®

RT8249A/B/C

Dual-Channel Synchronous DC/DC Step-Down Controller

with 5V/3.3V LDOs

General Description

The RT8249A/B/C is a dual-channel step-down, controller

generating supply voltages for battery-powered systems.

It includes two Pulse-Width Modulation (PWM) controllers

adjustable from 2V to 5.5V, and two fixed 5V/3.3V linear

regulators. Each linear regulator provides up to 100mA

output current and 3.3V linear regulator provides 1%

accura cy under 35mA. The RT8249A/B has an oscillator

output to driver the external charge pump a pplication. The

RT8249C provides a mode selection pin, SKIPSEL, to

select Diode-Emulation Mode (DEM) or Audio Skipping

Mode (ASM). Other features include on-board power-up

sequencing, a power-good output, internal soft-start, and

soft-discharge output that prevents negative voltage during

shutdown.

A con stant current ri pple PWM control scheme operates

without sense resistors and provides 100ns response to

load transient. For maximizing power efficiency, the

RT8249A/B/C automatically switches to the diodeemulation mode in light load a pplications. The RT8249A/

B/C is available in the WQFN-20L 3x3 package.

Features

Support Connected Standby Mode for Ultrabook

CCRCOT Control with 100ns Load Step Response

PWM Maximum Duty Ratio > 98%

5V to 25V Input Voltage Range

2V to 5.5V Output Voltage Range

5V/3.3V LDOs with 100mA Output Current

1% Accuracy on 3.3V LDO Output

Oscillator Driving Output for Charge Pump

Application

Internal Frequency Setting

RT8249A/B : 400kHz/475kHz (CH1/CH2)

RT8249C : 500kHz/600kHz (CH1/CH2)

Internal Soft-Start and Soft-Discharge

4700ppm/

Independent Switcher Enable Control

Built in OVP/UVP/OCP/OTP

Non-latch UVLO

Power Good Indicator

20-Lead WQFN Package

RoHS Compliant and Halogen Free

°°

°C R

°°

Current Sensing

DS(ON)

Simplified Application Circuit

V

IN

GND

UGATE2

BOOT2

PHASE2

LGATE2

FB2

CS1

CS2

LDO5

PGOOD

LDO3

V

O

U

T

2

V

5

r

o

t

a

d

i

I

c

n

O

D

G

O

P

V

3

.

3

VIN

RT8249A/B/C

UGATE1

BOOT1

V

U

O

T

1

Channel 1 Enable

Channel 2 Enable

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

Off

On

PHASE1

LGATE1

BYP1

FB1

EN1

EN2

DS8249A/B/C-02 June 2014 www.richtek.com

1

RT8249A/B/C

Applications

Notebook and Sub-Notebook Computers

System Power Supplies

3-Cell and 4-Cell Li+ Battery-Powered Devices

Ordering Information

RT8249A/B/C

Pin 1 Orientation***

(2) : Quadrant 2, Follow EIA-481-D

Package Type

QW : WQFN-20L 3x3 (W-Type)

Lead Plating System

G : Green (Halogen Free and Pb Free)

Pin Function With

A : VCLK, LDO3 Always On

B : VCLK, LDO3/LDO5 Always On

C : SKIPSEL, LDO3 Always On

Note :

***Empty means Pin1 orientation is Quadrant 1

Richtek products are :

RoHS compliant and compatible with the current require-

ments of IPC/JEDEC J-STD-020.

Suitable for use in SnPb or Pb-free soldering processes.

Marking Information

RT8249AGQW

2Q= : Product Code

2Q=YM

DNN

YMDNN : Date Code

Pin Configurations

(TOP VIEW)

EN1

VCLK

PHASE1

1

CS1

2

FB1

3

LDO3

FB2

CS2 LGATE2

CS1

FB1

LDO3

FB2

CS2 LGATE2

GND

4

EN2

PGOOD

PHASE2

RT8249A/B

EN1

SKIPSEL

PHASE1

1

2

3

GND

4

EN2

PGOOD

PHASE2

RT8249C

WQFN-20L 3x3

BOOT1

17181920

21

9876

BOOT2

BOOT1

17181920

21

9876

BOOT2

UGATE1

16

10

UGATE2

UGATE1

16

10

UGATE2

15

LGATE1

14

BYP1

13

LDO5

12

VIN

115

15

LGATE1

14

BYP1

13

LDO5

12

VIN

115

RT8249BGQW

2P= : Product Code

2P=YM

YMDNN : Date Code

DNN

RT8249CGQW

2N= : Product Code

2N=YM

YMDNN : Date Code

DNN

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

2

©

DS8249A/B/C-02 June 2014www.richtek.com

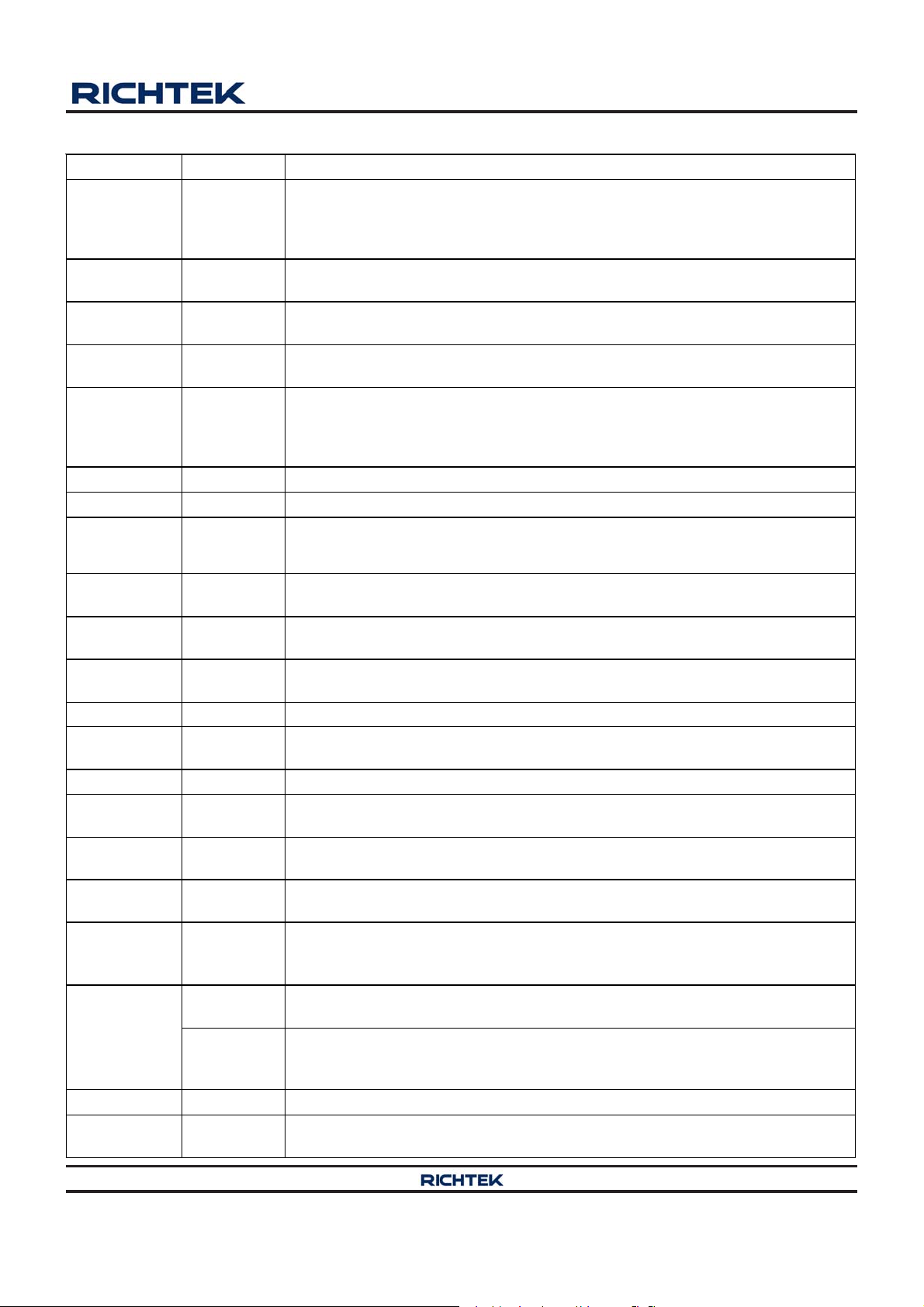

Functional Pin Description

Pin No. Pin Name Pin Funct ion

Curr ent Limit Setting. Connect a resistor to GND to set the threshold for Channel

1 CS1

2 FB1

3 LDO3

4 FB2

5 CS2

6 EN2 Enable Control Input for Channel 2.

7 PGOOD Power Good Indicator Output for Channel 1 and Channel 2. (Logical AND)

8 PHASE2

9 BOOT2

10 UGATE2

11 LGATE2

12 VIN Power Input for 5V and 3.3V LDO Regulators and Buck Controllers.

13 LDO5

14 BYP1 Switch-over Source Voltage Input for LDO5.

15 LGATE1

16 UGATE1

17 BOOT1

18 PHASE1

VCLK

(RT8249A/B)

19

20 EN1 Enable Control Input for Channel 1.

21

(Exposed Pad)

SKIPSEL

(RT8249C)

GND

1 synchronous R

1/8th the voltage seen at CS1 over a 0.2V to 2V range. There is an internal 50A

cur rent source from LDO5 to CS1.

Feedback Voltage Input for Channel 1. Connect FB1 to a resistive voltage divider

from VOUT1 to GND to adjust output from 2V to 5.5V.

3.3V Linear Regulator Output. It is always on when VIN is higher than VIN POR

thr eshold.

Feedback Voltage Input for Channel 2. Connect FB2 to a resistive voltage divider

from VOUT2 to GND to adjust output from 2V to 5.5V.

