Page 1

Allen-Bradley

Open-loop

Velocity

User

Control Module

(Cat. No. 1746-QV)

Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance and

safety requirements, including any applicable laws, regulations, codes

and standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for purposes of example. Since there are

many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability (to

include intellectual property liability) for actual use based upon the

examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration when

applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or

in part, without written permission of Allen-Bradley Company, Inc., is

prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death,

!

Attention statements help you to:

property damage or economic loss.

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is critical for successful

application and understanding of the product.

SLC is a trademark of Allen-Bradley Company, Inc. PKZIP and PKUNZIP are registered trademarks of PKWARE Inc.

Page 3

Manual Changes (Series A/D)

Changes to this revision of the manual include these additions:

• Considerations for Selecting the "15V dc Power Supply (chapter 4)

• Other Design Considerations (chapter 4)

• Testing for Proper System Operation (chapter 5)

• Power Supply Loading Specifications (appendix A)

Publication

1746-6.18 – April 1998

Page 4

Notes:

Summary of Changestoc–ii

Publication

1746-6.18 – April 1998

Page 5

Table of Contents

System Overview

Chapter Objectives

Is the 1746-QV Module?

What

What Is an SLC-500 System?

Why Use This System?

How Does It Work?

What

Are Typical Applications?

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

Quick Start

Procedure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Up the Software

Chapter Objectives

Obtaining

Configuring Your SLC Processor, Off-line

Modify

General

Profile

the Ladder Program Electronically from

BBS or the Internet

About the Rockwell Bulletin Board System (BBS)

To Access BBS:

To Access the Internet:

N Files in Y

Output

Image T

Conventions for Profiles

Operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

our SLC Processor, Off-line

able with Profile Data

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . .

1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–1

1–1

1–1

1–2

1–2

1–2

2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–1

3–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

3–1

3–1

3–1

3–1

3–2

3–2

3–4

3–4

3–5

3–5

Setting Up the Hardware

Chapter Objectives

Connect

Connect

Minimizing

Considerations

Other

the LDT to Module Inputs

Module Outputs to Output Devices

Interference from Radiated Electrical Noise

Selection

Application

of the "15V dc Power Supply

Design Considerations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

for the "15V dc Supply

of the "15V dc Power Supply

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

4–1. . . . . . . . . . . . . . . . . . . . . . . . . .

4–1

4–1

4–2

4–2

4–3

4–3

4–4

4–4

Page 6

Table of Contentsii

Operating the Module for the First Time

Chapter Objectives

Power Up the System

Check

Wiring and Grounding

Get Ready to Move the Ram

Move the Ram

Jog

the Ram to the Reference Position

Test

for Proper System Operation

Troubleshoot Possible Problems

Using

Status Bits for Errors Detected by the Module

Troubleshooting

Conditions

That Control Module Outputs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

T

able

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Specifications

Electrical

Physical

Environmental

Specifications

Specifications

Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Ladder Program

. . . . . . . . . .

. . . . . . . . . . . . . . . . . .

5–1. . . . . . . . . . . . . . .

5–1

5–1

5–1

5–2

5–2

5–3

5–4

5–4

5–4

5–5

5–5

A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–1

A–1

A–1

B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLC Processor Files

Input

G

File

Output

Image T

able

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image T

able

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C–1

C–2

C–2

Page 7

Chapter Objectives

What Is the 1746-QV Module?

What Is an SLC-500 System?

This chapter presents a conceptual overview of how you use the

1746-QV module in an application.

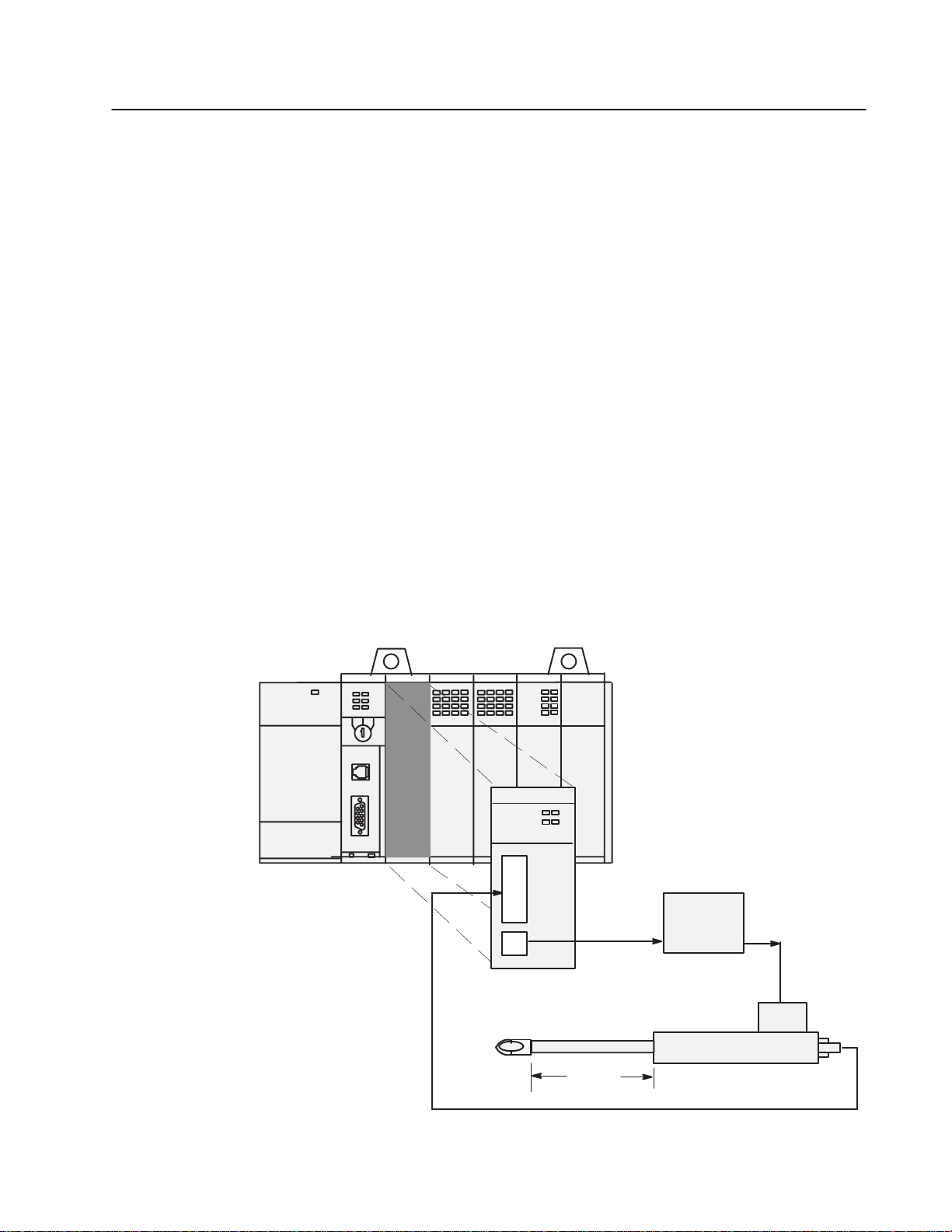

The 1746-QV module is part of an SLC-based open-loop control

system for controlling the speed and placement of an hydraulic ram.

The module accepts an input from a linear displacement transducer

(LDT) and motion profiles that you program into the SLC processor,

and varies its output in the range of "10V dc. The SLC processor

sends to the module a pair of extend and retract profiles that define

when to accelerate or decelerate hydraulic motion.

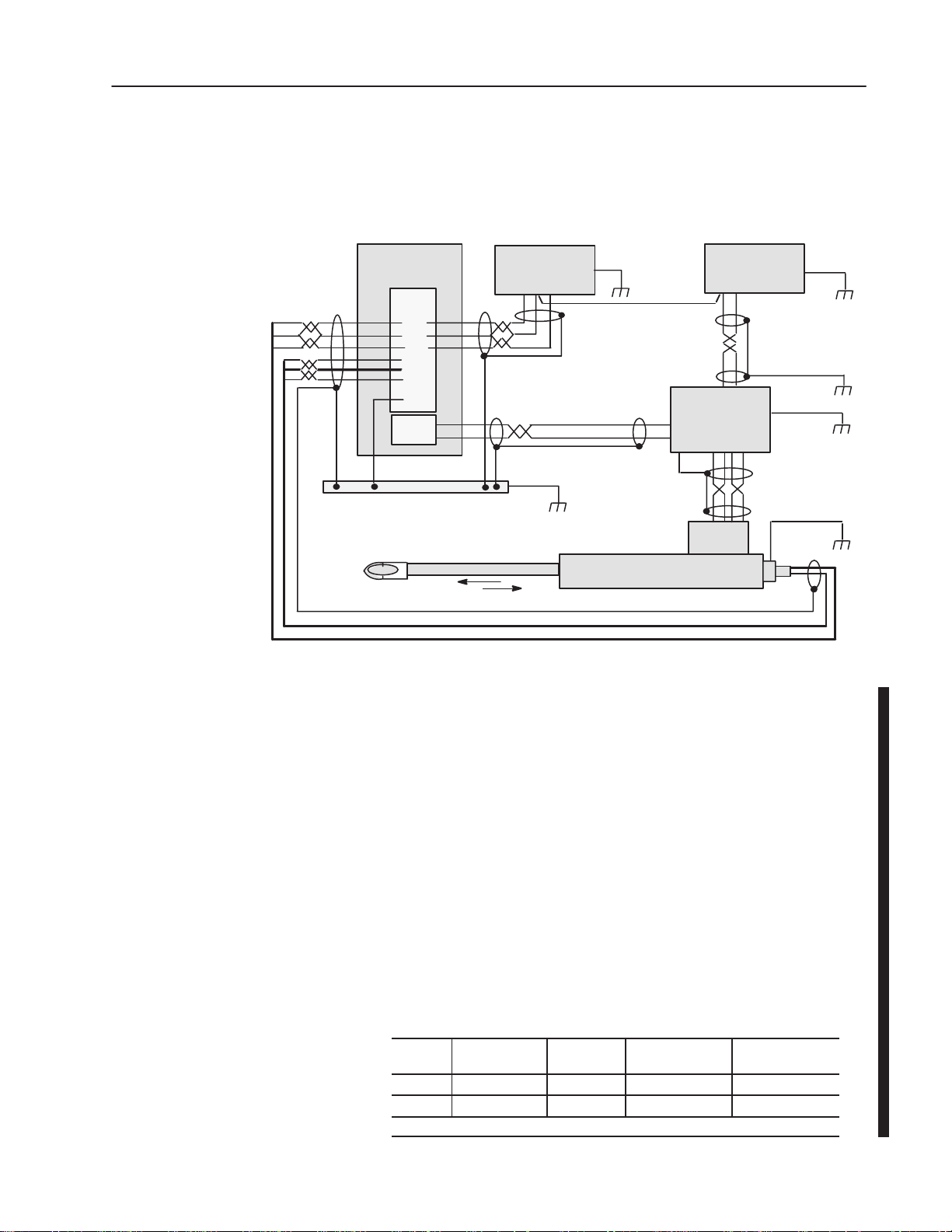

The Allen-Bradley Small Logic Controller (SLC) system is a

programmable control system with an SLC processor, I/O chassis

containing analog, digital, and/or special-purpose modules, and a

power supply. The 1746-QV module interfaces your hydraulic ram

and position-monitoring device (LDT) to the ladder sequence in your

SLC processor. The system can be illustrated as follows:

Power

Supply

SLC-500

Processor

Position

Input

from LDT

HYDRAULIC

RUN

FAULT

LDT/"10V DC

1746-QV

module

Analog

Output

"10v dc

Piston-type Hydraulic Cylinder and

Linear Displacement Transducer (LDT)

Axis

Motion

Proportional

Amplifier

Publication

Proportional

Valve

1746-6.18 April 1998

Page 8

1–2

Position

Position

Head

Head

System Overview

Why Use This System?

