Page 1

Installation Instructions

Mold Pressure Module

(catalog number 1746-MPM)

Before you begin

Use this document as a guide to installing and powering-up your Mold

Pressure Module. We assume that you are already familiar with the SLC

™

500

family of Small Logic Controllers and associated I/O modules.

Tools that you need

•

1/4” slotted (#2) or phillips screwdriver

•

needle-nose pliers

Handling the module

Take these precautions to guard against ESD damage:

!

!

ATTENTION:

module. Follow these guidelines:

• touch a grounded object to discharge potential static

• wear an approved grounding wriststrap

• do not touch circuit components inside the module

• if available, use a static-safe work station

• when not in use, store the module in its anti-static bag.

ATTENTION:

backplane power is on. An electrical arc may occur that can

cause an explosion in a hazardous environment and/or cause

damage to the module or degrade its performance.

Electrostatic discharge can damage the

Do not insert or remove this module while

Publication 1746-5.13 July 1998

Page 2

2 Mold Pressure Module

Recommendation for using associated software

We recommend the following software to use this module effectively:

•

To display molding parameters processed by the module,

your personal

opuer us e euppe n soare

ro ! enolo"es# $n% ra&erse y# ’$

on using the software, refer to DARTWin Software Installation and Use

manual.

•

To program the SLC processor to interface the module with molding

machine operation, your PC should be equipped with programming

software RSLogix 500™ from Rockwell Software. For instructions on

using the software, refer to the documentation that accompanied it.

. For instructions

What you need to do to set up and operate the module

This document covers installing, powering up, and operating the module.

Section Description Page

1 what the module does 3

2 wire module I/O 4

3 module I/O 5

4 configure the module with jumper plugs 7

5 configure the SLC processor’s I/O, G file, and M0/M1 files 8

6 set sensor inputs to zero 11

7 check channel operation 11

8 write ladder logic 12

9 troubleshoot the module 15

10 use DartWin software to display processed data 15

11 listing of M0/M1 file words 16

12 specifications 18

13 compliance with European Union directives 19

14 CSA hazardous location approval 20

Publication 1746-5.13 July 1998

Page 3

Mold Pressure Module 3

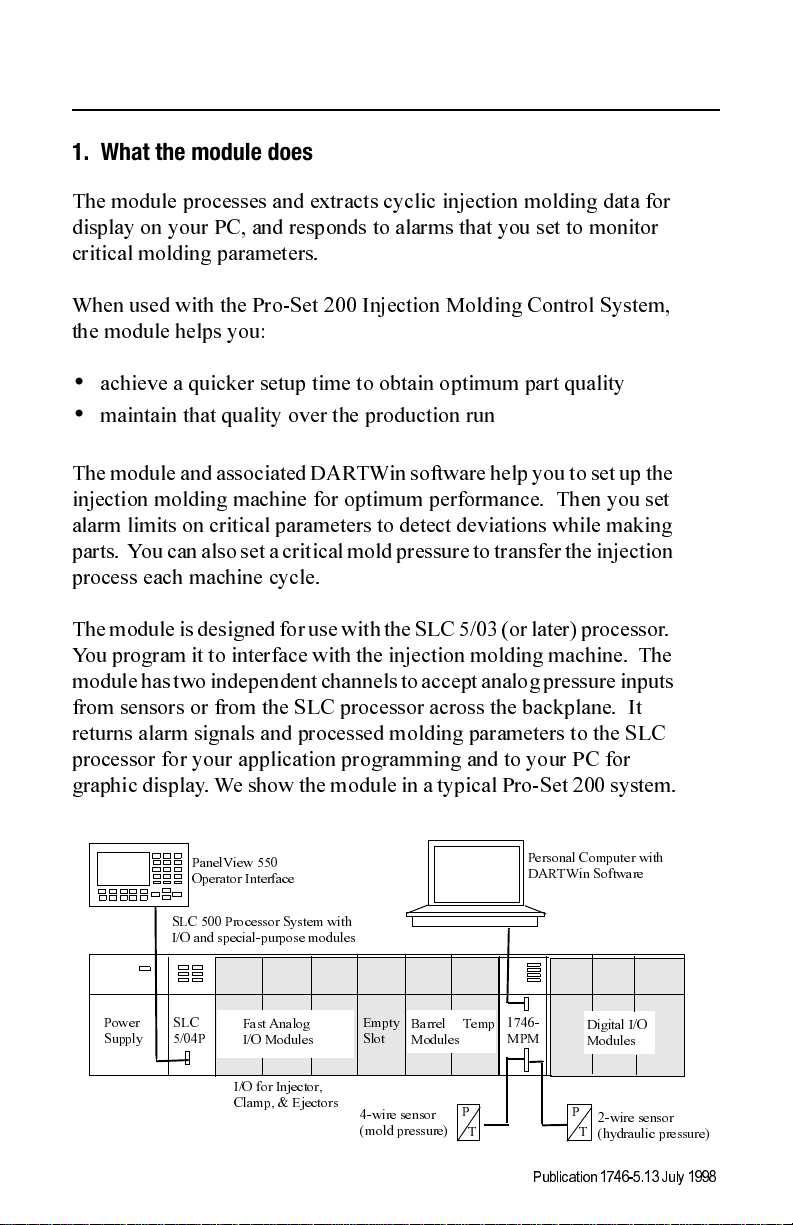

1. What the module does

The module processes and extracts cyclic injection molding data for

display on your PC, and responds to alarms that you set to monitor

critical molding parameters.

When used with the Pro-Set 200 Injection Molding Control System,

the module helps you:

•

achieve a quicker setup time to obtain optimum part quality

•

maintain that quality over the production run

The module and associated DARTWin software help you to set up the

injection molding machine for optimum performance. Then you set

alarm limits on critical parameters to detect deviations while making

parts. You can also set a critical mold pressure to transfer the injection

process each machine cycle.

The module is designed for use with the SLC 5/03 (or later) processor.

You program it to interface with the injection molding machine. The

module has two independent channels to accept analog pressure inputs

from sensors or from the SLC processor across the backplane. It

returns alarm signals and processed molding parameters to the SLC

processor for your application programming and to your PC for

graphic display. We show the module in a typical Pro-Set 200 system.

Power

Supply

PanelView 550

Operator Interface

SLC 500 Processor System with

I/O and special-purpose modul es

SLC

5/04P

Fast Analog

I/O Modules

I/O for Injector,

Clamp, & Ejectors

Empty

Barrel Temp

Slot

Modules

4-wire sensor

(mold pressure)

Personal Computer with

DARTWin Software

1746-

MPM

P

T

Digital I/O

Modules

P

2-wire sensor

T

(hydraulic pressure)