Curr ent Limit Setting. Connect a resistor to GND to set the threshold for Channel

2 synchronous R

1/8th the voltage seen at CS2 over a 0.2V to 2V range. There is an internal 50A

cur rent source from LDO5 to CS2.

Switch Node of Channel 2 MOSFETs. PHASE2 is the internal lower supply rail for

the UGATE2 high-side gate driver. PHA SE2 is also the current-sense input for the

Channel 2.

Bootstrap Supply for Channel 2 High-Side Gate Driver. Connect to an external

capacitor accor ding to the typical application circuits.

High-S ide Gate Driver Output for Channel 2. UGATE2 swings betw een PHA SE2

and BOOT2.

Low-Side Gate D river Output for Channel 2. LGATE2 swings between GND and

LDO5.

5V Linear Regulator Output. LDO5 is also the supply vol tage for the low-side

MOSFET and analog supply voltage for the device.

Low-Side Gate D river Output for Channel 1. LGATE1 swings between GND and

LDO5.

High-S ide Gate Driver Output for Channel 1. UGATE1 swings betw een PHA SE1

and BOOT1.

Bootstrap Supply for Channel 1 High-Side Gate Driver. Connect to an external

capacitor accor ding to the typical application circuits.

Switch Node of Channel 1 MOSFETs. PHASE1 is the internal lower supply rail for

the UGATE1 high-side gate driver. PHASE1 is also the current sense input for the

Channel 1.

Oscillat or Output for Charge Pump.

PWM Operating Mode Selection.

Diode-emulation M ode : Connect to LDO3

Audio Skipping Mode : Shor t to GND

Ground. The exposed pad must be soldered to a large PCB and connected to

GND for maximum power dissipation.

sense. The GND PHASE1 current limit threshold is

DS(ON)

sense. The GND PHASE2 current limit threshold is

DS(ON)

RT8249A/B/C

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8249A/B/C-02 June 2014 www.richtek.com

©

3

RT8249A/B/C

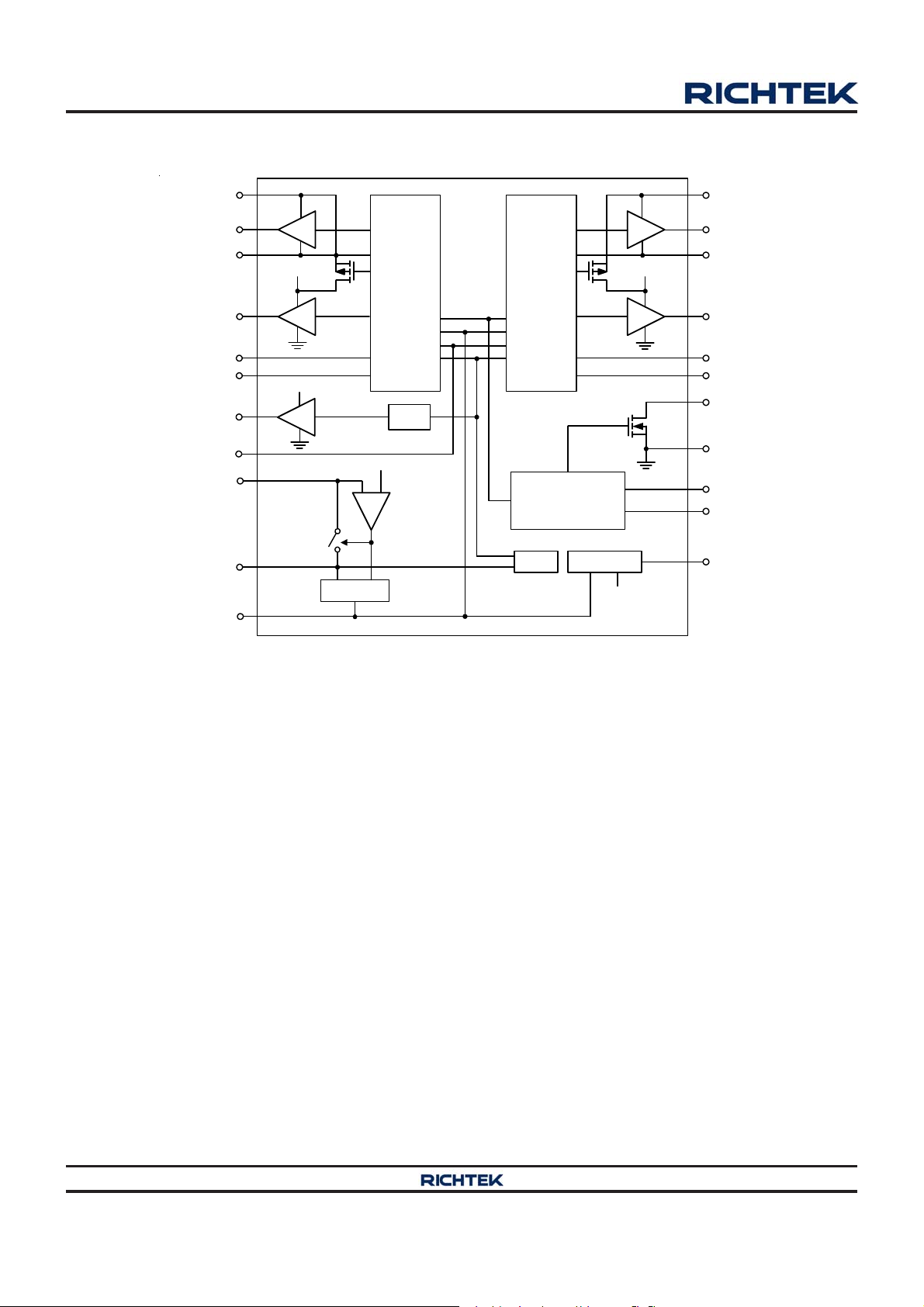

Function Block Diagram

BOOT1

UGATE1

PHASE1

LGATE1

FB1

CS1

VCLK

(RT8249A/B)

SKIPSEL

(RT8249C)

BYP1

LDO5

VIN

LDO5

BYP1

Channel 1

Buck

Controller

OSC

SW5 Threshold

LDO5

Channel 2

Buck

Controller

Power-On

Sequence

Clear Fault Latch

REF

BOOT2

UGATE2

PHASE2

LDO5

LGATE2

FB2

CS2

PGOOD

GND

EN1

EN2

LDO3 LDO3

BYP1

Operation

The RT8249A/B/C includes two constant on-time

synchronous step-down controllers and two linear

regulators.

Buck Controller

In normal operation, the high-side N-MOSFET is turned

on when the output is lower than V REF, and is turned off

after the internal one-shot timer expires. While the highside N-MOSFET is turned of f, the low-side N-MOSFET is

turned on to conduct the inductor current until next cycle

begins.

Soft-Start

For internal soft-start function, an internal current source

charges an internal capacitor to build the soft-start ra mp

voltage. The output voltage will track the internal ramp

voltage during soft-start interval.

PGOOD

The power good output is an open-drain architecture. When

the two channels soft-start are both finished, the PGOOD

open-drain output will be high impedance.

Current Limit

The current limit circuit employs a unique “valley” current

sensing algorithm. If the magnitude of the current sense

signal at PHASE is above the current limit threshold, the

PWM is not allowed to initiate a new cycle. Thus, the

current to the load exceeds the average output inductor

current, the output voltage falls and eventually crosses

the under-voltage protection threshold, inducing IC

shutdown.

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

4

©

DS8249A/B/C-02 June 2014www.richtek.com

Over-Voltage Protection (OVP) & Under-Voltage

Protection (UVP)

The two channel output voltages are continuously

monitored for over-voltage and under-voltage conditions.

When the output voltage exceeds over-voltage threshold

(1 13% of VOUT), UGA TE goes low a nd LGA TE is forced

high. When it is less than 52% of reference voltage, undervoltage protection is triggered and then both UGA TE a nd

LGA TE gate drivers are forced low. The controller is latched

until ENx is reset or LDO5 is re-supplied.

LDO5 and LDO3

When the VIN voltage exceeds the POR rising threshold,

LDO3 will default turn-on. The LDO5 can be power on by

ENx. The linear regulator LDO5 and LDO3 provide 5V and

3.3V regulated output.

Switching Over

RT8249A/B/C

The BYP1 is connected to the Channel 1 output. After the

Channel 1 output voltage exceeds the set threshold

(4.66V), the output will be bypassed to the LDO5 output

to maximize the efficiency.