How Does It Work?

Extend Direction

3

Voltage

2

1

4

Segments

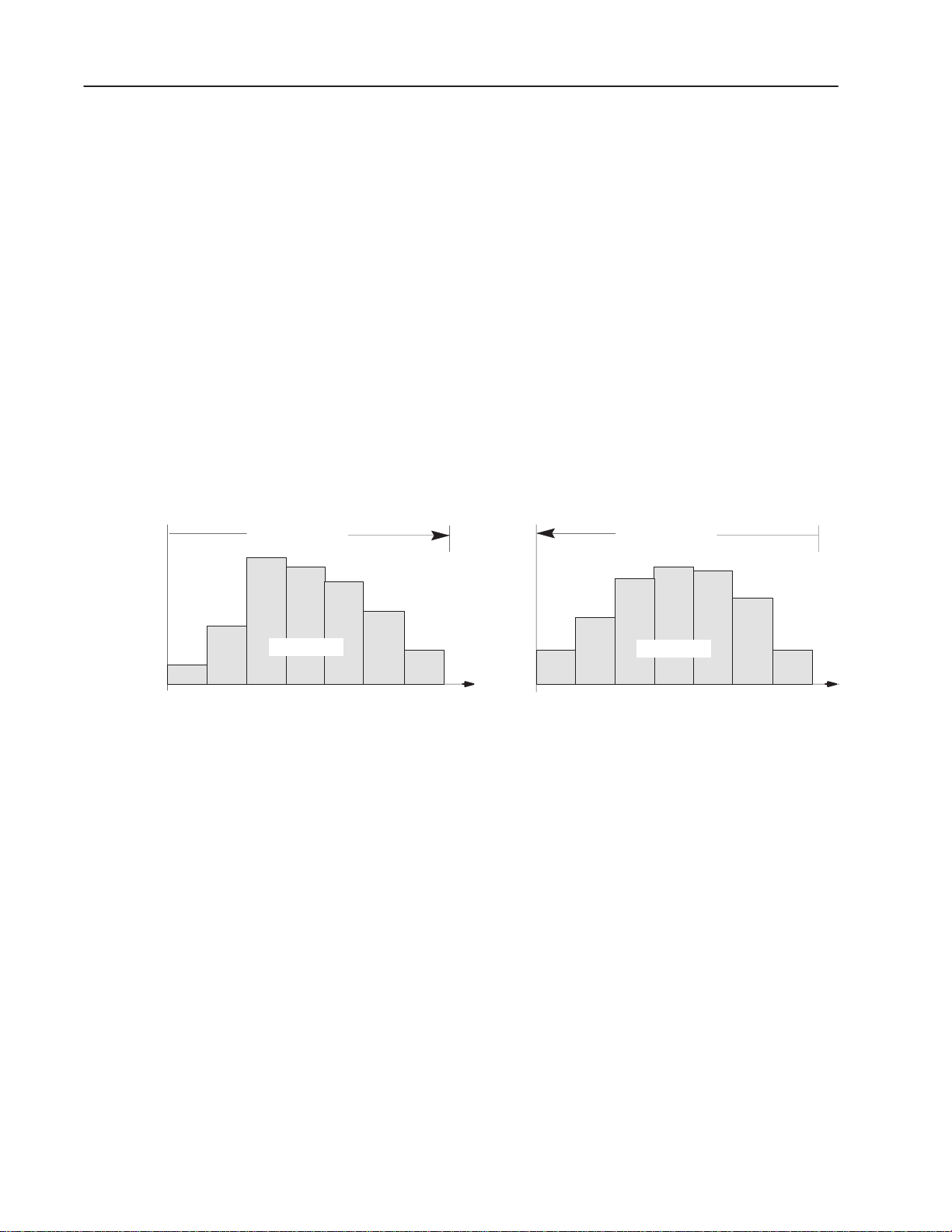

Because you can change the speed of the hydraulic ram with extend

and retract profiles and store additional profiles (recipes) in data

table iNteger (N) files, this control system has these benefits:

• reduced cycle time – you can increase ram speed for faster operation

• reduced or eliminated pressure spikes and water-hammering for

smoother operation and less wear and tear on the machine –

you can profile accelerations and decelerations of the hydraulic ram

• energy savings – you can match the speed of the hydraulic pump

to the force that you need

• faster new-part change-over – you can store your setups and

minimize mechanical re-adjustments between parts

The 1746-QV module executes the extend and retract profiles that you

load to control the motion of the hydraulic ram. You can program up

to seven different voltages over the length of travel in both the extend

and retract directions to control how the ram accelerates or decelerates.

Retract Direction

4

5

6

7

Voltage

1

3

2

Segments

5

6

7

LDT

What Are Typical Applications?

LDT

Each position setpoint triggers a corresponding voltage output in the

range of –10V to +10V dc that translates into speed. The LDT

provides high-speed position updates to the module for consistent and

repeatable motion.

Use the 1746-QV module in an SLC-based system for low-cost

control of:

• hydraulic machinery

• simple (non-CNC) hydraulic presses

• diecasting machinery

• welder placement

• pneumatic actuators for clamping or placement

In addition, the module is designed to support standard proportional

amplifiers and retrofit into most existing hydraulic systems.

Publication

1746-6.18 April 1998

Page 9

Procedure

Use this chapter as an abbreviated procedure for getting the 1746-QV

module into operation or as an overview if you need more information.

1746-QV Module

Input Terminal Block

(+) Gate Out

8

(–) Gate Out

7

(–) Interrogate

6

(+) Interrogate

5

Shield/Frame

4

–15V dc PS

3

PS Common

2

+15v dc PS

1

1.

Load Ladder Logic into Your Computer Chapter 3

Obtain the ladder program (appendix B) from Rockwell Software Bulletin Board (BBS) or the Internet.

From

BBS:

in the Allen-Bradley Products Library

directory

and decompress it with PKUNZIP available on BBS. The ladder program, VELMOD, is SLC500

code (65 Kbyte).

Download it into a hard drive subdirectory where your programming software looks for files.

.

The

(216) 646-ROCK (-7625). If a new user

, follow prompts to register

manual is in W

ord format. Download it

. Log in. Look for 1746QV

into a hard drive sub-

From Internet: webpage http://www.ab.com If a new user, click Join Now and follow prompts to

register. Log in. Search for QV: on homepage, click Search Our Site, insert QV in window, and click

button. The manual is PDF format and requires Adobe Acrobat viewer

search

. The ladder program is PDF

format and must be entered manually.

2.

Set Up Your Software Chapter 3

Configure the SLC Processor and I/O with your programming software. Enter the following:

a) processor type, b) module I/O-chassis slot, c) module ID (13115), d) G-file size (7 words), and

e) G-file configuration values from the ladder program (appendix B).

Modify N files for the profile found in the ladder program (appendix B) to suite your application.

3.

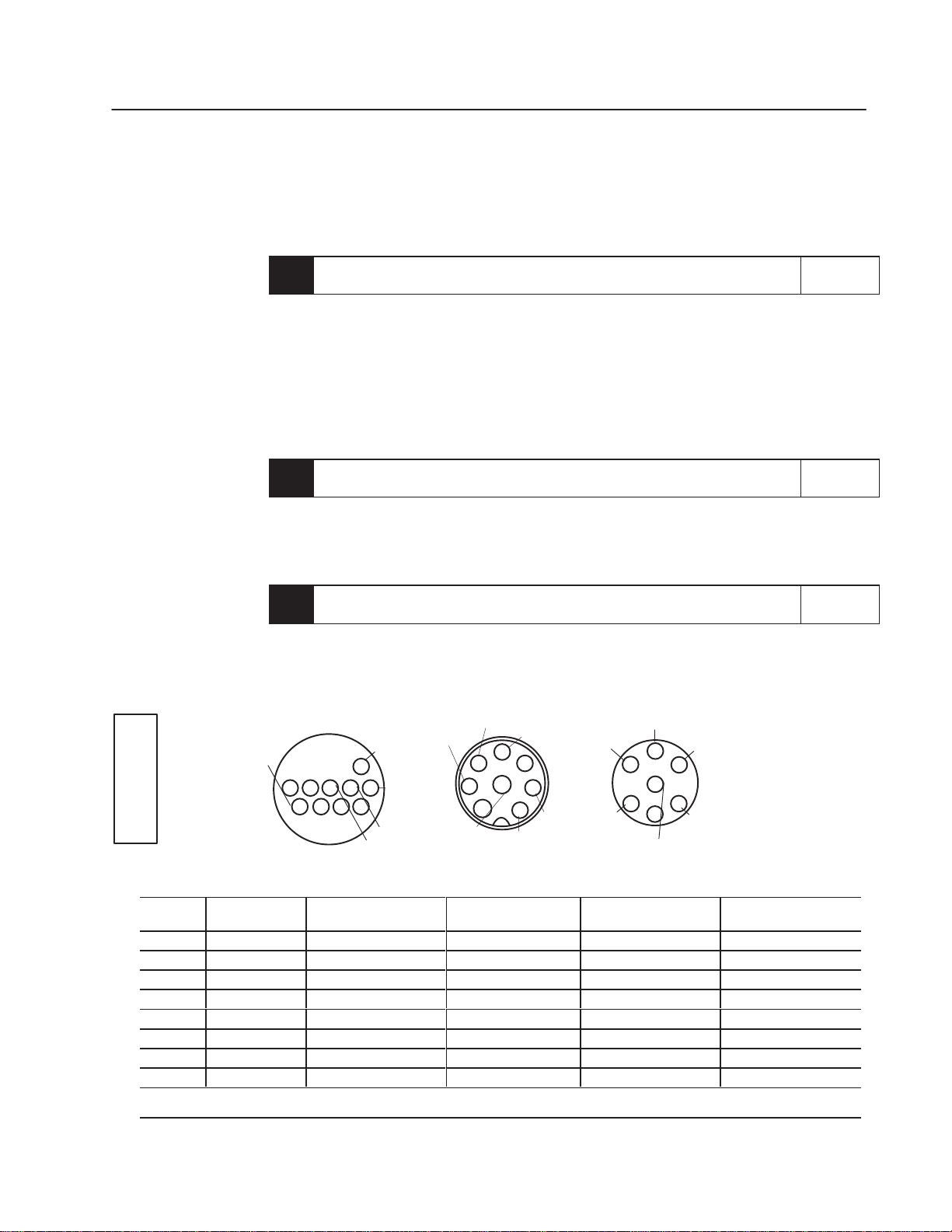

Connect the LDT to the Module’s Input Terminal Block Chapter 4

The following are connections between the 1746-QV module and typical LDTs such as

Temposonics, Balluff, Santest, and Gemco.

