Page 1

Allen-Bradley

Synchronized Axes

Control Module

(Cat. No. 1746-QS)

User

Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance and

safety requirements, including any applicable laws, regulations, codes

and standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for purposes of example. Since there are

many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability (to

include intellectual property liability) for actual use based upon the

examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration when

applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or

in part, without written permission of Allen-Bradley Company, Inc., is

prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: statements help you to:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is critical for successful

application and understanding of the product.

SLC is a trademark of Allen-Bradley Company, Inc. PKZIP and PKUNZIP are registered trademarks of PKWARE Inc.

Page 3

System Overview Chapter 1

Chapter Objectives

What

Is the 1746-QS Module?

What

Is the Hydraulic Configurator

What Is an SLC-500 System?

Why Use This System?

How Does It Work?

Controlling Axis Output

Programming

What

Are Typical Applications?

System Requirements

Setting Up the Hardware Chapter 2

Chapter Objectives

Connections

LDT

Connections (for fabricating your own LDT cable)

Typical

T

ypical Fusing of the Interface Module (IFM) T

Example

Wiring Example

Minimizing

Connecting Outputs to Output Devices

Output

Checking

Setting Up the Hydraulics

Regarding

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

to LDT

s and 4-axis Terminal Block

Connections to the Interface Module (IFM) T

Connections for T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interference from Radiated Electrical Noise

Polarity

Out the Wiring and Grounding

the Interface Module T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

emposonics II Dif

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

erminal Block and Cable

. . . . . . . . . . . . . . .

erminal Block

ferential Inputs

. . . . . . . . . . . . . . . . . . . .

. . . . . . . .

erminal Block

. . . .

. . . .

. . . . . . . . . .

. . . . . . .

toc–i

1–1

1–1

1–1

1–1

1–2

1–2

1–2

1–3

1–4

1–4

2–1

2–1

2–1

2–2

2–2

2–2

2–3

2–3

2–4

2–4

2–5

2–5

2–6

Setting Up Your PC

for the Hydraulic Configurator

Tuning an Axis with

the Hydraulic Configurator

Chapter 3

Chapter Objectives

Obtaining

Setting

the Hydraulic Configurator from the Internet

To Access Our Website:

To

Load the Hydraulic Configurator:

Up Communication Between PC and Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

Chapter 4

Chapter Objectives

Before Y

Finding

Moving

Getting

Tuning Each Axis

ou Begin

the V

alue of the Null Drive

the Axis to Set Scale, Of

Procedure

Alternate Open-loop Procedure to Set Scale and Of

General

to Set Scale and Of

Ready to Tune the Axes

Procedure for T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

fset, Extend, and Retract Limits

fset with Drive Output Disconnected

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

uning an Axis

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . .

. . .

fset

. . . . . . .

3–1

3–1

3–1

3–1

3–2

4–1

4–1

4–1

4–2

4–2

4–3

4–5

4–5

4–5

Publication

1746-6.19 – March 1998

Page 4

toc–ii

Adjusting

Adjusting

Using

Acceleration Feedforwards

Adjusting P-I-D Gains

Finding

the Value of the Dead Band Eliminator

Saving Parameters

Using Ladder Logic Chapter 5

Chapter Objectives

Obtaining

To Access the Internet:

Configuring Your SLC Processor, Off-line

Using

the Sample Ladder Program

Copy

Configuration Parameters to the SLC Processor

Copy

Configuration Parameters to the Module

Back

and Forth Motion with State-machine Logic

Jogging the Axes

Responds to Hydraulics On/Off

Running Synchronized Axes

Troubleshooting Chapter 6

Using

LED Indicators

Correcting

Command-word Speed and Acceleration V

Feedforward Parameters

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sample Ladder Program from the Internet

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T

ypical Problems

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

alues

. . . . .

. . . . . . . . . . . .

. . . . . . . .

. . . . . . . . . . . .

4–7

4–7

4–8

4–8

4–9

4–10

5–1

5–1

5–1

5–1

5–2

5–3

5–3

5–4

5–7

5–8

5–9

6–1

6–1

Module Specifications Appendix A

Electrical

Physical

Environmental

Certification

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Without the

Interface Module

Appendix B

Wiring Example B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Minimizing

Checking

Interference from Radiated Electrical Noise

Out the Wiring and Grounding

Using Processor Files Appendix C

Transferring

Transferring Motion Commands and Axis Status C–2. . . . . . . . . . . .

Transferring

Floating-point for V

Using

Using

M0 and M1 Files for Initial Configuration

M0

and M1 Memory Map for Ladder Logic

Bit

Map of Configuration W

Using

I/O Image T

Bit Map of Command Mode Word C–6. . . . . . . . . . . . . . . . . . . . . . .

Bit Map of Axis Status Word C–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data

Configuration Parameters

alues Above 32,767

ord (e:0, e:16, e:32. e:48)

ables for Commands and Status

A–2

A–2

A–2

A–2

B–2. . . . . . . . . .

B–2. . . . . . . . . . . . . . . . . . . .

C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C–2. . . . . . . . . . . . . . . . . . .

C–3. . . . . . . . . . . . . . .

C–4. . . . . . . . . . . . . . . .

C–4. . . . . . . . . . . . . . . . .

C–5. . . . . . . . .

C–5. . . . . . . . . . . . .

Publication

1746-6.19 – March 1998

Page 5

Chapter 1

Chapter Objectives

What Is the 1746-QS Module?

What Is the

Hydraulic Configurator

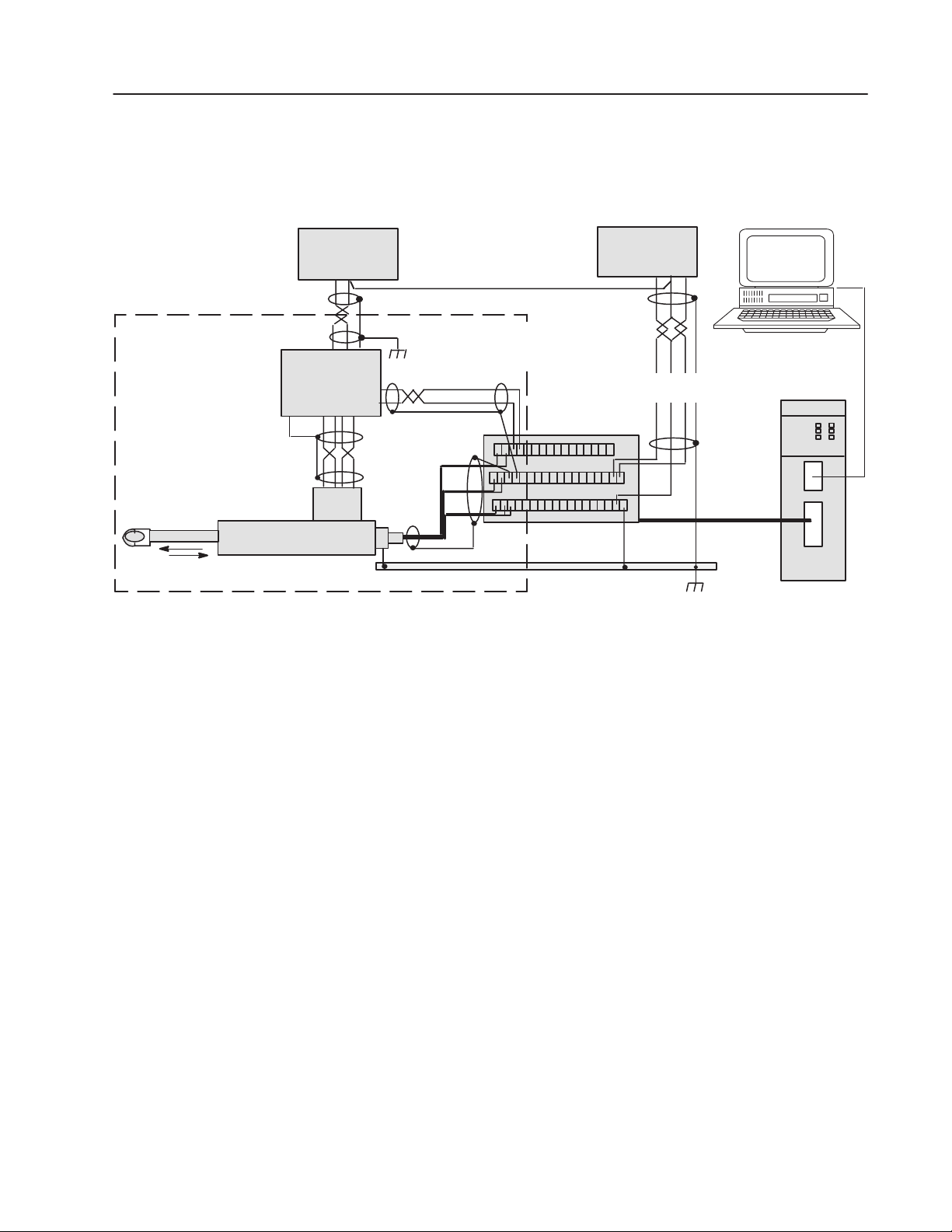

This chapter presents a conceptual overview of how you use the

1746-QS module in an application.

The 1746-QS Synchronized Axes Module provides four axes of

closed-loop synchronized servo positioning control, and lets you

change motion parameters while the axis is moving. The module has

four optically isolated inputs for signals from linear displacement

transducers (LDTs) and four optically isolated 10 volt outputs that

interface with proportional or servo valve amplifiers.

The module’s microprocessor provides closed-loop control. The

module reads the axis position and updates the drive output every

two milliseconds, for precise positioning even at high speeds.

The module is designed for use with the Hydraulic Configurator, a

software product that you can obtain from the Allen-Bradley website on

the Internet. The Hydraulic Configurator is an interactive executable

that lets you configure the module and tune its axes. With it, you can:

• configure axes and store configuration parameters

• tune each axis independent of the ladder program

• store multiple commands to initiate repetitive axis motion

• display a log of the last 64 motion commands sent to the module

• observe and/or store plots of each axis

• access help screens that explain and/or describe module features

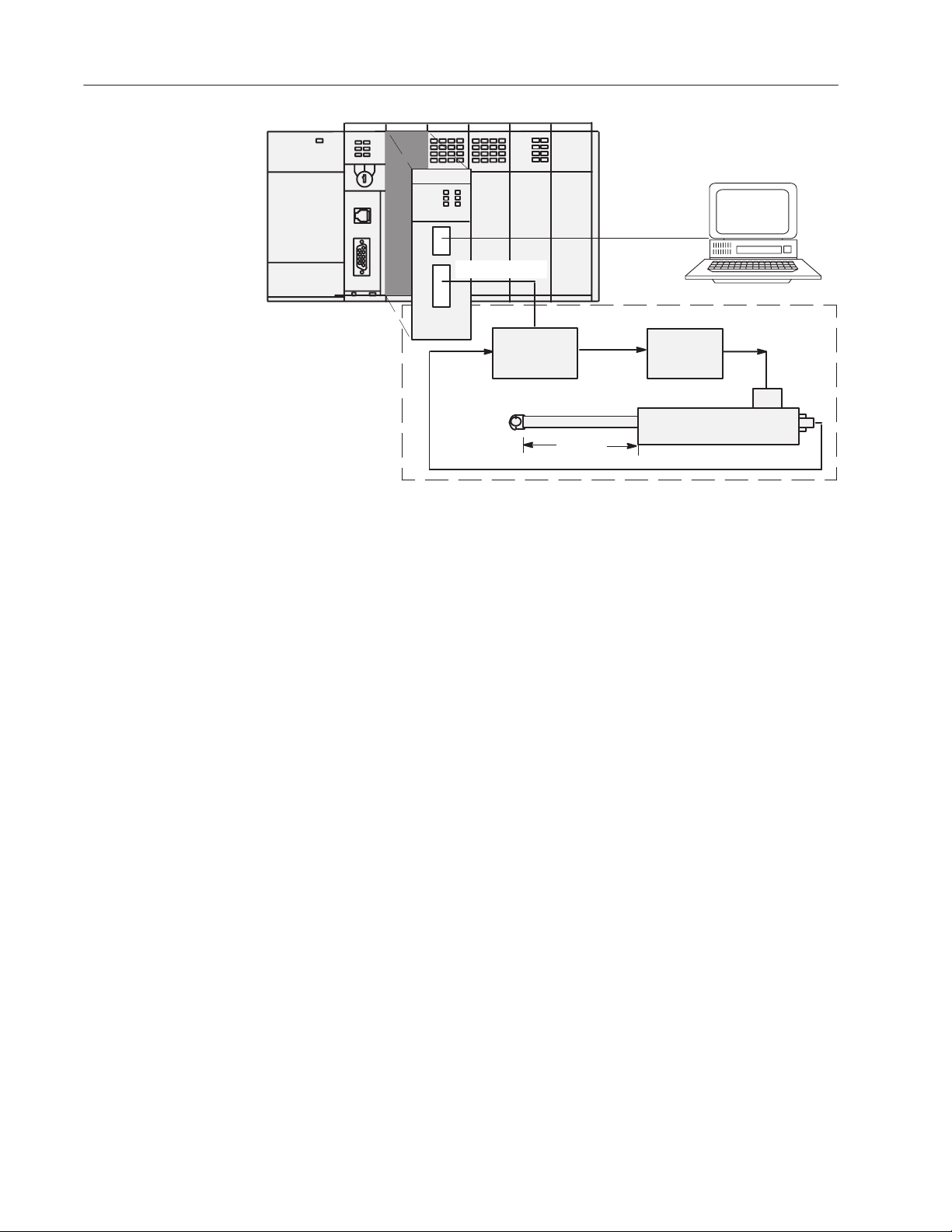

What Is an SLC-500 System?

Important: The Hydraulic Configurator saves considerable time when

tuning axes and troubleshooting faults. Thereafter, your ladder logic

sequences module operation with the machine.

The Allen-Bradley Small Logic Controller (SLC) system is a programmable control system with an SLC processor, I/O chassis containing

analog, digital, and/or special-purpose modules, and a power supply.

The 1746-QS module occupies one slot of the I/O chassis and

communicates with the SLC processor over the backplane using 32

words in the SLC processor’s output image table and 32 words in the

input image table. The processor loads or reads the module’s

configuration parameters using M0 or M1 files, respectively. Your

ladder logic sequences synchronized axes movement with machine

operation. The system can be illustrated as follows:

Publication

1746-6.19 March 1998

Page 6

1–2

HYDRAULIC

Hydraulic Configurator

Software on PC

For Setup and

Troubleshooting

Why Use This System?

Power

Supply

1747-CP3

Cable

One of Four Identical Motion-control Loops

Proportional

Analog

Output

10V dc

Amplifier

Piston-type Hydraulic Cylinder

and Position-monitoring Device

Servo-quality

Proportional

Valve

SLC-500

Processor

SYNCHR AXES

1746-QS

module

Position

Input

1492-ACABLE015Q

Interface Module

(terminal block)

1492-AIFMQS

Axis

Motion

"

Because you can interact quickly and easily with the module’s control of

axis motion via the Hydraulic Configurator, this control system has

these benefits:

• faster setup and tuning of axes – the Hydraulic Configurator lets you

quickly set up and tune each axis independent of your ladder program.

• reduced cycle time – you can increase axis speed for faster operation

• smoother operation for longer machine life – you can profile acceler-

ations and decelerations of the hydraulic actuator to limit pressure spikes

• faster change-over to new parts – you can store setups (configuration

parameters) for quick an accurate change-over between parts

How Does It Work?

Publication

1746-6.19 March 1998

Monitoring Axis Position

The module has four LDT inputs. You configure each axis for an LDT

with a Pulse Width Modulated output (DPM) or a Start/Stop output

(RPM) by changing axis configuration parameters.

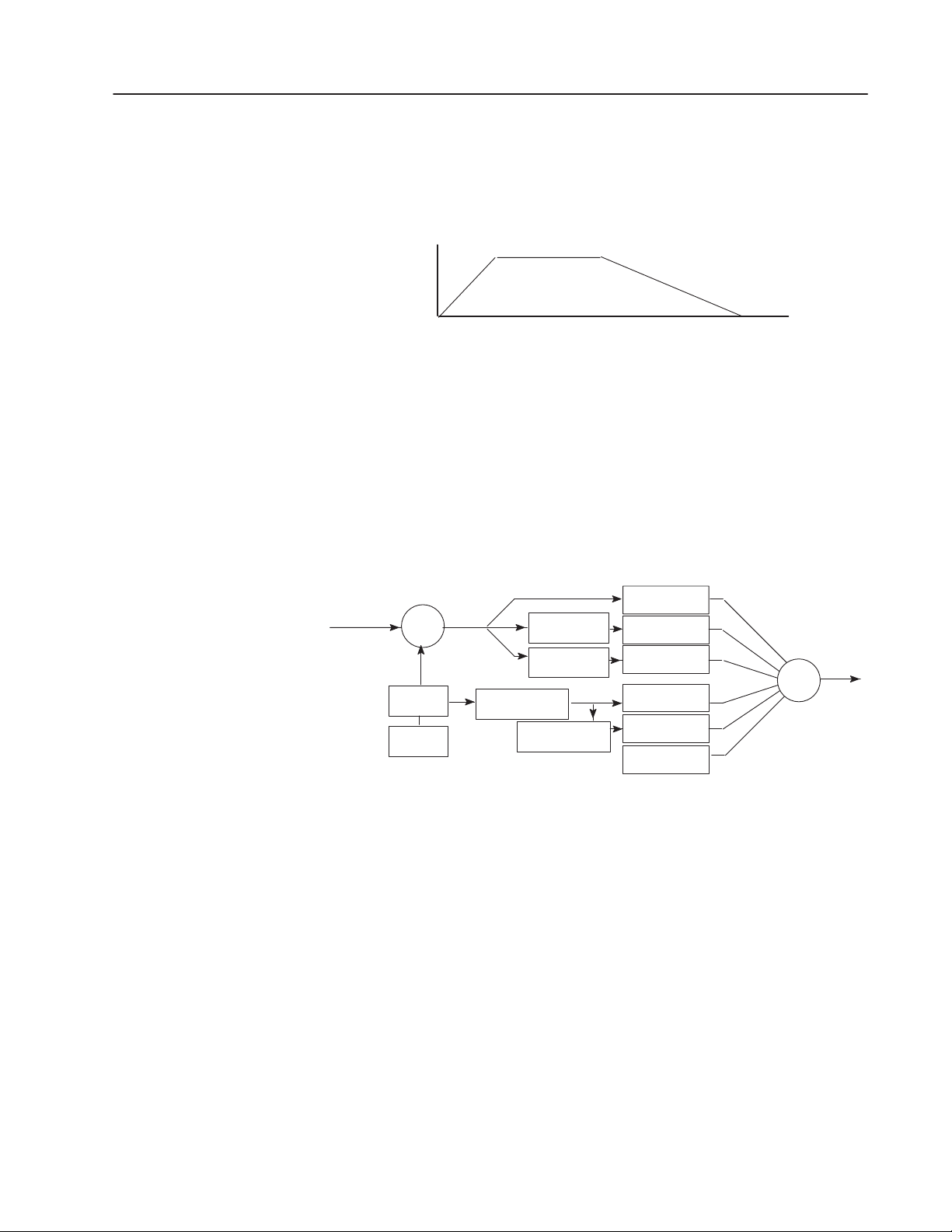

Controlling Axis Output

The module is a targeting controller: every two milliseconds its microprocessor updates

point-to-point moves,

resulting speed, accelerations, and decelerations follow either a

trapezoidal or s-curve profile.

TARGET POSITION and target SPEED values. For

TARGET POSITIONS are generated so that

Page 7

1–3

The MODE, ACCELERATION, DECELERATION, SPEED, and

COMMAND VALUE (requested position) are used to generate the

profile. You send these command words to the module through the

processor’s output image table. You may change them “on-the-fly“

while the axis is moving.

Max Speed

Actual

Position

Speed

Accel

Ramp

Motion

Time

Profile

Decel

Ramp

Command V

(Final Position)

alue

The module compares ACTUAL POSITION with TARGET POSITION to

determine position error. Every update, it uses the position error to adjust

drive output. PID gains are adjustable and can be applied selectively.

The module also provides two different feedforward algorithms;

EXTEND/RETRACT FEEDFORWARD, and EXTEND/RETRACT

ACCELERATION FEEDFORWARD. These feedforward terms provide

additional drive output to help the axis follow the target, freeing the

PID loop to correct for system nonlinearity and changes in load.

Proportional Gain

Integral Gain

Dif

ferential Gain

Feedforward

Accel

Feedforward

Deadband

Eliminator

ȍ

Drive

Output

T

arget

Position

ȍ

–

+

T

arget

Generator

SLC

Processor

Position

Error

Change in Position

(Velocity)

Accumulator

(Integrator)

Change in Error

(Differentiator)

Change in V

(Acceleration)

elocity

Diagram of the Control Loop

Programming

A sample ladder program for the module is available from

Allen-Bradley’s website on the Internet. You can download it as an

executable file to your PC’s disk drive and transfer it to your SLC

processor. But, you must modify it for your application.

Publication

1746-6.19 March 1998

Page 8

1–4

Ladder logic transfers motion commands to the module and axis

status from the module thru the I/O image table. Ladder logic also

copies configuration parameters to the module’s M0 file at power up.

It also copies configuration parameters (that you enter/change with

the Hydraulic Configurator) from the module’s M1 file to processor

files. Thus, you can establish a library of configurations (recipes) in

processor files that you can select and download to the module at

power up or each time you want to change the setup of your axes.

We explain the functions of the ladder logic later in this manual.

What Are Typical Applications?

System Requirements

Use the module in an SLC-based system for control of hydraulic

applications where two or more axes must reach their final position

at the same time, such as:

• plywood presses

• roll positioning

• palletizers and stackers

• forging machines

• hydraulic tailgate loaders

In addition, the module is designed to support independent axes using

either servo or proportional amplifiers, and retrofit into existing

hydraulic systems requiring a positive voltage irrespective of direction.

