Page 1

Installation Instructions

SLC 5/03™ and SLC 5/04™ Processors

Firmware/Operating System Upgrade

Introduction

Enclosed in this package is a firmware/operating system upgrade for

your SLC 5/03 or SLC 5/04 processor. Take anti-static precautions

when upgrading the firmware.

ATTENTION

The Flash EPROMs are electrostatic sensitive devices.

Do not handle without proper grounding

precautions. Do not install PROM with power

applied to the SLC 5/03 or SLC 5/04 processor.

!

If you upgrade an SLC 5/03 or SLC 5/04 processor, you receive

anomaly fixes as well as added functionality. During the upgrade, the

ladder logic program inside the processor is erased. Therefore, the

first step in upgrading the firmware/operating system is to save the

processor’s ladder logic program.

This product is CE compliant for all applicable directives when

product or packaging is marked.

Installation Procedure

1 Publication 1747-IN007C-EN-P - October 2002

Follow these instructions carefully. Refer to page 3 for component

placement information.

1. Save the current user program to your hard drive using your

programming software, to a memory module, or to a 1747-PSD

Program Storage Device.

IMPORTANT

2. Remove the communication cable between the processor and

your programming terminal.

The user program is cleared as part of the

firmware/operating system upgrade process.

You must restore your program after loading

the upgrade. Also, all communication ports are

returned to the default parameters.

Page 2

2 SLC 5/03™ and SLC 5/04™ Processors Firmware/Operating System Upgrade

3. Remove power from the chassis containing the processor.

ATTENTION

Do not remove the processor from the SLC 500

chassis until all power is removed from the SLC

500 power supply.

!

4. Remove the processor from the chassis.

5. Plug the firmware/operating system upgrade pack into the

memory module socket.

6. Move the operating system write-protect jumper (J4) to the

unprotected, or program, position.

IMPORTANT

Jumper J4, located in the bottom right corner of

the motherboard, provides write protection from

any download of a new operating system. The

“out of the box” position of this jumper is

“PROTECT,” or write protect. Without the

jumper, the processors are write protected.

