Page 1

ControlNet™

Adapter Module

(Catalog Numbers 1747-ACN15,

1747-ACNR15)

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this publication,

those responsible for the application and use of this control equipment must

satisfy themselves that all necessary steps have been taken to assure that each

application and use meets all performance and safety requirements, including

any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this

guide are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation,

Allen-Bradley does not assume responsibility or liability (to include intellectual

property liability) for actual use based upon the examples shown in this

publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application,

Installation and Maintenance of Solid-State Control (available from your local

Allen-Bradley office), describes some important differences between solid-state

equipment and electromechanical devices that should be taken into

consideration when applying products such as those described in this

publication.

Reproduction of the contents of this copyrighted publication, in whole or part,

without written permission of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION

Identifies information about practices or circumstances that

can lead to personal injury or death, property damage or

economic loss

!!!!

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT

ControlNet and SLC 500 are trademarks of Rockwell Automation.

PLC-5 is a registered trademark of Rockwell Automation.

Identifies information that is critical for successful

application and understanding of the product.

Page 3

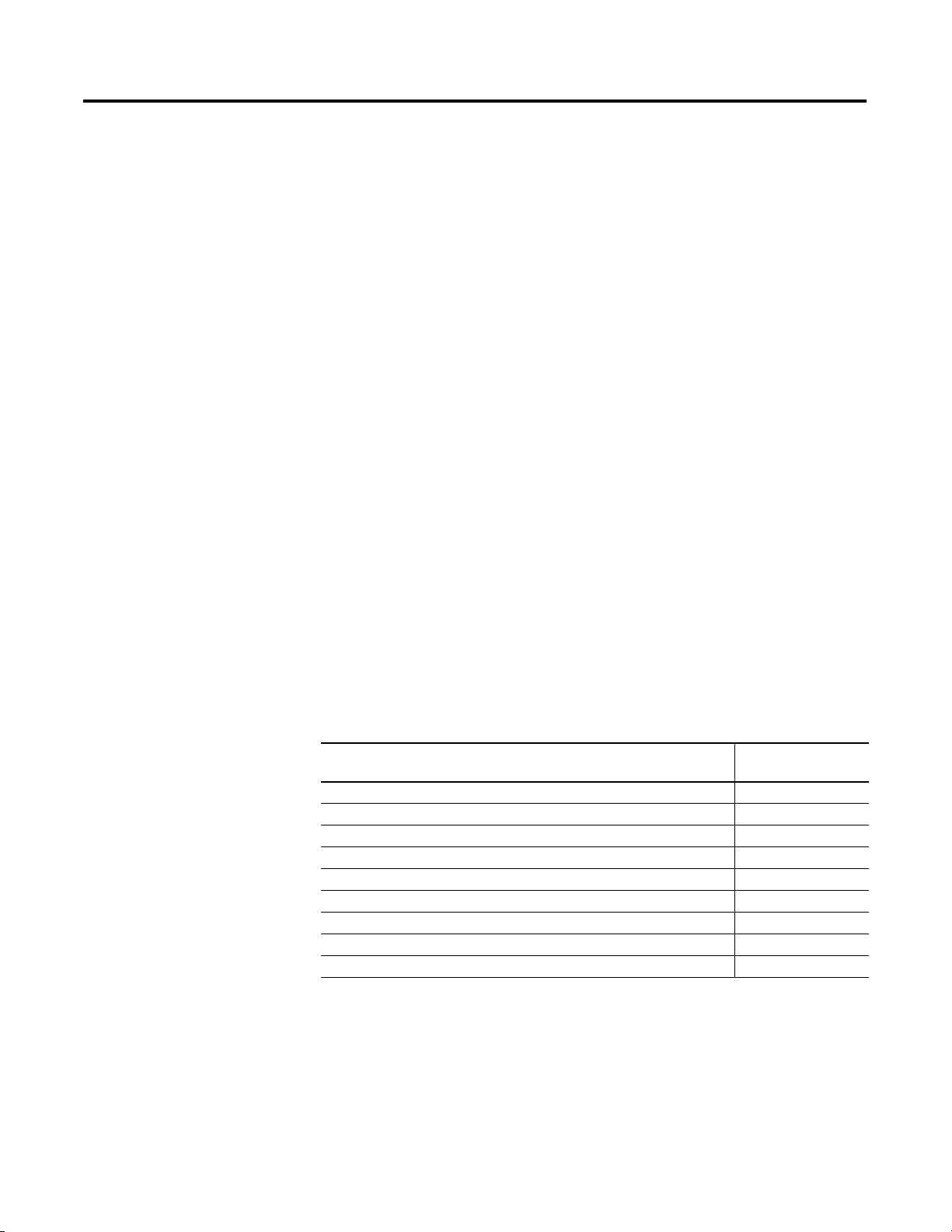

Table of Contents

Preface

Introducing the ControlNet

Adapter Module

Installing Your ControlNet Adapter

Module

Who Should Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Common Techniques Used in this Manual. . . . . . . . . . . . . . . . . . . P-1

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Technical Product Assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Your Questions or Comments on this Manual . . . . . . . . . . . . . P-2

Chapter 1

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Module Description and Features . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Diagnostic Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Network Access Port (NAP) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

ControlNet Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Network Address Switch Assemblies . . . . . . . . . . . . . . . . . . . . . 1-3

Chapter 2

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Compliance to European Union Directives. . . . . . . . . . . . . . . . . . . 2-1

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Low Voltage Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Determining Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Setting the Network Address Switches. . . . . . . . . . . . . . . . . . . . . . . 2-2

Installing the Adapter Module in the Chassis . . . . . . . . . . . . . . . . . 2-3

Connecting Your Adapter to the ControlNet Network . . . . . . . 2-4

Connecting Programming Terminals to the Network via the NAP . 2-6

Powerup Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Chapter 3

Planning to Use Your ControlNet

Adapter Module

i Publication 1747-UM003 A-EN-P

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Compatible 1746 and 1747 I/O Modules . . . . . . . . . . . . . . . . . . . . 3-1

Overview of Adapter Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Software Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Rack and Module Connections . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Optimizing SLC ControlNet Adapter Rack Connections . . . . . 3-4

Module Keying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Output Operation During Fault and Idle Modes . . . . . . . . . . . 3-6

Understanding ControlNet I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Scheduled Data-Transfer Connections on a

ControlNet Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Page 4

Table of Contents ii

Application Examples

Chapter 4

Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Configuring The ControlNet Network with

RSNetWorx™ for ControlNet . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Create a Ladder Logic Program . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Configuring The ControlNet Network with

RSNetWorx™ for ControlNet . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Create a Ladder Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Example 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Configuring The ControlNet Network with

RSNetWorx™ for ControlNet . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Create a Ladder Logic Program . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Example 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Configuring The ControlNet Network with

RSNetWorx™ for ControlNet . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Create Ladder Logic and Basic Module Programs . . . . . . . . . . 4-43

Example 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Configuring The ControlNet Network with

RSNetWorx for ControlNet . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Create a Ladder Logic Program . . . . . . . . . . . . . . . . . . . . . . . . 4-57

Troubleshooting

Specifications

Understanding Your SLC 500/1746

Control System

Publication 1747-UM003A-EN-P

Chapter 5

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Troubleshooting With the Status Indicators and Status Display . . . 5-1

Health Indicators and Display Mnemonics . . . . . . . . . . . . . . . . 5-2

ControlNet Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Appendix A

Appendix B

Selecting Your SLC 500/1746 Control Power Supply. . . . . . . . . . . B-1

Power Supply Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

SLC 500 System Installation Recommendations . . . . . . . . . . . . . . . B-6

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Selecting an Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Spacing Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Preventing Excessive Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Wiring Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Page 5

Table of Contents iii

Grounding Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Master Control Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

Emergency-Stop Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-13

Common Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-15

Loss of Power Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-16

Input States on Power Down . . . . . . . . . . . . . . . . . . . . . . . . . B-16

Other Types of Line Conditions . . . . . . . . . . . . . . . . . . . . . . . B-16

Power Conditioning Considerations . . . . . . . . . . . . . . . . . . . . B-16

Special Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-18

Output Contact Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . B-20

Mounting Your Control System . . . . . . . . . . . . . . . . . . . . . . . . . . B-21

Mounting Modular Hardware Style Units. . . . . . . . . . . . . . . . B-21

Installing Your I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-25

Features of an SLC 500 I/O Module. . . . . . . . . . . . . . . . . . . . B-25

Definition of Sinking and Sourcing. . . . . . . . . . . . . . . . . . . . . B-26

Inserting I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-28

Removing I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-30

Wiring the I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-31

Using Removable Terminal Blocks . . . . . . . . . . . . . . . . . . . . . B-32

Calculating Heat Dissipation for Your Control System. . . . . . . . . B-34

Module Heat Dissipation: Calculated Watts

vs. Maximum Watts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-34

Calculating the Power Supply Loading . . . . . . . . . . . . . . . . . . B-35

Determining the Power Supply Dissipation. . . . . . . . . . . . . . . B-38

Glossary

Index

Publication 1747-UM003 A-EN-P

Page 6

Table of Contents iv

Publication 1747-UM003A-EN-P

Page 7

Preface

Read this preface to familiarize yourself with the rest of the manual. It provides

information concerning:

• who should use this manual

• the purpose of this manual

• related documentation

• conventions used in this manual

• Allen-Bradley support

Who Should Use this Manual

Purpose of this Manual

Use this manual if you are responsible for designing, installing, programming, or

troubleshooting control systems that use the ControlNet Adapter Module.

You should have a basic understanding of electrical circuitry and familiarity with

relay logic. If you do not, obtain the proper training before using this product.

This manual is a reference guide for the ControlNet Adapter Module. It describes

the procedures you use to install, program and troubleshoot your module. This

manual also includes several application examples.

Related Documentation

The following documents contain additional information concerning

Allen-Bradley products. To obtain a copy, contact your local Allen-Bradley office or

distributor.

Publication Publication

Number

ControlNet PLC-5 Programmable Controllers User Manual Phase 1.5 1785-6.5.22

ControlNet Cable System Component List AG-2.2

ControlNet Cable System Planning and Installation Manual 1786-6.2.1

ControlNet Coax Tap Installation Instructions 1786-2.3

ControlNet Network Access Cable Installation Instructions 1786-2.6

ControlNet Repeater Installation Instructions 1786-2.7

Industrial Automation Wiring and Grounding Guidelines 1770-4.1

SLC 500™ Modular Hardware Style User Manual 1747-6.2

ControlNet Scanner Module Reference Manual 1747-6.23

Common Techniques Used in this Manual

1 Publication 1747-UM003 A-EN-P

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

• Italic type is used for emphasis.

Page 8

Preface 2

Rockwell Automation Support

Rockwell Automation offers support services worldwide, with over 75 Sales/

Support Offices, 512 authorized Distributors and 260 authorized Systems

Integrators located throughout the United States alone, plus Rockwell Automation

representatives in every major country in the world.

Local Product Support

Contact your local Rockwell Automation representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

If you need to contact Rockwell Automation for technical assistance, please review

the Troubleshooting appendix in your controller’s User Manual first. Then call your

local Rockwell Automation representative.

Your Questions or Comments on this Manual

If you find a problem with this manual, or you have any suggestions for how this

manual could be made more useful to you, please contact us at the address below:

Rockwell Automation

Control and Information Group

Technical Communication, Dept. A602V

P.O. Box 2086

Milwaukee, WI 53201-2086

or visit our internet page at:

http://www.rockwellautomation.com

Publication 1747-UM003A-EN-P

Page 9

Chapter

1

Introducing the ControlNet Adapter Module

Chapter Objectives

Module Description and Features

This chapter describes the ControlNet adapter modules (cat. no. 1747-ACN15

and 1747-ACNR15):

• features

• hardware components, including

– diagnostic indicators

– network access port (NAP)

– ControlNet connectors

– network address switch assemblies

The 1747-ACN15 and 1747-ACNR15 adapters control remote 1746 I/O on

the ControlNet network. The ControlNet network is a communication

architecture that allows the exchange of messages between ControlNet

products compliant with the CI specification.

The 1747-ACN15 and 1747-ACNR15 adapters features include:

• high-speed data transfer

• diagnostic messages

• local communication network access through the network access port

(NAP)

• redundant media (1747-ACNR15 only)

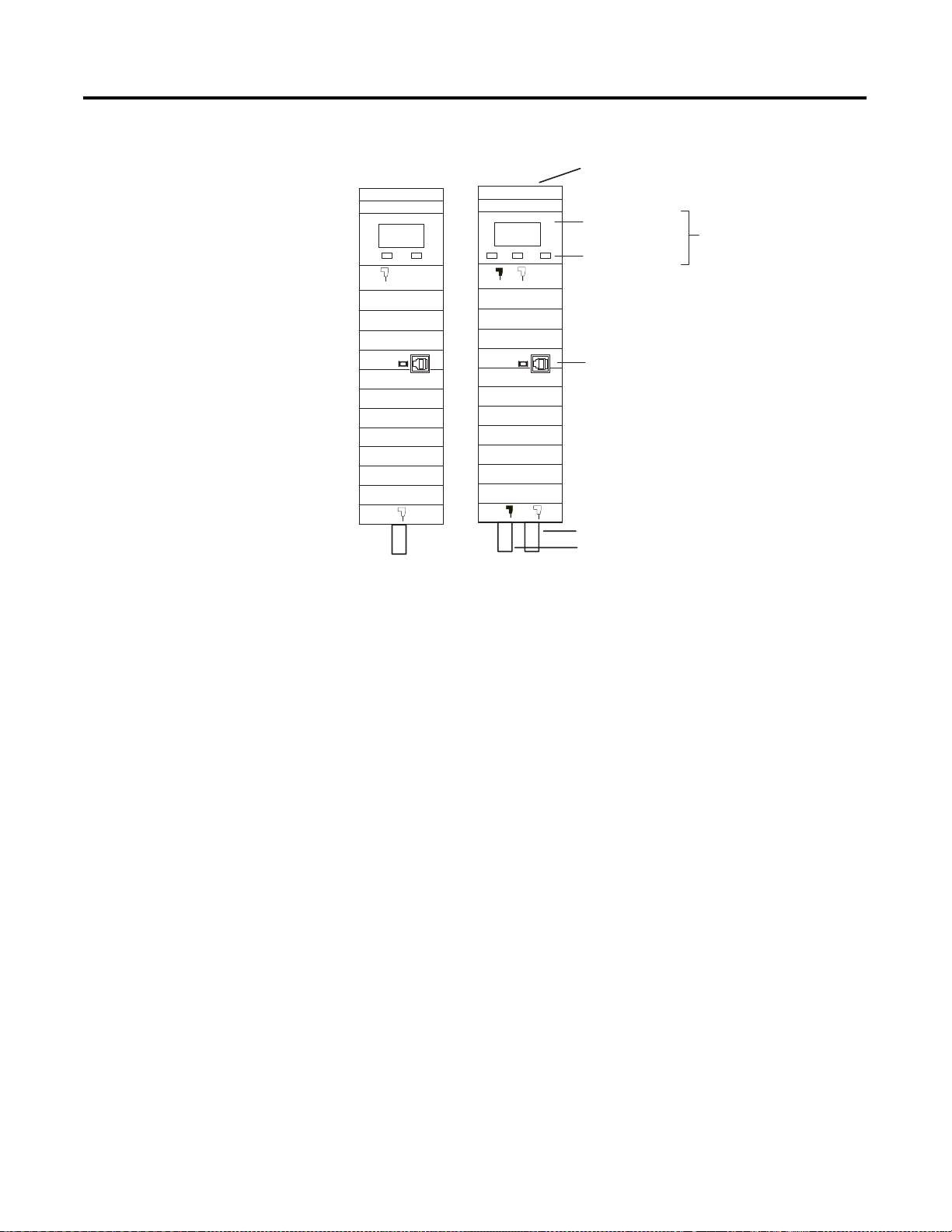

Hardware Components

1 Publication 1747-UM003 A-EN-P

The adapter module consists of the following major components:

• ControlNet status indicators

• status display

• network access port (NAP)

• ControlNet connectors (one on 1747-ACN15; two on 1747-ACNR15)

• module net address switch assemblies (on top of module)

Page 10

1-2 Introducing the ControlNet Adapter Module

Figure 1.1 ControlNet Adapter Module

Module Network Address Switches

(accessible through top of module)

1747-ACN15

ADDRESS/STATUS

OK OK

A

ADDRESS/STATUS

BAA

B

Diagnostic Indicators

Status Display and

Net Address

Health Indicators

ControlNet Status Indicators

Network Access Port (NAP)

1747-ACNR15

A

ControlNet Media Port

ControlNet Redundant Media Port (1747-ACNR15 only)

Diagnostic Indicators

Health indicators are located on the front panel of the adapter module,

See Figure 1.1. They show both normal operation and error conditions in your

remote I/O system.

In addition, an alphanumeric display (net address/status) provides status code

indications when an error occurs during initialization or operation.

A complete description of the diagnostic indicators and status display and how

to use them for troubleshooting is explained in Chapter 5.

