High Voltage 8 Channel LED Driver

RT8562

General Description

The RT8562 is a 40V 8-channel LED driver capable of

delivering 30mA to each channel with 10 LEDs (3.6V per

diode), total of 80 LEDs with one driver. The RT8562 is a

current mode boost converter opearated at 1MHz, wide

V

range covers from 6V to 24V and the on-chip current

IN

switch is rated at 2.5A.

The PWM output voltage loop regulates the LED pins to

0.6V with an auto-adjustment circuit allowing voltage

mismatches between LED strings. The RT8562 automati-

cally detects and disconnects any unconnected and/or

broken strings during operation from PWM loop to prevent

V

from over voltage.

OUT

The 1.5% matched LED currents on all channels are simply

programmed with a resistor or a current sink. Both analog

dimming and digitally controlled PWM dimming are

supported by RT8562. Analog dimming is linearly

controlled by an external voltage. A very high contrast ratio

true digital PWM dimming can be achieved by driving PWM

pin with a PWM signal.

Features

z High V oltage : V

up to 80 x 3.6V LEDs (10 each channel)

z Channel Current Progra mma be 10mA to 30mA a nd

Matched to 1.5%

z Current Mode PWM 1MHz Boost Converter

z Easy Analog and Digital Dimming Control

z Programmable Soft Start

z Automatic Detecting Unconnected and/or Broken

Channel

z Programmable Over Voltage Protection

z Disconnects LED in Shutdown

z Providing High Accuracy Digital Dimming by PWM

Signal

z V

Under Voltage Lockout

IN

zz

z Over Temperature Protection

zz

zz

z Current Limiting Protection

zz

zz

z Small 24-Lead WQFN Package

zz

zz

z RoHS Compliant and Halogen Free

zz

up to 24V , V

IN

up to 40V , Driving

OUT

Applications

Other protecting features include programmable output

over voltage protection, LED curren limit, PWM switch

current limit and thermal shutdown.

The RT8562 is packaged with a tiny footprint package of

WQFN-24L 4x4 packages.

Ordering Information

RT8562

Package Type

QW : WQFN-24L 4x4 (W-Type)

Lead Plating System

Note :

Richtek products are :

` RoHS compliant and compatible with the current require-

ments of IPC/JEDEC J-STD-020.

` Suitable for use in SnPb or Pb-free soldering processes.

G : Green (Halogen Free and Pb Free)

Marking Information

For marking information, contact our sales representative

directly or through a Richtek distributor located in your

area.

z UMPC and Notebook Computer Backlight

z GPS, Portable DVD Backlight

z Desk Lights and Room Lighting

Pin Configurations

(TOP VIEW)

