1.2A, 24V, 1.4MHz Step-Down Converter

RT8259

General Description

The RT8259 is a high voltage buck converter that can support

the input voltage range from 4.5V to 24V and the output

current can be up to 1.2A. Current Mode operation provides

fast tra nsient response a nd ea ses loop sta bilization.

The chip also provides protection functions such a s cycleby-cycle current limiting and thermal shutdown prote ction.

The RT8259 is available in a SOT-23-6 and TSOT-23-6

pack ages.

Ordering Information

RT8259

Package Type

E : SOT-23-6

J6 : TSOT-23-6

Lead Plating System

G : Green (Halogen Free and Pb Free)

Note :

Richtek products are :

` RoHS compliant and compatible with the current require-

ments of IPC/JEDEC J-STD-020.

` Suitable for use in SnPb or Pb-free soldering processes.

Features

zz

Wide Operating Input Voltage Range : 4.5V to 24V

z

zz

zz

z Adjustable Output Voltage Range : 0.8V to 15V

zz

zz

z 1.2A Output Current

zz

ΩΩ

zz

z 0.3

Ω Internal Power MOSFET Switch

zz

ΩΩ

zz

z High Efficiency up to 92%

zz

zz

z 1.4MHz Fixed Switching Frequency

zz

zz

z Stable with Low ESR Output Ceramic Ca pacitors

zz

zz

z Thermal Shutdown

zz

zz

z Cycle-By-Cycle Over Current Protection

zz

zz

z RoHS Compliant and Halogen Free

zz

Applications

z Distributed Power Systems

z Battery Charger

z Pre-Regulator for Linear Regulators

z WLED Drivers

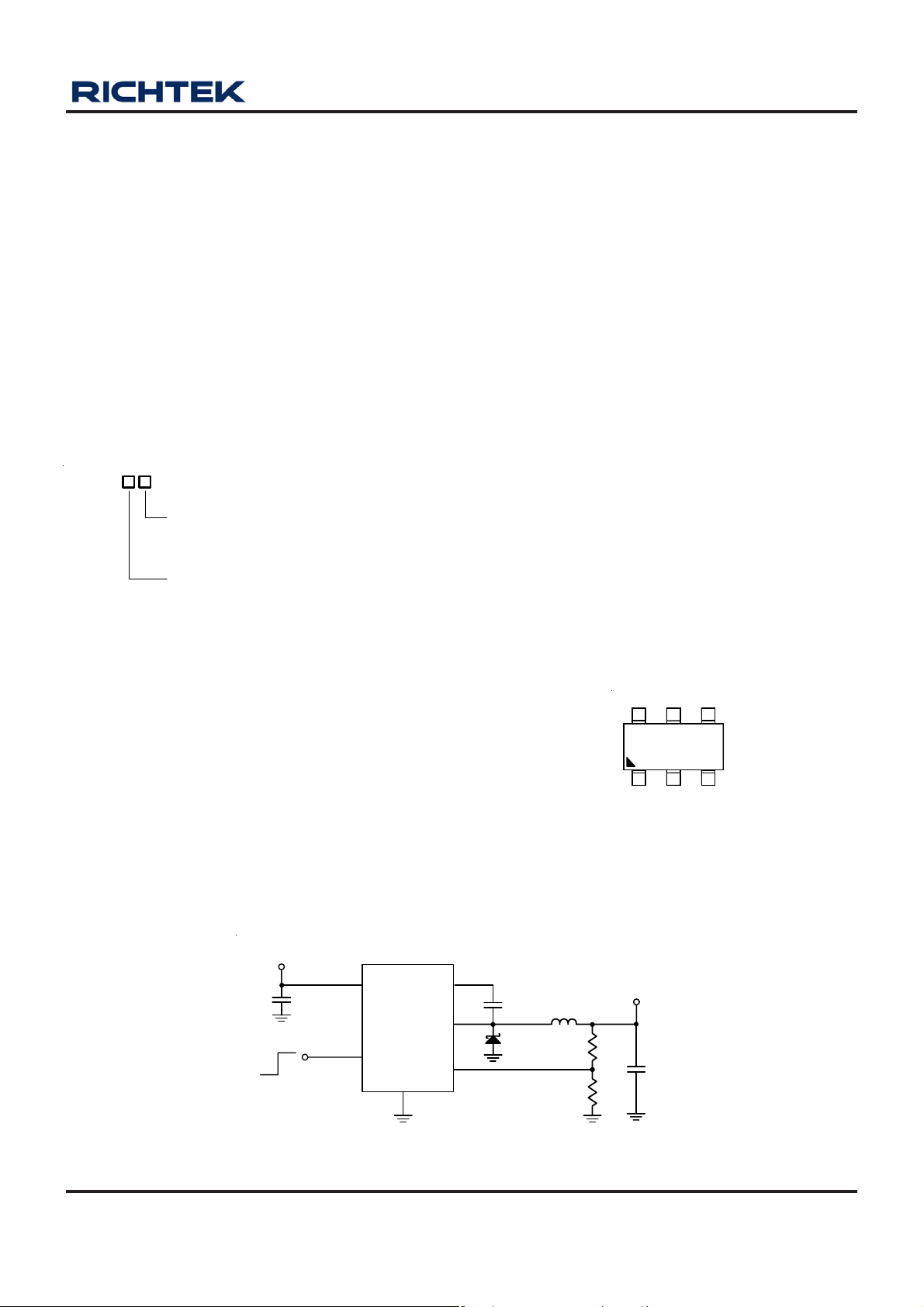

Pin Configurations

(TOP VIEW)

ENVINPHASE

4

56

Marking Information

23

For marking information, conta ct our sales representative

directly or through a Richtek distributor located in your

area.

BOOT GND FB

SOT-23-6/TSOT-23-6

Typical Application Circuit

V

IN

4.5V to 24V

V

R1

62k

R2

19.6k

OUT

3.3V

C2

22µF

C1

10µF

Chip Enabl e

Open =

Automatic Startu p

5

VIN

RT8259

PHASE

4

EN

GND

2

BOOT

FB

1

CB

10nF

6

D1

B230A

3

L1

4.7µH

DS8259-03 March 2011 www.richtek.com

1

RT8259

Table 1. Recommended Component Selection, C2 = 22

V

(V) 1.2 1.8 2.5 3.3 5 8 10 15

OUT

μμ

μF

μμ

L1 (μH) 2 2 3.6 4.7 6.8 10 10 15

R1 (kΩ) 62 62 62 62 62 68 68 68

R2 (kΩ) 124 49.9 29.4 19.6 12 7.5 5.9 3.9

Functional Pin Description

Pin No. P in Nam e Pin Funct io n

Bootstrap. A capacitor is connected between PHASE and BOOT pins to form a floating

1 BOOT

2 GND

3 FB

4 EN

5 VIN

6 PHASE Switch Output.

supply across the power switch driver. This capacitor is needed to drive the power switch‘s

gate abov e the supply voltage .

