Page 1

Installation Instructions

Chassis Interface Module for

1746 Local I/O

(Catalog Number 1747-PCIL)

Use this document to install the Chassis Interface module for 1746

Local I/O and connect it to a PCI Bus card for 1746 Local I/O.

The Chassis Interface module works with the PCI Bus card

(Cat. No. 1747-PCIS/PCIS2) and a connecting cable to make up

the 1747 PCI Bus Interface.

To install the card, read:

Compliance to European Union Directives

Verify Package Contents

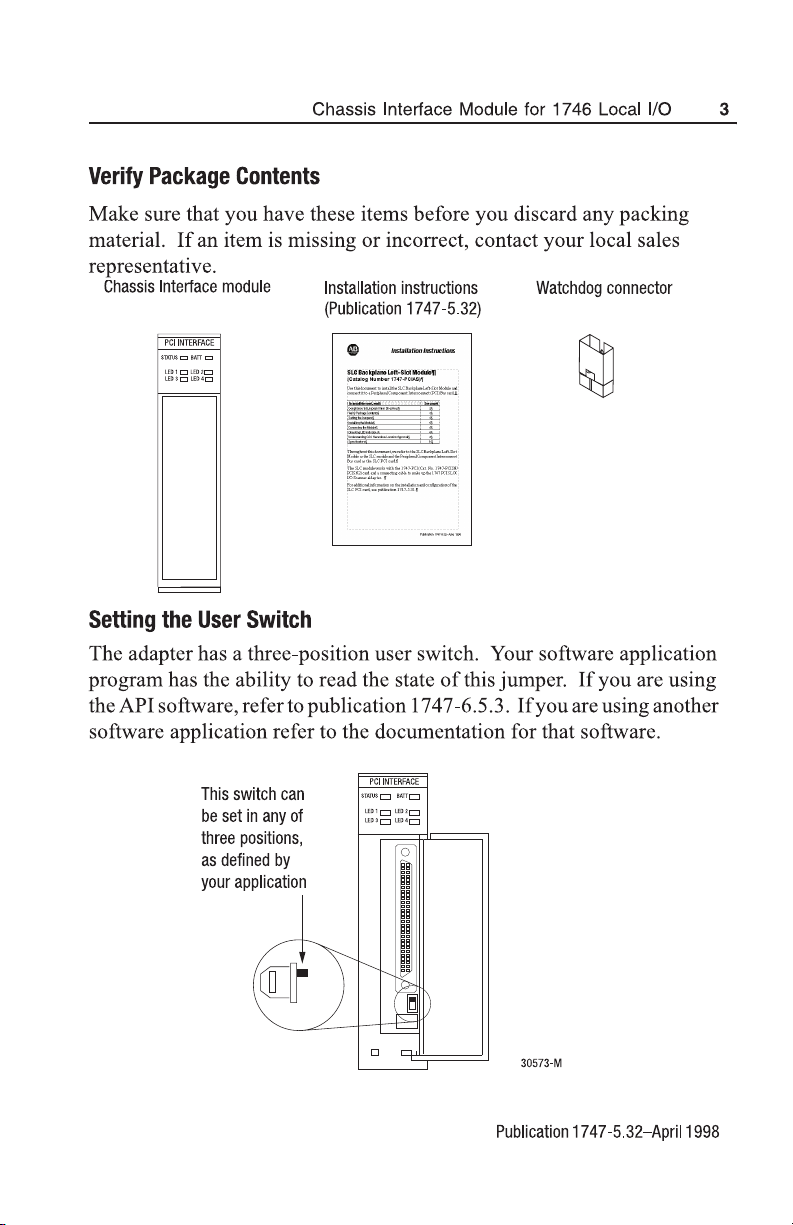

Setting the User Switch

Setting the Jumpers

Installing the Adapter

Selecting the Cable for Your Connections

Connecting the Adapter to the Scanner

Adapter LED Templates

Checking LED Indicators

General Operation

Understanding CSA Hazardous Location Approval

Specifications

See page:

2

3

3

4

6

6

7

8

9

11

12

14

In the instructional text of this document, we refer to the Chassis

Interface module as the adapter and the PCI Bus card as the scanner.