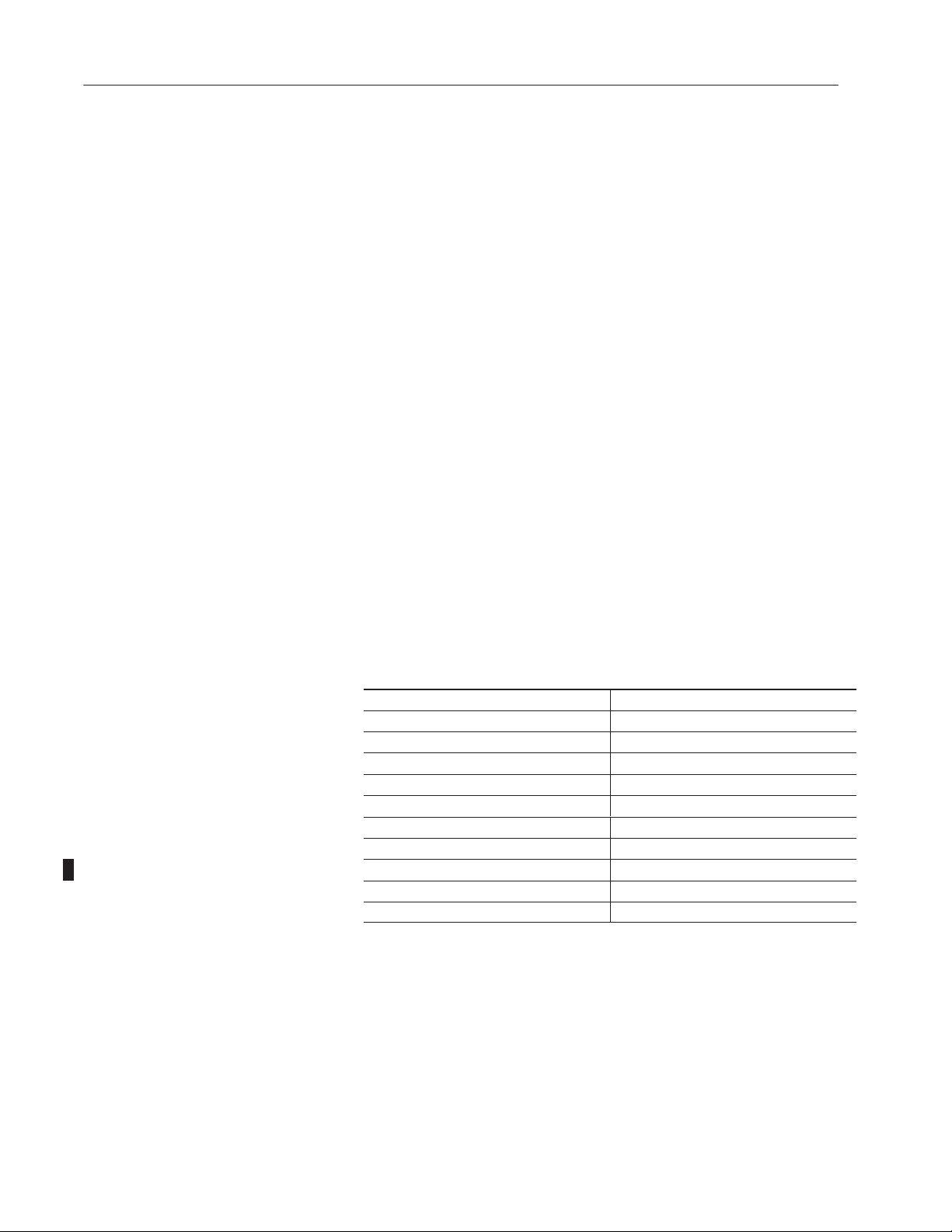

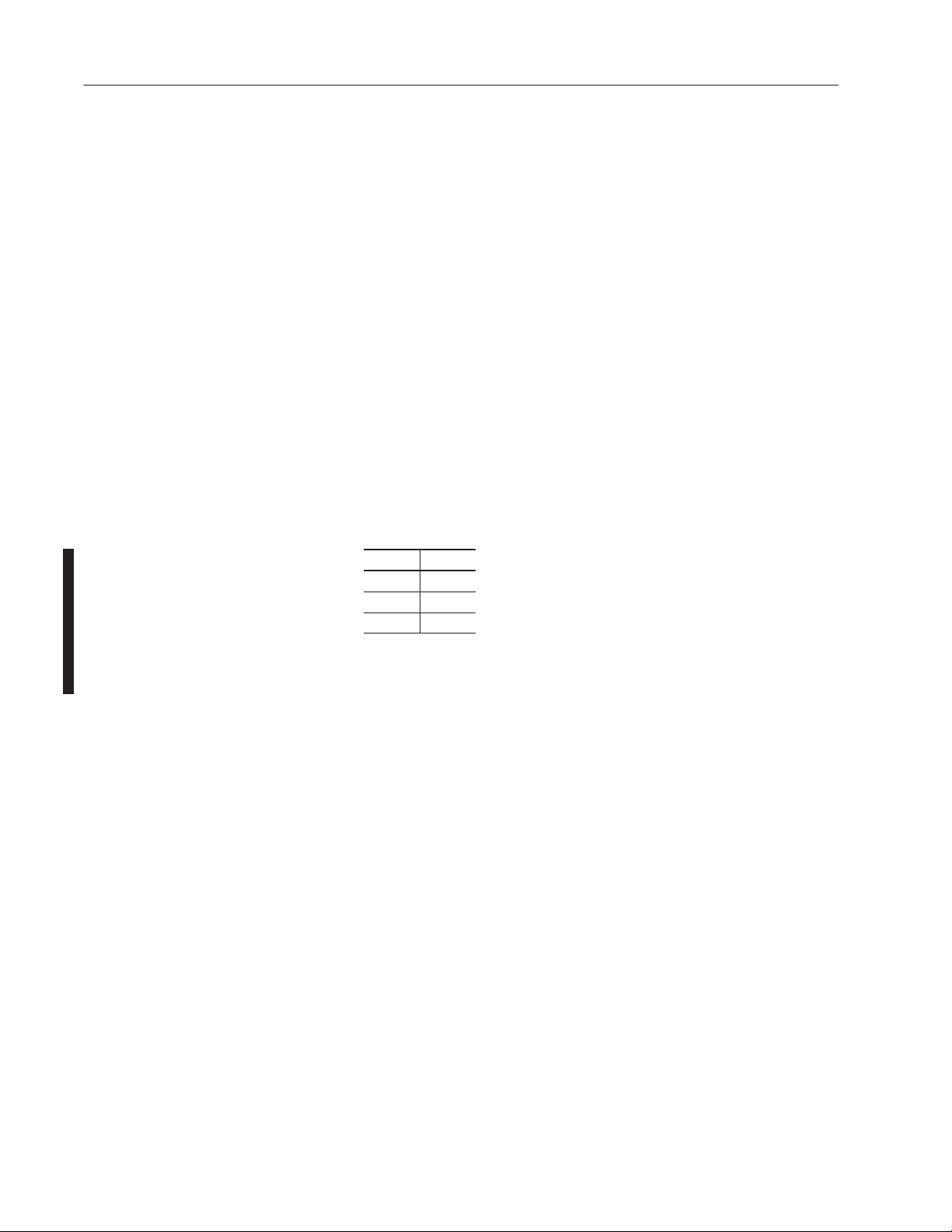

Hardware/software requirements of this SLC processor system include:

Component: Requirement:

SLC Processor SLC 5/03 or later

Comm. Interface Card (alternate COM port) 1784-KTx

Personal Computer 3.9 MByte of disk space

PC Operating System Windows 95

PC/QS Interface Cable 1747-CP3

Synchronized Axes Module 1746-QS

Interface Module (terminal block) 1492-AIFMQS

Interface Module Cable 1492-ACABLExxxQ

Programming Software RSLogix500

LDT (RPM or DPM) Temposonics, Baluff, Santest, Gemco, etc

Publication

1746-6.19 March 1998

Page 9

Chapter 2

Setting Up the Hardware

Chapter Objectives

Connections to LDTs and 4-axis Terminal Block

Temposonics II,

RPM or DPM

PS

(–)

(–)

"15V

Common

1

23456789

(+)

dc PS

Frame

GND

Return

Interrogate

(+)

(+)

10

(–)

This chapter helps you install the hardware with these tasks:

• connecting LDTs to the Interface Module (IFM) terminal block

• minimizing interference from radiated electrical noise

• connecting outputs to output devices

• checking out the wiring and grounding

• setting up the hydraulics

• regarding the Interface Module (IFM) terminal block and cable

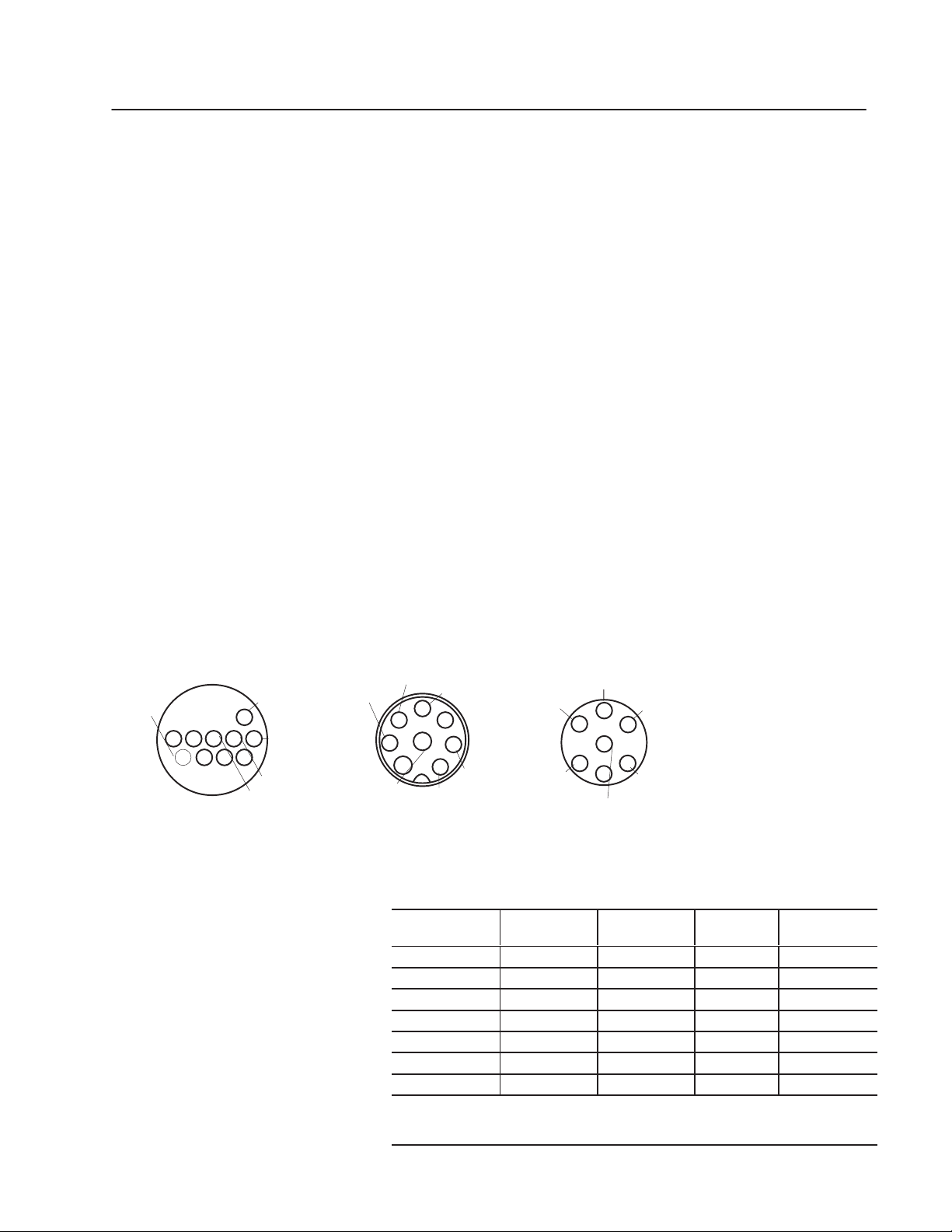

We assume that you will use one of the following types of LDT:

• Temposonics II: RPM TTSRxxxxxxR, or

DPM TTSRxxxxxxDExxx

• Balluff: BTL-2-L2, or BTL-2-M2

• Santest: GYRP, or GYRG

• Gemco Quick-Stick II: 951VP, or 951 RS

We illustrate connections for these types of LDTs. (There are other

suppliers with compatible LDTs.)