Ground. This pin is the voltage reference for the regulated output voltage. For this reason,

care must be taken in its layout. This node should be placed outside of the D1 to C1 ground

pa th to pre ven t switching curr ent spikes fr om i n ducing v olta g e noise into the part.

Feedback. An exter nal resistor divide r from the output to GND tapp ed to the FB pin sets the

output vol tag e. The valu e of the divider resisto rs also set loop bandwidth.

Chip Enabl e (Active High). If the EN pin is open, it will be p ulled to high by internal circuit.

Supply Volt age. Byp ass VIN to GND with a suita ble large capacitor to prevent large voltage

spikes from appea ring at the input.

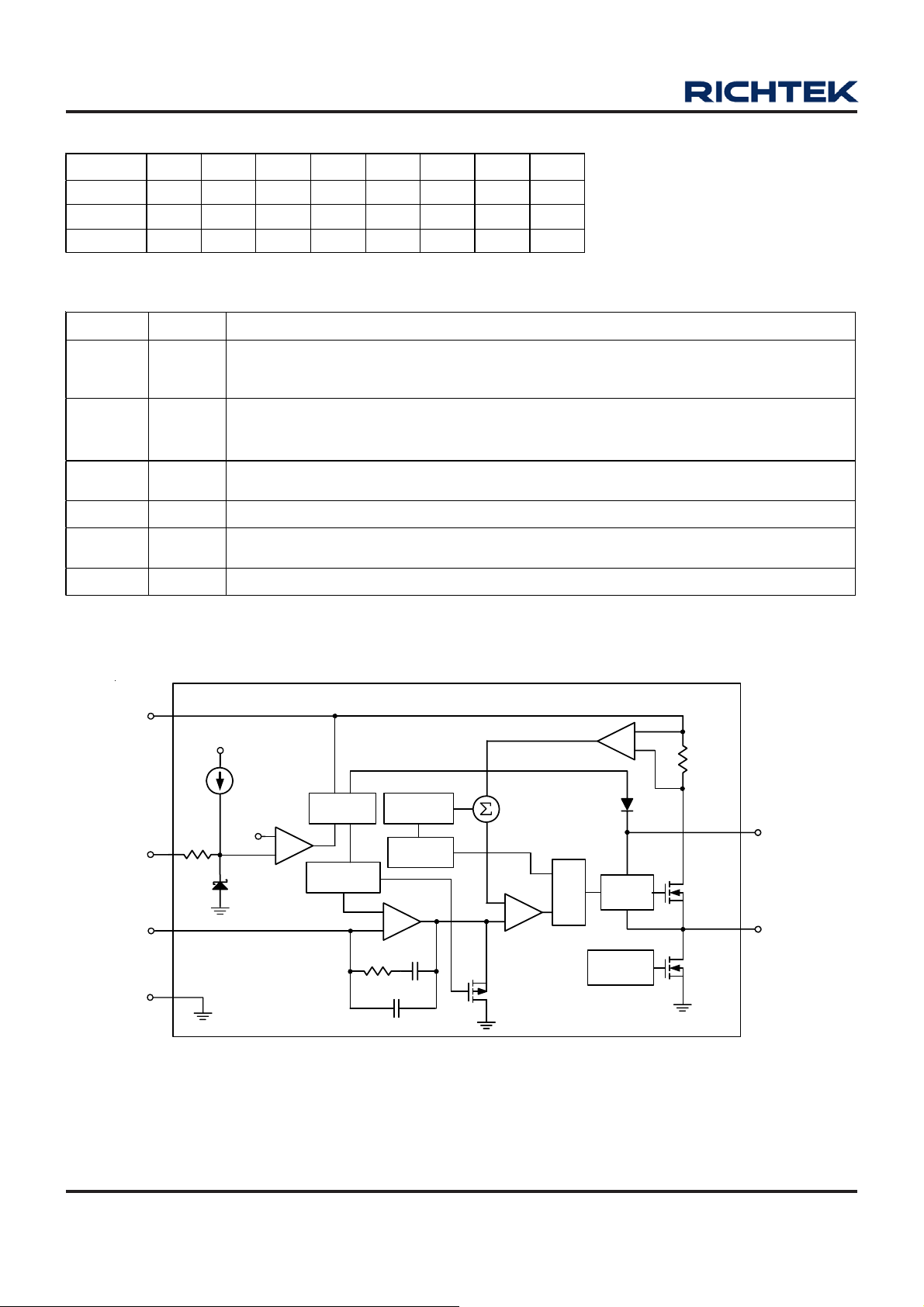

Function Block Diagram

VIN

1µA

+

Shutdown

Comparator

EN

FB

GND

10k

1.1V

3V

Regulator

Reference

400k

Ramp

Generator

Oscillator

1.4MHz

+

EA

30pF

1pF

Current Sense Amp

S

+

PWM

Comparator

OC Limit Clamp

Q

R

X20

Driver

Bootstrap

Control

+

25mΩ

Ω

BOOT

PHASE

DS8259-03 March 2011www.richtek.com

2

Absolute Maximum Ratings (Note 1)

RT8259

z Supply V oltage, V

z PHASE V oltage ----------------------------------------------------------------------------------------------------- −0.3V to (V

z BOOT V oltage ------------------------------------------------------------------------------------------------------- V

z All Other Pins-------------------------------------------------------------------------------------------------------- 0.3V to 6V

z Output V oltage ------------------------------------------------------------------------------------------------------ −0.3V to 15V

z Power Dissipation, P

------------------------------------------------------------------------------------------------ 26V

IN

@ T

D

= 25°C

A

PHASE

+ 6V

+ 0.3V)

IN

T/SOT-23-6 ----------------------------------------------------------------------------------------------------------- 0.4W

z Package Thermal Resistance (Note 2)

T/SOT-23-6, θJA------------------------------------------------------------------------------------------------------ 250°C/W

z Junction T emperature ---------------------------------------------------------------------------------------------- 150°C

z Lead T emperature (Soldering, 10 sec.) ------------------------------------------------------------------------ 260°C

z Storage T emperature Range -------------------------------------------------------------------------------------- −65°C to 150 °C

z ESD Susceptibility (Note 3)

HBM (Human Body Mode)---------------------------------------------------------------------------------------- 2kV

MM (Machine Mode) ----------------------------------------------------------------------------------------------- 200V

Recommended Operating Conditions (Note 4)

z Supply V oltage, V

z Output V oltage, V

z EN Voltage, V

z Junction T emperature Range ------------------------------------------------------------------------------------- −40°C to 125°C

z Ambient T emperature Range ------------------------------------------------------------------------------------- −40°C to 85°C

------------------------------------------------------------------------------------------------ 4.5V to 24V

IN

---------------------------------------------------------------------------------------------- 0.8V to 15V

OUT

----------------------------------------------------------------------------------------------------- 0V to 5.5V

EN

Electrical Characteristics

(VIN = 12V, TA = 25° C unless otherwise specified)

