Regency C34-NG2, C34-LP2 User Manual

www.regency-fire.com

C34 Classic Direct Vent |

Owners & |

Freestanding Gas Stove |

Installation Manual |

Classic C34 model shown above features optional gold plated door and gold legs.

MODELS: C34-NG2 Natural Gas C34-LP2 Propane

WARNING:

If the information in these instructions are not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

FOR YOUR SAFETY

What to do if you smell gas:

®Do not try to light any appliance

®Do not touch any electrical switch: do not use any phone in your building.

®Immediately call your gas supplier from a neighbour's phone. Follow the gas supplier's instructions.

®If you cannot reach your gas supplier, call the fire department.

Tested by:

Installer: Please complete the details on the back cover and leave this manual with the homeowner.

Homeowner: Please keep these instructions for future reference.

908-584a |

FPI FIREPLACE PRODUCTS INTERNATIONAL LTD. 6988 Venture St., Delta, BC Canada, V4G 1H4 |

01/09/06 |

REGENCY

Classic Direct Vent Freestanding Gas Stove

To the New Owner:

Congratulations! You are the owner of a state-of-the-art Gas Stove by Fireplace Products International Ltd. The Regency Gas Series of hand crafted appliances has been designed to provide you with all the warmth and charm of a woodstove, at the flick of a switch. The models C34G-NG/C34B-NG and C34G-LP/C34B-LP of this series have been approved by Warnock Hersey for both safety and efficiency. As it also bears our own mark, it promises to provide you with economy, comfort and security for many trouble free years to follow. Please take a moment now to acquaint yourself with these instructions and the many features of your CLASSIC Direct Vent Freestanding Gas Stove.

INFORMATION FOR MOBILE/MANUFACTURED HOMES AFTER FIRST SALE

This Regency product has been tested and listed by Warnock Hersey as a Direct Vent Room Heater to the following standards: CAN/CGA-2.17- M91, ANSI Z21.88b-2003/CSA 2.33b-2003.

This Direct Vent System Appliance must be installed in accordance with the manufacturer's installation instructions and the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280, or thecurrent Standard of Fire Safety Criteria for Manufactured Home Installations, Sites, and Communities ANSI/NFPA 501A, and with CAN/CSA Z240-MH Mobile Home Standard in Canada.

This appliance installation must comply with the manufacturer's installation instructions and local codes, if any. In the absence of local codes follow the current National Fuel Gas Code, ANSI Z223.1 and the current National Electrical Code ANSI/NFPA 70 in the U.S.A., and the current CAN/CGA B149 Gas Installation Code and the current Canadian Electrical Code CSA C22.1 in Canada.

This Regency Mobile/Manufactured Home Listed appliance comes factory equipped with a means to secure the unit.

This Regency Mobile/Manufactured Home listed appliance comes equipped with a dedicated #8 ground lug to which an 8 gauge copper wire from the steel chassis ground must be attached.