Network Access Port (NAP)

The network access port provides a bidirectional electrical interface for

programming, maintenance, and I/O monitoring devices in both redundant

and non-redundant connections. See Figure 1.1 connecting programming

terminals to the network using the NAP above.

Publication 1747-UM003A-EN-P

Page 11

Introducing the ControlNet Adapter Module 1-3

ControlNet Connectors

Cable connection to the module is through standard BNC connectors on the

module frontplate.

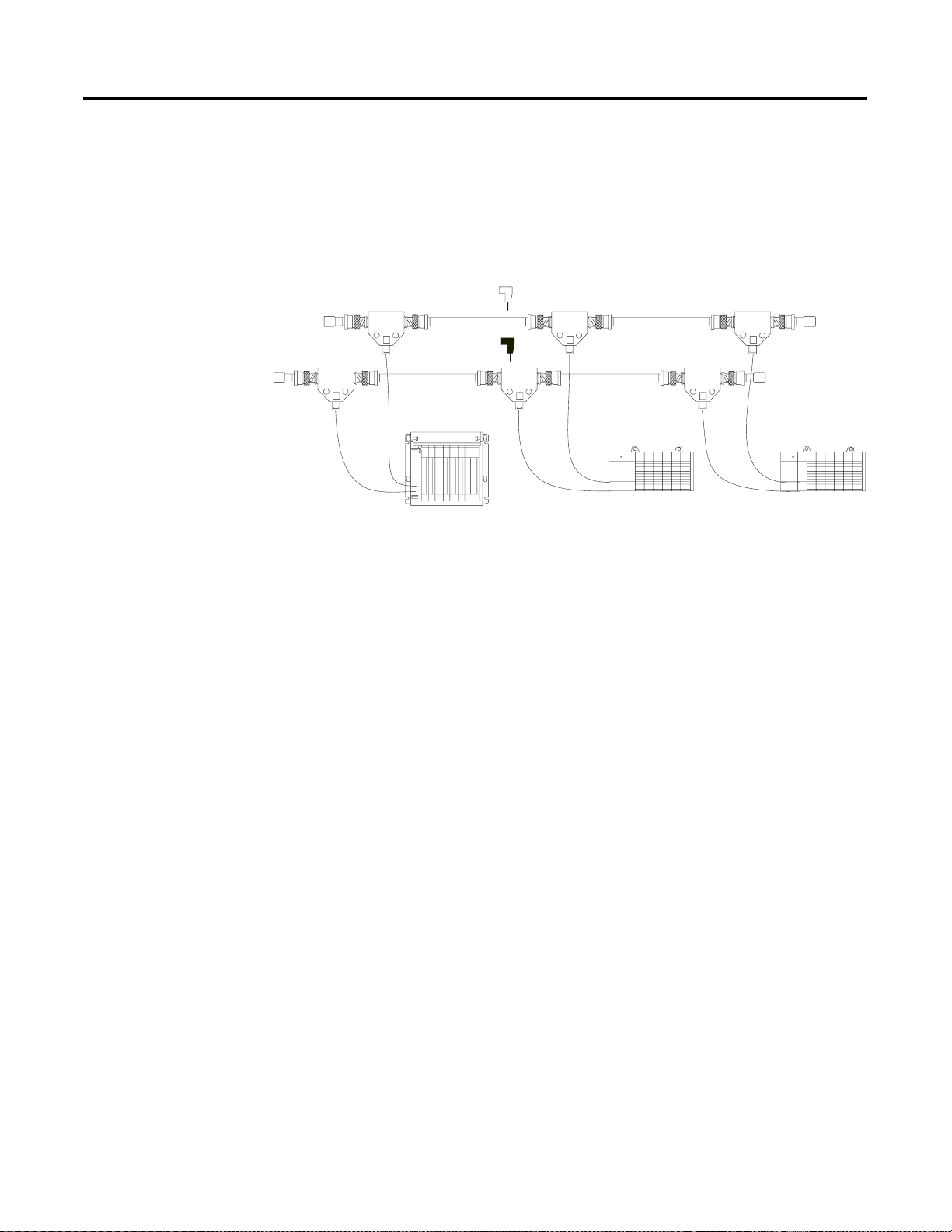

Figure 1.2 Redundant Media System

Terminator

Terminator

trunkline A =

trunkline B =

PLC-5C or SLC 5/02 or later

with 1747-SCNR

(1) End device supporting redundant cabling is a 1747-ACNR15.

A

Terminator

B

Terminator

end device

(1)

end device

(1)

Refer to the ControlNet Cable System Planning and Installation User Manual,

publication 1786-6.2.1 for more information.

Network Address Switch Assemblies

You must set two switch assemblies to configure your adapter module with its

unique network address. You access these switches through the top of the

module. Figure 1.3 shows the location of the switches. These switches are read

on powerup to establish the network address of the module. Network address

switch settings are described in Chapter 2.

For optimum throughput, assign sequential addresses to ControlNet nodes.

Publication 1747-UM003 A-EN-P

Page 12

1-4 Introducing the ControlNet Adapter Module

Publication 1747-UM003A-EN-P

Page 13

Chapter

2

Installing Your ControlNet Adapter Module

Chapter Objectives

Compliance to European Union Directives

This chapter describes the procedures for installing your ControlNet adapter

module. These include:

• European Directive compliance

• determining power requirements

• setting the network address switches

• setting the I/O chassis switches

• installing the adapter module in the chassis

• connecting programming terminals to the network via the network access

port (NAP)

• powerup sequence

For general installation guidelines, see SLC 500 System Installation

Recommendations on page B-6. If this product has the CE mark it is approved

for installation within the European Union and EEA regions. It has been

designed and tested to meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC Electromagnetic

Compatibility (EMC) and the following standards, in whole or in part,

documented in a technical construction file:

• EN 50081-2

EMC - Generic Emission Standard, Part 2 - Industrial Environment

• EN 50082-2

EMC - Generic Immunity Standard, Part 2 - Industrial Environment

This product is intended for use in an industrial environment.

1 Publication 1747-UM003 A-EN-P

Page 14

2-2 Installing Your ControlNet Adapter Module

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage, by

applying the safety requirements of EN 61131-2 Programmable Controllers,

Part 2 - Equipment Requirements and Tests.

For specific information required by EN 61131-2, see the appropriate sections

in this publication, as well as the following Allen-Bradley publications:

•

Industrial Automation Wiring and Grounding Guidelines For Noise

Immunity, publication 1770-4.1

•

Automation Systems Catalog, publication B111

Determining Power Requirements

Setting the Network Address Switches

The ControlNet adapter module requires a maximum backplane current of

900 mA at 5V dc. Remember to add this amount to other current

requirements for your I/O chassis.

The switches on the top of the adapter module determine the network address

of the adapter. The two switches are:

• the ten’s switch

• the one’s switch

The combination of these switches allows selection of network addresses from

01 to 99.

NOTE

Figure 2.1 Setting the Network Address

00 is an invalid number.

Ten ’s

Selection

One’s

Selection

Publication 1747-UM003A-EN-P

Page 15

Installing Your ControlNet Adapter Module 2-3

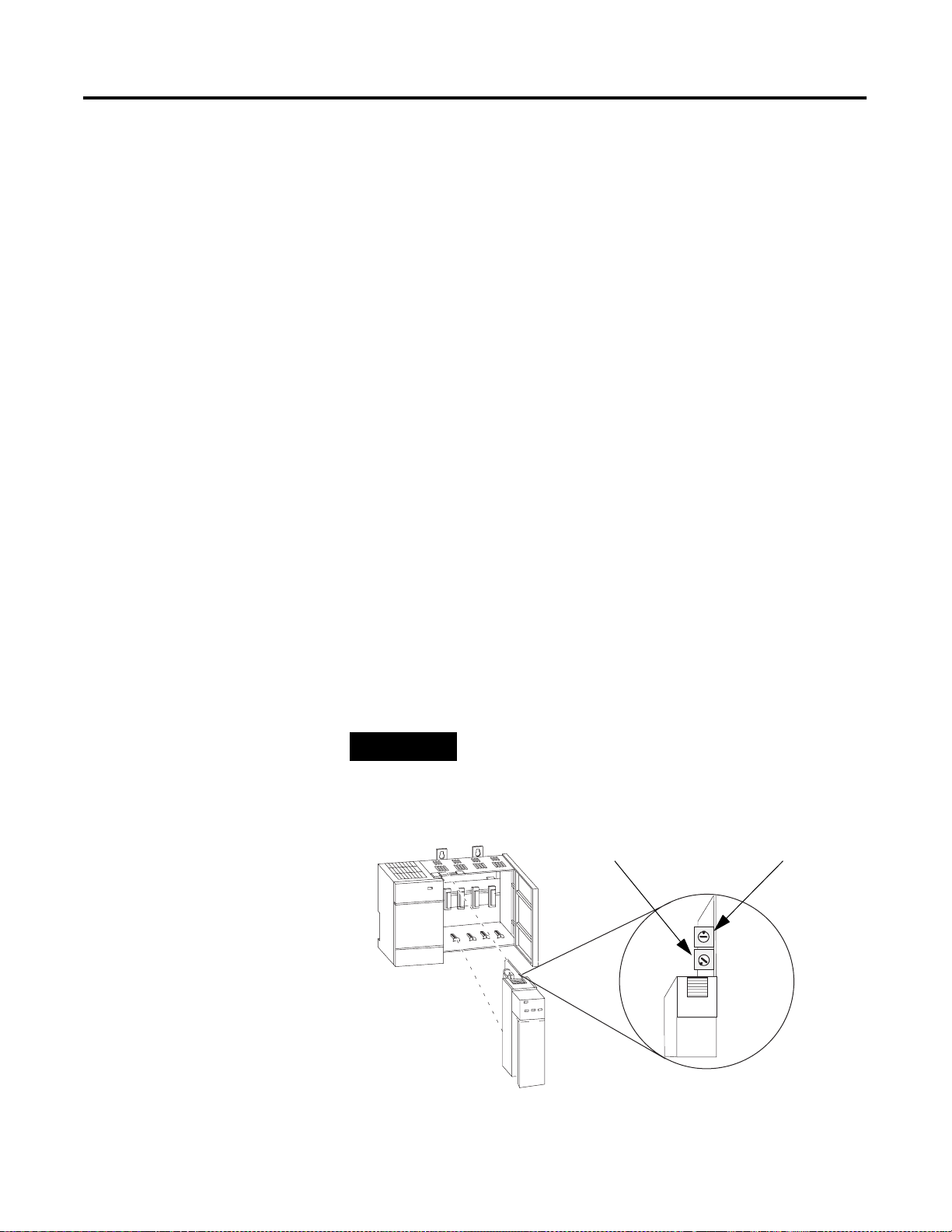

Installing the Adapter Module in the Chassis

Power

Supply

Card Guide

Once you’ve set the appropriate switch assemblies for your adapter module,

follow these procedures for installation.

Refer to the Industrial Controller Wiring and Grounding Guidelines, Publication

1770-4.1 for proper grounding and wiring methods to use when installing

your module.

ATTENTION

Remove system power before removing or installing your

module in the I/O chassis. Failure to observe this warning

could damage module circuitry and injure people.

!!!!

1. Remove power from the I/O chassis before inserting (or removing) the

module.

2. Align the circuit board with the chassis card guide in the left slot.

3. Slide the module into the chassis until the top and bottom latches are

Latch

latched. To remove the module, press the releases at the top and bottom

of the module and slide it out.

4. Press firmly and evenly to seat the module in its backplane connectors.

ATTENTION

!!!!

Do not force the module into the backplane connector. If

you cannot seat the module with firm pressure, check the

alignment. Forcing the module can damage the backplane

connector or the module.

Publication 1747-UM003 A-EN-P

Page 16

2-4 Installing Your ControlNet Adapter Module

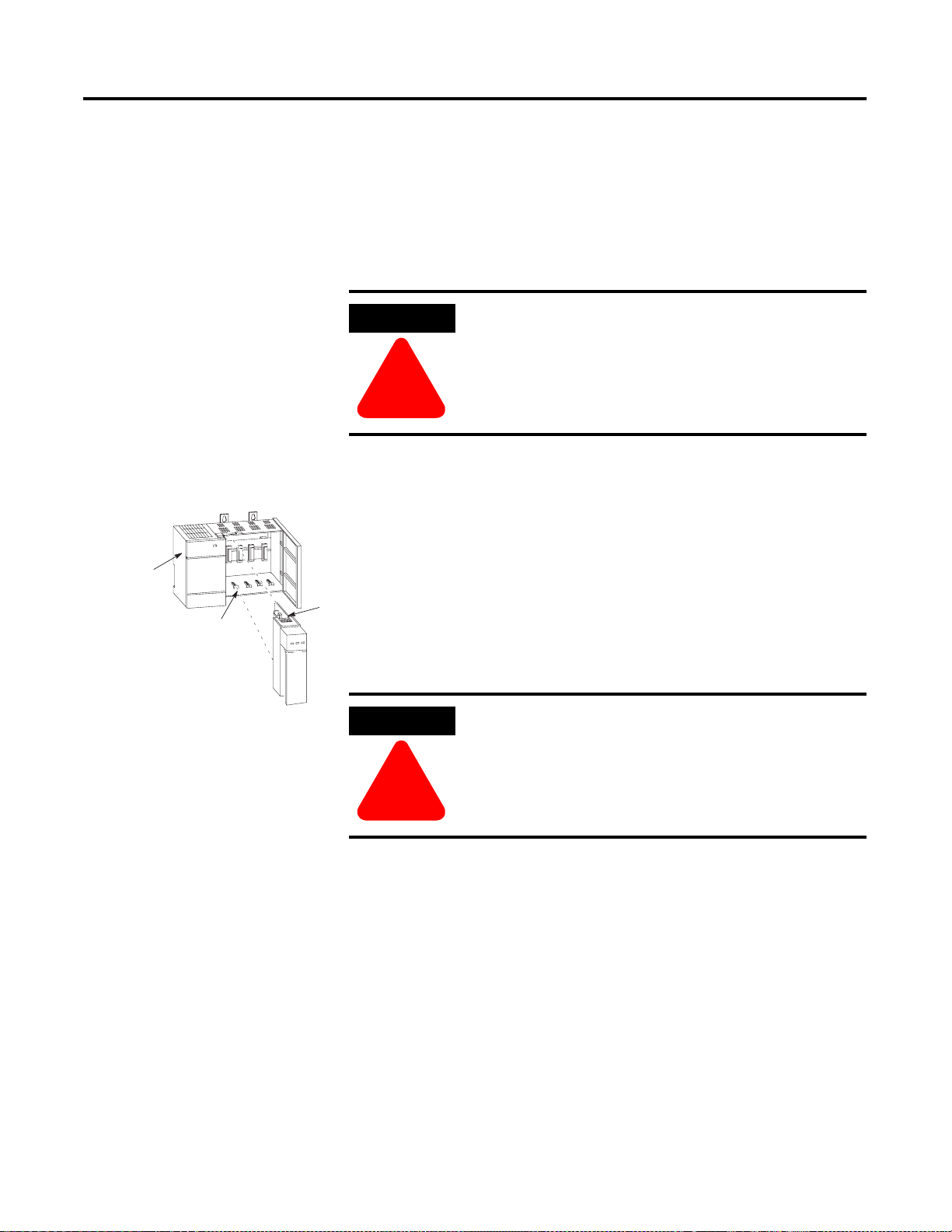

Connecting Your Adapter to the ControlNet Network

You connect your 1747-ACN15 or -ACNR15 adapter module to a

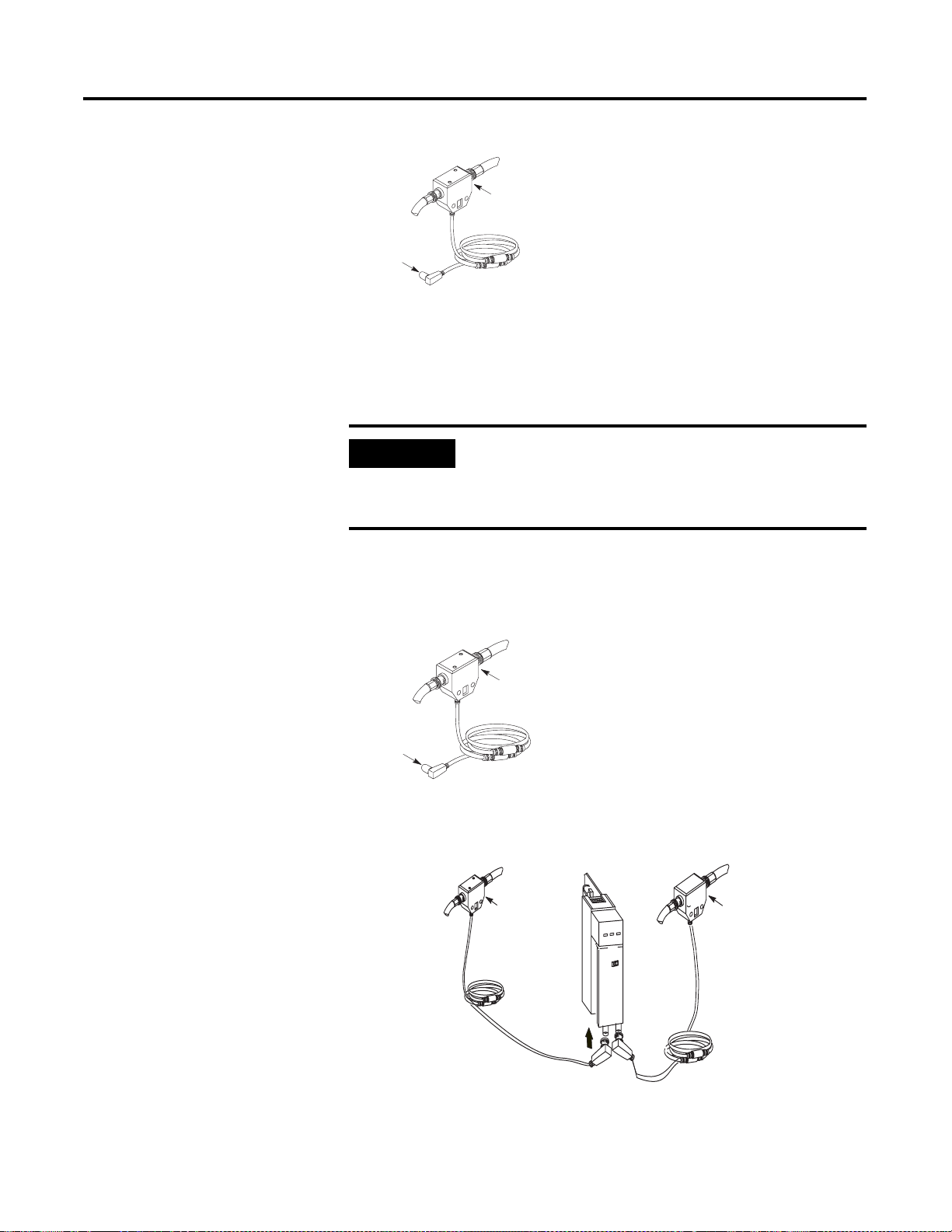

ControlNet network via taps. These taps are available:

Straight T-tap

1786-TPS 1786-TPYS

IMPORTANT

1. Remove the tap’s dust cap (located on the straight or right angle

connector).