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8249A/B/C-02 June 2014 www.richtek.com

©

5

RT8249A/B/C

Absolute Maximum Ratings (Note 1)

VIN to G ND--------------------------------------------------------------------------------------------------------- −0.3V to 30V

BOOTx to PHASEx---------------------------------------------------------------------------------------------- −0.3V to 6V

PHASEx to GND

DC-------------------------------------------------------------------------------------------------------------------- −0.3V to 30V

<20ns --------------------------------------------------------------------------------------------------------------- −8V to 38V

UGATEx to PHASEx

DC-------------------------------------------------------------------------------------------------------------------- − 0.3V to (LDO5 + 0.3V)

<20ns --------------------------------------------------------------------------------------------------------------- −5V to 7.5V

LGATEx to GND

DC-------------------------------------------------------------------------------------------------------------------- − 0.3V to (LDO5 + 0.3V)

<20ns --------------------------------------------------------------------------------------------------------------- −2.5V to 7.5V

Other Pins---------------------------------------------------------------------------------------------------------- −0.3V to 6V

Power Dissipation, P

WQFN-20L 3x3 ---------------------------------------------------------------------------------------------------3.33W

Package Thermal Re sistance (Note 2)

WQF N-20L 3x3, θJA---------------------------------------------------------------------------------------------- 30°C/W

WQFN-20L 3x3, θJC--------------------------------------------------------------------------------------------- 7.5°C/W

Junction T emperature-------------------------------------------------------------------------------------------- 150°C

Lead Temperature (Soldering, 10 sec.)---------------------------------------------------------------------- 260°C

Storage T emperature Range ----------------------------------------------------------------------------------- − 65°C to 150°C

ESD Susceptibility (Note 3)

HBM (Human Body Model)------------------------------------------------------------------------------------- 2kV

@ T

D

= 25°C

A

Recommended Operating Conditions (Note 4)

Supply V oltage, VIN --------------------------------------------------------------------------------------------- 5V to 25V

Junction T emperature Range----------------------------------------------------------------------------------- −40°C to 125°C

Ambient T emperature Range----------------------------------------------------------------------------------- −40°C to 85°C

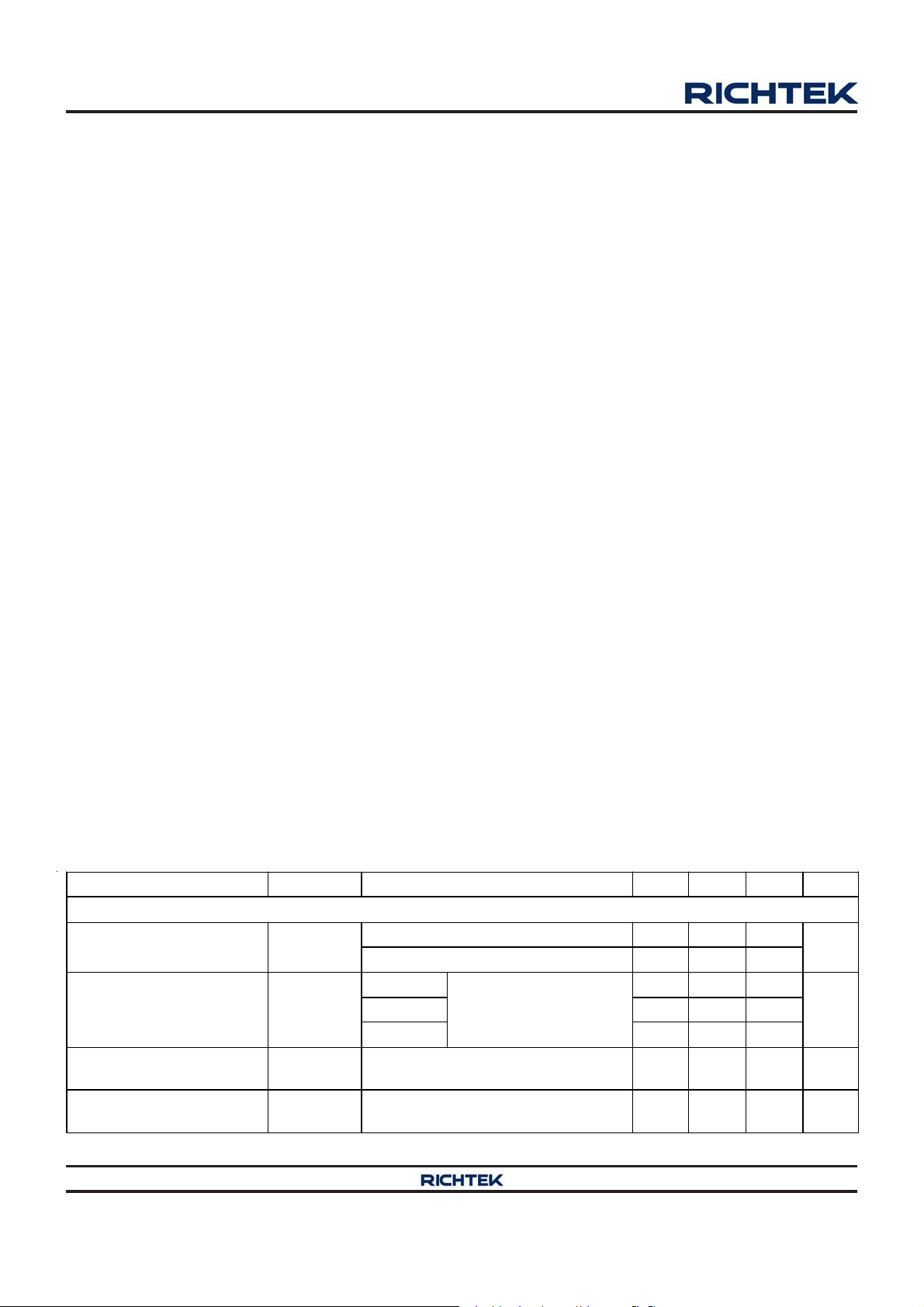

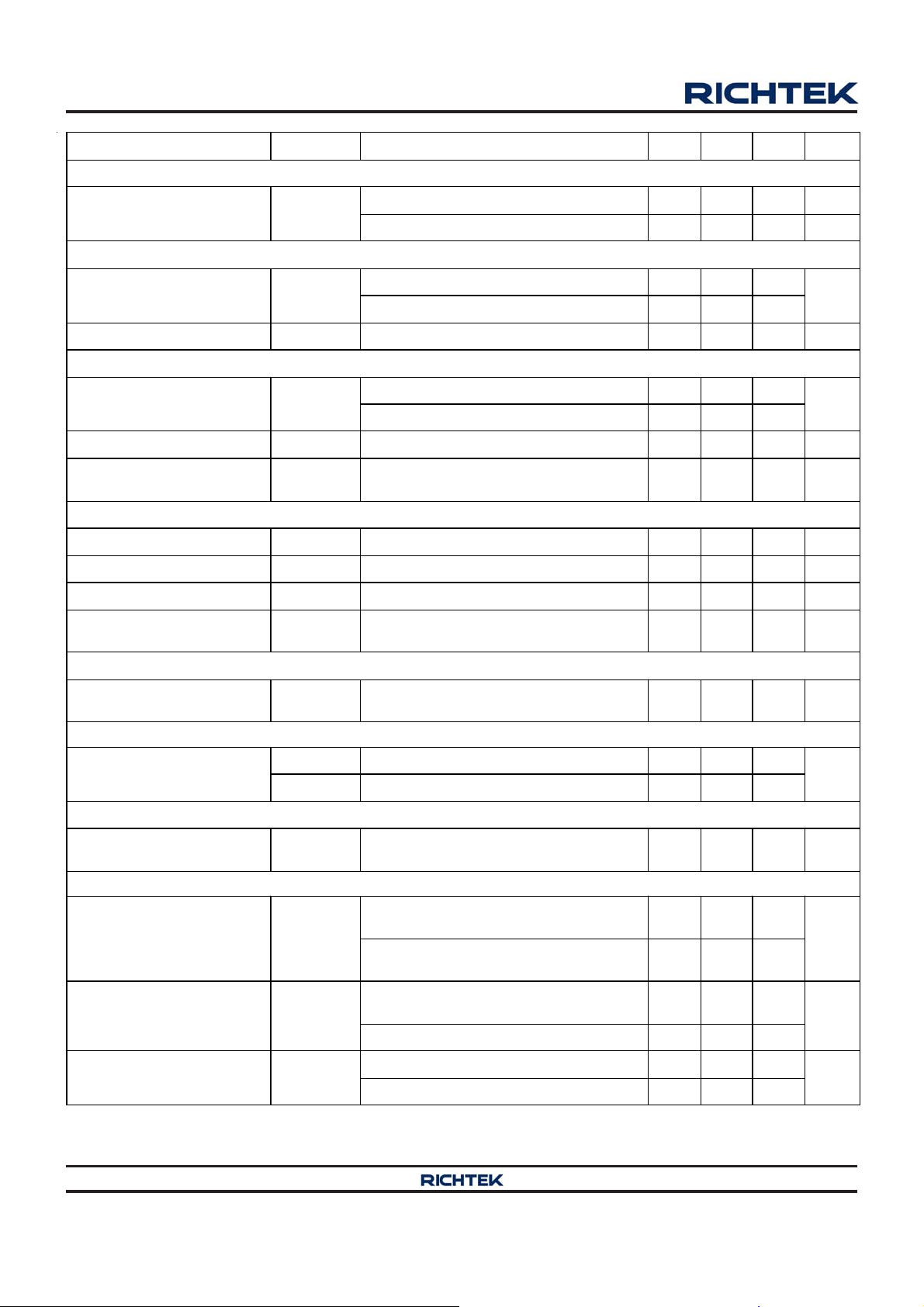

Electrical Characteristics

(VIN = 12V, V

specified)