Publication 1746-5.13 July 1998

Page 4

4 Mold Pressure Module

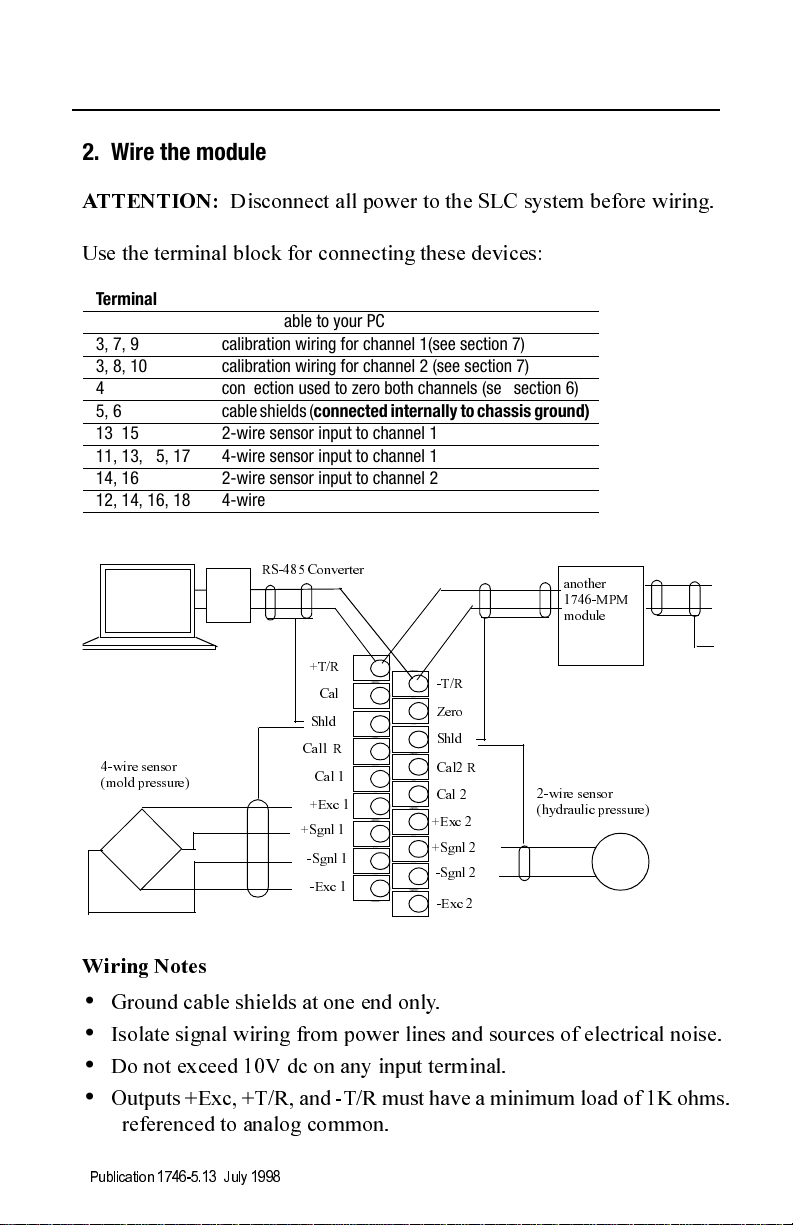

2. Wire the module

ATTENTION:

Disconnect all power to the SLC system before wiring.

Use the terminal block for connecting these devices:

Terminal # Device

1, 2 RS-485 cable to your PC

3, 7, 9 calibration wiring for channel 1(see section 7)

3, 8, 10 calibration wiring for channel 2 (see section 7)

4 connection used to zero both channels (see section 6)

5, 6 cable shield s (connected internally to chassis ground)

13, 15 2-wire sensor input to channel 1

11, 13, 15, 17 4-wire sensor input to channel 1

14, 16 2-wire sensor input to channel 2

12, 14, 16, 18 4-wire sensor input to channel 2

RS-485 Converter

+T/R

1

2

-T/R

4

Zero

Shld

6

8

Cal2 R

10

Cal 2

12

+Exc 2

14

+Sgnl 2

-Sgnl 2

16

18

-Exc 2

2-wire sensor

(hydraulic pressure)

4-wire sensor

(mold pressure)

Cal

Shld

Cal1 R

Cal 1

+Exc 1

+Sgnl 1

-Sgnl 1

-Exc 1

3

5

7

9

11

13

15

17

another

1746-MPM

module

Wiring Notes

•

Ground cable shields at one end only.

•

Isolate signal wiring from power lines and sources of electrical noise.

•

Do not exceed 10V dc on any input terminal.

•

Outputs +Exc, +T/R, and -T/R must have a minimum load of 1K ohms.

referenced to analog common.

Publication 1746-5.13 July 19 98

Page 5

Mold Pressure Module 5

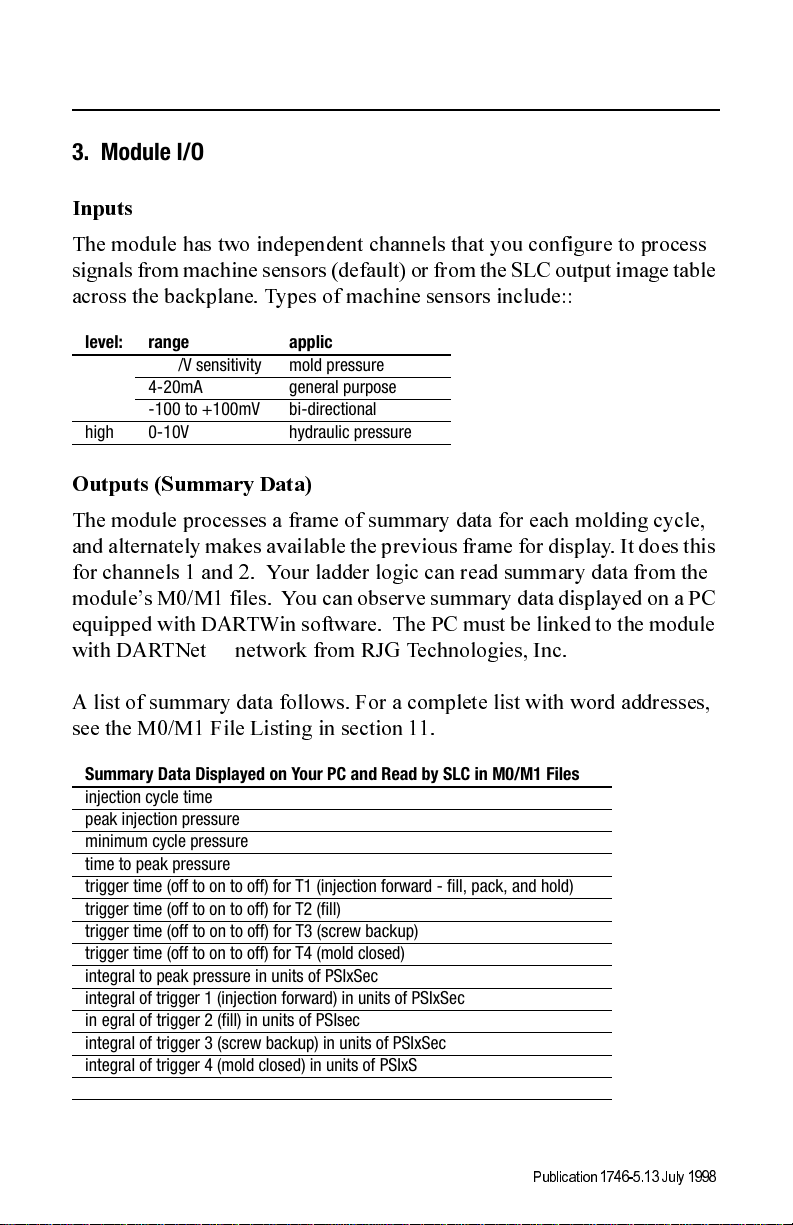

3. Module I/O

Inputs

The module has two independent channels that you configure to process

signals from machine sensors (default) or from the SLC output image table

across the backplane. Types of machine sensors include::

level: range application:

low 2mV/V sensitivity mold pressure

4-20mA general purpose

-100 to +100mV bi-directional

high 0-10V hydraulic pressure

Outputs (Summary Data)

The module processes a frame of summary data for each molding cycle,

and alternately makes available the previous frame for display. It does this

for channels 1 and 2. Your ladder logic can read summary data from the

module’s M0/M1 files. You can observe summary data displayed on a PC

equipped with DARTWin software. The PC must be linked to the module

with DARTNet

network from RJG Te chnolo gi es , Inc.

A list of summary data follows. For a complete list with word addresses,

see the M0/M1 File Listing in section 11.