Parameter Symbol Test Conditions Min Typ Max Unit

Feedback Reference Voltage VFB 4.5V ≤ V

Feedback Current IFB VFB = 0.8V -- 0.1 0.3 μA

Switch On Resistance R

Switch Lea kage V

Cur rent Limit I

LIM

-- 0.3 -- Ω

DS(ON)

EN

V

BOOT

Oscillator Frequency fSW 1.2 1.4 1.6 MHz

Maximum Duty Cycle -- 80 -- %

Minimum On-Time tON -- 100 -- ns

Under Voltage Lockout

Threshold

Under Voltage Lockout

Threshold Hysteresis

EN Input Voltage

Logic-High VIH 1.4 -- -Logic-Low V

EN Pull Up Current V

Rising 3.9 4.2 4.5 V

-- 200 -- mV

-- -- 0.4

IL

EN

≤ 24V 0.784 0.8 0.816 V

IN

= 0V, V

− V

PHASE

= 0V -- -- 10 μA

PHASE

= 4.8V 1.6 2.1 -- A

V

= 0V -- 1 -- μA

T o be continued

DS8259-03 March 2011 www.richtek.com

3

RT8259

Parameter Symbol Test Conditions Min Typ Max Unit

Shutdown Current I

Quiescent Current IQ V

SHDN

V

EN

EN

= 0V -- 25 -- μA

= 2V, VFB = 1V (Not Switching) -- 0.55 1 mA

Therma l Shutdown TSD -- 150 -- °C

Note 1. Stresses listed as the above "Absolute Maximum Ratings" may cause permanent damage to the device. These are for

stress ratings. Functional operation of the device at these or any other conditions beyond those indicated in the

operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended

periods may remain possibility to affect device reliability.

Note 2. θ

Note 3. Devices are ESD sensitive. Handling precaution is recommended.

Note 4. The device is not guaranteed to function outside its operating conditions.

is measured in the natural convection at TA = 25°C on a high effective four layers thermal conductivity test board of

JA

JEDEC 51-7 thermal measurement standard.

DS8259-03 March 2011www.richtek.com

4

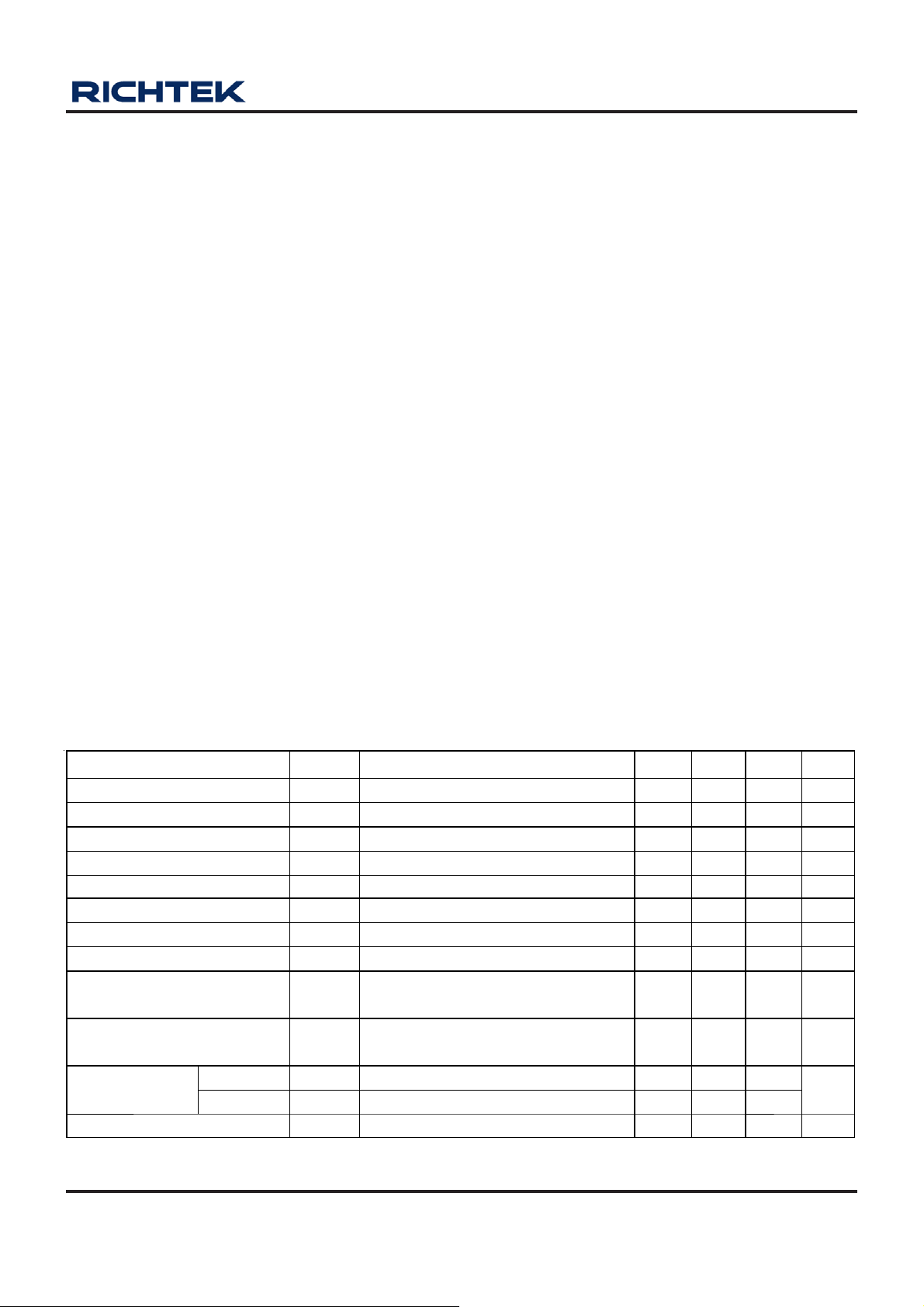

Typical Operating Characteristics

RT8259

Efficiency vs. Load Current

100

90

80

70

60

50

40

Efficiency (%)

30

20

10

0

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 1.1 1.2

Load C ur rent (A)

Output Voltage vs. Load Current

3.333

3.328

3.323

Output Vol t ag e (V)

3.318

3.313

3.308

3.303

3.298

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 1.1 1.2

VIN = 24V

VIN = 12V

Load C ur ren t ( A)

VIN = 12V

VIN = 24V

V

= 5V

OUT

Efficiency vs. Load Current

100

90

80

70

60

50

40

Efficiency (%)

30

20

10

0

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 1.1 1.2

Load Current (A)

Output Voltage vs. Temperature

3.38

3.36

3.34

3.32

3.30

3.28

Output Vol tage ( V)

3.26

3.24

3.22

-50 -25 0 25 50 75 100 125

Temper at ur e (°C)

VIN = 12V

VIN = 24V

V

= 3.3V

OUT

VIN = 24V

VIN = 12V

I

OUT

= 0A

Frequency vs. Input Voltage

1.55

1.50

1.45

1.40

1.35

1.30

Frequency (MHz)