2 |

Regency CLASSIC C34-2 Direct Vent Freestanding Gas Heater |

TABLE OF CONTENTS

|

Page |

Safety Label |

|

Safety Label ............................................................. |

4 |

Installation |

|

Specifications ........................................................... |

5 |

Before You Start ....................................................... |

5 |

General Safety Information ......................................... |

5 |

Installation Checklist ................................................. |

6 |

Locating Your Classic Gas Stove ............................... |

6 |

Manufactured Mobile Home Requirements ................... |

6 |

Combustion and Ventilation Air .................................. |

6 |

Clearances to Combustibles ...................................... |

6 |

Optional Fan Installation ............................................ |

7 |

Pedestal Assembly ................................................... |

8 |

Leg and Bottom Shield Assembly ............................... |

8 |

Venting ................................................................... |

9 |

Installation Precautions ............................................. |

9 |

Safety Precautions for the Installer ............................. |

9 |

Vent Restrictor Position ............................................. |

9 |

Exterior Vent Terminal Locations .............................. |

10 |

Rigid Pipe Venting Components List ......................... |

11 |

Rigid Pipe Venting Systems |

|

Horizontal and Vertical Terminations ................... |

12 |

Venting Arrangements |

|

Horizontal Terminations (all Systems) ................. |

13 |

Vertical Terminations (Dura-Vent) ....................... |

13 |

Horizontal and Vertical Venting With Two Elbows ...... |

14 |

DV Stove Horizontal Vent Kit 945-216 ....................... |

15 |

DV Stove Horizontal Vent Kit 945-216 Installation ...... |

15 |

Dura-Vent Termination Systems ............................... |

17 |

Planning Your Dura-Vent Installation ......................... |

17 |

Dura-Vent Venting Components ............................... |

17 |

Dura-Vent Horizontal Installations ............................. |

19 |

Dura-Vent Vertical Termination ................................. |

20 |

Offset Chart ............................................................ |

21 |

Cathedral Ceiling Installations .................................. |

21 |

Converting a Class-A Metal Chimney or Masonry |

|

Chimney to a Direct Vent System ...................... |

22 |

- Instructions for Converting a Factory Built |

|

Metal Chimney ............................................... |

22 |

- Instructions for Converting a Masonry Chimney .. |

23 |

System Data Table ................................................. |

24 |

|

Page |

Gas Connection ...................................................... |

24 |

High Elevation ......................................................... |

24 |

Gas Pressure Test .................................................. |

24 |

Valve Description .................................................... |

24 |

Log Set Installation ................................................. |

25 |

Door and Glass Frame ............................................ |

25 |

Door Handle ........................................................... |

26 |

Optional Remote Control Installation ......................... |

26 |

Remote Wall Switch................................................ |

26 |

Optional Wall Thermostat ........................................ |

26 |

Thermostat Wire Table ............................................ |

26 |

Final Check ............................................................ |

26 |

Wiring Diagram ....................................................... |

27 |

Operating Instructions |

|

Operating Instructions ............................................. |

28 |

Lighting Procedure .................................................. |

28 |

Shutdown Procedure ............................................... |

28 |

First Fire ................................................................ |

28 |

Pilot Adjustment ..................................................... |

28 |

Aeration Adjustment ................................................ |

29 |

Copy of Lighting Plate Instructions ............................ |

29 |

Normal Operating Sounds of Gas Appliances ............ |

30 |

Thermopile/Thermocouple ........................................ |

30 |

Maintenance |

|

Maintenance Instructions ......................................... |

30 |

General Vent Maintenance....................................... |

30 |

Log Replacement .................................................... |

30 |

Gold Plated Doors ................................................... |

31 |

Glass Gasket ......................................................... |

31 |

Glass Replacement ................................................. |

31 |

Removing Valve Assembly ....................................... |

31 |

Installing Valve Assembly ........................................ |

31 |

Parts List |

|

Replacement/Spare Parts list ................................... |

32 |

Warranty |

|

Warranty ................................................................ |

35 |

Regency CLASSIC C34-2 Direct Vent Freestanding Gas Heater |

3 |

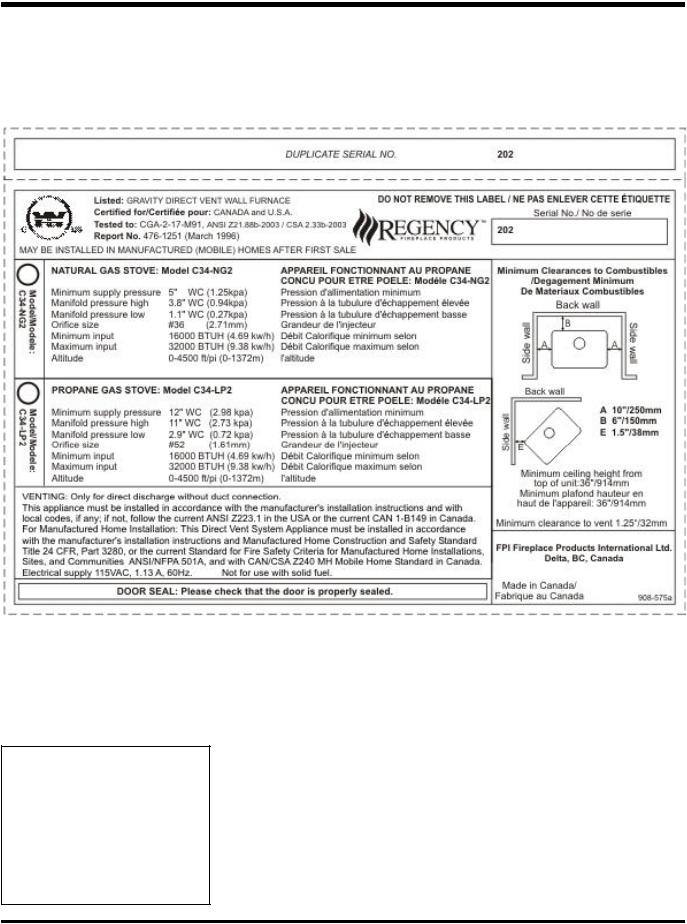

SAFETY LABEL

This is a copy of the label that accompanies each CLASSIC Direct Vent Freestanding Gas Stove. We have printed a copy of the contents here for your review. The safety label is located on the back panel.

For the State of Massachusetts, installation and repair must be done by a plumber or gasfitter licensed in the Commonwealth of Massachusetts.

For the State of Massachusetts, flexible connectors shall not exceed 36 inches in length.

For the State of Massachusetts, the appliances individual manual shut-off must be a t-handle type valve.

NOTE: Regency units are constantly being improved. Check the label on the unit and if there is a difference, the label on the unit is the correct one.

4 |

Regency CLASSIC C34-2 Direct Vent Freestanding Gas Heater |

INSTALLATION

IMPORTANT:

SAVE THESE

INSTRUCTIONS

The CLASSIC Direct Vent Freestanding Gas Stove must be installed in accordance with these instructions. Carefully read all the instructions in this manual first. Consult the building authority having jurisdiction to determine the need for a permit prior to starting the installation.

- WARNING -

Failure to follow the instructions could cause a malfunction of the heater which could result in death, serious bodily injury, and/or property damage. Failure to follow these instructions may also void your fire insurance and/or warranty.

Note: These instructions take precedence over Simpson Dura-Vent instructions

SPECIFICATIONS

Fuels: C34-NG is approved for use with natural gas. C34-LP is approved for use with liquefied petroleum gases (propane).

Electrical: 120V. A.C. system.

Optional circulation fan: Two speed, 125/ 75 CFM.

Log Sets: Ceramic fibre, 4 per set.

Vent System: Coaxial (6 5/8" outer/ 4" inner liner) rigid flue and termination cap.

SHOULD OVERHEATING OCCUR, OR THE GAS SUPPLY FAIL TO SHUT OFF, SHUT OFF THE MANUAL GAS VALVE TO THE APPLIANCE BEFORE SHUTTING OFF THE ELECTRICAL SUPPLY.

- WARNING -

Risk of fire or electric shock. Only qualified service personnel shall be used to install and provide maintenance of this appliance.

BEFORE YOU START

Safe installation and operation of this appliance requires common sense, however, we are required by the Canadian Safety Standards and ANSI Standards to make you aware of the following:

THIS APPLIANCE SHOULD BE INSTALLED, REPAIRED, INSPECTED BEFORE USE AND AT LEAST ANNUALLYBYAQUALIFIEDSERVICE PERSON. MORE FREQUENT CLEANING MAY BE REQUIRED DUE TO EXCESSIVE LINT FROM CARPETING, ETC. IT IS IMPERATIVE THAT THE CONTROL COMPARTMENT, BURNER AND CIRCULATING AIR PASSAGEWAYS OF THE APPLIANCE BE KEPT CLEAN.