Summary Data Displayed on Your PC and Read by SLC in M0/M1 Files

injection cycle time

peak injection pressure

minimum cycle pressure

time to peak pressure

trigger time (off to on to off) for T1 (injection forward - fill, pack, and hold)

trigger time (off to on to off) for T2 (fill)

trigger time (off to on to off) for T3 (screw backup)

trigger time (off to on to off) for T4 (mold closed)

integral to peak pressure in units of PSIxSec

integral of trigger 1 (injection forward) in units of PSIxSec

integral of trigger 2 (fill) in units of PSIsec

integral of trigger 3 (screw backup) in units of PSIxSec

integral of trigger 4 (mold closed) in units of PSIxSec

integral of injection cycle in units of PSIxSec

Publication 1746-5.13 July 1998

Page 6

6 Mold Pressure Module

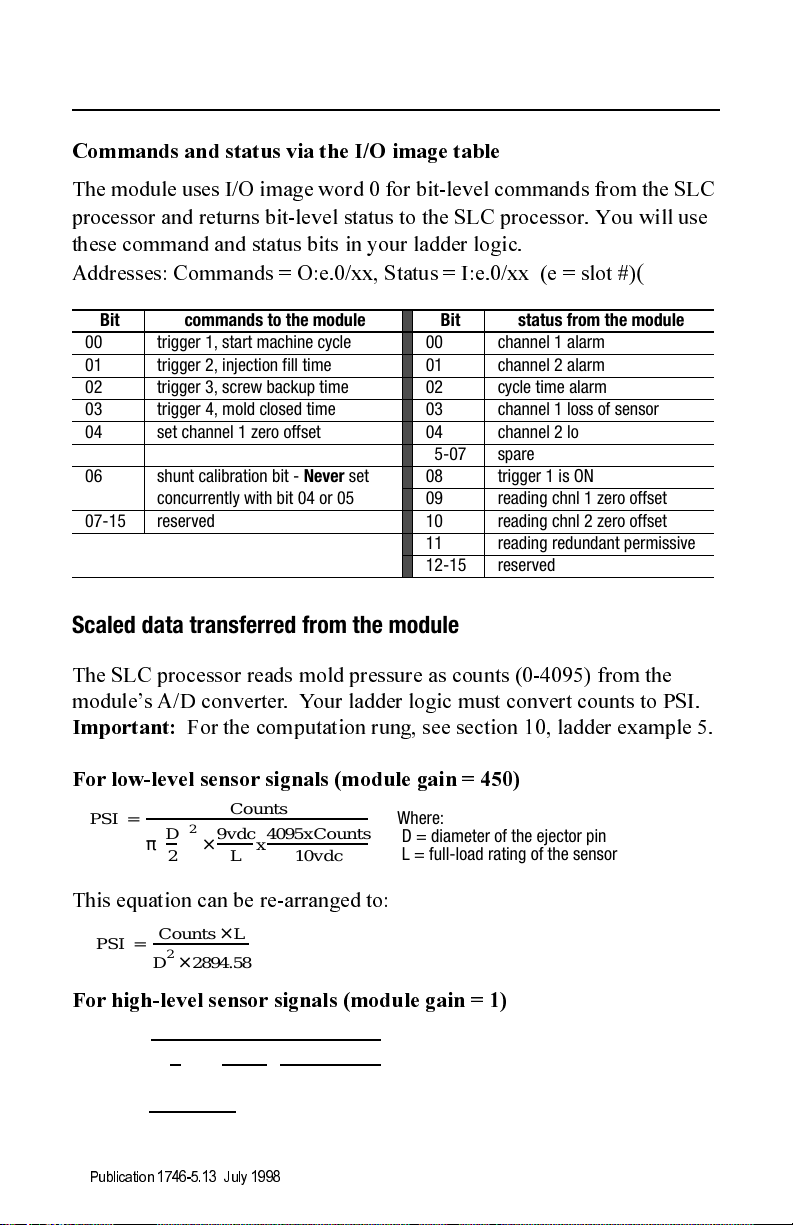

Commands and status via the I/O image table

The module uses I/O image word 0 for bit-level commands from the SLC

processor and returns bit-level status to the SLC processor. You will use

these command and status bits in your ladder logic.

Addresses: Comm ands = O:e.0/xx, Status = I: e.0/ xx (e = slot #)

Bit commands to the module Bit status from the module

00 trigger 1, start machine cycle 00 channel 1 alarm

01 trigger 2, injection fill time 01 channel 2 alarm

02 trigger 3, screw backup time 02 cycle time alarm

03 trigger 4, mold closed time 03 channel 1 loss of sensor

04 set channel 1 zero offset 04 channel 2 loss of sensor

05 set channel 2 zero offset 05-07 spare

06 shunt calibration bit - Never set

concurrently with bit 04 or 05

07-15 reserved 10 reading chnl 2 zero offset

08 trigger 1 is ON

09 reading chnl 1 zero offset

11 reading redundant permissive

12-15 reserved

(

Scaled data transferred from the module

The SLC processor reads mold pressure as counts (0-4095) from the

module’s A/D converter. Your ladder logic must convert counts to PSI.

Important:

For low-level sensor signals (module gain = 450)

PSI

For the computation rung, see section 10, ladder example 5.

2

× x

Counts

9vdc

------------

L

4095xCounts

----------------------------------

10vdc

Where:

D = diameter of the ejector pin

L = full-load rating of the sensor

--------------------------------------------------------------------------

=

D

--- -

π

2

This equation can be re-arranged to:

Counts L×

------------------------------- -

PSI

=

2

2894.58×

D

For high-level sensor signals (module gain = 1)

2

× x

3612.2×

Counts

10vdc

---------------

L

4095xCounts

----------------------------------

10vdc

Important:

For a sensor with 20mA full-load output,

use this same computation.

-----------------------------------------------------------------------------

PSI

=

D

--- -

π

2

Counts L×

-----------------------------

=

PSI

Publication 1746-5.13 July 19 98

2

D

Page 7

Mold Pressure Module 7

Pressure values transferred from the SLC data table to the module must be

integer numbers in units of PSI. If using the Pro-Set 200 Injection Control

System , the ladder logic provides pressur e val ues in the corre ct format.