Interrogate

Temposonics II,

RPM or DPM

(+)

(+)

10

(–)

(–)

(–)

"15V

PS

Common

1

Frame

23456789

GND

(+)

Gate

Out

dc PS

The

views are looking at the connector on the LDT head.

Balluff

BTL-2-L2 & -2-M2

Interrogate (–)

3

"15V

dc PS

Gate

7 (+)

Out (–)

Gate

2

45

(–)

8

6

PS

Common

Out (+)

1

Interrogate (+)

Santest

GYRP & GYRG

+15V

dc PS

Gate

Out (+)

NC

1

5

Interrogate

2

4

6

PS

Common

3

(+)

7

(–)

Gate

Out (–)

Gemco Quick-Stick II

951VP

w/PWM

Output

B–BLK PS Common

C–RED +15V dc PS

K–GRY + Interrogate

E–BRN –Sq Wave Out*

F–BLU +Sq Wave Out*

A–WHT –Interrogate

G, D, H RS232RXD

J–PUR 2nd PS COM

*951RS has pulse trigger

1746-QV

Input Pin #

(+) and (–) wires of same function should be a twisted pair within the cable.

Note 1: In the table, we use the term “gate out” for pulse trigger or square wave (Gemco) and start/stop (Balluf

Function Temposonics II

8

(+) Gate Out

7

(–) Gate Out

6

(–) Interrogate

5

(+) Interrogate

4 Shield/Frame n/a

3

–15V dc PS

2 PS

1 +15V dc PS

Common

RPM or DPM

4 – Pink

3 – Gray

10 – Green

9 – Y

6 – Blue

1 – White

5 – Red

ellow

Balluff

BTL-2-L2 & -M2

2 – Gray (note 1)

5 – Green (note 1)

3 – Pink

1 – Yellow

n/a

8 – White

6 – Blue

7 – Brown

Santest

GYRP/GYRG

pin

5

pin

7

pin

6

pin

4

n/a n/a

n/a n/a

pin

3

pin

1

f -M2) LDT signals.

Publication

Gemco

Quick-

Stick 951VP/RS

F – Blue (note 1)

E – Brown (note 1)

A – White

K – Gray

B – Black

C – Red

1746-6.18 April 1998

Page 10

2–2

Quick Start

4.

Important:

output cable to a 0V connection in the amplifier

1746-QV

Terminal Block

5.

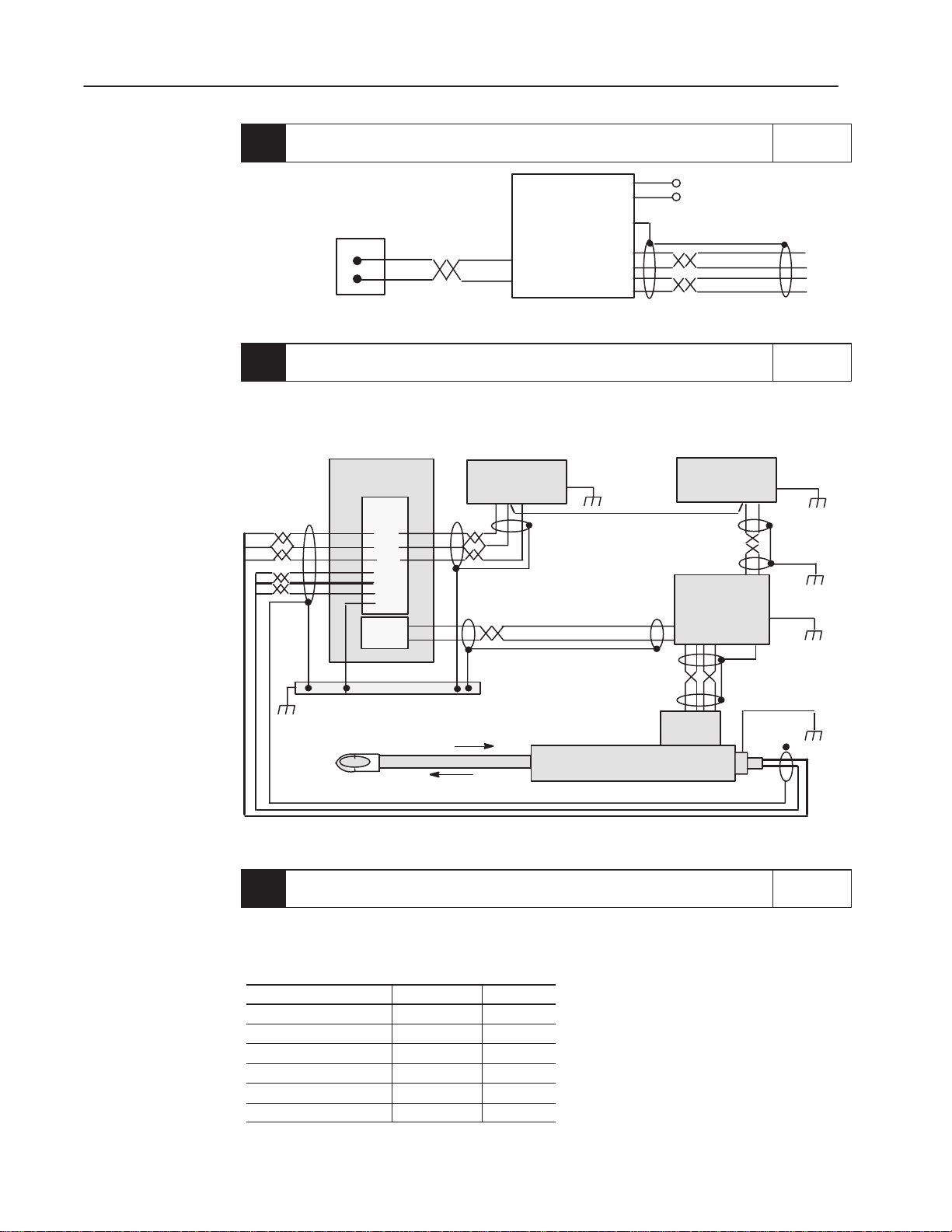

Connect Module Output Terminals to Output Devices With Correct Bonding Chapter 4

Connect the shield of the amplifier

Analog Output

("

Output

2

1

10v dc)

.

Servo Amplifier

(Proportional)

(+)

Dif

f.

Input

(–)

Outputs

to valves

0V

A

B

Minimize Interference from Electrical Noise with Correct Shielding and Grounding Chapter 4

Important: Connect PS output commons togerther.

Connect the following to earth ground: a) cable shields (except for amplifier outputs) at one end only

b) input terminal 4, c) case grounds of PS and amplifier, e) LDT flange.

Case

GND

Important:

connect PS output commons together

and isolate from earth ground.

Belden

8761

For correct bonding,

ransducer (LDT)

LDT

Power

LDT

Signals

1746-QV

Module

Input

1

2

3

5-8

4

2

Output

1

earth ground

"

15V PS

(+) (C) (–)

Belden

8770

Analog Output

Piston-type Hydraulic Cylinder and

Linear Displacement T

+24V dc PS

0V dc PS

Do NOT connect output

shields to earth ground

T

o solenoid A

T

o solenoid B

,

24V PS

(–) (+)

Servo

Proportional

Amplifier

0V

Valves

Case

GND

Belden

8761

Case

GND

Cable

Note

Cable Note: Use cable

recommended by the LDT

and amplifier manufacturer

Publication

1746-6.18 April 1998

LDT

Cable

.

Note

6.

After

loading profiles with the ladder program (step 1), alternately

Operate the Module for the First time Chapter 5

and Hydraulic Ram

run the extend profile (O:e.0/0 = 0-to-1),

then the retract profile (O:e.0/1 = 0-to-1). Modify the profile to reach the preset reference, and set it.

Important:

If motion is reversed: for a "10V dc output, change the sign (") of all extend/retract voltage

values; or for a +10V output, energize the other solenoid on the directional valve (with ladder logic).

To do this:

load all profiles 1 N7:40

set preset reference to zero

clear errors

read current position

run an extend profile

run a retract profile

Enter decimal:

8 N7:50

16 N7:50

read, only

1 N7:50

2 N7:50

at address:

N7:61

Page 11

Setting Up the Software

Chapter Objectives

Obtaining the Ladder Program Electronically from BBS or the Internet

This chapter helps you do the following:

• Obtain the ladder program electronically

• Configure your SLC processor off-line

• Modify N files in your SLC processor, off-line

• General conventions for profiles

• Profile operation

You can obtain ladder logic electronically and download it to your

SLC processor conveniently without the worry of data-entry errors.

About the Rockwell Bulletin Board System (BBS)

You can access the Rockwell Software Bulletin Board System (BBS)

by modem. Anyone is welcome. The BBS provides utilities, examples,

and technical information on Rockwell Software products and on

selected Allen-Bradley products.

