Page 1

General

Attribute Value

Signal terminal current, max 1734-RTBS and 1734-RTB3S: 2A

Isolation voltage 250V, Basic Insulation Type, field-side to system

(1)

Use this conductor category information for planning conduct or routing as describ ed in Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Type tested at 1000V AC for 60 s

.

Environmental

Attribute Value

Temperature, operating IEC 60068-2-1 (Test Ad, Operating Cold),

Temperature, nonoperating IEC 60068-2-1 (Test Ab, Unpackaged Non-operating Cold),

Relative humidity IEC 60068-2-30 (Test Db, Unpackaged Damp Heat):

Vibration IEC 60068-2-6 (Test Fc, Operating):

Shock, operating IEC 60068-2-27 (Test Ea, Unpackaged Shock):

Shock, nonoperating IEC 60068-2-27 (Test Ea, Unpackaged Shock):

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

-20…55 °C (-4…131 °F)

IEC 60068-2-2 (Test Bb, Unpackaged Non-operating Dry Heat),

IEC 60068-2-14 (Test Na, Unpackaged Non-operating Thermal Shock):

-40…85 °C (-40…185 °F)

5…95% non-condensing

5 g @ 10…500 Hz

30 g

50 g

Certifications (1734-TB3 and 1734-TB3S only)

Certification (when product

(1)

is marked)

c-UR-us UL Recognized Component Industrial Control Equipment, certified for US an d Canada.

C-Tick Australian Radiocommunications Act, compliant with: AS/NZS CISPR11; Industrial

(1)

See the Product Certification link at http://w ww.ab.com for Declaration of Conformity, Certificates, and other certification details.

Value

See UL File E195367.

EN 61326-1; Meas./Control/Lab., Industrial Requirements

EN 61000-6-2; Industrial Immunity

EN 61000-6-4; Industrial Emissions

EN 61131-2; Programmable Controllers (Clause 8, Zone A & B)

European Union 2006/95/EC LVD, compliant with:

EN 61131-2; Programmable Controllers (Clause 11)

Emissions

:htiw tnailpmoc ,evitceriD CME CE/801/4002 noinU naeporuEEC

Additional Resources

You can view or download publications at http://www.literature.rockwellautomation.com. To order

paper copies of technical documentation, contact your local Rockwell Automation distributor or sales

representative.

Installation Instructions

POINT I/O Wiring Base Assembly

Catalog Numbers 1734-TBS, 1734-TB3S, 1734-RTBS, 1734-RTB3S

Environment and Enclosure

ATTENTION

About the Assembly

Prepare the wires

The total wire size range for the RTBs is 22…14 AWG. The wire may be stranded or solid.

ATTENTION

This equipment is intended for use in a Pollution Degree 2 industrial env ironment, in over voltage Categ ory II

applications (as defined in IEC 60664-1), at altitudes up to 2000 m (6562 ft) wi thout derating.

This equipment is considered Group 1, Class A industrial equipment according to IEC/CISPR 11. Wit hout appropriate

precautions, there may be difficulties with electromagnetic

conducted and radiated disturbances.

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that is suitably des igned

for those specific environmental conditions that will be

resulting from accessibility to live parts. The enclosure must have suitable flame-retardant properties to prevent or

minimize the spread of flame, complying with a fla me spread rating of 5VA, V2, V1, V0 (or equivalent) if non-metallic.

The interior of the enclosure must be accessible only by the use of a tool. Subsequent sections of this pu blication may

contain additional information regarding specific enclosure type ratings that are required to comply with certain prod uct

safety certifications.

In addition to this publication, see:

• Industrial Automation Wiring and Grounding Guidelines, for additional installation requirements,

Allen-Bradley publication 1770-4.1.

• NEMA Standards 250 and IEC 60529, as applicable, for explanations of the degrees of protection pro vided

by different types of enclosure.