CH5 NC

LX1

LX2

18

17

16

15

14

25

13

11

CH4

ISET

EN

NC

SS

NC

GND

PWM

VDC

VIN

24 2223

1

2

3

4

5

6

7

8 9 10 12

CH8

CH7

WQFN-24L 4x4

COMP

21 20 19

GND

CH6

PGND2

PGND1

OVP

CH1

CH2

CH3

DS8562-01 April 2011 www.richtek.com

1

RT8562

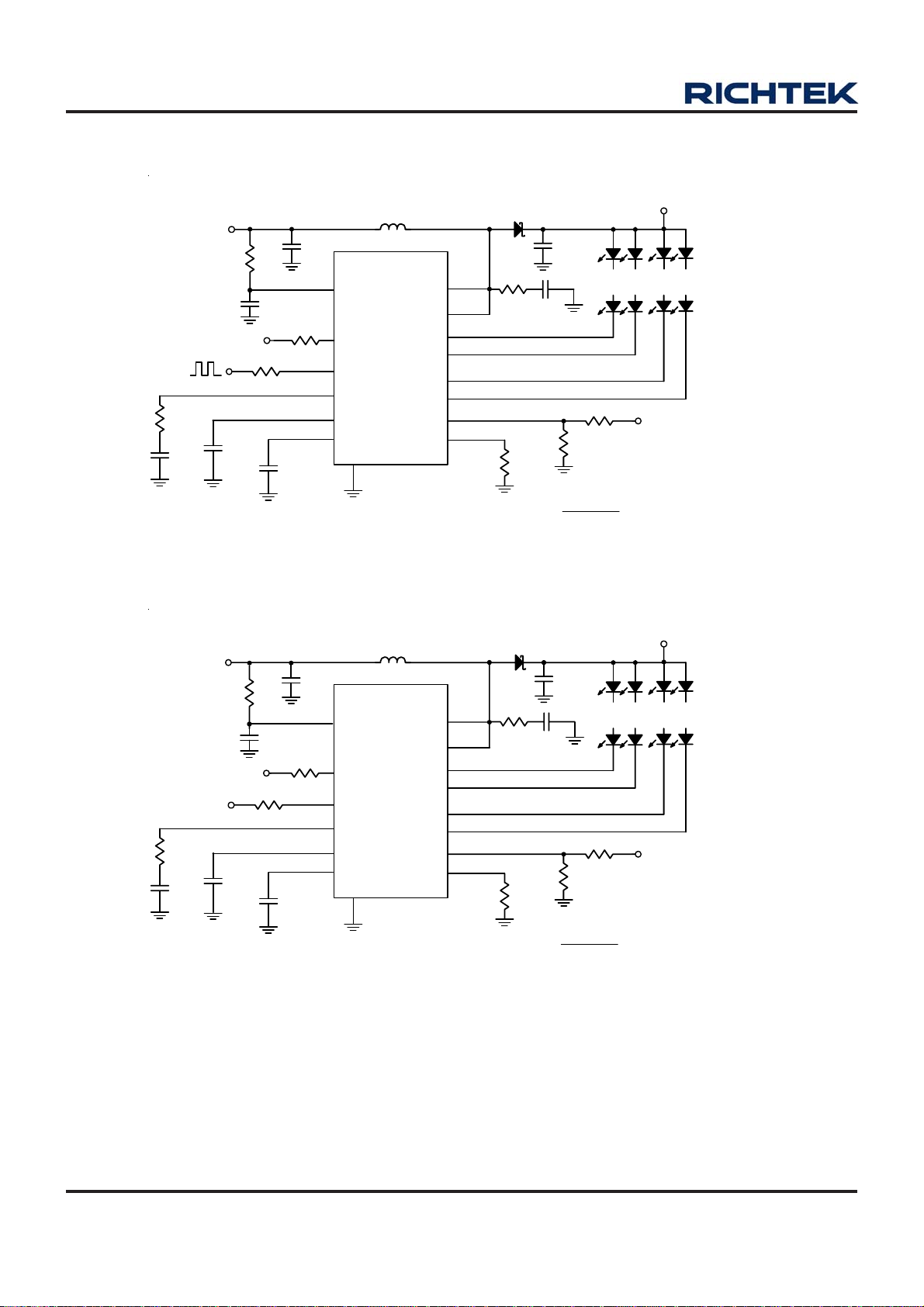

Typical Application Circuit

V

IN

6V to 24V

PWM Signal

R1

1.8k

C2

3.9nF

C3

4.7µF

10

R6

R4

1µF

C6

1k

C4

0.1µF

C1

10µF

R5

1k

23

1

6

22

24

3

L

10µH

RT8562

VIN

EN5V

PWM

COMP

VDC

SS

GND

5, Exposed Pad (25)

OVP

ISET

LX1

LX2

CH1

CH2

CH7

CH8

19

20

15

14

8

7

16

11

I

LED

D1

R7

R

ISET

4.75k

(mA) =

C7

...

C5

10µF

:

:

:

:

R2

R3

20 x 4.75

Ω)

R(k

ISET

V

OUT

40V MAX

:

:

...

:

:

:

:

:

:

V

OUT

:

10 LED String

:

:

:

V

6V to 24V

Analog

Dimming

R1

1.8k

C2

3.9nF

Figure 1. 1MHz, 20mA Full Scale Current PWM Dimming Control

IN

C3

4.7µF

R6

R4

10

C6

1µF

1k

R5

1k

C4

0.1µF

C1

10µF

10µH

RT8562

23

VIN

1

EN5V

6

PWM

22

COMP

24

VDC

3

SS

GND

5, Exposed Pad (25)

L

19

LX1

20

LX2

15

CH1

14

CH2

8

CH7

7

CH8

16

OVP

11

ISET

I

LED

D1

R7

...

R

ISET

4.75k

(mA) =

C5

10µF

C7

20 x 4.75

R(k

R3

ISET

R2

Ω)

:

:

:

:

Figure 2. 1MHz, 20mA Full Scale Current Analog Dimming Control

V

OUT

40V MAX

:

:

...

:

:

:

:

:

:

V

OUT

:

10 LED String

:

:

:

DS8562-01 April 2011www.richtek.com

2

V

4V to 36V

V

AVDD

6V to 24V

Analog

Dimming

R1

1.8k

C2

3.9nF

L

IN

C7

C1

1µF

10µF

R4

R5

R6

C3

4.7µF

10

1k

1k

C6

2.2µF

C4

0.1µF

23

1

6

22

24

3

10µH

RT8562

VIN

EN5V

PWM

COMP

VDC

SS

GND

5, Exposed Pad (25)

LX1

LX2

CH1

CH2

CH7

CH8

OVP

ISET

19

20

15

14

8

7

16

11

I

LED

D1

R7

R

ISET

4.75k

(mA) =

Note :

1. Due to the limitaion of maximum duty, 5V input can support typically to V

2. Due to the limitaion of maximum duty, 4V input can support typically to V

C8

...

OUT

OUT

C5

10µF

:

:

:

:

R2

R3

20 x 4.75

Ω)

R(k

ISET

= 33V.

= 26V.

V

OUT

40V MAX

:

:

...