Balluff

BTL-2-L2 & -2-M2

Return

7 (+)

(–)

Return

2

45

(–)

8

6

PS

Common

(+)

1

Interrogate (+)

Interrogate (–)

3

"15V

dc PS

The views are looking at the connector on the LDT head.

Santest

GYRP & GYRG

NC

+15V

dc PS

1

5

Return

(+)

Interrogate

2

4

6

PS

Common

3

(+)

7

(–)

Return

(–)

Gemco Quick-Stick II

951VP

w/PWM

B–BLK PS Common

C–RED +15V dc PS

K–GRY + Interrogate

E–BRN –Return*

F–BLU +Return*

A–WHT –Interrogate

G, D, H RS232RXD

J–PUR 2nd PS COM

*951RS has pulse trigger

Output

LDT Connections (for fabricating your own LDT cable)

Function Temposonics

RPM or DPM

(+) Return (note 1) 4 – Pink 2 – Gray pin 5 F – Blue

(–) Return (note 1) 3 – Gray 5 – Green pin 7 E – Brown

(–) Interrogate 10 – Green 3 – Pink pin 6 A – White

(+) Interrogate 9 – Yellow 1 – Yellow pin 4 K – Gray

–15V dc PS 6 – Blue 8 – White n/a n/a

PS Common 1 – White 6 – Blue pin 3 B – Black

+15V dc PS 5 – Red 7 – Brown pin 1 C – Red

(+) and (–) wires of the same function should be a twisted pair within the cable.

(note 1) We use the term “Return” for gate out, pulse trigger, or square wave (Gemco) and

start/stop (Balluff -M2) LDT signals.

II

Balluff

BTL-2-L2 & -M2

Santest

GYRP/GYRG

Publication

1746-6.19 March 1998

Gemco QuickStick 951VP/RS

Page 10

2–2

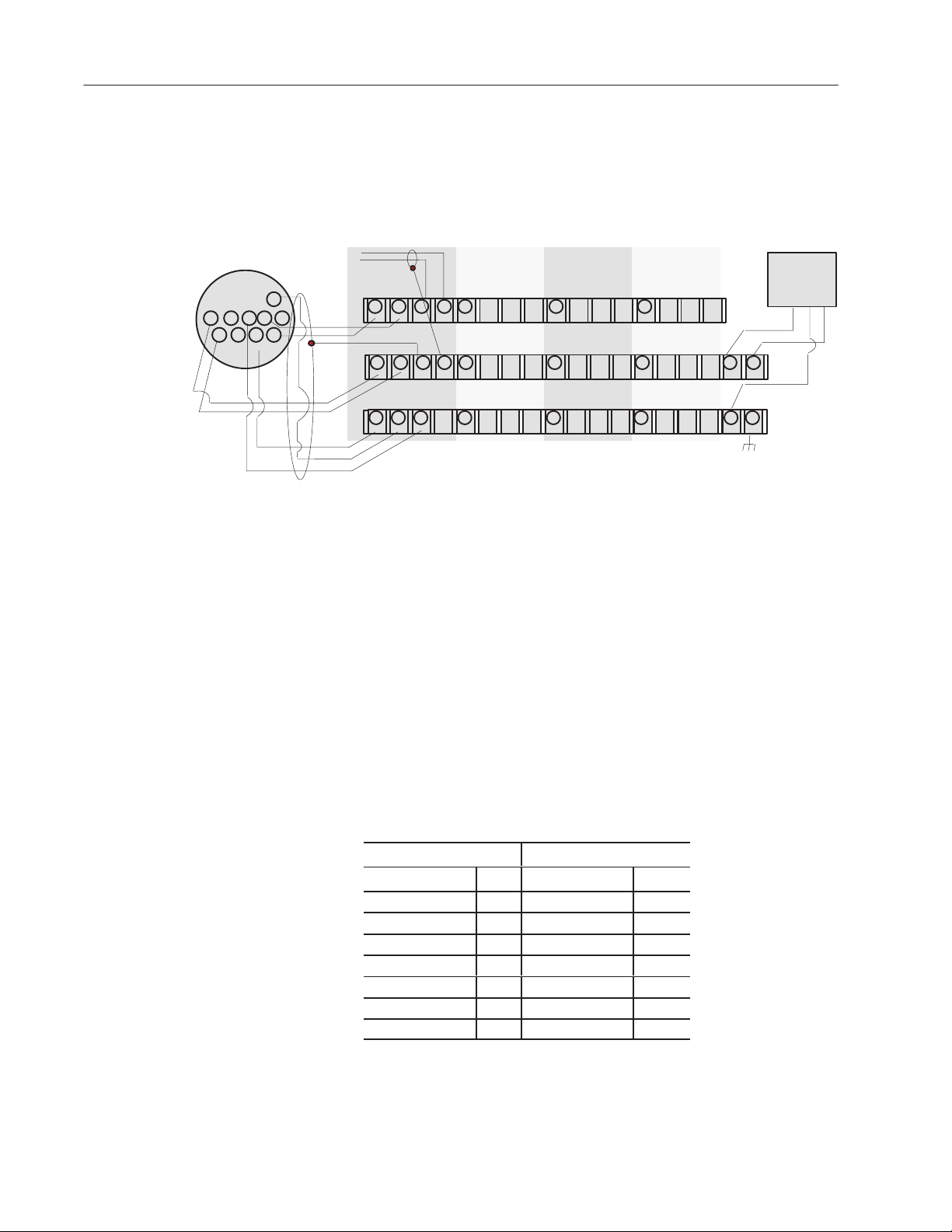

Typical Connections to the Interface Module (IFM) Terminal Block

Pin assignments of the IFM terminal block for I/O, power, shield, and

ground connections are as follows: (For example, we show connections

for one axis with a Temposonics LDT and power supply.)

Temposonics II,

RPM or DPM

(+)

(–)

(+)

9

10

(–)

(–)

1

45678

(+)

Drive Output

23

_

+

Axis Loop 1

+Ret –Ret +Out Out +Ret –Ret +Out Out +Ret –Ret +Out Out +Ret –Ret +Out Out

1 1 1 Com

0

1

2 3

+Int –Int SH SH

1 1 2 2 3 3 4 4

16 32 33

17

18 19

–V LDT +V

1F Com 1F

34 38 42 46

35 36

Internal Connections:

–V (32) is connected to (34) (38) (42) (46) through fuses that you provide

+V (33) is connected to (36) (40) (44) (48) through fuses that you provide

PS Com (50) is connected to all LDT Com (35) (39) (43) (47)

Earth GND (51) is connected to all SH (18) (19) (22) (23) (26) (27) (30)(31)

Axis Loop 2 Axis Loop 3 Axis Loop 4

2 2 2 Com 3 3 3 Com 4 4 4 Com

4 8

+Int –Int SH SH +Int –Int SH SH +Int –Int SH SH –V +V

20 24 28

–V LDT +V –V LDT +V –V LDT +V PS Earth

2F Com 2F 3F Com 3F 4F Com 4F Com GND

12

50 51

"

15V

Power

(– ) (C) (+)

Supply

Connect the "15V dc power supply to pin 50 (Com), pin 33 (+V), and

pin 32 (–V). Connect pin 51 (GND) to earth ground with 3/8” wire braid

(as short as possible).

Typical Fusing of the Interface Module (IFM) Terminal Block

The Interface Module (IFM) Terminal Block is wired for fusing of

("V) to each LDT. Provide proper fusing (T500L 250V, typical) for

each axis using fuse clips on the IFM terminal block.

Publication

1746-6.19 March 1998

Example Connections for Temposonics II Differential Inputs

Use differential inputs when connecting LDTs to the IFM terminal block.

Temposonics

Function Pin # Function (Axis 1) Term. #

(+) Interrogate 9 + Int 16

(–) Interrogate 10 – Int 17

(+) Return 4 + Ret 0

(–) Return 3 – Ret 1

+ 15V 5 +V 1F 36

–15V 6 –V 1F 34

Comm 1 LDT Com 35

If fabricating your own LDT cable, see connections on previous page.

II

IFM Terminal Block

Page 11

24V Power

Supply

(+) (–)

Wiring Example

We present a 1-axis loop with a differential LDT input.

(You must provide power supplies and servo amplifiers.)

"

15V Power

Supply

for

LDT

s

(–) (C) (+)

Hydraulic

Configurator

Software on PC

2–3

s

Belden

8761

Servo or

Proportional

Amplifier

0V (internal)

Axis Loop 1 of 4-axis system

Important:

analog outputs require an

external amplifier to drive

the valve.

Piston-type Hydraulic Cylinder and

Linear Displacement T

The module’

Grounding exception:

Connect this shield

to internal common.

ransducer (LDT)

Minimizing Interference from Radiated Electrical Noise

Valve

–

Belden

8770

isolated

+

from earth GND.

Cable 1492ACABLExxxQ

1746-QS

module

1747-CP3

Cable

HYDRAULIC

SYNCHR AXES

Connect cable shields of LDT

and drive output to SH terminals

on terminal block (to earth GND).

Drive

Output

Belden

8761

Ret

Int

Belden

Pwr

8105

Connect signal commons and PS commons

to Com terminals,

IFM Terminal Block

Cat. No. 1492-AIFMQS

earth

ground

Important: Signals in this type of control system are very susceptible to

radiated electrical noise. The module is designed to detect loss-of-sensor

and sensor noise conditions for any of the four axes when position values

are lost or corrupted. The Hydraulic Configurator displays these

conditions in the Status word window. The resulting hard or soft stop

depends on how you configured autostop conditions. (See Hydraulic

Configurator, Config word, and click on autostop “Help“).

To minimize interference from radiated electrical noise with correct

shielding and grounding:

• Connect LDT cable shields and drive output cable shields (all

shields at one end, only) to IFM terminal block SH terminals, and

connect the IFM terminal block GND terminal (51) to earth ground.

• Keep LDT signal cables far from motors or proportional amplifiers.

• Connect all of the following to earth ground:

– power supply cable shields (one end, only)

– LDT flange, frame, and machine

– I/O chassis

– AC ground

• Use shielded twisted pairs for all connections to inputs and outputs.

• Run shielded cables only in low-voltage conduit.

• Place the SLC-500 processor and I/O chassis in a suitable enclosure.

Publication

1746-6.19 March 1998

Page 12

2–4

Important: To minimize the adverse effects of ground loops, you must

isolate power supply and signal commons from earth ground as follows:

1. Connect power supply commons to IFM Com terminal (50), and

LDT commons to LDT Com terminals of the IFM terminal block.

Be sure that they are isolated from earth ground.

2. Connect the cable shield of the servo or proportional amplifier

output cable to a zero potential terminal inside the amplifier.