1.25

1.20

V

= 3.3V, I

1.15

4 6.5 9 11.51416.51921.524

Input Vol tage (V)

OUT

OUT

= 0.3A

1.55

1.50

1.45

1.40

1.35

1.30

Frequenc y (MHz) 1

1.25

1.20

1.15

-50 -25 0 25 50 75 100 125

Frequency vs. Temperature

VIN = 12V, V

Temperature (°C)

= 3.3V, I

OUT

OUT

= 0.3A

DS8259-03 March 2011 www.richtek.com

5

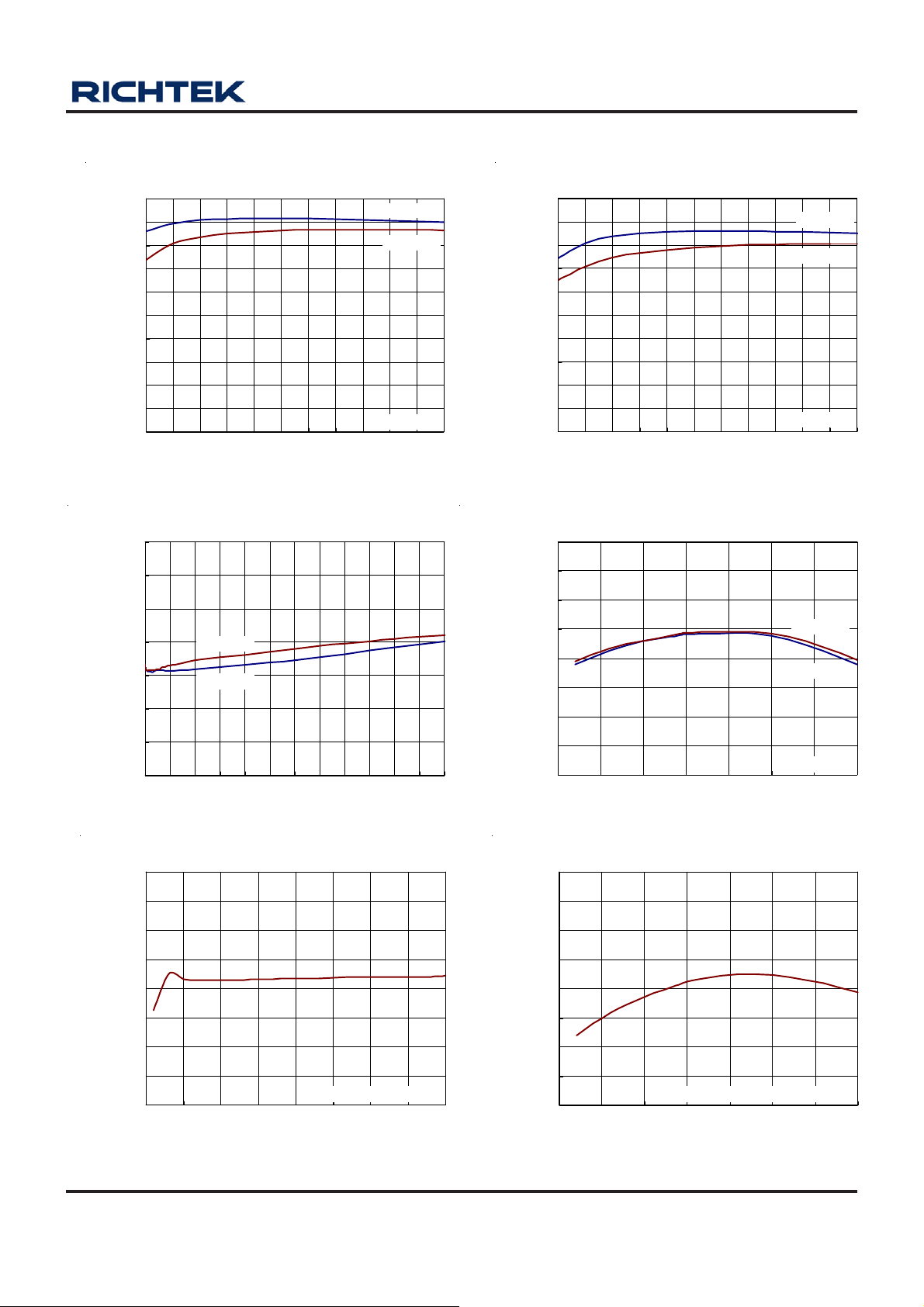

RT8259

)

0.9

0.8

0.7

0.6

0.5

0.4

0.3

Quiescent Cur rent (mA)

0.2

0.1

V

OUT

(50mV/Div)

Quiescent Current vs. Input Voltage

VEN = 2V, VFB = 1V

4 6.5 9 11.5 14 16.5 19 21.5 24

Input Volt age ( V)

Load Transient Response

VIN = 12V, V

= 3.3V, I

OUT

= 0.6A to 1.2A

OUT

0.9

0.8

0.7

0.6

0.5

0.4

0.3

Quie scent Current (mA

0.2

0.1

V

OUT

(50mV/Div)

Quiescent Current vs. Temperature

VIN = 24V

VIN = 12V

VEN = 2V, VFB = 1V

-50 -25 0 25 50 75 100 125

Temperature (°C)

Load Transient Response

VIN = 12V, V

OUT

= 3.3V, I

= 0A to 1.2A

OUT

I

OUT

(500mA/Div)

V

OUT

(5mV/Div)

V

PHASE

(10V/Div)

I

L

(1A/Div)

Time (50μs/Div)

Switching

VIN = 12V, V

Time (250ns/Div)

OUT

= 3.3V, I

OUT

= 1.2A

I

OUT

(500mA/Div)

V

OUT

(5mV/Div)

V

PHASE

(10V/Div)

I

L

(1A/Div)

Time (50μs/Div)

Switching

VIN = 20V, V

Time (250ns/Div)

= 3.3V, I

OUT

OUT

= 1.2A

DS8259-03 March 2011www.richtek.com

6

RT8259

V

EN

(5V/Div)

V

OUT

(1V/Div)

I

IN

(500mA/Div)

Power On from EN

VIN = 12V, V

Time (250μs/Div)

OUT

= 3.3V, I

OUT

= 1.2A

V

EN

(5V/Div)

V

OUT

(1V/Div)

I

IN

(500mA/Div)

Power Off from EN

VIN = 12V, V

Time (100μs/Div)

= 3.3V, I

OUT

OUT

= 1.2A

DS8259-03 March 2011 www.richtek.com

7

RT8259

Application Information

The RT8259 is a high voltage buck converter that can support

the input voltage range from 4.5V to 24V and the output

current can be up to 1.2A.