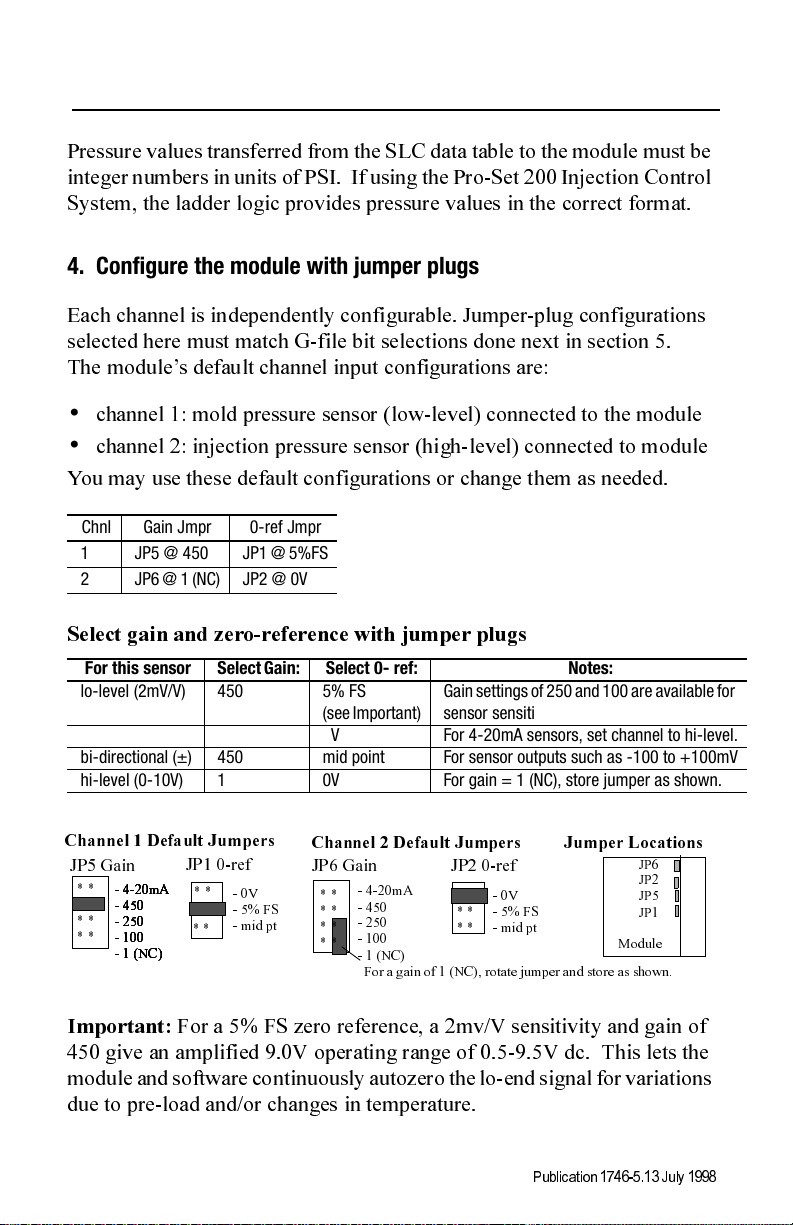

4. Configure the module with jumper plugs

Each channel is independently configurable. Jumper-plug configurations

selected here must match G-file bit selections done next in section 5.

The module’s default channel input configurations are:

•

channel 1: mold pressure sensor (low-level) connected to the module

•

channel 2: injection pressure sensor (high-level) connected to module

You may use these default configurations or change them as needed.

Chnl Gain Jmpr 0-ref Jmpr

1 JP5 @ 450 JP1 @ 5%FS

2 JP6 @ 1 (NC) JP2 @ 0V

Select gain and zero-reference with jumper plugs

For this sensor Select Gain: Select 0- ref: Notes:

lo-level (2mV/V) 450 5% FS

(see Important)

lo-level (4-20mA) 1 0V For 4-20mA sensors, set channel to hi-level.

bi-directional (±) 450 mid point For sensor outputs such as -100 to +100mV

hi-level (0-10V) 1 0V For gain = 1 (NC), store jumper as shown.

Gain settings of 250 and 100 are available for

sensor sensitivities of 6 and 9 mV/V.

Channel 1 Default Jumpers

JP5 Gain JP6 Gain

* *

- 4-20mA

- 4-20mA

- 4-20mA

- 4-20mA

- 4-20mA

- 450

- 450

- 450

- 450

- 450

* *

- 250

- 250

- 250

- 250

- 250

* *

- 100

- 100

- 100

- 100

- 100

- 1 (NC)

- 1 (NC)

- 1 (NC)

- 1 (NC)

- 1 (NC)

Important:

JP1 0-ref

* *

- 0V

- 5% FS

- mid pt

* *

For a 5% FS zero reference, a 2mv/V sensitivity and gain of

Channel 2 Default Jumpers

* *

* *

* *

* *

JP2 0-ref

- 4-20mA

- 450

- 250

- 100

- 1 (NC)

For a gain of 1 (NC), rotate jumper and store as shown.

* *

* *

- 0V

- 5% FS

- mid pt

Jumper Locations

JP6

JP2

JP5

JP1

Module

450 give an amplified 9.0V operating range of 0.5-9.5V dc. This lets the

module and software continuously autozero the lo-end signal for variations

due to pre-load and/or changes in temperature.

Publication 1746-5.13 July 1998

Page 8

8 Mold Pressure Module

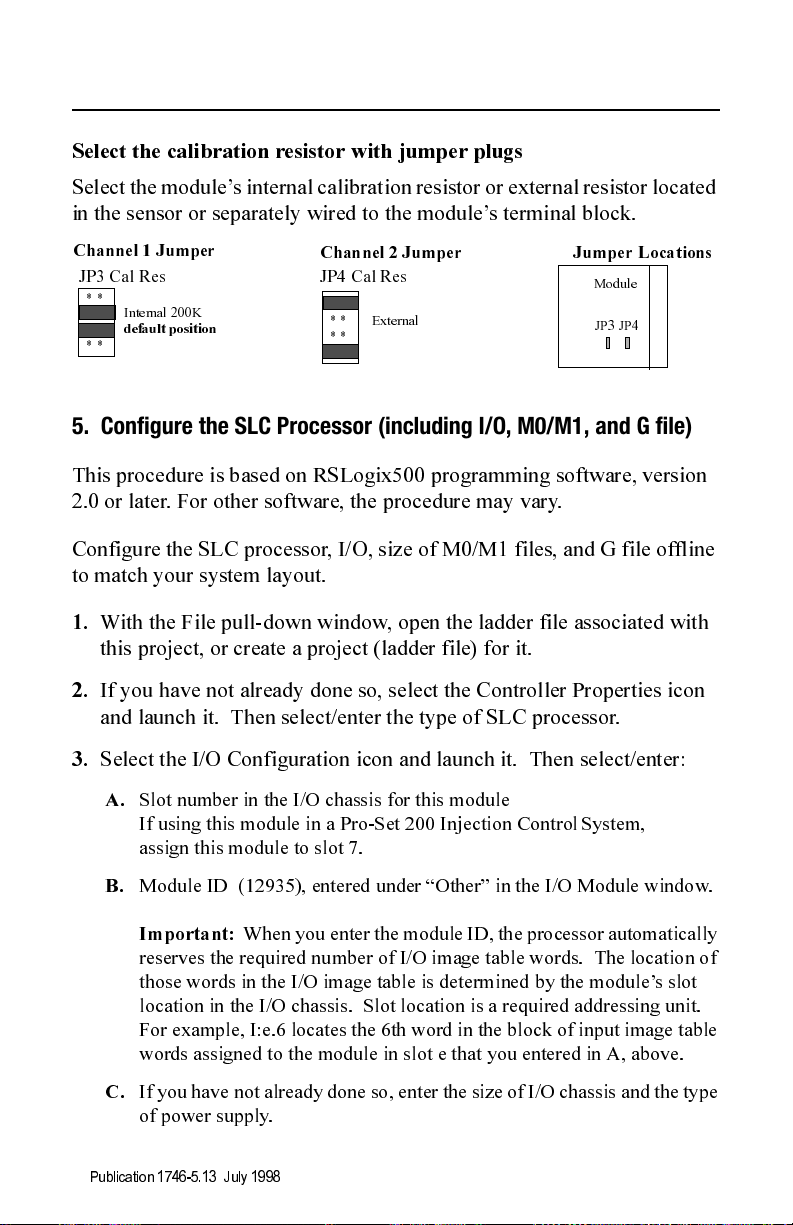

Select the calibration resistor with jumper plugs

Select the module’s internal calibration resistor or external resistor located

in the sensor or separately wired to the module’s terminal block.

Channel 1 Jumper

JP3 Cal Res JP4 Cal Res

* *

Internal 200K

default position

* *

Channel 2 Jumper

* *

External

* *

* *

* *

Jumper Locations

Module

JP3 JP4

5. Configure the SLC Processor (including I/O, M0/M1, and G file)

This procedure is based on RSLogix500 programming software, version

2.0 or later. For other software, the procedure may vary.

Configure the SLC processor, I/O, size of M0/M1 files, and G file offline

to match your system lay o ut.

1.

With the File pull-down window, open the ladder file associated wit h

this project, or create a project (ladder file) for it.

2.

If you have not already done so, selec t the Contr ol le r Prope rt ie s icon

and launch it. Then select/enter the type of SLC proce s so r.

3.

Select the I/O Configuration icon and launch it. Then select/enter :

A.