• new users may:

– send and receive messages

– download General Access files

– upload files for review by technical support specialists

• verified customers may:

– search for new and existing files

– download files such as utilities, example programs, tech info

– access software bulletins

• subscribers to tech bulletins, DataDisc CD-ROM may:

– download tech bulletins of the Tech Bulletin Subscription series

User accounts are automatically generated online. We use our product

data base to verify BBS accounts at your initial log-in, and we adjust

your security level according to your support status. Should your

registration information change, you can update your account from the

“Configure System Defaults” menu.

To Access BBS:

1. Set your modem to no parity, 8 data bits, and 1 stop bit.

2. Dial (216) 646-ROCK (-7625).

3. Follow prompts to log in. New users must create a new account.

4. Look for 1746QV in the Allen-Bradley Products Library. The manual

is formatted in Microsoft Word and compressed with PKZIP. The

ladder program, VELMOD, is SLC code.

Publication

1746-6.18 April 1998

Page 12

3–2

Setting Up the Software

5. Download ladder program VELMOD (65 Kbyte SLC code) into the

subdirectory on your hard drive where your programming software

looks for files. With RSLogix: C:\ . . . RSLogix 500 English\Project.

6. Download the ladder program to your SLC processor.

7. Download the manual into a hard drive subdirectory. You must

decompress the Word version with PKUNZIP available on BBS.

To Access the Internet:

1. Access the Allen-Bradley webpage at:

2. To access the member area, you must log in. If you do NOT have

an account, click Join Now and follow the prompts to register.

3. Search for QV: on homepage, click Search Our Site, insert QV into

the window, and click Search button. The manual is PDF format and

requires Adobe Acrobat viewer. The ladder program is PDF format

and must be entered manually.

Configuring Your SLC Processor, Off-line

This procedure assumes you are using RSLogix500 Programming Software, version 2.10 or later. For other software, the procedure may vary.

1. Open your 1746-QV project,

VELMOD.

2. Configure the type of SLC processor. To do this:

A. Open the file, Controller Properties.

B. Select the SLC processor type and click OK.

3. Configure the rack size, module slot, and module ID:

A. Open the file, I/O Configuration.

B. Select the rack size.

C. Highlight the slot number for the module.

D. From the list of modules, scroll to 1746-QV and double–click.

If the module is not listed:

– Scroll to Other and double-click.

– Enter the module’s ID (13115) and double-click.

4. Size the “G” file:

A.Highlight 1746-QV (or 13115 if module was not listed).

B. Click [A

dv Config].

Publication

1746-6.18 April 1998

C. In the dialog box, enter a G-file length of 7.

D. Press [E

dit G Data].

Page 13

Setting Up the Software

For e a ple o enter an calibration of 8.9373

Configuration Bit

1 1 0

–16,384

–32,768

1 1 0

–16,384

towards

3–3

5. Enter values in the G file:

If the module was listed: If the module was not listed (you entered the ID):

You get the G–file Setup screen.

Enter data from the table, below.

You get the following display, shown in decimal radix.

Enter a value in each word as shown, next.

G–file display for unlisted module (shown in decimal radix):

Ge:0 2056 0 0 0 0 0 0

Enter a value at each G-file word address and press [ENTER].

Then cursor to the next word address and repeat. For example:

Ge:0 2056 893 730 12 1200 –32768 0

We used values from the ladder logic example (appendix B).

You will want to use G-file values that suit your application:

Word: Function of G-file Word: Range: Description of G-file Word or Bit: Example:

0 Reserved. Do NOT use. n/a The processor stores a code for the 1746-QV module. 2056

words 1 & 2 refer to the gradient or transducer calibration value stamped on the name plate on the transducer housing.

1 LDT calibration: upper 3 digits

2 LDT calibration: lower 3 digits

3 Full-scale length (L) of LDT 2vLv160 inch Enter the length of the LDT (160 inches max). 12

4 Full-scale count (C) 2vCvLx100 Typically C = L x 100.

5 Configuration Bits

15 14 13 12-0 Equivalent V

0 1 0 0

1 0 0 0

0 1 1 0

6 Preset Reference –32,768 to +32,767 Typically zero or home reference value. 32,767 = 327.67 inches. 0

+16,384

–32,768

0

0

+24,576

800-999 ms/inch

000-999 ms/inch

bits 0-12 Set to zero.

alue

bit 13 0 = output maintained during LDT fault while running profiles and

bit 14 Type of LDT: 0 for RPM, 1 for DPM

bit 15 0 = position data increases when moving away from LDT head

For example: To enter an LDT calibration of 8.9373,

use decimal radix and enter 893 in word 1 and 730 in word 2.

Position Data (I:e.1) = C/(L x 100)

LDT Calibration

during SLC mode change

1 = output resets for LDT fault and SLC mode change

1 = position increases when moving toward LDT head

893

730

1200

–32,768

(bit

15 = 1

for position

increases

towards

LDT head)

Examples of Full-scale Count Values

LDT Physical

Length

from 160” to 2” 1 0.01 L (160” to 2”) L x 100

16” 2 0.01 160 8000

16” 4 0.01 160 4000

16” 10 0.001 160 16000

No. of

Recirculations

Resolution

Full-scale

Length (L)

Full-scale

Counts (C)

Important: The module checks for invalid data such as out of

range values or the setting of reserved bits 0-12. You can clear a

data-entry configuration error only by re-entering a corrected value.

6. Save when done

.

Click OK. Click OK. Close window.

Publication

1746-6.18 April 1998

Page 14

3–4

Co and Bit

Enable these bits

/bit #)

with your ladder logic, where e

Setting Up the Software

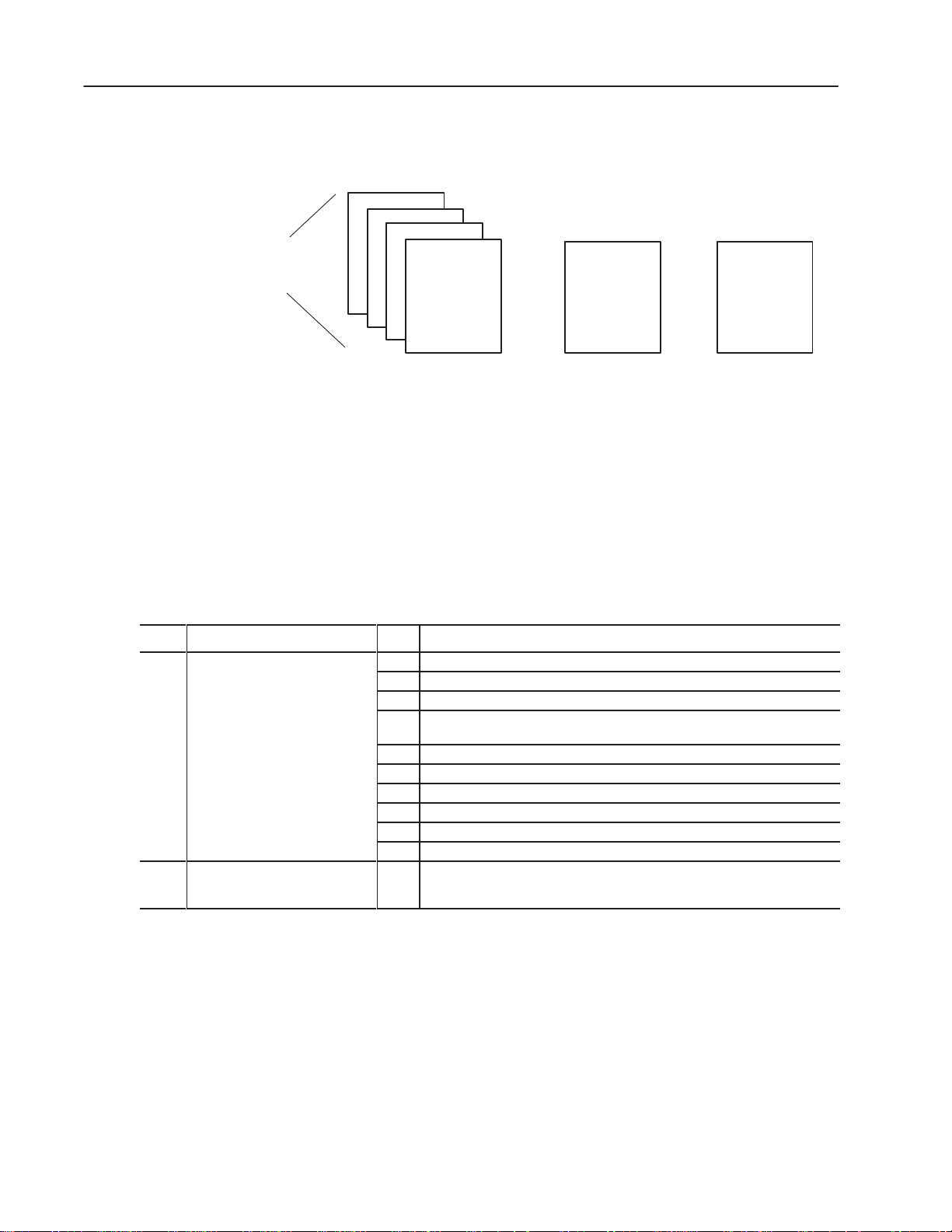

Modify N Files in Your SLC Processor, Off-line

A set of profile data

for initial configuration

One N file may contain the initial commands, setpoints, and values

for configuring the extend and retract profiles.

Retract Voltages

Retract Positions

Extend V

oltages

Extend Positions

Command

and

Setpoints

>>>

>>>

>>>

>>>

Output

Command

and

Setpoints

Image T

able

>>>

>>>

>>>

>>>

1746-QV

Extend

and Retract

Profiles

Module

The file contains commands and data starting at the these addresses:

• command and position setpoints for extend #N7:0

• command and voltage (velocity) values for extend #N7:10

• command and position setpoints for retract #N7:20

• command and voltage (velocity) values for retract #N7:30

The sample ladder program (appendix B) copies profile data into the

output image table from the above locations.

Output Image Table with Profile Data

Word: Function of Output Image Word: Bit #: Description: (For command bits, a 0-to-1 transition enables the command)

0 Command Bits

(O:e.0

represents the I/O slot number.

1-7 Position Setpoint or Voltage Value n/a Important: Position setpoints are in units of 0.01” (200 = 2.00”)

0 Set to run an extend profile.

1 Set to run a retract profile.

2 Set to disable the profile. This bit over-rides bit 0 or 1.

3 Set to change the current position data to the value of the preset reference

stored in Ge:6.