DUE TO HIGH TEMPERATURES, THE APPLIANCE SHOULD BE LOCATED OUT OF TRAFFIC AND AWAY FROM FURNITURE AND DRAPERIES.

WARNING: FAILURE TO INSTALL THIS APPLIANCE CORRECTLY MAY CAUSE A SERIOUS HOUSE FIRE AND WILL VOID YOUR WARRANTY.

CHILDREN AND ADULTS SHOULD BE ALERTED TO THE HAZARDS OF HIGH SURFACE TEMPERATURES, ESPECIALLY THE FIREPLACE GLASS, AND SHOULD STAY AWAY TO AVOID BURNS OR CLOTHING IGNITION.

YOUNG CHILDREN SHOULD BE CAREFULLY SUPERVISED WHEN THEY ARE IN THE SAME ROOM AS THE APPLIANCE.

CLOTHING OR OTHER FLAMMABLE MATERIAL SHOULD NOT BE PLACED ON OR NEAR THE APPLIANCE.

1)Provide adequate clearances for servicing, proper operation and around the air openings into the combustion chamber.

2)The appliance may be installed on a flat, solid, continuous surface (e.g. wood, metal, concrete). This may be the floor, or it can

be raised up on a platform to enhance its visual impact. If the appliance is going to be installed on carpeting, see clearances to combustibles on page 6.

The CLASSIC Direct Vent Freestanding Gas Stove can be installed in a wide variety of ways and will fit nearly any room layout. It may be installed in a recessed position, framed out into the room, or across a corner. This appliance is Listed for Alcove installations, maintain minimum Alcove clearances as follows, minimum ceiling height of 65-11/16", minimum width of 48" and a maximum depth of 36".

3)TheCLASSICDirectVentFreestandingGas Stove is approved for alcove installations, which meet the clearances listed on page6. This unit can be installed in a bedroom, when installed with a millivolt thermostat. This unit is approved for manufactured home installations, see page 13 for the required vent arrangements. If installed into a manufactured or mobile home the unit must be bolted down to the floor.

4)We recommend that you plan your installation on paper using exact measurements for clearances and floor protection before actually installing this appliance. Have a qualified building inspector review your plans before installation.

GENERAL SAFETY INFORMATION

1)The appliance installation must conform with local codes or, in the absence of local codes, with the current Canadian or National Electrical Codes,CAN1-B149orANSI Z223.1 Installation Codes.

2)The appliance when installed, must be electrically grounded in accordance with local codes, or in the absence of local codes with the current National Electrical Code, ANSI/NFPA 70 or CSA C22.1 Canadian Electrical Code.

3)The appliance should be inspected for shipping damage before use and serviced annually by a professional service person. More frequent cleaning may be required due to excessive lint from carpeting, bedding material, etc. It is imperative that control compartments, and circulating air passageways of the appliance be kept clean.

4)See general construction and assembly instructions. The appliance and vent should be enclosed when installed in or passing through a living area.

5)This appliance must be connected to the specified vent and termination cap to the outside of the building envelope.

Regency CLASSIC C34-2 Direct Vent Freestanding Gas Heater |

5 |

INSTALLATION

6)Never vent to another room or inside a building. Make sure that the vent is fitted as per the instructions starting on page 8.

7)Inspect the venting system annually for blockage and any signs of deterioration.

8)Venting terminals shall not be recessed into a wall or siding.

9)Any safety glass removed for servicing must be replaced prior to operating the appliance.

10)To prevent injury, do not allow anyone who is unfamiliar with the operation to use the fireplace.

Emissions from burning wood or gas could contain chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

INSTALLATION

CHECKLIST

1)Locate appliance, page 6, see Clearances to Combustibles, page 6. Check Venting Clearances, Vertical and Horizontal Termination requirements on pages 11 to 14.

2)Install Optional Fan, page 7.

3)Assemble stove base - pedestal or bottom shield and legs, page 8.

4)Install venting, either with the DV Stove Horizontal Vent Kit (page 15) or the DuraVent Termination kits (page 17). Check Vent Restrictor setting, page 9. If converting a Class-A Metal Chimney or Masonry Chimney to a Direct Vent system, see instructions on pages 22 and 23.

5)Make gas and electrical connections, page 24. Test the pilot. Must be as per diagram, pages 28.

6)Test gas pressure, page 24.

7)Install log set, see page 25.

.

8)Install optional Wall Switch, Remote Control, or Wall Thermostat, page 26.

9)Final check, page 26.

Before leaving this unit with the customer, the installer must ensure that the appliance is firing correctly and operation fully explained to customer.

This includes:

1)Clocking the appliance to ensure the correct firing rate (rate noted on label) after burning appliance for 15 minutes.

6

2)If required, adjusting the primary air to ensure that the flame does not carbon. First allow the unit to burn for 15-20 min. to stabilize.

3)Check for proper draft.

CAUTION: Any alteration to the product that causes sooting or carboning that results in damage is not the responsibility of the manufacturer.

LOCATING YOUR

CLASSIC

GAS STOVE

When selecting a location for your stove, ensure that the clearances on this page are met as well as ensuring that there is adequate accessibility for servicing and proper operation.