Input Supply

VIN Power On Reset V

VIN Standby Supply

Current

VIN Quiescent Current I

BYP1 Supply C urrent I

= V

EN1

= 3.3V, V

EN2

CS1

= V

= 2V, VCLK disable by 200Ω to GND, No Load, TA = 25°C, unless otherwise

CS2

Parameter Symbol Test Conditions Min Typ Max Unit

IN_POR

I

VIN_SBY

Falling Threshold 3.2 3.7 -RT8249A

RT8249B -- 35 55

Both Buck C ontro llers

Off, V

EN1

= V

EN2

= GND

-- 20 35

Rising Threshold -- 4.6 4.9

RT8249C -- 20 35

VIN_nosw

BYP1_nosw

Both Buck Controlle rs On ,

= 2.05V, V

V

FBx

BYP1

Both Buck Controlle rs On ,

= 2.05V, V

V

FBx

BYP1

= 5.05V

= 5.05V

-- 15 25 A

-- 120 180 A

V

A

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

6

©

DS8249A/B/C-02 June 2014www.richtek.com

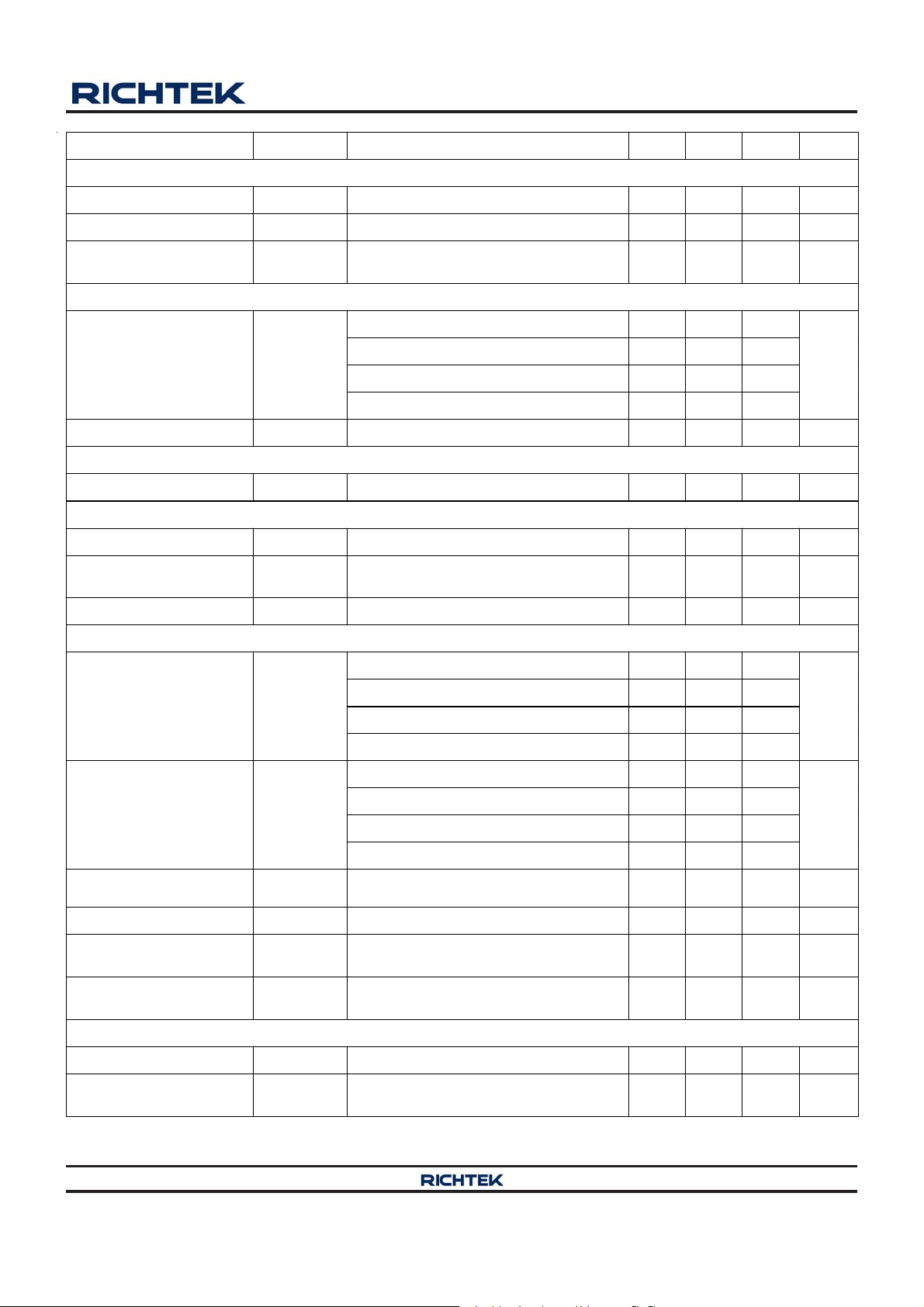

Parameter Symbol Test Conditions Min Typ Max Unit

Buck Controllers Outp ut and FB Voltage

RT8249A/B/C

FBx Valley Trip Voltag e V

BYP1 Discharge Current I

PHASEx Discharge

Current

CCM Operation 1.98 2 2.02 V

FBx

DCHG_BYP1

I

DCHG_LX

V

V

= 0.5V 10 45 -- mA

BYP1

PHASEx

= 0.5V 5 8 -- mA

Switchin g Frequency

RT8249A/B, V

RT8249A/B, VIN = 20V, V

Switching Frequency f

SWx

RT8249C, VIN = 20V, V

RT8249C, VIN = 20V, V

Minimum O ff-Time t

OFF(MIN)

V

FBx

= 1.9V -- 200 275 ns

Soft-Start

Soft-St a rt Time t

V

SSx

OUT

Ramp_Up Time -- 0.9 -- ms

Current Sense

CSx Source Current I

CSx Current

Tem per ature Coefficient

Zero-Current Thres h old VZC V

V

CSx

TCI

In Comparison with 25°C -- 4700 -- ppm/C

CSx

= 1V 47 50 53 A

CSx

= 2.05V, GND PHASEx -- 1 -- mV

FBx

Internal Regulator

= 20V, V

IN

= 5V 320 400 480

OUT1

= 3.33V 380 475 570

OUT2

= 5V 400 500 600

OUT1

= 3.33V 480 600 720

OUT2

kHz

LDO5 Output Voltage V

LDO3 Output Voltage V

LDO5 Output Current I

LDO3 Output Current I

LDO5 Switch-over

Threshold to BYP1

LDO5 Switch-over

Equivalent Resi stance

VCLK Output, RT8249A/B

VCLK On-Resistance R

VCLK Switching

Frequency

V

= 12V, No Load 4.9 5 5.1

IN

LDO5

VIN > 5.5V, I

VIN > 5V, I

VIN > 7V, I

V

= 12V, No Load 3.267 3.3 3.333

IN

VIN > 7V, I

LDO3

VIN > 5.5V, I

VIN > 5V, I

= 4.5V, V

V

LDO5

V

LDO3

Rising Edge at BYP1 Regulation Point -- 4.66 -- V

V

SWTH

LDO5 to BYP1, 10mA -- 1.5 3

R

SW

Pull-up and Pull-down Resistance -- 10 - -

VCLK

-- 260 -- kHz

f

VCLK

LDO5

= 7.4V

V

IN

= 3V, VIN = 7.4V 100 175 -- m A

LDO3

< 100mA 4.8 5 5.1

LDO5

< 35mA 4.8 5 5.1

LDO5

< 20mA 4.5 4.75 5.1

LDO5

< 100mA 3.217 3.3 3.383

LDO3

< 35mA 3.267 3.3 3.333

LDO3

< 20mA 3.217 3.3 3.383

LDO3

= GND,

BYP1

100 175 -- mA

V

V

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8249A/B/C-02 June 2014 www.richtek.com

©

7

RT8249A/B/C

Parameter Symbol Test Conditions Min Typ Max Unit

SKIP Mode Selection, RT8249C

SKIPSEL Input Voltage V

SKIPSEL

DEM Operation 1.2 -- --

UVLO

Ri si ng Edge -- 4.3 4. 6

ASM Operation -- -- 0.8 V

LDO5 UVLO Threshold V

LDO3 UVLO Threshold V

UVLO 5

UVLO 3

Falling Edge 3.7 3.9 4.1

Ch annel x Off -- 2.5 -- V

V

Power Good

PG OOD Threshold V

PGxTH

Hysteresis -- 8 --

PGOOD Leakage Current High state, V

PGOOD Detect, V

PGOO D Outpu t Low

Voltage

I

= 4mA -- -- 0.3 V

SINK

PGOOD

Rising Edge 84 88 92

FBx

= 5.5V -- -- 1 A

%

Fault Detection

OVP Trip Threshold V

FBx with Respect to Internal Reference 109 113 117 %

OVP

OVP Propagation Delay -- 1 -- s

UV P Trip Threshold V

UVP Shu tdown Bl anking

Time

UVP Detect, FBx Falling Edge 47 52 57 %

UVP

t

SHDN_UVP

From ENx Enable -- 1.3 -- ms

Thermal Shutdown

Thermal Shutdown

Threshold

-- 150 -- °C

T

SD

Logic Inputs

ENx Threshold Voltage

V

V

SMPS On 1.6 -- --

ENx_H

SMPS Off -- -- 0.4

ENx_L

Int ernal B oost Switc h

Internal Boost Switch

On-Resistance

LDO5 to BOOTx -- 80 --

R

BST

Power MOSFET Drivers

UGATEx On-Resistance RUG

LGATEx On-Resistance RLG

Hi gh Sta te, V

BOOTx

V

V

Low State, V

BOOTx

V

V

Hi gh Sta te, V

= 5V

V

LDO5

Low State, V

PHASEx

PHASEx

BOOTx

UGATEx

V

LDO5

LGATE x

V

= 5V

V

= 5V

LGATEx

UGATEx

PAHSEx

= 0.25V,

= 0.25V,

= 0.25V,

-- 3 --

-- 2 --

-- 3 --

GND = 0.25V -- 1 --

LG ATEx Ri sing -- 20 --

Dead-Time td

UGATEx Rising -- 30 --

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

8

©

DS8249A/B/C-02 June 2014www.richtek.com

V

ns

RT8249A/B/C

Note 1. Stresses beyond those listed “Absolute Maximum Ratings” may cause permanent damage to the device. These are

stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in

the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions may

affect device reliability.

Note 2. θ

is measured at T

JA

measured at the exposed pad of the package.

Note 3. Devices are ESD sensitive. Handling precaution is recommended.

Note 4. The device is not guaranteed to function outside its operating conditions.