For additional information on the installation and configuration of the

PCI Bus card, see publication 1747-5.31.

Publication 1747-5.32–April 1998

Page 2

2 Chassis Interface Module for 1746 Local I/O

Compliance to European Union Directives

If this product bears the CE marking, it is approved for installation within

the European Union and EEA regions. It has been designed and tested to

meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in

whole or in part, documented in a technical construction file:

• EN 50081-2 EMC - Generic Emission Standard, Part 2 - Industrial

Environment

• EN 50082-2 EMC - Generic Immunity Standard, Part 2 - Industrial

Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage,

by applying the safety requirements of EN 61131-2 Programmable

Controllers, Part 2 - Equipment Requirements and Tests.

For specific information required by EN 61131-2, see the appropriate

sections in this publication, as well as the following Allen-Bradley

publications:

• Industrial Automation Wiring and Grounding Guidelines For Noise

Immunity, publication 1770-4.1

• Automation Systems Catalog, publication B111

This equipment is classified as open equipment and must be installed

(mounted) in an enclosure during operation as a means of providing safety

protection.

Publication 1747-5.32–April 1998

Page 3

Page 4

4 Chassis Interface Module for 1746 Local I/O

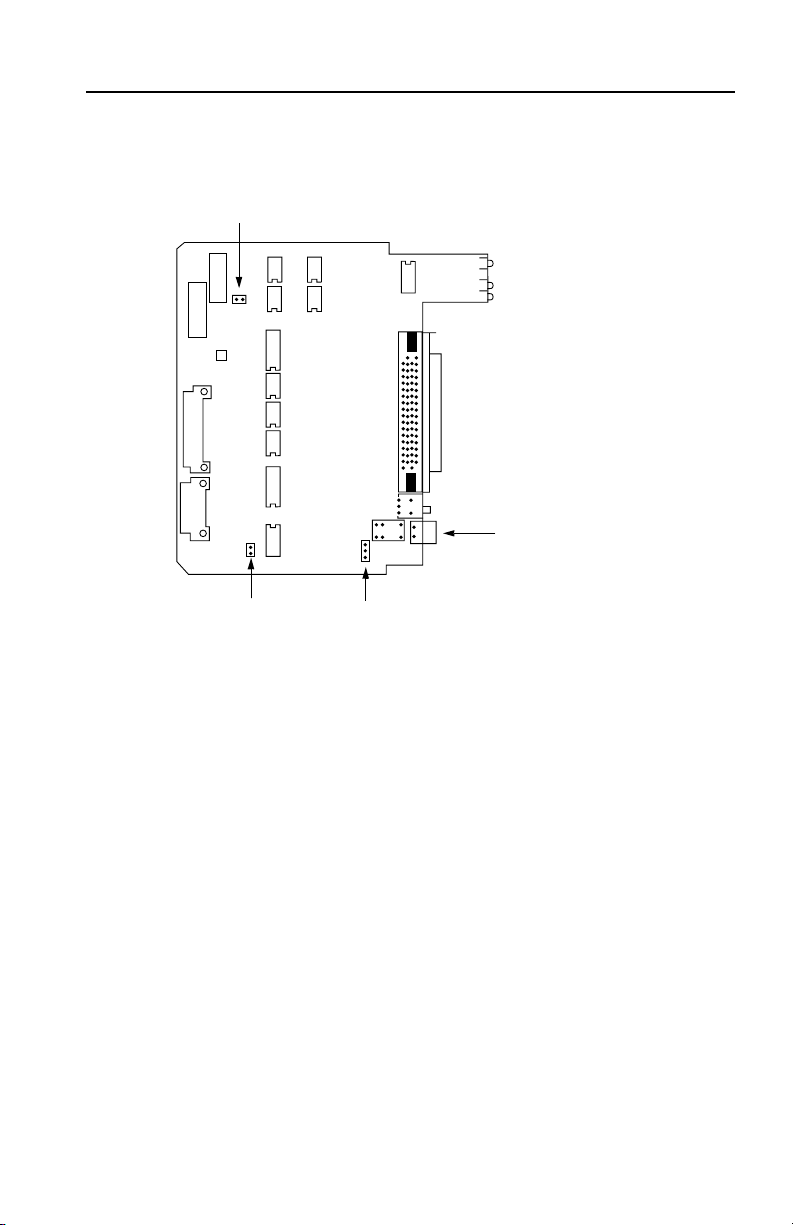

Setting the Jumper

The adapter has three separate jumpers on board.