Slot number in the I/O chassis for this module

If using this module in a Pro-Set 200 Injection Control System ,

assign this module to slot 7.

B.

Module ID (12935), entered under “Other” in the I/O Module window.

Important:

When you enter the module ID, the processor automatically

reserves the required number of I/O image table words. The location of

those words in the I/O image table is determined by the module’s slot

location in the I/O chassis. Slot location is a required addressing unit.

For example, I:e.6 locates the 6th word in the block of input image table

words assigned to the module in slot e that you entered in A, above.

C.

If you have not already done so, enter the size of I/O chassis and the type

of power supply.

Publication 1746-5.13 July 19 98

Page 9

Mold Pressure Module 9

4.

Select the Adv Configuration icon and launch it. Then select/enter:

A.

Length of M0/M1 files at 106 words, each (listed in section 11).

B.

Length of G file at 94 words.

5.

Select and launch the Enter G Data icon.

A.

Change the display radix to hex. You get this display:

0 4040000

5 00000

10 00000

: :::::

90 00000

B.

Select word one (as shown) and enter the bit-selected data word that

corresponds to the module’s configuration in your application. You

determine the equivalent hex value of this word in next section

G-file Configuration (Initial Hardware Configuration)

.

The module requires software-configured selections in G file word 1.

Bit Purpose Selection

00-02 reserved n/a

03 Chnl 1 source of data 0 = sensor, 1 = SLC output image table

04 Chnl 2 source of data 0 = sensor, 1 = SLC output image table

05-08 reserved n/a

09 Trigger Operation 0 = triggers, 1 = no triggers

10 channel 1 & 2 alarms turned off by T4 0 = no, 1 = yes

11 Channel 1 & 2 alarms go OFF when T4

(mold closed) trigger does the following:

12 Channel 1 sensor level 0 = high, 1 = low (must match jumpers)

13 Channel 2 sensor level 0 = high, 1 = low (must match jumpers)

14 Alarm operation 0 = alarms, 1 = no alarms

15 module reset 1 = set (required)

You may set bits by entering an equivalent bit-set word in hex

0 = goes ON (at mold close),

1 = goes OFF (at mold open)

%

For example, from tables that follow, a hex value of F200 represents:

Senser level = high for both channels, and alarms = off

(bits 15-12 = 1 1 1 1 = F)

Triggers and T4 = off (bits 11-08 = 0 0 1 0 = 2)

Data source = from sensors for both channels (bits 07-00 = 0)

F200

Publication 1746-5.13 July 1998

Page 10

10 Mold Pressure Module

Select the he x-equivalent value from the following table

Bits 07-00

07-05 04 03 02-00 Chnl 1 Data Source Chnl 2 Data Source Hex

0 0 0 0 sensor sensor xx00

0 1 SLC output image tbl sensor xx08

1 0 sensor SLC output image tbl xx10

1 1 SLC output image tbl SLC output image tbl xx18

Bits 11-08

11 10 09 08 Triggers T4 turns alarms OFF? Alarms OFF when T4 Hex

0 0 0 0 ON NO n/a x0xx

0 0 1 0 OFF NO n/a x2xx

0 1 0 0 ON YES Goes ON at mold close x4xx

0 1 1 0 OFF YES Goes OFF at mold open x6xx

1 0 0 0 ON NO n/a x8xx

1 0 1 0 OFF NO n/a xAxx

1 1 0 0 ON YES Goes ON at mold close xCxx

1 1 1 0 OFF YES Goes OFF at mold open xExx

Bits 15-12

15 14 13 12 Chnl 1 sensor level Chnl 2 sensor level Alarms Hex

1 0 0 0 low low ON 8xxx

1 0 0 1 high low ON 9xxx

1 0 1 0 low high ON Axxx

1 0 1 1 high high ON Bxxx

1 1 0 0 low low OFF Cxxx

1 1 0 1 high low OFF Dxxx

1 1 1 0 low high OFF Exxx

1 1 1 1 high high OFF Fxxx

(

Important:

Before operating the module for the first time, you must

download the G file to the module. Do this by downloading your ladder

file, even if it contains no rungs. The SLC processor must be in Program

mode for a download.

Publication 1746-5.13 July 19 98

Page 11

Mold Pressure Module 11

6. Set sensor inputs to zero

If using a sensor input, zero the channel to cancel any pre-load or offset

voltage in the sensor. For mold pressure, zero the channel every machine

cycle. The method to zero the channel depends on the type of sensor.

For this type of sensor: Zero it: with: With this method:

hydraulic pressure (lo-level),

or injection pressure (hi-level)

mold pressure (lo-level) ladder logic

both types (channels 1, 2) Each method works independently. While “zero” is ON, module

a jumper, manually momentarily short “zero” terminal (4) to

“shield” terminal (5 or 6) after wiring,

once at setup.

each machine cycle, toggle bit 04 (chnl 1)

(channel selectable)

or bit 05 (chnl 2) in output image word 0

(Rising-edge enabled, may remain ON for

the cycle, typically triggered on the mold-

closed bit (trigger 4).)

autozero feature of

DARTWin software

(channel selectable)

enabled on DARTWin’s Mold Setup screen

Software stores first value and subtracts it

from subsequent values any machine cycle.

returns status bit 09 (chnl 1) or 10 (chnl 2) in input image word 0.

7. Check channel operation

With DartWin software on your PC, use the calibration resistor to check

channel operation. The sensor must be connected. (See Cal R in Section 4.)

1.

Apply the calibration resistor.

If

configured:

for internal

cal resistor

for external

cal resistor

with

resistor

in module

(200K)

connect to module terminal block:

a) short “Cal” (terminal 3) to “Shld”

(terminal 5 for channel 1 or 6 for channel 2)

in sensor b) cal resistor between “Cal R” and “Cal”

(between terminals 7 & 9 for channel 1,

or terminals 8 & 10 for channel 2)

separate

from

sensor

c) make two connections:

•resistor between “Cal R” and “+Sgnl”

(between terminals 7 & 13 for channel 1,

or terminals 8 & 14 for channel 2)

• jumper wire between “Cal” and “+Exc”

(between terminals 9 & 11 for channel 1,

or terminals 10 & 12 for channel 2)

Publication 1746-5.13 July 1998

+T/R

Cal

Shld

Cal1 R

Cal 1

+Exc 1

+Sgnl 1

-Sgnl 1

-Exc 1

01

a

b

17

c

Page 12

12 Mold Pressure Module

2.

Observe the di splaye d pressure value.

With DARTWin softwa re running on your PC, obse rve t he displa yed peak

pressure. It should be proportional to the bridge imbalance.