:

:

:

:

:

:

V

OUT

:

10 LED String

:

:

:

RT8562

Figure 3. Wide Range VIN Application by Connecting VCC Pin to LCD Driver Power AVDD

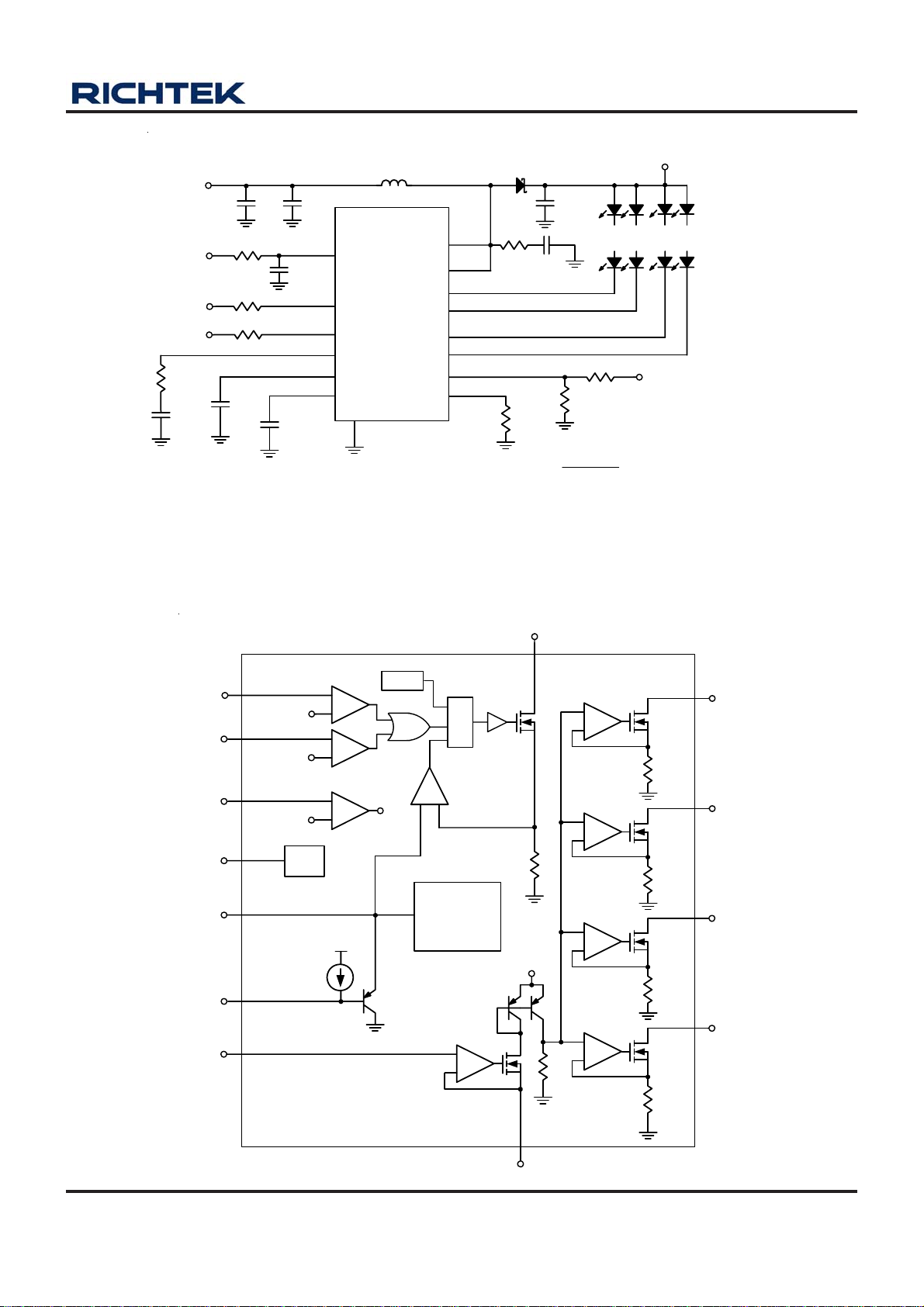

Function Block Diagram

VIN

5.6V

OVP

1.2V

EN

1.6V

VDC

COMP

SS

5V

LDO

5uA

+

+

-

+

Shutdown

OSC

S

R

R

+

-

V

OUT

Regulation

Unit

LX1, LX2

5V

+

-

+

-

CH1

CH2

.

.

.