Last State Jumper

Watchdog JumperUser Jumper

Watchdog Connector

(Internally connected to

the watchdog jumper

Last State Jumper

This jumper defines the state of I/O in case of a communication failure.

You must set the jumper to one of the following two settings:

• Last State –When communication with the scanner is lost (for

example, the cable is unplugged or the computer is turned off),

the 1746 I/O will hold their last state.

• Reset – When communication with the scanner is lost,

the 1746 I/O will be reset.

Watchdog Jumper

This jumper is internally connected to the watchdog connector. A detailed

explanation of this jumper’s usage is on the next page.

Publication 1747-5.32–April 1998

Page 5

Chassis Interface Module for 1746 Local I/O 5

User Jumper

Your software application program has the ability to read the state of this

jumper. If you are using the API software, refer to publication 1747-6.5.3.

If you are using another software application refer to the documentation

for that software.

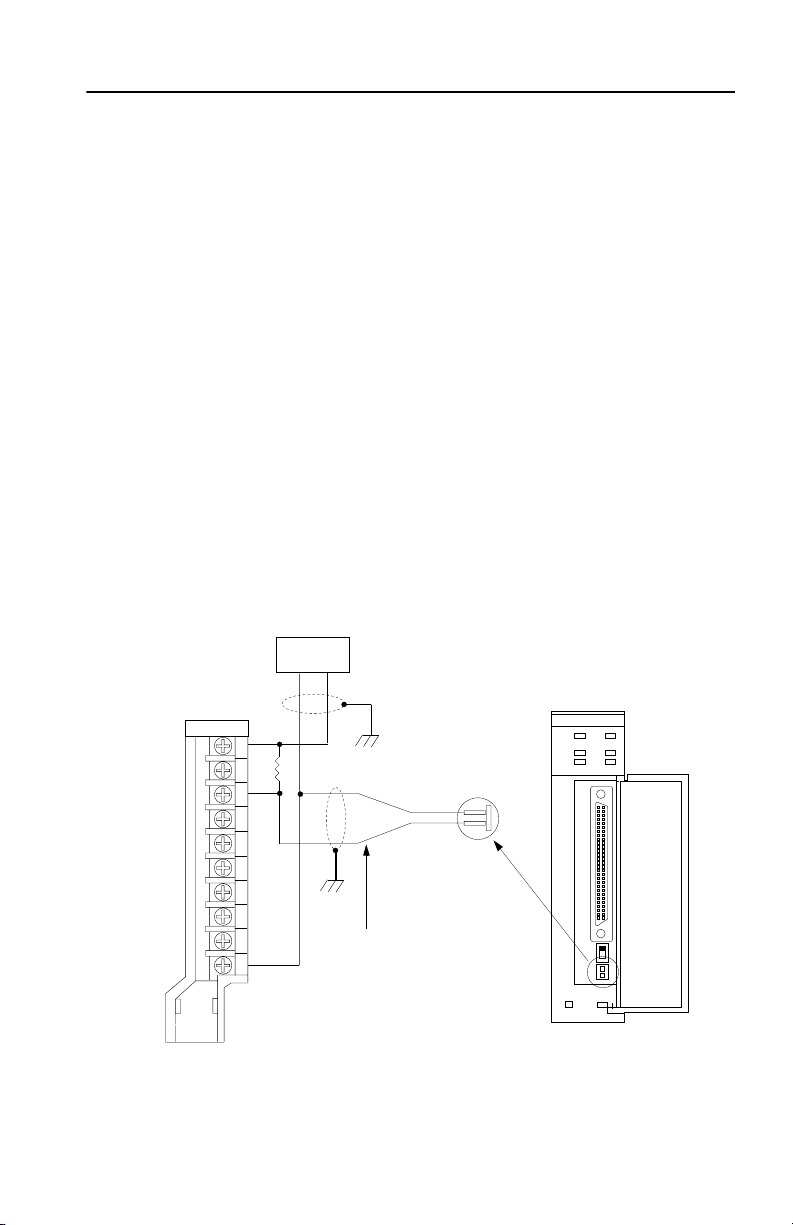

Using the Watchdog Jumper with the External Watchdog Connector

This jumper works in junction with the watchdog connector on the front

of the chassis interface module. The watchdog connector output is a solid

state switch that can switch a voltage range of 4.5V dc to 26.4V dc. The

connector plugs onto the front of the chassis interface module.

You need an external power supply to use the external watchdog. Adjust

the external load switched by the watchdog output to 20mA or less. The

watchdog output is normally off and turns on as a result of a watchdog

timeout condition due to an internal hardware failure. When this condition

occurs, a red indicator will light up on the status LED.

You must adhere to the watchdog output polarization to guarantee proper

operation.

dc or TTL input module

+ dc

input 0

input 1

input 2

input 3

input 4

input 5

input 6

input 7

- dc (common)

user power

supply

Ground the shields

at one end only.

Chassis mounting

bolt preferred.

common -

watchdog

contact +

Use 22-26 AWG

shielded twistedpair wire

Chassis

Interface

Module

contact

41165

Publication 1747-5.32–April 1998

Page 6