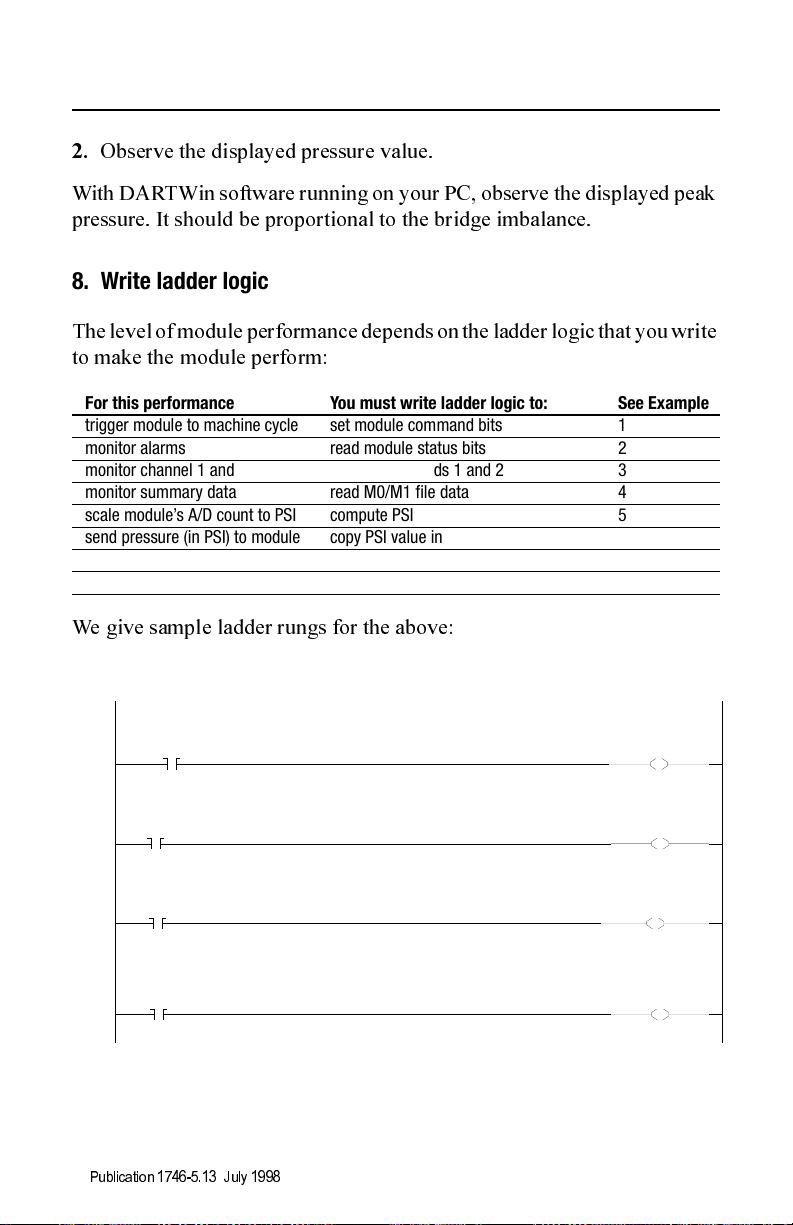

8. Write ladder logic

The level of module performance depends on the ladder logic that you write

to make the module perform:

For this performance You must write ladder logic to: See Example

trigger module to machine cycle set module command bits 1

monitor alarms read module status bits 2

monitor channel 1 and 2 data read status words 1 and 2 3

monitor summary data read M0/M1 file data 4

scale module’s A/D count to PSI compute PSI 5

send pressure (in PSI) to module copy PSI value into output image table 6

save M0/M1 config data copy M0/M1 files into selected N files 7

restore M0/M1 config data copy N files into M0/M1 files 8

We give sample ladder rungs for the above:

Example 1

Injection

Forward

(In For Inject,

Pack and Hold)

0000

0001

0002

0003

B9:16

Injection

Profile

Active

B106:1

15

Initiate

Plasticat ion

B3:4

9

Initiate

Clamp

Close

(Auto)

B3:7

1

4

Publication 1746-5.13 July 19 98

41317

MPM: Trigger 1 is

ON (start machine

cycle)

O:8

0

MPM: Trigger 2 is

ON (inject fill)

O:8

1

MPM: Trigger 3 is

ON (plasticate time)

O:8

2

MPM: Trigger 4 is

ON (cure time)

O:8

3

Page 13

Example 2

Mold Pressure Module 13

0000

Example 3

Read Channel 1 Sample Data

0000

Read Channel 1 Sample Data

0001

Channel 1 Alarm

I:8

0

OTHER

Channel 2 Alarm

I:8

1

OTHER

Cycle Time Alarm

I:8

2

OTHER

Ch. 1 Sensor Loss

I:8

3

OTHER

Ch. 2 Sensor Loss

I:8

4

OTHER

Jump to Alarm

Handler

JSR

JSR

Jump To Subroutine

SBR File Number U:100

41318

Move

Source I:8.1

0<

Dest N7:0

0<

Move

Source I:8.2

0<

Dest N7:1

0<

41319

MOV

MOV

MOV

MOV

Example 4

Read Frame 1 Status

0000

If Frame 1 summary data is new, copy to integer file

0001

0002

0003

N7:0

8

Read Frame 2 Status

If Frame 2 summary data is new, copy to integer file

N7:0

8

COP

COP

Copy File

Source #M0:8.49

Dest #N7:0

Length 1

COP

COP

Copy File

Source #M0:8.54

Dest #N7:1

Length 28

COP

COP

Copy File

Source #M0:8.76

Dest #N7:0

Length 1

COP

COP

Copy File

Source #M0:8.81

Dest #N7:1

41320

Length 28

Publication 1746-5.13 July 1998

Page 14

14 Mold Pressure Module

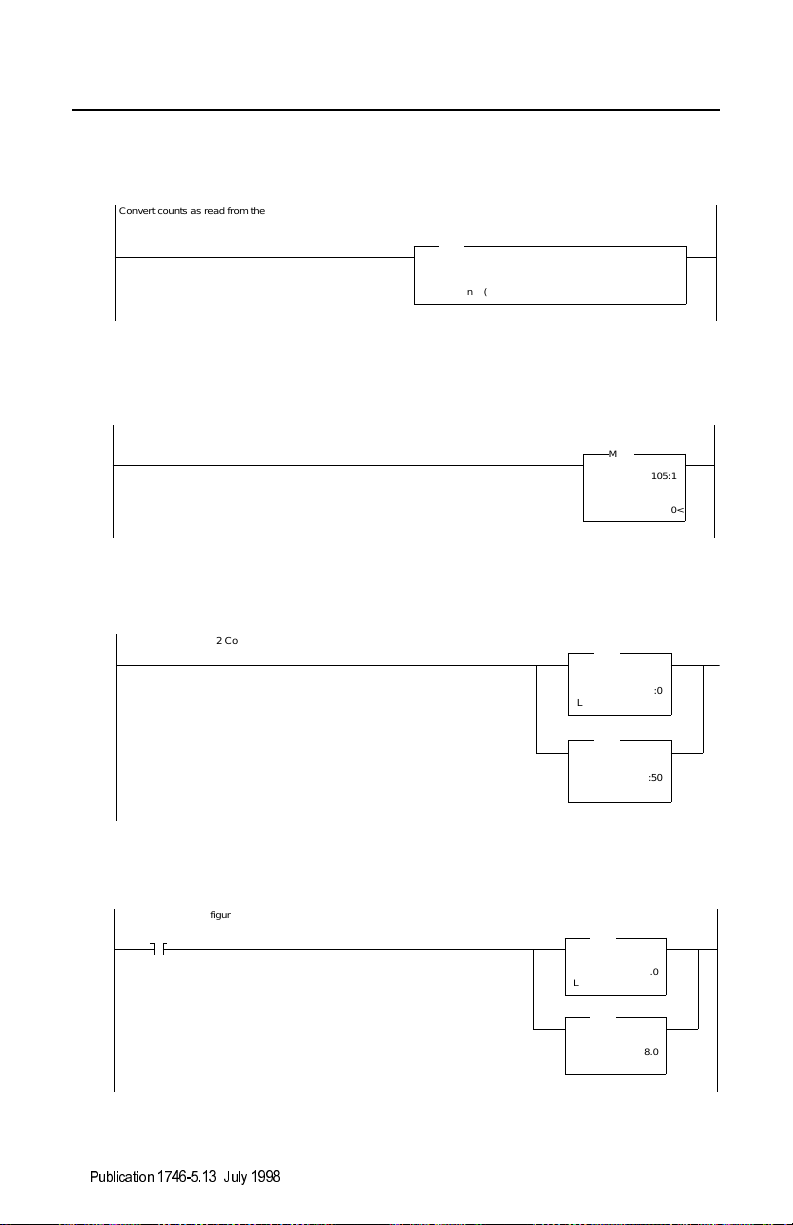

E

5

xample

Convert counts as read from the module to PSI, where

F8:0 = Full load sensor range, in pounds

F8:1 = Ejector pin diameter, in inches

0000

CPT

CPT

Compute

Dest F8:2

0.0<

Expression ( I:8.1 * F8:0 ) | ( ( F8:1 * F8:1 ) * 2894.58 )