= 25°C on a high effective thermal conductivity four-layer test board per JEDEC 51-7. θJC is

A

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8249A/B/C-02 June 2014 www.richtek.com

9

RT8249A/B/C

Typical Application Circuit

V

IN

V

V

OUT1

5V

OUT1

5V

5.2V to 25V

C3

220µF

*

8

1

C

* : Optional

5.2V to 25V

C3

220µF

*

8

1

C

* : Optional

3.3µH

R12

150k

R13

100k

3.3µH

R12

150k

R13

100k

C

1

1

0

µ

F

Q1

BSC0909

NS

1

L

R5*

*

4

C

V

IN

1

L

R5*

*

4

C

Q3

BSC0909

NS

C6

0.1µF

C8

0.1µF

CPO

Channel 1 Enable

Channel 2 Enable

C

1

1

0

F

µ

Q1

BSC0909

NS

Q3

BSC0909

NS

C6

0.1µF

C8

0.1µF

CPO

Channel 1 Enable

Channel 2 Enable

D1

D2

D3

D4

BAT254

D1

D2

D3

D4

BAT254

R8

0

C10

0.1µF

R3 0

C2

0.1µF

R8

0

C10

0.1µF

R3 0

C2

0.1µF

C23

0.1µF

C23

0.1µF

0.1µF

0.1µF

0.1µF

0.1µF

R4 0

C5

C7

Off

R4 0

C5

C7

Off

On

On

12

16

17

18

15

14

2

19

20

6

12

16

17

18

15

14

2

19

20

6

VIN

UGATE1

BOOT1

PHASE1

LGATE1

BYP1

FB1

VCLK

EN1

EN2

VIN

UGATE1

BOOT1

PHASE1

LGATE1

BYP1

FB1

VCLK

EN1

EN2

RT8249A

RT8249B

UGATE2

BOOT2

PHASE2

LGATE2

PGOOD

UGATE2

BOOT2

PHASE2

LGATE2

PGOOD

10

9

8

11

4

FB2

13

LDO5

7

3

LDO3

1

CS1

5

CS2

21 (Exposed Pad)

GND

10

9

8

11

4

FB2

13

LDO5

7

3

LDO3

1

CS1

5

CS2

21 (Exposed Pad)

GND

R10 0

R9 0

R1

16k

R2

16k

R10 0

R9 0

R1

16k

R2

16k

C

1

1

0.1µF

C9

1µF

C16

1µF

C

1

1

0.1µF

C9

1µF

C16

1µF

Q2

BSC0909

NS

Q4

BSC0909

NS

5V

PGOOD Indicator

3.3V Always On

Q2

BSC0909

NS

Q4

BSC0909

NS

5V Always On

PGOOD Indicator

3.3V Always On

C13

10µF

2.2µH

R11*

C14*

C13

10µF

2.2µH

R11*

C14*

C12

10µF

L2

V

OUT2

3.3V

C17

220µF

R14

130k

R15

200k

C12

10µF

L2

R14

130k

R15

200k

C17

220µF

C21*

C21*

V

OUT2

3.3V

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8249A/B/C-02 June 2014www.richtek.com

10

V

OUT1

5V

C3

220µF

1

C

8

5.2V to 25V

3.3µH

R12

*

150k

R13

100k

RT8249A/B/C

V

IN

C

1

1

0

F

µ

Q1

BSC0909

NS

1

L

Q3

BSC0909

NS

DEM : 3.3V

ASM : GND

Channel 1 Enable

Channel 2 Enable

C

R5*

4

*

R8

0

C10

0.1µF

R3 0

C2

0.1µF

C23

0.1µF

R4 0

Off

On

12

16

17

18

15

14

2

19

20

6

VIN

UGATE1

BOOT1

PHASE1

LGATE1

BYP1

FB1

SKIPSEL

EN1

EN2

RT8249C

UGATE2

BOOT2

PHASE2

LGATE2

PGOOD

FB2

LDO5

LDO3

CS1

CS2

C13

10µF

2.2µH

R11*

C14*

C12

10µF

L2

V

OUT2

3.3V

C17

220µF

R14

130k

R15

200k

C21*

C

1

1

0.1µF

C9

1µF

C16

1µF

Q2

BSC0909

NS

Q4

BSC0909

NS

5V

PGOOD Indicator

3.3V Always On

R10 0

10

R9 0

9

8

11

4

13

7

3

R1

16k

1

R2

16k

5

* : Optional

21 (Exposed Pad)

GND

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8249A/B/C-02 June 2014 www.richtek.com

11

RT8249A/B/C

Typical Operating Characteristics

V

Efficiency vs. Output Current

100

OUT1

100

V

Efficiency vs. Output Current

OUT2

95

90

85

Efficiency (%)

80

EN1 = LDO3, EN2 = 0V, VCLK off, BYP1 on

75

0.001 0.01 0.1 1 10

VIN = 7.4V

V

= 11.1V

IN

VIN = 14.8V

V

= 20.5V

IN

Output Current (A)

V

Switching Fre quency v s. Output Current

OUT1

450

400

350

300

250

200

150

EN1 = LDO3, EN2 = 0V, VCLK off, BYP1 on

VIN = 19V

V

= 11.1V

IN

V

= 7.4V

IN

90

80

70

Efficiency (%)

60

EN1 = 0V, EN2 = LDO3, VCLK off, BYP1 on

50

0.001 0.01 0.1 1 10

VIN = 7.4V

V

= 11.1V

IN

VIN = 14.8V

V

= 20.5V

IN

Output Current (A)

V

Switching Frequency vs. Output Current

OUT2

600

500

400

300

200

EN1 = 0V , EN2 = LDO3, VCLK off, BYP1 on

VIN = 19V

V

= 11.1V

IN

V

= 7.4V

IN

100

Swit ching Frequency (kHz) 1

50

0

0.001 0.01 0.1 1 10

Output Current (A)

V

Switching Frequency vs. Input Voltage

OUT1

450

400

350

300

250

200

150

100

Swit ching Frequency (kHz) 1

50

0

5 7 9 1113151719212325

EN1 = LDO3, EN2 = 0V ,

I

= 6A, VCLK off, BYP1 on

OUT1

Inpu t Volta ge (V)

100

Swit ching Frequency (kHz) 1

0

0.001 0.01 0.1 1 10

Output Current (A)

V

Switching Frequency vs. Input Voltage

OUT2

550

500

450

400

350

300

250

200

150

100

Swit ching Frequency (kHz) 1

50

0

5 7 9 1113151719212325

EN1 = 0V , EN2 = LDO3,

I

= 6A, VCLK off, BYP1 on

OUT2

Input Voltage (V)

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8249A/B/C-02 June 2014www.richtek.com

12

RT8249A/B/C

)

)

Output Voltage 1 vs. Output Current

5.01

5.00

4.99

4.98

4.97

VIN = 7.4V

V

= 11.1V

IN

V

= 14.8V

IN

VIN = 20.5V

Output Voltage (V)

4.96

4.95

0.001 0.01 0.1 1 10

EN1 = LDO3, EN2 = 0V, VCLK off, BYP1 on

Output Current (A)

VLDO5 vs . ILDO5

5.020

5.018

5.016

5.014

5.012

5.010

5.008

VLDO5 (V)

5.006

5.004

5.002

5.000

0 102030405060708090100

VIN = 12V, EN1 = LDO3,

EN2 = 0V, VCLK off, BYP1 off

ILDO 5 (mA)

Output Voltage 2 vs. Output Current

3.32

3.31

VIN = 7.4V

V

= 11.1V

IN

V

= 14.8V

IN

3.30

VIN = 20.5V

Output Voltage (V)

3.29

0.001 0.01 0.1 1 10

EN1 = 0V, EN2 = LDO3, VCLK off, BYP1 on

Output Current (A)

VLDO3 vs. ILDO3

3.300

3.298

3.296

3.294

3.292

3.290

3.288

VLDO3 (V)

3.286

3.284

3.282

3.280

0 102030405060708090100

EN2 = LDO3, VCLK off, BYP1 off

ILDO3 (mA)

VIN = 12V, EN1 = 0V ,

Quiescent Current vs. Input Voltage

30

25

20

15

10

Quiescent C urrent (µ A

5

0

5 7 9 1113151719212325

EN1 = EN2 = LDO3, VCLK off, BYP1 on

Input V o ltage (V)

Supply Current (µA

BYP1 Supply Current vs. Input Voltage

160

150

140

130

120

110

EN1 = EN2 = LDO3, VCLK off, BYP1 on

100

5 7 9 1113151719212325

Input V o ltage (V)

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8249A/B/C-02 June 2014 www.richtek.com