6 Chassis Interface Module for 1746 Local I/O

Installing the Adapter .

ATTENTION: Never install, remove, or connect cables

to the adapter with power applied to chassis.

!

Important: The adapter must be installed in the left slot of the chassis

as shown below.

Align circuit board with top

and bottom chassis guides.

21

Printed

Circuit

Board

30575–M 30574–M

Slide adapter into chassis

until adapter tabs ‘click’.

Locking tab

Selecting the Cable for Your Connections

The adapter must be connected to the scanner. Use one of the following

cables to make the connection:

• 3m interconnect cable (Cat. No. 1747-PCIC)

• 10m interconnect cable (Cat. No. 1747-PCIC2)

Publication 1747-5.32–April 1998

Page 7

Chassis Interface Module for 1746 Local I/O 7

Connecting the Adapter to the Scanner

To connect the adapter to the scanner, you:

1. Connect one end of the 1747-PCIC cable to the adapter.

2. Connect the other end of the 1747-PCIC cable to the scanner.

PCI Bus card

(scanner)

Chassis Interface module

(Adapter)

1747-PCIC cable

30576-M

The figure below shows an example of a connection between a Chassis

Interface module inside a local chassis and a PCI Bus card inside the

computer.

PCI Bus card (inside

the computer)

Personal Computer

1747-PCIC Cable

Chassis Interface

module (inside the

local chassis)

30173

Publication 1747-5.32–April 1998

Page 8

8 Chassis Interface Module for 1746 Local I/O

Adapter LED Templates

The adapter LED template allows you to create a custom template for

your application. Use the follow dimensions to create a template.

NOTES: Obtain these

parts to make a

custom LED.

1) Color is pantone

#431 grey over white

for opacity, opposite

adhesive side

2) Selective adhesive

around the perimeter

on the back

3) Clear windows

4) Protective cling

mask

5) Material .019 +/glossy polycarbonate

0.175 in.

+.002

0.200 in.

.002

+

0.350

.002

+

0.157 in.

0.400 in.

+.002

+.005

-.003

0.295 in.

.002

+

1.61 in.

+.002

0.078 in.

+.005

-.003

1.035 in.

.002

+

Initially, the LED template is easily removed from the front of the adapter.

After you have set the LED positions for your application, place the

display on the module and push it into place.