3. Use bond wires that are equal in size to signal wires.

4. When practical, use one power supply to power only your LDTs.

Connecting Outputs to Output Devices

Note: Follow manufacturer recommendations for shielding the output

cables of the proportional amplifier. Typically, pulse-width modulated

outputs radiate electrical noise originating from the +24V dc power

supply, so isolate the shields of the amplifier output cable to a 0V dc

connection inside the proportional amplifier.

You have a choice of three configurations to match your hydraulics:

• proportional amplifier integrated with a proportional valve

• servo amplifier and variable-volume pump or servo valve

• Allen-Bradley 1305 Drive and hydraulic pump

You may use either of the following output voltage ranges:

• 0-10V dc for an Allen-Bradley 1305 Drive or variable-volume pump

• –10 to +10V dc for a proportional or servo amplifier

If using servo valves, you must convert the module’s output from

voltage to current.

Output Polarity

In most hydraulic systems, the actuator extends (with increasing

LDT counts) when a positive voltage is sent to the output. The

extend direction is defined as the direction that causes the LDT to

return increasing counts moving away from the head.

Publication

You can make these selections in the Config word that affect output:

• To generate a positive drive output (0-10V dc) regardless of move

direction, you can select Absolute Mode.

• To extend the actuator by sending a negative voltage to the

output, you can select Reverse Drive Mode.

For additional information on the Configuration word, select that

subject in Help Topics.

1746-6.19 March 1998

Page 13

2–5

Checking Out the Wiring and Grounding

Repeat this procedure to check out each of the four axis loops

connected to the IFM terminal block.

ATTENTION: Be sure to remove all power to the SLC processor,

LDT, valve and pump beforehand.

1. Disconnect the LDT connector at the head end.

2. Disconnect the connector to the IFM terminal block.

3. Turn ON the power supplies for the LDT and SLC processor, and

check the LDT connector and IFM terminal block for:

• +15V dc

• PS common

• –15V dc

4. Observe that the module’s fault LED indicates Green.

5. Verify continuity between IFM COM terminal (50) and each of:

• shield of the amplifier output cable to the valve

• output common on "15V dc PS that powers the LDT

• (–) terminal on +24V dc PS that powers the proportional amplifier

6. Verify NO continuity between drive output commons connected to

IFM terminals 3, 7, 11, 15 and earth ground.

Setting Up the Hydraulics

7. To minimize ground loops, verify that all cable shields are grounded

(at one end, only) to SH terminals of the IFM terminal block, and

that GND terminal (51) of the IFM is connected to earth ground.

1. Design for adequate pressure and volume. Hydraulic systems

must have enough pressure and fluid volume (accumulator) to move the

desired load the commanded distance and speed. Inadequate pressure

or volume will cause the axis to lag the target position as the controller

attempts to move the axis faster than the system can move. Consider

monitoring system pressure or providing a low-limit (approx. 80%)

pressure switch.

2. Avoid flexible hose. Use no flexible hose between the valve and

the cylinder being controlled. Flexible hose will swell and contract

as the valve opens and closes, causing oscillation and loss of control.

3. Mount valve and cylinder in correct orientation. To avoid

problems from entrapped air, mount the valve directly to the cylinder

and positioned above it. Mount pressure sensors beneath the cylinder.

4. Use linear valves with minimal overlap. If using proportional

valves, they should have less than 3% overlap and a linear (not

curvilinear) response. Nonlinear valves or valves with excessive

(20%) overlap may cause oscillation or hunting. We recommend

using servo valves or servo-quality proportional valves.

Publication

1746-6.19 March 1998

Page 14

2–6

5. Avoid valves with a slow response (less than 60 Hz). Valves with

slow response cause the module to overcompensate for disturbances in

the motion of the system. Since the system does not respond immediately

to the control signal, the module continues to increase the drive signal.

By the time the system begins to respond to the error, the control signal

has become too large and the system overshoots. The module then

attempts to control in the opposite direction, but again overshoots. These

valves can cause the system to oscillate around the set point as the

module overshoots first in one direction, then the other.

Regarding the Interface

Module Terminal Block

(Cat. No. 1492-AIFMQS)

and Cable

We recommend that you use the Interface Module (IFM) terminal

block (Cat. No. 1492-AIFMQS) to connect module I/O and power.

It facilitates power supply, shield, and fuse connections.

It is required for CE certification.

The pre-wired cable that connects the IFM terminal block to the

module is available in standard sizes as indicated by its part number,

1492-ACABLExxxQ, where xxx indicates the length in meters:

length: xxx:

0.5 m 005

1.0 m 010

2.5 m 025

Important: Because the sytem was certified with a shorter cable,

you must re-certify the system if using the 2.5 m cable.

Publication 1492-5.1 describes the IFM terminal block and cables.

For information on the entire line of Allen-Bradley Interface

Modules and associated cables for wiring analog systems, refer to

publication 1492-2.15.

Publication

1746-6.19 March 1998

Page 15

Chapter 3

Setting Up Your PC for the

Hydraulic Configurator

Chapter Objectives

Obtaining the Hydraulic Configurator from the Internet

This chapter helps you do the following:

• Obtain the Hydraulic Configurator from the Internet

• Set up communication between your PC and the module

You can download the Hydraulic Configurator from our website to

your PC. (You can also download ladder logic and transfer it to your

SLC processor, but we cover that in chapter 6.)

System requirements for the Hydraulic Configurator are:

Windows ’95 series A or B and 4M available disk space.

To Access Our Website:

Access the Allen-Bradley website (and 1746-QS software) at:

The Hydraulic Configurator is stored there as a self-extracting

Winzip executable.

To Load the Hydraulic Configurator:

1. Download the Hydraulic Configurator (1746-QS.EXE) onto your

hard drive.

2. Run 1746-QS.EXE. The Winzip self-extractor will ask you

where you want to store the Hydraulic Configurator.

3. Launch it using the file, QsCfg.exe.

4. Set up a shortcut (optional).

Publication

1746-6.19 March 1998

Page 16

3–2

Setting Up Communication Between PC and Module

You must establish communication between Hydraulic Configurator

software on your PC and the module.

1. Connect your PC to the module with Allen-Bradley cable (cat. no.

1747-CP3): one end to a serial port on your PC such as COM1, the

other end to the 9-pin D-shell connector on the module.

Windows ’95 provides a virtual connection to the serial port without

any intervention unless that port is already used by another application.

Important: You may run RSLogix500 and Hydraulic Configurator

concurrently on your PC if you have both COM1 and COM2

available. If only one serial port is available, you may use the

Communication Interface Card (1784-KTx) for the connection

between PC and SLC processor.

2. Open the Hydraulic Configurator by running QsCfg.exe.

The main screen appears.

If you also get the message “No Motion Controller Detected,” then:

– check the1747-CP3 cable connection between PC and module

– match the software/hardware

COM ports (step 3.)

Otherwise, go to step 4.

3. Set the Hydraulic Configurator COM port to match your PC.

To do this, click T

the menu. Enter the

ools on the toolbar, then Monitor Options from

COM port number you used for your PC cable

connection to the module in step 1.

4. To verify communication with the module, observe that the Com:

window (screen bottom left) displays “Online“.

Important: You can run the Hydraulic Configurator offline to view

plots, stored data files, and access Help screens.

Publication

1746-6.19 March 1998

Page 17

Chapter 4

Tuning an Axis with the

Hydraulic Configurator

Chapter Objectives

Before You Begin

We cover these topics:

• Before You Begin

• Finding the Value of the Null Drive

• Moving the Axis to Set Offset, Scale, Extend and Retract Limits

• Getting Ready to Tune the Axes

• Tuning Each Axis

• Finding the Value of the Dead Band Eliminator

• Saving Parameters

ATTENTION: Great care must be taken to avoid accidents when

starting the module for the first time. The most common accident is

a runaway, where the module tries to move the axis to a position

beyond the physical limits, or in the wrong direction while in

closed-loop control.

When the module is first turned on, parameters are set to default

values. You must change these parameters (with the Hydraulic

Configurator) to operate the module in your application.

ATTENTION: Do not attempt to operate the module in closed-loop

mode until EXTEND and RETRACT limits have been determined

and initialized in the module using the Hydraulic Configurator.

Finding the Value of the Null Drive

Before starting, be sure that:

1. Hydraulic Configurator is communicating with the module

2. Important: You have identified the type of LDT output. To Do this:

– Double-click the Config word in the screen’s

– Click the transducer type that matches your LDT.

– Disable simulate mode.

Do this by removing the nfrom its check box in the Config word.

– Leave the other selections at default.

3. LDTs are connected and powered up

The Null Drive compensates for axis drift.

This procedure requires operating the module in open-loop mode

with drive outputs connected to the amplifier. In this procedure,

you will increase the drive output until the axis stops drifting. Then

you will initialize that value in the module with an “N” command.

PARAMETER section.

Publication

1746-6.19 March 1998

Page 18

4–2

1. Turn off the power to the module.

2. Connect the axis drive output to the amplifier.

3. Turn the power back on.

4. Turn on the hydraulics.

If the axis drifts, go to step 5.

If not, you are done. Go to the next procedure, Moving the Axis.

5. Find the Null Drive value to stop axis drift:

a) Estimate a drive output (mV) required to hold zero motion.

b) Command the module to output that value with the “O

– Select axis and enter value into

– From C

ommand in the CommandBar, click the “O“ command.

COMMAND VALUE number field.

“ command:

c) Repeat until the value produces no drift. This is the Null Drive

6. Zero the open-loop output with the “K

– Click [K] in the T

oolBar.

” (Kill) command. To do this:

Important: The axis will resume its initial drift until you do step 7.

7. Command the module to output the Null Drive with “N

– Enter Null Drive into

– From C

ommand in the CommandBar, click the “N“ command.

8. If drift persists, adjust Null Drive with “N

COMMAND VALUE number field.

” commands (as in step 7).

” command.

Moving the Axis to Set Scale, Offset, Extend, and Retract Limits

By moving the axis, you will calibrate these configuration parameters

with the Hydraulic Configurator:

• Scale

• Offset

• Extend and Retract Limits

We give you a preferred and an alternate procedure based on whether

the drive output is disconnected from or connected to the module:

If: Then:

You have a diddle box*

to move the axis

You do Not have a diddle box

* a control box that can electrically drive the valve amplifier

Use the preferred procedure

with the drive output disconnected

Use the alternate open-loop procedure

with the drive output connected

Procedure to Set Scale and Offset with Drive Output Disconnected

With the axis drive output disconnected and the LDT on, you will move

the axis with a diddle box (or manually) to two known machine positions

(typically the extend and retract limits). There you will use the Hydraulic

Configurator “S

POSITION and COUNTS values.

cale/Offset Calibration” feature to enter ACTUAL

Publication

1746-6.19 March 1998

Important: When moving to axis limits, be sure to leave space for safety.

Remember that extend is the direction that returns increasing

LDT COUNTS.

Page 19

4–3

1. Turn off the power to the module.

2. Disconnect the axis drive output to the amplifier.

3. Turn the power back on.

4. Turn on the hydraulics.

5. Move the axis to the first position with the diddle box.

It doesn’t matter whether the first position is an extend or retract.

6. In the Scale/Offset Calibration window (from T

ools in command bar):

a) Enter the desired position value into the Actual Position field for

the First Position. (For example, –4000)

b) In corresponding First Position Counts field, click “Use Current”.