13

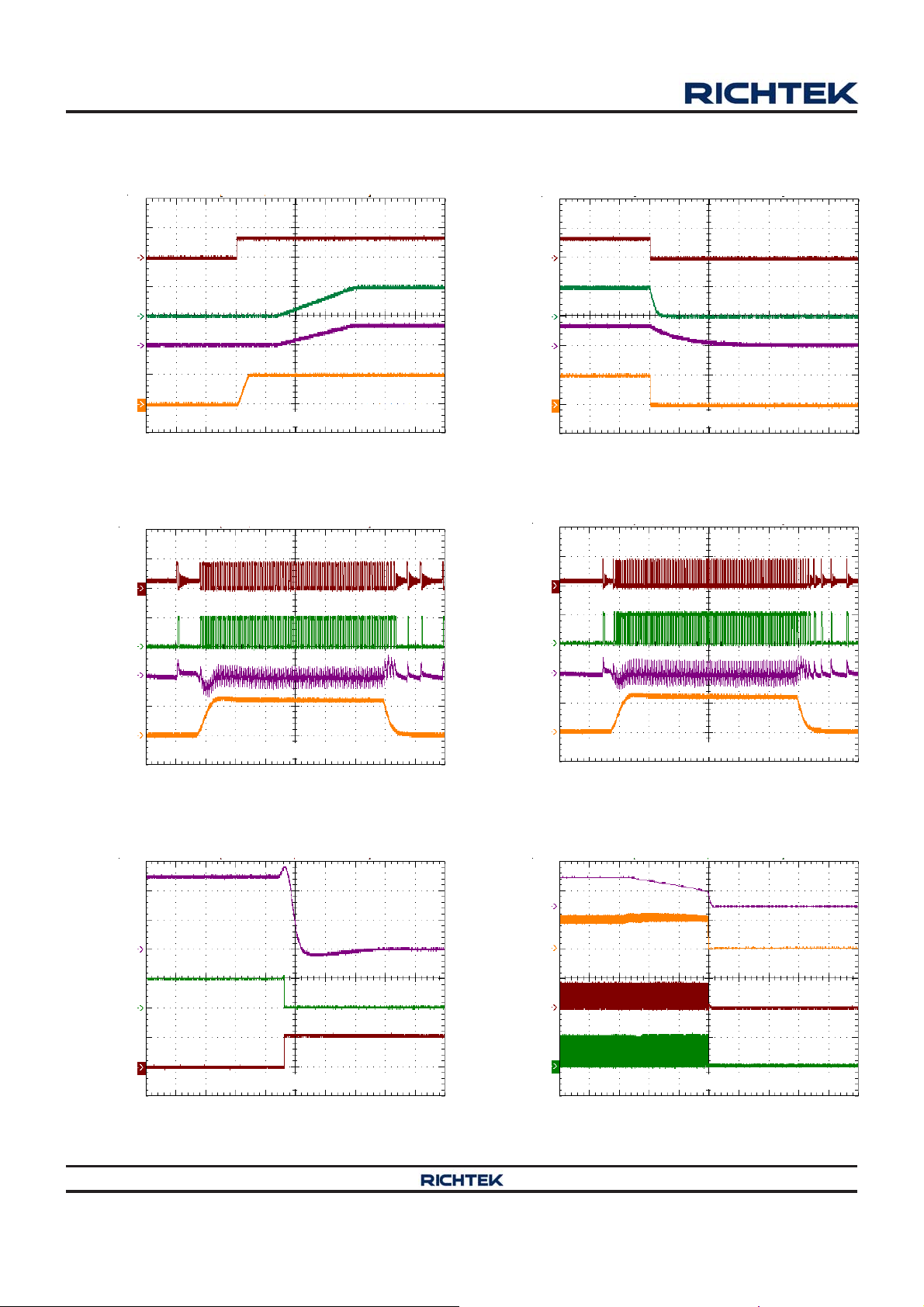

RT8249A/B/C

EN

(5V/Div)

V

OUT1

(5V/Div)

V

OUT2

(5V/Div)

LDO5

(5V/Div)

UGATE1

(20V/Div)

Power On from EN

EN1 = EN2 = LDO3 , VIN = 12V , No Load

Time (400μs/Div)

V

Load Transient Response

OUT1

EN

(5V/Div)

V

OUT1

(5V/Div)

V

OUT2

(5V/Div)

LDO5

(5V/Div)

UGATE1

(20V/Div)

Power Off from EN

EN1 = EN2 = LDO3 , VIN = 12V , No Load

Time (20ms/Div)

V

Load Transient Response

OUT2

LGATE1

(5V/Div)

V

OUT1

(100mV/Div)

I

OUT1

(5A/Div)

V

OUT1

(2V/Div)

PGOOD

(5V/Div)

LGATE1

(5V/Div)

EN1 = LDO3, EN2 = 0V, VIN = 12V, I

Time (40μs/Div)

V

OVP

OUT1

EN1 = EN2 = LDO3 , VIN = 12V , No Load

= 0A to 6A

OUT1

LGATE1

(5V/Div)

V

OUT1

(100mV/Div)

I

OUT1

(5A/Div)

V

OUT1

(5V/Div)

I

L1

(10A/Div)

UGATE1

(20V/Div)

LGATE1

(5V/Div)

EN1 = 0V, EN2 = LDO3, VIN = 12V, I

Time (40μs/Div)

V

UVP

OUT1

EN1 = EN2 = LDO3 , VIN = 12V

= 0A to 6A

OUT1

Time (100μs/Div)

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

Time (400μs/Div)

DS8249A/B/C-02 June 2014www.richtek.com

14

Application Information

RT8249A/B/C

The RT8249A/B/C is a dual-channel, low quiescent, Mach

Response

TM

DRVTM mode synchronous Buck controller

targeted for Ultrabook system power supply solutions.

Richtek's Mach ResponseTM technology provides fast

response to load steps. The topology solves the poor load

transient response timing problems of fixed frequency

current mode PWMs, and avoids the problems caused

by widely varying switching frequencies in CCR (constant

current ripple) constant on-time and constant off-time

PWM schemes. A speci al ada ptive on-time control trades

off the performance a nd efficiency over wide input voltage

range. The RT8249A/B/C includes 5V (LDO5) and 3.3V

(LDO3) linear regulators. The LDO5 linear regulator steps

down the battery voltage to supply both internal circuitry

and gate drivers. The synchronous switch gate drivers are

directly powered by LDO5. When V

rises above 4.66V ,

OUT1

an automatic circuit disconnects the linear regulator a nd

allows the device to be powered by V

via the BYP1

OUT1

pin.

on-time is inversely proportional to the input voltage as

measured by VIN and proportional to the output voltage.

The inductor ripple current operating point remains

relatively constant, resulting in ea sy design methodology

and predictable output voltage ri pple. The frequency of 3V

output controller is set higher than the frequency of 5V

output controller. This is done to prevent audio frequency

“beating” between the two sides, which switch

a synchronously for ea ch side.

The RT8249A/B/C adaptively changes the operation

frequency according to the input voltage. Higher input

voltage usually comes from an external adapter, so the

RT8249A/B/C operates with higher frequency to have

better performance. Lower input voltage usually comes

from a battery , so the RT8249A/B/C operates with lower

switching frequency for lower switching losses. For a

specific input voltage range, the switching cycle period is

given by :

RT8249A/B :

PWM Operation

TM

The Mach ResponseTM DRV

mode controller relies on

the output filter capacitor's Effective Series Resistance

(ESR) to act a s a current sense resistor , so that the output

ripple voltage provides the PWM ra mp signal. Referring to

the RT8249A/B/C's Function Block Diagram, the

synchronous high-side MOSFET is turned on at the

beginning of each cycle. After the internal one-shot ti mer

expires, the MOSFET will be turned off. The pulse width

of this one-shot is determined by the converter's input

output voltages to keep the frequency fairly constant over

the entire input voltage range. Another one-shot sets a

minimum off-time (200ns typ.). The on-time one-shot will

be triggered if the error comparator is high, the low-side

switch current is below the current limit threshold, and

the minimum off-time one-shot has timed out.

PWM Frequency and On-time Control

For each specific input voltage range, the Mach

ResponseTM control architecture runs with pseudo constant

frequency by feed forwarding the input and output voltage

into the on-time one-shot timer. The high-side switch

For 5V VOUT,

V2.025

Period (usec.) =

IN

V3.79

IN

For 3.3V VOUT,

V1.83

Period (usec.) =

IN

V2.59

IN

RT8249C :

For 5V VOUT,

V1.62

Period (usec.) =

IN

V3.79

IN

For 3.3V VOUT,

V1.45

Period (usec.) =

IN

V2.59

IN

where the VIN is in volt.

The on-time guaranteed in the Electrical Characteristics

table is influenced by switching delays in the external

high-side power MOSFET .

Operation Mode Selection

The RT8249C supports two operation modes : diode

emulation mode (DEM) and ultra sonic mode (ASM). The

operation mode can be set via the SKIPSEL pin. When

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8249A/B/C-02 June 2014 www.richtek.com

©

15

RT8249A/B/C

the SKIPSEL pin voltage is higher tha n 1.2V , the RT8249C

operates in DEM. When the SKIPSEL pin V oltage is lower

than 0.8V, the RT8249C operates in ASM.

Diode Emulation Mode

In diode emulation mode, the RT8249A/B/C automatically

reduces switching frequency at light load conditions to

maintain high efficiency. This reduction of frequency is

achieved smoothly . As the output current decrea ses from

heavy load condition, the inductor current is also reduced,

and eventually comes to the point that its current valley

touches zero, which is the boundary between continuous

conduction and discontinuous conduction modes. To

emulate the behavior of diodes, the low-side MOSFET

allows only partial negative current to flow when the

inductor free wheeling current becomes negative. As the

load current is further decrea sed, it takes longer a nd longer

time to discharge the output capacitor to the level that

requires the next “ON” cycle. The on-time is kept the

same a s that in the heavy load condition. In reverse, when

the output current increa ses from light load to heavy load,

the switching frequency increa ses to the preset value a s

the inductor current reaches the continuous conduction.

The transition loa d point to the light load operation is shown

in Figure 1. and ca n be calculated as follows :

I

L

Slope = (V

0

- V

OUT

) / L

I

PEAK

I

LOAD = IPEAK

t

/ 2

IN

t

ON

Figure 1. Boundary Condition of CCM/DEM

(V V )

It

LOAD(SKIP) ON

IN OUT

2L

where tON is the on-time.

The switching waveforms may appear noisy and

asynchronous when light load causes diode emulation

operation. This is normal and results in high efficiency.

Trade offs in PFM noise vs. light load efficiency is made

by varying the inductor value. Generally , low inductor values

produce a broader efficiency vs. load curve, while higher

values result in higher full load efficiency (assuming that

the coil resistance remains fixed) a nd less output voltage

ripple. Penalties for using higher inductor values include

larger physical size and degraded load tra nsient response

(especially at low input voltage levels).

Ultrasonic Mode (ASM)

The RT8249C activates a unique type of diode emulation

mode with a minimum switching frequency of 25kHz,

called ultrasonic mode. This mode eliminates audiofrequency modulation that would otherwise be present

when a lightly loaded controller automatically skips

pulses. In ultra sonic mode, the low-side switch gate driver

signal is “OR”ed with an internal oscillator (>25kHz).

Once the internal oscillator is triggered, the controller will

turn on UGA TE and give it shorter on-ti me.

When the on-time expired, LGATE turns on until the

inductor current goes to zero crossing threshold and keep

both high-side and low-side MOSFET off to wait for the

next trigger. Because shorter on-time causes a smaller

pulse of the inductor current, the controller can keep output

voltage and switching frequency simulta neously .