Publication 1747-5.32–April 1998

Page 9

Chassis Interface Module for 1746 Local I/O 9

Checking LED Indicators

PCI INTERFACE

STATUS BATT

LED 1 LED 2

LED 3 LED 4

STATUS

The STATUS indicator reports the status of the scanner. The following

table lists the LED states for STATUS:

This state:

Yellow The scanner is running POST. None

Flashing green The scanner is in idle mode and is

not scanning I/O.

Solid green The scanner is scanning I/O. None

Flashing red An I/O fault has occurred. Check software to identify

Solid red A scanner internal fault has

occurred.

Off The adapter is not powered up. Turn on p o w e r.

Means: Take this action:

None

fault condition.

Power system off and back on. If

the problem persists, service may

be required.

Publication 1747-5.32–April 1998

Page 10

10 Chassis Interface Module for 1746 Local I/O

BATT

The BATT indicator reports the health of the battery on the PCI scanner

board. The following table lists the LED states for BATT:

This state:

Off The battery is OK. None

Red The battery is low or dead. Replace the battery.

Means: Take this action:

LED 1, LED 2, LED 3, LED 4

Your application program can control the state of the four user LEDs on

the front of the adapter module. The default state is off. The following

table lists the possible LED states that your program can set.

This LED:

LED 1 & LED 2 Solid red

LED 3 & LED 4 Solid red

Can have these states: Take this action:

Flashing red

Solid green

Flashing green

Off

Solid green

Off

These actions are determined by

your specific application.

These actions are determined by

your specific application.

Publication 1747-5.32–April 1998

Page 11

Chassis Interface Module for 1746 Local I/O 11

During the power-on self test (POST), LED 1, LED 2, LED 3, and LED

4 indicate which test is running (if the STATUS LED is yellow) or which

test failed (if the STATUS LED is red). The following table lists the LED

patterns during POST.

This LED:

LED 1 Solid red

LED 2 Solid red

LED 3 Solid red

LED 4 Solid red

Can have these states: Which indicate these tests:

Flashing red

Solid green

Flashing green

Flashing red

Solid green

Flashing green

Solid green

Solid green

Software CRC checksum

Reserved

128K bytes RAM

Dual-port RAM

Backplane

Reserved

Reserved

Reserved

Reserved

Temperature sensor

Interrupt adapter

Timer

General Operation

The adapter has no microprocessor on board that scans or controls the

1746 backplane. The scanner board contains the I/O scanner

microprocessor and connects to the I/O backplane via the parallel cable

(1747-PCIC) and adapter module.

The control program running on the PC monitors and controls the 1746

I/O via the scanner’s dual port memory. All LED indicators on the adapter

are controlled by the scanner.

Publication 1747-5.32–April 1998

Page 12

12 Chassis Interface Module for 1746 Local I/O

Understand CSA Hazardous Location Approval

CSA certifies products for general use as well as for use in hazardous locations. Actual CSA

certification is indicated by the product label as shown below, and not by statements in any

user documentation.

Example of the CSA certification product label:

To comply with CSA certification for use in hazardous locations, the following information

becomes a part of the product literature for this CSA-certified industrial control product.

• This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D, or non-hazardous locations

only.

• The products having the appropriate CSA markings (that is, Class I, Division 2, Groups A, B, C, D) are

certified for use in other equipment where the suitability of combination (that is, application or use) is

determined by the CSA or the local inspection office having jurisdiction.

Important: Due to the mo dular nature of a programmable control system, th e product with the highest

temperature rating determines the overall temperature code rating of a programmable

control system in a Class I, Division 2, location. The temperature code rating is marked

on the product label as shown.

Temperature code rating:

CL I, DIV 2

GP A,B,C,D

TEMP

CL I, DIV 2

GP A,B,C,D

TEMP

Look for temperature

code rating h ere.

The following warnings apply to products having CSA certification for use in hazardous locations.

WARNING: Explosion hazard--

• Substitution of components may impair suitability for Class I, Division 2.

• Do not replace components unless power has been switched off or the area is

known to be non-hazardous.

• Do not disconnect equipment unless power has been switched off or the area

is known to be non-hazardous.

