65 in. (height) x 3.43 in (depth) x 1.38 in (width)

height including mounting tabs is 5.43 in.

280g (0.61 lbs.)

2000 meters (6561 feet)

Non-Operating: 40G panel mounted (30G DIN rail mounted)

• C-UL certified (under CSA C22.2 No. 142)

• UL 508 listed

• CE and C-Tick compliant for all applicable directives

• ODVA DeviceNet conformance tested

C-UL under CSA C22.2 No. 213)

• 4kV contact, 8kV air, 4kV indirect

• 10 V/m, 80 to 1000 MHz, 80% amplitude modulation,

+900 MHz keyed carrier

• 2 kV, 5 kHz

• 2 kV galvanic gun

• 10V, 0.15 to 80 MHz

(1)

(2)

Publication 1769-IN060C-EN-P - May 2002

Page 22

22 Compact I/O DeviceNet Scanner Module

Electrical and DeviceNet Specifications

Specification Value

Bus Current Draw (maximum) 440 mA at 5V dc (2.2 Watts)

DeviceNet Power Requirements N.E.C. Class 2

Heat Dissipation (maximum) 3.8 Watts (assumes typical network traffic)

Baud Rates 125K bits/second (default)

Maximum Cable Length 500 meters at 125K baud

DeviceNet Cable Allen-Bradley catalog number 1485C-P1-Cxxx. Refer to publication

Power Supply Distance Rating 4 (The module may not be more than 4 modules away from the

DeviceNet to Compact Bus Isolation Verified by one of the following dielectric tests: 500V ac for 1

Vendor I.D. code 1

Product Type Code 12

Product Code 105

90 mA at 11V dc (maximum)

110 mA at 25V dc (maximum)

200 mA for 1.5 ms (inrush)

250K bits/second

500K bits/second

100 meters at 500K baud

DN-2.5 for more information.

power supply).

minute or 707V dc for 1 minute.

30V dc working voltage (IEC Class 2 reinforced insulation)

Compact, CompactLogix, MicroLogix and RSNetWorx are trademarks of Rockwell Automation.

DeviceNet is a trademark of Open DeviceNet Vendors Association (ODVA).

Publication 1769-IN060C-EN-P - May 2002

Page 23

Notes:

Compact I/O DeviceNet Scanner Module 23

Publication 1769-IN060C-EN-P - May 2002

Page 24

Publication 1769-IN060C-EN-P - May 2002 PN 40072-107-01(3)

Supersedes Pub lication 1769-IN060B-EN -P - September 2001 Copyright © 2002 Rockwell Automa tion. All rights reser ved. Printed in the U.S.A.

Loading...

Loading...