Publication 1747-IN007C-EN-P - October 2002

Page 3

Catalog and Serial

Number Label

SLC 5/03™ and SLC 5/04™ Processors Firmware/Operating System Upgrade 3

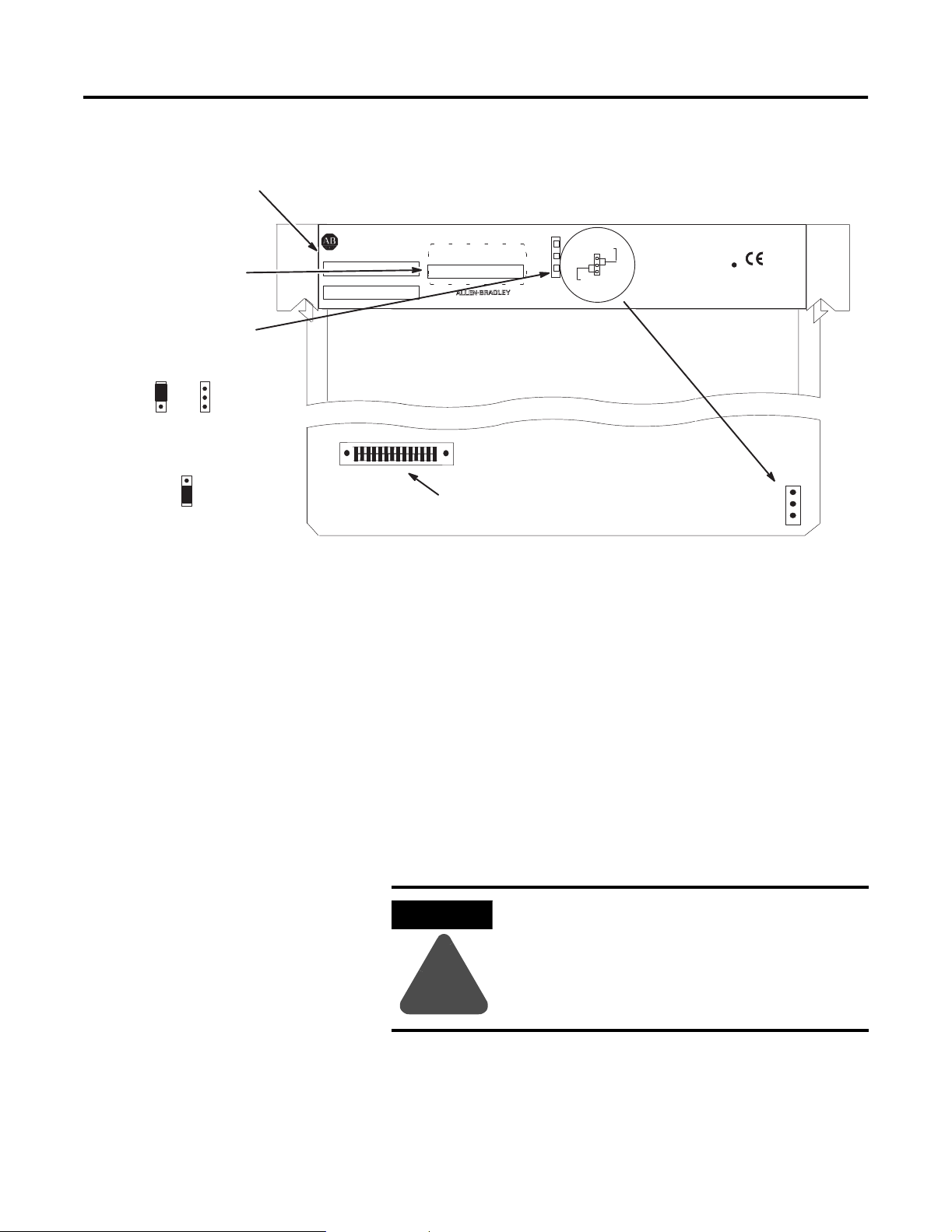

Figure 1 Component Placement Information

Place the firmware

upgrade label here.

The SLC 5/03 and SLC 5/04

processors are

protected

from the

firmware download when jumper J4

is in this position:

OR

The SLC 5/03 and SLC 5/04

processors accept the firmware

download when jumper J4 is in this

position:

SLC 500

PROCESSOR UNIT

CAT

SERIAL NO.

SER

FAC

PROC. REV.

PLACE FRN UPGRADE LABEL HERE

OPERATING SYSTEM INFO

OS #

SER

FRN

WHITE

RED

BATTERY

+

-

PROTECT

1

PROGRAM

J4

3

CURRENT REQUIREMENTS: 1A @ 5 VDC

LISTED IND. CONT. EQ.

U

L

FOR HAZ. LOC. A196

CLASS 1, GROUPS A, B, C AND D, DIV

OPERATING TEMPERATURE CODE T3C

SA

c

Daughter Board

Mother Board

Firmware

Upgrade/Memory

Jumper J4

Module Socket

7. Firmly seat the processor back into the chassis.

8. Apply power to the chassis containing the processor while

watching the LED display. All the LEDs should turn on and then

turn off. The download process of the firmware takes up to 2.5

minutes. While the download is in progress, the RUN and FLT

LEDs remain off. The other four LEDs – RS232, DH485 (DH+ on

the SLC 5/04), FORCE, and BATT – turn on and off in a walking

bit sequence. If the download is successful, these four LEDs

remain on together. If the FLT LED turns on and a combination

of LEDs flash on and off indicating an error condition, refer to

the troubleshooting information on page 4.

R

200mA @ 24 VDC

. 2

MADE IN USA

9. After completing the download, remove power from the chassis

containing the processor.