If your node

supports:

Non-redundant media to the channel A connector on the 1747-ACN15 or

Redundant media • from trunkline A to channel A on the 1747-ACNR15

(1)

While both channels are active, Allen-Bradley recommends using channel A for non-redundant media.

Straight Y-tap

Taps contain passive electronics and must be purchased

from Allen-Bradley for the network to function properly.

Connect the tap’s straight or right angle connector:

1747-ACNR15 (channel B on the 1747-ACNR is not used)

• from trunkline B to channel B on the 1747-ACNR15

Right-angle T-tap Right-angle Y-tap

1786-TPR

1786-TPYR

(1)

Publication 1747-UM003A-EN-P

ATTENTION

!!!!

Do not allow any metal portions of the tap to contact any

conductive material. If you disconnect the tap from the

adapter, place the dust cap back on the straight or right

angle connector to prevent the connector from accidentally

contacting a metallic grounded surface.

Page 17

Installing Your ControlNet Adapter Module 2-5

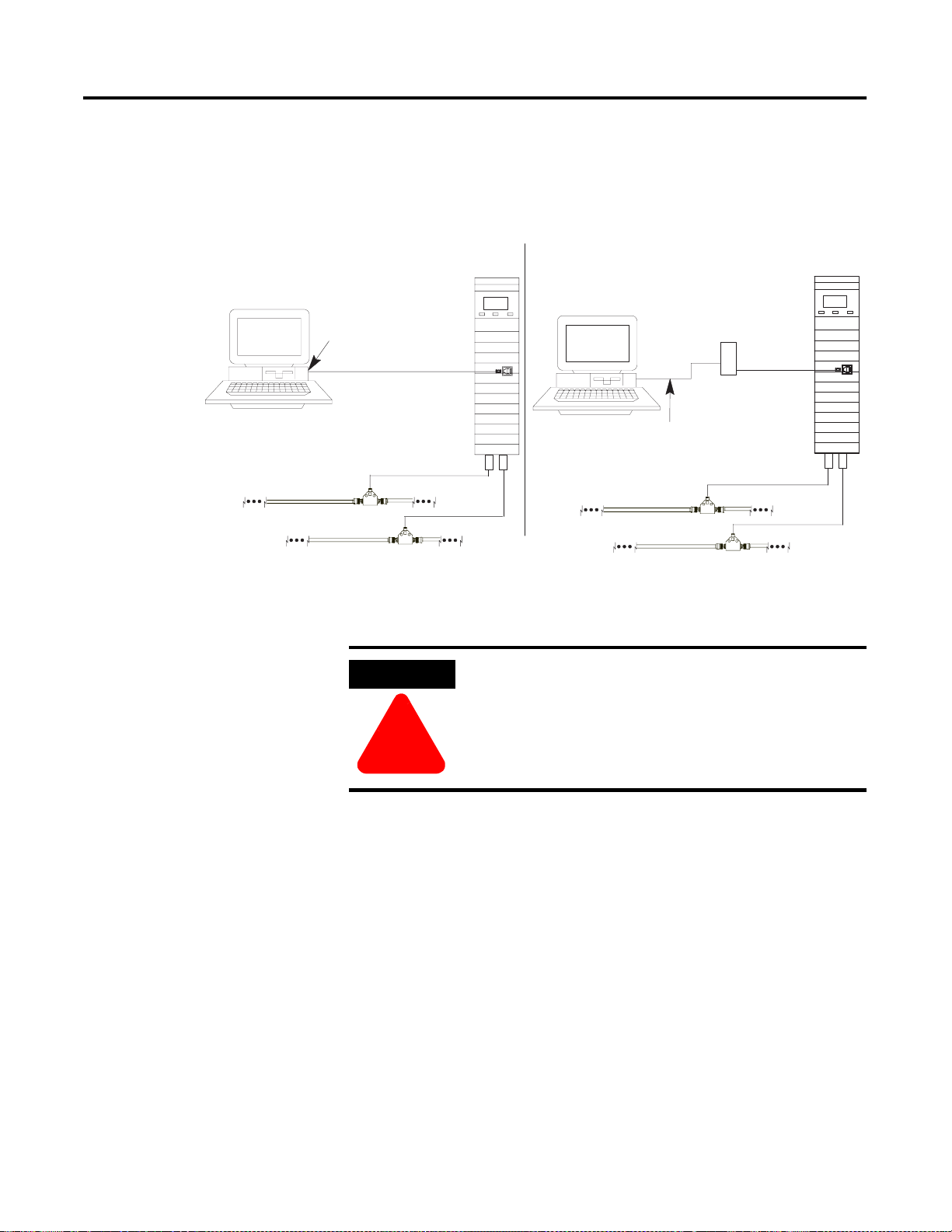

segment 1

Tap

dust cap

2. Remove and discard the dust caps from the adapter BNC jacks.

3. Connect this tap’s straight or right angle connector to the BNC

connector on the adapter.

IMPORTANT

To prevent inadvertent reversal of the tap connections

(resulting in incorrect LED displays and troubleshooting),

check the tap drop cable for a label indicating the attached

segment before making your connection.

4. For redundant adapters (1747-ACNR15), remove (and save) the dust

cap located on the straight or right angle connector of the designated tap

on the second segment (segment 2).

segment 2

tap

dust cap

5. Connect this tap’s straight or right angle connector to the BNC

connector on the adapter.

segment 1

tap

segment 2

tap

After terminating your segments, connect the node to the network.

Publication 1747-UM003 A-EN-P

Page 18

2-6 Installing Your ControlNet Adapter Module

Connecting Programming Terminals to the Network via the NAP

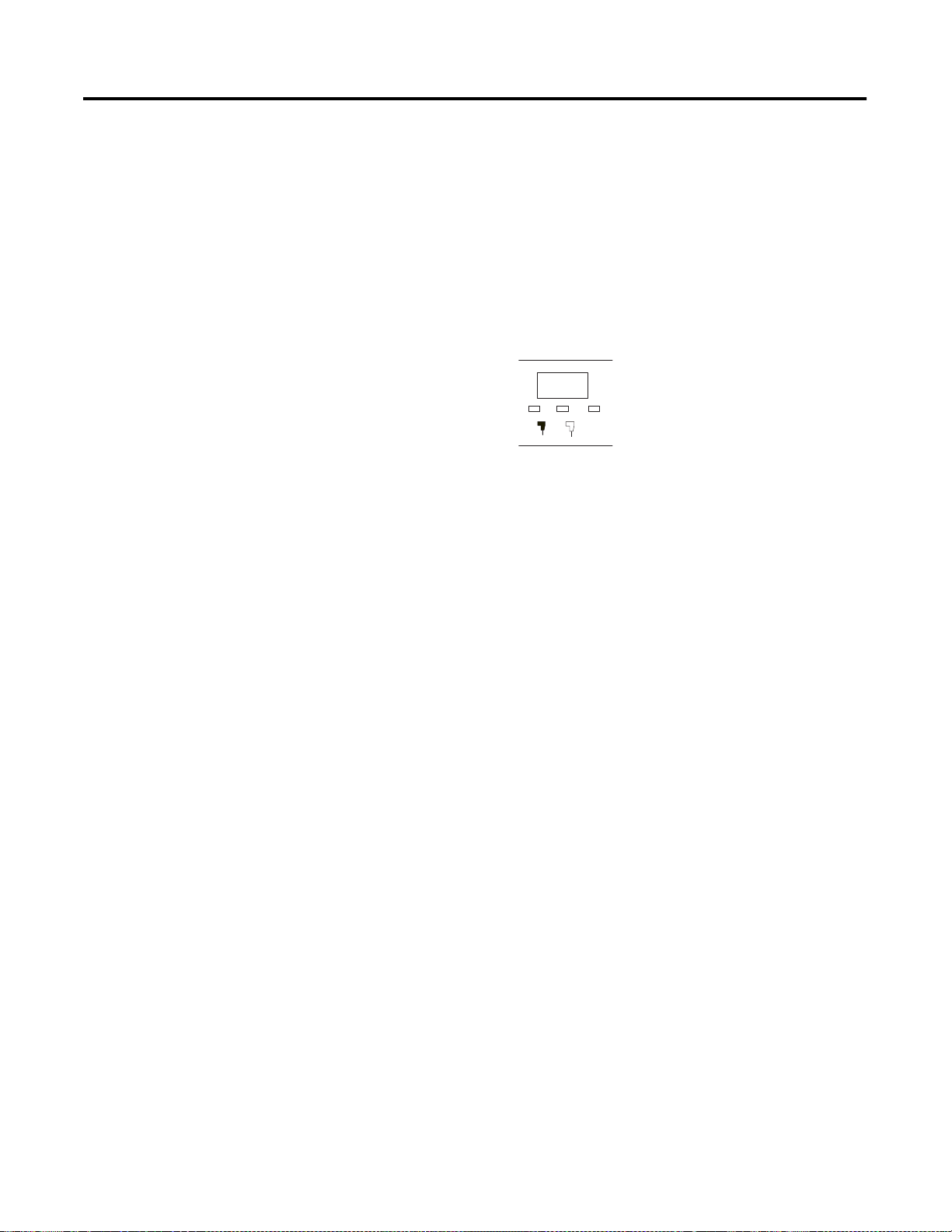

Using 1784-KTC or -KTCx Communication Card and NAP

Programming Terminal

1784-KTC or

-KTCx

ControlNet network

You can connect programming terminals to the ControlNet network by

connecting to the network access port (NAP). Two methods are shown below.

Using 1770-KFC Communication Interface and NAP

Programming Terminal

1770-KFC

(1)

1786-CP

ControlNet

product

(1) The 1786-CP cable can be plugged into any ControlNet product’s NAP to provide

programming capability on the ControlNet network. A programming terminal connected

through this cable is counted as a node and must have a unique address.

Serial or Parallel

Connection

ControlNet Network

1786-CP

ControlNet

product

(1)

ATTENTION

!!!!

Use the 1786-CP cable when connecting a programming

terminal to the network through NAPs. Using a

commercially available RJ-style cable could result in

possible network failures.

Publication 1747-UM003A-EN-P

Page 19

Installing Your ControlNet Adapter Module 2-7

Powerup Sequence

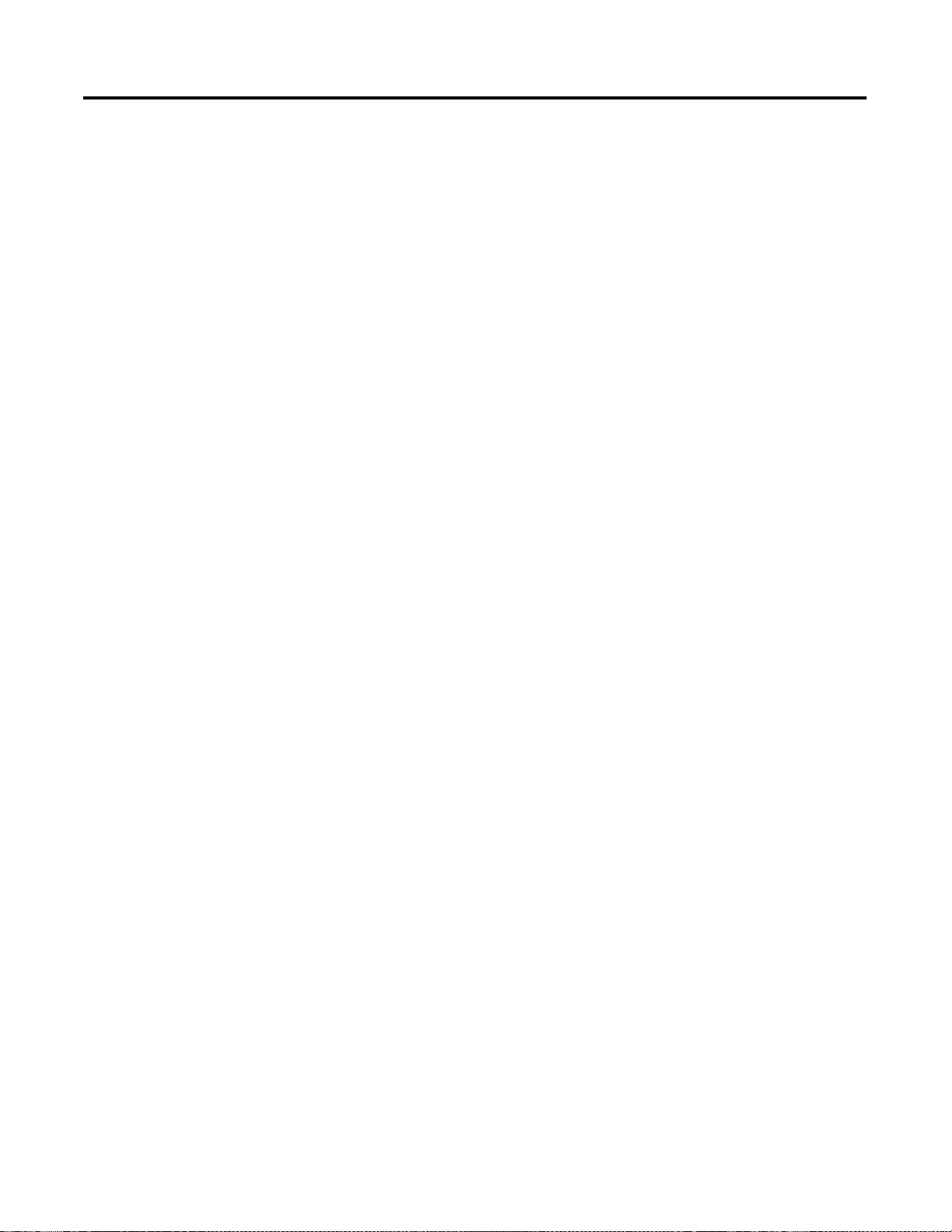

There are three health indicators on the module. The LED on the right

(labeled “OK”) is the generic module health indicator. The LED in the middle

(labeled “A”) is the health indicator of cable A. On the 1747-ACNR15, the

LED on the left (labeled “B”) is the health indicator for cable B. In addition,

the alphanumeric display can display module status. The following describes

the normal power-up sequence for the adapter module. (Refer

to Troubleshooting With the Status Indicators and Status Display on page 5-1

and ControlNet Status Indicators on page 5-3 for explanation of the LED’s

and alphanumeric display.)

ADDRESS/STATUS

B

A

Status

Health Indicators

Channel A and B

OK

indicators

1. Apply power to the chassis - notice that all three health indicators should

be off and the status window indicates “POST” (Power On Self Test).