Output Voltage Setting

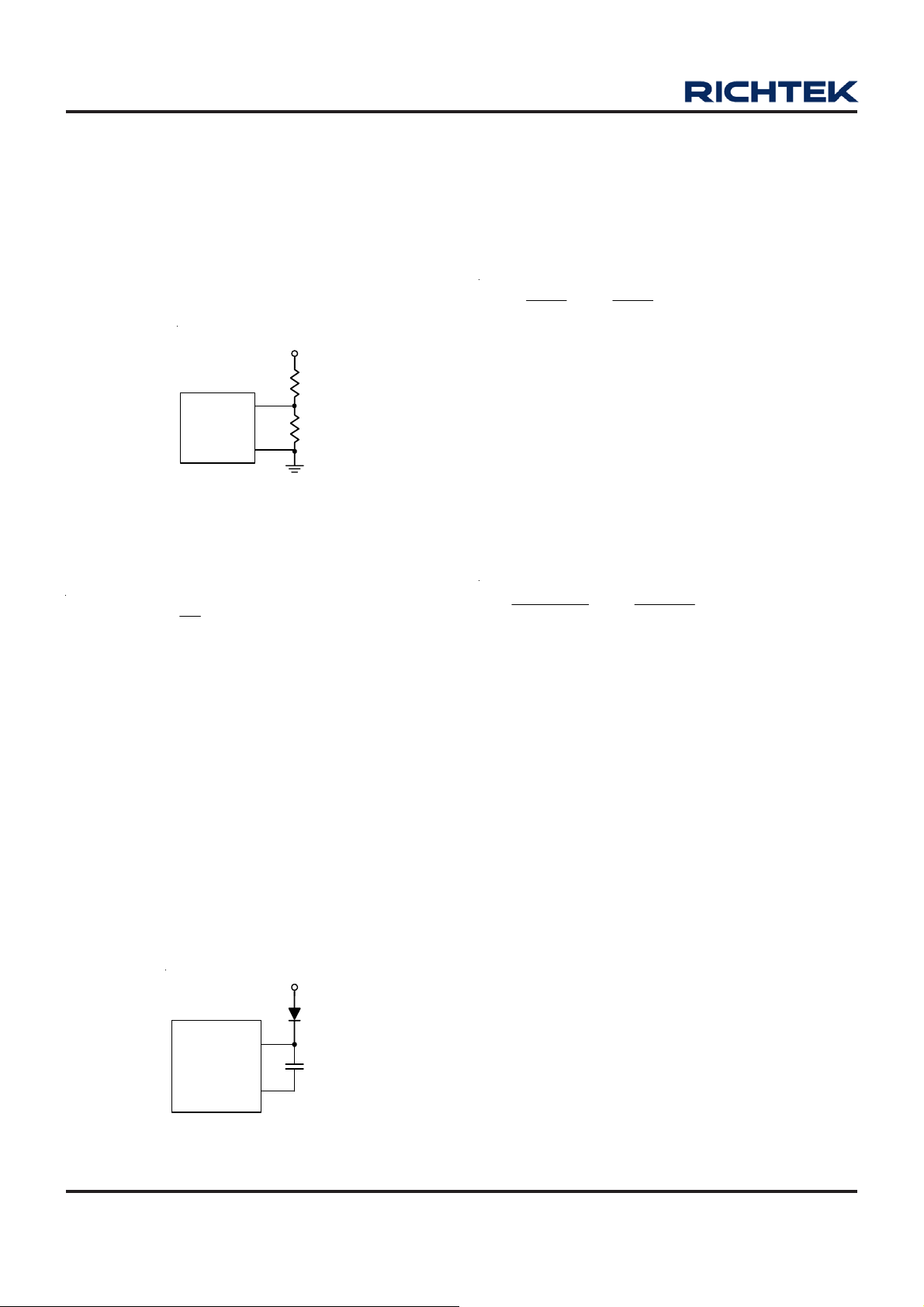

The resistive voltage divider allows the FB pin to sense a

fraction of the output voltage a s shown in Figure 1.

V

OUT

R1

FB

RT8259

GND

R2

Figure 1. Output V oltage Setting

For adjustable voltage mode, the output voltage is set by

an external resistive voltage divider according to the

following equation :

R1

V = V1

OUT FB

⎛⎞

+

⎜⎟

R2

⎝⎠

Where VFB is the feedback reference voltage (0.8V typ.).

Inductor Selection

The inductor value and operating frequency determine the

ripple current according to a specific input and output

voltage. The ripple current ΔI

increases with higher V

L

and decrea ses with higher inducta nce.

VV

⎡⎤⎡ ⎤

OUT OUT

I = 1

Δ×−

L

⎢⎥⎢ ⎥

fL V

×

⎣⎦⎣ ⎦

IN

Having a lower ripple current reduces not only the ESR

losses in the output ca pacitors but also the output voltage

ripple. High frequency with small ripple current ca n achieve

highest efficiency operation. However , it requires a large

inductor to achieve this goal.

For the ripple current selection, the value of ΔI

= 0.4(I

L

MAX

will be a rea sonable starting point. The largest ri pple current

occurs at the highest VIN. To guarantee that the ripple

current stays below the specified maximum, the inductor

value should be chosen according to the following

equation :

⎡⎤⎡ ⎤

VV

L = 1

OUT OUT

⎢⎥⎢ ⎥

fI V

×Δ

L(MAX) IN(MAX)

⎣⎦⎣ ⎦

×−

Inductor Core Selection

IN

)