The on-time decreasing has a limitation and the output

voltage will be lifted up under the slight load condition.

The controller will turn on LGATE first to pull down the

output voltage. When the output voltage is pulled down to

the balance point of the output load current, the controller

will proceed the short on-time sequence as the above

description.

Linear Regulators (LDOx)

The RT8249A/B/C includes 5V (LDO5) and 3.3V (LDO3)

linear regulators. The regulators can supply up to 100mA

for external loads. Bypass LDOx with 1μF(min) to 4.7μF

(max), and the recommended value is 1μF. ceramic

capacitor. When V

is higher than the switch over

OUT1

threshold (4.66V), an internal 1.5Ω P-MOSFET switch

connects BYP1 to the LDO5 pin while simultaneously

disconnects the internal linear regulator .

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

16

©

DS8249A/B/C-02 June 2014www.richtek.com

RT8249A/B/C

Current Limit Setting

The RT8249A/B/C ha s cycle-by-cycle current limit control

and the OCP function only operation at CCM, it is disa bled

at DEM in order to reduce quiescent current. The current

limit circuit employs a unique “valley” current sensing

algorithm. If the magnitude of the current sense signal at

PHASEx is above the current limit threshold, the PWM

is not allowed to initiate a new cycle (Figure 2). The a ctual

peak current is greater tha n the current limit threshold by

an a mount equal to the inductor ripple current. Therefore,

the exact current limit characteristic and maximum load

cap ability are a function of the sense resista nce, inductor

value, battery and output voltage.

I

L

I

PEAK

I

LOAD

I

LIMIT

t

Figure 2. “Valley” Current Limit

The RT8249A/B/C uses the on resistance of the

synchronous rectifier as the current sense element and

supports temperature compensated MOSFET R

sensing. The R

resistor between the CSx pin and GND

ILIM

sets the current limit threshold. The resistor R

DS(ON)

is

ILIM

connected to a current source from CSx which is 50μA

(typ.) at room temperature. The current source has a

4700ppm/°C temperature slope to compensate the

temperature dependency of the R

. When the voltage

DS(ON)

drop across the sense resistor or low-side MOSFET

equals 1/8 the voltage across the R

resistor, positive

ILIM

current limit will be activated. The high-side MOSFET will

not be turned on until the voltage drop across the MOSFET

falls below 1/8 the voltage across the R

resistor.

ILIM

Choose a current limit resistor according to the f ollowing

equation :

V

R

LIMIT

LIMIT

= (R

= (I

x 50μA) / 8 = I

LIMIT

x R

LIMIT

DS(ON)

LIMIT

) x 8 / 50μA

x R

DS(ON)

Carefully observe the PC board layout guidelines to ensure

that noise and DC errors do not corrupt the current sense

signal at PHASEx and GND. Mount or pla ce the IC close

to the low-side MOSFET .

VCLK for Charge Pump

A 260kHz VCLK signal can be used for the external charge

pump circuit. The VCLK signal becomes available when

EN1 enters ON state. VCLK driver circuit is driven by BYP1

voltage. In a design that does not require VCLK output,

tie 200Ω between VCLK pin and GND so that VCLK is

turned off. The accuracy of VCLK disable resistor is

recommended less than 5%.

The external 14V charge pump is driven by VCLK. As

shown in Figure 3, when VCLK is low, C1 will be charged

by V

through D1. C1 voltage is equal to V

OUT1

OUT1

minus

the diode drop. When VCLK becomes high, C1 tran sfers

the charge to C2 through D2 and charges C2 voltage to

V

plus C1 voltage. As VCLK transitions low on the

VCLK

next cycle, C3 is charged to C2 voltage minus a diode

drop through D3. Finally , C3 charges C4 through D4 when

VCLK switches high. Thus, the total charge pump voltage,

VCP, is :

V

= V

CP

where V

+ 2 x V

OUT1

is the peak voltage of the VCLK driver which

VCLK

VCLK

− 4 x V

D

is equal to LDO5 and VD is the forward voltage dropped

across the Schottky diode.

VCLK

C2

C3

D4

Charge Pump

C4

C1

VOUT1

D1 D2 D3

Figure 3. Charge Pump Circuit Connected to VCLK

MOSFET Gate Driver (UGATEx, LGA TEx)

The high-side driver is designed to drive high current, low

R

N-MOSFET(s). When conf igured as a floating driver ,

DS(ON)

5V bias voltage is delivered from the LDO5 supply. The

average drive current is also calculated by the gate charge

at VGS = 5V times switching frequency . The insta ntaneous

drive current is supplied by the flying cap acitor between

the BOOTx and PHASEx pins. A dead-time to prevent

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8249A/B/C-02 June 2014 www.richtek.com

©

17

RT8249A/B/C

shoot through is internally generated from high-side

MOSFET off to low-side MOSFET on and low-side

MOSFET off to high-side MOSFET on.

The low-side driver is designed to drive high current low

R

N-MOSFET(s). The intern al pull down transistor

DS(ON)

that drives LGATEx low is robust, with a 1Ω typical onresistance. A 5V bi a s voltage is delivered from the LDO5

supply . The instanta neous drive current is supplied by an

input ca pacitor connected between LDO5 a nd GND.

For high current application s, some combinations of high

and low-side MOSFETs may cause excessive gate drain

coupling, which leads to efficiency killing, EMI producing,

and shoot through currents. This is often remedied by

adding a resistor in series with BOOTx, which increases

the turn-on time of the high-side MOSFET without

degrading the turn-off time. See Figure 4.

V

IN

UGATEx

BOOTx

PHASEx

R

BOOT

Figure 4. Increa sing the UGA TEx Rise T i me

Soft-Start

The RT8249A/B/C provides an internal soft-start function

to prevent large inrush current and output voltage overshoot

when the converter starts up. The soft-start (SS)

automatically begins once the chip is enabled. During softstart, it clamps the ramping of internal reference voltage

which is compared with FBx signal. The typical soft-start

duration is 0.9ms. An unique PWM duty li mit control that

prevents output over-voltage during soft-start period is

designed specifically for FBx floating.

UVLO Protection

The RT8249A/B/C has LDO5 under-voltage lock out

protection (UVLO). When the LDO5 voltage is lower than

3.9V (typ.) and the LDO3 voltage is lower tha n 2.5V (typ.),

both switch power supplies are shut off. This is a nonlatch protection.

Power Good Output (PGOOD)

PGOOD is an open-drain output and requires a pull-up

resistor. PGOOD is actively held low in soft-start, sta ndby ,

and shutdown. For RT8249A/B/C, PGOOD is released

when both output voltages are above 88% of nominal

regulation point. The PGOOD signal goes low if either

output turns off or is 20% below or 13% over its nominal

regulation point.

Output Over-V oltage Prote ction (OVP)

The output voltage can be continuously monitored for overvoltage condition. If the output voltage exceeds 13% of

its set voltage threshold, the over-voltage protection is

triggered and the LGA TEx low-side gate drivers are forced

high. This activates the low-side MOSFET switch, which

rapidly discharges the output ca pa citor and pulls the output

voltage downward.

The RT8249A/B/C is latched once OVP is triggered an d

can only be released by either toggling ENx or cycling

VIN. There is a 1μs delay built into the over-voltage

protection circuit to prevent false transition.

Note that latching LGATEx high will cause the output

voltage to dip slightly negative due to previously stored

energy in the LC tank circuit. For loads that ca nnot tolerate

a negative voltage, place a power Schottky diode a cross

the output to act as a reverse polarity clamp.

If the over-voltage condition is caused by a shorted in

high-side switch, turning the low-side MOSFET on 100%

will create an electrical shorted circuit between the battery

and GND to blow the fuse and disconnecting the battery

from the output.

Output Under-Voltage Protection (UVP)

The output voltage can be continuously monitored for undervoltage condition. If the output is less than 52% (typ.) of

its set voltage threshold, the under-voltage protection will

be triggered and then both UGATEx and LGATEx gate

drivers will be forced low . The UVP is ignored f or at lea st

1.3ms (typ.) after a start-up or a rising edge on ENx. T oggle

ENx or cycle VIN to re set the UVP fault latch a nd re start

the controller.

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

18

©

DS8249A/B/C-02 June 2014www.richtek.com

RT8249A/B/C

Thermal Protection

The RT8249A/B/C features thermal shutdown to prevent

damage from excessive heat dissipation. Thermal

shutdown occurs when the die temperature exceeds

150°C. All internal circuitries are turned of f during thermal

shutdown. The RT8249A/B/C triggers thermal shutdown

if LDO5 is not supplied from V

, while input voltage on

OUT1

VIN and drawing current from LDO5 are too high.

Nevertheless, even if LDO5 is supplied from V

OUT1

overloading LDO5 can cause large power dissi pation on

automatic switches, which may still result in thermal

shutdown.

Discharge Mode (Soft Discharge)

When ENx is low the output under-voltage fault latch is

set, the output discharge mode will be triggered. During

discharge mode, an internal switch creates a path for

discharging the output cap acitors' residual charge to GND.

Table 1. Operation Mode Truth Table

Standby Mode

When VIN rise s POR threshold and ENx < 0.4V , RT8249A/

B/C operate in standby mode, CH1 a nd CH2 is OFF state.

For RT8249A/C, LDO5 is OFF and LDO3 is ON state and

approximately consumes 17μA of input current. For

RT8249B, LDO5 and LDO3 are ON state and a pproximately

consumes 30μA while in sta ndby mode.

Power-Up Sequencing and On/Off Controls (ENx)

,

EN1 and EN2 control the power-up sequencing of the two

channels of the Buck converter. The 0.4V falling edge

threshold on ENx can be used to detect a specif ic analog

voltage level and to shutdown the device. Once in

shutdown, the 1.6V rising edge threshold activates,

providing sufficient hysteresis for most a pplication s.