2. After “POST”, the status window displays the sequence “0000”, “1111”,

“2222”, through “9999”. During this time, the A and B LEDs are off

and the OK LED toggles between red and green; this happens so fast,

the OK LED appears amber.

3. The series and revision levels are then displayed in the status window. A

series A revision level B module would display “A/B”. During this time,

the A and B LEDs are off and the OK LED toggles between red and

green; this happens so fast, the OK LED appears amber.

4. After the operating system is loaded and initialized, the status window

and the LEDs indicate the status of the module and its connections to

the cable(s). If the module address is not zero and a valid ControlNet

connection is made to either channel A or B, the status window toggles

between “ACTV” (Active) and the module node address (“A#02”, node

address number 2). If there are no active connectors, the status window

displays “IDLE”.

5. If there is a hardware problem of any kind, the health LED turns red and

the status window toggles between “FATL” and up to four alphanumeric

characters. The “FATL” indicates that there was a fatal error and the

characters indicate what the error is.

For detailed information on planning and installing your ControlNet system,

refer to Related Publication on page P-1.

Publication 1747-UM003 A-EN-P

Page 20

2-8 Installing Your ControlNet Adapter Module

Publication 1747-UM003A-EN-P

Page 21

Chapter

3

Planning to Use Your ControlNet Adapter

Module

Chapter Objectives

Compatible 1746 and 1747 I/O Modules

This chapter explains how the adapter operates on ControlNet and

provides information to assist in configuring your system. This includes:

• compatible 1746 and 1747 I/O modules

• overview of adapter operation

• software requirements

• rack and module connections

• optimizing SLC ControlNet Adapter connections

• module keying

• output operation during Fault and Idle modes

• understanding ControlNet I/O

• scheduled Data-Transfer connections on a ControlNet network

The majority of 1746 and 1747 discrete, analo g and specialty modules

are compatible with the 1747-ACN15 and 1747-ACNR15 adapters.

Exceptions include any modules that require G file configuration. These

include:

• 1747-SN Remote I/O Scanner module

• 1747-BSN Back-Up Remote I/O Scanner module

• 1746-QV Open Loop Velocity Control module

• 1203-SM1 Scanport module (Class 4 operation) (This module is

compatible when configured for class 1 operation.)

• 1747-SCNR ControlNet Scanner module (G files not required,

however, this module is not supported by the 1747-ACN15/

ACNR15)

A small number of 1746 modules are currently not supported by the

adapter due to lack of an EDS (electronic data sheet) file. These

modules will be supported once EDS development is completed. A

complete list of compatible 1746 and 1747 modules can be found on the

Allen-Bradley Technical Support Knowledge Base at:

http://www.ab.com/support/kbhome.html.

Page 22

3-2 Planning to Use Your ControlNet Adapter Module

Overview of Adapter Operation

Connections are established between a scanner and an adapter to exchange

input and output data on the network. Status information is transferred along

with the I/O data and status.

1747-ACN15/ACNR15 adapters support connections to individual modules

and rack connections to a group of modules. The adapters support multiple

rack and group connections to the same modules, as long as only one scanner

controls any module’s outputs. Up to 64 connections per adapter are possible

with 240 words (max) supported per connection. An adapter can control up to

30 slots of 1746 I/O (3 chassis max). The input data attributes correspond

directly to the read area of the I/O module’s data table image. The output

attributes correspond directly to the write area of the I/O module’s data table

image.

RSNetWorx is the software tool that is used to schedule network bandwidth

for all scheduled traffic originators that reside on a ControlNet network

segment. RSLinx is the communication software tool used by RSNetWorx to

access the ControlNet network. A 1784-KTCX15 PC card or 1784-PCC

ControlNet card can be used as the hardware interface to the network.

Software Requirements

RSNetWorx for ControlNet version 2.23.00 or greater is required to configure

the 1747-ACN15/ACNR15 adapters. If you only have RSNetWorx for

ControlNet version 2.22.18, it is necessary to add the Service Pack in order to

configure connections with the 1747-ACNR15 adapter. To add the Service

Pack, follow the steps below.

1. Access the Rockwell Software support page at:

http://www.software.rockwell.com/support

2. Click Downloads form the list of choices in the left column.

3. Locate section 2, “Choose a Product”.

4. Click the down arrow and select RSNetWorx from the drop down list.

5. In section 4, click Search.

6. Click Service Pack 1, or click a later version for the Service Pack if it is

not the only Service Pack available.

7. After the download is completed, close all programs and run the

installation of the software. Follow the screen prompts to guide you

through the installation process. If you experience problems performing

the install, contact Rockwell Software Technical Support.

Publication 1747-UM003A-EN-P

When Service Pack 1 is installed, the version of RSNetWorx for ControlNet is

2.23.00 or greater.

Page 23

Planning to Use Your ControlNet Adapter Module 3-3

Rack and Module Connections

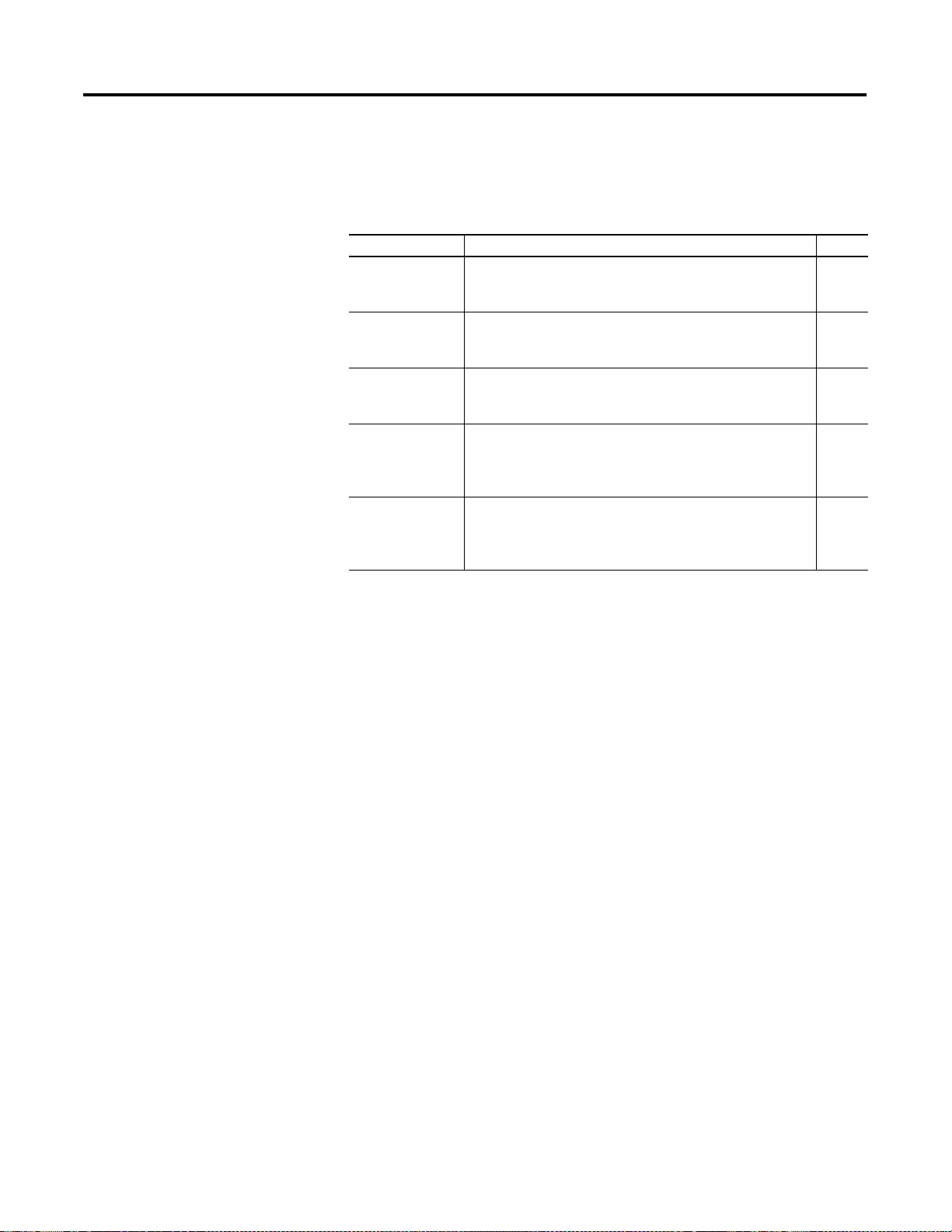

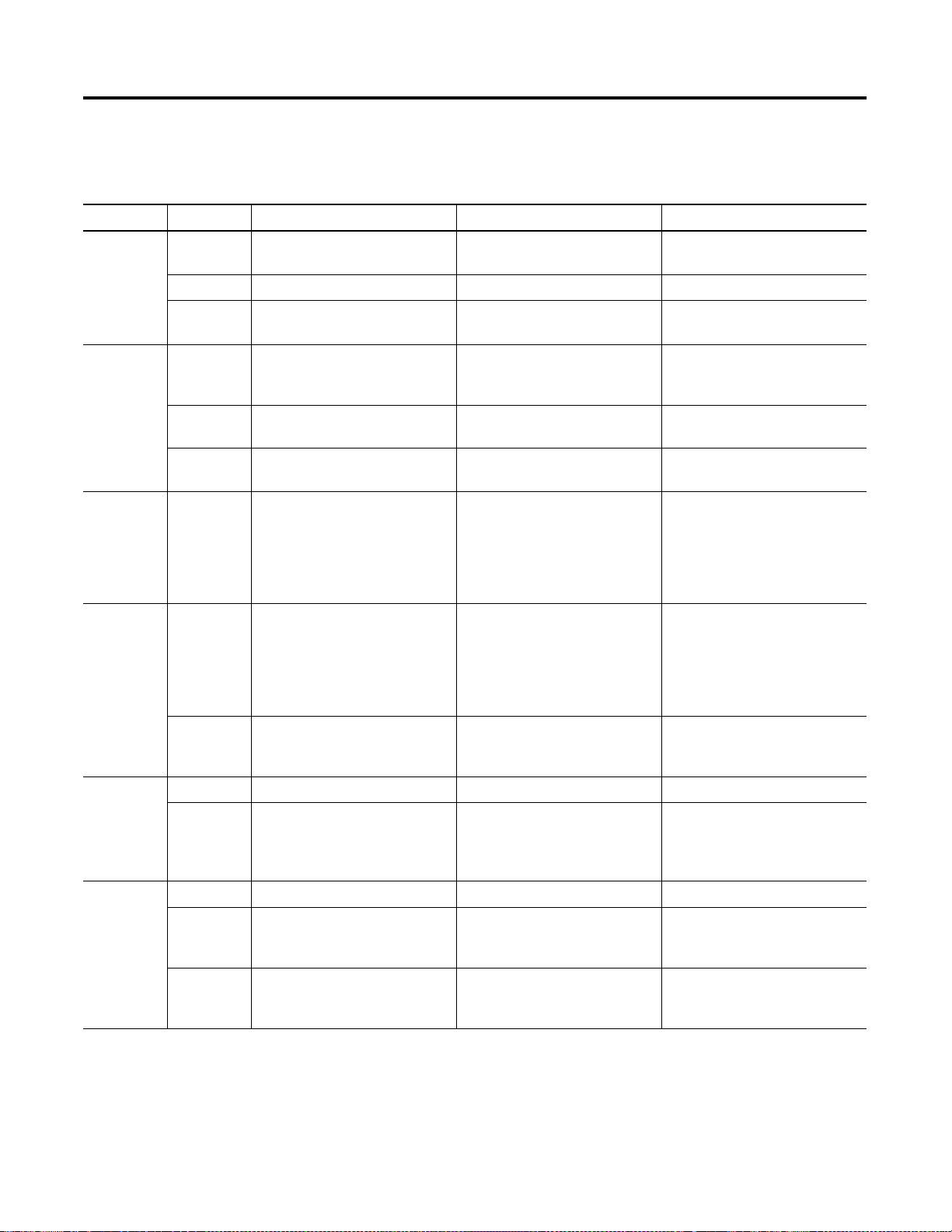

There are two types of scheduled connections supported by the 1747-ACN15,

-ACNR15: the rack connection and the individual module connection.

Rack Connections

For each rack connection, RSNetWorx maps 8, 16, or 32 input and output bits

per slot.

Operation Description

8-bit Rack

Connections

16-bit Rack

Connections

32-bit Rack

Connections

Performed in a deterministic and repeatable manner. This

connection allows a memory and ControlNet bandwidth

efficient way to connect to a rack of 8-bit modules

Performed in a deterministic and repeatable manner. This

connection allows a memory and ControlNet bandwidth

efficient way to connect to a rack of 16-bit modules.

Performed in a deterministic and repeatable manner. This

connection allows a memory and ControlNet bandwidth

efficient way to connect to a rack of 32-bit modules.

The rack connection is used to define a single connection for the discrete

I/O in the SLC backplane. Multiple rack connections, with limitations, are

supported in the SLC adapter. For example, a connection originator might

specify an 8-bit, 16-bit, or 32-bit data size.

IMPORTANT

RSNetWorx allows more than one exclusive owner rack

connection type to be configured to a 1747 adapter (e.g.

8-bit exclusive owner, 16-bit exclusive owner, and 32-bit

exclusive owner), however onl y one exclusive owner rack

connection can be operational at one time. It is

recommended that only one exclusive owner rack

connection type be configured to the adapter to avoid

contention between multiple connections.

IMPORTANT

If a rack connection type is changed to a smaller bit

configuration e.g. 32-bit to 16-bit, or 16-bit to 8-bit, the

unused bits for the new connection are reset to zero.

Publication 1747-UM003 A-EN-P

Page 24

3-4 Planning to Use Your ControlNet Adapter Module

Module Connections

Module connections are performed in a deterministic and repeatable manner.

This connection allows a memory and ControlNet bandwidth efficient way to

connect to an individual module with more I/O data than could be attempted

in the above rack connections, or to transfer M0/M1 file data.

Each rack and module connection can be configured with the following

connection types:

1. Exclusive Owner - specifies an independent connection where a single

device controls the output states in the target device. If you have an

existing Exclusive Owner connection to a target device, you cannot

specify another Exclusive Owner or Redundant connection to that same

target device.

2. Input Only - specifies an independent connection where a device

receives inputs fro m the target device and sends c onfiguration data to

the target device. An Input Only connection does not send outp uts; it

only receives inputs. You can specify multiple Input Only connect ions

to the target device from different originators.

3. Listen Only - specifies a dependent connection where a device receives

inputs from the target device, but does not send configuration data with

the target device. A Listen Only connection only functions properly

when another non-Listen Only connection exists to the same target

device. A Listen Only connection does not send outputs; it only receives

inputs. You can specify multiple Listen Only connections to the target

device from different originators.

NOTE

All Listen Only connections are terminated when all

associated independent connections are terminated.