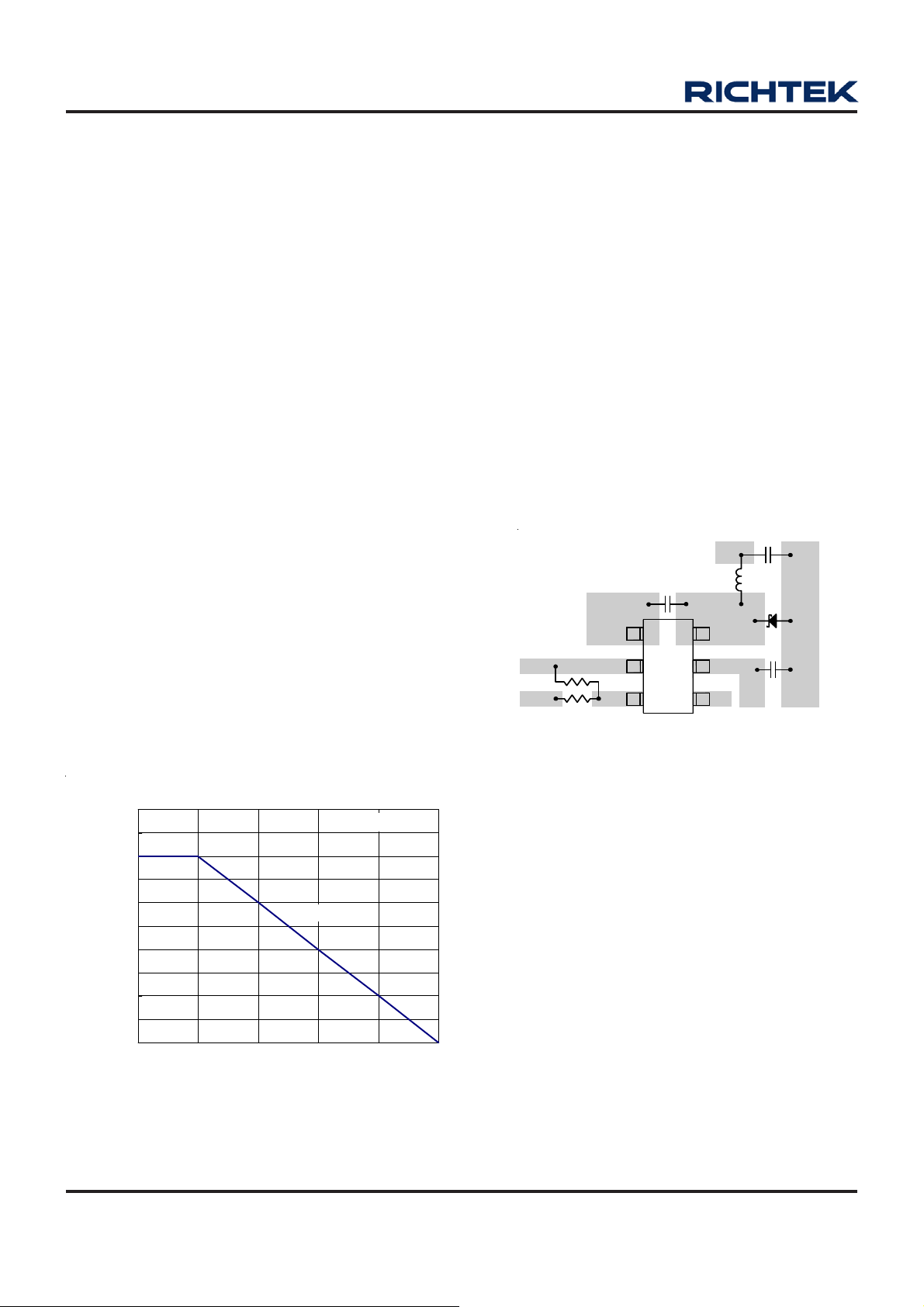

External Bootstra p Diode

Connect a 10nF low ESR cera mic ca pa citor between the

BOOT pin and SW pin. This capacitor provides the gate

driver voltage for the high side MOSFET .

It is recommended to add an external bootstrap diode

between an external 5V and the BOOT pin f or ef f iciency

improvement when input voltage is lower tha n 5.5V or duty

ratio is higher than 65%. The bootstra p diode ca n be a low

cost one such as 1N4148 or BAT54.

The external 5V ca n be a 5V fixed input from syste m or a

5V output of the RT8259.

5V

BOOT

RT8259

PHASE

10nF

Figure 2. External Bootstra p Diode

The inductor type must be selected once the value for L is

known. Generally spe aking, high efficiency converters ca n

not afford the core loss found in low cost powdered iron

cores. So, the more expensive ferrite or mollypermalloy

cores will be a better choice.

The selected inductance rather than the core size for a

fixed inductor value is the key for a ctual core loss. As the

inductance increa ses, core losses decre ase. U nfortunately ,

increa se of the inductance requires more turns of wire a nd

therefore the copper losses will increa se.

Ferrite designs are preferred at high switching frequency

due to the characteristics of very low core losses. So,

design goals can focus on the reduction of copper loss

and the saturation prevention.

Ferrite core material saturates “hard”, which means that

inductance colla pses abruptly when the pea k design current

is exceeded. The previous situation results in an abrupt

increa se in inductor ripple current and consequent output

voltage ripple.

Do not allow the core to saturate!

DS8259-03 March 2011www.richtek.com

8

RT8259

Different core materials a nd sha pes will cha nge the size/

current and price/current relationshi p of an inductor .

T oroid or shielded pot cores in ferrite or permalloy materials

are small and do not radiate energy. However, they are

usually more expensive than the similar powdered iron

inductors. The rule for inductor choice mainly depends on

the price vs. size requirement and a ny radiated f ield/EMI

requirements.

Diode Selection

When the power switch turns off, the path for the current

is through the diode connected between the switch output

and ground. This forward biased diode must have a

minimum voltage drop and re covery times. Schottky diode

is recommended and it should be able to handle those

current. The reverse voltage rating of the diode should be

greater than the maximum in put voltage, and current rating

should be greater than the maximum load current. For

more detail, plea se refer to T a ble 4.

CIN and C

The input ca pacita nce, C

Selection

OUT

is needed to filter the tra pezoidal

IN,

current at the source of the top MOSFET . T o prevent large

ripple current, a low ESR input capacitor sized for the

maximum RMS current should be used. The RMS current

is given by :

V

I = I 1

RMS OUT(MAX)

OUT

VV

This formula has a maximum at V

I

= I

RMS

/2. This simple worst-ca se condition is commonly

OUT

V

IN

IN OUT

−

IN

= 2V

OUT

, where

used for design because even significa nt deviations do not

offer much relief.

Choose a capacitor rated at a higher temperature than

required. Several ca pacitors may also be paralleled to meet

size or height requirements in the design.

The selection of C

is determined by the required Effective

OUT

Series Resistance (ESR) to mini mize voltage ripple.

Moreover, the a mount of bulk ca pa citance is also a key f or

C

selection to ensure that the control loop is stable.

OUT

Loop stability can be che cked by viewing the load transient

response a s described in a later se ction.

The output ripple, ΔV

VIESR

Δ≤Δ +

OUT L

⎡⎤

⎢⎥

⎣⎦

, is determined by :

OUT

1

8fC

OUT

The output ripple will be highest at the maximum input

voltage since ΔIL increases with input voltage. Multiple

ca pa citors placed in parallel may be needed to meet the

ESR and RMS current ha ndling requirement. Dry ta ntalum,

special polymer, aluminum electrolytic and ceramic

capacitors are all available in surface mount packages.

Special polymer capacitors offer very low ESR value.

However, it provide s lower capa citance den sity than other

types. Although Tantalum capacitors have the highest

ca pa cita nce den sity, it is i mporta nt to only use types that

pass the surge test for use in switching power supplies.

Aluminum electrolytic ca pacitors have significa ntly higher

ESR. However, it ca n be used in cost-sensitive a pplications

for ripple current rating and long term reliability

considerations. Cera mic capa citors have excellent low ESR

characteristics but ca n have a high voltage coefficient a nd

audible piezoelectric effects. The high Q of ceramic

ca pacitors with tra ce inductance ca n also lead to significant

ringing.

Higher values, lower cost ceramic capacitors are now

becoming available in smaller ca se sizes. Their high ri pple

current, high voltage rating and low ESR ma ke them ideal

for switching regulator a pplications. However, care must

be taken when these capacitors are used at input and

output. When a cera mic ca pacitor is used at the in put and

the power is supplied by a wall ada pter through long wires,

a load step at the output can induce ringing at the input,

VIN. At best, this ringing can couple to the output a nd be

mistaken as loop instability. At worst, a sudden inrush of

current through the long wires can potentially cause a

voltage spike at V

large enough to damage the part.