+

-

CH7

CH8

PWM

+

-

ISET

+

-

DS8562-01 April 2011 www.richtek.com

3

RT8562

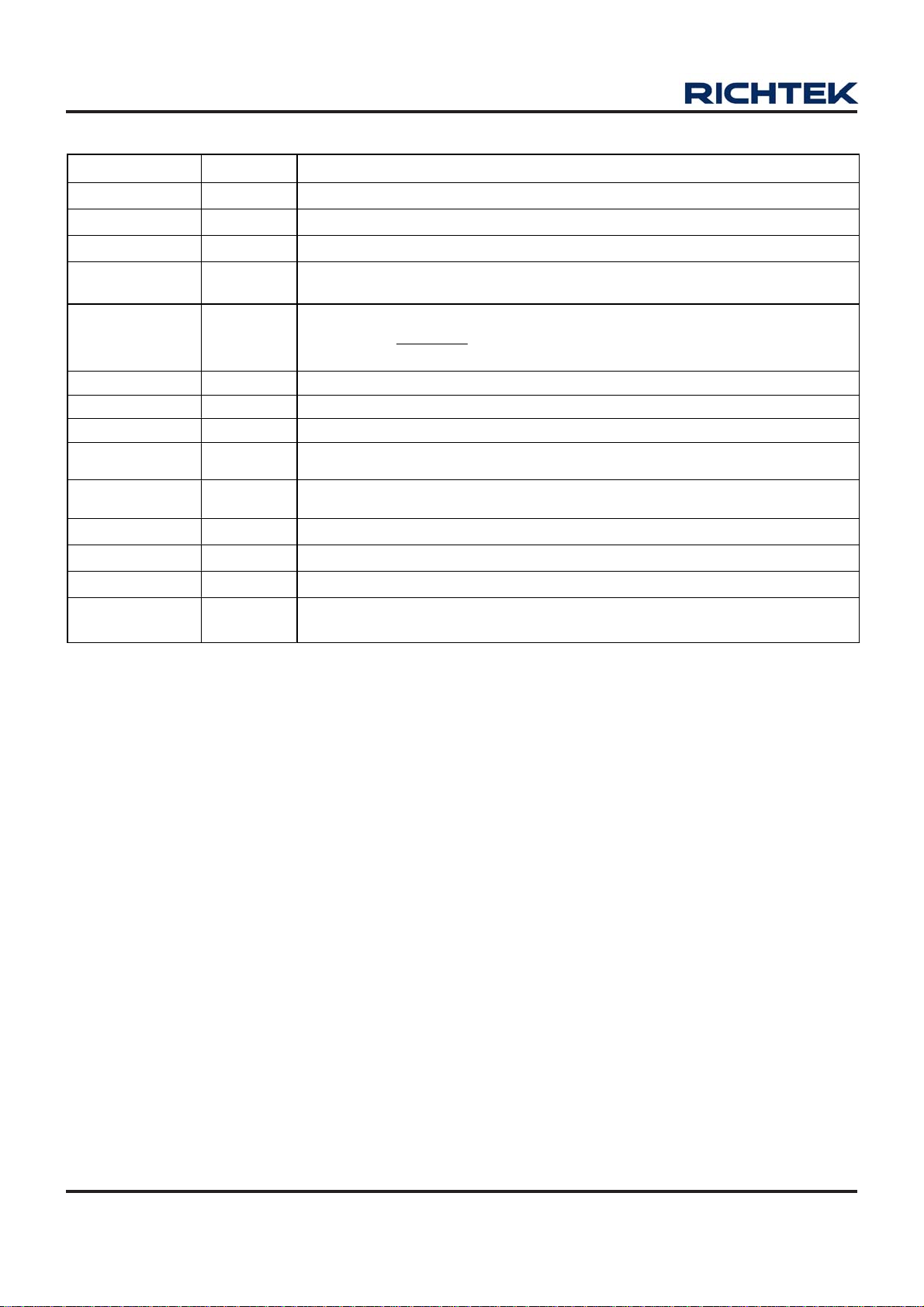

Functional Pin Description

Pin No. Pin Name Pin Function

1 EN Chip enable pin, when pulled low, chip is in shutdown mode.

2, 4, 21 NC No Internal Connection.

3 SS Soft Start Pin, a capacitor of at least 10nF is required for soft start.

5,

25 (Exposed Pad)

GND

6 PWM

11 ISET A resistor or a current from DAC on this pin programs the full LED current.

10, 9, 8, 7 CH5 to CH8 Channel 5 to Channel 8 LED current sink. Leave the pin unconnected if not used.

15, 14, 13, 12 CH1 to CH4 Channel 1 to Channel 4 LED current sink. Leave the pin unconnected if not used.

16 OVP

17, 18

PGND1,

PGND2

19, 20 LX1, LX2 PWM boost converter switch node.

Ground pin of the chip. The exposed pad must be soldered to a large PCB and

connected to GND for maximum power dissipation.

Analog/Digital dimming control. When using analog dimming,

I (mA) = for V 1.2V.

LED PW M

Over Voltage Protection. PWM boost converter turns off when V

20 x 4.75

R(kΩ)

ISET

≥

OVP

higher than 1.2V.

Power Ground (LX1/LX2 power return).

goes

22 COMP PWM boost converter loop compensation node.

23 VIN Power supply of the chip. For good bypass, a low ESR capacitor is required.

24 VDC

Put 1μF capacitor on this pin to stabilize the 5V output of the internal regulator.

This regulator is for chip internal use only.