Optimizing SLC ControlNet Adapter Rack Connections

Consider the following example placement of ControlNet devices when you

want to optimize your SLC ControlNet adapter connection:

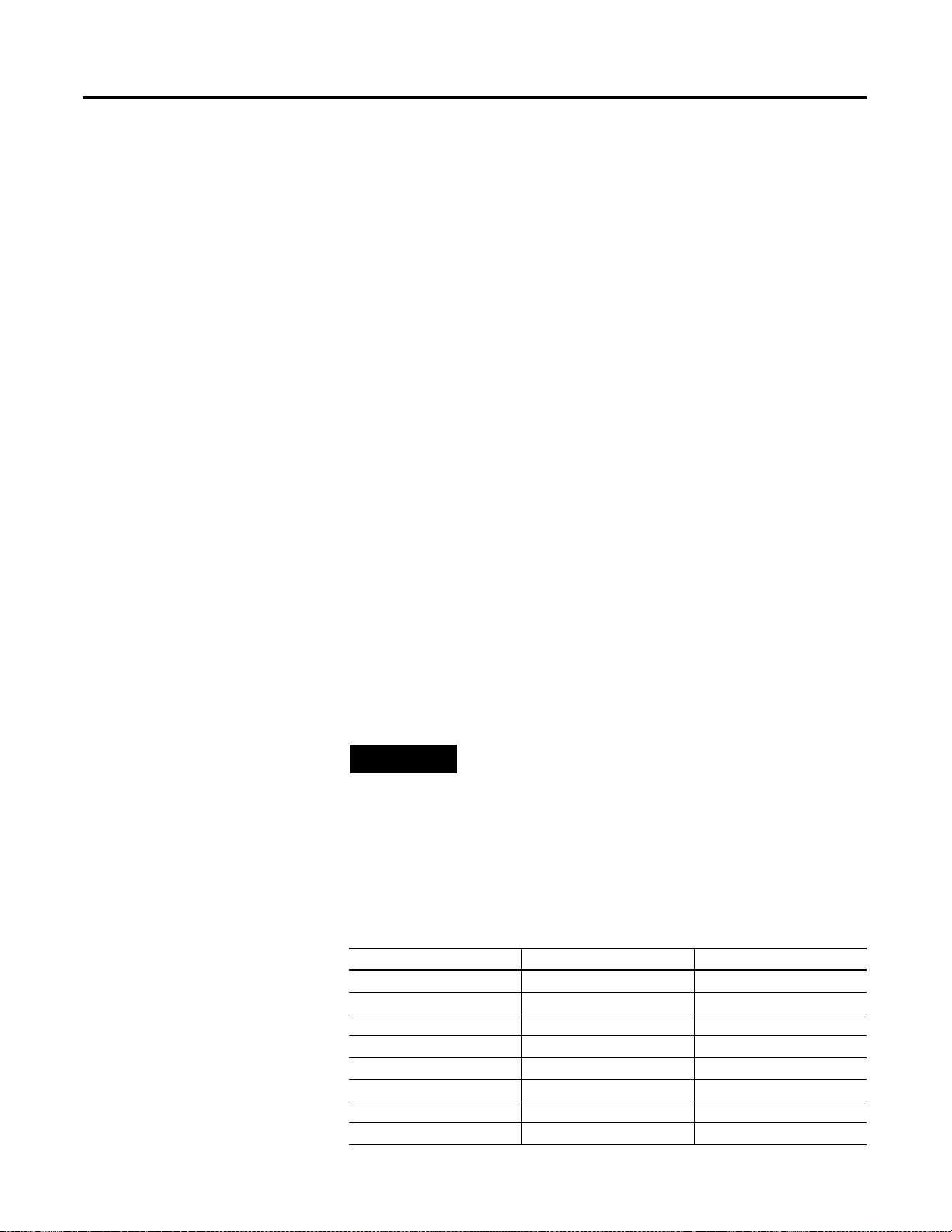

Node Slot Device

1 1747-SCNR

2 0 1747-ACNR15

1 1746-IB16

2 1746-IB16

3 1746-OB16

4 1746-OB16

5 1746-NIO4I

6 1746-HSCE

Publication 1747-UM003A-EN-P

Page 25

Planning to Use Your ControlNet Adapter Module 3-5

If we change the default number of words for the input and output values (to 4

and 4) when inserting the connection to the 1747-ACNR15 adapter, Node 2

will produce 4 input words over ControlNet and Node 1 will consume and

place those words at addresses I:e.1-4, where the slot 1 inp uts corresp ond to

I:e.3 and the slot 2 inputs correspond to I:e.4. In addition, Node 1 will produce

4 output words over ControlNet originating from addresses O:e.1-4 and Node

2 will consume them. A total of 8 words (4 input and 4 output) are transmitted

on ControlNet.

NOTE

To optimize ControlNet network bandwidth, place the

devices in the following order (left to right on the chassis):

• 1747-ACNR15 adapter

• Discrete input modules

• Discrete output modules

• Any intelligent and/or analog I/O modules that you want

to establish individual module connections to

Consider the following:

• The 1747-SCNR has 31 input words and 31 output words available for

rack connections to 1747-ACNR15 adapters.

• Each 1747-ACNR15 adapter requires 2 input words for status in addition

to the input words assigned to the slots.

• Adjust the rack connection size to match the maximum density I/O

module:

– Discrete 8-bit Exclusive Owner for 4 and 8-point modules

– Discrete 16-bit Exclusive Owner for 16-point modules

– Discrete 32-bit Exclusive Owner for 32-point modules.

Module Keying

Missing or misplaced modules are detected if the module in question is

configured with RSNetWorx as an individual module connection and

“compatible module” is selected for electronic keying. If a module connection

is attempted to a module which is a missing or misplaced module, the

connection will fail. The green OK LED on the initiating scanner will flash

and the module will display “I/O” with a partially filled bar indicating all

connections are not established, as shown below.

I/O

Publication 1747-UM003 A-EN-P

Page 26

3-6 Planning to Use Your ControlNet Adapter Module

NOTE

The electronic keying option offered by RSNetWorx for

rack connections applies to the 1747-ACN15 and

-ACNR15 modules only.

Missing or misplaced modules are not detected if the

module in question is configured within a rack connection.

Critical I/O modules that need to be detected when

missing or mispla ced must be configured with indiv idual

module connections.

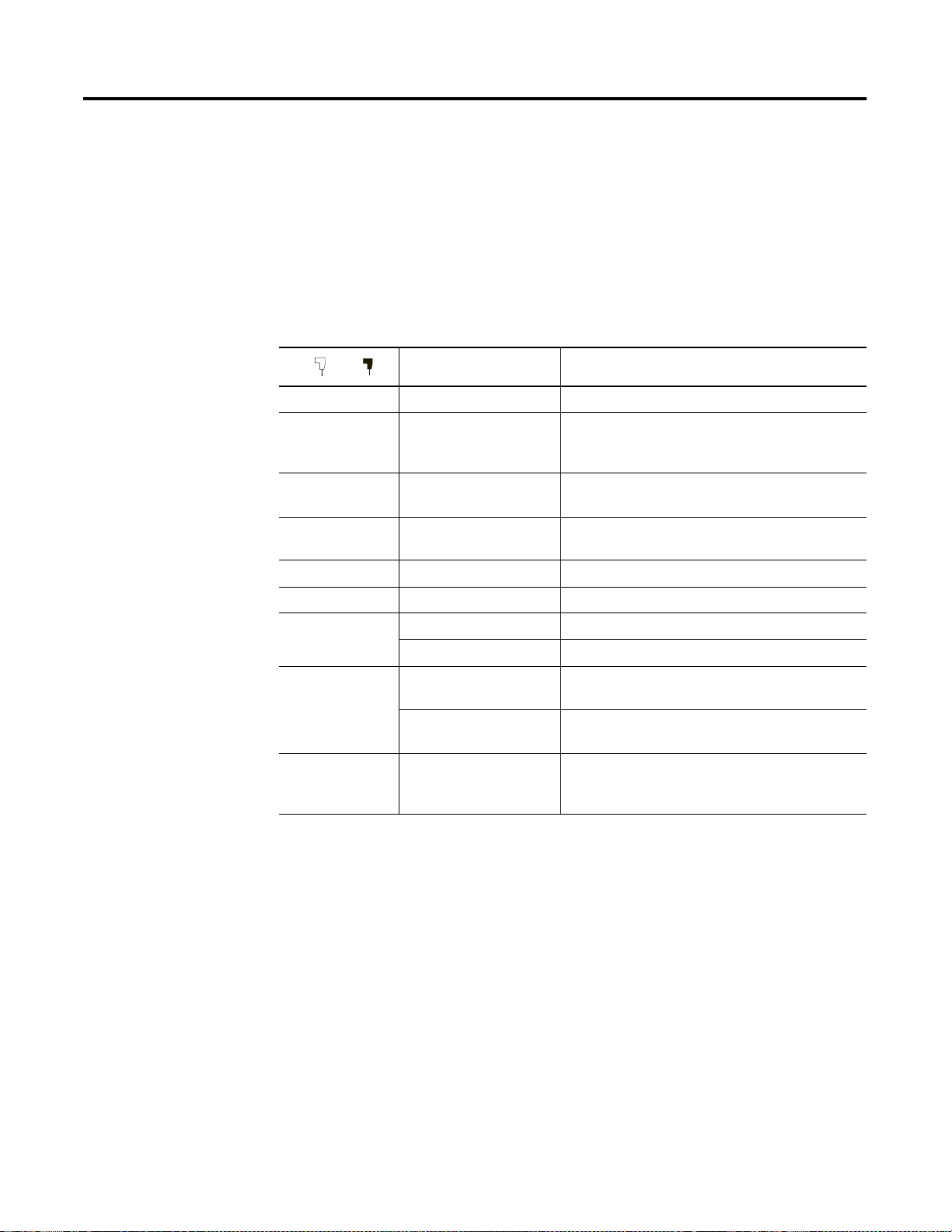

Output Operation During Fault and Idle Modes

RSNetworx allows configuration to characterize each module connection

activity during certain operational states.

During idle mode and fault modes, outputs are configured for one of the

following operation states:

Output Action

Reset outputs to off

Hold last state

Write Safe State data to outputs

Understanding ControlNet I/O

The ControlNet system is designed to:

• provide high-speed, repeatable, deterministic I/O transmission

• allow control and message information to co-exist on the same physical

media

• make sure that I/O data transfers are not affected by

– programming-terminal message activity

– inter-processor message activity on the network

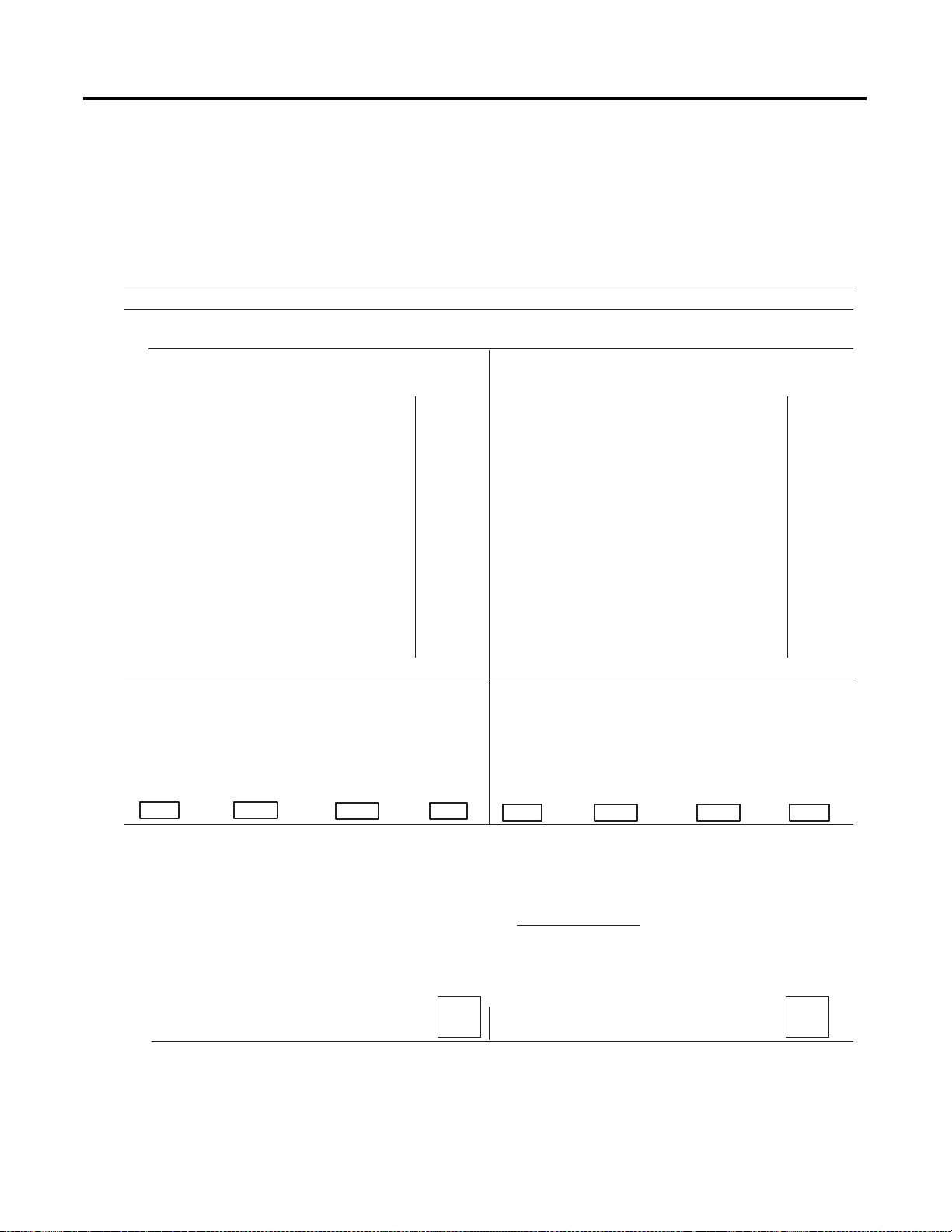

Scheduled Data-Transfer Connections on a ControlNet Network

Scheduled data transfer on a ControlNet processor:

• is continuous

• is asynchronous to the ladder-logic program scan

• occurs at the actual rate displayed in the Actual Packet Interval field on the

RSNetWorx ControlNet I/O mapping (monitor) screen

Publication 1747-UM003A-EN-P

Page 27

Planning to Use Your ControlNet Adapter Module 3-7

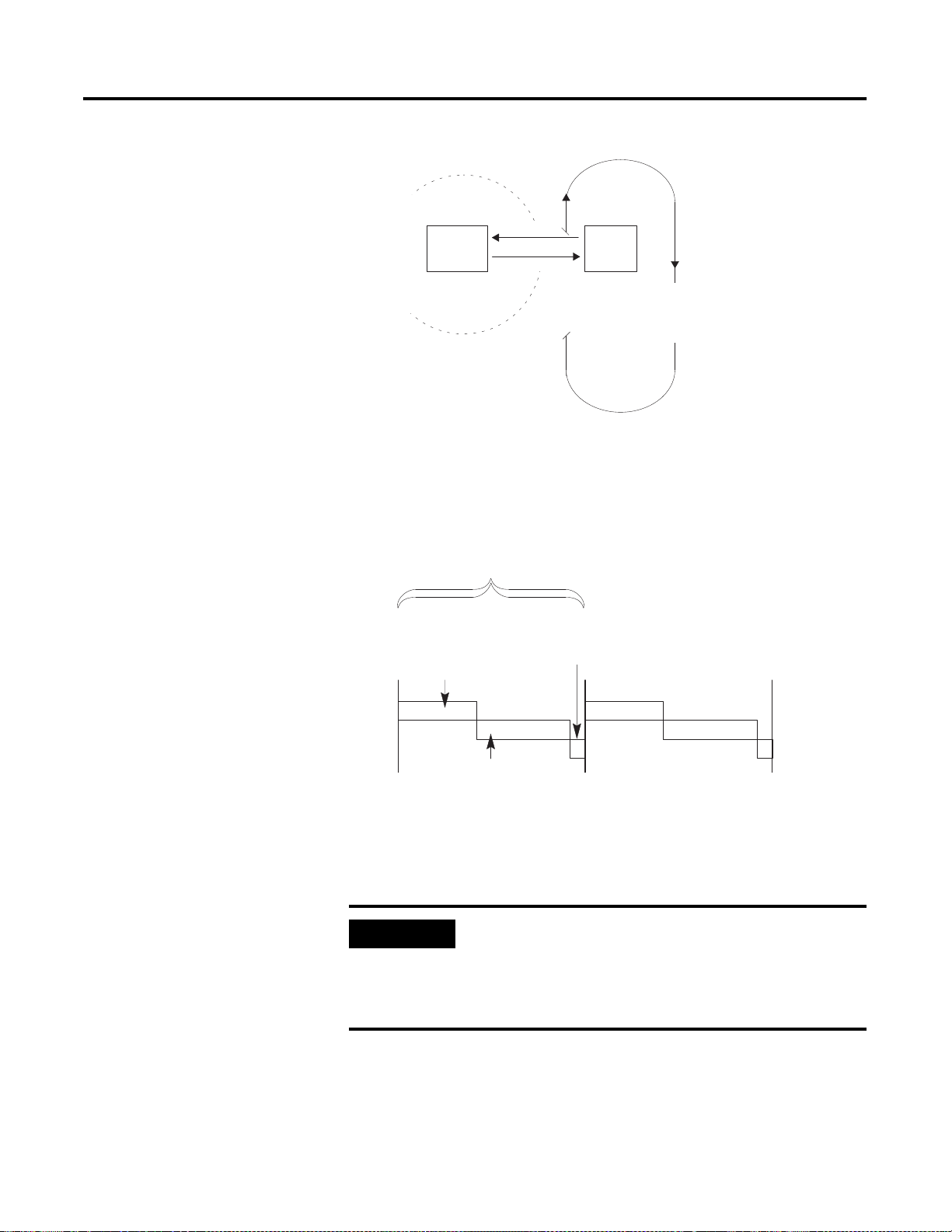

PrivateMemory

Buffers

Scheduled Data Transfers

Scheduled Data Transfer Program Scan

Data Update

DataTab le

Files

Housekeeping

Logic Scan

The ControlNet system places your scheduled transfers in the first part of each

Network Update Interval. Time is automatically reserved for network

maintenance. Unscheduled transfers are performed during the time remaining

in the interval.

You reserve a

specific amount

of time for all

scheduled

operations.

The system

reserves time for

network

maintenance

Any time remaining is used for

unscheduled operations

. . .. . .

Your application and your configuration-number of nodes, application

program, NUT (Network Update Time), amount of scheduled bandwidth

used, etc. determine how much time there is for unscheduled messaging.

IMPORTANT

The ControlNet network reserves time for at least one

maximum-sized unscheduled transfer per update interval.

Depending on how much time there is for unscheduled

messaging, every node may not have a chance to send

unscheduled data every update interval.