7. Move the axis from the first position to the second.

8. In the Scale/Offset Calibration window (from Tools in CommandBar):

a) Enter the desired position value in the Actual Position field for the

Second Position . (For example, 40,000)

b) In corresponding Second Position Counts field, click “Use Current”.

The New Parameters area of the window will show the calculated values

for the Config word, Scale, and offset. (Set extend/retract limits later.)

9. Confirm that the displayed New Parameters (step 8) are valid. Then,

a) Click “Apply” to enter the values into configuration parameter words.

b) Click “Done” to close the editor window.

Important: You must set the

EXTEND and RETRACT LIMITS after

setting the scale and offset. The Scale/Offset Calibration tool will

re-calculate any existing

EXTEND and RETRACT LIMITS automatically

when you use it to set a scale and offset.

10.For each axis, enter the desired end-point values for the

EXTEND

and RETRACT LIMITS in the screen’s PARAMETER section.

Enter them in the same engineering units as used in steps 6 and 8.

11. Transfer the parameters to the module using the “P

” Command.

12.Repeat this procedure for each axis in use.

Alternate Open-loop Procedure to Set Scale and Offset

You will move the axis with the module in open-loop mode to two

known machine positions (typically the extend and retract limits).

There you will use the Hydraulic Configurator “S

Calibration” feature to enter

ACTUAL POSITION and COUNTS values.

ATTENTION:

A. Drive outputs will be connected to the amplifier.

B. Open-loop operation will ignore all limits.

Be prepared to instantly remove drive power.

C. To avoid surprises, read the entire procedure before starting.

1. Turn off the power to the module.

2. Connect the axis drive output to the amplifier.

cale/Offset

Publication

1746-6.19 March 1998

Page 20

4–4

3. Turn the power back on.

4. Turn on the hydraulics.

If the axis drifts, go back to the Null Drive procedure.

If not, go to step 5.

5. To move the axis to the first position (either extend or retract).

a) Estimate drive output (mV) that would generate a slow safe speed.

Enter it into

the

COMMAND V

ALUE number field.

Note: In open-loop mode, this field sets the module output.

In closed-loop mode, this field sets the commanded position.

b) Command the module to output that value with the “O

“ command.

The axis should start to move.

6. To stop axis motion:

a) Zero the

b) Command the module to zero its output with an “O

7. In Scale/Offset Calibration window (from T

COMMAND VALUE number field.

” command.

ools in CommandBar):

a) Enter the desired position value in the Actual Position field for

the First Position . (For example, 40,000)

b) In corresponding Counts field, click “Use Current”.

8. To move the axis to the second position:

a) Command the module to output a negative value (such as –200)

with the “O” command (as with step 5b).

The axis should start to retract. If not, verify that the value is (–).

9. To stop axis motion:

a) Zero the

b) Command the module to zero its output with an “O

10. In the Scale/Offset Calibration window (from T

COMMAND VALUE number field.

” command.

ools in command bar):

a) Enter the desired position value in the Actual Position field for the

Second Position . (For example, –4000)

b) In corresponding Counts field, click “Use Current”.

The New Parameters area of the window will show the calculated values

for the Config word, Scale, and offset. (Set extend/retract limits later.)

11. Confirm that the displayed New Parameters (step 10) are valid. Then,

a) Click “Apply” to enter the values into configuration parameter words.

b) Click “Done” to close the editor window.

Important: You must set the

EXTEND and RETRACT LIMITS after

setting the scale and offset. The Scale/Offset Calibration tool will

re-calculate any existing

EXTEND and RETRACT LIMITS automatically

when you use it to set a scale and offset.

12.For each axis, enter the desired end-point values for the

EXTEND

and RETRACT LIMITS in the screen’s PARAMETER section.

Enter them in the same engineering units as used in steps 7 and 10.

13. Initialize (activate) axis parameters with the “P

” Command.

14.Repeat this procedure for each axis in use.

Publication

1746-6.19 March 1998

Page 21

4–5

Getting Ready to Tune the Axes

Once you have set scale, offset, and extend/retract limits in open-loop

mode, you can now use the Hydraulic Configurator to tune the axis

using closed-loop move commands and axis plots. We suggest that you:

1. Leave un-entered configurations parameters at default, except for:

– Auto Stop to 000E0 (hard stop, only for LDT faults)

2. If not done already, initialize the axes with the “P” command.

3. Store two 6-word motion commands in the S

tored Command Editor:

– Mode word = 00000

(This sets integrator to Always Active and accel/decel to slow ramp.)

–

SPEED, ACCEL, and DECEL values at 20% of typical machine move

(For safety, start slow and increase

COMMAND VALUEs to desired end positions for the axis to tune

–

SPEED gradually.)

– Zero all six command words of the axes not to be tuned

4. Set the plot clock (in even-numbered seconds, 20 max) to longer

than you expect for the axis to run “tuning” moves.

5. ATTENTION: Highlight the axis you want to move before moving

the axis back and forth using stored commands [1] and [2].

Unexpected motion could occur if the wrong axis is highlighted.

6. Open the status bits window (Ctrl-B), and check the

STATUS word

for errors while the axis is moving.

Tuning Each Axis

7. View captured axis plots (click [

2

Observe the Sum-Error

value displayed in the window.

∩ ] in the ToolBar).

‘There is no substitute for experience when tuning an axis. This

section offers some guidelines, tips, and suggestions for tuning your

system. While helpful for many systems, they may not be the best

for a particular system. We help you with:

• General Procedure for Tuning an Axis

• Adjusting Command-word Speed and Acceleration values

• Adjusting Feedforward Parameters

• Using Acceleration Feedforwards

• Adjusting PID Gains

General Procedure for Tuning an Axis

Use this generalized procedure with the Hydraulic Configurator.

• Move the axis using stored commands [1] and [2].

• Observe the axis plot for each move.

• Adjust one configuration parameter at a time in the order given.

1. Observe plots of axis moves between the two positions that you

set up with stored commands in the previous section, Getting

Ready. Observe following error, overshoots, and oscillations.

For adjusting command values and configuration parameters, refer to

Adjusting Command-word Speed and Acceleration Values, page 4-7.

Publication

1746-6.19 March 1998

Page 22

4–6

2. The Following Error will probably vary as indicated by diverging plots

of target and actual speeds during acceleration or deceleration.

Target Speed

(pink)

Actual Speed

(dark blue)

Following Error

3. To achieve a nearly constant steady-state Following Error, increase

the

PROPORTIONAL GAIN until the plots of target and actual speeds

become parallel during acceleration or deceleration.

4. To minimize the Following Error, use the auto Adjust Feedforward

“F

” command. With each “F” command, the module boosts

(prescales) the drive output by increasing the

FEEDFORWARD term.

This brings the plots of target and actual positions to coincide.

Target Position

(powder blue)

Actual Position

(red)

Following Error

For additional information, refer to Feedforward Parameters, below.

5. For critical tuning, adjust the

To do this, observe the Sum-Error

plot screen. Repeat axis moves with adjustments until Sum-Error

ACCELERATION FEEDFORWARD term.

2

value found in the window on the

2

value reaches a minimum. Too much ACCELERATION

FEEDFORWARD will increase the Sum-Error

2

value.

Important: Critical tuning may increase pressure spikes. If the

axis load is too large, consider lowering your expectations of

machine performance and use smaller accel/decel values in the

motion command. Using the S-curve feature (Command Mode)

is another alternative.

For additional information on Acceleration Feedforward, refer to

Using Acceleration Feedforward, below.

Publication

1746-6.19 March 1998

6. For end-point stability, adjust the

INTEGRAL GAIN) to minimize the end-point position error by either

PROPORTIONAL GAIN (and

of two ways. Adjust P and/or I until the:

– end position oscillates. Then back down to 75% of P.

– Sum-Error

Remember to enter an

2

value no longer decreases with each adjustment.

IN POSITION value in the Config word to

monitor end-position stability.

Page 23

4–7

7. If moving a relatively large mass with a relatively small hydraulic

cylinder, first investigate the affect of:

a) Integrator Mode selection in the Command-mode word:

active always, for accel/decels, in position, or never.

b) Integrator Limit selection in the Config word:

20% for a typical hydraulic system, 80% for a difficult system.

Also, see step 6 for using

INTEGRAL GAIN to help minimize the

end-point position error.

For additional information on PID Gains, refer to that topic, below.

Adjusting Command-word Speed and Acceleration Values

Increase the SPEED and ACCELERATION command words gradually

while making long moves. Use Hydraulic Configurator to plot the

moves and look for following errors, overshoot, or oscillations.

Eventually, when the SPEED and ACCELERATIONS are too high, the

moves will cause an error on the axis.

If an overdrive error occurs, there is not enough drive capacity to drive

the axis at the requested SPEED. Should this occur, reduce the SPEED.

If excess Following Error occurs, the appropriate

FEEDFORWARD

configuration parameter must be adjusted for extend and retract moves.

If excess Following Error persists, ACCEL and DECEL ramps may be too

steep for your system response. You can reduce their values, or increase

ACCEL FEEDFORWARD term.

the

Also remember that you can specify either the time or the distance in

which the

ACCELERATION or DECELERATION must occur.

After correcting the problem of excess Following Error, keep moving the

axis back and forth with increasing

SPEED values until you reach desired

speed. Should the system seem a little sloppy, try increasing the

PROPORTIONAL GAIN until the axis moves with a steady state

FOLLOWING

ERROR

(as observed by axis plot) and stops at the end point

with minimum in-position error. Remember: the parameters are not

updated in the module until you issue the “P” command.

Adjusting Feedforward Parameters

In many hydraulic systems the feedforward parameters (EXTEND

FEEDFORWARD and RETRACT FEEDFORWARD) are the most

important parameters for position tracking during a move.

Use the auto Feedforward Adjust command “F” to minimize the

FOLLOWING

ERROR

. Refer to General Tuning Procedure, step 2.

For move information, refer to these parameters in the Help Topics.

Publication

1746-6.19 March 1998

Page 24

4–8

Important: When tuning the Feedforward term with command “F”,

plot sequential axis moves and compare plots of target position and

actual position until the two plots coincide.

Another way to adjust these parameters is to set the

GAIN and INTEGRAL GAIN to zero and the PROPORTIONAL GAIN

DIFFERENTIAL

to a small value (between 1 and 5), then make long slow moves in

both directions.

Adjust the

EXT FEEDFORWARD and RET FEEDFORWARD until the

axis tracks within 10% in both directions. In hydraulic systems, the

EXTEND and RETRACT FEEDFORWARD terms typically differ by

the ratio of the extend and retract piston areas.

Alternately, you can find the appropriate value for the

FEEDFORWARD

terms by making moves with the axis at a SPEED of 1,000. The

amount of output drive required to maintain this

value for the

FEEDFORWARD parameter.

SPEED is the correct

Using Acceleration Feedforwards

The ACCELERATION FEEDFORWARD terms are particularly useful for

axes which move large masses with relatively small cylinders. This

combination delays the start of movement, and the

FEEDFORWARD terms can help compensate for this delay.

ACCELERATION

ACCELERATION FEEDFORWARDS are easiest to adjust with the PID

gains set low. After commanding a move, plot it using Hydraulic

Configurator and look for a following error during the acceleration.

Increase the

minimized. For large masses the

ACCELERATION FEEDFORWARD until the error is

ACCELERATION FEEDFORWARD can

be in the tens of thousands.