ATTENTION

Do not remove the processor from the SLC 500

chassis until all power is removed from the SLC

500 power supply.

!

10. Remove the processor from the chassis.

11. Carefully remove the firmware upgrade pack and place it in the

anti-static packaging it was shipped in.

Publication 1747-IN007C-EN-P - October 2002

Page 4

4 SLC 5/03™ and SLC 5/04™ Processors Firmware/Operating System Upgrade

12. Move the operating system write-protect jumper (J4) back to the

protected position (see diagram on page 3).

IMPORTANT

13. Apply the enclosed firmware upgrade label to the processor

nameplate.

14. Firmly seat the processor back into the chassis.

15. Attach the communication cable between the processor and

your programming terminal.

16. Apply power to the chassis containing the processor while

watching the LED display. All the LEDs should flash on and then

turn off except for the FLT LED which should remaining

flashing. If the FLT LED turns on and a combination of LEDs

flash on and off indicating an error condition, refer to the

troubleshooting information in this document.

Failure to return the J4 jumper to the protected

position results in an error (0x3D Hex) on the

power cycle following the download of a valid

program to the processor. This error condition

prevents the module from going to run and

causes Channel 0 communication settings to

return to their defaults. To properly clear the

error, place the J4 jumper in the protected

position, and then re-download a valid user

program to the processor.

Identifying Processor Errors While Downloading Firmware

Publication 1747-IN007C-EN-P - October 2002

17. Restore your program.

The download process of the firmware/operating system takes up to

2.5 minutes. While the download is in progress, the RUN and FLT

LEDs remain off. The other four LEDs – RS232, DH485 (DH+ on the

SLC 5/04), FORCE, and BATT – turn on and off in a walking bit

sequence. If the download is successful, these four LEDs remain on

together.

If the download is not successful, the FLT LED turns on and a

combination of LEDs flash on and off indicating an error condition.

The following LED diagrams and tables provide information regarding

error messages, possible cause(s) for the error, and recommended

action(s) to take to resolve the error.

Page 5

SLC 5/03™ and SLC 5/04™ Processors Firmware/Operating System Upgrade 5

If the LED’s indicate:

POWER

If the LED’s indicate:

POWER

If the LED’s indicate:

POWER

(1)

RUN

FLT

BATT

FORCE

DH485

RS232

The Following

Error Exists

Fatal Hardware

Error

Probable Cause Recommended Action

Major hardware failure due to

noise, improper grounding, or

poor power source.

Cycle power and see if the error

repeats itself. If the error clears,

you should be able to download

the firmware. If the error persists,

contact your Rockwell

Automation representative.

(1)

RUN

FLT

BATT

FORCE

DH485

RS232

The Following

Error Exists

Corrupted

Operating

System Memory

Module

Probable Cause Recommended Action

The operating system on the

Flash EPROM is corrupt.

Cycle power and see if the error

repeats itself. If the error persists,

either contact your Rockwell

Automation representative for a

new operating system upgrade

cartridge, or download the old

operating system, if available.

(1)

RUN

FLT

BATT

FORCE

DH485

RS232

The Following

Error Exists

Flash EPROM

Failure

Probable Cause Recommended Action

The processor flash EPROM is

corrupt.

Cycle power and see if the error

repeats itself. If the error clears,

you should be able to download

the firmware. If the error persists,

contact your Rockwell

Automation representative.

POWER

(1)

RUN

FLT

BATT

FORCE

DH485

RS232

The Following

Error Exists

Corrupt or

Missing

Probable Cause Recommended Action

The operating system is missing

or has been corrupted.

If the LED’s indicate:

Operating

System

Refer to the following key to determine the status of the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

(1) The DH485 LED on the SLC 5/03 processor is labeled DH+ on the SLC 5/04 processor.

Cycle power. If error clears, you

should be able to download the

firmware. If the error persists,

contact your Rockwell

Automation representative for a

new operating system.