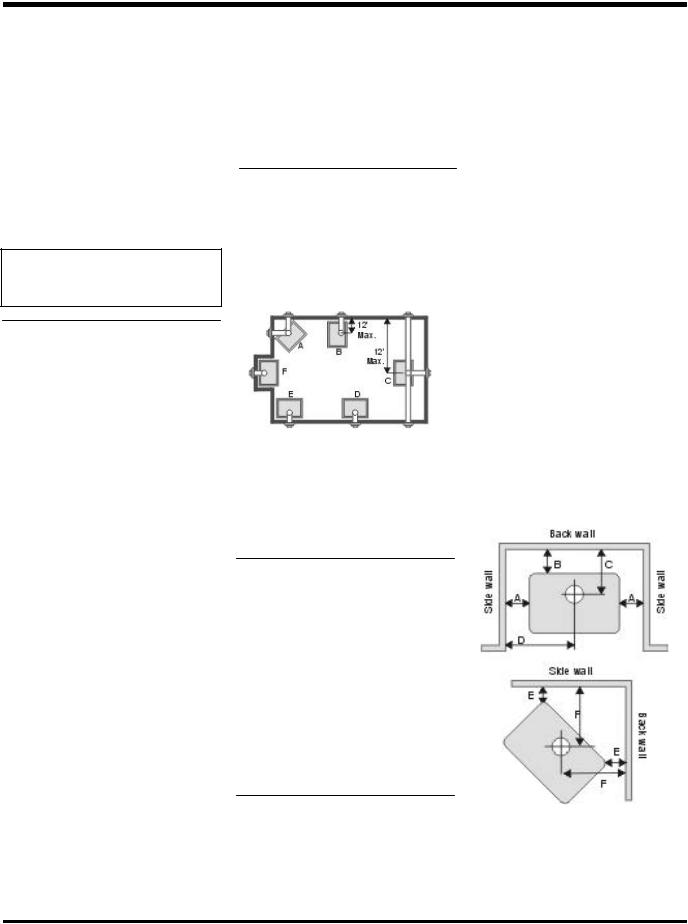

A)Cross Corner

B)Room Divider

C)Island

D)Flat on Wall

E)Flat on Wall Corner

F)Flush with Wall/Alcove

For Vent Termination requirements, see pages 10 to 11.

MANUFACTURED

MOBILE HOME

ADDITIONAL

REQUIREMENTS

CLEARANCES TO

COMBUSTIBLES

The clearances listed below are MINIMUM distances. Measure the clearance to both the appliance and the chimney connector. The farthest distance is correct if the two clearances do not coincide. For example, if the appliance is set as indicated in one of the diagrams but the back is too close, move the stove until the correct clearance to the back is obtained.

This unit can be installed on a solid combustible surface like a wood floor. This unit can also be installed directly on carpeting or vinyl when the bottom pedestal cover plate (provided with the unit) is installed.

This appliance may be installed only with the clearances as shown in the situations pictured. Do not combine clearances from one type of installation with another in order to achieve closer clearances.

Use the minimum clearances shown in the diagrams below:

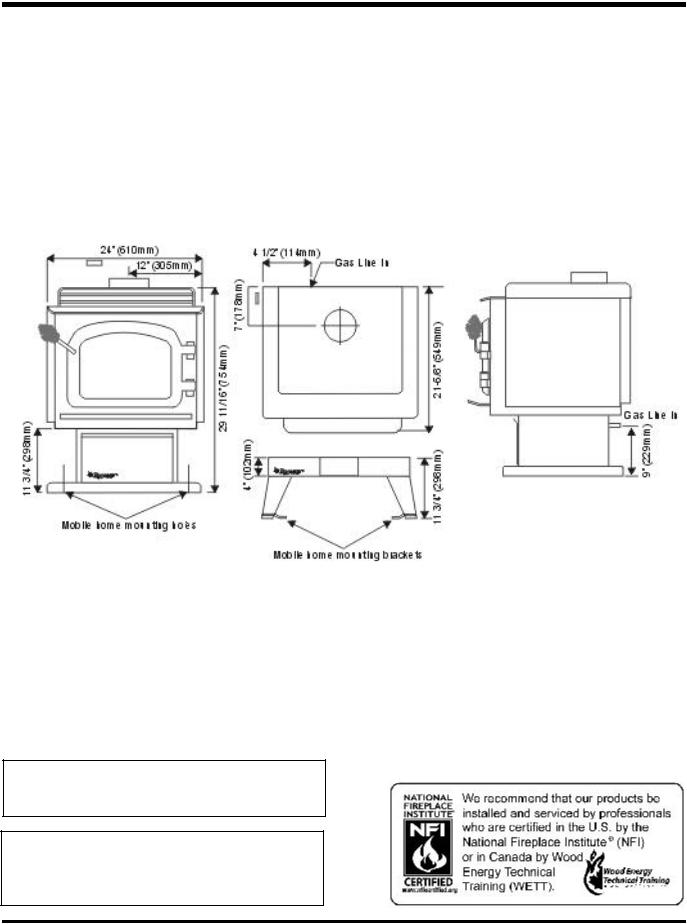

|

C34 Clearance to Combustibles |

|

A |

Side Wall to Unit |

10"/250mm |

B |

Back Wall to Unit |

6"/ 150 mm |

E |

Side Wall to Unit |

1.5"/ 38 mm |

|

|

|

|

C34 Reference Dimensions |

|

C |

Back Wall to Flue Centerline |

13"/330mm |

D |

Side Wall to Flue Centerline |

22"/559mm |

F |

Side Wall to Flue Centerline |

14"/356mm |

1)Ensure that structural members are not cut or weakened during installation.

2)Ensure proper grounding using the #8 ground lug provided. See page 7.

3)Appliance must be anchored to the floor. See page 8.

COMBUSTION AND VENTILATION AIR

The combustion air from this appliance is drawn from outside the building through the outer flue.

Extra provision for combustion air is not required.

Minimum ceiling height is 36" / 914 mm from top of unit.

Minimum clearance to vent 1-1/4" (32mm).