Important: When tuning acceleration feedforward terms, you can

plot multiple axis moves and observe the Sum-Error

2

value found in

the window on the plot screen. Repeat axis moves and adjust this

term until the Sum-Error

2

value reaches a minimum.

Adjusting P-I-D Gains

PROPORTIONAL GAIN affects the responsiveness of the system.

Low gains make the system sluggish and unresponsive. Gains that

are too high make the axis oscillate or vibrate. You can adjust the

PROPORTIONAL GAIN by slowly increasing it and moving the axis.

When you see a tendency to oscillate as the axis moves or stops,

reduce the gain by 10 to 30 percent.

Publication

1746-6.19 March 1998

Page 25

4–9

It is usually desirable to have some INTEGRAL GAIN (5 to 50 counts)

to help compensate for valve null drift or changes in system dynamics.

Some systems may require larger

they are moving a large mass or are nonlinear. Too much

will cause oscillations. On the other hand, some hydraulic

GAIN

systems do not require

DIFFERENTIAL GAIN is used mainly on systems which have a

INTEGRAL GAIN.

INTEGRAL GAIN, in particular if

INTEGRAL

tendency to oscillate. This happens when heavy loads are moved

with relatively small cylinders.

DIFFERENTIAL GAIN will tend to

dampen out oscillations and help the axis track during acceleration

and deceleration. If you use

to increase the

PROPORTIONAL GAIN somewhat without causing the

DIFFERENTIAL GAIN, you may be able

system to oscillate.

Finding the Value of the Dead Band Eliminator

A disadvantage to

DIFFERENTIAL GAIN is that it amplifies position

measurement noise which can cause the system to chatter or

oscillate if the gain is too high or there is too much noise.

The

DEAD BAND ELIMINATOR compensates for valve overlap.

Typically it is required if the valve has relatively:

• large overlap (up to 20%)

• slow speed (less than 40 Hz)

• large capacity for its application

(For a description of how Dead Band Eliminator affects the system,

refer that subject under Hydraulic Configurator Help Topics.)

Important: Use this procedure only if your valve needs the

BAND ELIMINATOR. If not, go to the next section, Saving Parameters.

This procedure requires operating the module in open-loop mode with

drive outputs connected to the amplifier. In this procedure, you will

increase the drive output until the axis just moves in one direction, then

in the other.

1. Select the axis and enter a small positive value (such as 200 mV)

in the

COMMAND VALUE number field.

2. Issue the open-loop output command “O”.

3. Look for axis motion.

4. Important: If necessary, be prepared to stop axis motion. To stop:

– Enter zero in the

COMMAND VALUE number field.

– Issue the open-loop output command “O”.

5. Slowly increase the value that you entered in the

COMMAND VALUE

number field, and repeat steps 2 and 3 until the axis just starts to move.

Important: Observe if the axis moved in the intended direction.

If in the wrong direction, check drive wiring polarity and hydraulic

plumbing before reversing the drive mode in the Config word.

DEAD

Publication

1746-6.19 March 1998

Page 26

4–10

6. Back down the value below no motion. Write down this valve.

7. Repeat steps 1-6 with negative values for opposite direction.

8. Determine

DEAD BAND ELIMINATOR value. It is the larger of the

values from step 6, regardless of sign (").

9. Enter the value of the

DEAD BAND ELIMINAT

OR

in the number

field in the Parameter section of the main screen.

10.Transfer the parameter to the module using the “P

” Command.

Saving Parameters

At any time during tuning, you can save configuration parameters:

• For PC backup, save the file of configuration parameters from the

Hydraulic Configurator with the “Save-as” function.

• Store them in integer (N) files of the SLC processor to insure that

the ladder program matches the configuration parameters, issue a

ladder logic command to copy the M1 file of configuration

parameters from the module into SLC processor integer (N) files.

For ladder logic examples, refer to chapter 5.

Publication

1746-6.19 March 1998

Page 27

Using Ladder Logic

Chapter 5

Chapter Objectives

Obtaining Sample Ladder Program from the Internet

This chapter covers:

• Obtaining sample ladder program from the Internet

• Configuring your SLC processor, off-line

• Using the sample ladder program, RSExampl.RSS, to:

– copy configuration parameters to the SLC processor

– copy configuration parameters to the module

– operate axis movement automatically

– jog the axis

– respond to loss or restoration of hydraulic power

– run multiple synchronized axes

You can obtain sample ladder logic from the Allen-Bradley website

on the Internet and download it to your PC as an executable file.

To Access the Internet:

1. Access the Allen-Bradley website (and module software logic) at:

2. The sample ladder program (130 Kbyte) is in the same file as the

Hydraulic Configurator (2.9Mbyte).

Configuring Your SLC Processor, Off-line

3. Download the Hydraulic Configurator and ladder program to your PC.

4. Move the sample program into the subdirectory on your hard drive

where your programming software looks for files.

For example, with

This procedure uses RSLogix500 version 2.0 or later. For other types of

programming software, the procedure and/or prompts may vary.

You must modify the I/O configuration to match your system layout and

change associated addresses, offline.

1. Open file QSEXAMPL.RSS from the file pull-down window.

2. Select the I/O Configuration icon and launch it. Then select:

A. Processor type (ladder sample is SLC 5/04).

B. Module slot number (ladder sample is slot 2 in 4-slot chassis).

C. Module ID is 13627 entered under “Other”.

3. The sample ladder logic creates M0/M1 files at 64 words each.

If you move the module to another slot, be sure to retain the files.

4. Search and replace all addresses that must be changed.

RSLogix500: C:\RSI\Logix500\QSEXAMPL.RSS.

5. Save the file as a new file to preserve the original file for backup.

Publication

1746-6.19 March 1998

Page 28

5–2

Using the Sample Ladder Program

Consider creating a bit and data address table for your own applicaion.

Data and bit addresses associated with the sample program are:

Address: Description:

N7:0 current state of axis 1, programmed automatic motion

N7:1 current state of axis 2, programmed automatic motion

N7:4 next state of axis 1, programmed automatic motion

N7:5 next state of axis 2, programmed automatic motion

N11 M-file initialization parameters

N12:0-5 axis 1 advance profile, programmed automatic motion

N12:6-11 axis 2 advance profile, programmed automatic motion

N12:12-17 axis 1 retract profile, programmed automatic motion

N12:18-23 axis 2 retract profile, programmed automatic motion

N12:24-29 axis 1 advance profile for jog

N121:30-35 axis 1 retract profile for jog

B3:0/0 copy M file from N11 into module and initialize axis 1 and 2

B3:0/1 copy M file from module into N11

B3:0/3 jog advance

B3:0/4 jog retract

B3:0/7 enter programming for automatic motion

Load the ladder file into the SLC processor.

Important: You can run the sample ladder program from the desktop

using pre-programmed configuration parameters in file N11 without

LDT or drive output connections to the module because the Simulate bit

is set by default in each axis Config word in the sample program.

ATTENTION: To guard against equipment damage or personal injury,

do NOT attempt to operate the module outside of simulate mode

without first initializing valid configuration parameters in the module.

If you have already initialized the module with valid configuration

parameters that suit your machine, you should copy them from the

module into the N11 file. (Refer to Copy Configuration Parameters to

the SLC Processor, next.)

If you have NOT initialized the module with valid configuration

parameters, copy the N file of the sample program to the module to

initialize axis 1 and 2 with pre-programmed configuration parameters

(Refer to Copy Configuration Parameters to the Module, next.)

Publication

1746-6.19 March 1998

Page 29

5–3

Copy Configuration Parameters to the SLC Processor

| INITIALIZE GET from QS Module

| Enable this rung to copy configuration parameters to the SLC N file |

| after you change them with the Hydraulic Configurator. |

| |

| Set ON to read |

| parameters |

| after tuning Parameters for Axis 1 |

| GET_PARAMETERS CONFIG1 |

| B3:0 +COP–––––––––––––––+ |

|–––] [–––––––––––––––––––––––––––––––––––––––––+–+COPY FILE +–+–|

| 1 | |Source #M1:2.0| | |

| | |Dest #N11:0| | |

| | |Length 64| | |

| | +––––––––––––––––––+ | |

| | | |

| | Set ON to read | |

| | parameters | |

| | after tuning | |

| | GET_PARAMETERS | |

| | B3:0 | |

| +––––––––––(U)–––––––––+ |

| 1 |

Copy Configuration Parameters to the Module

This rung copies configuration parameters from SLC N11 file to the

module’s M0 file and issues the “P” command for axis 1 and 2.

The “P” command is the decimal value “80” that is moved to output

image Command words O:2.5 (axis 1) and O:2.13 (axis 2).

Important: Configuration parameters copied to the module’s M0

file are not initialized (activated) until the “P” command is issued.

Important: This rung will overwrite configuration parameters

currently stored in the module. If you want to retain configuration

parameters stored in the module, be sure that you have copied them to

the N11 file (previous section) before activating this rung.

| Set ON to |

| initialize the |

| QS module |

| INITIALIZE M0_PARAMETER_DATA |

| B3:0 +COP–––––––––––––––+ |

|–––] [–––––––––––––––––––––––––––––––––––––––––+–+COPY FILE +–+–|

| 0 | |Source #N:11.0| | |

| | |Dest #M0:2.0| | |

| | |Length 64| | |

| | +––––––––––––––––––+ | |

| | | |

| | AXIS1_COMMAND | |

| | +MOV–––––––––––––––+ | |

| +–+MOVE FILE +–+ |

| | |Source 80 | | |

| | | 80<| | |

| | |Dest #O:2.5 | | |

| | | 71<| | |

| | +––––––––––––––––––+ | |

| | | |

| | AXIS2_COMMAND | |

| | +MOV–––––––––––––––+ | |

| +–+MOVE FILE +–+ |

| | |Source 80 | | |

| | | 80<| | |

| | |Dest #O:2.13 | | |

| | | 71<| | |

| | +––––––––––––––––––+ | |

| | | |

| | Set ON to | |

| | initialize the | |

| | the QS module | |

| | INITIALIZE | |

| | B3:0 | |

| +––––––––––(U)–––––––––+ |

| | 0 | |

| | | |

| | Last command | |

| | has NOT been | |

| | acknowledged | |

| | AXIS_WAIT_ACK | |

| | B13:0 | |

| +––––––––––(L)–––––––––+ |

| 0 |

Publication

1746-6.19 March 1998

Page 30

5–4

Back and Forth Motion with State-machine Logic

(Programming for Automatic Operation)

This ladder logic example moves axes 1 and 2 back and forth with

Go “G

” commands. Each move has its own set of motion profile

words (mode, accel, decel, speed, and position).

The example is a state machine with four automatic states:

State: Description:

0 No motion. Used when automatic mode is not enabled

Moves axis 1 and 2 independently

1

Uses profile command words N12:0-5 (axis 1) and N12:12-17 (axis 2)

Synchronizes axis 1 and 2 to reach the end point at the same time

2

Uses profile command words N12:6-11 (axis 1) and N12:18-23 (axis 2)

3 Pauses five seconds, then returns to state 1.

Error detection and recovery logic is application dependent, and

should include (for each axis) recovery from module-detected errors

and axis timeouts.

The mode words in these profile commands put the module into

simulate mode, which means it is isolated from LDT inputs and

output drive. It allows for axis-position update and axis plotting.

You cannot be jogging when you attempt to enter automatic mode, and

you cannot be in automatic mode when attempting a jog.