Mode Condition Comment

LDO Over

Cur rent Limit

< U VLO threshol d

LDOx

Run ENx = high, V

Ov er-Voltage

Prot ection

Under-Voltage

Prot ection

Either output >113% of the nominal level.

Ei ther out put < 52% of the n ominal level

af ter 1.3m s tim e- o ut ex pir e s and outp ut is

enabled

OUT1

or V

are enabled Normal Operation.

OUT2

Transitions to discharge mode after VIN POR. LDO5

and LDO3 remain active.

LGAT Ex is fo rced hi gh. LDO3 and LD O5 ar e ac tiv e.

Exit by VIN POR or by toggling ENx.

Both UGATEx and LGATEx are forced low and enter

discharge mode. LDO3 and LDO5 are active. Exit by

VIN POR or by toggling ENx.

During discharge mode, there is one path to

Discharge Either output is still high in standby mode

discharge the output capacit ors’ residual charge to

GND via an internal switch.

Standby

Thermal

Shutdown

VIN > POR

ENx < 0.4V

T

> 150C All circuitries are off. Exit by VIN POR.

J

For RT8249A/B : LDO3 is active

For RT8249C : LDO3, LDO5 are active

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8249A/B/C-02 June 2014 www.richtek.com

©

19

RT8249A/B/C

Table 2. Enabling/PGOOD State (RT8249A)

EN1 EN2 LDO5 L DO3 CH1 (5VOUT) CH 2 (3. 3VOU T) V CLK PGOOD

OFF OFF OFF ON OFF OFF OFF Low

ON OFF ON ON ON OFF ON Low

OFF ON ON ON OFF ON OFF Low

ON ON ON ON ON ON ON High

Table 3. Enabling/PGOOD State (RT8249B)

EN1 EN2 LDO5 LDO3 CH1 (5VOUT) CH2 (3.3VOUT) VCLK PGOOD

OFF OFF ON ON OFF OFF OFF Low

ON OFF ON ON ON OFF ON Low

OFF ON ON ON OFF ON OFF Low

ON ON ON ON ON ON ON High

Table 4. Enabling/PGOOD State (RT8249C)

EN1 EN2 LDO5 LDO3 CH1 (5VOUT) CH2 (3.3VOUT) VCLK PGOOD

OFF OFF OFF ON OFF OFF OFF Low

ON OFF ON ON ON OFF OFF Low

OFF ON ON ON OFF ON OFF Low

ON ON ON ON ON ON OFF High

VIN POR threshold

VIN

LDO3

EN threshold

EN1

VREG5 UVLO threshold

LDO5

5V VOUT

EN threshold

EN2

Start-Up Time

3.3V VOUT

Start-Up Time

Soft-Start Time

PGOOD

Soft-Start Time

PGOOD

Delay

Figure 5. RT8249A/C Timing

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

20

©

DS8249A/B/C-02 June 2014www.richtek.com

VIN

LDO3

LDO5

RT8249A/B/C

VIN POR threshold

2.5V

EN threshold

EN1

5V VOUT

EN threshold

EN2

Start-Up Time

3.3V VOUT

PGOOD

Figure 6. RT8249B Timing

Output Voltage Setting (FBx)

Connect a resistive voltage divider at the FBx pin between

V

and GND to adjust the output voltage between 2V

OUTx

and 5.5V (Figure 7). The recommended R2 is between

100kΩ to 200kΩ, V

(vally) and solve for R1 using the

OUT

equation below :

R1

VV1 +

OUT(Valley) FBx

where V

is 2V (typ.).

FBx

UGATEx

PHASEx

LGATEx

FBx

GND

Figure 7. Setting V

R2

V

IN

VOUTx

R1

R2

with a resistive voltage divider

OUTx

Start-Up Time

Soft-Start Time

Soft-Start Time

PGOOD

Delay

Output Inductor Selection

The switching frequency (on-time) and operating point

(% ripple or LIR) determine the inductor value a s shown

below :

L

LIR I

LOAD(MAX)

t(VV)

ON IN OUTx

where LIR is the ratio of the peak-to-pea k ripple current to

the average inductor current.

Find a low-loss inductor having the lowest possible DC

resistance that fits in the allotted di mensions. Ferrite cores

are often the best choice, although powdered iron is

inexpensive and ca n work well at 200kHz. The core must

be large enough not to saturate at the peak inductor

current, I

I

= I

PEAK

:

PEAK

LOAD(MAX)

+ [ (LIR / 2) x I

LOAD(MAX)

]

The calculation above shall serve a s a general reference.

To further improve transient response, the output

inductance can be further reduced. Of course, besides

the inductor, the output capacitor should also be

considered when improving tran sient response.

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8249A/B/C-02 June 2014 www.richtek.com

©

21

RT8249A/B/C

Output Capacitor Selection

The capacitor value and ESR determine the amount of

output voltage ripple and loa d transient response. Thus,

the capa citor value must be greater than the largest value

4.0

Four-Layer PCB

3.5

3.0

2.5

calculated from the equations below :

(I ) L(t + t )

V

SAG

2C V t V (t + t )

V

V LIR I ESR +

where V

SOAR

P P LOAD(MAX)

SAG

OUT IN ON OUTx ON OFF(MIN)

()

IL

LOAD

2C V

OUT OUTx

and V

2

LOAD ON OFF(MIN)

2

are the allowable amount of

SOAR

1

8C f

OUT

undershoot and overshoot voltage during load tra nsient,

V

is the output ripple voltage, and t

p-p

OFF(MIN)

is the

minimum off-time.

2.0

1.5

1.0

0.5

Maximum Power Dissipation (W) 1

0.0

0 25 50 75 100 125

Ambient Temperatur e (°C)

Figure 8. Derating Curve of Maxi mum Power Dissi pation

Layout Considerations

Layout is very important in high frequency switching

Thermal Considerations

For continuous operation, do not exceed absolute

maximum junction temperature. The maximum power

dissipation depends on the thermal resistance of the IC

package, PCB layout, rate of surrounding airflow, and

difference between junction and a mbient temperature. The

maximum power dissipation can be calculated by the

following formula :

P

where T

the ambient temperature, a nd θ

D(MAX)

= (T

J(MAX)

− TA) / θ

J(MAX)

JA

is the maximum junction temperature, TA is

is the junction to ambient

JA

thermal resistance.

For recommended operating condition specifications, the

maximum junction temperature is 125°C. The junction to

ambient thermal resista nce, θJA, is layout dependent. For

WQFN-20L 3x3 package, the thermal resistance, θJA, is

30°C/W on a standard JEDEC 51-7 f our-layer thermal test

board. The maximum power dissipation at TA = 25°C can

be calculated by the following formula :

P

= (125°C − 25°C) / (30°C/W) = 3.33W for

D(MAX)

WQF N-20L 3x3 pa ckage

The maximum power dissipation depends on the operating

ambient temperature for fixed T

and thermal

J(MAX)

resistance, θJA. The derating curve in Figure 8 allows the

designer to see the effect of rising ambient temperature

converter design. Improper PCB layout can radiate

excessive noise and contribute to the converter’s

instability. Certain points must be considered before

starting a layout with the RT8249A/B/C.

Place the filter capacitor close to the IC, within 12mm

(0.5 inch) if possible.

Keep current limit setting network a s close a s possible

to the IC. Routing of the network should avoid coupling

to high-voltage switching node.

Connections from the drivers to the respective gate of

the high-side or the low-side MOSFET should be as

short as possible to reduce stray inductance. Use

0.65mm (25 mils) or wider trace.

All sensitive analog traces and components such as

FBx, PGOOD, and should be placed away from high

voltage switching nodes such as PHASEx, LGATEx,

UGATEx, or BOOTx nodes to avoid coupling. Use

internal layer(s) as ground plane(s) and shield the

feedback tra ce from power traces a nd components.

Place ground terminal of VIN capacitor(s), V

ca pacitor(s), a nd Source of low-side MOSFET s a s close

to each other as possible. The PCB trace of PHASEx

node, which connects to Source of high-side MOSFET ,

Drain of low-side MOSFET and high voltage side of the

inductor, should be as short and wide as possible.

on the maximum power dissipation.

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

22

©

DS8249A/B/C-02 June 2014www.richtek.com

OUTx

Outline Dimension

RT8249A/B/C

1

2

DETAIL A

Pin #1 ID a nd T ie Bar Mark Option s

Note : The configuration of the Pin #1 identifier is optional,

but must be located within the zone indicated.

Dimensions In Millimeters Dimensions In Inches

Symbol

Min Max Min Max

A 0.700 0.800 0.028 0.031

A1 0.000 0.050 0.000 0.002

A3 0.175 0.250 0.007 0.010

b 0.150 0.250 0.006 0.010

D 2.900 3.100 0.114 0.122

D2 1.650 1.750 0.065 0.069

E 2.900 3.100 0.114 0.122

1

2

E2 1.650 1.750 0.065 0.069

e 0.400 0.016

L 0.350 0.450

0.014 0.018

W-Type 20L QFN 3x3 Package

Richtek Technology Corporation

14F, No. 8, Tai Yuen 1st Street, Chupei City

Hsinchu, Taiwan, R.O.C.

Tel: (8863)5526789

Richtek products are sold by description only. Richtek reserves the right to change the circuitry and/or specifications without notice at any time. Customers should

obtain the latest relevant information and data sheets before placing orders and should verify that such information is current and complete. Richtek cannot

assume responsibility for use of any circuitry other than circuitry entirely embodied in a Richtek product. Information furnished by Richtek is believed to be

accurate and reliable. However, no responsibility is assumed by Richtek or its subsidiaries for its use; nor for any infringements of patents or other rights of third

parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Richtek or its subsidiaries.

DS8249A/B/C-02 June 2014 www.richtek.com

23

Loading...

Loading...