Regency CLASSIC C34-2 Direct Vent Freestanding Gas Heater

INSTALLATION

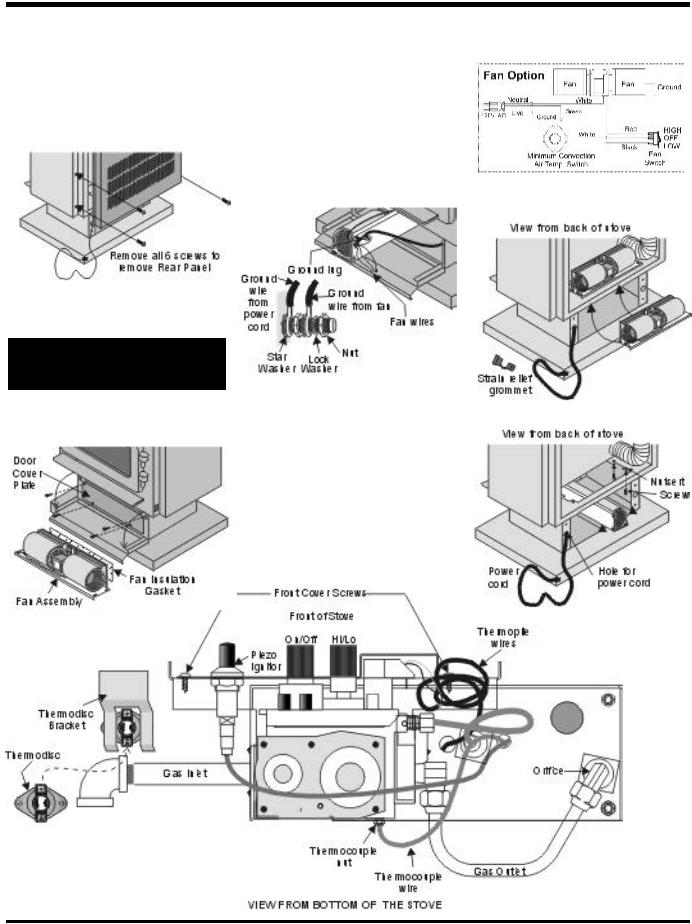

OPTIONAL FAN INSTALLATION

For pedestal unit: To install the fan in an installed stove-access from front through the pedestal by following the directions below. If the stove is not installed - access through rear and follow steps 4 to 17.

For leg unit: remove 7 screws, remove bottom access panel and install fan assembly, follow steps 4 to 17.

IMPORTANT

Disconnect power supply before servicing

2)Remove valve cover plate by removing 2 screws.

3)Remove wire from piezo ignitor.

4)Screw the four 8-32 x3/4 screws provided into the nutserts as shown in diagram 3. Do not tighten screws.

5)Push all the fan wires through the hole on the fan assembly. See diagram 2.

Diagram 2

1)Open pedestal door and remove door cover plate by removing 4 screws. See diagram 1.

6)Put power cord (shown in diagram 3) through the hole and pull through to the front of the unit for easier installation of ground wire.

7)Place the fan assembly partially in door cover plate hole. See diagram 2.

8)Attach the 2 ground wires (green) to the ground lug as per diagram 2.

Note: Ground lug is located on the bottom of the fan assembly. See diagram 2.

9)Lift the fan assembly in through the pedestal and up through the cut out as shown in diagrams 3 and 4.

Diagram 3

Diagram 1 |

Diagram 4 |

|

Caution: Ensure that the wires do not touch any hot surfaces.

Note: The #8 ground lug is a dedicated ground for mobile home use only.

Regency CLASSIC C34-2 Direct Vent Freestanding Gas Heater |

7 |

INSTALLATION

10)Put the insulation gasket on the back of the fan. Line up the keyhole slots with the matching screws and pull back slightly to lock into place. While holding fan assembly in place, tighten screws.

11)Remove the dummy plug from the right side of the bottom shield or pedestal and install the supplied fan switch.

12)Attach the hot wire from power cord to the thermodisc.

13)Slide thermodisc under the thermodisc bracket.

14)Connecting wires to the 3 way switch:

a.Connect the red wire from the fan to the top of the 3 way switch.

b.Connect black wire from fan to the bottom of the 3 way switch.

c.Connect white jumper wire to middle of the three way switch. See wiring diagram below.

15)Connect white wire from fan motor to neutral on the power cord.

16)Pull power wire back and put strain relief grommet in place as per diagram 4.

17)Reverse steps 3-1 to complete installation.

Fan Removal

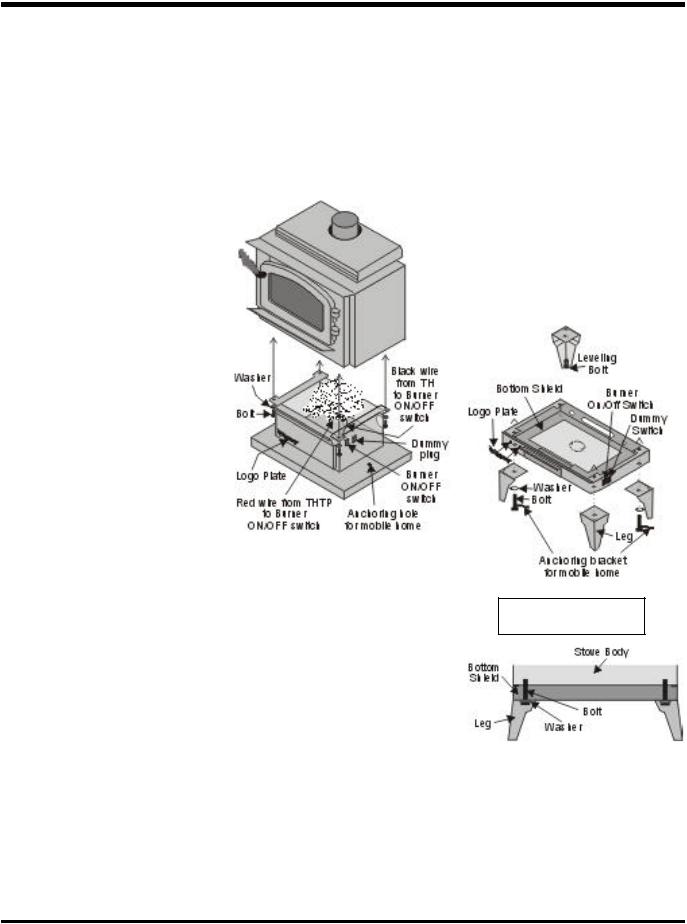

PEDESTAL ASSEMBLY

1)For easier assembly, tip the stove on its back (preferably onto a soft surface to prevent scratching).