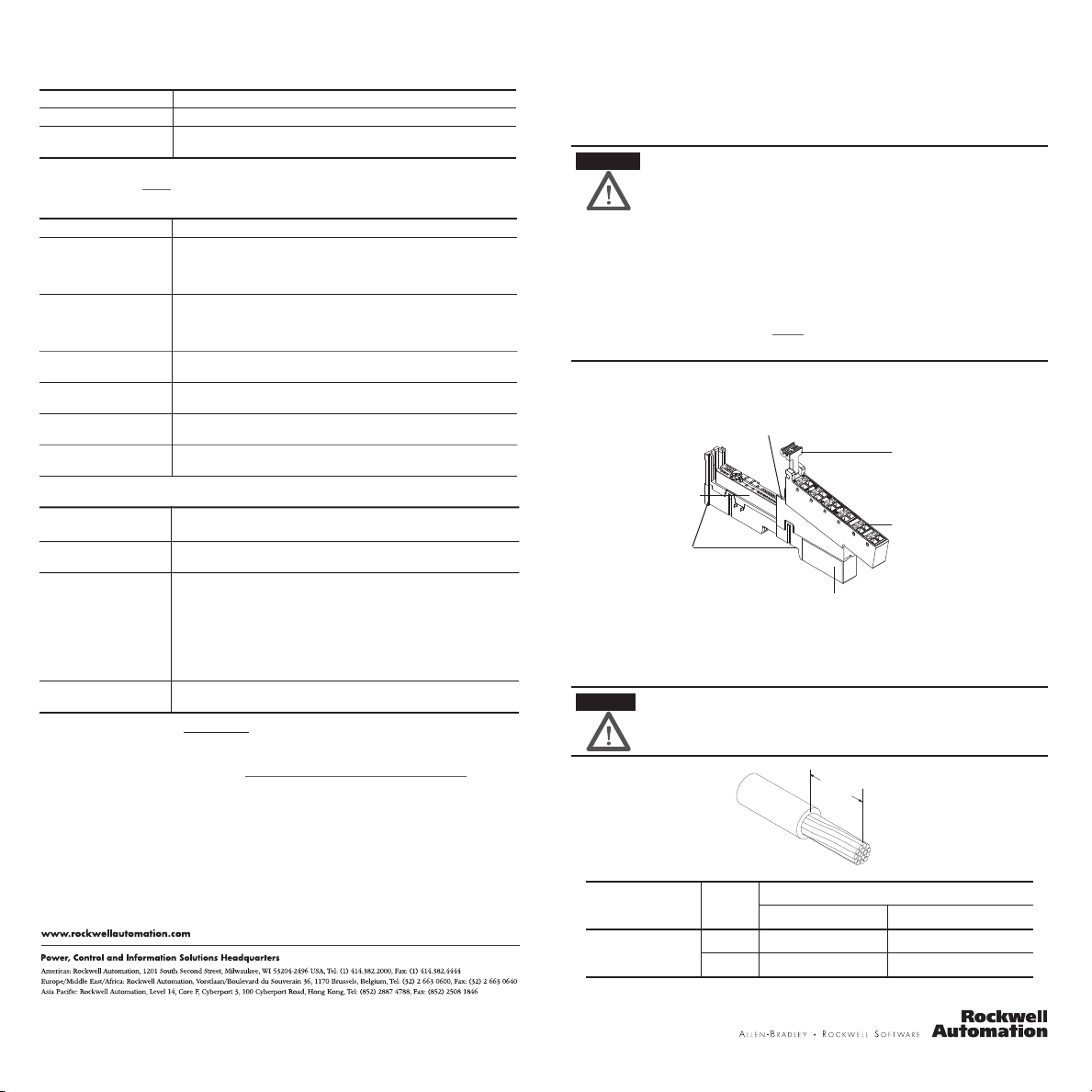

DIN Rail Locking

Screw (orange)

Mechanical Keying

(orange)

Interlocking Side

Pieces

1734-TB3 shown

Do not use wire ferrules on wires connected to the terminals on the modules.