4 Set to clear any data-entry errors.

5 Set to define words 1-7 as programmed position setpoints for extend.

6 Set to define words 1-7 as programmed voltage values for extend.

7 Set to define words 1-7 as programmed position setpoints for retract.

8 Set to define words 1-7 as programmed voltage values for retract.

9-15 Reserved. Do NOT use.

within the range of –327.68” to +327.67”, and voltage values in

5mV units (3005 = 3.005V) within the range of "10,000mV.

The data monitor mode of your programming software displays the

data files shown below (with values from the ladder program).

Important: Modify these values to suit the preset reference chosen

for the G file and/or to match the LDT length.

Extend Positions: N7:0 32 –45 50 200 300 400 425 500 0 0

Extend V

Retract Positions:

Retract V

Publication

elocities: N7:10 64 3000 3750 4000 4000 4000 4000 4000 0 0

N7:20 128 –45 50 200 300 400 425 500 0 0

elocities: N7:30 256 5000 6000 6000 3000 1000 50 25 0 0

1746-6.18 April 1998

Page 15

Setting Up the Software

3–5

General Conventions for Profiles

Consider the following when you set up your profiles:

• Extend and retract define the profile with respect to the LDT head:

extend is always away from the head, retract is always towards it

• Position data changes direction depending on how you set

configuration bit Ge:0/15 for LDT motion:

0 = position data increases when moving away from LDT head

1 = position data increases when moving towards LDT head

• Each position setpoint triggers from the absolute position data

(I:e.1) as modified by the preset reference.

• Position setpoints are in units of 0.01”.

For example, enter 2” as 200.

• If you enter position setpoints in random order, the module places

them in ascending order (P1 = lowest and P7 = highest) with their

associated voltage value.

• Speed segments are defined increasing from the LDT head,

regardless of position data direction.

• Speeds are reported in the input image table words 2-7 (I:e.2-I:e.7)

for the previous profile (extend speeds reported during the next

retract profile and vice versa)

• Voltage values (for speed) are in the range of "10,000mV in

multiples of 5mV. For example, enter –5.005V as –5005.

Important: Enter voltage values in multiples of 5mV or the module

will fault, causing you to correct and re-download the profile.

Profile Operation

• Voltage values are cleared when you re-program position

setpoints. The profile is cleared when the module loses power or

when you change the value of any G-file configuration word.

Important: Your application may require different position setpoints

and voltage values. Your profiles must be consistent with the physical

parameters of the LDT and G file to guard against damaging hardware.

In general:

• For relatively faster and smoother motion, use two speed segments

for acceleration and five speed segments for deceleration.

• Adjust the ramp rate on the proportional amplifier for the smoothest

operation. Initially, start with the ramp disabled (fastest ramp rate).

• You may compensate for deadband or valve overlap by specifying a

voltage value greater than or equal to the valve’s bias current.

Profile operation depends on how the module reports position data.

With the data-direction bit (Ge:0/15), you select whether:

– position data increasing towards the LDT head (Ge:0/15 = 1)

– position data increasing away from the LDT head (Ge:0/15 = 0)

Publication

1746-6.18 April 1998

Page 16

3–6

Setting Up the Software

For

Position Data Increasing Towards LDT Head (Ge:0/15 = 1)

Voltage

Output = 0

past position 1

Position

Position

Voltage

Output = 0

past position 7

Position

V1

Speed

Segment 6

V2 V3 V4

Speed

Segment 5

Speed

Segment 4

Speed

Segment 3

V5 V6 V7

Speed

Segment 2

Speed

Segment 1

P7P6P5P4P3P2P1

• Starting with the ram between P7 and the LDT head (open position),

running the extend profile results in V7 applied to the output.

As the ram passes below P7, V6 is applied to the output, etc.

• If the ram passes below P1, the output is forced to 0V dc, and the

profile is disabled. You must load new data to operate the profile.

• Placement operations require two segments.

For example, if P2 = 6.07”, V2 = 1.500V, P1 = 0.00” (or a value

less than P2), and V1 = –1.500V, then the module will place the

ram in the vicinity of P2 (between 6.02 and 6.12). The negative

voltage V1 causes motion to reverse or stop. To see this, enter the

example values for P2, V2, P1, and V1 in the previous diagram.

Data Increases from LDT Head (Ge:0/15 = 0)

V7

Speed

Segment 6

V6 V5 V4

Speed

Segment 5

Speed

Segment 4

Speed

Segment 3

P4P5P7

V3 V2 V1

Speed

Segment 2

Speed

Segment 1

P1P2P3P6

LDT

head

LDT

head

• Starting with the ram between P1 and the LDT head (open position),

running the extend profile results in V1 applied to the output.

As the ram passes P1 towards P2, V2 is applied to the output, etc.

• If the ram passes P7, the output is forced to 0V dc, and the extend

profile is disabled. You must load new data to operate the profile.

Publication

1746-6.18 April 1998

Page 17

Setting Up the Hardware

Chapter Objectives

Connect the LDT to Module Inputs

1746-QV Module

Input Terminal Block

(+) Gate Out

8

(–) Gate Out

7

(–) Interrogate

6

(+) Interrogate

5

Shield/Frame

4

–15V dc PS

3

PS Common

2

+15v dc PS

1

Interrogate

Temposonics II,

RPM or DPM

(+)

(–)

(+)

10

(–)

(–)

This chapter helps you install the hardware with these tasks:

• connect the LDT to module input terminals

• connect module output terminals to output devices

• minimize interference from radiated electrical noise

• considerations for the "15V dc power supply

• other design considerations

We assume that you will use one of the following types of LDT:

• Temposonics II: RPM TTSRxxxxxxR, or

DPM TTSRxxxxxxDExxx

• Balluff: BTL-2-L2, or BTL-2-M2

• Santest: GYRP, or GYRG

• Gemco Quick-Stick II: 951VP, or 951 RS

We illustrate typical connections between the 1746-QV module and

these types of LDTs. (There are other suppliers with compatible LDTs.)

Balluff

BTL-2-L2 & -2-M2

Gate

Out (–)

Gate

Out (+)

2

45

(–)

8

3

7 (+)

6

PS

Common

1

Interrogate (+)

+15V

dc PS

Gate

Out (+)

Frame

GND

Out

Interrogate (–)

"15V

dc PS

"15V

PS

Common

1

23456789

(+)

Gate

dc PS

The views are looking at the connector on the LDT head.

Santest

GYRP & GYRG

NC

PS

Common

2

1

5

Interrogate

3

(+)

4

7

(–)

6

Gate

Out (–)

Gemco Quick-Stick II

951VP

w/PWM

Output

B–BLK PS Common

C–RED +15V dc PS

K–GRY + Interrogate

E–BRN –Sq Wave Out*

F–BLU +Sq Wave Out*

A–WHT –Interrogate

G, D, H RS232RXD

J–PUR 2nd PS COM

*951RS has pulse trigger

Connect each 1746-QV input pin # to the corresponding LDT pin #.

1746-QV

Input Pin #

(+) and (–) wires of the same function should be a twisted pair within the cable.

Note 1: In the table, we use the term “gate out” for pulse trigger or square wave (Gemco) and start/stop (Balluff -M2) LDT signals.

Function Temposonics II

RPM or DPM

Balluff

BTL-2-L2 & -M2

Santest

GYRP/GYRG

Gemco QuickStick 951VP/RS

8 (+) Gate Out 4 – Pink 2 – Gray (note 1) pin 5 F – Blue (note 1)

7 (–) Gate Out 3 – Gray 5 – Green (note 1) pin 7 E – Brown (note 1)

6 (–) Interrogate 10 – Green 3 – Pink pin 6 A – White

5 (+) Interrogate 9 – Yellow 1 – Yellow pin 4 K – Gray

4 Shield/Frame n/a n/a n/a n/a

3 –15V dc PS 6 – Blue 8 – White n/a n/a

2 PS Common 1 – White 6 – Blue pin 3 B – Black

1 +15V dc PS 5 – Red 7 – Brown pin 1 C – Red

Publication

1746-6.18 April 1998

Page 18

4–2

Setting Up the Hardware

Connect Module Outputs to Output Devices

1746-QV

Output

Terminal Block

Module outputs connect to a separate 2-conductor output terminal

block located beneath the input terminal block.

+24V dc PS

0V dc PS

Analog Output

("

2

1

10v dc)

Servo Amplifier

(Proportional)

(+)

Dif

f.

Input

(–)

Outputs

to valves

Important:

output cable to a 0V connection in the amplifier

Do not connect the shield to earth ground.

0V

A

B

Ground the shield of the amplifier

T

o solenoid A

T

o solenoid B

.

Note: Follow manufacturer recommendations for shielding the output

cables of the proportional amplifier. Typically, pulse-width modulated

outputs radiate electrical noise originating from the +24V dc power

supply, so isolate the shields of the amplifier output cable to a 0V dc

connection inside the proportional amplifier.

You have a choice of three configurations to match your hydraulics:

• proportional amplifier with ramp and proportional valve

• servo amplifier with ramp and variable-volume pump

• Allen-Bradley 1305 Drive and hydraulic pump

Minimizing Interference from Radiated Electrical Noise

You may use either of the following output voltage ranges:

• 0-10V dc for the Allen-Bradley 1305 Drive or variable-volume pump

• –10 to +10V dc for the proportional amplifier and proportional valve

Important: Signals in this type of control system are very susceptible

to radiated electrical noise. The module is designed to set the loss-ofsensor bit I:e.0/8 and the LDT-error bit I:e.0/0 when it detects position

values that are lost or corrupted by electrical noise.

Connect module output terminals to output devices with correct bonding:

• connect power supply output commons together

• electrically isolate power supply output commons from earth ground

• use bond wires that are equal in size to signal wires

Minimize interference from radiated electrical noise with correct

shielding and grounding:

• connect all of the following to earth ground:

– LDT flange, frame, and machine

– I/O chassis

– protective ground

– AC ground

– cable shields at one end only, preferably with 3/8” braid wire

(for analog output, "15V dc PS, 24V dc PS, and LDT)

– terminal 4 of the input terminal block

Publication

1746-6.18 April 1998

Page 19

Setting Up the Hardware

• run shielded cables only in low-voltage conduit

• place the SLC-500 processor, power supply, and I/O chassis

assembly in a suitable enclosure

Typical grounding and shielding for this type of control system:

4–3

LDT

Power

LDT

Signals

Cable Note: Use cable

recommended by the LDT

and amplifier manufacturer

.