2)Unscrew the 4 bolts in the underside of the stove. Align the holes in the corners of the pedestal top with the corresponding holes in the base of the stove. Use washers which are supplied with the pedestal as shown in diagram. Reinstall bolts.

1)Disconnect the power to the fan.

2)Allow the stove to cool to room temperature.

3)Open the pedestal door and remove the screws on the door cover plate. (Leg units: remove the bottom access panel.)

4)Loosen the screws of the nutserts.

5)Remove the fan assembly from the key slots at the fan base and pull fan out through the rectangular opening. (Diagram 3).

6)Turn fan 90 degrees. (Diagram 2). (Pedestal units only).

7)Disconnect the green ground wires to the grounding lug.

8)Disconnect the white wire of the fan from the power cord.

9)Disconnect the red wire and black wire (from fan to Fan Switch).

10)Take fan out from the stove body. (Diagram 1).

3)Hook up wires to Burner ON/OFF switch and valve assembly (be careful not to pinch wires). See diagram above.

4)Push the Regency logo into the two holes in the front bottom left corner of the pedestal cover plate.

Note: Any paint touch up should be done prior to placing logo on pedestal.

LEG AND BOTTOM SHIELD ASSEMBLY

These instructions apply to the steel leg, painted cast leg and the gold plated cast leg. It will be easier to attach the legs to the stove if it is tipped on its back (preferably on a soft surface to prevent scratching).

1)Remove the 4 bolts in the underside of the base and discard.

2)Slide the bolt and washer (supplied with the bottom shield) through the leg, then slide the bottom shield in between the leg and the base of the stove. Tighten the bolts.

3)Hook up the Burner ON/OFF switch.

4)Level the stove by adjusting the levelling bolts in the bottom of each leg.

Anchoring Brackets Hold

DownPackagePart#846-585

8 |

Regency CLASSIC C34-2 Direct Vent Freestanding Gas Heater |

|

|

INSTALLATION |

VENTING |

INSTALLATION |

VENT RESTRICTOR |

INTRODUCTION |

PRECAUTIONS |

POSITION |

The DV Stove Horizontal Vent Kit and the Simpson Dura-Vent Direct Vent System Model DV-GS venting systems, in combination with theClassicDirectVentFreestandingGasStove, C34B-NG/C34G-NG and C34B-LP/C34G-LP, have been tested and listed as direct vent heater systems by Warnock Hersey.

If converting a Class-A Metal Chimney or Masonry Chimney to a Direct Vent system, see instructions on pages 22 and 23.

The C34 uses the "balanced flue" technology Co-Axial system. The inner liner vents products of combustion to the outside while the outer pipe draws outside combustion air into the combustion chamber thereby eliminating the need to use heated room air for combustion and losing warm room air up the chimney.

Note: These flue pipes must not be connected to any other appliance.

The gas appliance and vent system must be vented directly to the outside of the building, and never be attached to a chimney serving a separate solid fuel or gas burning appliance. Each direct vent gas appliance must use it's own separate vent system. Common vent systems are prohibited.

IMPORTANT

Read all instructions carefully before starting the installation. Failure to follow these instructions may create a fire or other safety hazard, and will void the warranty. Be sure to check the venting and clearance to combustible requirements. Consult your local building codes before beginning installation.

The location of the termination cap must conform to the requirements in the Exterior Vent Terminal Locations diagram on page 10.

These venting systems are engineered products that have been designed and tested for use with the C34B-NG/C34G-NG and the C34B- LP/C34G-LP. The warranty will be voided and serious fire, health or other safety hazards may result from any of the following actions:

1)Installation of any damaged Direct Vent component

2)UnauthorizedmodificationoftheDirectVent System

3)Installation of any component part not manufactured or approved by Simpson DuraVent or Fireplace Products International Ltd.

4)Installation other than as instructed by Simpson Dura-Vent and Fireplace Products International Ltd.

Warning: Always maintain required clearances (air spaces) to nearby combustibles to prevent a fire hazard. Do not fill air spaces with insulation.

Be sure to check the vent termination clearance requirements from decks, windows, soffits, gas regulators, air supply inlets and public walkways as specified in the Exterior Vent Terminal Locations on page 10 and in your local building codes.

The gas appliance and vent system must be vented directly to the outside of the building, and never be attached to a chimney serving a separate solid fuel or gasburning appliance. Each direct vent gas appliance must use it's own separate vent system. Common vent systems are prohibited.

SAFETY

PRECAUTIONS FOR THE INSTALLER

1)Wear gloves and safety glasses for protection.

2)Exercise extreme caution when using ladders or on roof tops.

3)Be aware of electrical wiring locations in walls and ceilings.