• Do not disconnect connectors unless power has been switched off or the area

is known to be non-hazardous. Secure any user-supplied connectors that mate

to external circuit s on this equipment by using s crews, sliding latches, threaded

connectors, or oth er means such that any c onnection can withstand a 15 Newton

(3.4 lb.) separating force applied for a minimum of one minute.

• Batteries must only be changed in an area known to be non-hazardous.

CSA logo is a registered trademark of the Canadian Standards Association.

Publication 1747-5.32–April 1998

Page 13

Chassis Interface Module for 1746 Local I/O 13

Approbation d’utilisation dans des environments dangereux par la CSA

La CSA certifie des produits pour une utilisation générale aussi bien que pour une utilisation en

environnements dangereux. La certification CSA en vigueur est indiquée par l'étiquette produit

et non par des indications dans la documentation utilisateur.

Exemple d'étiquette de certification d'un produit

par la CSA :

Pour satisfaire à la certification CSA en environnements dangereux, les informations suivantes

font partie intégrante de la documentation des produits de commande industrielle certifiés.

• Cet équipement ne convient qu’à une utilisation dans des environnements de Classe I, Division 2,

Groupes A, B, C, D ou non dangereux.

• Les produits portant le marquage CSA approprié (c'est-à-dire Classe I, Division 2, Groupes A, B, C, D)

sont certifiés pour une utilisation avec d'autres équipements, les combinaisons d’applications et

d’utilisation étant déterminées par la CSA ou le bureau local d'inspection.

Important: De par la nature modulaire des systèmes de commande programmables, le produit ayant le

code de température le plus élevé détermine le code de température global du système dan s

un environnement de Classe I, Division 2. Le code de température est indiqué sur l'étiquette

produit.

Code de température :

CL I, DIV 2

GP A,B,C,D

TEMP

CL I, DIV 2

GP A,B,C,D

TEMP

Le code de tem pérature

est indiqué ici.

Les avertissements suivants s’appliquent aux produits ayant la certification CSA pour une utilisation dans des

environnements dangereux.

AVERTISSEMENT : Risque d’explosion --

• La subs titution de composants peut rendre ce matériel ina dapté à une utilisation

en environnement de Classe I, Division 2.

• Couper le courant ou s'assurer que l’environnement est classé non dangereux

avant de remplacer des composants.

• Couper le courant ou s’assurer que l’environnement est classé non dangereux

avant de débrancher l'équipement.

• Couper le courant ou s'assurer que l’environnement est classé non dangereux

avant de débrancher les connecteurs. Fixer tous les connecteurs fournis par

l'utilisateur pour se brancher aux circuits externes de cet appareil à l 'aide de

vis, loquets coulissants, connecteurs filetés ou autres, de sorte que les

connexions résistent à une force de séparation de 15 Newtons (1,5 kg - 3,4 lb.)

appliquée pendant au moins une minute.

• S'ass urer que l'environnement est classé non dangereux avant de changer le s piles.

Le sigle CSA e st une marque déposée de l a Canadian Sta ndards Assoc iation.