Considerations for the

"15V dc Supply

Cable

Note

1746-QV

Module

Input

1

2

3

5-8

4

Output

earth ground

"

15V Power

Supply

(+) (C) (–)

Analog Output

Piston-type Hydraulic Cylinder and

Linear Displacement T

Case

GND

Belden

8770

Belden

8761

ransducer (LDT)

LDT

Belden

8761

Servo

Proportional

Amplifier

0V

and Hydraulic Ram

24V Power

Supply

(–) (+)

Cable

Note

Valves

Case

GND

Case

GND

Selection of the "15V Power Supply

The positive and negative supply of some "15V dc power supplies

decay at different rates when ac power is removed. The module’s

output will be biased, based upon the difference in voltage level

between the positive and negative supply. The duration is dependent

upon the magnitude of the difference and the decay rate. For these

reasons, the "15V dc power supply should have or be equipped with:

• proper interlocks with machine operation and e-stop circuits

• an internal voltage-sense relay that drops the "15V (without

variation in decay rates) upon loss of ac power

• auxiliary relay to indicate proper operation and voltage

(such as loss of +15V but not –15 V dc)

Power

Supply Loading

The module and LDT load the power supply typically as follows:

Supply No Transducer

No Load

+15V dc 86mA 128mA 141mA 128mA

–15V dc 14mA 30mA 30mA 40mA

*MTS Temposonics II, model T1SR0U0120R (Other LDTs will have different loading.)

Transducer

Only *

LDT + Module:

+10V dc @ 10mA

Publication

LDT + Module:

–10V dc @ 10mA

1746-6.18 April 1998

Page 20

4–4

Setting Up the Hardware

Application of the "15V Power Supply

The module uses the "15V dc power supply to drive the "10V dc

valve output and to power the LDT. The module detects loss of

"15V dc with its internal LDT diagnostic. The diagnostic

concludes loss of "15V when it detects loss of LDT magnet.

Partial failure of the "15V dc power supply may cause limited

machine operation when the LDT continues to operate properly. Some

LDTs will operate with its supply voltage down to 12V. If you monitor

the "15V dc with SLC diagnostics, you can enable a blocking valve

to lock the actuator in its last position upon detection of:

• e-stop

• power loss

• low voltage condition of the "15V dc supply

ATTENTION: If you provide a system e-stop circuit and design the

system to manage power to the SLC chassis and "15V dc supply, in

all cases DO NOT connect the e-stop to ac power for power supplies.

Other Design Considerations

ATTENTION: We recommend using reasonable methods to assure

that unintended motion does not cause machine damage or create a

safety issue with personnel who will operate the machine.

(Chapter 5 covers testing for proper system operation.)

• Use a proportional valve that does not respond to voltage spikes

created by power supply operation.

• Shut down the hydraulic system upon loss of ac power and

automatically vent pressurized fluid back to the tank.

• Provide ladder programming that interlocks the operation of the

power supply with permissives to run the hydraulic pump.

• Connect a high-speed relay between the module and the valve

amplifier to drop-out the valve signal upon loss of ac power.

Publication

1746-6.18 April 1998

Page 21

Operating the Module

for the First Time

Chapter Objectives

Power Up the System

This chapter outlines the steps for operating the module for the first

time with an operating hydraulic ram. We cover these steps:

• power-up the system

• test for proper system operation

• troubleshoot possible problems

Starting with module and LDT power turned off, bring the system

on-line for the first time as follows (refer to I/O wiring in chapter 4):

Check Wiring and Grounding

1. Disconnect the LDT connector at the head end.

2. Disconnect both of the module’s input and output terminal blocks.

3. Turn ON the power supplies for the LDT and SLC processor, and

check the LDT connector and module input terminal block for:

• pin 1 +15V dc

• pin 2 PS common

• pin 3 –15V dc

4. Observe that the module’s fault LED (red) is ON.

5. Verify NO continuity between pin 2 (PS commons) and pin 4

(shield/frame) on the module’s input terminal block.

6. Verify NO continuity between the LDT cable shield and pin 2

(PS commons) on the module’s input terminal block.

7. Verify continuity between pin 2 (PS commons) on the module’s

input terminal block and the output common on the "15V dc PS

that powers the LDT and module.

8. Verify continuity between pin 2 (PS commons) on the module’s

input terminal block and the (–) terminal on the +24V dc PS

that powers the proportional amplifier.

9. Verify NO continuity between the +24V dc PS (–) connection

and earth ground.

10.Verify continuity between the shield of the amplifier output cable

and pin 2 (PS commons) on the module’s input terminal block.

11. Verify continuity between the cable shield (Belden 8761 or

equivalent) on the +24V dc PS and earth ground.

Publication

1746-6.18 April 1998

Page 22

5–2

N

FA

Operating the Module

Get Ready to Move the Ram

1. Turn on the +24V dc PS that powers the amplifier.

2. Turn on the hydraulic pump and “null” the ram for no movement.

3. Turn off all power supplies.

4. Connect the LDT cable and input terminal block.

5. Turn on all power supplies.

6. Be sure that you have loaded the extend and retract profiles into

the module.

7. Observe module LEDs. The RUN LED (green) should be blinking.

If not blinking, refer to troubleshooting covered last in this chapter.

Module LEDs indicate the following to assist you with the procedures:

This LED: Is: When the Module detects:

RUN

(green)

FAULT

(red)

For Series A Revision A: During startup, Run LED ON and Fault LED

flashing indicate outputs are at 0V dc. During profiles, Fault LED is OFF.

Flashing output is at 0V dc

ON

OFF no internal faults

Flashing

ON an internal fault

profiles are loaded and output is active

an LDT fault

8. Observe that the output image table word 0 (O:e.0) is zero.

If not zero, toggle the value of N7:50 from 0 to 16 to 0.

Reload the profiles by entering the value of 1 into N7:40.

If profiles do not reload, refer to Troubleshooting on page 5-4.

9. With the output terminal block still disconnected, run the extend

profile by changing the value in N7:50 to 1. The RUN LED should

change to ON. If not, refer to troubleshooting covered last.

Important: Reset the value in N7:50 to 0.

10.Connect the output terminal block.

Move the Ram

Important: When you set an output bit with your programming

terminal, the commanded action takes place immediately.

1. Run the extend profile by momentarily changing the value in

N7:50 to 1, and observe the direction of ram movement in N7:61.

If the ram moves in the wrong direction:

If using this type of valve and signal: Then reverse the:

proportional valve with "10V input sign (") of all voltage values and load them into the module

hydraulic motor or ac drive with 0-10V input other solenoid on the directional valve (with ladder logic)

Publication

1746-6.18 April 1998

Page 23

Operating the Module

2. After reversing the sign of voltages (if needed), run the extend

profile again by changing the value in N7:50 to 1.

Observe that the direction of ram travel is correct.

Important: Reset the value in N7:50 to 0.

3. Check the position value reported in the status word, N7:61, as

you run the ram to the end of its travel. If the position data is

reversed, you may need to change the data-direction bit (Ge:5/15)

in the G file off-line as follows:

• 0 = position increases while moving away from LDT head

• 1 = position increases while moving toward LDT head

Important: You must reload profiles for either of these conditions:

• Changing a value in the G file. (This clears the profiles).

• When position data exceeds the position setpoint that is

farthest from the LDT head, the profile is disabled and

you must modify position setpoints and reload the profiles.

4. Verify operation of the retract profile by changing the value in

N7:50 to 2. Important: Reset the value in N7:50 to 0, afterwards.

5–3

Jog the Ram to the Reference Position

The reference position may require that you jog the ram beyond a

position defined by the profile in the ladder program (appendix B).

You may jog the ram as follows:

1. Observe the current position data (in I:e.1).

2. Modify profile position setpoint(s) to permit the ram to travel to the

required reference position using the current position. For example:

If position data reads –100, change P1 to –1300 (length of the LDT)

3. Important: Reset the value in N7:50 to 0.

Load the profiles into the module.

4. Run the extend profile by changing the value in N7:50 to 1, and

jog the ram to the reference position.

5. At the reference position, the position data, I:e.1, (N7:61) will be an

arbitrary value. Set the position data to the value of the preset

reference by changing the value in N7:50 to 8 (N7:40 must = 0).

Position data will change to preset reference (0 in this example).

6. Verify that N7:61 now reads zero at the reference position.

Important: Once you establish the reference position:

• the module will maintain the preset reference’s position data in I:e.1

• all profile position setpoints will be referenced to it

(until you clear Ge:6 by changing any G-file value or set another

reference position. The preset reference is retained during power up.

Publication

1746-6.18 April 1998

Page 24

5–4

Operating the Module

Test for Proper System Operation

Troubleshoot Possible Problems

ATTENTION: Test for proper system operation to verify that

precautions to guard against unexpected motion perform as intended.

(See Power Supply and Design Considerations in chapter 4)

Because of the wide variety of applications for this module, we leave

the procedural details to you.

Look for proper system operation as you test for these conditions:

• controlled system startup/shutdown when turning hydraulics on/off

• startup/shutdown of ac to power supplies

("15V dc, SLC chassis, and 24V dc)

• loss of LDT input

• effect of the last-state-of-output bit (G-file, word 5, bit 13)

regarding one or more of the above

Using Status Bits for Errors Detected by the Module

The module is designed to detect and indicate status as follows

(in the input image table word I:e.0 or N7:60 in the ladder program):

• hardware operational faults

• data entry errors when entering setpoints or setting control bits

• acknowledgement of stored setpoints

Important: To clear error bits, toggle N7:50 from 0 to 16 to 0.

Bit #: Description: (for error & fault bits 0-8, status of 0 = OK, status of 1 = fault.)

0 The module sets this LDT error bit when it detects a:

– broken or mis-wired LDT cable

– faulty LDT

– incompatible LDT type (DPM or RPM)

– missing LDT magnet

– loss of "15V dc PS

1 Module fault, such as EEPROM error. May turn outputs OFF (fault dependent)

2 The module sets this bit when it detects any of the following invalid command bits

or bit combinations in output image table word 0 (O:e.0):

– one or more of the reserved bits 9-15 were set

– bit 5 or 7 (position) was set concurrently with bit 6 or 8 (voltage)

– output enable bit 0 (extend) or 1 (retract) was set before loading valid profiles

– both output enable bits 0 (extend) and 1 (retract) were set concurrently

– started to run a profile after the module had flagged an LDT error (I:e.0/0)

3 You set one or more of the reserved bits 0-13 in G-file word 5 (Ge:5).

4 You entered an invalid length (word 3) or count (word 4) in the G file.

5 You entered an invalid LDT calibration (words 1 and/or 2) in the G file.

6 You entered position setpoint outside the range –32,768 to +32,767 in O:e.1-O:e.7.

7 You entered a voltage value outside the range of "10,000mV in O:e.1-O:e.7.

8 Loss of sensor. The module detected position data (in I:e.1) greater than the LDT

length plus the preset reference. Clear this bit by running a profile.