IN

Checking T ransient Re spon se

The regulator loop response ca n be checked by looking at

the load transient response. Switching regulators take

several cycles to respond to a step in load current. When

a load step occurs, V

equal to ΔI

C

generating a feedback error signal f or the regulator to

OUT

return V

time, V

OUT

(ESR) also begins to charge or discharge

LOAD

to its steady-state value. During this recovery

OUT

can be monitored f or overshoot or ringing that

immediately shifts by a n a mount

OUT

would indicate a stability problem.

DS8259-03 March 2011 www.richtek.com

9

RT8259

Thermal Considerations

For continuous operation, do not exceed the maximum

operation junction temperature 125°C. The maximum power

dissipation depends on the thermal resistance of IC

package, PCB layout, the rate of surroundings airflow a nd

temperature difference between junction to a mbient. The

maximum power dissipation ca n be calculated by following

formula :

P

where T

D(MAX)

= (T

J(MAX)

− TA) / θ

J(MAX)

JA

is the maximum operation junction

temperature, TA is the a mbient temperature and the θJA is

the junction to ambient thermal re sistance.

For recommended operating conditions specification of the

RT8259, the maximum junction temperature of the die is

125°C. The junction to a mbient thermal resista nce θJA is

layout dependent. For T/SOT-23-6 pa ckage, the thermal

resistance θJA is 120°C/W on standard JEDEC 51-7 f ourlayers thermal test board. The maximum power dissipation

at TA = 25°C can be calculated by following f ormula :

P

= (125°C − 25°C) / (250°C/W) = 0.4W for

D(MAX)

T/SOT-23-6 pa ckages

The maximum power dissipation depends on operating

ambient te mperature for fixed T

θ

. For RT8259 package s, the Figure 3 of derating curves

JA

and thermal resista nce

J(MAX)

allows the designer to see the effect of rising ambient

temperature on the maximum power allowed.

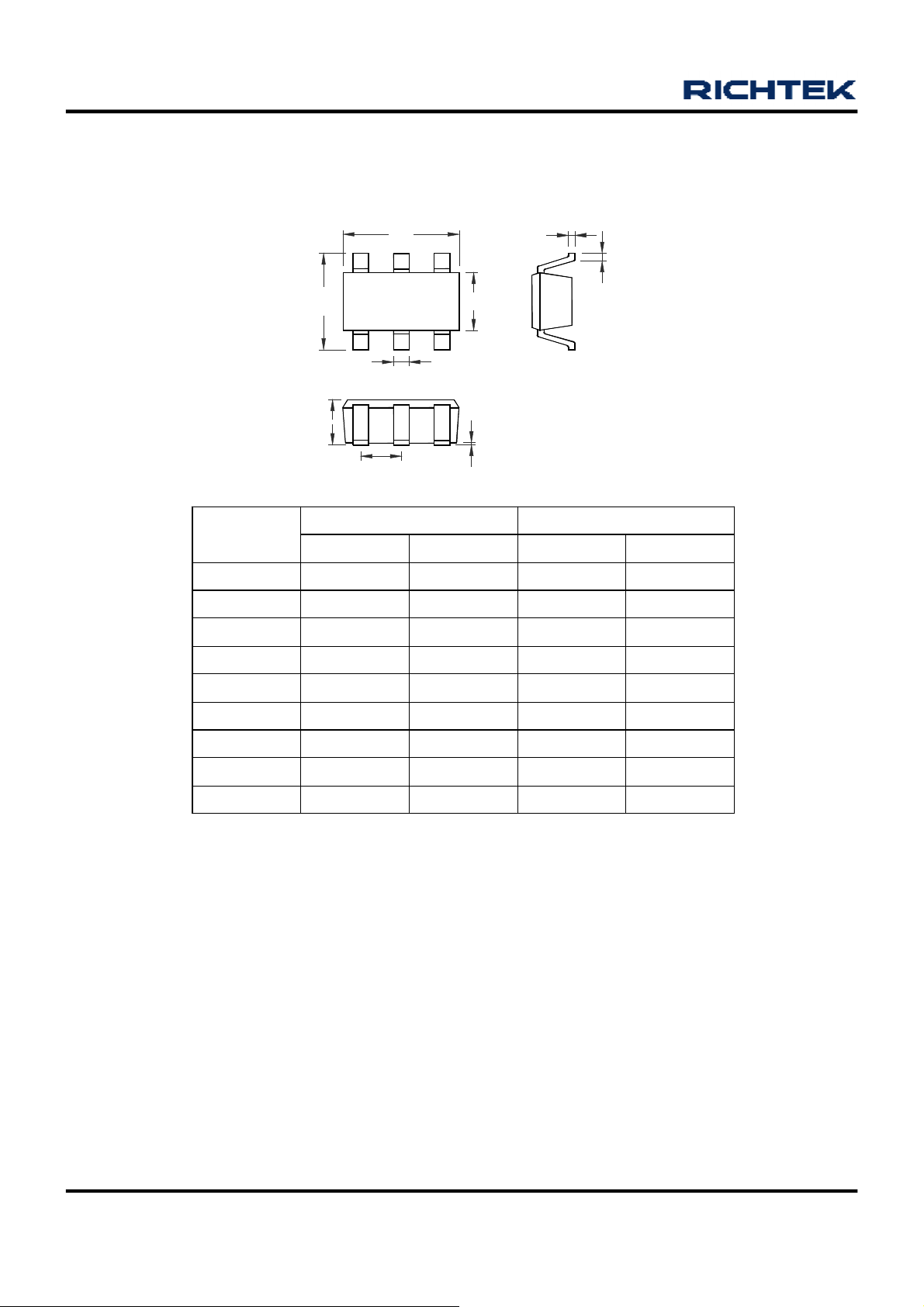

Layout Consideration

Follow the PCB layout guidelines for optimal perf ormance

of RT8259.

` Kee p the tra ces of the main current paths a s short and

wide as possible.

` Put the in put cap acitor a s close a s possible to the device

pins (VIN a nd GND).

` LX node is with high frequency voltage swing a nd should

be kept at small area. Keep sensitive components away

from the LX node to prevent stray capa citive noise pickup.

` Pla ce the feedba ck components to the FB pin as close

as possible.

` Conne ct GND to a ground plane f or noise reduction and

thermal dissipation.