compatibility in residential an d other environments due to

present and appropriately designed to prevent per sonal injury

RTB Removal

Handle

Removable

Terminal Block

(RTB)

Mounting Base

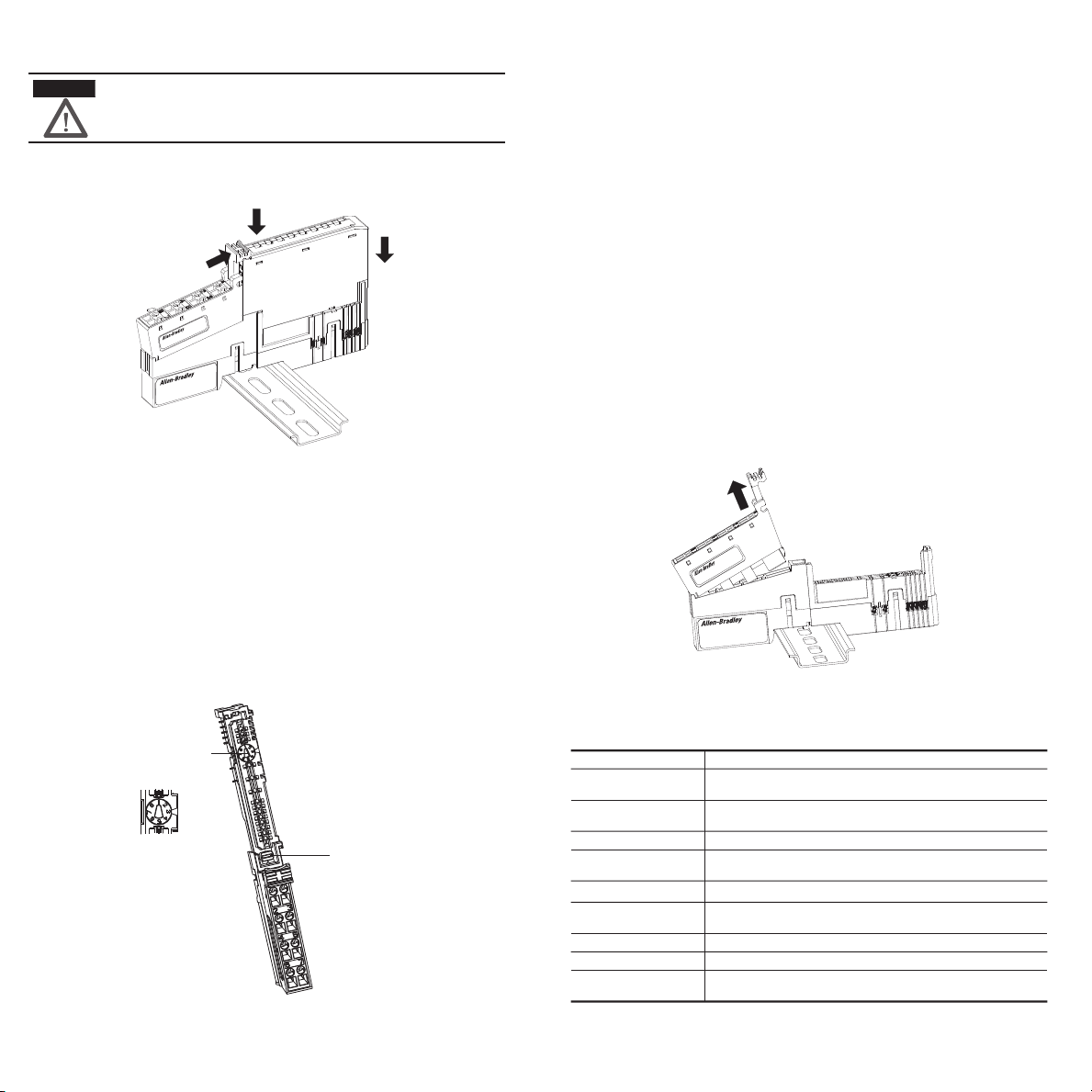

Strip Length

44895

Copyright © 2009 Rockwell Automation, Inc. All rights reserved. Printed in Singapore.