9-11 Reserved. Do NOT use.

Publication

1746-6.18 April 1998

Page 25

Operating the Module

ha wrong ign .

Module reect pre- et reference when

Profile will not load into the odule.

Bit #: Description: (for error & fault bits 0-8, status of 0 = OK, status of 1 = fault.)

12 The module sets this bit after it stores retract position setpoints or voltage values,

or when retract profile is active. It remains set until another operation is performed.

13 The module sets this bit after it stores your position setpoints.

It resets it after you reset the “program position” bit (O:e.0/5 or O:e.0/7)

14 The module sets this bit after it stores your voltage values.

It resets it after you reset the “program voltage” bit (O:e.0/6 or O:e.0/8)

15 The module sets this bit when it detects the profile is active (output is applied).

Troubleshooting Table

If you observe this condition: Try this solution: Refer to this part of the manual:

5–5

Sensor signal (N7:61)

has wrong sign ().

After download, sensor values do not

match values in N7:61 before download.

Module rejects pre-set reference when

N7:50 is toggled from 0 to 8 to 0.

Profiles will not load into the module.

Unable to initiate extend/retract profiles. Write ladder rung for extend profile, another for retract.

1. Change direction bit (Ge:5/15) and re–download. a) Enter values in G file, page 3-3.

2. Calibrate the sensor at opposite end of cylinder. Re-do Jog Ram to Reference, pg 5-3.

After axis calibration (preset ref = set, and N7:50 = 8),

you must upload and save SLC data files in the PC.

1. Pre-set Ref in G file must be within profile range. Enter values in G file, page 3-3.

2. N7:40 must = 0 when setting N7:50 = 8.

1. Each profile setpoint must be within sensor’s range. Verify full-scale count in Ge:4, page 3-3.

2. Clear any errors by toggling N7:50 (0 to 16 to 0) Prior to step 8 in Get Ready to Move Ram.

3. N7:40 must = 0 when setting pre-set reference

with N7:50 = 8.

Each must include appropriate permissives to enable

a MOV instruction with Source (1 = extend, 2 = retract)

and Destination = N7:50.

Conditions That Control Module Outputs

The module is designed to control its outputs as follows:

The module is designed to: When these conditions are satisfied:

apply profile voltages

to the output

retain its outputs

in last state

turn OFF its outputs any of the following:

all of the following:

– valid extend and retract profiles are stored in the module

– the “stop profile” bit (O:e.0/2) is reset.

– a “run profile” bit (O:e.0/0 or O:e.0/1) is set

any of the following:

– loss of backplane power ("15V dc PS remains applied)

– loss of sensor (LDT)

– SLC mode change or LDT fault (G:e:0/13 = 0)

– LDT position exceeded the setpoint farthest from LDT head

– loss of "15V dc PS

– the “disable output” bit (O:e.0/2) is set

– SLC mode change or LDT fault (G:e:0/13 = 1)

b) Move the Ram, step 3, page 5-3.

none

Re-do Jog Ram to Reference, pg 5-3.

Jog Ram to Reference, step 5, pg 5-3.

none

Publication

1746-6.18 April 1998

Page 26

5–6

Notes:

Operating the Module

Publication

1746-6.18 April 1998

Page 27

Electrical Specifications

Module Specifications

This appendix lists the specifications for the

1746-QV Open-loop Velocity Control Module.

215 mA at 5V dc (from backplane)

Power Requirements

I/O Chassis Location Any I/O-chassis slot except slot 0

Isolation

LDT Inputs

Compatible LDT Input Devices

Module Range

and Resolution

Analog Output

Accuracy of Voltage Output Within "1% of its programmed value

Module Update Time 2 ms

400 mA at +15V dc and 295 mA at –15V dc

(from independent PS, typical but LDT dependent)

1500V ac optical isolation

between LDT input and backplane

"Interrogate

"Gate

"15V dc PS

PS Common

Shield/Frame

Linear Displacement Transducer such as:

Balluff BTL-2-L2 or -M2

Gemco Quick-Stick II

Santest GYRP or GYRG

Temposonics II with DPM or RPM

160 inches

"0.01 inch

0-10V dc @ 250 mA or

–10 to +10V dc @ 250 mA

Physical Specifications

Environmental Specifications

Run ON Profile running, Output active

(green): Flashing Output at 0V dc

LED Indicators

Module ID Code 13115

Maximum Wire Size Two 18 AWG wires per terminal on terminal block

Operating Temperature

Storage Temperature

Relative Humidity 5% to 95% (without condensation)

Agency Certification

(when marked on

product or package)

Fault OFF Module OK

(red): Flashing LDT fault

ON Module fault

0°C to 60°C (32°F to 140°F)

–40°C to +85°C (–40°F to +185°F)

CE marked for all applicable directives

Publication

1746-6.18 April 1998

Page 28

Notes:

Module SpecificationsA–2

Publication

1746-6.18 April 1998

Page 29

The following data define extend and retract profiles for the

sample program:

Extend position setpoints #N7:0

Extend voltage values #N7:10

Retract position setpoints #N7:20

Retract voltage values #N7:30

This ladder program loads profiles into the module through the output

image table. (The 1746-QV module is in slot 1 for this example.)

Rung 2.0 Program Profile |

| S:1 N7:40 |

|–––] [––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––(L)–––––––+

| 15 0 |

|

Rung 2:1 |

| Set to |Extend |Positions |Voltages |

| program |profile |stored |stored |

| profile |complete Extend Position Setpts. |

| |

| N7:40 N7:8 I:1.0 I:1.0 +COP–––––––––––––––+ |

|–––] [–––––––––]/[–––––––]/[––––––––]/[––––––––––––––––––+COPY FILE +–|

| 0 0 13 14 |Source #N7:0| |

| |Dest #O:1.0| |

| |Length 8| |

| +––––––––––––––––––+ |

Rung 2:2

| Set to |Extend |Positions |Voltages |

| program |profile |stored |stored |

| profile |complete Extend Velocity Setpts. |

| |

| N7:40 N7:8 I:1.0 I:1.0 +COP–––––––––––––––+ |

|–––] [–––––––––]/[–––––––] [––––––––]/[––––––––––––––––––+COPY FILE +–|

| 0 0 13 14 |Source #N7:10| |

| |Dest #O:1.0| |

| |Length 8| |

| +––––––––––––––––––+ |

Rung 2:3

| Set to |Extend |Run/store |Positions |Voltages Extend |

| program |profile |retract |stored |stored profile |

| profile |complete complete |

| |

| N7:40 N7:8 I:1.0 I:1.0 I:1.0 N7:8 |

|–––] [–––––––––]/[–––––––]/[––––––––]/[––––––] [––––––––––––––––+––––(L)––––+–|

| 0 0 12 13 14 | 0 | |

| | Program | |

| | extend | |

| | voltages | |

| | O:1.0 | |

| +––––(U)––––+ |

| 6 |

Rung 2:4

| Set to |Extend |Positions |Voltages |

| program |profile |stored |stored |

| profile |complete Retract Position Setpts.|

| |

| N7:40 N7:8 I:1.0 I:1.0 +COP–––––––––––––––+ |

|–––] [–––––––––] [–––––––]/[––––––––]/[––––––––––––––––––+COPY FILE +–|

| 0 0 13 14 |Source #N7:20| |

| |Dest #O:1.0| |

| |Length 8| |

| +––––––––––––––––––+ |

Publication

1746-6.18 April 1998

Page 30

Ladder ProgramB–2

Rung 2:5

| Set to |Extend |Run/store |Positions |Voltages |

| program |profile |retract |stored |stored |

| profile |complete Retract Velocity Setpts.|

| |

| N7:40 N7:8 I:1.0 I:1.0 I:1.0 +COP––––––––––––+ |

|–––] [–––––––––] [–––––––] [––––––––] [––––––]/[––––––––––––+COPY FILE +–|

| 0 0 12 13 14 |Source #N7:30| |

| |Dest #O:1.0| |

| |Length 8| |

| +–––––––––––––––+ |

Rung 2:6

| Set to |Extend |Run/store |Positions |Voltages Retract |

| program |profile |retract |stored |stored profile |

| profile |complete complete |

| |

| N7:40 N7:8 I:1.0 I:1.0 I:1.0 N7:8 |

|–––] [–––––––––] [–––––––] [––––––––]/[––––––] [––––––––––––––––+––––(L)––––+–|

| 0 0 12 13 14 | 1 | |

| | Program | |

| | retract | |

| | voltages | |

| | O:1.0 | |

| +––––(U)––––+ |

| 8 |

Rung 2:7

| Set to |Extend |Retract Loading |

| program |profile |profile profiles |

| profile |complete |complete complete |

| |

| N7:40 N7:8 N7:8 N7:40 |

|–––] [–––––––––] [–––––––] [––––––––––––––––––––––––––––––––––––+––––(U)––––+–|

| 0 0 1 | 0 | |

| | Extend | |

| | Profile | |

| | Complete | |

| | N7:8 | |

| +––––(U)––––+ |

| | 0 | |

| | Retract | |

| | Profile | |

| | Complete | |

| | N7:8 | |

| +––––(U)––––+ |

Rung 2:8 1

| Set to |

| program |

| profile |

| |

| N7:40 +COP–––––––––––––––+ |

|–––]/[–––––––––––––––––––––––––––––––––––––––––––––––+–+COPY FILE +–+–|

| 0 | |Source #I:1.0| | |

| | |Dest #N7:60| | |

| | |Length 8| | |

| | +––––––––––––––––––+ | |

| | | |

| | +MOV–––––––––––––––+ | |

| +–+MOVE FILE +–+ |

| |Source N7:50 | |

| | 0 | |

| |Dest O:1.0 | |

| | 0 | |

| +––––––––––––––––––+ |

Rung 2:9

|–––––––––––––––––––––––––––––––––––+END+––––––––––––––––––––––––––––––––––––––+

Extend Positions

Extend V

oltages

Retract Positions

Retract V

oltages

G-file for Module

Configuration

Publication

1746-6.18 April 1998

Address Data

(radix = DECIMAL)

#N7:0 32 –45 50 200 300 400 425 500 0 0

#N7:10 64 3000 3750 4000 4000 4000 4000 4000 0 0

#N7:20 128 –45 50 200 300 400 425 500 0 0

#N7:30 256 5000 6000 6000 3000 1000 50 25 0 0

G1:0 2056 890 640 12 1200

SLC Code for

QV Module

LDT

Calibration

Length Counts

–32,768 0

Config W

ord 5

bit 15=1

(position increases

toward LDT head)

Preset

Reference

Page 31

Input Image Table

SLC Processor Files

You use the following files when programming the SLC processor

for an application with the 1746-QV module:

• input image table to indicate status

• G file to configure the module for its LDT

• output image table for commands and loading profiles

Word 0 (I:e.0 or N7:60 in the ladder program) reports status such as

hardware faults, your data-entry errors, and acknowledgement of

profile data stored in the module. Word 1 reports position data.