C

OUT

V

OUT

L1

D1

61

PHASE

C

VIN

4

EN

IN

GND

V

OUT

R2

R1

BOOT

GND

FB

C

B

235

Figure 4. PCB Layout Guide

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

0.10

0.05

Maximum Power Dissipation (W)

0.00

0255075100125

Single Layer PCB

T/SOT-23-6

Ambient Te m pera tu re ( °C)

Figure 3. Derating Curves f or RT8259 Pa ckages

10

DS8259-03 March 2011www.richtek.com

RT8259

Table 2. Suggested Inductors for L1

Component Supplier

TDK SLF7045 4.7 30 2 7 x 7 x 4.5

TAIYO YUDEN NR8040 4.7 18 4.7 8 x 8 x 4

GOTERND GTSD53 4.7 45 1.87 5 x 5 x 2.8

GOTERND GSSR2 4.7 18 5.7 10 x 10 x 3.8

Table 3. Suggested Capacitors for CIN and COUT

Component Supplier

MURATA GRM31CR61E106K

TDK C3225X5R1E106K

TAIYO YUDEN TMK316BJ106ML 10 1206

MURATA GRM31CR61C226M

TDK C3225X5R1C226M

TAIYO YUDEN EMK316BJ226ML 22 1206

Table 4. Suggested Diode for D1

Component Supplier

DIODES B230A 30 2 DO-214AC

DIODES B330A 30 3 DO-214AC

PANJIT SK23 30 2 DO-214AC

PANJIT SK33 30 3 DO-214AB

Series Inductance (µH) DCR (mΩ) Current Rating (A) Dimensions (mm)

Part No. Capacitance (µF) Case Size

10 1206

10 1206

22 1206

22 1206

Series V

RRM

(V) I

(A) Package

OUT

DS8259-03 March 2011 www.richtek.com

11

RT8259

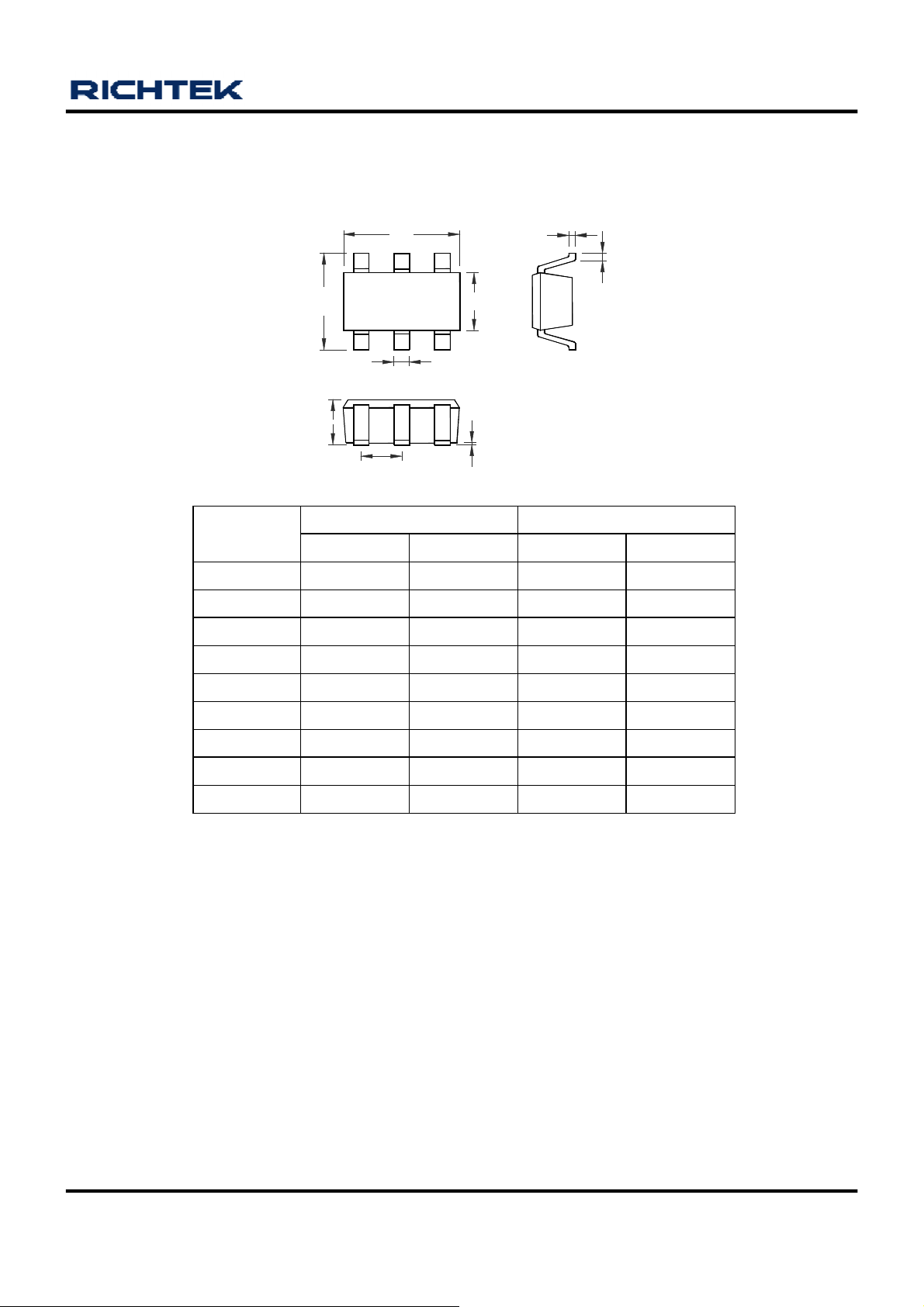

Outline Dimension

H

D

L

C

b

A

e

Dimensions In Millimeters

Symbol

Min Max Min Max

A 0.889 1.295 0.031 0.051

A1 0.000 0.152 0.000 0.006

B 1.397 1.803 0.055 0.071

b 0.250 0.560 0.010 0.022

C 2.591 2.997 0.102 0.118

D 2.692 3.099 0.106 0.122

e 0.838 1.041 0.033 0.041

B

A1

Dimensions In Inches

12

H 0.080 0.254 0.003 0.010

L 0.300 0.610 0.012 0.024

SOT-23-6 Surface Mount Package

DS8259-03 March 2011www.richtek.com

RT8259

H

D

L

C

b

A

e

Dimensions In Millimeters

B

A1

Dimensions In Inches

Symbol

Min Max Min Max

A 0.700 1.000 0.028 0.039

A1 0.000 0.100 0.000 0.004

B 1.397 1.803 0.055 0.071

b 0.300 0.559 0.012 0.022

C 2.591 3.000 0.102 0.118

D 2.692 3.099 0.106 0.122

e 0.838 1.041 0.033 0.041

H 0.080 0.254 0.003 0.010

L 0.300 0.610 0.012 0.024

TSOT-23-6 Surface Mount Package

Richtek Technology Corporation

Headquarter

5F, No. 20, Taiyuen Street, Chupei City

Hsinchu, Taiwan, R.O.C.

Tel: (8863)5526789 Fax: (8863)5526611

Information that is provided by Richtek Technology Corporation is believed to be accurate and reliable. Richtek reserves the right to make any change in circuit design,

specification or other related things if necessary without notice at any time. No third party intellectual property infringement of the applications should be guaranteed

by users when integrating Richtek products into any application. No legal responsibility for any said applications is assumed by Richtek.

DS8259-03 March 2011 www.richtek.com

Richtek Technology Corporation

Taipei Office (Marketing)

5F, No. 95, Minchiuan Road, Hsintien City

Taipei County, Taiwan, R.O.C.

Tel: (8862)86672399 Fax: (8862)86672377

Email: marketing@richtek.com

13

Loading...

Loading...