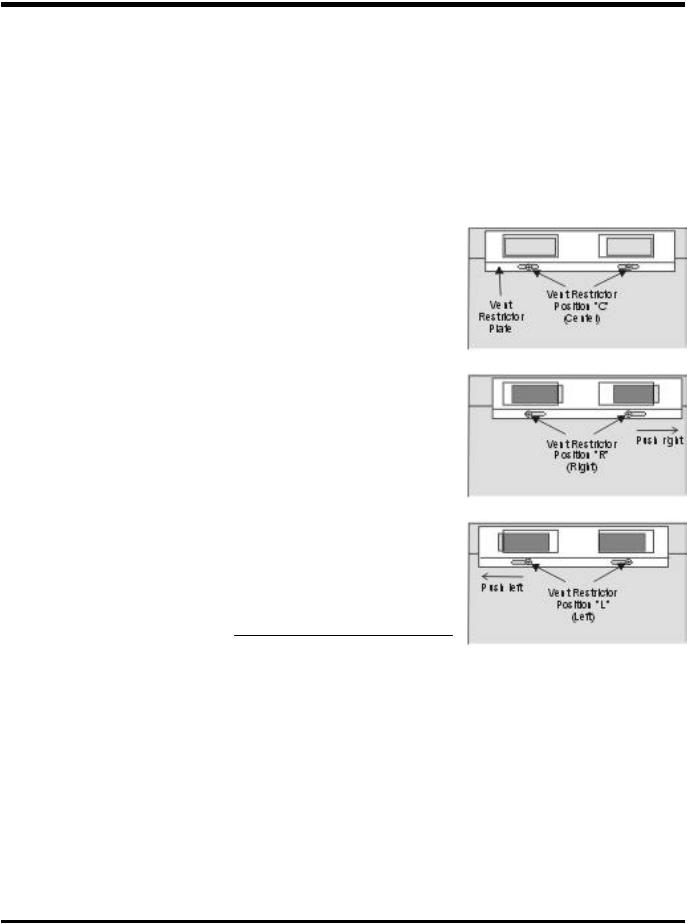

Vent restriction is required for certain venting installations, see the diagrams on page 13 to determine if they are required for your installation.

The vent restrictor has three settings: "C" Center (factory setting), "L" Left, and "R" Right. Simply loosen the screws and push the vent restrictor plate to the correct position. Tighten the screws.

Regency CLASSIC C34-2 Direct Vent Freestanding Gas Heater |

9 |

10

Heater Gas Freestanding Vent Direct 2-C34 CLASSIC Regency

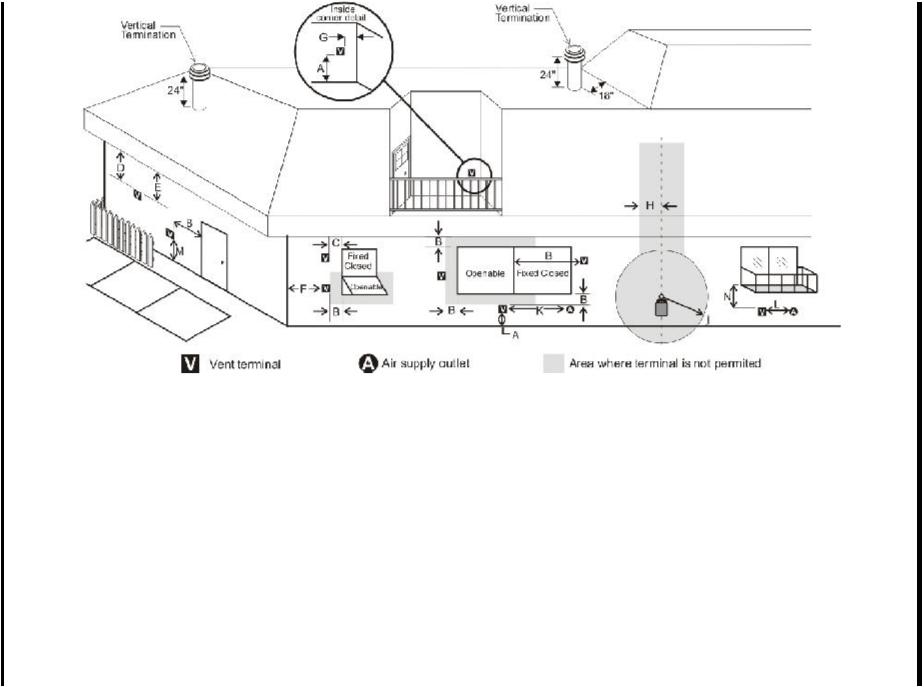

A= Clearance above grade, veranda, porch, deck, or balcony |

H= *Not to be installed above a meter/regulator assembly within 36" |

[*12" (30 cm) min.] |

(90 cm) horizontally from the centre-line of the regulator. |

B= Clearance to window or door that may be opened [*12" (30cm)] |

J= clearance to service regulator vent outlet [*min. 36" (90cm)] |

C= Clearance to permanently closed window min. 12" (30 cm) |

K= clearance to non-mechanical air supply inlet to building or |

D= Vertical clearance to ventilated soffit located above the terminal within a horizontal |

the combustion air inlet to any other appliance [*12 inches] |

distance of 24" (60 cm) from the centre-line of the terminal [18" (46 cm) min.] |

L= clearance to a mechanical air supply inlet [*min. 72" (1.8 m) |

E= Clearance to unventilated soffit [12" (30 cm) min.] |

M= **clearance above paved side-walk or a paved driveway |

F= Clearance to outside corner: with AstroCap Termination Cap (min 6"/15cm), with |

located on public property [*84" (2.1 m) min.] |

Dura-Vent Termination Cap (12"/30cm) |

N=clearance under veranda, porch,, deck, or balcony [*12" |

G= Clearance to inside corner: withAstroCapTermination Cap (min 6"/15cm), with Dura- |

(30 cm) min.***] |

Vent Termination Cap (12"/30cm) |

|

*As specified in CGA B149 or ANZI 223.1 Installation Codes. Note: local Codes or Regulations may require different clearances.