41321

Example 6

0000

Example 7

Save Channel 1 and 2 Configuration

0000

Example 8

Restore module configuration on first program scan

First Pass

0000

S2:1

15

41322

41323

Write Hydraulic

Pressure to MPM

MOV

MOV

Move

Source N105:1

0<

Dest O:8.2

0<

COP

COP

Copy File

Source #M0:8.0

Dest #N7:0

Length 49

COP

COP

Copy File

Source #M1:8.0

Dest #N7:50

Length 49

COP

COP

Copy File

Source #N7:1

Dest #M0:8.0

Length 49

COP

COP

Copy File

Source #N7:50

Dest #M1:8.0

Length 49

41324

Publication 1746-5.13 July 19 98

Page 15

Mold Pressure Module 15

9. Troubleshooting with LEDs

LEDs indicate operating conditions detected by the module:

INPUT

FAULT

TRIGGER 1

TxDATA

RxDATA

Status: Indicates:

loss of a sensor signal, or

on

on running a machine cycle

flicker transmitting on DartNet

flicker receiving on DartNet

lo-level sensor is out of range

10. Use DARTWin software to display processed data

Refer to the DARTwin Software Instruction and Use Manual.

This concludes the procedures to set up and operate the 1746-MPM module.

In the next section, we present the M0/M1 file listing .

Publication 1746-5.13 July 1998

Page 16

16 Mold Pressure Module

11. Listing of M0/M1 file words

You load M0/M1 file data into the module from your PC equipped with

DARTwin software. M0 and M1 files contain:

•

module configuration data, loaded by DARTWin software (words 0-48)

•

summary data processed by the module (words 49-106)

Summary data (in units of A/D counts x 1/100 sec.) is stored in t wo frames:

frame 1 = words 49-75

frame 2 = words 76-106

Important:

Address (e = module slot number) Description

Module Config Data

Channel 1 (M0) Channel 2 (M1)

M0:e.0, 2, 4, 6 M1:e.0, 2, 4, 6 Dead time, trigger ON (for triggers 1, 2, 3, 4)

M0:e.1, 3, 5, 7 M1:e.1, 3, 5, 7 Dead time, trigger OFF (for triggers 1, 2, 3, 4)

M0:e.8 M1:e.8 Alarm control word (enable/disable)

M0:e.9 M1:e.9 Alarm level, cycle time low

M0:e.10 M1:e.10 Alarm level, cycle time high

M0:e.11 M1:e.11 Alarm level, peak high

M0:e.12 M1:e.12 Alarm level, peak low

M0:e.13 M1:e.13 Alarm level, peak time high

M0:e.14 M1:e.14 Alarm level, peak time low

M0:e.15, 17, 19, 21 M1:e.15, 17, 19, 21 Alarm level, trigger time low (triggers 1, 2, 3, 4)

M0:e.16, 18, 20, 22 M1:e.16, 18, 20, 22 Alarm level, trigger time high (triggers 1, 2, 3, 4)

M0:e.23 M1:e.23 Alarm level, minimum in frame, low

M0:e.24 M1:e.24 Alarm level, minimum in frame, high

M0:e.25, 26 M1:e.25, 26 Alarm level, peak integral low

M0:e.27, 28 M1:e.27, 28 Alarm level, peak integral high

M0:e.29, 30 M1:e.29, 30 Alarm level, trigger 1 integral low

M0:e.31, 32 M1:e.31, 32 Alarm level, trigger 1 integral high

M0:e.33, 34 M1:e.33, 34 Alarm level, trigger 2 integral low

M0:e.35, 36 M1:e.35, 36 Alarm level, trigger 2 integral high

M0:e.37, 38 M1:e.37, 38 Alarm level, trigger 3 integral low

M0:e.39, 40 M1:e.39, 40 Alarm level, trigger 3 integral high

M0:e.41, 42 M1:e.41, 42 Alarm level, trigger 4 integral low

M0:e.43, 44 M1:e.43, 44 Alarm level, trigger 4 integral high

M0:e.45, 46 M1:e.45, 46 Alarm level, frame integral low

M0:e.47, 48 M1:e.47, 48 Alarm level, frame integral high

See summary data notes on page 18.

Publication 1746-5.13 July 19 98

Page 17

Mold Pressure Module 17

Frame 1 summary data

M0:e.49 M1:e.49 Read bit 8 for new frame data

M0:e.50 M1:e.50 Pointer to frame data

M0:e.51 M1:e.51 Number of summary-data samples (incl 1st & last)

M0:e.52, 53 M1:e.52, 53 Start time of frame (30 bits)

M0:e.54, 55 M1:e.54, 55 Integral to peak (30 bits)

M0:e.56, 57 M1:e.56, 57 Integral over trigger 1 (30 bits)

M0:e.58, 59 M1:e.58, 59 Integral over trigger 2 (30 bits)

M0:e.60, 61 M1:e.60, 61 Integral over trigger 3 (30 bits)

M0:e.62, 63 M1:e.62, 63 Integral over trigger 4 (30 bits)

M0:e.64, 65 M1:e.64, 65 Integral over frame (30 bits)

M0:e.66, 67 M1:e.66, 67 Alarm bits (30 bits)

M0:e.68 M1:e.68 Frame length in 1/100 second (15 bits)

M0:e.69 M1:e.69 Peak in frame (15 bits)

M0:e.70 M1:e.70 Time to peak in frame (in 1/100 second)15 bits)

M0:e.71 M1:e.71 Trigger 1 ON time

M0:e.72 M1:e.72 Trigger 2 ON time

M0:e.73 M1:e.73 Trigger 3 ON time

M0:e.74 M1:e.74 Trigger 4 ON time

M0:e.75 M1:e.75 Min value in fram e (12 bits) or first sample (autozero)

Frame 2 summary data

M0:e.76 M1:e.76 Read bit 8 for new frame data

M0:e.77 M1:e.77 Pointer to frame data

M0:e.78 M1:e.78 Number of summary-data samples (incl 1st & last)

M0:e.79, 80 M1:e.79, 80 Start time of frame (30 bits)

M0:e.81, 82 M1:e.81, 82 Integral to peak (30 bits)

M0:e.83, 84 M1:e.83, 84 Integral over trigger 1 (30 bits)

M0:e.85, 86 M1:e.85, 86 Integral over trigger 2 (30 bits)

M0:e.87, 88 M1:e.87, 88 Integral over trigger 3 (30 bits)

M0:e.89, 90 M1:e.89, 90 Integral over trigger 4 (30 bits)

M0:e.91, 92 M1:e.91, 92 Integral over frame (30 bits)

M0:e.93, 94 M1:e.93, 94 Alarm bits (30 bits)

M0:e.95 M1:e.95 Frame length in 1/100 second (15 bits)

M0:e.96 M1:e.96 Peak in frame (15 bits)

M0:e.97 M1:e.97 Time to peak in frame (in 1/100 second)15 bits)

M0:e.98 M1:e.98 Trigger 1 ON time

M0:e.99 M1:e.99 Trigger 2 ON time

M0:e.100 M1:e.100 Trigger 3 ON time

M0:e.101 M1:e.101 Trigger 4 ON time

M0:e.102 M1:e.102 Min value in frame (12 bits ) or first sample (autozero)

M0:e.103 M1:e.103 Alarm limit time in 1/100 second

M0:e.104 M1:e.104 Alarm limit counts in 1/100 second

M0:e.105 M1:e.105 Cycle counter

M0:e.106 M1:e.106 Rejects counter

Publication 1746-5.13 July 1998

Page 18

18 Mold Pressure Module

Summary data notes

Single-word

summary values are stored with bytes reversed. You must use

the Swap instruction to convert them to integ er format.