Absolute Maximum Ratings (Note 1)

z Supply Voltage, VIN ------------------------------------------------------------------------------------------------------ 28V

z LX1, LX2 Pin Voltage at Switching Off -------------------------------------------------------------------------------- 45V

z CH1 to CH8 Pin ------------------------------------------------------------------------------------------------------------ 35V

z PWM, EN, OVP Pin Voltage ------------------------------------------------------------------------------------------- −0.3V to 5.5V

z Power Dissipation, P

WQFN-24L 4x4 ------------------------------------------------------------------------------------------------------------ 1.923W

z Package Thermal Resistance (Note 2)

WQFN-24L 4x4, θJA------------------------------------------------------------------------------------------------------- 52°C/W

WQFN-24L 4x4, θJC------------------------------------------------------------------------------------------------------ 7°C/W

z Junction Temperature ----------------------------------------------------------------------------------------------------- 150°C

z Lead Temperature (Soldering, 10 sec.) ------------------------------------------------------------------------------- 260°C

z Storage Temperature Range -------------------------------------------------------------------------------------------- −65°C to 150°C

z ESD Susceptibility (Note 3)

HBM (Human Body Mode) ---------------------------------------------------------------------------------------------- 2kV

MM (Machine Mode) ------------------------------------------------------------------------------------------------------ 200V

@ TA = 25°C

D

Recommended Operating Conditions (Note 4)

z Supply Input Voltage, VIN ----------------------------------------------------------------------------------------------- 6V to 24V

z Junction Temperature Range --------------------------------------------------------------------------------------------

z Ambient Temperature Range --------------------------------------------------------------------------------------------

4

−40°C to 125°C

−40°C to 85°C

DS8562-01 April 2011www.richtek.com

RT8562

Electrical Characteristics

(VIN = 17V, T

Supply Current I

VIN Under Voltage Lockout

Threshold

Shutdown Current I

EN Pin Input Current IEN VEN ≤ 5V -- -- 0.1 μA

EN Logic Input

PWM Logic Input

L E D Curr e nt Programmi n g

LED Current I

LEDs Current Matching

ISET Pin Voltage V

Input Current of PWM I

Threshold of PWM V

V

Threshold Un-connection -- 0.1 -- V

CHx

PWM Boost Converter

Switching Frequency 0.8 1 1.2 MHz

Minimum On Time -- 100 -- ns

Regulat ed V

Amplifier (gm) Output Current 2.4V > COMP > 0.2V -- ±15 -- μA

COMP Threshold PWM Switch Off 0.1 0.2 -- V

LX1, LX2 R

LX1, LX2 Current Limit I

SW Maximum Duty -- 88 -- %

OVP & Soft Start

OVP Threshold V

OVP Input Current I

Soft Start Current ISS VSS ≤ 2.5V 3 5 8 μA

Thermal Shutdown Temperature TSD -- 150 -- °C

Thermal Shutdown Hysteresis -- 20 -- °C

= 25°C, unless otherwise specified)

A

Parameter Symbol Test Conditions Min Typ Max Unit

COMP ≤ 0.2V (Switching off) -- 3 5 mA

VIN

VIN Rising -- 5.6 5.95

V

UVLO

SHDN

High Level V

Low Level V

High Level V

Low Level V

Highest Voltage LED String 0.5 0.6 0.7 V

CHx

-- 0.3 0.5 Ω

DS(ON)

EN_H

EN_L

PWM_H

PWM_L

CHx

ISET

PWM

PWM

LIM

OVP

OVP

V

Falling -- 4.9 --

IN

VEN ≤ 0.7V -- -- 10 μA

1.6 -- 5

-- -- 1

1.3 -- 5

-- -- 0.15

2V > V

V

PWM

2V > V

V

PWM

(I

(MAX)

3.6kΩ ≤ R

0.3V ≤ V

> 0.6V, R

CHx

> 1.2V

> 0.6V, R

CHx

> 1.2V, Calculating

− I

) / I

(MIN)

ISET

PW M

Averag e

≤ 9.6kΩ, V

≤ 1.2V -- 1 2 μA

= 4.75kΩ,

ISET

= 4.75kΩ,

ISET

x 100%

PWM

19 20 21 mA

-- -- 1.5 %

> 1.2V 1.17 1.2 1.23 V

LED Current Off -- 0.2 -- V

2.5 -- -- A

1.1 1.2 1.3 V

V

≤ 3V -- -- 50 nA

OVP

V

V

V

Note 1. Stresses listed as the above “Absolute Maximum Ratings” may cause permanent damage to the device. These are for

stress ratings. Functional operation of the device at these or any other conditions beyond those indicated in the

operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended

periods may remain possibility to affect device reliability.

Note 2. θ

Note 3. Devices are ESD sensitive. Handlin

Note 4. The device is not guaranteed to function outside its operating conditions.

DS8562-01 April 2011 www.richtek.com

is measured in the natural convection at TA = 25°C on a high effective four layers thermal conductivity test board of

JA

JEDEC 51-7 thermal measurement standard. The case point of θ

g precaution is recommended.

is on the expose pad for the WQFN package.