Publication 1747-IN007C-EN-P - October 2002

Page 6

6 SLC 5/03™ and SLC 5/04™ Processors Firmware/Operating System Upgrade

If the LED’s indicate:

POWER

If the LED’s indicate:

POWER

If the LED’s indicate:

POWER

(1)

RUN

FLT

BATT

FORCE

DH485

RS232

The Following

Error Exists

Downloadable

Operating

Probable Cause Recommended Action

Failure during transmission of

Download the operating system.

downloadable operating system.

System Failure

(1)

The Following

RUN

FLT

BATT

(1)

FORCE

DH485

RS232

Error Exists

Incompatible

Platform

The Following

RUN

FLT

BATT

FORCE

DH485

RS232

Error Exists

Memory Write

Protected

Probable Cause Recommended Action

The upgrade of the operating

system is incompatible with the

processor hardware.

Use an operating system that is

compatible with your processor

hardware.

Probable Cause Recommended Action

An attempt was made to

download the operating system

onto write-protected memory.

Change the J4 jumper of the

SLC 5/03 and SLC 5/04

processors to the program

position.

Refer to the following key to determine the status of the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

(1) The DH485 LED on the SLC 5/03 processor is labeled DH+ on the SLC 5/04 processor.

Publication 1747-IN007C-EN-P - October 2002

Page 7

SLC 5/03™ and SLC 5/04™ Processors Firmware/Operating System Upgrade 7

If the LED’s indicate:

POWER

If the LED’s indicate:

POWER

(1)

The Following

Probable Cause Recommended Action

Error Exists

RUN

FLT

BATT

FORCE

DH485

RS232

NVRAM error Major hardware failure due to

noise, improper grounding, or

poor power source.

Cycle power and see if the error

repeats itself. If the error clears,

you should be able to download

the firmware. If the error persists,

contact your Rockwell

Automation representative.

(1)

RUN

FLT

BATT

FORCE

DH485

RS232

The Following

Error Exists

Hardware

Watchdog

Time-out

Probable Cause Recommended Action

Major hardware failure due to

noise, improper grounding, or

poor power source.

Cycle power and see if the error

repeats itself. If the error clears,

you should be able to download

the firmware. If the error persists,

contact your Rockwell

Automation representative.

Refer to the following key to determine the status of the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

(1) The DH485 LED on the SLC 5/03 processor is labeled DH+ on the SLC 5/04 processor.

Publication 1747-IN007C-EN-P - October 2002

Page 8

Rockwell Automation

Support

Rockwell Automation provides technical information on the Web to assist

you in using its products. At http://support.rockwellautomation.com

find technical manuals, a knowledge base of FAQs, technical and application

notes, sample code and links to software service packs, and a MySupport

feature that you can customize to make the best use of these tools.

For an additional level of technical phone support for installation,

configuration, and troubleshooting, we offer TechConnect Support programs.

For more information, contact your local distributor or Rockwell Automation

representative, or visit http://support.rockwellautomation.com

, you can

.

Installation Assistance

If you experience a problem with a hardware module within the first 24

hours of installation, please review the information that's contained in this

manual. You can also contact a special Customer Support number for initial

help in getting your module up and running.

United States 1.440.646.3223

Monday – Friday, 8am – 5pm EST

Outside United

States

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell tests all of its products to ensure that they are fully operational

when shipped from the manufacturing facility. However, if your product is

not functioning, it may need to be returned.

United States Contact your distributor. You must provide a Customer Support case

number (see phone number above to obtain one) to your distributor in

order to complete the return process.

Outside United

States

Please contact your local Rockwell Automation representative for

return procedure.

Publication 1747-IN007C-EN-P - October 2002 21 PN 40071-093-01(3)

Supersedes Publication 1747-IN007B- EN-P - October 2001 Copyright © 2007 Rockwell Automation, Inc . All rights reserved. Printed in Singapore.

Loading...

Loading...