Publication 1747-UM003 A-EN-P

Page 28

3-8 Planning to Use Your ControlNet Adapter Module

Publication 1747-UM003A-EN-P

Page 29

Chapter

Application Examples

Table 4.A Table of Contents

Example Number Title Page

1 1747-SCNR ControlNet Scanner Controlling Discrete I/O on

ControlNet via a 1747-ACN15 ControlNet Adapter Using a

Rack Connection

2 1747-SCNR ControlNet Scanner Controlling Discrete and

Analog I/O on ControlNet via a 1747-ACN15 ControlNet

Adapter Using a Rack Connection

3 1747-SCNR ControlNet Scanner Controlling Discrete and

Analog I/O on ControlNet via a 1747-ACN15 ControlNet

Adapter Using Rack and Module Connections

4 1747-SCNR ControlNet Scanner Controlling Discrete I/O and

Serial Data with a 1746-BAS Module on ControlNet via a

1747-ACN15 ControlNet Adapter Using Rack and Module

Connections

5 1747-SCNR ControlNet Scanner Controlling Discrete I/O and

Specialty Modules Requiring M0 File Configuration on

ControlNet via a 1747-ACN15 ControlNet Adapter Using Rack

and Module Connections

4-2

4-11

4-21

4-31

4-46

4

1 Publication 1747-UM003 A-EN-P

Page 30

4-2 Application Examples

Example 1

1747-SCNR ControlNet Scanner Controlling Discrete I/O on ControlNet via a

1747-ACN15 ControlNet Adapter Using a Rack Connection

This example is organized into the following sections:

• Hardware Setup

• Configuring The ControlNet Network with RSNetWorx™ for

ControlNet, Revision 2.23.02 or later

• Create a Ladder Logic Program

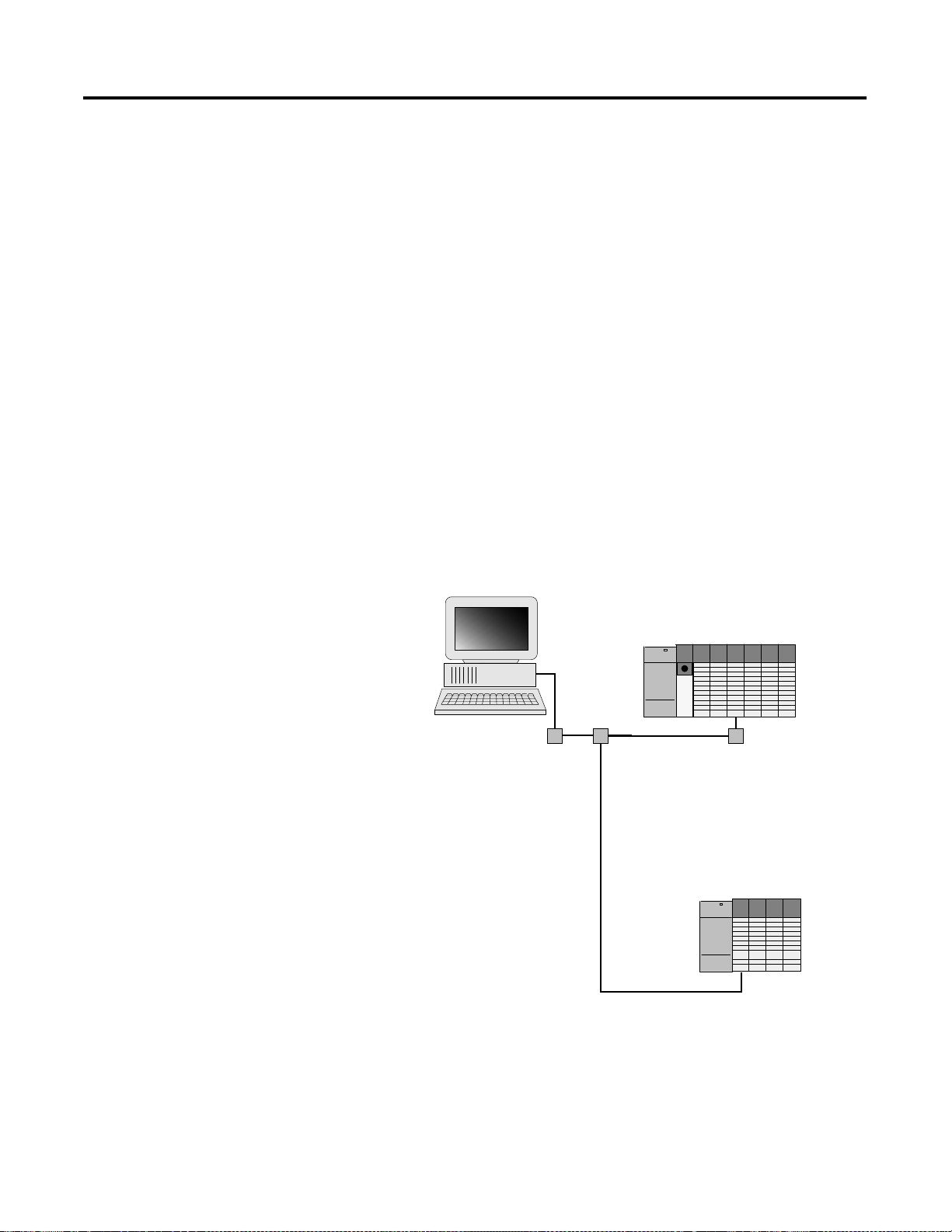

Hardware Setup

The following hardware setup is referenced throughout this example.

Computer with:

• RSLogix 500 Software

• RSLinx Software

• RSNetWorx Software for ControlNet

• 1784-KTCX15 ControlNet PC Card

tap

tap

ControlNet

SLC 5/04

tap

1747-SCNR

1747-ACN15

1746-IA16

1746-OB16

1746-IV16

Publication 1747-UM003A-EN-P

Page 31

Application Examples 4-3

Configuring The ControlNet Network with RSNetWorx™ for ControlNet

Start RSNetWorx for ControlNet by double clicking on its icon. The following

screen appears:

At this point, you could configure your ControlNet network off-line and then

download it to the network. This example will, instead, go on-line and

configure the network. Therefore, click on the on-line icon or click on the

Network pull-down menu and select On-line.

A Browse for Network window appears, where you must select the

communication path previously configured in RSLinx for communicating

with your ControlNet network. In this example, a KTC ControlNet PC card

was used. Click on the KTCX15 card to select it and then click OK.

Publication 1747-UM003 A-EN-P

Page 32

4-4 Application Examples

The software attempts to communicate with all possible node numbers on the

network, from 1 to 99. Click on the Edits Enabled box to allow changes to be

made. For this example, the on-line network screen should look like the

following, where node 99 is the programming terminal.

Node 1 is the 1747-SCNR and node 3 is the 1747-ACN15. The

1747-ACN15 resides in slot 0 of its chassis, while slot 1 contains a 1746-IA16,

slot 2 contains a 1746-OB16, and slot 3 contains a 1746-IV16. For this

example, a single 16-bit rack connection will be configured to read/write the

three discrete I/O modules.

Before creating the connection, verify the chassis configuration for the

1747-ACN15 chassis. To do this, right click on the 1747-ACN15, then choose

Edit Chassis. Verify that the chassis configuration is as follows:

slot 0: 1747-ACNR15

slot 1: 1746-IA16

slot 2: 1746-OB16

slot 3: 1746-IV16

If the chassis is not already configured, manually configure it by dragging the

appropriate modules from the list on the right to the proper slot on the left of

the chassis configuration screen. When on-line, the software reads the module

types for you. When this is complete, click Apply, then OK.

Publication 1747-UM003A-EN-P

Page 33

Application Examples 4-5

Configuring a Chassis Connection

You are now ready to configure the necessary ControlNet connection to read/

write data from the SLC processor to the discrete I/O modules. Right click on

the 1747-SCNR and choose Scanlist Configuration. (If you are prompted to

enter the edit mode, click YES.) The following screen appears:

Publication 1747-UM003 A-EN-P

Page 34

4-6 Application Examples

The 1747-SCNR and 1747-ACN15 are shown as nodes 1 and 3 respectively.

Under the 1747-ACN15, the 3 I/O modules in slots 1 through 3 of the

1747-ACN15 chassis are listed. In order to establish a 16-bit rack connection

to the 1747-ACN15 chassis, right click on the 1747-ACN15 and choose Insert

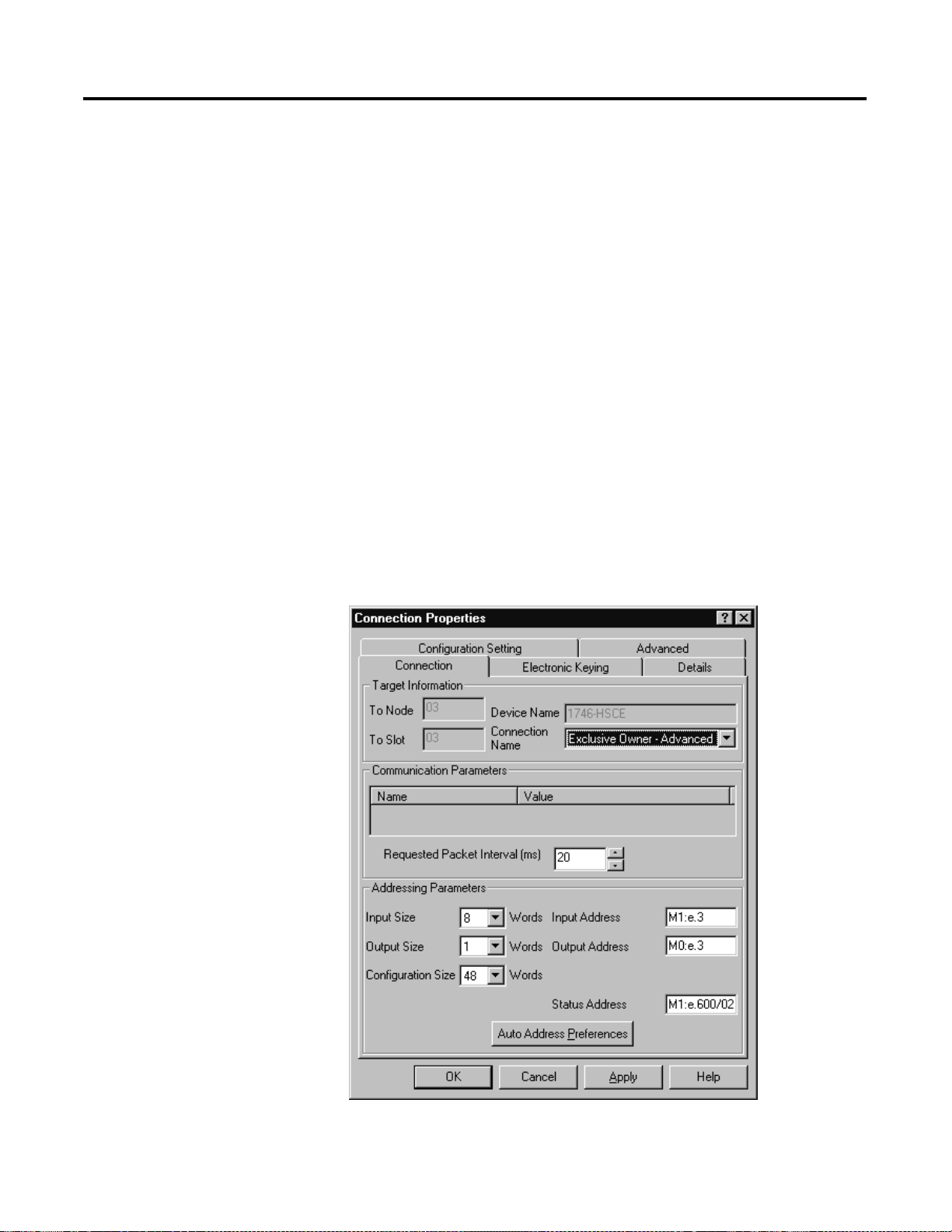

Connection. The following window opens:

Publication 1747-UM003A-EN-P

Note that addresses in the Connection Properties screen above are already filled

in. To have RSNetWorx choose the next available valid I/O or M-file addresses

for all connections, click on the Auto Address Preferences button. Next, click on

the box next to Enable Automatic Addressing on Insert so a check mark appears

in the box. Then click OK. Auto Addressing enabled is the default.

IMPORTANT

RSNetWorx allows more than one exclusive owner rack

connection type to be configured to a 1747 adapter (e.g.

8-bit exclusive owner, 16-bit exclusive owner, and 32-bit

exclusive owner), however only one exclusive owner rack

connection can be operational at one time. It is

recommended that only one exclusive owner rack

connection type be configured to the adapter to avoid

contention between multiple connections.

Page 35

Application Examples 4-7

IMPORTANT

If a rack connection type is changed to a smaller bit

configuration e.g. 32-bit to 16-bit, or 16-bit to 8-bit, the

unused bits for the new connection remains in their

previously programmed states for program mode or lost

communications e.g. last state, safe state, reset off.

The Connection Name, by default, is Discrete 16-Bit Exclusive Owner and this is

the 16-bit rack connection you want. The first available I/O addresses are I:3.1

and O:3.1, where the 1747-SCNR is in slot 3 of the processor chassis. The first

available starting I/O addresses have been placed into the Input Address and

Output Address fields, because automatic addressing was previously selected in

the Auto Address Preference screen. Words I:3.0 and O:3.0 contain status and

control data and are not used for I/O data.

Note that the input data from the 1746-IA16 is found in the processor’s input

image word I:3.3 and the output data written to the 1746-OB16 module is

from the processor’s output image word O:3.2. The input data from the

1746-IV16 is in the processor’s input image word I:3.5.

NOTE

There is a 2-word offset for input data for rack connections.

Therefore, for this example, the input data for the input

module in slot 1 of the remote 1747-ACN15 chassis is

written to I:3.3 in the SLC processor’s input image. The

input module in slot 3 is written to I:3.5.

The starting input address configured in RSNetWorx for

this rack connection was I:3.1, but I:3.1 and I:3.2 are used

for rack slot status information. Note the resulting input

size of 5 shown in the Connection Properties screen.

Therefore, the actual input data begins after the 2 words of

status information. I:3.4 is not used in this example because

an output module resides in slot 2.

Also, note that there is no offset for the outputs in a rack

connection. O:3.2 is the output image word written to the

output module located in slot 2 of the 1747-ACN15

chassis. O:3.1 is also not used in this example because an

input card is in slot 1.

The Status Address field must also be filled in. This field supplies Connection

Status information to the processor for each unique connection. The starting

bit address for this field must be an even number because two consecutive bits

are used as status for each connection. The even numbered bit indicates

whether the connection is open or closed. The odd numbered bit indicates

whether the connection is in normal operation or Idle mode. In this example,

the starting address chosen is the first available bit pair, M1:3.600/00.

Publication 1747-UM003 A-EN-P

Page 36

4-8 Application Examples

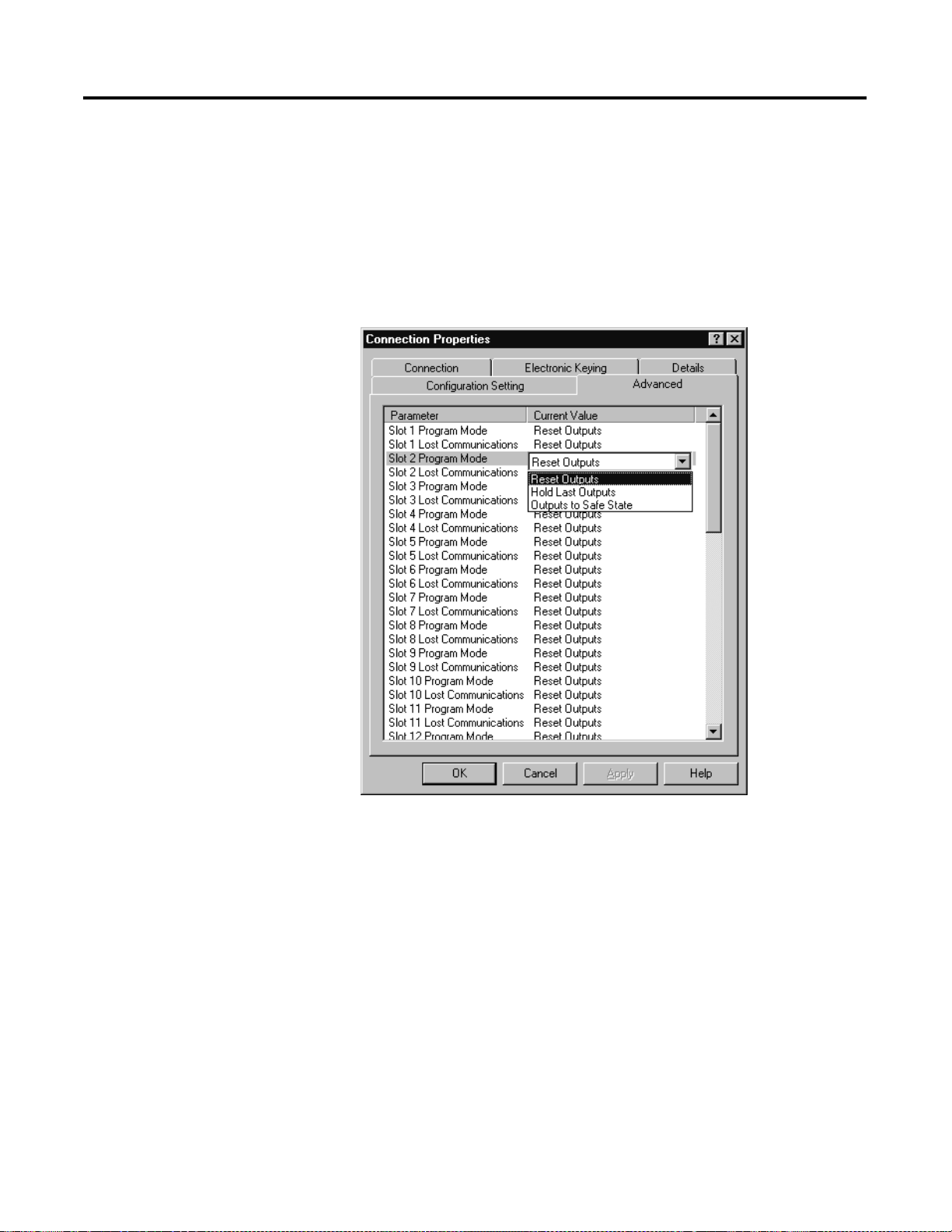

You have successfully configured a rack connection to the remote chassis to

communicate with the discrete I/O modules. At this point, you may also

configure the state of the outputs in the remote ControlNet chassis when the

controlling processor is placed into the Program mode or if communications

are lost to the remote chassis. This is optional. The default is to turn all outputs

off when one of the two conditions occur. To select other options, click on the

Advanced tab in the Connection Properties window. The following window

appears:

Publication 1747-UM003A-EN-P

By default, outputs in all slots in the remote chassis are reset if the processor is

placed into the Program mode or if communications are lost for any reason.