JC

5

RT8562

Typical Operating Characteristics

Efficiency vs. Input Voltage

100

90

80

70

60

50

40

Efficiency (%)

30

20

10

0

8 1012141618202224

Input Voltage (V)

LED Current vs. Tem perature

24

23

22

21

20

19

LED Current (mA)

18

80LEDs

LED Current v s. Input Voltage

26

24

22

20

18

16

LED Current (mA)

14

12

10

8 10 12141618202224

Input Voltage (V)

V

vs. Temperature

1.24

1.22

1.20

1.18

(V)

ISET

1.16

V

1.14

ISET

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

17

16

-40 -15 10 35 60 85 110 135

Temperature

V

vs. Input Voltage

1.25

1.24

1.23

1.22

(V)

1.21

ISET

V

1.20

1.19

1.18

1.17

8 1012141618202224

ISET

(°C)

Input Voltage (V)

V

IN

= 12V

1.12

1.10

-40 -15 10 35 60 85 110 135

Temperature

(°C)

V

LED Curre nt vs. PWM Duty Cycle

25

20

15

PWM = 200Hz

10

LED Current (mA)

5

V

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0 10 20 30 40 50 60 70 80 90 100

PWM

Duty Cycle (%)

PWM = 1kHz

PWM = 10kHz

PWM = 30kHz

= 0V to 3V, V

IN

IN

= 12V

= 12V

DS8562-01 April 2011www.richtek.com

6

RT8562

LED Current vs. PWM Analog Voltage

28

24

20

16

12

8

LED Current (mA)

4

0

0 0.25 0.5 0.75 1 1.25 1.5

PWM Analog Voltage(V)

Shutdown Current vs. Input Voltage

10

8

6

4

2

Shutdown Current (uA)

0

6 8 10 12 14 16 18 20 22 24

Input Voltage (V)

V

V

IN

EN

= 12V

= 0V

Frequency vs. Input Voltage

1100

1060

1020

980

Frequency (kHz)

940

900

8 1012141618202224

Input Voltage (V)

Switch Off Current vs. Input Voltage

4.0

3.9

3.8

3.7

3.6

3.5

3.4

3.3

3.2

Switch Off Current (mA)

3.1

3.0

8 10 1214 1618202224

Input Voltage (V)

COMP = 0V

SS Current vs. Temperature

8.0

7.6

7.2

6.8

6.4

6.0

5.6

5.2

SS Current (uA)

4.8

4.4

4.0

-40 -15 10 35 60 85 110 135

Temperature

V

IN

= 12V, C

(°C)

= 0.1μF

SS

9

8

7

6

5

SS Current (uA)

4

3

2

SS Current vs. Input Voltage

C

= 0.1μF

SS

8 1012141618202224

Input Volatge (V)

DS8562-01 April 2011 www.richtek.com

7

RT8562

OVP Voltage vs. Temperature

1.30

1.28

1.26

1.24

1.22

1.20

1.18

1.16

OVP Voltage (V)

1.14

1.12

1.10

-40 -15 10 35 60 85 110 135

Temperature

(°C)

V

IN

= 12V

PWM SW-OFF Threshold Voltage vs. Temperature

0.22

0.21

0.20

OVP Voltage vs. Input Volatge

1.3

1.2

1.1

1.0

OVP Voltage (V)

0.9

0.8

8 1012141618202224

Input Voltage (V)

Line Transient Response

V

= 10.8V to 13.2V

IN

0.19

0.18

0.17

0.16

0.15

0.14

PWM SW-OFF Threshold Voltage (V)

V

EN

(2V/Div)

V

OUT

(20V/Div)

I

IN

(500mADiv)

V

= 12V

IN

-40 -15 10 35 60 85 110 135

Temperature

(°C)

Power On from EN

V

= 12V, C

IN

= 0.1μF

SS

V

IN

(5V/Div)

I

OUT

(100mA/Div)

V

IN

(10V/Div)

V

OUT

(50V/Div)

LX1, LX2

(50V/Div)

Time (50ms/Div)

OVP

V

= 12V, All LED Pin Open

IN

Time (10ms/Div)

Time (2.5ms/Div)

DS8562-01 April 2011www.richtek.com

8

Applications Information

RT8562

The RT8562 is a current mode boost converter operating

at 1MHz to power up to 80 white LEDs with a

programmable current for uniform intensity. The part

integrates current sources, soft-start, and easy analog

and digital dimming control. The protection block provides

the circuitry for over-temperature, over-voltage and current-

limit protection features.

Input UVLO

The input operating voltage range of the RT8562 is 6V to

24V. An input capacitor at the VIN pin can reduce ripple

voltage. It is recommended to use a ceramic 10uF or larger

capacitance as the input capacitor. This IC provides an

under voltage lockout (UVLO) function to enhance the

stability when startup. The UVLO threshold of input rising

voltage is set at 5.6V typically with a 0.7V hysteresis.