**A vent shall not terminate directly above a side-walk or paved driveway which is located between two single family dwellings and serves both dwellings

***Only permitted if veranda, porch, deck or balcony, is fully open on a minimum of 2 sides beneath the floor.

LOCATIONS TERMINAL VENT EXTERIOR

INSTALLATION

INSTALLATION

RIGID PIPE VENTING COMPONENTS LIST

All Simpson Dura-Vent components are available directly from FPI.

Description |

Simpson Dura-Vent |

Selkirk |

AmeriventR |

|

Direct VentGSR |

Direct-TempTM |

Direct Vent |

6" Pipe Length, Galvanized |

908 |

4DT-6 |

N/A |

6" Pipe Length, Black |

908B |

4DT-6B |

N/A |

7" Pipe Length, Galvanized |

N/A |

N/A |

4D7 |

7" Pipe Length, Black |

N/A |

N/A |

4D7B |

9" Pipe Length, Galvanized |

907 |

4DT-9 |

N/A |

9" Pipe Length, Black |

907B |

4DT-9B |

N/A |

12" Pipe Length, Galvanized |

906 |

4DT-12 |

4D12 |

12" Pipe Length, Black |

906B |

4DT-12B |

4D12B |

18" Pipe Length, Galvanized |

N/A |

4DT-18 |

N/A |

18" Pipe Length, Black |

N/A |

4DT-18B |

N/A |

24" Pipe Length, Galvanized |

904 |

4DT-24 |

4D2 |

24" Pipe Length, Black |

904B |

4DT-24B |

4D2B |

36" Pipe Length, Galvanized |

903 |

4DT-36 |

4D3 |

36" Pipe Length, Black |

903B |

4DT-36B |

4D3B |

48" Pipe Length, Galvanized |

902 |

4DT-48 |

4D4 |

48" Pipe Length, Black |

902B |

4DT-48B |

4D4B |

Adjustable Length, 11"-14", Galv. |

911 |

4DT-AJ |

N/A |

Adjustable Length, 11"-14", Black |

911B |

4DT-AJB |

N/A |

Adjustable Length, 17"-24", Black |

917B |

N/A |

N/A |

Adjustable Length, 7" Galvinized |

N/A |

N/A |

4D7A |

Adjustable Length, 7" Black |

N/A |

N/A |

4D7AB |

Adjustable Length, 12" Galvinized |

N/A |

N/A |

4D12A |

Adjustable Length, 12" Black |

N/A |

N/A |

4D12AB |

45O Elbow, Galvinized |

945 |

4DT-EL45 |

4D45L |

45O Elbow, Black |

945B |

4DT-EL45B |

4D45LB |

45O Elbow, Swivel, Galvinized |

945G |

N/A |

N/A |

45O Elbow, Swivel, Black |

945BG |

N/A |

N/A |

90O Elbow, Galvinized |

990 |

4DT-EL90S |

4D90LS |

90O Elbow, Black |

990B |

4DT-EL90SB |

4D90LBS |

90O Elbow, Swivel, Galvinized |

990G |

N/A |

N/A |

90O Elbow, Swivel, Black |

990BG |

N/A |

N/A |

Ceiling Support |

949 - n/a from FPI |

4DT-CS |

4DFSP |

Cathedral Support Box |

941 |

4DT-CSS |

4DRSB |

Wall Support/Band |

988 |

4DT-WS/B |

4DWS |

Offset Support |

989 - n/a from FPI |

4DT-OS |

N/A |

Wall Thimble, Black |

942 |

4DT-WT |

4DWT |

Wall Thimble Support Box/Ceiling Support |

940 |

N/A |

N/A |

Firestop Spacer |

963 |

4DT-FS |

4DFSP |

Trim Plate, Black |

N/A |

4DT-TP |

4DFPB |

Brass Trim for Wall Thimble/Ceiling Support |

3951 |

N/A |

N/A |

Attic Insulation Shield 12" |

N/A |

N/A |

4DAIS12 |

Attic Insulation Shield - Cold Climates 36" |

N/A |

N/A |

4DAIS36 |

Basic Horizontal Termination Kit (A) |

970 |

4DT-HKA |

4DHTK2 |

Horizontal Termination Kit (B) |

971 |

4DT-HKB |

4DHTK1 |

Vertical Termination Kit |

978 |

4DT-VKC |

4DVTK |

High Wind Vertical Cap |

991 |

N/A |

N/A |

High Wind Horizontal Cap |

985 |

N/A |

N/A |

Horizontal Square Termination Cap |

984 |

4DT-HHC |

4DHC |

Verical Termination Cap |

980 |

4DT-HVC |

4DVC |

Storm Collar |

953 |

4DT-SC |

4DSC |

Adjustable Flashing, 0/12-6/12 |

943 |

4DT-AF6 |

4DF |

Adjustable Flashing, 6/12-12/12 |

943S |

4DT-AF12 |

4DF12 |

Vinyl Siding Standoff |

950 |

4DT-VS |

N/A |

Vinyl Siding Shield Plate |

N/A |

4DT-VSP |

N/A |

Snorkel Termination 14" |

982 |

4DT-ST14 |

4D12S |

Snorkel Termination 36" |

981 |

4DT-ST36 |

4D36S |

|

|

|

|

946-506/P |

Vent Guard (Optional) |

946-208/P |

Vent Guard (Optional) - Riser Vent Terminal |

640-530/P |

Riser Vent Terminal |

946-523/P |

AstroCap Horizontal Cap |

946-205 |

Vinyl Siding Shield for Riser Vent Terminal |

946-206 |

Vinyl Siding Standoff - AstroCap |

|

|

|

|

Regency CLASSIC C34-2 Direct Vent Freestanding Gas Heater |

11 |

Loading...

Loading...