Two other choices are offered when one of the two conditions occur. They are:

• Hold Last Outputs

• Outputs to Safe State

Hold Last Outputs holds outputs in their last state if one of the two conditions

occur. Safe State allows you to choose the exact state of each output. If Safe

State is selected, you must click on the Configuration Settings tab and enter your

Safe State data for each output word in decimal. Then, if the SLC processor is

Page 37

Application Examples 4-9

placed in the Program mode or if communications are lost to the ACN15

adapter, the outputs revert to the Safe State data you entered for each output

word.

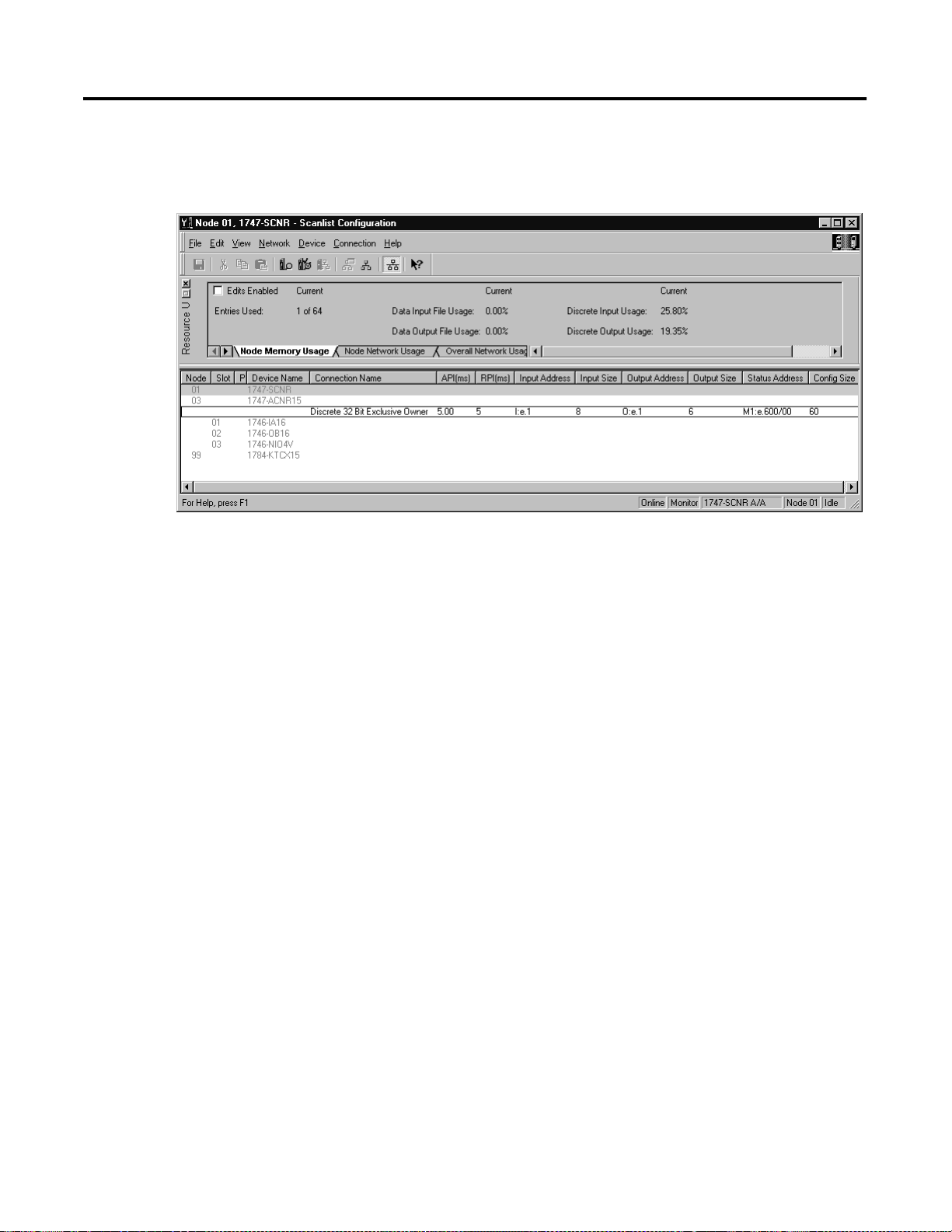

Click Apply, then OK to return to the ScanList Configuration window which

should look like the following:

You have now successfully configured your rack connection to read/write data

between the SLC processor and the remote ControlNet chassis. All that

remains is to Save this configuration to the network keeper which, in this case,

is the 1747-SCNR.

Click on the Save icon or choose the File pull-down menu and select Save. You

are prompted to Optimize and re-write schedule for all connections. Click OK,

then click YES to the subsequent warning message. Your network

configuration information is then written to the network keeper and scanner

devices.

The display on the front of your 1747-SCNR should show a Full Glass next to

I/O. This indicates that all configured connections have been successfully

downloaded to the scanner. In addition, the A and OK LEDs should be solid

green and the B LED should be off, unless you are using the redundant media

option, which is not being used in this example. The 1747-ACN15 should be

displaying that it is active (ACTV) and its LEDs should be solid green for A

and OK.

Publication 1747-UM003 A-EN-P

Page 38

4-10 Application Examples

Create a Ladder Logic Program

The final step is to write a ladder program for the SLC processor, including

configuring the 1747-SCNR for slot 3 of the processor’s chassis. After

downloading the program to your processor, place it into the RUN mode. Your

program should now be able to read data from the 1746-IA16 in word I:3.3,

write to the 1746-OB16 in word O:3.2 and read data from the 1746-IV16 in

word I:3.5.

Note that your ladder program should also contain an unconditional rung with

an OTE instruction addressed to the SCNR scanner’s RUN/IDLE bit, O:3.0/

10 for this example. When the SLC processor is placed into the RUN mode,

this rung sets the SCNR scanner’s RUN/IDLE bit and places the scanner into

the RUN mode as well. The scanner begins executing the configured

connections when the RUN/IDLE bit is set.

Publication 1747-UM003A-EN-P

Page 39

Application Examples 4-11

Example 2

1747-SCNR ControlNet Scanner Controlling Discrete and Analog I/O on

ControlNet via a 1747-ACN15 ControlNet Adapter Using a Rack Connection

This example is organized into the following sections:

• Hardware Setup

• Configuring The ControlNet Network with RSNetWorx™ for

ControlNet

• Create a Ladder Program

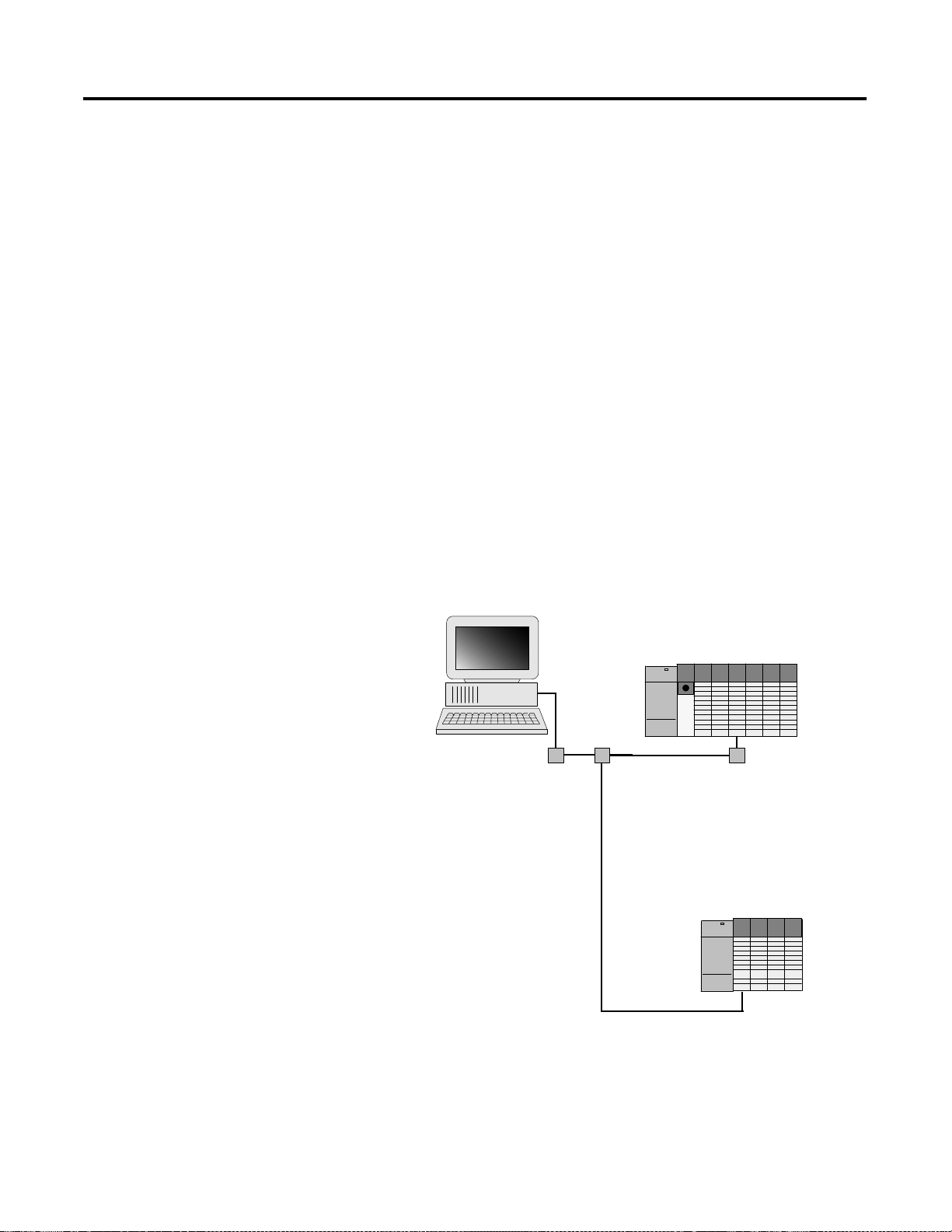

Hardware Setup

The following hardware setup is referenced throughout this example.

Computer with:

• RSLogix 500 Software

• RSLinx Software

• RSNetWorx Software for ControlNet

• 1784-KTCX15 ControlNet PC Card

tap

tap

ControlNet

SLC 5/04

tap

1747-SCNR

1747-ACN15

1746-IA16

1746-OB16

1746-NIO4V

Publication 1747-UM003 A-EN-P

Page 40

4-12 Application Examples

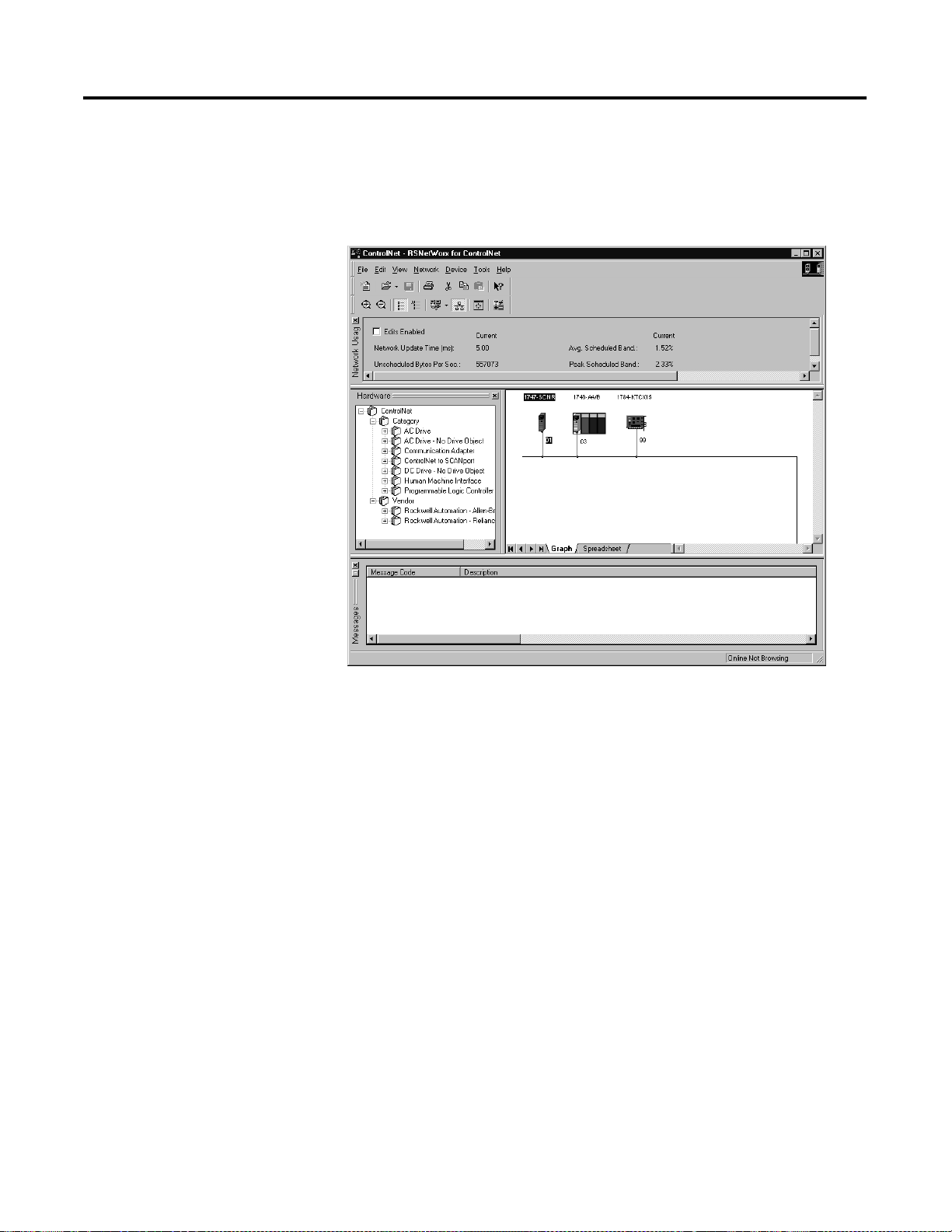

Configuring The ControlNet Network with RSNetWorx™ for ControlNet

Start RSNetWorx for ControlNet by double clicking on its icon. The following

screen appears:

Publication 1747-UM003A-EN-P

At this point, you could configure your ControlNet network off-line and then

download it to the network. This example, instead, goes on-line and configure

the network. Therefore, click on the on-line icon or click on the Network

pull-down menu and select On-line.

A Browse for Network window appears, where you must select the

communication path previously configured in RSLinx for communicating

with your ControlNet network. In this example, a 1784-KTCX15 ControlNet

PC card was used. Click on the KTC card to select it and then click OK.

Page 41

Application Examples 4-13

The software attempts to communicate with all possible node numbers on the

network, from 1 to 99. Click the Edits Enabled box to allow changes to be

made. For this example, the on-line network screen should look like the

following, where node 99 is the programming terminal.