Words 2-7 report speeds of the previous profile.

Word #: Bit #: Description: (for error & fault bits 0-8, status of 0 = OK, status of 1 = fault.)

0

1 n/a Position data

2-7 n/a Speed segments 1-6, respectively

0 The module sets this LDT error bit when it detects a:

– broken or mis-wired LDT cable

– faulty LDT

– incompatible LDT type (DPM or RPM)

– missing LDT magnet

– loss of "15V dc PS

1 Module fault, such as EEPROM error. May turn outputs OFF (fault dependent)

2 The module sets this bit when it detects any of the following invalid command bits or bit

combinations in output image table word 0 (O:e.0):

– one or more of the reserved bits 9-15 were set

– bit 5 or 7 (position) was set concurrently with bit 6 or 8 (voltage)

– output enable bit 0 (extend) or 1 (retract) was set before loading valid profiles

– both output enable bits 0 (extend) and 1 (retract) were set concurrently

– started to run a profile after the module had flagged an LDT error (I:e.0/0)

3 You set one or more of the reserved bits 0-13 in G-file word 5 (Ge:5).

4 You entered an invalid length (word 3) or count (word 4) in the G file.

5 You entered an invalid LDT calibration (words 1 and/or 2) in the G file.

6 You entered a position setpoint outside the range of –32,768 to +32,767 in O:e.1-O:e.7.

7 You entered a voltage value outside the range of "10,000mV in O:e.1-O:e.7.

8 Loss of sensor. The module detected position data (in I:e.1) greater than the LDT

length plus the preset reference. Clear this bit by running a profile.

9-11 Reserved. Do NOT use.

12 The module sets this bit after it stores the retract position setpoints or voltage values, or

when the retract profile is active. It remains set until another operation is performed.

13 The module sets this bit after it stores your position setpoints.

It resets it after you reset the “program position” bit (O:e.0/5 or O:e.0/7)

14 The module sets this bit after it stores your voltage values.

It resets it after you reset the “program voltage” bit (O:e.0/6 or O:e.0/8)

15 The module sets this bit when it detects the profile is active (output is applied).

.

The module computes the speed of each segment and reports them in the subsequent

profile (reports extend speeds during the next retract profile, etc.)

Publication

1746-6.18 April 1998

Page 32

SLC Processor FilesC–2

For e a ple o enter an calibration of 8.9373

1 0 0 0

–32,768

0 1 1

+24,576

increa e

towards

0 1 1

+24,576

head

Co and Bit

Enable these bit

with your ladder logic.

G File

Use this file (Ge:0) to configure the module for use with the LDT.

Example values are those from the sample ladder logic (appendix B).

Word: Function of G-file Word: Range: Description of G-file Word or Bit: Example:

0 Reserved. Do NOT use. n/a The processor stores a code for the 1746-QV module. 2056

words 1 & 2 refer to the gradient or transducer calibration value stamped on the name plate on the transducer housing.

1 LDT calibration: upper 3 digits

2 LDT calibration: lower 3 digits

800-999 ms/inch

000-999 ms/inch

For example: To enter an LDT calibration of 8.9373,

use decimal radix and enter 893 in word 1 and 730 in word 2.

3 Full-scale length (L) of LDT 2vLv160 inch Enter the length of the LDT (160 inches max). 12

4 Full-scale count (C) 2vCvLx100 Typically C = L x 100.

1200

Position Data (I:e.1) = C/(L x 100)

LDT Calibration

5 Configuration Bits

15 14 13 12-0 Equivalent V

0 1 0 0

1 0 0 0

1 1 0 0

0

0

+16,384

–32,768

–16,384

bits 0-12 Set to zero.

alue

bit 13 0 = output maintained during LDT fault or SLC mode change

1 = output resets for LDT fault or SLC mode change

bit 14 Type of LDT: 0 for RPM, 1 for DPM

–32,768

(bit

for position

increases

LDT head)

bit 15 0 = position data increases when moving away from LDT head

1 = position increases when moving toward LDT head

6 Preset Reference –32,768 to +32,767 Typically zero or home reference value. 32,767 = 327.67 inches. 0

Examples of Full-scale Count Values

893

730

15 = 1

Output Image Table

Word: Function of Output Image Word: Bit #: Description: (For command bits, a 0-to-1 transition enables the command)

0 Command Bits

1-7 Position 1-7 Setpoint or Voltage

(i.e. word 2 = position 2, etc.)

LDT Physical

Length

No. of

Recirculations

Resolution

Full-scale

Length (L)

Full-scale

Counts (C)

from 160” to 2” 1 0.01 L (160” to 2”) L x 100

16” 2 0.01 160 8000

16” 4 0.01 160 4000

16” 10 0.001 160 16000

The ladder program loads commands and profile data into the

module through the output image table, O:e.0–O:e.7.

0 Set to run an extend profile.

s

1 Set to run a retract profile.

2 Set to disable the profile. This bit over-rides bit 0 or 1.

3 Set to change current position data to the value of preset reference in Ge:6.

4 Set to clear any data-entry errors.

5 Set to define words 1-7 as programmed position setpoints for extend.

6 Set to define words 1-7 as programmed voltage values for extend.

7 Set to define words 1-7 as programmed position setpoints for retract.

8 Set to define words 1-7 as programmed voltage values for retract.

9-15 Reserved. Do NOT use.

n/a Important:

Enter position setpoints in units of 0.01” (200 = 2.00”) within the range of

–327.68 to +327.67”, and voltage values in 5mV units (3005 = 3.005V)

within the range of "10,000mV.

Publication

1746-6.18 April 1998

Page 33

A

access

to BBS or Internet, 3-1, 3-2

applications of module, 1-2

B

BBS, Rockwell Software Bulletin Board, 3-1

benefits, of module, 1-2

bits

command, 3-4, C-2

G-file configuration, 3-3, B-2, C-2

status, 5-4, C-1

C

cables, 4-3

calibration (value) of LDT, 3-3, B-2, C-2

configure

G file, 3-3, B-2, C-2

motion profiles, 1-2, 3-4

SLC processor

connections,

inputs to module, 4-1

outputs from module, 4-2

count, full-scale, 3-3

, 3-2

I, J, K

ID

of module, 3-2, A-1

input terminal block, of module, 4-1, 5-1

input image table (status), 5-4, C-1

Internet, access to, 3-2

L,M

ladder program, B-1

LDT

calibration value, 3-3

configuration in G file, 3-3

connections to, 4-1

fault, 5-2, 5-4

length of, 3-3

movement of, 3-5

types of, 4-1

LEDs, 5-2, A-1

N

N file, 3-4, 5-2, B-1

noise, electrical, 4-2

O

D

data direction (bit), 3-3, 3-5, 5-3, C-2

data, profile, 3-4, 3-5, B-2, C-2

download, from BBS, 3-1

E

error

, see fault

extend profile, 1-2, 3-4, 5-2, C-2

F

fault, module and LDT

, 5-2, 5-4, C-1

G,H

G file, 3-2, 3-3, 3-5, 3-6, 5-3, B-2, C-2

grounding, 4-2, 4-3, 5-1

output

conditions, 5-5

connections, of module, 4-2, 5-1

image table, 3-4, C-2

terminal block, 4-2

status, 5-4

overview of module and system, 1-1

P

position data, 3-4, 3-5, 5-3, C-1

position setpoints, 3-4, 3-5, 5-2, 5-3, C-2

power supply, considerations, 4-3

preset reference, 3-3, 5-3

profile, 1-2, 3-3, B-1, C-2

conventions, 3-5

operation of, 3-5

Page 34

I–2

Q

quick

start, 2-1

R

ram, hydraulic, 1-1, 1-2

procedure to move, 5-2, 5-3

set reference position of, 5-3

reference, preset, 3-3, 5-3

retract profile, 1-2, 3-4, 5-3

reverse motion, 5-2

S

segments, speed, 1-2, 3-4, 3-5

(also see voltage values)

shielding, of cables, 4-2, 4-3, 5-1

specifications, of module, A-1

status (input image table) 5-4, C-1

of outputs, 5-4

system, power up, 5-1

T, U, V

testing,

for proper system operation, 5-4

travel, length of LDT

troubleshooting, with

LEDs, 5-2

module status bits, 5-4

output conditions, 5-5

troubleshooting table, 5-5

voltage values, 3-4, 3-5, 5-2, C-2

W, X, Y

wiring,

system, 4-1, 4-2, 5-1

, 1-2, 3-3

, Z

Publication

1746-6.18 April 1998

Page 35

Worldwide representation.

Allen-Bradley, a Rockwell Automation Business, has been helping its customers improve

productivity and quality for more than 90 years. We design, manufacture and support a broad

range of automation products worldwide. They include logic processors, power and motion

control devices, operator interfaces, sensors and a variety of software. Rockwell is one of the

world’s leading technology companies.

Argentina •

Denmark • Ecuador • Egypt • El Salvador

Ireland

Philippines •

Sweden

Australia • Austria • Bahrain • Belgium

• Israel • Italy • Jamaica •

Poland • Portugal • Puerto Rico • Qatar • Romania • Russia–CIS • Saudi Arabia • Singapore

• Switzerland • T

Japan • Jordan • Korea • Kuwait • Lebanon

aiwan

• Thailand • T

• Brazil •

• Finland •

urkey • United Arab Emirates • United Kingdom • United States • Uruguay • V

Bulgaria • Canada • Chile • China, PRC • Colombia • Costa Rica • Croatia • Cyprus • Czech Republic

France • Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary • Iceland • India • Indonesia •

• Malaysia • Mexico •

Netherlands

• New

• Slovakia • Slovenia •

Zealand • Norway

South Africa, Republic • Spain

enezuela • Y

ugoslavia

Allen-Bradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1) 414 382-2000 Fax: (1) 414 382-4444

Publication

Supercedes

1746-6.18 April 1998

Publication 1746-6.18 – February 1998

Copyright 1998 Allen-Bradley Company

• Pakistan •

•

Peru

•

•

PN955132-83

, Inc. Printed in USA

Loading...

Loading...