Important: If you intend to use this sample program on a live machine

(module NOT in simulate mode), be sure that you have:

– stored valid motion profiles in N12 files

– initialized the module with valid configuration parameters such as

axis limits, scale, offset, and feedforwards

Assuming that axes are initialized, the setting of bit B3:0/7 simulates

an auto operation switch that starts the state machine in state 1.

| To run this example, set HYDRAULICS OK bit in the data table. |

| Then set the AUTO_SS bit. |

| |

| Valve drive power |

| Imitates and pumps are ON, |

| Operator electronic servo Run state |

| Auto Mode valve is enabled, Axis has received machine |

| select SW blocking valves open valid “P” command Axis is jogging example |

| AUTO_SS HYDRAULICS_OK AXIS1_INITIALIZED AXIS JOGGING AUTO_MODE |

| B3:0 B3:0 I:2 B13:3 B3:0 |

|–––] [–––––––––] [–––––––––––––––––––] [–––––––––––––––––––]/[––––––––––––( )––––|

| 7 2 70 0 14 |

| |

| Set the state machine to state 1 for all axes when entering auto mode. |

| This fill command initializes all four axes. |

| |

| Run state |

| machine |

| example One Shot |

| AUTO_MODE AUTO_MODE_OS AXIS1_NEXT_STATE |

| B3:0 B3:0 +FLL–––––––––––––––+ |

|–––] [––––––––––––––[OSR]––––––––––––––––––––––––––––––––––––+FILE FILL +–|

| 14 15 |Source 1 | |

| |Dest #N7:4 | |

| |Length 4 | |

| +––––––––––––––––––+ |

Publication

1746-6.19 March 1998

Page 31

5–5

| |

| Reset the state machine for all axes if not in auto mode. |

| In state 0, the auto mode state machine does not write to the module’s I/O. |

| |

| Run state |

| machine |

| example |

| AUTO_MODE AXIS1_NEXT_STATE |

| B3:0 +FLL–––––––––––––––+ |

|–––]/[–––––––––––––––––––––––––––––––––––––––––––––––––––––––+FILE FILL +–|

| 14 |Source 0 | |

| |Dest #N7:4 | |

| |Length 4 | |

| +––––––––––––––––––+ |

| |

| Copy next state to state machine. |

| This technique avoids race conditions. |

| AXIS1_NEXT_STATE |

| +COP–––––––––––––––+ |

|–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––+COPY FILE +–|

| |Source #N7:4 | |

| |Dest #N7:0 | |

| |Length 4 | |

| +––––––––––––––––––+ |

| AXIS 1 and 2 STATE 1 |

| |

| Use motion profile words (mode, accel, decel, speed, and command) stored in |

| N12:0-5 (axis 1) and N12:12-17 (axis 2). |

| Wait for IN-POSITION bit to go high. Then set NEXT STATE to 2. |

| |

| Oneshot |

| AXIS1_STATE storage Bit AXIS1_MODE |

| +EQU–––––––––––––––+ B3:1 +COP–––––––––––––––+ |

|––+EQUAL +––+–––[OSR]––––––––––––––––––––––+–+COPY FILE +–+–+–|

| |Source A N7:0 | | 0 | |Source #N:12.0| | | |

| | 3<| | | |Dest #O:2.0| | | |

| |Source B 1 | | | |Length 6| | | |

| | 1<| | | +––––––––––––––––––+ | | |

| +––––––––––––––––––+ | | | | |

| | | AXIS2_MODE | | |

| | | +COP–––––––––––––––+ | | |

| | +–+COPY FILE +–+ | |

| | | |Source #N12:12| | | |

| | | |Dest #O2:8| | | |

| | | |Length 6| | | |

| | | +––––––––––––––––––+ | | |

| | | | | |

| | | Last command | | |

| | | has not been | | |

| | | acknowledged | | |

| | | AXIS_WAIT_ACK | | |

| | | B13:0 | | |

| | +––––––––(L)–––––––––––+ | |

| | 0 | |

| | Last command ACTUAL POSITION is | |

| | has not been within IN POSITION | |

| | acknowledged units of COMMAND | |

| | AXIS_wAIT_ACK POSITION AXIS1_NEXT STATE | |

| | B13:0 I/2 +–+MOV–––––––––––––––+ | |

| +–––––––]/[––––––––––] [–––––––––+–+MOVE FILE +–+ |

| 0 64 | |Source 2 | | |

| | | 2<| | |

| | |Dest N7:4 | | |

| | | 3<| | |

| | +––––––––––––––––––+ | |

| | | |

| | AXIS2_NEXT STATE | |

| | +MOV–––––––––––––––+ | |

| +–+MOVE FILE +–+ |

| |Source 2 | |

| | 2<| |

| |Dest N7:5 | |

| | 3<| |

| +––––––––––––––––––+ |

| |

Publication

1746-6.19 March 1998

Page 32

5–6

| AXIS 1 and 2 STATE 2 |

| |

| Use motion profile words (mode, accel, decel, speed, and command) stored in |

| N12:6-11 (axis 1) and N12:18-23 (axis 2). |

| Wait for IN-POSITION bit to go high. Then set NEXT STATE to 3. |

| |

| Oneshot |

| AXIS1_STATE storage Bit AXIS1_MODE |

| +EQU–––––––––––––––+ B3:1 +COP–––––––––––––––+ |

|––+EQUAL +––+–––[OSR]––––––––––––––––––––––+–+COPY FILE +–+–+–|

| |Source A N7:0 | | 12 | |Source #N:12.6| | | |

| | 3<| | | |Dest #O:2.0| | | |

| |Source B 2 | | | |Length 6| | | |

| | 2<| | | +––––––––––––––––––+ | | |

| +––––––––––––––––––+ | | | | |

| | | AXIS2_MODE | | |

| | | +COP–––––––––––––––+ | | |

| | +–+COPY FILE +–+ | |

| | | |Source #N12:18| | | |

| | | |Dest #O2:8| | | |

| | | |Length 6| | | |

| | | +––––––––––––––––––+ | | |

| | | | | |

| | | Last command | | |

| | | has not been | | |

| | | acknowledged | | |

| | | AXIS_WAIT_ACK | | |

| | | B13:0 | | |

| | +––––––––(L)–––––––––––+ | |

| | 0 | |

| | Last command ACTUAL POSITION is | |

| | has not been within IN POSITION | |

| | acknowledged units of COMMAND | |

| | AXIS_wAIT_ACK POSITION AXIS1_NEXT STATE | |

| | B13:0 I/2 +–+MOV–––––––––––––––+ | |

| +–––––––]/[––––––––––] [–––––––––+–+MOVE FILE +–+ |

| 0 64 | |Source 3 | | |

| | | 3<| | |

| | |Dest N7:4 | | |

| | | 3<| | |

| | +––––––––––––––––––+ | |

| | | |

| | AXIS2_NEXT STATE | |

| | +MOV–––––––––––––––+ | |

| +–+MOVE FILE +–+ |

| |Source 3 | |

| | 3<| |

| |Dest N7:5 | |

| | 3<| |

| +––––––––––––––––––+ |

| |

| AXIS 1 and 2 STATE 3 |

| |

| Wait for 5 seconds. Then set the NEXT_STATE to 1. |

| Axis 1 |

| State 3 |

| AXIS1_STATE Delay |

| +EQU–––––––––––––––+ +TON–––––––––––––––+ |

|––+EQUAL +––+–––––––––––––––––––––––––––+TIMER ON DELAY +–(EN)–––+–|

| |Source A N7:0 | | |Timer T4:0 | | |

| | 3<| | |Time Base 1.0 +–(DN)–– | |

| |Source B 3 | | |Preset 5<| | |

| | 3<| | |Accum 1<| | |

| +––––––––––––––––––+ | +––––––––––––––––––+ | |

| | Axis 1 | |

| | State 3 | |

| | Delay | |

| | Complete AXIS1_NEXT STATE | |

| | T4:0 +–+MOV–––––––––––––––+ | |

| +–––––––] [––––––––––––––––––––––+–+MOVE FILE +–+ |

| DN | |Source 1 | | |

| | | 1<| | |

| | |Dest N7:4 | | |

| | | 3<| | |

| | +––––––––––––––––––+ | |

| | | |

| | AXIS2_NEXT STATE | |

| | +MOV–––––––––––––––+ | |

| +–+MOVE FILE +–+ |

| |Source 1 | |

| | 1<| |

| |Dest N7:5 | |

| | 3<| |

| +––––––––––––––––––+ |

Publication

1746-6.19 March 1998

Page 33

5–7

Jogging the Axes

In the sample program:

– Commands for jogging axis 1 are stored in N12:24-29 (to advance)

and N12: 30-35 (to retract).

– Jog “pushbutton” addresses are B3:0/3 (advance) and B3:0/4 (retract).

When either jog “pushbutton” is pressed:

– extend and retract limits are copied into the jog command position

words in the N files

– the corresponding N file is copied to the output word to the module

This provides a target position at the end of travel in each direction.

When the jog “pushbutton” is released, zero is copied into the jog

command speed word, allowing the axis to decelerate to a stop and

unlatch the jog command.

You cannot be in automatic mode when attempting a jog, and you cannot

be jogging when you attempt to enter automatic mode.

Important: If you intend to use this sample program on a live machine

(module NOT in simulate mode), be sure that you have:

– stored valid motion profiles in N12 files

– initialized the module with valid configuration parameters such as

axis limits, scale, offset, and feedforwards

| AXIS 1 and 2 STATE 2 |

| |

| This example uses different motion profile words (stored in N12:24-35) |

| than used by the ones for the state machine example (rungs 4-10). |

| |

| Axis 1 Jog Extend |

| (Jog Pushbutton |

| + interlocks Oneshot Jog Advance Limit |

| B3:0 B13:4 +COP–––––––––––––––+ |

|––+–––––––] [–––––––––––+–––[OSR]––––––––––––––––––––––––+–+COPY FILE +–+–|

| | 3 | 7 | |Source #N11.3| | |

| | | | |Dest #N12:28| | |

| | Axis 1 Jog Retract | | |Length 1| | |

| | (Jog Pushbutton | | +––––––––––––––––––+ | |

| | + interlocks) | | | |

| | B3:0 | | Jog Retract Limit | |

| +––––––] [––––––––––––+ | +COP–––––––––––––––+ | |

| 4 +–+COPY FILE +–+ |

| |Source #N11:4| |

| |Dest #N12:34| |

| |Length 1| |

| Run State +––––––––––––––––––+ |

| Axis 1 Jog Extend Machine Oneshot |

| (Jog Pushbutton Example Axis is jogging Storage |

| + interlocks AUTO_MODE AXIS JOGGING Bit AXIS1_MODE |

| B3:0 B3:0 B13:3 B13:4 +COP–––––––––––––––+ |

|–––––––––] [––––––––––––––]/[––––+––––––]/[––––––––[OSR]–––+COPY FILE +–+–|

| 3 14 | 0 4 |Source #N12.24| | |

| | |Dest #O:2.0| | |

| | |Length 6| | |

| | +––––––––––––––––––+ | |

| | | |

| | Axis is jogging | |

| | AXIS_JOGGING | |

| | B13:3 | |

| +––––––––––––––––––––––––––––––––(L)–––––––––––+ |

| 0 |

Publication

1746-6.19 March 1998

Page 34

5–8

| Run State |

| Axis 1 Jog Retract Machine Oneshot |

| (Jog Pushbutton Example Storage |

| + interlocks AUTO_MODE Bit AXIS1_MODE |