Node 1 is the 1747-SCNR and node 3 is the 1747-ACN15. The

1747-ACN15 resides in slot 0 of its chassis, while slot 1 contains a 1746-IA16,

slot 2 contains a 1746-OB16, and slot 3 contains a 1746-NIO4V. For this

example, a single 32-bit rack controller is configured to read/write the three I/

O modules.

Before creating the connection, verify the chassis configuration for the

1747-ACN15 chassis. To do this, right click on the 1747-ACN15, then choose

Edit Chassis. Verify that the chassis configuration is as follows:

slot 0: 1747-ACNR15

slot 1: 1746-IA16

slot 2: 1746-OB16

slot 3: 1746-NIO4V

If the chassis is not already configured, manually configure it by dragging the

appropriate modules from the list on the right to the proper slot on the left of

the chassis configuration screen. When on-line, the software reads the module

types for you. When this is complete, click Apply, then OK.

Publication 1747-UM003 A-EN-P

Page 42

4-14 Application Examples

Configuring a Rack Connection

You are now ready to configure the necessary ControlNet connection to read/

write data from the SLC processor to the discrete I/O modules and to the

1746-NIO4V analog module. Right click on the 1747-SCNR and choose

Scanlist Configuration. (If you are prompted to enter the edit mode, click YES.)

The following screen appears:

Publication 1747-UM003A-EN-P

Page 43

Application Examples 4-15

The 1747-SCNR and 1747-ACN15 are shown as nodes 1 and 3 respectively.

Under the 1747-ACN15, the 3 I/O modules in slots 1 through 3 of the

1747-ACN15 chassis are listed. We specify a 32-bit rack connection so that the

two words of analog input and two words of analog output data from the

1746-NIO4V module can be transferred via the rack connection. In order to

establish a 32-bit rack connection to the 1747-ACN15 chassis, right click on

the 1747-ACN15 and choose Insert Connection. The following window opens:

Note that addresses in the Connection Properties screen above are already filled

in. To have RSNetWorx choose the next available valid I/O or M-file addresses

for all connections, click on the Auto Address Preferences button. Next, click on

the box next to Enable Automatic Addressing on Insert so a check mark appears

in the box. Then click OK. Automatic Addressing enabled is the default.

Publication 1747-UM003 A-EN-P

Page 44

4-16 Application Examples

IMPORTANT

RSNetWorx allows more than one exclusive owner rack

connection type to be configured to a 1747 adapter (e.g.

8-bit exclusive owner, 16-bit exclusive owner, and 32-bit

exclusive owner), however only one exclusive owner rack

connection can be operational at one time. It is

recommended that only one exclusive owner rack

connection type be configured to the adapter to avoid

contention between multiple connections.

IMPORTANT

If a rack connection type is changed to a smaller bit

configuration e.g. 32-bit to 16-bit, or 16-bit to 8-bit, the

unused bits for the new connection remains in their

previously programmed states for program mode or lost

communications e.g. last state, safe state, reset off.

The Connection Name, by default, is Discrete 16-Bit Exclusive Owner. Change

this to Discrete 32-bit Exclusive Owner. The first available I/O addresses are

I:3.1 and O:3.1, where the 1747-SCNR is in slot 3 of the processor chassis.

The first available starting I/O addresses have been placed into the Input

Address and Output Address fields, because automatic addressing was previously

selected in the Auto Address Preference screen. Words I:3.0 and O:3.0 are used

for status and control data.

Note that the input data from the 1746-IA16 is found in the processor’s input

image word I:3.3 and the output data written to the 1746-OB16 module is

from the processor’s output image word O:3.3. The 1746-NIO4V input data

is in I:3.7 and I:3.8, and the output data is in O:3.5 and O:3.6.

Publication 1747-UM003A-EN-P

Page 45

Application Examples 4-17

NOTE

There is a 2-word offset for input data for rack connections.

Therefore, for this example, the input data for the input

module in slot 1 of the remote 1747-ACN15 chassis is

written to I:3.3 in the SLC processor’s input image.

The starting input address configured in RSNetWorx for

this rack connection was I:3.1, but I:3.1 and I:3.2 are used

for rack slot status information. Therefore, the actual input

data begins after the 2 words of status information. I:3.4 is

not used in this example because although 32 input bits are

assigned to slot 1, the 1746-IA16 only uses the first 16

input bits.

I:3.5 and I:3.6 are not used in this example because an

output module resides in slot 2. Also, note that there is no

offset for the outputs in a rack connection. O:3.3 is the

output image word written to the output module located in

slot 2 of the 1747-ACN15 chassis.

The Status Address field must also be filled in. This field supplies Connection

Status information to the processor for each unique connection. The starting

bit address for this field must be an even number because two consecutive bits

are used as status for each connection. The even numbered bit indicates

whether the connection is open or closed. The odd numbered bit indicates

whether the connection is in normal operation or Idle mode. In this example,

the starting address chosen is the first available bit pair, M1:3.600/00.

Publication 1747-UM003 A-EN-P

Page 46

4-18 Application Examples

You have successfully configured a rack connection to the remote chassis to

communicate with the two discrete and one analog I/O modules. At this point

you may also configure the state of the outputs in the remote ControlNet

chassis when the processor is placed into the Program mode or if

communications are lost to the remote chassis. This is optional. The default is

to turn all outputs off when one of the two conditions occur. To select other

options, click on the Advanced tab in the Connection Properties window. The

following window will appear:

Publication 1747-UM003A-EN-P

By default, outputs in all slots in the remote chassis are reset if the processor is

placed into the Program mode or if communications are lost for any reason.

Two other choices are offered when one of the two conditions occur. They are:

• Hold Last Outputs

• Outputs to Safe State

Hold Last Outputs holds outputs in their last state if one of the two conditions

occur. Safe State allows you to choose the exact state of each output. If Safe

State is selected, you must click on the Configuration Settings tab and enter your

Safe State data for each output word in decimal. Then, if the SLC processor is

placed in the Program mode or if communications are lost to the ACN15

adapter, the outputs revert to the Safe State data you entered for each output

word.

Click Apply, then OK to return to the ScanList Configuration screen.

Page 47

Application Examples 4-19

Click Apply, then OK. The Connection Properties window closes and the Scanlist

Configuration window appears and looks like the following:

You have now successfully configured your connection to read/write data

between the SLC processor and the remote ControlNet chassis. All that

remains is to Save this configuration to the network keeper which, in this case,

is the 1747-SCNR.

Click on the Save icon or choose the File pull-down menu and select Save. You

are prompted to Optimize and re-write schedule for all connections. Click OK,

then click YES to the subsequent warning message. Your network

configuration information is then written to the network keeper.

The display on the front of your 1747-SCNR should show a Full Glass next to

I/O. This indicates that all configured connections have been successfully

downloaded to the scanner. In addition, the A and OK LEDs should be solid

green and the B LED should be off, unless you are using the redundant media

option, which is not being used in this example. The 1747-ACN15 should be

displaying that it is active (ACTV) and its LEDs should be solid green for A

and OK.

Publication 1747-UM003 A-EN-P

Page 48

4-20 Application Examples

Create a Ladder Program

The final step is to write a ladder program for the SLC processor, including

configuring the 1747-SCNR for slot 3 of the processor’s chassis. After

downloading the program to your processor, place it into the RUN mode. Your

program should now be able to read data from the 1746-IA16 in word I:3.3

and write to the 1746-OB16 in word O:3.3. The analog input data resides in

words I:3.7 and I:3.8, while the analog output data must be copied to words

O:3.5 and O:3.6.

Note that your ladder program should also contain an unconditional rung with

an OTE instruction addressed to the SCNR scanner’s RUN/IDLE bit, O:3.0/

10 for this example. When the SLC processor is placed into the RUN mode,

this rung sets the SCNR scanner’s RUN/IDLE bit and places the scanner into

the RUN mode as well. The scanner begins executing the configured

connections when the RUN/IDLE bit is set.

Publication 1747-UM003A-EN-P

Page 49

Application Examples 4-21

Example 3

1747-SCNR ControlNet Scanner Controlling Discrete and Analog I/O on

ControlNet via a 1747-ACN15 ControlNet Adapter Using Rack and Module

Connections

This example is organized into the following sections:

• Hardware Setup

• Configuring The ControlNet Network with RSNetWorx™ for

ControlNet

• Create a Ladder Logic Program

Hardware Setup

The following hardware setup is referenced throughout this example.

Computer with:

• RSLogix 500 Software

• RSLinx Software

• RSNetWorx Software for ControlNet

• 1784-KTCX15 ControlNet PC Card

tap

tap

ControlNet

SLC 5/04

tap

1747-SCNR

1747-ACN15

1746-IA16

1746-OB16

1746-NI8

Publication 1747-UM003 A-EN-P

Page 50

4-22 Application Examples

Configuring The ControlNet Network with RSNetWorx™ for ControlNet

Start RSNetWorx for ControlNet by double clicking on its icon. The following

screen appears:

Publication 1747-UM003A-EN-P

At this point, you could configure your ControlNet network off-line and then

download it to the network. This example, instead, goes on-line and configure

the network. Therefore, click on the on-line icon or click on the Network

pull-down menu and select On-line.

A Browse for Network window appears, where you must select the

communication path previously configured in RSLinx for communicating

with your ControlNet network. In this example, a KTC ControlNet PC card

was used. Click on the KTC card to select it and then click OK.

Page 51

Application Examples 4-23

The software attempts to communicate with all possible node numbers on the

network, from 1 to 99. Click on the Edits Enabled box allow changes to be

made. For this example, the on-line network screen should look like the

following, where node 99 is the programming terminal.

Node 1 is the 1747-SCNR and node 3 is the 1747-ACN15. The

1747-ACN15 resides in slot 0 of its chassis, while slot 1 contains a 1746-IA16,

slot 2 contains a 1746-OB16, and slot 3 contains a 1746-NI8. For this

example, 2 separate ControlNet connections are configured. The first is a

Discrete 16 Bit Exclusive Owner rack connection for the 2 discrete I/O modules

and the second is an Module Connection to the 1746-NI8 8-input analog

module.

Before creating these necessary connections, verify the chassis configuration for

the 1747-ACN15 chassis. To do this, right click on the 1747-ACN15, then

choose Edit Chassis. Verify that the chassis configuration is as follows:

slot 0: 1747-ACNR15

slot 1: 1746-IA16

slot 2: 1746-OB16

slot 3: 1746-NI8

If the chassis is not already configured, manually configure it by dragging the

appropriate modules from the list on the right to the proper slot on the left of

the chassis configuration screen. When on-line, the software reads the module

types for you. When this is complete, click Apply, then OK.

Publication 1747-UM003 A-EN-P

Page 52

4-24 Application Examples

Configuring a Rack Connection

You are now ready to configure the necessary ControlNet connections to read/

write data from the SLC processor to the discrete I/O modules and to the

analog input module. Right click on the 1747-SCNR and choose Scanlist

Configuration. (If you are prompted to enter the edit mode, click YES.) The

following screen appears:

Publication 1747-UM003A-EN-P

Page 53

Application Examples 4-25

As you can see, the 1747-SCNR and 1747-ACN15 are shown as nodes 1 and 3

respectively. Under the 1747-ACN15, the 3 I/O modules in slots 1 through 3

of the 1747-ACN15 chassis are listed. In order to establish a 16-bit rack

connection to the 1747-ACN15 chassis, right click on the 1747-ACN15 and

choose ControlNet Configuration. The following window opens:

Note that addresses in the Connection Properties screen above are already filled

in. To have RSNetWorx choose the next available valid I/O or M-file addresses

for all connections, click on the Auto Address Preferences button. Next, click on

the box next to Enable Automatic Addressing on Insert so a check mark appears

in the box. Then click OK. Automatic Addressing enabled is the default.

IMPORTANT

RSNetWorx allows more than one exclusive owner rack

connection type to be configured to a 1747 adapter (e.g.

8-bit exclusive owner, 16-bit exclusive owner, and 32-bit

exclusive owner), however only one exclusive owner rack

connection can be operational at one time. It is

recommended that only one exclusive owner rack

connection type be configured to the adapter to avoid

contention between multiple connections.

Publication 1747-UM003 A-EN-P

Page 54

4-26 Application Examples

IMPORTANT

If a rack connection type is changed to a smaller bit

configuration e.g. 32-bit to 16-bit, or 16-bit to 8-bit, the

unused bits for the new connection remains in their

previously programmed states for program mode or lost

communications e.g. last state, safe state, reset off.

The Connection Name by default is Discrete 16-Bit Exclusive Owner and this is

the 16-bit rack connection you want. The first available I/O addresses are I:3.1

and O:3.1, where the 1747-SCNR is in slot 3 of the processor chassis. The first

available starting I/O addresses have been placed into the Input Address and

Output Address fields, because automatic addressing was previously selected in

the Auto Address Preference screen. Words I:3.0 and O:3.0 are used for status

and control data.

Note that the input data from the 1746-IA16 is found in the processor’s input

image word I:3.3 and the output data written to the 1746-OB16 module is

from the processor’s output image word O:3.2.

NOTE

There is a 2-word offset for input data for rack

connections. Therefore, for this example, the input data for

the input module in slot 1 of the remote 1747-ACN15

chassis is written to I:3.3 in the SLC processor’s input

image.

The starting input address configured in RSNetWorx for

this rack connection was I:3.1, but I:3.1 and I:3.2 are used

for rack slot st atus information. Therefore, the actual input

data begins after the 2 words of status information. I:3.4

and I:3.5 are not used in this example because an output

module resides in slot 2 and an analog module resides in

slot 3.

Also, note that there is no offset for the outputs in a rack

connection. O:3.2 is the output image word written to the

output module located in slot 2 of the 1747-ACN15

chassis. O:3.1 is not used because an input module resides

in slot 1. In addition, no offset applies to module

connections at all.

The Status Address field must also be filled in. This field supplies Connection

Status information to the processor for each unique connection. The starting

bit address for this field must be an even number because two consecutive bits

are used as status for each connection. The even numbered bit indicates

whether the connection is open or closed. The odd numbered bit indicates

whether the connection is in normal operation or Idle mode. In this example,

the starting address chosen is the first available bit pair, M1:3.600/00.

Publication 1747-UM003A-EN-P

Page 55

Application Examples 4-27

You have successfully configured a rack connection to the remote chassis to

communicate with the two discrete I/O modules. At this point you may also

configure the state of the outputs in the remote ControlNet chassis when the

processor is placed into the Program Mode or if communications are lost to the

remote chassis. This is optional. The default is to turn all outputs off when one

of the two conditions occur. To select other options, click on the Advanced tab

in the Connection Properties window. The following window appears:

By default, outputs in all slots in the remote chassis are reset if the processor is

placed into the Program mode or if communications are lost for any reason.

Two other choices are offered when one of the two conditions occur. They are:

• Hold Last Outputs

• Outputs to Safe State

Hold Last Output holds outputs in their last state if one of the two conditions

occur. Safe State allows you to choose the exact state of each output. If Safe

State is selected, you must click on the Configuration Settings tab and enter you

Safe State data for each output word in decimal. Then, if the SLC processor is

placed in the Program mode or if communications are lost to the ACN adapter,

the outputs revert to the Safe State data you entered for each output word.

Publication 1747-UM003 A-EN-P

Page 56

4-28 Application Examples

Configuring a Module Connection

Next, you need to configure a module connection for the 1746-NI8 8-input

analog module. If the previous window is still open, click Apply, then OK to

accept the rack connection.

Right click on the 1746-NI8 module in the Scanlist Configuration window and

select Insert Connection. A Connection Properties window again appears. Choose

Exclusive Owner for the Connection Name.

In this case choose M-file addresses for the 8-input analog module. The NI8

module must use Class 3 operation in a 1747-ACN15 chassis. It requires 12

output words and 16 input words. M-file words are used for this in the

1747-SCNR. M0:3.3 through M0:3.14 are used for the 12 output words to

configure the module. M1:3.3 through M1:3.18 are used for the input

information, including actual analog data and analog channel status. Refer to

your 1746-NI8 User’s Manual for additional information on this module.

M-file words M1:3.0 through M1:3.2 and M0:3.0 through M0:3.2 are

reserved. The next available Status Address is M1:3.600/02 since bits 0 and 1

are used by the 1747-SCNR for the rack connection. The Connection Properties

window for the module connection should look like the following.

Publication 1747-UM003A-EN-P

Page 57

4-29

Click Apply, then OK. The Connection Properties window closes and the Scanlist

Configuration window appears and looks like the following:

You have now successfully confi gured your two connections to read/write

data between the SLC processor and the remote ControlNet chassis. All that

remains is to Save this configuration to the network keeper which, in this case,

is the 1747-SCNR.

Click on the Save icon or choose the File pull-down menu and select Save. You

are prompted to Optimize and re-write schedule for all connections. Click OK, then

click YES to the subsequent warning message. Your net work configuration

information is then written to the network keeper.

The display on the front of your 1747-SCNR should show a Full Glass next to