Wire Size Range,

AWG

Number

of Wires

Strip Length

8-position RTB 12-position RTB

22…14 AWG 1 16±1 mm (0.63±0.03 in) 14±1 mm (0.55±0.03 in)

2 18±1 mm (0.71±0.03 in) 16±1 mm (0.63±0.03 in)

15594-NP 9002 enuJ - P-NE-B310NI-4371 noitacilbuP

Page 2

ATTENTION

Do not wire more than 2 conductors on any single terminal.

Install the Mounting Base

To install the mounting base on the DIN rail, proceed as follows.

1. Position the mounting base vertically above the installed units (adapter, power supply or

existing module.

2. Slide the mounting base down allowing the interlocking side pieces to engage the

adjacent module or adapter.

3. Press firmly to seat the mounting base on the DIN rail. The mounting base will snap into

place.

4. To remove the mounting base from the DIN rail, remove the module, and use a small

bladed screwdriver to rotate the base locking screw to a vertical position. This releases the

locking mechanism. Then lift straight up to remove.

1. Using a bladed screwdriver, rotate the keyswitch on the mounting base clockwise until the

number required for the type of module being installed aligns with the notch in the base.

2. Make certain the DIN rail locking screw is in the horizontal position. (You cannot insert

the module if the locking mechanism is unlocked.)

3. Insert the module straight down into the mounting base and press to secure. The module

will lock into place.

Install the Removable Terminal Block (RTB)

A removable terminal block is supplied with your wiring base assembly. To remove, pull up on the

RTB handle. This allows the mounting base to be removed and replaced as necessary without

removing any of the wiring. To reinsert the removable terminal block, proceed as follows.

1. Insert the end opposite the handle into the base unit. This end has a curved section that

engages with the wiring base.

2. Rotate the terminal block into the wiring base until it locks itself in place.

3. If an I/O module is installed, snap the RTB handle into place on the module.

Remove a Mounting Base

To remove a mounting base, you must remove any installed module, and the module installed in

the base to the right. Remove the removable terminal block (if wired).

1. Unlatch the RTB handle on the I/O module.

2. Pull on the RTB handle to remove the removable terminal block.

3. Press on the module lock on the top of the module.

4. Pull on the I/O module to remove from the base.

5. Repeat steps 1, 2, 3 and 4 for the module to the right.

6. Use a small bladed screwdriver to rotate the orange base locking screw to a vertical

position. This releases the locking mechanism.

7. Then lift straight up to remove.

Install the I/O Module

The module can be installed before, or after base installation. Make sure that the mounting base is

correctly keyed before installing the module into the mounting base. In addition, make sure the

mounting base locking screw is positioned horizontal referenced to the base.

1734-MB

Turn the keyswitch to align

the number with the notch.

Notch position 3 is shown.

44009

Be sure the DIN-rail locking

screw is in the horizontal

position.

44896

Specifications

General

Attribute Value

Field power bus supply voltage,

max

Field power bus supply current,

max

Dimensions (HxWxD), approx. 65 x 12 x 160 mm (2.56 x 0.472 x 6.25 in.)

Wire size 0.34... 2.1 mm² (22...14 AWG) solid or stranded copper wire rated at 75 °C (167 °F )

Wiring category

(1)

Weight, approx. 1734-TB3 — 97.5 g (3.44 oz)

Terminal base screw torque 0.5…0.6 Nm (5…7 lb-in)

Enclosure type rating None (open-style)

Signal terminal voltage, max 1734-RTBS: 300V

1734-TBS and 1734-TB3S: 300V

1734-TBS and 1734-TB3S: 10A

or greater, 1.2 mm (3/64 in.) insulation max.

Dependent on installed module

1734-TB3S — 87.0 g (3.07 oz)

1734-RTB3S: 30V

Loading...

Loading...