Power Sequence

Please refer to the below Figure 4 and 5. The

recommended power-on sequence is that the PWM ready

before EN and/or VIN ready. If not, the Soft-Start function

will be disabled. As to power-off sequence, the EN/VIN

must be pulled low within 10ms to prevent “Hard-Start”

shown as Figure 6.

Abnormal Poweron sequence

UVLO

No Soft-Start

If PWM turns

on late

VIN

PWM

EN

VOUT

Power-on

sequence

EN must be turned

on late than VIN

and PWM signal

Soft-Start

Power-off

sequence

EN must be turned

off early than VIN

and PWM signal

Figure 4. Power-On Sequence Control by EN

Power-on

sequence

VIN

PWM

EN

VOUT

Power-off

sequence

VIN must be turned

off early than EN and

PWM signal

Soft-Start

VIN must be

turned on late

than EN and

PWM signal

Abnormal Poweron sequence

UVLO

No Soft-Start

If PWM turns

on late

Figure 5. Power-On Sequence Control by VIN

EN/VIN

PWM

10ms

EN and/or VIN should be

pulled low once PWM pull low

for over 10 ms

Figure 6. To Prevent “Hard-Start” Sequence

Soft Start

The RT8562 employs a soft start feature to limit the inrush

current. The soft-start circuit prevents the excessive inrush

current and input voltage droop. The soft-start time is

determined by capacitor CSS connected to SS pin with

5uA constant current to charge CSS. The value of capacitor

CSS is user-defined to satisfy the designer's requirement.

The recommended soft-start capacitor is 0.1uF.

LED connection

The RT8562 equips 8 channel LED drivers and each channel

supports up to 10 LEDs. The 8 LED strings are connected

from VOUT to pin 7, 8, 9, 10, 12, 13, 14, and 15

respectively. If one of the LED channel is not used, the

LED pin should be opened directly.

Setting and Regulation of LED current

The LED current can be calculated by the following

equation :

I(mA) =

LED

DS8562-01 April 2011 www.richtek.com

20 x 4.75

R(kΩ)

ISET

9

RT8562

Where, the R

is the resister between ISET pin and

ISET

GND.

This setting is the reference for the LED current at CH1 to

CH8 and represents the sensed LED current for each string.

The DC/DC converter regulates the LED current according

to the setting.

If VIN is close to V

and smaller than V

OUT

, the control

OUT

loop may turn on the power switch with minimum on time

and then skip cycles to maintain LED current regulation.

Brightness Control

The RT8562 features both analog and digital dimming

control. Analog dimming is linearly controlled by an

external voltage (0.3V to 1.2V) at PWM pin. A very high

contrast ratio true digital PWM dimming can be achieved

by driving PWM pin with a PWM signal and the

recommended PWM frequency is 100Hz to 10kHz.

Dimming frequency can be sufficiently adjusted from

100Hz to 30kHz. However, LED current cannot be 100%

proportional to duty cycle especially for high frequency

and low duty ratio because of physical limitation caused

by inductor rising time. Refer to Figure 7, the minimum

dimming duty can be as low as 1% for the frequency range

from 100Hz to 300Hz. For the dimming frequency from

300Hz to 1kHz, the duty is about 5%. If the frequency is

increased to 1kHz to 30kHz, the duty will be about 10%.

LED Curre nt vs. PWM Duty Cycle

25

20

Over Voltage Protection

The RT8562 equips over voltage protection (OVP) function.

When the voltage at the OVP pin reaches a threshold of

approximately1.2V, the MOSFET driver output (LX1, LX2)

will be turned “OFF”. The MOSFET driver output (LX1,

LX2) will be turned “ON” again once the voltage at OVP

drops below the threshold voltage 1.2V.

So, the output voltage can be clamped at a certain voltage

level and it can be calculated by the following equation :

R2

V = V1+

OUT, OVP OVP

⎛⎞

×

⎜⎟

R3

⎝⎠

Where

R2 and R3 are the voltage divider connected to OVP pin.

V

is typically 1.2V.

OVP

If at least one string is in normal operation, the controller

will automatically ignore the open strings and continue to

regulate the current for the string(s) in normal operation.

Current Limit Protection

The RT8562 can limit the peak current to achieve over

current protection. RT8562 senses the inductor current

through LX1, LX2 pins in the switch-on period. The duty

cycle depends on the current sense signal summing with

the internal slope compensation compared to the COMP

signal. The internal N-MOSFET will be turned off when

the current signal is larger than the COMP signal. In the

off period, the inductor current will descend. The internal

MOSFET is turned on by the oscillator in the next begining

cycle.

15

PWM = 200Hz

10

LED Current (mA)

5

V

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0 10 20 30 40 50 60 70 80 90 100

PWM

Duty Cycle (%)

PWM = 1kHz

PWM = 10kHz

PWM = 30kHz

= 0V to 3V, V

IN

= 12V

Figure 7. LED Current vs. PWM Dimming Duty Cycle

10

Over Temperature Protection

The RT8562 has over temperature protection (OTP)

function to prevent the excessive power dissipation from

overheating. The OTP will shut down switching operation

while the junction temperature exceeds 150°C. Main

converter starts switching when junction temperature

cooling down approximately 20°C.