Publication 1747-5.32–April 1998

Page 14

14 Chassis Interface Module for 1746 Local I/O

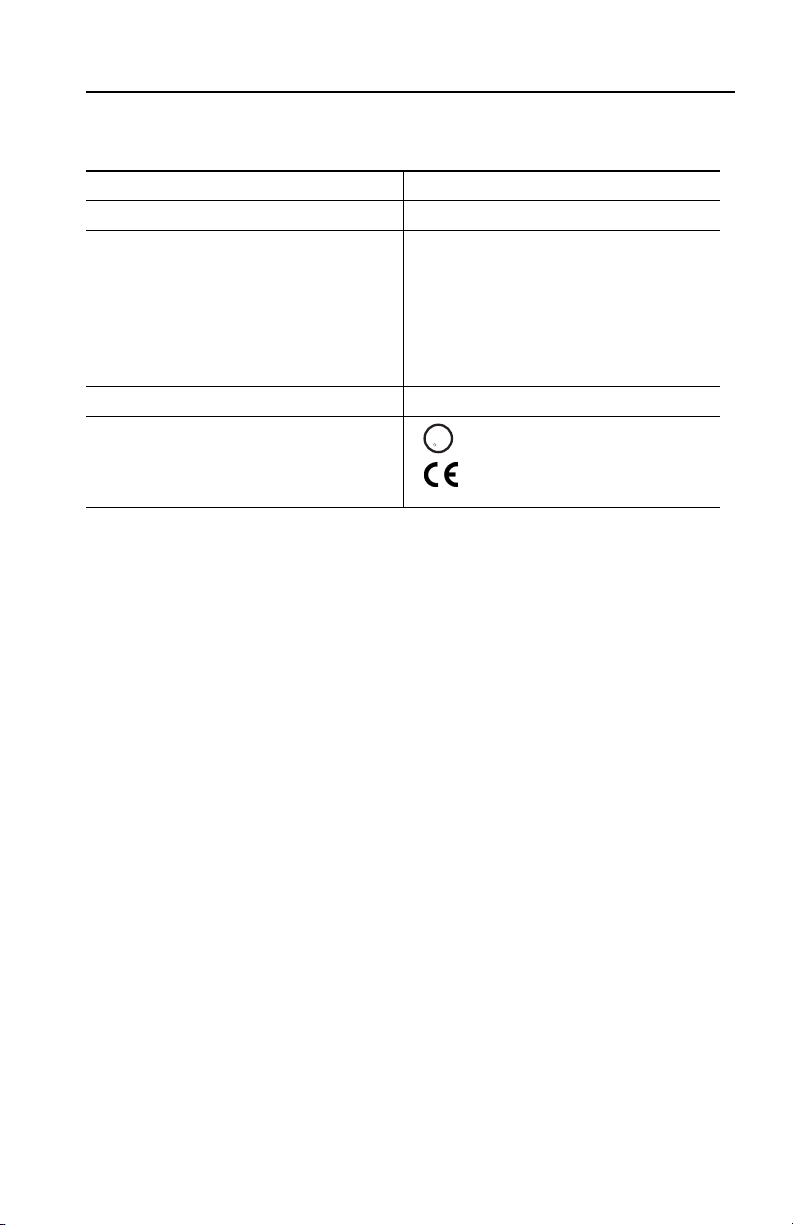

Specifications

Adapter Location Left slot of a 1746 I/O chassis

Backplane Current 100mA @ 5V dc

Environmental Conditions

Wiring Category 2

Agency Certification

(when product or packaging is marked)

Slot Operating Temperature

Slot Storage Temperature

Relative Humidity

Vibration

Operating Shock

Storage Shock

0 to 60oC

-40o to 95oC

5-95% without condensation

Constant 10-60Hz, 0.015 in. displacement

Constant 60-2000Hz, 2.5G acceleration

30G

50G

U

listed

R

L

USC

marked for all applicable directives

Publication 1747-5.32–April 1998

Page 15

Chassis Interface Module for 1746 Local I/O 15

Publication 1747-5.32–April 1998

Page 16

16 Chassis Interface Module for 1746 Local I/O

•

Worldwide representation.

Argentina • Australia • Austria • Bahrain • Belgium • Brazil • Bulgaria • Canada • Chile • China, PRC •

Colombia • Costa Rica • Croatia • Cyprus • Czech Republic • Denmark • Ecuador • Egypt • El Salvador • Finland •

France • Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary • Iceland • India • Indonesia •

Ireland • Israel • Italy • Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Malaysia • Mexico • Netherlands

New Zealand • Norway • Pakistan • Peru • Philippines • Poland • Portugal • Puerto Rico • Qatar • Romania •

Russia-CIS • Saudi Arabia • Singapore • Slovakia • Slovenia • South Africa, Republic • Spain • Sweden •

Switzerland • Taiw a n • Thailand • Tur k ey • United Arab Emirates • United Kingdom • United States • Uruguay •

Venezuela • Yugoslavia

Allen-Bradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA,

Tel: (1) 414 382-2000 Fax: (1) 414 382-4444

.Publication 1747-5.32 – April 1998 PN 955131-21

Copyright 1998 Allen-Bradley, Inc. Printed in USA

Loading...

Loading...