Double-word

summary values are stored as integer pairs, with the low-

word value stored in the lower address of the pair, high-word value in upper.

12. Specifications

Description: Value:

electrical

backplane current

backplane power

number of input channels

A/D conversion

common-mode rejection

dynamic response

sensor inputs

input types lo-level

input types hi-level

gain settings

sensor excitation voltage

sensor excitation current

isolation from backplane

mechanical

module ID

number of LED indicators

cable for channels

cable for DartNets

temperature

operating

storage

relative humidity 5% to 95% noncondensing

agency certification

(when product or packaging is marked)

1

0.3A @ 5V dc

1.5W

2

12-bit successive approximation

115 do @ 500 gain

200K Hz @ 500 gain

2, 6, and 9 mV/V strain gage

4-20mA self-powered

0-10V dc

1, 100, 250, 450

10.000V dc ±0.002V dc

35mA per channel

1500V rms

12935

4 (alarm condition and module status)

Belden 8102

Belden 9462

0° to 60° C (32 to 140° F)

-40° to 85° C (-40 to 185° F)

Class I Division 2 Hazardous

marked for all applicable directives

1. CSA certification - Class I Division 2, Group A, B, C, D or nonhazardous locations

FM approved - Class I, Division 2, Group A, B, C, D or nonhazardous locations

Publication 1746-5.13 July 19 98

Page 19

Mold Pressure Module 19

13. Compliance with European Union Directive

If this product has the CE mark it is approved for installation within the

European Community or EEA regions. It has been designed and tested to

meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) and the following standards, in

whole or in part, documented in a technical construction file:

• EN 50081-2

EMC - Generic Emission Standard, Part 2 - Industrial Environment

• EN 50082-2

EMC - Generic Immunity Standard, Part 2 - Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive73/23/EEC Low Voltage,

by applying the safety requirements of EN 61131-2 Programmable

Controllers, Part 2 - Equipment Requirements and Tests. For specific

information required by EN 61131-2, see the appropriate sections in this

publication, as well as the Industrial Automation Wiring and Grounding

Guidelines for Noise Immunity, publication 1770-4.1.

This equipment is classified as open equipment and must be mounted in

an enclosure during operation to provide safety protection

.

Publication 1746-5.13 July 1998

Page 20

20 Mold Pressure Module

14. CSA Hazardous Location Approval

CSA certifies products for general use as well as for use in hazardous

locations.

below, and not by statements in any user documentation.

CSA certification is indicated by the product label

as shown

Example of the CSA certification product label:

To comply with CSA certification for use in

CL I, DIV 2

GP A,B,C,D

TEMP

hazardous locations, the following information

becomes a part of the product literature for this

CSA-certified industrial control product.

•

This equipment is suitable for use in Class I, Division 2, Groups A, B,

C, D, or non-hazardous locations only.

•

The products having the appropriate CSA markings (that is, Class I,

Division 2, Groups A, B, C, D) are certified for use in other equipment

where the suitability of combination (that is, application or use) is

determined by the CSA or the loca l inspection o ffice having jurisdiction.

Important:

Due to the modular nature of a pr ogr am mabl e control system,

the product with the highest temperature rating determines the

overall temperature code rating of a programmable control

system in a Class I, Divisi on 2, location. The temperature code

rating is marked on the product label as shown.

Temperature code rating

:

CL I, DIV 2

GP A,B,C,D

TEMP

Look for temperature

code rating here.

Publication 1746-5.13 July 19 98

Page 21

Mold Pressure Module 21

The following warnings apply to products having CSA certification for use

in hazardous locations.

ATTENTION:

!

CSA logo is a registered trademark of the Canadian Standards Association.

• Substitution of components may impair suitability for

Class I, Divisio n 2

• Do not replace components unless power has been

switched off or the area is known to be non-hazardous.

• Do not disconnect equipment unle ss power has been

switched off or the area is known to be non-hazardous.

• Do not disconnect connectors unless power has been

switched off or the area is known to be non-hazardous.

Secure any user-supplied connectors that mate to external

circuits on this equipm e nt by using screws, sliding latches,

threaded connectors, or other means such that any

connection can wit hst and a 15 Newton (3.4 lb.) separa t i ng

force applied for a minimum of one minute.

• Batteries must only be changed in an area known to be non-

hazardous.

Explosion hazard:

Publication 1746-5.13 July 1998

Page 22

22 Mold Pressure Module

Approbation d’utilisation dans des emplacements dangereux par CSA

La CSA certifie les produits d'utilisation generale aussi bien que ceux qui

s'utilisent dans des emplacements dangereux. La certification CSA en

vigueur est indiquee par l'etiquette du produit et non par des affirmations

dans la documentation a l'usage des utilisateurs.

Exemple d'etiquette de certification d'un produit par

la CSA:

CL I, DIV 2

GP A,B,C,D

TEMP

Pour satisfaire a la certification de la CSA dans des

endroits dangereux, les informations suivantes font

partie integrante de la documentation ce produit

industriel de controle certifie par la CSA.

•

Cet equipement convient a l'utilisation dans des emplacements de Classe

1, Division 2, Groupes A, B, C, D, ou ne convient qu'a l'utilisation dans

des endroits non dangereux.

•

Les produits portant le marquage approprie de la CSA (c'est a dire,

Classe 1, Division 2, Groupes A, B, C, D) sont certifies a l'utilisation

pour d'autres equipements ou la convenance de combinaison

(application ou utilisation) est determinee par la CSA ou le bureau local

d'inspection qualifie.

Important:

Par suite de la nature modulaire du systeme de controle

programmable, le produit ayant le taux le plus eleve de

temperature determine le taux d'ensemble du code de

temperature du systeme de controle d'un programmable dans

un emplacement de Classe 1, Division 2. Le taux du code de

temperature est indique sur l'etiquette du produit.

Taux du code de temperature:

Publication 1746-5.13 July 19 98

CL I, DIV 2

GP A,B,C,D

TEMP

Look for temperature

code rating here.

Page 23

Mold Pressure Module 23

Les avertissements suivants s'appliquent aux produits ayant la certification

CSA pour leur utilisation dans des emplacements dangereux.

ATTENTION:

!

Le sigle CSA est la marque deposee de l'Association des Standards pour le Canada.

• La substitution de composants peut rendre ce materiel

inacceptable pour lesemplac em ents de Classe I, Div. 2.

• Couper le courant ou s'assurer quel'em plac eme nt est

designe non danger e ux avant de rempla cer lescomposants.

• Avant de debrancher l'equipement, couper le courant ou

s'assurer que l'emplacement est designe non dangereux.

• Avant de debranche r les connecte urs, couper le courant ou

s'assurer que l'emplacement est reconnu non dangereux.

Attacher tous co nnec teurs fournis par l'utilisate ur et re li es

aux cir cui ts externes de cet appareil a l 'aide de vis, loquets

coulissants, connect eurs fil etes ou autres moy ens

permettant aux connexions de resister a une force de

separation de 15 newtons (3,4 lb. - 1,5 kg) appliquee

pendant au moins une minute.

• Afin d'eviter tout risque d'explosio n, s'ass ure r que

l'emplacement est designe non dangereux avant de changer

la batterie.

Risque d'explosion:

Publication 1746-5.13 July 1998

Page 24

Mold Pressure Module 24

SLC500™ is a trademark of Rockwell Automation

DARTW in™ is a trademark of RJG Technologies

Publication 1746-5.13 July 1998 PN 955132-89

Copyright 1998 Rockwell International Corp. Printed in USA.

Loading...

Loading...