Inductor Selection

The value of the output inductor (L), where the transition

from discontinuous to continuous mode occurs is

approximated by the following equation :

2

(V V V

OUT IN IN

L =

2I f V

×××

OUT OUT

)

−×

2

DS8562-01 April 2011www.richtek.com

RT8562

Where,

V

= maximum output voltage.

OUT

VIN = minimum input voltage.

f = operating frequency.

I

= sum of current from all LED strings.

OUT

η is the efficiency of the power converter.

The boost converter operates in discontinuous mode over

the entire input voltage range when the L1 inductor value

is less than this value L. With an inductance greater than

L, the converter operates in continuous mode at the

minimum input voltage and may be discontinuous at higher

voltages.

The inductor must be selected with a saturation current

rating greater than the peak current provided by the

following equation :

I =

PEAK

××−

OUT OUT IN OUT IN

η

××

+

V2LV

IN OUT

⎛⎞

⎜⎟

⎝⎠

VI VTV V

Diode Selection

Schottky diode is a good choice for an asynchronous

Boost converter due to the small forward voltage. However,

for power dissipation, reverse voltage rating and pulsating

peak current are the important parameters of Schottky

diode consideration. Choose a suitable diode whose

reverse voltage rating is greater than the maximum output

voltage.

Capacitor Selection

The input capacitor reduces current spikes from the input

supply and minimizes noise injection to the converter. For

most applications, a 10uF ceramic capacitor is sufficient.

A value higher or lower may be used depending on the

noise level from the input supply and the input current to

the converter.

Layout Guideline

PCB layout is very important to design power switching

converter circuits. The following layout guide lines should

be strictly followed for best performance of the RT8562.

` The power components L, D1, C1, C

OUT1

and C

OUT2

must

be placed as close as possible to reduce the ac current

loop. The PCB trace between power components must

be short and wide as possible due to large current flow

through these trace during operation.

` Place L and D1 connected to LX pin as close as possible.

The trace should be short and wide as possible.

` It is recommend to place C6 close to VIN pin.

` Pin22 is the compensation point to adjust system

stability. Place the compensation components to pin22

as close as possible.

V

C2

R1

COMP

GND

CH6

IN

C1

L

LX2

21 20 19

25

11

CH5 NC

ISET

Place power components

as close as possible.

GND

C

D1

LX1

CH4

18

17

16

15

14

13

C

OUT1

PGND2

PGND1

OVP

CH1

CH2

CH3

OUT2

V

OUT

Locate the compensation

components to COMP

pin as close as possible.

Locate the C

close to VIN pin as

possible.

VIN2

as

EN

NC

SS

NC

GND

PWM

R4

C6

1

2

3

4

5

6

C

VDC

24 2223

7

CH8

VC2

VIN

8 9 10 12

CH7

Figure 8

It is recommended to choose a ceramic capacitor bases

on the output voltage ripple requirements. The minimum

value of the output capacitor C

is approximately given

OUT

by the following equation :

(V V ) I

−×

C =

OUT

DS8562-01 April 2011 www.richtek.com

OUT IN OUT

VVf

η

×××

RIPPLE OUT

11

RT8562

Outline Dimension

D

E

A

A3

A1

D2

SEE DETAIL A

1

be

E2

L

1

2

1

2

DETAIL A

Pin #1 ID and Tie Bar Mark Options

Note : The configuration of the Pin #1 identifier is optional,

but must be located within the zone indicated.

Dimensions In Millimeters Dimensions In Inches

Symbol

Min Max Min Max

A 0.700 0.800 0.028 0.031

A1 0.000 0.050 0.000 0.002

A3 0.175 0.250 0.007 0.010

b 0.180 0.300 0.007 0.012

D 3.950 4.050 0.156 0.159

D2 2.300 2.750 0.091 0.108

E 3.950 4.050 0.156 0.159

E2 2.300 2.750 0.091 0.108

e 0.500 0.020

L 0.350 0.450

Richtek Technology Corporation

Headquarter

5F, No. 20, Taiyuen Street, Chupei City

Hsinchu, Taiwan, R.O.C.

Tel: (8863)5526789 Fax: (8863)5526611

0.014 0.018

W-Type 24L QFN 4x4 Package

Richtek Technology Corporation

Taipei Office (Marketing)

5F, No. 95, Minchiuan Road, Hsintien City

Taipei County, Taiwan, R.O.C.

Tel: (8862)86672399 Fax: (8862)86672377

Email: marketing@richtek.com

Information that is provided by Richtek Technology Corporation is believed to be accurate and reliable. Richtek reserves the right to make any change in circuit

design, specification or other related things if necessary without notice at any time. No third party intellectual property infringement of the applications should be

guaranteed by users when integrating Richtek products into any application. No legal responsibility for any said applications is assumed by Richtek.

DS8562-01 April 2011www.richtek.com

12

Loading...

Loading...